Page 1

Instructions

TLACAL1 & TLACAL2

Performance Verification Fixture

071-1125-01

This document applies to TLA System Software

version 4.20 and above.

www.tektronix.com

*P071112501*

071112501

Page 2

Copyright © Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price c hange privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Page 3

WARRANTY

Tektronix warrants that the products that it manufactures and sells will be free from defects in materials and

workmanship for a period of one (1) year from the date of shipment. If a product proves defective during this

warranty period, Tektronix, at its option, either will repair the defective product without charge for parts and labor,

or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by Tektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the Tektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products returned to any ot her locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible e quipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS W ARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR

THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Contacting Tektronix

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: techsupport@tektronix.com

1-800-833-9200, select option 3*

6:00 a.m. -- 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please

leave a voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see

the Tektronix web site for a list of offices.

Page 5

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Use Proper Voltage Setting. Before applying power, ensure that the line selector is

in the proper position for the power source being used.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Connect the ground lead of the probe to earth ground only.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Wear Eye Protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

TLACAL1 & TLACAL2 Performance Verification Fixture

1

Page 6

General Safety Summary

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

WARNING

High Voltage

Protective Ground

(Earth) Terminal

Mains Disconnected

OFF (Power)

Mains Connected

ON (Power)

2

TLACAL1 & TLACAL2 Performance Verification Fixture

Page 7

TLACAL1 & TLACAL2 Performance Verification Fixture

Instructions

The TLACAL1 performance verification fixture is designed for use with the

TLA5000 series logic analyzer mainframe and P64xx logic analyzer probes; the

TLACAL2 performance verification fixture is designed for use with the

TLA7Axx series logic analyzer modules and the P68xx series logic analyzer

probes. Each test fixture uses unique software to complete the performance

verification and certification procedures for the respective logic analyzer

hardware and probes.

Refer to the appropriate service manual for performance verification and

certification procedures. For the TLACAL1, refer to the TLA5000 Series Logic

Analyzer Mainframe Service Manual; for the TLACAL2, refer to the TLA7Axx

Logic Analyzer Module Service Manual.

Parts and Accessories

Table 1 lists the parts and accessories that accompany the performance verification fixtures. Use this table to verify that you have all of the parts and accessories. If any parts or accessories are missing, contact your local Tektronix

representative for information on replacing any missing parts.

TLACAL1 & TLACAL2 Performance Verification Fixture

3

Page 8

TLACAL1 & TLACAL2 Performance Verification Fixture Instructions

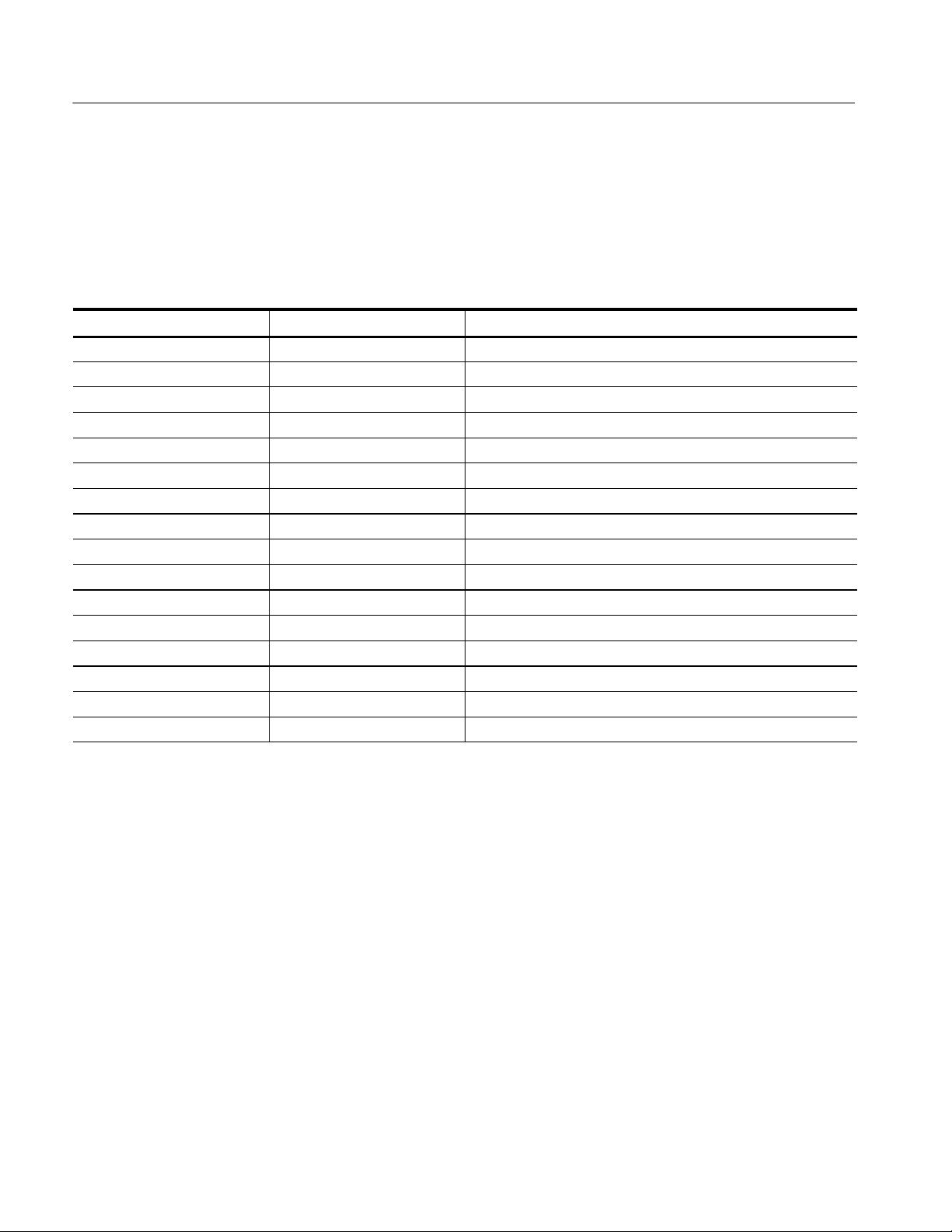

Table 1: TLACAL1 & TLACAL2 parts and accessories

Item and description Tektronix part number

TLACAL1 Performance Verification fixture

None --

TLACAL2 Performance Verification fixture

4 Module Interface Cards 650-4298-00

1 Probe Interface Card 650-4299-00

4 34-pin ribbon cables 174-4678-00

8 MCX-to-MCX coaxial cables 174-4138-00

1 Package of color bands (used with MCX-to-MCX coaxial cables to assist in identification) 016-1315-00

4 P6041 BNC-to-SMB cables P6041

1 GPIB 2 m cable 012-0991-00

4 BNC to BNC, low-loss, 36-inch 10x cables 174-4595-00

Parts and accessories common to both TLACAL1 and TLACAL2 fixtures

1 RS-232 serial null modem cable 012-1651-00

1 USB to RS-232 adapter 119-6837-00

1 TLACAL1 & TLACAL2 Performance Verification Fixture Instructions 071-1125-01

1 Certificate of calibration or compliance --

4

TLACAL1 & TLACAL2 Performance Verification Fixture

Page 9

TLACAL1 & TLACAL2 Performance Verification Fixture Instructions

Required Test Equipment

In addition to the performance verification fixture and accessories, you will need

the test equipment listed in Table 2 and the performance verification software to

run the performance verification and certification procedures. This equipment

must be ordered separately from the performance verification test fixture.

The performance verification software is available on the TLA Application CD

that comes with your Tektronix logic analyzer. The software must be installed on

the hard disk of your Tektronix logic analyzer mainframe before you can use it.

Refer to the TLA5000 Series Logic Analyzer Mainframe Service Manual

(TLACAL1 fixture) or the TLA7Axx Logic Analyzer Module Service Manual

(TLACAL2 fixture) for instructions on installing and using the software.

Table 2: Required test equipment

Item and description Tektronix part number

TLACAL1 Performance Verification

Tektronix TLA5000 series mainframe TLA520x

1 Tektronix P6419 probe for every 34 channels on the TLA5000 series logic analyzer mainframe P6419

TLA5000 Series Logic Analyzer Mainframe Service Manual 071-1236-XX

TLACAL2 Performance Verification

Tektronix TLA700 Logic Analyzer mainframe TLA7xx

Tektronix TLA7Axx Logic Analyzer module TLA7Axx

Tektronix TDS694C Digital Oscilloscope TDS694C

1 Tektronix P6860 probe for every 34 channels on the TLA7Axx Logic Analyzer module P6860

TLA7Axx Logic Analyzer Module Service Manual 071-1043-XX

TLACAL1 and TLACAL2 Performance Verification

iView External Oscilloscope cable kit 012-1614-00

Agilent 34401A Digital Multimeter --

TLACAL1 & TLACAL2 Performance Verification Fixture

5

Page 10

TLACAL1 & TLACAL2 Performance Verification Fixture Instructions

Options

Table 3 lists both TLACAL1 and TLACAL2 product options and Service

Options. These options must be selected at the time of purchase.

Table 3: TLACAL1 and TLACAL2 Options

Option Tektronix part number Description

A0 061-0104-00 North American power cord, IEC320, right angle (125 V, 10A)

A1 161-0104-06 Universal European power cord, IEC320, right angle

A2 161-0104-07 United Kingdom power cord, IEC320, right angle

A3 161-0104-05 Australian power cord, IEC320, right angle

A4 161-0104-08 North American power cord, IEC320, right angle (250 V, 10 A)

A5 161-0167-00 Switzerland power cord, IEC320, right angle

A6 161-A005-00 Japanese power cord, IEC320, right angle

A10 161-0306-00 China power cord, IEC320, straight

A99 -- No power cord

C3 -- Initial certification plus two years further certification

C5 -- Initial certification plus four years further certification

D1 -- Test data report

D3 -- Test data report (must order Option C3)

D5 -- Test data report (must order Option C5)

R3 -- Repair warranty extended to cover three years

R5 -- Repair warranty extended to cover five years

6

TLACAL1 & TLACAL2 Performance Verification Fixture

Page 11

Installation Instructions

TLACAL1 & TLACAL2 Performance Verification Fixture Instructions

This section describes line fuse and power cord information for both TLACAL1

and TLACAL2 test fixtures. For detailed installation instructions, connection

procedures, and operation procedures, refer to the TLA5000 Series Logic

Analyzer Mainframe Service Manual (TLACAL1 fixture) or the TLA7Axx Logic

Analyzer Module Service Manual (TLACAL2 fixture).

Line Fuse Information

Setting the Line Voltage or

Replacing a Fuse

Check that the line fuse is correct for your application; see Table 4. The fuse and

line cord connector are located at the back of the instrument.

WARNING. To avoid electrical shock, disconnect the power cord before removing

the line fuse.

Table 4: TLACAL2 line fuses

Line voltage Description Tektronix part number

100 V to 120 V operation 5.0 mm x 20 mm, 1.0 A FAST 250 V 159-0356-00

200 V to 240 V operation 5.0 mm x 20 mm, 0.5 A FAST 250 V 159-0351-00

The line voltage is properly set at the factory. If you need to change the line

voltage setting, complete the following steps:

1. Disconnect the power cord at the rear of the instrument.

2. Locate the line selector/fuse holder at the rear of the instrument. The voltage

setting appears in the small window on the line selector.

3. Note the fuse setting, either 115 V or 230 V. If you need to change the line

voltage selection or if you need to change the line fuse, continue with the

following steps.

4. Pry open the latch over the line voltage selector with a small flat-blade

screwdriver.

5. Remove the red fuse holder with the flat-blade screwdriver.

6. Remove the fuse. If you are replacing a blown fuse, install the fuse holder

and fasten the latch in place.

7. Remove the conversion clip from its current location and install it on the

other side of the fuse holder.

8. Turn the fuse holder over.

9. Install the new fuse into the holder (see Table 4 for fuse information).

TLACAL1 & TLACAL2 Performance Verification Fixture

7

Page 12

TLACAL1 & TLACAL2 Performance Verification Fixture Instructions

10. Install the fuse holder.

11. Fasten the latch in place.

Connecting the Line Cord

Additional Installation and

Operating Instructions

Connect the line cord to the rear of the instrument. Connect the other end of the

line cord to the appropriate power connector.

Refer to the Performance Verification chapter of the TLA5000 Series Logic

Analyzer Mainframe Service Manual (TLACAL1 fixture) or the TLA7Axx Logic

Analyzer Module Service Manual (TLACAL2 fixture) for detailed installation

instructions, connection procedures, and operation procedures.

CAUTION. Do not connect or disconnect any ribbon cables, module interface

cards, or the probe interface card to or from the test fixture while power is

applied. Doing so will damage the fixture, the module interface cards, or the

probe interface card. Refer to the TLA7Axx Logic Analyzer Module Service

Manual for complete installation instructions.

Performance Verification Fixture Service

Both the TLACAL1 and TLACAL2 fixtures are calibrated at the factory. No

additional calibration is required. If your fixture requires servicing or calibration

you must return the fixture and all accessories to Tektronix.

Preventive Maintenance

8

Preventive maintenance mainly consists of periodic cleaning. Periodic cleaning

reduces instrument breakdown and increases reliability. Clean the instrument as

needed, based on the operating environment. Dirty conditions may require more

frequent cleaning than computer room conditions.

Clean the exterior surfaces with a dry, lint-free cloth or a soft-bristle brush. If dirt

remains, use a cloth or swab dampened with a 75% isopropyl alcohol solution. A

swab is useful for cleaning in narrow spaces around the controls and connectors.

Do not use abrasive compounds on any part of the instrument.

TLACAL1 & TLACAL2 Performance Verification Fixture

Page 13

Specifications

TLACAL1 & TLACAL2 Performance Verification Fixture Instructions

CAUTION. Avoid getting moisture inside the instrument during external cleaning;

use only enough solution to dampen the cloth or swab.

Use only deionized water when cleaning. Use a 75% isopropyl alcohol solution

as a cleanser and rinse with deionized water.

Do not use chemical cleaning agents; they may damage the instrument. Avoid

chemicals that contain benzene, toluene, xylene, acetone, or similar solvents.

The Table 5 provides abbreviated information on performance verification fixture

specifications. For detailed specifications, refer to the TLA5000 Series Logic

Analyzer Mainframe Service Manual (TLACAL1 fixture) or the TLA7Axx Logic

Analyzer Module Service Manual (TLACAL2 fixture).

Table 5: Performance verification test fixture characteristics

Characteristic Description

Power consumption 40 W maximum

Source voltage and frequency 100 V

115 V

Cooling clearance 51 mm (2 inches) front, sides, and rear.

Temperature:

Operating and nonoperating

Relative Humidity:

Operating and nonoperating

Altitude:

Operating and nonoperating

Operating:

+20 _Cto+30_C

Nonoperating:

+5 _Cto+50_C, 15 _C/hr maximum gradient, non-condensing.

Operating:

20% to 80% relative humidity, non-condensing. Maximum wet bulb temperature: +29 _C

(derates relative humidity to approximately 22% at +50 _C).

Nonoperating:

8% to 80% relative humidity, non-condensing. Maximum wet bulb temperature: +29 _C

(derates relative humidity to approximately 22% at +50 _C).

Operating:

To 3040 m (10,000 ft.), derated 1_ C per 305 m (1000 ft.) above 1524 m (5000 ft.) altitude.

Nonoperating:

12190 m (40,000 ft.)

to 240 V

RMS

±10%, 400 Hz, ±10%, continuous range CAT II

RMS

±10%,50Hzto60Hz±10%, continuos range CAT II

RMS

TLACAL1 & TLACAL2 Performance Verification Fixture

9

Page 14

TLACAL1 & TLACAL2 Performance Verification Fixture Instructions

g

gyp

Table 6: TLACAL1 and TLACAL2 Performance verification and adjustment fixture certifications and

compliances

Category Standards or description

EC Declaration of Conformity -Low Voltage

U.S. Nationally Recognized

Testing Laboratory Listing

Canadian Certification CAN/CSA C22.2 No. 1010.1 Safety requirements for electrical equipment for measurement,

Additional Compliance IEC61010-1/A2:1995 Safety requirements for electrical equipment for measurement,

Installation (Overvoltage)

Category Descriptions

Pollution Degree Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor use only.

Pollution Degree Descriptions A measure of the contaminates that could occur in the environment around and within a product.

Equipment Type Test and measuring

Safety Class Class 1 (as defined in IEC 61010-1, Annex H) -- grounded product

Overvoltage Category Overvoltage Category II (as defined in IEC 61010-1, Annex J)

Compliance was demonstrated to the following specification as listed in the Official Journal of the

European Communities:

Low Voltage Directive 73/23/EEC, amended by 93/68/EEC

EN 61010-1/A2:1995 Safety requirements for electrical equipment for measurement

control and laboratory use.

UL3111-1 Standard for electrical measuring and test equipment.

control, and laboratory use.

control, and laboratory use.

Terminals on this product may have different installation (overvoltage) category designations. The

installation categories are:

CAT III Distribution-level mains (usually permanently connected). Equipment at this level is

typically in a fixed industrial location.

CAT II Local-level mains (wall sockets). Equipment at this level includes appliances, portable

tools, and similar products. Equipment is usually cord-connected.

CAT I Secondary (signal level) or battery operated circuits of electronic equipment.

Typically the internal environment inside a product is considered to be t he same as the external.

Products should be used only in the environment for which they are rated.

Pollution Degree 1 No pollution or only dry, nonconductive pollution occurs. Products in

this category are generally encapsulated, hermetically sealed, or

located in clean rooms.

Pollution Degree 2 Normally only dry, nonconductive poll ution occurs. Occasionally a

temporary conductivity that is caused by condensation must be

expected. This location is a typical office/home environment.

Temporary condensation occurs only when the product is out of

service.

Pollution Degree 3 Conductive pollution, or dry, nonconductive pollution that becomes

conductive due to condensation. These are sheltered locations

where neither temperature nor humidity is controlled. The area is

protected from direct sunshine, rain, or direct wind.

Pollution Degree 4 Pollution that generates persistent conductivity through conductive

dust, rain, or snow. Typical outdoor locations.

10

TLACAL1 & TLACAL2 Performance Verification Fixture

Loading...

Loading...