Technical Reference

RSA3408A

8 GHz Real-Time Spectrum Analyzer

Performance Verification and Specifications

077-0007-00

www.tektronix.com

Copyright © Tektronix Japan, Ltd. All rights reserved.

Copyright © Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Tektronix Japan, Ltd., Shinagawa Intercity Building B 6th Floor, 2-15-2 Konan, Minato-ku, Tokyo 108-6106 Japan

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Windows and Windows XP are trademarks of Microsoft Corporation.

WARRANTY

Tektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defective during this warranty period, Tektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by Tektronix, with shipping charges prepaid.

Tektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

Tektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than Tektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Table of Contents

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Manuals vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting Tektronix viii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification

Performance Verification Procedures 1–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brief Procedures 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Tests 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Tests 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prerequisites 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Frequency Checks 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Noise Sideband Checks 1–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Amplitude Checks 1–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spurious Response Checks 1–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Record 1–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications

Performance Conditions 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Characteristics 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical Characteristics 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Characteristics 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital IQ Output Connector Pin Assignment (Option 05 Only) 2–19. . . . . . . . . . . .

RSA3408A Technical Reference

i

Table of Contents

List of Figures

Figure 1–1: Spectrum of the calibration signal (100 MHz, –20 dBm) 1–5

Figure 1–2: Setup display 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–3: Reference level setting and A/D overflow indicator 1–7. . . .

Figure 1–4: Spectrogram display 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–5: Diagnostic screen 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–6: Hookup for calibrating the power sensor 1–20. . . . . . . . . . . . .

Figure 1–7: Hookup for setting the signal generator output 1–20. . . . . . . .

Figure 1–8: Hookup for checking the absolute amplitude accuracy 1–21.

Figure 2–1: Definition of the setup and hold time 2–15. . . . . . . . . . . . . . . .

Figure 2–2: Digital IQ output connector pin assignment 2–19. . . . . . . . . .

ii

RSA3408A Technical Reference

List of Tables

Table of Contents

Table 1–1: Span and RBW 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–2: Internal diagnostic program 1–8. . . . . . . . . . . . . . . . . . . . . . . .

Table 1–3: Test equipment 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–4: Level linearity test result 1–30. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–5: Spurious measurement 1–42. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–1: Frequency 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–2: Noise sideband 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–3: Input 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–4: Amplitude 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–5: Spurious response 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–6: Acquisition 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–7: Trigger 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–8: RBW (Resolution Bandwidth) 2–9. . . . . . . . . . . . . . . . . . . . . .

Table 2–9: Trace and display line 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–10: Display 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–11: Measurement function 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–12: Analog demodulation accuracy 2–10. . . . . . . . . . . . . . . . . . . .

Table 2–13: Pulse measurement 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–14: Digital demodulation (Option 21 only) 2–11. . . . . . . . . . . . . .

Table 2–15: ACLR measurement (Option 27) 2–13. . . . . . . . . . . . . . . . . . .

Table 2–16: Wireless LAN measurement (Option 29) 2–13. . . . . . . . . . . . .

Table 2–17: Controller 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–18: External output connector 2–14. . . . . . . . . . . . . . . . . . . . . . . .

Table 2–19: Power requirements 2–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–20: Physical characteristics 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–21: Environmental characteristics 2–16. . . . . . . . . . . . . . . . . . . . .

Table 2–22: Certifications and compliances 2–17. . . . . . . . . . . . . . . . . . . . .

Table 2–23: I OUTPUT connector pin assignment 2–19. . . . . . . . . . . . . . .

Table 2–24: Q OUTPUT connector pin assignment 2–21. . . . . . . . . . . . . .

RSA3408A Technical Reference

iii

Table of Contents

iv

RSA3408A Technical Reference

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

Injury Precautions

Product Damage

Precautions

Use Proper Power Cord. To avoid fire hazard, use only the power cord specified

for this product.

Avoid Electric Overload. To avoid electric shock or fire hazard, do not apply a

voltage to a terminal that is outside the range specified for that terminal.

Avoid Electric Shock. To avoid injury or loss of life, do not connect or disconnect

probes or test leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Do Not Operate Without Covers. To avoid electric shock or fire hazard, do not

operate this product with covers or panels removed.

Do Not Operate in Wet/Damp Conditions. To avoid electric shock, do not operate

this product in wet or damp conditions.

Do Not Operate in an Explosive Atmosphere. To avoid injury or fire hazard, do not

operate this product in an explosive atmosphere.

Use Proper Power Source. Do not operate this product from a power source that

applies more than the voltage specified.

RSA3408A Technical Reference

Provide Proper Ventilation. To prevent product overheating, provide proper

ventilation.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

v

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

Certifications and

Compliances

WARNING

High Voltage

Protective Ground

(Earth) Terminal

CAUTION

Refer to Manual

Refer to the specifications section for a listing of certifications and compliances

that apply to this product.

vi

RSA3408A Technical Reference

Preface

Related Manuals

This is the Performance Verification for the RSA3408A 8 GHz Real-Time

Spectrum Analyzer. It contains procedures suitable for determining that the

analyzer functions, is adjusted properly, and meets the performance characteristics as warranted.

This document also contains the specifications for the RSA3408A analyzer.

The following documents relate to the use or service of the analyzer:

H The RSA3408A User Manual describes how to operate your analyzer.

H The RSA3408A Programmer Manual describes how to use a computer to

control the analyzer through the GPIB interface.

H The RSA3408A Service Manual provides information for maintaining and

servicing your analyzer to the module level.

RSA3408A Technical Reference

vii

Preface

Contacting Tektronix

Phone 1Ć800Ć833Ć9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1Ć800Ć833Ć9200, select option 1*

Service support 1Ć800Ć833Ć9200, select option 2*

Technical support www.tektronix.com/support

1Ć800Ć833Ć9200, select option 3*

6:00 a.m. - 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

viii

RSA3408A Technical Reference

Performance Verification

Performance Verification Procedures

Two types of Performance Verification procedures can be performed on this

product; Brief Procedures and Performance Tests. You may not need to perform

all of these procedures, depending on what you want to accomplish.

H To rapidly confirm that the analyzer functions properly and was adjusted

properly, do the brief procedures under Functional Tests and Diagnostics,

which begin on page 1–3.

Advantages: These procedures are quick to do, require no external

equipment or signal sources, and perform functional and accuracy testing to

provide high confidence that the analyzer will perform properly. They can be

used as a quick check before making a series of important measurements.

H If more extensive confirmation of performance is desired, do the Perfor-

mance Tests, beginning on page 1–9, after doing the Functional Tests and

Diagnostics just referenced.

Advantages: These procedures add direct checking of warranted specifications.

Disadvantages: They require more time to perform and suitable test

equipment is required. (Refer to Equipment Required on page 1–11.)

RSA3408A Technical Reference

1-1

Performance Verification

Conventions

Throughout these procedures, the following conventions apply:

H Each test procedure uses the following general format:

Title of Test

Equipment Required

Prerequisites

Procedure

H Each procedure consists of as many steps, substeps, and subparts as required

to do the test. Steps, substeps, and subparts are sequenced as follows:

1. First Step

a. First Substep

H First Subpart

H Second Subpart

b. Second Substep

2. Second Step

H Instructions for menu selection follow this format:

FRONT PANEL KEY Õ Side Menu Key Õ Submenu Key.

For example, “Press MODE: DEMOD Õ Digital Demod Õ Constellation”.

“MODE: DEMOD” indicates the DEMOD key in the MODE menu area on

the front panel.

H In steps and substeps, the lead-in statement in italics tells you what to do,

and the instructions that follow tell you how to do it.

The example step below is telling you to set the analyzer controls by

pressing the specified key sequence.

Set the RSA3408A analyzer controls:

Press MODE: DEMOD Õ Digital Demod Õ Constellation.

STOP. The symbol at the left is accompanied by information you must read to do

the procedure properly.

1-2

RSA3408A Technical Reference

Brief Procedures

The Functional Tests use the internal calibration signal as a test-signal source for

further verifying that the analyzer functions properly.

The Diagnostics use internal routines to verify that the instrument functions

properly and passes the internal circuit tests.

The following section provides the details.

RSA3408A Technical Reference

1-3

Brief Procedures

Functional Tests

The analyzer has a built-in calibration signal source with an amplitude of

approximately –20 dBm and frequency of 100 MHz. Using this source, perform

this quick functional check to verify that your instrument is operating correctly.

Equipment

Required

Prerequisites Power on the analyzer and allow a 20 minute warmĆup before doing

1. Initialize the analyzer:

a. Press the SYSTEM key on the front panel.

b. Press the Reset All to Factory Defaults side key.

2. Check the system version and options:

a. Press the SYSTEM key on the front panel.

b. Press the Versions and Installed Options... side key.

c. Check the version in the “Main System” field and the options in the

option table.

3. Check the display brightness:

a. Press the Cancel-Back (top) side key.

b. Press the Display Brightness side key.

None

this procedure.

1-4

c. Change the value from 0 to 100% using the general purpose knob to

check that the brightness changes normally.

4. Display spectrum of the calibration signal:

a. Press S/A → Spectrum Analyzer.

b. Press the PRESET key on the front panel to reset the analyzer.

c. Press INPUT → Signal Input Port...→ Cal100M.

The spectrum of the calibration signal appears.

d. Check that “INPUT: CAL” and “FREE RUN” are displayed in the status

indicator at the upper right of the screen (see Figure 1–1).

RSA3408A Technical Reference

Status indicator

Brief Procedures

Marker readout

Marker

Figure 1-1: Spectrum of the calibration signal (100 MHz, -20 dBm)

5. Check the center frequency and peak amplitude using the marker:

a. Press the PEAK key on the front panel to place the marker on the peak

(see Figure 1–1).

RSA3408A Technical Reference

b. Check the marker readouts on screen. The frequency should be 100 MHz

and the amplitude should be approximately –20 dBm.

c. Press MARKER SETUP → Markers → Off.

Check that the marker disappears.

6. Check the RBW (Resolution Bandwidth) while changing the span setting.

a. Press the SPAN key on the front panel.

b. Confirm that the span is 36 MHz and the RBW is 100 kHz in the setup

display on the upper part of the screen (see Figure 1–2).

1-5

Brief Procedures

Setup display

Span RBW

Span setting

Figure 1-2: Setup display

c. Using the general purpose knob, change the span setting as listed in

Table 1–1 and check that the RBW is displayed correctly.

Table 1-1: Span and RBW

Span RBW

36 MHz 100 kHz

15 MHz 80 kHz

5 MHz 20 kHz

100 kHz 500 Hz

1 kHz 20 Hz

d. Using the numeric keypad, set the span back to 36 MHz.

(Press 3 Õ 6 Õ MHz, in that order, on the keypad.)

7. Check the reference level:

a. Press the AMPLITUDE key on the front panel.

b. Make sure that the reference level is set to 0 dBm with the Ref Level

side key. Check that 0 dBm is displayed on the upper left side of the

graticule (see Figure 1–3).

c. Use the general purpose knob to set the reference level to –30 dBm.

d. Confirm that A/D OVERFLOW is indicated in the red box at the top

center of the screen. Make sure that –30 dBm is displayed on the upper

left side of the graticule and that the spectrum waveform is distorted as

shown in Figure 1–3.

e. Using the numeric keypad, set the reference level back to 0 dBm.

(Press 0 Õ ENTER, in that order, on the keypad.)

1-6

RSA3408A Technical Reference

Reference level

Brief Procedures

A/D overflow indicator Reference level setting

Figure 1-3: Reference level setting and A/D overflow indicator

8. Check the spectrogram display:

a. Press S/A → S/A with Spectrogram. Check that the spectrogram is

displayed on the lower side of the screen (see Figure 1–4).

Spectrogram

RSA3408A Technical Reference

Figure 1-4: Spectrogram display

b. Press the RUN/STOP key on the front panel to stop data acquisition.

Confirm that the trace display freezes and PAUSE is displayed in the

status indicator at the top right of the screen.

1-7

Brief Procedures

Diagnostics

You can run the internal diagnostic program to check hardware states.

Table 1–2 shows the test items and their descriptions.

Table 1-2: Internal diagnostic program

Menu item Description Possible failure

Temp Sensor Checks that the temperature sensor works correctly. RF5 module

Data Memory Checks that the acquisition memory works correctly. A40 board

The process is

graphically displayed

on the upper views.

Equipment

Required

Prerequisites Power on the analyzer and allow a 20 minute warmĆup before doing

None

this procedure.

1. Press CAL Õ Service...Õ Password.

2. Enter 270833 and then press the ENTER key using the numeric keypad.

3. Press the DIAG side key.

4. Select the diagnostic menu item to be executed.

You may press the All side key to run all the tests.

5. Check the result shown in the lower left view with “Pass” or “Fail”.

1-8

Figure 1-5: Diagnostic screen

RSA3408A Technical Reference

Performance Tests

This section contains procedures for checking that the RSA3408A 8 GHz

Real-Time Spectrum Analyzer performs as warranted.

The procedures are arranged in four logical groupings:

H Frequency Checks

H Noise Sideband Checks

H Amplitude Checks

H Spurious Response Checks

They check all the characteristics that are designated as checked in Chapter 2,

Specification. (The characteristics that are checked appear with the n symbol in

the Characteristics column in Chapter 2.) You can use the form at the end of this

section as a test record.

Read Performance Verification Procedures that start on page 1-1. Also, if you

are not familiar with operating this analyzer, read the RSA3408A User Manual

before doing any of these procedures.

STOP. These procedures extend the confidence level provided by the basic

procedures described on page 1–3. Perform the basic procedures first and then

perform the following procedures if desired.

RSA3408A Technical Reference

1-9

Performance Tests

Prerequisites

The tests in this section make up an extensive, valid confirmation of performance

and functionality when the following requirements are met:

H The cabinet must be installed on the analyzer.

H The instrument must have passed the procedures under Brief Procedures

found on page 1–3.

H A signal-path compensation must have been done within the recommended

calibration interval and at a temperature within ±3 _C of the present

operating temperature. (If at the time you did the prerequisite Brief Proce-

dures, the temperature was within the limits just stated, consider this

prerequisite met.)

H The analyzer must have been last adjusted at an ambient temperature

between +20 _C and +30 _C, must have been operating for a warm-up

period of at least 20 minutes, and must be operating at an ambient temperature of between +10 _C and +40 _C. (The warm-up requirement is usually

met in the course of meeting the Brief Procedures prerequisites listed above.)

1-10

RSA3408A Technical Reference

Equipment Required

Table 1-3: Test equipment

Item number and

description

Performance Tests

These procedures use external, traceable signal sources to directly check

warranted characteristics. The required equipment list follows this introduction.

Minimum requirements Example Purpose

1. Signal generator Frequency range : 10 kHz to 3.5ĂGHz;

Variable amplitude from -70ĂdBm to

+13ĂdBm into 50 W;

Accuracy: <±1 dB; Function: FM

2. Signal generator Frequency range: 10 MHz to 8 GHz;

Output level: -30ĂdBm to +10 dBm;

Accuracy: <±1dB

3. Signal generator Frequency: 2 GHz; Output: ≥-10dBm;

Digital modulation: QPSK;

Symbol rate: 4.096 M/s

4. Spectrum analyzer Frequency: >8 GHz;

Display scale fidelity: <±0.13 dB

5. Frequency counter Frequency range: 10 MHz;

Aging rate: <5 10

Accuracy: <0.01 ppm at 10 MHz

6. RF power meter 1 MHz to 8 GHz Agilent E4418B Adjusting the signal generator

7. RF power sensor 10 MHz to 8 GHz; RF Flatness: <3 %;

Uncertainty of calibration factor data:

<2 % (RSS)

8. Power combiner Range: 500 MHz to 2 GHz; Isolation:

>18 dB; Insertion loss: <1.0 dB

9. BNC cable 50 W, 36 in, male to male BNC

connectors

10. NĆN cable 50 W, 36 in, male to male N

connectors

11. NĆSMA cable

(Three required)

12. Terminator Impedance: 50 W; connectors: female

50 W, 36 in, male N to male SMA

connectors

BNC input, male BNC output

-10

/day;

Agilent 8648D Checking baseband and RF

flatness

Agilent E8257D Checking RF flatness

Rohde & Schwartz SMIQ03B

Agilent E4438C

Agilent E4440A Checking level linearity

Agilent 53132A option 010 Checking the reference outĆ

Agilent E4412A Adjusting the signal generator

MiniĆCircuits ZAPDĆ21 Checking intermodulation

Tektronix part number

012Ć1341Ć00

Tektronix part number

011Ć0049Ć01

Checking intermodulation

distortion

put frequency accuracy

output level

output level

distortion

Signal interconnection

Signal interconnection

Signal interconnection

Signal termination for checkĆ

ing frequency accuracy

RSA3408A Technical Reference

1-11

Performance Tests

Frequency Checks

These procedures check the frequency-related characteristics and are listed as

checked in Chapter 2, Specifications, Table 2–1 on page 2–2.

Check Frequency Readout

Accuracy

Equipment

Required

Prerequisites Refer to page 1-10.

One signal generator (Item 2)

One 50 W NĆN coaxial cable (Item 10)

1. Prepare for the test:

a. Initialize the analyzer:

H Press the SYSTEM key on the front panel.

H Press the Reset All to Factory Defaults side key.

b. Set the generator controls:

Frequency 10 MHz. . . . . . . . . . . . . . . . .

Level –10 dBm. . . . . . . . . . . . . . . . . . . .

c. Hook up the signal generator:

Connect the generator output through a 50 W N-N coaxial cable to the

analyzer INPUT. See the figure below.

RSA3408A

1-12

Signal generator

Output

50 W NĆN coaxial cable

RSA3408A Technical Reference

2. Check frequency accuracy in the baseband:

a. Modify the analyzer default settings:

H Press the FREQUENCY/CHANNEL key on the front panel.

H With the Center Freq side key, set the frequency to 10 MHz using

the numeric keypad.

H Press the SPAN key on the front panel.

H With the Span side key, set the span to 1 MHz using the general

purpose knob.

b. Measure peak frequency:

H Press the PEAK key to place the marker on the peak signal.

H Read the marker readout. Confirm that the value is

10 MHz "1 kHz.

Performance Tests

H Press MEASURE Õ Carrier Frequency.

H Read the measurement result at the bottom of the screen. Confirm

that the value is 10 MHz "1.2 Hz.

3. Check frequency accuracy in the RF1 band:

a. Modify the generator control:

Frequency 2 GHz. . . . . . . . . . . . . . . . .

b. Modify the analyzer controls:

H Press the FREQUENCY/CHANNEL key on the front panel.

H With the Center Freq side key, set the frequency to 2 GHz using the

numeric keypad.

c. Measure peak frequency:

H Press the PEAK key to place the marker on the peak signal.

H Read the marker readout. Confirm that the value is

2 GHz "1.2 kHz.

H Press MEASURE → Carrier Frequency.

RSA3408A Technical Reference

H Read the measurement result at the bottom of the screen. Confirm

that the value is 2 GHz "210 Hz.

1-13

Performance Tests

4. Check frequency accuracy in the RF2 band:

a. Modify the generator control:

Frequency 5 GHz. . . . . . . . . . . . . . . . .

b. Modify the analyzer controls:

H Press the FREQUENCY/CHANNEL key on the front panel.

H With the Center Freq side key, set the frequency to 5 GHz using the

numeric keypad.

c. Measure peak frequency:

H Press the PEAK key to place the marker on the peak signal.

H Read the marker readout. Confirm that the value is

5 GHz "1.5 kHz.

H Press MEASURE → Carrier Frequency.

H Read the measurement result at the bottom of the screen. Confirm

that the value is 5 GHz "510 Hz.

5. Check frequency accuracy in the RF3 band:

a. Modify the generator control:

Frequency 7 GHz. . . . . . . . . . . . . . . . .

b. Modify the analyzer controls:

H Press the FREQUENCY/CHANNEL key on the front panel.

H With the Center Freq side key, set the frequency to 7 GHz using the

numeric keypad.

c. Measure peak frequency:

H Press the PEAK key to place the marker on the peak signal.

H Read the marker readout. Confirm that the value is

7 GHz "1.7 kHz.

H Press MEASURE → Carrier Frequency.

H Read the measurement result at the bottom of the screen. Confirm

that the value is 7 GHz "710 Hz.

1-14

6. Disconnect the test equipment: Disconnect the cable at the analyzer input.

RSA3408A Technical Reference

Performance Tests

Check 10 MHz Reference

Output Accuracy

Equipment

Required

Prerequisites Refer to page 1-10.

One frequency counter (Item 5)

One 50 W BNC coaxial cable (Item 9)

One 50 W terminator (Item 12)

The frequency counter must have been operating for a warmĆup period

of at least 24 hours.

1. Prepare for the test:

a. Hook up the frequency counter:

Connect REF OUT on the rear panel of the analyzer through a 50 W

precision coaxial cable and a 50 W precision terminator to Channel 1 of

the counter. See the figure below.

Frequency counter

RSA3408A (rear)

REF OUT

CH1 input

50 W terminator

50 W BNC coaxial cable

b. Set the counter controls:

Function Frequency 1. . . . . . . . . . . . . . . . . .

Gate time 2 s. . . . . . . . . . . . . . . . .

2. Check the frequency:

Check that the frequency counter reads 10 MHz "1.2 Hz.

3. Disconnect the hookup:

Disconnect the cable at REF OUT.

RSA3408A Technical Reference

1-15

Performance Tests

Noise Sideband Checks

These procedures check the noise sideband-related characteristics and are listed

as checked in Chapter 2, Specifications, Table 2–2 on page 2–3.

Check Noise Sideband

Equipment

Required

Prerequisites Refer to page 1-10.

1. Prepare for the test:

a. Initialize the analyzer:

H Press the SYSTEM key on the front panel.

H Press the Reset All to Factory Defaults side key.

b. Modify the default settings:

H Press the AMPLITUDE key on the front panel

H Press the RF Atten/Mixer side key to select Mixer.

H With the Mixer Level side key, set the level to –10 dBm.

H Press TRACE/AVG → Trace 1 Type...Õ Average.

H Press the Number Of Averages side key and set the value to 50

using the general purpose knob.

One signal generator (Item 3)

One 50 W NĆN coaxial cable (Item 10)

1-16

c. Set the generator controls:

Frequency 1000 MHz. . . . . . . . . . . . . . . . .

Amplitude 0 dBm. . . . . . . . . . . . . . . .

RF output On. . . . . . . . . . . . . . . . .

d. Hook up the signal generator:

Connect the generator output through a 50 W N-N coaxial cable to the

analyzer INPUT. See the figure above on the next page.

RSA3408A Technical Reference

Performance Tests

Signal generator

Output

50 W N-N coaxial cable

2. Check phase noise for a span of 50 kHz:

a. Modify the analyzer controls:

H Press the SPAN key on the front panel.

H With the Span side key, set the span to 50 kHz using the general

purpose knob or the numeric keypad.

b. Perform the C/N measurement:

H Press MEASURE → C/N → MEAS SETUP.

RSA3408A

H Press the Offset Frequency side key and set the value to 10 kHz

using the general purpose knob.

H Press the Carrier Bandwidth side key and set the value to 5 kHz

using the general purpose knob.

H Press the Noise Bandwidth side key and set the value to 1 kHz

using the general purpose knob.

c. Check against limits:

Read the phase noise (C/No) at the bottom of the screen.

Confirm that the value is 110 dBc/Hz or more.

RSA3408A Technical Reference

1-17

Performance Tests

3. Check phase noise for a span of 500 kHz:

a. Modify the analyzer controls:

H Press the SPAN key on the front panel.

H With the Span side key, set the span to 500 kHz using the general

purpose knob or the numeric keypad.

b. Perform the C/N measurement:

H Select MEASURE → C/N → MEAS SETUP.

H Press the Offset Frequency side key and set the value to 100 kHz

using the general purpose knob.

H Press the Carrier Bandwidth side key and set the value to 50 kHz

using the general purpose knob.

H Press the Noise Bandwidth side key and set the value to 10 kHz

using the general purpose knob.

c. Check against limits:

Read the phase noise (C/No) at the bottom of the screen.

Confirm that the value is 112 dBc/Hz or more.

4. Check phase noise for a span of 5 MHz:

a. Modify the analyzer controls:

H Press the SPAN key on the front panel.

H With the Span side key, set the span to 5 MHz using the general

purpose knob or the numeric keypad.

b. Perform the C/N measurement:

H Select MEASURE → C/N → MEAS SETUP.

H Press the Offset Frequency side key and set the value to 1 MHz

using the general purpose knob.

H Press the Carrier Bandwidth side key and set the value to 300 kHz

using the general purpose knob.

H Press the Noise Bandwidth side key and set the value to 100 kHz

using the general purpose knob.

1-18

c. Check against limits:

Read the phase noise (C/No) at the bottom of the screen.

Confirm the value is 132 dB/Hz or more.

5. Disconnect the test equipment: Disconnect the cable at the analyzer input.

RSA3408A Technical Reference

Amplitude Checks

Performance Tests

These procedures check the amplitude-related characteristics and are listed as

checked in Chapter 2, Specifications, Table 2–4 on page 2–5.

Check Absolute

Amplitude Accuracy

Equipment

Required

Prerequisites Refer to page 1-10.

One signal generator (Item 1)

One power meter (Item 6)

One power sensor (Item 7)

One 50 W NĆN coaxial cables (Item 10)

1. Set up the power meter and sensor:

NOTE. Store the power sensor correction factors in the power meter, if you have

not yet done so.

a. Connect the power meter and the power sensor. See the figure below.

Power meter

Power sensor

Sensor input

RSA3408A Technical Reference

b. Warm up the power meter and sensor for more than 20 minutes.

c. Press ZERO on the power meter.

d. Connect the RF input of the power sensor to the power reference output

of the power meter. See Figure 1–6 on page 1–20.

e. Turn on POWER REF and execute the calibration.

f. Disconnect the RF input of the power sensor from the reference output

of the power meter.

1-19

Performance Tests

Power meter

Power reference output

Figure 1-6: Hookup for calibrating the power sensor

Baseband.

2. Set the signal generator output:

a. Hook up the instruments:

Connect the signal generator (Item 1) output through a 50 W N-N coaxial

cable to the power sensor input. See Figure 1–7.

Signal generator

Power meter

Output

Power sensor

Figure 1-7: Hookup for setting the signal generator output

b. Set the signal generator controls:

Frequency 25 MHz. . . . . . . . . . . . . . . . .

Level –10 dBm. . . . . . . . . . . . . . . . . . . .

c. Set the power meter control:

Frequency 10 MHz. . . . . . . . . . . . . . . . .

d. Adjust the output level of the signal generator so that the power meter

reads –10 dBm "0.05 dBm.

1-20

e. Disconnect the cable from the power sensor input.

RSA3408A Technical Reference

3. Prepare for the test:

a. Hook up the instruments:

Connect the signal generator output through a 50 W N-N coaxial cable to

the RSA3408A INPUT. See Figure 1–8.

Signal generator

Output

Performance Tests

RSA3408A

50 W NĆN coaxial cable

Figure 1-8: Hookup for checking the absolute amplitude accuracy

b. Initialize the analyzer:

H Press the SYSTEM key on the front panel.

H Press the Reset All to Factory Defaults side key.

c. Modify the default settings:

H Press the FREQUENCY/CHANNEL key on the front panel.

H With the Center Freq side key, set the frequency to 25 MHz using

the numeric keypad.

H Press the SPAN key on the front panel.

H With the Span side key, set the span to 10 MHz using the general

purpose knob.

d. Calibrate the analyzer gain:

H Press CAL → Calibrate Gain.

H Press Amplitude → Auto Level.

RSA3408A Technical Reference

1-21

Performance Tests

4. Check the amplitude:

a. Press the PEAK key on the front panel to place the marker on the peak.

b. Check that the marker readout is within –10 dBm "0.3 dB.

5. Disconnect the hookup:

Disconnect the cable at the analyzer input.

RF.

6. Modify the signal generator output:

a. Hook up the test equipment:

Connect the signal generator output through a 50 W N-N coaxial cable to

the power sensor input. See Figure 1–7 on page 1–20.

b. Modify the signal generator controls:

Frequency 100 MHz. . . . . . . . . . . . . . . . .

Level –20 dBm. . . . . . . . . . . . . . . . . . . .

c. Modify the power meter control:

Frequency 100 MHz. . . . . . . . . . . . . . . . .

d. Adjust the output level of the signal generator so that the power meter

reads –20 dBm "0.05 dBm.

e. Disconnect the cable from the power sensor input.

7. Modify the test hookup and preset the instrument controls:

a. Hook up the instruments:

Connect the signal generator output through a 50 W N-N coaxial cable to

the RSA3408A INPUT. See Figure 1–8 on page 1–21.

b. Modify the analyzer controls:

H Press the FREQUENCY/CHANNEL key on the front panel.

H With the Center Freq side key, set the frequency to 100 MHz using

the numeric keypad.

H Press the AMPLITUDE key on the front panel.

H Press the RF Atten/Mixer side key to select RF Att.

1-22

H With the RF Att side key, set the attenuation to 0 dB.

RSA3408A Technical Reference

Performance Tests

c. Calibrate the analyzer gain:

H Press CAL → Calibrate Gain.

H Press Amplitude → Auto Level.

8. Check the amplitude:

a. Press the PEAK key on the front panel to place the marker on the peak.

b. Check that the marker readout is within –20 dBm "0.5 dB.

9. Disconnect the test equipment:

Disconnect the cable at the analyzer input.

RSA3408A Technical Reference

1-23

Performance Tests

Check Input Attenuator

Setting Uncertainty

Equipment

Required

Prerequisites Refer to page 1-10.

One signal generator (Item 1)

One 50 W NĆN coaxial cables (Item 10)

1. Prepare for the test:

a. Set the generator controls:

Frequency 100 MHz. . . . . . . . . . . . . . . . .

Amplitude –25 dBm. . . . . . . . . . . . . . . .

RF output On. . . . . . . . . . . . . . . . .

b. Hook up the generator:

Connect the generator output through a 50 W N-N coaxial cable to the

analyzer INPUT. See the figure below.

Signal generator

RSA3408A

Output

50 W NĆN coaxial cable

c. Initialize the analyzer:

H Press the SYSTEM key on the front panel.

H Press the Reset All to Factory Defaults side key.

1-24

RSA3408A Technical Reference

Performance Tests

d. Modify the default settings:

H Press the FREQUENCY/CHANNEL key on the front panel.

H With the Center Freq side key, set the frequency to 100 MHz using

the numeric keypad.

H Press the SPAN key on the front panel.

H With the Span side key, set the span to 10 MHz using the general

purpose knob.

H Press the AMPLITUDE key on the front panel.

H With the Ref Level side key, set the reference level to –20 dBm

using the general purpose knob.

H Press the RF Atten/Mixer side key to select RF Att.

H With the RF Att side key, set the attenuation to 0 dB using the

numeric keypad or the general purpose knob.

2. Measure the reference amplitude at 0 dB attenuation:

a. Press the PEAK key on the front panel to place the marker on the peak.

b. Record the peak amplitude at the marker readout as the reference value.

(Let the value be P

)

0.

3. Check the amplitude for the attenuation from 5 to 30 dB:

a. Press the RF Att side key and set the attenuation (initially 5 dB).

b. Press the PEAK key on the front panel to place the marker on the peak.

c. Record the peak amplitude at the marker readout. (Let the value be P

d. Check that the error (P

– P0) is within "0.5 dB.

X

e. Repeat substeps a through d for attenuation from 5 to 30 dB in 5 dB

steps.

4. Modify the generator controls:

Amplitude –5 dBm. . . . . . . . . . . . . . . .

.)

X

RSA3408A Technical Reference

1-25

Performance Tests

5. Modify the analyzer controls:

a. Press the AMPLITUDE key on the front panel.

b. With the Ref Level side key, set the reference level to 0 dBm using the

general purpose knob.

c. Make sure that RF Att is set to 30 dB.

6. Measure the reference amplitude at 30 dB attenuation:

a. Press the PEAK key on the front panel to place the marker on the peak.

b. Record the peak amplitude at the marker readout as the reference value.

(Let the value be P

)

1.

7. Check the amplitude for attenuation from 35 to 55 dB:

a. Press the RF Att side key and set the attenuation (initially 35 dB).

b. Press the PEAK key on the front panel to place the marker on the peak.

c. Record the peak amplitude at the marker readout. (Let the value be P

d. Check that the error (P

– P1) is within "0.2 dB.

X

e. Repeat substeps a through d for attenuation from 35 to 55 dB in 5 dB

steps.

8. Disconnect the test equipment: Disconnect the cable at the analyzer input.

.)

X

1-26

RSA3408A Technical Reference

Performance Tests

Check Level Linearity

Equipment

Required

Prerequisites Refer to page 1-10.

One signal generator (Item 2)

One spectrum analyzer (Item 4)

One power meter (Item 6)

One power sensor (Item 7)

One 50 W NĆN coaxial cable (Item 10)

1. Set up the power meter and sensor:

Do step 1 on page 1–19 to set up the power meter and sensor.

2. Set the signal generator output:

a. Hook up the instruments:

Connect the signal generator (Item 1) output through a 50 W N-N coaxial

cable to the power sensor input. See the figure below.

Signal generator

Power meter

Output

Power sensor

b. Set the signal generator controls:

Frequency 100 MHz. . . . . . . . . . . . . . . . .

Level +10 dBm. . . . . . . . . . . . . . . . . . . .

RSA3408A Technical Reference

1-27

Performance Tests

3. Determine the reference power in 0 to –30 dBm:

a. Measure the power and record it as Pr0.

b. Set the signal generator amplitude to 0 to –30 dBm in 10 dB steps and

measure the power as Pr1 to 4, respectively.

Signal generator amplitude Reference power

+10 dBm Pr0

0 dBm Pr1

-10 dBm Pr2

-20 dBm Pr3

-30 dBm Pr4

4. Modify the hookup:

a. Connect the generator output through a 50 W N-N coaxial cable to the

spectrum analyzer (Item 4) input. See the figure below.

Spectrum analyzer

Signal generator

Output

50 W NĆN coaxial cable

b. Set the signal generator control:

Amplitude –30 dBm. . . . . . . . . . . . . . . .

c. Set the spectrum analyzer controls:

Measurement mode SA mode. . . . . . . . .

Reference level –20 dBm. . . . . . . . . . . .

Center frequency 100 MHz. . . . . . . . . . .

Span 1 MHz. . . . . . . . . . . . . . . . . . . . .

RF attenuation 10 dB. . . . . . . . . . . . .

RBW Auto. . . . . . . . . . . . . . . . . . . .

1-28

RSA3408A Technical Reference

Performance Tests

5. Set the reference offset:

a. Set the spectrum analyzer control:

Average 10. . . . . . . . . . . . . . . . . .

b. Measure the peak power Ppr using the maker peak.

c. Modify the spectrum analyzer control:

Reference offset Pr4 – Ppr. . . . . . . . . . . .

6. Determine the reference power in –40 to –50 dBm:

Set the signal generator amplitude to –40 and –50 dBm to measure the power

as Pr5 and 6, respectively.

Signal generator amplitude Reference power

-40 dBm Pr5

-50 dBm Pr6

7. Modify the hookup:

a. Connect the signal generator output to the RSA3408A analyzer input.

See the figure below.

RSA3408A

Signal generator

Output

50 W NĆN coaxial cable

b. Set the signal generator control:

Amplitude +10 dBm. . . . . . . . . . . . . . . .

c. Modify the RSA3408A analyzer controls:

Center frequency 100 MHz. . . . . . . . . . .

Span 5 MHz. . . . . . . . . . . . . . . . . . . . .

Reference level 10 dBm. . . . . . . . . . . .

RF attenuation 20dB. . . . . . . . . . . . .

RSA3408A Technical Reference

1-29

Performance Tests

8. Measure the power:

a. Measure the power and record it as Pm0.

b. Set the signal generator amplitude to 0 to –50 dBm in 10 dB steps to

measure the power as Pm1 to 6.

c. Get the level linearity Pfx (x = 1 to 6) as:

Pfx = (Pmx – Pm0) – (Prx – Pr0)

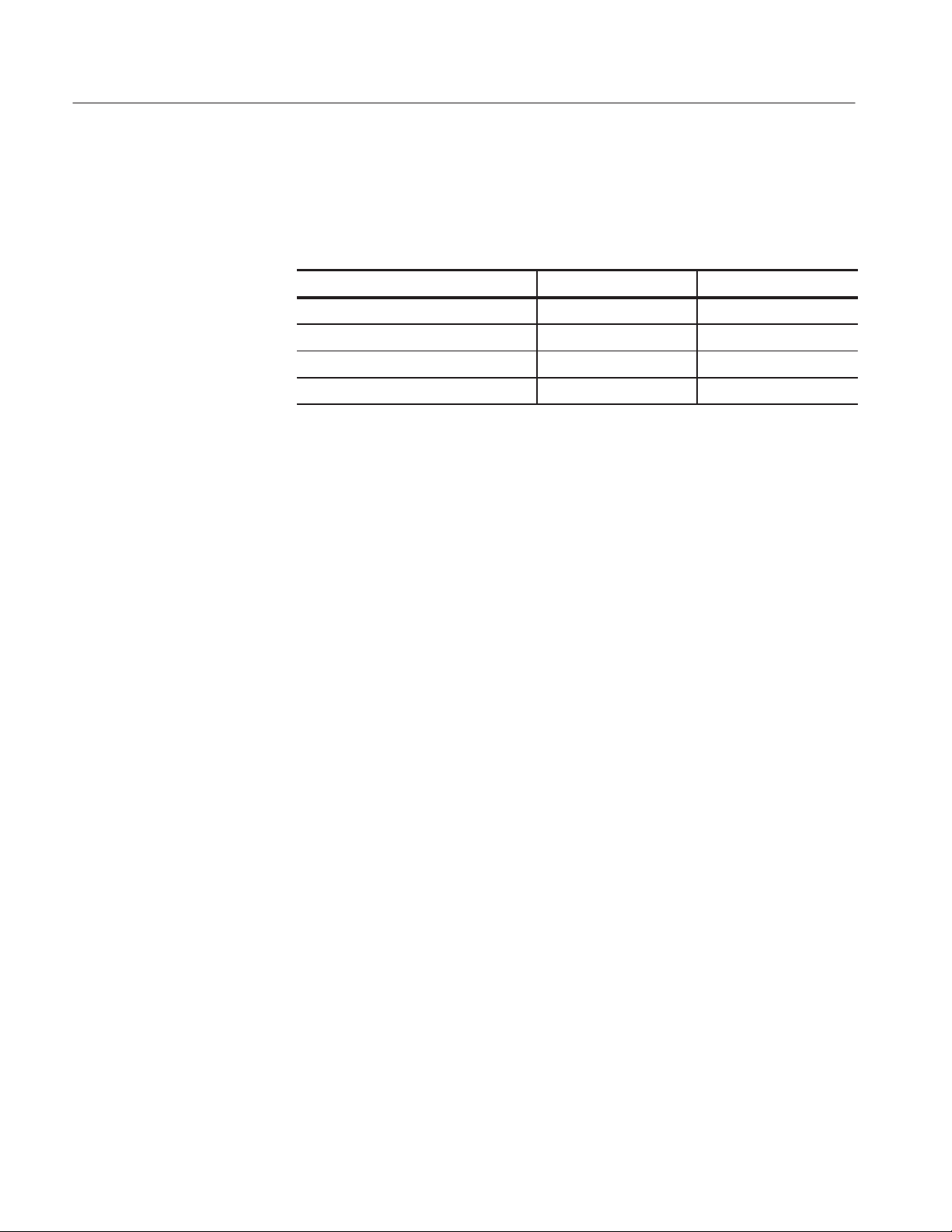

Table 1-4: Level linearity test result

Signal generator

amplitude

+10 dBm Pr0 Pm0 -

0 dBm Pr1 Pm1 Pf1 = (Pm1 - Pm0) - (Pr1 - Pr0)

-10 dBm Pr2 Pm2 Pf2 = (Pm2 - Pm0) - (Pr2 - Pr0)

-20 dBm Pr3 Pm3 Pf3 = (Pm3 - Pm0) - (Pr3 - Pr0)

-30 dBm Pr4 Pm4 Pf4 = (Pm4 - Pm0) - (Pr4 - Pr0)

-40 dBm Pr5 Pm5 Pf5 = (Pm5 - Pm0) - (Pr5 - Pr0)

-50 dBm Pr6 Pm6 Pf6 = (Pm6 - Pm0) - (Pr6 - Pr0)

Reference

power

Measured

power

Level linearity

9. Disconnect the test equipment:

Disconnect the cable at the analyzer input.

1-30

RSA3408A Technical Reference

Spurious Response Checks

These procedures check the spurious-related characteristics and are listed as

checked in Chapter 2, Specifications, Table 2–5 on page 2–6.

Performance Tests

Check 3rdOrder

Intermodulation Distortion

Equipment

Required

Prerequisites Refer to page 1-10.

Two signal generators (Items 2 and 3)

One power combiner (Item 8)

Three 50 W NĆSMA coaxial cables (Item 11)

1. Prepare for the test:

a. Connect each generator output through a 50 W N-SMA coaxial cable to

each power combiner input. See the figure below.

RSA3408A

Signal generator

Output

NĆSMA cable

Signal generator

RSA3408A Technical Reference

Power

combiner

NĆSMA cable

Output

b. Connect the power combiner output through a 50 W N-SMA coaxial

cable to the analyzer INPUT.

1-31

Performance Tests

c. Set the signal generator (Item 2) controls:

Frequency 1999.85 MHz. . . . . . . . . . . . . . . . .

Level 0 dBm. . . . . . . . . . . . . . . . . . . .

ALC BW 100 Hz. . . . . . . . . . . . . . . . .

d. Set the signal generator (Item 3) controls:

Frequency 2000.15 MHz. . . . . . . . . . . . . . . . .

Level 0 dBm. . . . . . . . . . . . . . . . . . . .

ALC BW 100 Hz. . . . . . . . . . . . . . . . .

e. Initialize the analyzer:

H Press the SYSTEM key on the front panel.

H Press the Reset All to Factory Defaults side key.

f. Modify the default controls:

H Press the FREQUENCY/CHANNEL key on the front panel.

H With the Center Freq side key, set the frequency to 2 GHz using the

numeric keypad.

H Press the SPAN key on the front panel.

H With the Span side key, set the span to 1 MHz using the general

purpose knob.

H Press the AMPLITUDE key on the front panel.

H With the Ref Level side, and set the level to 5 dBm using the

general purpose knob.

H Press the RF Atten/Mixer side key to select Rf Att.

H With the RF Att side key, set the attenuation to 15 dB using the

general purpose knob.

H Press the RBW/FFT key on the front panel.

H Press the RBW/FFT side key to select Man.

H Press the Extended Resolution side key to select On.

H Press the RBW side key, set the RBW to 2 kHz.

1-32

RSA3408A Technical Reference

g. Modify the generator output level:

H Press MARKERS: A or " to place the marker on the signal of

1999.85 MHz.

H Adjust the generator (Item 2) output level so that the signal level is

–10 dBm.

H Press MARKERS: A or " to place the marker on the signal of

2000.15 MHz.

H Adjust the generator (Item 3) output level so that the signal level is

–10 dBm.

2. Check the amplitude:

a. Modify the analyzer controls:

H Press TRACE/AVG → Trace 1 Type...→ Average.

H Press the Number Of Averages side key and set the value to 50

using the general purpose knob.

Performance Tests

H Press the MARKER SETUP key.

H Press the Markers side key to select Delta.

b. Measure the amplitude for the signals of 1999.55 MHz and

2000.45 MHz:

H Press the Select Marker side key to select 1.

H Place the first marker at the signal of 1999.55 MHz using the

MARKERS: A or " key.

H Press the Select Marker side key to select 2.

H Place the second marker at the signal of 2000.45 MHz using the

MARKERS: A or " key.

c. Check against limits:

Read the first and the second marker readouts. Confirm that the larger

value meets the requirement of –78 dBc.

3. Disconnect the test equipment: Disconnect the cable at the analyzer input.

RSA3408A Technical Reference

1-33

Performance Tests

Check Displayed Average

Noise Level

Equipment

Required

Prerequisites Refer to page 1-10.

None

1. Prepare for the test:

a. Initialize the analyzer:

H Press the SYSTEM key on the front panel.

H Press the Reset All to Factory Defaults side key.

RSA3408A

b. Modify the analyzer controls:

H Press the FREQUENCY/CHANNEL key on the front panel.

H With the Center Freq side key, set the frequency to 10 MHz using

the general purpose knob.

H Press the SPAN key on the front panel.

H With the Span side key, set the span to 1 MHz using the general

purpose knob.

H Press the AMPLITUDE key on the front panel.

H With the Ref Level side key, set the level to –30 dBm using the

general purpose knob.

H Press the RBW/FFT key on the front panel.

H Press the RBW/FFT side key to select Man.

H With the RBW side key, set the value to 10 kHz using the general

purpose knob.

1-34

RSA3408A Technical Reference

H Press TRACE/AVG → Trace 1 Type...→ Average.

H Press the Number Of Averages side key and set the value to 50.

H Press MEASURE → Channel Power → MEAS SETUP.

H Press the Channel Bandwidth side key and set the value to 1 MHz

using the general purpose knob.

2. Check noise in the baseband:

Read the measurement result of Density at the bottom of the screen.

Check that the value is –151 dBm/Hz or less.

3. Check noise at 2 GHz in the RF1 band:

a. Modify the analyzer control:

H Press the FREQUENCY/CHANNEL key on the front panel.

H With the Center Freq side key, set the frequency to 2 GHz using the

general purpose knob.

Performance Tests

H Press the AMPLITUDE key on the front panel.

H With the Ref Level side key, set the level to –50 dBm using the

general purpose knob.

H Press the RF Atten/Mixer side key to select RF Att.

H With the RF Att side key, set the attenuation to 0 dB using the

general purpose knob.

b. Check against limits:

Read the measurement result of Density at the bottom of the screen.

Check that the value is –150 dBm/Hz or less.

4. Check noise at 3 GHz in the RF1 band:

a. Modify the analyzer control:

H Press the FREQUENCY/CHANNEL key on the front panel.

H With the Center Freq side key, set the frequency to 3 GHz using the

general purpose knob.

b. Check against limits:

Read the measurement result of Density at the bottom of the screen.

Check that the value is –150 dBm/Hz or less.

RSA3408A Technical Reference

1-35

Performance Tests

5. Check noise at 7 GHz in the RF3 band:

a. Modify the analyzer control:

H Press the FREQUENCY/CHANNEL key on the front panel.

H With the Center Freq side key, set the frequency to 7 GHz using the

general purpose knob.

b. Check against limits:

Read the measurement result of Density at the bottom of the screen.

Check that the value is –142 dBm/Hz or less.

1-36

RSA3408A Technical Reference

Performance Tests

Check Residual Response

Equipment

Required

Prerequisites Refer to page 1-10.

None

1. Prepare for the test:

a. Initialize the analyzer:

H Press the SYSTEM key on the front panel.

H Press the Reset All to Factory Defaults side key.

RSA3408A

b. Modify the default settings:

H Press the FREQUENCY/CHANNEL key on the front panel.

H With the Center Freq side key, set the frequency to 20 MHz using

the general purpose knob.

H Press the SPAN key on the front panel.

H With the Span side key, set the span to 40 MHz using the general

purpose knob.

H Press the AMPLITUDE key on the front panel.

H With the Ref Level side key, set the level to –30 dBm using the

general purpose knob.

H Press the RBW/FFT key on the front panel.

H Press the RBW/FFT side key to select Man.

H With the RBW side key, set the RBW to 100 kHz using the general

purpose knob.

H Press TRACE/AVG → Trace 1 Type...→ Average.

H Press the Number Of Averages side key and set the value to 50

using the general purpose knob.

RSA3408A Technical Reference

1-37

Performance Tests

2. Check residual response in the baseband:

a. Measure residual response:

H Press the LINES key on the front panel.

H Press the Show Line side key to select Vertical.

H Press the Number Of Line key to select 1.

H With the Line1 side key, set the value to 1 MHz using the numeric

keypad.

H Press the Show Line side key to select Horizontal.

H Press the Number Of Line key to select 1.

H With the Line1 side key, set the value to –93 dBm using the numeric

keypad.

b. Check against limits:

Confirm that the residual signal level is –93 dBm or less at 1 MHz or

more.

3. Check residual response in the RF1 band:

a. Modify the analyzer controls:

H Press the FREQUENCY/CHANNEL key on the front panel.

H With the Center Freq side key, set the frequency to 2 GHz using the

numeric keypad.

H Press the SPAN key on the front panel.

H With the Span side key, set the span to 3 GHz using the numeric

keypad.

b. Measure residual response:

H Press the LINES key

H Press the Show Line side key to select Horizontal.

H Press the Number Of Line key to select 1.

H Press the Line1 side key and set the value to –90 dBm using the

numeric keypad.

c. Check against limits:

Confirm that the residual signal level is –90 dBm or less.

1-38

RSA3408A Technical Reference

4. Check residual response in the RF2 band:

a. Modify the analyzer controls:

H Press the FREQUENCY/CHANNEL key on the front panel.

H With the Center Freq side key, set the frequency to 5 GHz using the

numeric keypad.

b. Measure residual response:

Press the PEAK key to place the marker at the peak on the noise floor.

c. Check against limits:

Read the marker readout. Confirm that the residual signal level is

–85 dBm or less within the whole bandwidth.

5. Check residual response in the RF3 band:

a. Modify the analyzer controls:

H Press the FREQUENCY/CHANNEL key on the front panel.

Performance Tests

H With the Center Freq side key, set the frequency to 6.5 GHz using

the numeric keypad.

b. Measure residual response:

Press the PEAK key to place the marker at the peak on the noise floor.

c. Check against limits:

Read the marker readout. Confirm that the residual signal level is

–85 dBm or less within the whole bandwidth.

RSA3408A Technical Reference

1-39

Performance Tests

Check Spurious Response

Equipment

Required

Prerequisites Refer to page 1-10.

One signal generator (Item 2)

One 50 W NĆN coaxial cable (Item 10)

1. Prepare for the test:

a. Initialize the analyzer:

H Press the SYSTEM key on the front panel.

H Press the Reset All to Factory Defaults side key.

b. Modify the default controls:

H Press the SPAN key on the front panel.

H With the Span side key, set the span to 10 MHz using the general

purpose knob.

H Press the RBW/FFT key on the front panel.

H Press the RBW/FFT side key to select Man.

H With the RBW side key, set the value to 50 kHz using the general

purpose knob.

H Press TRACE/AVG → Trace 1 Type...→ Average.

H Press the Number Of Averages side key and set the value to 50.

H Press the MARKER SETUP key.

H Press the Markers side key to select Delta.

c. Set the generator controls:

Level –5 dBm. . . . . . . . . . . . . . . . . . . .

d. Hook up the signal generator:

Connect the generator output through a 50 W N-N coaxial cable to the

analyzer INPUT. See the figure above on the next page.

1-40

RSA3408A Technical Reference

Signal generator

Output

2. Check spurious response:

a. Modify the generator controls:

Set the generator output frequency to the value as shown in Table 1–5

(initially 25 MHz).

b. Modify the analyzer controls:

Performance Tests

RSA3408A

50 W NĆN coaxial cable

H Press the FREQUENCY/CHANNEL key on the front panel.

H With the Center Freq side key, set the frequency to the same value

as the generator output using the numeric keypad.

c. Measure the amplitude:

H Press the Select Marker side key to select 1.

H Press the PEAK key and then the MARKERS: B (marker down)

key once to place the first marker at the peak on the noise floor.

H Press the Select Marker side key to select 2.

H Press the PEAK key to place Marker 2 on the peak signal.

H Read the delta marker readout (D1–2) on the screen. Check that the

components other than the carrier meet the requirement as shown in

Table 1–5 (initially –73 dBc).

RSA3408A Technical Reference

1-41

Performance Tests

d. Repeat substeps a through c until all frequency settings listed in

Table 1–5, are checked.

Table 1-5: Spurious measurement

Band Frequency Spurious response

Baseband 25 MHz -73 dBc

RF1 2 GHz -73 dBc

RF2 5 GHz -70 dBc

RF3 7 GHz -70 dBc

3. Disconnect the test equipment: Disconnect the cable at the analyzer input.

1-42

RSA3408A Technical Reference

Test Record

Performance Tests

Photocopy the following test record pages and use them to record the performance test results for your analyzer.

RSA3408A Technical Reference

1-43

Performance Tests

RSA3408A Test Record

Serial Number: Certificate Number:

Calibration Date:

Frequency readout test

Frequency Measurement Low limit Test result High limit

10 MHz Marker 9,999 kHz 10,001 kHz

Carrier frequency meas. 9,999,998.8 Hz 10,000,001.2 Hz

2 GHz Marker 1,999,998.8 kHz 2,000,001.2 kHz

Carrier frequency meas. 1,999,999,790 Hz 2,000,000,210 Hz

5 GHz Marker 4,999,998.5 kHz 5,000,001.5 kHz

Carrier frequency meas. 4,999,999,490 Hz 5,000,000,510 Hz

7 GHz Marker 6,999,998.3 kHz 7,000,001.7 kHz

Carrier frequency meas. 6,999,999,290 Hz 7,000,000,710 Hz

Technician:

10 MHz reference output test Low limit Test result High limit

Accuracy 9,999,998.8 Hz 10,000,001.2 Hz

Noise sideband test

Span Offset Low limit Test result High limit

50 kHz 10 kHz 100 dBc/Hz

500 kHz 100 kHz 112 dBc/Hz

5 MHz 1 MHz 132 dBc/Hz

Absolute amplitude accuracy test

Frequency Test level Low limit Test result High limit

25 MHz -10 dBm -10.3 dBm -9.7 dBm

100 MHz -20 dBm -20.5 dBm -19.5 dBm

1-44

RSA3408A Technical Reference

Performance Tests

Input attenuator setting uncertainty test

Attenuation Measurement (PX) Low limit Test result (PX-P

0dB P0: - - -

5dB -0.2 dB +0.2 dB

10 dB -0.2 dB +0.2 dB

15 dB -0.2 dB +0.2 dB

20 dB -0.2 dB +0.2 dB

25 dB -0.2 dB +0.2 dB

30 dB -0.2 dB +0.2 dB

30 dB P1: - - -

35 dB -0.2 dB +0.2 dB

40 dB -0.2 dB +0.2 dB

45 dB -0.2 dB +0.2 dB

50 dB -0.2 dB +0.2 dB

) High limit

0/1

55 dB -0.2 dB +0.2 dB

Level linearity test

Amplitude Low limit Test result High limit

0dB -0.2 dB +0.2 dB

-10 dB -0.2 dB +0.2 dB

-20 dB -0.2 dB +0.2 dB

-30 dB -0.2 dB +0.2 dB

-40 dB -0.2 dB +0.2 dB

-50 dB -0.2 dB +0.2 dB

3rdorder intermodulation distortion test Low limit Test result High limit

3rdorder intermodulation distortion

+5 dBm reference level, 2 GHz center frequency

-78 dBc

RSA3408A Technical Reference

1-45

Performance Tests

Displayed average noise level test

Frequency Low limit Test result High limit

10 MHz -151 dBm/Hz

2 GHz -150 dBm/Hz

3 GHz -150 dBm/Hz

7 GHz -142 dBm/Hz

Residual response test

Band Frequency range Low limit Test result High limit

Baseband 1to40MHz -93 dBm

RF1 0.5 to 3.5 GHz -90 dBm

RF2 3.5 to 6.5 GHz -85 dBm

RF3 5to8GHz -85 dBm

Spurious response test

Frequency Low limit Test result High limit

25 MHz -73 dBc

2 GHz -73 dBc

5 GHz -70 dBc

7 GHz -70 dBc

1-46

RSA3408A Technical Reference

Specifications

Specifications

This section contains the RSA3408A 8 GHz Real-Time Spectrum Analyzer

specifications. All specifications are guaranteed unless labeled Typical. Typical

specifications are provided for your convenience.

NOTE. In these tables, those warranted characteristics that are checked in the

Performance Verification appear with the n symbol in the Characteristics

column.

Performance Conditions

The performance limits in this specification are valid with these conditions:

H The analyzer must have been calibrated and adjusted at an ambient tempera-

H The analyzer must be in an environment with temperature, altitude,

ture between +20

humidity, and vibration within the operating limits described in these

specifications.

_C and +30 _C.

H The analyzer must have had a warm-up period of at least 20 minutes.

RSA3408A Technical Reference

2-1

Specifications

Electrical Characteristics

Table 2-1: Frequency

Characteristics Description

Measurement frequency

Frequency range Overall: DC to 8 GHz

Baseband: DC to 40 MHz

RF1: 40 MHz to 3.5 GHz

RF2: 3.5 GHz to 6.5 GHz

RF3: 5 GHz to 8 GHz

Center frequency setting resolution 0.1 Hz

n Frequency marker readout accuracy

Residual FM (Typical) 2Hzp-p

Span accuracy ±1 bin

RBW filter bandwidth accuracy 0.1% against noise bandwidth

Reference frequency

Aging per day 1 × 10-9(after 30 days of operation)

Aging per year 1 × 10-7(after 30 days of operation)

Temperature drift 1 × 10-7(10 to 40 _C)

n Total frequency error

Reference output level >0 dBm

External reference input 10 MHz, -10 to +6 dBm. Spurious level must be <-80 dBc within 100 kHz offset.

Baseband:±(RE × MF + 0.001 × Span + 0.2) Hz

RF1 to 3: ±(RE × MF + 0.001 × Span+2)Hz

RE: Reference frequency error; MF: Marker frequency [Hz]

The first term of these formula shows the frequency uncertainty due to the reference

frequency error. The second term shows the uncertainty due to the limited bin number.

Because more than 500 bins are available in the frequency display, 0.5 bin uncertainty

corresponds to 0.001. The third term shows the residual FM.

2 × 10-7(within one year after calibration)

2-2

RSA3408A Technical Reference

Table 2-2: Noise sideband

Characteristics Description

Noise sideband Offset

Frequency = 1000 MHz -105 dBc/Hz

-110 dBc/Hz

-110 dBc/Hz

-110 dBc/Hz

-112 dBc/Hz

-132 dBc/Hz

-138 dBc/Hz

-138 dBc/Hz

-138 dBc/Hz

Frequency = 2000 MHz -103 dBc/Hz

-109 dBc/Hz

-109 dBc/Hz

-109 dBc/Hz

-112 dBc/Hz

-132 dBc/Hz

-138 dBc/Hz

-138 dBc/Hz

-138 dBc/Hz

Frequency = 6000 MHz -97 dBc/Hz

-106 dBc/Hz

-106 dBc/Hz

-106 dBc/Hz

-111 dBc/Hz

-132 dBc/Hz

-137 dBc/Hz

-137 dBc/Hz

-137 dBc/Hz

Frequency = 1000 MHz, Typical -107 dBc/Hz

-112 dBc/Hz

-112 dBc/Hz

-112 dBc/Hz

-115 dBc/Hz

-135 dBc/Hz

-140 dBc/Hz

-140 dBc/Hz

-140 dBc/Hz

Specifications

1 kHz

10 kHz

20 kHz

30 kHz

100 kHz

1 MHz

5 MHz

7 MHz

10 MHz

1 kHz

10 kHz

20 kHz

30 kHz

100 kHz

1 MHz

5 MHz

7 MHz

10 MHz

1 kHz

10 kHz

20 kHz

30 kHz

100 kHz

1 MHz

5 MHz

7 MHz

10 MHz

1 kHz

10 kHz

20 kHz

30 kHz

100 kHz

1 MHz

5 MHz

7 MHz

10 MHz

RSA3408A Technical Reference

2-3

Specifications

Table 2-2: Noise sideband (Cont.)

Characteristics Description

Frequency = 2000 MHz, Typical -105 dBc/Hz

-111 dBc/Hz

-111 dBc/Hz

-111 dBc/Hz

-115 dBc/Hz

-135 dBc/Hz

-140 dBc/Hz

-140 dBc/Hz

-140 dBc/Hz

Frequency = 6000 MHz, Typical -99 dBc/Hz

-108 dBc/Hz

-108 dBc/Hz

-108 dBc/Hz

-113 dBc/Hz

-134 dBc/Hz

-139 dBc/Hz

-139 dBc/Hz

-139 dBc/Hz

1 kHz

10 kHz

20 kHz

30 kHz

100 kHz

1 MHz

5 MHz

7 MHz

10 MHz

1 kHz

10 kHz

20 kHz

30 kHz

100 kHz

1 MHz

5 MHz

7 MHz

10 MHz

Table 2-3: Input

Characteristics Description

Signal input

Input connector N type (RF and baseband input); BNC type (Option 03 IQ input)

Input impedance 50 W

VSWR <1.4 (2.5 GHz, RF attenuation≥10 dB)

<1.8 (7.5 GHz, RF attenuation≥10 dB)

Typical <1.4 (300 kHz to 40 MHz, RF attenuation≥10 dB)

<1.3 (40 MHz to 3 GHz, RF attenuation≥10 dB)

<1.4 (3 GHz to 8 GHz, RF attenuation≥10 dB)

Maximum input level

Maximum DC voltage ±0.2 V (RF1 to 3)

±5 V (Baseband)

±5 V (Option 03 IQ input)

Maximum input power +30 dBm (RF1 to 3, RF attenuation≥10 dB)

Input attenuator

RF/Baseband attenuator 0 to 55 dB (5 dB step)

I/Q attenuator (Option 03) 0 to 35 dB (5 dB step)

2-4

RSA3408A Technical Reference

Table 2-4: Amplitude

Characteristics Description

Reference level

Reference level setting range Baseband: -30 to +20 dBm (5 dB step)

RF: -50 to +30 dBm (1 dB step)

Option 03 IQ input: -10 to +20 dBm (5 dB step)

Accuracy (-10 to -50 dBm)

Frequency response (RF attenuation≥10 dB)

at 20 to 30 _C ±0.5 dB (100 kHz to 40 MHz)

Typical ±0.3 dB (100 kHz to 40 MHz)

at 10 to 40 _C ±0.7 dB (100 kHz to 40 MHz)

n Absolute amplitude accuracy

at calibration point (20 to 30 _C)

n Input attenuator setting uncertainty

n Level linearity in display range

±0.2 dB (at 100 MHz, 10 dB attenuation, 20 to 30 _C)

±1.2 dB (40 MHz to 3.5 GHz)

±1.7 dB (3.5 GHz to 6.5 GHz)

±1.7 dB (5 GHz to 8 GHz)

±0.5 dB (40 MHz to 3.5 GHz)

±1.0 dB (3.5 GHz to 6.5 GHz)

±1.0 dB (5 GHz to 8 GHz)

±1.5 dB (40 MHz to 3.5 GHz)

±2.0 dB (3.5 GHz to 6.5 GHz)

±2.0 dB (5 GHz to 8 GHz)

Baseband: ±0.3 dB (at 25 MHz, -10 dBm signal)

RF: ±0.5 dB (at 100 MHz, -20 dBm signal, 0 dB attenuation)

±0.2 dB (at 100 MHz)

±0.2 dB (0 to -50 dBfs); ±0.12 dB (0 to -50 dBfs, Typical)

Specifications

RSA3408A Technical Reference

2-5

Specifications

Table 2-5: Spurious response

Characteristics Description

1 dB compression input +2 dBm (RF attenuation = 0 dB, 2 GHz)

2ndharmonic distortion

(-30 dBm tone at input mixer)

3rdorder intermodulation distortion (Reference level = +5 dBm , RF attenuation adjusted optimally, Total signal power = -7 dBm)

n Center frequency=2GHz

100 MHz to 3 GHz -75 dBc

3 GHz to 8 GHz -72 dBc

n Displayed average noise level

Local feedĆthrough to input connecter

(Typical)

Image Suppression (Typical)

1stIF 75 dB (40 MHz to 3.5 GHz)

2ndand 3rdIF 80 dB (40 MHz to 3.5 GHz)

Alias suppression (Typical) 65 dB (DC to 40 MHz)

-65 dBc (10 MHz to 1400 MHz)

-70 dBc (1400 MHz to 1750 MHz)

-78 dBc

-144 dBm/Hz (100 Hz to 10 kHz)

-151 dBm/Hz (10 kHz to 10 MHz)

-151 dBm/Hz (10 MHz to 100 MHz)

-150 dBm/Hz (100 MHz to 1 GHz)

-150 dBm/Hz (1 GHz to 2 GHz)

-150 dBm/Hz (2 GHz to 3 GHz)

-142 dBm/Hz (3 GHz to 5 GHz)

-142 dBm/Hz (5 GHz to 8 GHz)

-40 dBm (local frequency 4.2 to 5 GHz)

-55 dBm (local frequency 5 to 6 GHz)

-60 dBm (local frequency 6 to 7 GHz)

-60 dBm (local frequency 7 to 7.7 GHz)

70 dB (3.5 GHz to 8 GHz)

75 dB (3.5 GHz to 8 GHz)

n Residual response (Reference level = -30 dBm, RBW = 100 kHz)

Baseband, 1 to 40 MHz -93 dBm (Span = 20 MHz)

RF1, 0.5 to 3.5 GHz -90 dBm (Span = 3 GHz)

RF2, 3.5 to 6.5 GHz -85 dBm (Span = 3 GHz)

RF3, 5 to 8 GHz -85 dBm (Span = 3 GHz)

n Spurious response (Span = 10 MHz, Reference level = 0 dBm, RBW = 50 kHz)

Baseband, 25 MHz -73 dBc (Signal frequency = 25 MHz, Signal level = -5 dBm)

RF1, 2 GHz -73 dBc (Signal frequency = 2 GHz, Signal level = -5 dBm)

RF2, 5 GHz -70 dBc (Signal frequency = 5 GHz, Signal level = -5 dBm)

RF3, 7 GHz -70 dBc (Signal frequency = 7 GHz, Signal level = -5 dBm)

2-6

RSA3408A Technical Reference

Table 2-6: Acquisition

Characteristics Description

RealĆtime capture bandwidth Baseband: 40 MHz; RF: 36 MHz; IQ: 40 MHz (Option 03 only)

A/D converter 14 bits, 102.4 Msps

Sampling rate (Real Time S/A, Demod, and Time modes)

40 MHz span (Baseband) 51.2 Msps

40 MHz span (IQ, Option 03) 51.2 Msps

36 MHz span (RF) 51.2 Msps

20 MHz span 25.6 Msps

10 MHz span 12.8 Msps

5 MHz span 6.4 Msps

2 MHz span 2.56 Msps

1 MHz span 1.28 Msps

500 kHz span 640 ksps

200 kHz span 256 ksps

100 kHz span 128 ksps

50 kHz span 64 ksps

20 kHz span 25.6 ksps

10 kHz span 12.8 ksps

5 kHz span 6.4 ksps

2 kHz span 2.56 ksps

1 kHz span 1.28 ksps

500 Hz span 640 sps

200 Hz span 256 sps

100 Hz span 128 sps

Acquisition length

(Real Time S/A, Demod, and Time modes)

Acquisition length setting resolution 1024 samples (Real Time S/A, Demod, and Time modes)

Acquisition memory size Standard: 64 Mbytes; Option 02: 256 Mbytes

Minimum: 1024 samples

Maximum: 16,384,000 samples (Standard); 65,536,000 samples (Option 02)

Specifications

RSA3408A Technical Reference

2-7

Specifications

Table 2-7: Trigger

Characteristics Description

Trigger mode Free run, Triggered

Trigger event source Power (Span BW), Frequency mask (Option 02), External

Pre/Post trigger setting Trigger position is settable from 0 to 100% of total data length.

Power trigger 0 to -40 dBfs

Frequency mask trigger (Option 02)

Mask resolution 1 bin

Level range 0 to -60 dBfs

RealĆtime event detection bandwidth Baseband: 40 MHz (1024 point FFT, 50% overlapping)

RF: 36 MHz (1024 point FFT, 50% overlapping)

External trigger

Threshold voltage -1.5 to +1.5 V settable

Setting Resolution 0.1 V

Input impedance >2 kW

Trigger output voltage High: >2.0 V, Low: <0.4 V (output current <1 mA)

Trigger marker position timing uncertainty ±2 sample points (Power/External trigger)

2-8

RSA3408A Technical Reference

Table 2-8: RBW (Resolution Bandwidth)

Characteristics Description

Filter shape Gaussian, Rectangle, Root Nyquist

Setting range 1Hzto10MHz

Minimum settable RBW (extended resolution on)

Span >2 GHz 100 kHz

1 GHz< Span ≤2 GHz 50 kHz

500 MHz< Span ≤1 GHz 20 kHz

20 MHz< Span ≤500 MHz 10 kHz

500 kHz< Span ≤20 MHz 1 kHz

200 kHz < Span ≤500 kHz 500 Hz

100 kHz < Span ≤200 kHz 200 Hz

50 kHz < Span ≤100 kHz 100 Hz

20 kHz < Span ≤50 kHz 50 Hz

10 kHz < Span ≤20 kHz 20 Hz

5 kHz < Span ≤10 kHz 10 Hz

2 kHz < Span ≤5 kHz 5Hz

1 kHz < Span ≤2 kHz 2Hz

100 Hz ≤ Span ≤1 kHz 1Hz

Specifications

Table 2-9: Trace and display line

Characteristics Description

Number of traces 2

Trace type Normal, Average, Max Hold, Min Hold

Display detector Positive peak, Negative peak, and PositiveĆNegative peak

Display line Horizontal line 1 and 2, Vertical line 1 and 2

RSA3408A Technical Reference

2-9

Specifications

Table 2-10: Display

Characteristics Description

Views

S/A mode Spectrum

S/A with Spectrogram mode Spectrum and Spectrogram

Real TIme S/A mode Spectrum and Spectrogram

Analog Demod mode Overview: Power versus Time/Spectrogram

Subview: Spectrum

Main view: Measurement Results

Time mode Overview: Power versus Time/Spectrogram

Subview: Spectrum

Main view: Measurement results

LCD

Size 213 mm (8.4 in)

Resolution 800 × 600 pixels

Color Maximum 256 colors

Table 2-11: Measurement function

Characteristics Description

S/A mode Channel power, Adjacent channel power ratio, Occupied bandwidth,