Page 1

SPG700

xx

ZZZ

Multiformat Reference Sync Generator

User Manual

*P077122502*

077-1225-02

Page 2

Page 3

xx

SPG700

ZZZ

Multiformat Reference Sync Generator

User Manual

Register now!

Click the following link to protect your product.

► www.tek.com/register

This document supports firmware version 3.0 and above.

www.tek.com

077-1225-02

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 5 0 0

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

Worldwide, visit www.tek.com to find contacts in your area.

Page 5

Table of Contents

Important safety information ......................... .................................. ......................... viii

General safety summary .................................................................................... viii

Service safety summary ...................... .................................. ............................... x

Terms in this manual ..... ................................ .................................. .................. xi

Symbols and terms on the product .......................................................................... xi

Environmental considerations.............................................................................. xii

Preface ............................................................................................................. xiii

Product description . .................................. ................................ ....................... xiii

Methods of operation................................... ................................ ...................... xv

Product documentation....... ................................ ................................ ............... xvi

System timing....................................................................................................... 1

Frame reset signals ................. ................................ ................................ ........... 1

Time flow block diagram ........ ................................ .................................. ........... 1

Web user interface .................................................................................................. 7

Operational considerations.................................................................................... 7

Elements of the Web user interface .......................................................................... 8

SNMP remote control ............. ................................ ................................ ................ 11

SNMP configuration.......................................................................................... 11

Download the MIB ........................................................................................... 12

How to backup/restore presets and user data ..... .................................. ............................ 13

How the backup and restore operations work ............................................................. 13

Memory requirements........................................................................................ 14

Backup/restore procedure .............................. ................................ ...................... 15

How to transfer or install user files .............................................................................. 17

To transfer or install user files using FTP .............. ................................ .................... 17

To transfer or install user files using a USB drive......................... ................................ 19

How to upgrade the instrument firmware ....................................................................... 23

Determine if a firmware upgrade is needed................................................................ 23

Firmware upgrade overview................................................................................. 25

USB firmware upgrade................. .................................. ................................ .... 25

Network firmware upgrade .................................................................................. 28

Verify the firmware upgrade and reinstall user files ...................................................... 30

Firmware upgrade troubleshooting ..... .................................. ................................ .. 30

How to operate an instrument with two power supplies (Option DPW only) ...... ........................ 32

Power supply status........................................................................................... 32

To con figure the preferred (active) supply ................................................................. 33

To hot-swap a Power Supply module....................................................................... 35

How to use Stay Genlock

About Stay Genlock

®

®

....................................................................................... 37

......................................................................................... 37

SPG700 User Manual i

Page 6

Table of Contents

To enable Stay G

AES menu .......................................................................................................... 39

AES TIMING OFFSET submenu. . . .... . . .... . . .... . . .... . . .... . . .... . . .... . . .... . . .... . . .... . . .... . . .... . . 40

AES menu factory default settings.... . ..... . ... . . ..... . ..... . ..... . ..... . ..... . ... . . . .... . ..... . ..... . ..... 41

Black menu........................... .................................. ................................ ............ 43

Black Output settings.. . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . .. 44

Black Timing settings .... . . .... . . .... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ... . . ..... . ..... . ..... . 45

Black Timecode settings . ..... . ... . . . .... . ..... . ..... . ... . . ..... . ..... . .... . ..... . ..... . ..... ..... . ..... . .... 46

Blank On Reference Unlock settings ..... .... . . ..... . ..... . ..... . ..... . ..... . ..... . ..... . .... . . .... . . .... . . 47

Black 1-3 HD Tri-level Sync setting. . ..... . ..... . ..... . ... . . . .... . . .... . ..... . ..... . ..... . ..... . ..... . ..... 47

Black menu factory default settings ...................... .................................. ................ 48

Embedded menu (Option SDI only)............................................................................. 49

Embedded menu factory default settings. ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ... . . . .... . . .... . . 52

LTC menu .......................................................................................................... 53

LTC menu factory default settings . ..... . ..... . ... . . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . .. 54

Reference menu.................................................................................................... 55

Reference settings .......... .................................. ................................ ................ 55

Genlock Timing settings . . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... 56

Reference menu factory default settings . ..... . ... . . . .... . ..... . ..... . ..... . ..... . ..... . ..... . ... . . ..... . .. 57

SDI menu (Option SDI only)..................................................................................... 59

SDI Signal submenu...................... ................................ ................................ .... 60

SDI Configure Zoneplate submenu ................... .................................. .................... 64

SDI Moving Picture submenu... ................................ ................................ ............ 67

SDI Video submenu .......................................................................................... 68

SDI Overlay submenu........................................................................................ 70

SDI Ancillary Data submenu .... . ..... . ..... . .... . ..... . ..... . .... . . .... . ..... . ..... . .... . ..... . ..... . .... . . 76

SDI Timecode submenu...................................................................................... 81

SDI menu factory default settings . . .... . . .... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . . 82

How to select an SDI output signal......................................................................... 85

Test signal sets ................................................................................................ 87

SDI picture file generation. ................................ ................................ .................. 94

SDI Zone plate signals ....... ................................ .................................. .............. 95

Zone plate dependent parameters ......................................................................... 100

Status menu .... .................................. ................................ ................................ 107

System menu ..................................................................................................... 109

Status submenu.............................................................................................. 110

Presets submenu ............................................................................................ 112

General Settings submenu . . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . . 113

SNMP Settings submenu. . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ... 114

GPI Settings submenu...................................................................................... 116

Options submenu ................. .................................. ................................ ........ 119

enlock

®

........................ ................................ ............................ 37

ii SPG700 User Manual

Page 7

Table of Contents

Diagnostics su

System menu factory default settings..................................................................... 129

Time menu.................................... ................................ .................................. .. 131

Time of Day submenu...................................................................................... 132

Daylight Savings Time submenu........ ................................ .................................. 136

Program Time submenu........................ ................................ ............................ 138

Jam Sync sub

TIME button menu factory default settings.... . ..... ..... . ..... . ..... . ..... . ..... . .... . . .... . ..... . ..... 140

Front panel menu operation .................................................................................... 141

AES button menu diagrams................................................................................ 144

BLACK button menu diagrams ... ................................ .................................. ...... 145

EMBED button menus (Option SDI only)............................................................... 149

LTC b utt

REF button menus ...... ................................ ................................ .................... 153

SDI button menus (Option SDI only) .................................................................... 154

STATUS button menus ..................................................................................... 169

SYSTEM button menu . ... . . . .... . . .... . ..... . ..... . ..... . ..... . ..... . ... . . ..... . ..... . ..... . ..... . ..... . .. 170

TIME button menus .................... ................................ ................................ .... 190

x

Inde

bmenu............... ................................ ................................ ........ 120

menu ......................................................................................... 139

on menus .......................................................................................... 152

SPG700 User Manual iii

Page 8

Table of Contents

List of Figure

Figure i: SPG700 front and rear panels ......................... ................................ ............... xiii

Figure 1: Time flow block diagram........................ ................................ ....................... 2

Figure 2: Example SPG700 Web User Interface window...................................................... 8

Figure 3: Example FTP view of the SPG700 file structure ......... ................................ .......... 18

Figure 4: Example FTP error message when flash memory is full................... ........................ 18

Figure 5: File structure for installing custom user files ....................... ................................ 22

Figure 6: Sample of transfer.exe window after the upgrade is complete .................................... 29

Figure 7: Removing a Power Supply modu

Figure 8: AES button menu diagram............................ .................................. .............. 39

Figure 9: AES TIMING OFFSET submenu diagram ..... . ..... . ... . . ..... . ..... . .... . . .... . ..... . ..... . .... . 40

Figure 10: Black menu with the Black 2 submenu expanded ........ ................................ ........ 43

Figure 11: Partial Embedded menu diagram ................................................................... 50

Figure 12: LTC menu with LTC 1 selected..................................................................... 53

Figure 13: Reference tab menu ...................... ................................ ............................ 55

Figure 14: SDI menu with the SDI 1 submenu expanded....................... .............................. 59

Figure 15: SDI Signal submenu ................................................................................. 60

Figure 16: Circle zone plate configuration parameters ........................................................ 64

Figure 17: Configure Zoneplate video menu selections....................................................... 65

Figure 18: Configure Zoneplate parameters for all zone plate signals. ................................ ...... 66

Figure 19: SDI Moving Picture submenu....................................... ................................ 67

Figure 20: SDI Video submenu.................................................................................. 68

Figure 21: SDI Overlay submenu................................................................................ 70

Figure 22: SDI Overlay Logo settings . ..... . .... . ..... . ..... . ..... . ..... . ... . . . .... . ..... . ..... . ..... . ..... . ... 71

Figure 23: SDI Overlay ID Text settings ....................................................................... 73

Figure 24: SDI Overlay Circle settings . ... . . ..... . ..... . ..... ..... . ..... . ..... . .... . . .... . ..... . ..... . .... . .... 74

Figure 25: SDI Overlay Burnt-In Timecode settings . ..... . ..... . ..... . ... . . ..... . ..... . ..... . .... . . .... . ..... 75

Figure 26: SDI Anci

Figure 27: SDI Ancillary Data Output settings ..... . ..... . ..... . ... . . . .... . ..... . ..... . ..... . ..... . .... . ..... . 78

Figure 28: AFD code “1001” for a 16:9 coded frame......................................................... 80

Figure 29: SDI Timecode submenu ............................................................................. 81

Figure 30: Optical zone plates (enlarged)....................................................................... 95

Figure 31: A “K

Figure 32: A “K

Figure 33: A “K

Figure 34: A “K

Figure 35: Status display – left side ........................................................................... 107

Figure 36: LTC status display ...................... ................................ ............................ 108

Figure 37: System menu ........................ ................................ ................................ 109

s

le .................. .................................. .............. 36

llary Data Payload settings .... . ..... . .... . . .... . ..... . ..... . ..... . ..... . .... . ..... . ..... . 76

2

-only” zone plate....... .................................. ................................ .. 100

Y

-only” zone plate ............................................................................ 102

X

2

-only” zone plate....... .................................. ................................ .. 103

X

-only” zone plate ............................................................................ 105

Y

iv SPG700 User Manual

Page 9

Table of Contents

Figure 38: Syst

Figure 39: Frame Resets example ............................................................................. 111

Figure 40: System Presets submenu........................................................................... 112

Figure 41: SNMP Settings submenu ..... . .... . . .... . ..... . ... . . ..... . ..... . .... . ..... . ..... . .... . ..... . ... . . . 114

Figure 42: GPI Settings submenu.... . ..... . ..... . .... . ..... . ..... . .... . ..... . ..... . ... . . ..... . ..... . .... . ..... 116

Figure 43: Options submenu ......... ................................ ................................ .......... 119

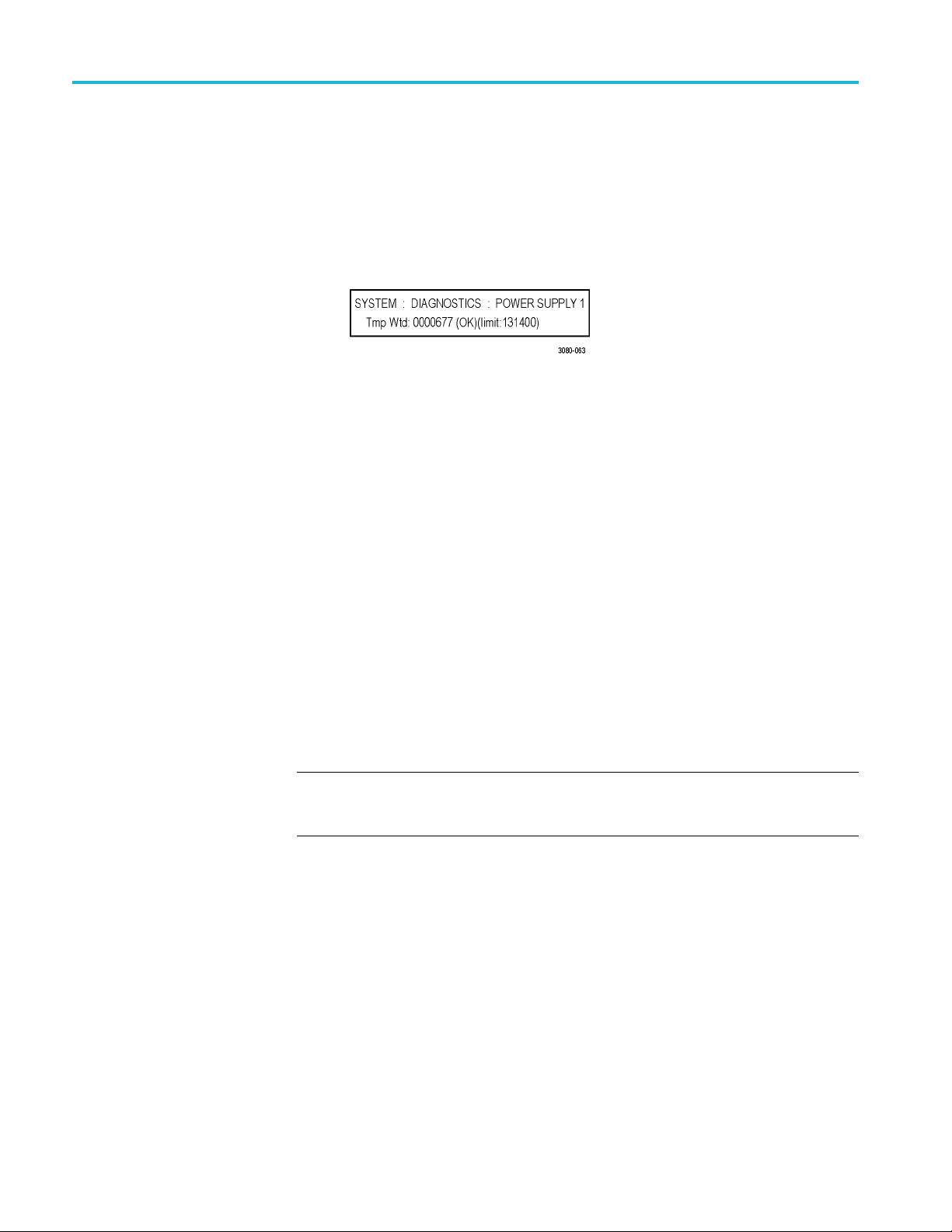

Figure 44: Mainframe diagnostic readouts ................................................................... 121

Figure 45: Power Supplies diagnostic readouts (load test in progress)...... .............................. 124

Figure 46: Reference Module diagnostic readouts........................................................... 127

Figure 47: SDI Module diagnostic readouts................ ................................ .................. 128

Figure 48: Time menu ................ ................................ ................................ .......... 131

Figure 49: Time of Day submenu.................................... ................................ .......... 132

Figure 50: Daylight Savings Time submenu . ................................ ................................ 136

Figure 51: Program Time submenu ... ................................ .................................. ...... 138

Figure 52: Jam Sync submenu ......................... .................................. ...................... 139

Figure 53: Example display readouts ......................................................................... 142

Figure 54: AES button menu diagram .......... .................................. ............................ 144

Figure 55: AES button – AES TIMING OFFSET submenu diagram ..................................... 144

Figure 56: BLACK button menu diagram – part 1 ............ ................................ .............. 145

Figure 57: BLACK button menu diagram – part 2 ............ ................................ .............. 146

Figure 58: BLACK button – BLACK TIMING submenu diagram........................................ 146

Figure 59: BLACK button – BLACK TIMECODE submenu diagram ............. ...................... 147

Figure 60: BLACK button – BLACK TIMECODE VITC submenu diagram............................ 148

Figure 61: EMBED button menu diagram.............. .................................. .................... 149

Figure 62: EMBED button – Embedded Audio Group submenu diagram................ ................ 150

Figure 63: EMBED button – EMBEDDED CHANNEL submenu diagram.............................. 151

Figure 64: LTC button menu diagram......................................................................... 152

Figure 65: LTC button – LTC TIMING submenu diagram................................................. 153

Figure 66: REF button menu diagram......................................................................... 153

Figure 67: REF button – GENLOCK TIMING submenu diagram ........................................ 154

Figure 68: SDI button menu diagram - part 1 .......... ................................ ...................... 155

Figure 69: SDI button menu diagram - part 2 .......... ................................ ...................... 156

Figure 70: SDI button – SDI TEST SIGNAL submenu diagram ..... . ..... . .... . . .... . ..... . ..... . ... . . .. 157

Figure 71: SDI button – SDI MOVING PICTURE submenu diagram.................................... 158

Figure 72: SDI button – SDI OVERLAY submenu diagram............................................... 159

Figure 73: SDI button – SDI OVERLAY LOGO submenu diagram .............. ........................ 160

Figure 74: SDI button – SDI OVERLAY ID TEXT submenu diagram ................................... 161

Figure 75: SDI button – SDI OVERLAY CIRCLE submenu diagram.............. ...................... 162

Figure 76: SDI button – SDI Overlay BURNT-IN TIMECODE submenu diagram..................... 163

Figure 77: SDI button – SDI TIMING submenu diagram .................................................. 164

Figure 78: SDI button – SDI TIMECODE submenu diagram.............................................. 165

em Status submenu............................................................................ 110

SPG700 User Manual v

Page 10

Table of Contents

Figure 79: SDI b

Figure 80: SDI button – SDI ANC PAYLOAD submenu diagram - part 1 ............................... 167

Figure 81: SDI button – SDI ANC PAYLOAD submenu diagram - part 2 ............................... 168

Figure 82: STATUS button menu diagram - part 1 .................. ................................ ........ 169

Figure 83: STATUS button menu diagram - part 2 .................. ................................ ........ 170

Figure 84: SYSTEM button menu diagram - part 1 . . ..... . ..... . ... . . ..... . ..... . ..... . ..... . ..... . ... . . . .. 171

Figure 85: S

Figure 86: SYSTEM button menu diagram - part 3 . . ..... . ..... . ... . . ..... . ..... . ..... . ..... . ..... . ... . . . .. 173

Figure 87: SYSTEM button – PRESET submenu diagram . .... . ..... . ..... . ..... . ..... . .... . ..... . ..... . .. 175

Figure 88: SYSTEM button – NETWORK SETUP submenu diagram . . ..... . ..... . ..... . ..... . ..... . ... 176

Figure 89: SYSTEM button – SNMP submenu diagram . ..... . ..... . ..... . ... . . . .... . ..... . ..... . ..... . ... 177

Figure 90: SYSTEM button – SNMP TRAPS submenu diagram - part 1 ..... . ..... . ..... . ..... . ... . . . .. 178

Figure 9

Figure 92: SYSTEM button – GPI submenu diagram... . ..... . ..... . ... . . ..... . ..... . ..... . ... . . . .... . ..... 180

Figure 93: SYSTEM button – GPI OUTPUT <1, 2, or 3> submenu diagram . ..... ..... . ..... . ..... . .... 181

Figure 94: SYSTEM button – GPI ALARM DELAY submenu diagram ..... . ..... . ... . . ..... . ..... . .... 182

Figure 95: SYSTEM button – OPTIONS submenu diagram . ..... . ..... . ... . . . .... . ..... . ..... . ..... . ..... 183

Figure 96: SYSTEM button – FRAME RESET STATUS submenu diagram .... . ..... . ..... . ... . . ..... . 183

Figu

Figure 98: SYSTEM button – DIAGNOSTICS submenu diagram - part 1. . ..... . ..... . ..... . ... . . ..... . 187

Figure 99: SYSTEM button – DIAGNOSTICS submenu diagram - part 2. . ..... . ..... . ..... . ... . . ..... . 188

Figure 100: SYSTEM button – POWER SUPPLY LOAD TEST submenu diagram... . ... . . . .... . ..... 189

Figure 101: TIME button menu diagram ..................................................................... 190

Figure 102: TIME button – TIME OF DAY submenu diagram............................................ 191

Fi

Figure 104: TIME button – PROGRAM TIME submenu diagram........................................ 193

Figure 105: TIME button – JAM SYNC submenu diagram.......... ................................ ...... 194

1: SYSTEM button – SNMP TRAPS submenu d iagram - part 2 .... . ..... . ..... . ..... . ..... . ... 179

re 97: SYSTEM button – EVENT LOG submenu diagram . . ..... ..... . ..... . ..... . ..... . .... . . .... . . 184

gure 103: TIME button – DST SCHEDULE submenu diagram................. ........................ 192

utton – SDI VIDEO submenu diagram.................... ................................ 166

YSTEM button menu diagram - part 2 ..... . ..... . ..... . ..... . ... . . ..... . ..... . ..... . ..... . .... 172

vi SPG700 User Manual

Page 11

List of Tables

Table i: Product documentation................................................................................. xvi

Table 1 : Ele

Table 2: SNMP parameters ........................... .................................. .......................... 11

Table 3: AES button menu factory default settings........ ................................ .................... 41

Table 4: Black output formats........................ ................................ ............................ 44

Table 5: Black output timing adjustment ranges..................... ................................ .......... 45

Table 6: Black button menu factory default settings . . ..... . .... . ..... . ..... . ... . . ..... . ..... . .... . ..... . ..... 48

Table 7 : E

Table 8: LTC output signal formats ............................................................................. 54

Table 9: LTC button menu factory default settings . ..... ..... . ..... . ..... . ... . . . .... . ..... . ..... . ..... . ... . . .. 54

Table 10: Timing adjustment ranges for reference input signals ............................................. 56

Table 11: REF button menu factory default settings........................................................... 57

Table 12: SDI button menu factory default settings ..... . ..... . ... . . ..... . ..... . ..... . ..... . ... . . . .... . ..... . . 82

Table

Table 14: SDI – 3G Level A (1280 × 720) ............... ................................ ...................... 86

Table 15: SDI – 3G Level A (2K × 1080) ...................................................................... 86

Table 16: SDI – 3G Level B (1920 × 1080) .............................. .................................. .... 86

Table 17: SDI – 3G Level B (2K × 1080) ...................................................................... 87

Table 18: SDI – 3G Level B (2×HD 1080) ..................................................................... 87

ble 19: SDI – 3G Level B (2×HD 720) ...................................................................... 87

Ta

Table 20: SDI – HD-SDI (1920 × 1080).................. ................................ ...................... 87

Table 21: SDI – HD-SDI (1280 × 720) ......................................................................... 87

Table 22: SDI – SD-525 (720 × 486).............................. .................................. ............ 87

Table 23: SDI – SD-625 (720 × 576).............................. .................................. ............ 87

Table 24: Standard SDI test signal sets ............. ................................ ............................ 88

Table 25: Enhanced SDI test signal sets ........................................................................ 93

Table 26: Zone plate pattern control parameters ............................. ................................ .. 99

Table 27: System button menu factory default settings . . ..... . ... . . ..... . ..... . ..... . ... . . . .... . ..... . ..... 129

Table 28: TIME button menu factory default settings... . ..... . ..... . .... . ..... . ..... . ... . . . .... . ..... . ..... 140

ments of the Web user interface .................................................................... 9

mbedded menu factory default settings . ..... . ... . . . .... . ..... . ... . . ..... . ..... . .... . ..... . ..... . ... 52

13: SDI – 3G Level A (1920 × 1080)...................... ................................ .............. 86

Table of Contents

SPG700 User Manual vii

Page 12

Important safety information

Important saf

ety information

This manual c

for safe operation and to keep the product in a safe condition.

To safely perform service on this product, additional information is provided at

the end of this section. (See page x, Service safety summary.)

General safety summary

Use the product only as specified. Review the following safety precautions to

avoid injury and prevent damage to this product or any products connected to it.

Carefully read all instructions. Retain these instructions for future reference.

Comply with local and national safety codes.

For correct and safe operation of the product, it is essential that you follow

generally accepted safety procedures in addition to the safety precautions specified

in this manual.

The product is designed to be used by trained personnel only.

Only qualified personnel who are aware of the hazards involved should remove

the cover for repair, maintenance, or adjustment.

ontains information and warnings that must be followed by the user

To avoid fire or personal

injury

Before use, always check the product with a known source to be sure it is

operating correctly.

This product is not intended for detection of hazardous voltages.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions related to operating the system.

When incorporating this equipment into a system, the safety of that system is the

responsibility of the assembler of the system.

Use proper power cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, make sure that the product is properly g rounded.

Power disconnect. The power cord disconnects the product from the power

source. See instructions for the location. Do not position the equipment so that

it is difficult to operate the power cord; it must remain accessible to the user at

all times to allow for quick disconnection if needed.

viii SPG700 User Manual

Page 13

Important safety information

Observe all ter

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do not operate without covers. Do not operate this product with covers or panels

removed, or with the case open. Hazardous voltage exposure is possible.

Avoid exposed circuitry. Do not touch exposed connections and components

when power is present.

Do not operate with suspected failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Disable the product if it is damaged. Do not use the product if it is damaged

or operates incorrectly. If in doubt about safety of the product, turn it off and

disconnect the power cord. Clearly mark the product to prevent its further

operation.

Before use, inspect voltage probes, t est leads, and accessories for mechanical

damage and replace when damaged. Do not use probes or test leads if they are

damaged, if there is exposed metal, or if a wear indicator shows.

minal ratings. To avoid fire or shock hazard, observe all ratings

Examine the exterior of the product before you use it. Look for cracks or missing

pieces.

Use only specified replacement parts.

Do not operate in wet/damp conditions. Be aware that condensation may occur if

a unit is moved from a cold to a warm environment.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry. Remove the input signals before you clean

the product.

Provide proper ventilation. Refer to the installation instructions in the manual for

details on installing the product so it has proper ventilation.

Slots and openings are provided for ventilation and should never be covered or

otherwise obstructed. Do not push objects into any of the openings.

Provide a safe working envi

convenient for viewing the display and indicators.

Be sure your work area meets applicable ergonomic standards. Consult with an

ergonomics professional to avoid stress injuries.

ronment. Always place the product in a location

Use only the Tektronix rackmount hardware specified for this product.

SPG700 User Manual ix

Page 14

Important safety information

Service safet

ysummary

The Service safety summary section contains additional information required to

safely perform service on the product. Only qualified personnel should perform

service proc

summary before performing any service procedures.

To avoid electric shock. Do not touch exposed connections.

Do not service alone. Do not perform internal service o r adjustments of this

product un

present.

Disconnect power. To a void electric shock, s witch off the product power a nd

disconnect the power cord from the mains power before removing any covers or

panels, or opening the case for servicing.

Use care when servicing with power on. Dangerous voltages or currents may exist

in this product. Disconnect power, remove battery (if applicable), and disconnect

test leads before removing protective panels, soldering, or replacing components.

Verify safety after repair. Always recheck ground continuity and mains dielectric

stre

edures. Read this Service safety summary and the General safety

less another person capable of rendering first aid and resuscitation is

ngth after performing a repair.

x SPG700 User Manual

Page 15

Terms in this manual

These terms may appear in this manual:

WAR NI NG . Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Symbols and terms on the product

Important safety information

These ter

The following symbol(s) may appear on the product:

ms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read

the mark

WARNING indicates an injury hazard not immediately accessible as you

read th

CAUTION indicates a hazard to property including the product.

ing.

emarking.

When this symbol is marked on the product, be sure to consult the manual

to find out the nature of the potential hazards and any actions which have to

be taken to avoid them. (This symbol may also be used to refer the user to

ratings in the manual.)

SPG700 User Manual xi

Page 16

Important safety information

Environmental considerations

This section provides information about the environmental impact of the product.

Restriction of hazardous

substances

Product end-of-life

handling

Complies wit

Observe the following guidelines when recycling an instrument or component:

Equipment recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could be

harmful to the environment or human health if improperly handled at the product’s

end of life. To avoid release of such substances into the environment and to

reduce the use of natural resources, we encourage you to recycle this product in

an approp

recycled appropriately.

Battery recycling. This product contains a small installed lithium metal button

cell. Please properly dispose of or recycle the cell at its end of life according to

local government regulations.

h RoHS2 Directive 2011/65/EU.

riate system that will ensure that most of the materials are reused or

This symbol indicates that this product complies w ith the applicable European

Union requirements according to Directives 2012/19/EU and 2006/66/EC

on waste electrical and electronic equipment (WEEE) and batteries.

For information about recycling options, check the Tektronix Web site

(www.tek.com/productrecycling).

Transporting batteries

Perchlorate materials. This product contains one or more type CR lithium

batteries. According to the state of California, CR lithium batteries are

classified as perchlorate materials and require special handling. See

www.dtsc.ca.gov/hazardouswaste/perchlorate for additional information.

The small lithium primary button cell contained in this equipment does not

exceed 1 gram of lithium metal content per cell, and the cell type has been

shown by the manufacturer to comply with the applicable requirements of the

UN Manual of Tests and Criteria Part III, Sub-section 38.3. Consult your carrier

o determine which lithium battery transportation requirements are applicable

t

to your configuration, including to its re-packaging and re-labeling, prior to

reshipment of the product by any mode of transport.

xii SPG700 User Manual

Page 17

Preface

Preface

Product description

This manual p

Multiformat Reference Sync Generator.

Refer to the SPG700 Installation and Safety Instructions manual for information

about how to install the instrument, for descriptions of the front and rear panel

controls and connectors, and for information about initial configuration.

The SPG700 is a precision multiformat video signal generator, suitable for master

synchronization and reference applications. It provides multiple video reference

signals, such as black burst, HD tri-level sync and serial digital test patterns, and

provides time reference signals such as time code. Audio reference signals such

as word clock and DARS are also provided.

Thebaseconfiguration includes three sync outputs that can be configured with

independent output formats (NTSC/PAL black burst and/or HD tri-level sync) and

independently adjustable timing offsets. A high-accuracy, oven-controlled crystal

oscillator provides a stable frequency reference for the system, or the loop-through

genlock input can be used to lock to an external video reference or 10 MHz

continuous wave signal. The Stay GenLock® feature avoids “synchronization

shock” if the external reference suffers a temporary disturbance, by maintaining

the frequency and phase of each output signal. When the external reference is

restored, Stay GenLock® ensures that any accumulated clock drift is removed by

slowly adjusting the system clock within standard limits instead of “jamming”

back to the correct phase.

rovided detailed operating information about the SPG700

Time reference outputs are available in multiple formats. Three independent

linear time code (LTC) outputs are available, and a fourth LTC connection can be

used as input or output. Each LTC output has independent frame rate selection,

time source (timeof- day or program time) and time zone offset. Vertical interval

time code (VITC) is available on each NTSC or PAL black output, also with

independent time sources and offset

Figure i: SPG700 front and rear panels

SPG700 User Manual xiii

s.

Page 18

Preface

Test signal outputs

Audio reference signals

The SPG700 can b

Option SDI adds two fully independent serial digital video generator channels of

two outputs each. Each channel can be configured to any standard SD/HD/3G-SDI

format and frame rate. The selected test pattern can be generated on both outputs

per channel, or one output can generate digital black. A wide variety of standard

test patterns are included, such as color bars, convergence grid, step scales, ramps,

multiburst

generator.

Bitmap ima

user-defined test patterns. ID text, burn-in time code, circle, and color logo

overlays can be added to any test pattern, and several ancillary data packet types,

including ancillary time code and user-defined packets, can be inserted into the

SDI output signal.

The four SDI outputs can be configured to support 4K/UHD full frame, 100% and

75% color bars for quad link square division mode. This allows simple verification

of your 4K/UHD workflow within the production studio or mobile truck. Note:

VPIDs a

Also included is an audio/video delay test sequence, which in conjunction with a

Tektr

Several audio reference signals are available. The base configuration includes

a 48 kHz word clock output and a dedicated Digital Audio Reference Signal

(DA

audio on each of the SDI outputs.

, SDI pathological test matrix and a real-time programmable zone plate

ges can be downloaded to the SPG700’s flash memory for arbitrary

re compliant only to HD and 3G formats in 4K/UHD formats.

onix waveform monitor, can be used to ensure A/V delay compliance.

RS) output. With Option SDI, audio tone generation is included as embedded

e optionally configured with a variety of test signal outputs.

Remote access

For remote access to the instrument, a 10/100/1000BASE-T Ethernet interface is

cluded. A web-based user interface can be used for all configuration settings and

in

for monitoring system status. Alarm and key status information is also available

via Simple Network Management Protocol (SNMP) messaging, enabling easy

integration with network management systems. Remote control and alarm

reporting is also available via a general purpose interface (GPI). The front-panel

USB port can be used to backup and restore presets and other user data, and to

perform system firmware upgrades.

xiv SPG700 User Manual

Page 19

Preface

Optional backup power

supply

Key features

For critical ap

supply module. Under normal operation, the designated backup supply is seldom

used, ensuring that it has maximum remaining life should the primary supply

fail. The backup supply is load-tested once each day to verify that it can serve

as the primary supply if necessary. The usage time of each supply is logged

as “temperature-weighted hours”, a metric that best estimates the calculated

life of the s

its end-of-life. If the primary supply is interrupted for any reason, the system

will switch to the backup without any disruption to system operation. Power

supply modules are hot-swappable for easy replacement, and feature a locking

mechanism to prevent the power cable from accidental disconnection.

Multiple independent black burst and HD tri-level sync outputs provide all the

video reference signals required in a video broadcast or production facility

Four LTC outputs, VITC on black burst outputs

Stay GenLock® prevents synchronization shock when the external reference

input signal is temporarily lost

Wide selection of video test patterns in serial digital formats (SD, HD and

3G-SDI)

4K/UHD formats support with full frame 100% and 75% color bars (Quad

Link Square Division)

plications, the instrument can be configure d with a second power

upply. A front-panel LED will indicate when the supply is nearing

Applications

Methods of operation

Dual hot-swappable power supplies ensure continuous availability of

reference signals

Easy to manage with Web-based interface for remote configuration and SNMP

for status and alert information

ync pulse generator and time reference generator for broadcast, studio,

S

mobile, and post-production facilities

aster or slave (genlock) operation for distributed system architectures

M

Video equipment verification, facility link testing, and display calibration

This instrument can be operated using either the front panel or the SPG700 Web

Interface. It is recommended that you use the SPG Web Interface to operate the

instrument since it is easier to use and more intuitive. The majority of this manual

describes how to operate the instrument using the SPG700 We b Interface. For

your convenience, menu diagrams of the front-panel menus are also provided.

(See page 141, Front panel menu operation.)

SPG700 User Manual xv

Page 20

Preface

Product documentation

The following table lists the product documentation that is available for the

SPG700 g ene rator.

Table i: Product documentation

Availability

Document Tektronix Part Number Description Print Web

Installation and Safety

Instructions

User Manual

Specifications and

ance Verification

Perform

Service Manual

Declassification and

ity Instructions

Secur

se Notes

Relea

0UP Upgrade

SPG7

Instructions

Video Sync Pulse

Generator and Electronic

ngeover Unit System

Cha

Integration Technical

Reference

071-3480-xx (English)

077-1223-xx (Japanese)

077-1224-

077-1225

077-1226-xx (Japanese)

077-1227-xx (Russian)

077-1228-xx

077-122

077-1230-xx Describes how to clear or sanitize

077-1

075-1093-xx

077-0563-xx (ECO422D)

077-0877-xx (ECO 8000, ECO8020)

xx (Russian)

-xx (English)

9-xx

231-xx

Describes h

instrument and provides basic

operating information

Provides detailed operating

informati

Lists the product specifications and

provide

performance of the instrument

Describ

instrument to the module level (such

as circuit boards and fuses)

the data storage (memory) devices in

the pr

security concerns

Describes the new features,

improvements, and limitations of the

rument firmware

inst

Prov

your SPG700 instrument

Provides information for system

integrators who are designing

tems for high-definition (HD) and

sys

standard-definition (SD) digital video

content where Tektronix electronic

angeover units and video sync

ch

pulse generators are to be deployed.

ow to install the

on

s procedures for verifying the

es how to service the

oduct for customers with data

ides instructions for upgrading

xvi SPG700 User Manual

Page 21

System timing

Frame reset si

FRAME RESET

FRAME RESET 2

FRAME R

gnals

ESET 3

The SPG700 uses the three frame reset signals described below to output different

video formats simultaneously.

This frame reset signal runs at 2.997 Hz and supports the 1/1.001 system signal,

1

and is used by the following video formats. These signals are synchronized with

each other.

NTSC

525-270

1080 23.98p

1080 23.98sF

1080 29.97p

1080 59.94i

720 59.94p

30 fps DF LTC

23.98 fps LTC

This frame reset signal runs at 6.250 Hz and is used only for PAL, 625, or HD /

LTC f orm

ats with 50 Hz or 25 Hz frame rates. These signals are synchronized

with each other.

PAL

625-270

1080 25p

1080 50i

25 fps LTC

This frame reset signal runs at 3.000 Hz and is used for HD / LTC formats with

60 Hz, 30 Hz or 24 Hz frame rates. These signals are synchronized with each other.

1

Frame reset signal 1 is not synchronized with frame reset signals 2 or 3.

Time flow block diagram

The following time flow diagram shows time information is used at different

points in the system. In particular, it illustrates how the different user inputs and

configuration settings combine with the time base to create the timecode. An

asterisk (*) denotes points of possible user input.

1080 24p

1080 2

1080 30p

1080 60p

1080

720 60p

Not drop frame.

60i

4sF

LTC

24 fps

25 fps LTC

30 fps LTC

1

SPG700 User Manual 1

Page 22

System timing

Figure 1: Time flow block diagram

2 SPG700 User Manual

Page 23

System timing

The following p

Internal Time Set *. If you want to set Time Setup to internal mode, enter

the current da

transfer that time to the Master Time. The time zone o ffset information is

used to convert local time to a master time. Set the local time zone offset

before setting the internal time.

VITC Reader. When the instrument is genlocked to NTSC or PAL, the

Vertical Interval Timecode on the genlock reference input can be decoded

and used as the time source. This time can be viewed on the status bar, and

is used as the time source for all the time code outputs. Since the phase of

the video

from the VITC input. If SMPTE309 date data is available, the time and date

information on the VITC input will be used if enabled in the TIME OF DAY

submenu. (See page 132, Time of Day submenu.)

LTC R e ader. When the reference source is set to INTERNAL, NTSC, PAL

or HD SYNC, the LTC signal applied to the LTC 1 input can be used at the

time source. This time can be viewed on the status bar and is used as a time

source for all the time code outputs. If SMPTE309 date data is available, the

time a

TIME OF DAY submenu. (See page 132, Time of Day submenu.)

Time

selected Reference source. If Genlock is the selected reference source, then

VITC, LTC, or internal time is available. If Internal is the selected reference

source, then internal time is the time code source.

aragraphs describe portions of the Time flow block diagram.

te and time and then set the Time Setup to Internal in order to

signals are s et by the genlock, the epoch system does not operate

nd date information on the LTC input will be used if enabled in the

Setup Selection. The possible Time code sources depend on the

If VITC or LTC is the time code source, then the time synchronization Mode

needs to be set. There are three choices. Synchronize now sets the time

when the user presses the ENTER button (if the incoming time is valid and

stable). Synchronize once sets the time once when a valid and stable time

ode is detected. Follow sets the time every time a new stable and valid time

c

is detected.

Genlock. When NTSC or PAL is selected as the reference and the time source

is LTC or VITC with ST309 date, then the timing of the reference sync may

be used to improve the accuracy of the master time.

Master Time. The Master Time is the basis for all timecode outputs and for

the phase reference of all video outputs.

Offset to TAI. TAI is the International Atomic Time, represented as the

number of seconds since the epoch of 0:00:00 January 1, 1958. Proposed

standard SMPTE 404M defines the SMPTE Epoch at that same moment.

There are exactly 8040 days and 19 leap seconds between the SMPTE Epoch

(TAI) and the GPS Epoch.

SPG700 User Manual 3

Page 24

System timing

Epoch Calculat

is used to precisely align video frames with the Master Time clock. For

example, an NTSC system operates at 29.97 frames per second (30 fps/1.001),

so there are precisely 30,000 frames every 1001 seconds. By knowing the

total number of seconds since the SMPTE Epoch, when all video frames were

perfectly aligned, the instrument can determine "where" the pulse-per-second

signal is lo

made in reference to the user-selected Epoch setting: January 1, 1958 or

January 1, 1970.

Frame Engine. The frame engine supplies frame pulse signals based on

the SMPTE Epoch to each video output. This ensures that they are properly

aligned with respect to the calculated phase for the selected video format of

each output.

Output Timing. Each video output has an independent offset that can be

specified to shift that output in order to align the video and LTC signals in the

studio. This time adjustment does not affect the timecode that is applied to

that ou

The timing offset r ange and resolution depend on the signal. See the specific

output menu for details.

Time Zone Offset *. The SPG700 has a selectable offset between UTC and

the local time, usually representing the local time z one. This offset can be

specified in hours+minutes+seconds, allowing specification of time zones that

do not align with the usual hours-only offset, or for other applications not

related to time zones. You can also use this setting to set the internal time to

cal

tput; the signal and timecode stay together as the timing is changed.

culate “backwards” to the Master Time.

ions *. The number of seconds since the SMPTE Epoch

cated with respect to video framing. The Epoch adjustment is

When the input time source is set to VITC or LTC, the instrument works

milar to how it works in internal mode, pre-correcting the master time of

si

day by the time zone offset. This pre-correction a ssumes that the incoming

time code has the correct local time, and causes the outgoing time codes to

nominally match the incoming ones, regardless of time-zone offset. However,

if the time code synchronization mode is set to "Synchronize now" or

"Synchronize once", a nd the time-zone offset is changed after the time-code

sync has occurred, then the time-zone change offsets the incoming and

outgoing time codes until the user reasserts the time synchronization.

Additionally, if the time is being set by LTC or VITC with SMPTE309 date

data, the system can be configured to use the time zone and DST from the

input. (See page 132, Time of Day submenu.)

4 SPG700 User Manual

Page 25

System timing

DST Change *.Da

time zones, but some locations do not observe daylight savings time. The

SPG700 has a user programmable DST adjustment to the time zone offset that

is made by adding or subtracting a specified amount from the current time

setting. The scheduled date and time of the change must be programmed into

the instrument. There are two methods for scheduling the DST offset:

Once. In Once mode, the DST offset is applied only once on the date and

time you specify. Set the DST offset to either add or subtract an hour from

the time zo

in your location.

Recurrin

START date and time that you specify occurs, and is removed when

the DST END date and time that you specify occurs. The recurring

DST offset can only be a positive number, such as one hour. The DST

START/END dates are formatted as the DST rules are written (e.g., DST

starts on the First Sunday in March at 02:00). For example, to change

to dayl

time zone offset at 02:00:00 (local time) on March 6, 2011. To return to

standard time, schedule the system to remove the DST offset at 02:00:00

on November 6, 2011. At the scheduled time and date, the DST change is

added to the time zone offset as seen from the instrument display. You can

then program the next scheduled DST change.

ight savings time, schedule the system to add one hour to the

ylight Saving Time (DST) changes twice a year in m any

ne offset, depending on whether DST is starting or ending

g. In Recurring mode, the DST offset is applied when the DST

An incoming VITC or LTC reference may have DST shift already applied.

To avoid duplicating DST shifts, disable the DST SCHEDULER if the time

ay reference has DST applied.

of d

Task Scheduler. The task scheduler is responsible for triggering scheduled

ents at the appropriate time. This includes DST changes and triggered

ev

alarm outputs.

C Offset *. Every timecode output has an independent offset (hours,

T

minutes, seconds, frames) that can be added t o the value of the selected

timecode source.

TC Engine. The timecode engine runs at the rate specified through the user

interface and generates the actual timecode bits needed for each output.

LTC. The instrument has four independent linear timecode outputs. Each

output can be set independently with regard to timecode format, module

timing, and timecode delay.

Analog Black. The instrument provides three analog sync outputs. Each

output can be configured as NTSC or PAL Black burst (with optional VITC

insertion) or HD trilevel sync.

HD-SDI. Option SDI provides two independent HD-SDI test signal

generators, for which ancillary timecode (ATC) can be added.

SPG700 User Manual 5

Page 26

System timing

Program Time.A

counter can be used as a timecode source for any output. This counter can

represent elapsed time, such as the time code associated with program content

during the editing process, for example.

Reset Value. The program time counter will start c ounting from the specified

reset value. Program time can be reset to this value at any time using either

the user interface or a general purpose interface (GPI) input.

Alarm Time. An alarm can be set to generate when the program time counter

matches a predefined value. F or example, you can specify the start timecode

of your program content at 01:00:00:00. The program time can be initialized

to 00:59:

time could be set at 00:59:55:00 to signal a five second countdown before the

program start, perhaps to signal a change from color bars to Black within

the pre-program leader.

GPI Out. The instrument has two General Purpose Interface (GPI) outputs,

either of which may be configured to begin when the program time matches a

specified alarm time.

00:00 to start a one minute leader before the program. The alarm

s an alternate to the local time of day, a program time

6 SPG700 User Manual

Page 27

Web user interface

When the Web user interface is enabled in the System menu, you can use a Web

browser to remotely control the instrument. Enter the IP address of the instrument

in a supporte

Click the various tabs to access the instrument settings and controls as you would

using the front panel buttons.

NOTE. The Web user interface must be enabled from the System menu on the

instrument front-panel before it can be accessed from a Web browser. (See

page 109, System menu.)

Operational considerations

It is recommended that a maximum of four simultaneous users be connected to the

instrument using the Web interface. If more users are connected, it may result in

lower performance and inconsistent behavior.

Some front panel operations may interrupt or reduce the performance of the Web

interface. For example, the Web server may experience temporary delays when

alargefile is being transferred using the USB port or when many buttons are

being pressed on the front panel.

d Web browser to open the SPG700 Web Interface. (See Figure 5.)

Levels of control

Supported Web browsers

From the instrument front panel, use the Web User Interface setting in the System

menu to control the level of instrument access from a Web browser. Use the left

(◄)orright(►)

ENTER button to confirm the selection.

Full-Control. Allows a user to have full control of instrument settings when

using the Web User Interface.

Disable. Disables the instrument from being accessed by the Web User

Interface.

Read-Only. Allows a u ser to have read-only access to instrument settings

when using the Web User Interface.

NOTE. Remote port 5000 is not required for the Web UI to function. If the SCPI

remote is not required it should be disabled to increase security and prevent

disruption by port scanners.

For best results, use Google Chrome, Mozilla Firefox, Safari, or Internet Explorer

9.0 or later when you connect to the SPG700 Web Interface.

NOTE. The Web user interface requires Javascript to run.

arrow button to select between the following options. Press the

SPG700 User Manual 7

Page 28

Web user interface

Elements of th

e Web user interface

The following figure highlights elements of the Web user interface window. Some

display elements are dependent on certain options being installed in the instrument.

NOTE. Arede

Click the item to view the alert details.

xclamation mark next to a menu item indicates that an a lert exists.

Figure 2: Example SPG700 Web User Interface window

8 SPG700 User Manual

Page 29

Web user interface

Table 1: Elemen

Item number Description

1

ts of the Web user interface

Menu tabs. Cli

Status menu.U

changes to instrument settings from the Status menu. For more information, see the Status menu

section. (See page 107.)

Reference menu. Use this menu to view or change the signal reference or genlock timing settings for

the instrum

Time menu.U

divided between the Time of Day, Daylight Savings Time, Program Time, and Jam Sync submenus.

Click on the arrow next to the desired submenu to access that menu. For more information, see the

Time menu s

Black menu

the Black 1–3 tri-level sync signals. Click on the arrow next to the desired Black output to access the

menu for that output. For more information, see the Black menu section. (See page 43.)

LTC menu. Use this menu to view or change the settings for the LTC outputs. Click one of the

selectio

the LTC menu section. (See page 53.)

SDI menu (Option SDI only). Use this menu to view or change the settings for the SDI outputs. Click

on the arrow next to the desired SDI output to access the menu for that output. For more information,

see the S

ck a tab to access one of the following menus:

se this menu to view the status of various instrument functions. You cannot make

ent. For more information, see the Reference menu section. (See page 55.)

se this menu to view or change the time settings in the instrument. The settings are

ection. (See page 131.)

. U se this menu to view or change the settings for the Black outputs. You can configure

ns for the desired LTC output to access the submenu for that output. For more information, see

DI button m enu section. (See page 59.)

AES menu

all instruments, use the AES button menu to view or change the settings for the Word Clock (48 kHz)

output. For more information, see the AES button menu section. (See page 39.)

Embedded menu (Option SDI only). Use this menu to view or change the embedded audio settings

for the

output. For more information, see the Embedded menu section. (See page 49.)

System m enu . Use this menu to view or change general instrument settings and to view diagnostic

results. The system settings includes Status, Presets, G eneral Settings, SNMP Settings, GPI Settings,

Optio

submenu for that group. For more information, see the System menu section. (See page 109.)

. At the release of this document, a Web interface for the AES menu was not available. For

SDI outputs. Click on the arrow next to the desired SDI output to access the menu for that

ns, and Diagnostics submenus. Click on the arrow next to the desired setting group to access the

SPG700 User Manual 9

Page 30

Web user interface

Table 1: Elements of the Web user interface (cont.)

Item number Description

2

3

4

5

Indicators matching the indicators on the front panel of the instrument:

INT and EXT. Indicates the status of the reference signal used to time signals. Click on INT or EXT to

view the reference status on the Status menu tab.

TIME. Indicates the status of the selected time input. Click on TIME to view the time status on the

Status menu tab.

PWR1 and PWR2. Indicates the status of the Power Supply modules. Click on PWR1 or PWR2 to

view the status of the Power Supply m odules on the System menu tab.

FAULT. Indicates the status of the instrument hardware. Click on FAULT to view the status of any

faults on the System menu tab.

For information about the possible states for each indicator, see the SPG700 Installation and Safety

Instructions.

Click on Help to open a separate browser window that opens to the Tektronix SPG product Web page.

Click on Refresh to refresh the Web user interface.

Locked / Unlocked. Indicates whether the instrument front panel is locked or unlocked. Click to toggle

the setting.

System settings available

only b

yusingthe

front panel

The System menu in the SPG700 Web Interface does not include all of the menu

ons that are available using the SYSTEM button on the instrument front panel.

opti

(See page 170, SYSTEM button menu.)

ormation on the following menu items, which are available only from the front

Inf

panel, is available as described below:

Backup and restore Presets to USB (See page 13, How to backup/restore

esets and user data.)

pr

Audio/video Epoch selection (See page 174, Settings available only in the

ront-panel SYSTEM button menu.)

f

Front panel time out period (See page 174, Settings available only in the

ront-panel SYSTEM button menu.)

f

Oven calibration (See the SPG700 Installation and Safety Instructions manual

for instructions on how to calibrate the oven oscillator.)

Enable / Disable for SCPI remote

Fault log – tracks the last 1000 significant events to help in troubleshooting

10 SPG700 User Manual

Page 31

SNMP remote control

When the SPG700 is connected to an Ethernet network, you can confi gure the

instrument to send SNMP traps to an NMS (Network Management Station) when

certain erro

instrument, you must configure SNMP parameters.

SNMP configuration

The following table shows the SNMP parameters you can set using the System

button SNMP submenu or the Web user interface.

Table 2: SNMP parameters

rs are d etected. If you intend to use SNMP commands to control the

Setting

Enable SNMP Use this setting to turn on or off the remote access using SNMP.

Enable Traps

SNMP Traps Use this setting to enable or disable the following traps. For

Description

Use this setting to turn on or off the traps that are sent out

through SNMP.

more information about each trap, see the SNMP TRAPS

submenu section. (See page 115.)

Main fan fault

Voltage error

Temperature error

Genlock input missing

Loss of lock

Near loss of lock

VITC/LTC missing

LTC out of SMPTE specifications

Alarm time

PS1 fault

PS2 fault

PS1 TWH (Temperature Weighted Hours)

PS2 TWH (Temperature Weighted Hours)

Trap Destinations

Use this setting to set the IP addresses to which SNMP traps are

sent through SNMP. Traps can be sent to up to four addresses

when error conditions are detected.

NOTE. A value of all zeroes for the address will disable that

trap output.

SPG700 User Manual 11

Page 32

SNMP remote control

Download the MIB

Table 2: SNMP parameters (cont.)

Public Community Use this setting to set the Public Community string. This string

is effectively a password. Without this string, SNMP commands

cannot read values from the instrument.

NOTE. The Public String is necessary for SNMP access to

read values from the instrument.

Private Community Use this setting to set the Private Community string. This string

is effectively a password. Without this string, SNMP commands

cannot change values in the instrument.

NOTE. The Private String is necessary for SNMP access to

write changes into the instrument.

You can download the SPG8000 MIB file from the SNMP Settings submenu

under t

he System menu. (See page 114, SNMP Settings submenu.) The SPG8000,

SPG8000A, and SPG700 share the same MIB file. Some of the commands in

the file will apply to features and functions available only on the SPG8000 and

SPG8000A.

12 SPG700 User Manual

Page 33

How to backup/restore presets and user data

You c an use the backup and restore functions to duplicate settings and signal files

between different SPG700 generators.

You can view the USB drive status under the SYSTEM button menu (not available

on the Web interface) a nd all user data using a USB drive that is connected to the

instrument

CAUTION. To prevent the loss of data on the USB drive, be sure to unmount the

USB drive before you remove the drive from the instrument.

. The following information shows the status of the USB drive:

Not Connected displayed when no USB drive is connected to the instrument.

Not Mounted is displayed when a USB drive is connected to the instrument

but is not mounted. Press the ENTER button to mount the drive. Normally, a

USB drive

Mounted is displayed when a USB drive is connected to the instrument and

is mount

message You May Now Safely Remove USB Drive appears when it is safe

to remove the drive.

will automatically mount when connected to the instrument.

ed. Press the ENTER button to safely unmount the drive. The

How the backup and restore operations work

ng the backup operation, files are copied to a directory named “SpgBackup”

Duri

in the root directory of the USB drive. The restore operation expects to copy

files from this same directory.

All of the copy operations will create new directories/files on either the SPG700

ortheUSBdriveasneeded. Ifafile with the same n ame exists in the destination

location, it will be overwritten. However, if a file exists in the destination location

and not in the source location, the file will be left alone. Therefore, the restore

and backup operations act as an overlay, and do not guarantee that there will not

e additional files left in the destination location that did not exist in the source

b

location.

SPG700 User Manual 13

Page 34

How to backup/restore presets and user data

Presets

All user data

When presets ar

directory structure to hold them in their correct locations (for example,

SDI7/PRESET/MSTATE4.P00) will be copied or created.

NOTE. The preset file names use the format MSTATEX.PYY. In this example,

X denotes the slot name, YY denotes the preset number (there are 13 possible

presets). Separate presets are stored for each individual mainframe slot.

Only presets that have content are copied or written by the backup/restore

processes. This is because only presets that have been saved have files associated

with them

that has never been saved will not have an associated file and therefore will not

be copied.

When all

configuration files will be copied. This function is useful in that all user-created

files can be saved, restored, or copied to other SPG700 instruments.

User files are defined as any file that exists in the /app/F0 directory on the

instrument. The files in this directory ca n include presets, signal files, frame

picture files, logo files, sequence files, and for Option SDI, c an also include text

and font files. The user data files do not include the application software or any

Linux files.

e copied, only the MSTATEX.YY files and enough

and the backup/restore process copies only those files. Any preset

of the user data is copied, every user file except for the FPGA

Memory requirements

It is recommended that you use the Flash Memory readout in the System button

nu to determine how much memory is available on the instrument before you

me

perform a restore operation. You can also go to the Status submenu of the System

menu in the Web interface to see the amount of free and used space. Here is

how much memory is required:

If you are backing up or restoring only presets, you will need up to 1 MB of

free space on the USB drive or in the flash memory of the instrument.

If you are backing up or restoring all of the user data in the instrument, you

will need up to 96 MB of free space on the USB drive or in the flash memory

of the instrument.

If the backup or restore operation runs out of memory on the USB drive or the

flash memory on the instrument before the operation is complete, the operation

will copy as much data as it can and will then display an error message stating that

the backup or restore operation was incomplete because the drive or device is full.

14 SPG700 User Manual

Page 35

How to backup/restore presets and user data

Backup/resto

re procedure

1. Connect a USB drive to the instrument.

2. Press the System button to select System : PRESET.

3. Verify the status of the USB drive:

4. Press th

5. Press th

a. Press the up (▲)ordown(▼)arrowbuttontoselectSystem : USB

<status>.

b. Verify that the USB status is Mounted.

c. If the sta

drive.

BACKUP/RESTORE.

Backup Presets to USB

Backup All User Data to USB

Restore Presets from USB

Restore All User Data from USB

tus is Not Mounted, press the ENTER button to mount the USB

eup(▲)ordown(▼) arrow button to select System :

eleft(◄)orright(►) arrow button to select one of the following:

6. Press the ENTER button to start the selected backup or restore operation.

7. Awar

8. Mon

ning message is displayed asking you to v erify the operation. Press the

ENTER button to proceed or press the BACK button to cancel the operation.

itor the progress of the file copy operation:

a. During the first stage of the copy process, the display shows the names

the files as they are copied. Depending on the size of the files being

of

copied, this may take a couple of minutes.

hen all of the files have been copied, the message “Finishing copy...” is

b.W

displayed while the file system buffers are emptied. This message may

appear for a couple of minutes.

c. When the backup or restore operation is complete, the message “Backup

completed successfully” or “Restore completed successfully” is displayed

before the menu display returns to normal.

NOTE. If the USB drive or the flash memory on the instrument fills up before

the backup or restore operation completes, a n error message is dis played.

Press the ENTER or BACK button to clear the error message. (See page 14,

Memory requirements.)

SPG700 User Manual 15

Page 36

How to backup/restore presets and user data

9. After the backu

(▼) arrow button to select System : USB (Mounted).

10. Press the ENTE

may now safely remove the USB drive” is displayed, the menu readout should

change to System : USB (Not mounted).

11. Remove the USB drive from the instrument.