Page 1

xx

RSA56KR Rackmount for

ZZZ

RSA6100A Series and RSA5100A Series Analyzers

Instructions

www.tektronix.com

P075102300*

*

075-1023-00

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. B o x 5 0 0

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

Worl dwid e, vis it www.tektronix.com to find contacts in your area.

Page 3

Table of Contents

Service Safety Summary.......................................... ................................ ................. 1

Kit Description........................................... ................................ ........................... 2

Products ................................ ................................ ................................ ......... 2

Kit Parts Li

Warranted Characteristics..................................................................................... 3

Environmental Requirements................................................................................. 4

Clearance Requirements ....... ................................ .................................. ............. 5

Installation Instructions............................................................................................ 7

Minimum Tool and Equipment List ........ ................................ ................................. 7

Remove .... .................................. ................................ ................................ ... 8

Install......................... ................................ ................................ .................. 11

Rackmount the Rack-Adapted Instrument ................................................................. 14

st .............. ................................ ................................ ..................... 2

RSA56KR Rackmount Installation Instructions i

Page 4

Table of Contents

ii RSA56KR Rackmount Installation Instructions

Page 5

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary located in the Service m anual

for your inst

manual part number: 077-0522-XX) before performing any service procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

To prevent the instrument and rack from falling onto the operator, two or more

installers should install the instrument into the rack cabinet. After completing the

install

cabinet will not tip forward while the instrument is in the extended position.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

rument (RSA6100A manual part number: 077-0250-XX; RSA5100A

ation procedure, the installers should verify that the instrument and rack

Use Ca

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

re When Servicing With Power On. Dangerousvoltagesorcurrentsmay

RSA56KR Rackmount Installation Instructions 1

Page 6

Kit Description

Kit Description

Products

Kit Parts List

This kit describes the installation of the RSA56KR Rackmount kit on your

RSA6100A Series or RSA5100A Series analyzer. The rackmount kit is a

collection o

f parts that, once installed, configures the instrument for mounting

into a standard 19-inch equipment rack.

RSA6100A Series. All instruments

RSA5100A Series. All instruments

Figure 3

on page 8 Quantit

–––

–––

3-1 1 ea 441-2665-XX

3-2 1 ea 351-0313-01

3–3 4 ea

3-3

3-3 14 e

3-3 4 ea

3-3 4 ea

3-3 8 ea

3-3 4 ea

3-3 9 ea

3-4 1 ea 351-0241-XX

3-4 1 ea

3-5 2 ea 367-0525-XX Handle: Bracket, aluminum, silver gray

y

1 ea 016-2040-XX

1 ea 075-10

7ea

a

Part num

NS Scre

NS

NS Screw, mach: 10-32, Truss head, 0.5

NS Screw, mach: M6 x 20 ovl head, Phillips

NS Screw, mach: M5 x 20 ovl head, Phillips

NS Screw, mach: 10-32 x 0.75 ovl head,

NS Screw, mach: 12-32 x 0.75 ovl head,

NS Washer: flat, nylon

NS

ber

23-XX

Descrip

Rackmou

consisting of the following:

Techni

Rackmount,RSA6100A Series,

RSA5100A Series

Bracket, rackmount (right and left)

Guide rack, consisting of: left and right

side

in l, Phillips

Nut

in l, phillips

P

Phillips

Slide, drawer, extenders: Sliders

Rack: Mounting screws, nut blocks

tion

nt Kit: RSA5000/6000 Series,

cal manual: Instructions,

w, mach: 10-32, pan head, 0.375

, locking washer: 10-32 assembly

hillips

2 RSA56KR Rackmount Installation Instructions

Page 7

Figure 3

on page 8 Quantity Part number Description

3-6 4 ea 212-0577-XX

NS — Not Saleable

Warranted Characteristics

Kit Description

Screw, mach: 10-32, Truss head, 0.625

in, Pozidriv

®

When the ins

trument is installed as instructed in this document, the rackmounted

instrument meets all warranted requirements listed in the instrument specification

except for those listed in Environmental Requirements.(See page 4, Environmental

Requirements.) Use of mounting methods other than those described in these

instructions can cause the instrument to not meet warranted requirements.

See the Specifications and Performance Verification Technical Reference for your

instrument for tables of the warranted characteristics.

Cooling air enters from the left side of the instrument. (See Figure 1.). You assume

the responsibility to provide adequate cool air to meet the ambient temperature

requirements listed in the Warranted Characteristics table. (See Table 1.).

RSA56KR Rackmount Installation Instructions 3

Page 8

Kit Description

Figure

Environmental Requirements

The following environmental characteristics supersede those listed in the user

or service manual for your instrument.

Table 1: Warranted characteristics

Characteristic Description

Temperature, Inside rack cabinet

Operating RSA6100A Series: +5° C to +50° C

Non-operating

1: Instrument cooling

When accessing

DVD

RSA5100A Series: +5° C to +40° C

+5° C to +40° C

–20° C to +60° C

4 RSA56KR Rackmount Installation Instructions

Page 9

Table 1: Warranted characteristics, (cont.)

Characteristic Description

Vibration

Operating 0.22 Grms. Profile = 0.00010 g2/Hz at 5 Hz to 350 Hz,

-3 dB/Octave slope from 350 Hz to 500 Hz, 0.00007 g

at 500 Hz, 3 Axes at 10 min/axis (Except when equipped

with optional Removable HDD (RSA6100A Series), or

when accessing DVD/CD)

RSA6100A Series: When equipped with Option 08,

Non-operating

Shock

Operating and

Non-operating

Removable Solid State HardDrive:0.27Grms.Profile =

0.00015 g

350 Hz to 500 Hz, 0.000105 g

10 min/axis

RSA6100A Series: 2.28 Grms. Profile = 0.0175 g2/Hz at 5

Hz to 100 Hz, -3 dB/Octave slope from 100 Hz to 200 Hz,

0.00875 g

from 350 Hz to 500 Hz, 0.00613 g

at 10 min/axis

RSA5100A Series: 2.28 Grms. Profile = 0.0175 g

Hz to 100 Hz, -3 dB/Octave slope from 100 Hz to 200 Hz,

0.00875 g

from 350 Hz to 500 Hz, 0.00613 g

at 10 min/axis

RSA6100A Series: 20 g, 11 ms, half sine, each axis, 3

drops each

RSA5100A Series: 15g, 11 ms, half sine, each axis, 3

drops each

2

/Hz at 5 Hz to 350 Hz, -3dB/Octave slope from

2

/Hz at 200 Hz to 350 Hz, -3 dB/Octave slope

2

/Hz at 200 Hz to 350 Hz, -3 dB/Octave slope

2

/Hz at 500 Hz, 3 Axes at

2

/Hz at 500 Hz, 3 Axes

2

/Hz at 500 Hz, 3 Axes

Kit Description

2

/Hz

2

/Hz at 5

Clearance Requirements

The rack in which the rack-adapted instrument is mounted must provide the

following clearance requirements:

A minimum of 266.7 mm (10.5 in) of vertical space.

A minimum width of 448 mm (17 5/8 in) between the left- and right-front

rails in the rack.

A minimum inside depth of at least 508 mm (20.5 in).

CAUTION. By adhering to these clearance requirements, the rack-adapted

instrument will be mounted with sufficient clearance for air circulation and

accommodation of the power cord and mounting hardware. Failure to provide

these clearances can result in overheating and will cause the instrument to not

operate properly and/or fail.

RSA56KR Rackmount Installation Instructions 5

Page 10

Kit Description

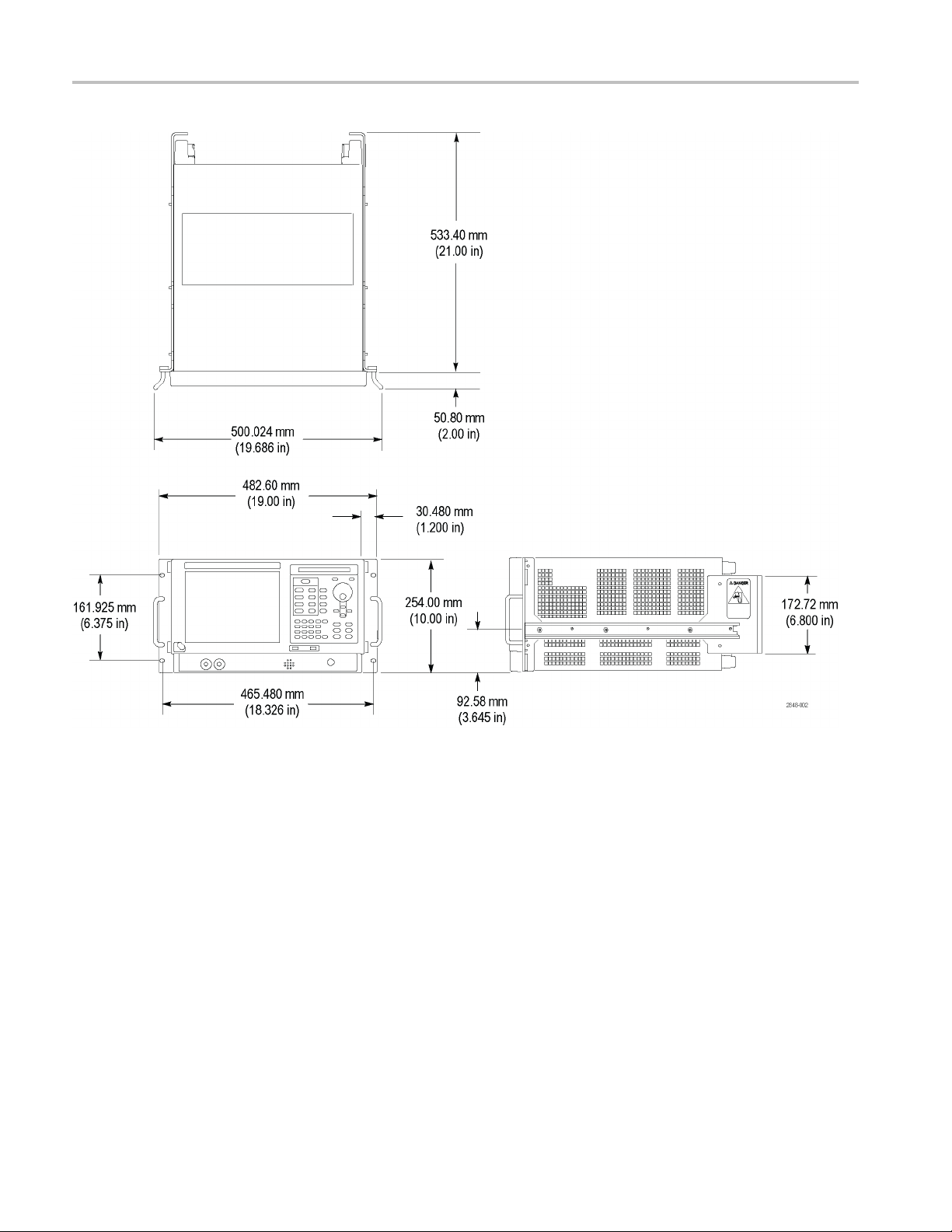

Figure 2: Instrument dimensions with rack adapter installed

6 RSA56KR Rackmount Installation Instructions

Page 11

Installation Instructions

This section contains all procedures needed to rackmount RSA6100A Series and

RSA5100A Series instruments.

Minimum Tool and Equipment List

The following tools are required to attach the rack-adapter kit hardware, install

cabling har

equipment cabinet. All tools are standard tools that are readily available.

Table 2: Tools required for installation

Item

no. Name Description

1

2

3

4

5

dware, and mount the rack-adapted instrument into a standard

Screwdriver

handle

(magnetic)

T-15 TORX

tip

5/32-in. hex

wrenc

T-10 T

tip

3/16-in. nut

driver

h

ORX

Installation Instructions

Torque driver handle. Accepts 1/4-in. hex-head driver tips

TORX-driver tip for T-15 size screws on the instrument covers

Hex wrench to remove Allen head screws at front of top cover

driver tip for T-10 size screw heads on the VGA cable

TORXconnector

Nut driver to remove the hex posts from the bracket (Slot PC

board)

These instructions are for qualified service personnel who are familiar with

vicing the product. If you need further details for disassembling or reas sembling

ser

the product, refer to the appropriate product manual. Contact your nearest

Tektronix Service Center or Tektronix Factory Service for installation assistance.

WAR NI NG . To prevent the rackmounted instrument from tipping forward onto the

operator, install the instrument so that the operator will be able to access all of its

rear devices without pushing down on the instrument.

Verify that the rack does not become unstable with the instrument fully extended.

Do not leave the i nstrument extende d when you are finished accessing the rear

panel.

RSA56KR Rackmount Installation Instructions 7

Page 12

Installation Instructions

Figure 3: Rackmount k it parts

Remove

Strip the Instrument for

ersion

Conv

8 RSA56KR Rackmount Installation Instructions

Equipment required. Torxdriver (Item 1) with T-15 and T-20 tips (Items 3 and

4), 5/32 hex wrench (Item 7).

NOTE. All parts removed from the instrument in this procedure should be retained

for later use. Store any parts not needed for r ackmounting in case you want to

vert back to a standard instrument configuration at a later time.

con

Right-side or left-side references in these instructions assume you are viewing the

strument from the front panel.

in

Page 13

Installation Instructions

1. Remove the powe

2. If it is installed, pull the front cover off the instrument.

3. Remove the two screws that se cure the plastic carrying handle to the side of

the instrument. (It is not necessary to remove the black metal handles.) (See

Figure 4.)

4. Remove four T-15 Torxdrive screws along each side and two 5/32 Allen head

screws near

secure the top and bottom covers to the instrument.

5. Remove the

back about 1 inch. Then pull out on the sides of the top cover outward,

flexing them slightly to clear the instrument chassis, and pull it away from the

instrument.

r cord.

the front edge of the top cover (next to the folding handles) that

top and bottom covers. Remove the top cover by pulling straight

RSA56KR Rackmount Installation Instructions 9

Page 14

Installation Instructions

Figure 4: Strip instrument for conversion

10 RSA56KR Rackmount Installation Instructions

Page 15

Installation Instructions

Figure

Install

5: Rackmount panel preassembly

NOTE. Preassemble all subparts on the right-and left-side panels before installing

the rackmount panels on the instrument. (See Figure 5.)

1. To install the bracket handle:

a. Install the bracket handle to the right-side rackmount panel.

b. Secure the bracket handle to the right-side rackmount panel using the two

10-32 x 0.375 flat head screws. Install the scr ews through the beveled,

recessed holes on the back of the flange. Apply 15 inch-lbs of torque to

the scr ews.

2. Install the right-side rackmount track over the three screw posts on the

right-side rackmount panel. Use the three 10-32 locking-nut washer

RSA56KR Rackmount Installation Instructions 11

Page 16

Installation Instructions

assemblies to s

applying 28 inch-lbs of torque.

CAUTION. To prevent the rackmount track from not locking, make sure the track

button latch is located towards the bottom of the rackmount panel. (See Figure 6.)

ecure the right-side rack track onto the rackmount panel,

Figure

3. Insta

4. Repeat steps 1 through 3, to install the left-side rackmount panel, substituting

6: Right inside track identification

ll the right-side rackmount panel assembly to the right side of the

instrument. Secure it by using the four 10-32 Truss head Phillips screws,

applying 28 inch-lbs of torque. (See Figure 7.)

left-side for the right-side.

12 RSA56KR Rackmount Installation Instructions

Page 17

Installation Instructions

Figure 7: Installation of rackmount assemblies

RSA56KR Rackmount Installation Instructions 13

Page 18

Installation Instructions

This completes

complete the installation, proceed to Rackmount the Rack-Adapted Instrument..

the installation of the rack-adapter hardware to the instrument. To

Rackmount the Rack-Adapted Instrument

This procedure describes how to assemble and install the slide-out tracks in the

equipment rack, and how to install the rack-adapted instrument in the rack.

The slide-out tracks permit the rack-adapted instrument to be extended out of the

rack for rear-panel and connector maintenance without removing the instrument

from the rack.

WARNING. If slide-out track assemblies are disassembled for maintenance, do not

interchange t he left and right inner tra cks when reinstalling them in the left and

right ou

feature of the tracks. Equipment could, when extended, come out of the slides and

fall from the rack, possibly causing personal injury and equipment damage.

WARNING. To prevent the rackmounted instrument from tipping forward onto the

operator, install the instrument so that the operator will be able to access all of its

rear devices without pushing down on the instrument.

ter tracks. If you do so, you will defeat the extension stop (safety latch)

Verify that the rack does not become unstable with the instrument fully extended.

Do not leave the instrument extended when finished accessing the rear panel.

NOTE. The rack hardware kit contains hardware needed for mounting the

instrument in s everal configurations. Not all of the hardware in the kit will be

needed.

TE. A standard equipment rack has rails with universal hole spacing. If

NO

you use a rack with other than universal hole spacing, you may have to drill

additional mounting holes in the rack.

14 RSA56KR Rackmount Installation Instructions

Page 19

Installation Instructions

Install Track A

instrument in Rack

ssembly and

Equipment Requ

tip (Item 2).

NOTE. The slide-out track assemblies that are included in this kit (See Figure 3

on page 8.) come partially assembled with the inner tracks inside of the outer

tracks. Leave them partially assembled to simplify their installation and to avoid

accidental swapping of their inner tracks. (See WARNING on the previous page.)

If assemblies are disassembled, you need to match left and right slides (See

Figure 8 on page 16.). (Note that when the left and right tracks are oriented as

shown, the

tracks.)

Procedure:

1. Assemble the slide-out track:

a. Identify the right versus left slide-out track assemblie s by finding the date

code label on each assembly. The assembly to be mounted in the left side

of the equipment rack (the side nearest the left side of the instrument when

it is r

right assembly has a date code ending with “RH”, for right hand.

ired. One screwdriver handle (Item 1), one number two Pozidriv

round cutout is below the square cutout at the end of the both inner

ackmounted) has a date code that ends with “LH,” for left hand. The

b. Meas

c. Align the rear bracket to the right slide-out track as shown (See Figure 8.).

d. Using a screwdriver with a number two Pozidriv tip, secure the rear

e. Repeat substeps c and d to assemble the left slide-out track assembly.

2. Mount the slide-out track assemblies, using the slide drawer hardware listed

in the kit parts list (See Figure 3.):

a. Select the mounting position in rack: Select two ½ inch spaced holes in

ure the distance between the front and rear rail of the equipment rack.

e the rear bracket has multiple pairs of mount-through holes. When

Not

aligning the bracket and track, be sure to select a pair of holes that mount

the rear bracket so the flange-to-flange distance (see figure) matches the

front rail to rea r rail spacing of the rackmount rack just measured.

bracket to the right slide out track using two screws (10-32) and a nut bar

as illustrated. Leave the screws loose so that the overall length o f the

slide-out track assembly can be adjusted when installing it in the rack.

the front rail. Verify that the 10.500 inch clearances exist relative to those

mounting holes. (See Figure 9 on page 17.)

RSA56KR Rackmount Installation Instructions 15

Page 20

Installation Instructions

Figure 8: Assembly of slide-out track assemblies

16 RSA56KR Rackmount Installation Instructions

Page 21

Installation Instructions

Figure 9: Vertical clearances for rack installation (left-front rail shown)

b. Select mounting method according to rack type:

To mount the slide-out tracks with their front and rear flanges outside

of the front and rear rails use Mounting Method A (See Figure 10.)

RSA56KR Rackmount Installation Instructions 17

Page 22

Installation Instructions

when doing subs

rails have untapped holes.

To mount with f

Method B outlined in the following figure. (See Figure 10.). This

mounting method assumes untapped holes.

c. Install in rack: Using the method and hardware determined from substep

b, secure the right slide-out track assembly to its front and rear rails. The

screws should be fully, but lightly, seated so mounting can be adjusted

later.

d. Fix the length of the slide-out track assembly: Tighten the screws,

applying 28 inch-lbs of torque, that were left loose in step 1, substep d, to

fix the front to rear flange spacing of t he slide-out track assembly.

e. Mount the left slide-out track assembly: Repeat substeps a through d to

mount the left slide-out track assembly.

tep c. Add a nut bar to the installation only if the

ront and rear flanges inside of rails use Mounting

18 RSA56KR Rackmount Installation Instructions

Page 23

Installation Instructions

Figure 1

0: Installation of slide-out track assemblies in rack (top view)

3. Mount i

WAR NI NG . To prevent the instrument from tipping or dropping onto the installers,

two or more people should install this instrument into the rack cabinet.

After completing the installation procedure, the installers should verify that the

instrument and r ack cabinet will not tip forward while the instrument is in the

extended position.

a. Install the instrument:

nstrument in rack:

Working from the front of the rack, slide the inner track of each

slide-out track assembly until it extends out the front of the rack.

Continue to slide them out until they lock.

Insert the left and right tracks that extend from the rear of the

instrument into the ends of the tracks just extended. Make sure the

tracks mounted on the instrument slip inside the inner tracks extended

arlier.

e

RSA56KR Rackmount Installation Instructions 19

Page 24

Installation Instructions

Slide the rear o

Push to release the button latches, located on the outside of each track,

and continue t

e. Level the rackmounted instrument:

Tighten the four screws that were left loose at the rear of the rack

when you did step 2, substep c, and then pull the instrument part way

out of the ra

Be sure the four screws that were left loose at the front of the rack are

loose enou

normal positions.

Retighte

the rack. If the tracks do not slide smoothly, readjust the level using

the method just detailed.

When leveling is completed, tighten the 10-32 screws using 28

inch-lbs of torque.

e. Secure the instrument and install the power cord:

Locat

or M6-20 oval head screws. Insert each screw through its nylon finish

washer as shown on the data sheet included with the hardware kit.

n the four screws and push the instrument all the way into

e and use one of the following types: 10-32 or 1 2-24 or M5-20

f the instrument backwards until it stops.

o slide the instrument all the way into the cabinet.

ck.

gh to allow t he slide-out track assemblies to seek their

Using a number two Phillips screwdriver, install the screw/washer

assembly in one of the two mounting holes in the right front bracket.

Repeat for the second mounting hole. Tighten b oth screws using 25

inch-lbs of torque.

Install the two remaining screw/washer as semblies in the left front

bracket using the method just described.

Install the optional front trim panel if the uncovered blank space

below the rack-mounted instrument is undesirable. Use the four 10-32

x 0.750 oval head Phillips drive screws with four nylon washers

to secure the front trim panel to the rack frame. (See Figure 3 on

page 8.)(See Figure 5 on page 11.)

Reinstall the power cord.

♦ End of document ♦

20 RSA56KR Rackmount Installation Instructions

Loading...

Loading...