Page 1

Service Manual

TLA 711

Color Benchtop Chassis

070-9773-00

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

Page 2

Copyright T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defective during this warranty period, T ektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A P ARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY T O

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

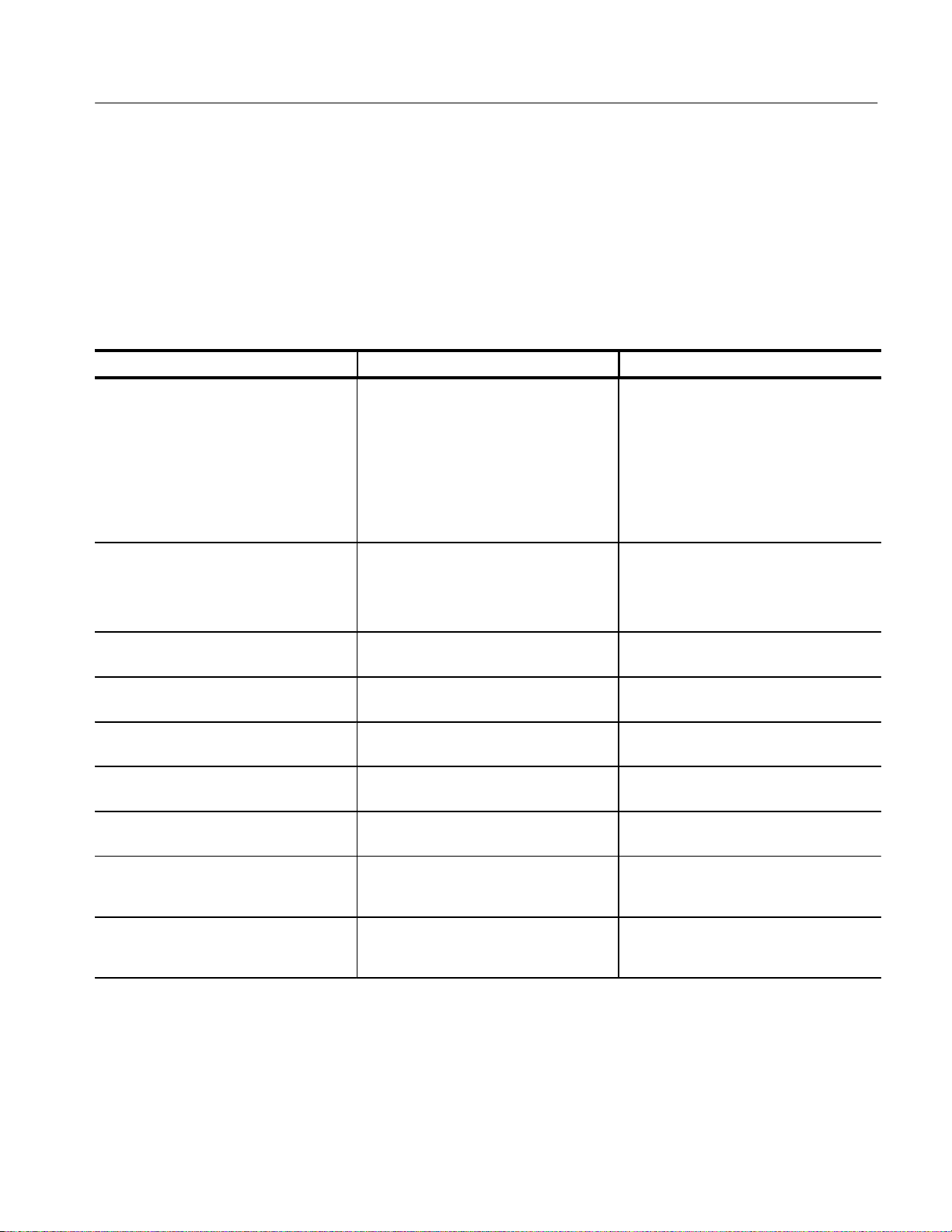

TEKTRONIX SERVICE OPTIONS

T ektronix offers the following service options. These options are modular, flexible, and easy to order with your instrument. Designed to ease installation and start up, to support tracking of calibration to requirements of ISO9000, and

to provide for extended repair coverage, these options help fix your long-term maintenance costs and eliminate unplanned expenditures. And these options can be converted from service at T ektronix service depots to service on-site

(see Option S3), which helps keep downtime to a minimum.

Product installation service

1

Option IN Provides initial installation of the product and

familiarizes new users with some of its operation features

Three years of calibration services Option C3 Provides initial Certification on delivery, plus

two more annual calibrations from your service center

Test data Option D3 Provides test data on delivery and when annu-

al calibration services are provided (three total, requires Option C3)

Three years repair coverage Option R3 Provides three years of repair coverage for the

instrument, including displays and accessories

sold with the instrument

One year uplift to on–site service

1,2

Option S1 Converts the standard one year, “return to de-

pot” warranty to provide service on site for

one year

Three year uplift to on-site service

1,2

Option S3 Converts any C3, D3, and R3 options pur-

chased to on-site services for three years

Tektronix Service Options are available at the time you order your instrument. Contact your local Tektronix Sales

Office for more information.

1

Availability of installation and on-site services depends on the type of product and may vary by geography.

2

Uplift options are ordered with the mainframe products and cover individual modules.

Page 5

Table of Contents

Specifications

Operating Information

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Conventions x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Manuals xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Interval xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strategy for Servicing xiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ektronix Service Offerings xiv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting T ektronix xv. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Characteristics T ables 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Information 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting the Correct Power Cord and Fuse 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theory of Operation

Standard Chassis 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification

Adjustment Procedures

Maintenance

Related Maintenance Procedures 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventing ESD 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Cleaning 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation Procedures 6–5. . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation — Please Read 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of Replaceable Parts 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Summary of Procedures 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ools Required 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Removal and Replacement 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Blower Assembly 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Monitor Board 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Power Supply 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Card Guides 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the T emperature Sense Board 6–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Backplane 6–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TLA711 Benchtop Chassis Service Manual

i

Page 6

Table of Contents

Options

Electrical Parts List

Diagrams

Mechanical Parts List

Special Configuration Options 6–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 6–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check for Common Problems 6–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Eliminate Other Problem Sources 6–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshoot the Benchtop Chassis 6–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of Procedures 6–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment After Repair 6–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repackaging Instructions 6–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Packaging 6–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage 6–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Accessories 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Accessories 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Replaceable Parts 10–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List 10–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

TLA711 Benchtop Chassis Service Manual

Page 7

List of Figures

Table of Contents

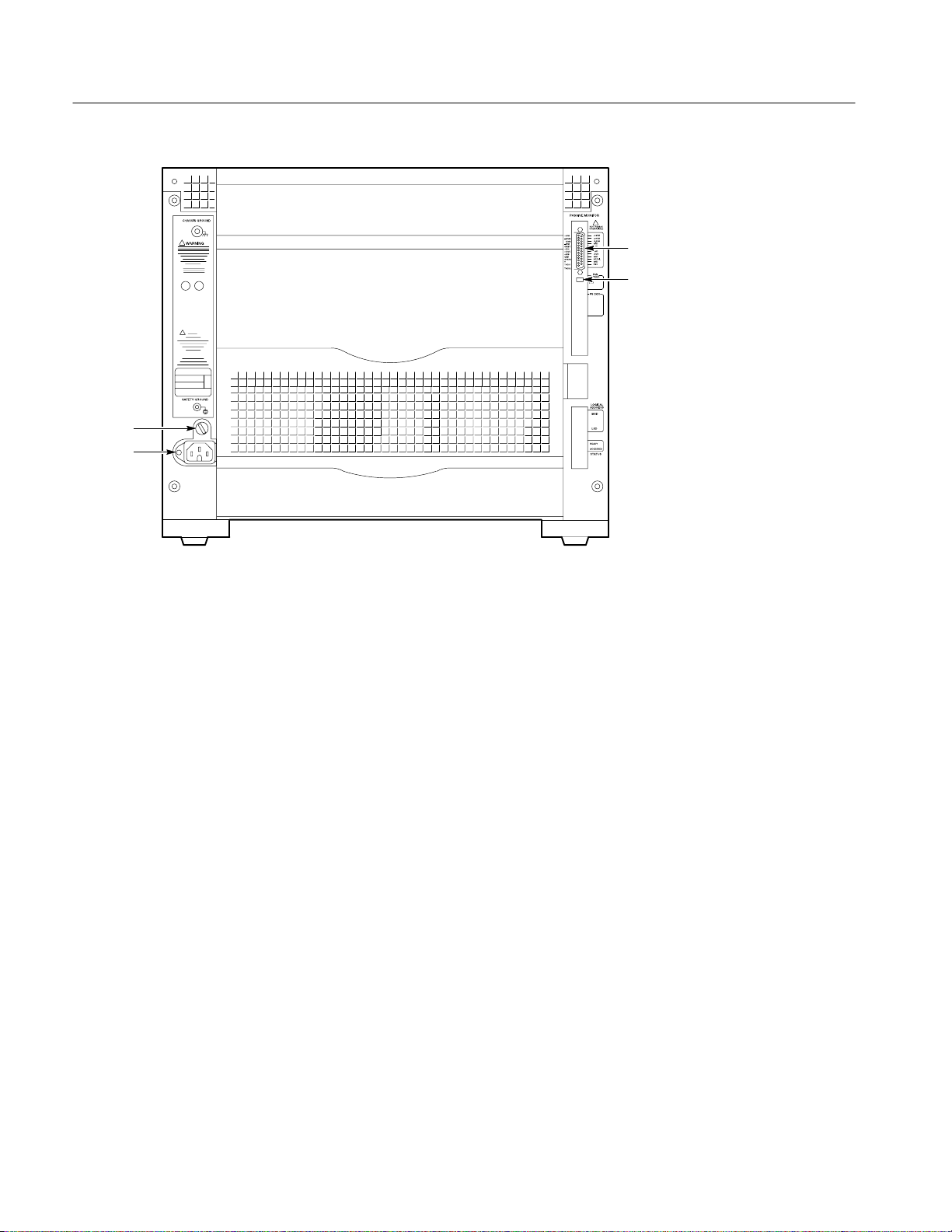

Figure 1–1: Front view and side view of standard Benchtop Chassis 1–10

Figure 1–2: Front view and side view of Benchtop Chassis with

Rackmount Option 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–1: Front view of the standard Benchtop Chassis 2–1. . . . . . . . .

Figure 2–2: Rear view of the standard Benchtop Chassis 2–2. . . . . . . . . .

Figure 2–3: Power cord identification chart 2–3. . . . . . . . . . . . . . . . . . . . .

Figure 3–1: Chassis block diagram 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3–2: Passive monitor connector 3–4. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–1: Location of blower assembly screws on the rear of

the chassis 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–2: Removing the blower assembly 6–9. . . . . . . . . . . . . . . . . . . . .

Figure 6–3: Removing the blower 6–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–4: Removing the Monitor board 6–11. . . . . . . . . . . . . . . . . . . . . .

Figure 6–5: Removing the power supply 6–12. . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–6: Removing the Power Supply Interface board 6–13. . . . . . . . .

Figure 6–7: Removing the top and bottom card guides 6–15. . . . . . . . . . . .

Figure 6–8: Replacing the top and bottom nut rails 6–16. . . . . . . . . . . . . .

Figure 6–9: Removing the Temperature Sense board 6–17. . . . . . . . . . . . .

Figure 6–10: Removing the Backplane 6–19. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–11: Power switch connectors 6–21. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–12: 8/10 and 13/15 jumper location on the

Monitor board 6–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–13: Primary troubleshooting procedure 6–27. . . . . . . . . . . . . . . .

Figure 6–14: Rear-panel connector diagram 6–28. . . . . . . . . . . . . . . . . . . .

Figure 9–1: Interconnections 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9–2: Chassis block diagram 9–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–1: Cabinet and chassis assembly 10–9. . . . . . . . . . . . . . . . . . . . .

Figure 10–2: Circuit boards and chassis parts 10–11. . . . . . . . . . . . . . . . . . .

Figure 10–3: Power supply and blower assembly 10–13. . . . . . . . . . . . . . . .

Figure 10–4: 1R rackmount assembly 10–15. . . . . . . . . . . . . . . . . . . . . . . . . .

TLA711 Benchtop Chassis Service Manual

iii

Page 8

Table of Contents

List of Tables

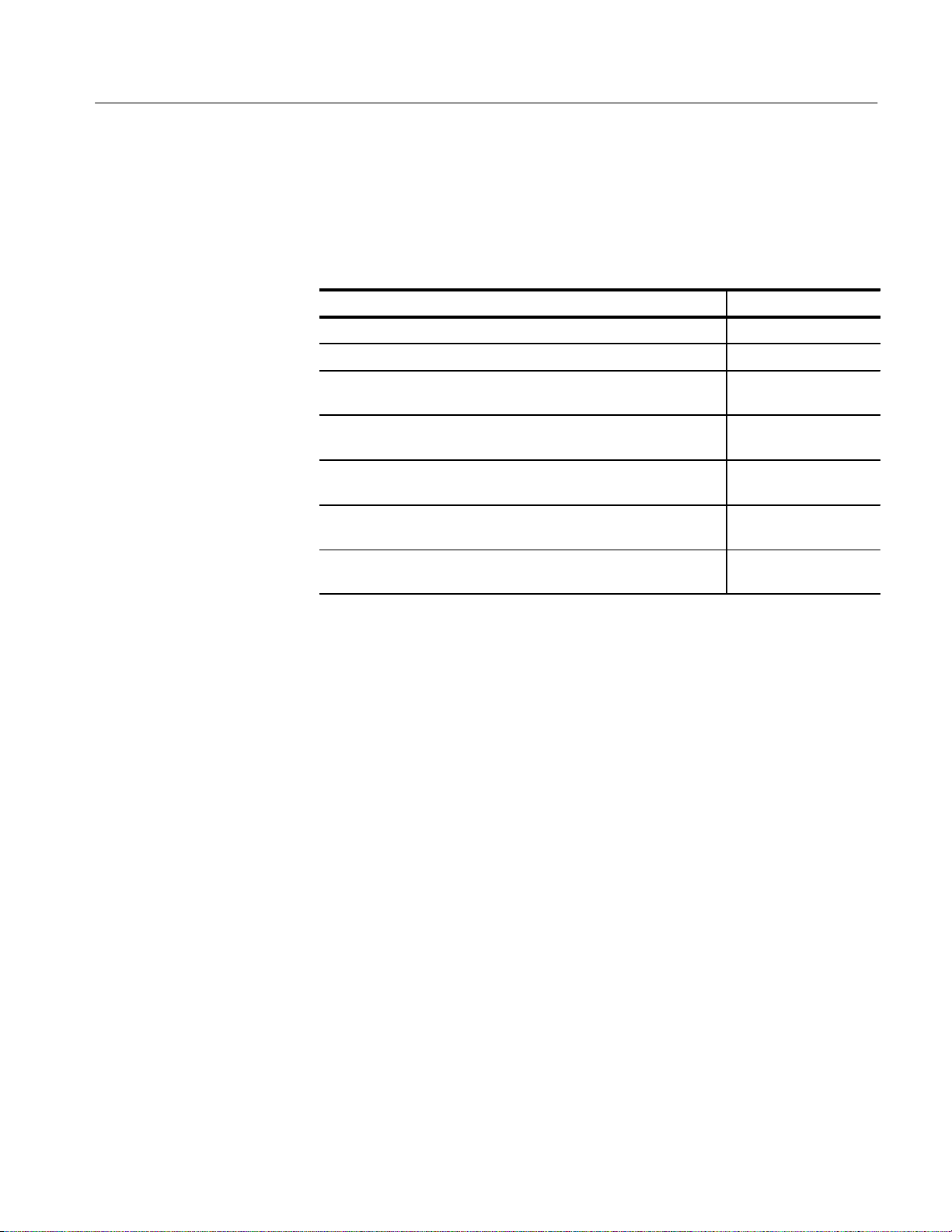

Table 1–1: AC power source 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–2: Secondary power 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–3: Cooling 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–4: Safety 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–5: Environmental 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–6: Electromagnetic compatibility (EMC) 1–8. . . . . . . . . . . . . . . .

Table 1–7: Mechanical 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–1: Passive monitor connector pinouts 3–4. . . . . . . . . . . . . . . . . . .

Table 6–1: Tools required for parts replacement 6–6. . . . . . . . . . . . . . . . .

Table 6–2: Failure symptoms and possible causes 6–24. . . . . . . . . . . . . . . .

Table 6–3: Troubleshooting overview 6–29. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7–1: Options 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10–1: Standard accessories 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10–2: Power cord identification 10–2. . . . . . . . . . . . . . . . . . . . . . . . .

Table 10–3: Optional accessories 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10–4: Common replaceable parts 10–5. . . . . . . . . . . . . . . . . . . . . . . .

Table 10–5: Parts lists column descriptions 10–6. . . . . . . . . . . . . . . . . . . . .

iv

TLA711 Benchtop Chassis Service Manual

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly . Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and marking on the product. Consult the product manual for further ratings

information before making connections to the product.

The common terminal is at ground potential. Do not connect the common

terminal to elevated voltages.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry .

TLA711 Benchtop Chassis Service Manual

v

Page 10

General Safety Summary

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Symbols and Terms

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

vi

WARNING

High Voltage

Protective Ground

(Earth) T erminal

CAUTION

Refer to Manual

Double

Insulated

TLA711 Benchtop Chassis Service Manual

Page 11

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the main power by means

of the power cord or, if provided, the power switch.

Use Caution When Servicing the CRT. To avoid electric shock or injury, use

extreme caution when handling the CRT. Only qualified personnel familiar with

CRT servicing procedures and precautions should remove or install the CRT.

CRTs retain hazardous voltages for long periods of time after power is turned off.

Before attempting any servicing, discharge the CRT by shorting the anode to

chassis ground. When discharging the CRT, connect the discharge path to ground

and then the anode. Rough handling may cause the CRT to implode. Do not nick

or scratch the glass or subject it to undue pressure when removing or installing it.

When handling the CRT, wear safety goggles and heavy gloves for protection.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

X-Radiation. To avoid x-radiation exposure, do not modify or otherwise alter the

high-voltage circuitry or the CRT enclosure. X-ray emissions generated within

this product have been sufficiently shielded.

TLA711 Benchtop Chassis Service Manual

vii

Page 12

Preface

Manual Structure

This is the service manual for the TLA711 Benchtop Chassis. Read this preface

to learn how this manual is structured, what conventions it uses, and where you

can find other information related servicing this product. Read the Introduction,

which follows this preface, for safety and other important background information needed before using this manual for servicing this product.

The TLA 711 Benchtop Chassis Service Manual is divided into chapters, which

are made up of related subordinate topics. These topics can be cross referenced

as sections.

Be sure to read the introductions to all procedures. These introductions provide

important information needed to do the service correctly, safely, and efficiently.

A brief description of each chapter follows:

H Specifications contains a product description of the Benchtop Chassis and

tables of the characteristics and descriptions that apply to it.

H Operating Information includes basic installation and operating instructions

at the level needed to safely operate and service the Benchtop Chassis. For

complete installation and configuration procedures, refer to the Installation

Manual. Instructions for shipping the module are also found in this chapter.

H Theory of Operation contains circuit descriptions that support general service

to the replaceable part level.

H Performance Verification refers you to the TLA 700 Series Performance

Verification and Adjustment Technical Reference Manual that contains the

performance verification procedures for the Benchtop Chassis and for other

major components in the TLA 700 Series Logic Analyzer.

H Adjustment Procedures refer you to the TLA 700 Series Performance

Verification and Adjustment Technical Reference Manual that contains the

adjustment procedures for the Benchtop Chassis and for other major

components in the TLA 700 Series Logic Analyzer.

H Maintenance contains information and procedures for doing preventive and

corrective maintenance on the Benchtop Chassis. Included are instructions

for cleaning, for removal and installation of replaceable parts, and for

troubleshooting.

TLA711 Benchtop Chassis Service Manual

ix

Page 13

Preface

Manual Conventions

H Options contains information on the factory-installed options that may be

available for the Benchtop Chassis.

H Diagrams contains a block diagram and an interconnection diagram useful

for isolating failed circuit boards or assemblies.

H Mechanical Parts List includes a table of all replaceable parts, their

descriptions, and their Tektronix part numbers.

This manual uses certain conventions that you should become familiar with

before attempting service.

Modules

Replaceable Parts

Safety

Throughout this manual, the term module refers to a TLA 700 Series Logic

Analyzer or DSO unit that mounts inside a TLA 700 Series Portable or Benchtop

Chassis. A module is composed of circuit cards, interconnecting cables, and a

user-accessible front panel.

This manual refers to any field-replaceable assembly or mechanical part

specifically by its name or generically as a replaceable part. In general, a

replaceable part is any circuit board or assembly, such as the hard disk drive, or a

mechanical part, such as the I/O port connectors, that is listed in the replaceable

parts list of Chapter 10. Also, see Strategy for Servicing on page xiii.

Symbols and terms related to safety appear in the Service Safety Summary found

at the beginning of this manual.

x

TLA711 Benchtop Chassis Service Manual

Page 14

Related Manuals

The following manuals are available as part of the TLA 700 Series Logic

Analyzer documentation set. See Standard Accessories on page 10–1 and

Optional Accessories on page 10–17 for part numbers.

The procedures and information in this manual assumes that service personnel

have access to all manuals listed in the following table.

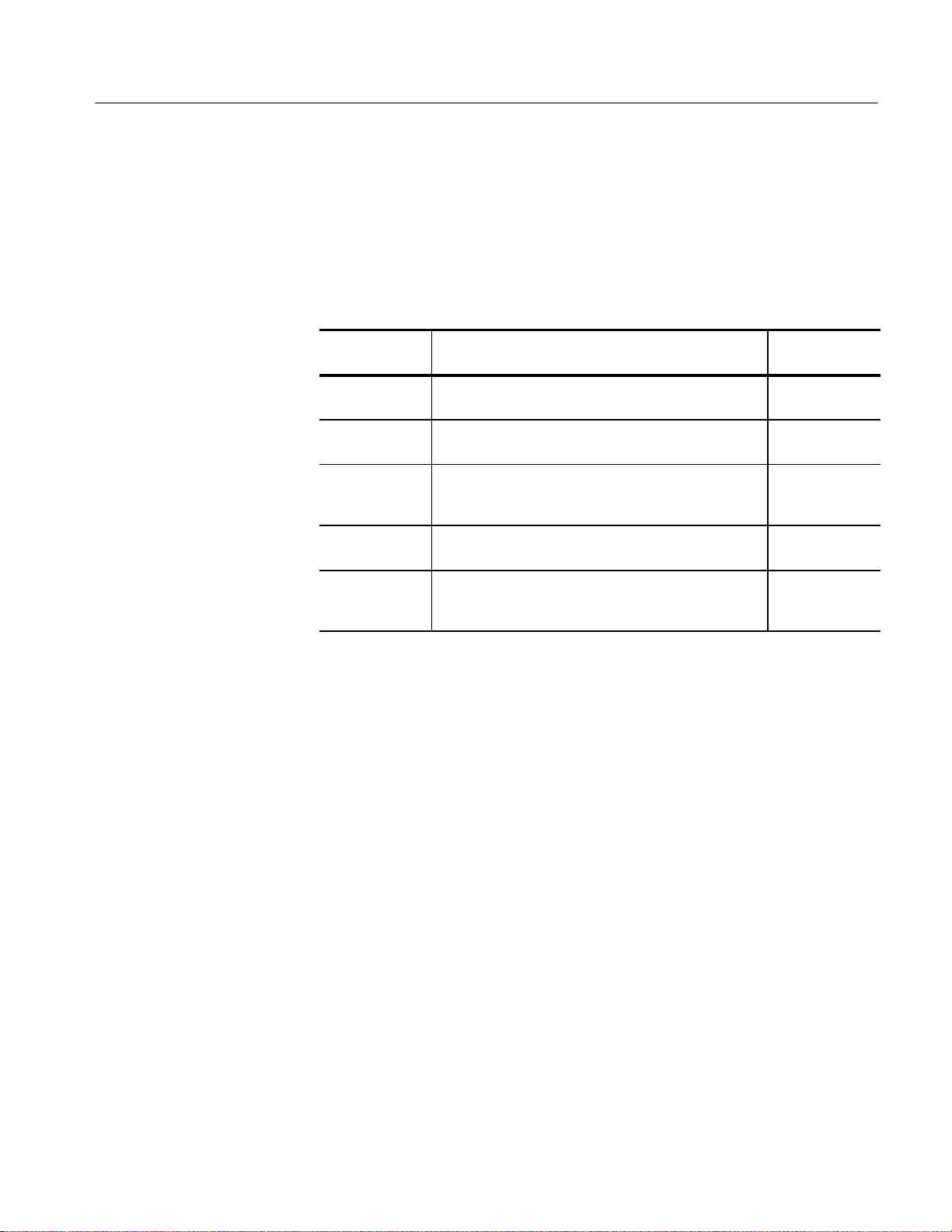

Manual Name Description Service Use

Preface

The TLA 700 Series Installation Manual Provides the basic installation instructions

for the TLA 700 Series Logic Analyzer.

The TLA 700 Series Performance Verifica-

tion and Adjustment T echnical Reference

Manual

The TLA 700 Series User Manual and TLA

700 Online Help

The TLA 711 Color Benchtop Controller

Service Manual

The TLA 704 Color Portable Mainframe

Service Manual

The TLA 7Lx/TLA 7Mx Logic Analyzer

Service Manual

The TLA Dx/TLA 7Ex Digitizing Oscilloscope Service Manual

Provides performance verification, certification, and adjustment procedures for the

TLA 700 Series Logic Analyzer.

Provides operating information on the

TLA 700 Series Logic Analyzer.

Provides service information for the slot 0

controller in the benchtop chassis.

Provides service information for the portable

mainframe.

Provides service information for the logic

analyzer modules.

Provides service information for the

digitizing oscilloscope modules.

Installation and removal of DSO, Logic

Analyzer, and Benchtop-Controller Modules

Reinstallation of Windows 95 and TLA 700

software

Replacing individual podlet cables in the

logic analyzer probes

Reformatting hard disk

Performing periodic or after-repair functional

or performance verifications

Performing periodic or after-repair adjust-

ment

Augments operating information found in

chapter 2 of this manual

Isolating and correcting failures in the

benchtop controller

Isolating and correcting failures in the

portable mainframe

Isolating and correcting failures in the logic

analyzer module

Isolating and correcting failures in the DSO

module

The TLA 7QS Training Manual Provides examples of using the TLA

QuickStart training board with TLA 700

Series Logic Analyzers.

The TLA 7QS Technical Reference Manual Provides service information and technical

information for the TLA QuickStart Training

board.

TLA711 Benchtop Chassis Service Manual

Used for training on operation of TLA 700

Series Logic Analyzer.

Servicing the TLA Quickstart Training board

only .

xi

Page 15

Introduction

Adjustment Interval

This manual contains information needed to properly service the Benchtop

Chassis This introduction contains information critical to safe and effective

servicing.

To prevent personal injury or damage to the Benchtop Chassis, consider the

following requirements before attempting service:

H The procedures in this manual should be performed only by a qualified

service person.

H Read the General Safety Summary and Service Safety Summary found at the

beginning of this manual.

H Read the Preface beginning on page ix.

H Read Operating Information beginning on page 2–1.

When using this manual for servicing, be sure to follow all warnings, cautions,

and notes.

Strategy for Servicing

There are no adjustments or certifiable parameters for the TLA711 Benchtop

Chassis. Refer to the TLA 711 Color Benchtop Controller Service Manual for

more information on adjustment and certification of the controller.

This manual supports and contains all the information needed for periodic

maintenance of the Benchtop Chassis. (Examples of such information are

procedures for fault isolation of a failed circuit board or assembly and for

removal and replacement of same.)

This manual also supports and contains information for corrective maintenance

of this product:

H supports isolation of faults to the failed circuit board or assembly level

shown in the replaceable parts list of Chapter 10

H supports removal and replacement of those boards or assemblies

H supports removal and replacement of fuses, knobs, chassis, and other

mechanical parts listed in the replaceable parts list

This manual does not support component-level fault isolation and replacement.

TLA711 Benchtop Chassis Service Manual

xiii

Page 16

Introduction

Service Offerings

Tektronix provides service to cover repair under warranty as well as other

services that are designed to meet your specific service needs.

Whether providing warranty repair service or any of the other services listed

below, Tektronix service technicians are well equipped to service the TLA 711

Benchtop Chassis. Tektronix technicians train on Tektronix products; they have

access to the latest information on improvements to the TLA 711 Benchtop

Chassis as well as the latest new product upgrades. Services are pr ovided at

Tektronix Services Centers and on-site at your facility, depending on your

location.

Warranty Repair Service

Calibration and Repair

Service

Tektronix warrants this product for one year from date of purchase. (The

warranty appears behind the title page in this manual.) Tektronix technicians

provide warranty service at most Tektronix service locations worldwide. The

Tektronix product catalog lists all service locations worldwide or you can visit us

on our Customer Services World Center web site at http://www.tek.com/Mea-

surement/Service. See our latest service offerings and contact us by email.

In addition to warranty repair, Tektronix Service offers calibration and other

services which provide cost-effective solutions to your service needs and qualitystandards compliance requirements. Our instruments are supported worldwide by

the leading-edge design, manufacturing, and service resources of Tektronix to

provide the best possible service.

The following services can be tailored to fit your requirements for calibration

and/or repair of the TLA 711 Benchtop Chassis.

Service Options. Tektronix Service Options can be selected at the time you

purchase your instrument. You select these options to provide the services that

best meet your service needs. These service options are listed on the Tektronix

Service Options page following the title page of this manual.

xiv

Service Agreements. If service options are not added to the instrument purchase,

then service agreements are available on an annual basis to provide calibration

services or post-warranty repair coverage for the TLA 711 Benchtop Chassis.

Service agreements may be customized to meet special turn-around time and/or

on-site requirements.

Service on Demand. Tektronix also offers calibration and repair services on a

“per-incident” basis that is available with standard prices for many products.

TLA711 Benchtop Chassis Service Manual

Page 17

Contacting Tektronix

Introduction

Self Service. Tektronix supports repair to the replaceable-part level by providing

for circuit board exchange.

Use this service to reduce down-time for repair by exchanging circuit boards for

remanufactured ones. Tektronix ships updated and tested exchange boards. Each

board comes with a 90-day service warranty.

For More Information. Contact your local Tektronix service center or sales

engineer for more information on any of the Calibration and Repair Services just

described.

Product

Support

Service

Support

For other

information

To write us Tektronix, Inc.

For application-oriented questions about a Tektronix measurement product, call toll free in North America:

1-800-TEK-WIDE (1-800-835-9433 ext. 2400)

6:00 a.m. – 5:00 p.m. Pacific time

Or contact us by e-mail:

tm_app_supp@tek.com

For product support outside of North America, contact your

local Tektronix distributor or sales office.

Contact your local Tektronix distributor or sales office. Or visit

our web site for a listing of worldwide service locations.

http://www.tek.com

In North America:

1-800-TEK-WIDE (1-800-835-9433)

An operator will direct your call.

P.O. Box 1000

Wilsonville, OR 97070-1000

TLA711 Benchtop Chassis Service Manual

xv

Page 18

Specifications

Product Description

This chapter provides a general description of the Benchtop Chassis and a list of

specifications under Characteristics Tables beginning on page 1–3.

The Benchtop Chassis is designed to be used as part of a TLA 700 Series Logic

Analyzer. It is an intelligent, 13-slot chassis with the following features:

H High output power supply

H Intelligent cooling for installed modules

H High quality auto-configurable backplane

H Optional adjustable rackmounts

Standard features are explained in more detail in the following paragraphs. Refer

to the Options chapter for a description of optional features.

Power Supply

Intelligent Cooling

The Benchtop Chassis provides voltages at levels sufficient for the most

demanding TLA 700 Series applications. The power supply has a volt-ampere

capacity of 1660 VA with 872 watts usable by TLA 700 Series instrument

modules at any one time. The chassis accommodates exclusively digital

applications (using the logic analyzer module), exclusively analog applications

(using the DSO module), or combinations of both.

The power supply plugs directly into the rear of the chassis and has no cables to

disconnect. Because of this design, you can replace the power supply in less than

three minutes, keeping downtime to a minimum. The power supply automatically accommodates the appropriate input voltage and frequency; no mechanical

switch is required to select the correct line voltage.

The Benchtop Chassis provides optimal cooling for all installed modules. The

chassis uses an intelligent, adaptive cooling scheme to efficiently remove heat

while maintaining quiet operation. When you set the blower to variable speed

(default), the chassis automatically adjusts the blower speed to keep the

temperature rise above the modules to approximately 10° C, or less. Using a rear

panel switch, you can set the blower to full speed to provide maximum cooling

at all times.

TLA711 Benchtop Chassis Service Manual

1–1

Page 19

Specifications

Air is exhausted at the sides of the chassis allowing you to stack the chassis with

other rackmount equipment. You don’t have to to worry about restricting any

airflow out of the top of the chassis or creating a chimney effect.

Cooling is not wasted on empty slots. Card guides automatically direct air to

only those slots containing modules; empty slots are shut off. The chassis directs

airflow across each installed module from the bottom to the top of each slot.

Baffles balance the airflow from the front to back and across occupied slots in

the chassis.

You can replace the blower without disassembling the entire chassis.

Backplane

The Benchtop Chassis has an autoconfigurable, solid-state backplane that uses

electronic jumpering of the IACK and BUS GRANT signal lines. There are no

jumpers to move or install on the backplane. This results in a high quality

backplane that is ideal for automatic test environment systems that must be

reconfigured frequently.

Full differential distribution of the CLK10 signals provide a clean timing source

for your TLA 700 Series instruments.

1–2

TLA711 Benchtop Chassis Service Manual

Page 20

Characteristics Tables

Specifications

This section lists specifications for the Benchtop Chassis. All specifications are

warranted unless noted “typical.” Typical characteristics describe typical or

average performance and provide useful reference information. Specifications

marked with the n symbol are checked in the Performance Verification chapter.

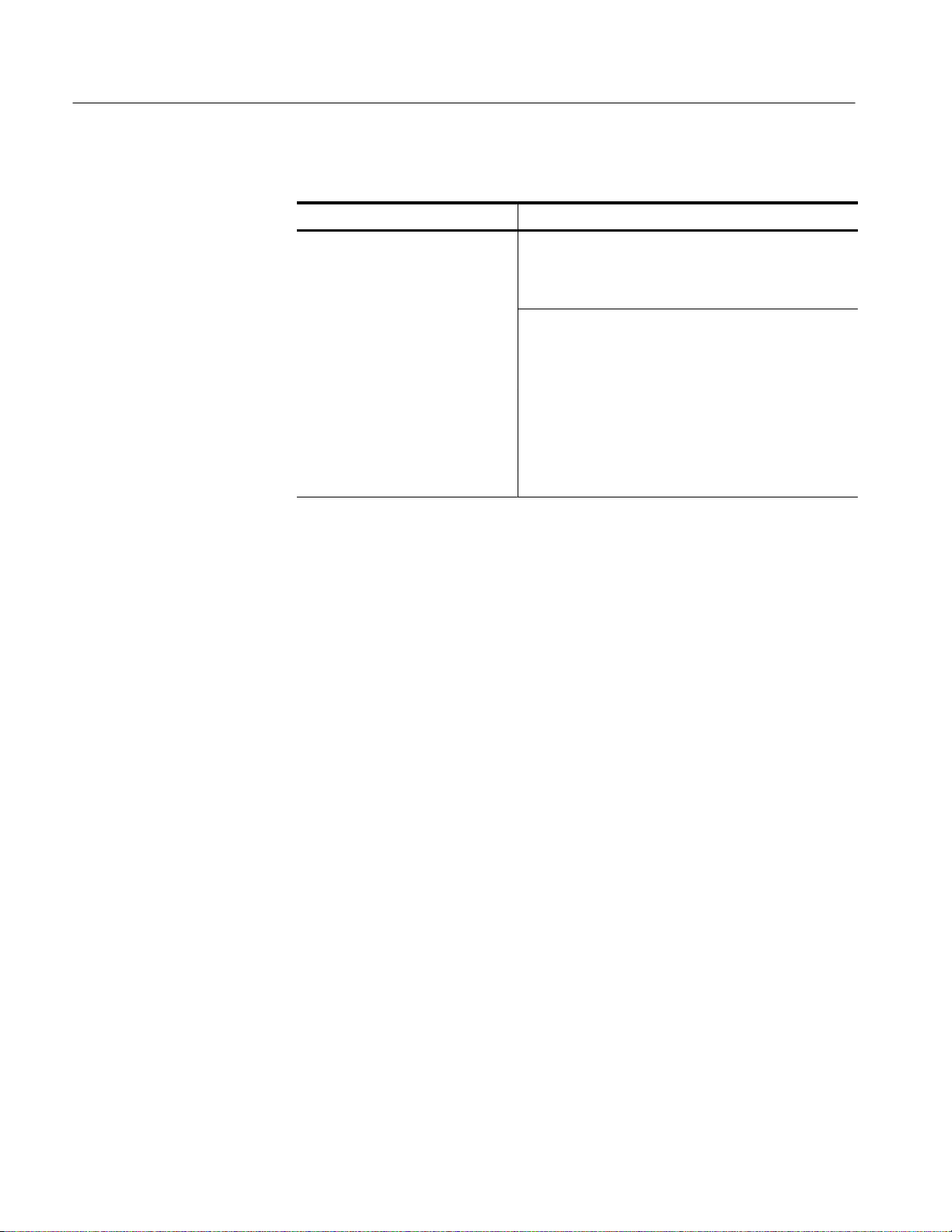

T able 1–1: AC power source

Characteristic Description

Source Voltage 90–250 V

100–132 V

45–66 Hertz, continuous range CA T II

RMS,

RMS,

Maximum Power Consumption 1350 W line power

(The maximum power consumed by a fully loaded 13-slot

instrument)

Fuse Rating

(Current and voltage ratings and

type of fuse used to fuse the source

line voltage)

90 V – 132 VAC

(High-power/Low Line

(159-0379-00)

Operation

RMS

Safety: UL198G/CSA C22.2,

Size: 0.25 in × 1.25 in,

Style: Slow acting,

Rating: 20 A/250 V

103 V – 250 VAC

(159-0256-00)

Operation

RMS

Safety: UL198G/CSA C22.2,

Size: 0.25 in × 1.25 in,

Style: No. 59/Fast acting,

Rating: 15 A/250 V

207 V – 250 VAC

(159-0381-00)

Operation

RMS

Safety: IEC 127/sheet 1

Size: 5 mm × 20 mm,

Style: Sheet 1, Fast acting “F”, high-breaking capacity,

Rating: 6.3 A/250 V

360–440 Hertz, continuous range CA T II

Inrush Surge Current 70 A maximum

Steady State Input Current 15 A RMS maximum at 90 VAC

Power Factor Correction Yes

TLA711 Benchtop Chassis Service Manual

6.3 Amps RMS maximum at 207 V AC

RMS

RMS

1–3

Page 21

Specifications

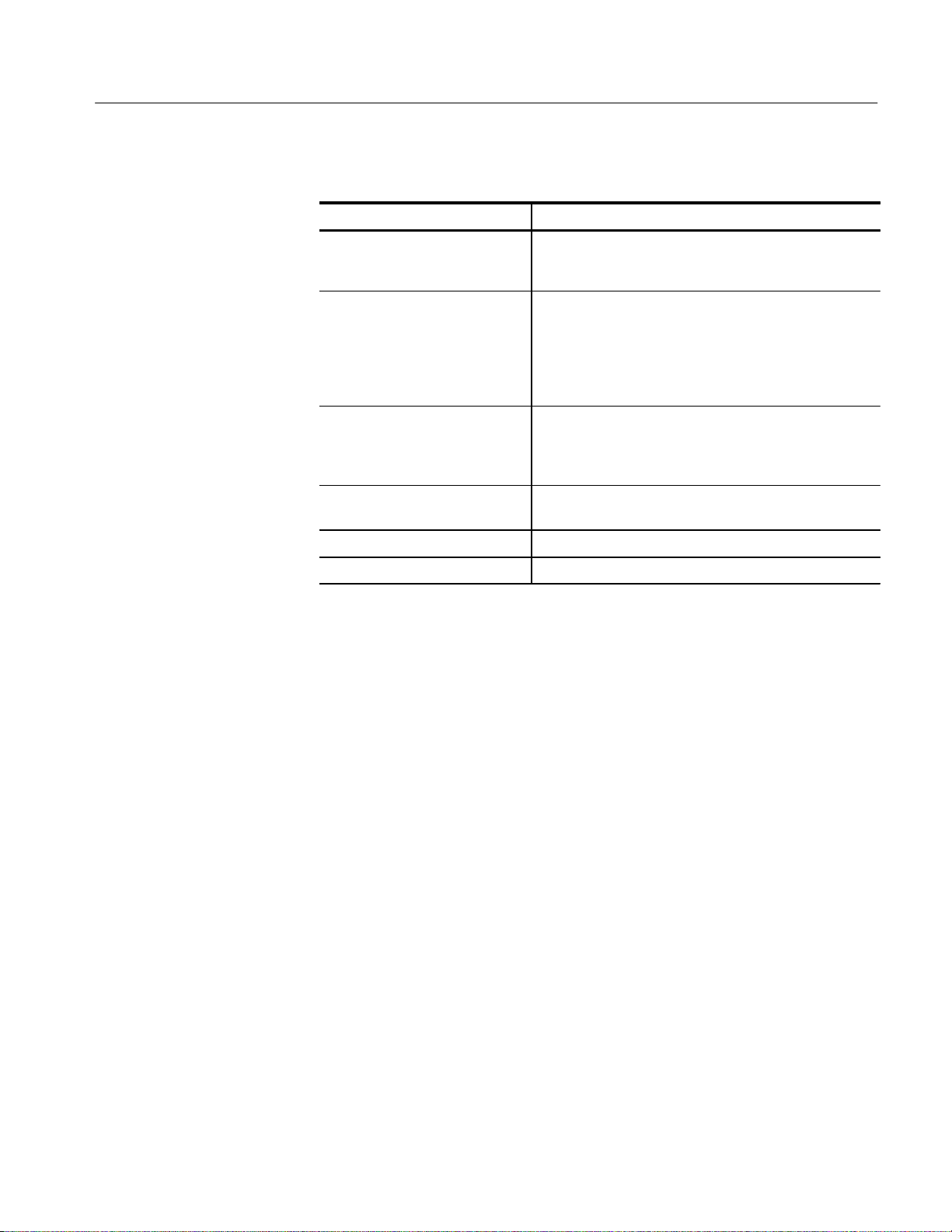

T able 1–2: Secondary power

Characteristic Description

n DC Voltage Regulation

(Combined System, voltage avail-

able at each slot)

Voltage Vmin, Vnom, Vmax

+24 V 23.28 V , 24.24 V , 25.20 V

+12 V 11.64 V, 12.12 V, 12.60 V

+5 V

–2 V

–5.2 V

–12 V

–24 V –25.20 V, –24.24 V, –23.28 V

4.875 V , 5.063 V , 5.25 V

–2.1 V , –2.000 V ,–1.9 V

–5.46 V , –5.252 V ,–5.044 V

–12.60 V, –12.12 V, –11.64 V

1–4

TLA711 Benchtop Chassis Service Manual

Page 22

Specifications

T able 1–3: Cooling

Characteristic Description

Cooling System Forced air circulation system (positive pressurization)

Blower Speed Control Rear panel switch selects between full speed and variable

Slot Activation Installing a module activates the cooling for the corresponding

Delta Temperature Readout

Sensitivity

Temperature Sense Range –10° C to +90° C, Delta temperature ≤ 50° C

Clearance 2 in (50.8 mm), rear, top, and sides of chassis

utilizing a single low-noise centripetal (squirrel cage)

blower configuration with no removable filters.

speed. Slot exhaust temperature and ambient air

temperature are monitored such that a constant delta

temperature is maintained across the module with the

highest exit air temperature at the minimum operational

blower speed.

occupied slots by opening the air flow shutter mechanism.

Optimizes cooling efficiency by only applying airflow to

modules that are installed.

100 mV/° C with 0° C corresponding to 0 V output

TLA711 Benchtop Chassis Service Manual

1–5

Page 23

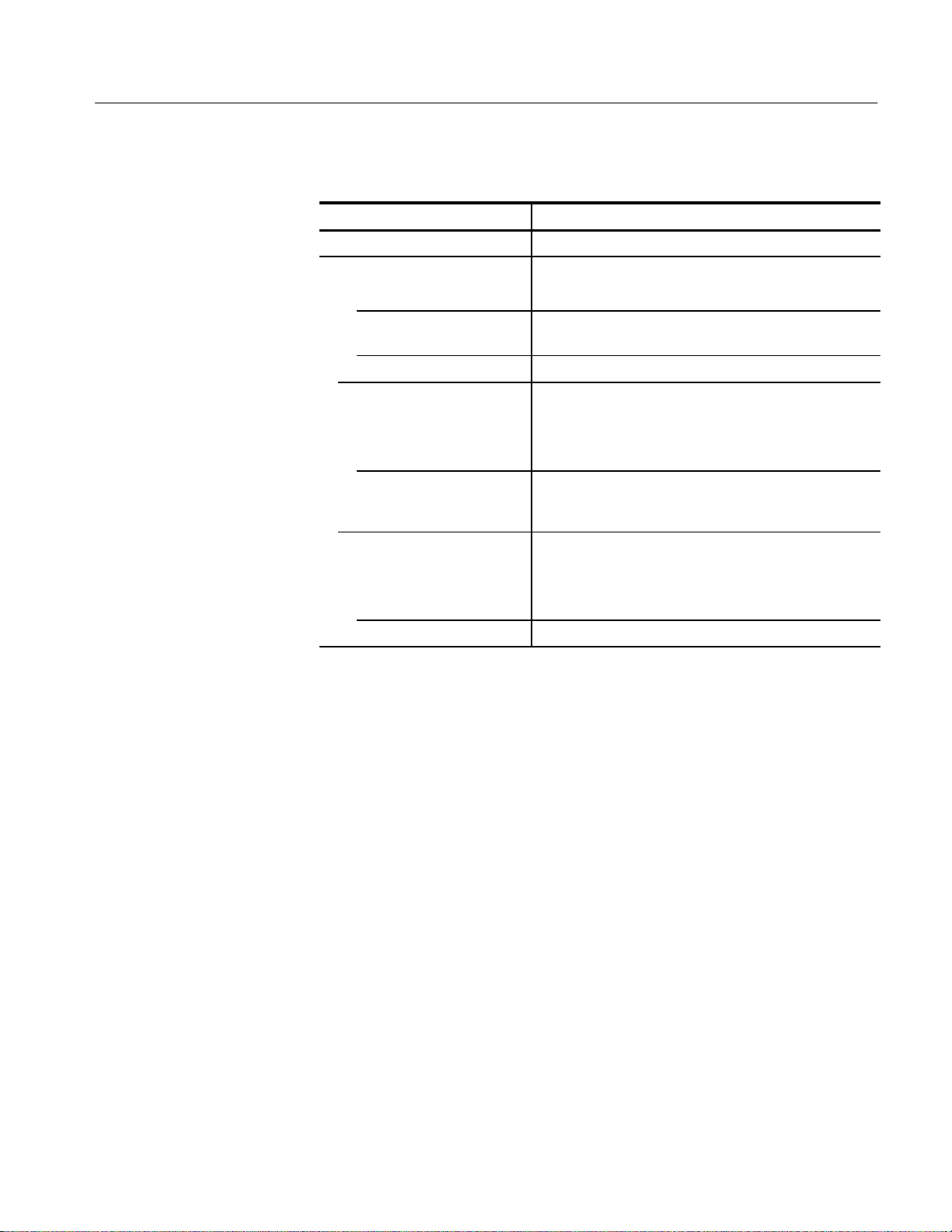

Specifications

T able 1–4: Safety

Characteristic Description

Safety Certification Conforms to, and is certified where appropriate to the

IEC Characteristics Installation Category II

following requirements:

Listed to UL3111-1 for Electrical Measuring and Test

Equipment,

Approved (cUL) to CAN/CSA–22.2 No. 1010.1 – 92 Safety

Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use, Part 1

Manufacturers declaration of conformity to EN 61010–1/A2

1995 “Safety Requirements for Electrical Equipment for

Measurement, Control and Laboratory Use.” Following the

directive 73/23/EEC

Pollution Degree 2

Safety Class I

1–6

TLA711 Benchtop Chassis Service Manual

Page 24

Specifications

T able 1–5: Environmental

Characteristic Description

Classification

Atmospherics

Temperature

Operating +5° C to 50° C, 15 ° C/hr max gradient, non-condensing

Nonoperating –20° C to 60° C, 15° C/hr max gradient, non-condensing

Relative Humidity

Operating 20% to 80% relative humidity, non-condensing.

Nonoperating 8% to 80% relative humidity, non-condensing.

Altitude

Operating To 10,000 ft. (3,048 m)

Nonoperating 40,000 ft. (12,190 m)

(derated 1° C per 1000 ft. above 5000 ft. altitude

Max wet bulb temperature: +29°C

(derates relative humidity to approximately 22% @ 50°C).

Max wet bulb temperature: +29° C

(derates relative humidity to ~55% @ 50°C).

(derated 1° C/1000 ft. (305m) above 5000 ft. (1524m)

altitude)

TLA711 Benchtop Chassis Service Manual

1–7

Page 25

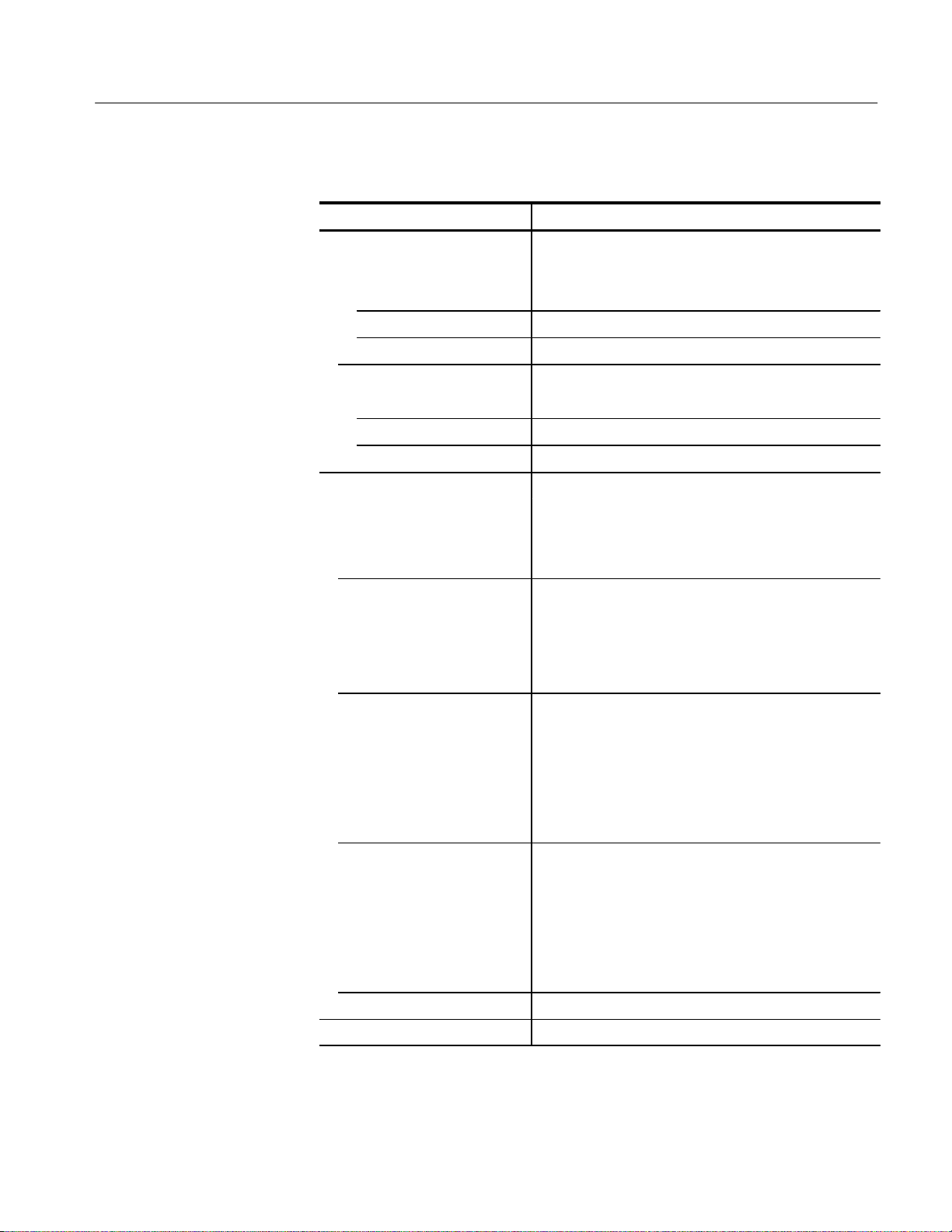

Specifications

T able 1–6: Electromagnetic compatibility (EMC)

Characteristic Description

Emissions Emissions shall be within the limits specified by the

following requirements:

Enclosure: EN 55011 Class A limits for radiated emissions

AC Mains: EN 55011 Class A limits for conducted emissions

EN 60555-2 AC power line harmonic emissions

Immunity , Enclosure,

RF Electromagnetic Field

Immunity , Enclosure,

Electrostatic Discharge

Immunity, Fast Transients, Common Mode

No instrument failures when the instrument is subjected to

a 3 V/m electromagnetic field over the frequency range of

27 MHz to 500 MHz.

Up to 8 kV with no change to control settings or

impairment of normal operation.

No loss of stored data, change to control settings,

degradation of performance, or temporary loss of function

will occur when the system is subjected to the following

transients:

Port Peak Voltage Tr/Th Rep Frequency

(k/V) (ns) (k/Hz)

––––––––––––––––––––––––––––––––––––––––––––

Signal & 0.5 5/50 5

Control

AC Power 1 5/50 5

1–8

TLA711 Benchtop Chassis Service Manual

Page 26

Specifications

T able 1–7: Mechanical

Characteristic Description

Overall Dimensions (See Figure 1–1 for overall chassis dimensions)

Standard Chassis

Height (with feet) 14.25 in (362.0 mm)

Width 16.75 in (425.5 mm)

Depth 26.5 in (673.1 mm)

Chassis with Rackmount

Height 14.0 in (355.6 mm)

Width 18.9 in (480.1 mm)

Depth 29.4 in (746.7 mm) min to 34.4 in (873.8 mm) max

Weight

Minimum mainframe configuration with Benchtop Controller

and slot filler panels installed (5

dual wides and 1 single wide

Typical configuration: same as

as minimum above with the

addition of 2 TLA7x4 LA’ s and

1 TLA7x2 DSO at 5 lbs 10 oz’s

each, and removal of 3 slot

filler panels

Shipping weight: minimum

configuration with Benchtop

Controller module (only) and all

mainframe standard accessories (2 manuals, 5 dual wide, 1

single slot filler panels, power

cord, empty pouch, front cover,

keyboard, software, and cables

Shipping weight: fully configured instrument. Same as

minimum above with the addition of 3 LA’s (TLA7M1,

TLA7M2, and TLA7M3) and 2

DSO’s (TLA 7D1 and TLA7E1),

and all module standard accessories (probes, clips)

62 lbs 2 oz. (28.18 kg)

77 lbs 14 oz. (35.32 kg)

118 lb (53.52 kg)

175 lb (79.38 kg)

Rackmount kit adder 20 lbs (9.07 kg)

Module Size 13 plug-in slots

TLA711 Benchtop Chassis Service Manual

1–9

Page 27

Specifications

16.75 in

(425.5 mm)

14.25 in

(362.0 mm)

Figure 1–1: Front view and side view of standard Benchtop Chassis

18.9 in

(480.1 mm)

26.5 in

(673.1 mm)

29.4 in (746.7 mm) Min to

34.4 in (873.8 mm) Max

14.0 in

(355.6 mm)

Figure 1–2: Front view and side view of Benchtop Chassis with Rackmount Option

1–10

TLA711 Benchtop Chassis Service Manual

Page 28

Operating Information

This chapter contains information about operating the Benchtop Chassis. Refer

to the TLA 700 Series Installation Manual for information on how to install and

configure the Benchtop Chassis. For more detailed operating information, refer

to the TLA 700 Series Logic Analyzer User Manual (Tektronix part number

070-9775-XX) and in the online help.

Installation

Basic installation instructions are contained in the TLA 700 Series Installation

Manual.

Operating Information

Figure 2–1 and Figure 2–2 show front and rear views, respectively, of the

Benchtop Chassis. Chassis slots 2 through 11 are labeled on the top and bottom

of the chassis. Slots 0 and 1 are reserved for the dual-wide controller; all other

slots are available for any other TLA 700 Series modules.

On/Standby

switch

Figure 2–1: Front view of the standard Benchtop Chassis

TLA711 Benchtop Chassis Service Manual

2–1

Page 29

Operating Information

Fuse

AC Power

25-Pin PASSIVE

MONITOR connector

Fan speed switch

Figure 2–2: Rear view of the standard Benchtop Chassis

When you install a module with a front panel, shutters on the bottom of each slot

automatically open to provide cooling for the installed modules. The shutters

remain closed for empty slots so that airflow is directed only where it is needed.

On/Standby Switch

The On/Standby switch on the top-left corner of the front panel applies DC

voltages to the chassis. The switch is a momentary contact switch. The switch is

lighted when DC voltages are applied to the chassis. You can also remotely

control the chassis.

You can configure your chassis to bypass the On/Standby switch. (Refer to

Remote Power Switch Configuration on page 6–20 of the Maintenance chapter

for information on configuring the power switch.) In this configuration, the

On/Standby switch remains lighted while power is applied, but the switch itself

no longer controls the chassis.

AC Power Connector

The AC power connector is located on the bottom left side on the rear of the

chassis. The AC fuse holder is located just above the power connector.

2–2

TLA711 Benchtop Chassis Service Manual

Page 30

Operating Information

Chassis Ground Screw

The chassis ground screw (if installed) can be used to connect more than one

chassis to a common ground point.

Fan Speed Switch

The Fan Speed switch controls the speed of the system cooling fan. When the

switch is set to the VAR (variable) position, the chassis automatically controls

the speed of the fan depending on the air temperature and amount of cooling

required by the modules. When the switch is in the FULL position, the fans

operate at full speed.

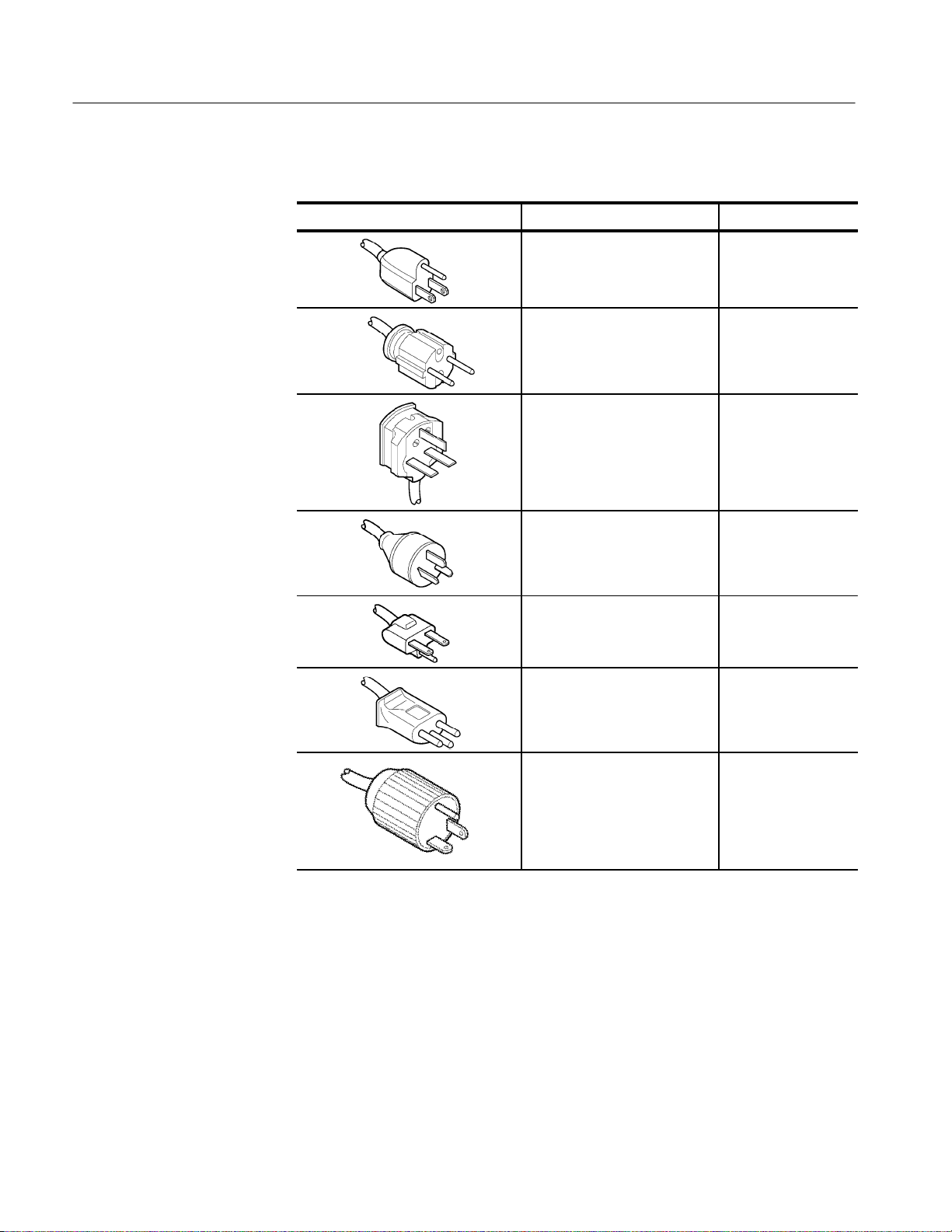

Selecting the Correct Power Cord and Fuse

The Benchtop Chassis comes standard with two power cords and three fuses.

Before installing the chassis, you must determine the correct fuse and power cord

for your application. Use the following information to determine the appropriate

power cord and line fuse. This information is important to avoid overloading the

power distribution system and to comply with the National Electrical Code.

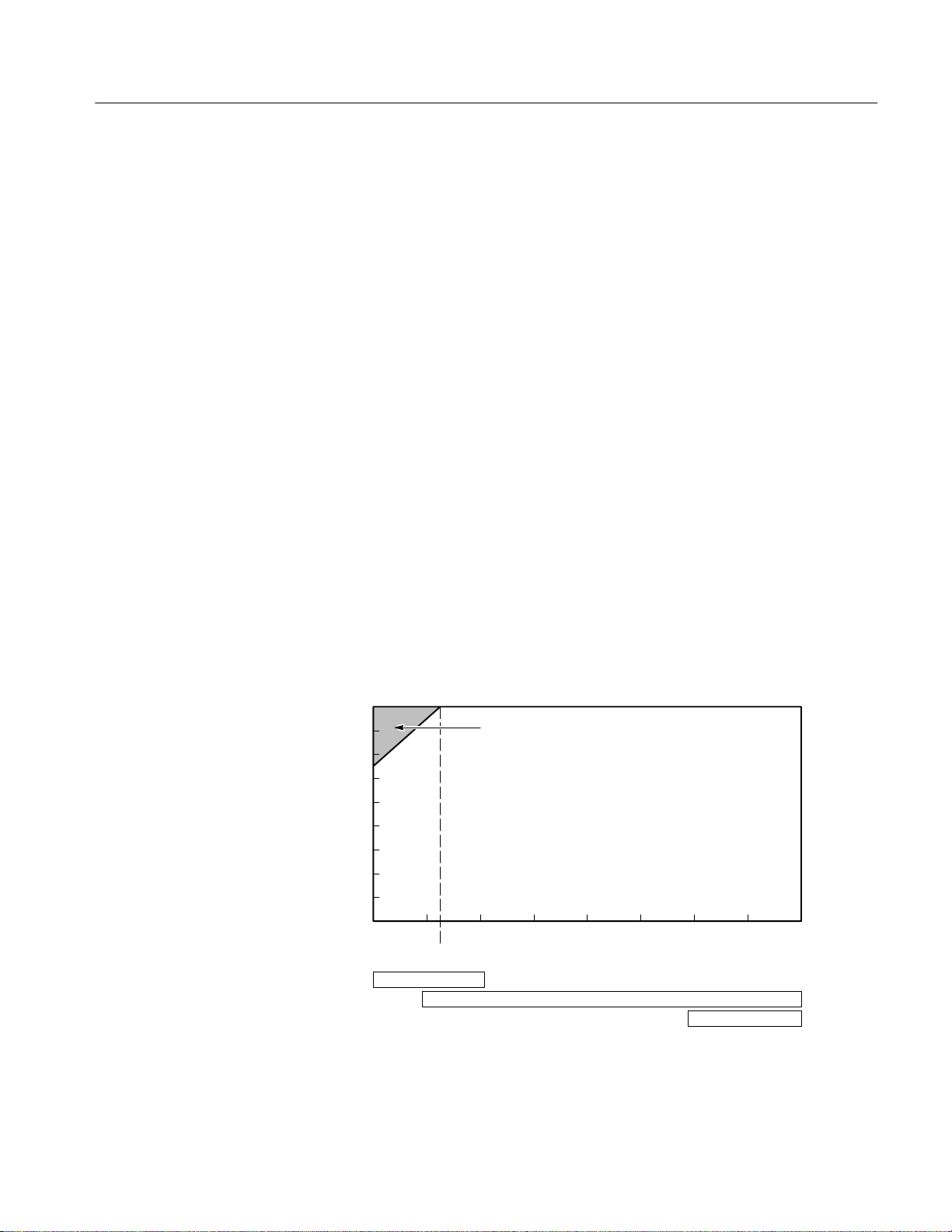

For card cage loads in the nonshaded region of Figure 2–3, use the power cord

with the 15 A plug (Tektronix part number 161-0213-XX) or the power cord

with the 20 A plug (Tektronix part number 161-0218-XX). For high card cage

loads combined with low input line voltages (shaded region), use only the power

cord with the 20 A plug.

Select the proper fuse based on the ranges shown in Figure 2–3.

Power Cord with 20A plug (NEMA 5–20P) ONLY!

Power Cord with 15A plug (NEMA 5–15P)

Power Cord with 20A plug (NEMA 5–20P)

130 150 170 190 210 230 250

Input Line Voltage (Volts AC)

6.3AF Fuse

Card Cage Power Consumption (Watts)

800

700

600

500

400

300

200

100

0

90 110

20AT Fuse

115

15AF Fuse

Figure 2–3: Power cord identification chart

TLA711 Benchtop Chassis Service Manual

2–3

Page 31

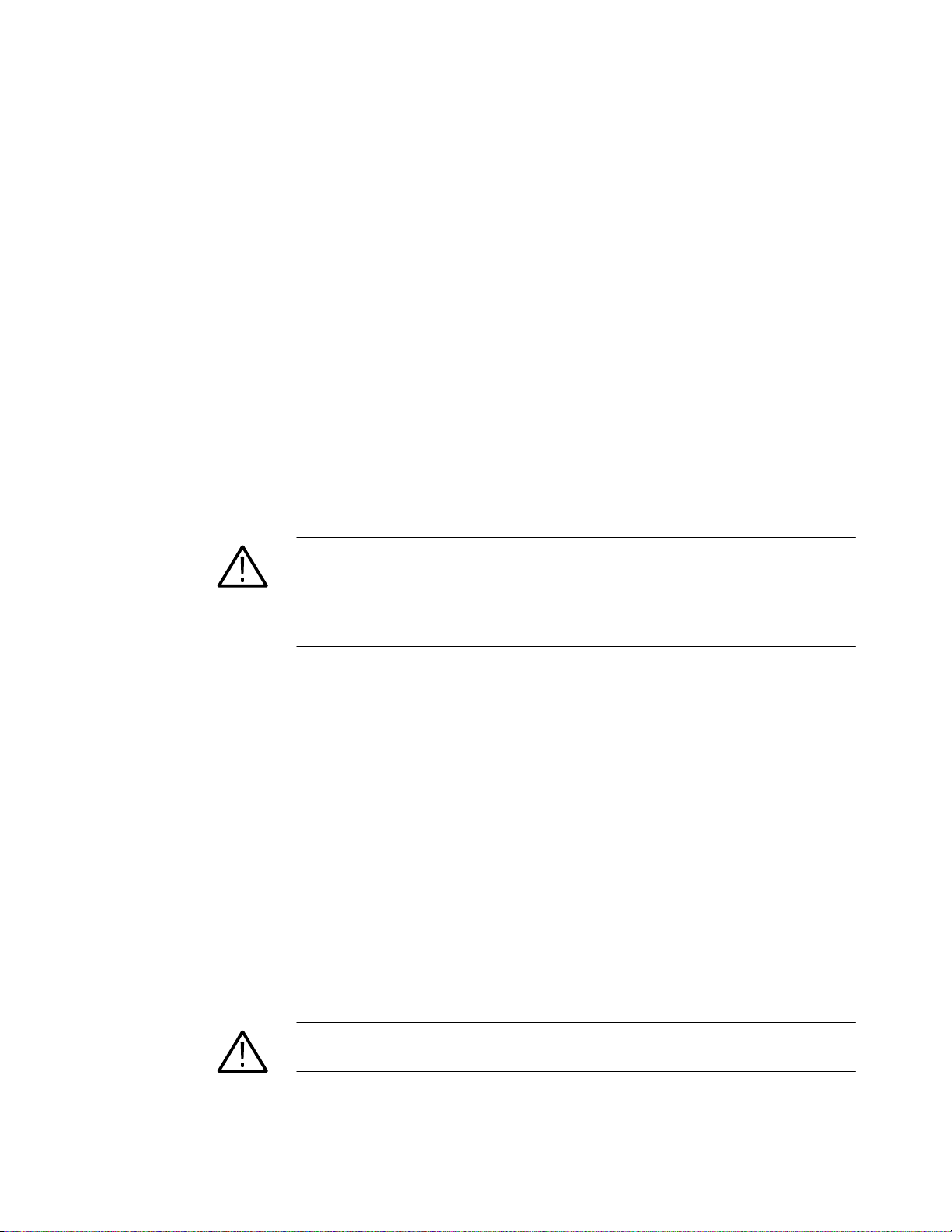

Theory of Operation

This section provides a brief overview of the theory of operation for the

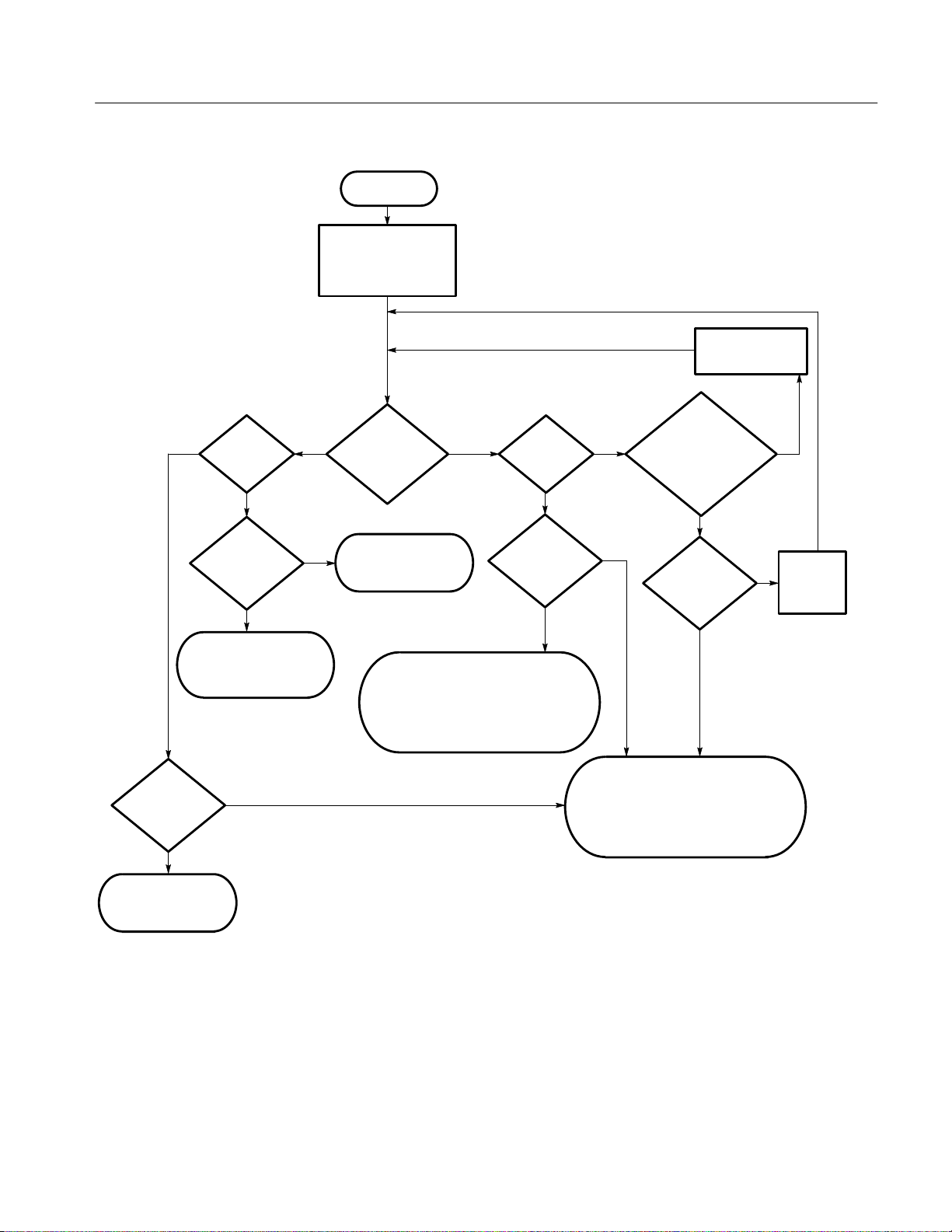

Benchtop Chassis. Figure 3–1 shows a functional block diagram of the major

components.

Standard Chassis

The standard chassis contains the following major components:

H Power supply

H Power Supply Interface board

H Backplane

H Monitor board

H Temperature Sense board

H Blower assembly

Power Supply and Power

Supply Interface Board

Backplane

The power supply provides all voltages and currents to the chassis. The power

supply connects to the backplane at J1 and J2 through the Power Supply

Interface board.

The backplane (A4) provides all the connections to module slots 0 through 12 in

the chassis. It also has connections to all other circuit boards and modules in the

chassis.

The front panel On/Standby DC switch connects to one of two connectors at the

top of the backplane. When the switch is connected to J22, the switch controls

the power in the chassis. When the switch is connected to J23, the power-on

functions are controlled by an external source through the 25-pin connector on

the Monitor board. Although the switch still illuminates when power is applied

to the chassis, the on/off function of the switch is disabled. (Refer to Remote

Power Switch Configuration on page 6–20.)

The backplane connects to the Power Supply Interface board at J20 and J21. A

34-wide ribbon cable at 0J4 on the backplane connects to J16 on the Temperature

Sense board. Connectors 0J1, 0J2, and 0P3 carry instrument monitoring

information from the backplane to the Monitor board.

TLA711 Benchtop Chassis Service Manual

3–1

Page 32

Theory of Operation

3

25

J6

S2/3 J10 P9 S1 J7 J8

A3

Monitor Board

Passive Monitor

Fan Speed Switch

4

Blower

AC in

3

A1

Power Supply

Interface

Board

P1

J1

Power Supply

0J3 0P1 0P2

30 96

3

P20

P2

P21

J2

96

3

3

0J4 0P3 0J1 0J2

0P1 1P1 2P1 3P1 4P1 5P1 6P1 7P1 8P1 9P1 10P1 11P1 12P1

0P2

J20 J21

J23 J22

1P2 2P2 3P2 4P2 5P2 6P2 7P2 8P2 9P2 10P2

J16

3

J24

A4

Backplane

A2

Temperature Sense Board

Slot 0 Slot 1 Slot 2 Slot 3 Slot 4 Slot 5 Slot 6 Slot 7 Slot 8 Slot 9 Slot 10 Slot 11

11P2

12P2

Slot 12

On / Standby

Switch

Figure 3–1: Chassis block diagram

3–2

TLA711 Benchtop Chassis Service Manual

Page 33

Theory of Operation

Monitor Board

Temperature Sense Board

The Monitor board (A3) collects the monitoring information from the power

supply, blower, and Temperature Sense board and passes the information to the

25-pin D connector. The Monitor board connects directly to the backplane at 0J3,

0P1 and 0P2.

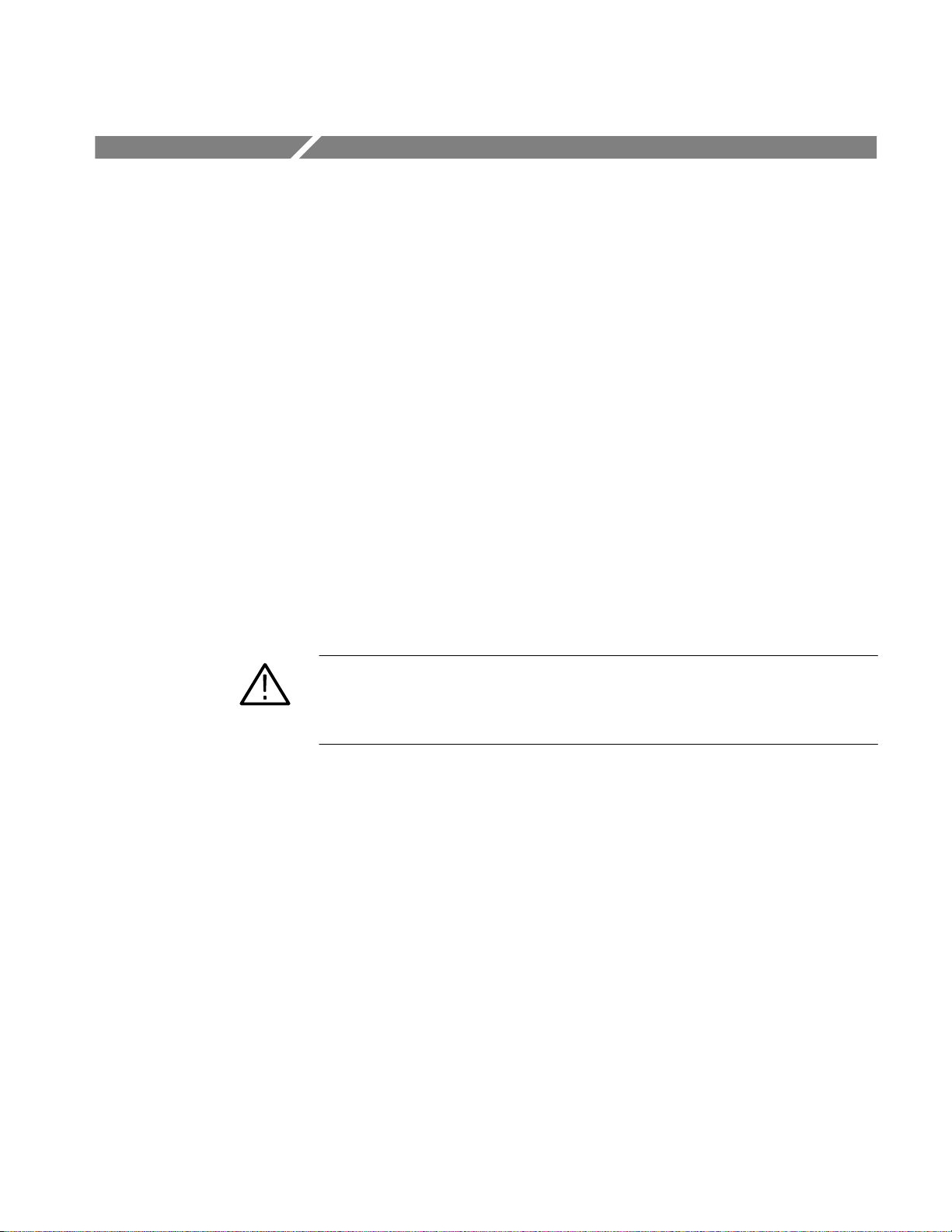

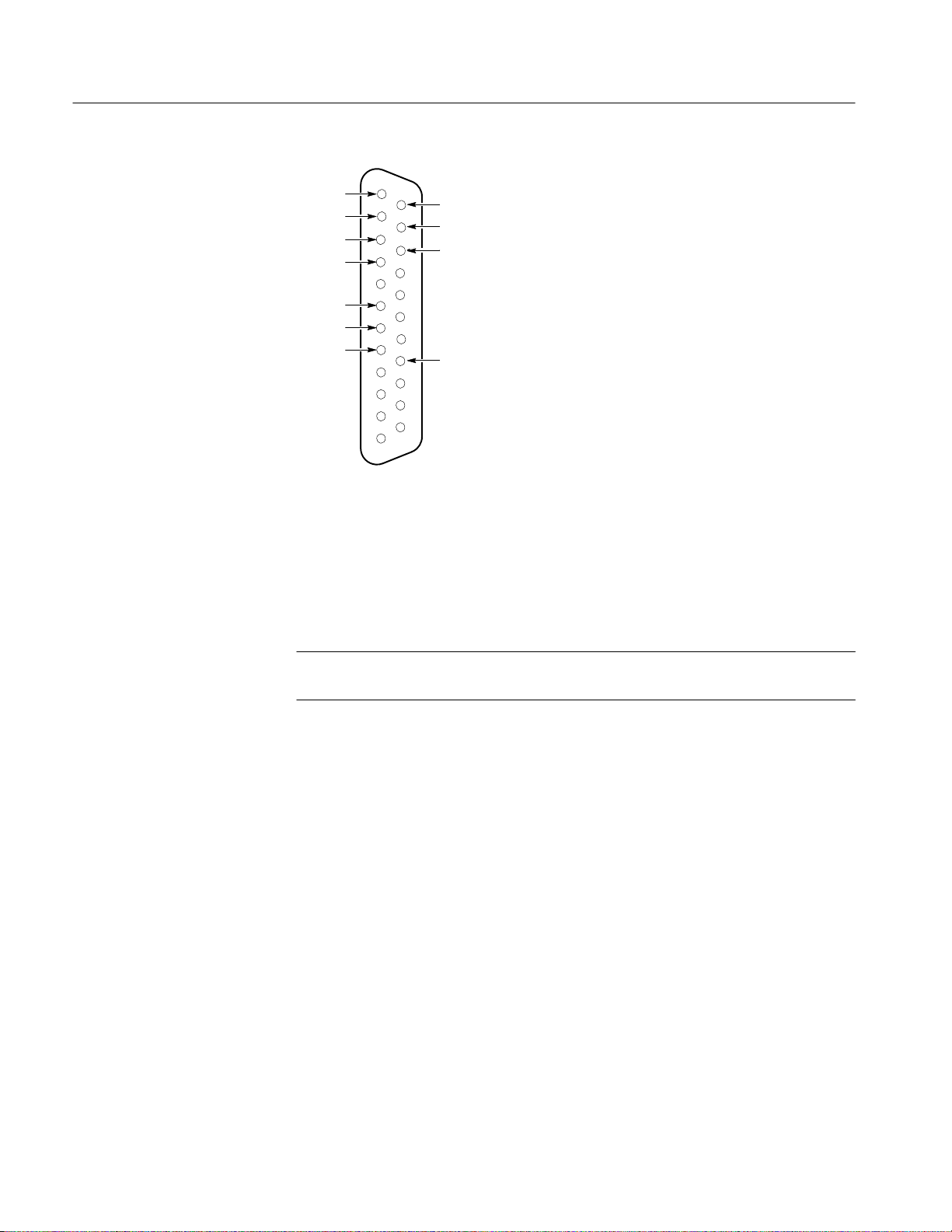

The 25-pin D Passive Monitor Connector lets you monitor the power supply

voltages, blower speed, and the maximum slot temperature rise within the

chassis. The connector also provides remote on and off capability and access to

the SYSRESET* and ACFAIL* signals. Figure 3–2 shows the pinouts of the

Passive Monitor Connector. Table 3–1 describes each of the pins and its

function.

WARNING. Do not connect an RS-232 cable to the 25-pin connector. The

connector is not an RS-232 connector. Connecting an RS-232 cable to the

connector can result in damage to the equipment.

The blower connects to the Monitor board at J7 (Fan2) and J8 (Fan1). The Fan

Speed switch (S1) lets you select either variable fan speed (VAR) or full speed

(FULL).

The Temperature Sense board (A2) monitors the temperatures for each slot

within the chassis. The Temperature Sense board connects to the backplane

through the ribbon cable at J16.

TLA711 Benchtop Chassis Service Manual

3–3

Page 34

Theory of Operation

Pin 1

Pin 25

Figure 3–2: Passive monitor connector

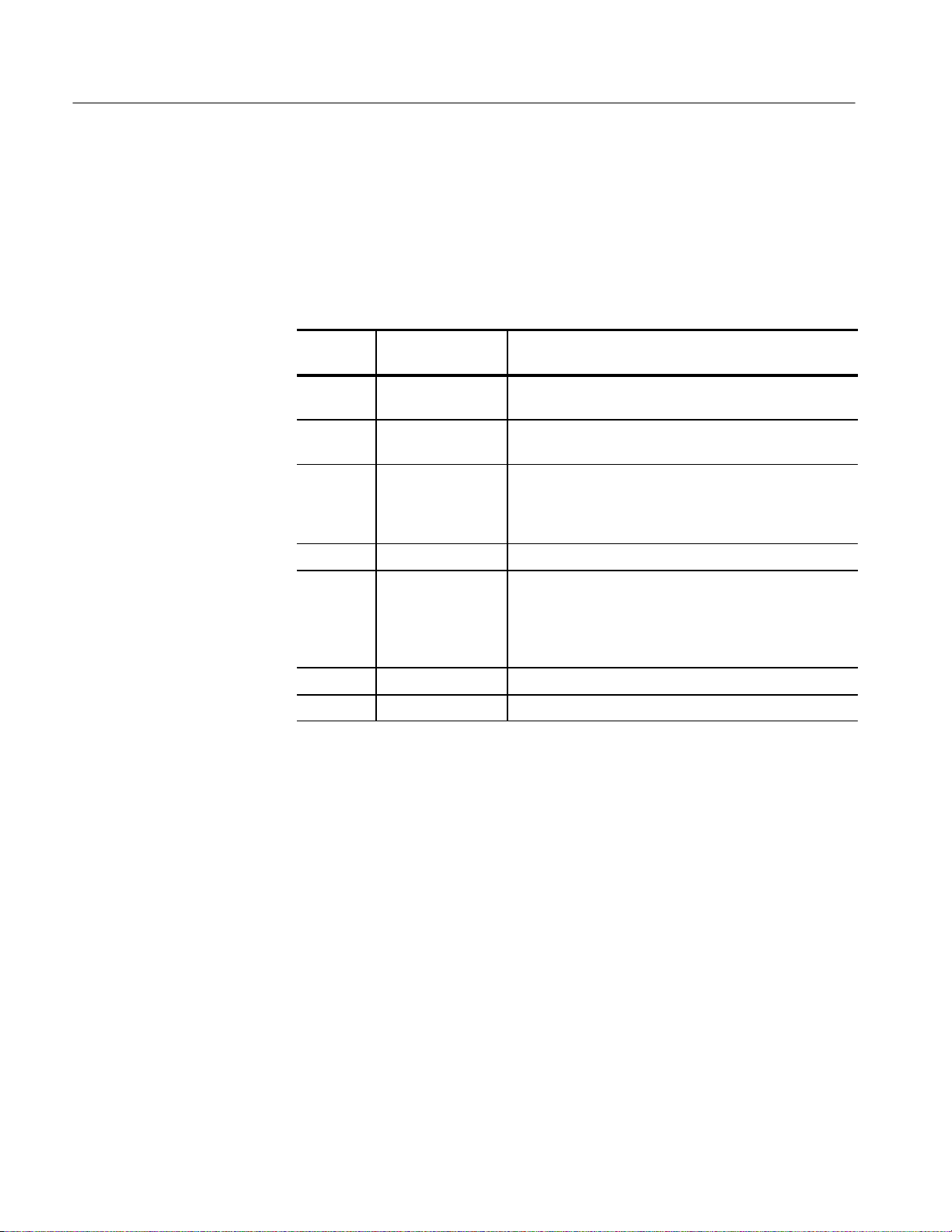

T able 3–1: Passive monitor connector pinouts

Pin Function Description

1 +5 VM +5 V for voltage monitoring

2 –12 VM –12 V for voltage monitoring

3 –24 VM –24 V for voltage monitoring

4 –2 VM –2 V for voltage monitoring

5 ON/ST Remote On/Standby Power Switch

6 +5 VC +5 V output for running external circuitry. 1 A max

7 +12 VC +12 V output for running external circuitry. 1 A max

8 +5 VB Input for +5 V standby current. 1 A max (pins 8 & 21)

9 GND Logic Ground

10 SYSR Backplane SYSRESET* signal (input or output). Use of this pin

requires adherence to VXI Specifications 1.4 (short extender cable,

etc.)

11 ∆T An analog output signal proportional to the maximum temperature

rise of the 13 modules (100 mV/°C rise)

1

3–4

TLA711 Benchtop Chassis Service Manual

Page 35

Theory of Operation

T able 3–1: Passive monitor connector pinouts (Cont.)

Pin DescriptionFunction

12 TACH1 A square wave output signal whose period is proportional to the

speed of fan #1

13 TACH2 A square wave output signal whose period is proportional to the

speed of fan #2 when a second fan is used. In the current Benchtop

Mainframe only a single blower is used

14 +12 VM +12 V for voltage monitoring

15 +24 VM +24 V for voltage monitoring

16 –5.2 VM –5.2 V for voltage monitoring

17 GND Logic Ground

18 GND Logic Ground

19 GND Logic Ground

20 GND Logic Ground

21 +5 VB Input for +5 V standby current. 1 A max (pins 8 & 21)

22 GND/T ACH3 Logic Ground OR a square wave output signal whose period is

proportional to the speed of fan #3 when a third fan is used. The

Benchtop Mainframe currently only utilizes a single blower so this

output will be grounded

1

23 ACFAIL Backplane ACFAIL* signal (input or output). Use of this pin requires

adherence to VXI Sys Specifications 1.4 (short extender cable, etc.)

24 GND/T ACH4 Logic Ground OR a square wave output signal whose period is

proportional to the speed of fan #4 when a fourth fan is used. The

Benchtop Mainframe currently only utilizes a single blower so this

output will be grounded

25 RSV Reserved as per the VXI Sys Specification 1.4

1 25-pin Sub-D connector provided on the upper left of the rear panel corner

(referenced from front of instrument) to provide access for power supply, temperature, and fan speed control monitoring.

TLA711 Benchtop Chassis Service Manual

3–5

Page 36

Performance Verification

The performance verification procedures for the TLA711 Benchtop Chassis are

located in the TLA 700 Series Performance Verification and Adjustment

Technical Reference Manual. There are no calibration (certification) procedures.

TLA711 Benchtop Chassis Service Manual

4–1

Page 37

Adjustment Procedures

There are no adjustment procedures for the TLA711 Benchtop Chassis.

TLA711 Benchtop Chassis Service Manual

5–1

Page 38

Maintenance

This chapter provides procedures for inspecting and cleaning the Benchtop

Chassis, removing and replacing internal chassis components, and isolating

problems to module levels.

H The Maintenance section provides general information on preventing

damage to internal circuit boards when doing maintenance and cleaning

external and internal parts.

H The Removal and Installation Procedures (page 6–5) provide procedures for

removing and installing circuit boards.

H Troubleshooting (page 6–23) provides information for isolating faulty circuit

boards and probes.

H Repackaging Instructions (page 6–31) provides packaging information for

shipment or storage.

You must accomplish instrument-level repairs by exchanging faulty modules

with known-good modules or parts. This chapter does not provide componentlevel procedures.

Related Maintenance Procedures

The following chapters contain information/procedures related to maintenance.

H The Operating Information chapter provides instructions for operating the

Benchtop Chassis in order to perform the maintenance procedures within this

manual.

H The Theory of Operation chapter contains a circuit description to the board,

or block, level.

H The Performance Verification chapter references the Performance Verifica-

tion and Adjustment Technical Reference manual. That manual contains tests

that may be useful in isolating problems by testing Benchtop Chassis

performance.

H The Diagrams chapter contains a block diagram using individual boards as

blocks and an interconnection diagram showing connections between the

circuit boards.

H The Mechanical Parts List chapter lists all field replaceable parts by part

number.

TLA711 Benchtop Chassis Service Manual

6–1

Page 39

Maintenance

Preparation

Preventing ESD

The TLA 700 Series Installation Manual may contain maintenance procedures

not included in this manual.

The information in this chapter is designed for use by qualified service personnel. Read the Safety Summary at the front of this manual before attempting any

procedures in this chapter. Refer to the Operating Basics chapter for information

on the location of controls, indicators, and connectors used with the chassis.

When performing any service which requires internal access to the mainframe

benchtop chassis, adhere to the following precautions to avoid damaging internal

circuit boards and their components due to electrostatic discharge (ESD).

CAUTION. Many components within the chassis are susceptible to staticdischarge damage. Service the chassis only in a static-free environment. Observe

standard handling precautions for static-sensitive devices while servicing the

chassis. Always wear a grounded wrist strap, or equivalent, while servicing the

chassis.

1. Minimize handling of static-sensitive circuit boards.

2. Transport and store static-sensitive circuit boards in their static protected

containers or on a metal rail. Label any package that contains static-sensitive

boards.

3. Discharge the static voltage from your body by wearing a grounded antistatic

wrist strap while handling these circuit boards. Do service of static-sensitive

circuit boards only at a static-free work station.

4. Nothing capable of generating or holding a static charge should be allowed

on the work station surface.

5. Handle circuit boards by the edges when possible.

6. Do not slide the circuit boards over any surface.

7. Avoid handling circuit boards in areas that have a floor or work-surface

covering capable of generating a static charge.

6–2

WARNING. To avoid electric shock, always power off the chassis and disconnect

the power cord before cleaning or servicing the chassis.

TLA711 Benchtop Chassis Service Manual

Page 40

Inspection and Cleaning

Maintenance

The chassis is inspected mechanically and electrically before shipment. It should

be free of marks or scratches and should meet or exceed all electrical specifications. To confirm this, inspect the chassis for physical damage incurred during

transit. Retain the chassis packaging in case shipment for repair is necessary. If

there is damage or deficiency, contact your local Tektronix representative.

Cleaning procedures consist of exterior and interior cleaning of the chassis and

cleaning the fan filter. Periodic cleaning reduces instrument breakdown and

increases reliability. Clean the chassis as needed, based on the operating

environment. Refer to your module documentation for information on cleaning

the individual TLA 700 Series modules.

Interior Cleaning

Exterior Cleaning

Use a dry, low-velocity stream of air to clean the interior of the chassis. Use a

soft-bristle brush for cleaning around components. If you must use a liquid for

minor interior cleaning, use a 75% isopropyl alcohol solution and rinse with

deionized water.

Clean the exterior surfaces of the chassis with a dry lint-free cloth or a softbristle brush. If any dirt remains, use a cloth or swab dipped in a 75% isopropyl

alcohol solution. Use a swab to clean narrow spaces around controls and

connectors. Do not use abrasive compounds on any part of the chassis.

CAUTION. Avoid getting moisture inside the chassis during exterior cleaning; use

just enough moisture to dampen the cloth or swab.

Do not wash the front-panel On/Standby switch. Cover the switch while washing

the chassis.

Use only deionized water when cleaning. Use a 75% isopropyl alcohol solution

as a cleanser and rinse with deionized water.

Do not use chemical cleaning agents; they may damage the chassis. Avoid

chemicals that contain benzene, toluene, xylene, acetone, or similar solvents.

TLA711 Benchtop Chassis Service Manual

6–3

Page 41

Removal and Installation Procedures

This section describes how to remove and install the major mechanical and

electrical modules. It provides the following information:

H List of Replaceable Parts on page 6–5 describes where to locate a list of

replaceable parts.

H Summary of Procedures on page 6–6 lists the procedures for removal and

installation of replaceable parts.

H Tools Required on page 6–6 describes the tools needed to perform the

procedures.

H Beginning with Removing the Blower Assembly on page 6–7, detailed

procedures describe the removal and installation of replaceable parts.

Preparation — Please Read

Please read the following warning statement. Then read the following general

instructions before removing a part.

WARNING. Before doing this or any other procedure in this manual, read the

General Safety Summary and Service Safety Summary found at the beginning of

this manual. Also, to prevent possible damage to electrical components, read

Preventing ESD on page 6–2.

Read the Summary of Procedures on page 6–6 to understand how the proce-

dures are grouped. Then read Tools Required on page 6–6 for a list of tools

needed to remove and install replaceable parts in the benchtop chassis.

List of Replaceable Parts

The Mechanical Parts List section provides a list of all replaceable parts.

TLA711 Benchtop Chassis Service Manual

6–5

Page 42

Removal and Installation Procedures

Summary of Procedures

The procedures are listed below in the order in which they appear in this section:

H Removing the Blower Assembly

H Removing the Monitor Board

H Removing the Power Supply

H Removing the Card Guides

H Removing the Top and Bottom Nut Rails

H Removing the Temperature Sense Board

H Removing the Backplane

Tools Required

Table 6–1 lists the tools needed to to disassemble the Benchtop Chassis:

T able 6–1: Tools required for parts replacement

Item Number Name Description

1 Flat Blade Screwdriver Small flat blade screwdriver

2 Cutters Diagonal cutters (for removing cable ties)

3 Screwdriver handle Accepts TorxR driver bits

8 T-15 Torx tip TorxR driver bit for T-15 size screw heads

9 T-20 Torx tip TorxR driver bit for T-20 size screw heads

10 Allen wrench A 3/32-inch Allen wrench (hex wrench)

11 Phillips screwdriver Phillips #1 screwdriver

6–6

TLA711 Benchtop Chassis Service Manual

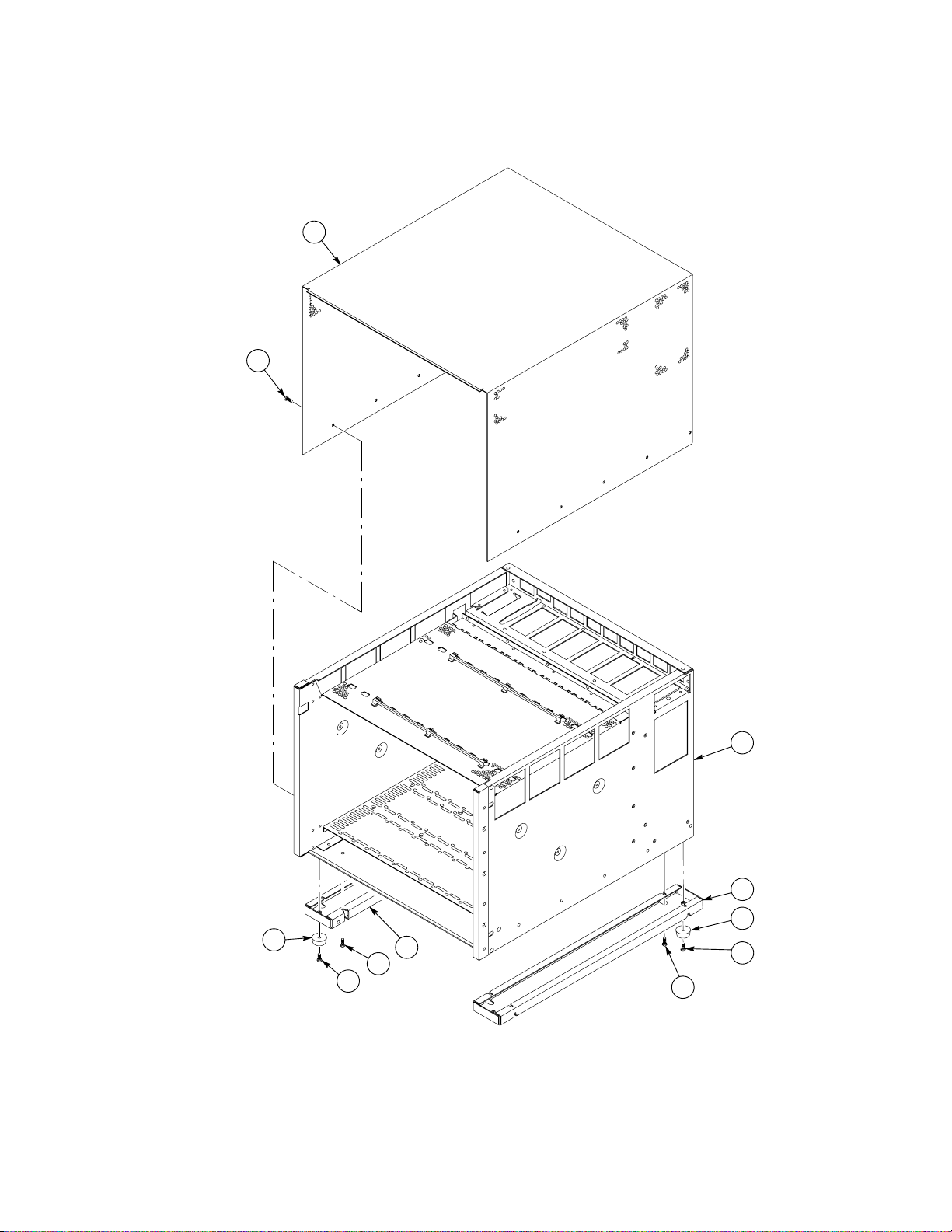

Page 43

Module Removal and Replacement

The following procedures describe how to remove and replace Benchtop Chassis

modules. Refer to the parts lists and exploded view illustrations beginning on

page 10–8 for an overview of chassis assembly and disassembly.

Removing the Blower Assembly

To remove the blower assembly, refer to Figure 6–2 and Figure 6–3 while

performing the following steps:

1. From the back of the chassis, loosen the five 8-32 captive screws including

the safety ground using a Phillips #1 screwdriver (refer to Figure 6–1 for the

screw locations).

2. Remove the Chassis Ground screw (if installed) using a T-20 tip.

3. Gently pivot the blower assembly outward from the chassis far enough to

access the blower cable on the right side of the chassis.

Removal and Installation Procedures

4. Unplug the blower cable and set the blower assembly aside on a clean

working surface.

5. To remove the blower, remove the ten 8-32 screws (with the Allen wrench)

holding the shroud part of the blower assembly to the chassis part of the

assembly. Set the shroud aside. There are three screws on each side and four

on the bottom. See Figure 6–3.

6. Remove the two sheet metal screws at the top of the blower.

7. Remove the four 8–32 screws that hold the blower to the chassis part of the

blower assembly.

8. For convenience, replace the two sheet metal screws from step 6 onto the top

of the blower.

NOTE. When reconnecting the blower cables to the chassis, verify that you

connect the blower cable to the proper connector

TLA711 Benchtop Chassis Service Manual

6–7

Page 44

Removal and Installation Procedures

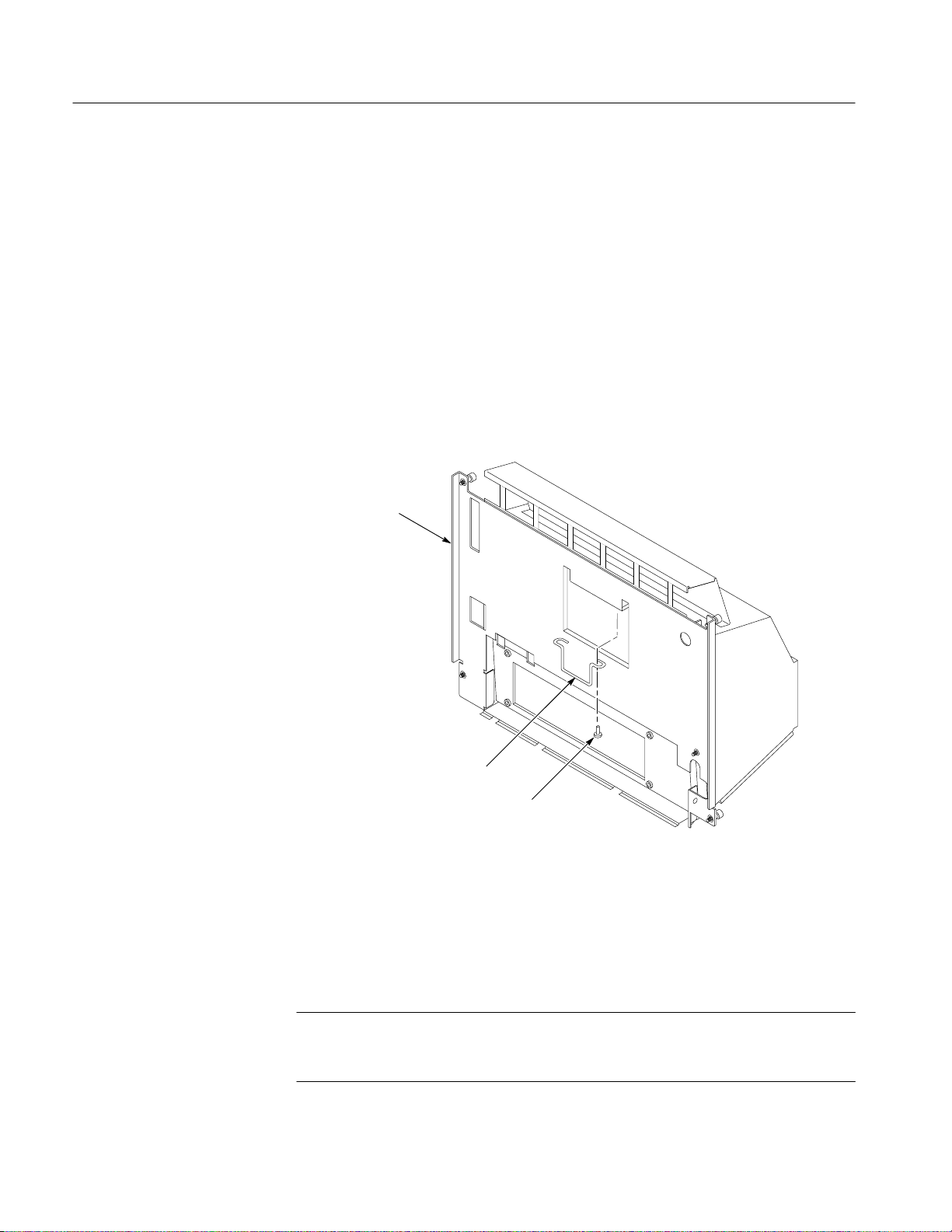

8-32 Captive

screw

Chassis ground

(8-32 Screw

not installed)

Safety ground

8-32 captive

screw

8-32 captive

screw

Figure 6–1: Location of blower assembly screws on the rear of the chassis

8-32 captive

screw

8-32 captive

screw

6–8

TLA711 Benchtop Chassis Service Manual

Page 45

Power supply

Removal and Installation Procedures

Ledge

Blower assembly

Figure 6–2: Removing the blower assembly

Blower cable

TLA711 Benchtop Chassis Service Manual

6–9

Page 46

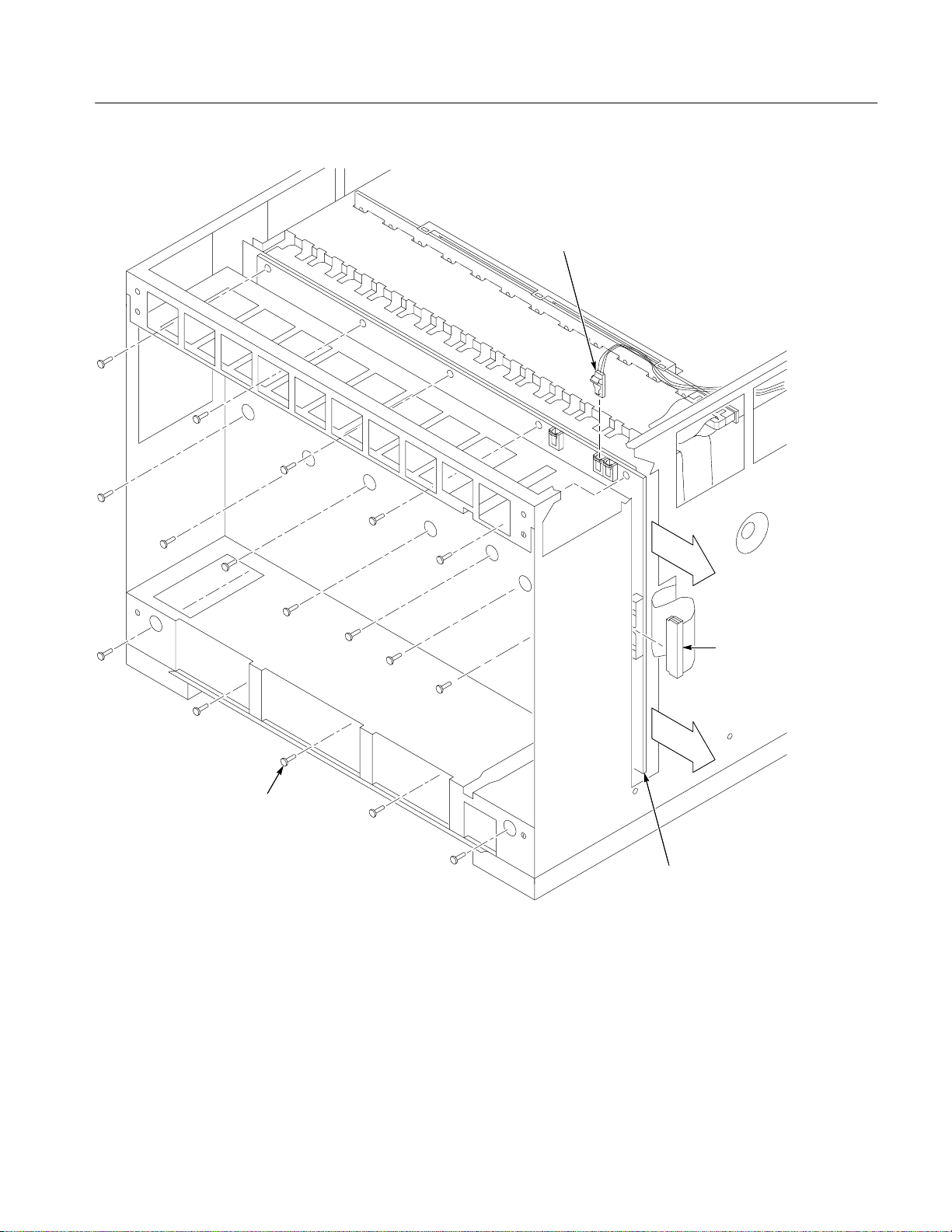

Removal and Installation Procedures

Shroud

Screws (4)

Blower assembly

Chassis

Screws (2)

Blower

Cable tie

Screws (4)

Screws (6)

Figure 6–3: Removing the blower

6–10

TLA711 Benchtop Chassis Service Manual

Page 47

Removing the Monitor Board

To remove the Monitor board, perform Removing the Blower Assembly and then

refer to Figure 6–4.

Grasp the cable tie loop and pull the monitor board until it comes loose from the

backplane. Then slide the board out of the right side of the chassis.

Monitor board

Removal and Installation Procedures

Cable tie loop

Figure 6–4: Removing the Monitor board

TLA711 Benchtop Chassis Service Manual

6–11

Page 48

Removal and Installation Procedures

Removing the Power Supply

To remove the power supply from the chassis, perform steps 1 through 4 of the

Removing the Blower Assembly procedure to remove the blower assembly.

Perform the Removing the Monitor Board procedure to remove the Monitor

board; then continue with the following steps:

1. Look in the recess in the chassis side of the blower assembly. You should

find in the recess the power supply handle and the two screws holding the

handle.

2. Remove the two screws and the power supply handle.

3. Reinstall the handle and the screws on the power supply. See Figure 6–5.

Blower assembly

(chassis side)

6–12

Power supply handle

Screws (2)

Figure 6–5: Removing the power supply

4. Using the handle on the power supply, firmly pull out the power supply from

the rear of the chassis.

5. Set the power supply assembly on a clean working surface.

NOTE. Step 6 is necessary only if you intend to replace the Power Supply

Interface board. This step is normally not necessary because the Power Supply

and the Power Supply Interface board can be replaced as a single unit.

TLA711 Benchtop Chassis Service Manual

Page 49

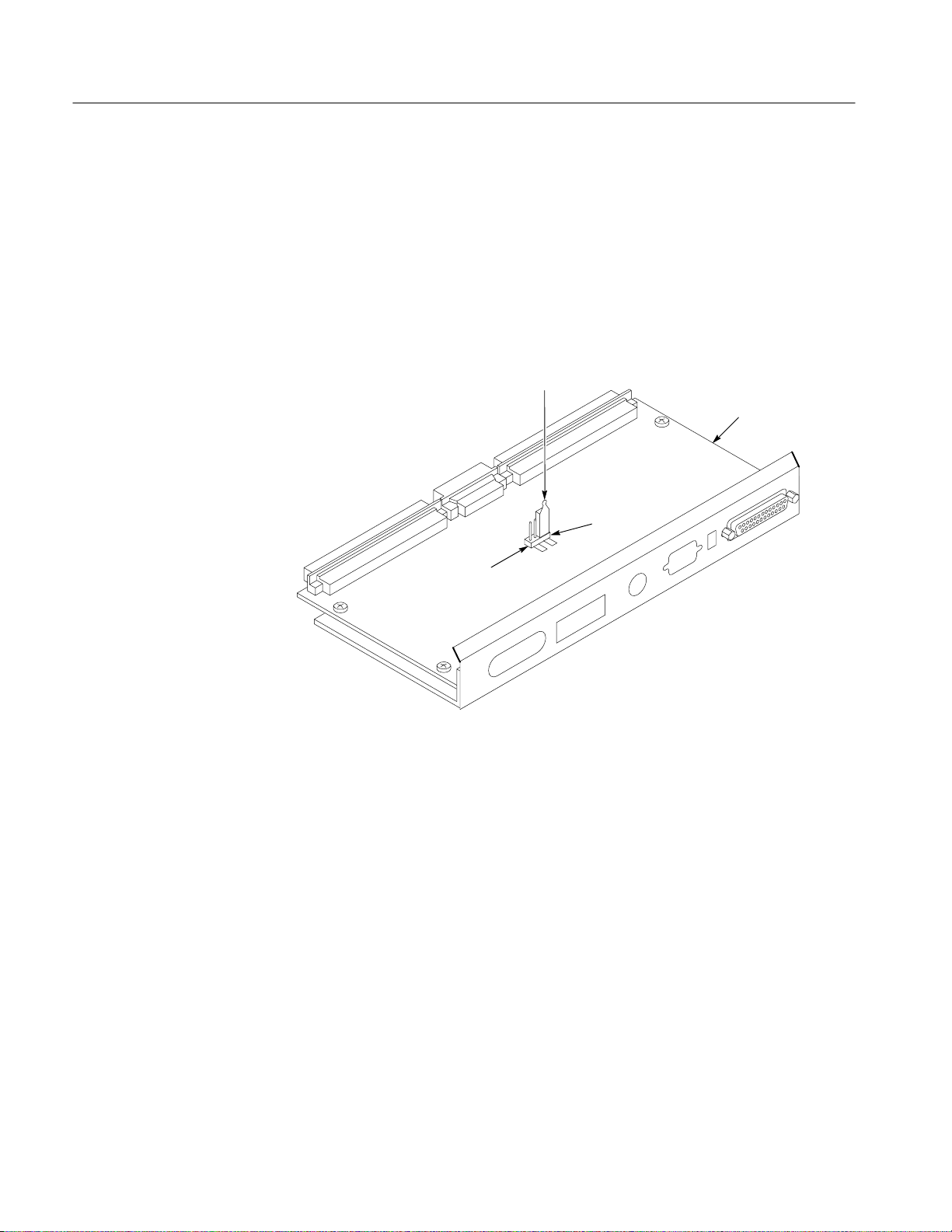

Removal and Installation Procedures

6. Refer to Figure 6–6 and remove the Power Supply Interface board from the

power supply module as shown.

8-32 Screws (4)

Power supply

interface board

Figure 6–6: Removing the Power Supply Interface board

TLA711 Benchtop Chassis Service Manual

6–13

Page 50

Removal and Installation Procedures

Removing the Card Guides

The card guides at the top and bottom of the chassis are very similar. The main

difference is that the bottom guides include the spring-loaded shutters to redirect

air into the chassis. The procedure for removing both guides is identical. Refer to

Figure 6–7 while performing the following steps:

1. Use a small flat blade screwdriver to pry up the tab of the card guide at the

2. Gently pull the card guide forward until it pops out of place.

3. Remove the card guide.

NOTE. The bottom card guides are replaced as a unit. These guides are not

intended to be disassembled.

To replace a card guide, slide the card guide towards the rear of the chassis and

allow the front of the card guide to snap into place.

front of the chassis being careful not to damage the card guide or the chassis.

6–14

TLA711 Benchtop Chassis Service Manual

Page 51

Gently pull the card guide

forward until it pops out of place.

Removal and Installation Procedures

Slide the card guides toward the rear of

the chassis and allow the front of the

card guide to snap into place.

Figure 6–7: Removing the top and bottom card guides

The nut rails at the top and the bottom of the front of the Benchtop Chassis allow

you to securely install the modules in the chassis by screwing the top and bottom

of the modules to the front of the chassis. Refer to Figure 6–8 to remove these

nut rails.

TLA711 Benchtop Chassis Service Manual

6–15

Page 52

Removal and Installation Procedures

1. Loosen all module retaining screws (it may be necessary to slide the modules

2. Remove the 12 screws holding the top cover to the chassis using a 3/32-inch

3. Slide the top cover of the chassis back far enough to expose the hole just

4. Slide the nut rail out of the hole on the side of chassis.

Replace the nut rail by sliding it back in the side of the chassis and pushing it

into place.

partially out of the chassis).

Allen wrench.

inside the top and bottom extrusions.

Top cover

Remove module

retaining screws.

Figure 6–8: Replacing the top and bottom nut rails

Nut rail

8-32 Screws (12)

Nut rail

6–16

TLA711 Benchtop Chassis Service Manual

Page 53

Removing the Temperature Sense Board

To remove the Temperature Sense board, remove the chassis cover and then

perform the following steps:

1. Disconnect the ribbon cable from the Temperature Sense board.

2. Refer to Figure 6–9 and gently pry back on each retainer holding the

Temperature Sense board in place.

3. Lift the board out of the holes at the top of the chassis being careful not to

damage any components on the circuit board.

Temperature

Sense board

Removal and Installation Procedures

Retainer

Figure 6–9: Removing the Temperature Sense board

Cable

TLA711 Benchtop Chassis Service Manual

6–17

Page 54

Removal and Installation Procedures

Removing the Backplane

To remove the backplane, perform the Removing the Blower Assembly, Removing

the Monitor Board, and Removing the Power Supply procedures. Refer to Figure

6–10 and then perform the following steps:

1. Remove the top cover of the chassis (see Figure 6–8, if necessary).

2. Disconnect the ribbon cable on the right side of the backplane.

NOTE. Before disconnecting the power switch cable, note which connector the

cable is connected to (J22, normally, or J23). Remember to reconnect the cable

to the correct connector.

3. Disconnect the power switch cable at J22 (or from J23) at the top of the

4. From the rear of the chassis, remove the five 6-32 screws on the top of the

backplane.

backplane, seven 6-32 screws from the center, and five 6-32 screws from the

bottom.

5. After removing all screws from the backplane, remove the backplane from

the chassis by sliding it out of the right side.

Install the backplane by reversing the disassembly procedure.

6–18

TLA711 Benchtop Chassis Service Manual

Page 55

Power switch

connector

Removal and Installation Procedures

6-32 Screws (17)

Figure 6–10: Removing the Backplane

Ribbon

cable

(connector)

Backplane

TLA711 Benchtop Chassis Service Manual

6–19

Page 56

Removal and Installation Procedures

Special Configuration Options

This section contains information for configuring your Benchtop Chassis for

specific situations not documented earlier in this manual. These special

configuration options require you to disassemble parts of the chassis to access

jumpers or circuit boards. Refer to the Maintenance chapter for detailed

information on the assembly and disassembly procedures. You may also need to

refer to the exploded views in Mechanical Parts List.

The information in this section is intended for use by qualified service personnel.

Read the Safety Summary at the front of this manual and the static precautions on

page 6–2 before attempting any procedures in this appendix. Refer to Operating

Information for information on the location of controls, indicators, and connectors used with the chassis.

CAUTION. To avoid damage from high currents on the backplane, always power

off the chassis and disconnect the power cord before performing any of the

configuration procedures described in this section.

Remote Power Switch

Configuration

You can control the power-on function of the chassis using the front panel

On/Standby switch and from a remote momentary switch through the connections of the 25-pin rear panel connector. If you connect a remote switch to

pins 5 and 18 (return side) of the 25-pin connector, the remote switch and the

front-panel On/Standby switch control the power-on functions of the chassis.

You can also disable the front-panel switch and control the power-on functions

from the remote switch only. The backplane has two connectors that control the

power-on functions. If the front panel switch is connected to the backplane at

J22, the switch controls the power-on functions. If the switch is connected to

J23, the front panel switch is disabled, however, the light still illuminates when

the chassis is powered on. To configure the chassis to disable the front panel

On/Standby switch, perform the following steps:

6–20

TLA711 Benchtop Chassis Service Manual

Page 57

Removal and Installation Procedures

1. Disconnect the power cord from the chassis.

2. Remove the cover from the chassis.

3. Refer to Figure 6–11 and locate the two connectors at the top of the

backplane.

4. Disconnect the On/Standby switch cable at J22 and connect it to J23.

5. Replace the chassis cover.

6. Connect the momentary switch to pins 5 and 18 (return side) of the 25-pin

rear panel connector.

Power switch

connector

J22

J23

Figure 6–11: Power switch connectors

Backplane

TLA711 Benchtop Chassis Service Manual

6–21

Page 58

Removal and Installation Procedures

8°/10° and 13°/15° Jumper

on the Monitor board

Jumper J11 on the Monitor board (see Figure 6–12) allows you to further define

the temperature sensitivity of the Temperature Sense board. The jumper

determines the maximum allowable temperature rise in the chassis. The jumper

is shipped in the 8°/10° position.

You can move the jumper to the 13 ° /15° position if you do not expect a high