Page 1

xx

RSA6106A/RSA6114A (S/N B020000 and Above),

and RSA6120A

ZZZ

Real-Time Spectrum Analyzer

Service Manual

*P077025001*

077-0250-01

Page 2

Page 3

xx

RSA6106A/RSA6114A (S/N B020000 and Above),

and RSA6120A

ZZZ

Real-Time Spectrum Analyzer

Service Manual

www.tektronix.com

077-0250-01

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O . B ox 5 00

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

Worl d wide , vi s it www.tektronix.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, with shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other than Tektronix representatives to install, repair or service the product;

Page 6

Page 7

Table of Contents

General Safety Summary .......................................................................................... v

Service Safety Summary.......................................... ................................ ............... vii

Preface .............................................................................................................. ix

Manual Content ............. ................................ ................................ .................. ix

Manual Conventions.......... ................................ ................................ ................ ix

Related User Documents...................................................................................... x

Operating Information

Operating Information ........................................................................................... 1-1

Theory of Operation

Theory of Operation....................... ................................ ................................ ....... 2-1

General..................... ................................ .................................. ................. 2-1

Signal Path and Processing ................................................................................. 2-1

Display Panel.................... ................................ .................................. ........... 2-2

Front Panel ................................ ................................ ................................ ... 2-2

Rear Panel ..................... ................................ .................................. ............. 2-2

Power Supply................................................................................................. 2-3

Fans............................................................................................................ 2-3

Adjustment Procedures

Adjustment Procedure............. ................................ .................................. ............. 3-1

Running Alignments................................ .................................. ....................... 3-1

Maintenance

Maintenance....................................................................................................... 4-1

Preventing ESD .............................................................................................. 4-1

Inspection and Cleaning.................. ................................ .................................. . 4-2

Restoring the Windows Operating System (OS)..... ................................ ......................... 4-5

Creating a Disk Backup Image............................................................................. 4-6

Restoring the Instrument Operating System ........... ................................ ................... 4-7

Formatting the Drive in Option 06/08 Instruments . . . .. . ... ... ... . ... ... ... . ... ... ... . ... ... ... .. .. . ... . 4-7

Restoring the Operating System from the Instrument Hard Disk (Options 06/07) ................... 4-9

Restoring the Hard Disk from a Backup Image ..................... ................................ ..... 4-9

Removal and Installation Procedu

Preparation......................................... .................................. ....................... 4-11

Trim, Cabinet, and Module Removal....................................... ............................. 4-13

res......................................................................... 4-11

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual i

Page 8

Table of Contents

Removal Proced

Troubleshooting................................................................................................. 4-20

Service Level.......................... .................................. ................................ ... 4-20

Check for Common Problems............................................................................ 4-20

Diagnostics ................................................................................................. 4-23

Replaceable Parts

Replaceable Parts...... ................................ ................................ ........................... 5-1

Parts Ordering Information ................ ................................ ................................ . 5-1

Using the Replaceable Parts List........................................................................... 5-3

ures.................. ................................ .................................. ... 4-15

ii RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 9

List of Figures

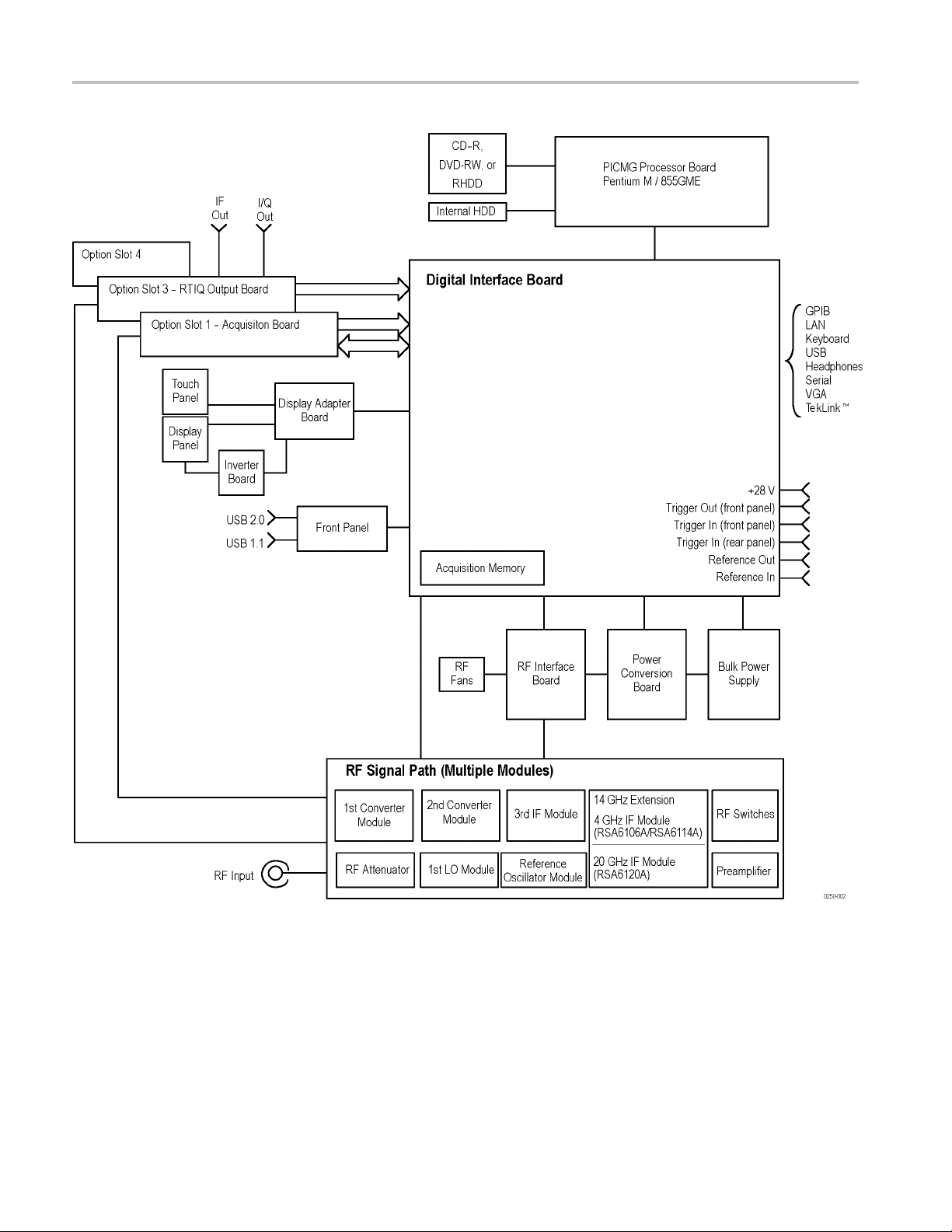

Figure 2-1: RSA6100A Series block diagram............................ ................................ ..... 2-4

Figure 4-1: Primary customer replaceable module locations.............................................. 4-14

Figure 4-2: Status indicator locations ........................................................................ 4-22

Figure 4-3:

Figure 4-4: Diagnostics Failure Info tab ..................................................................... 4-24

Figure 4-5: Event viewer initial display ... ... . ... ... ... . ... ... ... .. .. . ... ... ... . ... ... ... .. .. . ... ... ... . ... . 4-25

Figure 4-6: Event viewer applications error view ....... ................................ ................... 4-26

Figure 4-7: Event Properties window, showing error log information ................................... 4-26

Figure 4-8: Starting Extended Diagnostics ............... ................................ ................... 4-27

Figure 4

Figure 4-10: Diagnostics test iteration control ............................. ................................ . 4-28

Figure 5-1: External parts .................................. ................................ ..................... 5-5

Figure 5-2: Display, front panel, DVD, and removeable hard drive ................... ..................... 5-7

Figure 5-3: Detail 1 of display, front panel, DVD, and removeable hard drive cabling .. ... ... . ... ... . . . 5-8

Figure 5-4: Detail 2 of display, front panel, and removable hard drive cabling ........................... 5-9

re 5-5: Detail 3 of display, front panel, DVD, and removeable hard drive cabling .. ... ... . ... ... . 5-10

Figu

Figure 5-6: Modules..... ................................ .................................. ..................... 5-12

Figure 5-7: Detail 1 of Slot PC cabling ........................... ................................ ........... 5-13

Figure 5-8: Detail 2 of Slot PC cabling ........................... ................................ ........... 5-14

Figure 5-9: Detail of RT/IQ Option 05 cabling ............................................................. 5-15

Figure 5-10: Power supply and internal hard drive......................................................... 5-17

gure 5-11: Detail 1 of power supply and internal hard drive cabling................................... 5-18

Fi

Figure 5-12: Detail 2 of power supply and internal hard drive cabling ........................... ....... 5-19

Figure 5-13: Upper and lower deck fans.......... ................................ ........................... 5-21

Figure 5-14: Detail of cabling shown in Figure 5-13....................................................... 5-22

Figure 5-15: RF interface board and cables ................................................................. 5-24

Diagnostics Power On Self Test results view.................................................. 4-24

-9: Embedded Diagnostics Interface .......................... ................................ ..... 4-28

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual iii

Page 10

Table of Contents

List of Tables

Table 2-1: Rear panel connectors................ .................................. ............................. 2-2

Table 4-1 : E

Table 4-2: Internal inspection check list ....................................................................... 4-4

Table 4-3: Tools required for module removal............. .................................. ............... 4-12

Table 4-4: Legend for Accessing Modules table............................................................ 4-13

Table 4-5: Accessing Modules........... ................................ ................................ ..... 4-13

Table 4-6: Power conversion board connectors ...................... ................................ ....... 4-18

Table 4-7

Table 4-8: Power Converter board status indicators........................................................ 4-23

Table 4-9: Digital Interface board status indicators......................................................... 4-23

Table 4-10: Diagnostic error messages....................................................................... 4-29

Table 5-1: External parts.... .................................. ................................ ................... 5-4

Table 5-2: Display, front panel, DVD, and removeable hard drive ......................................... 5-6

Table

Table 5-4: Power supply and internal hard drive............................................................ 5-16

Table 5-5: Upper and lower deck fans .................. ................................ ..................... 5-20

Table 5-6: RF interface board and cables.................................................................... 5-23

xternal inspection checklist....................................................................... 4-3

: Failure symptoms and possible causes ... ................................ ....................... 4-20

5-3: Modules...................................... ................................ ....................... 5-11

iv RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 11

General Safety Summary

General Safet

To Avoid Fire or Personal

Injury

ySummary

Review the fo

this product or any products connected to it.

To avoid pot

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions r

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avo i d fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

rmation before making connections to the product.

info

llowing safety precautions to avoid injury and prevent damage to

ential hazards, use this product only as specified.

elated to operating the system.

The inputs are not rated for connection to mains or Category II, III, or IV circuits.

Power Disconnect. The power cord disconnects the product from the power source.

Do not block the power cord; it must remain accessible to the user at all times.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Do Not Operate With Suspected Failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Replace Batteries Properly. Replace batteries only with the specified type and

rating.

Use Proper Fuse. Use only the fuse type and rating specifi ed for this product.

Wear Eye Protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual v

Page 12

General Safety Summary

TermsinthisManual

Symbols and Terms on the

Product

Do Not Operate i

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Prop

details on installing the product so it has proper ventilation.

These terms may appear in this manual:

WARNING.

in injury or loss of life.

CAUTION

damage to this product or other property.

These t

. Caution statements identify conditions or practices that could result in

erms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read

the ma

n Wet/Damp Conditions.

er Ventilation. Refer to the manual’s installation instructions for

Warning statements identify conditions or practices that could result

rking.

WARNING indicates an injury hazard not immediately accessible as you

the marking.

read

CAUTION indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

vi RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 13

Service Safety Summary

Service Safet

y Summary

Only qualifie

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

UseCareWhenServicingWithPowerOn. Dangerousvoltagesorcurrentsmay

exist in

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

d personnel should perform service procedures. Read this Service

this product. Disconnect power, remove battery (if applicable), and

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual vii

Page 14

Service Safety Summary

viii RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 15

Preface

Manual Content

Manual Conventions

This is the service manual for the RSA6100A Series Real-time Spectrum

Analyzers.

Read this preface to learn how this manual is structured, what conventions it uses,

and where you can find other information related to servicing this product.

This manual contains only information related to se rvicing an RSA6100A Series

Real-tim

the instrument or for a list of instrument specifications, refer to the appropriate

user document as described in Related User Documents on the following page.

Be sure to read the introductions to all procedures. These introductions provide

important information needed to perform the service correctly, safely, and

efficiently.

e Spectrum Analyzer. For information related to installing and operating

Module

Plug-in Module

Replaceable Parts

Safety

This manual uses certain conventions that you should become familiar with

before attempting service.

The term module refers to a collection of items that are replaceable as a unit. A

module may contain electrical and mechanical assemblies, circuit boards, and

interconnecting cables.

The term Plug-in Module refers to the units that plug into the Main Digital

Interface board.

This manual refers to any field-replaceable assembly or mechanical part by its

name or generically as a replaceable part. In general, a replaceable part is any

circuit board or assembly that is listed in the Replaceable Parts section.

Symbols and terms related to safety appear in the General Safety Summary found

at the beginning of this manual. Be sure to read both the General Safety Summary

and Service Safety Summary before performing any service to this instrument.

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual ix

Page 16

Preface

Related User Documents

The following related English user documents are available if you need more

information about operating the instrument. These documents are located on the

RSA6100A Series Real-time Spect rum Analyzer User Documentation CD-ROM

or can be downloaded from the Tektronix Web site (www.tektronix.com/manuals).

RSA6100A Series Real-time Spectrum Analyzer Quick Start User Manual.

This document provides the basic information you need to install and operate

the instru

for the instrument.

ment. Included is a listing of the options and accessories available

RSA6100A

Performance Verification Technical Reference (English). Contains the

following technical information about the instrument:

Electrical and physical specifications, including a list of certifications

and compliances.

A performance verific ation procedure to check instrument performance

against guaranteed specifications.

RSA6100A Series Real-time Spectrum Analyzer Programmer Manual

(English). Describes the GPIB instrument programming commands and

interface.

RSA6100A Series Real-time Spectrum Analyzer Security and Declassification

Instructions (English). Provides instruction on how customers with data

security concerns can sanitize or remove memory devices from the instrument.

Series Real-time Spectrum Analyzer Series Specifications and

x RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 17

Operating Information

Page 18

Page 19

Operating Information

For information on installing and operating your RSA6100A Series Real-time

Spectrum Analyzer, refer to the Quick Start User Manual.

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 1–1

Page 20

Operating Information

1–2 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 21

Theory of Operation

Page 22

Page 23

Theory of Operation

This section provides a basic description of the Real-Time Spectrum Analyzer

(RTSA) operation. A block diagram of the instrument is shown in this section.

(See Figure 2

General

A processor system controls the RSA6100A instrument. The instrument features

an XGA resolution flat-panel display, a transparent touch-screen, and a front-panel

with direct access to commonly used RTSA features. You can also use the RTSA

with a mouse or other pointing device, and/or a key

The RTSA uses the Microsoft Windows XP operating system.

Signal Path and Processing

-1 on page 2-4.)

board.

RF Signal Path

Acquisition System

Processor System

An RF signal enters the RTSA through a direct coaxial connection (N-type for the

RSA6106A and RSA6114A, 3.5 mm for the RSA6120A) to the input connector.

The RF signal path conditions the input signals and passes them to the acquisition

system for sampling and processing. The RF signal path consists of three

frequency conversion stages, band-limiting filters, and signal level adjustment

stages. The purpose of the RF signal path is to translate a band-limited replica

of a portion of the input signal range (9 kHz to 6.2 GHz for the RSA6106A,

9 kHz to 14 GHz for the RSA6114A, or 9 kHz to 20 GHz for the RSA6120A) to a

intermediate frequency (IF) where it can be sampled by a high dynamic range A/D.

Control of the RF signal path is performed by the processor system.

The acquisition system samples the IF signal and converts it to digital signals.

These digital signals are then filtered numerically and processed either for direct

display or by measurement applications to provide metrics of signal quality

to the user. The acquisition data processing is performed by one of several

field-programmable gate arrays (FPGAs) under control of the processor. The

processor performs measurement applications.

The processor system consists of a PCI-based processor board and a digital

interface board that connects the processor to the acquisition board.

Trigger Inputs

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 2–1

There are two coaxial trigger inputs. One is on the front panel below the display

and the other is on the rear panel. Both trigger inputs connect directly to the digital

interface board. Trigger signals are processed by an FPGA on the digital interface

board. The information from the trigger system is combined with acquisition

data by the processor system.

Page 24

Theory of Operation

Display Panel

Display system

Touch Panel

Front Panel

The Trigger Out

The trigger out signal comes from the Acquisition Control FPGA via the digital

interface board.

Waveforms, spectral traces, measurement results, and control menus are displayed

on a 10.4 inch, color, active-matrix LCD display with touch panel.

The display system consists of a display adapter board and inverter board, which

sends text and waveform information to the display panel.

The display adapter board sends information from the touch panel to the processor.

The touch panel appears as a USB HID device in the Window Device Manager

tool.

The processor system reads the front-panel switches and encoder. Any changes in

their settings are reported to the processor. The processor also turns the LEDs on

and off.

signal is accessed below the display with a coaxial connection.

The ON/STBY switch passes through the display adapter board, the digital

interface board, and to the processor on the front panel board.

Communication between the processor system and the front panel is performed

over an internal USB connection.

The DVD-RW, removable HDD (hard disk drive), or removable solid-state hard

drive communicate over an IDE connection directly to the processor system.

Rear Panel

The following table describes the connectors available on the RTSA rear panel.

Table 2-1: Rear panel connectors

Name Input or Output Connector type Description

Reference In

Reference Out Output BNC 10 MHz output or loop-through of user

TekLink™

LAN

Input

Input/Output

Input/Output

BNC External time-base reference. See data sheet

for signal quality requirements.

Reference In signal

Proprietary 40-pin

RJ-45

TekLink™ multi-instrument interface connector

10/100/1000baseT Ethernet connector

2–2 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 25

Theory of Operation

Table 2-1: Rear panel connectors (cont.)

Name Input or Output Connector type Description

USB Input/Output USB Two USB 2.0 connectors

Keyboard Input

VGA Output D-Sub

Serial Input/Output D-Sub Serial communications port (COM2) to

Trigger In Input

Headset

+28 V

GPIB Input/Output

IF Output Output BNC 500 MHz Analog IF Output signal (Option 05)

Digital I/Q Output

Output

Output BNC

PS/2 Keyboard-only PS/2 connector

External monitor connector

processor system

BNC TTL Gate/trigger input signal

3.5 mm stereo E xternal headphone connection

Noise source drive power

IEEE-488

2x50

General Purpose Interface Bus

Two connectors for digital I and Q output

signals. (Option 05)

All connections except the IF Output and Digital I/Q are connected directly to the

digital interface board. The IF Output and Digital I/Q outputs are connected to the

Real-Time I/Q (RTIQ) option board.

Power Supply

Fans

The Power Conversion board provides instrument power. The Power Conversion

board consists of several switching supplies that translate and balance the power

taken from the power supply module.

Power is distributed from the Power Conversion board to both the RF Deck and

the Digital Interface board.

The ON/STBY switch, located on the front panel, controls all of the power to the

instrument except for the part of the circuitry in the standby power supply.

Seven individual fans provide cooling to the RTSA. Three fans are dedicated to

the RF Deck and are controlled by the RF Interface. Two fans provide cooling

for the digital side of the instrument.

The bulk power supply module has an internal fan. Control signals to the power

supply fan are sent through the Power Conversion board from the Digital Interface

board.

A seventh fan is resident on the processor board heat sink, and is controlled by

the Slot PC board.

If Option 200 is installed, eight individual fans provided cooling to the RTSA.

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 2–3

Page 26

Theory of Operation

Figure 2-1: RSA6100A Series block diagram

2–4 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 27

Adjustment Procedures

Page 28

Page 29

Adjustment Procedure

There are no physical user adjustment procedures for the RSA6100A Series

instruments. However, you can run Alignments from the RSA6100A Series

application. Alignments are software-controlled adjustment procedures.

Running Ali

Alignment Status

gnments

Alignments are adjustment procedures run by the instrument using internal

reference signals and measurements, and do not require any external equipment or

connectio

There are two settings for Alignments:

If Automatically align as needed is selected, alignments run whenever the

spectrum analyzer detects a sufficient change in ambient conditions to warrant

an alignment.

If Run alignments only when "Align Now" button is pressed is selected,

the spectrum analyzer never runs an alignment unless you manually initiate an

alignment using the Align Now button.

NOTE

Automatically align as needed is not enabled.

Whe

screen. If no message is displayed, you can assume that the spectrum analyzer is

properly aligned.

ns.

Automatically align as needed (Auto mode)

Run alignments only when the "Align Now" button is pressed

. There are a few critical adjustments that must run occasionally even if

n the spectrum analyzer needs to run an alignment, it displays a message on

o initiate an alignment:

Initiating an Alignment

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 3–1

T

1. Select Setup > Alignments.

2. Select the Align Now button.

The spectrum analyzer will run an alignment procedure. Status messages are

displayed while the alignment procedure is running. If the instrument fails the

alignment procedure, an error message will be displayed. If the instrument fails

an alignment, run Diagnostics (Tools > Diagnostics) to see if you can determine

why the alignment failed.

NOTE. While an alignment is running, both the IF and IQ outputs are disabled.

Page 30

Adjustment Procedure

Alignments During

Warm-Up

Alignments During Normal

Operation

Alignments Are Not

Calibrations

Alignments are

oscillator alignments) because default alignment values are used, (if Auto mode is

selected). During the specified period for warm-up, the instrument performance

is not warranted.

Once the spectrum analyzer reaches operating temperature, a full alignment is then

run every two hours (for up to two minutes). Alignments can run more frequently

if the operating temperature changes. If an alignment becomes necessary during

a measurement cycle (if Auto mode is selected), the measurement is aborted

and an alignment procedure is run. Once an alignment procedure is completed,

the measu

Alignments are adjustment procedures run by the instrument using internal

referen

Tektronix service center and require the use of traceable test equipment (signal

sources and measuring equipment) to verify the performance of the instrument.

ce signals and measurements. Calibrations can only be performed at a

not run during the 20 minute warm-up period (except, for the RF

rement cycle restarts.

3–2 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 31

Maintenance

Page 32

Page 33

Maintenance

This section contains the information needed to do periodic and corrective

maintenance on the instrument. The following subsections are included:

Preventing ESD — General information on preventing damage by electrostatic

discharge.

Inspection and Cleaning — Information and procedures for inspecting the

instrument and cleaning its external and internal modules.

Removal and Installation Procedures — Procedures for the removal of

defective modules and replacement of new or repaired modules. Also

included is a procedure for disassembly of the instrument for cleaning.

Troubleshooting — Information for isolating and troubleshooting failed

modules. Included are instructions for operating the instrument diagnostic

routines and troubleshooting trees. Most of the trees make use of the internal

diagnos

Repackaging Instructions — Information on returning an instrument for

servic

tic routines to speed fault isolation to a module.

e.

Preventing ESD

re servicing this product, read the Safety Summary and Introduction at the

Befo

front of the manual and the ESD information below.

CAUTION. Static discharge can damage any semiconductor component in this

instrument.

When perfo

adhere to the following precautions to avoid damaging internal modules and their

components due to electrostatic discharge (ESD).

1. Minimize handling of static-sensitive circuit boards and components.

2. Transpo

or on a metal rail. Label any package that contains static-sensitive boards.

3. Discha

wrist strap while handling these modules. Perform service of static-sensitive

modules only at a static-free work station.

4. Do not allow anything capable of generating or holding a static charge on the

work station surface.

rming any service that requires internal access to the instrument,

rt and store static-sensitive modules in their static protected containers

rge the static voltage from your body by wearing a grounded antistatic

5. Handle circuit boards by the edges when possible.

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 4–1

Page 34

Maintenance

6. Do not slide the

7. Avoid handling circuit boards in areas that have a floor or work-surface

Inspection and Cleaning

Inspection and Cleaning describes how to inspect for dirt and damage. It also

describes how to clean the exterior and interior of the instrument. Inspection and

cleaning are done as preventive maintenance. Preventive maintenance, when done

regularly, may prevent instrument malfunction and enhance its reliability.

Preventive maintenance consists of visually inspecting and cleaning the

instrument and using general care when operating it.

How often preventive maintenance should be performed depends on the seve

of the e nvironment in which the instrument is used. A proper time to perform

preventive maintenance is just before instrument adjustment.

General Care

The cabinet helps keep dust out of the instrument and should normally be in

place when operating the instrument.

circuit boards over any surface.

covering capable of generating a static charge.

rity

Interior Cleaning

Exterior Cleaning

Use a dry, low-velocity stream of air to clean the interior of the chassis. Use a

soft-bristle, non-static-producing brush for cleaning around components. If you

must use a liquid for minor interior cleaning, use a 75% isopropyl alcohol solution

and rinse with deionized water.

WARNING. Before performing any procedure that follows, power down the

instrument and disconnect it from line voltage. Failure to do so could cause

personal injury, or death.

Clean the exterior surfaces of the chassis with a dry lint-free cloth or a soft-bristle

brush. If any dirt remains, use a cloth or swab dipped in a 75% isopropyl alcohol

solution. Use a swab to clean narrow spaces a round controls and connectors.

Do not use abrasive compounds on any part o f the chassis that may damage the

chassis.

Clean the On/Standby switch using a dampened cleaning towel. Do not spray or

wet the switch directly.

CAUTION. Avoid the use of chemical cleaning agents which might damage the

plastics used in this instrument. Use o nly deionized water when cleaning the

menu buttons or front-panel buttons. Use a 75% isopropyl alcohol solution as a

cleaner and rinse with deionized water. Before using any other type of cleaner,

consult your Tektronix Service Center or representative.

4–2 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 35

Maintenance

Inspection — Ex

terior. Inspect the outside of the instrument for damage, wear,

and missing parts, using the following table as a guide. Immediately repair defects

that could cause personal injury or lead to further damage to the instrument.

Table 4-1: External inspection checklist

Item Inspect for Repair action

Cabinet, front panel, and

cover

Front-panel knob Missing, damaged, or loose

Connectors

Carrying handle, and

cabinet feet

Accessories

Cracks, scratches,

deformations, damaged

hardware

knob

Broken shells, cracked

insulation, and deformed

contacts; dirt in connectors

Correct operation Repair or replace defective

Missing items or parts of

items, bent pins, broken or

frayed cables, and damaged

connectors

Repair or replace defective

module

Repair or replace missing or

defective knob

Repair or replace defective

modules; clear or wash out

dirt

module

Repair or replace damaged

or missing items, frayed

cables, and defective

modules

anel Display Cleaning

Flat P

The display is a soft plastic display and must be treated with care during cleaning.

CAUTION. Improper cleaning agents or methods can damage the flat panel

display. Avoid using abrasive cleaners or commercial glass cleaners to clean the

display surface. Avoid spraying liquids directly on the display surface. Avoid

scrubbing the display with excessive force.

Clean the flat panel display surface by gently rubbing the display with a

clean-room wipe (such as Wypall Medium Duty Wipes, #05701, available from

Kimberly-Clark Corporation).

If the display is very dirty, moisten the wipe with distilled water or a 75%

isopropyl alcohol solution and gently rub the display surface. Avoid using excess

orce or you may damage the plastic display surface.

f

CAUTION. To prevent moisture from getting inside the instrument during external

cleaning, use only enough liquid to dampen the cloth or applicator.

Inspection — Interior. To access the inside of the instrument for inspection and

cleaning, refer to the Removal and Installation Procedures in this section.

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 4–3

Page 36

Maintenance

Inspect the ins

ide of the instrument for damage and wear, using the following

table as a guide. Defects found should be repaired immediately.

CAUTION. To prevent damage from electrical arcing, ensure that circuit boards

and components are dry before applying power to the instrument.

Table 4-2: Internal inspection check list

Item Inspect for Repair action

Circuit boards

Resistors Burned, cracked, broken,

Solder connections Cold solder or rosin joints.

Capacitors

Wiring and cables Loose plugs or connectors.

Chassis Dents, deformations, and

Loose, broken, or corroded

solder connections.

Burned cir

Burned, broken, or cracked

circuit-run plating.

blistered condition.

Damaged or leaking cases.

Corroded solder on leads or

termina

Burned

wiring.

damag

cuit boards.

ls.

, broken, or frayed

ed hardware.

Remove and replace

damaged circuit board.

Remove and replace

damaged circuit board.

Resolder joint and clean

with isopropyl alcohol.

Remove and replace

damaged circuit board.

Firmly seat connectors.

or replace modules

Repair

with defective wires or

cables.

Straighten, repair, or replace

tive hardware.

defec

Cleaning Procedure — Interior. To clean the instrument interior, do the following

steps:

1. Blow off dust with dry, low-pressure, deionized air (approximately 9 psi).

2. Remove any remaining dust with a lint-free cloth dampened in isopropyl

alcohol (75% solution), and a clean lint-free cloth dampened in warm

deionized water. (A cotton-tipped applicator is useful for cleaning in narrow

aces and on circuit boards.)

sp

Lubrication. There is no lubrication required for this instrument.

4–4 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 37

Restoring the Windows Operating System (OS)

Restoring the

Windows Operating System (OS)

This section

on some models of RSA6100A Series spectrum analyzers.

To determin

following:

1. On the spec

2. Double-click the System icon.

3. Check the System software version to see if you are running Microsoft

Windows XP Embedded or Windows XP Professional.

4. If your instrument is running Microsoft Windows XP Embedded, the restore

procedure in this section will not work with your instrument. Use the

operati

the operating system.

5. If your

Windows desktop for a shortcut to Acronis True Image.

a. If you

contains procedures that describe how to restore the operating system

e if your system can use the procedures in this section, do the

trum analyzer, click Start > Control Panel.

ng system restore disk that shipped with your instrument to restore

instrument is running Microsoft Windows XP Professional, check the

r instrument does not have a shortcut to Acronis True Image, the

restore procedure in this section will not work with your instrument. Use

the operating system restore disk that shipped with your system to restore

the operating system.

b. If your instrument does have a shortcut to Acronis True Image, the

restore procedure in this section works with your instrument. Follow

theproceduresinthissectiontorestore the operating system on your

instrument.

OTE. Some instruments did not ship with operating system restore disks.

N

The procedures in this section apply only to instruments that did not ship with

operating system restore disks.

For Option 06/07 instruments, files to restore the operating system are located

on a partition of the hard drive. For Option 08 instruments, you should use the

Creating a Disk Backup Image procedure below, before placing the instrument

into service, to create a file that you can use to restore the operating system. The

Creating a Disk Backup Image procedure can also be used for Option 06/07

instruments.

For Option 08 instruments (and Option 06/07 if you use the Create a Disk Backup

Image procedure), the restore procedure also restores the product software, thus,

you do not have to restore the product software after performing the restore

procedure.

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 4–5

Page 38

Restoring the Windows Operating System (OS)

Creating a Dis

k Backup Image

Prerequisites

Create the Backup Image

Use the following procedure to backup the hard drive or solid-state drive in your

instrument as a disk backup image (for Option 08 instruments, this is the only way

to create a ba

hard drive or solid-state hard drive should the drive become corrupted.

You will need:

An external USB hard drive or a connection to a Local Area Network with

write permissions on a server.

To create a disk backup image:

1. Connect the instrument to a local area network.

2. On the in

TrueImage icon.

3. Click B

4. Click Next.

5. Click the check box for Disk 1 if it is not checked.

ckup of the drive). You will use the d isk backup image to restore the

strument Microsoft Windows desktop, double-click the Acronis

ackup to run the Create Backup Wizard.

6. Click Next to display the Backup Archive Selection screen.

7. Navigate to a location on the local network where you can save a disk backup

image.

8. Type in a descriptive name for the backup (such as the instrument m odel

number and serial number or corporate asset number).

9. Click Next to display the Choose Backup Options screen.

10. Do not change the default settings. Click Next to display the Archive

Comments screen. Type in any comments you want to include with the

backup.

11. Click Next to display a summary screen that shows the settings to be used to

create the disk backup image.

12. Click Proceed to begin the backup process.

13. When the backup is complete, click OK. Exit the Acronis TrueImage

application.

To verify that the disk backup image was created properly:

4–6 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 39

Restoring the Windows Operating System (OS)

1. Locate the disk

image appears as a single filename with a tib extension (for example,

RSA6106A_backup.tib).

2. Double-click the icon for the disk backup image. Double-click the next icon

that appears in the window.

3. Compare the files and folders that appear in the root directory of the backup

image to the root directory of the solid-state drive. If the files and folders in

the backup image are the same as the files and folders in the root directory of

the solid-state drive, the backup completed correctly. If you do not see the

same files and folders, repeat the disk backup procedure.

backup image on the local area network. The backup

Restoring the Instrument Operating System

You can restore the instrument operating system from either a file on the

instrum

(all drive options).

CAUTION. Using the restore process reformats the hard drive and reinstalls the

operating system. All saved data will be lost. If possible, save important files to

external media before performing a system restore.

ent hard disk drive (Options 06/07 only), or from a disk backup image

Formatting the Drive in Option 06/08 Instruments

sure a successful operating system restore on instruments with a removable

To en

hard drive (Option 06) or solid-state hard drive (Option 08), you should delete the

partition before performing the operating system restore procedure. To perform

this procedure, you will need a PC with internet access, a CD burner and disk

burning software. You will also need an USB external CD drive and keyboard

that you can connect to the RSA6100A Series instrument.

To delete the disk partition:

1. On a PC, use a web browser to go to:

http://www.allbootdisks.com/download/iso.html

2. Download the DOS6.0_bootdisk.iso image.

3. Burn the ISO image to a CD using disk burning software. Additional

information on burning the image to disk is available on the Web page.

4. Attach an external CD drive to the instrument. Verify that the CD drive is set

as the first boot device in the BIOS.

5. Attach a keyboard to the instrument.

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 4–7

Page 40

Restoring the Windows Operating System (OS)

6. Boot the instru

ment from the DOS boot disk that you created earlier in this

procedure.

7. When the comma

Fdisk and press Enter,

3 and press Enter,

Type

4 and press Enter,

Type

1 and press Enter,

Type

Y and press Enter,

Type

Press the

escape key twice to exit and reboot the instrument.

nd prompt appears, type:

8. When the process is complete, restore the operating system to the instrument

using th

e appropriate procedure.

4–8 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 41

Restoring the Windows Operating System (OS)

Restoring the

Operating System from the Instrument Hard Disk (Options 06/07)

On Option 06/07 instruments, an operating system restore file is saved on a

separate partition of the hard drive. The following procedure uses that restore file

to restore th

1. Attach a keyboard to the instrument.

2. Restart the instrument. During the boot-up process you will see the following

message at the top of the screen:

Starting Acronis Loader…press F5 for Acronis Startup Recovery Manager

3. Repeatedly press the F5 key until the Acronis True Image Tool opens. There

is a three-second time period from when the message appears until the

instrument proceeds with the normal instrument startup. If the instrument

does not

on the instrument and try again.

4. Within

5. In the Confirmation dialog box, click Ye s to restore the instrument operating

syste

approximately 30 minutes; the actual time depends on the instrument

configuration.

e operating system.

open the Acronis application, power off the instrument, then power

the Acronis TrueImage window, click Restore.

m, or No to exit the restore process. The restore proce ss takes

Restoring the Hard Disk from a Backup Image

To restore the hard drive or solid-state hard drive from a backup image, you must

be able to access the disk backup image from the instrument. The disk image can

be on a network or USB hard drive or flash drive.

Prerequisites

You will need:

An external USB CD-R/W drive (Option 06/08 only)

Bootable Rescue Media CD (Tektronix part number 063-4180-XX, a standard

accessory that ships with all instruments )

Backup image of hard drive (See page 4-6, Creating a Disk Backup Image.)

To restore the hard drive:

1. Option 06/08: Connect the USB CD-R/W drive to a high-speed USB port

on the rear panel.

2. Connect the instrument to the local area network or USB hard drive or flash

drive on which the disk backup image is stored.

3. Insert the Bootable Rescue Media CD in to the CD drive.

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 4–9

Page 42

Restoring the Windows Operating System (OS)

4. Restart the ins

opens automatically.

5. Click Recover

6. Click Next.

7. Navigate to the location of the disk backup image. Click Next to display the

Partition or Disk to Restore window.

8. Select Disk 1.ClickNext to display the Restored Hard Disk Drive Location

window.

9. Select Disk 1 as the Restored Hard Drive. Click Next to begin the restore

process.

10. Click OK when the restore process completes.

11. Remove the Bootable Rescue Media CD from the external CD drive and

restart the instrument. The instrument opens into the operating system with its

settings and appearance set as shipped from the factory.

trument. The Acronis TrueImage OEM Edition window

y to run the Restore Data Wizard.

4–10 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 43

Removal and Installation Procedures

This subsection contains procedures for the removal and installation of all

customer-replaceable mechanical and electrical modules.

Preparation

WAR N ING. Before doing this or any other procedure in this manual, read

the Safety Summary found at the beginning of this manual. Also, to prevent

possible injury to service personnel or damage to the instrument components,

read Installation in the RSA6100A Series Real-Time Spectrum Analyzers Quick

Start Use

Preventing ESD in this section.

r Manual, available on the Web at www.tektronix.com/manuals, and

Removal and Installation Procedures

This sub

WAR N

cord from the line voltage source. Failure to do so could cause serious injury

or death.

NOTE. Read Equipment Required for a list of the tools needed to remove and

install modules in this instrument. (See Table 4-3 on page 4-12.) Read the

cl

Equipment Required. Most modules in the RSA6100A Series Real-Time

pectrum Analyzers can be removed with a screwdriver handle mounted with a

S

size T15, TORX screwdriver tip. Other tools needed for complete disassembly are

listed in the following table.

section contains the following items:

Preparatory information that you need to properly do the procedures that

.

follow

List of tools re quired to remove and disassemble all modules.

Procedures for removal and reinstallation of the electrical and mechanical

modules.

ING. Before doing any procedure in this subsection, disconnect the power

eaning procedure before disassembling the instrument for cleaning.

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 4–11

Page 44

Removal and Installation Procedures

Table 4-3: Tool

Item no. Name Description General tool number

1

2

3

4

5

6 Angle-

7

8

9

s required for module removal

Screwdriver handle Accepts TORX-driver

bits

T10 TORX tip Used for removing

instrument

TORX-driver bit for

T10 size screw heads

T15 TORX tip Used for removing most

instrumen

TORX-driver bit for

T15 size screw heads

1/8 inch flat-bladed

ver

screwdri

#0 Phillips screwdriver Screwdriver for

tip Tweezers

3/16 inch open-end

h

wrenc

inch open-end

5/16

wrench

MA-800G Soldering Aid

Screwdriver for

unlockin

connectors

removing small phillips

screws,

hard drive

Used to remove front

panel knobs

Used to remove nut

posts

Used to remove nut

post

Used

front panel trim

.screws

tscrews.

g cable

CDRW, and

s

to remove the

620-440

640-235

640-247

Standard tool

Standard tool

Standard tool

Standard tool

dard tool

Stan

Standard tool

4–12 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 45

Removal and Installation Procedures

Trim, Cabinet

, and Module Removal

Use the following two tables to determine items of the instrument that you will

need to remove to access replaceable parts. The first table lists items that may

need to be rem

oved before you can access a replaceable module. The second

table lists customer replaceable modules and which items must be removed

to access the replaceable module. The approximate location of the primary

customer replaceable modules is shown in the following figure. (See Figure 4-1

on page 4-14.)

Table 4-4: Legend for Accessing Modules table

A - Front Cover (if installed) F - Internal Cover, top

B - Front panel trim

C - Pouch (if installed) H - DVD Drive (if installed) M - Internal HDD (if installed)

D - Cabinet, top I - Removable HDD/Solid State Drive (if

E - Cabinet, bottom J - DVD Drive/Removable HDD Frame O - Power Supply

4-5: Accessing Modules

Tabl e

les to replace

Modu

Display Assembly

Front Panel

DVD Drive (if installed)

Removable HDD Dr ive (if installed)

Removable Solid State Drive (if

talled)

ins

D D rive/ Removable HDD Frame

DV

Digital Fan Tray (Upper Deck)

eck Fan Tray

RF D

Real Time IQ/IF Output Acquisition

board (if installed)

RTT/DPSA board

lot PC

S

Internal HDD (if installed)

Power Conversion board

Power Supply

RF Interface board

1

Display module does not need to be removed for earlier RSA6106A and RSA6114A models. See removal instructions.

G - Internal Cover, bottom

installed)

e these items to access the module

Remov

ABCDEFGHI JKLMNO

K - Display Assembly

L - Front Panel

N - Power Conversion board

1

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 4–13

Page 46

Removal and Installation Procedures

Figure 4-1: Primary customer replaceable module locations

4–14 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 47

Removal Procedures

Removal and Installation Procedures

NOTE. Unless directed otherwise, installation is the reverse of the removal

procedure.

These procedures assume you have access to the module you are removing. Use

the tables to determine which trim and/or modules to remove to gain access. (See

Table 4-4 on

as a quick reference for customer replaceable module locations. (See Figure 4-1

on page 4-14.)

CAUTION. When removing or installing the keypad, make sure you do not touch

the switch c ontacts with your fingers. The oils in your fingers will degrade or

damage the switch contacts. To help prevent damage to the keypad use cotton

gloves w

CAUTION. To avoid damage to the front panel Standby/On switch assembly, do

not set

over the edge of the work surface could break off the On/Standby switch assembly.

page 4-13.)(See Table 4-5 on page 4-13.) A figure is also provided

hen removing or installing the keyboard pad.

the Display module assembly on a work surface. Sliding the instrument

Display

Front Panel

orm these steps to remove the Display module:

Perf

1. Remove the four screws securing the display to the Main chassis; two on the

topandtwoontheleftside.

2. Gently remove the Display module from the Main chassis.

CAUTION. Be careful when removing and reinstalling the Display module cables.

If the connectors have bent pins or are installed incorrectly the Display may

be destroyed.

3. Disconnect the smaller Display cable from J3 on the Display Adapter board.

4. Disconnect the larger Display cable from J2 on the Display Adapter board.

Perform these steps to remove the Front Panel:

1. Remove the six T15 screws that secure the Front Panel to the chassis; two o n

op, two on the right side, and two on the front.

the t

2. Pull the Front Panel as sembly from the chassis.

3. Disconnect the Front Panel cable from connector J1 on the Front Panel circuit

board.

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 4–15

Page 48

Removal and Installation Procedures

Digital Deck Fans

DVD Drive

Perform these s

1. Unplug the fan control cable from the Main board connector, marked Fan1

and Fan2.

2. Remove the four T15 TORX screws securing the fan assembly, located on the

left side of the instrument.

3. Lift the fan assembly up through the narrow slot between the side panel and

the card cage.

NOTE. You may have a DVD drive, solid-state drive, or a removable HDD

mounted above the front panel. If you ordered a solid-state drive or a removable

HDD, the i

Follow these steps to remove the DVD drive (if installed):

1. Remove

2. Pull the DVD drive out from the Main chassis.

3. Remove the four screws securing the DVD drive and Adapter board to the

DVD drive bracket.

teps to remove the fan assembly from the digital deck:

nstrument will not have an internal hard disk drive.

the two screws securing the DVD bezel, and remove the bezel.

vable Hard Disk

Remo

Drive / Solid State Drive

Perform these steps to remove the removable hard disk/solid state drive (if

installed):

1. Loosen the thumbscrews securing the drive to the front panel.

2. Grasp the drive assembly by the thumb screws and pull until the handle is

exposed. Grasp the handle and pull the assembly straight out of the instrument.

3. Pry the detents retaining the top cover apart, and remove the top cover.

4. Remove the four screws securing the hard drive/solid state drive to the bottom

cover.

5. Separate the hard disk drive/solid state drive from the HDD Adapter board.

To Replace the Hard Drive.

1. Connect the hard disk drive/solid state drive to the HDD Adapter board.

2. Attach the hard disk drive/solid state drive to the bottom cover with the four

screws removed in the previous procedure.

3. Snap the top cover onto the bottom cover.

4. Leaving the cover/handle extended, push the hard disk drive/solid state

drive assembly into place until it stops, ensuring that it is straight. Push the

assembly firmly to ensure that the connector is seated properly.

4–16 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 49

Removal and Installation Procedures

CD-ROM Drive/Removable

HDD Frame

Slot PC

board

5. Slide the cover

panel.

6. Finger tighte

driveisproperlyseated.

Follow these steps to remove the frame used for the CD-ROM drive or removable

hard disk dr

1. Disconnect the IDE cable from the Slot PC to the CD Drive adapter board.

2. Remove the

3. Remove the two T10 flathead screws securing the frame to the front of the

chassis,

4. Remove the two T15 screws securing the drive frame to the right chassis rail.

5. Remove the drive frame by sliding it toward the back of the spectrum

analyzer, and rotating the back of the frame to the left.

Perform these steps to remove the Slot PC board

1. Lift the S lot PC board from the spectrum analyzer.

ive:

/handle in until it stops. It will be almost flush with the back

n the two thumb screws to ensure that the removeable hard disk

cable connected to P3 on the Drive Adapter board.

through the access holes.

Internal Hard Disk Drive

Power Conversion board

2. Disconnect the PC Network cable from the board.

Follow these steps to remove the internal hard disk drive:

E. If you have a removable HDD mounted above the front panel you will

NOT

not have an internal hard disk drive.

1. Disconnect the IDE cable from the Slot PC to the hard disk drive.

2. Disconnect the DISP ADPTR CTRL and DISP ADPTR VID c ables from

the Main board.

3. Disconnect the power plug from the hard disk drive.

4. Remove the four T15 screws securing the hard disk drive assembly to the

Power Supply shield.

5. Lift the hard disk drive up and remove it from the spectrum analyzer.

Perform these steps to remove the Power Conversion board:

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 4–17

Page 50

Removal and Installation Procedures

Power Supply

1. Remove the cabl

es connected to the Power Conversion board:

Table 4-6: Power conversion board connectors

Connector Connector

Number Name Number Nam e

J3

J4

J5

ATX POWER

ANALOG P OWER

RF PWR CTRL

J6

J7 Line trigger sense

CD-ROM/HDD

2. Remove the four T15 screws securing the Power Converter board to the

chassis.

3. Slide the Power Converter board to the right, to disengage the connector

to the Power Supply.

4. Lift the Power Converter board from the spectrum analyzer.

Follow

these steps to remove the Power Supply assembly:

1. Disconnect the mains wires from the Line Filter on the rear-panel.

2. Remove the RTT/DPSA board.

3. Remove the Slot PC board.

4. Remove the Power Conversion board.

5. Dis

connect the EXT TRIG IN (J24) and TRIG OUT (J25) cables from the

Main board.

6. Re

move the three T15 screws securing the power supply shield tabs to the

front chassis.

7. Re

move the one T15 screw securing the power supply shield tab to the bottom

chassis, toward the rear of the spectrum analyzer.

emove the four T15 screws securing the power supply shield to the bottom

8.R

chassis. These four are located in the Power Converter footprint, to the right

of the power supply.

9. If the Power Supply will not move at this point you have a later model

spectrum analyzer. You will need to remove the Display assembly before you

can proceed. (See page 4-15, Display.)

10. If you had to remove the Display assembly in step 9, remove the two T15

screws that were revealed. These screws secure the power supply to the front

chassis.

4–18 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 51

Removal and Installation Procedures

11. Tip the Power Su

of the spectrum analyzer first.

12. Remove the one

shield.

pply/shield assembly to lift the Power Supply (left) side out

T15 screw securing the ground wire to the power supply

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 4–19

Page 52

Troubleshooting

Troubleshooting

WARNING. Before doing this or any other procedure in this manual, read

theSafetySu

possible injury to service personnel or damage to the instrument components,

read Installation in the RSA6100A Series Real-Time Spectrum Analyzers Quick

Start User Manual, available o n the Web at www.tektronix.com/manuals, and

Preventing ESD in this section.

Troubleshooting contains information and procedures designed to help you isolate

faults to a module.

This subsection assumes that service personnel have the skills required to work on

the Real-Time Spectrum Analyzer, including PC troubleshooting and Windows

operating system skills. Details of PC and Windows operation and service are

not in t

For assistance, please contact your local Tektronix Service Center.

mmary found at the beginning of this manual. Also, to prevent

his manual.

Service Level

This section contains information and procedures designed to help you isolate

ty modules in the RSA6100A Series Real-Time Spectrum Analyzer. If a

faul

module needs to be replaced, follow the Removal and Installation Procedures,

located in this section.

Check for Common Problems

Use the following table to quickly isolate possible failures. The table lists

problems and possible causes. The list is not exhaustive, but it may help you

eliminate a problem that is quick to fix, such as a blown fuse or loose cable.

Table 4-7: Failure symptoms and possible causes

Symptom Possible cause(s)

Instrument will not power on Power cord not plugged in

Faulty power supply (check Status LEDs)

Faulty power conditioner board

Faulty front panel power switch

Faulty display adapter board

4–20 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 53

Table 4-7: Failure symptoms and possible causes (cont.)

Symptom Possible cause(s)

Front panel light comes on (instrument

powers on), but one or more fans will

not operate

No beeps on startup or multiple beeps

on startup (single beep is OK)

Flat panel display blank

Faulty fan cable

Defective fan assembly

Faulty power supply (check Status LEDs)

Faulty Slot PC

Faulty CPU

Digital Interface board problem

Faulty Slot PC

BIOS setting not Advanced Chipset F eatures

> - On Chip VGA > Enabled - Boot Display >

CRT + LFP

Defective cable from Slot PC board to Digital

Interface board

Troubleshooting

Defective cable from display adapter board to

digital interface board

Defective cable from inverter board to display

adapter board

Defective cable from inverter board to

backlighting display lamp

Defective backlighting display lamp

Faulty display

Faulty digital interface board

Faulty inverter board

Faulty display adapter board

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 4–21

Page 54

Troubleshooting

Table 4-7: Failure symptoms and possible causes (cont.)

Symptom Possible cause(s)

DVD-ROM related symptoms Defective DVD-ROM

Defective DVD-ROM drive cable

Defective DVD-ROM Adapter board

Incorrect DVD-ROM configuration in the BIOS

setup

Hard disk drive related symptoms

Defective hard disk drive

Incorrect hard disk type selected in the BIOS

setup

Replaceable hard disk drive not installed

Power supply failure

Corrupted BIOS module firmware, reinstall

firmware

Loose cable

Status Indicator LEDs

Corrupted OS image

Check that the Status Indicator LEDs on the Power Converter and Digital

rface boards to ensure the power supplies are operating. (See Figure 4-2.)

Inte

(See Table 4-8.) (See Table 4-9.)

Figure 4-2: Status indicator locations

4–22 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 55

Troubleshooting

Table 4-8: Powe

LED Status Indication

DS171 STANDBY

DS172 -15 V OK

DS173 -8 V OK

DS174 +8 V OK

DS175 +15 V OK

DS176 +30 V OK

r Converter board status indicators

Table 4-9: Digital Interface board status indicators

LED Status Indication

DS481 CLOCK FAIL (normally off)

DS482 +5 VSB OK

DS483 +5 V OK

DS484 +3.3 V OK

DS485 +2.5 V OK

DS486 +1.8 V OK

DS487 +1.5 V OK

DS488 FPGA INIT

DS489 FPGA DONE

DS4810 STATUS 0

DS4811 STATUS 1 (normally off)

Diagnostics

This section describes how to use and interpret the embedded Diagnostics

Interface for both the Power On Self Tests (POST) and the Extended Diagnostics

tests. These tests are used to determine whether there has been a module failure

in the instrument.

Power On Self Tests

(POST)

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 4–23

The Power On Self Tests (POST) run automatically, every time the instrument is

powered up. If a failure is detected during this process the POST Result view will

be displayed to show which module(s) failed. (See Figure 4-3.)

Page 56

Troubleshooting

Figure 4-3: Diagnostics Power On Self Test results view

Further information about the failure can be obtained from the Diags Failure Info

tab in the Diagnostics window. (See Figure 4-4.)

Figure 4-4: Diagnostics Failure Info tab

All failure information is logged in the Windows Event Viewer. You can

access the Windows Event Viewer by clicking the Event Viewer button on the

Diagnostics Failure Info tab. The Windows Event Viewer is also available in the

Administrative Tools portion of the Windows Control Panel.

NOTE. Che

and may be from earlier power cycles.

4–24 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

ck the timestamp in the Event Viewer, as errors are stored on disk

Page 57

Troubleshooting

Windows Event Viewer

The Windows Eve

Failure information, along with other messages regarding the operating system.

If there is not a shortcut to the Event Viewer on the desktop you can access it

by clicking the Event Viewer button on the Diagnostics Failure Info tab. (See

Figure 4-5.)

nt Viewer maintains a permanent record of the Diagnostics

e 4-5: Event viewer initial display

Figur

w the Diagnostics failure information, first click the Application icon in the

To vie

left frame (under Event Viewer (Local)). The view changes to show the individual

error reports, as shown in the following figure. Note that this view shows errors,

warnings, and information for both the spectrum analyzer application and for the

operating system. Pay attention to the date and time stamps, as the information

is a permanent record and will show failure information from earlier diagnostic

sions.

ses

Also note that the spectrum analyzer diagnostic errors will show TekRSA in the

urce column, to differentiate them from operating system messages.

So

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 4–25

Page 58

Troubleshooting

Figure 4-6: Event viewer applications error view

Double-click an error message and the Event Properties window opens for that

error message. (See Figure 4-7.)

Figure 4-7: Event Properties window, showing error log information

The event properties window shows the date and time the error message was

generated and the source of the error message. The text of the error message is

shown in the Description area. The three buttons at the upper right are used to

navigate through the error list (using the up and down arrows), or to send the

record to the default printer.

4–26 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 59

Troubleshooting

Extended Diagnostics

If you scroll do

that says For more information, see Help and Support Ce nte r at and includes a

link to Microsoft.com. Do not use this link, as Microsoft has no information on

Tektronix instrument error messages.

The Extended Diagnostics allow you to run all of the diagnostics tests in the

instrument, including the POST tests. Access the Extended Diagnostics by

selecting Diagnostics in the Tools menu. (See Figure 4-8.)

wn in the error description, the event viewer always adds a line

Figure 4-8: S tarting Extended Diagnostics

This opens the Embedded Diagnostics Interface. (See Figure 4-9.)

Diagnostics Interface allows you to sele ct specific tests, and control how

The

many times the selected tests are repeated.

RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual 4–27

Page 60

Troubleshooting

Figure 4-9: Embedded Diagnostics Interface

In the Repeat segment of the window (see the following figure), you can check the

radio bu

A) Repeat the test(s) a specified number of times,

B) Repeat the test(s) until a failure occurs,

C) Repeat the test(s) continuously even if failures occur, or

D) Run the test(s) only one time.

Figure 4-10: Diagnostics test iteration control

ttons to:

While the diagnostic tests are in process, a green dot is shown beside the test that

is currently running. If the test completes successfully the green dot is replaced by

a black check mark. If the test fails, the green dot is replaced by a red X.

4–28 RSA6106A/RSA6114A (S/N B020000 and Above), and RSA6120A Service Manual

Page 61

Troubleshooting

Tabl e 4-10: Dia

Module Test Error message Recommended a

Hardware

Digital Interface Board Digital Board ID Verification Failed. Send the instrument to a Tektronix

gnostic error messages

Hardware Init

Read Programmable

rt Versions

Pa

Digital Board ID

Verification

Digital Board FPGA

Load Test

ction

Digital Inter

Digital Discovery Failed. Run digital tests in extended

The Acquisition Board was not found. Send the instrument to a Tektronix

The Contin

Board was not found.

Load Digital Interface Board Failed. Send the instrument to a Tektronix

RF Interface Board not found or

FPGA Loa

First L

failed.

Reference Oscillator not found or

FPGA Load failed.

Second Converter not found. Send the instrument to a Tektronix

The T

failed.

Dev

Error reading ID’s.