Tektronix RSA6106A, RSA6120A Service

xx

RSA6106A/RSA6114A (S/N B020000 and Above),

and RSA6120A

ZZZ

Real-Time Spectrum Analyzer

Service Manual

*P077025001*

077-0250-01

xx

RSA6106A/RSA6114A (S/N B020000 and Above),

and RSA6120A

ZZZ

Real-Time Spectrum Analyzer

Service Manual

www.tektronix.com

077-0250-01

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O . B ox 5 00

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

Worl d wide , vi s it www.tektronix.com to find contacts in your area.

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, with shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other than Tektronix representatives to install, repair or service the product;

Table of Contents

General Safety Summary .......................................................................................... v

Service Safety Summary.......................................... ................................ ............... vii

Preface .............................................................................................................. ix

Manual Content ............. ................................ ................................ .................. ix

Manual Conventions.......... ................................ ................................ ................ ix

Related User Documents...................................................................................... x

Operating Information

Operating Information ........................................................................................... 1-1

Theory of Operation

Theory of Operation....................... ................................ ................................ ....... 2-1

General..................... ................................ .................................. ................. 2-1

Signal Path and Processing ................................................................................. 2-1

Display Panel.................... ................................ .................................. ........... 2-2

Front Panel ................................ ................................ ................................ ... 2-2

Rear Panel ..................... ................................ .................................. ............. 2-2

Power Supply................................................................................................. 2-3

Fans............................................................................................................ 2-3

Adjustment Procedures

Adjustment Procedure............. ................................ .................................. ............. 3-1

Running Alignments................................ .................................. ....................... 3-1

Maintenance

Maintenance....................................................................................................... 4-1

Preventing ESD .............................................................................................. 4-1

Inspection and Cleaning.................. ................................ .................................. . 4-2

Restoring the Windows Operating System (OS)..... ................................ ......................... 4-5

Creating a Disk Backup Image............................................................................. 4-6

Restoring the Instrument Operating System ........... ................................ ................... 4-7

Formatting the Drive in Option 06/08 Instruments . . . .. . ... ... ... . ... ... ... . ... ... ... . ... ... ... .. .. . ... . 4-7

Restoring the Operating System from the Instrument Hard Disk (Options 06/07) ................... 4-9

Restoring the Hard Disk from a Backup Image ..................... ................................ ..... 4-9

Removal and Installation Procedu

Preparation......................................... .................................. ....................... 4-11

Trim, Cabinet, and Module Removal....................................... ............................. 4-13

res......................................................................... 4-11

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual i

Table of Contents

Removal Proced

Troubleshooting................................................................................................. 4-20

Service Level.......................... .................................. ................................ ... 4-20

Check for Common Problems............................................................................ 4-20

Diagnostics ................................................................................................. 4-23

Replaceable Parts

Replaceable Parts...... ................................ ................................ ........................... 5-1

Parts Ordering Information ................ ................................ ................................ . 5-1

Using the Replaceable Parts List........................................................................... 5-3

ures.................. ................................ .................................. ... 4-15

ii RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

List of Figures

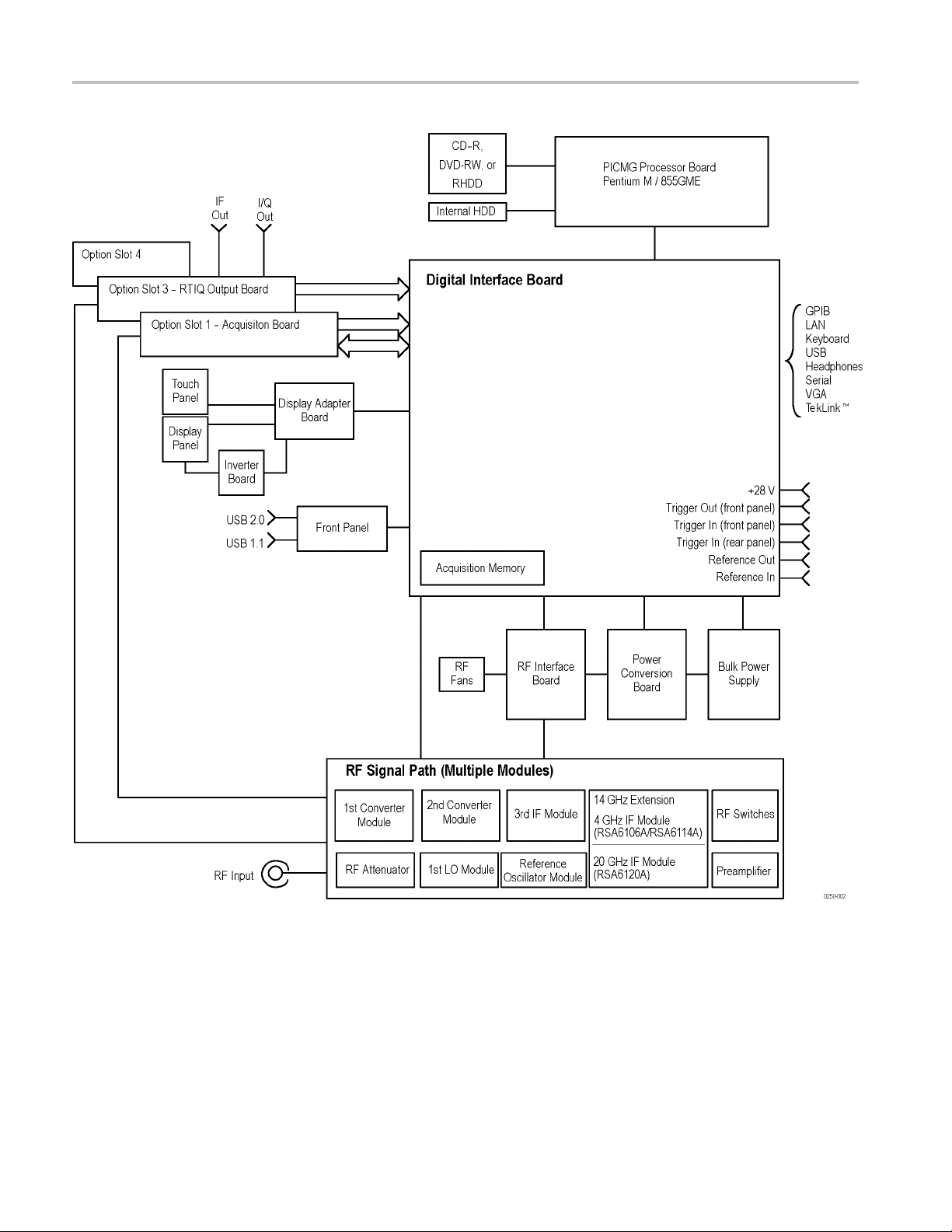

Figure 2-1: RSA6100A Series block diagram............................ ................................ ..... 2-4

Figure 4-1: Primary customer replaceable module locations.............................................. 4-14

Figure 4-2: Status indicator locations ........................................................................ 4-22

Figure 4-3:

Figure 4-4: Diagnostics Failure Info tab ..................................................................... 4-24

Figure 4-5: Event viewer initial display ... ... . ... ... ... . ... ... ... .. .. . ... ... ... . ... ... ... .. .. . ... ... ... . ... . 4-25

Figure 4-6: Event viewer applications error view ....... ................................ ................... 4-26

Figure 4-7: Event Properties window, showing error log information ................................... 4-26

Figure 4-8: Starting Extended Diagnostics ............... ................................ ................... 4-27

Figure 4

Figure 4-10: Diagnostics test iteration control ............................. ................................ . 4-28

Figure 5-1: External parts .................................. ................................ ..................... 5-5

Figure 5-2: Display, front panel, DVD, and removeable hard drive ................... ..................... 5-7

Figure 5-3: Detail 1 of display, front panel, DVD, and removeable hard drive cabling .. ... ... . ... ... . . . 5-8

Figure 5-4: Detail 2 of display, front panel, and removable hard drive cabling ........................... 5-9

re 5-5: Detail 3 of display, front panel, DVD, and removeable hard drive cabling .. ... ... . ... ... . 5-10

Figu

Figure 5-6: Modules..... ................................ .................................. ..................... 5-12

Figure 5-7: Detail 1 of Slot PC cabling ........................... ................................ ........... 5-13

Figure 5-8: Detail 2 of Slot PC cabling ........................... ................................ ........... 5-14

Figure 5-9: Detail of RT/IQ Option 05 cabling ............................................................. 5-15

Figure 5-10: Power supply and internal hard drive......................................................... 5-17

gure 5-11: Detail 1 of power supply and internal hard drive cabling................................... 5-18

Fi

Figure 5-12: Detail 2 of power supply and internal hard drive cabling ........................... ....... 5-19

Figure 5-13: Upper and lower deck fans.......... ................................ ........................... 5-21

Figure 5-14: Detail of cabling shown in Figure 5-13....................................................... 5-22

Figure 5-15: RF interface board and cables ................................................................. 5-24

Diagnostics Power On Self Test results view.................................................. 4-24

-9: Embedded Diagnostics Interface .......................... ................................ ..... 4-28

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual iii

Table of Contents

List of Tables

Table 2-1: Rear panel connectors................ .................................. ............................. 2-2

Table 4-1 : E

Table 4-2: Internal inspection check list ....................................................................... 4-4

Table 4-3: Tools required for module removal............. .................................. ............... 4-12

Table 4-4: Legend for Accessing Modules table............................................................ 4-13

Table 4-5: Accessing Modules........... ................................ ................................ ..... 4-13

Table 4-6: Power conversion board connectors ...................... ................................ ....... 4-18

Table 4-7

Table 4-8: Power Converter board status indicators........................................................ 4-23

Table 4-9: Digital Interface board status indicators......................................................... 4-23

Table 4-10: Diagnostic error messages....................................................................... 4-29

Table 5-1: External parts.... .................................. ................................ ................... 5-4

Table 5-2: Display, front panel, DVD, and removeable hard drive ......................................... 5-6

Table

Table 5-4: Power supply and internal hard drive............................................................ 5-16

Table 5-5: Upper and lower deck fans .................. ................................ ..................... 5-20

Table 5-6: RF interface board and cables.................................................................... 5-23

xternal inspection checklist....................................................................... 4-3

: Failure symptoms and possible causes ... ................................ ....................... 4-20

5-3: Modules...................................... ................................ ....................... 5-11

iv RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

General Safety Summary

General Safet

To Avoid Fire or Personal

Injury

ySummary

Review the fo

this product or any products connected to it.

To avoid pot

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions r

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avo i d fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

rmation before making connections to the product.

info

llowing safety precautions to avoid injury and prevent damage to

ential hazards, use this product only as specified.

elated to operating the system.

The inputs are not rated for connection to mains or Category II, III, or IV circuits.

Power Disconnect. The power cord disconnects the product from the power source.

Do not block the power cord; it must remain accessible to the user at all times.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Do Not Operate With Suspected Failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Replace Batteries Properly. Replace batteries only with the specified type and

rating.

Use Proper Fuse. Use only the fuse type and rating specifi ed for this product.

Wear Eye Protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual v

General Safety Summary

TermsinthisManual

Symbols and Terms on the

Product

Do Not Operate i

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Prop

details on installing the product so it has proper ventilation.

These terms may appear in this manual:

WARNING.

in injury or loss of life.

CAUTION

damage to this product or other property.

These t

. Caution statements identify conditions or practices that could result in

erms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read

the ma

n Wet/Damp Conditions.

er Ventilation. Refer to the manual’s installation instructions for

Warning statements identify conditions or practices that could result

rking.

WARNING indicates an injury hazard not immediately accessible as you

the marking.

read

CAUTION indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

vi RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Service Safety Summary

Service Safet

y Summary

Only qualifie

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

UseCareWhenServicingWithPowerOn. Dangerousvoltagesorcurrentsmay

exist in

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

d personnel should perform service procedures. Read this Service

this product. Disconnect power, remove battery (if applicable), and

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual vii

Service Safety Summary

viii RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Preface

Manual Content

Manual Conventions

This is the service manual for the RSA6100A Series Real-time Spectrum

Analyzers.

Read this preface to learn how this manual is structured, what conventions it uses,

and where you can find other information related to servicing this product.

This manual contains only information related to se rvicing an RSA6100A Series

Real-tim

the instrument or for a list of instrument specifications, refer to the appropriate

user document as described in Related User Documents on the following page.

Be sure to read the introductions to all procedures. These introductions provide

important information needed to perform the service correctly, safely, and

efficiently.

e Spectrum Analyzer. For information related to installing and operating

Module

Plug-in Module

Replaceable Parts

Safety

This manual uses certain conventions that you should become familiar with

before attempting service.

The term module refers to a collection of items that are replaceable as a unit. A

module may contain electrical and mechanical assemblies, circuit boards, and

interconnecting cables.

The term Plug-in Module refers to the units that plug into the Main Digital

Interface board.

This manual refers to any field-replaceable assembly or mechanical part by its

name or generically as a replaceable part. In general, a replaceable part is any

circuit board or assembly that is listed in the Replaceable Parts section.

Symbols and terms related to safety appear in the General Safety Summary found

at the beginning of this manual. Be sure to read both the General Safety Summary

and Service Safety Summary before performing any service to this instrument.

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual ix

Preface

Related User Documents

The following related English user documents are available if you need more

information about operating the instrument. These documents are located on the

RSA6100A Series Real-time Spect rum Analyzer User Documentation CD-ROM

or can be downloaded from the Tektronix Web site (www.tektronix.com/manuals).

RSA6100A Series Real-time Spectrum Analyzer Quick Start User Manual.

This document provides the basic information you need to install and operate

the instru

for the instrument.

ment. Included is a listing of the options and accessories available

RSA6100A

Performance Verification Technical Reference (English). Contains the

following technical information about the instrument:

Electrical and physical specifications, including a list of certifications

and compliances.

A performance verific ation procedure to check instrument performance

against guaranteed specifications.

RSA6100A Series Real-time Spectrum Analyzer Programmer Manual

(English). Describes the GPIB instrument programming commands and

interface.

RSA6100A Series Real-time Spectrum Analyzer Security and Declassification

Instructions (English). Provides instruction on how customers with data

security concerns can sanitize or remove memory devices from the instrument.

Series Real-time Spectrum Analyzer Series Specifications and

x RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Operating Information

Operating Information

For information on installing and operating your RSA6100A Series Real-time

Spectrum Analyzer, refer to the Quick Start User Manual.

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 1–1

Operating Information

1–2 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Theory of Operation

Theory of Operation

This section provides a basic description of the Real-Time Spectrum Analyzer

(RTSA) operation. A block diagram of the instrument is shown in this section.

(See Figure 2

General

A processor system controls the RSA6100A instrument. The instrument features

an XGA resolution flat-panel display, a transparent touch-screen, and a front-panel

with direct access to commonly used RTSA features. You can also use the RTSA

with a mouse or other pointing device, and/or a key

The RTSA uses the Microsoft Windows XP operating system.

Signal Path and Processing

-1 on page 2-4.)

board.

RF Signal Path

Acquisition System

Processor System

An RF signal enters the RTSA through a direct coaxial connection (N-type for the

RSA6106A and RSA6114A, 3.5 mm for the RSA6120A) to the input connector.

The RF signal path conditions the input signals and passes them to the acquisition

system for sampling and processing. The RF signal path consists of three

frequency conversion stages, band-limiting filters, and signal level adjustment

stages. The purpose of the RF signal path is to translate a band-limited replica

of a portion of the input signal range (9 kHz to 6.2 GHz for the RSA6106A,

9 kHz to 14 GHz for the RSA6114A, or 9 kHz to 20 GHz for the RSA6120A) to a

intermediate frequency (IF) where it can be sampled by a high dynamic range A/D.

Control of the RF signal path is performed by the processor system.

The acquisition system samples the IF signal and converts it to digital signals.

These digital signals are then filtered numerically and processed either for direct

display or by measurement applications to provide metrics of signal quality

to the user. The acquisition data processing is performed by one of several

field-programmable gate arrays (FPGAs) under control of the processor. The

processor performs measurement applications.

The processor system consists of a PCI-based processor board and a digital

interface board that connects the processor to the acquisition board.

Trigger Inputs

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 2–1

There are two coaxial trigger inputs. One is on the front panel below the display

and the other is on the rear panel. Both trigger inputs connect directly to the digital

interface board. Trigger signals are processed by an FPGA on the digital interface

board. The information from the trigger system is combined with acquisition

data by the processor system.

Theory of Operation

Display Panel

Display system

Touch Panel

Front Panel

The Trigger Out

The trigger out signal comes from the Acquisition Control FPGA via the digital

interface board.

Waveforms, spectral traces, measurement results, and control menus are displayed

on a 10.4 inch, color, active-matrix LCD display with touch panel.

The display system consists of a display adapter board and inverter board, which

sends text and waveform information to the display panel.

The display adapter board sends information from the touch panel to the processor.

The touch panel appears as a USB HID device in the Window Device Manager

tool.

The processor system reads the front-panel switches and encoder. Any changes in

their settings are reported to the processor. The processor also turns the LEDs on

and off.

signal is accessed below the display with a coaxial connection.

The ON/STBY switch passes through the display adapter board, the digital

interface board, and to the processor on the front panel board.

Communication between the processor system and the front panel is performed

over an internal USB connection.

The DVD-RW, removable HDD (hard disk drive), or removable solid-state hard

drive communicate over an IDE connection directly to the processor system.

Rear Panel

The following table describes the connectors available on the RTSA rear panel.

Table 2-1: Rear panel connectors

Name Input or Output Connector type Description

Reference In

Reference Out Output BNC 10 MHz output or loop-through of user

TekLink™

LAN

Input

Input/Output

Input/Output

BNC External time-base reference. See data sheet

for signal quality requirements.

Reference In signal

Proprietary 40-pin

RJ-45

TekLink™ multi-instrument interface connector

10/100/1000baseT Ethernet connector

2–2 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Theory of Operation

Table 2-1: Rear panel connectors (cont.)

Name Input or Output Connector type Description

USB Input/Output USB Two USB 2.0 connectors

Keyboard Input

VGA Output D-Sub

Serial Input/Output D-Sub Serial communications port (COM2) to

Trigger In Input

Headset

+28 V

GPIB Input/Output

IF Output Output BNC 500 MHz Analog IF Output signal (Option 05)

Digital I/Q Output

Output

Output BNC

PS/2 Keyboard-only PS/2 connector

External monitor connector

processor system

BNC TTL Gate/trigger input signal

3.5 mm stereo E xternal headphone connection

Noise source drive power

IEEE-488

2x50

General Purpose Interface Bus

Two connectors for digital I and Q output

signals. (Option 05)

All connections except the IF Output and Digital I/Q are connected directly to the

digital interface board. The IF Output and Digital I/Q outputs are connected to the

Real-Time I/Q (RTIQ) option board.

Power Supply

Fans

The Power Conversion board provides instrument power. The Power Conversion

board consists of several switching supplies that translate and balance the power

taken from the power supply module.

Power is distributed from the Power Conversion board to both the RF Deck and

the Digital Interface board.

The ON/STBY switch, located on the front panel, controls all of the power to the

instrument except for the part of the circuitry in the standby power supply.

Seven individual fans provide cooling to the RTSA. Three fans are dedicated to

the RF Deck and are controlled by the RF Interface. Two fans provide cooling

for the digital side of the instrument.

The bulk power supply module has an internal fan. Control signals to the power

supply fan are sent through the Power Conversion board from the Digital Interface

board.

A seventh fan is resident on the processor board heat sink, and is controlled by

the Slot PC board.

If Option 200 is installed, eight individual fans provided cooling to the RTSA.

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 2–3

Theory of Operation

Figure 2-1: RSA6100A Series block diagram

2–4 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Adjustment Procedures

Adjustment Procedure

There are no physical user adjustment procedures for the RSA6100A Series

instruments. However, you can run Alignments from the RSA6100A Series

application. Alignments are software-controlled adjustment procedures.

Running Ali

Alignment Status

gnments

Alignments are adjustment procedures run by the instrument using internal

reference signals and measurements, and do not require any external equipment or

connectio

There are two settings for Alignments:

If Automatically align as needed is selected, alignments run whenever the

spectrum analyzer detects a sufficient change in ambient conditions to warrant

an alignment.

If Run alignments only when "Align Now" button is pressed is selected,

the spectrum analyzer never runs an alignment unless you manually initiate an

alignment using the Align Now button.

NOTE

Automatically align as needed is not enabled.

Whe

screen. If no message is displayed, you can assume that the spectrum analyzer is

properly aligned.

ns.

Automatically align as needed (Auto mode)

Run alignments only when the "Align Now" button is pressed

. There are a few critical adjustments that must run occasionally even if

n the spectrum analyzer needs to run an alignment, it displays a message on

o initiate an alignment:

Initiating an Alignment

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 3–1

T

1. Select Setup > Alignments.

2. Select the Align Now button.

The spectrum analyzer will run an alignment procedure. Status messages are

displayed while the alignment procedure is running. If the instrument fails the

alignment procedure, an error message will be displayed. If the instrument fails

an alignment, run Diagnostics (Tools > Diagnostics) to see if you can determine

why the alignment failed.

NOTE. While an alignment is running, both the IF and IQ outputs are disabled.

Adjustment Procedure

Alignments During

Warm-Up

Alignments During Normal

Operation

Alignments Are Not

Calibrations

Alignments are

oscillator alignments) because default alignment values are used, (if Auto mode is

selected). During the specified period for warm-up, the instrument performance

is not warranted.

Once the spectrum analyzer reaches operating temperature, a full alignment is then

run every two hours (for up to two minutes). Alignments can run more frequently

if the operating temperature changes. If an alignment becomes necessary during

a measurement cycle (if Auto mode is selected), the measurement is aborted

and an alignment procedure is run. Once an alignment procedure is completed,

the measu

Alignments are adjustment procedures run by the instrument using internal

referen

Tektronix service center and require the use of traceable test equipment (signal

sources and measuring equipment) to verify the performance of the instrument.

ce signals and measurements. Calibrations can only be performed at a

not run during the 20 minute warm-up period (except, for the RF

rement cycle restarts.

3–2 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Loading...

Loading...