Page 1

Series 2600-PCT-xB

Parametric Curve Tracer

User’s Manual

-900-01 Rev. B August 2022

PCT

tek.com/keithley

*PPCT-900-01B*

PCT-900-01B

Page 2

Parametric Curve Tracer

Series 2600-PCT-xB

User's Manual

Page 3

© 2022, Keithley Instruments, LLC

Cleveland, Ohio, U.S.A.

All rights reserved.

Any unauthorized reproduction, photocopy, or use of the information herein, in whole or in part,

without the prior written approval of Keithley Instruments, LLC, is strictly prohibited.

These are the original instructions in Engli sh.

All Keithley Instruments product names are trademarks or registered trademarks of Keithley

Instruments, LLC. Other brand names are trademarks or registered trademarks of their respective

holders.

Microsoft, Visual C++, Excel, and Windows are either registered trademarks or trademarks of

Microsoft Corporation in the United States and/or other countries.

Document number: PCT-900-01 Rev. B August 2022

Page 4

Safety precaut ions

The following safety precautio ns should be observed before using this product and any associated ins tr ument a tion . Alt ho ugh

some instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by personnel who recognize shock hazards and are familiar with the safety precautions required

to avoid possible injury. Read and follow all installation, operation, and maintenance information careful ly before using the

product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform insta llat ion and service procedures.

Keithley products are designed for use with electrical signals that are measurement, control, and data I/O connections, with low

transient overvoltages, and must not be directly connected to mains voltage or to voltage sources with high transient

overvoltages. Measurement Category II (as referenced in IEC 60664) connections require protection for high transient

overvoltages often associated with local AC mains connections. Certain Keithley measuring instruments may be connected to

mains. These instruments will be marked as category II or higher.

Unless explicitly allowed in the specifications, operating manual, and instrument labels, do not connect any instrument to mains.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000 V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited

sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective

devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided in close proximity to the equipment and within easy reach of the oper ator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

Page 5

For safety, instruments and accessories must be used in accordance with the operating instructions. If the instruments or

accessories are used in a manner not specified in the operating instructions, the protection provided by the equipment may be

impaired.

Do not exceed the maximum signal levels of the instruments and accessories. Maximum signal levels are defined in the

specifications and operating information and shown on the instrument panels, test fixture panels, and switching cards.

When fuses are used in a product, replace with the same type and rating for continued protection again st fire haz ar d.

Chassis connections must only be used as shield connections for measuring circuits, NOT as protective earth (safety ground)

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to protective earth (safety ground) using the wire recommended in the user documentation.

The symbol on an instrument means caution, risk of hazard. The user must refer to the operating instructions located in the

user documentation in all cases where the symbol is mark ed on the instr u ment .

The symbol on an instrument means warning, risk of electric shock. Use standard safety precautions to avoid personal

contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this symbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be

properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains hazards that might result in personal injury or death. Always read

the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains h azard s that coul d dama ge the instrument. Such damage may

invalidate the warranty.

The CAUTION heading with the symbol in the user documentation explains hazards that could result in moderate or minor

injury or damage the instrument. Always read the associated information very carefully before performing the indicated

procedure. Damage to the instrument may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits — including the power

transformer, test leads, and input jacks — must be purchased from Keithley. Standard fuses with applicable national safety

approvals may be used if the rating and type are the same. The detachable mains power cord provided with the instrument may

only be replaced with a similarly rated power cord. Other components that are not safety-related may be purcha sed fr om ot her

suppliers as long as they are equivalent to the original component (note that selected parts should be purchased only through

Keithley to maintain accuracy and functionality of the product). If you are unsure about the applicability of a replacement

component, call a Keithley office for information.

Unless otherwise noted in product-specific literature, Keithley instruments are designed to operate indoors only, in the following

environment: Altitude at or below 2,000 m (6,562 ft); temperature 0 °C to 50 °C (32 °F to 122 °F); and pollution degree 1 or 2.

To clean an instrument, use a cloth dampened with deionized water or mild, water-based cleaner. Clean the exterior of the

instrument only. Do not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that

consist of a circuit board with no case or chassis (e.g., a data acquisition board for installation into a computer) should never

require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board

should be returned to the factory for proper cleaning/servicing.

Safety precaution revision as of June 2018.

Page 6

Table of contents

Introduction ............................................................................................................... 1-1

Welcome .............................................................................................................................. 1-1

Introduction to this manual ................................................................................................... 1-1

Available configurations ....................................................................................................... 1-2

Extended warranty ............................................................................................................... 1-2

Contact information .............................................................................................................. 1-2

Instruments and connections .................................................................................. 2-1

Introduction .......................................................................................................................... 2-1

Unpacking the PCT .............................................................................................................. 2-1

About the Model 8010 High Power Device Test Fixture ...................................................... 2-2

About the Model 8020 High Power Interface Panel ............................................................. 2-3

Connections to protective earth (safety ground) .................................................................. 2-3

Interlock connections ........................................................................................................... 2-4

Connect instruments to the Model 8010 .............................................................................. 2-5

Connect instruments to the Model 8020 .............................................................................. 2-6

Getting started with ACS Basic ............................................................................... 3-1

Introduction .......................................................................................................................... 3-1

Installing and configuring the GPIB interface ....................................................................... 3-1

TSP-Link system setup ........................................................................................................ 3-2

Assign TSP-Link node numbers ................................................................................................ 3-2

Connect the instrument for communications ............................................................................. 3-3

Software installation ............................................................................................................. 3-4

Verify hardware configuration .............................................................................................. 3-5

Start ACS Basic ................................................................................................................... 3-9

ACS Basic test modes ....................................................................................................... 3-10

I-V applications for power MOSFETs ....................................................................... 4-1

Section overview and equipment requirements ................................................................... 4-1

On-state characteristics ....................................................................................................... 4-1

Configure the test fixture ........................................................................................................... 4-1

Collecting I-V curves in TraceMode .......................................................................................... 4-4

Configure a fixed plot .............................................................................................................. 4-11

Collecting I-V curves in MultiM ode .......................................................................................... 4-13

Digitizing pulses and improving timing .................................................................................... 4-26

Off-state characteristics ..................................................................................................... 4-34

Configure the test fixture ......................................................................................................... 4-34

Measuring leakage current in MultiMo de ................................................................................ 4-37

Page 7

Table of contents

s Manual

Series 2600-PCT-xB Parametric Curve Tracer User'

C-V applications on power MOSFETs ..................................................................... 5-1

Overview and requirements ................................................................................................. 5-1

Background of MOSFET capacitance measurements ......................................................... 5-1

Safety precautions and discharge procedures .................................................................... 5-4

Discharging bias tee capacitance in the Model 8010 ................................................................ 5-4

Discharging bias tee capacitance within the Model 8020 .......................................................... 5-8

Discharge system capacitance from SMU front panel interface .............................................. 5-10

Model 8010 connections .................................................................................................... 5-10

Model 8010 Crss test connections .......................................................................................... 5-10

Model 8010 Ciss test connections ........................................................................................... 5-12

Model 8010 Coss test connections ......................................................................................... 5-13

Model 8010 connections to the device for Crss....................................................................... 5-14

Model 8010 connections to the device for Ciss and Coss ....................................................... 5-15

Model 8020 connections .................................................................................................... 5-15

Model 8020 Crss test connections .......................................................................................... 5-16

Model 8020 Ciss test connections ........................................................................................... 5-17

Model 8020 Coss connections ................................................................................................ 5-18

Model 8020 test connections to the device ............................................................................. 5-19

Perform connection compensations on C-V measurements ............................................. 5-20

Ciss compensatio n .................................................................................................................. 5-20

Coss compensation ................................................................................................................. 5-27

Crss compensation ................................................................................................................. 5-32

Make a Ciss measurement ................................................................................................ 5-38

Make a Coss measurement ............................................................................................... 5-46

Make a Crss measurement ................................................................................................ 5-57

Optimizing Crss measurement connections for difficult measure ments ............................ 5-64

Troubleshooting FAQs ............................................................................................. 6-1

Missing cables ...................................................................................................................... 6-1

2600-PCT-1B and C-V measurements ................................................................................ 6-1

2600-PCT-2B and C-V measurements ................................................................................ 6-1

Custom tests in ACS Basic .................................................................................................. 6-2

Page 8

Contact information ...................................................................1-2

In this section:

Welcome

The Keithley Instrument Parametric Curve Tracer provides configurations that are complete solutions

configured with a variety of high quality instruments, cables, and test fixtures. This building block

approach offers the advantages of easy upgrade or modifications to meet changing test needs. For

example, a low cost 200 V at 10 A system can be purchased initially, and 50 A or 100 A capability

can be added later. Additionally, you can use these instruments and accessories with different test

system platforms, such as for reliability or device qualification testing.

Section 1

Introduction

Welcome ...................................................................................1-1

Introduction to this manual ........................................................1-1

Available configurations ............................................................1-2

Extended warranty ....................................................................1-2

Parametric Curve Trace configurations include everything you need to quickly develop a complete

test system.

The ACS Basic Edition software provides complete device characterization, including both real-time

trace mode for quickly checking fundamental device parameters like breakdown voltage and full

parametric mode for extracting precise device parameters. ACS Basic Edition goes beyond traditional

curve tracer interfaces by offering a broad array of sample device libraries. You have complete

control of all test resources, allowing you to create more advanced tests than previously possible on a

curve tracer.

Introduction to this manual

This manual describes how to set up and use the Parametric Curve Tracer and ACS Basic software,

including:

• Assembling the PCT

• Getting started with ACS Basic

• Performing tests with the software, using both TraceMode and Parametric Test mode

This manual provides detailed applications to help you achieve success with your Keithley

Instruments PCT.

Page 9

Section

User's Manual

2600-PCT-1B

200 V / 10 A

200 V / 10 A

200 V / 10 A

N/A

2600-PCT-2B

200 V / 10 A

40 V / 50 A

200 V / 10 A

200 V / 10 A

2600-PCT-3B

3 kV / 120 mA

200 V / 10 A

200 V / 10 A

200 V / 10 A

2600-PCT-4B

3 kV / 120 mA

40 V / 50 A

200 V / 10 A

200 V / 10 A

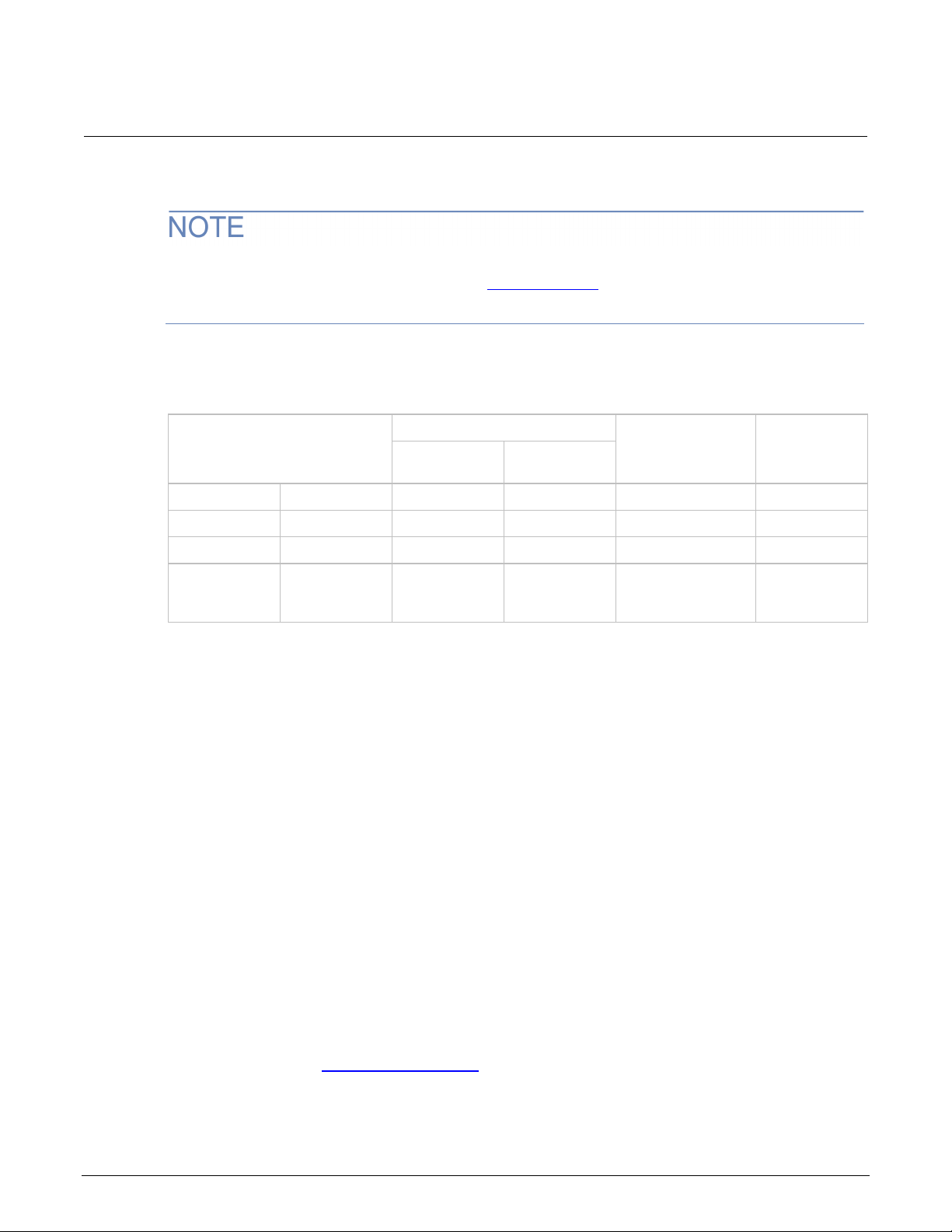

1: Introduction Series 2600-PCT-xB Parametric Curve Tracer

Each application is presented with an overview of the application, followed by instructions to complete

the application.

For more detailed information on specific system components, refer to the documentation. For

instruments, the documentation is available at tek.com/keithley

available from the Help menu.

Available configurations

. For ACS Basic, documentation is

Model Collector / Drain Supply Step Generator

Low power

High current

High voltage

High current

and high

voltage

The Keithley Instruments Model 2651A may be added to increase the high current mode to either 50

A or 100 A. Other available accessories include the PCT-CVU Multi-Frequency Capacitance-Voltage

(C-V) Meter, the Model 8010 High Power Device Test Fixture, the Model 8020 High Power Interface

Panel, and the CVU-200-KIT and CVU-3K-KIT bias tee kits.

Extended warrant y

Additional years of warranty coverage are available on many products. These valuable contracts

protect you from unbudgeted service expenses and provide additional years of protection at a fraction

of the price of a repair. Extended warranties are available on new and existing products. Contact your

local Keithley Instruments office, sales partner, or distributor for details.

High Voltage

Mode

High Current

Mode

Base / Gate Supply

Auxiliary

Supply

Contact information

If you have any questions after you review the information in this documentation, please contact your

local Keithley Instruments office, sales partner, or distributor. You can also call the Tektronix

corporate headquarters (toll-free inside the U.S. and Canada only) at 1-800-833-9200. For worldwide

contact numbers, visit tek.com/en/contact-tek

1-2 PCT-900-01 Rev. B August 2022

.

Page 10

Connect instruments to the Model 8020 ...................................2-6

In this section:

Introduction ...............................................................................2-1

Unpacking the PCT ...................................................................2-1

About the Model 8010 High Power Device Test Fixture ............2-2

About the Model 8020 High Power Interface Panel ..................2-3

Connections to protective earth (safety ground) .......................2-3

Interlock connections ................................................................2-4

Connect instruments to the Model 8010 ...................................2-5

Introduction

Section 2

Instruments and connections

You must connect the instruments to either the Model 8010 High Power Device Test Fixture or the

Model 8020 High Power Interface Panel and then set up the TSP-Link network. The cables supplied

with your PCT can be used with either fixture. This describes how to make these connections.

If you choose to install the instruments in a rack, install the instruments in the rack before connecting

the instruments to the test fixture or interface panel. Please refer to the instructions in the rack mount

kits for more information.

Unpacking the PCT

The PCT shipping container contains a box labeled “Open Me First” that contains all the instrument

accessories and user documentation. In this box, the accessories for each instrument in your

configuration are enclosed in individual boxes and bags. Each box includes a document describing

the contents of the box.

On the same shipping pallet are each SMU of your PCT configuration and any other larger PCT

accessories, such as a Model 8010 High Power Device Test Fixture, a Model 8020 High Power

Interface Panel, the PCT-CVU instrument option, or the optional 200 V or 3 KV bias tee kits.

The PCT is generally connected to either a Model 8010 or a Model 8020. The following section

provides overview for these devices.

Page 11

Section

User's Manual

2: Instruments and connections Series 2600-PCT-xB Parametric Curve Tracer

About the Model 8010 Hi gh Power Device Test Fixture

The Model 8010 High-Power Device Test Fixture provides a safe, low noise, complete environment

for testing a variety of packaged device types. The replaceable socket module test boards allow for a

variety of package types, in cluding the user-supplied socket types.

The Model 8010 allows you to connect one Model 2657A High Power SourceMeter for up to 3 KV

testing. You can use one or two Model 2651A High Power SourceMeters for 15 A dc testing or 50 A

or 100 A pulse testing. For lower power terminals, you can connect up to two other SourceMeters,

such as Models 2611B, 2612B, 2635B, 2636B, 4200-SMU, or 4210-SMU.

The Model 8010 includes :

• Kelvin (remote sense) connections for five instruments

• Guarded pathways for picoampere level measurements even at 3 kV

• An access port for a variety of probes, such as scope or temperature

• Integrated protection circuits to protect Models 2611B, 2612B, 2635B, 2636B, 4200-SMU, and

4210-SMU from high voltage instruments

• Two independent test sockets, one for high current and one for high voltage

The test fixture is fully interlocked, providing safe operation for up to six different instruments. It is

declared safe through CE marking and certified through nationally recognized testing laboratories.

The Model 8010 is shipped with two 8010-DTB high power socket module test boards installed. The

boards include sockets for TO-247 and axial lead devices.

The high current side of the test fixture can be used with up to 100 amps pulsed, 15 amps dc,

200 V dc. Up to four measurement resources can be connected (two high current, two low power).

The high voltage side of the test fixture can be used with up to 3030 V dc at 120 mA, 200 V dc up to

10 A pulsed. Connections are provided for up to three measurement resources (one high voltage, two

low power).

For information on the Model 8010, including fixture setup within a test system, see the Model 8010

High Power Device Test Fixture User's Manual, available at tek.com/keithley

.

2-2 PCT-900-01 Rev. B August 2022

Page 12

Series 2600

Instruments and connections

-PCT-xB Parametric Curve Tracer User's Manual Section 2:

About the Model 8020 High Power In t er f ace Panel

The Model 8020 has six measurement pathways accommodating 3 kV, 200 V, and 100 A

measurements. You can configure five of the pathways with a variety of output connector types to

match your probe station. You can configure four pathways with the optional bias tees. This provides

high voltage C-V measurements on up to 4 pins of the device under test.

The Model 8020 comes with a selection of resistors that you can install to provide stability and extra

protection to the device.

Additionally, the Model 8020 offers the following:

• A common LO reference

• Overvoltage protection for all 200 V channels, ideal for device testing configurations using 200 V

SMUs and higher voltage SMUs

• A variety of connector types

• A single interlock interface for multiple instruments

• An interface for adding series resistor elements for measurement stability and absolute current

limit

• Optional transient overcurrent protection on the 200 V channels

• Expansion ports to easily link multiple 8020 interface panels

The Model 8020 can be configured to suit your probe station and test system. Contact your Keithley

Instruments applications engineer or see the Model 8020 High Power Interface Panel User's Manual,

available at tek.com/keithley

.

Connections to protective earth (safety ground)

The ground wires must be attached to a known protecti ve earth (safety ground) before

powering on instruments. Failure to attach the ground wires to a known protective earth may

result in electric shock.

Connections to protective earth (safety ground) are made at terminals labeled with the

following symbol.

Figure 1: Protective earth (safety ground) symbol

For detailed Model 8010 and Model 8020 instrument connection diagrams, including safety ground

details, see Connect instruments to the Model 8010 (on page 2-5) or

Model 8020 (on page 2-6).

PCT-900-01 Rev. B August 2022 2-3

Connect instruments to the

Page 13

Section

User's Manual

2: Instruments and connections Series 2600-PCT-xB Parametric Curve Tracer

Interlock connections

For proper interlock functionality, any instruments connected to the interlock must be powered on or

disconnected from the interlock.

Each Parametric Curve Tracer configuration contains instruments that can output hazardous live

voltages. To ensure operator safety, it is important to use the instrument interlock properly with the

Model 8010 and Model 8020 test fixtures. Both the Model 8010 and Model 8020 include interlock

connectors to interface with Series 2600B, Series 2650A, and 4200A-SCS instruments. Refer to the

instrument connection diagrams later in this section for illustrations on how to connect to the

individual SMU instruments.

With the Model 8010, the interlock switch is engaged when the lid is closed and latched. When the

interlock switch is engaged, a light on the enclosure is illuminated. You can turn on a SMU output

only when the interlock switch is engaged. If the lid is open, the interlock switch will not engage and

any SMUs with outputs that are configured for high voltage will not turn on.

For the Model 8020, the Interlock OUT connector on its device connections panel side of the panel is

designed for use with the supplied 8020-ILC-UNT interlock to unterminated cable. The interlock

enables the high-voltage outputs of the connected instruments when the normally-open switch at the

device under test (DUT) access point is closed.

The Model 8020 interlock is satisfied only when:

• The top cover to the 8020 is correctly installed and any top covers to other Model 8020s in the

test configuration are also correctly installed

• The system interlock is engaged (all normally-open switches are closed at DUT access points of

the test configuration)

When the 8020 interlock is satisfied, lights on the instrument connection and device connection

panels of the 8020 are illuminated.

For detailed information on the interlock requirements for the Model 8010 or Model 8020, see the

user's manual for that test fixture. For detailed information on the interlock requirements for a specific

SMU, see the reference manual for that SMU.

There is no safety interlock on the Model 2651A because its output voltage is below hazardous

evels. To activate Output Enable on the 2651A, refer to the Model 2651A Reference Manual. Output

l

Enable can be activated using the front panel or by remote control.

2-4 PCT-900-01 Rev. B August 2022

Page 14

Series 2600

Instruments and connections

-PCT-xB Parametric Curve Tracer User's Manual Section 2:

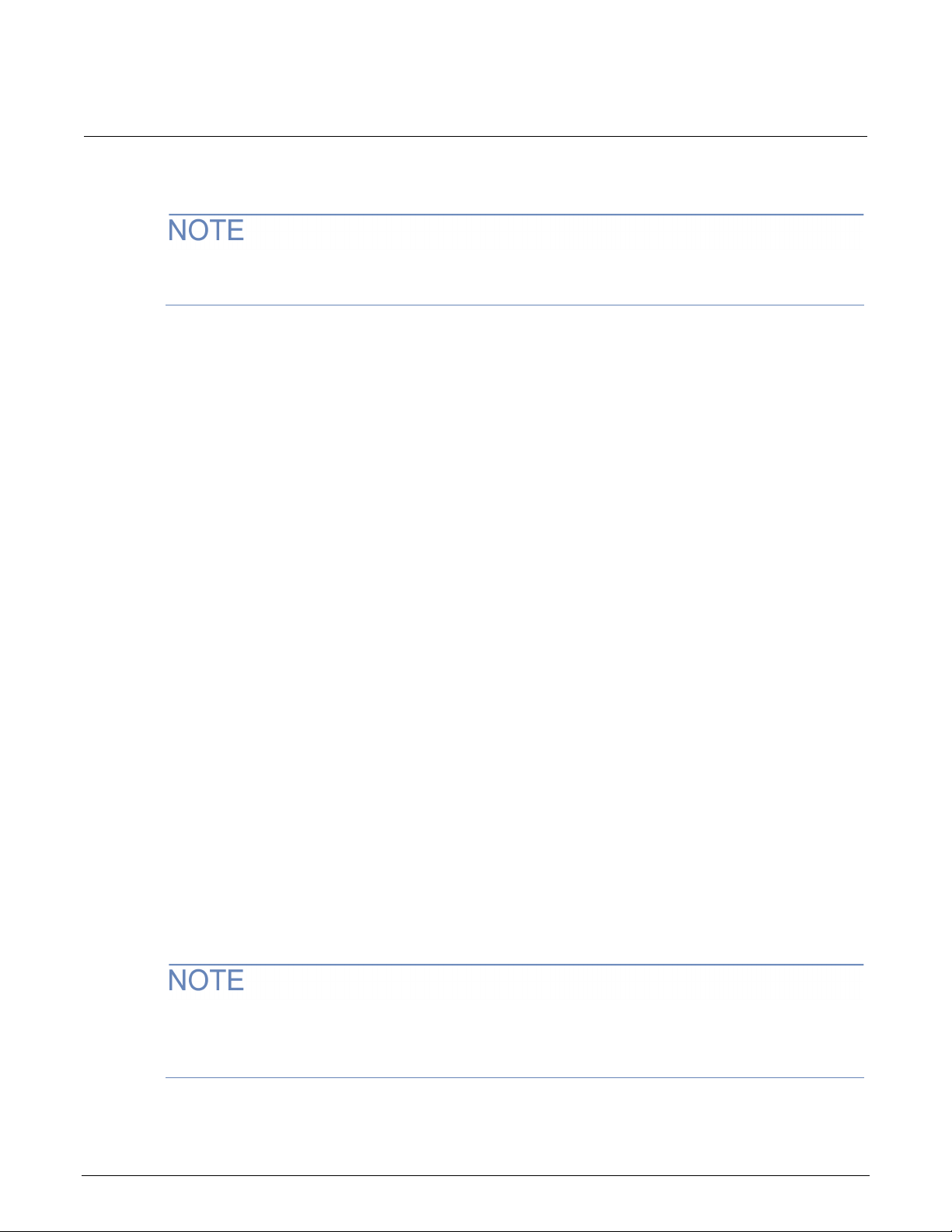

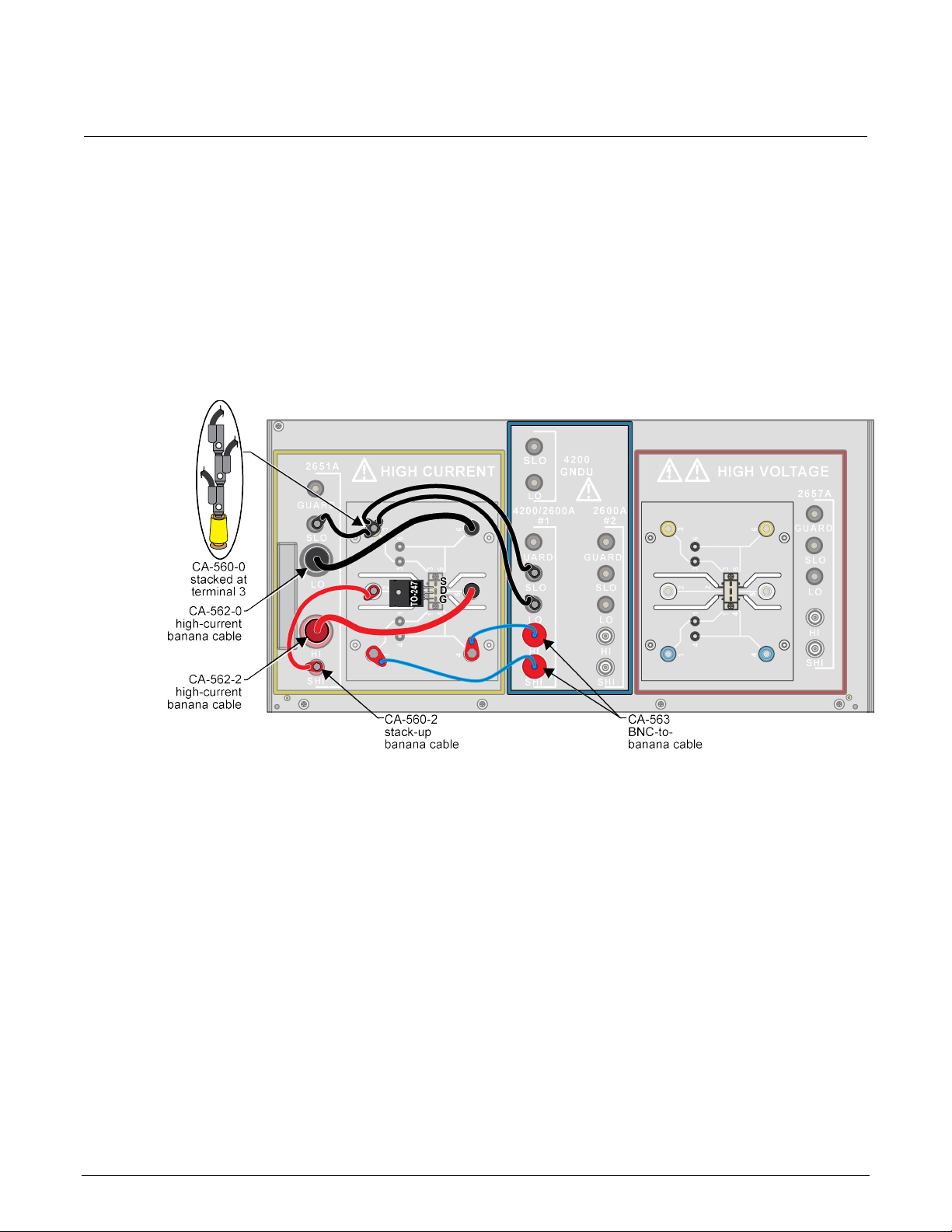

Connect instruments to the Model 8010

The following figure shows connections for I-V and C-V measurements. To make only connections for

I-V measurements, refer to the Model 8010 High Power Device Test Fixture User's Manual.

Figure 2: Instrument connections to the Model 8010

PCT-900-01 Rev. B August 2022 2-5

Page 15

Section

User's Manual

2: Instruments and connections Series 2600-PCT-xB Parametric Curve Tracer

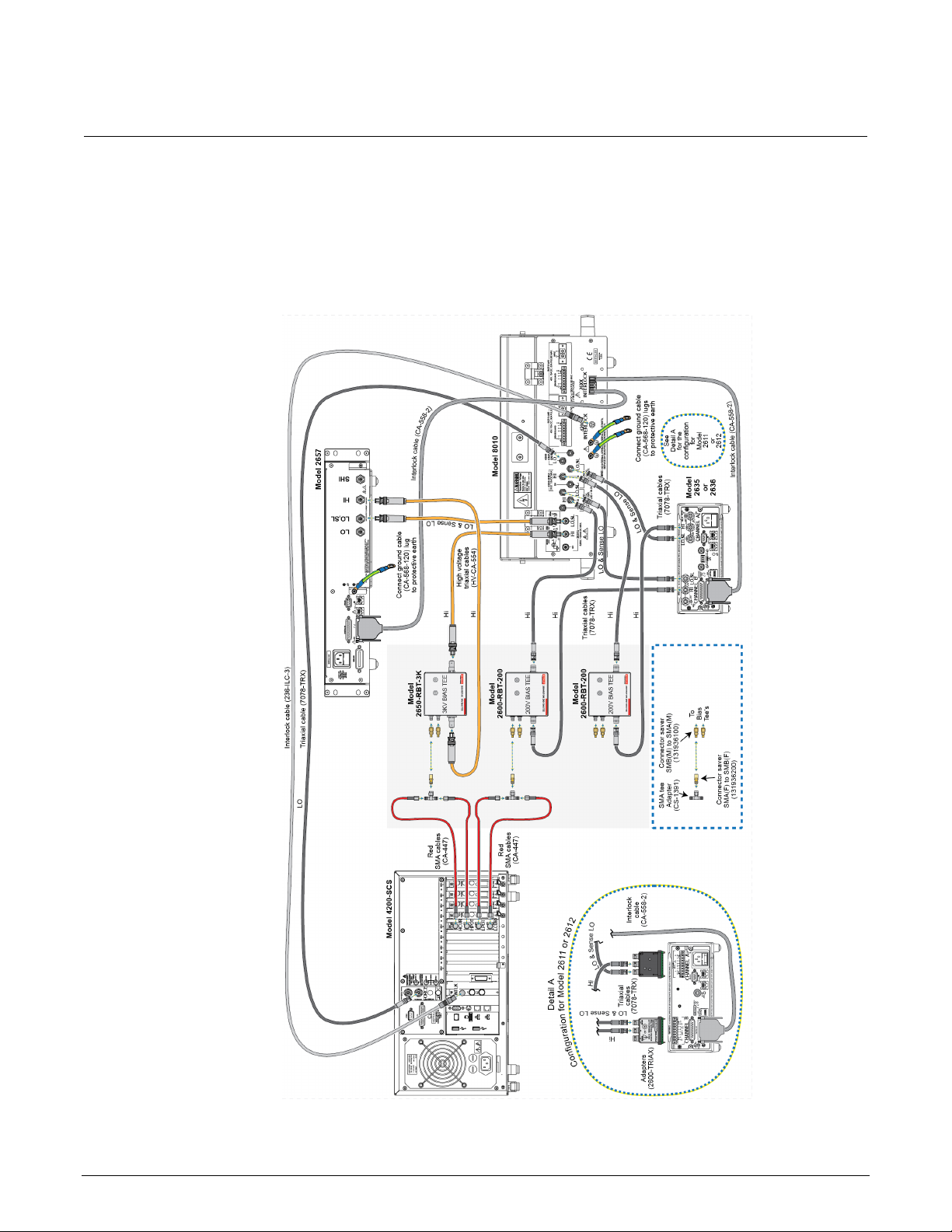

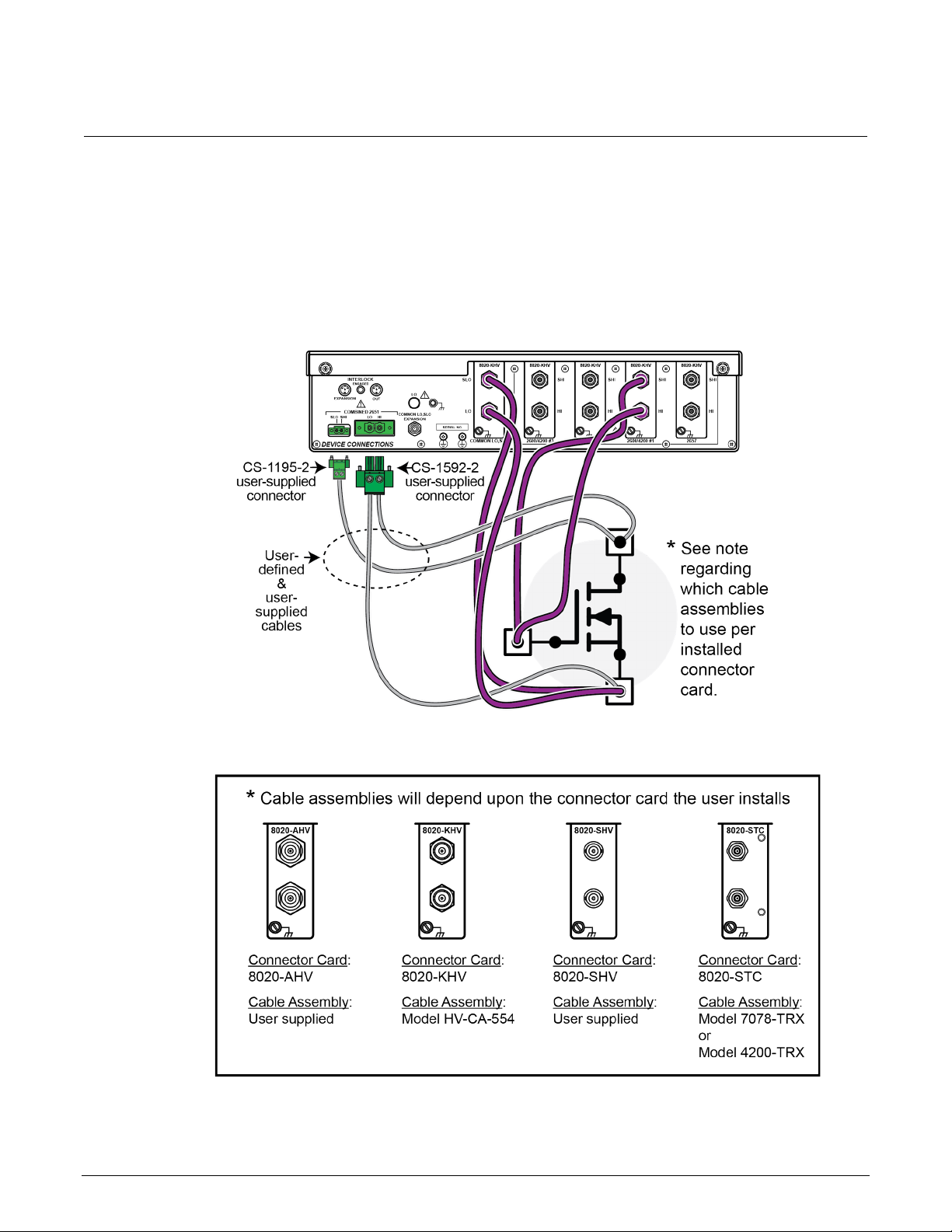

Connect instruments to the Model 8020

Figure 3: Connecting instruments to the Model 8020

2-6 PCT-900-01 Rev. B August 2022

Page 16

ACS Basic test modes ............................................................3-10

In this section:

Introduction ...............................................................................3-1

Installing and configuring the GPIB interface ............................3-1

TSP-Link system setup .............................................................3-2

Software installation ..................................................................3-4

Verify hardware configuration ...................................................3-5

Start ACS Basic ........................................................................3-9

Introduction

Section 3

Getting started with ACS Basic

ACS Basic Edition software is optimized for parametric testing of component and discrete (packaged)

semiconductor devices. ACS Basic supports all Keithley source and measure instrument products,

including Series 2600B, Series 2400, and Model 2651A and 2657A SourceMeter Instruments, and

Model 4200A-SCS Parameter Analyzers.

ACS Basic has a large device test library to allow you to get a test up and running quickly.

This section outlines how to configure the instruments in the PCT to prepare for connection to ACS

Basic, how to install the software, and how to get started using the software.

Installing and configuring the GPIB interface

If you ordered the PCT-CVU for high-voltage capacitance measurements, a GPIB interface is

installed on the Model 4200A-SCS that is included with the PCT-CVU. There is no need to use a

separate computer or install the KUSB-488B. Go to TSP-Link system setup (on page 3-2).

Page 17

Section

User's Manual

3: Getting started with ACS Basic Series 2600-PCT-xB Parametric Curve Tracer

ACS Basic software works with the following GPIB interfaces:

• KUSB-488

• KUSB-488A

• KUSB-488B

• KPCI-488

• KPCI-488A

• KPCI-488LP

• KPCI-488LPA

• NI USB-488

• NI PCI-488

If one of the above interfaces is already installed on your computer, please continue to

system setup (on page 3-2).

The PCT is supplied with Keithley’s Model KUSB-488B GPIB interface. If you are using a separate

computer for software control, install the GPIB interface if there is not one already installed. Refer to

the KUSB-488B documentation for instructions on installing the interface software.

TSP-Link system setup

ACS Basic automatically assigns the SMU identification numbers based on the TSP-Link setup. The

numbers differ based on your PCT configuration.

Assign TSP-Link node numbers

Each instrument in the TSP-Link network must have a unique TSP-Link node number. In addition,

ACS Basic requires that you set the master node to TSP-Link node number 1 and that each node that

is connected to the master has an incremental node number. For example, if you have a TSP-Link

network with three nodes, you must assign the instruments to the nodes 1, 2 and 3. Do not skip

numbers.

In PCT configurations, use the Model 2636B as the master node, assigned to node 1.

TSP-Link

If the PCT includes a Model 2657A , assign the 2657A to node 2.

The Model 2651A in a PCT-2B configuration should be assigned to node 2. If you have a second

2651A, assign it to the subsequent node.

The Model 2651A in a PCT-3B or -4B configuration should be assigned to node 3.

While other node configurations are possible, these assignments allow for simpler use of the

default ACS Basic tests.

3-2 PCT-900-01 Rev. B August 2022

Page 18

Series 2600

started with ACS Basic

-PCT-xB Parametric Curve Tracer User's Manual Section 3: Getting

To assign a node number from the front panel of the instrument:

1. Press the MENU key.

2. Select TSPLINK > NODE.

3. Press the navigation wheel and select the node number.

4. Press the ENTER key to save the node number.

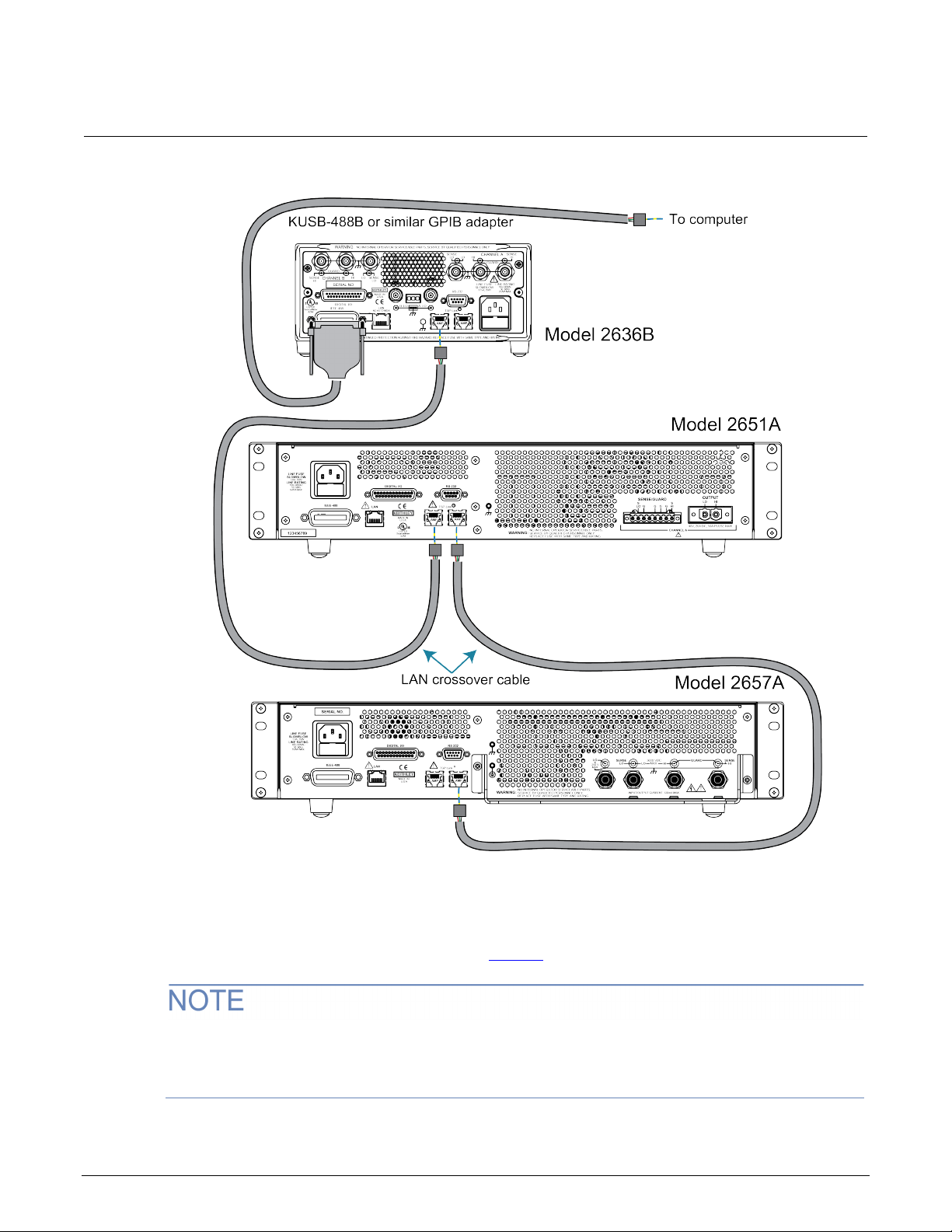

Connect the instrument for communications

All configurations require a KUSB-488B or similar GPIB adapter cable connecting the instrument and

your computer. For additional connections, see the following details for your PCT configuration.

The 2600-PCT-1B configuration is shipped with the Model 2636B. The KUSB-488B or similar GPIB

adapter cable linking the Model 2636B and your computer is the only connection.

The 2600-PCT-2B configuration is shipped with the Models 2636B and 2651A. For this configuration,

connect the TSP-Link port of the Model 2636B to the TSP-Link port of the Mod el 2651A.

The 2600-PCT-3B configuration is shipped with the Models 2636B and 2657B. For this configuration,

connect the TSP-Link port of the Model 2636B to the TSP-Link port of the Model 2657A.

The following figure shows a 2600-PCT-4B configuration. The -4B configuration is shipped with the

Models 2636B, 2651A, and 2657B.

5. Press the EXIT key as needed to return to the main display.

PCT-900-01 Rev. B August 2022 3-3

Page 19

Section

User's Manual

3: Getting started with ACS Basic Series 2600-PCT-xB Parametric Curve Tracer

Figure 4: Communications connections

Software installation

See the ACS Basic release notes, availab le at tek.com, for instructions on installing the software.

It is recommended that you review the ACS Basic release notes. The release notes contain valuable

information about known issues and provide guidance on how to handle issues that you

may encounter.

3-4 PCT-900-01 Rev. B August 2022

Page 20

Series 2600

Getting started with ACS Basic

-PCT-xB Parametric Curve Tracer User's Manual Section 3:

Verify hardware configuration

Before starting ACS Basic, you need to set up the hardware for your test configuration.

ASC Basic checks for hardware changes when it starts up. You need to run ACS Hardware

gement whenever the hardware is changed.

Mana

To manage the hardware:

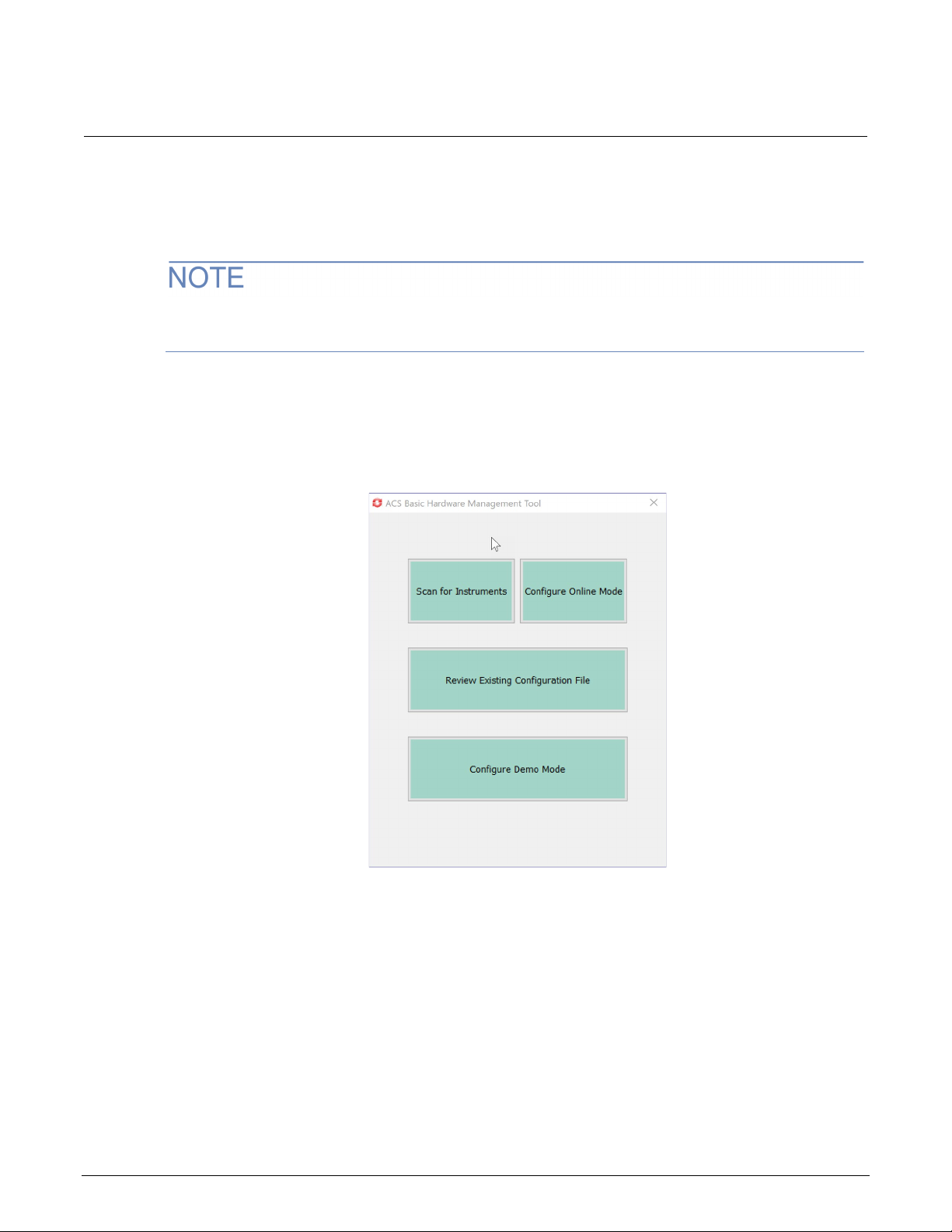

1. From Start, select Keithley ACS Basic HardwareManagement. The dialog shown in the

following figure is displayed.

Figure 5: Hardware Management Tool options

2. Select Scan for Instruments. The Scan Hardware By dialog is displayed, as shown in the

following figure.

PCT-900-01 Rev. B August 2022 3-5

Page 21

Section

User's Manual

3: Getting started with ACS Basic Series 2600-PCT-xB Parametric Curve Tracer

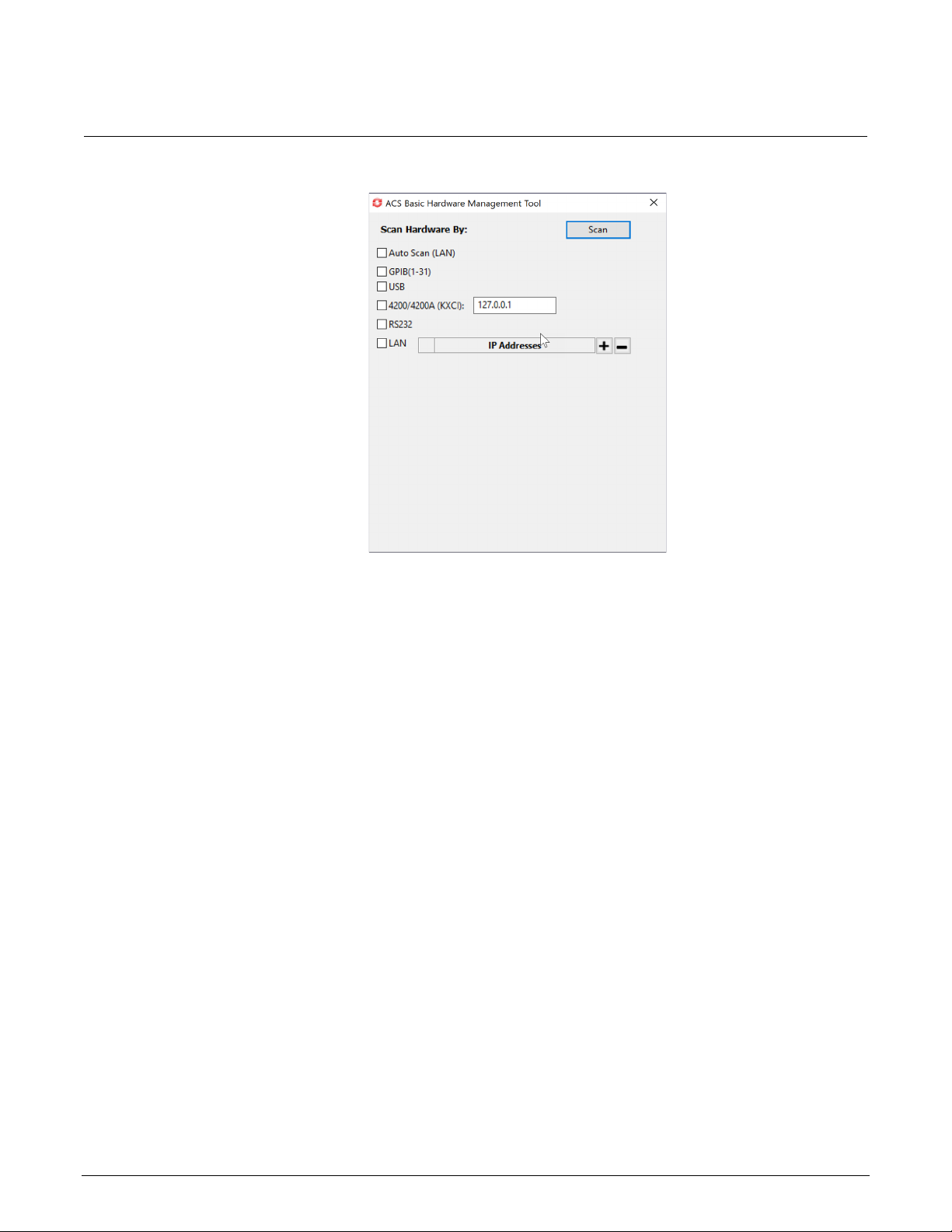

Figure 6: Scan Hardware By dialog

3. Select the options for your test. You can choose:

Auto Scan (LAN): Instruments are on the same subnet as the system computer (the first

three fields of the IP address are the same).

GPIB: Instrument addresses from 1 to 30 are supported.

Prober GPIB Address: Default value is 31.

USB

4200/4200A (KXCI): E nter the IP address in the text box.

RS-232

LAN: Use IP Addresse s to add or remove an IP address. To add an IP address, select + to

add a field. Enter the IP address. To remove an IP address, select the address and select –.

4. Select Scan. ACS Basic compares the instruments that were previously configured with the

present online instrument configuration. When the scan is complete, the Comparison Results

dialog is displayed, as shown in the following figure.

3-6 PCT-900-01 Rev. B August 2022

Page 22

Series 2600

Getting started with ACS Basic

-PCT-xB Parametric Curve Tracer User's Manual Section 3:

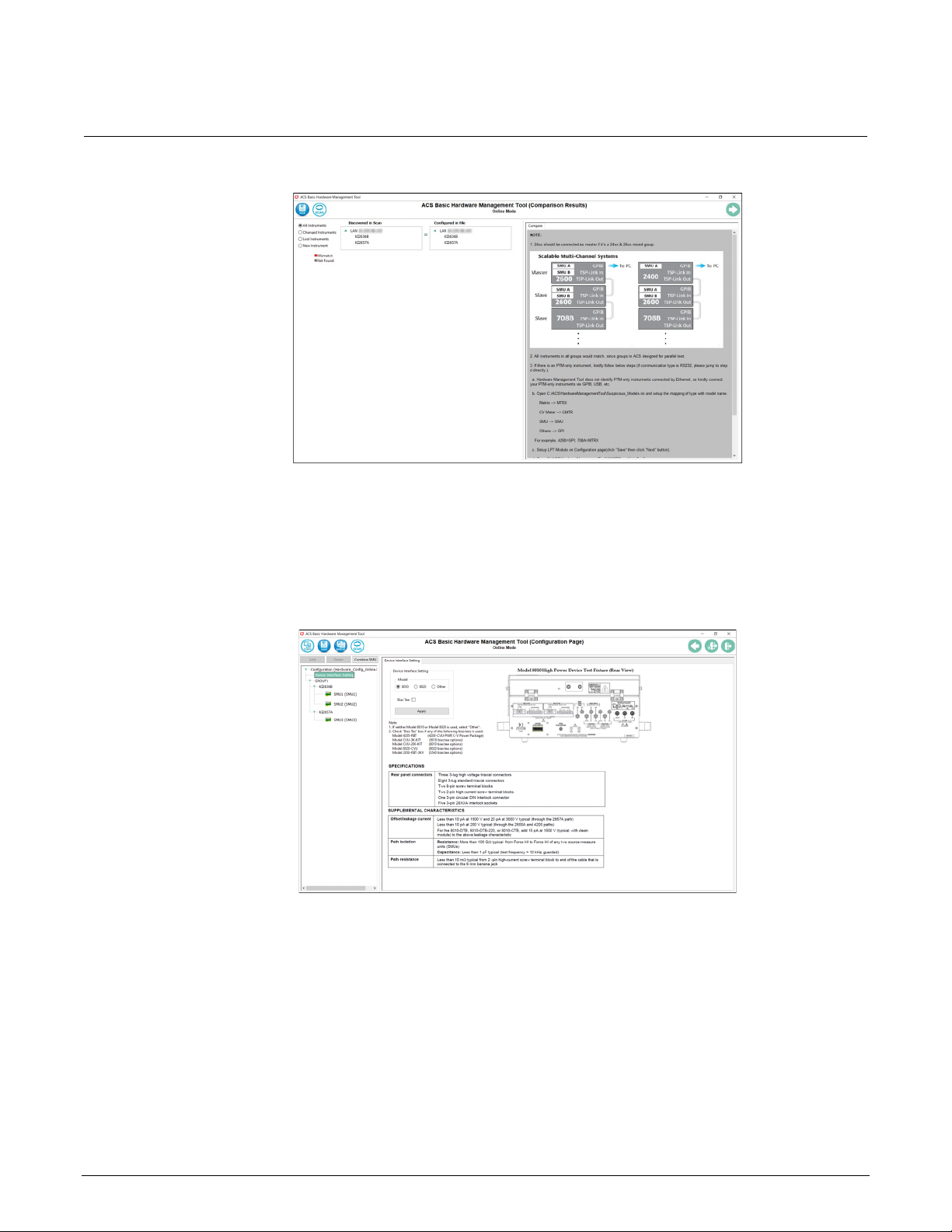

Figure 7: Comparison results

5. Verify the instruments. If you need to delete an instrument, right-click the instrument and select

Delete.

6. Select Save. The Configuration Page (Online Mode) opens.

7. Select Device Interface Setting. The information shown in the following figure is displayed.

Figure 8: Device Interface Setting

8. Select the Model of the device interface.

9. If you are using a bias tee (CVU-3K-Kit, CVU-200-KIT, 8020-CVU, or Model 4205-RBT), select

Bias Tee.

10. Select Apply.

PCT-900-01 Rev. B August 2022 3-7

Page 23

Section

User's Manual

3: Getting started with ACS Basic Series 2600-PCT-xB Parametric Curve Tracer

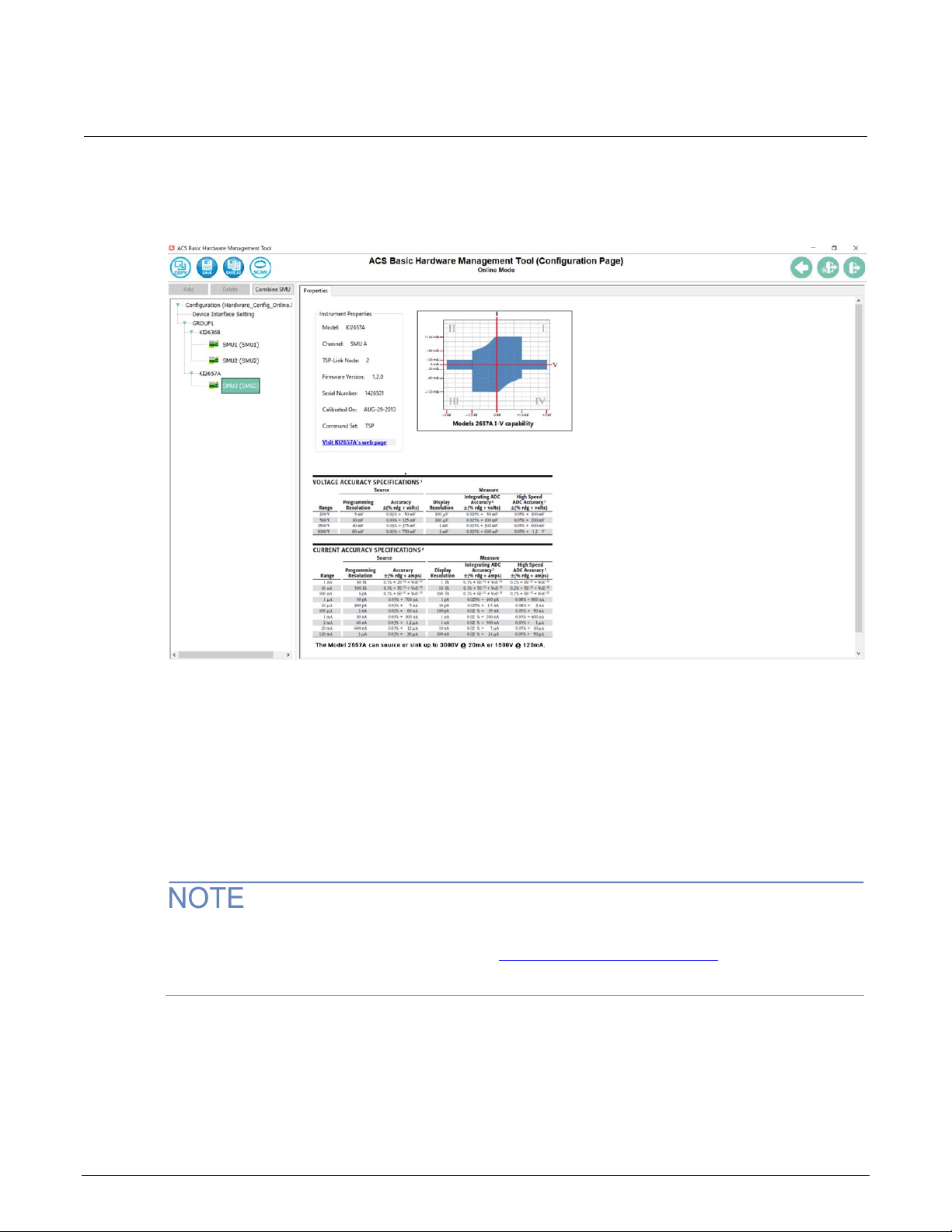

11. To set up the instruments, select an instrument from the left pane. An example of the

Configuration Page with a 2657A selected is shown in the following figure.

Figure 9: Configuration Page of the Hardware Management Tool

12. From this page, you can:

Add an instrument: Select Add. The instrument must be connected to the test system.

Delete an instrument: Select the instrument in the tree and select Delete.

Combine SMU instruments: Select the SMU instruments and select Combine SMU.

13. Select Save.

14. Close the Hardware Management Tool.

15. Restart ACS Basic.

ACS Basic automatically assigns the SMU numbers. The numbers differ based on your PCT

configuration and TSP-Link node numbers. See Assign TSP-Link node numbers (on page 3-2

) for

the recommended TSP-Link configuration.

3-8 PCT-900-01 Rev. B August 2022

Page 24

Series 2600

ted with ACS B asic

-PCT-xB Parametric Curve Tracer User's Manual Section 3: Getting star

For more information on using the Hardware Management Tool, refer to the ACS Basic

documentation.

If one or more SMUs are missing:

• Ensure that the GPIB adapter is securely attached to instrument and is working.

• Ensure that all instruments are powered on.

• Ensure that all TSP-Link cables are secure.

After checking the instruments, select Scan to scan the hardware configuration again.

Start ACS Basic

FATAL ERROR POSSIBLE. To avoid fatal errors to instruments, never start the ACS Basic

software until all the instruments have completed self-testing. If you are using Series 2600

and 2600B instruments with TSP-Link, always power-on the subordinate instruments first and

then the master. Since the master scans through all the linked subordinate instruments, it

must be powered on after all the subordinate machines are turned on, or errors may occur

when you start ACS Basic.

Before you open the ACS Basic software, make sure that all instruments are turned on and all selftests have completed.

To start the ACS software:

1. Select the ACS software icon on the desktop of your computer. The User Login dialog opens, as

shown in the following figure.

Figure 10: User login

PCT-900-01 Rev. B August 2022 3-9

Page 25

Section

User's Manual

3: Getting started with ACS Basic Series 2600-PCT-xB Parametric Curve Tracer

2. Type a user name and password in the User Name and Password fields. The default user name

is ACSADMIN; however, there is no default password.

3. Select OK. The software start window opens.

4. You can create more than one new user account at this time. To create a new account, select

New User. To change the password, select Change Password.

When you start the ACS Basic software, the startup time depends on how many instruments are in

t

he hardware configuration group. For example, if there are several instruments, the startup time

is longer.

ACS Basic test mod es

ACS Basic has three test modes: SingleMode, MultiMode, and TraceMode.

In SingleMode, ACS Basic opens and runs a single test on a single device at a time.

In MultiMode, you can create multiple test modules on one or more devices and organize them into a

single project. For example, MultiMode can perform multiple tests on a single device (target

application) or multiple tests on multiple devices (secondary use case). You can work with external

instruments such as DMMs and switches in MultiMode much easier than in any other mode.

TraceMode provides interactive operation with a SMU. TraceMode is useful for quickly checking the

operating boundaries of a device and for verifying its basic functionality.

In the following sections of this manual, you will learn how to perform common power semiconductor

tests in MultiMode and in TraceMode.

3-10 PCT-900-01 Rev. B August 2022

Page 26

Off-state characteristics ..........................................................4-34

I-V applications for power MOSFETs

In this section:

Section overview and equipment requirements ........................4-1

On-state characteristics ............................................................4-1

Section overview and equipment requirements

This section provides step-by-step instructions to use the Parametric Curve Tracer (PCT) to perform

common tests on a sample power MOSFET device. These tests include collecting family of curves

) on a power MOSFET and measuring leakage current (I

(V

ds-Id

) using the ACS Basic software.

dss

Section 4

The following instructions are tailored to the 2600-PCT-4B, which has both high voltage and high

current capability. However, the test parameters can be adjusted to suit the PCT configuration and

instrumentation that you have.

The PCT is provided with a sample test device, located in the PCT-DOC-KIT box of the “Open Me

First” box. The sample device is a 1000 V MOSFET and is available from onsemi as part number

FQH8N100C. You can download a datasheet for this part from the manufacturer's website at

onsemi.com (onsemi.com/

This section refers to SMUs that are numbered as suggested in Assign TSP-Link node numbers (on

page 3-2). Your configuration may vary.

).

On-state characterist ics

Configure the test fixture

The PCT supports either the Keithley Instruments Model 8010 or Model 8010 test fixtures. For

instructions on how to connect instruments to the 8010 or 8020, refer to Instruments and connections

(on page 2-1). To make connections to the device, see the following procedure for your test fixture.

Page 27

Section

User's Manual

4: I-V applications for power MOSFETs Series 2600-PCT-xB Parametric Curve Tracer

To configure the Model 8010 test fixtur e:

1. On the High Current side of the fixture, insert the test device into the test socket. Place the device

with the Gate pin closest to the front of the test fixture.

2. Wire the test fixture as shown in the following figure:

Connect the 2651A HI and SHI signals to the Drain terminal.

Connect the 2600A #1 HI and SHI signals to the Gate terminal.

Connect the LO and SLO signals from both SMUs to the Source terminal.

Figure 11: Three-terminal DUT with one or two 2651A instruments and Series 2600A

instrument connected

4-2 PCT-900-01 Rev. B August 2022

Page 28

Series 2600

V applications for power MOSFETs

-PCT-xB Parametric Curve Tracer User's Manual Section 4: I-

To configure the Model 8020 test fixtur e:

1. Wire the test fixture as shown in the following figure:

Connect both COMMON LO, SLO signals and the COMBINED 2651 LO signal to the Source

terminal of the device.

Connect the COMBINED 2651 SHI and HI signals to the Drain terminal of the device.

Connect both 2600/4200 SHI and HI signals to the Gate terminal of the device.

Figure 12: 8020 test fixture confi g uration (device side)

PCT-900-01 Rev. B August 2022 4-3

Page 29

Section

User's Manual

4: I-V applications for power MOSFETs Series 2600-PCT-xB Parametric Curve Tracer

Collecting I-V curves in TraceMode

TraceMode allows you to generate rapid visual results of device characteristics and to have real-time

control of one of the test parameters. This example application instructs you on how to collect a family

of curves on a MOSFET device.

These instructions demonstrate how to do the following tasks:

• Configure TraceMode

• Gather a family of curves on a MOSFET using TraceMode

• View and save data in TraceMode

An overview of the steps to do the test are:

1. Enter TraceMode of ACS Basic

2. Load the IdVd_StepVg test for the nPowerMOSFET device into the project

3. Configure the settings to match the DUT

4. Run the test

5. View and save the data

TraceMode supports the Series 2400, Series 2600B, and the Series 2650A SMUs. However, you

cannot connect a Series 2400 and a Series 2600B instrument to the same device. If you are using a

Series 2400 on one device terminal, you must use a Series 2400 instrument on the other device

terminals. TraceMode only supports the SCPI protocol for Series 2400 SMUs.

You can use a Series 2600B and a Series 2650A instrument in any combination.

TraceMode provides interactive control of SMU instruments to achieve real-time performance. Only

Series 2600B instruments (Models 2601B, 2602B, 2611B, 2612B, 2635B, or 2636B), Series 2650A

(Models 2651A or 2657A) and Series 2400 instruments (Models 2400, 2401, 2410, 2420, 2425, 2440)

are supported. ACS Basic can perform dc and pulse tests on Series 260 0B and 2650 A instr um ents in

TraceMode, but it can only perform dc measurements on Series 2400 instruments.

4-4 PCT-900-01 Rev. B August 2022

Page 30

Series 2600

V applications for power MOSFETs

-PCT-xB Parametric Curve Tracer User's Manual Section 4: I-

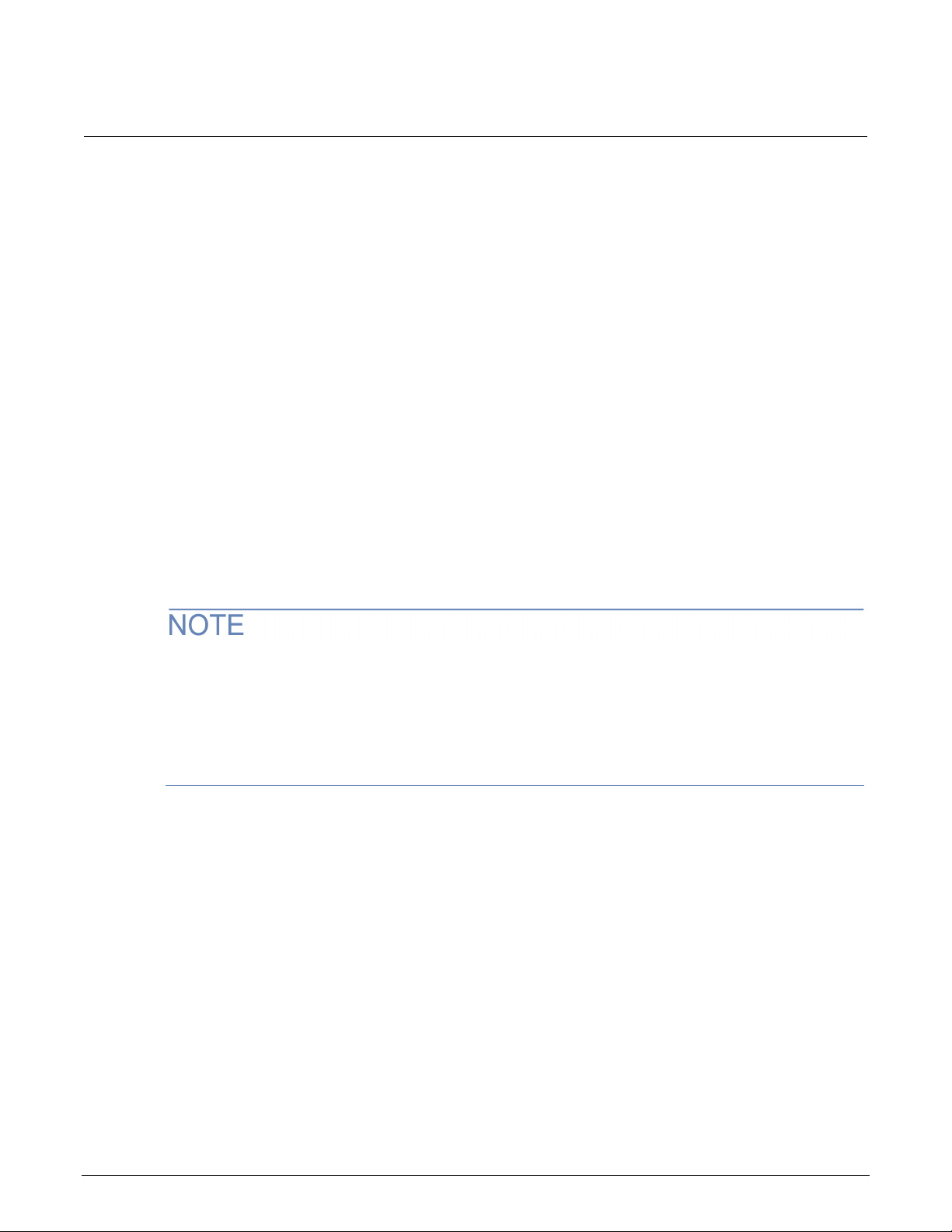

See the following figure. The GUI includes:

1. Device setting: Used to map the SMU, select the test module, and set the advanced settings.

2. Test setting: Used to set the test information when the test module is enabled.

3. Trace Test Data: Used to show the test result.

Figure 13: TraceMode GUI

To collect curves in TraceMode:

1. Launch ACS Basic.

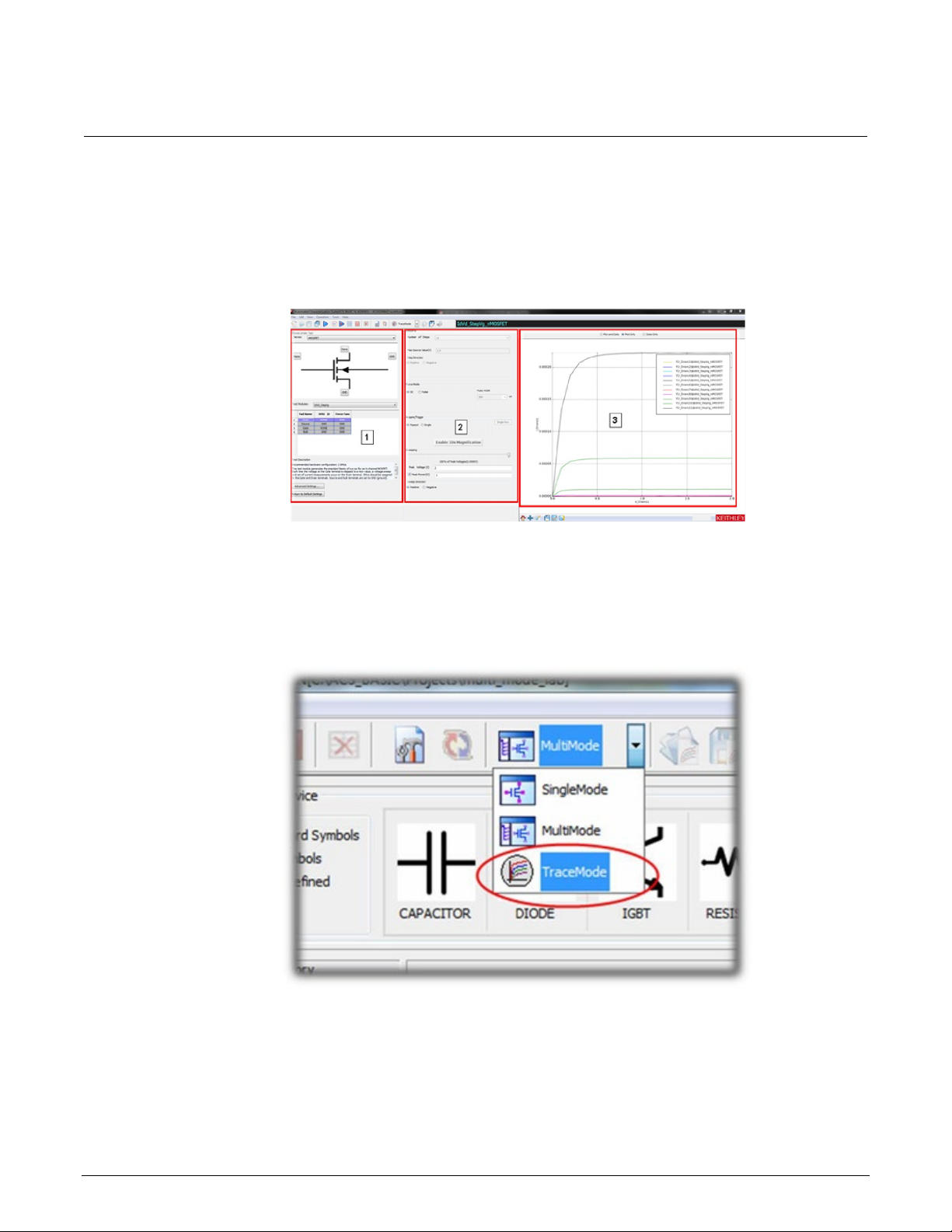

2. From the MultiMode menu, select TraceMode.

Figure 14: Select TraceMode

PCT-900-01 Rev. B August 2022 4-5

Page 31

Section

User's Manual

4: I-V applications for power MOSFETs Series 2600-PCT-xB Parametric Curve Tracer

3. From Device, select nPowerMOSFET.

Figure 15: Select nPowerMOSFET

4. From Test Modules, select IdVd_StepVg. The test loads with default settings and sample data.

Figure 16: Selecting IdVd_Ste pVg

4-6 PCT-900-01 Rev. B August 2022

Page 32

Series 2600

V applications for power MOSFETs

-PCT-xB Parametric Curve Tracer User's Manual Section 4: I-

5. Connect a SMU to the device terminal by selecting the button next to the device terminal and

selecting the appropriate SMU. In the following example, SMU 4 is connected to the

Drain terminal.

Figure 17: Selecting a device terminal for SMU assignment

6. Select the SMU resource to connect to this device terminal. In this example, the high current

SMU (2651A, SMU 4) is connected to the Drain.

Figure 18: SMU 4 settings

PCT-900-01 Rev. B August 2022 4-7

Page 33

Section

User's Manual

4: I-V applications for power MOSFETs Series 2600-PCT-xB Parametric Curve Tracer

7. Select Ok.

8. Repeat these steps for the remaining device terminals. For this example, connect 2636A Channel

A (SMU1) to the gate and connect the Source to the GND terminal, which represents the

Common LO terminal.

9. Change the Stepping values. In this example, the gate SMU steps from 5 V to 7 V in 0.5 V

increments. Therefore, set the Number of Steps to 5, the Offset Value to 5 V, the Max Source

Value (V) to 7, and the Step Direction to Positive, as shown in the following figure.

Figure 19: Stepping settings

10. For Acquire/Trigger, select Repeat, as shown in the follow ing fig ur e. The Acquire/Trigger option

selects whether the sweep runs once or repeatedly in force mode.

Figure 20: Force Mode setting

11. Move the Sweeping slider to 0% so that no voltage is applied to the DUT when you start the test,

as shown in the following figure.

12. For this example, chang e the Peak Vol tag e to 10 and make sure that t he Sw eep Direc tio n

is Positive.

4-8 PCT-900-01 Rev. B August 2022

Page 34

Series 2600

V applications for power MOSFETs

-PCT-xB Parametric Curve Tracer User's Manual Section 4: I-

Figure 21: Sweeping slider at 0 percent of peak voltage

13. Select the Advanced Settings button near the lower-left part of the application window to display

the Advanced Settings dialog, as shown in the following figure.

Figure 22: Advanced Settings dialog

PCT-900-01 Rev. B August 2022 4-9

Page 35

Section

User's Manual

4: I-V applications for power MOSFETs Series 2600-PCT-xB Parametric Curve Tracer

The Advanced Settings are automatically configured based upon the type of test being run.

However, values can be changed to accommodate the DUT.

14. Adjust the following Advanced Settings:

Sense Mode: Remote for the Gate and Drain SMU

On the drain, change Compliance to 10 A and Meas Range to 10 A

On the gate, change the Compliance to 100 mA

Change the Duty Cycle to 5%

The pulse duty cycle of the pulses impacts the update rate of the display. Using a lower duty cycle

lows higher current without thermal stress to the device. However, a lower duty cycle means that

al

the display does not update as quickly as in this example.

15. Select OK.

16. Select Run to begin the test.

Figure 23: Run icon

17. Move the Sweeping slider to adjust the peak voltage. Notice that the I-V curves sweep out further

as you move the slider right.

4-10 PCT-900-01 Rev. B August 2022

Page 36

Series 2600

V applications for power MOSFETs

-PCT-xB Parametric Curve Tracer User's Manual Section 4: I-

Figure 24: Test results

You can also use the arrows keys on the keyboard to adjust the slider. The up and down arrow keys

result in coarse changes in the sweeping voltage of 10% of peak voltage The left and right arrow

keys result in fine changes in the sweeping voltage of 1% of peak voltage.

18. To stop the test, select Stop at the top of the application window.

Configure a fixed plot

As you increase the sweep voltage, the graph automatically scales to fit the collected data into

the plot.

To change the graph to be fixed:

1. Right-click in the plot, then select Plot and Axis Settings.

PCT-900-01 Rev. B August 2022 4-11

Page 37

Section

User's Manual

4: I-V applications for power MOSFETs Series 2600-PCT-xB Parametric Curve Tracer

Figure 25: Select Plot and Axis Settings

2. Select Axis Settings.

Figure 26: Plot Settings dialog

3. Change the following options for the X-Axis Scale:

a. Clear Auto

b. Change the X-Axis Scale Min to 0

c. Change the X-Axis Scale Max to 10

4-12 PCT-900-01 Rev. B August 2022

Page 38

Series 2600

ns for power MOSFETs

-PCT-xB Parametric Curve Tracer User's Manual Section 4: I-V applicatio

4. Make the following modifications to the Y-Axis Scale:

a. Clear Auto

b. Change the Y-Axis Scale Min to 0

c. Change the Y-Axis Scale Max to 10

5. Change the X and Y Axis Title Text:

a. Re-name the X-Axis title to Vds (Volts)

b. Re-name the Y-Axis title to Ids (Amps)

6. Select Save.

Collecting I-V curves in MultiMode

In SingleMode and MultiMode, you program all test parameters before test operation. Tests run

without operator intervention or interaction. These modes are useful for generating precise data on

the DUT and for extracting device parameters from the data set.

In this example application, you collect a family of curves on the sample MOSFET.

This example application demonstrates how to do the following tas ks :

• Create a MultiMode project in ACS Basic

• Add tests to the project using the built-in test libraries

• Configure a test in MultiMode

• View, append, and save data in MultiMode

To make connections to the test fixture for this test, refer to Configure the test fixture (on page 4-1

To do the test:

1. Place the DUT into the Model 8010 test fixture and configure the connections

2. Enter MultiMode of ACS Basic

3. Create a new MultiMode project

4. Load the IdVd_StepVg test for the nPowerMOSFET device into the project

5. Configure the settings to match the device under test

6. Run the test

7. Save the data

).

PCT-900-01 Rev. B August 2022 4-13

Page 39

Section

User's Manual

4: I-V applications for power MOSFETs Series 2600-PCT-xB Parametric Curve Tracer

MultiMode GUI overview

The configuration navigator, shown in the following figure, has the following logical hierarchy:

• Project

Device 1

Test module 1 (ITM, STM, or PTM)

Test module 2 (ITM, STM, or PTM)

Device 2

Test module 1 (ITM, STM, or PTM)

Test module 2 (ITM, STM, or PTM)

Figure 27: MultiMode user interface

The configuration navigator is the primary interface for building, editing, and viewing a project plan,

and for specifying and accessing each project plan component.

4-14 PCT-900-01 Rev. B August 2022

Page 40

Series 2600

V applications for power MOSFETs

-PCT-xB Parametric Curve Tracer User's Manual Section 4: I-

When you select a navigator component (test or device) you can do the following:

• Add a new component

• Delete an existing component

• Run the tests associated with this component

Selecting a navigator component opens the configuration interface on the right panel, which includes

settings, test results, and status information.

Typical project plan components of the configuration navigator are shown in the following figure.

Figure 28: Project plan components of the configuration navigator view

The project plan components include:

• Project Plan: Defines and sequences all devices tested, and all tests and operations to be

performed at each. It typically corresponds to one die on a wafer.

• Device Plan: Defines and sequences all tests for a specific device, including transistors, diodes,

and resistors.

• ITM: Completely defines a parametric test without programming, using a series of configured

graphical user interfaces that show data numerically and graphically in real time. Provides for the

PCT-900-01 Rev. B August 2022 4-15

display of both raw data and analyzed data.

Page 41

Section

User's Manual

4: I-V applications for power MOSFETs Series 2600-PCT-xB Parametric Curve Tracer

Set up a new MultiMode project

You can use the ACS Basic MultiMode to create multiple test modules on one or more devices and

organize them into a single project. You can work with external instruments, such as DMMs and

switches, in MultiMode more easily than in any other mode.

MultiMode starts with the most recently used MultiMode project. In this application, you replace it with

a new project.

To set up a new MultiMode project:

1. Start ACS Basic, if it is not already open.

2. From the Mode Selection list, select MultiMode.

Figure 29: Select MultiMode

3. From the File menu, select New.

Figure 30: Create a new project

4-16 PCT-900-01 Rev. B August 2022

Page 42

Series 2600

V applications for power MOSFETs

4. Select No to the prompt to save the current project. The New Test Project dialog opens, as

shown in the following figure.

Figure 31: New Test Project dialog

-PCT-xB Parametric Curve Tracer User's Manual Section 4: I-

5. In the Project Name field, enter a project name.

6. Select OK.

When the new project opens, the project navigation pane on the left is empty and the test libraries

area fills the remainder of the window. The test libraries area is the easiest way to add devices and

tests to your project.

PCT-900-01 Rev. B August 2022 4-17

Page 43

Section

User's Manual

4: I-V applications for power MOSFETs Series 2600-PCT-xB Parametric Curve Tracer

Figure 32: Project navigation and test libraries

Add the IdVd_StepVg test to the project

To add the IdVd_StepVg test to the project:

1. From the Select a Device pane, select nPowerMOSFET.

Figure 33: nPowerMOSFET selected on the Select a Device pane

4-18 PCT-900-01 Rev. B August 2022

Page 44

Series 2600

V applications for power MOSFETs

-PCT-xB Parametric Curve Tracer User's Manual Section 4: I-

2. Select the IdVd_StepVg test from the Test Modules pane at the bottom left of the window.

Figure 34: Select the IdVd_StepVg test module

3. Select Add Test. The device and test are added to your project tree.

Figure 35: Device and test added to project tree

PCT-900-01 Rev. B August 2022 4-19

Page 45

Section

User's Manual

4: I-V applications for power MOSFETs Series 2600-PCT-xB Parametric Curve Tracer

4. In the Project Tree, select the device nPowerMOSFET_26. The Device Settings dialog opens.

Figure 36: Device Settings dialog

In the Device Settings dialog, you can configure which SMU is connected to which pin of the device,

set the SMU sense mode, and assign a name to the pad. This SMU mapping applies to all tests in the

project tree under the dev ice.

When you add the test to the project, ACS Basic automatically assigns SMUs to the pins. You should

verify that the pin assignments are correct:

• Make sure that the high current SMU (for this example, Model 2651A, SMU 4) is connected to

the drain

• Make sure that the 2636A Channel A (SMU 1) is connected to the gate

• Make sure that both the gate and drain are configured for remote sense

• Make sure that the source terminal is connected to GND

4-20 PCT-900-01 Rev. B August 2022

Page 46

Series 2600

V applications for power MOSFETs

-PCT-xB Parametric Curve Tracer User's Manual Section 4: I-

Configu re the test

You configure the settings each test in the Test Definition dialog. From this dialog, you can set every

aspect of how your test runs. Many of the settings are preconfigured, but you need to make some

changes for this application.

You can check your SMU assignments by hovering the mouse cursor over t

he pad numbers in the

device diagram.

This section refers to SMUs that are numbered as suggested in Assign TSP-Link node numbers (on

page 3-2). Your configuration may vary.

To set up the IV curve test:

1. In the project navigator, select the test named IdVd_StepVg.

2. For SMU4 (drain), confirm that Compliance is set to 10 A.

3. For SMU4 (drain), set the Meas. Range to 10A.

4. For SMU1 (gate), confirm that Compliance is set to 0.1 A.

5. For SMU4 (drain), double-click the Source Settings cell to open the Sweep V Settings dialog.

Figure 37: Sweep V settings

6. Set the Mode to Linear.

7. Set the Start value to 0.

8. Set the Stop value to 10.

9. Set the Step value to 0.1.

10. Set the Base value to 0.

11. Select OK.

PCT-900-01 Rev. B August 2022 4-21

Page 47

Section

User's Manual

4: I-V applications for power MOSFETs Series 2600-PCT-xB Parametric Curve Tracer

Figure 38: Modified Sweep V Setting s

12. For SMU1 (gate), double-click the Source Settings cell to open the Step V Settings dialog.

13. Set the Start value to 5.

14. Set the Stop value to 7.

15. Set the Points value to 5.

16. Set the Base value to 0.

17. Select OK.

Figure 39: Modified Step V Settings

4-22 PCT-900-01 Rev. B August 2022

Page 48

Series 2600

MOSFETs

Run the test

-PCT-xB Parametric Curve Tracer User's Manual Section 4: I-V applications for power

The Data tab contains the data from the last time the test was run. Because this test is new, it

contains sample data. When the test is run, the new data overwrites the sample data.

To run the test:

1. Select the Data tab of the Test dialog.

2. Select Run ( ) to start the test. Once data collection is complete, the test stops.

3. At the top of the Data tab, select Plot Only to get a better view of the plot.

4. Select Data Only to get a better view of the data in the spreadsheet.

5. Select Plot and Data to return to the dual view.

6. As the test runs and ACS Basic collects data, the curves are displayed on the graph.

Figure 40: Test result curves and data

You can also run the test without overwriting the existing data. This is useful for comparing data

between two devices or doing a before and after comparison after making some changes to the test

settings or device connections.

PCT-900-01 Rev. B August 2022 4-23

Page 49

Section

User's Manual

4: I-V applications for power MOSFETs Series 2600-PCT-xB Parametric Curve Tracer

To run the test and append data:

1. Select Append Run to start the test.

After the test runs, the appended data is graphed on the plot next to the original data. An additional

tab on the datasheet holds the new data. Since no changes were made, the curves of the appended

data should align with the original curves. If the curves align, this is a good indicator that you are

making settled measurements. If they do not align, there could be a problem with your test

configuration.

Save project and data

Figure 41: Append Run icon

When you save the project with Save All, all your test settings and collected data are saved with it so

the next time you load ACS Basic and open the test, your settings and data are still there. You can

also save the data to a Microsoft Excel spreadsheet or to a .csv file for analysis in another

application.

To save a project:

1. Select Save in the top toolbar.

Figure 42: Save a project

To save test data:

1. Above the plot in the test results window, select the data to be saved. You can select Plot and

Data, Plot Only, or Data Only. For this example, select Plot and Data.

Figure 43: Data view options in test results

4-24 PCT-900-01 Rev. B August 2022

Page 50

Series 2600

V applications for power MOSFETs

-PCT-xB Parametric Curve Tracer User's Manual Section 4: I-

2. Select Save at the bottom of the plot.

Figure 44: Save test data

3. From Save as Type, select the data type. The default is .xls. You can also save

in .csv, .png, .ps, .eps., and .svg formats.

Figure 45: Save to File dialog

PCT-900-01 Rev. B August 2022 4-25

Page 51

Section

User's Manual

4: I-V applications for power MOSFETs Series 2600-PCT-xB Parametric Curve Tracer

Digitizing pulses and improving timing

For many devices, you must adjust the measurement timing to produce good test results.

In particular, you may need to increase the pulse width to give the test signal more time to settle

before making the measurement. Often test engineers use an oscilloscope to see what the pulse

looks like and determine the proper pulse width and measurement time from this information. The

Series 2650A SMUs feature a built-in 18-bit fast analog-to-digital (ADC) converter that can digitize the

pulse without the need of the oscilloscope. This application demonstrates how to use the fast ADC to

digitize the output of the SMU to examine the shape of the pulse.

To introduce you to digitizing pulses, this application shows you how to:

• Adjust timing settings

• Digitize the pulse from a data point in the test

• Plot dig itized data

• Read the digitized pulse to configure the correct timing settings

To make connections to the test fixture for this test, refer to Configure the test fixture (on page 4-1).

To do the test, you do the following steps:

1. Configure the test fixture.

2. Load the IdVdStepVg test that was created in MultiMode (on pa ge 4-4).

3. Configure the test to digitize a pulse.

4. Configure the plot to display the digitized data.

5. Adjust the timing settings and then use the digitize function to review the changes.

Configure the test to digitize a pulse

For instructions on creating a new IdVd_StepVg test, refer to Add the IdVd_StepVg test to the project

(on page 4-18).

To configure the test to digitize a pulse:

1. Select the IdVd_StepVg test.

2. Select the Definition tab.

3. Select Timing, highlighted in the following figure, to open the ITM Timing dialog.

4-26 PCT-900-01 Rev. B August 2022

Page 52

Series 2600

V applications for power MOSFETs

Speed

Adjust the measurement aperture of the integrating ADC and configure any averaging.

Timing settings for outputting dc signals. Most of these settings can only be changed if

the test is running under DC Only Mode, which is set in the Test Definition dialog.

General Parameters

Settings for the period between data points and for when the measurement is made

relative to the start of the period.

Pulse Timing

1 and 2 Parameters

Configure the Pulse Width of any pulse signals and specify when the pulse is output

relative to the start of the period.

Force Mode

Assignments

Displays which SMUs are assigned to each of the three timing configurations.

-PCT-xB Parametric Curve Tracer User's Manual Section 4: I-

Figure 46: Timing button

Configure the General Timing tab settings

You configure the SMU output timing and measurements in the General Timing tab of the ITM Timing

dialog. The following table describes each of the setting categories.

ITM Timing dialog, General Timing tab setting categories

Category Function

DC Parameters

PCT-900-01 Rev. B August 2022 4-27

Page 53

Section

User's Manual

Start of a period

End of a period

Measurement trigger time

Measurement aperture (area)

4: I-V applications for power MOSFETs Series 2600-PCT-xB Parametric Curve Tracer

Figure 47: ITM Timing dialog

In the previous figure, the output preview is based on the settings for the DC Parameters, Pulse

Timing 1 Parameters, and Pulse Timing 2 Par a met er s.

Preview output definitions

1

2

3

4

To ensure good pulsed measurements, this aperture must be in the width of the pulse. It should also

be placed far enough from the leading edge of the pulse to ensure that the signal has settled before

the measurement is started.

To capture digitized pulse waveforms, capture the timing data by selecting Timestamp Enabled in the

General Parameters.

You will also enable and configure Pulse Transient Mode, as described in the following topic.

4-28 PCT-900-01 Rev. B August 2022

Page 54

Series 2600

V applications for power MOSFETs

Configure the Pulse Transient tab settings

You enable and configure the digitize feature of the 2650A Series SMUs in the Pulse Transient tab of

the ITM Timing dialog. The following table describes each of the settings.

Figure 48: ITM Timing dialog, Pulse Transient tab

-PCT-xB Parametric Curve Tracer User's Manual Section 4: I-

PCT-900-01 Rev. B August 2022 4-29

Page 55

Section

User's Manual

Pulse Transient

Mode

Digitizes a single point of the step/sweep sequen ce. S ele ctin g Pulse Tra ns ient Mo de

enables the mode and the controls to configure the mode.

Single Point /

Controls whether ACS Basic goes directly to the select ed step/sweep point and digitizes it or

Differences in data is most commonly due to device self-heating.

Transient Start /

Transient End

Sets the start and end times of the digitizing window and are relative to the start of the

period. This window is represented in the previous figure by the blue shaded area.

Sweep Point / Step

Point

Selects which points in the step/sweep sequence you want to digitize.

SMU Info

Displays the programed levels for the SMUs at that step and sweep point. By default, the

there is 7 V on the Gate and 10 V on the Drain.

Force Mode

Assignments

Displays which SMUs have been assigned to each of the three timing configurations.

4: I-V applications for power MOSFETs Series 2600-PCT-xB Parametric Curve Tracer

ITM Timing, Pulse Transient tab setting categories

Setting Function

Entire step/sweep

if it runs through the entire step/sweep sequence to digitize the selected point. To get to

results quickly, use Single Point. If the data you get when going directly to the point differs

from the data you get when you run the entire sweep, select Entire step/sweep to see results

that most closely match the output when the full test is run.

last point of the step/sweep sequence is selected, which corresponds to the point where

To configure the digitize feature:

1. Select Step and Sweep points that correspond to a Gate voltage of 6.5 V and a Drain voltage of

5 V.

2. Select Pulse Transient Mode to enable pulse transient mode.

3. Set Transient Start to 0.

4. Set Transient End to 1e-3.

5. Set the Sweep Point to 51.

6. Set the Step Point to 4.

7. Select OK.

8. Select the Data tab.

9. Select Run ( ) to start the test. The results are displayed on the Data tab and resemble the

following figure.

4-30 PCT-900-01 Rev. B August 2022

Page 56

Series 2600

V applications for power MOSFETs

-PCT-xB Parametric Curve Tracer User's Manual Section 4: I-

Figure 49: ITM Timing test results

By default, the graph for the IdVd_StepVg test is configured to show current versus voltage. To get a

scope-like view, you need to plot the signals versus time. Since the default plot is already setup for

displaying the IV curves of the device, it is preferable to not make any changes to its settings when

trying to view the digitized data. Instead, create a new plot to graph the data.

Create a new plot

1. Select the plot icon, then select New Plot.

Figure 50: New Plot

2. In the XY Settings dialog, scroll down to time(4).

3. For time(4), select X.

4. For V_Drain(4), select Y1.

5. For I_Drain(4), select Y2.

6. Select OK.

PCT-900-01 Rev. B August 2022 4-31

Page 57

Section

User's Manual

4: I-V applications for power MOSFETs Series 2600-PCT-xB Parametric Curve Tracer

Figure 51: XY Settings dialog

The digitized data now appears on a second plot to the right of the original. The voltage waveform is

shown on the plot in red and the current waveform is shown on the plot in blue.

Figure 52: New digitized data

4-32 PCT-900-01 Rev. B August 2022

Page 58

Series 2600

V applications for power MOSFETs

-PCT-xB Parametric Curve Tracer User's Manual Section 4: I-

Adjust the pulse timing set tin gs

When a waveform has been established, you can change some of the timing settings to observe

differences.

To change the timing settings:

1. Select the Definition tab.

2. Select Timing.

Figure 53: Timing example wave fo rm

In this test, the Drain is configured to use Pulse Timing 1 and the Gate is configured to use Pulse

Timing 2. The default settings have the rising edge of the Gate signal (Pulse Timing 2) 60 µs

before the rising edge of the Drain signal and the falling edge of both signals occurring at the

same time.

3. Change the Pulse Width of Pulse Timing 1 to 5e-4 (500 µs).

4. Change the Pulse Width of Pulse Timing 2 to 6e-4 (600 us).

5. Set the Measure Delay to 4e-4 (400 us).

6. Set the Period to 5e-3 (50 ms ).

7. Select OK.

8. Select the Data tab of the Test dialog.

9. Select Run ( ) to start the test.