Page 1

www.keithley.com

A GREATER MEASURE OF CONFIDENCE

Series 3400 Pulse Pattern Generators

User’s Manual

3400S-900-01 Rev. B / January 2007

Page 2

Page 3

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of

1 year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables,

rechargeable batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley Instruments representative, or contact

Keithley Instruments headquarters in Cleveland, Ohio. You will be given prompt assistance and return instructions.

Send the product, transportation prepaid, to the indicated service facility. Repairs will be made and the product

returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original

warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley Instruments’ express

written consent, or misuse of any product or part. This warranty also does not apply to fuses, software,

non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow

instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES

PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF

ITS INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN

ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT

ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT

OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

A G R E A T E R M E A S U R E O F C O N F I D E N C E

Keithley Instruments, Inc.

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139

440-248-0400 • Fax: 440-248-6168 • 1-888-KEITHLEY (534-8453) • www.keithley.com

12/06

Page 4

Page 5

Series 3400

Pulse/Pattern Generators

User’s Manual

©2007, Keithley Instruments, Inc.

Document Number:

All rights reserved.

Cleveland, Ohio, U.S.A.

3400S-900-01 Rev. B / January 2007

Page 6

Manual Print History Series 3400 Pulse/Pattern Generators User’s Manual

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this

manual. The Revision Level letter increases alphabetically as the manual undergoes subsequent

updates. Addenda, which are released between Revisions, contain important change information that the

user should incorporate immediately into the manual. Addenda are numbered sequentially. When a new

Revision is created, all Addenda associated with the previous Revision of the manual are incorporated

into the new Revision of the manual. Each new Revision includes a revised copy of this print history page.

Revision A (Document Number 3400S-900-01)..................................................... July 2006

Revision B (Document Number 3400S-900-01)...............................................January 2007

All Keithley Instruments product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand names are trademarks or registered trademarks of their respective holders.

3400S-900-01 Rev. B / January 2007

Page 7

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions

required to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using

the product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state

if the operator may perform them. Otherwise, they should be performed only by service personnel.

Safety Precautions

Service personnel are trained to work on live circuits, and perform safe installations and repairs of products. Only properly

trained service personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are rated Measurement Category I and

Measurement Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most

measurement, control, and data I/O signals are Measurement Category I and must not be directly connected to mains voltage or

to voltage sources with high transient over-voltages. Measurement Category II connections require protection for high transient

over-voltages often associated with local AC mains connections. Assume all measurement, control, and data I/O connections are

for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30V RMS, 42.4V peak, or 60VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock.

If the circuit is capable of operating at or above 1000 volts, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to

limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

12/06

Page 8

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

!

power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground.

Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being

measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions or the safety of the

equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating

information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of

normal and common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

The WARNING heading in a manual explains dangers that might result in personal injury or death. Always read the associated

information very carefully before performing the indicated procedure.

The CAUTION heading in a manual explains hazards that could damage the instrument. Such damage may invalidate the

warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits, including the power transformer,

test leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety

approvals, may be used if the rating and type are the same. Other components that are not safety related may be purchased

from other suppliers as long as they are equivalent to the original component. (Note that selected parts should be purchased only

through Keithley Instruments to maintain accuracy and functionality of the product.) If you are unsure about the applicability of a

replacement component, call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with

no case or chassis (e.g., data acquisition board for installation into a computer) should never require cleaning if handled

according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the

factory for proper cleaning/servicing.

Page 9

Table of Contents

Section Topic Page

1 Pulse/Pattern Generators Overview .................................................. 1-1

Series 3400 summary ................................................................................. 1-2

Features................................................................................................ 1-2

Basic pulse parameters............................................................................... 1-3

Pulse level parameters ......................................................................... 1-4

Pulse timing and triggering parameters................................................ 1-5

Operating modes......................................................................................... 1-5

Pulse mode........................................................................................... 1-5

Burst mode ........................................................................................... 1-5

Pattern mode ........................................................................................ 1-6

External Width mode ............................................................................ 1-7

Additional pulse characteristics................................................................... 1-8

Duty cycle ............................................................................................. 1-8

Interchannel delay (skew)..................................................................... 1-8

Jitter ...................................................................................................... 1-9

Distortion............................................................................................... 1-9

2 Getting Started........................................................................................ 2-1

General information..................................................................................... 2-2

Warranty information ............................................................................ 2-2

Keithley Instruments website – contact information.............................. 2-2

Inspection ............................................................................................. 2-2

Options and accessories ...................................................................... 2-2

Front and rear panel familiarization............................................................. 2-3

Front panel............................................................................................ 2-3

Rear panel ............................................................................................ 2-4

Power-up..................................................................................................... 2-5

Ventilation............................................................................................. 2-5

Display ........................................................................................................ 2-6

Editing parameter values and settings.................................................. 2-8

Defaults ....................................................................................................... 2-9

3 Signal Connections ............................................................................... 3-1

Introduction ................................................................................................. 3-2

Out 1 and Out 2 connections ...................................................................... 3-2

Trig Out and Ext In connections.................................................................. 3-3

Strobe Out connection................................................................................. 3-4

Clk In connections....................................................................................... 3-4

Ref Out and Ref In connections .................................................................. 3-5

Page 10

Table of Contents Series 3400 Pulse/Pattern Generators User’s Manual

Section Topic Page

4 Pulse/Pattern Generators Operation................................................. 4-1

Pulse, Burst and External Width operation ................................................. 4-3

Pulse mode .......................................................................................... 4-4

Burst mode ........................................................................................... 4-6

External Width mode ............................................................................ 4-7

Pattern operation ........................................................................................ 4-8

Saving and recalling setups ...................................................................... 4-12

Saving a setup.................................................................................... 4-12

Recalling a setup................................................................................ 4-12

Returning to default settings............................................................... 4-12

Pulse/pattern parameters.......................................................................... 4-13

Ampl – amplitude................................................................................ 4-13

Bit # .................................................................................................... 4-14

Block................................................................................................... 4-14

Brst Cnt – burst count......................................................................... 4-14

Cal – calibration.................................................................................. 4-14

ChAdd (3402 only) – channel add...................................................... 4-15

Channel .............................................................................................. 4-15

ClkIn – clock input .............................................................................. 4-15

Delay .................................................................................................. 4-15

Display................................................................................................ 4-16

Double ................................................................................................ 4-16

Edit ..................................................................................................... 4-16

Emul – emulation................................................................................ 4-16

ExtIn – external input.......................................................................... 4-17

Format ................................................................................................ 4-17

Freq – frequency ................................................................................ 4-17

GPIBAdd – GPIB address .................................................................. 4-17

Hi Cur – high current limit................................................................... 4-17

HiLvl – high level ................................................................................ 4-18

Hi Volt – high voltage limit .................................................................. 4-18

IOPort – I/O port (interface)................................................................ 4-18

I/V – current or voltage ....................................................................... 4-18

LeadE – leading edge ........................................................................ 4-18

Length ................................................................................................ 4-19

LoadZ – load impedance.................................................................... 4-20

Lo Cur – low current limit.................................................................... 4-21

LoLvl – low level ................................................................................. 4-21

Lo Volt – low voltage limit ................................................................... 4-21

Offset.................................................................................................. 4-21

On/Off (limits) ..................................................................................... 4-22

Per – period........................................................................................ 4-22

PerSrc – period source....................................................................... 4-22

Pol – polarity....................................................................................... 4-23

PLLRef – PLL reference..................................................................... 4-23

PRBS n – pseudo random bit sequence ........................................... 4-23

Recall ................................................................................................. 4-24

Save ................................................................................................... 4-24

SrcZ – source impedance .................................................................. 4-24

System ............................................................................................... 4-24

TrailE – trailing edge........................................................................... 4-24

TrgFreq – trigger frequency................................................................ 4-25

TrgMode – trigger mode ..................................................................... 4-25

TrigPer – trigger period....................................................................... 4-25

TrgSlope – trigger slope ..................................................................... 4-25

TrgSrc – trigger source....................................................................... 4-26

Update................................................................................................ 4-26

Width .................................................................................................. 4-26

ii 3400S-900-01 Rev. B / January 2007

Page 11

Series 3400 Pulse/Pattern Generators User’s Manual Table of Contents

Section Topic Page

5 Triggering................................................................................................. 5-1

Triggering overview..................................................................................... 5-2

Double pulse ........................................................................................ 5-2

Period source (PerSrc)......................................................................... 5-2

Trigger source (TrgSrc) ........................................................................ 5-3

Trigger Out and Strobe Out .................................................................. 5-3

PLL reference (PLLRef) ...................................................................... 5-3

Continuous.................................................................................................. 5-4

Continuous Pulse mode ....................................................................... 5-4

Continuous Burst mode........................................................................ 5-4

Continuous Pattern mode..................................................................... 5-5

Triggered..................................................................................................... 5-6

Triggered Pulse mode .......................................................................... 5-6

Triggered Burst mode........................................................................... 5-8

Triggered Pattern mode...................................................................... 5-10

Gated ........................................................................................................ 5-13

Gated Pulse mode.............................................................................. 5-13

Gated Burst mode .............................................................................. 5-14

Gated Pattern mode ........................................................................... 5-16

External Width........................................................................................... 5-17

User Interface and remote programming mapping ................................... 5-18

6 Remote Programming........................................................................... 6-1

Introduction ................................................................................................. 6-2

Remote interfaces....................................................................................... 6-2

Selecting an interface........................................................................... 6-2

IEEE-488 interface ............................................................................... 6-2

USB interface ....................................................................................... 6-3

Status model ............................................................................................... 6-4

Status register sets............................................................................... 6-5

Status byte and service request (SRQ) ................................................ 6-5

Standard Event Status Register ........................................................... 6-6

Operation Status group ........................................................................ 6-7

Questionable Status group ................................................................... 6-7

Service request programming example................................................ 6-7

Common commands................................................................................... 6-7

Command summary ............................................................................. 6-7

Command examples ............................................................................ 6-8

SCPI command reference........................................................................... 6-9

Command summary ............................................................................. 6-9

Command descriptions....................................................................... 6-14

Appendix Topic Page

A Specifications............................................................................................ A-1

Index I-1

3400S-900-01 Rev. B / January 2007 iii

Page 12

Table of Contents Series 3400 Pulse/Pattern Generators User’s Manual

This page left blank intentionally.

iv 3400S-900-01 Rev. B / January 2007

Page 13

List of Figures

Section Figure Title Page

1 Figure 1-1 Default pulse level and timing parameter settings

(Pulse mode, continuous triggering) .............................................. 1-3

Figure 1-2 Example output pattern for RZ and NRZ data formats................... 1-6

Figure 1-3 External Width mode ...................................................................... 1-7

Figure 1-4 Example of 50% duty cycle ............................................................ 1-8

Figure 1-5 Interchannel delay (skew) .............................................................. 1-8

Figure 1-6 Distortion – Preshoot, overshoot and ringing ................................. 1-9

2 Figure 2-1 Front panel familiarization (Model 3402-F)..................................... 2-3

Figure 2-2 Rear panel familiarization (Model 3402-R)..................................... 2-4

Figure 2-3 VOLTS menu options (default parameters).................................... 2-6

3 Figure 3-1 Out 1 and Out 2 connections ......................................................... 3-2

Figure 3-2 Trig Out connections ...................................................................... 3-3

Figure 3-3 Ext In connections.......................................................................... 3-3

Figure 3-4 Strobe Out connections.................................................................. 3-4

Figure 3-5 Clk In connections.......................................................................... 3-4

Figure 3-6 Ref Out and Ref In connections ..................................................... 3-5

4 Figure 4-1 Select operating mode .................................................................. 4-3

Figure 4-2 Configure Pulse mode parameters ............................................... 4-4

Figure 4-3 Configure triggering ....................................................................... 4-5

Figure 4-4 Setting Burst mode count............................................................... 4-6

Figure 4-5 PATTERN menu ........................................................................... 4-8

Figure 4-6 Block soft key options ................................................................... 4-9

Figure 4-7 Insert bit and delete bit examples ................................................ 4-10

Figure 4-8 Series 3400 output diagrams ....................................................... 4-20

Figure 4-9 Polarity ......................................................................................... 4-23

Page 14

List of Figures Series 3400 Pulse/Pattern Generators User’s Manual

Section Figure Title Page

5 Figure 5-1 Continuous Pulse mode ................................................................ 5-4

Figure 5-2 Continuous Burst mode ................................................................ 5-5

Figure 5-3 Continuous Pattern mode............................................................. 5-6

Figure 5-4 Triggered Pulse mode (positive slope) ......................................... 5-7

Figure 5-5 Triggered Pulse mode (negative slope) ........................................ 5-7

Figure 5-6 Triggered Pulse mode (positive and negative slope) .................... 5-8

Figure 5-7 Triggered Burst mode (VCO period source) ................................. 5-9

Figure 5-8 Triggered Burst mode (PLL or ClkIn period source) .................... 5-10

Figure 5-9 Triggered Pattern mode (VCO period source) ............................ 5-11

Figure 5-10 Triggered Pattern mode (PLL or ClkIn period source) ................ 5-12

Figure 5-11 Gated Pulse mode (VCO period source) .................................... 5-13

Figure 5-12 Gated Pulse mode (PLL or ClkIn period source) ........................ 5-14

Figure 5-13 Gated Burst mode (VCO period source) ..................................... 5-15

Figure 5-14 Gated Burst mode (PLL or ClkIn period source)......................... 5-15

Figure 5-15 Triggered Pattern mode (VCO period source) ............................ 5-16

Figure 5-16 Triggered Pattern mode (PLL or ClkIn period source) ................ 5-17

6 Figure 6-1 IEEE-488 and USB connector locations on rear panel.................. 6-3

Figure 6-2 Status model .................................................................................. 6-4

vi 3400S-900-01 Rev. B / January 2007

Page 15

List of Tables

Section Table Title Page

1 Table 1-1 Pulse level parameters................................................................... 1-4

Table 1-2 Pulse timing and triggering parameters.......................................... 1-5

2 Table 2-1 Menu summary .............................................................................. 2-7

Table 2-2 Power-on defaults .......................................................................... 2-9

4 Table 4-1 Pulse mode triggering .................................................................... 4-5

Table 4-2 Burst mode triggering..................................................................... 4-6

Table 4-3 External Width mode triggering...................................................... 4-7

Table 4-4 PRBS length settings ................................................................... 4-11

Table 4-5 Pattern mode triggering................................................................ 4-11

Table 4-6 Soft key parameters ..................................................................... 4-13

Table 4-7 Programmed voltage vs. actual voltage (VDUT)

for DUT impedance variations...................................................... 4-21

5 Table 5-1 Triggering summary ....................................................................... 5-2

Table 5-2 Mapping for User Interface settings and remote

programming commands ............................................................. 5-18

6 Table 6-1 Status Byte Register and Service Request Enable Register bits ... 6-6

Table 6-2 Standard Event Status Register bits............................................... 6-6

Table 6-3 Common commands ...................................................................... 6-7

Table 6-4 SCPI command summary ............................................................ 6-10

Table 6-5 :ARM:SOUR source selections.................................................... 6-17

Table 6-6 :DIG:PATT:DATA[1|2|3]................................................................. 6-19

Table 6-7 :TRIG:SOUR ................................................................................ 6-42

Page 16

List of Tables Series 3400 Pulse/Pattern Generators User’s Manual

This page left blank intentionally.

viii 3400S-900-01 Rev. B / January 2007

Page 17

In this section:

Top ic Page

Series 3400 summary ................................................................... 1-2

Basic pulse parameters .................................................................... 1-3

Operating modes............................................................................... 1-5

Section 1

Pulse/Pattern Generators Overview

Features........................................................................................ 1-2

Pulse level parameters ................................................................. 1-4

Pulse timing and triggering parameters ........................................ 1-5

Pulse mode................................................................................... 1-5

Burst mode ................................................................................... 1-5

Pattern mode ................................................................................ 1-6

External Width mode .................................................................... 1-7

Additional pulse characteristics ...................................................... 1-8

Duty cycle ..................................................................................... 1-8

Interchannel delay (skew)............................................................. 1-8

Jitter .............................................................................................. 1-9

Distortion....................................................................................... 1-9

Page 18

Section 1: Pulse/Pattern Generators Overview Series 3400 Pulse/Pattern Generators User’s Manual

Series 3400 summary

The Series 3400 Pulse/Pattern Generators, currently available in two basic models, offer extensive

control over pulse parameters - including amplitude, offset, leading and trailing edge times, pulse

width and duty cycle. The Model 3401 is a single-channel, 165MHz pulse/pattern generator; the

Model 3402 is similar, but includes a second signal output channel.

NOTE Each basic model is available with connectors located on the front panel (Model 3401-F

and Model 3402-F) or with all connectors located on the rear panel (Model 3401-R and

Model 3402-R).

The operational flexibility and pattern generation capability of the Series 3400 Pulse/Pattern

Generators makes them readily suitable to the specific needs of many different applications,

including simplified simulation of serial data patterns when testing devices to characterize their

performance under sub-optimal conditions.

Features

• Frequency Output Range: 1mHz to 165MHz

• Pulse Amplitude: ±10V (50Ω source impedance)

±20V (1kΩ source impedance)

• Pulse Width: Programmable from 3.02ns to (Period - 3.02ns)

• Leading and Trailing Edge Times: Programmable from 2.0ns to 200ms

• Pulse output programmable as voltage or current

• Four Operating Modes: Pulse mode

Burst mode

Pattern mode

External Width mode

• Channel Add (Model 3402 only): Make complex waveforms by adding pulse output for

Channel 1 and Channel 2

• Internal PLL and VCO period sources

• Save up to nine pulse/pattern generator setups in non-volatile memory

• GPIB and USB interfaces

• 2U full-rack design

1-2 Return to Section Topics 3400S-900-01 Rev. B / January 2007

Page 19

Series 3400 Pulse/Pattern Generators User’s Manual Section 1: Pulse/Pattern Generators Overview

Ampl

(Amplitude)

1Vpp

Width

+500mV

-500mV

Per

(Period)

LeadE

(Leading Edge)

2.5ns

Trigger

Delay

0ps

0V

HiLvl

(High

Level)

LoLvl

(Low Level)

Offset

(Median)

100ns

1µs

Freq

(Frequency)

1MHz

SrcZ (Source Impedance) = 50W

LoadZ (Load Impedance) = 50W

LeadE

(Leading Edge)

2.5ns

TrailE

(Trailing Edge)

2.5ns

Time Parameters

Not Drawn To Scale

Basic pulse parameters

On power-up, the instrument is in the Pulse mode with continuous triggering selected. When a

channel is enabled, it will continuously output pulses.

Figure 1-1 shows the first two pulses of the continuous pulse output. Shown are the fundamental

default settings. The parameter names in italic correspond to the parameter names in the front

panel VOLTS and TIME menus.

Figure 1-1

Default pulse level and timing parameter settings (Pulse mode, continuous triggering)

3400S-900-01 Rev. B / January 2007 Return to Section Topics 1-3

The basic pulse level, timing and triggering parameters are summarized in Table 1-1 and

Table 1-2. The last column (“yes” or “no”) in the two tables does not apply to the Model 3401.

Page 20

Section 1: Pulse/Pattern Generators Overview Series 3400 Pulse/Pattern Generators User’s Manual

Pulse level parameters

Table 1-1

Pulse level parameters

Independent

Channel

Settings*

Parameter Description

Output Function Configure pulse output as Current or Voltage. Yes

Source Impedance Set the source impedance of the Series 3400 for 50 Ohms or 1k Ohms. Ye s

Load Impedance The allowable setting ranges for pulse parameters are specified for a

Ω load. However, the load impedance setting of the Series 3400 can

50

be set to match the impedance of the DUT. Load impedance can be set

from 0.1 Ohm to 1M Ohm.

High Level

Low Level

Amplitude Amplitude is the low-to-high magnitude of the pulse. The Amplitude

Offset Offset is the median (average) value of the high and low levels:

Polarity Polarity can be set to Norm (normal) or Comp (complement).

Channel Add 3402 Only – Enable or Disable Channel Add. When enabled, Channel

Pulse Level Limits To protect DUT, high and low limits can be set for pulse output. Limits

* Yes = The parameter can be independently set for each of the two channels of the Model 3402.

No = The parameter setting applies to both channels of the Model 3402.

Configure the pulse high/low levels by setting the High Level and the

Low Level. Setting range depends on the source impedance setting:

50Ω into 50Ω: 0 to ±10V (or 0 to ±200mA)

1kΩ into 50Ω: 0 to ±20V (or 0 to ±400mA)

Changing the high and/or low level may change the amplitude and

offset.

setting range depends on the source impedance setting:

50Ω into 50Ω: 100mV to 10Vpp (or 2mApp to 200mApp)

1kΩ into 50Ω: 200mV to 20Vpp (or 4mApp to 400mApp)

Changing the amplitude will change the high and low levels. Offset is

not affected.

Offset = (High Level + Low Level) / 2.

The offset can be set to any value that allows the pulse to fit within the

level window. For a 100mVpp amplitude, offset can be programmed up

to 9.95V.

Changing the offset will change the high and/or low levels. Amplitude is

not affected.

Complement means that the pulse transitions from the High Level to

the Low Level.

1 pulse output is added to Channel 2 pulse output. The complex result

is available on channel 1; Channel 2 is disabled.

can be enabled (On) or disabled (Off). The Hi Lim and Lo Lim setting

ranges are the same as the setting ranges for High Level and Low

Level.

(3402 only)

Yes

Yes

Yes

Yes

Yes

No

Yes

1-4 Return to Section Topics 3400S-900-01 Rev. B / January 2007

Page 21

Series 3400 Pulse/Pattern Generators User’s Manual Section 1: Pulse/Pattern Generators Overview

Pulse timing and triggering parameters

Table 1-2

Pulse timing and triggering parameters

Independent

Channel

Settings*

Parameter Description

Frequency

Period

Width Pulse width is measured at the 50% amplitude level of the pulse. Width

Delay A delay between the trigger event and the start of each pulse can be set

Leading Edge

Trailing Edge

Pulse Number With Single pulse selected, one pulse per period will be output. With

Period Source The source for period generation can be PLL, VCO or an external clock

Trigger Source Select the trigger source to start pulse output: ExtIn (external input),

Trigger Mode Select the trigger mode: Cont (continuous), Trig’ d (triggered) or Gated. No

Trigger Frequency

Trigger Period

* Yes = The parameter can be independently set for each of the two channels of the Model 3402.

No = The parameter setting applies to both channels of the Model 3402.

Pulse cycle time can be set as frequency or period. Frequency can be

set from 1mHz to 165MHz. Period can be set from 6.06ns to 1000s.

can be set from 3.02ns to (Period - 3.02ns).

from 0 to (Period - 3.02ns).

Time intervals between corresponding 10% and 90% amplitude points

on the leading/trailing edge of the pulse. Leading and trailing edge

times (LeadE and Trai lE) can be individually set from 2ns to 200ms.

Double pulse selected, two pulses per period will be output.

input (ClkIn).

PLL or Manual.

Trigger speed for the PLL trigger source can be set as frequency or

period. Trigger Frequency can be set from 1mHz to 165MHz. Trigger

Period can be set from 6.06ns to 1000s.

(3402 only)

No

Yes

Yes

Yes

Yes

No

No

No

No

No

Operating modes

The Series 3400 Pulse/Pattern Generators have four operating modes: Pulse mode, Burst mode,

Pattern mode and External Width mode.

Pulse mode

Outputs a single pulse or continuous pulses per trigger event to the two output channels. The

basic pulse level, timing and triggering parameters are summarized in

Burst mode

This mode is similar to the Pulse mode, except that each trigger event will output a series (burst) of

pulses. In Burst mode, two to 65,536 pulses can be output.

Table 1-1 and Table 1-2.

3400S-900-01 Rev. B / January 2007 Return to Section Topics 1-5

Page 22

Section 1: Pulse/Pattern Generators Overview Series 3400 Pulse/Pattern Generators User’s Manual

RZ format

11

00

1

0

1

0

5V

0V

Logic 1 = 5V

Logic 0 = 0V

NRZ format

11

00

1

0

1

0

5V

Output Pattern

11100010

0V

Period Period PeriodPeriod PeriodPeriod Period Period

Bit 1 Bit 2 Bit 3 Bit 4 Bit 5 Bit 6 Bit 7 Bit 8

Bit 1 Bit 2 Bit 3 Bit 4 Bit 5 Bit 6 Bit 7 Bit 8

Pattern mode

Each channel can output a user configured bit pattern that consists of Logic 0’s and 1’s. The length

of the bit pattern can be two to 16,384 bits.

The two channels of a Model 3402 can have different bit patterns, but must be the same length.

Logic 0 represents the low pulse level (e.g., 0V) and Logic 1 represents the high pulse level. The

following example shows different 8-bit output patterns for the two channels:

Channel 1 Output Pattern: 00110011

Channel 2 Output Pattern: 11100010

Pattern data formats

There are two data formats for output patterns: RZ (return-to-zero) and NRZ (non-return-to-zero).

Figure 1-2 shows the difference between the RZ format and the NRZ format. The 8-bit pattern is

the same for both formats (11100010), and the logic levels are the same (Logic 0 = 0V, Logic 1 =

5V):

• RZ Format – For 50% duty cycle, a Logic 1 bit goes to 5V for the first half of the period, then

returns to 0V for the second half of the period (return-to-zero). A Logic 0 bit remains at 0V

for the entire period.

• NRZ Format – A Logic 1 bit goes to 5V and stays at 5V for the entire period (non-return-tozero). A Logic 0 bit goes to 0V and remains at 0V for the entire period.

NOTE For either data format, the level for Logic 0 does not have to be 0V. It simply must be less

positive (more negative) than Logic 1.

Example 1: Example 2:

Logic 1 = 4V Logic 1 = 0V

Logic 0 = 1V Logic 0 = -3V

Figure 1-2

Example output pattern for RZ and NRZ data formats

Pseudo Random Bit Sequencer (PRBS)

The PRBS is used to output a pseudo random pattern for testing purposes. The number of bits for

the PRBS output pattern can be set as follows:

1-6 Return to Section Topics 3400S-900-01 Rev. B / January 2007

PRBS size = 2n-1 where n = 5 to 14

The RZ or NRZ data format can be used for the PRBS pattern.

Page 23

Series 3400 Pulse/Pattern Generators User’s Manual Section 1: Pulse/Pattern Generators Overview

Amplitude

3 to 6V

(±)

External Input

(Ext In)

Pulse Output

(Out 1, Out 2)

Leading edge of external trigger

causes output to go high

Trailing edge causes

output to go low

External Width mode

In this mode, pulse output follows the edges of an external input trigger that is applied to the Ext In

connector. As shown in

causes the output to go low.

The external input trigger can be positive or negative polarity up to 6V. However, the external input

trigger voltage must be at least ±10mV in order to be detected by the pulse/pattern generator as a

valid trigger.

Figure 1-3

External Width mode

Figure 1-3, a rising edge causes the output to go high, while a falling edge

3400S-900-01 Rev. B / January 2007 Return to Section Topics 1-7

Page 24

Section 1: Pulse/Pattern Generators Overview Series 3400 Pulse/Pattern Generators User’s Manual

Period

1µs

Amplitude

50%

Width

500ns

Duty Cycle = (Width / Period) x 100%

= (500ns / 1µs) x 100%

= 0.5 x 100%

= 50%

Channel A

Output

Channel B

Output

Interchannel Delay Skew

Amplitude

Amplitude

Additional pulse characteristics

The following are characteristics inherent to pulse generation, and may or may not be affected by

various instrument settings and/or the load.

Duty cycle

The duty cycle is the amount of time – as a percentage of the pulse period – that the pulse is on

(pulse width). Duty cycle (as a percentage) is calculated as follows:

Duty Cycle = (Width / Period) x 100

Figure 1-4 shows an example for duty cycle.

Figure 1-4

Example of 50% duty cycle

Interchannel delay (skew)

As shown in Figure 1-5, interchannel delay is the time interval between the leading pulse edge of

the two Model 3402 output channels (Channel 1 and Channel 2). Skew can be adjusted through

the use of the pulse Delay for each individual channel.

Figure 1-5

Interchannel delay (skew)

1-8 Return to Section Topics 3400S-900-01 Rev. B / January 2007

Page 25

Series 3400 Pulse/Pattern Generators User’s Manual Section 1: Pulse/Pattern Generators Overview

0

100%

Preshoot (e.g., 2%)

Ringing (negative)

(e.g., -2%)

Ringing (positive)

(e.g., +3%)

Overshoot

(e.g., 5%)

Amplitude

Time

Jitter

Jitter is the short-term instability of one edge relative to a reference edge. Jitter is usually specified

as an RMS value, which is one standard deviation (or sigma). If distribution is assumed Gaussian,

six sigma represents 99.74% of peak-to-peak jitter.

The reference edge for period jitter is the previous leading edge. The reference edge for delay

jitter is the leading edge of the trigger output. Width jitter is the stability of the trailing edge with

respect to the leading edge.

Distortion

Distortion includes preshoot, overshoot and ringing. Preshoot and overshoot are peak distortions

preceding/following an edge. Ringing is the positive-peak and negative-peak distortion (excluding

overshoot) on pulse top or base. Distortion for a pulse is shown in

preshoot, overshoot and ringing specification of 5% implies an overshoot and undershoot <5% of

pulse amplitude.

Figure 1-6

Distortion – Preshoot, overshoot and ringing

Figure 1-6. A combined

3400S-900-01 Rev. B / January 2007 Return to Section Topics 1-9

Page 26

Section 1: Pulse/Pattern Generators Overview Series 3400 Pulse/Pattern Generators User’s Manual

This page left blank intentionally.

1-10 Return to Section Topics 3400S-900-01 Rev. B / January 2007

Page 27

In this section:

Top ic Page

General information........................................................................... 2-2

Front and rear panel familiarization ................................................. 2-3

Power-up ............................................................................................ 2-5

Section 2

Getting Started

Warranty information ..................................................................... 2-2

Keithley Instruments website – contact information ...................... 2-2

Inspection ...................................................................................... 2-2

Options and accessories ............................................................... 2-2

Front panel .................................................................................... 2-3

Rear panel..................................................................................... 2-4

Ventilation...................................................................................... 2-5

Display ................................................................................................ 2-6

Editing parameter values and settings .......................................... 2-8

Defaults............................................................................................... 2-9

Page 28

Section 2: Getting Started Series 3400 Pulse/Pattern Generators User’s Manual

General information

Warranty information

Warranty information is located at the front of this manual. Should your instrument require

warranty service, contact the Keithley representative or authorized repair facility in your area for

further information. When returning the instrument for repair, be sure to fill out and include the

service form at the back of this manual to provide the repair facility with necessary information.

Keithley Instruments website – contact information

Visit the Keithley website at www.keithley.com for information on contacting Keithley for your

customer service needs, such as calibration and repair.

Inspection

The instrument was carefully inspected electrically and mechanically before shipment. After

unpacking all items from the shipping carton, check for any obvious signs of physical damage that

may have occurred during transit. (there may be a protective film over the display lens, which can

be removed). Report any damage to the shipping agent immediately. Save the original packing

carton for possible future shipment. The following items are included with every instrument order:

• Series 3400 with line cord.

• Rack Mount/Handle Kit

• Accessories as ordered.

• CD with the Quick Start Guide, User’s Manual and any Release Notes

• Hardcopy of the Quick Start Guide

Options and accessories

Cables/adapters

• Model 7051-2 General Purpose BNC to BNC Cable (2 ft)

• Model 7007-1 Shielded GPIB Cable, 1m

• Model 7007-2 Shielded GPIB Cable, 2m

• Model 7051-2 General Purpose BNC to BNC Cable, 0.6m (2 ft)

• Model 7051-5 General Purpose BNC to BNC Cable, 1.5 (5 ft)

• 7755 50Ω Feed-Through Terminator

Communication interfaces

• Model KPCI-488 GPIB/IEEE488 Interface Board for PCI Bus

• Model KUSB-488 USB-to-GPIB interface adapter for USB

• When using USB directly, use one of the following USB cables:

– USB-B-1 USB Cable Type A to B, 1m

– USB-B-3 USB Cable Type A to B, 3m

2-2 Return to Section Topics 3400S-900-01 Rev. B / January 2007

Page 29

Series 3400 Pulse/Pattern Generators User’s Manual Section 2: Getting Started

On/Off

Switch

1

2

LCD Display

Channel 1

Parameters

2a

Selected

Parameter

2c

Channel 2

Parameters

2b

5

Rotory Knob

Cursor Keys

7

6

Numeric Keypad

3

Menu

Keys

Clock, Trigger and

Strobe Connectors

(BNC)

10

Clock

Input

10a

External

Input

10b

Trigger

Output

10c

Strobe

Output

10d

8

Output Enable

Pulse/Pattern

Output

Connectors

(BNC)

9

Soft Keys

4

Soft Key

Options

For the Rear Panel Output option,

items 9 and 10 connectors are

moved to the rear panel.

2 Width

Delay

LeadE

TrailE

3.00 ns

0 ps

2.5 ns

2.5 ns

Pulse Mode

Ch 1 Width

3.04 ns

Trigger = PLL

1 Width

Delay

LeadE

TrailE

3.04 ns

0 ps

2.5 ns

2.5 ns

Freq 165.0 MHz Per 6.06 ns

Channel Freq Per Width Delay More

+/-

Front and rear panel familiarization

Front panel

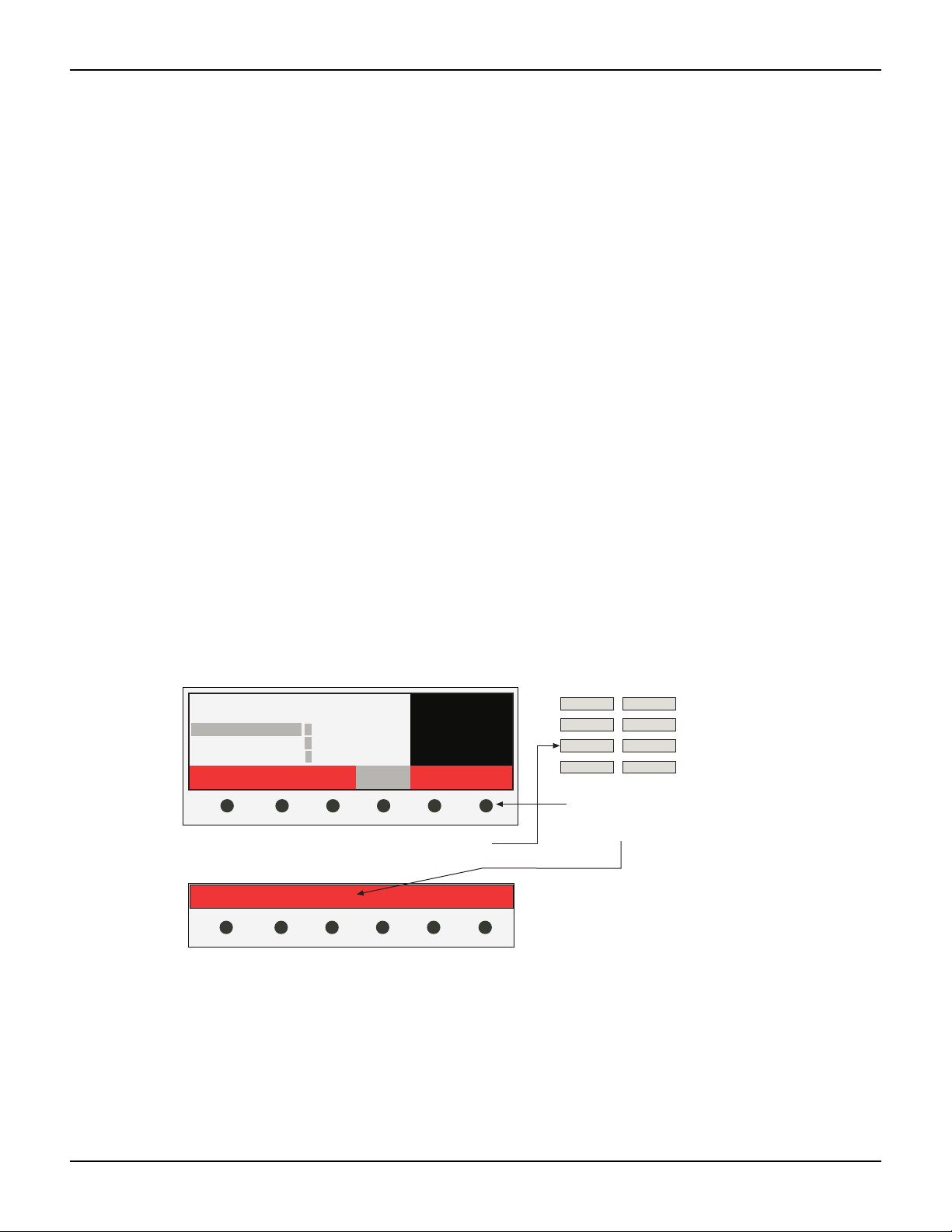

The front panel of the Model 3402-F is shown in Figure 2-1. The front panel controls and

connectors for the Model 3401-F single-channel pulse/pattern generator are similar except there is

only one channel. For the Model 3401, disregard all references to the second channel.

Figure 2-1

Front panel familiarization (Model 3402-F)

1. On/Off Switch – Push button switch toggles instrument on and off. When on, the green

indicator in the button turns on. Note that the main power switch for the rear panel Power

Module must be on (refer to

Figure 2-2).

2. LCD Display – On the Time and Volts menu keys, the display is divided into three areas:

a. Channel 1 Parameters – Displays Channel 1 parameters for the selected Function.

b. Channel 2 Parameters – Displays Channel 2 parameters for the selected Function.

c. Parameter Value – Displays the value of the selected parameter. Also displays related

information.

3. Menu Select Keys – The various menus are selected using these keys. The display then

shows the parameters, options and other choices available for the selected menu.

4. Soft Keys – The options that can be selected depend on the selected menu and are positioned in the display immediately above the soft keys.

5. Rotary Knob – Use this knob to modify (increase or decrease) the displayed parameter

value.

6. Numeric Keypad – Use this keypad to enter parameter values. After keying in a value,

available options (e.g., MHz range) are displayed as soft keys.

7. Cursor Keys – Use to increment/decrement parameter values.

8. Output Enable – Push button toggles output enable for each channel on and off. When on,

the green indicator in the button turns on. A trigger event will then start pulse/pattern output.

9. Pulse/Pattern Output Connectors – Output for the two channels is available at these

female BNC connectors. For the Rear Panel Output option, these connectors are moved to

3400S-900-01 Rev. B / January 2007 Return to Section Topics 2-3

the rear panel for greater convenience in rack-mounted environments.

Page 30

Section 2: Getting Started Series 3400 Pulse/Pattern Generators User’s Manual

2

Pulse/Pattern

Output

Connectors

(BNC)

3

Strobe, Trigger and

Clock Connectors

(BNC)

Reference

Output

Connector

(BNC)

5

Reference

Input

Connector

(BNC)

4

USB

Connector

6

IEEE-488

Connector

7

1

Power

Module

3a

Clock

Input

3b

External

Input

3c

Trigger

Output

3d

Strobe

Output

For the Front Panel Output

option, items 2 and 3

connectors are moved to the

front panel.

Cooling Vents

8

10. Clock, Trigger and Strobe Connectors – The following input/output female BNC connectors are provided:

NOTE For the Rear Panel Output option, these connectors are moved to the rear panel for

greater convenience in rack-mounted environments:

a. Clock Input – Connect an external clock.

b. External Input – Connect an external signal for external triggering.

c. Trigger Output – Provides a trigger pulse on each period.

d. Strobe Output – Programmable NRZ in Pattern mode, marks burst width in Burst mode.

Rear panel

The rear panel of the Model 3402-R is shown in Figure 2-2. The connectors for the Model 3401-R

single-channel pulse/pattern generator are similar except there is only one pulse/pattern output

channel. For the Model 3401, disregard all references to the second channel.

Figure 2-2

Rear panel familiarization (Model 3402-R)

1. Power Module – Contains the AC line receptacle, main power switch and the power line

fuse. Uses a toggle switch for AC power. The “0” position is off, and the “1” position is on.

This toggle switch must be in the “1” (on) position to enable the front panel On/Off Switch

(refer to

Figure 2-1).

2. Pulse/Pattern Output Connectors – Output for the two channels is available at these

3. Clock, Trigger and Strobe Connectors – The following input/output female BNC connec-

female BNC connectors. For the Rear Panel Output option, these connectors are moved to

the rear panel for greater convenience in rack-mounted environments:

tors are provided:

NOTE For the Rear Panel Output option, these connectors are moved to the rear panel for

greater convenience in rack-mounted environments.

a. Clock Input – Connect an external clock.

b. External Input – Connect an external signal for arming.

c. Trigger Output – Provides a trigger pulse on each period.

d. Strobe Output – Programmable NRZ in Pattern mode, marks burst width in Pulse mode.

2-4 Return to Section Topics 3400S-900-01 Rev. B / January 2007

Page 31

Series 3400 Pulse/Pattern Generators User’s Manual Section 2: Getting Started

4. Reference Input Connector – This female BNC connector accepts an external 10MHz

oscillator signal for PLL reference.

NOTEUse the Ref In and Ref Out to daisy-chain multiple Series 3400 units for the purpose

of using one PLL as the period source.

5. Reference Output Connector – This female BNC connector provides 10MHz single phase

locked to PLL.

6. USB Connector – For USB remote operation. Use a USB cable (Model USB-B-1 or USBB-3) to connect to the USB interface of the PC.

7. IEEE-488 Connector – For GPIB remote operation. Use a shielded cable (Model 7007-1 or

7007-2).

8. Cooling Vents – The instrument uses a cooling fan and vents to keep it from overheating.

Note that there is also a cooling vent on each side panel of the unit. Refer to “

information on maintaining proper ventilation for the instrument.

Ventilation” for

Power-up

The Series 3400 operates from a line voltage in the range of 100 to 240V single phase at a

frequency of 50 or 60Hz. Line voltage and line frequency are automatically sensed. Therefore,

there are no switches to set. Check to be sure the operating voltage in your area is compatible.

CAUTION Operating the instrument on an incorrect line voltage may cause damage, pos-

sibly voiding the warranty.

Perform the following steps to connect the Series 3400 to line power and turn it on:

1. Before plugging in the power cord, make sure the Series 3400 is turned off and the rear

panel power switch is in the off (0) position.

2. Connect the female end of the supplied power cord to the AC receptacle on the rear panel,

and return the power switch to the on (1) position.

WARNING The power cord supplied with the Series 3400 contains a separate ground for

use with grounded outlets. When proper connections are made, the instru

ment chassis is connected to power line ground through the ground wire in

the power cord. Failure to use a grounded outlet may result in personal injury

or death due to electric shock.

3. Turn on the instrument by pressing the front panel on/off button.

-

Line fuse replacement

Two line fuses are located in a drawer in the Power Module above the AC receptacle (refer to

Figure 2-2). After turning the power switch off and removing the line cord, remove the fuses and

replace a blown fuse with the following type:

Keithley Instruments Part Number: FU-81

Fuse Type: 2A, 250V, SlowBlo, 5mm x 20mm

Ventilation

The Series 3400 uses a fan and cooling vents in the rear panel and side panels to keep it from

overheating.

3400S-900-01 Rev. B / January 2007 Return to Section Topics 2-5

Page 32

Section 2: Getting Started Series 3400 Pulse/Pattern Generators User’s Manual

1 Ampl

Offset

HiLvl

LoLvl

Pol

1000 mVpp

0 mV

500 mV

-500 mV

Norm

2 Ampl

Offset

HiLvl

LoLvl

Pol

1000 mVpp

0 mV

500 mV

-500 mV

Norm

Pulse Mode

Ch 1 Ampl

1000 mVpp

Trigger = PLL

Channel Pol SrcZ LoadZ ChAdd More

1 Ampl

Offset

HiLvl

LoLvl

Pol

1000 mVpp

0 mV

500 mV

-500 mV

Norm

2 Ampl

Offset

HiLvl

LoLvl

Pol

1000 mVpp

0 mV

500 mV

-500 mV

Norm

Pulse Mode

Ch 1 Ampl

1000 mVpp

Trigger = PLL

Press More key to

display more VOLTS

menu options

Channel I/V Limits More

Press More key to

display more VOLTS

menu options

Press More to

wrap back to 1st

group of VOLTS

options

Ampl = Amplitude

HiLvl = High Level

LoLvl = Low Level

Pol = Polarity

SrcZ = Source Impedance

LoadZ = Load Impedance

ChAdd = Channel Add

I/V = Current or Voltage

Limits = User

programmable amplitude limits

Soft Keys (6)

Channel Ampl Offset HiLvl LoLvl More

Pulse Mode

Ch 1 Ampl

1000 mVpp

Trigger = PLL

1 Ampl

Offset

HiLvl

LoLvl

Pol

1000 mVpp

0 mV

500 mV

-500 mV

Norm

2 Ampl

Offset

HiLvl

LoLvl

Pol

1000 mVpp

0 mV

500 mV

-500 mV

Norm

CAUTION Observe the following precautions to maintain proper ventilation:

Keep the cooling vents from becoming blocked.

Do not position any devices adjacent to the instrument that force air (heated

or unheated) into or onto its surfaces or cooling vents. This additional airflow

could compromise accuracy performance.

When rack mounting the instrument, make sure there is adequate airflow

around the rear and sides to ensure proper cooling. Adequate airflow enables

air temperatures within approximately one inch of the instrument surfaces to

remain within specified limits under all operating conditions.

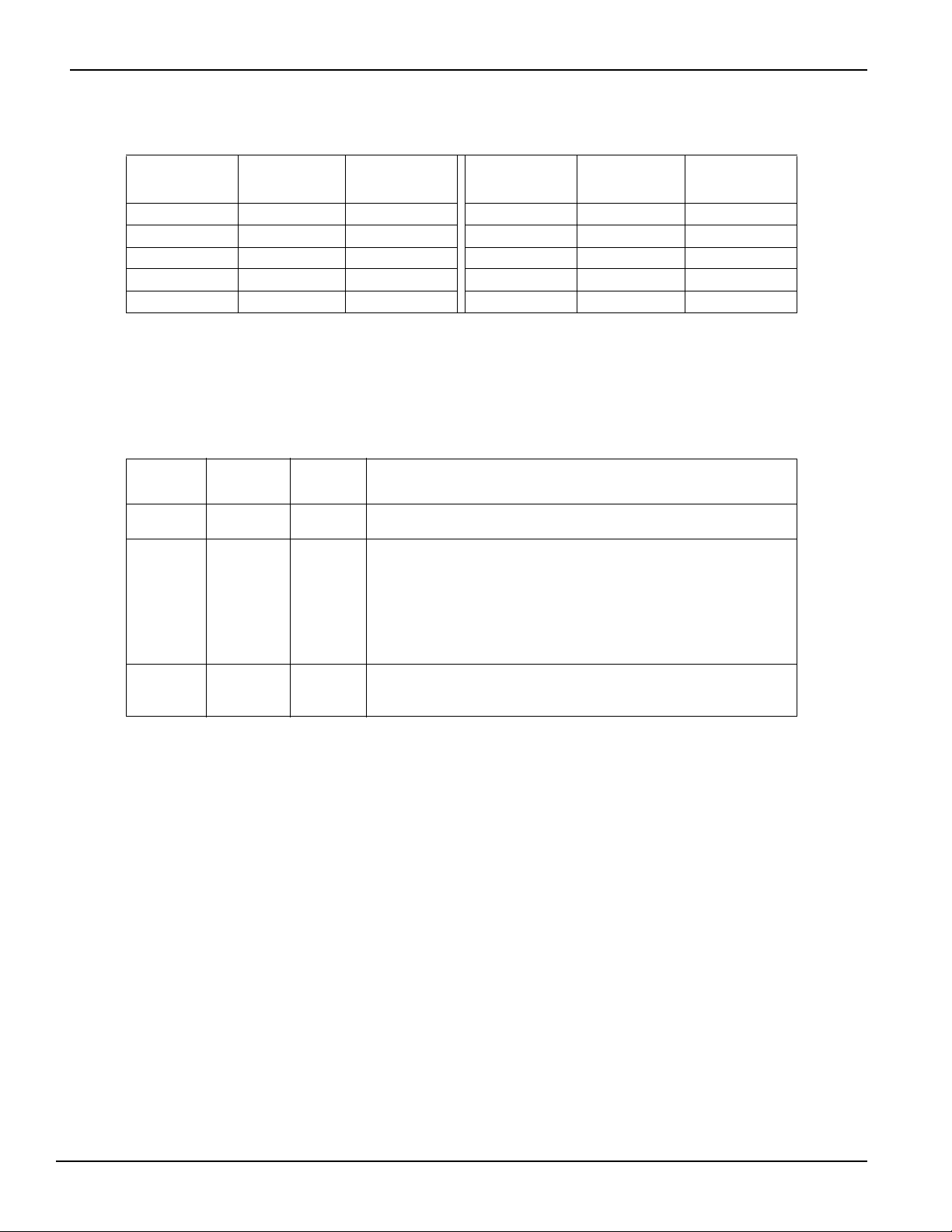

Display

The Series 3400 uses an LCD display to view and set the various pulse/pattern parameters. The

parameters that are displayed pertain to the selected menu.

items for the VOLTS menu. The pulse output for these default parameter settings are shown in

Figure 1-1.

As shown, the More soft key is used to display all the various options for the VOLTS menu. All of

the menus are summarized in

Table 2-1. For the Model 3402, the Channel soft key is used to

toggle between the two channels. Parameters are then set for the selected channel.

Figure 2-3 shows the default display

2-6 Return to Section Topics 3400S-900-01 Rev. B / January 2007

Figure 2-3

VOLTS menu options (default parameters)

The displays for the other menus (MODE, TIME, BURST, PATTERN, UTILITY, TRIGGER and

HELP) are similar in structure to the VOLTS menu, but use different parameter options.

A summary for all the menus is provided in Table 2-1.

Page 33

Series 3400 Pulse/Pattern Generators User’s Manual Section 2: Getting Started

Table 2-1

Menu summary

Menu Key Menu Item Description

MODE Pulse Select Pulse mode

Pattern Select Pattern mode

Burst Select Burst mode

ExtWidth External Width – Select External Width mode

VOLTS Channel 3402 only – Select channel

Ampl Amplitude – Set peak-to-peak amplitude

Offset Set offset

HiLvl High Level – Set high level

LoLvl Low Level – Set low level

Pol Polarity – Set polarity – Norm (normal) or Comp (complement)

SrcZ Source Impedance – Select source impedance – 50 Ohms or 1k Ohms

LoadZ Load Impedance – Set load impedance

ChAdd Channel Add (3402 only) – Enable or Disable Channel Add

I/V Current or Voltage – Select Current (I) or Voltage (V) output

Limits Set and control (On/Off) high and low limits (Hi Volt, Lo Volt, Hi Cur and

Lo Cur)

PATTE RN Channel Select output channel or Strobe

Format Set format (RZ or NRZ) for selected channel

Edit Change bit for to 0 or 1 (use “0”, “1” or “+” key)

Length Set the number of bits of the pattern

Bit # Select the bit to be edited

PRBS n Set PRBS length by setting the “n” in formula 2n-1; n = 5 to 14.

Block Edit pattern using Fill 0, Fill 1, Invert, Ins Bit and Del Bit

Update Update pattern continuously (Cont) or when Now soft key is pressed

TRIGGER TrgSrc Trigger Source – Select trigger source: External input (ExtIn), PLL or

Manual

TrgMode Trigger Mode – Select trigger mode; Continuous (Cont), triggered

(Trig’d) or Gated

TrgFreq Trigger Frequency – Set frequency for PLL trigger source

TrgPer Trigger Period – Set period for PLL trigger source

TrgSlope Trigger Slope – Set trigger slope; Pos, Neg or Both.

TIME Channel 3402 only – Select channel

Freq Frequency – Set pulse/pattern speed as frequency (Hz)

Per Period – Set pulse/pattern speed as period (time)

Width Set time for pulse width

Delay Set delay time

LeadE Leading Edge – Set transition time for leading edge

TrailE Trailing Edge – Set transition time for trailing edge

Double Enable (On) or disable (Off) double pulses per period

PerSrc Period Source – Select period source – VCO, PLL or clock input (ClkIn)

BURST Brst Cnt Burst Count – Set burst count for Burst mode

3400S-900-01 Rev. B / January 2007 Return to Section Topics 2-7

Page 34

Section 2: Getting Started Series 3400 Pulse/Pattern Generators User’s Manual

Table 2-1 (continued)

Menu summary

Menu Key Menu Item Description

UTILITY ClkIn Clock Input – Configure clock input – Termination (ClkInTrm; 50 Ohm

or 10 kOhm), slope (ClkInSlp; Pos or Neg) and threshold (ClkInThr)

ExtIn External Input – Configure external input – Termination (ExtInTrm; 50

Ohm or 10 kOhm) and threshold (ExtInThr).

Save Save instrument setup in memory – Save to Mem1 to Mem9.

Recall Recall instrument setup from memory – Recall from Mem1 to Mem9, or

return to Default settings.

PLLRef PLL Reference – Select Internal PLL or use Auto to check for PLL at

REF IN connector.

System System settings for Display, Calibration (Cal), GPIB address

(GPIBAdd), IOPort (GPIB or USB) and Emulation (Emul).

HELP N/A Provides a brief description for the presently selected parameter (soft

key). Press any menu key or soft key to cancel help.

Editing parameter values and settings

NOTE For the Model 3402, the soft key for Channel toggles the display between Channel 1 and

Channel 2.

1. Select a menu (e.g. VOLTS). The menu keys are located next to the keypad.

2. Press the soft key for the parameter to be edited. Use the More key to display additional

options. The parameter value or setting is displayed on the right side of the display.

3. Change a parameter value or setting as follows:

• Parameter value – If the parameter is a value, it can be changed using the rotary knob or

the keypad.

Rotary Knob – The knob increments or decrements the value.

Keypad – When keying in a value, the available ranges (e.g., mV, V) for the value will

appear at the bottom of the display. After keying in the value, use a soft key to select the

range.

Cursor keys – Use to increment or decrement values.

• Parameter setting – For a parameter setting, options (e.g., Enable, Disable, Cancel, etc.)

may appear on the bottom of the display and can be selected by pressing a soft key.

Additional soft keys for menu navigation will appear as needed:

Enter soft key – Use to enter the parameter setting or value.

Back soft key – Use to back up to the previous menu view.

Cancel soft key – Use to cancel a menu selection. Menu returns to the previous view.

Invalid entry error message

Trying to enter an invalid parameter setting will result in the following message in the upper righthand corner of the display:

Error, Press Help

Press the HELP menu key to display a message that explains the error. Press any key to cancel

the help message.

2-8 Return to Section Topics 3400S-900-01 Rev. B / January 2007

Page 35

Series 3400 Pulse/Pattern Generators User’s Manual Section 2: Getting Started

Defaults

The power-on defaults are listed in Table 2-2.

Table 2-2

Power-on defaults

Setting

Menu Parameter Setting or Value Menu Parameter

MODE Operating mode Pulse PATTERN Channel 1

TIME Channel 1 Format RZ

Frequency 1.000MHz Pattern Length 2 bits

Period 1.000µs Update Cont

Width 100.0ns PRBS Length 5

Delay 0.0ps UTILITY Clock Input:

Leading Edge 2.5ns Clock Input Terminator 50Ω

Trailing Edge 2.5ns Clock Input Slope Positive

Double Pulse Off Clock Input Threshold 1.0V

Period Source VCO External Input:

VOLTS Channel 1 External Input Terminator 50Ω

Amplitude 1000mVpp External Input Threshold 1.0V

Offset 0mV PLL Reference Auto

High Level 500mV System:

Low Level -500mV Display:

Polarity Normal Bright 8

Source Impedance 50Ω Contrast 6

Load Impedance 50Ω Timeout (in secs) 30

Channel Add (3402) Disabled GPIB Address* 10*

I/V Voltage IOPort* GPIB*

Limits Off, ± 500mV, ±10mA Emulation Mode Off

BURST Burst Count 2 bits TRIGGER Trigger Source ExtIn

Trigger Mode Cont

Trigger Frequency 100kHz

Trigger Period 10µs

Trigger Slope Positive

* At the factory, the GPIB is selected as the remote programming interface and the address is set to 10. Changing the

interace or address is saved in NVRM, and will therefore be remembered on subsequent power-on. You must reboot

the instrument after changing any communication parameters to ensure that such parameters are applied.

or Value

3400S-900-01 Rev. B / January 2007 Return to Section Topics 2-9

Page 36

Section 2: Getting Started Series 3400 Pulse/Pattern Generators User’s Manual

This page left blank intentionally.

2-10 Return to Section Topics 3400S-900-01 Rev. B / January 2007

Page 37

In this section:

Top ic Page

Introduction .......................................................................................... 3-2

Out 1 and Out 2 connections ............................................................... 3-2

Trig Out and Ext In connections........................................................... 3-3

Strobe Out connection ......................................................................... 3-4

Clk In connections................................................................................ 3-4

Section 3

Signal Connections

Ref Out and Ref In connections ........................................................... 3-5

Page 38

Section 3: Signal Connections Series 3400 Pulse/Pattern Generators User’s Manual

Out 1

DUT

HI

LO

DUT

HI

LO

Equivalent Circuit

BNC Cable

All Connectors: Female BNC

BNC Cable

All Connectors: Female BNC

BNC Cable

HI

HI

LO

Out 1

HI

Equivalent Circuit

DUT

Out 2

HI

LO

DUT

Connections to 2-Terminal Device:

Connections to 3-Terminal Device:

+/-

+/-

Introduction

For the Series 3400 Pulse/Pattern Generators front panel output option, signal connectors (except

Ref Out and Ref In) are located on the front panel. For the rear panel output option, all connectors

are on the rear panel to facilitate convenience for rack mounting. All signal connectors are female

BNC.

Out 1 and Out 2 connections

Figure 3-1 shows how to connect an output channel of the Series 3400 to a 2-terminal DUT. It also

shows an example of using both channels of a Model 3402 to pulse the gate and drain of a fieldeffect transistor (FET).

Figure 3-1

Out 1 and Out 2 connections

3-2 Return to Section Topics 3400S-900-01 Rev. B / January 2007

Page 39

Series 3400 Pulse/Pattern Generators User’s Manual Section 3: Signal Connections

BNC Cable

Trig Out

External Instrument

Ext In or

Ext Trig or

Trig In*

External Instrument can be one of the following:

· Scope being triggered to capture a waveform.

· Another Series 3400 being triggered to start Pulse, Burst, ExtWidth, or Pattern.

· Any other instrument being triggered to perform an operation.

* The actual label name

for the connector may

be different.

+/-

BNC Cable

Ext In

External Instrument

Ext Out or

Trig Out*

* The actual label name

for the connector may

be different.

External Instrument can be one of the following:

· Scope triggering the Series 3400 to start Pulse, Burst, ExtWidth or Pattern.

· A second Series 3400 triggering the first Series 3400 to start Pulse, Burst,

ExtWidth, or Pattern.

· Any other instrument triggering the Series 3400 to start Pulse, Burst, ExtWidth,

or Pattern.

+/-

Trig Out and Ext In connections

Figure 3-2 shows connections for Trig Out, and Figure 3-3 shows connections for Ext In. Trigger

output (Trig Out) marks each pulse or bit period (for Pattern mode). Trigger output is used to

trigger an external instrument to start an operation (e.g., trigger scope to capture the waveform).

After an external instrument completes the operation, (e.g., waveform capture), it can send a

trigger back to Ext In of the Series 3400 to output another pulse or bit. Using Trig Out and Ext In in

this manner together allows for synchronized operation between two instruments. Refer to

Section 5 for details on triggering.

Figure 3-2

Trig Out connections

Figure 3-3

Ext In connections

3400S-900-01 Rev. B / January 2007 Return to Section Topics 3-3

Page 40