Page 1

xx

SPG600 & SPG300

ZZZ

Sync Pulse Generators

Service Manual

Warning

The servicing instructions are for use by qualified personnel

only. To avoid personal injury, do not perform any servicing

unless you are qualified to do so. Refer to all safety summaries

prior to performing service.

www.tektronix.com

071-1342-03

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O . B o x 50 0

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to fi nd contacts in your area.

Page 3

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty p eriod and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, with shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX' R ESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other than Tektronix representatives to install, repair or service the product;

Page 4

Page 5

Table of Contents

Specifications

Operating Information

General Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Service Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Finding Other Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Performance Check Interval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Strategy for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Tektronix Service Offerings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

General Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Theory of Operation

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Supplying Operating Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Applying and Interrupting Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Repackaging Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Installed Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Video Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Audio Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Genlock Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

A10 Main Board (SPG600) and A50 Main Board (SPG300) . . . . . . . . . . . . . . . . . . . 3-1

A20 Front-Panel Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

A30 Analog Board (SPG600 Option 02) and A50 Analog Board (SPG300) . . . . . . . 3-4

A40 SDI Board (SPG600 Option 03) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

. . . . . . 2-4

. 2-20

. . . . . . 3-3

SPG600 & SPG300 Sync Pulse Generators Service Manual i

Page 6

Table of Contents

Performance Verification

Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Preparation for Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Calibration Data Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Performance Verification Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Adjustment

Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Requirement for Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Master Clock Frequency Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Maintenance

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Related Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Inspection and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Removal and Installation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Access Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Procedures for SPG600 External Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Procedure for SPG600 Internal Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Procedures for SPG300 External Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

Procedures for SPG300 Internal Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

Setting Main Board Parameters after Replacement . . . . . . . . . . . . . . . . 6 -33

Setting the Instrument Serial Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

Installing the Option Key (Option 01 Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

Setting the Date and Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

Options

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Additional Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Service Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Electrical Parts List

Electrical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Diagrams

Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

ii SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 7

Mechanical Parts List

Table of Contents

Mechanical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Parts Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Using the Replaceable Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

SPG600 & SPG300 Sync Pulse Generators Service Manual iii

Page 8

List of Figures

List of Figures

Figure 1-1: SPG600 dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Figure 1-2: SPG300 dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Figure 2-1: Video menu diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Figure 2-2: Test signal (analog) submenu diagram . . . . . . . . . . . . . . . . . . 2-9

Figure 2-3: Test signal (SDI) submenu diagram . . . . . . . . . . . . . . . . . . . 2-10

Figure 2-4: Timing (analog) submenu diagram . . . . . . . . . . . . . . . . . . . . 2-11

Figure 2-5: Timing (SDI) submenu diagram . . . . . . . . . . . . . . . . . . . . . . 2-11

Figure 2-6: Overlay submenu diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Figure 2-7: Logo submenu diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Figure 2-8: ID text submenu diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Figure 2-9: SDI parameters submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Figure 2-10: Audio menu diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Figure 2-11: AES/EBU submenu diagram . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Figure 2-12: Embedded submenu diagram . . . . . . . . . . . . . . . . . . . . . . . 2-18

Figure 2-13: Audio channel submenu diagram . . . . . . . . . . . . . . . . . . . . 2-19

Figure 2-14: Genlock menu diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Figure 2-15: Genlock timing submenu diagram . . . . . . . . . . . . . . . . . . . 2-21

Figure 2-16: System menu diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Figure 2-17: Preset submenu diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Figure 2-18: Network information submenu diagram . . . . . . . . . . . . . . 2-24

Figure 2-19: Network setup submenu diagram . . . . . . . . . . . . . . . . . . . . 2-25

Figure 2-20: GPI submenu diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Figure 2-21: System information submenu diagram . . . . . . . . . . . . . . . . 2-27

Figure 2-22: System setup submenu diagram . . . . . . . . . . . . . . . . . . . . . 2 -27

Figure 2-23: Configuration submenu diagram . . . . . . . . . . . . . . . . . . . . 2-28

Figure 4-1: Equipment connection for verifying subcarrier frequency . . 4-4

Figure 4-2: Equipment connections for verifying the genlock function . 4-6

Figure 4-3: Equipment connection for verifying the blanking level . . . . 4-9

Figure 4-4: Equipment connection for verifying the serial digital

outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Figure 4-5: Initial equipment connection for verifying the serial

digital audio outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

iv SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 9

List of Figures

Figure 4-6: Second equipment connection for verifying the serial

digital audio outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Figure 4-7: Equipment connection for verifying the XLR digital

audio outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Figure 4-8: Equipment connection for verifying the XLR analog

audio outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Figure 4-9: Equipment connection for verifying the 48 kHz clock

output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Figure 5-1: Equipment connection for adjusting master clock

frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Figure 6-1: Instrument orientation (SPG600) . . . . . . . . . . . . . . . . . . . . . . 6-7

Figure 6-2: SPG600 external modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Figure 6-3: SPG600 internal modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Figure 6-4: SPG300 external modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Figure 6-5: SPG300 internal modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Figure 6-6: Guide to removal procedures . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Figure 6-7: Top cover removal (SPG600) . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Figure 6-8: Front-panel assembly removal (SPG600) . . . . . . . . . . . . . . . 6-16

Figure 6-9: A30 Analog board removal . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Figure 6-10: A40 SDI board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

Figure 6-11: A10 Main board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Figure 6-12: Power supply module removal (SPG600) . . . . . . . . . . . . . . 6-22

Figure 6-13: Top cover removal (SPG300) . . . . . . . . . . . . . . . . . . . . . . . 6-24

Figure 6-14: Front-panel assembly removal (SPG300) . . . . . . . . . . . . . . 6-25

Figure 6-15: A60 Analog board removal . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Figure 6-16: A50 Main board removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

Figure 6-17: Power supply module removal (SPG300) . . . . . . . . . . . . . . 6-31

Figure 6-1: Troubleshooting procedure (1) . . . . . . . . . . . . . . . . . . . . . . . 6-38

Figure 6-2: Troubleshooting procedure (2) . . . . . . . . . . . . . . . . . . . . . . . 6-39

Figure 6-3: Troubleshooting procedure (3) . . . . . . . . . . . . . . . . . . . . . . . 6-40

Figure 6-4: Troubleshooting procedure (4) . . . . . . . . . . . . . . . . . . . . . . . 6-41

Figure 6-5: A10 Main board view of SPG600 . . . . . . . . . . . . . . . . . . . . . 6-42

Figure 6-6: A10 Main board view of SPG300 . . . . . . . . . . . . . . . . . . . . . 6-43

Figure 9-1: SPG600 block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Figure 9-2: SPG300 block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

SPG600 & SPG300 Sync Pulse Generators Service Manual v

Page 10

List of Figures

Figure 9-3: Main function block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Figure 9-4: SPG600 interconnect diagram . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Figure 9-5: SPG300 interconnect diagram . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Figure 10-1: SPG600 external modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Figure 10-2: SPG600 internal modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

Figure 10-3: SPG300 external modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

Figure 10-4: SPG300 internal modules . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

vi SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 11

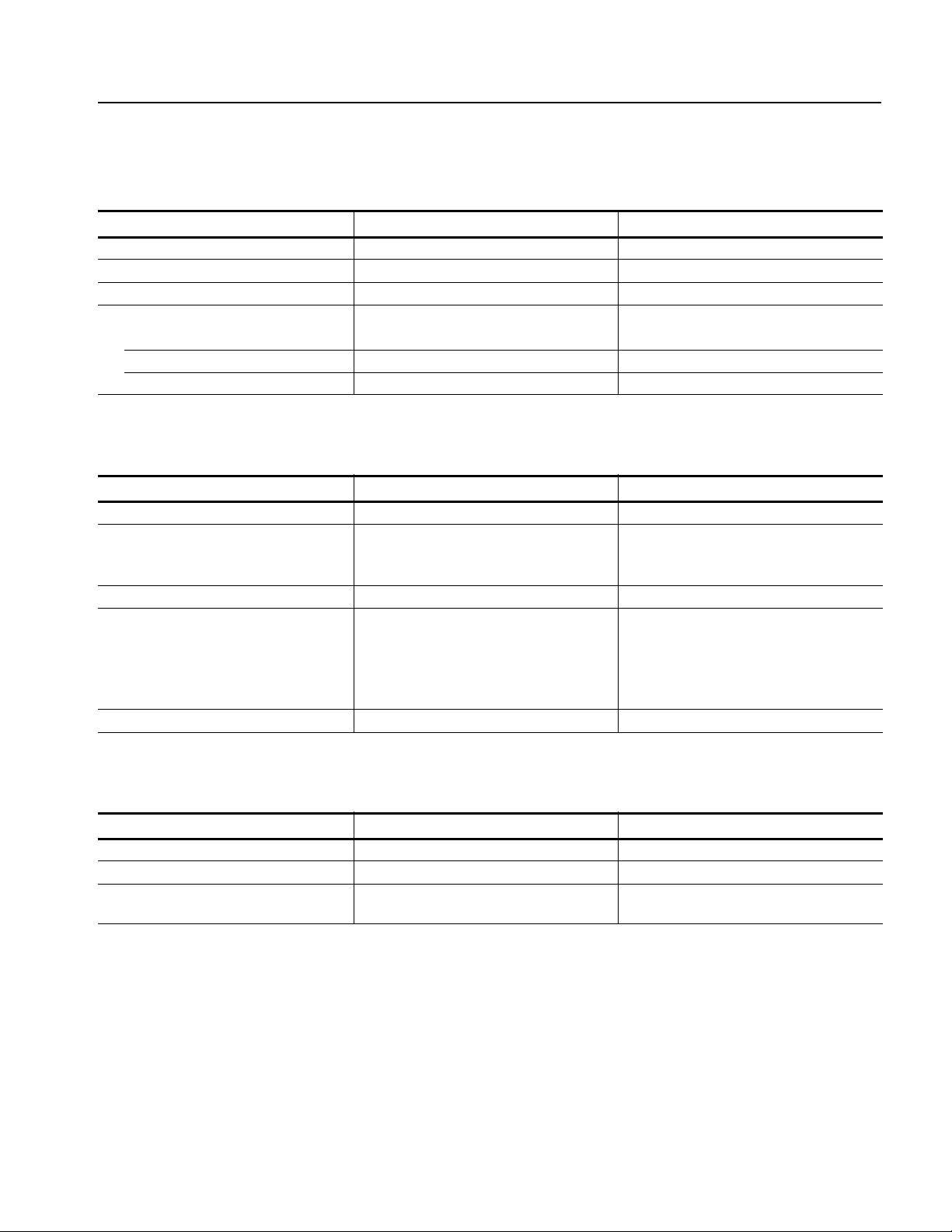

List of Tables

List of Tables

Table 1-1: Output capability of the SPG600 and the SPG300 . . . . . . . . . 1-1

Table 1-1: Reference Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table 1-2: Analog outputs (standard and Option 02) . . . . . . . . . . . . . . . . 1-4

Table 1-3: Serial digital interface (standard and Option 03) . . . . . . . . . . 1-5

Table 1-4: AES/EBU audio outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Table 1-5: Analog audio outputs . . . . . . . . . . . . . . . . . . . .

Table 1-6: GPI (general purpose interface) . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Table 1-7: SNMP error report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Table 1-8: AC power source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Table 1-9: Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Table 1-10: Mechanical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Table 1-11: Environmental char

acteristics . . . . . . . . . . . . . . . . . . . . . . . 1-11

. . . . . . . . . . . . . 1-7

Table 2-1: Power-cord conductor identification . . . . . . . . . . . . . . . . . . . . 2-2

Table 2-2: Power cord identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Table 4-1: Equipment required for performance verification . . . . . . . . . 4-1

Table 4-2: SPG600 and SPG300 calibration data report . . . . . . . . . . . . . 4-2

Table 5-1: Equipment required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Table 6-1: External inspection ch

Table 6-2: Internal inspection check list . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Table 6-1: Summary of procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Table 6-2: Tools required for module removal . . . . . . . . . . . . . . . . . . . . . 6-7

Table: Parts list column descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Table: Manufacturers cross index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Table: Replaceable parts li

Table: Replaceable parts list (SPG600) . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

Table: Replaceable parts list (SPG300) . . . . . .

Table: Replaceable parts list (SPG300) . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

Table: Replaceable parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

eck list . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

st (SPG600) . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

. . . . . . . . . . . . . . . . . . . . 10-8

SPG600 & SPG300 Sync Pulse Generators Service Manual vii

Page 12

List of Tables

viii SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 13

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to this

product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the Product. This p roduct is grounded through the grounding conductor of

the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Avoid Exposed Circuitry. Do not touch exposed connections and components when

power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

No Power Switch. Power supply cord is considered the disconnecting device,

disconnect the main power by means of the power cord.

SPG600 & SPG300 Sync Pulse Generators Service Manual ix

Page 14

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WAR NIN G. Warning statements identify conditions or practices that could result in

injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

DANGER

High Voltage

Protective Ground

(Earth) Terminal

ATTENTION

Refer to Manual

x SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 15

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the mains power by means

of the power cord or, if provided, the power switch.

Use Care When Servicing With Power On. Dangerous voltages or currents may exist

in this product. Disconnect power, remove battery (if applicable), and disconnect

test leads before removing protective panels, soldering, or replacing components.

To avoid electric shock, do not touch exposed connections.

SPG600 & SPG300 Sync Pulse Generators Service Manual xi

Page 16

Service Safety Summary

xii SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 17

Preface

About This Manual

This is the service manual for the SPG600 and SPG300 Sync Pulse Generators.

This manual contains information needed to service a sync pulse generator to the

module level.

This manual is divided into sections, such as the Specifications and Theory of

Operation. Further, some sections are divided into subsections, such as Product

Description and Removal and Installation Procedures.

Sections containing procedures also contain introductions to those procedures. Be

sure to read these introductions because they provide information needed to do the

service correctly and efficiently. The following are brief descriptions of each

manual section.

Specifications contains a description of the sync pulse generator and the

characteristics that apply to it.

Operating Information includes general information and operating

instructions.

Theory of Operation contains circuit descriptions that support service to the

module level.

Performance Verification contains procedures for confirming that a sync pulse

generator functions properly and meets warranted characteristics.

Adjustment Pr ocedure contains procedures for adjusting a sync pulse generator

to meet warranted characteristics.

Maintenance contains information and procedures for performing preventive

and corrective maintenance of a sync pulse generator. These instructions

include cleaning, module removal and installation, and fault isolation to the

module level.

Options contains descriptions of factory-installed options.

Electrical Parts List contains a statement referring you to Mechanical Parts

List section, where both the electrical and mechanical modules are listed.

Diagrams contains a block diagram and an interconnection diagram.

Mechanical Parts List includes a table of all replaceable modules, their

descriptions, and their Tektronix part numbers.

SPG600 & SPG300 Sync Pulse Generators Service Manual xiii

Page 18

Preface

Manual Conventions

This manual uses certain conventions with which you should become familiar.

Some sections of the manual contain procedures for you to perform. To keep those

instructions clear and consistent, this manual uses the following conventions:

Names of front-panel controls and menus appear in the same case (initial

capitals, all uppercase, etc.) in the manual as is used on the sync pulse

generator front panel and menu.

Instruction steps are numbered unless there is only one step.

Bold text refers to specific interface elements that you are instructed to select,

click, or clear.

Example: Press the SYSTEM button to display the System menu.

Italic text refer to document names or sections. Italics are also used in NOTES,

CAUTIONS, and WARNINGS.

Modules

Safety

Throughout this manual, any replaceable component, assembly, or part of the sync

pulse generator is referred to generically as a module. In general, a module is an

assembly (like a circuit board), rather than a component (like a resistor or an

integrated circuit). Sometimes a single component is a module. For example, the

chassis of the sync pulse generator is a module.

Symbols and terms related to safety appear in the General Safety Summary and

Service Safety Summary near the beginning of this manual.

Finding Other Information

Other documentation for the sync pulse generator includes:

The SPG600 & SPG300 Sync Pulse Generators User Manual (Tektronix part

The SPG600 & SPG300 Sync Pulse Generators Quick Reference Manual

Example: Section 10, Mechanical Parts List, lists all field replaceable modules

by part number.

number 071-1340-XX) contains a tutorial to quickly describe how to operate

the sync pulse generator. It also includes an in-depth discussion on how to

more completely use the sync pulse generator features.

(Tektronix part number 071-1341-XX) contains information to enable you to

quickly get an overview of front-panel buttons, rear-panel connectors, and

menus.

xiv SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 19

Introduction

This manual contains information needed to properly service the SPG600 and

SPG300 Sync Pulse Generators, as well as general information critical to safe and

effective servicing.

To prevent personal injury or damage to the sync pulse generator, consider the

following before attempting service:

The procedures in this manual should be performed only by a qualified service

person.

Read the General Safety Summary and the Service Safety Summary , beginning

on page ix.

Read Installation in section 2, Operating Information.

When using this manual for servicing, be sure to follow all warnings, cautions, and

notes.

Performance Check Interval

Strategy for Servicing

Generally, the performance check described in section 4, Performance

Verification, should be done every 12 months. In addition, a performance check is

recommended after module replacement.

If the sync pulse generator does not meet performance criteria, repair is necessary.

Throughout this manual, the term “module” refers to any field-replaceable

component, assembly, or part of the sync pulse generator.

This manual contains all the information needed for periodic maintenance of the

sync pulse generator (examples of such information are procedures for checking

performance).

Further, this manual contains all information for corrective maintenance down to

the module level. T o isolate a failure to a module, use the fault isolation procedures

found in Troubleshooting, part of section 6, Maintenance. To remove and replace

any field module, follow the instructions in Removal and Installation Procedures,

also part of section 6. After isolating a faulty module, replace it with a fully-tested

module obtained from the factory. Section 10, Mechanical Parts List, contains part

number and ordering information for all replaceable modules.

SPG600 & SPG300 Sync Pulse Generators Service Manual xv

Page 20

Introduction

Tektronix Service Offerings

T ektronix provides service to cover repair under warranty as well as other services

that may provide a cost-effective answer to your service needs.

Whether providing warranty repair service or any of the other services listed

below, Tektronix service technicians are well trained to service the sync pulse

generator. They have access to the latest information on improv ements to the sync

pulse generator as well as the latest new options.

Warranty Repair Service

Self Service

Tektronix warrants this product for one year from date of purchase. The warranty

appears after the title page in this manual. T ektronix technicians pr ovide warranty

service at most Tektronix service locations. The Tektronix product catalog lists all

worldwide service locations or you can visit our web site for service information:

www.tektronix.com.

Tektronix supports repair to the module level by providing Module Exchange.

Module Exchange. This service reduces down-time for repair by allowing you to

exchange most modules for remanufactured ones. Each module comes with a

90-day service warranty.

For More Information. Contact your local T ektronix service center or sales engineer

for more information on any of the repair or adjustment services just described.

xvi SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 21

Specifications

Page 22

Page 23

Product Overview

The SPG600 and SPG300 Sync Pulse Generators are designed for high stability

master sync operation. The sync pulse generators provide a wide range of accurate

reference signals including analog video, analog black burst, serial digital video,

serial digital black, and AES/EBU digital audio.

Key Features

The sync pulse generator features include:

High stability internal reference

Genlocks to the following signals:

NTSC/PAL black burst signal

1, 5, 10 MHz, and NTSC/PAL Fsc CW signals

Serial digital video signal outputs

AES/EBU serial digital audio outputs (XLR and BNC)

Overlay a logo or ID text on the color bars or test signal

Up to 16 channels of embedded audio

48 kHz word clock output

GPI (general purpose interface) for error status report and user preset

Ethernet (100 BASE-T) interface remote control

Table 1-1: Output capability of the SPG600 and the SPG300

SPG600 outputs

Signal Standard Option 02 Option 03 SPG300 outputs

Serial digital

Video 2 2 4 2

BNC audio 4 4 4 None

XLR audio* 2 2 2 2

Analog video 4 8 4 4

48 kHz word clock Yes Yes Yes Yes

* The XLR outputs can be set to either serial digital or analog audio ports.

SPG600 & SPG300 Sync Pulse Generators Service Manual 1-1

Page 24

Product Overview

1-2 SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 25

Specifications

General Characteristics

This section is divided into two subsections. General Characteristics lists the

electrical, mechanical, and environmental characteristics of the Sync Pulse

Generator. Certifications and Compliances lists the national and international

standards to which the sync pulse generator complies.

This section lists the electrical, mechanical, and environmental characteristics of

the sync pulse generator.

All listed specifications are guaranteed unless labeled with typical. Typical

specifications are provided for your convenience but are not guaranteed.

Performance Conditions

The electrical characteristics listed on the following pages are valid under the

following conditions:

The sync pulse generator must be in an environment where the temperature,

altitude, humidity, and vibration conditions are within the operating limits

described in Table 1-11 on page 1-11.

The sync pulse generator must have a warm-up period of at least 20 minutes.

The sync pulse generator must have been calibrated and adjusted at an ambient

temperature between +20 °C and +30 °C.

The sync pulse generator must be operating at an ambient temperature between

0 °C to +40 °C, unless otherwise noted.

SPG600 & SPG300 Sync Pulse Generators Service Manual 1-3

Page 26

Specifications

Table 1-1: Reference Inputs

Characteristic Performance requirement Reference information

Input connector type 75 Ω BNC X 2, loopthrough

Return loss > 40 dB to 5 MHz

Genlock inputs NTSC Burst

525 Sync

PA L B ur s t

PAL Sync

CW 1 MHz, 5 MHz, NTSC Burst, PAL Burst,

and 10 MHz

Input requirements

Reference inputs

Amplitude -6 dB to 6 dB

S/N ratio > 40 dB

SCH phase 40 °

CW amplitude 1 to 2.5 Vp-p

Pull-in range ± 5 ppm

Jitter

Burst < 0.5 °

Sync < 1 ns

Genlock time offset range

Range Full color frame

Resolution < 0.5 degree of subcarrier

Table 1-2: Analog outputs (standard and Option 02)

Characteristic Performance requirement Reference information

Output connector type BNC

Number of outputs

Standard 4 CH1 to CH4

Option 02 (SPG600 only) 8 CH1 to CH8

Output impedance 75 Ω

Return loss > 30 dB to 5 MHz

Formats NTSC, NTSC No Setup, and PAL

Burst amplitude accuracy ± 5%

Burst frequency accuracy ± 1 Hz of burst frequency

Burst frequency long term stability < 1 ppm/year

Sync amplitude accuracy ± 3%

Blanking level ± 50 mV

SCH phase accuracy ± 5 °

1-4 SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 27

Specifications

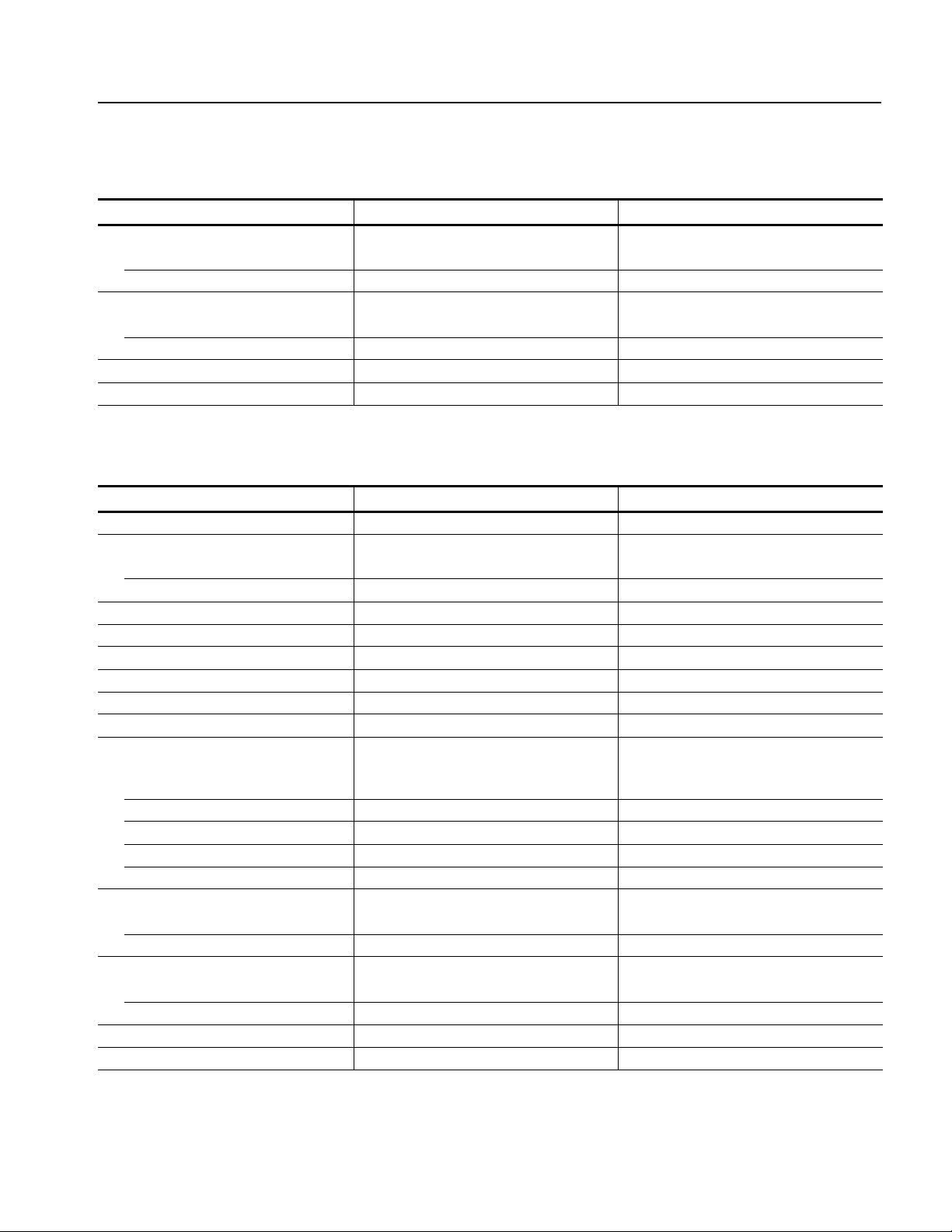

Table 1-2: Analog outputs (standard and Option 02) (cont.)

Characteristic Performance requirement Reference information

Timing offset

Range Full color frame

Resolution < 1/27 MHz

Output signals

NTSC and NTSC No Setup

PA L

ID text Maximum 20 characters Blinking interval: Fast, Slow, or OFF

Logo Gray scale, 4 level Blinking interval: Fast, Slow, or OFF

Table 1-3: Serial digital interface (standard and Option 03)

Characteristic Performance requirement Reference information

Output connector type BNC

Number of outputs

Standard 2 SDI 1 and SDI 2

Option 03 (SPG600 only) 4 SDI 1, SDI 2, SDI 3, and SDI 4

Output impedance 75 Ω

Return loss > 15 dB

Formats 525-270, 625-270 (270 Mbps)

Signal amplitude, typical 800 mV ± 10%

Rise and fall time 0.4 ns to 1.5 ns 20% to 80%

Jitter, typical < 0.2 UI

Embedded audio The settings of the channels 9 to 16 are a

copy of those of the channels 1 to 8.

Number of channels 16 (4 groups)

Frequency Silence to 20 kHz 31 descrete settings

Level -60 dBFS to 0 dBFS 1 dB resolution

Preemphasis None, CD, and FCC

Click 1 s, 2 s, 3 s, 4 s, and Off

Timing offset

Range Full color frame

Resolution < 1/27 MHz

Output signals

525-270

625-270

ID text Maximum 20 characters Blinking interval: Fast, Slow, or OFF

Logo Gray scale, 4 level Blinking interval: Fast, Slow, or OFF

SPG600 & SPG300 Sync Pulse Generators Service Manual 1-5

Page 28

Specifications

Table 1-4: AES/EBU audio outputs

Characteristic Performance requirement Reference information

Output connector type

SPG600 75 Ω BNC: 4, XLR: 2

SPG300 XLR: 2

Number of outputs

SPG600 8 1+2, 3+4, 5+6, and 7+8

SPG300 4 1+2 and 3+4

Quantized resolution 20 or 24 bits (user selectable)

Audio parameters

Frequency Silence to 20 kHz 31 discrete settings

Level -60 dBFS to 0 dBFS 1 dB resolution

Preemphasis None, CD, and FCC

Click 1 s, 2 s, 3 s, 4 s, and Off

Output level 1 V ± 0.1 V

5 V ± 0.3 V

Required receiver termination 75 Ω ± 10% for unbalanced to BNC

Terminated 75 Ω, unbalanced to BNC

Terminated 110 Ω, balanced to XLR

110 Ω ± 10% for balanced to XLR

Rise and fall time 30 ns to 44 ns

5 ns to 30 ns

Jitter ± 8 ns

Timing offset

Range 160 ms

Resolution 1 µs

Word clock

Connector BNC

Frequency 48 kHz

Level CMOS compatible

Impedance 75 Ω ± 10%

10% to 90% to BNC

10% to 90% to XLR

1-6 SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 29

Specifications

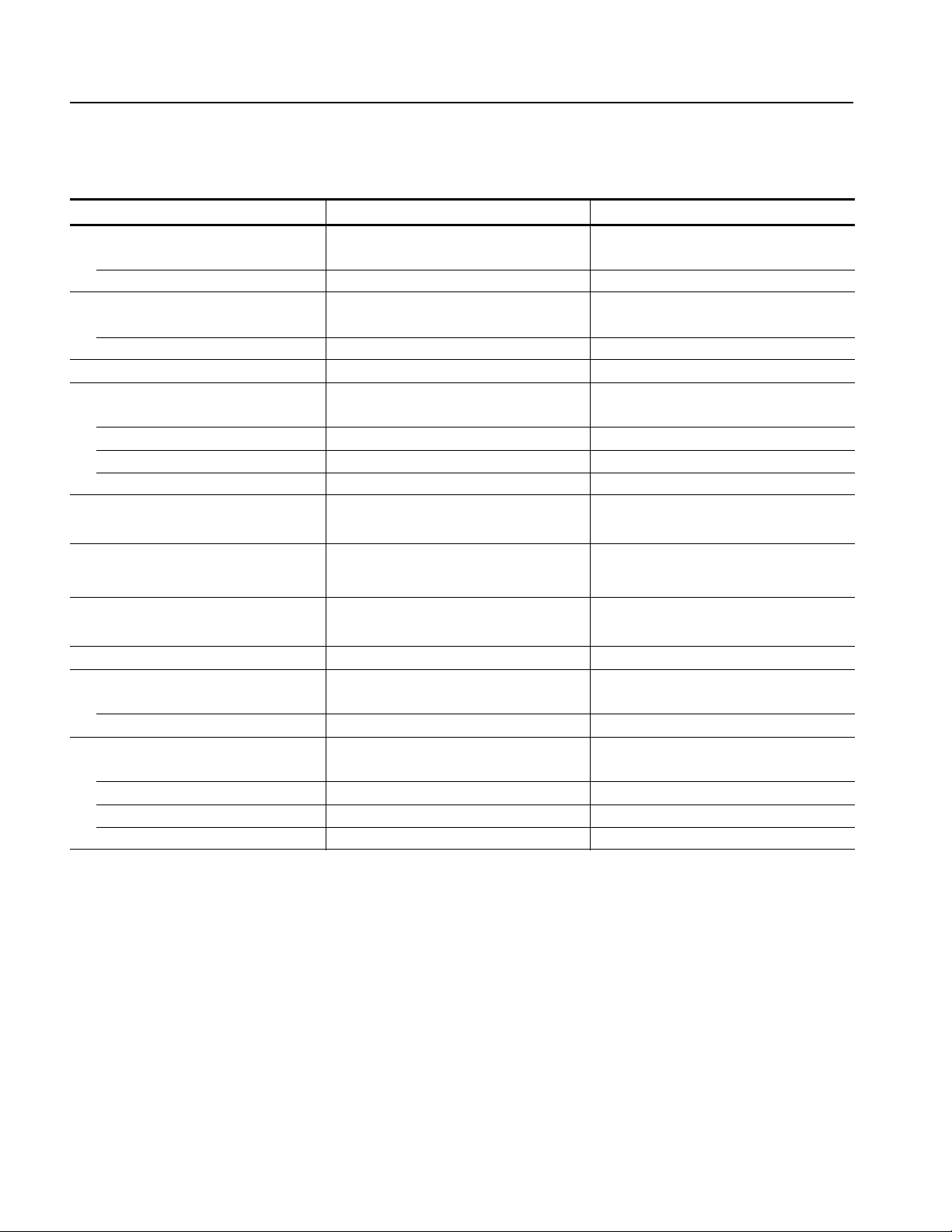

Table 1-5: Analog audio outputs

Characteristic Performance requirement Reference information

Output connector type XLR

Number of channels 2 1+2/RIGHT and 3+4/LEFT

Output impedance 12 Ω

Audio parameters

Frequency Silence to 20 kHz 31 discrete settings

Level -48 dBu to 12 dBu 1 dB resolution

Click 1 s, 2 s, 3 s, 4 s, and Off

Table 1-6: GPI (general purpose interface)

Characteristic Performance requirement Reference information

Output connector type D-sub, 9 pin

Outputs Pin 1: Error output (go to low when an error

Output level < 0.4 V Measured at 100 mA sink or maximum 4 Ω

Inputs Pin 3: Input 1

occurs)

Pin 9: GND

Active low input

Pin 4: Input 2

Pin 5: Input 3

Pin 6: GND

Input level TTL compatible Inputs are pulled up with 10 kΩ

Table 1-7: SNMP error report

Characteristic Performance requirement Reference information

Protocol SNMP v1, v2c

Alarm The same alarm as the GPI will be reported.

Status Serial number, firmware and hardware

version, hardware configuration/option, etc.

SPG600 & SPG300 Sync Pulse Generators Service Manual 1-7

Page 30

Specifications

Table 1-8: AC power source

Characteristic Performance requirement Reference information

Rating voltage 100 V to 240 V, 50/60 Hz

Voltage range 90 V to 250 V, 50/60 Hz

Power consumption SPG600: 85 VA, 35 W

SPG300: 65 VA, 30 W

Surge current < 20 A: SPG600 and SPG300

Table 1-9: Clearance

Characteristic Performance requirement Reference information

Side 5 cm (2 in)

Rear 7.5 cm (3 in)

Table 1-10: Mechanical characteristics

Characteristic Description

SPG600

Dimensions See Figure 1-1.

Height 43.6 mm (1.7 in)

Width 482.5 mm (19.0 in)

Depth 557.5 mm (21.9 in)

Net weight Approximately 6 kg (with rack rail)

SPG300

Dimensions See Figure 1-2.

Height 43.6 mm (1.7 in)

Width 206.2 mm (8.1 in)

Depth 435.7 mm (17.2 in)

Net weight Approximately 2.5 kg

1-8 SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 31

13.0 mm

(0.5 in)

115.7 mm

320.7 mm

(12.6 in)

(4.6 in)

439.4 mm (17.3 in)

425.4 mm (16.7 in)

Specifications

15.4 mm

(0.6 in)

514.5 mm

(20.3 in)

544.5 mm

(21.4 in)

43.6 mm

(1.7 in)

482.5 mm (19.0 in)

Figure 1-1: SPG600 dimensions

SPG600 & SPG300 Sync Pulse Generators Service Manual 1-9

Page 32

Specifications

13.5 mm

(0.5 in)

15.4 mm

(0.6 in)

422.2 mm

(16.6 in)

206.2 mm (8.1 in)

Figure 1-2: SPG300 dimensions

43.6 mm

(1.7 in)

1-10 SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 33

Table 1-11: Environmental characteristics

Characteristic Description

Temperature

Operating 0 °C to +40 °C

Nonoperating -20 °C to +60 °C

Relative humidity

Operating 20% to 80% relative humidity (% RH) at up to +40 °C, noncondensing.

Nonoperating 5% to 90% relative humidity (% RH) at up to +60 °C, noncondensing.

Attitude

Operating To 3,000 m (10,061 feet)

Nonoperating To 12,192 m (40,000 feet)

Vibration

Operating 2.65 m/s

Nonoperating 22.3 m/s

Shock

Nonperating 294 m/s

2

(0.27 Grms), 5 Hz to 500 Hz, 10 minutes per axis, three axes.

2

(2.28 Grms), 5 Hz to 500 Hz, 10 minutes per axis, three axes.

2

(30 G), half-sine, 11 ms duration.

Specifications

SPG600 & SPG300 Sync Pulse Generators Service Manual 1-11

Page 34

Specifications

1-12 SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 35

Operating Information

Page 36

Page 37

Installation

This section contains the following topics:

Supplying operating power

Operating environment

Applying and interrupting power

Repackaging instructions

Supplying Operating Power

NOTE. Read all information and heed all warnings in this subsection before

connecting the sync pulse generator to a power source.

WARNING. AC POWER SOURCE AND CONNECTION. The sync pulse generator

operates from a single-phase power source. It has a three-wire power cord and

two-pole, three-terminal grounding type plug. The voltage to ground (earth) from

either pole of the power source must not exceed the maximum rated operating

voltage, 250 volts.

Before making connection to power sour ce, be sur e the sync pulse generator has a

suitable two-pole, three-terminal grounding-type plug.

GROUNDING. This instrument is safety Class 1 equipment (IEC designation). All

accessible conductive parts are directly connected through the grounding

conductor of the power cord to the grounded (earthing) contact of the power plug.

SPG600 & SPG300 Sync Pulse Generators Service Manual 2-1

Page 38

Installation

WARNING. The power input plug must be inserted only in a mating r eceptacle with

a grounding contact where earth ground has been verified by a qualified service

person. Do not defeat the grounding connection. Any interruption of the gr ounding

connection can create an electric shock hazard.

For electric shock protection, the grounding connection must be made before

making connection to the instrument’s input or output terminals.

Power Cord Information

A power cord with the appropriate plug configuration is supplied with each sync

pulse generator. Table 2-1 gives the color-cording of the conductors in the power

cord. If you require a power cord other than the one supplied, refer to Table 2-2,

Power cord identification.

Table 2-1: Power-cord conductor identification

Conductor Color Alternate color

Ungrounded (Line) Brown Black

Grounded (Neutral) Light Blue White

Grounded (Earthing) Green/Yellow Green

2-2 SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 39

Installation

.

Table 2-2: Power cord identification

Plug configuration Normal usage Option number

North America

115 V

Standard (A0)

Universal Euro

220 V

United Kingdom

240 V

Australia

240 V

North America

250 V

Switzerland

240V

Japan

100 V

A1

A2

A3

A4

A5

A6

Operating Voltage

China

240 V

No power code supplied. A99

The sync pulse generator operates with any line voltage from 90-250 VAC

A10

RMS

with line frequency 50 or 60 Hz. Before plugging the cord into the outlet, be sure

that the line voltage is in the proper range.

SPG600 & SPG300 Sync Pulse Generators Service Manual 2-3

Page 40

Installation

Operating Environment

The following environment requirements are provided to ensure proper operation

and long instrument life.

Operating Temperature

Ventilation Requirements

Operate the sync pulse generator where the ambient air temperature is from 0 ºC to

+40 ºC. Store the sync pulse generator in ambient temperatures from -20 ºC to

+60 ºC. After storage at temperatur es outside the operating limits, allow the chassis

to stabilize at a safe operating temperature before applying power.

Leave space for cooling by ensuring standard side clearance for rack mounting or

2 inches (5.1 cm) of side clearance for countertop use. Also, ensure sufficient rear

clearance (approximately 3 inches) so that cables are not damaged by sharp bends.

Applying and Interrupting Power

Consider the following information when you power on or power off the sync pulse

generator, or when external power loss occurs.

Connect the Power Cable

Connect the power cable to the instrument first, and then connect it to the AC

power source. Note that connecting the power cable causes the instrument to power

on. Refer to Table 2-2 for power cord identification.

CAUTION. The instrument does not have a power switch. When you connect the

power cable to AC line connector, the instrument powers on.

After connecting the power, make sure that the fan inside the instrument is

working. If the fan is not working, turn off the power by disconnecting the power

cable from the AC power source and contact your local Tektronix Field Office or

representative.

Power Off

2-4 SPG600 & SPG300 Sync Pulse Generators Service Manual

To power off the sync pulse generator, disconnect the power cable from the AC

power source.

Page 41

Repackaging Instructions

When you ship this instrument, use the original packaging material if possible. If

the original packaging is unfit for use or is not available, repackage the instrument

using the following procedure:

1. Obtain a corrugated cardboard shipping carton having inside dimensions at

2. If the instrument is being shipped to a Tektronix Service Center for repair or

Installation

least six inches greater than the instrument dimensions and having a carton test

strength of at least 125 kg (275 pounds).

calibration, attach a tag to the instrument showing the following information:

The owner of the instrument (with address).

The name of a person at your company who may be contacted if additional

information is needed.

The complete instrum e nt type and serial number.

A description of the service required.

Installed Options

3. Wrap the instrument with polyethylene sheeting or equivalent to protect the

outside finish and prevent entry of packing materials into the instrument.

4. Cushion the instrument on all sides by tightly packing dunnage or urethane

foam between the carton and the instrument, allowing for three inches

(7.62 cm) of padding on each side (including top and bottom).

5. Seal the carton with shipping tape or with an industrial stapler.

6. Mark the carton with the address of the Tektronix Service Center and your

return address in one or more prominent locations.

Y o ur instrument may be equipped with one or more instrumen t options. Except for

the line-cord options described by Table 2-2 on page 2-3, all options are listed and

described in Section 7, Options. For further information and prices of instrument

options, see your Tektronix Products catalog or contact your Tektronix Field

Office.

SPG600 & SPG300 Sync Pulse Generators Service Manual 2-5

Page 42

Installation

2-6 SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 43

Menus

Video Menu

This section describes all of the available sync pulse generator menus and

submenus. The following menus are available from the front-panel menu buttons:

Video menu

Audio menu

Genlock menu

System menu

Pressing the VIDEO button displays the V ideo menu. This menu lets you set output

signals, timing of the output signals, overlay, and SDI parameters. Use the up (

or down (

menu diagram. Use the left (

submenus in each Video menu.

T) arrow button to scroll through the menu. Figure 2-1 shows the Video

W) or right (X) arrow button to select functions or

S)

SPG600 & SPG300 Sync Pulse Generators Service Manual 2-7

Page 44

Menus

Press the VIDEO button

ANALOG SYNC (STD)

Black Burst ↵

ANALOG SYNC (OPT)

Black Burst ↵

TEST SIGNAL (ANALOG)

Standard

TEST SIGNAL (SDI)

Standard

TIMING (ANALOG)

CH-1

TIMING (SDI)

SDI-1

Black Burst

BB with Fld REF

Black Burst

BB with Fld REF

ENTER

Standard

1

Option

CANCEL

ENTER

Standard

2

Option

CANCEL

CH-1 CH-5

CH-2 CH-6

CH-3 CH-7

CH-4 CH-8

SDI-1 SDI-3

SDI-2 SDI-4

2

2

SPG600 Option 02 only

To Test signal (analog) submenu

(page 2-9)

To Test signal (SDI) submenu

(page 2-10)

1

ENTER

1

1

1

CANCEL

To Timing (analog) submenu

(page 2-11)

ENTER

To Timing (SDI) submenu

(page 2-11)

CANCEL

ENTER

OVERLAY

Analog (STD)

Analog (STD) Analog (OPT)

SDI (STD) SDI (OPT)

2

1

To Overlay submenu

(page 2-12)

CANCEL

ENTER

PA R A M E T E R

SDI (STD)

SDI (STD)

SDI (OPT)

2

To SDI Parameters submenu

(page 2-15)

CANCEL

1 SPG600 Option 02 only

2 SPG600 Option 03 only

Figure 2-1: Video menu diagram

2-8 SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 45

Menus

Test Signal (Analog)

Submenu

This menu allows you to select a test signal for analog output(s). Use the up (S) or

down (

signal (analog) submenu diagram. Use the left (

T) arrow button to scroll through the menu. Figure 2-2 shows the Test

W) or right (X) arrow button to

select a signal.

Select TEST SIGNAL (ANALOG) in the Video menu

COLOR BAR

100% Color Bars

FLAT FIELD

0% Flat Field

LINEARITY

10 Step

Select a signal

Select a signal

Select a signal

MONITOR

100% Red Field

MULTIBURST

100% Multiburst

SWEEP

100% Sweep

PULSE BAR

2T Pulse & Bar

OTHE R

FCC Composite

Select a signal

Select a signal

Select a signal

Select a signal

Select a signal

Figure 2-2: Test signal (analog) submenu diagram

SPG600 & SPG300 Sync Pulse Generators Service Manual 2-9

Page 46

Menus

Test Signal (SDI) Submenu

Select TEST SIGNAL (SDI) in the Video menu

COLOR BAR

SMPTE Color Bars

FLAT FIELD

0 % Flat Field

LINEARITY

10 Step

This menu allows you to select a serial digital test signal for the SDI 2 output(s).

Use the up (

shows the T est signal (SDI) submenu diagram. Use the left (

S) or down (T) arrow button to scroll through the menu. Figure 2-3

W) or right (X) arrow

button to select a signal.

Select a signal

Select a signal

Select a signal

SWEEP

100% Sweep

SDI

Checkfield

TIMING

2.5 MHz Bowtie

Select a signal

Select a signal

Select a signal

MONITOR

2 Pedestal & Pluge

MULTI BURST

60% Y Multiburst

Figure 2-3: Test signal (SDI) submenu diagram

Select a signal

Select a signal

PULSE BAR

2T Pulse & Bar

OTHER

Chroma Freq. Resp.

REC 801

100% Color Bars

Select a signal

Select a signal

Select a signal

2-10 SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 47

Menus

Timing (Analog) Submenu

This menu allows you to adjust the selected analog output timing offset relative to

the genlock signal or the internal reference signal. Use the up (

S) or down (T)

arrow button to scroll through the menu. Figure 2-4 shows the Timing (analog)

submenu diagram.

Select TIMING (ANALOG) in the VIDEO menu

TIMING : VERTICAL

0 Line (s)

TIMING : HORIZONTAL

0.0000 µsec

TIMING : FINE

0.0 nsec

Set the vertical timing in 1 line steps

Set the horizontal timing in 1 clock steps

Set the horizontal timing in 0.1 ns steps

Option 01 only

Timing (SDI) Submenu

Figure 2-4: Timing (analog) submenu diagram

This menu allows you to adjust the timing offset of the selected serial digital output

relative to the genlock signal or the internal reference signal. Use the up (

down (

T) arrow button to scroll through the menu. Figure 2-5 shows the Timing

S) or

(SDI) submenu diagram.

Select TIMING (SDI) in the Video menu

TIMING : VERTICAL

0 Line (s)

TIMING : HORIZONTAL

0.00

µsec

Set the vertical timing in 1 line steps

Set the horizontal timing in 1 clock steps

Figure 2-5: Timing (SDI) submenu diagram

SPG600 & SPG300 Sync Pulse Generators Service Manual 2-11

Page 48

Menus

Overlay Submenu

This menu allows you to select an item (logo or ID text) that is overlaid on the

output test signal. Use the up (

S) or down (T) arrow button to scroll through the

menu. Figure 2-6 shows the Overlay submenu diagram.

NOTE. The Overlay submenu contents are common for both analog and serial

digital signals except for the menu title on the first line (ANALOG or SDI).

Select OVERLAY in the Video menu

ENTER

: ANALOG (STD)

Logo

: ANALOG (STD)

Blink OFF ↵

Logo

ID Text

CANCEL

OFF

Fast

Low

To Logo submenu (page 2-13)

To ID text submenu (page 2-14)

Figure 2-6: Overlay submenu diagram

2-12 SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 49

Menus

Logo Submenu

This menu allows you to overlay and position a logo graphic on an output test

signal. Use the up (

S) or down (T) arrow button to scroll through the menu.

Figure 2-7 shows the Logo submenu diagram.

Select Logo in the Overlay submenu

: LOGO

Logo: OFF ↵

: LOGO

X : 0.0 % APH

: LOGO

Y : 0.0 % APH

: LOGO : SAVE

Press ENTER to sav

↵

ENTER

Select OFF or a logo

Set the horizontal position

Set the vertical position

Save the display position for the logo

Figure 2-7: Logo submenu diagram

You can create a logo file using the Logo Generator application. Refer to the

SPG600 & SPG300 Sync Pulse Generators User Manual included on the product

CD-ROM for detailed information for using Logo Generator.

SPG600 & SPG300 Sync Pulse Generators Service Manual 2-13

Page 50

Menus

ID Text Submenu

This menu allows you to edit and position a text string that is overlaid on the output

test signal. Use the up (

S) or down (T) arrow button to scroll through the menu.

Figure 2-8 shows the ID text submenu diagram.

Select ID Text in the Overlay submenu

: ID TEXT

Statu s: Dis abl e ↵

: ID TEXT

X : 10.0 %APH

: ID TEXT

Y : 80.0 %APH

: ID TEXT : EDIT

ENTER

Disable

Enable

Set the horizontal position

Set the vertical position

Edit text

: ID TEXT : SAVE

Press ENTER to sav

↵

Figure 2-8: ID text submenu diagram

ENTER

Save the text to the signal file

2-14 SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 51

Menus

SDI Parameters Submenu

This menu allows you to select which component(s) of the serial digital signal is

(are) available, the serial digital signal resolution, and the insertion of the EDH

(Error Detection and Handling) bits. Use the up (

S) or down (T) arrow button to

scroll through the menu. Figure 2-9 shows the SDI parameters submenu diagram .

Select PARAMETER in the VIDEO menu

Y,Cb,Cr Cb,Cr

: SDI (STD) COMPONENT

Y, Cb, Cr ↵

: SDI (STD) PRECISION

10-bit ↵

: SDI (STD) EDH

Enable ↵

YY,Cb

Cb Y,Cr

Cr

10-bit

8-bit

Disable

Enable

Figure 2-9: SDI parameters submenu

SPG600 & SPG300 Sync Pulse Generators Service Manual 2-15

Page 52

Menus

Audio Menu

Pressing the AUDIO button displays the Audio menu. This menu lets you set the

parameters of the AES/EBU audio and embedded audio in the serial digital signal.

Use the up (

shows the Audio menu.

Press the AUDIO button

S) or down (T) arrow button to scroll through the menu. Figure 2-10

AES/EBU

EMBEDDED (STD/BLK)

Group 1

EMBEDDED (STD/TEST)

Group 1

EMBEDDED (OPT/BLK)

Group 1

EMBEDDED (OPT/TEST)

Group 1

ANALOG

Left

ENTER

CANCEL

To AES/EBU submenu

(page 2-17

Group 1 Group 3

Group 2 Group 4

Group 1 Group 3

Group 2 Group 4

Group 1 Group 3

Group 2 Group 4

Group 1 Group 3

Group 2 Group 4

Left

Right

Both

ENTER

CANCEL

ENTER

To Embedded submenu

(page 2-18)

CANCEL

ENTER

To Embedded submenu

(page 2-18)

CANCEL

ENTER

To Embedded submenu

(page 2-18)

CANCEL

ENTER

To Embedded submenu

(page 2-18)

CANCEL

SPG600 Option 03 only

To Audio channel submenu

(page 2-19)

Figure 2-10: Audio menu diagram

NOTE. The ANALOG menu item is only available when you select Analog Audio in

the CONFIGRATION: XLR OUTPUT menu.

2-16 SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 53

Menus

AES/EBU Submenu

Select AES/EBU in the Audio menu

AES/EBU

Channel : 1

AES/EBU

Emp has is: NO ↵

AES/EBU

Resolution: 20 bi ts ↵

This menu allows you to select an audio channel, the state of the audio emphasis

bits, the resolution of the serial digital audio signal data, and the audio timing. Use

the up (

S) or down (T) arrow button to scroll through the menu. Figure 2-11

shows the AES/EBU submenu diagram.

Channel: 1 Channel: 6

Channel: 2 Channel: 7

Channel: 3 Channel: 8

Channel: 4 Channel: ALL

Channel: 5

Emphasis: NO

Emphasis: CD

Emphasis: CCITT

Resolution: 20 bits

Resolution: 24 bits

1

1

ENTER

1

1

1

CANCEL

To Audio channel submenu

(page 2-19)

1 SPG600 only

AES/EBU

Delay: 0.0

µsec

Figure 2-11: AES/EBU submenu diagram

Set the audio timing in 1 µs steps.

SPG600 & SPG300 Sync Pulse Generators Service Manual 2-17

Page 54

Menus

Embedded Submenu

Select EMBEDDED in the Audio menu

STD/BLK : GRP-1

n Status: Disable ↵

STD/BLK : GRP-1

Channel: 1

This menu allows you to enable or disable the generation of embedded audio, select

an audio channel, set the state of the audio emphasis bits, and set the resolution of

the serial digital audio signal data. Use the up (

S) or down (T) arrow button to

scroll through the menu. Figure 2-12 shows the Embedded submenu diagram.

NOTE. The Embedded submenu contents are common for the serial digital black

signals and the serial digital test signals except for the menu title on the first line.

Status: Disable

Status: Enable

Channel: 1

Channel: 2

Channel: 3

Channel: 4

Channel: ALL

ENTER

To Audio Channel submenu

(page 2-19)

CANCEL

STD/BLK : GRP-1

Emphasis: NO ↵

STD/BLK : GRP-1)

Sync: Frame ↵

STD/BLK : GRP-1

Resolution: 20 bits ↵

Figure 2-12: Embedded submenu diagram

Emphasis: NO

Emphasis: CD

Emphasis: CCITT

Sync: Frame

Sync: w/o Frame No.

Sync: Async

Resolution: 20 bits

Resolution: 24 bits

2-18 SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 55

Menus

Audio Channel Submenu

This menu allows you to set the frequency, amplitude, and audio click of the

selected audio channel. Use the up (

S) or down (T) arrow button to scroll through

the menu items. Figure 2-13 shows the Audio channel submenu diagram.

NOTE. The Audio channel submenu contents are common for AES/EBU audio,

Embedded audio, and Analog audio except for the menu title in the first line and

some parameter settings.

Select a channel in the AES/EBU or Embedded

submenu, or Audio: ANALOG menu item

Inactive* 300 Hz 1200 Hz 4000 Hz 12000 Hz

Silence 400 Hz 1500 Hz 4800 Hz 15000 Hz

AES/EBU : CH-1

Freq.: 1000 Hz ↵

AES/EBU : CH-1

Ampl.: -20.0 dBFS

AES/EBU : CH-1

Audio Click: OFF ↵

50 Hz 500 Hz 1600 Hz 5000 Hz 16000 Hz

100 Hz 600 Hz 2000 Hz 6000 Hz 20000 Hz

150 Hz 750 Hz 2400 Hz 8000 Hz

200 Hz 800 Hz 3000 Hz 9600 Hz

250 Hz 1000 Hz 3200 Hz 10000 Hz

-60 dBFS to 0 dBFS (for AES/EBU and embedded audio)

-48 dBu to 12 dBu (for analog audio)

OFF

1 Sec

2 Sec

3 Sec

4 Sec

* Not available for analog audio

Figure 2-13: Audio channel submenu diagram

SPG600 & SPG300 Sync Pulse Generators Service Manual 2-19

Page 56

Menus

Genlock Menu

Pressing the GENLOCK button displays the Genlock menu. This menu lets you

select the genlock source, set the timing offset, and set the instrument actions when

lock is lost. Use the up (

S) or down (T) arrow button to scroll through the menu.

Figure 2-14 shows the Genlock menu diagram.

Press the Gen Lock button

GENLOCK STATUS

Internal

Internal CW 1 MHz

GENLOCK SOURCE

Internal ↵

525 SYNC CW 3.58 MHz

NTSC Burst CW 4.43 MHz

625 SYNC CW 5 MHz

PAL Burst CW 10 MHz

GENLOCK TIMING

LOCK LOSS ACTION

Internal Mode ↵

Figure 2-14: Genlock menu diagram

ENTER

To Genlock timing submenu

(page 2-21)

CANCEL

Internal Mode

Stay Mode

2-20 SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 57

Menus

Genlock Timing Submenu

This menu allows you to adjust the timing offset of the input signal relative to the

internal reference signal (frame reset signal). Use the up (

S) or down (T) arrow

button to scroll through the menu. Figure 2-15 shows the Genlock timing submenu

diagram.

Select GENLOCK TIMING in the Genlock menu

TIMING : VERTICAL

0 Line (s)

TIMING : HORIZONTAL

µs

0.0000

TIMING : FINE

0.0 nsec

Set the vertical timing in 1 line steps

Set the horizontal timing in 1 clock steps

Set the horizontal timing in 0.1 ns steps

Figure 2-15: Genlock timing submenu diagram

SPG600 & SPG300 Sync Pulse Generators Service Manual 2-21

Page 58

Menus

System Menu

Pressing the SYSTEM button displays the System menu. This menu lets you set the

system-related settings such as network parameters and output configuration. Use

the up (

shows the System menu diagram.

Press the SYSTEM button

S) or down (T) arrow button to scroll through the menu. Figure 2-16

PRESET

LCD CONTRAST

Low << 17 >> HIGH

FRONT PANEL DISABLE

Time Out: OFF ↵

NETWORK

Information

GPI

SYSTEM PARAMETER

Information

ENTER

CANCEL

ENTER

CANCEL

To Preset submenu

(page 2-23)

Adjust the display contrast

Off 10 Minute

Immediately 30 Minute

1 Minute 1 Hour

ENTER

Information

Setup

CANCEL

To GPI submenu

(page 2-26)

ENTER

Information

Setup

CANCEL

To Network information submenu (page 2-24)

To Network setup submenu (page 2-25)

To System information submenu (page 2-27)

To System setup submenu (page 2-27)

ENTER

CONFIGURATION

CANCEL

To Configuration submenu

(page 2-28)

Figure 2-16: System menu diagram

2-22 SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 59

Menus

Preset Submenu

This menu allows you to store and recall instrument configuration settings. Use the

up (

S) or down (T) arrow button to scroll through the menu items. Figure 2-17

shows the Preset submenu diagram.

Select PRESET in the SYSTEM menu

PRESET : RECALL

Power On Default

PRESET : SAVE

Power On Default

PRESET : RENAME

PRESET 1

PRESE T : DELETE

PRESET 1

↵

↵

Select a preset to recall

Select a preset number to save the current

instrument settings

ENTER

Select a preset to

rename

CANCEL

Select a preset to delete

Edit the preset name

Figure 2-17: Preset submenu diagram

SPG600 & SPG300 Sync Pulse Generators Service Manual 2-23

Page 60

Menus

Network Information

Submenu

This menu allows you to display all of the current network parameters. Use the up

(

S) or down (T) arrow button to scroll through the menu. Figure 2-18 shows

Network information submenu diagram.

Select Information in the NETWORK menu item

: IP ADDRESS

1 2 3. 1 2 3 .1 2 3 . 12 3

: SUBNET MASK

255.254.253.252

: BROADCAST ADDR

111.255.255.255

: GATEWAY ADDR

000.000.000.000

: MAC ADDRESS

00-0-95-00-01-AE

Figure 2-18: Network information submenu diagram

2-24 SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 61

Menus

Network Setup Submenu

Select Setup in the NETWORK menu item

: DHCP

Disable ↵

: IP ADDRESS

000.000.000.000

: SUBNET MASK

000.000.000.000

This menu allows you to set the sync pulse generator network parameters when

connecting to a 100BASE-T Ethernet. Use the up (

S) or down (T) arrow button

to scroll through the menu items. Figure 2-19 shows the Network setup submen u

diagram.

ENTER

ENTER

Disable

Enable

Set the address

Set the address

: SNMP TRAPS

Disable ↵

: SNMP TRAP DEST-1

000.000.000.000

: SNMP TRAP DEST-2

000.000.000.000

ENTER

ENTER

Disable

Enable

Set the address

Set the address

: BRDCAST ADDR

000.000.000.000

: GATEWAY ADDR

000.000.000.000

: WEB INTERFACE

Disable ↵

: SNMP MODE

Disable ↵

ENTER

ENTER

Figure 2-19: Network setup submenu diagram

Set the address

Set the address

Disable

Enable

Disable

Enable

: SNMP TRAP DEST-3

000.000.000.000

: SNMP TRAP DEST-4

000.000.000.000

: SNMP SET COMMUNITY

private

: SNMP GET COMMUNITY

public

ENTER

Set the address

ENTER

Set the address

ENTER

Set the string

ENTER

Set the string

SPG600 & SPG300 Sync Pulse Generators Service Manual 2-25

Page 62

Menus

GPI Submenu

This menu allows you to enable or disable the alarm signal output, reset alarm

signal output, and display the alarm status. Use the up (

S) or down (T) arrow

button to scroll through the menu. Figure 2-20 shows the GPI submenu diagram.

Select GPI in the System menu

: ALARM STATUS

No Alarm

: ALARM RESET

Press ENTER ↵

: GPI ALARM OUTPUT

Disable ↵

Disable

Enable

Figure 2-20: GPI submenu diagram

2-26 SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 63

Menus

System Information

Submenu

This menu allows you to display the system information. Use the up (S) or down

(

T) arrow button to scroll through the menu. Figure 2-21 shows the System

information submenu diagram.

Select Information in the SYSTEM PARAMETER menu item

: FPGA VERSION (STD)

A:1.3 D:1.6

: FPGA VERSION (OPT)

A:1.3 D:1.5

: F/W VERSION

1.0.3

: S/N

J310000

System Setup Submenu

: OPTION KEY

ABCDEFGHIJKLMNOPQRST

Figure 2-21: System information submenu diagram

This menu allows you to enter the option key that enables the fine timing

adjustment feature (Option 01). Figure 2-22 shows the System setup submenu

diagram.

Select Setup in the SYSTEM PARAMETER menu item

: SETUP : OPTION KEY

ABCDEFGHIJKLMNOPQRST

ENTER

Enter the option key

Figure 2-22: System setup submenu diagram

SPG600 & SPG300 Sync Pulse Generators Service Manual 2-27

Page 64

Menus

Configuration Submenu

This menu allows you to select the video standard for the output signals and

configure the output connectors. Use the up (

S) or down (T) arrow button to scroll

through the menu. Figure 2-23 shows the Configuration submenu diagram.

Select CONFIGURATION in the System menu

: VIDEO STANDARD

NTS C ↵

: ANALOG OUTPUT (STD)

BB : 1,2 ,3 TEST : 4 ↵

: ANALOG OUTPUT (OPT)

BB : 5,6 ,7 TEST : 8 ↵

: SDI OUTPUT (STD)

BLACK : 1 TES T: 2 ↵

NTSC

NTSC No Setup

PA L

BB : 1,2,3 TEST : 4

BB : 1,2 TEST : 3,4

BB : 1 TEST : 2,3,4

BB : TEST : 1,2,3,4

BB : 5,6,7 TEST : 8

BB : 5,6 TEST : 7,8

BB : 5 TEST : 6,7,8

BB : TEST : 5,6,7,8

BLACK : 1 TEST : 2

BLACK : TEST : 1,2

SPG600 Option 02 only

: SDI OUTPUT (OPT)

BLACK : 3 TES T: 4 ↵

: XLR OUTPUT

AES/EBU Audio ↵

Figure 2-23: Configuration submenu diagram

BLACK : 3 TEST : 4

BLACK : TEST : 3,4

SPG600 Option 03 only

AES/EBU Audio

Analog Audio

2-28 SPG600 & SPG300 Sync Pulse Generators Service Manual

Page 65

Theory of Operation

Page 66

Page 67

Theory of Operation

This section describes the basic operation of the major circuit blocks or modules in

the sync pulse generator. The Diagram section, beginning on page 9-1, includes

block diagrams and interconnect diagrams.

A10 Main Board (SPG600) and A50 Main Board (SPG300)

The A10/A50 Main board consists of the following blocks:

Master Clock Oscillator

Audio Clock

Video Clock

Frame Reset

D/A Converter

CPU

Flash Memory and SDRAM

Parallel to Serial Converter

This block generates a master clock signal. It is generated from the 13.5 MHz

OCXO with high accuracy. The frequency is controlled by a 16-bit D/A converter .

This block generates a 12.7 MHz clock for AES/EBU audio. The clock is phase

locked to 13.5 MHz master oscillator.

This block generates a 27 MHz clock for video signals. The clock is phase locked

to the 13.5 MHz master clock.

This block generates a 15/1.001 Hz frame reset signal for the NTSC standard and

a 6.25 Hz frame reset signal for the PAL standa rd.

The 16-bit D/A converter controls the master clock oscillator frequency.

The CPU manages all functions in the sync pulse generator.

This block consists of an 8 MB flash memory and a 16 MB SDRA M. The flash

memory holds the data for system boot (1 MB) and the program code (7 MB).

This block converts the CPU parallel bus to the original serial bus.

GPI Interface

Network Interface

DC/DC Converter

SPG600 & SPG300 Sync Pulse Generators Service Manual 3-1

This block controls the general purpose interface. The interface is used to recall a

preset and output an alarm signal.

This block controls the Ethernet interface for Web and SNMP application. The

sync pulse generator has a 100 BASE-T connector on the rear panel.

This block converts the +5 V power, supplied by the Power Supply Module, to

-5 V, 3.3 V, 8 V, and 12 V.

Page 68

Theory of Operation

Analog Genlock

Analog Generator (A10

Main Board Only)

The analog genlock consists of the following blocks:

Genlock Controller. This block controls the A/D converter, memory, and sync

separator to obtain correct digital data.

A/D Converter. The A/D converter digitizes the analog input signal to 10-bits digital

data for genlock operation. This data is read by the CPU and used to control the

master oscillator frequency.

Sync Separator. The sync separator separates the sync signal such as H sync or V

sync from the input signal.

Amp & Restorer. This block consists of amplifiers to adjust the amplitude of the

signal from the REF input and restorer to recover the DC component of the signal.

The analog generator consists of the following blocks:

Sync Memory. The sync memory is a part of the FPGA and keeps the data of the

sync pulses.

Line Memory. The line memory is a part of the FPGA and contains the active part

of the line data of the test signal. It can store up to four line data.

SDI Generator