TAP2500 and TAP3500

2.5 GHz and 3.5 GHz Probes

Instruction Manual

www.tektronix.com

071-1836-01

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are protected by

national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all previously

published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

TekVPI is a trademark of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O . Bo x 5 0 0

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

Warranty 2

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year from the date of shipment. If

any such product proves defective during this warranty period, Tektronix, at its option, either will repair the defective product without charge for parts

and labor, or will provide a replacement in exchange for the defective product. Parts, modules and replacement products used by Tektronix for

warranty work may be new or reconditioned to like new performance. All replaced parts, modules and products become the property of Tektronix.

In o rd er to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the warranty period and make

suitable arrangements for the performance of service. Customer shall be responsible for packaging and shipping the defective product to the service

center designated by Tektronix, with shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the Tektronix service cent er is located. Customer shall be responsible for paying all shipping charges, duties,

taxes, and any other charges for products returned t o any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inade quate ma intenance and care. Tektronix

shall not be obligated to furnish service under this warranty a) to repair damage resulting from attempts by personnel other than Tektronix

representatives to install, repair or service the product; b) to repair damage resulting from improper use or connection to incompatible equipment; c) to

repair any damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or integrated with

other products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. TEKTRONIX’ RESPONSIBILITY TO REPAIR OR R EPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY

PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER T EKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Table of Contents

General Safety Summary . . ................................................................................................................. v

Environmental Considerations ............................................................................................................. ix

Preface...................................................................................................................................... xi

Documentation........................................................................................................................ xi

Conventions Usedin this Manual .................................................................................................... xi

Returning theProbe for Servicing ...................................................................................................xii

KeyFeatures ............................................................................................................................... 1

Installation .................................................................................................................................. 2

Connecting to the Host Instrument ................................................................................................... 2

Probe Controls andIndicators........................................................................................................ 3

Functional Check........................................................................................................................... 6

Required Equipment.................................................................................................................. 6

Calibration .................................................................................................................................. 8

Prerequisites.......................................................................................................................... 8

Required Equipment.................................................................................................................. 8

Test Procedure........................................................................................................................ 9

Table of Contents

Basic Operation............................................................................................................................ 13

Probe Head Assembly...............................................................................................................13

Probe Input........................................................................................................................... 14

TAP2500 and TAP3500 Instruction Manual i

Table of Contents

Accessoriesand Options.................................................................................................................. 19

Probing Principles ......................................................................................................................... 33

Ground Lead Inductance .................................................................................................................. 34

Low-inductance Grounding. ............................................................................................................... 35

SureFoot™ G rounding . ................................................................................................................... 36

Probe Tip Test Points...................................................................................................................... 37

Probe Tip Stabilization..................................................................................................................... 38

Specifications.............................................................................................................................. 39

Performance Verification .................................................................................................................. 47

Probe Offset.......................................................................................................................... 16

Using Standard Accessories . .. ..................................................................................................... 19

OptionalAccessories ................................................................................................................ 29

Options ............................................................................................................................... 32

Ground Lea d Length .. . .............................................................................................................. 33

Warranted Characteristics ........................................................................................................... 40

Typical Characteristics............................................................................................................... 41

Nominal Characteristics ............................................................................................................. 46

Equipment Required................................................................................................................. 47

Equipment Setup..................................................................................................................... 49

DC Gain Accuracy................................................................................................................... 50

Rise Time ............................................................................................................................ 53

ii TAP2500 and TAP3500 Instruction M a nual

Table of Contents

Test Record .......................................................................................................................... 61

Maintenance............................................................................................................................... 63

Error Condition....................................................................................................................... 63

ReplacementParts .................................................................................................................. 63

Cleaning.............................................................................................................................. 64

Index

TAP2500 and TAP3500 Instruction Manual iii

Table of Contents

iv TAP2500 and TAP3500 Instruction Manual

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to this product or any prod ucts connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should pe rform service procedures.

While using this product, you may need to access other parts of a larger system. Read the safety sections of the other component

manuals for warnings and cautions related to operating the system.

To Avoid Fire or Personal Injury

Connect and Disconnect Properly. Do not connect or disconnect probes or test leads while they are connected to a voltage

source.

Connect and Disconnect Properly. Connect the probe output to the measurement instrument before connecting the probe to the

circuit under test. Connect the probe reference lead to the circuit under test before connecting the probe input. Discon nect the prob e

input a nd the probe reference lead from the circuit under test before disconnecting the probe from the measure ment instrument.

Ground the Product. This product is ind irectly grounded through the grounding conductor of the mainframe power cord. To avoid

electric shock, the grounding conductor must be connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings and markings on the product. Consult the

product manual for further ratings information before making connections to the product.

General Safety Summary

Connect the probe reference lead to earth ground only.

Do not apply a potential to any terminal, including the common terminal, that exceeds the maximum rating of that terminal.

TAP2500 and TAP3500 Instruction Manual v

General Safety Summary

Do Not Operate Withou t Covers. Do not operate this product with covers or panels removed.

Do Not Operate With Suspected Failures. If you s uspe ct that there is damage to this product, have it inspected by qualified

service personnel.

Avoid Exposed Circuitry. Do not touch exposed connections and components when power is present.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

vi TAP2500 and TAP3500 Instruction Manual

General Safety Summary

Terms in this Manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in damage to this product or other property.

Symbols and Terms on the Product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the marking.

WARNING indicates an injury hazard not immediately accessible as you read the marking.

CAUTION indicates a hazard to property including the product.

TAP2500 and TAP3500 Instruction Manual vii

General Safety Summary

The following symbols may appear on the product:

viii TAP2500 and TAP3500 Instruction M a nual

Environmental Considerations

This section provides information about the environmental impact of the product.

Product End-of-Life Handling

Observe the following guidelines when recycling an instrument or component:

Equipment Recycling. Production of this equipment required the extraction and use of natural resources. The equipment may

contain substances that could be harmful to the environment or human health if improperly handled at the product’s end of life. In

order to avoid release of such substances into the environment and to reduce the use of natural resources, we encourage you to

recycle this product in an appropriate system that will ensure that most of the materials are reused or recycled appropriately.

The symbol shown below indicates that this product complies with the European Union’s requirements according to Directive

2002/96/EC on w aste electrical and electronic equipment (WEEE). For information about recycling options, check the

Support/Service section of the Tektronix Web site (www.tektronix.com).

Environmental Considerations

TAP2500 and TAP3500 Instruction Manual ix

Environmental Considerations

Restriction of Hazardous Substances

This product has been classified as Monitoring and Control equipment, and is outside the scope of the 2002/95/EC RoHS Directive.

This product is known to contain lead, cadmium, and hexavalent chromium.

x TAP2500 and TAP3500 Instruction Manual

Preface

This manual describes the installation and operation of the TAP2500 and TAP3500 active probes. Basic probe operations and

concepts are presented in this manual. The TAP2500 probe is used in all illustrations in this manual, unless noted otherwise. You

can access this document and other related information from the Tektronix Web site.

Documentation

Preface

To read about Use these documents

TAP2500 and TAP3500 Probes: First Time Operation, Functional Ch eck,

Operating Basics, Specifications, Performance Verification

In-depth oscilloscope operation, user interface help, GPIB commands Access the online help from the Help menu on

*

To access the documentation that is installed on your instrument, click Start in the taskbar and select Programs > TekApplications .

Read this Instruction Manual.

the host instrument.

*

Conventions Used in this Manual

The following icon is used throughout this manual to indicate a step sequence.

TAP2500 and TAP3500 Instruction Manual xi

Preface

Returning the Probe for Servicing

If your probe requires servicing, you must return the probe to Tektronix. If the original packaging is unfit for use or not available, use

the following packaging guidelines:

Preparation for Shipment

1. Use a corrugated cardboard shipping

carton having inside dimensions at

least one inch greater than the probe

dimensions. The box should have a carton

test strength of a t least 200 pounds.

2. Put the probe into an antistatic bag or wrap

it to protect it from dampness.

3. Place the probe into the box and stabilize it

with light packing material.

4. Seal the carton with shipping tape.

5. Refer to Contacting Tektronix at the

beginning of this manual for the shipping

address.

xii TAP2500 and TAP3500 Instruction Manual

Key Features

The TAP2500 and TAP3500 active probes enable you to make accurate measurements with minimal circuit loading from DC to

2.5 GHz and 3.5 GHz respectively, using oscilloscopes featuring the new Tektronix Te kVPI oscilloscope interface. Key features

include:

Bandwidth

DC to ≥2.5 GHz (TAP2500)

DC to ≥3.5 GHz (TAP3500)

±4 Volts Dynamic Range with ±10 volt

offset capability

10X Attenuation

40 kΩ Input Resistance

<0.8 pF Input Capacitance

TekVPI Interface

Small, low-mass probe head for probing

dense circuitry

Key Features

TAP2500 and TAP3500 Instruction Manual 1

Installation

Installation

Connecting to the Host Instrument

1. Slide the probe into the TekVPI receptacle.

The probe snaps when fully engaged.

When the probe is connected, the host

instrument reads information from the

probe and identifies the device.

2. To disconnect, press the latch release

button and pull away from the instrument.

2 TAP2500 and TAP3500 Instruction Manual

Probe Controls and Indicators

Status LED

When the probe is powered on, the multicolor

Status LED:

Glows green after successfully completing

the power-on self test routin e. The probe is

in normal operating mode.

Glows red if an error condition exists. ( See

page 63, Error Condition.)

Installation

TAP2500 and TAP3500 Instruction Manual 3

Installation

Menu Button

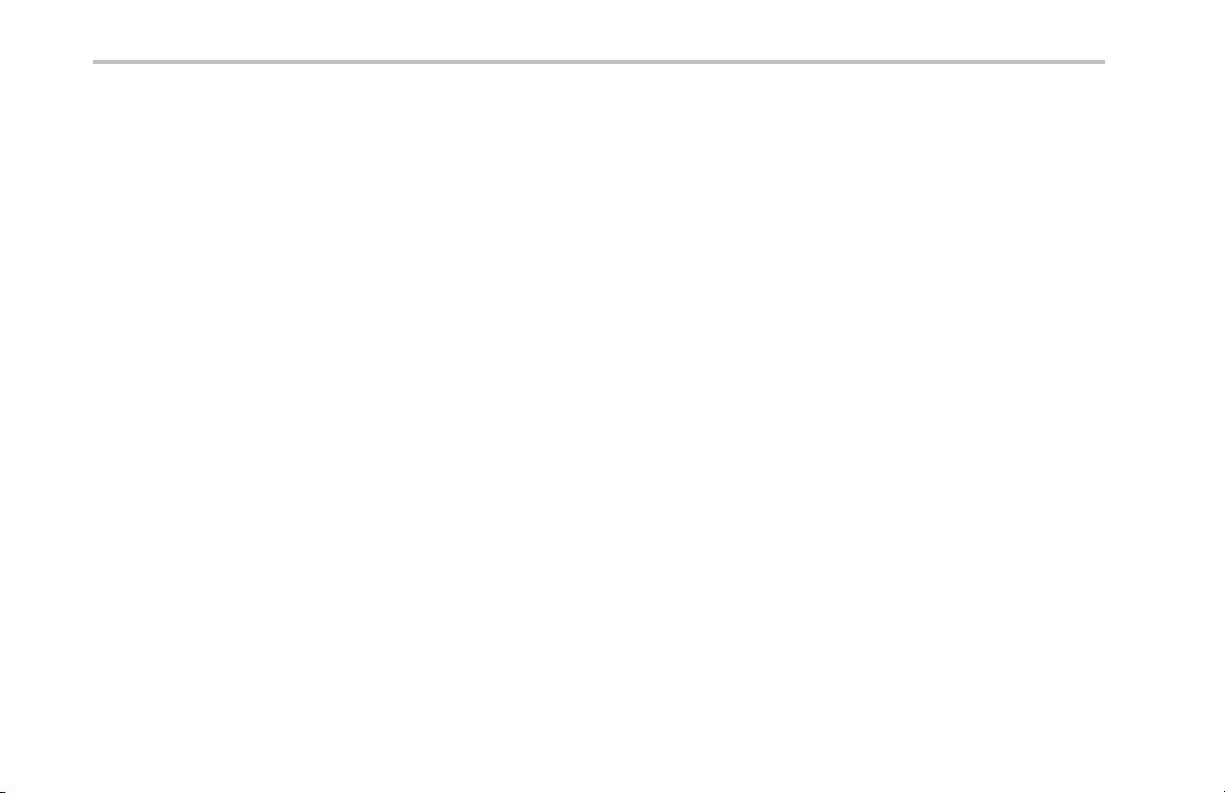

1. Press the probe Menu button to display the

Probe Control screen on the oscilloscope.

2. Use the touch-screen buttons on the

instrument to set the probe parameters.

3. Press the probe Menu buttonagainto

close the Probe Control screen.

4 TAP2500 and TAP3500 Instruction Manual

AutoZero

We recommend that you run the probe

AutoZero routine:

After the 20 minute warm-up period

When the operating temperature of the

probe changes by ±5 °C

1. Press the probe Menu b utton to display the

Probe Control screen on the oscilloscope.

2. Short the probe tip to ground.

3. Press the AutoZero buttononthe

instrument to execute the AutoZero routine .

Installation

TAP2500 and TAP3500 Instruction Manual 5

Functional Check

Functional Check

Use the following procedure to check that your probe is functioning properly. If you want to verify that your probe meets the

warranted specifications, refer to the Performance Verification procedures. (See page 47.)

Required Equipment

Description and quantity Performance requirement Recommended example

1

Oscilloscope TekVPI Interface Tektronix DPO7000 Series

Y-Lead adapter

0.25-in square pins fo r probe tip

196-3463-XX

2

connections

SMT KlipChip adapters (2)

1

Nine-digit part numbers (xxx-xxxx-xx) are Tektronix part numbers.

2

Standard probe accessory

0.25-in square pins-to-mini clips 206-0364-XX

2

6 TAP2500 and TAP3500 Instruction Manual

Signal

1. Connect the p robe to any channel of the

oscilloscope and set the oscilloscope to

display that channel.

2. Use the Y-lead Adapter and two SMT

KlipChips to connect the probe tip to

the PROBE COMP terminals on the

oscilloscope.

3. Press AUTOSET (or adjust the

oscilloscope) to d isplay the calibration

waveform. A stable waveform indicates

that your probe is functioning correctly.

Functional Check

TAP2500 and TAP3500 Instruction Manual 7

Calibration

Calibration

The probe calibration routine m inimizes yo ur measurem ent errors by optimizing the gain and offset of the probe and oscilloscop e

combination. We recommend that you repeat the probe calibration on each channel that you use. Individual calibration constants

are stored for each probe on each channel.

Prerequisites

The equipment must be warmed up for 20 minutes, and the calibration status of the host instrument must be pass.

Required Equipment

The r equired equipment for calibration is the same as for the functional check. (See page 6, Required Equipment.)

8 TAP2500 and TAP3500 Instruction Manual

Test Procedure

Check the Calibration Status of the instrument:

1. From the Utilities menu, select Instrument

Calibration.

2. In the Calibration box, check that Pass is

displayed in the Status field. If it is not,

disconnect all probes and signal sources

from the oscilloscope, and run the Signal

Path Compensation routine (see next step).

Calibration

TAP2500 and TAP3500 Instruction Manual 9

Calibration

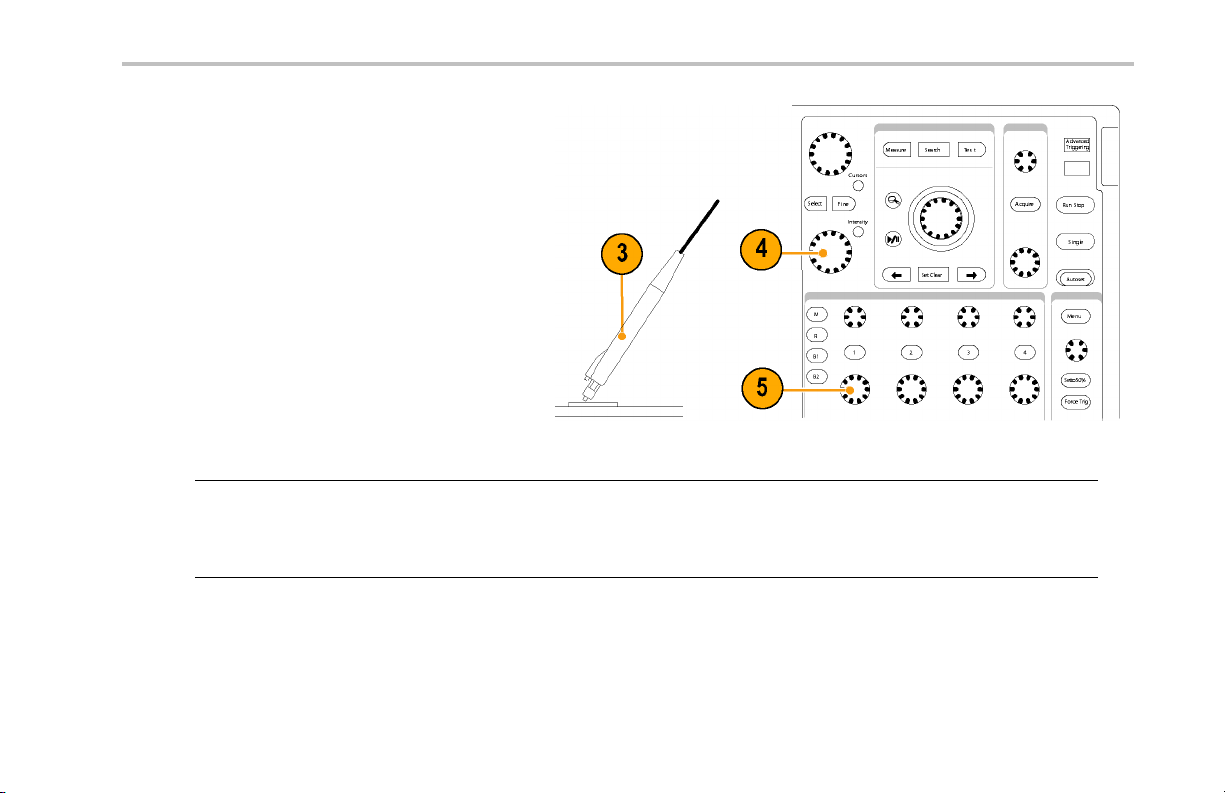

3. Connect the probe to the oscilloscope

PROBE C OMP connector as shown.

4. From the Vertical menu, select Probe Cal.

10 TAP2500 and TAP3500 Instruction Manual

5. When th e Probe Setup screen appears,

select Clear ProbeCal, and then select

Calibrate Probe.

The probe calibration routine begins. When

the routine completes, a notifier appears.

Close the notifier and begin using your

probe.

Calibration

TAP2500 and TAP3500 Instruction Manual 11

Calibration

12 TAP2500 and TAP3500 Instruction Manual

Basic Operation

Follow these operating guidelines to get optimum performa nce from your probe.

Probe Head Assembly

The probe head is de signed for ease of use

andhighperformance. Itssmallsizemakesit

easy to handle in tight areas.

1. The probe tip socket is sized to easily press

onto 0.025-inch pins for direct access.

2. The ground socket provides a short ground

path for high-fide lity ground connections.

3. The stabilization notch permits you to use

adjacent pins to reduce stresses on the

probe and pins.

Basic Operation

TAP2500 and TAP3500 Instruction Manual 13

Basic Operation

Probe Input

The probe is electrically protected against static voltage. However, applying voltages above its design limits may damage the

probe tip amplifier. (See Figure 1 on page 15.)

Input Linear Dynamic Range

The pro be head amplifier used by the probe has a limited linear operating range. To keep the input linearity error less than 1% you

must limit the signal input voltage to ±4 V (including any DC offset).

14 TAP2500 and TAP3500 Instruction Manual

Figure 1: Dynamic and Offset Limitations

Basic Operation

TAP2500 and TAP3500 Instruction Manual 15

Basic Operation

Probe Offset

The probe offset is adjustable to permit operation within the linear range of the probe, and to increa se the sensitivity of the probe

at higher DC measurement voltages. Using the offset to cancel DC signal compon ents enables optimal probe performance.

(See Figure 1 on page 15.)

NOTE. See your oscilloscope manual for specific instructions on using the offset control.

To set the probe offset, follow these steps:

1. Use th e vertical position control to set a

zero reference level on the oscilloscope

display.

2. Set the oscilloscope coupling to DC and

5 V/div. This sets the oscilloscope to

display the full offset dynamic range of the

probe.

16 TAP2500 and TAP3500 Instruction Manual

Basic Operation

3. Attach the probe to the circuit.

4. Adjust the probe offset to bring the trace to

the oscilloscope zero reference.

5. Change the volts/division setting to the

desired range, a djusting the offset to keep

the trace on the zero reference level.

NOTE. The probe has a ±10 V offset range. The linear opera ting range is ±4 V. (See Figure 1 on page 15.) If cursors are used on

the oscilloscope, the zero reference will be at the probe offset voltage. When you adjust the probe offset with no signal applied to

the probe input, the output range is ±4V, (the linear operating range of the probe), not the ±10V offset range of the probe. However,

when you apply ±10V to the probe input, the probe offset control is capable of zeroing this offset.

TAP2500 and TAP3500 Instruction Manual 17

Basic Operation

18 TAP2500 and TAP3500 Instruction Manual

Accessories and Options

This section lists the standard accessories and provides information on how to use the acce ssories. Specifications are provided

where appropriate so that you can choose the accessory that best fits your needs. In some cases, reorder kit quantities differ from

the actual number of accessories included with the probe.

Using Standard Accessories

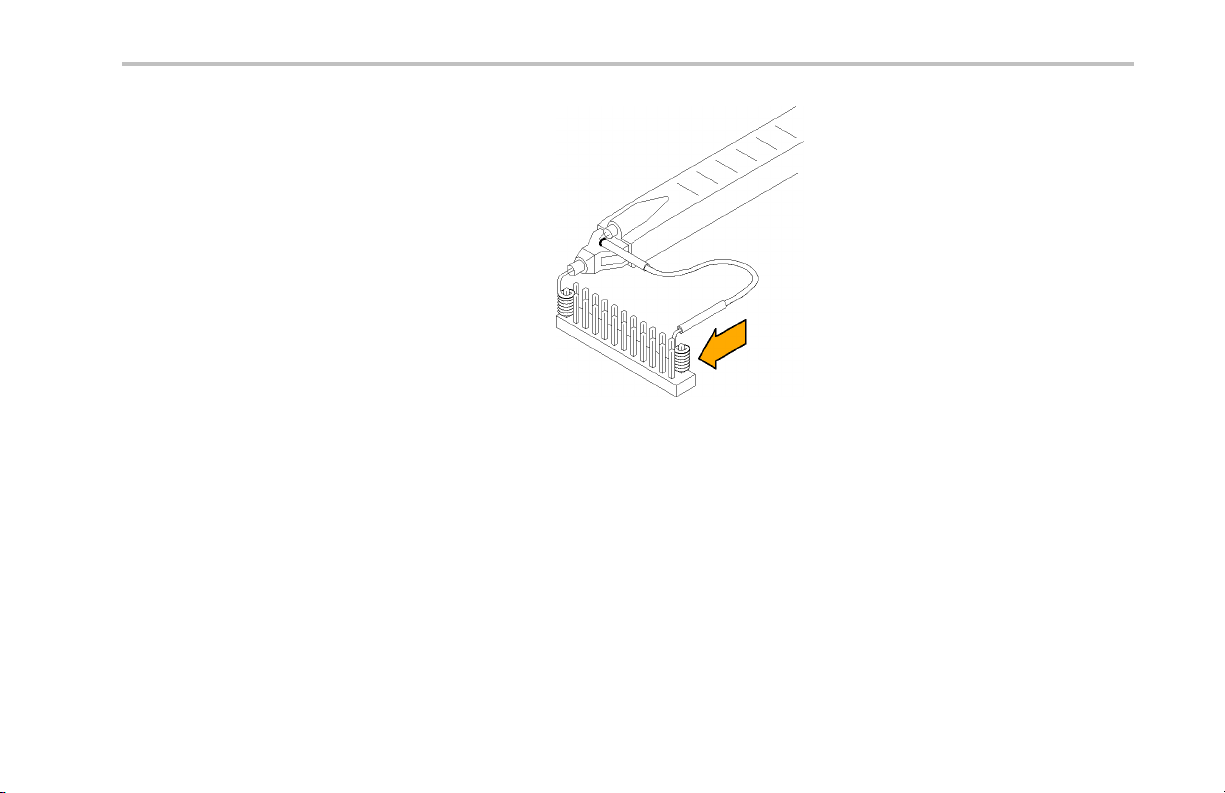

Push-in Probe Tip

Use the push-in probe tip for general purpose

probing by ha nd. You can also use the push-in

probe tip with the other socketed leads and

adapters.

Push the tip into the socket until it is seated.

Either end of the tip may be u sed. Do not force

the tip. Also, be careful not to injure yourself

on the sharp point.

Reorder Tektronix part number:

131-5638-11 qty. 10

Accessories and Options

TAP2500 and TAP3500 Instruction Manual 19

Accessories and Options

SureToe Adapter

The SureToe adapter is a pointed probe tip

useful for probing in dense circuitry. Attach the

SureToe adapters the same way as the push-in

probe tips.

Do not force the adapter. Also, be careful not to

poke yourself with the sharp probe tip. SureToe

adapters can be used with any of the socketed

accessory leads. Four Su reToe adap ters are

included with the probe.

Reorder Tektronix part number:

131-6254-XX qty. 4

20 TAP2500 and TAP3500 Instruction Manual

Pogo Pin Ground

Use the low-inductance ground pogo pin to

substantially reduce ground lead inducta nce

and t o easily move the probe to different points

on the circuit under test.

To attach, press the pogo pin into the probe

head ground socket. To maint ain signal fidelity

while probing, use as short a ground path as

possible. (See page 33, Ground Lead Length.)

Reorder Tektronix part number:

016-1772-10 qty. 10

Accessories and Options

TAP2500 and TAP3500 Instruction Manual 21

Accessories and Options

Square Pin Socket

The square pin socket is ideal for use with

signal/ground pairs on 0.100-inch square

header pins. Attach the socket by gently

pressing it into the ground socket on the probe

head.

Be sure to use the stabilization notch wheneve r

possible to avoid slipping and damaging the

probe or circuitry under test.

Reorder Tektronix part number:

016-1773-10 qty. 10

Customizable Ground Lead

You can be nd or shorten this ground lead.

Cut the tip of the ground lead wire at a 30° to

60° angle to ease insertion into the ground

socket of the probe.

To maintain signal fidelity while probing, use as

short a ground path as possible. (See page 33,

Ground Lead Length.)

Reorder Tektronix part number:

196-3482-XX qty. 5

22 TAP2500 and TAP3500 Instruction Manual

Right-Angle Adapter

Use the righ t-angle adapter for low-profile

probing of 0.025-inch square pins. T he

right-angle adapter allows the probe to lie flat

against a circuit board, enabling you to probe

in tight areas such as between circuit cards.

The right-angle adapter can be used directly

with the probe head, or attached to the Y-lead

adapter or ground leads.

Attach the right-angle adapter the same way as

the push-in probe tip.

Reorder Tektronix part number:

016-1774-XX qty. 10

Accessories and Options

TAP2500 and TAP3500 Instruction Manual 23

Accessories and Options

Y-Lead Adapter and Ground Leads

Use the Y-lead adapter to extend the reach

of the probe and ground. The Y-lead adapter

accepts any of the probe tips or adapters, and

can be pushed directly onto 0.025 inch square

pins.

Use the ground leads for general,

lower-frequency probing. The socketed

end of the leads may be connected to any

of the probe tips and adapters, or fitted onto

0.025-inch square pins.

When selecting the grounding connection,

maintain as short a ground path as possible.

(See page 33, Ground Lead Length.)

Reorder Tektronix part number: 196-3456-XX

Kit includes:

Y-lead adapter, qty. 2

Three-in ground leads, qty. 3

24 TAP2500 and TAP3500 Instruction Manual

SMT KlipChip Adapter

Use the SMT KlipChip test clips to access

fragile, dense circuitry. KlipChip test clips can

be connected to the Y-lead or ground leads.

Simply press the lead socket into the KlipChip

handle.

The KlipChip body freely turns, allowing better

probe orientation. To reduce stress and provide

a lower profile on components being tested,

the flexible sleeve of the KlipChip bends up to

a 35° angle.

Reorder Tektronix part number:

206-0364-XX qty. 1

Accessories and Options

TAP2500 and TAP3500 Instruction Manual 25

Accessories and Options

Color Band Kit (Five Colored Pairs)

1. Attach one band to the probe cable and

another one of the same color n ear the

probe compensation box.

2. Connect the probe to the channel that

matches the color of the band.

Reorder Tektronix part number:

016-1315-XX qty. Set of 5 colors

Antistatic Wrist Strap

When using the probe, always work at an

antistatic work station and wear the antistatic

wrist strap.

Reorder Tektronix part number:

006-3415-XX

26 TAP2500 and TAP3500 Instruction Manual

Pouch, Nylon Carrying Case with

Inserts

Use the carrying case to hold the probe, the

accessories, and th e instruction manual.

1. Place the probe, accessories, and manual

in the carrying case.

2. Close the carrying case to transp ort the

accessories to another location or for

storage.

Reorder Tektronix part number:

016-1952-XX

Accessories and Options

TAP2500 and TAP3500 Instruction Manual 27

Accessories and Options

Instruction Manual

The instruction manual provides instructions for

operating and maintaining the TAP2500 and

TAP3500 active probes. Store the instruction

manual in the probe case for easy r eference.

Reorder Tektronix part number:

071-1836-XX (English)

071-1884-XX (Japanese)

071-1885-XX (S. Chinese)

28 TAP2500 and TAP3500 Instruction Manual

Optional Accessories

This section lists the optional accessories that you can purchase to help you with your probing tasks.

SureFoot™ Probe Tips

The SureFoot tips are an inte gral probe tip

and miniature guid e that enables fault-free

probing of fine-pitch SMD packages. A ttach

the SureFoot adapters the same way as the

push-in probe tips.

SureFoot tips are available in three sizes:

The yellow, 0.050-inch SureFoot tip is

compatible with 50 mil JEDEC packages such

as SOIC, PLCC, CLCC, etc.

Order Tektronix part number SF501 qty. 12

The blue, 0.025-inch SureFoot t ip is compatible

with 0.65 mm JEDEC and EIAJ packages.

Order Tektronix part number SF502 qty. 12

Accessories and Options

TAP2500 and TAP3500 Instruction Manual 29

Accessories and Options

The red, 0.5 mm SureFoot tip is comp atible

with EIAJ packages.

Order Tektronix part number SF503 qty. 12

IC Micro-Grabber

Use the IC Micro-Grabber to probe the leads

on integrated circuits that are surface-mounted.

Order Tektronix part number:

013-0309-XX qty. 2

SMA-to-Probe Tip Adapter

Use the adapter to connect the probe to SMA

cables and for calibration and performance

verification. The adapter includes a 50 Ω SMA

termination.

Order Tektronix part number: 015-0678-XX

30 TAP2500 and TAP3500 Instruction Manual

TekVPI Calibration Fixture

The calibration fixtureisrequiredtodoa

performance verification on the probe. It

provides an SMA connector in the probe signal

path for internal probe measurements.

Order Tektronix part number: 067-1701-XX

Accessories and Options

TAP2500 and TAP3500 Instruction Manual 31

Accessories and Options

Options

Service Options

Option CA1. Provides coverage for a single Calibration Event

Option C3. Calibration Service 3 years

Option C5. Calibration Service 5 years

Option D1. Calibration Data Report

Option D3. Calibration Data Report, 3 y ears (with Option C3)

Option D5. Calibration Data Report, 5 y ears (with Option C5)

Option R3. Repair Service 3 years

Option R5. Repair Service 5 years

Manual Options

Option L0. English language Instruction Manual

Option L5. Japanese language Instructio n Manual

Option L7. Simplified Ch inese language Instruction Manual

32 TAP2500 and TAP3500 Instruction Manual

Probing Principles

Follow these helpful hints to make probing easier and noise free.

Ground Lead Length

When you are probing a circuit, you should

always use as short a ground lead as possible

between the probe head and circuit ground.

(See the illus tration for the effects of lead length

on waveform distortion.)

The series inductance added by the probe tip

and ground lead can result in a resonant circu it;

this circuit may cause parasitic ringing within

the bandwidth of your oscilloscope.

Probing Principles

TAP2500 and TAP3500 Instruction Manual 33

Ground Lead Inductance

Ground Lead Inductance

When you touch your probe tip to a circuit element, you are introducing a new resistance, capacitance, and inductance into the

circuit.

You can determine if ground lead effects may

be a problem in your application if you know

the self-inductance (L) and capacitance (C)

of your probe and ground lead. Calculate the

approximate resonant frequency (f

this parasitic circuit will resonate with the

following formula:

The equation shows that reducing the ground

lead inductance will raise the resonant

frequency. If your measurements are affected

by ringing, your goal is to lower the inductance

of your ground path until the resulting resonant

frequency is well above the frequency of your

measurements.

The low-inducta nce ground contacts described

in Accessories can help y ou reduce the

effects of ground lead inductance on your

measurements.

0

)atwhich

34 TAP2500 and TAP3500 Instruction Manual

Low-inductance G rounding

Use a ground plane on the package to m ake

probing the package easier, and to avoid

adding unnecessary ground lead length and

distortion:

1. Attach a small piece of copper clad on top

of the package.

2. Connect the copper clad to the package

ground connection.

3. Use the low-inductance ground lead to

keepthegroundleadlengthasshortas

possible.

Quick Tip

This method is very useful when making many

measurements on the same package.

Low-inductance Grounding

TAP2500 and TAP3500 Instruction Manual 35

SureFoot™ Grounding

SureFoot™ Grounding

If you cannot use the low-inductance grounding

method recommended, the probe may be

grounded to the package under test using a

SureFoot adapter.

1. Connect a short ground lead to the probe.

2. Attach a SureFoot adapter at the end of

the ground lead.

3. Connect the Sure Foot adapter directly to

the package ground.

This method is preferred over using an adjacent

circuit ground because it is the shortest ground

path possible.

36 TAP2500 and TAP3500 Instruction Manual

Probe Tip Test Points

The push-in probe tip or a 0.025-inch square

pin can be soldered into a circuit to be used as

a temporary test point:

1. Solder the tip onto a lead or pin with a

low-power soldering iron.

2. Press the probe head onto the tip to make

a measurement.

3. Pull the probe head off when you are done.

Quick Tip

The probe tip m ay be remove d and reused by

desoldering it from the circuit, and soldering it

into another circuit in the future.

Probe Tip Test Points

NOTE. Do not use pieces of solid-core copper wire as test points. If the wire breaks off in the probe tip socket, it may be impossible

to remove the wire, and it will prevent insertion of other accessory tips.

TAP2500 and TAP3500 Instruction Manual 37

Probe Tip Stabilization

Probe Tip Stabilization

The probe head has a stabilizing notch for use

with 0.100 inch-spaced header pins:

1. Press the probe onto the header pin.

2. Insert the stabilizing notch of the probe

onto an adjacent pin. This prevents

unnecessary force from being applied

directly to the probe tip or pins.

The signal-ground adapter can rest on the

stabilized pin without a risk of its moving

outofplace.

38 TAP2500 and TAP3500 Instruction Manual

Specifications

The specifications are valid under the following conditions:

The probe has been calibrated at an ambient tempe rature of 23 °C ±5 °C.

The probe is connected to a host instrument with an input imped ance of 50 Ω .

The probe and oscilloscope must have a warm-up period of at least 20 minutes and be in an environment that does not

exceed the limits described. (See Table 1.)

The Signal Path Compensation (SPC) has been run on the oscilloscope prior to testing the probe specifications.

Specifications for the TAP2500 and TAP3500 active probes fall into three categories: warra nted, typical, and nominal characteristics.

Specifications

TAP2500 and TAP3500 Instruction Manual 39

Specifications

Warranted Characteristics

Warranted characteristics describe guaranteed performance within tolerance limits or c ertain type-t ested requirement s. Warranted

characteristics th at have checks in the Performance Verification section are marked with the

and Mechanical cha racteristics apply to the TAP2500 and th e TAP3500, probes unless noted otherwise.

Table 1: Warranted electrical characteristics

Characteristic Description

DC a ttenua tio n accuracy (probe only)

Rise time (probe only)

Temperature

Humidity

Altitude

symbol. The Warranted, Typical,

10:1 ±2% (excludes offset error)

≤140 ps (TAP2500)

≤130 ps (TAP3500)

Operating: 0 to + 50 _C (+32 to +122 °F), Nonoperating: -40 to +71 °C (-40 to

+160 °F)

Operating: 5-95% RH, tested up to +30 °C (+86 °F) 5-85% RH, tested at + 30 °C to

+50°C(+86to+122°F)

Nonoperating: 5-95% RH, tested up to +30 °C (+86 °F) 5-85% RH, tested at

+30 °C to +75 °C (+86 to +167 °F)

Operating: Up to 3000 meters (9,843 feet),

Nonoperating: Up to 12,000 meters (39,370 feet)

40 TAP2500 and TAP3500 Instruction Manual

Typical Characteristics

Typical characteristics describe typical but not guaranteed performance.

Table 2: Typical electrical characteristics

Characteristic Description

Bandwidth (probe only) DC to ≥2.5 GHz (TAP2500)

Input resistance

Input capacitance ≤0.8 pF

Input signal range -4.0 V to +4.0 V

Input offset range

Output Zero

Maximum non destructive input voltage ±30 V

Linearity

DC offset drift 1.5 mV/ °C or less displayed on screen

Signal delay

Specifications

DC to ≥3.5 GHz (TAP3500)

40 kΩ

-10.0 V to +10.0 V

±10 mV or less displayed on screen

(DC + peak AC)

±0.1% or less over a dynamic range of -3.75 V to +3.75 V ±1.0% or less over a

dynamic range of -4.0 V to +4.0 V.

5.3 ns ±0.2 ns

TAP2500 and TAP3500 Instruction Manual 41

Specifications

Figure 2: TAP2500 Typical bandwidth

42 TAP2500 and TAP3500 Instruction Manual

Figure 3: TAP3500 Typical bandwidth

Specifications

TAP2500 and TAP3500 Instruction Manual 43

Specifications

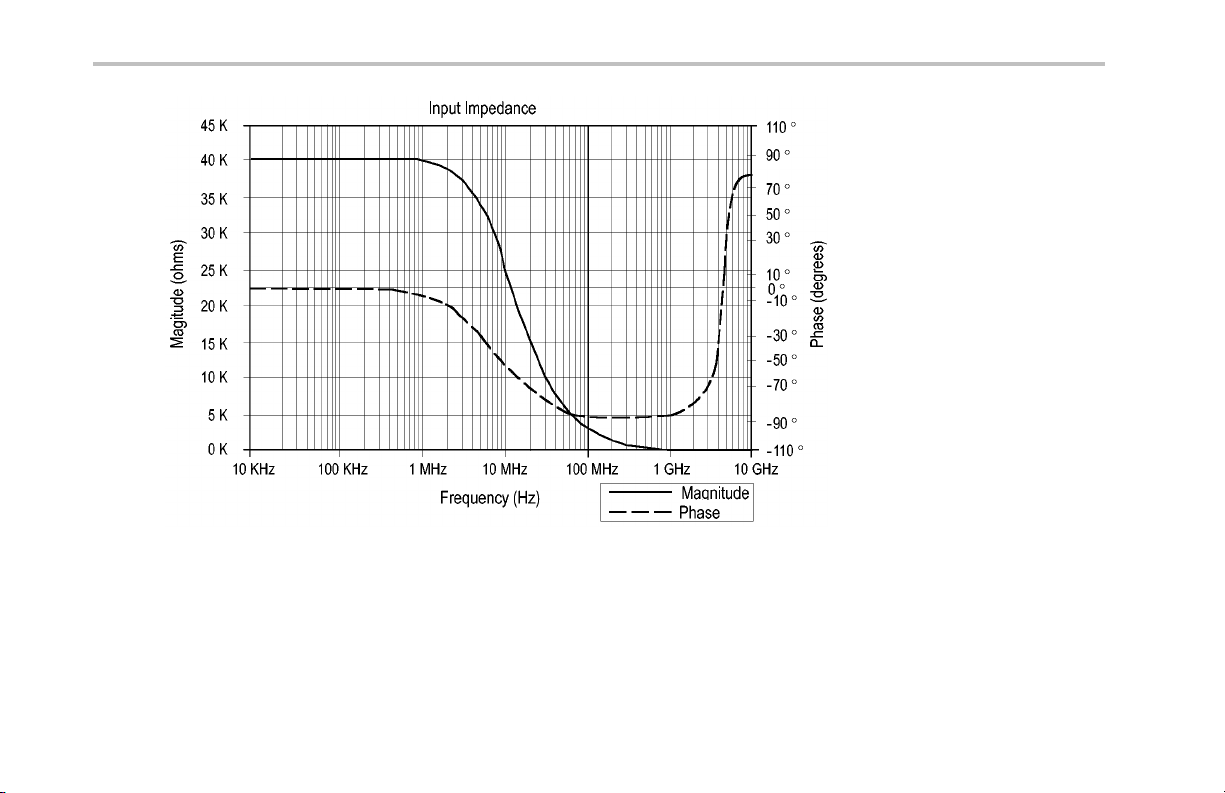

Figure 4: Typical input impedance and phase versus frequency

44 TAP2500 and TAP3500 Instruction Manual

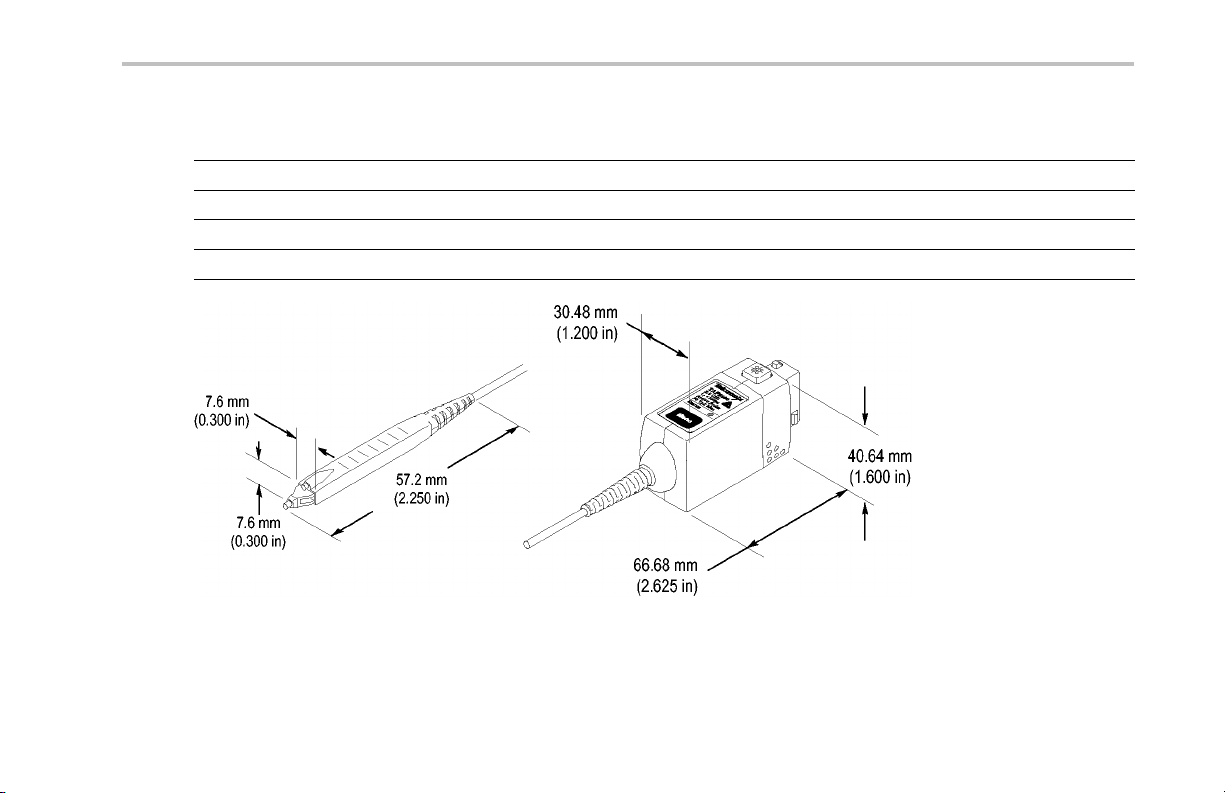

Table 3: Typical mechanical characteristics

Characteristic Description

Dimensions, compensation box

Dimensions, probe head

Dimensions, cable length

Unit weight

107mm×41mm×26mm(4.2in×1.6in×1.0in)

19.43 mm × 3.30 mm × 7.6 mm (0.765 in × 0.130 in × 0.300 in)

1.3 m (51 in) (from the probe head to the compensation box)

1.55 kg (3.44 lbs) (probe, accessories and packaging)

Specifications

TAP2500 and TAP3500 Instruction Manual 45

Specifications

Nominal Characteristics

Nominal characteristics describe guaranteed traits, but the traits do not have tolerance limits.

Table 4: Nominal electrical characteristics

Characteristic Description

Input coupling

Term i n atio n

Compatibility Oscilloscopes equipped with the TekVPI interface

Pollution Degree 2, Indoor use only

DC

Terminate output into 50 Ω

46 TAP2500 and TAP3500 Instruction Manual

Performance Verification

The procedures that follow verify the warranted specifications of the probe. The recommended calibration interval is one year.

Perform the verification procedures in the order listed.

Equipment Required

The following equipment is required for the performance verification procedures.

Table 5: Test equipment

Description and quantity Performance requirement Recommended example

Oscilloscope TekVPI Interface Tektronix DPO7000 Series

Sampling oscilloscope ≥12.5 GHz bandwidth Tektronix TDS8000 Series

Sampling module ≥12.5 GHz bandwidth

Sampling module

TekVPI Calibration/Verification adapter TekVPI Interface

DC voltage source -1.0 to +1. 0 VDC, 0.2% accuracy

Digital multimeter (DMM) Resistance, 0.1% accuracy

HF Probe Tip adapter

SMA M-to-BNC F adapter SMA male-to-BNC female

TDR output: 250 mV step, <30 ps rise

time

Probe tip adapter with 50 Ω termination

Performance Verification

1

Tektronix 80E0X

Tektronix 80E04

067-1701-XX

Wavetek 9100

Keithley 2700

015-0678-00

015-0554-00

TAP2500 and TAP3500 Instruction Manual 47

Performance Verification

Table 5: Test equipment (cont.)

Description and quantity Performance requirement Recommended example

BNC-to-dual banana adapter (2)

BNC cable 50 Ω , 0.76 m (30 in) length

SMA cable (2) Male-to-Male SMA cable

Precision termination

Y-Lead adapter

SMT KlipChip adapters (2)

SMA torque wrench 5/16-in, 7 in-lb.

SMA adapter wrench 7/32-in

1

Nine-digit part numbers (xxx-xxxx-xx) are Tektronix part numbers.

2

Standard accessories included with the probe.

103-0090-00

012-0117-00

012-0649-00

50 Ω ,0.1%,0.5W

0.25-in square pins fo r probe tip

011-0129-00

196-3463-xx

connections

0.25-in square pins-to-mini clips 206-0364-xx

1

2

2

48 TAP2500 and TAP3500 Instruction Manual

Equipment Setup

Use the following procedure to set up and warm up the equipment to test the probe.

1. Turn on the TekVPI oscilloscope.

2. Connect the TekVPI Calibration/Verification

adapter to the oscilloscope.

3. Connect the prob e to the TekVPI

Calibration/Verification ada pter and verify

that the Status LED on the probe turns

green.

4. Turn on the remaining test equipment.

5. Allow 20 minutes for the equipment to

warm up.

6. Photocopy the test record and use it to

record the test results. (See page 61, Te st

Record.)

Performance Verification

TAP2500 and TAP3500 Instruction Manual 49

Performance Verification

DC Gain Accuracy

This test checks the DC gain accuracy of the probe.

1. Connect the BNC-to-dual banana adapter

to the DMM input.

2. Connect the SMA M-to-BNC F adapter

to the SMA output of the TekVPI

Calibration/Verification adapter.

3. Connect the precision termination to the

BNC end of the SMA M-to-BNC F adapter.

4. Connect the BNC cable between the

precision termination and the BNC-to-dual

banana adapter attached to the DMM.

50 TAP2500 and TAP3500 Instruction Manual

5. Connect the second BNC-to-dual banana

adapter to the output of the DC voltage

source.

6. Connect the Y-lead adapter and K lipChip

adapters to the probe input.

7. Attach the KlipChip adapters to the

BNC-to-dual banana adapter connected

to the DC voltage source. Make sure the

polarity is correct-ground to outer shield

and probe input to center conductor.

Performance Verification

TAP2500 and TAP3500 Instruction Manual 51

Performance Verification

8. Set oscilloscope offset to 0.0 V.

9. Set the DMM to DCV.

10. PresstheREL(relative)buttontoZerothe

DMM.

11. Set the DC voltage source to +1.00 VDC

and enable the output.

12. Record the DMM measurement in the test

record.

13. Set the DC voltage source to -1.00 VDC.

14. Record the DMM measurement in the test

record.

NOTE. An unacceptable error value may

result if a precision 50 Ω termination is not

used for the recommended term ination, or if

the o scilloscope offset is not set to zero.

15. Leave the TekVPI Calibration/Verification

adapter and probe connected the

oscilloscope to keep the probe warm.

52 TAP2500 and TAP3500 Instruction Manual

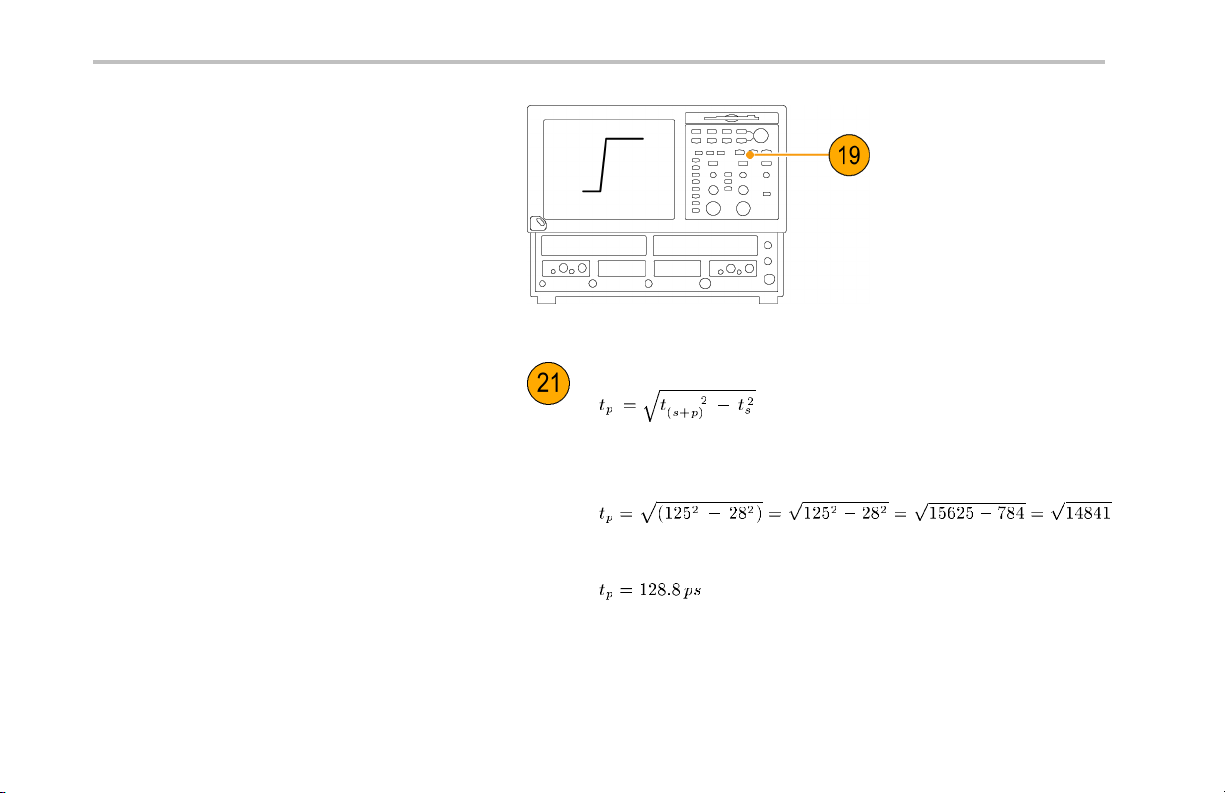

Rise Time

This procedure verifies that the probe meets the rise time specification. Two rise times are measured; the test system alone, and

then the test system with the probe included. The probe rise time is calculated using the two measurements.

This test uses the TDR function of the 80E04 sampling head as a fast rise tim e signal source. A second 80E0X sampling head

is used to take the measurements. Although the following procedure assigns the TDR and measurement functions t o specific

oscilloscope channels, any channels can be used. However, the TDR function is only available on 80E04 sampling heads.

CAUTION. To preve nt damage, use care when working with SMA connectors: support equipment to avoid mechanical strain on

the connectors, and when tightening connections, use a torqu e wrench to 7.5 in-lbs.

Performance Verification

TAP2500 and TAP3500 Instruction Manual 53

Performance Verification

Test System Rise Time

1. Connect the 80E04 sampling head to

Channel1 of the sampling oscilloscope.

2. Connect the 80E0X sampling head to

Channel8 of the sampling oscilloscope.

3. Connect SMA cables to Channels 1 and 8.

4. Connect the SMA cable from Channel 1 to

the HF Probe Tip adapter.

54 TAP2500 and TAP3500 Instruction Manual

5. Remove the 50 Ω termination from the HF

Probe Tip adapter and connect the SMA

cable from Channel 8 to the adapter.

6. Turn on Channel 8 and set the vertical

scale to 50 mV/div.

Performance Verification

TAP2500 and TAP3500 Instruction Manual 55

Performance Verification

7. Set the Channel 1/2 sampling head to TDR

mode: Press the SETUP DIALOGS button

and select the TDR tab.

8. Set the Channel 1 (C1) Polarity to positive

(rising).

9. Set the Preset of Channel 1 on.

TDR Preset sets Internal Clock in the

Trigger menu, turns on the TDR Step in the

TDR Setups menu, turns on the channel

and selects the acquisition Units in the

TDR Setups menu, and sets the horizontal

scale, position, and reference.

The sampling module will turn on a red

light next to the SELECT channel button,

indicating that TDR is activated for that

channel.

56 TAP2500 and TAP3500 Instruction Manual

10. Turn off the display for Channel 1 so that

only Channel 8 is shown on screen.

11. Adjust the oscilloscope horizontal and

vertical position controls to display a signal

similar to that shown.

12. Set the oscilloscope horizontal scale to

50 ps/div and center the waveform.

NOTE. Do not touch the HF Probe Tip adapter

when making calibration measurements.

Measurement accuracy is degraded when the

probe tip adapter is handled.

13. Use the oscilloscope measurement

capability to display rise time. Increase the

stability of the pulse edge measurement

by using ave raging, if available. Rise time

is determined from the 10% and 90%

amplitude points on the waveform. Record

therisetimeast

.

s

Performance Verification

TAP2500 and TAP3500 Instruction Manual 57

Performance Verification

Test System and Probe Rise Time

14. Disconnect the SMA cable from the

Channel-8 side of the HF Probe Tip

adapter and reconnect the 50 Ω SMA

termination to the adapter.

15. Connect the SMA cable from Channel 8

of the sampling oscilloscope to

the S MA connector on the TekVPI

Calibration/Verification adapter.

16. Connect the probe to the HF Probe Tip

adapter.

17. Set the TekVPI oscilloscope offset to 0.0 V.

58 TAP2500 and TAP3500 Instruction Manual

NOTE. The following measurements are taken

with the sampling oscilloscope. The TekVPI

oscilloscope only provides power and o ffset to

the probe.

18. On the sampling oscilloscope, expand

the horizontal scale to locate the step

edge: Set the vertical scale to 5 mV/div,

and adjust horizontal range to 100 ps/div

while maintaining the edge view. For a

more stable measurement display, turn

averaging on.

NOTE. Do not touch the HF Probe Tip adapter

when making calibration measurements.

Measurement accuracy is degraded when the

probe tip adapter is handled.

Performance Verification

TAP2500 and TAP3500 Instruction Manual 59

Performance Verification

19. Adjust the position controls on the sampling

oscilloscope to display the entire leading

edge waveform.

20. Use the measurement capability of the

sampling oscilloscope to display rise

time: Increase the stability of the pulse

edge measurement by using averaging,

if available. Risetime is determined from

the 10% and 90% amplitude points on the

waveform. Record the rise time as t

21. Using the test system rise time (ts) that

you measured in step 13, and the test

system and probe rise time (t

youmeasuredinstep20,calculatethe

probe-only rise time using the formula

shown.

22. Check that the calculated rise time m eets

the probe specification.

23. Record the results on the test record.

.

s+p

) that

s+p

Example:

60 TAP2500 and TAP3500 Instruction Manual

Test Record

Probe Mo del/Serial Number: Certificate Number:

Temperature:

Date of Calibration:

Performance Verification

RH %:

Technician:

Performance test Source voltage

DC Gain Accuracy

Rise Time

(TAP2500)

(TAP3500)

TAP2500 and TAP3500 Instruction Manual 61

+1.00 VDC

-1.00 VDC

NA

NA

Minimum Measured

+98 mV NA +102 mV

-102 mV NA -98 mV

NA

NA

NA

NA

Calculated

Maximum

140 ps

130 ps

Performance Verification

62 TAP2500 and TAP3500 Instruction Manual

Maintenance

This section contains maintenance information for your probe.

Error Condition

The TAP2500 and TAP3500 active probes are designed to work with all TekVPI-interface oscilloscopes and adapters. However,

there may be some cases where all of the probe f eatures may not work properly.

If the Status LED glows red during or after probe power on, an internal pro be diagnostic fault exists. Disconnect and reconnect the

probe to restart the power-on diagnostic sequence. If the Status LED continues to glow red, the probe is defective, and must

be returned to Tektronix for repair.

Replacement Parts

There are no user replaceable parts within the probe. Refer to Accessories for a list of replacea ble accessories for your probe.

Maintenance

TAP2500 and TAP3500 Instruction Manual 63

Maintenance

Cleaning

Protect the probe from adverse weather conditions. The probe is not waterproof.

CAUTION. To prevent damage to the probe, do not expose it to sprays, liquids, or solvents. Avoid getting moisture inside

the probe during exterior cleaning.

Do not use chemical cleaning agents; they may dama ge the probe. Avoid using chemicals that contain benzine, benzene,

toluene, xylene, acetone, or similar solvents.

Clean the exterior surfaces of the probe with a dry, lint-free cloth or a soft-bristle brush. If dirt remains, use a soft cloth or swab

dampened with a 75% isopropyl alcohol solution. A swab is useful for cleaning narrow spaces on the probe, use only enough

solution to dampen the swab or cloth. Do not use abrasive compounds on any part of the probe.

64 TAP2500 and TAP3500 Instruction Manual

Index

Index

A

Accessories

optional, 29

standard, 19

AutoZero, 5

C

Calibration, 8

Cleaning the probe, 64

Connecting the probe, 2

D

DC gain accuracy

performance check, 50

Documentation, xi

E

Error condition, 63

F

Features, 1

Functional check, 6

G

Ground lead

inductance, 34

selecting length, 33

I

Indicators, 3

L

LED

Status, 3

M

Maintenance, 63

Menu Button, 4

O

Offset, 16

Options, 32

P

Performance verification, 47

equipment required, 47

equipment setup, 49

Probe controls and indicators, 3

Probe head, 13

R

Related documentation, xi

Replacement parts, 63

Rise Time

performance check, 53

S

Safety Summary, v

Signal path compensation, 9

Specifications, 39

nominal, 46

typical, 41

warranted, 40

Status LED, 3, 63

TAP2500 and TAP3500 Instruction Manual 65

Index

T

TekVP I , 2

Test record, 61

66 TAP2500 and TAP3500 Instruction Manual

Loading...

Loading...