Page 1

x

SPG8000

Master Sync / Clock Reference Generator

ZZZ

Quick Start User Manual

*P071308005*

071-3080-05

Page 2

Page 3

xx

SPG8000

Master Sync / Clock Reference Generator

ZZZ

Quick Start User Manual

This document supports firmware version 1.6 and above.

www.tektronix.com

071-3080-05

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are

protected by na

tional copyright laws and international treaty provisions.

Tektronix pro

previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

ducts are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year from the date of

shipment. If any such product proves defective during this warranty period, Tektronix, at its option, either will repair the defective

product without charge for parts and labor, or will provide a replacement in exchange for the defective product. Parts, modules and

replacement products used by Tektronix for warranty work may be new or reconditioned to like new performance. All replaced

parts, modules and products become the property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the warranty period

and make suitable arrangements for the performance of service. Customer shall be responsible for packaging and shipping the

defective product to the service center designated by Tektronix, with shipping charges prepaid. Tektronix shall pay for the return of the

product to Customer if the shipment is to a location within the country in which the Tektronix service center is located. Customer shall

be responsible for paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate maintenance and

care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting from a ttempts by personnel

other than Tektronix representatives to install, repair or service the product; b) to repair damage resulting from improper use or

connection to incompatible equipment; c) to repair any damage or malfunction caused by the use of non-Tektronix supplies; or

d) to service a product that has been modified or integrated with other products when the effect of such modifi cation or integration

increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY O TH ER WARRANTIES,

EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS

IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

[W2 – 15AUG04]

Page 6

IMPORTANT

READ BEFORE OPERATING EQUIPMENT

This software is provided under license from Tektronix, Inc. Retention of this program for more than thirty (30) days or use of the

program in any manner constitutes acceptance of the license terms.

CAREFULLY READ THE ENCLOSED SOFTWARE LICENSE AGREEMENT. If you cannot agree to the license terms,

promptly contact the nearest Tektronix Field Office for return assistance.

TEKTRONIX SOFTWARE LICENSE AGREEMENT

THE PROGRAM, OR PROGRAMS, ENCODED OR INCORPORATED WITHIN EQUIPMENT, IS FURNISHED SUBJECT TO THE

TERMS AND COND ITIO NS OF THIS AGREE MENT. RETENTION OF TH E PROGRAM FOR M OR E THAN THIRTY DAYS OR USE

OF THE PROGRAM IN ANY MANNER WILL BE C ONSIDE RED ACCEPTANCE OF THE AGREEMENT TERMS. IF THESE TERMS

ARE NOT ACCEPTABLE, THE UNUSED PROGRAM AND ANY ACCOMPANYING DOCUMENTATION SHOULD BE RETURNED

PROMPTLY TO TEKTRONIX FOR A FULL REFUND OF THE LICENSE FEE PAID. (FOR INFOR M ATION R EGARDING THE RETURN

OF PROGRAMS ENCODED OR INCORPORATED WITHIN EQUIPMENT, CONTACT THE NEAREST TEKTRONIX SALES OFFICE.

DEFINITIONS. “Tektronix” means Tektronix, Inc., an Oregon corporation, or local Tektronix’ legal entity that is supplying the

equipment.

“Program” means the Tektronix software product (executable program and/or data) enclosed with this Agreement or included within the

equipment with which this Agreement is packed.

“Customer” means the person or organization in whose name the Program was ordered.

LICENSE. Customer may:

1. Use the Program on a single machine at any one time;

2. If the Program is provided in connection with a floating−user license, the Program may be used on multiple machines provided that

the user is authorized, and the total number of users at any one time does not exceed the total number of licensed concurrent users;

3. Modify the Program or merge it with another for use on the single machine; and

4. Copy the Program for archival or backup purposes, provided that no more than one (1) such copy is permitted to exist at any one

time. If the Program is provided in connection with a floating−user license, the Program may be copied onto multiple machines

for use by authorized users.

Each copy of the Program made by Customer must include a reproduction of any copyright notice or restrictive rights legend appearing

in or on the copy of the Program as received from Tektronix.

Customer may not:

1. Use the Program on more than one machine at any one t

2. Transfer the Program to any person or organization outside of Customer or the corporation of which Customer is a part without

the prior written consent of Tektronix, except in connection with the transfer of the equipment within which the programs are

encoded or incorporated;

3. Export or re-export, directly or indirectly, the program, any associated documentation, or the direct product thereof, to any country

to which such export or re-export is restricted by law or regulation of the United States or any foreign government having jurisdiction

without the prior authorization, if required, of the Office of Export Administration, Department of Commerce, Washington, D.C.

and the corresponding agency of such foreign government;

4. For object-code Programs only, reverse compile or disassemble the Program for any purpose; or

ime, unless covered by a floating-user license o r separate site license;

5. Copy the documentation accompanying the Program.

Page 7

For Programs designed to reside on a single-machine and support one or more additional machines, either locally or remotely, without

permitting the

within the definition of “single machine”. For programs permitting the Program to be transferred to an additional machine for local

execution, a separate license shall be required for each such machine with which the Program may be used, or each concurrent user

authorized un

Title to the Program and all copies thereof, but not the media on which the Program or copies may reside, shall be and remain with

Tektronix or others for whom Tektronix has obtained a respective licensing right.

Customer shall pay when due all property taxes that may now or hereafter be imposed, levied or assessed with respect to the

possession or use of the Program or this license and shall file all reports required in connection with such taxes.

Any portion of the Program modified by Customer or merged with another program shall remain subject to these terms and conditions.

If the Program is acquired by or for an agency of the U.S. Government, the Program shall be considered computer software developed

at private expense and the license granted herein shall be interpreted as granting Customer restricted rights in the Program and related

documentation as de fined in the applicable acquisition regulation.

THE PROGRAM MAY NOT BE USED, COPIED, MODIFIED, MERGED, OR TRANSFERRED TO ANOTHER EXCEPT AS

EXPRESSLY PERMITTED BY THESE TERMS AND CONDITIONS.

UPON TRANSFER O F ANY COPY, MODIFICATION, OR MERGED PORTION OF THE PROGRAM, THE LICENSE GRANTE D

HEREIN IS AUTOMATICALLY TERMINATED.

Program to be transferred to an additional machine for local execution, the additional machines shall be considered

der a floating-user license.

TERM. The license granted herein is effective upon acceptance by Customer, and shall remain in effect until terminated as provided

herein. The license may be terminated by Customer at any time upon written notice to Tektronix. The license may be terminated

by Tektronix or any third party from whom Tektronix may have obtained a respective licensing right if Customer fails to comply with

any term or condition and such failure is not remedied within thirty (30) days after notice hereof from Tektronix or such third party.

Upon termination by either party, Customer shall return to Tektronix or destroy, the Program and all associated documentation,

together with all copies in any form.

LIMITED WARRANTY. Tektronix warrants that the media on which the Program is furnished and the encoding of the Program

on the media will be free from defects in materials and workmanship for a period of three (3) months from the date of s hipment. If

any such medium or encoding proves defective during the warranty period, Tektronix will provide a replacement in exchange for the

defective medium. Except as to the media on which the Program is furnished, the Program is provided “as is” without warranty of

any kind, either express or implied. Tektronix does not warrant that the functions contained in the Program will meet Customer’s

requirements or that the operation of the Program will be uninterrupted or error-free.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the warranty period. If

Tektronix is unable to provide a replacement that is free from defects in materials and workmanship within a reasonable time thereafter,

Customer may terminate the license for the Program and return the Program and any associated materials for credit or refund.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PROGRAM IN LIEU OF ANY OTHER WARRANTIES,

EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO REPLACE DEFECTIVE MEDIA, OR REFUND

CUSTOMER’S PAYMENT IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS

WARRANTY.

LIMITATION OF LIABILITY, IN NO EVENT

LICENSING RIGHT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES ARISING OUT OF

OR CONNECTED WITH CUSTOMER’S PO SSESS ION OR USE OF THE PROGRAM, EVEN IF TEKTRONIX OR SUCH OTHERS

HAS ADVANCE NOTICE OF THE POSSIBIL

SHALL TEKTRONIX OR OTHERS FRO M WHOM T EKTRO NIX HAS OBTAINED A

ITY OF SUCH DAMAGES.

THIRD-PARTY DISCLAIMER. Except as expressly agreed otherwise, third parties from whom Tektronix may have obtained a

licensing right do not warrant the program, do not assume any liability with respect to its use, and do not undertake to furnish any

support or information relating thereto.

Page 8

GENERAL. This Agreement contains the entire agreement between the parties with respect to the use, reproduction, and transfer o f

the Program.

Neither this A

of Tektronix.

This Agreement and the license granted herein shall be governed by the laws of the state of Oregon.

All questions regarding this Agreement or the license granted herein should be directed to the nearest Tektronix Sales Office.

greement nor the license granted herein is assignable or transferable by Custo mer without the prior written consent

Page 9

Table of Contents

Important safety information .......................................................................................................... iii

General safe

Service safety summary ......................................................................................................... iv

Terms in this manual . .. . .. . .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . . . . . . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. ... .. . .. . .. . .. . .. . v

Symbols and

Compliance information ............................................................................................................... vi

EMC compliance ................................................................................................................. vi

Safety com

Environmental considerations ................................................................................................... x

Preface................................................................................................................................. xi

Product do

Conventions used in this manual .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. . . . .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. . . . .. . . xii

Installation.............................................................................................................................. 1

Product d

Accessories ...................................................................................................................... 4

Initial product inspection .. . .. .. . .. . .. . .. . .. . . . .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. . . . .. . .. . .. . .. . .. .. . .. . .. . .. . ... 5

Product

Power connection . .. . .. . .. . .. . .. . .. ... .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . . . . . . . . . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. 9

Network installation .............................................................................................................10

GPS and

Oven oscillator calibration ...................................................................................................... 15

Functional checks .. . .. . .. . . . . . . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. ... .. . .. . .. . .. . .. . .. . .. . .. . 20

ion.............................................................................................................................. 34

Operat

Front panel controls . .. . . . . . . . . . .. . .. . .. . .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. ... .. . .. . .. . .. . .. . .. . .. . .. . .. . . . . . . .. . . 34

Rear panel connectors . .. . .. . .. . .. . .. . .. . .. . .. . .. . . . . . . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. .. . 42

Manag

LCD display readouts . .. . .. . .. ... .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . . . . . . .. . .. . .. . .. . .. . .. . . 48

Menu diagrams.................................................................................................................. 49

Remo

Presets .......................................................................................................................... 67

How to upgrade the instrument firmware....................................................................................... 68

How

How to operate an instrument with two power supplies (Option DPW only). .. . .. . .. .. . .. . .. . .. . . . .. . .. . .. . . . .. . .. . .. . . . .. . .. 81

How to enter the option key (Options 3G and DBT only)...................................................................... 85

How

Index

ty summary......................................................................................................... iii

terms on the product .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . . . . . . . . . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. v

pliance.............................................................................................................. viii

cumentation .......................................................................................................... xi

escription............................................................................................................... 1

installation............................................................................................................... 6

/or GLONASS antenna installation (Option GPS only) . .. . .. . .. . .. . .. . .. . .. . .. . .. ... .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. 12

ement of tri-level sync output rates ..................................................................................... 47

te control .................................................................................................................. 65

to transfer or install user files ............................................................................................. 76

to use Stay Genlock

Table of Content

®

...................................................................................................... 87

s

SPG8000 Quick Start User Manual i

Page 10

Table of Content

s

ii SPG8000 Quick Start User Manual

Page 11

Important safet

y information

Important saf

This manual contains information and warnings that must be followed by the user for safe operation and to keep the

product in a safe condition.

To safely perform service on this product, additional information is provided at the end of this section. (See page iv,

Service safety summary.)

ety information

General safety summary

Use the product only as specified. Review the following safety precautions to avoid injury and prevent damage to this product

or any products connected to it. Carefully read all instructions. Retain these instructions for future reference.

Comply with local and national safety codes.

For correct and safe operation of the product, it is essential that you follow generally accepted safety procedures in addition

to the safety precautions specified in this manual.

The product is designed to be used by trained personnel only.

Only qualified personnel who are aware of the hazards involved should remove the cover for repair, maintenance, or

adjustment.

Before use, always check the product with a known source to be sure it is operating correctly.

This product is not intended for detection of hazardous voltages.

While using this product, you may need to access other parts of a larger system. Read the safety sections of the other

component manuals for warnings and cautions related to operating the system.

When incorporating this equipment into a system, the safety of that system is the responsibility of the assembler of the system.

To avoid fire or personal injury

Use proper power cord. Use only the power cord specified for this product and certified for the country of use.

Ground the product. This product is grounded through the grounding conductor of the power cord. To avoid electric

shock, the grounding conductor must be connected to earth ground. Before making connections to the input or output

terminals of the product, make sure that the product is properly grounded.

Power disconnect. The power cord disconnects the product from the power source. See instructions for the location.

Do not position the equipment so that it is difficult to operate the power cord; it must remain accessible to the user at all

times to allow for quick disconnection if needed.

Observe all terminal ratings. To avoid fire or shock hazard, observe all ratings and markings on the product. Consult

the product manual for further ratings information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that exceeds the maximum rating of that terminal.

Do not operate without covers. Do not operate this product with covers or panels removed, or with the case open.

Hazardous voltage exposure is possible.

Avoid exposed circuitry. Do not touch exposed connections and components when power is present.

SPG8000 Quick Start User Manual iii

Page 12

Important safet

Do not operate with suspected failures. If you suspect that there is damage to this product, have it inspected by

qualified servi

Disable the product if it is damaged. Do not use the product if it is damaged or operates incorrectly. If in doubt about safety of

the product, turn it off and disconnect the power cord. Clearly mark the product to preve

Before use, inspect voltage probes, test leads, and accessories for mechanical damage and replace when damaged. Do not

use probes or test leads if they are damaged, if there is exposed metal, or if a wear indicator shows.

Examine the exterior of the product before you use it. Look for cracks or missing pieces.

Use only specified replacement parts.

Do not operate in wet/damp conditions. Be aware that condensation may occur if a unit is moved from a cold to a

warm environment.

Do not operate in an explosive atmosphere.

y information

ce personnel.

nt its further operation.

Keep product surfaces clean and dry.

Provide proper ventilation. Refe

so it has proper ventilation.

Slots and openings are provided for ventilation and should never be covered or otherwise obstructed

into any of the openings.

Provide a safe working environment. Always place the product in a location convenient for viewing the display

and indicators.

Be sure your work area meets applicable ergonomic standards. Consult with an ergonomics professional to avoid stress

injuries.

Use only the Tektronix rackmount hardware specified for this product.

Servicesafetysummary

The Service safety summary section contains additional information required to safely perform service on the product. Only

qualified personnel should perform service procedures. Read this Service safety sum m a ry and the General safety summary

before performing any service procedures.

To avoid electric shock. Do not touch exposed connections.

Do not service alone. Do not perform internal service or adjustments of this product unless another person capable of

rendering first aid and resuscitation is present.

Remove the input signals before you clean the product.

r to the installation instructions in the manual for details on installing the product

. Do not push objects

Disconnect power. To avoid electric shock, switch off the product power and disconnect the power cord from the mains

power before removing any covers or panels, or opening the case for servicing.

Use care when servicing with power on. Dangerous voltages or currents may exist in this product. Disconnect

power, remove battery (if applicable), and disconnect test leads before removing protective panels, soldering, or replacing

components.

Verify safety after repair. Always recheck ground continuity and mains dielectric strength after performing a repair.

iv SPG8000 Quick Start User Manual

Page 13

Terms in this manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in damage to this product or other property.

Symbols and terms on the product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the marking.

WARNING indicates an injury hazard not immediately accessible as you read the marking.

CAUTION indicates a hazard to property including the product.

Important safet

y information

When this symbol is marked on the product, be sure to consult the manual to find out the nature of the

potential hazards and any actions which have to be taken to avoid them. (This symbol may also be used to

refer the user to ratings

The following symbol(s) may appear on the product:

in the manual.)

SPG8000 Quick Start User Manual v

Page 14

Compliance info

rmation

Compliance in

This section lists the EMC (electrom agnetic compliance), safety, and environmental standards with which the instrument

complies.

EMC compliance

EC declarati

Meets intent of Directive 2004/108/EC for Electromagnetic Compatibility. Compliance was demonstrated to the following

specifications as listed in the Official Journal of the European Communities:

EN 55103-1:2009. Product family standard for audio, video, audio-visual and entertainment lighting control apparatus for

professio

Environme

Part 1 Emi

Part 2 Im

on of conformity – EMC

nal use.

EN 55022:

EN 55103-

12

nt E2 – commercial and light industrial

ssion

2006. Class B radiated and conducted emissions

1:2009 Annex A. Radiated magnetic field emissions

munity

formation

IEC 6100

IEC 6100

IEC 610

IEC 610

IEC 610

IEC 61

EN 551

0-4-2:2000. Electrostatic discharge immunity

0-4-3:2007. RF electromagnetic field immunity

00-4-4:2004. Electrical fast transient / burst immunity

00-4-5:2005. Power line surge immunity

00-4-6:2006. Conducted RF Immunity

000-4-11:2004. Voltage dips and interruptions immunity

03-2:2009 Annex A. Radiated magnetic field immunity

EN 61000-3-2:2006. AC power line harmonic emissions

EN 61

000-3-3:1995.

Voltage changes, fluctuations, and flicker

European contact.

Tektronix UK, Ltd.

Western Peninsula

Western Road

Bracknell, RG12 1RF

United Kingdom

vi SPG8000 Quick Start User Manual

Page 15

Compliance info

EMC compliance

Meets the intent of Directive 2004/108/EC for Electromagnetic Compatibility when it is used with the product(s) stated in

the specifications table. Refer to the EMC specification published for the stated products. May not meet the intent of the

directive if used with other products.

European contact.

Tektronix UK

Western Peninsula

Western Road

Bracknell,

United Kingdom

1

To ensure compliance with the EMC standards listed here, high quality shielded interface cables should be used.

2

Average hal

,Ltd.

RG12 1RF

f-cycle r.m.s. inrush current at initial switch-on: 1.8 A; average half-cycle r.m.s. after 5 second power interruption: 1.6 A.

Australia / New Zealand declaration of conformity – EMC

Complies with the EMC provision of the Radiocommunications Act per the following standard, in accordance w ith ACMA:

EN 55022:2006. Radiated and conducted emissions, Class B, in accordance with EN 55103-1:2009.

rmation

SPG8000 Quick Start User Manual vii

Page 16

Compliance info

rmation

Safety compliance

This section lists the safety standards with which the product complies and other safety compliance information.

EU declaration of conformity – low voltage

Compliance was demonstrated to the following specification as listed in the Official Journal of the European Union:

Low Voltage Directive 2006/95/EC.

EN 61010-1. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – P art

1: General R

U.S. nationally recognized testing laboratory listing

UL 61010-1. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part

1: General Requirements.

Canadian certification

CAN/CSA-C22.2 No. 61010-1. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory

Use – Par

equirements.

t 1: General Requirements.

Additional compliances

IEC 61010-1. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part

1: General Requirements.

Equipment type

Test and measuring equipment.

ety class

Saf

Class 1 – grounded product.

Pollution degree description

easure of the contaminants that could occur in the environment around and within a product. Typically the internal

Am

environment inside a product is considered to be the same as the external. Products should be used only in the environment

for which they are rated.

Pollution Degree 1. No pollution or only dry, nonconductive pollution occurs. Products in this category are generally

ncapsulated, hermetically sealed, or located in clean rooms.

e

ollution Degree 2. Normally only dry, nonconductive pollution occurs. Occasionally a temporary conductivity that is

P

caused by condensation must be expected. This location is a typical office/home environment. Temporary condensation

occurs only when the product is out of service.

viii SPG8000 Quick Start User Manual

Page 17

Compliance info

Pollution Degree 3. Conductive pollution, or dry, nonconductive pollution that becomes conductive due to condensation.

These are shelt

sunshine, rain, or direct wind.

Pollution Degree 4. Pollution that generates persistent conductivity through conductive dust, rain, or snow. Typical

outdoor locations.

ered locations where neither temperature nor humidity is controlled. The area is protected from direct

rmation

Pollution de

Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor, dry location use only.

gree rating

IP rating

IP20 (as de

fined in IEC 60529).

Measurement and overvoltage category descriptions

Measurement terminals on this product may be rated for measuring mains voltages from one or more of the following

categories (see specific ratings marked on the product and in the manual).

Category II. Circuits directly connected to the building wiring at utilization points (socket outlets and similar points).

Category III. In the building wiring and distribution system.

Category IV. At the source of the electrical supply to the building.

NOTE. Only mains power supply circuits have an overvoltage category rating. Only measurement circuits have a

measurement category rating. Other circuits within the product do not have either rating.

Mains overvoltage category rating

Overvoltage category II (as defined in IEC 61010-1).

SPG8000 Quick Start User Manual ix

Page 18

Compliance info

rmation

Environmental considerations

This section provides information about the environmental impact of the product.

Product end-of-life h andling

Observe the following guidelines when recycling an instrument or component:

Equipment r

contain substances that could be harmful to the environment or human health if improperly handled at the product’s end of life. In

order to avoid release of such substances into the environment and to reduce the use of natural resources, we encourage you to

recycle thi

ecycling.

s product in an appropriate system that will ensure that most of the materials are reused or recycled appropriately.

This symbol

to Directives 2002/96/EC and 2006/66/EC on waste electrical and electronic equipment (WE EE) and

batteries. For information about recycling options, check the Support/Service section of the Tektronix Web

site (www.

Production of this equipment required the extraction and use of natural resources. The equipment may

indicates that this product complies with the applicable European Union requirements according

tektronix.com).

Perchlorate materials. This product contains one or more type CR lithium batteries. According to the state

of California, CR lithium batteries are classified as perchlorate materials and require special handling. See

www.dtsc.ca.gov/hazardouswaste/perchlorate for additional information.

Restriction of hazardous substances

This product is classified as an industrial monitoring and control instrument and is not required to comply with the substance

ctions of the recast RoHS Directive 2011/65/EU until July 22, 2017.

restri

x SPG8000 Quick S tart User Manual

Page 19

Preface

This manual describes how to install the SPG8000 Master Sync / Clock Reference Generator and provides basic operating

information.

Product documentation

Table i: Product documentation

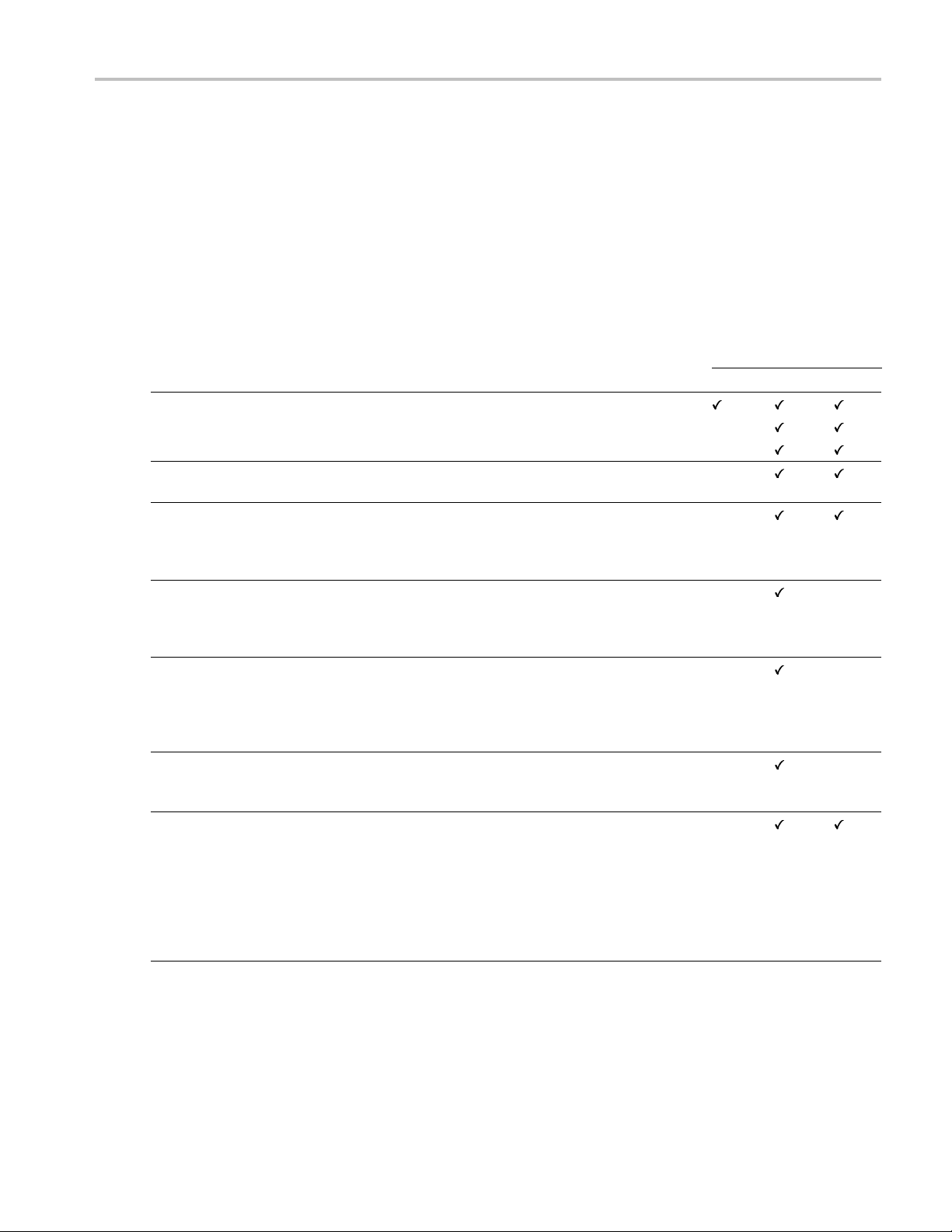

Document Tektronix Part Number Description Print Web CD

Quick Start User Manual 071-3080-xx (English)

Technica

Specific

Performance Verification

Servic

Declassification and

Secur

Release Notes 077-0751-xx

Video Sync Pulse

Generator and Electronic

Cha

Integration Technical

Reference

l Reference

ations and

e Manual

ity Instructions

ngeover Unit System

Describes

077-0745-xx (Japanese)

077-0746

077-0747-xx Provides detailed operating

077-0748-xx

077-0749-xx Describes how to service the

077-0750-xx Describes how to clear or

077

(ECO422D)

077-0877-xx

(EC

-xx (Russian)

-0563-xx

O8000, ECO8020)

instrument and provides basic

operating information

informat

Lists th

and provides procedures for

verifying the performance of the

instrum

instru

(such as circuit boards and

fuses)

sanitize the data storage

(memo

product for customers with data

security concerns.

Describes the new features,

impr

of the instrument firmware

Provides information for system

integrators who are designing

sys

and standard-definition (SD)

digital video content where

ktronix electronic changeover

Te

units and video sync pulse

generators are to be deployed.

how to install the

ion

e product specifications

ent

ment to the module level

ry) devices in the

ovements, and limitations

tems for high-definition (HD)

Preface

Availability

SPG8000 Quick Start User Manual xi

Page 20

Preface

Conventions used in this manual

Terms

Instruments with earlier Option GPS modules have a GPS receiver that can receive only GPS signals. Instruments with later

Option GPS mo

throughout this manual to generically refer to GPS and GLONASS signal functionality.

Icons

The following icons are used throughout this manual.

dules have a GPS receiver that can receive both GPS and GLONASS signals. The term “GPS” is used

Sequence

Step

Front panel

power

Connect

power

Network

PS2 SVGA USB

xii SPG8000 Quick Start User Manual

Page 21

Installation

Product description

Figure 1: S PG8000 Master Sync / Clock Reference Generator front and back panels

The SPG8000 is a precision multi-format video signal generator, suitable for master synchronization and reference

applications. It provides multiple video reference signals, such as black burst, HD tri-level sync, and serial digital and

composit

e analog test patterns, and it provides time reference signals such as time code and NTP (Network Time Protocol).

Installation

The base c

black burst and/or HD tri-level sync) and independently adjustable timing offsets. With the BG option, four more analog

outputs can be added. A high-accuracy, oven-controlled crystal oscillator provides a stable frequency reference for the

system,

signal. The SPG8000’s Stay GenLock

disturbance, by maintaining the frequency and phase of each output signal. When the external reference is restored, Stay

GenLoc

instead of “jamming” back to the correct phase.

Time reference outputs are available in multiple formats. Three independent linear time code (LTC) outputs are available,

and a fourth LTC connection can b e used as input or output. Each LTC output has independent frame rate selection, time

sourc

PAL black output, also with independent time sources and offsets. The SPG8000 can also serve as a Network Time Protocol

(NTP) server, providing the time-of-day reference to network-attached devices.

Opti

The GPS option adds an internal GPS/GLONASS receiver to the SPG8000. When connected to an external antenna that

supplies the standard GPS and/or GLONASS RF signal, the SPG8000 can utilize the GPS/GLONASS system’s stable

frequency reference. The GPS and/or GLONASS signal also includes a precise time-of-day reference that can be used for all

time code outputs. Similar to the Stay GenLock

the GPS and/or GLONASS signal is interrupted, and the Holdover Recovery mode will ensure a shock-free re-alignment of

frequency and phase when the GPS and/or GLONASS signal is restored.

Earlier versions of the GPS module included a receiver that could receive only GPS signals. Later versions of the GPS

module include a receiver that can receive both GPS and GLONASS signals. See GPS receiver types to determine which

type of GPS receiver is installed in your instrument. (See page 12.)

onfiguration includes three sync outputs that can be configured with independent output formats (NTSC/PAL

or the loop-through genlock input can be used to lock to an external video reference or 10 MHz continuous wave

®

k

ensures that any accumulated clock drift is removed by slowly adjusting the system clock within standard limits

e (time-of-day or program time) and time zone offset. Vertical interval time code (VITC) is available on each NTSC or

®

feature avoids “synchronization shock” if the external reference suffers a temporary

onal GPS receiver

®

feature, the SPG8000 can maintain the video frequency and phase when

SPG8000 Quick Start User Manual 1

Page 22

Installation

Test signal outputs

The SPG8000 can be optionally configured with a variety of test signal outputs. Option BG adds two additional black outputs

and adds two composite analog outputs (NTSC or PAL) that can be used to generate test patterns such as color bars, or serve

as additional black burst outputs. Option SDI adds two fully independent serial digital video generator channels of two outputs

each. Each channel can be configured to any standard SD or HD-SDI format and frame rate. The selected test pattern can

be generated on both outputs per channel, or one output can generate digital black. Option 3G extends the functionality of

the SDI test signal outputs by adding 3 Gb/s SDI formats. A wide variety of standard test patterns are included, such as color

bars, convergence grid, step scales, ramps, multiburst, SDI pathologica l test matrix and a real-time programmable zone plate

generator. Bitmap images can be downloaded to the SPG8000’s flash memory for arbitrary user-defined test patterns. ID

text, burn-in time code, circle, and color logo overlays can be added to any test pattern, and several ancillary data packet

types, including ancillary time code and user-defined packets, c an be inserted into the SDI output signal.

Audio Reference Sig nals

Several audio reference signals are available on the SPG8000. The base configuration includes a 4 8 kHz word clock output,

and option

and the other four pairs are used for test tone generation, with independent tone frequency and amplitude settings for each of

the 8 channels. Audio tone generation is also included with the SDI option, as embedded audio on each of the SDI outputs.

AG adds five AES/EBU output pairs. One pair is dedicated to a Digital Audio Reference Signal (DARS) output,

Remote A

The SPG8000 includes a 10/100/1000BASE-T Ethernet interface for remote access to the instrument. A web-based user

interface can be used for all configuration settings and for monitoring system status. Alarm and key s tatus information is

also available via Simple Network Management Protocol (SNMP) messaging, enabling easy integration with network

management systems. Remote control and alarm reporting is also available via a general purpose interface (GPI). The

SPG8000 has a front-panel USB port that can be used to backup and restore presets and other user data, and to perform

system firmware upgrades.

ccess

Optional Backup P ower Supply

For critical applications, the SPG8000 can be configured with a second power supply module. Under normal operation, the

nated backup supply is seldom used, ensuring that it has maximum remaining life should the primary supply fail. The

desig

backup supply is load-tested once each day to verify that it can serve as the primary supply if necessary. The usage time of

each supply is logged as “temperature-weighted hours”, a metric that best estimates the calculated life of the supply. A

t-panel LED will indicate when the supply is nearing its end-of-life. If the primary supply is interrupted for any reason, the

fron

system will switch to the backup without any disruption to system operation. Power supply modules are hot-swappable for

easy replacement, and feature a locking mechanism to prevent the power cable from accidental disconnection.

2 SPG8000 Quick Start User Manual

Page 23

Key features

Multiple independent black burst and HD tri-level sync outputs provide all the video reference signals required in a

video broadcast or production facility

Four LTC outputs, VITC on black burst outputs, and NTP server provide time reference signals in a variety of formats;

the NTP server requires Option GPS

GPS and GLONASS-based synchronization gives an accurate time-of-day reference and deterministic video phase

reference, and locks remote SPG8000 systems to each other

Stay GenLock®and GPS Holdover Recovery prevent synchronization shock when the external reference input or

GPS/GLONASS signal is temporarily lost

Wide selection of video test patterns in serial digital formats (SD, HD and 3G-SDI) and composite analog formats

(NTSC and PAL); 3G-SDI test patterns require Option 3G

Dual hot-swappable power supplies ensure continuous availability of reference signals

Easy to manage with Web-based interface for remote configuration and SNMP for status and alert information

Applications

Sync pulse generator and time reference generator for broadcast, studio, mobile, and post-production facilities

Installation

Master or slave (genlock) operation for distributed system architectures

Video equipment verification, facility link testing, and display calibration

SPG8000 Quick Start User Manual 3

Page 24

Installation

Accessories

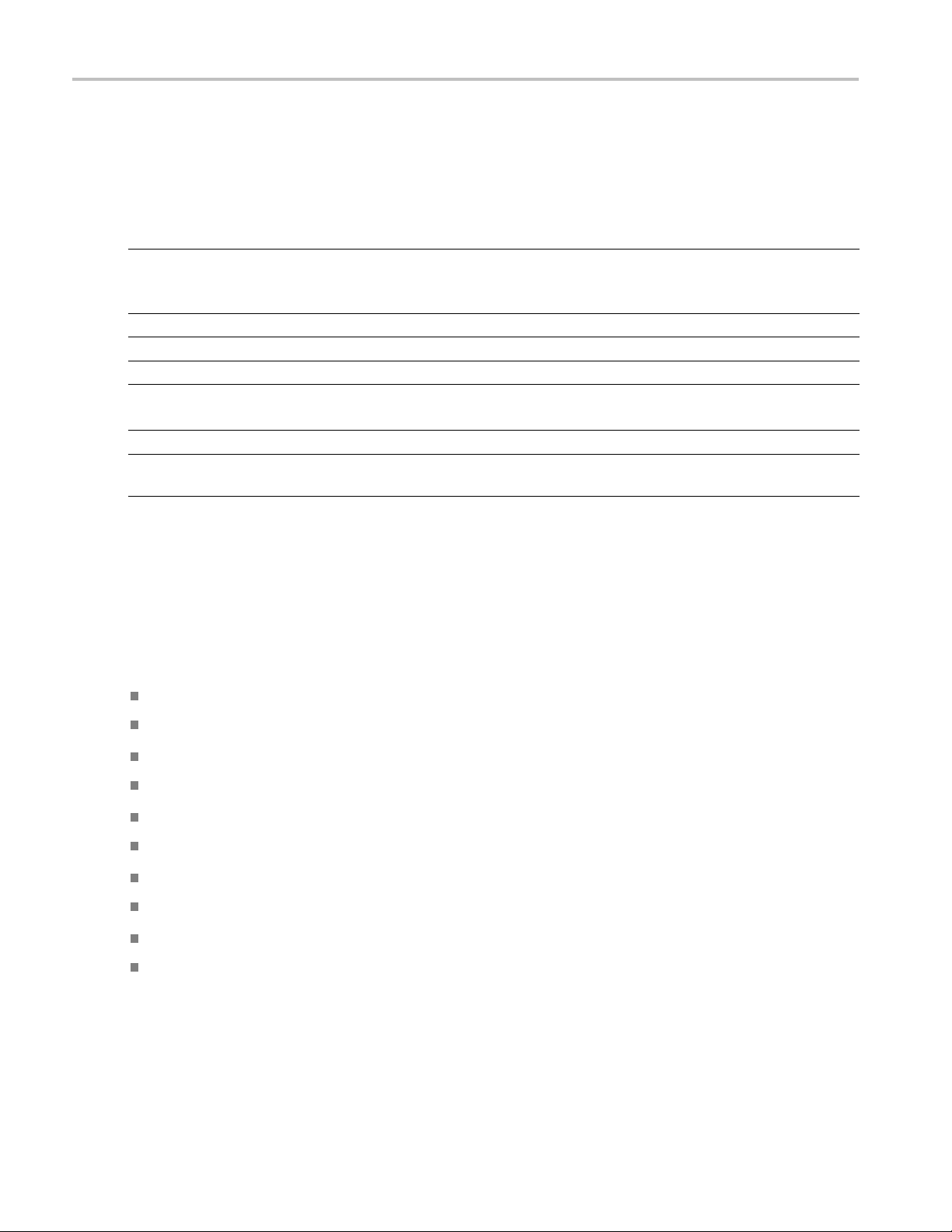

The following table lists the standard and optional accessories provided with the SPG8000 generator.

Table 1: Standard and optional accessories

Accessory Std. Opt.

SPG8000 Quick Start User Manual (English)

Note: Japanese and Russian language versions of this document

are available in PDF format on the Product D ocumentation CD

SPG8000 Product Documentation CD

Rackmounting hardware

Rackmount installation instructions

Power cord

(See page 4, International power cord options.)

D-sub to XLR/BNC adapter cable (Option XLR only)

GPS/GLONASS rooftop antenna (5.0 VDC, 1588 MHz range signals, F connector) for

GPS and GLONASS satellites

1

This 6 fo

and three BNC male connectors (for General Purpose Interface (GPI) input/outputs).

2

For a replacement cable, order SPG8UP Option XLR.

3

The antenna works with the integrated internal GPS/GLONASS receiver of a SPG8000 with Option GPS.

Tektronix

part number

●

●

●

●

●

071-3080-xx

063-4474-xx

351-1137-00

071-2746-xx

Varies by

option

1

●

●

3

ot adapter cable connects from the 15‐pin D‐sub GPI/LTC connector on the SPG8000 to four XLR male connectors (for LTC input/outputs)

2

NA

SPG8000ANT

International power cord options

All of the available power cord options listed below include a lock mechanism except as noted to keep the power cord

hed to the instrument.

attac

0 – North America power (standard)

Opt. A

1 – Universal EURO power

Opt. A

A2 – United Kingdom power

Opt.

A3 – Australia power

Opt.

A5 – Switzerland power

Opt.

. A 6 – Japan power

Opt

. A10 – China power

Opt

. A11 – India power (no locking power cord)

Opt

t. A12 – Brazil power (no locking power cord)

Op

t. A99 – No power cord

Op

4 SPG8000 Quick Start User Manual

Page 25

Initial product inspection

Perform the following product inspection procedure when you receive your instrument:

1. Inspect the shipping carton for external damage, which may indicate damage to the instrument.

2. Remove the SPG8000 generator from the shipping carton, and then check that the instrument has not been damaged in

transit. Prior to shipment the instrument is thoroughly inspected for mechanical defects. The exterior should not have

any scratches or impact marks.

NOTE. Save the shipping carton and packaging materials for instrument repackaging in case shipment becomes necessary.

3. Verify that the shipping carton contains the instrument, the standard accessories, and any optional accessories that you

ordered. (See Table 1.)

4. Verify that all of the product options that you ordered are installed:

Before installation, you can verify the hardware options by viewing the rear panel. (See Figure 5 on page 42.) After

installation, use the SYSTEM : OPTIONS menu selection to view which options are installed (GPS, BG, AG, and SDI).

If you ordered Option 3G and/or DBT when you purchased the instrument, these software option(s) should already

be enabled and you should have received a document showing the option key. After the instrument is installed, use

the SYSTEM : OPTIONS menu selection to verify that the option(s) is enabled. If you need to enter the option key,

see How to enter the option key (Options 3G and DBT only). (See page 85.)

Installation

The following example display shows all of the available hardware options (GPS, BG, AG, SDI) and software

options (3G, DBT) that may be installed.

Contact your local Tektronix F ield Office or representative if there is a problem with your instrument or if your shipment is

incomplete.

SPG8000 Quick Start User Manual 5

Page 26

Installation

Product installation

This section provides installation information for the SPG8000 generator.

Rackmount installation

WARNING. Personal injury or damage to the instrument can occur if the instrument is not properly secured in the equipment

rack.

The SPG8000 is configured at shipment for use in an equipment rack. Refer to the Rackmount Slides and Rails Kit

Instructions, Tektronix part number 071-2746-XX, that was supplied with the instrument for instructions on how to install

the rackmounting hardware.

To install the instrument into an equipment rack. After you have installed the rackmounting hardware, perform the

following steps to

WARNING. To prevent injury during product installation, use care not to pinch hands or fingers in the rails and slides.

install the instrument into an equipment rack:

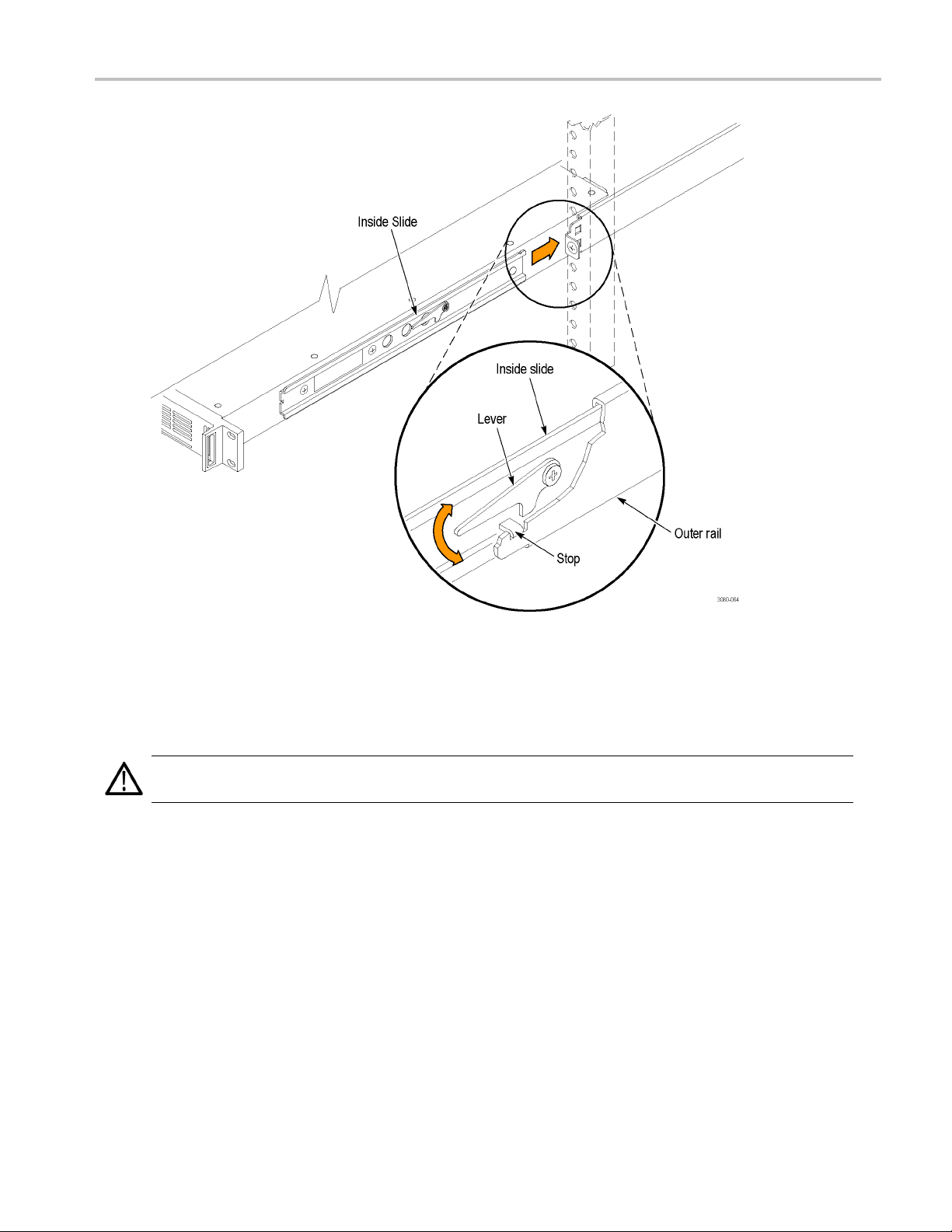

1. Insert the instrument le

upward. (See Figure 2.)

NOTE. Make sure to insert the instrument slides inside the inner rack rails. You may also need to tilt the rear of the

instrument up or down a

2. Push the instrument into the rack until it stops.

CAUTION. To prevent damage to the instrument and rackmount, do not force the instrument into the rack if it does not slide

smoothly. The rails a

3. Retighten any loose screws and push the instrument all the way into the rack. If the tracks do not slide smoothly,

readjust the rail assemblies.

4. When adjusting is completed, tighten all rail assembly 10-32 screws using 28 inch-lbs of torque.

5. If the instrument has knob screws on the front corners, tighten them so that they are secured in the rack.

6. To remove the instrument from the rack, loosen the knob screws.

ft and right slides into the ends of the rack rails while tilting the long handle part of each lever

t a slight angle to fit the slides into the rails.

ssembly may need to be adjusted to resolve the problem.

6 SPG8000 Quick Start User Manual

Page 27

Installation

Figure 2: Installing or removing the instrument into or from the rack

To remove the instrument from an equipment rack. Perform the following steps to remove an instrument that

talled in an equipment rack:

is ins

WARNING. To prevent injury when removing the product from the rack, do not forcefully and abruptly pull the product from

the rack. Pull with the minimum force required to move the instrument with a consistent, even motion.

1. Loosen the k

2. Gently pull

3. Tilt both le

4. Pull the ins

nob screws, if present, that attach the front of the instrument to the rack.

the instrument toward you until you can reach the levers at the rear of the instrument.

ver handles upward simultaneously to allow them to clear the stops. (See Figure 2.)

trument past the stops and out of the rack.

SPG8000 Quick Start User Manual 7

Page 28

Installation

Environmental operating requirements

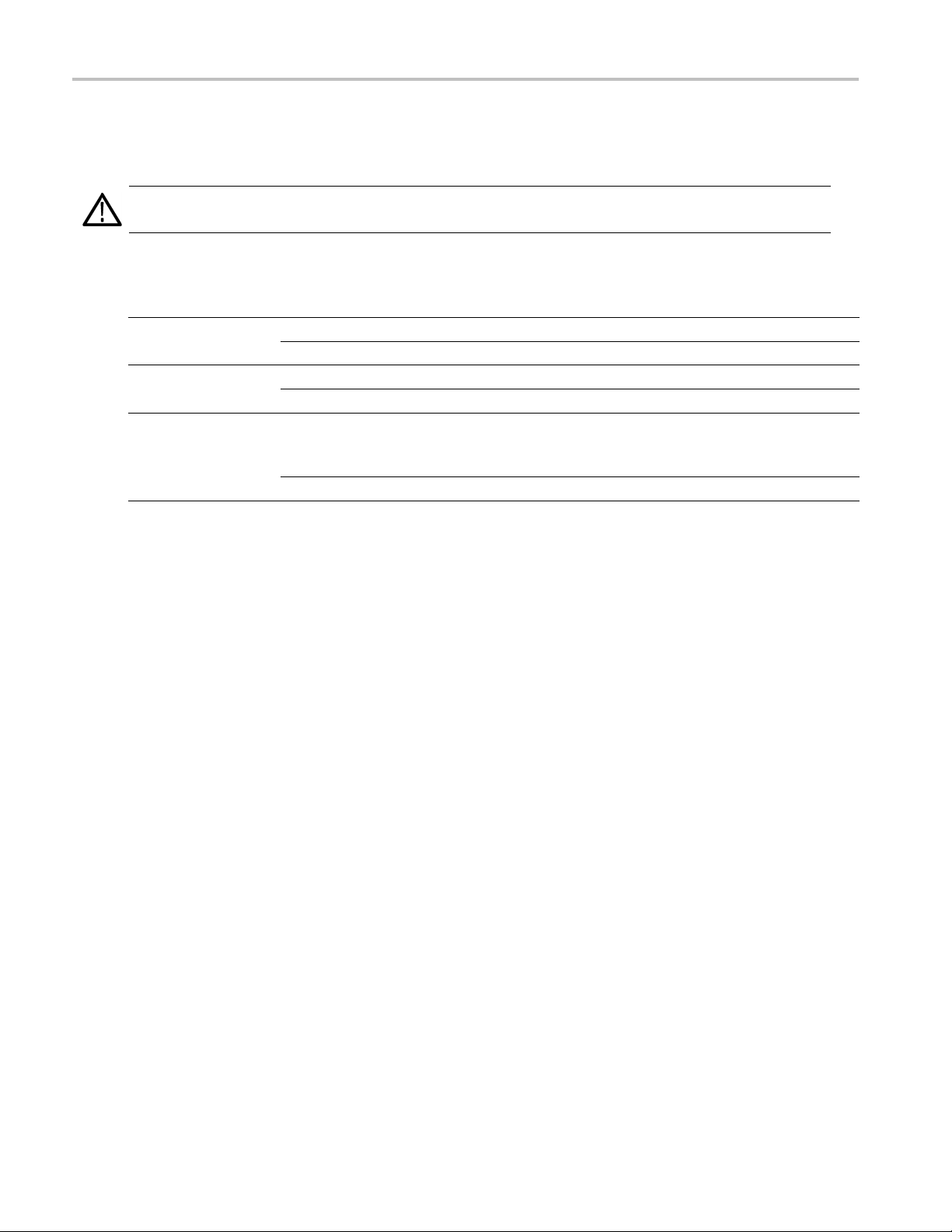

Check that the location of your installation has the proper operating environment as listed in the following table. (See Table 2.)

CAUTION. Damage to the instrument can occur if this instrument is powered on at temperatures outside the specified

temperature range.

Table 2: SPG8000 environmental requirements

Parameter Description

Temperature

Relative Humidity

Altitude

Operating 0 °C to +50 ° C

Nonoperating

Operating 20% to 80% (No condensation); Maximum wet-bulb temperature 29.4 °C

Nonoperating

Operating To 3,000 m (9,842 feet)

Nonoperating

–20 °C to +60 °C

5% to 90% (No condensation); Maximum wet-bulb temperature 40.0 °C

Maximum operating temperature decreases 1 °C each 300 m above

1.5 km.

To 15,000 m (49,212 feet)

Leave space for cooling by ensuring standard side clearance for rack mounting or 2 inches (5.1 cm) of side clearance for

benchtop use. Also, ensure sufficient rear clearance (approximately 2 inches) so that cables are not damaged by sharp

bends.

For complete specifications for the instrument, refer to the SP G8000 Specifications and Performance Verification Technical

Reference manual.

Firmware upgrades

Tektronix releases product updates to add new features and to fix problems with the product firmware. During installation, it

is recommen

for your product at the Tektronix Web site (www.tektronix.com/downloads). (See page 68, How to upgrade the instrument

firmware.)

ded that you verify your instrument has the latest firmware version installed. You can find the latest firmware

8 SPG8000 Quick Start User Manual

Page 29

Power connection

The SPG8000 operates from a single-phase power source with the neutral conductor at or near earth ground. The line

conductor is fused for over-current protection. A protective ground connection through the grounding conductor in the

locking power cord is essential for safe operation.

The standard instrument has one Power Supply module installed. With Option DPW, a second hot-swappable redundant

(backup) Power Supply module i s installed. When two Power Supply modules are installed in the instrument, one is

configured to be the primary supply and the other is configured to be the backup supply. In the event that the primary supply

fails, the backup supply will automatically provide power to maintain instrument operation. (See page 81, How to operate an

instrument with two power supplies (Option DPW only).)

CAUTION. The instrument does not have a power switch. When you connect the power cable to the AC line connector,

the instrument powers on.

Do not install or remove a Power Supply module when a power cord is attached to that module.

AC power requirements

Check that your location provides the proper electrical power requirements as listed in the following table. (See Table 3.)

Installation

Table 3: A

Paramete

Line Voltage Range

Line fr

Maximum power 130 VA

C line power requirements

r

equency

Descript

100 - 240

WARNING. To reduce the risk of fire and shock, ensure

that the mains supply voltage fluctuations do not exceed

10% of t

50/60 H

ion

VAC

he operating voltage range.

z

To connect the power cable(s)

Connect the power cable to the instrument first, and then connect it to the AC power source. Connecting the power cable

causes the instrument to power on.

After the instrument boots up and initializes, make sure that the FAULT indicator is not illuminated and than no faults are

reported on the instrument display. If the FAULT indicator is illuminated, perform the appropriate user action. (See Table 8

on page 40.)

Backup supply (Option DPW). If the instrument has two Power Supply modules installed (Option DPW), connect a

er cable to each of the supplies. After the instrument powers on, configure the instrument for the preferred (active)

pow

supply. (See page 81, How to operate an instrument with two power supplies (Option DPW only).)

SPG8000 Quick Start User Manual 9

Page 30

Installation

Network installation

The SPG8000 has a 10/100/1000 BASE-T Ethernet port on the rear panel that allows you to use a PC to remotely control the

instrument and to upload and download user files such as signal or logo files.

This section provides instructions for connecting the SPG8000 to a single PC or to a network and for setting the network

parameters on the Ethernet port.

See How to transfer user files for instructions on how to upload and download user files using the Ethernet port. (See

page 76.)

Connecting the SPG8000 to your PC(s)

You can use one of the following two methods to connect the SPG8000 to your PC(s):

If you are connecting the SPG8000 directly to a single PC, use an Ethernet cable to connect between the Ethernet

port on the SPG8000 and the Ethernet port on the PC.

If you are connecting the SPG8000 to your local Ethernet network, use an Ethernet cable to connect between the

Ethernet p

you can access the SPG8000 using any PC on the network.

ort on the SPG8000 and the Ethernet hub port of your local network. By connecting to an Ethernet network,

To configure the network parameters

The following two procedures describe how to configure the SPG8000 network parameters. Use the first p rocedure if your

network supports DHCP; use the second procedure if your network does not support DHCP.

To configure parameters for a network with a DHCP server. If your network has a DHCP server, perform the

following steps to configure the instrument to function as a DHCP client. When the SPG8000 is connected to the network

and DHC

NOTE. Under some network environments, the SPG8000 may not be able to get the IP address automatically from a DHCP

server. In this case, you need to enter the appropriate address value in each submenu item.

Refer to your network administrator or to the user documentation supplied with your network server operating system

(OS) f

1. Press the front-panel SYSTEM button to access the SYSTEM menu.

2. Press the up (▲) or down (▼) arrow button to select SYSTEM : NETWORK.

3. Press the left (◄) or right (►) arrow button to s elect Setup, and then press the ENTER button. This accesses the

4. Press the left (◄)orright(►) arrow button to select Enable, and then press the ENTER button.

5. Press the BACK button to exit the NETWORK SETUP submenu.

P service is enabled, the SPG8000 obtains the necessary network addresses automatically from the DHCP server.

or detailed information about DHCP server functions.

NETWORK SETUP submenu. The top line of the display should read SYSTEM : NET SETUP : DHCP.

10 SPG8000 Quick Start User Manual

Page 31

Installation

To configure parameters for a network without a DHCP server. If your network does not have a DHCP server,

perform the fol

lowing procedure to set the network parameters:

1. Press the fron

2. Press the up (▲

3. Press the left

NETWORK SETUP submenu. The top line of the display should read SYSTEM : NET SETUP : DHCP.

4. Press the left (◄) or right (►) arrow button to select Disable, and then press the ENTER button.

5. If you connected the SPG8000 directly to a single PC:

a. Press the up (▲)ordown(▼) arrow button to select SYSTEM : NET SETUP : IP ADDRESS, and then press

the ENTER button to enter the edit mode.

b. Use the arrow buttons to set the IP address to be the same IP address as the PC's address except for the last

number, an

in the PC's IP address.

c. Press the up (▲) or down (▼) arrow button to select SYSTEM : NET SETUP : SUBNET MAS K, and then press

the ENTER button to enter the edit mode.

d. Use the arrow buttons to set the subnet mask to be the same net mask (subnet mask) used by the PC, and then

press the

e. Youdonot

f. Press th

6. If you co

t-panel SYSTEM button to access the SYSTEM menu.

) or down (▼) arrow button to select SYSTEM : NETWORK.

(◄) or r ight (►) arrow button to select Setup, and then press the ENTER button. This accesses the

d then press the ENTER button. The last number in the address must be different than the last number

ENTER button. Do not enter a number if the PC does not have a net mask.

need to enter a GATEWAY address if you are directly connected to a single PC.

e BACK button to exit the NETWORK SETUP submenu.

nnect the SPG8000 to your local Ethernet network, see the Caution note below.

CAUTION. To prevent communication conflicts on your Ethernet network, ask your local network administrator for the correct

numbers to enter in the NETWORK PARAMETERS submenu if you connect the SPG8000 to your local Ethernet network.

7. Verify the Eth

ernet connection by using a ping command from the PC.

SPG8000 Quick Start User Manual 11

Page 32

Installation

GPS and/or GLONASS antenna installation (Option GPS only)

If your instrument has Option GPS installed, you need to connect a GPS and/or GLONASS antenna and check the main

oscillator calibration before you put the instrument into service.

If you o rdered SPG8000ANT, you received a GPS/GLONASS rooftop antenna (5.0 VDC, 1588 MHz range signals, F

connector) for GPS and/or GLONASS signals that works with the integrated internal GPS/GLONASS receiver of a SPG8000

with Option GPS installed.

GPS receiver types

Earlier versions of the GPS module included a receiver that could receive only GPS signals. Later versions of the GPS

module incl

receiver, use the REFERENCE menu to con fi gure the module for the type of signal you are using. (See page 54, REF

button menu diagram.)

ude a receiver that can receive both GPS and GL ONASS signals. If your module has the GPS/GLONASS

How to det

NOTE. Firmware version 1.5 or above must be installed in the instrument in order to view the GPS receiver type readout.

1. Press the SYSTEM button to access the SYSTEM menu.

2. Use the up (▲)ordown(▼) arrow button to select SYSTEM : VERSION INFO (H/W).

3. Use the left (◄)orright(►) arrow button to select the version display with the ID field on the second line of the

displa

ermine which GPS receiver is installed in your instrument.

y as shown below.

ID value is 3015, then the later GPS receiver is installed that can receive GPS and GLONASS signals.

If the

e ID value is 3002, then the earlier GPS receiver is installed that can receive only GPS signals.

If th

12 SPG8000 Quick Start User Manual

Page 33

Installation

Antenna requirements

The SPG8000 generator requires an external antenna to receive GPS and/or GLONA SS signals from satellites. You must

set up an antenna system to provide the GPS and/or GLONASS signal as an input to the SPG8000 generator. You can

configure the instrument to provide 3.3 V or 5 V DC power for the antenna.

WARNING. Prevent risk of shock or fire by ensuring that the GPS and/or GLONASS antenna is protected from lightning

strikes when it is mounted outside a building or facility. The SPG8000 generator does not have isolation protection from

lightning, so the facility installation must provide suitable protection for the GPS and/or GLONASS antenna external to the

instrument. Failure to use appropriate precautions can result in injury or death.

CAUTION. To avoid antenna damage, do not turn on the DC antenna power until you know that the antenna is designed to

handle the selected voltage. Antenna damage can occur if the antenna is not designed to handle the voltage you select.

The frequencies for GPS and GLONASS signals are slightly different. Be sure to choose an antenna that supports all of

the satellite constellations you intend to use. It is recommended that you use an antenna that can receive both GPS and

GLONASS signals. This allows the instrument timing to be more stable since a GPS/GLONASS antenna can communicate

with more satellites.

When a GPS and/or GLONASS feed is first connected to the antenna input on the SPG8000 generator, it can take several

minutes for the signal quality to reach its nominal potential. How long that takes depends on such things as antenna site,

cable plant design, and available satellites. Excluding those variables, the typical tim e to acquire satellites and achieve

specified stability with a good satellite signal, known position, and a warmed up instrument, is two minutes.

Antenna system

a systems vary depending on the operating environment and on safety and regulatory requirements. A simplified

Antenn

typical system is shown in the following figure to help you with planning and understanding the trade-offs of one set up versus

another. (See Figure 3.)

Figure 3: Simplified GPS/GLONASS antenna system

A GPS and/or GLONASS specific antenna with amplifier provides sufficient gain to drive a reasonable length of cable, and

provides filtering to reject signals at other frequencies. A typical example of this for GPS signals is the Trimble Bullet III,

35 dB, 5 V, antenna.

In a simple system without the optional booster, Cable 1 connects the antenna to the SPG8000 generator. The length of

this cable is limited by its attenuation at the carrier frequency (GPS: 1575 MHz, GLONASS: 1602 MHz). The SPG8000

generator should have a signal that is 18 dB or greater above the ambient level. For example, for a 35 dB antenna, the

allowed cable loss is 35 – 18 = 17 dB. (See Figure 3.)

SPG8000 Quick Start User Manual 13

Page 34

Installation

Cables. Attenuation varies significantly depending on cable type. Cable loss is about 13 dB/100 ft for a miniature coaxial

cableliketheB

allowable length of 130 ft for the small cable, to over 300 ft for the larger cable.

A booster amplifier can be added if more length is needed, as shown in the optional block in the signal path system.

(See Figure 3.)

Ifa20dBamplifier is added, then 20 dB more cable l oss can be accommodated. This equates to another 150 ft of small

coax, or 360 f

elden 1855, while for a RG11 style like the Belden 7731, the loss is only 5.5 dB/100 ft. This correlates to an

t of large coax.

Although the

most installations. The reflections from the impedance mismatch will not cause s ignificant changes in the system because

the signal is narrow band and the cable loss is usually many dBs. However, you should not mix short cable lengths of

different i

GPS/GLONASS input and most of the other components are 50 Ω, either 50 Ω or 75 Ω cablescanbeusedin

mpedances, as this might create reflections with the potential to cause signal degradation.

Amplification. The SPG8000 generator provides either 3.3 V or 5 V DC power to drive the amplified antenna and

booster amplifier. The power is carried on the same coax as the GPS and/or GLONASS signal, and can be turned off if the

antenna is powered by a separate supply. When you are designing the antenna system, check the voltage and current

requirements of the components to insure compatibility.

The location of the booster amplifier is important. It needs to be before the second length of cable shown in the simplified

antenna system diagram. If the booster amplifier is placed just before the SPG8000 generator, then the signal will have been

attenuated too far and the output may be noisy. If you cannot put the optional booster amplifier in the middle of a long run of

cable, then put it near the antenna rather than near the SPG8000 generator end.

For more complex systems, a variety of booster amplifiers, powered and passive splitters, DC blocks, and filters are

available from a number of vendors.

Antenna location. It is important that the GPS and/or GLONASS antenna location has a clear view of a large part of the

sky. Since GPS and GLONASS satellites are constantly orbiting the earth, they may be in any direction at a given time. If

the sky is blocked by buildings, trees, mountains, etc., then fewer satellites will be visible. It is also possible to get

part of

reflected signals that will have come by a longer path than expected and thus may degrade timing accuracy and stability.

When evaluating a site, it is important to monitor it over several days and with a variety of weather conditions present.

This antenna information is not intended to cover all aspects of the antenna system design. Important topics that were not

d include items like lightening protection and drip loops. For information about the cable plant design in your system,

covere

contact the appropriate person or group in your organization, or contract with a qualified installer.

Check the oven oscillator calibration

You should not need to adjust the oven oscillator frequency immediately after the initial installation since the oscillator

frequency was adjusted accurately at the factory. However, you can adjust the oscillator frequency at any time to improve the

accuracy of the internal frequency. When Option GPS is installed, you may be able to improve the accuracy slightly after

installation since the instrument will be at the normal temperature for your specific installation site. The steps for checking the

oscillator accuracy are included in the oven calibration procedure. (See page 15, O ven oscillator calibration.)

GPS constellation configuration

u can use the REFERENCE menu to confi gure the instrument for the type of satellite constellations you want the

Yo

instrument to use. If your antenna can receive both GPS and GLO NAS S signals, it is recommended that you configure

the instrument to use both GPS and GLONASS signals. This allows the instrument timing to be more stable since a

S/GLONASS antenna can communicate with more satellites.

GP

14 SPG8000 Quick Start User Manual

Page 35

Oven oscillator calibration

You can calibrate the internal oscillator frequency at any time after you install the instrument in its operating environment

and allow it to reach a stable operating condition. When the instrument is locked to a GPS/GLONASS reference, you can

perform this calibration while the instrument is in service.

This adjustment stores the current frequency of the master clock oscillator for use when the instrument is set to Internal

mode. You can calibrate the internal oscillator frequency at any time after you install the instrument in its operating

environment and allow it to reach a stable operating condition.

NOTE. It is recommended that you perform the internal oscillator frequency calibration at least once a year to compensate

for oscillator drift.

Check if calibration is needed

While locked to a G PS/GLO NA SS reference, perform the following steps to determine if the oven oscillator needs to

be calibrated.

1. Press the SYSTEM button to access the SYSTEM menu.

2. Press the up (▲) arrow button to select SYSTEM : DIAGNOSTICS.

3. Press the ENTER button to access the DIAGNOSTICS menu.

Installation

4. Check that Fine is showing on the right side of the TUNE readout on the LCD display.

5. Check the Tune readout value. If the value is greater than ±0.10e–6, then you need to calibrate the oven oscillator. If the

s less than ±0.10e–6, then no calibration is required.

value i

NOTE. Even if the value is less than ±0.10e–6 and no calibration is required, you may want to calibrate the oven oscillator

anyway to ensure maximum accuracy and to postpone the need for a calibration in the future.

6. Press

the BACK button to exit the DIAGNOSTICS menu.

Adjustment methods

You can calibrate the oscillator using GPS, GLONASS or reference signals such as NTSC Burst or CW. If you are not using

a GPS or GLONASS reference signal, the reference signal from a frequency signal generator must be at the correct

frequency. Procedures for using either method are provided.

If your SPG8000 generator has Option GPS installed, you should use a GPS or GLONASS signal to adjust the master clock

frequency. When you use a GPS or GLONASS signal to adjust the master clock, the calibration can be performed while the

instrument is in service, which avoids any system downtime or any warm-up period.

If you do not have Option GPS installed or if you do not have access to a GPS or GLONASS signal, you will need to take the

instrument out of service to adjust the master clock using an input from a frequency generator.

SPG8000 Quick Start User Manual 15

Page 36

Installation

How to adjust the oven oscillator using GPS and/or GLONASS

If your SPG8000 has Option GPS installed, perform the following procedure to use GPS and/or GLONASS to set the internal

frequency of the instrument internal oscillator. This procedure can be done without any disruption to operation and is best

performed in the operating environment of the instrument.

CAUTION. For instruments in service: To prevent inaccurate cali bration, be sure the instrument is warmed up and locked

to a GPS and/or GLONASS signal for at least 20 minutes before you perform this procedure. The instrument requires a

20 minute warm-up time in a +20 °C to +30 °C environment before it is adjusted. Adjustments done before the operating

temperature has stabilized may cause errors in performance.

1. Press the STATUS button to access the STATUS menu.

2. Use the up (▲)ordown(▼) arrow button to check that there are no faults or alerts reported.

3. If you are adjusting the oven oscillator with the instrument in service, proceed to step 12. Otherwise, perform the next step.

CAUTION. To prevent problems with the output signals, do not perform steps 4-9 w hile your instrument is in service.

4. Press the REF button to access the REFERENCE menu.

5. Press the left (◄) or right (►) arrow button to select GPS Signal as the reference source.

6. Press the ENTER buttontoconfirm the selection. A bullet appears in front of the readout to indicate the current selection.

7. Press the up ( ▲) arrow button to select REFERENCE : GPS CONSTELLATION.

8. Press the left (◄) or right (►) arrow button to select GPS & GLONASS.

9. Press the ENTER buttontoconfirm the selection. A bullet appears in front of the readout to indicate the current selection.

10. Let the instrument warm up for 20 minutes with the GPS signal connected before proceeding.

11. Press the STATUS button to access the STATUS menu.

12. Press the up (▲) arrow button to select STATUS : REFERENCE : GPS.

13. Check that the status readout shows Locked.

14. Check the signal lock indicator and check the tune setting:

a. Press the S YSTE M button to access the SYSTEM menu.

b. Press the up (▲) arrow button to select SYSTEM : DIAGNOSTICS.

c. Press the ENTER button to access the DIAGNOSTICS menu.

d. Check that Fine is showing on the right side of the TUNE readout on the LCD display.

e. Press the BACK button to exit the DIAGNOSTICS menu.

15. Press the up (▲) arrow button to select SYSTEM : CALIBRATE OVEN.

16 SPG8000 Quick Start User Manual

Page 37

16. Press the ENTER button to access the Internal Frequency Calibration submenu.

17. In the Execute Calibration? confirmation display, press the ENTER button to start the calibration.

18. When the calibration is complete, verify that the message “CALIBRATION result = xxxxxxx” is displayed. The result

should be seve

n characters near the value of 2,097,152.

Installation

19. Press the ENTE

20. Press the BAC

21. Verify the ca

a. Press the SY

b. Press the up

R button to exit the calibration mode.

K button to exit the calibration menu.

libration:

STEM button to display the SYSTEM menu.

(▲) or down (▼) arrow button to select SYSTEM : DIAGNOSTICS, and then press the ENTER button

to access the DIAGNOSTICS submenu.

c. Press the up (▲) or down (▼) arrow button to select SYSTEM : DIAGNO STICS : CALIBRATION.

d. Check that the CAL value is less than 2.5 e

NOTE. If the CAL value is greater than 2.6 e

-6

.

-6

, then the oscillator oven may need to be serviced.

How to adjust the oven oscillator without GPS

If your SPG8000 does not have Option GPS installed, perform the following procedure to use a signal generator to set the

internal frequency of the instrument internal oscillator. This procedure requires that you take the instrument out of service in

order to adjust the master clock.

CAUTION. To prevent inaccurate calibration, be sure the instrument is warmed up for at least 20 minutes before you perform

this procedure. The instrument requires a 20 minute warm-up time in a +20 °C to +30 ° C environment before it is adjusted.

Adjustments done before the operating temperature has stabilized may cause errors in performance.

In addition, be sure the signal generator is allowed an appropriate warm-up time to meet the frequency accuracy.

Required equipment. The following table lists the equipment required to adjust the master clock frequency using a

frequency signal generator.

Table 4: Equipment required to adjust the SPG8000 master clock using a signal generator

Item No. Minimum requirement Recommended equipment

Frequency standard 1 Frequency: 10 MHz ±1×10

Amplitude: 8 dBm

75 Ω BNC cable

75 Ω termination

1 Length: 42 inches Tektronix part number 012-0074-00

1 Tektronix part number 011-0163-00

–9

Tektronix GPS7 locked to GPS

and/or GLONASS or equivalent

Spectracom/Pendulum 6689

SPG8000 Quick Start User Manual 17

Page 38

Installation

Procedure. Perform the following steps to use a signal generator to set the frequency of the SPG8000 internal oscillator.

1. Set the output of the frequency generator as follows:

Frequency: 10.000000 MHz

Output level:

8 dBm

2. Use the 75 Ω BNC

generator as shown in the following figure.