Page 1

x

RSA306B Real-Time

USB Spectrum Analyzer

Specifications and Performance Verification

ZZZ

Technical Reference

*P077124301*

077-1243-01

Page 2

Page 3

xx

RSA306B Real-Time

USB Spectrum Analyzer

Specifications and Performance Verification

ZZZ

Technical Reference

www.tek.com

077-1243-01

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are

protected by na

tional copyright laws and international treaty provisions.

Tektronix pro

previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

SignalVu-PC is a trademark of Tektronix, Inc.

ducts are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tek.com to find contacts in your area.

Page 5

Table of Contents

Important safety information .......................................................................................................... iii

General safety summary......................................................................................................... iii

Service safety summary ......................................................................................................... iv

Terms in this manual ... .... . . ... . . ... . . ... . . ... . . .. . . . ... . . ... . . .. . . . .. . . . .. . . . .. . . . .. . . . .. . . ... . . ... . . . .. . . ... . . ... . . ... . . ... . . . v

Terms and symbols on the product . . . .. . . . .. . . . .. . . . ... . . ... . . ... . . ... . . . .. . . ... . . . .. . . . ... . . .. . . . ... . . ... . . ... . . ... . . ... . . . .. . . v

Preface ................................................................................................................................. vi

Documentation ...................................................................................................................vi

Specifications .......................................................................................................................... 1

Frequency . .. . . . .. . . . ... . . .. . . . ... . . ... . . .. . . . ... . . ... . . .. . . . ... . . ... . . .. . . . ... . . ... . . .. . . . ... . . ... . . ... . . ... . . ... . . ... . . ... . . .. .. 2

Amplitude......................................................................................................................... 2

Trigger . . . ... . . .. . . . .. . . . .. . . ... . . ... . . ... . . ... . . ... . . .. . . . .. . . . .. . . ... . . ... . . .. . . . .. . . . .. . . ... . . ... . . ... . . ... . . ... . . .. . . . .. . . . .... 4

Intermediate frequency and acquisition system . ... . . .. . . . .. . . . .. . . ... . . ... . . . .. . . ... . . ... . . ... . . ... . . ... . . .. . . . .. . . . .. . . ... . . . 4

Noise and distortion..............................................................................................................5

Swept and Real time............................................................................................................. 9

Interfaces, input, output ports... . . ... . . ... . . ... . . .. . . . .. . . . .. . . ... . . ... . . . .. . . ... . . ... . . ... . . ... . . ... . . .. . . . .. . . . .. . . ... . . . .. . . . 10

Power............................................................................................................................ 10

Physical.......................................................................................................................... 10

Regulatory....................................................................................................................... 10

Environmental pe

Performance verification.............................................................................................................. 12

Prerequisites . ... . . .. . . . .. . . ... . . ... . . ... . . ... . . ... . . .. . . . .. . . . .. . . ... . . ... . . .. . . . .. . . . .. . . ... . . ... . . ... . . ... . . ... . . .. . . . .. . . . ... 12

Required equipment .. . . ... . . ... . . . .. . . ... . . . .. . . . .. . . ... . . . .. . . . .. . . ... . . . .. . . . .. . . ... . . . .. . . . .. . . . .. . . . .. . . . .. . . . .. . . . .. . . . .. . 13

Preliminary checks.............................................................................................................. 14

Performance verification procedures .. . . ... . . .. . . . ... . . ... . . .. . . . ... . . ... . . .. . . . .. . . . ... . . .. . . . .. . . . ... . . .. . . . .. . . . .. . . . .. . . . .. 15

Internal reference frequency accuracy .. . . ... . . ... . . ... . . .. . . . ... . . ... . . .. . . . .. . . . .. . . ... . . . .. . . . .. . . ... . . ... . . ... . . ... . . 15

External reference i nput, functional test . . . . .. . . ... . . ... . . ... . . ... . . ... . . .. . . . .. . . . .. . . ... . . ... . . .. . . . .. . . . .. . . ... . . ... . . . 17

Amplitude accuracy at all center frequencies . . ... . . ... . . ... . . ... . . ... . . .. . . . ... . . ... . . .. . . . ... . . ... . . .. . . . .. . . . ... . . .. . . 18

Channel amplitude flatness ............................................................................................... 26

DANL (Displayed Average Noise Level).................................................................................. 31

Phase noise. .. . . ... . . . .. . . . .. . . ... . . ... . . ... . . ... . . ... . . ... . . ... . . ... . . .. . . . .. . . . ... . . .. . . . .. . . . .. . . ... . . . .. . . . .. . . ... . . ... 33

Third-order intermodulation distortion . . . . .. . . .. . . . .. . . .. . . . .. . . ... . . .. . . ... . . .. . . . .. . . .. . . . .. . . .. . . . .. . . ... . . .. . . ... . . .. . 36

Input-related spurious response: A DC . .. . . . .. . . . .. . . ... . . ... . . ... . . ... . . ... . . .. . . . .. . . . .. . . ... . . ... . . ... . . ... . . ... . . .. . . 38

Input-related spurious response: second converter images . . .. . . . ... . . .. . . . ... . . ... . . ... . . ... . . . .. . . . .. . . . .. . . . ... . . ... 41

Input-related spurious response: first converter images . .. . . . .. . . . ... . . .. . . . .. . . . .. . . . .. . . . .. . . . .. . . . .. . . . .. . . . .. . . ... . . 43

Input-related spurious response: IF feedthrough ... . . . .. . . ... . . ... . . .. . . . .. . . . .. . . . .. . . . .. . . . .. . . ... . . ... . . .. . . . .. . . . .. . 45

Input-related spurious response: RF X 2LO... . . . .. . . ... . . ... . . . .. . . ... . . ... . . . .. . . ... . . ... . . . .. . . ... . . . .. . . . .. . . ... . . . .. 47

Input-related spurious response: RF X 3LO... . . . .. . . ... . . ... . . . .. . . ... . . ... . . . .. . . ... . . ... . . . .. . . ... . . . .. . . . .. . . ... . . . .. 49

Input-related spurious response: signal 2RF X 2LO . . . ... . . . ... . . ... . . ... . . . ... . . ... . . . .. . . . ... . . ... . . . .. . . . ... . . ... . . .. 51

Test record....................................................................................................................... 53

rformance .................................................................................................... 11

Table of Content

s

RSA306B Specifications and Performance Verification i

Page 6

Table of Content

s

ii RSA306B Specifications and Performance Verification

Page 7

Important safet

y information

Important saf

This manual contains information and warnings that must be followed by the user for safe operation and to keep the

product in a safe condition.

To safely perform service on this product, additional information is provided at the end of this section. (See page iv,

Service safety summary.)

ety information

General safety summary

Use the product only as specified. Review the following safety precautions to avoid injury and prevent damage to this product

or any products connected to it. Carefully read all instructions. Retain these instructions for future reference.

Comply with local and national safety codes.

For correct and safe operation of the product, it is essential that you follow generally accepted safety procedures in addition

to the safety precautions specified in this manual.

The product is designed to be used by trained personnel only.

Only qualified personnel who are aware of the hazards involved should remove the cover for repair, maintenance, or

adjustment.

This product is not intended for detection of hazardous voltages.

While using this product, you may need to access other parts of a larger system. Read the safety sections of the other

component manuals for warnings and cautions related to operating the system.

When incorporating this equipment into a system, the safety of that system is the responsibility of the assembler of the system.

To avoid fire or personal injury

Connect and disconnect properly. Do not connect or disconnect probes or test leads while they are connected

to a voltage source.

Use only insulated voltage probes, test leads, and adapters supplied with the product, or indicated by Tektronix to be

suitable for the product.

Observe all terminal ratings. To avoid fire or shock hazard, observe all ratings and markings on the product. Consult

the product manual for further ratings information before making connections to the product.

Do not app

The measuring terminals on this product are not rated for connection to mains or Category II, III, or IV circuits.

Do not operate without covers. Do not operate this product with covers or panels removed, or with the case open.

Avoid exposed circuitry. Do not touch exposed connections and components when power is present.

Do not operate with suspected failures. If you suspect that there is damage to this product, have it inspected by

qualified service personnel.

Disable the product if it is damaged. Do not use the product if it is damaged or operates incorrectly. If in doubt about safety of

the product, turn it off and disconnect the power. Clearly mark the product to prevent its further operation.

ly a potential to any terminal, including the common terminal, that exceeds the maximum rating of that terminal.

RSA306B Specifications and Performance Verification iii

Page 8

Important safet

Examine the exterior of the product before y ou use it. Look for cracks or missing pieces.

Use only specified replacement parts.

Do not operate in wet/damp conditions. Be aware that condensation may occur if a unit is moved from a cold to a

warm environment.

Do not operate in an explosive atmosphere.

y information

Keep product surfaces clean and dry.

Provide proper ventilation. Refer to the installation instructions in the manual for details on installing the product

so it has proper ventilation.

Provide a s

Improper or prolonged keyboard or pointer use may result in serious injury.

Be sure your work area meets applicable ergonomic standards. Consult with an ergonomics professional to avoid stress

injuries.

Use only the Tektronix rackmount hardware specified for this product.

Service

The Service safety summary section contains additional information required to safely perform service on the product. Only

qualified personnel should perform service procedures. Read this Service safety summary and the General safety summary

before performing any service procedures.

To avoi

Do not service alone. Do not perform internal service or adjustments of this product unless another person capable of

rendering first a id and resuscitation is present.

afe working environment.

safety summary

d electric shock.

Remove the input signals before you clean the product.

Avoid improper or prolonged use of keyboards, pointers, and button pads.

Do not touch exposed connections.

Disconnect power. To avoid electric shock, disconnect the USB 3.0 cable from the instrument before removing any

covers or panels, or opening the case for servicing.

Use care when servicing with power on. Disconnect power, remove battery (if applicable), and disconnect test leads

before removing protective panels, soldering, or replacing components.

iv RSA306B Specifications and Performance Verification

Page 9

Terms in this manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in damage to this product or other property.

Terms and symbols on the product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the marking.

WARNING indicates an injury hazard not immediately accessible as you read the marking.

CAUTION indicates a hazard to property including the product.

Important safet

y information

When this symbol is marked on the product, be sure to consult the manual to find out the nature of the

potential hazards and any actions which have to be taken to avoid them. (This symbol may also be used to

refer the user to ratings

The following symbol(s) m ay appear on the product:

in the manual.)

RSA306B Specifications and Performance Verification v

Page 10

Preface

Preface

Verify the software version

The SignalVu-PC software version must be version 3.11.0x or greater.

Purpose

This manual lists the electrical, mechanical, and environmental specifications, and the certification and compliance

statements for the Tektronix RSA306B USB Spectrum Analyzer. Also provided are procedures for verifying the performance

of the inst

Documentation

The following table lists some of the documentation that is available for this product.

Product documentation

Document Purpose Location

Installation and Safety Instructions Provides software and hardware

Specifications and Performance

Verification Technical Reference

(this manual)

SignalVu-PC application help

RSA306B API Programmer

manual

SignalVu-PC Programmer manual

rument.

installation instructions and

associated safety warnings

Specifications and performance

verification procedures for

checking instrument performance

Using the application and

interpreting the measurement

results

Details on commands used to

control the instrument through an

API

Details on commands used with

the SignalVu-PC application

Printed manual and also available in electronic

format on the product flash drive and at

www.tektronix.com/manuals

Available at www.tektronix.com/manuals

Application help files located within the

application

Available at www.tektronix.com/manuals

Available at www.tektronix.com/manuals

vi RSA306B Specifications and Performance Verification

Page 11

Specifications

Specification

All specifications are guaranteed unless labeled Typical. Typical specifications are provided for your convenience.

NOTE. Warranted characteristics that are checked in the Performance Verification are marked with a

The performance limits in this specification are valid within the following conditions:

The SignalVu-PC software version is 3.7.0114 or greater.

Operate the instrument in an environment that meets the temperature, altitude, and humidity characteristics listed in

these specifications.

The instrument must have been operating for a warm-up period of at least for 30 minutes (after being connected to the

PC, starting the SignalVu-PC application, and SignalVu-PC is connected to the RSA306B instrument and continuously

acquiring data).

NOTE. The RSA306B does not fully power on until SignalVu-PC has established communication with the RSA306B

and is acquiring data.

The instrument must have had its signal–path–compensation routine last executed after at least a 30 minute warm–up

period at an ambient temperature within ±2 °C of the current ambient temperature.

s

symbol.

RSA306B Specifications and Performance Verification 1

Page 12

Specifications

Frequency

RF input frequency range 9kHzto6.2GHz

Frequency reference accuracy

Over 18 °C to 28 °C ambient

temperature range

Aging, typical

Over operating temperature

range (–10

ambient), typical

External frequency reference

input

Input Frequency Range 10 MHz ± 10 Hz

Input Lev

Impedance

Center

Block I

Strea

°C to +55 °C

el Range

frequency resolution

Q samples

med ADC samples

±3 x 10–6+ aging (after 20 minute warm up)

–6

±3 x 10

±20 x 10

–10 dBm to

50

1Hz

500 kHz

(first year), ±1 x 10–6each year thereafter

–6

+ aging

+10 dBm sinusoid

Amplitude

RF input impedance

RF input VSWR, typical 1.8:1 (10 MHz to 6200 MHz, reference level +10 dBm)

Maximum RF input level without

age

dam

DC

Re

R

Maximum RF input operating

evel

l

Center frequency < 22 MHz

Center frequency 22 MHz

voltage

fLevel –10 dBm

ef Level < –10 dBm

50

uivalent Return Loss: 11 dB)

(Eq

The maximum voltage or power that the RF input can withstand without creating

ock hazard or damaging the input.

ash

±40 V

DC

3 dBm (continuous or peak)

+2

15 dBm (continuous or peak)

+

he maximum level at the RF input for which the instrument will meet its

T

measurement specifications.

+15 dBm

+20 dBm

2 RSA306B Specifications and Performance Verification

Page 13

Specifications

Amplitude accuracy at all center

frequencies

Center freque

<3GHz

Center frequency 3GHzto

6.2 GHz

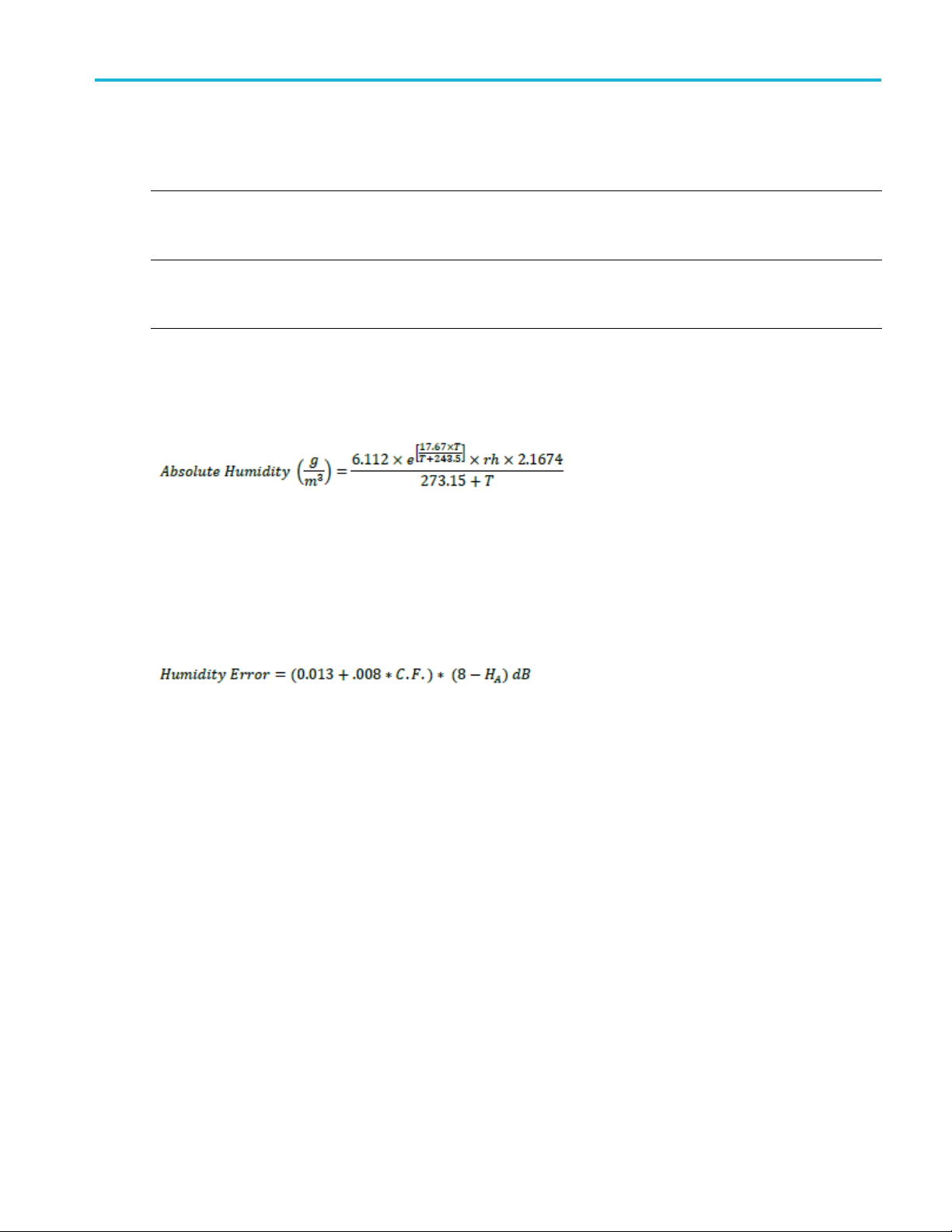

The above Amplitude accuracy at all center frequencies specifications apply when operated and stored at the same ambient

absolute h

Absolute humidity can be estimated from ambient temperature ⁰C and relative humidity rh (%) using readily available online

calculators or the following relation:

Losses in the RF path of the product are proportional to its PCB moisture content which is in turn proportional to the amount

of moisture in the air. PCB moisture responds slowly to ambient conditions and it may take a day or more for an ambient

humidit

original ambient condition. Amplitude errors due to humidity are minimal when the ambient conditions are the same as the

factory calibration conditions, nominally 8 g/m3 and increase proportional to the difference from that value averaged over

time. T

umidity conditions as the average factory calibration environment (8 grams of water per cubic meter of air).

y change to cause a significant amplitude shift, it may require a similar length of time to recover after return to the

he additional amplitude error is given by

ncy9kHzto

Reference leve

Applies to corrected IQ data, with signal to noise ratios > 40 dB

Accuracy may degrade up to ±0.6 dB after storage at maximum storage temperature,

recovers with

±1.2 dB (18 °C t

±0.8 dB (18 °C to 28 °C), typical (95% confidence)

±1.0 dB (–10 °C to 55 °C), typical

±1.65 dB (18 °C to 28 °C)

±1.0 dB (18 °

±0.85 dB (–10 °C to 55 °C), typical

l +20 dBm to –30 dBm, alignment run prior to testing

in 24 hours

o28°C)

C to 28 °C), typical (95% confidence)

(C.F. = center frequency in GHz, HA = Absolute Humidity in g/m^3). Worst case amplitude error is the greater of the error in

the table or the sum of the value in the table combined with the humidity error.

Example:

Center Freq. = 4 GHz, temperature = 28C, R.H. = 80%.

Absolute Humidity= 21.8 g/ m3

Humidity Error (4 GHz, 21.8 g/ m3) = -0.62 dB

P-TYP-S95 error from table = +1, -1 dB

Sum of table plus hum. error= (1-0.62)=0.38 dB, (-1-0.62)= -1.62 dB

Worst case amplitude error = +1 dB, -1.62 dB

RSA306B Specifications and Performance Verification 3

Page 14

Specifications

Trigger

Channel amplitude flatness

At 18 °C to 28 °C

Center frequency 22 MHz to

24 MHz

Center frequency 24 MHz to

6.2 GHz

At –10 ⁰Cto55⁰C

Center frequency 22 MHz to

24 MHz

Center frequency 24 MHz to

6.2 GHz

Trigger/sync input

Voltage range

Trigger level Positive-going threshold voltage: 1.6 V minimum, 2.1 V maximum

Impedance

Power trigger

Threshold range

Type

Trigger re-arm time 100 s

Reference leve

Applies to corrected IQ data, with signal to noise ratios > 40 dB

±1.2 dB

±1.0 dB, typical

±1.0 dB

±0.4 dB, typical

±2.5 dB, typ

±0.5 dB, typical

TTL(0.0V–5.0V)

Negative-going threshold voltage: 1.0 V minimum, 1.35 V maximum

10 k (with Schottky clamps to 0 V, +5 V)

Trigger on RF power level transitions which cross the trigger level, for signals

the IF BW.

0 dB to –50 dB (from reference level, for trigger levels > 30 dB above the noise

floor, 0.1 dB steps)

Rising or falling edge

l +20 dBm to –30 dBm, alignment run prior to testing

ical

within

Intermediate frequency and acquisition system

IF bandwidth 40 MHz

ADC sample rate and bit width 112 Ms/s, 14 bits

Sample rate and bit-width of the Analog/Digital Converter used to digitize the IF signal

Real-time IF acquisition data

(uncorrected)

Block baseband acquisition data

(corrected)

Maximum acquisition time 1 s

Bandwidths

Sample rates 56 / (2N) Ms/s, 32-bit float complex samples, N 0

4 RSA306B Specifications and Performance Verification

112 Ms/s, 16-bit integer samples

40 MHz BW, at digital IF = 28 ±0.25 MHz, uncorrected

Block streaming data at an average rate of 224 MB/sec

N

40 /( 2

) MHz, 0 Hz Digital IF, N 0

Page 15

Noise and distortion

Specifications

Displayed average noise level

(DANL)

Phase noise

Reference level = –50 dBm, input terminated with 50 load, log-average (10 averages)

DANL (dBm/Hz),

DANL (dBm/Hz),

Center frequency Frequency range

< 22 MHz (LF path)

22 MHz (RF path)

Phase Noise (dBc/Hz) measured with 1 GHz CW signal at 0 dBm

100 kHz to

<42MHz

2MHzto<5MHz –145 –148

5 MHz to < 1.0 GHz

1.0 GHz to

<1.5GHz

1.5 GHz to

<2.5GHz

2.5 GHz to

<3.5GHz

3.5 GHz to

<4.5GHz

4.5 GHz to 6.2 GHz

18 ⁰Cto28⁰C

–130 –133

–161 –163

–160 –162

–157 –159

–154 –156

–152 –155

–149 –151

–10 ⁰Cto55⁰C,

typical

Offset: Center frequency, dBc/Hz

1kHz –84 –115 –89 –78 –83

10 kHz –84 –122 –87 –84 –85

100 kHz –88 –126 –93 –92 –95

1MHz –118 –127 –120 –114 –110

Residual spurious response,

typical

Center frequency

9kHzto<1GHz

1to<3GHz

3to6.2GHz

With the following exceptions:

<–80 dBm, Center Frequency 2080-2120

<–80 dBm, Center Frequency 3895 -3945 MHz

<–85 dBm, Center Frequency 4780-4810 MHz

Input related spurious response

(SFDR)

Reference level –50 dBm, RF input terminated with 50

< –100 dBm

< –95 dBm

< –90 dBm

Conditions: 18 °C to 28 °C, auto settings on, reference level -30 dBm, input

amplitude at or below reference level.

1GHz

10 MHz

(typical)

1GHz

(typical)

2.5 GHz

(typical)

6GHz

(typical)

RSA306B Specifications and Performance Verification 5

Page 16

Specifications

Input frequen

Spurious responses due to the following mechanisms: RFx2*LO1, 2RFx2*LO1,

RFx3*LO1, RFx5*LO1, RF to IF feed-through, IF2 Image.

–60 dBc

Spurious responses due to First IF images (RFXLO1):

–60 dBc, < 2700 MHz center frequency

–50 dBc, 270

Exceptions:

IF feedthrough: –45 dBc for 1850 MHz – 2700 MHz center frequency, typical

First IF Image: –55 dBc for 1850 MHz – 1870 MHz center frequency, typical

–35 dBc fo

Second IF I

-50 dBc 4175-4225 MHz

RFx2LO: –50 dBc for 4750 MHz – 4810 MHz center frequency, typical

2RFx2LO: –50 dBc for 3900 MHz – 3940 MHz center frequency, typical

RFx3LO: –45 dBc for 4175 MHz – 4225 MHz center frequency, typical

Spurious responses due to ADC images:

–60 dBc, offset from center frequency > 56 MHz

–50 dBc

Input f

Spurious responses due to the following mechanisms: First IF Image, RFX2LO1,

2RFX2LO1, RFX3LO1, RFX5LO1, IF2 Image.

–60 dB

Exceptions:

cies ≤ 6.2 GHz

0 – 6200 MHz center frequency

–35 dBc for 3700 MHz – 3882 MHz center frequency, typical

r 5350 MHz – 5700 MHz center frequency, typical

mage: -50 dBc 22 - 1850 MHz

,56MHz offset from CF 36 MHz

requencies > 6.2 GHz – 8.0 GHz (typical)

c

First IF Image: –40 dBc for 3800 MHz center frequency, typical

RFx2LO: –25 dBc for 4800 MHz – 5150 MHz center frequency, typical

–40 dBc for 5150 MHz – 5800 MHz center frequency, typical

RFx3LO: –40 dBc for 4150 MHz – 4250 MHz center frequency, typical

6 RSA306B Specifications and Performance Verification

Page 17

Specifications

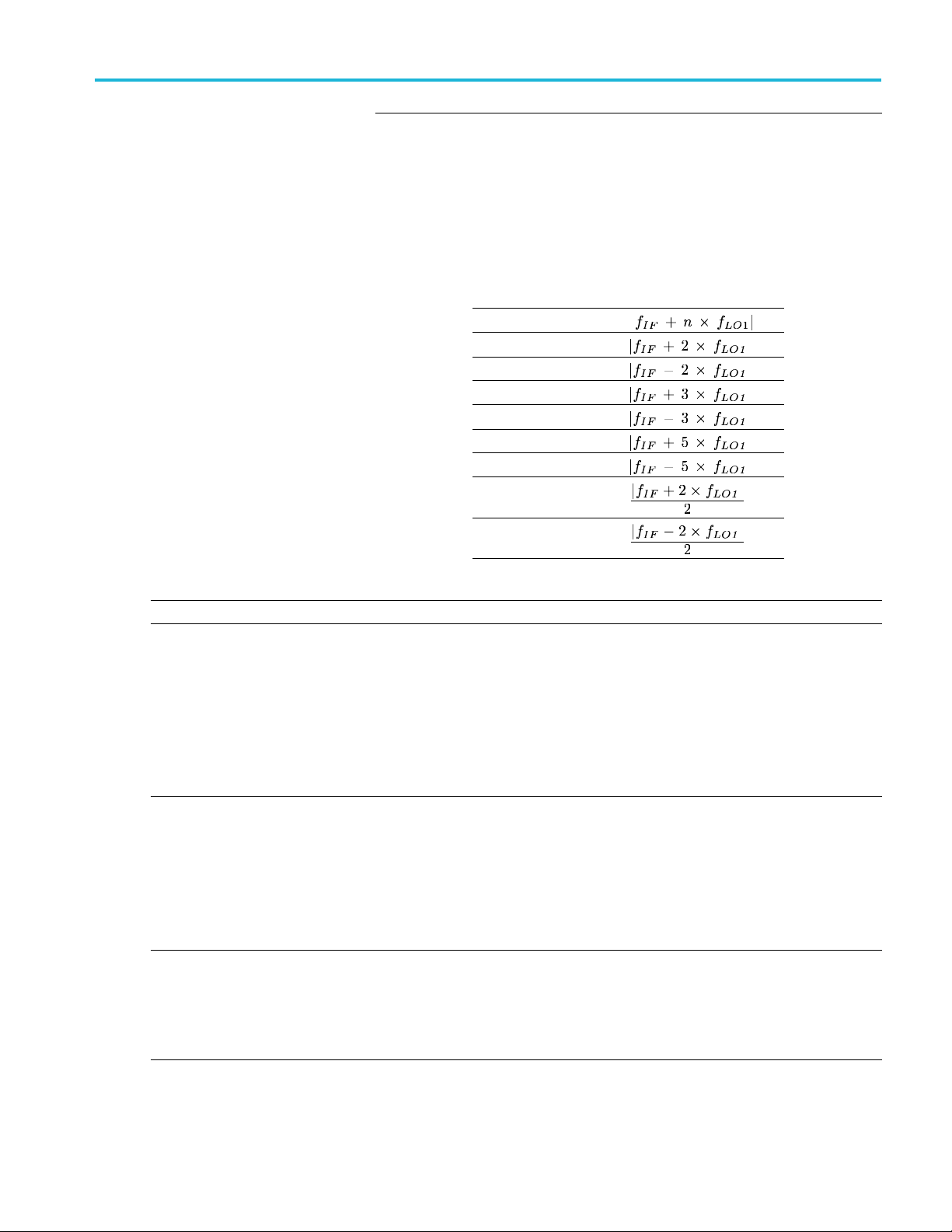

Spurious Resp

spurious signals caused by RF input signals (blockers) mixing with local oscillators

(LO1 or LO2) at a frequency determined by the hardware settings for the IF and

LO1 frequency

For a given center frequency setting, use the Frequency Tuning Table to determine

the corresponding n and the IF and LO1 frequencies. (See Table 1 on page 8.) Use

the formulas

will cause a spur at the center frequency.

Residual FM, typical <10Hz

er IM distortion

3RDord

–63 dBc at center frequency 2130 MHz, reference level = –15 dBm, 18 ⁰Cto28⁰C

–63 dB

55 ⁰C, typical

–63 dBc at center frequency 2130 MHz, reference level = –30 dBm, typical

< –58 d

< –50 dBc, 40 MHz to 6.2 GHz, reference level = –50 dBm, typical

Two CW signals, 1 MHz separation, each input signal level 5 dB below the reference

l setting at the RF input

leve

rder intercept (TOI)

3RDo

dBm at center frequency 2130 MHz, reference level –15 dBm, 18 ⁰Cto28⁰C

+13

+13 dBm at center frequency 2130 MHz, reference level –15 dBm, –10 ⁰Cto

55 ⁰C, typical

dBm at center frequency 2130 MHz, reference level –30 dBm, typical

–2

+14 dBm, 40 MHz to 6.2 GHz, reference level = –10 dBm, typical

–30 dBm, 40 MHz to 6.2 GHz, reference level = –50 dBm, typical

ese are indirectly tested by the 3rd Order IM Distortion test

Th

2NDharmonic distortion, typical

55 dBc, 10 MHz to 300 MHz, reference level = 0 dBm

<–

< –60 dBc, 300 MHz to 3.1 GHz, reference level = 0 dBm

< –50 dBc, 10 MHz to 1850 MHz, and 2330 MHz to 3100 MHz, reference level =

40 dBm

–

< –45 dBc , 1850 MHz to 2330 MHz, reference level = –40 dBm

onse Definitions: For each center frequency setting, any on-screen

.

below to calculate the required input signal (blocker) frequency which

Spur Type

Blocker Fre

quency

(Source Frequency)

|IF1 Image|

|RF+2LO|

|RF-2LO|

|RF+3LO|

|RF-3LO|

|RF+5LO|

|RF-5LO|

|2RF+2LO

|

|2RF-2LO|

RF to IF Feedthrough 1190 MHz or 2440

MHz

p-p

c at center frequency 2130 MHz, reference level = –15 dBm, –10 ⁰Cto

Bc, 40 MHz to 6.2 GHz, reference level = –10 dBm, typical

RSA306B Specifications and Performance Verification 7

Page 18

Specifications

2NDharmonic distortion

intercept (SHI

Local oscillator feedthrough to

input connector, typical

), typical

+55dBm,10MHz

+60 dBm, 300 MHz to 3.1 GHz, reference level = 0 dBm

+10 dBm, 10 MHz to 1850 MHz, and 2330 MHz to 3100 MHz, reference level =

–40 dBm

+5 dBm, 1850 MHz to 2330 MHz, reference level = –40 dBm

< –75 dBm

Reference level = –30 dBm

to 300 MHz, reference level = 0 dBm

Table 1: Frequency Tuning Table

CenPreSelec-

Subband

0 LF 0.009 22 None None

1 1 22 700 2462 3140 2440 1 –1 1 2300

2 2 700 1850 3140 4290 2440 1 –1 1 2300

3 3 1850 2700 3040 3890 1190 1 –1 1 1050

4 4 2700 3100 3890 4290 1190 1 –1 1 1050

5

6

75

8

9

10 6 4960 5100 3770 3910 1190 –1 1 –1 1050

11 6 5100 5695 3910 4505 1190 –1 1 –1 1050

12 6 5695 5700 4505 4510 1190 –1 1 –1 1050

13

14

tor Filter

4 3100 3700 4290 4890 1190 1 –1 1 1050

5

5

5

7

7

ter

Freq.

Min.

(MHz)

3700 4175 4890 5365 1190 1 –1 1 1050

4175 4225 1735 1785 2440 –1 1 –1 2300

4225 4750 5415 5940 1190 1 –1 1 1050

4750 4960 3560 3770 1190 –1 1 –1 1050

570

5900 6220 4710 5030 1190 –1 1 –1 1050

Center

Freq.

Max

(MHz)

0

590

LO1

Min

(MHz)

0

451

LO1

Max

(MHz)

0

471

IF1

(MHz)

DC

0

119

LO1

High

/Low

Side

111None

0

–1 1 –1 105

m

(RF) n (LO)

LO2

(MHz)

0

8 RSA306B Specifications and Performance Verification

Page 19

Swept and Real time

Specifications

RF full band sweep time,typical

mean

DPX bitmap image resolution 201 pixels vertical x 801 pixels horizontal

DPX s pectro

resolution

Audio dem

Types AM, FM

IF bandwidth range Five selections, 8 kHz – 200 kHz

Audio output frequency range

Minimum

POI),typical

gram minimum time

odulation

signal duration (100%

16.5 GHz/sec (RBW = 1 MHz)

16.5 GHz/sec (

13.7 GHz/sec (RBW = 10 kHz)

1.9 GHz/sec (RBW = 1 kHz)

(Measured us

Processor, 8GB RAM, 256GB SSD, Windows®7 Pro.)

(Spectrum display is only measurement on screen.)

1 milliseco

(10,000 spectrums per second)

Due to the non-deterministic execution time of programs running under Microsoft

Windows OS

with other processing tasks

(Audio fil

50Hz–10kHz

Minimum signal

on for 100% POI

durati

27

34

36

35

37

DPX settings: Span = 40 MHz, RBW = 300 kHz (Auto)

10,000 per second (span independent)

Due to the nondeterministic execution time of programs running under Microsoft

indows OS, this specification may not be met when the host PC is heavily loaded

W

with other processing tasks

RBW = 100 kHz)

ing a Panasonic Toughpad FZ-G1, Intel® Core™ i5-5300U 2.3GHz

nd

, this specification may not be met when the host PC is heavily loaded

e output: 16 bits at 32 ksps in .wav format.)

Test controller

sktop (Windows® 10 E nterprise, Intel® Core™

Dell De

i7-4790 CPU, 3.6GHz, 8GB RAM, 256GB SSD)

Dell Desktop (Windows® 7 Enterprise, Intel® Core™

i7-2600 CPU, 3.4GHz, 8GB RAM, 256GB SSD)

Dell Laptop Latitude E6430 (Windows® 10 Enterprise,

l® Core™ i7-3520M CPU, 2.9GHz, 8GB RAM,

Inte

250 GB SSD)

Dell Laptop Precision M4700 (Windows® 8 Enterprise,

Intel® Core™ i7-3520M CPU, 2.9GHz, 8GB RAM,

GB HD)

750

asonic ToughPad SAPL-TP-04 (Windows® 7 Pro,

Pan

Intel® Core™ i5-5300U CPU, 2.3GHz, 8GB RAM,

256GB SSD)

RSA306B Specifications and Performance Verification 9

Page 20

Specifications

Interfaces, input, output ports

RF input

External frequency reference

input

Trigger/syn

Status indi

USB device port USB 3.0 - M icro-B (with thumbscrews)

Power

Power consumption

Physical

Weight

Dimensions

Heigh

Width

Dept

c input

cator

t

h

Type N, female

SMA, female

SMA, female

LED, dual co

LED states:

Steady Red: USB power applied, or resetting

Steady Gre

Flickering Green: Transferring acquired data to host PC

Per USB 3

0.59 kg (1.3 lbs)

30.5 mm (1.2 in)

127 mm (5.0 in)

190.5 mm (7.5 in)

lor red/green

en: Initialized, ready for use

.0 SuperSpeed requirements: 5.0 V, 900 mA, nominal

ulatory

Reg

ety

Saf

gional certifications

Re

Cemissions

EM

MC immunity

E

10 RSA306B Specifications and Performance Verification

1010-1, CAN/CSA-22.2 No.61010-1, EN61010-1, IEC61010-1

UL6

Europe: EN61326

stralia/New Zealand: AS/NZS 2064

Au

EN61000-3-2, EN61000-3-3, EN61326-2-1

N61326–1/2, IEC61000-4-2/3/4/5/6/8/11

E

Page 21

Environmental performance

Tem peratu re

Operating –10 °C to +55 °C (+14 °F to +131 °F)

Nonoperatin

Humidity, op

Altitude

Operating 9144 meters (30,000 feet)

Nonopera

Dynamic

Random vibration:

nonoper

Mechanical shock: operating

ng and transit

Handli

Bench handling, operating

Trans

g

erating

ting

s

ating

it drop, nonoperating

Specifications

–51 °C to +71 °C (–60 °F to +160 °F)

5% to 95 ±5% RH (relative humidity) in the temperature range of +10 °C to 30 °C

(+50°Fto86°F)

5% to 75% ±5%

5% to 45% RH above +40 °C to +55 °C (+86 °F to +131 °F)

<10 °C humidity is uncontrolled; non-condensing

15,240 meters (50,000 feet)

2

0.030 g

Half-s

in each direction of each axis (18 total)

Per MI

on appropriate sides of the equipment

Per MIL-PRF-28800F Class 2 nonoperating: Transit drops onto six faces and four

corners of the equipment, from a height of 30 cm (11.8 in.) for a total of 10 impacts

/Hz, 10 Hz – 500 Hz, 30 minutes per axis, three axes (90 minutes total)

ine mechanical shocks, 30 g peak amplitude, 11 ms duration, three d rops

L-PRF-28800F Class 2 operating: Rotational-edge-drops of appropriate edges

RH from +30 °C to +40 °C (+86 °F to 104 °F)

RSA306B Specifications and Performance Verification 11

Page 22

Performance ver

ification

Performance v

NOTE. The performance verification procedure is not a calibration procedure. The performance verification procedure

only verifies that your instrument meets key specifications. For your instrument to be calibrated, it must be returned to

a Tektronix se

Prerequisi

Thetestsinthissectionmakeupaconfirmation of performance and functionality when the following requirements are met:

The SignalVu-PC application must be version 3.11.0x or greater.

Operate the instrument in an environment that meets the temperature, altitude, and humidity characteristics listed in

the specifications.

The instrument must be completely assembled and covers installed per factory specification.

The instrument must have been operating for a warm-up period of at least for 30 minutes (after being connected to the

PC, starting the SignalVu-PC application, and SignalVu-PC is connected to the RSA306B instrument and continuously

acquiring data).

NOTE. The RSA306B does not fully power on until SignalVu-PC has established communication with the RSA306B

and is acquiring data.

rvice facility.

tes

erification

The instrument must have had its last alignment routine done after at least a 30 minute warm–up period at an ambient

temperature not more than ±2 °C different than the current ambient temperature.

12 RSA306B Specifications and Performance Verification

Page 23

Required equipment

These procedures use external, traceable signal sources to directly check warranted characteristics. The following table lists

the equipment required for this procedure.

Table 2: RSA306B required test equipment

Item Description Qty Model Number Purpose

Performance ver

ification

Desktop or Laptop PC Intel Core i7-4-core with Intel

HD4000 (clock speed 3.6 GHz

or in this proximity),

8.00 GB RAM,

WIN7 64 Bit OS,

Solid State Drive

(SSD) 128 GB with >

300 MBytes/sec sustained

write speed,

USB 3.0

Locking USB3 cable

Signal generator DC – 8 GHz

Signal generator DC – 6 GHz

Power meter

Power sensor

1 meter length, A to Micro

B, with thumbscrews (can be

locked in plac e for units with

mating faceplate)

9 kHz – 18 G Hz (power head

dependent)

9kHz–18GHz

1

1

1

1

1 Keysight E4418B

1 Keysight power head

Dell Optiplex 9020 MT, or

equivalent

L-Com CAVISU3AMICB-1M

174-6796-00 (Tekronix P /N)

Stanford Research Systems

SG386 option 02

Tektronix TSG4106A Second signal generator

E9304A H18

Run SignalVu-PC

Required for the RSA306B

communication and power

Test full frequency range

require to perform

third-order distortion test

Verifies RSA306B input

signal amplitude

Measures RSA306B input

signal amplitude

Power splitter

Power combiner

Attenuator

Termination

Adapter N(male) to

N(male)

Adapter N(male) to

SMA(female)

RSA306B Specifications and Performance Verification 13

DC–18GHz,N

2 –18 GHz, SMA

3 dB, SMA, >8 GHz bandwidth

DC -18 GHz, N-m

DC -18 GHz coaxial adapter

DC -18 GHz adapter

1 Keysight 11667A Amplitude adjustments

and input amplitude setting

in spurious tests

1

2

1 Maury Microwave 2510B6 For DANL tests

1 Pasternack PE91034 or

2-6

(as

needed)

M/A-COM

2089-6208-00

Mini-Circuits Labs

FW-3+

Maury Microwave 8828B

Needed for SG386

generator

Third-order distortion

measurement

For third-order distortion

measurement

Amplitude adjustments

May be needed for signal

generator and filter RF

connections

Page 24

Performance ver

Table 2: RSA306B required test equipment (cont.)

Item Description Qty Model Number Purpose

ification

Band pass filter 2150 MHz, SMA

Low pass filter 5000 MHz cutoff, L250 filter

Tunable filter

Alternative to tunable

filter

Cable, SMA-to-N ST18/SMAm/Nm/36in

Cable, SMA ST18/SMAm/SMAm/36in

Cable, SMA ST18/SMAm/SMAm/8

Cable, BNC-to-SMA BNC(m) to SMA(m) cable -

Torque wrench 12 in-lb - Type N 1

Torque wrench 8 in-lb Torque wrench - 3.5 mm 1

1500 MHz to 3000 MHz, N

connectors

300 MHz lowpass cutoff, L250

filter

1 meter

2

1

1

1

1

2

2

1 Pasternack PE3615-36

Mini-Circuits Labs

ZX75BP-2150+

K&L 5L250-5000/E 15000 –

O/OP

K&L 5BT-1500/3000-5-N/N Spurious test

K&L 5L250-3300/E 10000 O/OP

Huber-Suhner 84004594 Generator output to RF

Huber-Suhner 84002061 TOI and tests requiring

Huber-Suhner 84028563 TOI tests

Maury Microwave 2698C2

Huber-Suhner 74Z-0-0-21 SMA-connector

For third-order distortion

measurement

Spurious test

input

low-pass filters

Generator timebase output

to Ref IN.

(External-timebase to

generator-timebase input

may need a similar cable)

N- connector attachments

attachments

NOTE. Make sure that any adaptor and cable you use is specified to operate at the frequency range of the test you

are performing. Connector frequency ranges:

BNC: DC to 1 GHz typical, up to 3 GHz for certain BNC cable/connectors.

N:DCto18GHztypical

SMA: DC to 18 GHz typical, up to 26.5 GHz for certain SMA cable/connectors.

Preliminary checks

Do these steps before starting the performance verification procedures.

Warm up the instrument

1. Connect the RSA306B USB cable to the host PC. The LED on the RSA306B should initially glow red then turn green

after a few moments.

2. Make sure the SignalVu-PC application is connected to the RSA306B over USB.

14 RSA306B Specifications and Performance Verification

Page 25

3. View hardware status bar in the lower left corner of the SignalVu display. Verify that there are no errors or messages

indicating los

4. Start the application acquiring data and allow the instrument to warm up for at least 30 minutes.

s of o r invalid calibration data. At startup, the application may show the message, “Not Aligned:” this is OK.

Run the alignment process

Align the instrument after the 30 minute warm-up period and before proceeding with the Warranted Characteristics tests:

1. Select Alignments in the Tools menu to open the Alignments dialog box.

2. Select Align Now. The alignment process takes a few seconds.

3. Verify that no alignment failures are reported in the status bar.

Performance verification procedures

Internal reference frequency accuracy

Performance ver

ification

1. Connect a signal generator to the N-connector RF input of the RSA306B.

NOTE. The signal generator accuracy must be better than ±0.05 ppm. If the signal generator accuracy does not meet this

requirement, it must have its frequency reference phase locked to a precision frequency reference.

NOTE. The Stanford Research Systems SG386 signal generator has adequate frequency stability without use of an external

timebase, but only if it has been calibrated/verified within 1 year. If this is not the case, the signal generator must have an

accurate external timebase connected to its timebase input (rear panel, BNC, 10 MHz).

2. Set the signal generator to output a 0 dBm, 1 GHz CW frequency.

3. Reset the RSA 306B to factory defaults: (Presets > Main) (The center frequency will be set to 1 GHz via Preset.)

4. Set the frequency span to 10 kHz.

5. Connect the signal generator output to the RF Input, N-connector input of the RSA306B.

6. Enter the measured marker frequency in the calculations table. (See Table 3.)

7. Calculate the specification based on aging rate. (See Table 4.)

8. Compare the measured value with the specification for Internal Frequency accuracy. Enter the results in the test record.

RSA306B Specifications and Performance Verification 15

Page 26

Performance ver

Table 3: Internal reference frequency instability calculations

Marker frequency Value

Instability measured

[(Marker freq

Instability due to aging

(See Table 4.)

ification

uency – 1x10

9

)/1000] ppm

Instability due to other drift

(18°Cto28°C)

Total specified Instability

(aging plus other drift)

Table 4: In

Time period

0 to 3 months ±1 ppm ±0.5 ppm

3 to 6 months ±2 ppm ±0.8 ppm

6 to 12 months ±3 ppm ±1 ppm

1 year to 2 years ±4 ppm ±2 ppm

stability due to aging

Aging aft

calibration

(same date of

manufacture)

er initial

±3 ppm

Aging after

calibrat

(Calibrated more

than 1 year after

manufacture)

ion

16 RSA306B Specifications and Performance Verification

Page 27

Performance ver

ification

External reference input, functional test

This check is a functional check. It is an important check for customer use, but does not check warranted specification limits.

1. Connect a signal generator RF output to the N-connector Ref input of the RSA306B, as shown. The signal generator

accuracy must be better than ±0.05 ppm. If it does not, it must have its frequency reference phase locked to a precision

frequency reference.

Note: The Stanford Research Systems SG386 signal generator has adequate frequency stability w ithout use of an

external timebase, but only if it has been calibrated/verified within 1 year. If this is not the case, the signal generator must

have an accurate external timebase c onnected to its timebase input (10 MHz).

2. Set the signal generator controls:

a. Frequency = 10 MHz

b. Amplitude =0dBm

3. Set the RSA306B to use the external reference (Setup > Acquire > Frequency Reference).

4. Under the source field, select the External (10 MHz) radio button.

5. Check that the Status Bar shows Ref: Ext. This generally occurs within 5 seconds.

6. Enter pass/fail result in the test record.

RSA306B Specifications and Performance Verification 17

Page 28

Performance ver

Amplitude accuracy at all center frequencies

Amplitude accuracy is tested for four different reference levels which exercises the different RF gain conditions used in

the RSA306B.

1. Connect the signal generator, power splitter, power sensor, power meter, and RSA306B as shown. Connect the power

sensor and RF signal generator directly to the power splitter, which is connected directly to the RSA306B.

ification

2. Reset the RSA306B to factory defaults (Presets > Main).

3. Run the RSA306B alignment procedure (Tools > Alignments > Align Now).

4. Set the RSA306B as follows:

a. Reference Level = +20 dBm

b. Detection = +PEAK (Setup > Settings > Traces > Detection > +PEAK)

c. Filter shape = Flat-Top (Setup > Settings > BW > Filter Shape > Flat-top)

d. Center Frequency: as listed in the amplitude accuracy tabl

Table 8 . )

e. Span:

For CF < 1 MHz, Span = 100 kHz

For 1 MHz CF 30 MHz, Span = 1 MHz

For CF 30 MHz, Span = 10 MHz

d. RBW:

ForCF<1MHz,RBW=1kHz

For 1 MHz CF 30 MHz, RBW = 10 kHz

For CF > 30 MHz, RBW = 100 kHz

es. (See Table 5.) (See Table 6.) (See Table 7.) (See

5. Set the signal generator output amplitude to +12 dBm. The RF amplitude at the power sensor and RSA306B i

= +6 dBm nominal.

6. Set the signal generator frequency to the first frequency in the +20 dBm reference level accuracy table. (See Table 5.)

7. Set the RSA306B center frequency to the same frequency. (See Table 5.)

18 RSA306B Specifications and Performance Verification

nput

Page 29

Performance ver

8. On the RSA306B, peak the marker on the signal at the center frequency; measure and record the amplitude.

9. Measure and record the power meter amplitude.

10. Repeat steps 6 through 8 for all of the +20 dBm reference level frequencies in the table, measuring power meter

amplitude and RS A306B amplitude.

11. Set the signal generator output amplitude to +1 dBm for the 0 dBm reference level tests. RF amplitude at the power

sensor and the RSA306B = –5 dBm nominal.

12. Repeat steps 6 through 8 for all of the +0 dBm reference level frequencies in the table, measuring power meter amplitude

and RSA306B amplitude. Enter the values in the 0 dB m accuracy table. (See Table 6.)

ification

13. Set the signal generator output amplitud

power sensor and the RSA306B = –18 dBm nominal.

14. Repeat steps 6 through 8 for all of the –13 dB m reference level frequencies in the table, measuring power meter

amplitude and RSA306B amplitude. Enter the values in the –13 dBm accuracy table. (See Table 7.)

15. Set the signal generator output amplitude to –29 dBm for the –30 dBm reference level tests. RF amplitude at the

power sensor and the RSA306B = –35 dBm nominal.

16. Repeat steps 6 through 8 for all of the –30 dB m reference level frequencies in the table, measuring power meter

amplitude and RSA306B amplitude. Enter the values in the –30 dBm accuracy table. (See Table 8.)

17. Calculate the amplitude errors for each frequency of each reference level accuracy table. Error = RSA306B measurement

– power meter measurement. Readings are in dBm, error is in dB.

18. Note the largest positive and negative errors in the Error column

19. Enter these values in the Amplitude accuracy results table. (See Table 9.)

20. Compare the +peak and –peak errors against the specifications.

21. Enter pass or fail in the test record.

eto–12 dBm for the –13 dBm reference level tests. RF amplitude at the

in all the reference level measurement tables.

Table 5: Amp litude accuracy, +20 dBm reference level measurements

Center/signal

frequency

9kHz

RSA306B reading,

dBm

Power meter value,

dBm

Error (RSA306B –

Pwr meter), dB

20 kHz

50 kHz

100 kHz

300 kHz

1MHz

3MHz

10 MHz

20 MHz

22 MHz

100 MHz

699 MHz

RSA306B Specifications and Performance Verification 19

Page 30

Performance ver

Table 5: Amplitude accuracy, +20 dBm reference level measurements (cont.)

ification

Center/signal

frequency

701 MHz

1GHz

1.849 GHz

1.851 GHz

2.339 GHz

2.341 GHz

2.419 GHz

2.421 GHz

2.699 GHz

2.701 GHz

3.000 GHz

3.699 GHz

3.701 GHz

4.569 GHz

4.571 GHz

4.629 GHz

RSA306B reading,

dBm

Power meter value,

dBm

Error (RSA306B –

Pwr meter), dB

4.631 GHz

4.749 GHz

4.751 GHz

4.959 GHz

4.961 GHz

5.699 GHz

5.701 GHz

5.804 GHz

5.806 GHz

6.200 GHz

Table 6: Amplitude accuracy, 0 dBm reference level measurements

Center/signal

frequency

9kHz

20 kHz

50 kHz

RSA306B reading,

dBm

Power meter value,

dBm

Error (RSA306B –

Pwr meter), dB

20 RSA306B Specifications and Performance Verification

Page 31

Table 6: Amplitude accuracy, 0 dBm reference level measurements (cont.)

Performance ver

ification

Center/signal

frequency

100 kHz

300 kHz

1MHz

3MHz

10 MHz

20 MHz

22 MHz

100 MHz

699 MHz

701 MHz

1GHz

1.849 GHz

1.851 GHz

2.339 GHz

2.341 GHz

2.419 GHz

RSA306B reading,

dBm

Power meter value,

dBm

Error (RSA306B –

Pwr meter), dB

2.421 GHz

2.699 GHz

2.701 GHz

3.000 GHz

3.699 GHz

3.701 GHz

4.569 GHz

4.571 GHz

4.629 GHz

4.631 GHz

4.749 GHz

4.751 GHz

4.959 GHz

4.961 GHz

5.699 GHz

5.701 GHz

RSA306B Specifications and Performance Verification 21

Page 32

Performance ver

Table 6: Amplitude accuracy, 0 d Bm reference level measurements (cont.)

ification

Center/signal

frequency

5.804 GHz

5.806 GHz

6.200 GHz

RSA306B reading,

dBm

Power meter value,

dBm

Error (RSA306B –

Pwr meter), dB

Table 7: Amplitude accuracy, –13 dBm reference level measurements

Center/signal

frequency

9kHz

20 kHz

50 kHz

100 kHz

300 kHz

1MHz

3MHz

10 MHz

20 MHz

RSA306B reading,

dBm

Power meter value,

dBm

Error (RSA306B –

Pwr meter), dB

22 MHz

100 MHz

699 MHz

701 MHz

1GHz

1.849 GHz

1.851 GHz

2.339 GHz

2.341 GHz

2.419 GHz

2.421 GHz

2.699 GHz

2.701 GHz

3.000 GHz

3.699 GHz

3.701 GHz

4.569 GHz

22 RSA306B Specifications and Performance Verification

Page 33

Table 7: Amplitude accuracy, –13 dBm reference level measurements (cont.)

Performance ver

ification

Center/signal

frequency

4.571 GHz

4.629 GHz

4.631 GHz

4.749 GHz

4.751 GHz

4.959 GHz

4.961 GHz

5.699 GHz

5.701 GHz

5.804 GHz

5.806 GHz

6.200 GHz

RSA306B reading,

dBm

Power meter value,

dBm

Error (RSA306B –

Pwr meter), dB

Table 8: Amplitude accuracy, –30 dBm reference level measurements

Center/signal

frequency

RSA306B reading,

dBm

Power meter value,

dBm

Error (RSA306B –

Pwr meter), dB

9kHz

20 kHz

50 kHz

100 kHz

300 kHz

1MHz

3MHz

10 MHz

20 MHz

22 MHz

100 MHz

699 MHz

701 MHz

1GHz

1.849 GHz

1.851 GHz

2.339 GHz

RSA306B Specifications and Performance Verification 23

Page 34

Performance ver

Table 8: Amplitude accuracy, –30 dBm reference level measurements (cont.)

ification

Center/signal

frequency

2.341 GHz

2.419 GHz

2.421 GHz

2.699 GHz

2.701 GHz

3.000 GHz

3.699 GHz

3.701 GHz

4.569 GHz

4.571 GHz

4.629 GHz

4.631 GHz

4.749 GHz

4.751 GHz

4.959 GHz

4.961 GHz

RSA306B reading,

dBm

Power meter value,

dBm

Error (RSA306B –

Pwr meter), dB

5.699 GHz

5.701 GHz

5.804 GHz

5.806 GHz

6.200 GHz

Table 9: Amplitude accuracy results

Frequency

Reference level

range

9kHzto

2.701 GHz

3GHzto6.2GHz

9kHzto

2.701 GHz

3GHzto6.2GHz

9kHzto

2.701 GHz

3GHzto6.2GHz

Maximum

+error

Maximum

–error Specification

±1.2 dB+20 dBm

±1.65 dB

±1.2 dB0 dBm

±1.65 dB

±1.2 dB-13 dBm

±1.65 dB

24 RSA306B Specifications and Performance Verification

Page 35

Table 9: Amplitude accuracy results (cont.)

Performance ver

ification

Reference level

Frequency

range

9kHzto

2.701 GHz

3GHzto6.2GHz

Maximum

+error

Maximum

–error Specification

±1.2 dB-30 dBm

±1.65 dB

RSA306B Specifications and Performance Verification 25

Page 36

Performance ver

Channel amplitude flatness

The amplitude flatness test verifies amplitude at the two normalized bands and the band most likely to encounter a channel

response problem. The channel flatness is measured for 2 MHz – 42 MHz, 1260 MHz – 1300 MHz, and 2140 MHz

– 2180 MHz.

1. Connect the signal generator, power splitter, power sensor, power meter, and RSA306B as shown in the following figure.

Connect the power splitter outputs directly to the RSA306B RF Input and to the power sensor.

ification

2. Reset the RSA306B to factory defaults (Presets > Main).

3. Run the RSA306B alignment procedure (Tools > Alignments > Align Now).

4. Set the RSA306B as follows:

a. Reference Level = 0dBm.

b. Detection = +PEAK (Setup > Settings > Traces > Detection > +PEAK).

c. Filter shape = Flat-Top (Setup > Settings > BW > Filter Shape > Flat-top).

d. Center Frequency = 22 MHz

e. Span = 40 MHz

f. RBW = Auto (300 kHz)

g. Function = Normal (Setup > Settings > Traces > Function)

5. Set the signal generator frequency to the first frequency in the 2 M Hz – 42 MHz channel flatness table. (See Table 10.)

6. Set the signal generator amplitude for –5 dBm at the power meter and RSA306B.

7. Record the power meter reading in the 2 MHz – 42 MHz channel flatness table. (See Table 10.)

8. On the RSA306B, position the marker on the peak amplitude of the signal; record the amplitude in the channel flatness

table.

9. Repeat steps 5 through 8 to measure and record for all the frequencies in the channel flatness table, 2 MHz through

42 MHz. Do not change the RSA306B center frequency setting.

10. Set the RSA center frequency to 1280 MHz.. Keep other settings the same.

11. Set the signal generator frequency to 1260 MHz.

26 RSA306B Specifications and Performance Verification

Page 37

Performance ver

12. S e t the signal generator amplitude for –5 dBm at the power meter and RSA306B.

13. Repeat steps 5 through 8 to measure and record for all the frequencies in the channel flatness table, 1260 MHz through

1300 MHz. (See

Table 11.) Do not change the RSA306B center frequency setting.

ification

14. Change the RSA

15. Set the signal

16. S et the signa

17. Repeat steps

2180 MHz. (See Table 12.) Do not change the RSA306B center frequency setting. An alternate IF setting is used in

this range. This verifies the alternate setting.

18. Use the recorded values to calculate the amplitude differences for each measured frequency in the three channel

flatness tab

Differenc

The measur

19. Calculate

22 MHz for

1280 MHz f

2160 MHz f

The flatn

Error = (

difference amplitude, each frequency – difference amplitude, center screen frequency)

306B center frequency to 2160 MHz. Keep other settings the same.

generator frequency to 2140 MHz.

l generator amplitude for –5 dBm at the power meter and RSA306B.

5 through 8 to measure and record for all the frequencies in the channel flatness table, 2140 MHz through

les.

e amplitude = (power meter amplitude – RSA306B marker amplitude)

ed amplitudes are dBm. The difference amplitude is dB.

the channel flatness error relative the center screen amplitude. Center screen value:

the 2 – 42 MHz channel

or the 1260 – 1300 MHz channel

or the 2140 – 2180 MHz channel

ess error at each frequency is:

NOTE. All amplitudes are in dB.

At center screen, Error = 0 dB.

Example calculation for 2 MHz frequency, 22 MHz center screen:

22 MHz Center screen difference amplitude = +0.13 dB

2 MHz Frequency difference amplitude = –0.32 dB

Error = (–0.32 dB – (0.13 dB)) = –0.45 dB

RSA306B Specifications and Performance Verification 27

Page 38

Performance ver

Table 10: 22 MHz channel flatness, 2 MHz – 42 MHz

ification

Signal

generator

frequency

2MHz

4MHz

6MHz

8MHz

10 MHz

12 MHz

14 MHz

16 MHz

18 MHz

20 MHz

22 MHz

24 MHz

26 MHz

28 MHz

30 MHz

Power meter

amplitude, dB

RSA306B marker amplitude,dBDifference

amplitude, dB

Channel

flatness error,

m

dB

32 MHz

34 MHz

36 MHz

38 MHz

40 MHz

z

42 MH

Maximum difference amplitude

Minimum difference amplitude

<+1.2dB

.2 dB

>–1

28 RSA306B Specifications and Performance Verification

Page 39

Table 11: 1280 MHz channel flatness, 1260 MHz – 1300 MHz

Performance ver

ification

Signal

generator

frequency

1260 MHz

1262 MHz

1264 MHz

1266 MHz

1268 MHz

1270 MHz

1272 MHz

1274 MHz

1276 MHz

1278 MHz

1280 MHz

1282 MHz

1284 MHz

1286 MHz

1288 MH

RSA306B marPower meter

amplitude, dB

z

ker amplitude,dBDifference

amplitude, dB

Channel

flatness error,

m

dB

1290 MHz

1292 MHz

Hz

1294 M

1296 MHz

1298 MHz

MHz

1300

Maximum difference amplitude

Minimum difference amplitude

<+1dB

dB

>–1

RSA306B Specifications and Performance Verification 29

Page 40

Performance ver

Table 12: 2160 MHz Channel flatness, 2140 MHz – 2180 MHz

ification

Signal

generator

frequency

2140 MHz

2142 MHz

2144 MHz

2146 MHz

2148 MHz

2150 MHz

2152 MHz

2154 MHz

2156 MHz

2158 MHz

2160 MHz

2162 MHz

2164 MHz

2166 MHz

2168 MH

RSA306B marPower meter

amplitude, dB

z

ker amplitude,dBDifference

amplitude, dB

Channel

flatness error,

m

dB

2170 MHz

2172 MHz

Hz

2174 M

2176 MHz

2178 MHz

MHz

2180

Maximum difference amplitude

Minimum difference amplitude

<+1dB

dB

>–1

30 RSA306B Specifications and Performance Verification

Page 41

Performance ver

DANL (Displayed Average Noise Level)

The intent of the DANL test is to measure the average internal noise level of the instrument. The DANL specification does

not cover residual spurs. If the specific measurement frequency results in measuring a residual spur that is visible above

the noise level, the DANL specification applies not to the spur but to the noise level on either side of the spur. Please

refer to the Spurious Response specifications.

ification

1. Connect a 5

2. Reset the R

3. Run the RS

4. Set the RS

a. Referenc

The refe

spurious signals since it is easier to determine the presence of spurious.

b. Set Detection = Avg (Vrms) (Setup > Settings > Traces > Detection > Avg).

c. Set Function = Avg (of logs) (Setup > Settings > Traces > Function)

d. Averaging = 100 (Setup > Settings > Traces > Function: select 100 in field)

e. Filter shape = Flat-Top (Setup > Settings > BW > Filter Shape > Flat-top).

f. Center Frequency = 22 MHz

g. Span = 100 kHz

h. RBW = Auto (100 Hz)

5. Set the marker for POWER measurement:

a. Marker function = Pow er (dBm/Hz) (Markers > Define Markers > Readouts (near bottom of screen) > Power)

0 N termination to the RSA306B RF Input.

SA306B to factory defaults (Presets > Main).

A306B alignment procedure (Tools > Alignments > Align Now).

A306B as follows:

e Level = –50 dBm to –90 dBm.

rence level can be set lower than -50 dBm to display the noise on screen. This helps avoid measuring on

b. Turn on marker (Markers > Define Markers > Add)

6. Set the RSA306B to each of the center frequencies listed in the DANL frequencies of interest table. (See Table 13 on

page 32.) After averaging is completed, move the marker near the center screen to the baseline noise on either side of

center screen spurious. Make sure the marker is not on a coherent spurious signal. Enter the marker noise level

the

amplitude in the DANL frequencies of interest table and the test record and compare with the specification.

RSA306B Specifications and Performance Verification 31

Page 42

Performance ver

Table 13: DANL frequencies of interest

ification

RSA306B center

frequency

100 kHz

1MHz

10 MHz

20 MHz

22 MHz

100 MHz

500 MHz

1GHz –160 dB

1.5 GHz –157 dBm/Hz

2.0 GHz –157 dBm/Hz

z

2.5 GH

3.0 GHz –154 dBm/Hz

3.5 GHz –152 dBm/Hz

GHz

4.0

4.5 GHz –149 dBm/Hz

5.0 GHz –149 dBm/Hz

Marker noise

level Specification

–130 dBm/Hz

–130 dBm/Hz

–130 dBm/Hz

–130 dBm/Hz

–161 dBm/

–161 dBm/Hz

–161 dBm/Hz

m/Hz

dBm/Hz

–154

52 dBm/Hz

–1

Hz

.5 GHz

5

6.0 GHz –149 dBm/Hz

6.2 GHz –149 dBm/Hz

–149 dBm/Hz

32 RSA306B Specifications and Performance Verification

Page 43

Performance ver

ification

Phase noise

The intent of the Phase Noise test is to measure the phase noise level of the instrument. The phase noise specification does

not cover residual spurs. If the specific measurement frequency results in measuring a residual spur that is visible above the

noise level, the phase noise specification applies not to the spur but to the noise level on either side of the spur. Please

refer to the Spurious Response specifications. Also, refer to the Spurious Response section of this procedure to determine

whether or not a residual spur is within the specification.

Connect the signal generator and RSA306B as shown in the following figure.

1. Reset the RSA306B to factory defaults (Presets > Main).

2. Run the RSA306B alignment procedure (Tools > Alignments > Align Now). Note: the Center frequency should be

1GHz.

3. Set the signal generator CW frequency = 1GHz.

4. Set the signal generator CW amplitude = 0dBmat the RS306 input.

5. Select External Reference (Setup > Acquire > Frequency Reference > External)

6. Set trace detection = +PEAK (Setup > Settings > Traces > Detection)

7. Measure the CW amplitude for the following settings:

a. Trace Function = Avg (Vrms), 10 averages (Setup > Settings > Traces > Function: Avg (Vrms

b. Span = 100 kHz

c. RBW = 1kHz

d. Move MR marker to highest amplitude signal after 10 averages, write the marker value as the CW amplitude (for the

1kHzfilter) in the measurement table. (See Table 14.)

8. Measure the CW amplitude for the following settings:

a. Span = 10 kHz

b. RBW = 100 Hz

c. Move MR marker to highest amplitude signal after 10 averages, write marker value as the CW amplitude for the

100 Hz filter and 10 Hz filter in the measurement table. (See Table 14.)

), count = 10)

9. Set Trace detection = Avg (Vrms).

10. Set Marker function = Power (dBm/Hz) (Markers > De fi ne Markers > Readouts (near bottom of window) > Power).

11. Turn on marker (Markers > Define Markers > Add)

RSA306B Specifications and Performance Verification 33

Page 44

Performance ver

12. Measure noise for 1 MHz offset:

a. CF = 1000.95 MHz

b. Span = 1MHz

c. RBW = 1kHz

d. Avg count = 100

e. Marker frequency = 1000.997 MHz (note, this avoids the 1 MHz offset spur)

f. After averaging is completed, enter the raw noise amplit ude in dBm/Hz in the measurement table. (See Table 14.)

g. Calculate and record Phase noise, the difference of CW amplitude in 1 kHz filter and noise measured with the

ification

POWER marke

r. (See Table 14.)

13. Measure noi

a. CF = 1000.0

b. Span = 100 k

c. RBW = 1kHz

d. Avg count

e. Marker fr

f. After ave

and test record.

g. Calculate and record Phase noise, the difference of CW amplitude in 1 kHz filter and noise measured with the

POWER marker. (See Table 14.)

14. Measure noise f or 10 kHz offset:

a. CF = 1000.0095 MHz

b. Span = 10 kHz

c. RBW = 100 Hz

d. Avg count =100

e. Marker frequency = 1000.010 MHz

se for 100 kHz offset:

95 MHz

Hz

= 100

equency = 1000.100 MHz

raging is completed, enter the raw noise amplitude in dBm/Hz in the measurement table (See Table 14.)

f. After averaging is completed, enter the raw noise amplit ude in dBm/Hz in the measurement table. (See Table 14.)

g. Calculate and record Phase noise, the difference of CW amplitude in 100 Hz filter and noise measured with the

R marker.(See Table 14.)

POWE

34 RSA306B Specifications and Performance Verification

Page 45

Performance ver

15. Measure noise for 1 kHz offset:

a. CF = 1000.000950 Hz

b. Span = 1kHz

c. RBW =10 Hz

d. Avg count = 20 (note: If 20 averages does not result in a stable amplitude, more averages can be used.)

e. Marker frequency = 1000.001 MHz

f. After averaging is completed, enter the raw noise amplitude in dBm/Hz in the measurement table. (See Table 14

on page 35.)

ification

g. Calculate a

power marker. (See Table 14.)

16. Record the results in the Test record.

Table 14: P

Phase noise offset

frequenc

1kHz 10Hz

10 kHz 100 Hz

100 kHz 1 kHz

1MHz 1kHz

y

nd record Phase noise, the difference of CW amplitude in 100 Hz filter and noise measured with the

hase noise at 1 GHz center frequency

RBW

CW amplitude,

dBm

Raw noise,

dBm/Hz

Phase noise

(raw noise – CW

amplitud

e), dBc/Hz

Specifica

< –84 dBc/Hz

< –84 dBc/Hz

< –88 dBc

< –118 dBc/Hz

tion

/Hz

RSA306B Specifications and Performance Verification 35

Page 46

Performance ver

Third-order intermodulation distortion

Set up the RF signal generators, band-pass filters, signal combiner, and RSA306B as shown.

ification

1. Reset the RSA306B to factory defaults (Presets > Main).

2. Run the RSA306B alignment procedure (Tools > Alignments > Align Now).

3. Set the RSA306B as follows:

a. Reference Level = –15 dBm

b. Span = 100 kHz

c. RBW = 1kHz

d. Detection mode = +PEAK (Setup > Settings > Traces > Detection > +PEAK)

e. Function = Avg (Vrms) (Setup > Settings > Traces > Function)

f. Averaging = 10 (Setup > S ettings > Traces > Function: set count = 10)

g. Select External Reference (Setup > Acquire > F requency Reference > External)

4. Set one RF signal generator frequency to 2.1295 GHz. Set the second RF signal generator frequency to 2.1305 G Hz .

5. Set each of the RF signal generators to provide a power level of –20 dBm each at the RSA306B. The initial generator

amplitude setting is should be -13 dBm, and the amplitude is fine-tuned as follows:

a. Set the RSA306B center frequency to 2.1295 GHz. Move the marker to the largest amplitude. Adjust the first

generator output level for a marker reading of –20.0 dBm (±0.1 dB) (after averaging).

b. Set the RSA306B center frequency to 2.1305 GHz. Move the marker to the largest amplitude. Adjust the second

generator output level for a marker reading of –

20.0 dBm (± 0.1 dB) (after averaging).

6. Set the RSA306B center frequency to 2.1285 GHz. After averaging has completed, position the marker on the highest

amplitude trace point and read the marker amplitude. Record the IMD #1 amplitude. (See Table 15 on page 37.)

7. Set the RSA306B center frequency to 2.1315 GHz. After averaging has completed, position the marker on the largest

trace point and read the marker amplitude. Record the IMD #2 amplitude.

36 RSA306B Specifications and Performance Verification

Page 47

8. Calculate and record IMD (dBc):

(maximum of IMD #1 or IMD #2) +20 dBm = IMD (dBc)

9. Record the result in the Test record.

Table 15: Third order intermodulation distortion measurements

Performance ver

ification

Item Measurement Specificatio

Carrier #1 amplitude

Carrier #2 amplitude

IMD #1 ampl

IMD #2 amplitude

IMD

(Max IMD – (–20 dBm))

itude

–20 dBm

–20 dBm

< –83 dBm typ.

< –83 dBm typ.

< –63 dBc

n

RSA306B Specifications and Performance Verification 37

Page 48

Performance ver

Input-related spurious response: ADC

Requirements:

An RF signal generator capable of at least 8 GHz (example: Stanford Research Systems SG386 Option 02)

ification

1. Connect the signal generator, power splitter, power sensor, power meter, and RSA306B as shown. Connect the power

sensor and RF signal generator directly to the power splitter, which is connected directly to the

2. Reset the RSA306B to factory defaults (Presets > Main).

3. Run the RSA306B alignment procedure (Tools > Alignments > Align Now).

4. Set the RSA306B as follows:

a. Reference Level = –30 dBm

b. Span = 40 MHz

c. RBW = 1kHz

d. Detection mode = +PEAK (Setup > Settings > Traces > Detection > +PEAK)

e. Function = Avg (Vrms) (Setup > Settings > Traces > Function)

f. Averaging = 10 (Setup > S ettings > Traces > Function: set count = 10)

g. Select External Reference (Setup > Acquire > F requency Reference > External)

RSA306B.

LF ADC image.

5. Set the signal generator frequency to 21 MHz.

6. Set the signal generator output level for –30 dBm on the power meter. This amplitude is also at the RSA306B input (the

signal generator setting will be near –24 dBm).

7. Set the RSA306B center frequency to 21 MHz (40 MHz span).

8. Position the marker on the signal at 21 MHz.

9. Record the value in the ADC measurements table. (See Table 16 on page 40.) The amplitude will be near –30 dBm, but

may have some measurement error.

38 RSA306B Specifications and Performance Verification

Page 49

10. S et the signal generator frequency to 72 MHz.

Performance ver

ification

NOTE. Do not ch

11. Set the signal generator amplitude for –30 dBm on the power meter. This amplitude is also at the RSA306B input. Note:

In this case, the signal generator setting will be near –24 dBm.

12. S et the RSA306B marker on the image spur at 40 MHz, right edge of the span. Note its amplitude in the table.

13. Calculate and record the image amplitude in dBc:

Image (dBc) = Image amplitude at 40 MHz – CW amplitude at 21 MHz

RF ADC imag

14. Set the signal generator frequency to 140 MHz.

15. S e t the signal generator amplitude for –30 dBm at the power meter. This amplitude is also at the RSA306B input. The

signal generator setting will be near -24 dBm.

16. S e t the RSA306B Center Frequency to 140 MHz.

17. P eak the marker on the CW signal at 140 MHz. Record the value in the ADC measurements table. (See Table 16

on page 40.)

18. Set the signal generator frequency to 103.8 MHz.

NOTE. Do not change the center frequency of the RSA306B.

ange the center frequency of the RSA306B.

e.

19. S e t the signal generator amplitude for –30 dBm on the power meter. This amplitude is also at the RSA306B input.

20. S et the RSA306B marker on the image spur seen at 120.2 MHz, at left edge of the s pan. Record the amplitude in the

ADC measurements table.

21. Set the signal generator frequency to 176.2 MHz.

NOTE. Do not change the center frequency of the RSA306B.

22. Set the signal generator amplitude to –30 dBm on the power meter. This amplitude is also at the RSA306B input.

23. S et the RS A306B marker on the image spur seen at 159.8 MHz, at right edge of the span. Record the amplitude in the

ADC measurements table. Mark which image amplitude is larger: 159.8 MHz, or 120.2 MHz.

24. Calculate and record the largest image amplitude in dBc:

Image (dBc) = Largest Image amplitude at (120.2 MHz or 159.8 MHz) - CW amplitude at 140 MHz

25. R ecord results in the Test record.

RSA306B Specifications and Performance Verification 39

Page 50

Performance ver

Table 16: ADC images (LF, RF) measurements

ADC images (LF, RF) Measurement Specification

ification

LF CW amplitud

LF Image amplitude 40 MHz CF

LF ADC Image, dBc

RF CW amplit

RF Image amplitude 159.8 MHz

RF Image amplitude 120.2 MHz

RF ADC Image, dBc

(largest RF image -140 MHz CW)

e21MHz

ude 140 MHz

< –50 dBc

< –50 dBc

40 RSA306B Specifications and Performance Verification

Page 51

Input-related spurious response: second converter images

Performance ver

ification

NOTE. You d o no

response tests in sequence.

1. Connect the signal generator, power splitter, power sensor, power meter, and RSA306B as shown. Connect the power

sensor and RF si

2. Reset the RSA306B to factory defaults (Presets > Main).

t need to do the first three steps (setup, reset, and alignment) when you perform the input-related spurious

gnal generator directly to the power splitter, which is connected directly to the RSA306B.

3. Run the RSA306B alignment procedure (Tools > Alignments > Align Now).

4. Set the RSA306B as follows:

a. Center frequency = 1GHz

b. Reference Level = –30 dBm

c. Span = 1MHz

d. RBW = 1kHz

e. Detection mode = +PEAK (Setup > Settings > Traces > Detection > +PEAK)

f. Function = Avg (Vrms) (Setup > Settings > Traces > Function)

g. Averaging = 10 (Setup > Settings > Traces > Function: count = 10)

h. Select External Reference (Setup > Acquire > Frequency Reference > External)

5. Set the signal generator frequency to 1.0 GHz.