Technical Reference Manual

TLA7000 Series Mainframes

071-1764-00

This document applies to System Software version 5.0 and above.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Copyright © Tektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or

suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Spec ifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

H In North America, call 1-800-833-9200.

H Worldwide, visit www.tektronix.com to find contacts in your a rea.

Warranty 2

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a re placement in

exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty work

may be new or reconditioned to like new performance. All replaced parts, modules and products become the

property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by Tektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the Tektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products ret urned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or c onnection to incom patible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Table of Contents

General Safety Summary v...................................

Service Safety Summary vii....................................

Environmental Considerations viii...............................

Preface ix...................................................

Manual Structure ix................................................

Manual Conventions ix..............................................

Mainframes ix.................................................

Replaceable Parts ix............................................

Related Documentation x...........................................

Introduction xi..............................................

Adjustment and Certification Interval xi................................

Service Strategy xi.................................................

Service Offerings xi................................................

Warranty Repair Service xii.......................................

Calibration and Repair Service xii..................................

Maintenance 1..............................................

Preventing ESD 1.................................................

Inspection and Cleaning 2...........................................

Exterior Inspection 2...........................................

Exterior Cleaning Procedure 3....................................

Interior Inspection 3............................................

Interior Cleaning Procedure 4....................................

Portable Mainframe Removal and Installation Procedures 5.......

Equipment Required 5..............................................

Instrument Covers 6..............................................

Front Panel Display 8.............................................

DVD Drive 10.....................................................

Motherboard 10....................................................

Interface Board 11.................................................

Backplane 12......................................................

Power Supply 13...................................................

Benchtop Mainframe Removal and Installation Procedures 15......

Equipment Required 15..............................................

Instrument Modules 16..............................................

Blower Assembly 16................................................

Removing the Enhanced Monitor Board 19..............................

Power Supply 21...................................................

Mainframe Cover 22................................................

Card Guides 23....................................................

Temperature Sense Board 25..........................................

Front Panel and Display Module 26....................................

EMI DIN Shields 29................................................

Backplane 30......................................................

Repackaging Instructions 33...................................

Packaging 33......................................................

TLA7000 Series Mainframe Technical Reference Manual

i

Table of Contents

Shipping to the Service Center 33......................................

Parts List 35.................................................

Parts Ordering Information 35.........................................

Part Number Revision Level 36....................................

Module Servicing 36............................................

Using the Replaceable Parts List 37....................................

Abbreviations 37...............................................

Mfr. Code to Manufacturer Cross Index 37...........................

ii

TLA7000 Series Mainframe Technical Reference Manual

List of Figures

Table of Contents

Figure 1: Locator diagram 6..................................

Figure 2: Instrument enclosure detail 7.........................

Figure 3: Tilt the panel forward for cable access 8................

Figure 4: Front panel cable locations 9..........................

Figure 5: Dress the cables properly 9...........................

Figure 6: Removing the motherboard 11.........................

Figure 7: Removing the interface board 12.......................

Figure 8: Removing the backplane 13...........................

Figure 9: Location of blower assembly screws 17..................

Figure 10: Removing the blower assembly 18.....................

Figure 11: Removing the blower 18..............................

Figure 12: Removing the enhanced monitor board 19..............

Figure 13: Removing the power supply 21........................

Figure 14: Removing the mainframe cover 22.....................

Figure 15: Removing the top and bottom card guides 24............

Figure 16: Removing the temperature sense board 26..............

Figure 17: Removing the instrument front panel 27................

Figure 18: Installing the new front panel 28......................

Figure 19: Removing the backplane EMI DIN shields 29...........

Figure 20: Removing the backplane 31..........................

Figure 21: Soft power down jumper setting 32....................

Figure 22: External parts 41...................................

Figure 23: Front panel assembly 43.............................

Figure 24: Interface, backplane and motherboard 45..............

Figure 25: Power supply and fans 47............................

Figure 26: Cabinet and chassis assembly 49......................

Figure 27: Circuit boards and chassis parts 51....................

Figure 28: Power supply, monitor, and fan assembly 53............

Figure 29: Slot 0 Interface module 54............................

Figure 30: iView cables 55.....................................

TLA7000 Series Mainframe Technical Reference Manual

iii

Table of Contents

List of Tables

Table i: Tektronix Logic Analyzer Family documentation x........

T able 1: External inspection check list 2........................

T able 2: Internal inspection check list 3........................

Table 3: Equipment required to service the mainframes 5.........

Table 4: Equipment required to service the mainframes 15.........

Table 5: Enhanced monitor board jumpers 20....................

Table 6: Mainframe backplane jumpers 32.......................

Table 7: Parts lists column descriptions 37.......................

iv

TLA7000 Series Mainframe Technical Reference Manual

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions related to operating the system.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

The inputs are not rated for connection to mains or Category II, III, or IV

circuits.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Power Disconnect. The power cord disconnects the product from the power

source. Do not block the power cord; it must remain accessible to the user at all

times.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Do Not Operate in Wet/Damp Conditions.

TLA7000 Series Mainframe Technical Reference Manual

v

General Safety Summary

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Terms in this Manual

Symbols and Terms

on the Product

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

H DANGER indicates an injury hazard immediately accessible as you read the

marking.

H WARNING indicates an injury hazard not immediately accessible as you

read the marking.

H CAUTION indicates a hazard to property including the product.

The following symbols may appear on the product:

CAUTION

Refer to Manual

WARNING

High Voltage

vi

Protective Ground

(Earth) Terminal

Chassis Ground

Standby

TLA7000 Series Mainframe Technical Reference Manual

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

TLA7000 Series Mainframe Technical Reference Manual

vii

Environmental Considerations

This section provides information about the environmental impact of the

product.

Product End-of-Life

Handling

Observe the following guidelines when recycling an instrument or component:

Equipment Recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could be

harmful to the environment or human health if improperly handled at the

product’s end of life. In order to avoid release of such substances into the

environment and to reduce the use of natural resources, we encourage you to

recycle this product in an appropriate system that will ensure that most of the

materials are reused or recycled appropriately.

The symbol shown to the left indicates that this product

complies with the European Union’s requirements

according to Directive 2002/96/EC on waste electrical and

electronic equipment (WEEE). For information about

recycling options, check the Support/Service section of the

Tektronix Web site (www.tektronix.com).

Mercury Notification. This product uses an LCD backlight lamp that contains

mercury. Disposal may be regulated due to environmental considerations. Please

contact your local authorities or, within the United States, the Electronics

Industries Alliance (www.eiae.org) for disposal or recycling information.

Restriction of Hazardous

Substances

viii

This product has been classified as Monitoring and Control equipment, and is

outside the scope of the 2002/95/EC RoHS Directive. This product is known to

contain lead, cadmium, mercury, and hexavalent chromium.

TLA7000 Series Mainframe Technical Reference Manual

Preface

Manual Structure

Manual Conventions

This is the service manual for the TLA7012 Portable Mainframe and the

TLA7016 Benchtop Mainframe. For service information on the TLA7PC1, refer

to the documentation that came with the product.

This document contains the following information:

H Maintenance contains information and procedures for doing corrective

maintenance on the instruments. Included are instructions for removal and

installation of replaceable parts.

H Mechanical Parts List includes tables of all replaceable parts for the

instrument along with the Tektronix part number.

This manual uses certain conventions that you should become familiar with

before attempting service.

Mainframes

Replaceable Parts

The TLA7012 Portable Mainframe has a built-in controller and display with

room for two TLA plug-in modules. The benchtop mainframe consists of a

mainframe with an interface module. Slots are available for installing other

modules.

This manual refers to any field-replaceable assembly or mechanical part

specifically by its name or generically as a replaceable part. In general, a

replaceable part is any circuit board or assembly, such as the hard disk drive, or a

mechanical part, such as the I/O port connectors, that is listed in the replaceable

parts list.

TLA7000 Series Mainframe Technical Reference Manual

ix

Preface

Related Documentation

The following documents are available as part of the Tektronix Logic Analyzer

Family documentation set. The procedures in this manual assume that the service

personnel have access to the manuals listed in the following table. Contact your

local Tektronix Service Representative for the latest part numbers of the service

documentation. All manuals are available at the Tektronix Web Site.

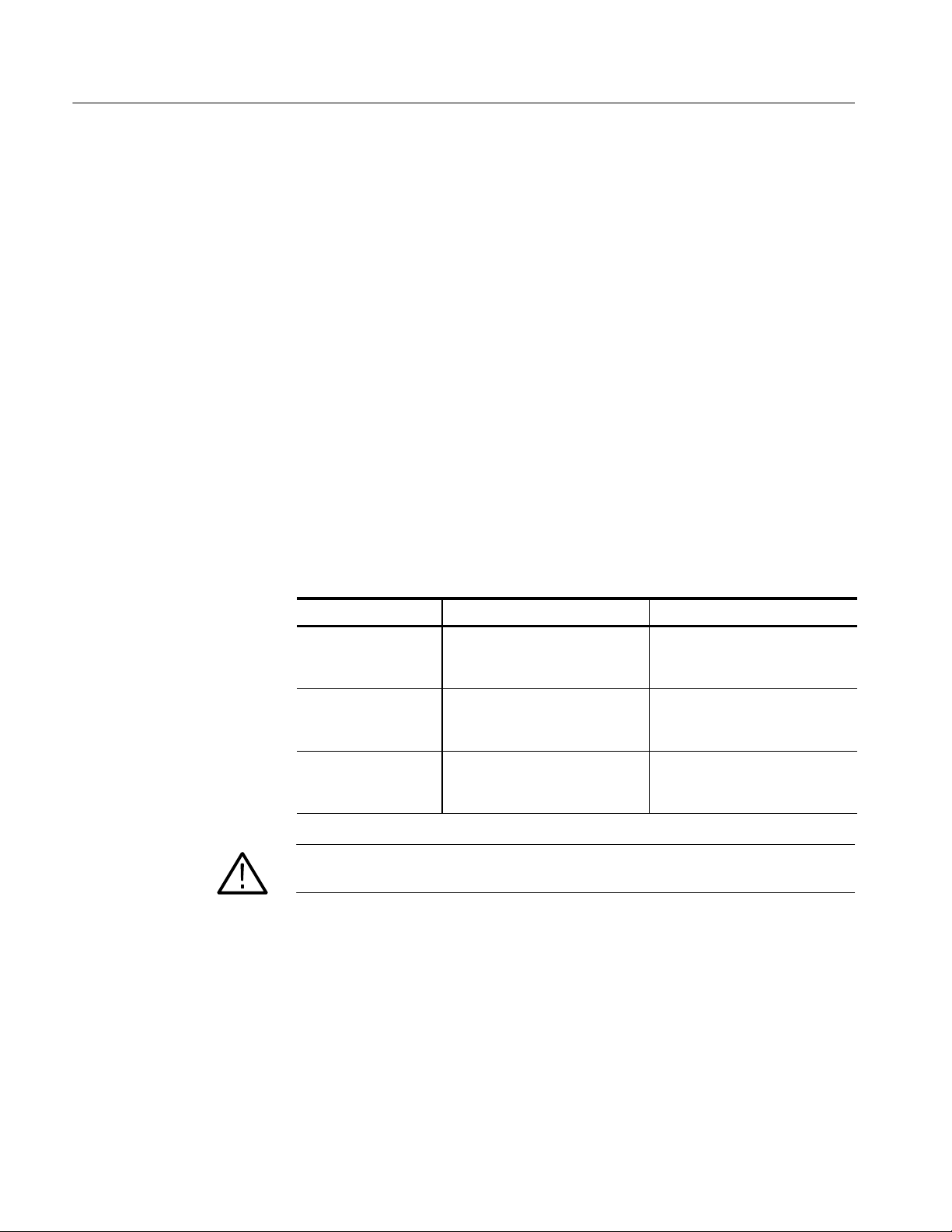

Table i: Tektronix Logic Analyzer Family documentation

Manual name Description

TLA Quick Start User Manuals High--level operational overview

Online Help In-depth operation and User Interface help

Installation Quick Reference Cards High-- level installation information

Installation Manuals Detailed first-time installation information

TLA Product Specifications & Performance Verification Procedures Product specifications and performance verification procedures for

TLA7000 series products

Field upgrade kits Upgrade information for your logic analyzer

Optional Service Manuals Self-service documentation for modules and mainframes

x

TLA7000 Series Mainframe Technical Reference Manual

Introduction

This manual contains information needed to service the TLA7000 series

mainframes.

To prevent personal injury or damage to the instrument, consider the following

requirements before attempting service:

H Read the General Safety Summary and Service Safety Summary found at the

beginning of this manual.

H The procedures in this manual should only be performed by a qualified

service person.

Be sure to follow all warnings, cautions and notes.

Adjustment and Certification Interval

Generally, you should perform the adjustments and certification (calibration)

once per year, or following repairs that may affect adjustment or calibration.

Service Strategy

Service Offerings

This manual supports and contains information needed for periodic maintenance

of the instrument. It supports and contains the following information for

corrective maintenance:

H Supports removal and replacement of boards or assemblies.

H Supports removal and replacement of the mechanical parts listed in the parts

lists.

This manual does not support component-level fault isolation and replacement.

Tektronix provides service to cover repair under warranty as well as other

services that are designed to meet your specific service needs.

Whether providing warranty repair service or any of the other services listed

below, Tektronix service technicians are equipped to service the instrument.

Services are provided at Tektronix Services Centers and on-site at your facility,

depending on your location.

TLA7000 Series Mainframe Technical Reference Manual

xi

Introduction

Warranty Repair Service

Calibration and Repair

Service

Tektronix warrants this product for one year from date of purchase. The warranty

is located behind the title page in this manual. Tektronix technicians provide

warranty service at most Tektronix service locations worldwide. The Tektronix

product catalog lists all service locations worldwide.

In addition to warranty repair, Tektronix Service offers calibration and other

services which provide solutions to your service needs and quality standards

compliance requirements.

The following services can be tailored to fit your requirements for calibration

and/or repair of your portable mainframe.

Service Options. Tektronix Service Options can be selected at the time you

purchase your instrument. You select these options to provide the services that

best meet your service needs.

Service Agreements. If service options are not added to the instrument purchase,

then service agreements are available on an annual basis to provide calibration

services or post-warranty repair coverage. Service agreements may be customized to meet special turn-around time and/or on-site requirements.

Service on Demand. Tektronix offers calibration and repair services on a

“per-incident” basis that is available with standard prices.

Self Service. Tektronix supports repair to the replaceable-part level by providing

for circuit board exchange.

Use this service to reduce down-time for repair by exchanging circuit boards for

remanufactured ones. Tektronix ships updated and tested exchange boards. Each

board comes with a 90-day service warranty.

For More Information. Contact your local Tektronix service center or sales

engineer for more information on any of the Calibration and Repair Services just

described.

xii

TLA7000 Series Mainframe Technical Reference Manual

Maintenance

Preventing ESD

This chapter provides information and procedures for removing and replacing

components in the TLA7012 Portable Mainframe and the TLA7016 Benchtop

Mainframe.

WARNING. To avoid electric shock, always power off the instrument and

disconnect the power cord before cleaning or servicing the instrument.

When performing any service which requires internal access to the instrument,

adhere to the following precautions to avoid damaging internal circuit boards and

their components due to electrostatic discharge (ESD).

CAUTION. Many components within the instrument are susceptible to static

discharge damage.

Service the instrument only in a static-free environment. Observe standard

handling precautions for static-sensitive devices.

1. Minimize handling of static-sensitive circuit boards.

2. Transport and store static-sensitive circuit boards in their static protected

containers or on a metal rail. Label any package that contains static-sensitive

boards.

3. Discharge the static voltage from your body by wearing a grounded antistatic

wrist strap while handling these circuit boards.

4. Nothing capable of generating or holding a static charge should be allowed

on the work station surface.

5. Handle circuit boards by the edges when possible.

6. Do not slide the circuit boards over any surface.

7. Avoid handling circuit boards in areas that have a floor or work-surface

covering capable of generating a static charge.

TLA7000 Series Mainframe Technical Reference Manual

1

Maintenance

Inspection and Cleaning

The instrument is inspected mechanically and electrically before shipment. It

should be free of marks or scratches and should meet or exceed all electrical

specifications. To confirm this, inspect for physical damage incurred during

transit. Retain the packaging in case shipment for repair is necessary. If there is

damage or deficiency, contact your local Tektronix representative.

Cleaning procedures consist of exterior and interior cleaning. Periodic cleaning

reduces instrument breakdown and increases reliability. Clean the instrument as

needed, based on your operating environment.

Exterior Inspection

Inspect the outside of the instrument for damage, wear, and missing parts. Use

Table 1 as a guide. Modules that appear to have been dropped or otherwise

abused should be checked thoroughly to verify correct operation and performance. Immediately repair defects that could cause personal injury or lead to

further damage to the benchtop controller, expansion module, or the mainframes

that the module plug into.

Table 1: External inspection check list

Item Inspect for Repair action

Front panel Cracks, scratches, deformations,

missing or damaged retainer

screws, or ejector handles.

Front and rear connectors

Accessories Missing items or parts of items,

Broken shells, cracked insulation,

and deformed contacts. Dirt in

connectors.

bent pins, broken or frayed

cables, and damaged connectors.

Replace defective or missing

parts.

Replace defective parts. Clear dirt

out of connectors.

Replace damaged or missing

parts, frayed cables.

CAUTION. To prevent damage to electrical components from moisture during

external cleaning, use only enough liquid to dampen the cloth or applicator.

2

TLA7000 Series Mainframe Technical Reference Manual

Maintenance

Exterior Cleaning

Procedure

Interior Inspection

Clean the exterior surfaces with a soft dry lint-free cloth, or a soft-bristle brush.

If any dirt remains, use a soft cloth or swab dipped in a 75% isopropyl alcohol

solution. Use a swab to clean narrow spaces around controls and connectors. Do

not use abrasive cleaning compounds.

CAUTION. Avoid getting moisture inside the instrument during exterior cleaning;

use just enough moisture to dampen the cloth or swab.

Use only deionized water when cleaning. Use a 75% isopropyl alcohol solution

as a cleanser and rinse with deionized or distilled water.

Do not use chemical cleaning agents; they may damage the chassis. Avoid

chemicals that contain benzene, toluene, xylene, acetone, or similar solvents.

Remove the module covers to access the inside of the instrument for inspection

and cleaning. Refer to the Removal and Installation Procedures for detailed

information on cover removal. Inspect the internal portions of the modules and

the mainframes for damage and wear using Table 2 as a guide. Defects found

should be repaired immediately.

Table 2: Internal inspection check list

Item Inspect for Repair action

Circuit boards Loose, broken, or corroded

solder connections. Burned

circuit boards. Burned, broken,

or cracked circuit-run plating.

Solder connections Cold solder or rosin joints. Return to a Tektronix Service Center.

Wiring and cables Loose plugs or connectors.

Burned, broken, or frayed

wiring.

Chassis Dents, deformations, and

damaged hardware.

Return to a Tektronix Service Center.

Firmly seat connectors. Repair or replace

parts with defective wires or cables.

Straighten, repair, or replace defective

hardware.

CAUTION. To prevent damage from electrical arcing, ensure that circuit boards

and components are dry before applying power.

TLA7000 Series Mainframe Technical Reference Manual

3

Maintenance

Interior Cleaning

Procedure

Use a dry, low-velocity stream of air to clean the interior of the modules and the

mainframes. Use a soft-bristle brush for cleaning around components. If you

must use a liquid for minor interior cleaning, use a 75% isopropyl alcohol

solution and rinse with deionized or distilled water.

Clean the exterior (face) of the DVD drive and replaceable hard disk drive

cartridge with a soft, clean cloth and a mild detergent.

4

TLA7000 Series Mainframe Technical Reference Manual

Portable Mainframe Removal and Installation Procedures

This section provides procedures for removing and installing mechanical and

electrical modules in the portable mainframe. The following procedures provide

only high-level remove and replacement procedures. Refer to the Replaceable

Parts Lists for additional remove and replace information.

CAUTION. Before doing this or any other procedure in this manual, read the

General Safety Summary and Service Safety Summary found at the beginning of

this manual.

Equipment Required

Table 3 lists the tools needed to remove and replace components in the mainframe.

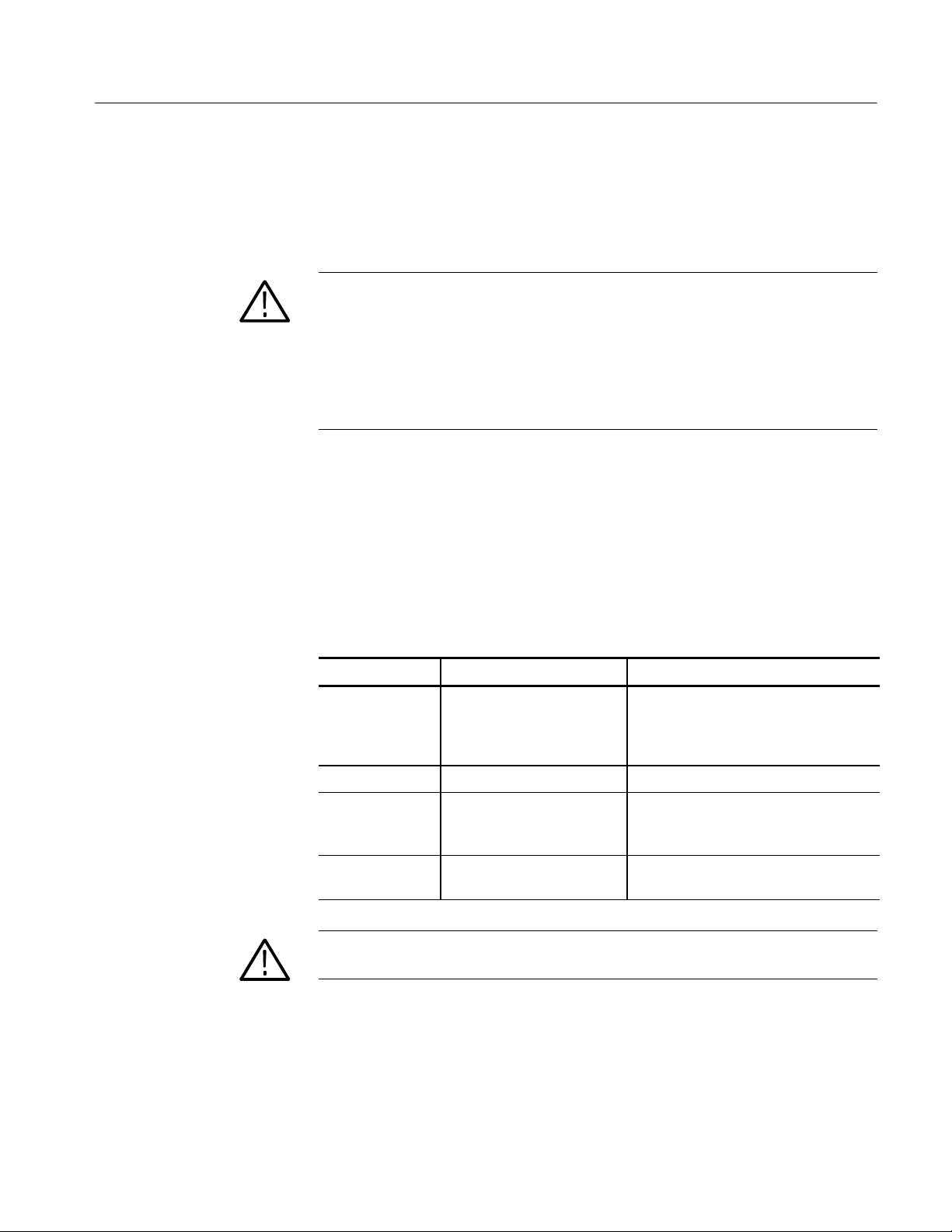

Table 3: Equipment required to service the mainframes

Item number Item Descri pti on

1 Screwdriver handle Accepts Torx driver bits

2 T-15 Torx tip Torx drive bit for T-15 size screws

3 Phillips screwdriver Phillips #1 screwdriver

4 3/16-inch nut driver For motherboard and jack screw removal

5 9/16-inch socket For interface board removal

6 Torque wrench 2 in-lb minimum

NOTE. When installing the screws, use a torque screwdriver and tighten the

screws to 8 in-lbs unless otherwise noted.

TLA7000 Series Mainframe Technical Reference Manual

5

Portable Mainframe Removal and Installation Procedures

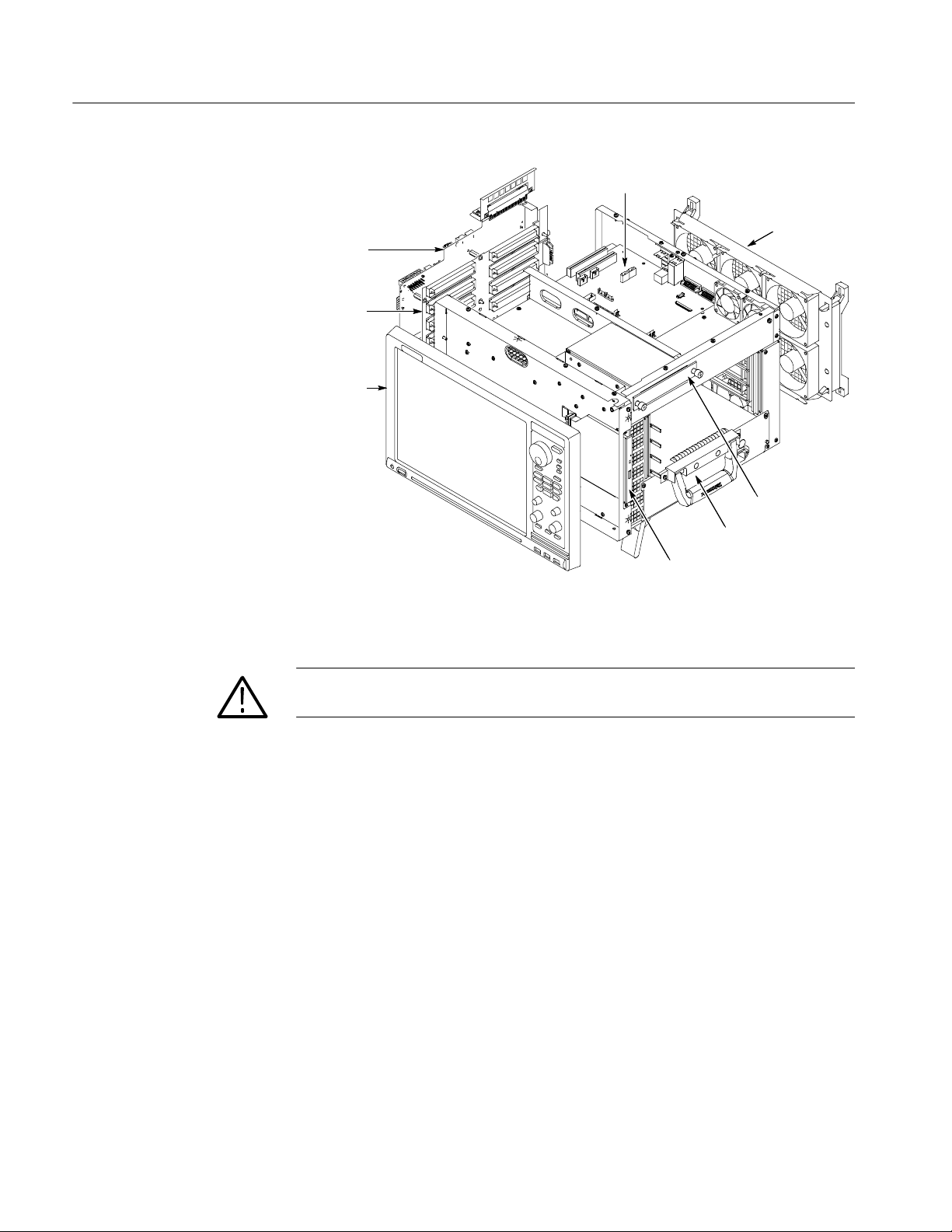

Interface

board

Backplane

board

Front panel

and display

Motherboard

Fan

assembly

Hard disk

drive

Power

supply

DVD

drive

Instrument Covers

Figure 1: Locator diagram

WARNING. To avoid electric shock, always power off the instrument and

disconnect the power cord before cleaning or servicing the instrument.

Complete the following steps to remove the instrument covers:

1. Disconnect all cords, cables, and probes from the instrument.

2. Carefully remove all instrument modules (if any) from the instrument.

3. Set the instrument on the bottom feet.

4. Remove the six T-15 screws from the right cover and remove the cover.

6

TLA7000 Series Mainframe Technical Reference Manual

Portable Mainframe Removal and Installation Procedures

Pouch

Snap

Top cover

Skid foot

Front

panel/display

Figure 2: Instrument enclosure det ail

Top left

cover

Right side

cover

5. Remove the accessory pouch and snap studs (4 T-15 screws).

6. Remove the four skid feet from the left side (4 T-15 screws).

7. Remove the remaining T-15 screws from the top left cover and then remove

the cover.

8. Set the instrument on the rear feet.

TLA7000 Series Mainframe Technical Reference Manual

7

Portable Mainframe Removal and Installation Procedures

Front Panel Display

Complete the following steps to remove the front panel display:

1. Remove the 12 T-15 screws from the front panel trim.

2. Set the instrument back on the bottom feet.

3. Tilt the top of the front panel trim out about 8 inches.

When reinstalling make sure that

the alignment pins go into hollow

posts (Alignment pins not shown)

Figure 3: Tilt the panel forward f or cable access

4. Disconnect the two display cables and three USB cables from the front panel

assembly.

5. Remove the ground wire with a 5/16 in driver.

8

TLA7000 Series Mainframe Technical Reference Manual

Ground

wire

Portable Mainframe Removal and Installation Procedures

Display cables

USB cables

Figure 4: Front panel cable locations

6. Remove the front panel assembly.

Note the following steps when reinstalling the front panel display:

H When connecting the display cable, carefully line up the centers of the plug

and socket before pressing them together.

H To avoid damaging the USB and DVD cables, dress the cables properly just

before you attach the new panel to the chassis. See Figure 5.

Route USB cables below

DVD drive to prevent

pinching when reinstalling

Keep the ribbon

cables flat

against chassis

Figure 5: Dress the cables properly

TLA7000 Series Mainframe Technical Reference Manual

9

Portable Mainframe Removal and Installation Procedures

DVD Drive

Complete the following steps to remove the DVD drive. Refer to Figure 23 on

page 43 for the detailed exploded view drawings. Installation procedures are the

reverse of the removal procedures.

1. Remove the instrument covers. (See Instrument Covers on page 6.)

2. Remove the front panel display. (See Front Panel Display on page 8.)

3. Disconnect the ribbon cable and the power cable from the DVD drive.

4. Remove the two screws securing the DVD drive to the chassis.

5. Slide the DVD drive out of the chassis.

6. Remove the four screws securing the DVD drive to bracket assembly.

7. Remove the two screws securing the DVD board and spacer to the DVD

drive.

Motherboard

NOTE. Tighten the two screws securing the DVD board and spacer board to the

DVD drive to 2.0 in-lbs. Tighten the four screws securing the DVD drive to the

bracket assembly to 2.0 in-lbs.

Complete the following steps to remove the motherboard. Refer to Figure 24 on

page 45 for the detailed exploded view drawings. Installation procedures are the

reverse of the removal procedures.

1. Remove the instrument covers. (See Instrument Covers on page 6.)

2. Remove the top EMI cover. (Refer to Figure 22 on page 41.)

3. Remove the six screws securing the motherboard to the chassis.

4. Remove the four rear jack screws.

5. Disconnect and pull all cables clear of the motherboard. (Refer to Figure 6

on page 11.)

6. Pass the DVD ribbon cable through chassis to clear the motherboard.

10

7. Move the motherboard forward to clear the USB grounding bracket and then

lift board out.

TLA7000 Series Mainframe Technical Reference Manual

Portable Mainframe Removal and Installation Procedures

NOTE. When installing the four jack screws, tighten them to 4 in-lbs.

USB grounding

bracket

Motherboard

DVD cable

Interface Board

Chassis bracket

Figure 6: Removing the motherboard

Complete the following steps to remove the interface board. Refer to Figure 24

on page 45 for the detailed exploded view drawings. Installation procedures are

the reverse of the removal procedures.

1. Remove the instrument covers. (See Instrument Covers on page 6.)

2. Remove the top EMI cover. (Refer to Figure 22 on page 41.)

3. Remove the hardware from the I/O bracket -- four BNC nuts, two jack

screws, and two chassis screws. (Refer to Figure 7 on page 12)

4. Gently pull out the I/O bracket.

5. Disconnect the cables from the interface board and move them out of the

way.

6. Remove the five screws securing the interface board to the chassis.

To install the interface board, watch the ground fingers on top left. (Gently bend

the board down while pushing it into place.)

TLA7000 Series Mainframe Technical Reference Manual

11

Portable Mainframe Removal and Installation Procedures

NOTE. When installing the BNC nuts and the two jack screws, tighten them to

12 in-lbs ±1.5 in-lbs.

To install, press

downonEMIclipto

prevent damage to

ground fingers.

Screws (5)

Backplane

Jack

screws (2)

BNC nuts and

washers (4)

Screws (2)

Screw (1)

Interface board

assembly

Figure 7: Removing the interface board

Complete the following steps to remove the backplane. Refer to Figure 24 on

page 45 for the detailed exploded view drawings. Installation procedures are the

reverse of the removal procedures.

1. Remove the instrument covers. (See Instrument Covers on page 6.)

2. Remove the top EMI cover. (Refer to Figure 22 on page 41.)

3. Remove the interface board. (See Interface Board on page 11.)

12

4. Gently remove the interface board from the backplane board.

5. Remove the four screws and four binding posts from the backplane board.

6. Slide the backplane under the chassis post as indicated in Figure 8 on

page 13.

7. Pull out the backplane.

TLA7000 Series Mainframe Technical Reference Manual

Portable Mainframe Removal and Installation Procedures

NOTE. When installing the binding posts, tighten them to 10 in-lbs.

Interface

board

Chassis post

Power Supply

Figure 8: Removing the backplane

Complete the following steps to remove the power supply. Refer to Figure 25 on

page 47 for the detailed exploded view drawings. Installation procedures are the

reverse of the removal procedures.

1. Remove the top and right plastic covers. (See Instrument Covers on

page 6.)

2. Remove bottom cover with the feet.

3. Remove the eight screws (four on the bottom EMI cover and four on the

side) securing the power supply to the chassis.

4. Pull out the assembly.

5. Remove the handle from the assembly.

TLA7000 Series Mainframe Technical Reference Manual

13

Portable Mainframe Removal and Installation Procedures

14

TLA7000 Series Mainframe Technical Reference Manual

Benchtop Mainframe Removal and Installation Procedures

This section provides procedures for removing and installing mechanical and

electrical modules in the benchtop mainframe.

CAUTION. Before doing this or any other procedure in this manual, read the

General Safety Summary and Service Safety Summary found at the beginning of

this manual.

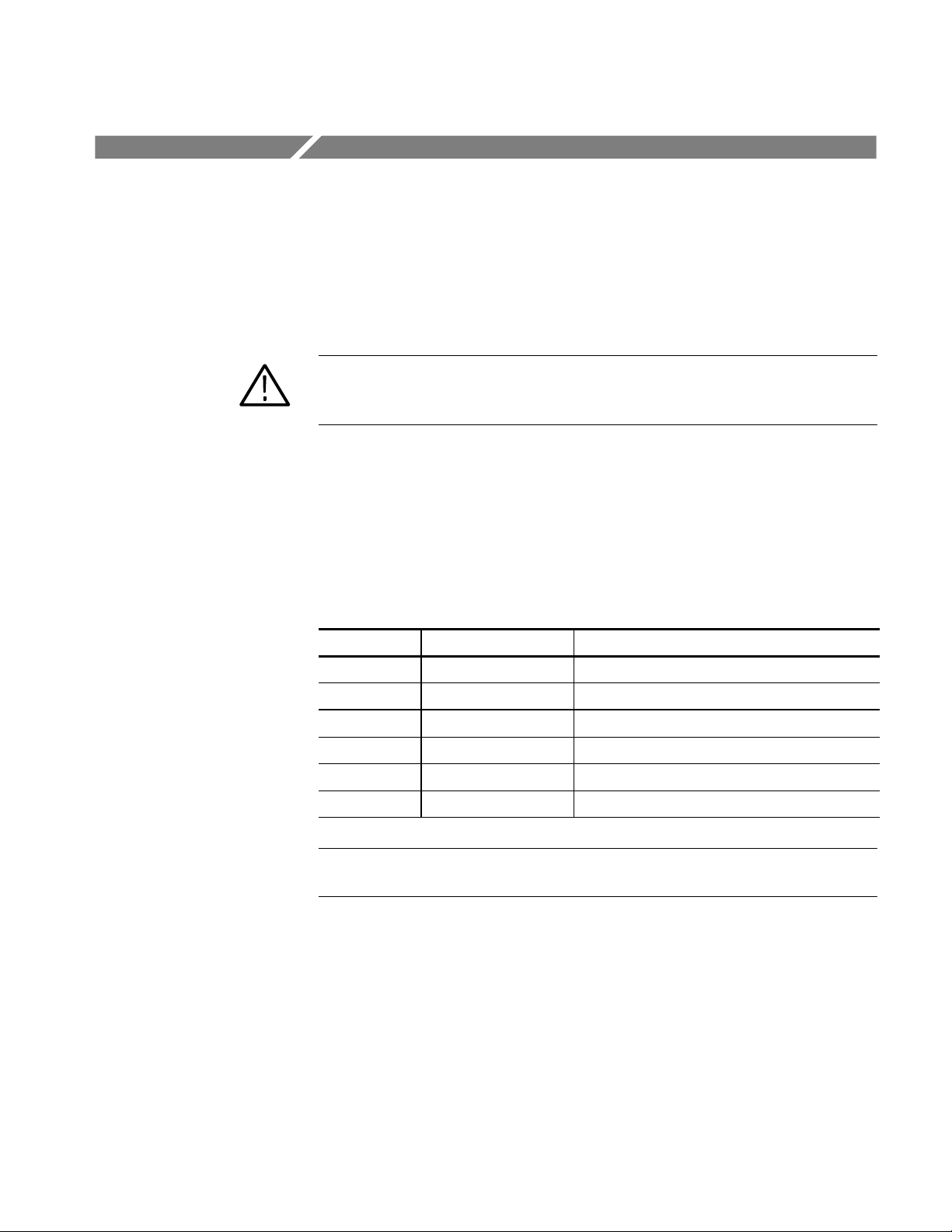

Equipment Required

Table 4 lists the tools needed to remove and replace components in the mainframe.

Table 4: Equipment required to service the mainframes

Item number Item Descri pti on

1 Flat blade screwdriver Small flat blade screwdriver

2 Cutters Diagonal cutters (for removing cable ties)

3 Screwdriver handle Accepts Torx driver bits

4 T-7 Torx tip Torx drive bit for T-7 size screws

5 T-15 Torx tip Torx drive bit for T-15 size screws

6 T-20 Torx tip Torx drive bit for T-20 size screws

7 Allen wrench A 3/32-inch Allen wrench (hex wrench)

8 Phillips screwdriver Phillips #1 screwdriver

9 Cable ties 4-inch tie-down straps (Tektronix part number

343-0549-00)

NOTE. When installing the screws, use a torque screwdriver and tighten the

screws to 8 in-lbs unless otherwise noted.

WARNING. To avoid electric shock, always power off the instrument and

disconnect the power cord before cleaning or servicing the instrument.

TLA7000 Series Mainframe Technical Reference Manual

15

Benchtop Mainframe Removal and Installation Procedures

Instrument Modules

CAUTION. To avoid damaging any the instrument or any instrument modules,

remove the modules and the Slot 0 Interface module from the chassis before

performing any procedures in this section.

To remove the instrument modules and the Slot 0 Interface module from the

mainframe, loosen the retaining screws, use the ejector/injector handles to unseat

the modules, and then slide the modules out to the mainframe.

To install the modules, slide the modules into the mainframe, and secure the

modules with the ejector/injector handles. Use a screwdriver to tighten the

retaining screws to 2.5 in-lbs after seating the modules in place.

Blower Assembly

To remove the blower assembly, refer to Figures 9, 10, and 11 while performing

the following steps:

1. From the back of the chassis, loosen the five captive screws including the

safety ground (refer to Figure 9 for the screw locations).

2. Loosen the four 8-32 hex screws (see Figure 11 on page 18) under the

mainframe so that you can easily remove the blower assembly.

3. Remove the cable cover.

4. Unplug the blower cable and set the blower assembly aside on a clean

working surface.

5. To remove the blower, remove the ten screws with (the Allen wrench)

holding the shroud part of the blower assembly to the chassis part of the

assembly. Set the shroud aside. There are three screws on each side and four

on the bottom. See Figure 11.

6. Remove the two sheet metal screws at the top of the blower.

7. Remove the four screws that hold the blower to the chassis part of the blower

assembly.

8. For convenience, replace the two sheet metal screws from step 6 onto the top

of the blower.

Install the blower assembly by following the removal procedures in reverse

order.

16

TLA7000 Series Mainframe Technical Reference Manual

Benchtop Mainframe Removal and Installation Procedures

NOTE. When reconnecting the blower cables to the chassis, verify that you

connect the blower cable to J8, 1/BLOWER.

8-32 Captive

screw/fan housing

8-32 Captive

screw/fan housing

8-32 Captive

screw/fan housing

8-32 Captive

screw/fan housing

Figure 9: Location of blower assembly screws

8-32 Captive

screw/Enhance monitor

8-32 Captive

screw/cable cover

8-32 Captive

screw/Enhance monitor

8-32 Captive

screw/fan housing

TLA7000 Series Mainframe Technical Reference Manual

17

Benchtop Mainframe Removal and Installation Procedures

Power supply

Cable cover

Fan cable

Blower

assembly

Figure 10: Removing the blower assembly

Blower assembly

Shroud

Screws (4)

Screws (6)

Screws (4)

Chassis

Screws (2)

Blower

Cable tie

18

Figure 11: Removing the blower

TLA7000 Series Mainframe Technical Reference Manual

Removing the Enhanced Monitor Board

To remove the enhanced monitor board, complete the following steps:

1. Refer to Figure 10 and unscrew the captive screw that attaches the cable

cover. Remove the cable cover and set it aside.

2. Unplug the blower cable from the connector labeled 1/BLOWER.

3. Unscrew the two captive screws that attach the monitor board to the

mainframe.

4. Slide the enhanced monitor board out of the mainframe as shown in

Figure 12.

Benchtop Mainframe Removal and Installation Procedures

Figure 12: Removing the enhanced monitor board

TLA7000 Series Mainframe Technical Reference Manual

Monitor board

19

Benchtop Mainframe Removal and Installation Procedures

To install the enhanced monitor board, complete the following steps:

1. Refer to Table 5 and verify that the jumpers on the enhanced monitor board

are in the default locations before installing the board in the mainframe.

Table 5: Enhanced monitor board jumpers

Jumpers (location) Pins Label on board

J2 (top of board) 1-2 and 3-4 TLA721

J38 (middle of board) 2-3 Blower

J19 (bottom of board) 2-3 Blower

2. Slide the enhanced monitor board into the mainframe as shown in Figure 12.

You may have to adjust the enhanced monitor board to engage the connectors on the rear of the board.

3. Push the enhanced monitor board into the mainframe to fully mate the rear

connectors.

4. Tighten the two screws that attach the enhanced monitor board to the

mainframe.

5. Connect the blower cable into the connector labeled 1/BLOWER.

6. Install the cable cover and tighten the captive screw to that attaches to the

mainframe.

20

TLA7000 Series Mainframe Technical Reference Manual

Power Supply

Benchtop Mainframe Removal and Installation Procedures

To remove the power supply from the mainframe, perform Blower Assembly

procedure on page 16 and then complete the following steps:

1. Using the handle on the power supply, firmly pull out the power supply from

the rear of the mainframe.

2. Remove the two 3/32 hex drive screws and washers to remove the handle

from the power supply.

Mainframe

Power supply

Handle

Figure 13: Removing the power supply

Complete the following steps to reinstall the power supply in the mainframe:

1. Reinstall the handle to the power supply if you removed it earlier.

2. Slide the power supply into the mainframe.

3. Push the power supply handle in firmly to ensure that the connectors are

completely seated into the back plane connectors.

4. Reinstall the blower assembly.

TLA7000 Series Mainframe Technical Reference Manual

21

Benchtop Mainframe Removal and Installation Procedures

Mainframe Cover

To remove the mainframe cover, refer to Figure 14 while performing the

following steps (Note that this procedure assumes that the mainframe does not

include any rails for the rackmount option; if it does, remove the rails before

continuing this procedure).

1. Remove the 12 hex drive screws (6 on each side) using a 3/32 Allen wrench.

2. Remove the eight T-7 screws: four on the top front and four on the top rear.

3. Lift the front bottom corners up.

4. After tilting the cover up about 3 inches, lift the cover straight off the

instrument.

Remove screws (20)

Step 1 Step 2

Step 3

Figure 14: Removing the mainfram e cover

22

TLA7000 Series Mainframe Technical Reference Manual

Benchtop Mainframe Removal and Installation Procedures

Complete the following steps to install the mainframe cover (refer to Figure 14

as necessary):

1. Slide the cover over the mainframe.

2. Tilt the rear of the cover in place and then lower the front until the cover

binds slightly (do not force the cover down).

3. Slowly push the cover down until the screw holes on the sides of the cover

line up with those on the mainframe. Use care not to damage the front panel

label while installing the cover.

4. Install the eight T-7 screws on the top of the mainframe cover; tighten them

to4in-lbs.

5. Install the remaining 12 screws on the sides of the mainframe.

6. Tighten all screws.

Card Guides

The card guides at the top and bottom of the mainframe are very similar. The

main difference is that the bottom guides include the spring-loaded shutters to

redirect air into the mainframe. The procedure for removing both guides is

identical. Refer to Figure 15 while performing the following steps:

1. Use a small flat blade screwdriver to pry up the tab of the card guide at the

front of the mainframe being careful not to damage the card guide or the

mainframe.

2. Gently pull the card guide forward until it pops out of place.

3. Remove the card guide.

To install the card guides refer to Figure 15 while completing the following

steps:

NOTE. The bottom card guides are replaced as a unit. These guides are not

intended to be disassembled.

1. Slide the card guide towards the rear of the mainframe and allow the front of

the card guide to snap into place.

2. Test the card guides in the mainframe and verify that they do not move.

3. Reinstall the mainframe cover.

TLA7000 Series Mainframe Technical Reference Manual

23

Benchtop Mainframe Removal and Installation Procedures

Installing card guides

Slide the card guides toward the rear of

the mainframe; allow the front of the

card guide to snap into place.

Front

Rear

Removing card guides

Gently pull the card guide

forward until it pops out of place.

Figure 15: Removing the top and bottom card guides

24

TLA7000 Series Mainframe Technical Reference Manual

Temperature Sense Board

To remove the temperature sense board complete the following steps:

1. Remove the mainframe cover by following the Mainframe Cover removal

2. Disconnect the ribbon cable from the temperature sense board.

3. Refer to Figure 16 and gently pry back on each retainer holding the

4. Tilt the board forward and lift it out of the holes at the top of the mainframe

Complete the following steps to install the temperature sense board in the

mainframe:

1. Refer to Figure 16 and install the temperature sense board in the mainframe

Benchtop Mainframe Removal and Installation Procedures

procedure on page 22.

temperature sense board in place.

being careful not to damage any components on the circuit board.

as shown.

2. Make sure that the circuit board snaps into place under each retainer.

3. Reconnect the ribbon cable.

4. Reinstall the mainframe cover.

TLA7000 Series Mainframe Technical Reference Manual

25

Benchtop Mainframe Removal and Installation Procedures

Temperature

sense board

Retainer

Cable

Figure 16: Removing the temperature sense board

Front Panel and Display Module

Perform the following steps to replace the front panel and display module:

1. Remove the mainframe cover by following the Mainframe Cover removal

procedure on page 22.

2. Note the orientation of the power switch. (The green LED is toward the

front-left side; see Figure 17).

3. Using needle-nose pliers, remove the five wires from the power switch. (The

color-coded connections are shown later in the installation procedure).

4. Remove the two T-7 screws from the front panel and remove the front panel.

26

TLA7000 Series Mainframe Technical Reference Manual

Front view

Green LED on left side

Front panel

Benchtop Mainframe Removal and Installation Procedures

Power switch

Five wires

Figure 17: Removing the instrument fr ont panel

5. Unsnap the power switch from the front panel by squeezing the snaps on

each side of the switch and pushing the switch through the front of the panel.

NOTE. Before removing the display from the front panel, note the orientation so

that you don’t install it reversed

6. Disconnect the ribbon cable from the display assembly.

7. Remove the four screws securing the diaplay assembly to the bracket and

remove the display.

Install the display assembly and front panel by performing the following steps:

1. Install the new display assembly using the four screws removed earlier.

2. Orient the power switch to the front panel so that the four terminals are on

top, and the green LED is toward the front-left side. See Figure 18.

3. Snap the power switch into the front panel.

TLA7000 Series Mainframe Technical Reference Manual

27

Benchtop Mainframe Removal and Installation Procedures

4. Connect the wires to the power switch as shown in Figure 18.

Brown

Red Green Yellow

1254

Green LED

on left side

Five wires

3

Orange

New front panel

Ribbon

cable

Figure 18: Installing the new front panel

5. Connect the ribbon cable from the mainframe to the front panel.

6. Position the front panel in the chassis. If there is a plastic cable retainer in

the way, remove it. Dress the ribbon cable around the display board to avoid

pinching the cable.

7. Dress the excess power switch cable towards the back of the chassis, away

from the card guides.

8. Attach one T-7 screw on each side of the front panel.

9. Replace the cover and partially install the side cover screws first, and then

the top screws, until the cover is aligned and all of the screws are started.

10. Tighten all of the cover screws.

28

TLA7000 Series Mainframe Technical Reference Manual

EMI DIN Shields

Benchtop Mainframe Removal and Installation Procedures

Perform the following steps to remove the EMI DIN shields:

1. Remove any modules surrounding the slots where you intend to remove the

Backplane EMI DIN shields. Refer to Figure 19.

2. Remove two 4-40 Torxdrive T-10 screws that secure each EMI DIN shield to

the backplane.

3. Remove EMI DIN shield from the backplane.

Install the EMI DIN shield by reversing the removal procedure.

Polarization hole

Screws (2)

Backplane EMI

DIN shield

Figure 19: Removing the backplane EMI DIN shields

TLA7000 Series Mainframe Technical Reference Manual

29

Benchtop Mainframe Removal and Installation Procedures

Backplane

To remove the backplane from the mainframe, complete the following steps:

1. Follow the instructions on page 16 to remove the blower assembly from the

mainframe.

2. Follow the instructions on page 19 to remove the enhanced monitor board

from the mainframe.

3. Follow the instructions on page 21 to remove the power supply from the

mainframe.

4. Follow the instructions on page 22 to remove the cover from the mainframe.

5. Refer to Figure 20 and disconnect the ribbon cable on the right side of the

backplane.

6. Note the location of the power switch cable at J22 (or from J23) at the top of

the backplane and disconnect the cable.

NOTE. If the front panel switch is connected to the backplane at J22, the switch

controls the power-on functions. If the switch is connected to J23, the front panel

switch is disabled, however, the light still illuminates when the chassis is

powered on.

7. From the rear of the mainframe, remove the five 6-32 screws on the top of

the backplane, remove the seven 6-32 screws from the center, and then

remove the five 6-32 screws from the bottom (refer to Figure 20 if necessary).

8. After removing all of the screws from the backplane, remove the backplane

from the mainframe by sliding it out of the right side.

30

TLA7000 Series Mainframe Technical Reference Manual

Benchtop Mainframe Removal and Installation Procedures

J24

Power switch

connector

J22

J23

J29

6-32 Screws (17)

Figure 20: Removing the backplane

Connector

0J4

TLA7000 Series Mainframe Technical Reference Manual

31

Benchtop Mainframe Removal and Installation Procedures

Before installing the backplane board in the mainframe verify the correct

position and location of the jumpers (refer to Figure 21 and to Table 6).

Install the backplane board following the removal procedures in reverse order.

Table 6: Mainframe backplane jumpers

Location Pins

JP1 No Jumper installed

JP2 pins 2--5

32

Figure 21: Soft power down jumper setting

TLA7000 Series Mainframe Technical Reference Manual

JP1

1

2

3

4

5

JP2

Repackaging Instructions

This section contains the information needed to repackage the instrument for

shipment or storage.

Packaging

When repacking the instrument for shipment, use the original packaging. If the

packaging is unavailable or unfit for use, contact your local Tektronix representative to obtain new packaging.

Seal the shipping carton with an industrial stapler or strapping tape.

Shipping to the Service Center

Contact the Service Center to get an RMA (return material authorization)

number, and any return or shipping information you may need.

If the instrument is being shipped to a Tektronix Service Center, enclose the

following information:

H The RMA number.

H The owner’s address.

H Name and phone number of a contact person.

H Type and serial number of the instrument.

H Reason for returning.

H A complete description of the service required.

Mark the address of the Tektronix Service Center and the return address on the

shipping carton in two prominent locations.

TLA7000 Series Mainframe Technical Reference Manual

33

Repackaging Instructions

34

TLA7000 Series Mainframe Technical Reference Manual

Parts List

This chapter contains a list of the replaceable parts for the TLA7012 Portable

Mainframe and the TLA7016 Benchtop Mainframe. Use this chapter to order

replacement parts for your instrument. Refer to the individual module service

manuals for replaceable parts for those product modules.

NOTE. The term “module” in this chapter refers to a replaceable subcomponent

of the mainframe such as a power supply. It does not refer to a TLA product

module.

Parts Ordering Information

Replacement parts are available through your local Tektronix field office or

representative.

Changes to Tektronix products are sometimes made to accommodate improved

components as they become available and to give you the benefit of the latest

improvements. Therefore, when ordering parts, it is important to include the

following information in your order.

H Part number (see Part Number Revision Level below)

H Instrument type or model number

H Instrument serial number

H Instrument modification number, if applicable

If you order a part that has been replaced with a different or improved part, your

local Tektronix field office or representative will contact you concerning any

change in part number.

TLA7000 Series Mainframe Technical Reference Manual

35

Parts List

Part Number Revision

Level

Module Servicing

Tektronix part numbers contain two digits representing the revision level of the

part. For most parts in this manual, you will find the letters XX in place of the

revision level number.

Part Number Revision Level

670-7918-03

When you order parts, Tektronix will provide you with the most current part for

your product type, serial number, and modification (if applicable). At the time of

your order, Tektronix will determine the part number revision level needed for

your product, based on the information you provide.

Modules can be serviced by selecting one of the following options. Contact your

local Tektronix service center or representative for repair assistance.

Module Repair and Return. You may ship your module to Tektronix for repair,

after which Tektronix will return it to you.

Revision Level May Show as XX

670-7918-XX

New Modules. You may purchase replacement modules in the same way as other

replacement parts.

36

TLA7000 Series Mainframe Technical Reference Manual

Using the Replaceable Parts List

The following table describes each column in the replaceable parts lists.

Table 7: Parts lists column descriptions

Column

number

1 Figure & index num-

Column name Description

Figure and index numbers in the exploded view

ber

illustrations.

Parts List

Abbreviations

Mfr. Code to Manufacturer

Cross Index

2 Tektronix part

number

3 and 4 Serial number Column 3 indicates the serial number at which the part

5 Qty Quantity of parts used.

6 Name & description An item name is separated from the description by a

7 Mfr. code Manufacturer code.

8 Mfr. part number Manufacturer’s or vendor’s part number.

Use this part number when ordering replacement parts

from Tektronix.

was first effective. Column 4 indicates the serial number at

which the part was discontinued. No entries in either

column indicates the part is good for all serial numbers.

colon (:). Because of space limitations, an item name may

sometimes appear incomplete. Use the U. S. Federal

Catalog Handbook H6-1 for further item name

identification.

Abbreviations conform to American National Standard ANSI Y1.1-1972.

The table titled Manufacturers Cross Index shows codes, names, and addresses

of manufacturers or vendors of components listed in the parts list.

TLA7000 Series Mainframe Technical Reference Manual

37

Parts List

Manufacturers Cross Index

Mfr.

code

00779 TYCO ELECTRONICS CORPORATION CUSTOMER SERVICE DEPT ~PO BOX

060D9 TENSOLITE COMPANY PRECISION HARNESS AND ASSEMBLY~3000

06915 RICHCO 5825 N TRIPP AVE~P.O. BOX 804238 CHICAGO, IL 60646

0KB01 STAUFFER SUPPLY CO 810 SE SHERMAN PORTLAND, OR 97214-- 4657

0KB05 NORTH STAR NAMEPLATE INC METAL PRODUCTS~5750 NE MOORE COURT HILLSBORO, OR 97124--6474

0L0L7 RADISYS CORPORATION 5445 NE DAWSON CREEK DRIVE HILLSBORO, OR 97124

1LT13 ARTESYN TECHNOLOGY 7575 MARKET PLACE DR EDEN PRAIRIE, MN 55344

12136 PHC INDUSTRIES INC 1643 HADDON AVE CAMDEN, NJ 08103

26742 METHODE ELECTRONICS INC 7444 WEST WILSON AVE CHICAGO, IL 60656--4548

27264 MOLEX PRODUCTS COMPANY 2222 WELLINGTON CT. LISLE, IL 60532

2W944 PAPST MECHATRONIC CORP AQUIDNECK INDUSTRIAL PARK NEWPORT, RI 02840

3M099 PORTLAND SCREW COMPANY 6520 N BASIN AVE PORTLAND, OR 97217

50356 TEAC AMERICA INC 7733 TELEGRAPH RD~PO BOX 750 MONTEBELLO, CA 90640--6537

52152 3M COMPANY INDUSTRIAL TAPE DIVISION~3M CENTER ST PAUL, MN 55144-- 1000

55566 RAF ELECTRONIC HARDWARE INC 95 SILVERMINE ROAD SEYMOUR, CT 06483

61081 APW ELECTRONIC SOLUTIONS WEST COAST OPERATIONS~6790 FLANDERS

68167 BELKIN COMPONENTS 1303 WALNUT PARKWAY COMPTON, CA 90220

71400 BUSSMANN DIVISION COOPER INDUSTRIES INC~PO BOX

74594 ESCO LLC 14525 SW WALKER ROAD BEAVERTON, OR 97006

75915 LITTELFUSE INC 800 E NORTHWEST HWY DES PLAINES, IL 60016--3049

78189 SHAKEPROOF DIVISION OF ILLINOIS TOOL WORK~ST.

7X318 KASO PLASTICS INC 5720--C NE 121ST AVE, STE 110 VANCOUVER, WA 98682

93907 CAMCAR DIV OF TEXTRON INC 516 18TH AVE ROCKFORD, IL 611045181

TK0EM MOLEX ELECTRONICS FARNHAM ROAD~BORDON HAMPSHIRE, ENGLAND

TK0588 UNIVERSAL PRECISION PRODUCT 1775 NW CORNELIUS PASS RD HILLSBORO, OR 97124

TK1163 POLY-- CAST INC 14140 SW 72ND AVE~SUITE 100 TIGARD, OR 97224

TK1269 NORITAKE COMPANY INC ELECTRONICS DIV LA BRANCH~2050 E VISTA

TK1943 NEILSEN MANUFACTURING INC 3501 PORTLAND RD NE SALEM, OR 97303

TK2157 APW ELECTRONIC SOLUTIONS 14100 DANIELSON ST POWAY, CA 92064

TK2565 VISION PLASTICS INC 26000 SW PARKWAY CENTER DRIVE WILSONVILLE, OR 97070

TK6314 MCX INC 1315 OREGON AVE KLAMATH FALLS, OR 97601--6540

Manufacturer Address City, State, Zip code

HARRISBURG, PA 17105--3608

3608~M/S 38--35

VANCOUVER, WA 98661

COLUMBIA HOUSE BLVD~#120

SAN DIEGO, CA 92121--2902

DRIVE

ST LOUIS, MO 63178--4460

14460

ELGIN, IL 60120

CHARLES ROAD

COMPTON, CA 90220

BELLA WAY

38

TLA7000 Series Mainframe Technical Reference Manual

Parts List

TLA7000 Series Mainframe Technical Reference Manual

39

Parts List

Replaceable Parts List

Fig. &

index

number

22-1 211-- 1093-- XX 4 SCREW,MACHINE; 4--40 X 0.25,FLH 100 DEG,STL BLK

-2 016--1441--XX 1 ACCESSORY POUCH; BLACK CORDURA 80009 016-- 1441-- XX

-3 211--0721--XX 35 SCREW,MACHIN E; 6--32 X 0.375,PNH,STL,CDPL,T-- 15 TORXDR80009 211--0721--XX

-4 200--4946--XX 1 COVER; TOP LEFT,EMI TK1943 200-- 4946-- XX

-5 200--4940--XX 1 COVER, RIGHT (COSMETIC) TK2565 200--4940--XX

-6 343--1213--XX 1 CLAMP,PWR CORD; POLYMIDE TK1163 343--1213--XX

-7 200--4947--XX 1 COVER; BOTTOM,COSMETIC WITH FEET TK1943 200-- 4947-- XX

-8 200--4939--XX 1 COVER,FRONT;PROTECTIVE,PLASTIC TK2565 200--4939-- XX

-9 335--1322--XX 1 LABEL, INDENTI FICATION (TEKTROINIX LOGO) 80009 335--1322--XX

-10 101--0169--XX 1 TRIM RING;FRONT 80009 101--0169--XX

-11 348--1817--XX 4 FOOT, SKID 80009 348--1817--XX

-12 200--4948--XX 1 COVER; TOP COSMETIC TK1943 200-- 4948-- XX

-13 355--0298--XX 4 STUD.SNAP; 0.570 DIA,0.165 THK,STAINLESS STEEL TK0588 355-- 0298-- XX

Tektronix part

number

Serial no.

effective

Serial no.

discont’d

Qty Name & description

OXIDE,T7

Mfr.

code

0KB01 211--1093--XX

Mfr. part number

40

TLA7000 Series Mainframe Technical Reference Manual

12

Parts List

2

1

3

13

3

3

3

11

10

9

8

4

5

3

6

7

3

Figure 22: External parts

TLA7000 Series Mainframe Technical Reference Manual

41

Parts List

Replaceable Parts List

Fig. &

index

number

23--1 441--2425--XX 1 CHASSI S ASSY; MAIN TK1943 441--2425--XX

-2 343--1701--XX 1 CLAMP,CABLE; WITH ADHESIVE BACK 06915 PCC --12

-3 650--4815--XX 1 HARD DRIVE ASSY; TLA7012 REMOVABLE HARD DISK

-4 211--1174--XX 4 SCREW,MACHINE; W/HEAVY PATCH THREADLOCKING

-5 351--1118--XX 2 GUIDE,HD; REMOVABLE,3.5 INCH HARD DISK DRIVE TK2565 3511118 00

-6 211--0721--XX 12 SCREW,MACHIN E; 6--32 X 0.375,PNH,STL,CDPL,T-- 15 TORXDR80009 211072100

Tektronix part

number

Serial no.

effective

Serial no.

discont’d

Qty Name & description

DRIVE ASSEMBLY W/OUT SW INSTALLED

MATERIAL; 6--32 X 0.312 L,PNH,STL CAD PLT,T15

Mfr.

code

80009 650--4815--XX

0KB01 211--1174-- XX

Mfr. part number

-7 407--5068--XX 1 BRACKET,HD; REMOVABLE 3.5 INCH HARD DRIVE

CARTRIDGE

-8 211--0734--XX 4 SCREW,MACHINE; 6--32 X 0.25O,FLH100,STL,CDPL,T--10

TORX DR

-9 174--5057--XX 3 CABLE ASSY; USB 2.0 TK6314 174505700

-10 679--5974--XX 3 CKT BD SUBASSY; USB ADAPTER BOARD ,UNTESTED 80009 679--5974--XX

-11 366--0837--XX 2 KNOB,CAP;0.650 DIAMETER,SOFT FEEL COATING 80009 366--0837--XX

-12 366--0836--XX 2 KNOB,CAP; 0.430 D,SOFT FEEL COATING,TEK SILVER GRAY 80009 366--0836--XX

-13 366--0846--XX 1 KNOB; GENERAL PURPOSE 80009 366--0846--XX

-14 650--4676--XX 1 DISPLAY/FRONT PANEL ASSY; 15 INCH LCD,WITH TOUCH

PANEL,LOGIC NALYZER,PORTABLE; TLA7012 OPT 18

-14 650--4804--XX 1 DISPLAY/FRONT PANEL ASSY; 15 INCH LCD W/OUT TOUCH

SCREEN, STANDARD,LOGIC ANALYZER,PORTABLE;

TLA7012

-15 174--5053--XX 1 CABLE ASSY; DISPLAY ADAPTER TO INTERFACE,30 PIN 060D9 174505300

-16 119--7123--XX 1 DISK DRIVE; OPTICAL,CD--RW/DVD--R/RW DVD+R/RW,16.7

MB/SEC,650MEG/8.5GIG,IDE/ATAPI;TEAC MODEL

DV--W28E-- 793,ROHSC ONV

-17 679--5915--XX 1 CKT BD SUBASSY; DVD--CD/RW ADAPTER 80009 679--5915--XX

-18 211--0888--XX 2 SCREW,METRIC; M--2 X 0.4 X 6MM,PHILLIPS PAN,ZINC

PLATED,PHIL PAN HEAD,STEEL

-19 129--1618--XX 1 SPACER; DVD--CD/RW SLIMLINE DRIVE ADAPTER,PLASTIC TK2565 129161800

-20 211--0950--XX 4 SCREW,MACHINE; M2X.4X3L,PHL, PNH, STL NI PL 0KB01 0310248--0

-21 407--5070--XX 1 BRACKET,DVD--CD/RW; ADAPTER FOR DVD--CD/RW,SLIMLINE

-22 174--4671--XX 1 CA ASSY,SP; ULTRA DMA/ATA HARD DISK DRIVE,IDE,18.0 L 68167 F2N1107--18INCH

-23 174--5017--XX 1 CABLE ASSEMBLY; DVD POWER 060D9 174-- 5017-- XX

-24 407--5069--XX 1 BRACKET,RHDD; SATA COMBO CABLE,3.5 INCH

REMOVABLE HARD DISK DRIVE RECEPTACLE

-25 174--5169--XX 1 CABLE ASSY; SATA COMBO,HARD DRIVE CABLE 27264 174516900

TK1943 407506800

93907 MACHINE SCREW:

6--32 X .250, T1

80009 650--4676--XX

80009 650--4804--XX

50356 DV--W28EA--793

0KB01 211--0888--XX

TK1943 407507000

TK1943 407506900

42

TLA7000 Series Mainframe Technical Reference Manual

Parts List

J390

J69

Motherboard

PL33

IDE

Interface

board

15

25

22

18

17

16

23

19

C40

Motherboard

6

24

20

21

20

2

5

1

6

3

7

14

13

12

6

Display

6

11

Interface board

R890

6

10

Figure 23: Front panel assembly

TLA7000 Series Mainframe Technical Reference Manual

4

9

RP21

PL19

Motherboard

8

43

Parts List

Replaceable Parts List

Fig. &

index

number

24--1 214--3903--XX 4 SCREW,JACK; 4-- 40 X 0.312 LONG,0.188 H HEX HEAD

-2 174--5056--XX 1 CABLE ASSY; 30 POSITION LVDS 060D9 174505600

-3 210--0457--XX 2 NUT,PL,ASSEM WA; 6--32 X 0.312,STL CD PL,W/LOCKWASH-ER78189 511--061800--XX

-4 039--0164--XX 1 MOTHER BOARD 0L0L7 ABGD00-- P20-- 1G

-5 210--1039--XX 4 WASHER,LOCK; 0.521 ID,INT,0.025 THK,SST 0KB01 1224-- 02-- XX-- 0541C

-6 220--0497--XX 4 NUT,PLAIN,HEX; 0.5-- 28 X 0.562 HEX,BRS CD PL 0KB01 220-- 0497--XX

-7 211--1206--XX 2 SCREW,JACK; 2-- 56 ID X 4-- 40 OD,.188 HEX,SS 749087-- 7

-8 116--1121--XX 1 BACKPLANE; CIRCUIT BD ASSY,CUSTOM VXI BACKPLANE 61081 VXIBP--1648190 R.A

-9 211--0721--XX 18 SCREW,MACHIN E; 6--32 X 0.375,PNH,STL,CDPL,T-- 15 TORX

-10 129--1613--XX 4 SPACER;POST TK0588 129--1613--XX

-11 174--5137--XX 1 CABLE ASSEMBLY; (20 PIN ATX POWER) 060D9 174--5137--XX

-12 664--5920--XX 1 CIRCUIT BD ASSY; INTERFACE,FUNCTIONAL BOARD

-13 174--5070--XX 1 CABLE ASSY; ATX FRONT PANEL 060D9 174--5070-- XX

-14 174--5073--XX 1 CABLE ASSY; BACKLIGHT CONTROL 060D9 174--5073--XX

-15 174--5071--XX 1 CABLE ASSY; USB 2.0 INTERFACE 060D9 174--5071--XX

-16 407--5075--XX 1 BRACKET ASSEMBLY,REAR I/O (WITH LABEL & GASKET) TK1943 407507500

-17 343--1701--XX 2 CLAMP,CABLE; WITH ADHESIVE BACK 06915 PCC --12

-18 174--5052--XX 1 CABLE ASSY: PCI SEM I --RIGID FLEX,INTERFACE TO

Tektronix part

number

Serial no.

effective

Serial no.

discont’d

Qty Name & description

STAND OFF,4--40 INT THD, X 0.312 THD EXT 4-- 40

DR

TESTED LEVEL

MOTHER BOARD

Mfr.

code

55566 4750--3--12 (+LOCK-

80009 664--5920--XX

TK0EM 12243--XX01

Mfr. part number

WASHER)

211072100

44

TLA7000 Series Mainframe Technical Reference Manual

Parts List

3

15

18

Motherboard

13

PL22

1

9

Backlight

PL26

14

LVDS

cable

9

Display

Nut

GND

post

17

Motherboard

2

3

4

6

9

5

7

6

5

16

8

Fans

PL24

PL27

9

10

11

J150

J280

J260

9

J140

J69

12

Figure 24: Interface, backplane and motherboard

Motherboard

RP28

TLA7000 Series Mainframe Technical Reference Manual

45

Parts List

Replaceable Parts List

Fig. &

index

number

25--1 211--0721--XX 10 SCREW,MACHINE; 6--32 X 0.375,PNH,STL,CD PL,T--15 TORXDR80009 211--0721--XX

-2 436--0296--XX 1 TRAY,FAN; CHASSIS ASSY,W/FANS MOUNTED TK1943 436--0296--XX

-3 119--7143--XX 2 FAN,TUBEAXIAL; 60MM,12VDC,0.12A,1.44W,3600RPM, W/2

-4 211--1213--XX 8 SCREW, METRIC 5 X 10MM, FLATHEAD, STL, ZINC, POSI 0KB01 211--1213--XX

-5 351--0979--XX 1 GUIDE,CARD; GUIDE,DIN 41612;ACCOM C MALE,FR ONT

-6 407--4459--XX 1 BRACKET; HANDLE BRACKET,PLASTIC 7X318 1428

-7 367--0477--XX 1 HANDLE,CARRYING; DUAL DUROMETER MOLDED

-8 378--0449--XX 1 SHUTTER ASSY; INCLUDING FRAME,ACTUATOR, FIN,

-9 119--4933--XX 1 POWER SUPPLY ASSY 80009 119--4933--XX

Tektronix part

number

Serial no.

effective

Serial no.

discont’d

Qty Name & description

PIN CONN

PANEL,3 X 32

HANDLE, POLYPROPYLENE HANDLE VINYL GRIP SECTION

SPRING

Mfr.

code

80009 2410ML--04W--B20--

7X318 1426

12136 PT 3170

7X318 2TEK1550

Mfr. part number

P00

46

TLA7000 Series Mainframe Technical Reference Manual

Parts List

Fanplugto

Backplane board

1

2

3

4

5

8

1

9

Figure 25: Power supply and fans

TLA7000 Series Mainframe Technical Reference Manual

6

7

1

47

Parts List

Replaceable parts list

Fig. &

index

number

26-1 212--0193--XX 12 SCREW, EXT RLV: 8-- 32 X 0.375 BUTTON HEAD,

-2 211--1093--XX 8 SCREW, MACHINE: 4--40 X 0.25, FLH 100 DEG, STL

-3 200--4547--XX 1 COVER: MAINFRAME, AL TK1943 200--4547--XX

-4 441--2191--XX 1 CHASSIS ASSY: MAIN, AL TK1943 441--2191--XX

-5 348--1542--XX 4 FOOT, CABINET: BLACK RUBBER 74594 348-- 1542-- XX

Tektronix

part number

Serial no.

effective

Serial no.

discont’d

Qty Name & description Mfr. code Mfr. part number

CABINET AND CHASSIS ASSEMBLY

HEX DRIVE, STAINLESS STEEL, BLACK OXIDE

FINISH, 0.093 DRIV

BLK OXIDE, T7

0KB01 ORDER BY

DESCRIPTION

0KB01 211--1093--XX

48

TLA7000 Series Mainframe Technical Reference Manual

Parts List

2

3

1

Figure 26: Cabinet and chassis assembly

4

5

TLA7000 Series Mainframe Technical Reference Manual

49

Parts List

Replaceable parts list

Fig. &

index

number

27-1 260--2682--XX 1 SWITCH, PUSH: SPST, GOLD OVER NICKEL

-2 333--4521--XX 1 PANEL,FRONT ASSEMBLY; BENCH TOP, DISPLAY 0KB05 333--4521--XX

-3 119--7163--XX 1 DISPLAY, 128 X 32 ACTIVE DOT MATRIX; GRAPHIC

-4 211--0721--XX 4 SCREW,MACHINE; 6--32 X 0.375, PNH,STL T--15

-5 366--1538=XX 2 PUSH BUTTON; IVORY GRAY,0.3 X 0.665 H TK1163 366--1538=XX

-6 174--3697--XX 1 CABLE ASSY: RIBBON, CABLE TEMP

-7 679--3219--XX 1 CIRCUIT BD ASSY: TEMP SENSE 80009 679--3219--XX

-8 211--0720--XX 17 SCR, ASSEM WSHR: 6--32 X 0.500, PNH, STL, CDPL,

-9 118--9417--XX 1 BACKPLANE VXI: BACKPLANE VXI COMPATIBLE

-10 343--0775--XX 2 CABLE, CLAMP: RIBBON, 1.0X1.0, GRAY, POLYVI-

-11 378--0438--XX 13 BAFFLE ASSY: VXI SLOT, SINGLE, SHUTTER 80009 378--0438--XX

-12 351--1007--XX 13 GUIDE, SINGLE: PLASTIC 80009 351--1007--XX

-13 334--9920--XX 1 MARKER, IDENT: LABEL, FRONT BOTTOM SLOT,

-14 333--4206--XX 5 PANEL, FRONT: DOUBLE, BLANK, EMI, AL, PAINTED

Tektronix

part number

212--0112-- XX 2 SCREW,MACHINE:8--32 X 0.188,TRH,SST POZ 0KB01 OR DER BY

211-- 1093-- XX 2 SCREW,MACHINE:4--40 X 0.25,FLH 100 DEG,STL

Serial no.

effective

Serial no.

discont’d

Qty Name & description Mfr. code Mfr. part number

CIRCUIT BOARDS AND CHASSIS PARTS

CONTACT, 0.4V @ 28V, ILLUMINATED BUTTON,

PANEL MNT W/CABLE

VDF MODULE

TORX DR

SENSE/BACKPLANE, 28AWG, 2x15, 2x10, 2x15

T--15 TORX DR

WITH 13 C--SIZE SLOTS ELECTRONIC AUTOMATIC

NYL, W/URETHANE FOAM TAPE BACKING

0.010 LEXAN, 1.25 X 15.60, BACKGROUND SILVER

GRAY, TLA721

SILVER GRAY

BLK OXIDE,T7

80009 260-- 2682-- XX

80009 119--7163--XX

80009 211--0721--XX

TK2469 174--3697--XX

0KB01 ORDER BY

DESCRIPTION

80009 118--9417--XX

52152 80610029243/3484--

1000

0KB05 334--9920--XX

TK1943 333--4206--XX

DESCRIPTION

0KB01 211--1093--XX

50

TLA7000 Series Mainframe Technical Reference Manual

Parts List

6

8

1

3

2

1

14

4

5

7

9

10

13

12

11

Figure 27: Circuit boards and chassis parts

TLA7000 Series Mainframe Technical Reference Manual

51

Parts List

Replaceable parts list

Fig. &

index

number

28-1 679--6146--XX 1 CIRCUIT BD ASSY: ENHANCED MONITOR

-2 333--4236--XX 1 PANEL, MONITOR: ENHANCED, 0.062 AL, W/LEXAN

-3 214--3903--XX 4 SCREW, JACK: 4--40 X 0.312 EXT THD, 4--40 INT

-4 211--0747--XX 4 SCREW, MACHINE: 6--32 X 0.188, PNH, STL, CDPL,

-5 200--4344--XX 1 COVER: BLOWER CABLE, 0.040 A1 ALLOY TK1943 200--4344--XX

-6 380--1112--XX 1 HOUSING: BLOWER HOUSING BLOWER TK1943 380--1112--XX

-7 212--0193--XX 10 SCREW, EXT RLV: 8-- 32 X 0.375 BUTTON HEAD,

-8 119--7089--XX 1 FAN, DC: BLOWER, 48V, DUAL INLET, 450 CFM,

-9 212--0400--XX 4 SCREW, MACHINE: 8--32 X 0.250, PNH, STL, ZINC,