Page 1

User Manual

RFA300A

Measurement Set 8VSB

071-0697-01

www.tektronix.com

Page 2

Copyright © Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications a nd pric e change privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Page 3

WARRANTY

Tektronix warrants that the products that it manufactures and sells will be free from defects in materials and

workmanship for a period of one (1) year from the date of shipment. If a product proves defec tive during this

warranty period, Tektronix, at its option, either will re pair the defective product without charge for parts and labor,

or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suita ble arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by Tektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the Tektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any othe r charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than Tektronix re presentatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or i ntegration increases the time

or difficul ty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS W ARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR

THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

Getting Started

General Safety Summary vii.........................................

Preface ix........................................................

Related Documentation ix...........................................

Contacting Tektronix x.............................................

Getting Started 1--1............................................

Product Description 1--1..............................................

Accessories 1--4.....................................................

Installation 1--5...............................................

Check the Shipping List 1--5...........................................

Operating Requirements 1--6...........................................

Hardware Installation 1--6.............................................

Creating a Startup Disk 1--13...........................................

RF Connections 1--14.................................................

Interface Connections 1--16.............................................

Keyboard and Mouse Connections 1--16...................................

Powering On and Off 1--17.............................................

Selecting RF Input Channel and Channel Freque ncy 1--18....................

Incoming Inspection 1--20..............................................

Operating Basics

Reference

Operating Basics 2--1..........................................

Front Panel 2--1.....................................................

Home Window 2--4..................................................

Making a Measurement 2--6...........................................

Online Help 2--9.....................................................

Backing Up Files 2--10................................................

RFA300A Reference 3--1........................................

Out of Channel Emissions 3--1.........................................

S/N, EVM, and Pilot Amplitude Error 3--3................................

Phase Noise 3--4.....................................................

Frequency Response and Group Delay 3--6...............................

Amplitude and Phase Errors 3--8........................................

Peak-to-Average and Channel Spectrum 3--10..............................

Signal Monitor 3--12..................................................

8VSB Overview 3--14.................................................

Closed-Loop Transmitter Control 3--18...................................

RFA300A Measurement Set 8VSB

i

Page 6

Table of Contents

Appendices

Appendix A: Specifications A--1..................................

Specification Tables A--1..............................................

Performance Conditions A--1...........................................

RFA300A Measurement Set Specifications A--2............................

Measurement Specifications A--4........................................

Platform Characteristics A--9...........................................

Power Characteristics A-- 13.............................................

Environmental Characteristics A--14......................................

Electromagnetic Compatibility A--16.....................................

Mechanical (Physical) Characteristics A--18................................

Appendix B: User Service B--1...................................

General Care B--1....................................................

Preventive Maintenance B --1...........................................

In Case of Problems B--3..............................................

Repackaging for Shipment B--5.........................................

Appendix C: System Recovery C--1...............................

Overview C--1.......................................................

Restore the BIOS Settings C--3.........................................

Restore the Contents of the Partitions C--4................................

Install and Configure Individual Components C--6..........................

Appendix D: Mask File Formatting D--1...........................

Glossary

Index

ii

RFA300A Measurement Set 8VSB

Page 7

List of Figures

Table of Contents

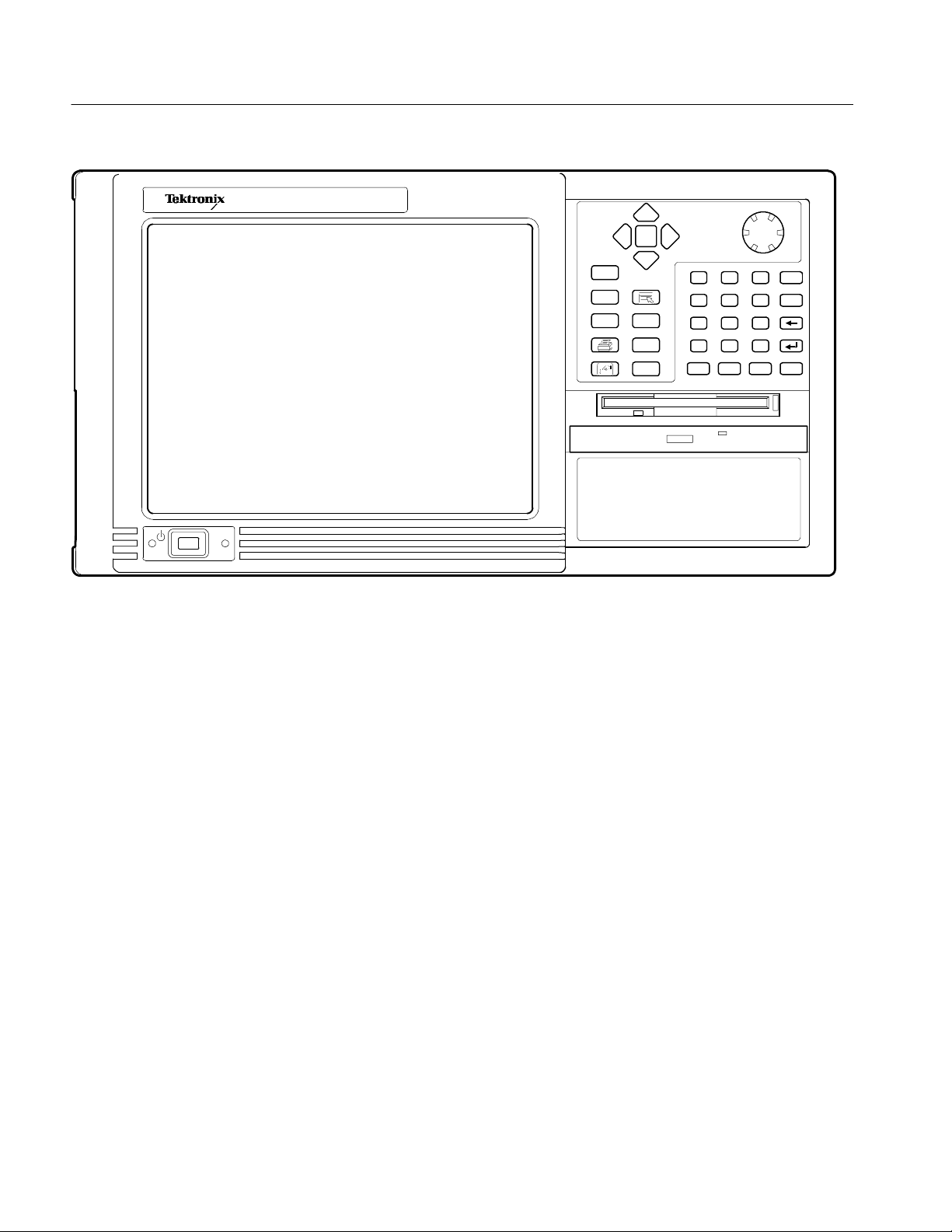

Figure 1--1: RFA300A 8VSB Measurement Set front panel 1--2.......

Figure 1--2: Home window 1--3..................................

Figure 1--3: Attaching the extension brackets to the

stationary tracks 1 --8.......................................

Figure 1--4: Mounting hole selection on the front rails of the

equipment rack 1--8........................................

Figure 1--5: Attaching the extension bracket to the rear rail of the

equipment rack 1--9........................................

Figure 1--6: Mounting the stationary section to the front rail of the

equipment rack 1--10........................................

Figure 1--7: Stationary bracket, extension bracket, and

attaching screws 1--10........................................

Figure 1--8: Installing the instrument into the equipment rack 1--11....

Figure 1--9: Transmitter connection 1--14...........................

Figure 1--10: Rear view 1--15.....................................

Figure 1--11: Keyboard and mouse connections 1--16.................

Figure 1--12: On/Standby switch 1--17.............................

Figure 1--13: System setup 1-- 19..................................

Figure 2--1: Front panel 2--1.....................................

Figure 2--2: Home window 2--4..................................

Figure 2--3: Toolbar 2--5........................................

Figure 2--4: Help menu 2--9.....................................

Figure 3--1: Out of Channel Emissions measurement window 3--2.....

Figure 3--2: Out of Channel Emissions setup 3--2...................

Figure 3--3: S/N, EVM, and Pilot Amplitude measurement window 3--3

Figure 3--4: Phase Noise Measurement window 3--5.................

Figure 3--5: Phase Noise setup 3--5...............................

Figure 3--6: Frequency Response and Group Delay measurement

window 3--7...............................................

Figure 3--7: Frequency Response and Group Delay setup 3--7.........

Figure 3--8: Amplitude and Phase Errors measurement window 3--9...

Figure 3--9: Amplitude Error and Phase Error setup 3--9............

Figure 3--10: Peak-to-Average and Channel Spectrum measurement

window 3--10...............................................

RFA300A Measurement Set 8VSB

iii

Page 8

Table of Contents

Figure 3--11: Peak-to-Average Setup 3--11..........................

Figure 3--12: Signal Monitor measurement window 3--12.............

Figure 3--13: Signal Monitor Setup 3--13...........................

Figure 3--14: 8VSB exciter block diagram 3--14......................

Figure 3--15: Data interleaving 3--15...............................

Figure 3--16: Data segment sync 3--16..............................

Figure 3--17: Frame synchronizing segment 3--17....................

Figure A--1: IF filter characteristics A--3...........................

Figure A--2: 8VSB transmitter emissions mask A--8.................

Figure B--1: Repackaging the instrument (new packagin g) B--6.......

Figure B--2: Repackaging the instrument (old p ackaging) B--8........

Figure B--3: Placement of bottom spacer pad in inner shipping box B--9

iv

RFA300A Measurement Set 8VSB

Page 9

List of Tables

Table of Contents

T able 1--1: Standard accessories 1--4.............................

Table 1--2: Optional accessories 1--4..............................

Table 1--3: Operating requirements 1--6..........................

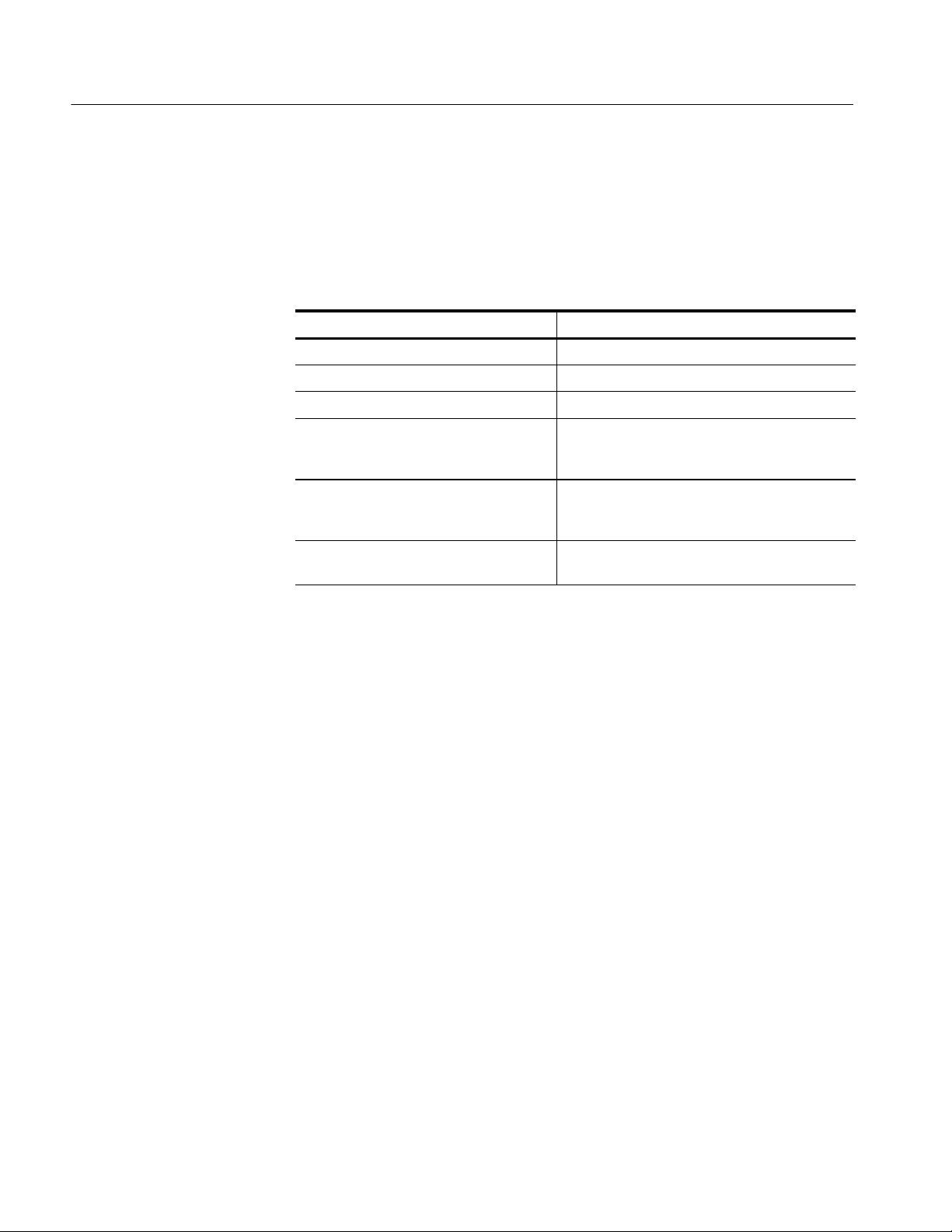

Table 2--1: Front panel-key controls 2--2..........................

Table 2--2: Control key combination functions 2--3.................

Table 2--3: Toolbar functions 2--5................................

Table A--1: Input specifications A--2..............................

T able A--2: Measurement specifications A--4.......................

T able A--3: System components A--9..............................

T able A--4: Front panel interface characteristics A--10................

Table A--5: Rear panel interface characteristics A--11................

T able A--6: AC power source characteristics A--13...................

T able A--7: Environmental characteristics A--14.....................

Table A--8: Dynamics A--15......................................

Table A--9: Transportation A--15..................................

Table A--10: Certifications and compliances A--16...................

T able A--11: Mechanical characteristics A--18.......................

Table B--1: Troubleshooting B--4.................................

Table D--1: ResultID Values for Mask Tests D--2....................

RFA300A Measurement Set 8VSB

v

Page 10

Table of Contents

vi

RFA300A Measurement Set 8VSB

Page 11

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

RFA300A Measurement Set 8VSB

vii

Page 12

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

Protective Ground

(Earth) Terminal

viii

RFA300A Measurement Set 8VSB

Page 13

Preface

This manual contains operating information for the RFA300A Measurement Set

8VSB. The manual consists of the following sections:

H Chapter 1: Getting Started. Provides a product description, installation

procedures, connection information, and information on getting the

instrument ready for use.

H Chapter 2: Operating Basics. Provides basic information about using the

instrument.

H Chapter 3: Reference. Contains an overview of each measurement window

and of the 8VSB standard.

H Appendix A: Specifications. Lists the environmental, physical, and electrical

properties of the instrument.

H Appendix B: User Service. Provides user service information including

general care, preventive maintenance, troubleshooting, and repackaging.

H Appendix C: Software Installation. Describes how to format a hard drive and

reinstall the operating system software and associated hardware drivers.

Related Documentation

H Appendix D: Mask File Formatting. Describes how to format a mask file

using a text editor.

In addition to this user manual, the following documentation is available for your

measurement set.

H The online help provides information about using the measurement set. To

view online help, select Help Topics from the Help menu.

H The optional RFA300A Measurement Set 8VSB Service Manual provides

board-level service information.

RFA300A Measurement Set 8VSB

ix

Page 14

Preface

Contacting Tektronix

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Dri ve

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: techsupport@tektronix.com

1-800-833-9200, select option 3*

6:00 a.m. -- 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

x

RFA300A Measurement Set 8VSB

Page 15

Getting Started

Product Description

This chapter provides basic information about using and installing the RFA300A

Measurement Set 8VSB. There is information about the physical instrument and

introductory material on how to operate it. Once you have a basic understanding,

proceed to the next chapter, Operating Basics, to form a conceptual model of

how the measurement set works.

The measurement set provides information on 8VSB digital television signals in

conformance with the ATSC Digital Television Standard. Signals are acquired at

the transmitter and the measurements consist of the following:

H Complex Modulation Error Ratio

H Signal to Noise Ratio

H Error Vector Magnitude

H Pilot Amplitude Error

H Out-of-Channel Emissions

H Frequency Response Error

H Group Delay

H Amplitude Error

H Phase Error

H Phase Noise Error

H Peak to Average Ratio

H Channel Spectrum (display of the selected channel, not a measurement)

The instrument’s measurements can run continuously, thereby monitoring

transmitter performance on a constant basis. Operation of the instrument is

controlled from the front panel keypad and the touch screen or from an attached

keyboard and mouse. Figure 1--1 shows the front panel of the measurement set.

RFA300A Measurement Set 8VSB

1- 1

Page 16

Getting Started

Figure 1- 1: RFA300A 8VSB Measurement Set front panel

The measurement set uses the Microsoft Windows NT operating system. The

Home window is the point-of-entry into the program. Access each measurement

from the Home window by clicking on the appropriate icon as shown in

Figure 1--2 on page 1--3.

1- 2

RFA300A Measurement Set 8VSB

Page 17

RFA300A --Home

Figure 1- 2: Home window

Getting Started

Refer to the next chapters Operating Basics and Reference for an overview on

operating the measurement set. For detail information, refer to the online help.

RFA300A Measurement Set 8VSB

1- 3

Page 18

Getting Started

Accessories

Table 1--1 and Table 1--2 list the standard and optional accessories.

Table 1- 1: Standard accessories

Description Quantity Part number

RFA300A Measurement Set 8VSB User Manual 1 071-0697-XX

RFA300A Measurement Set 8VSB Application Software on

CD-ROM

Windows NT Software and manual on CD-ROM 1 119-5514-XX

WINNT keyboard (US) 1 119-6216-XX

Tektronix three-button mouse 1 119-4330-XX

Standard IEC power cord, 125 V 1 161-0104-00

Front protective cover 1 200-4408-XX

10 dB Attenuator 1 119-6328-00

Rackmount slides hardware kit 1 -- -- -- -- -- -- -- -- --

1 063-3410-XX

Table 1- 2: Optional accessories

Description Quantity Part number

Accessory pouch 1 016-1441-XX

Power cord options

Opt. A1 Universal Euro 230 V, 50 Hz 1 161-0104-06

Opt. A4 North America 240 V, 60 Hz 1 161-0104-08

1- 4

Portable cabinet kit w/ instructions 1 016-1929-XX

Option D1, Calibration certificate 1 -- -- -- -- -- -- -- -- --

RFA300A Measurement Set 8VSB Service Manual

with

Performance Procedure and Adjustment Procedure software disk

1

1

071-0698-XX

063-3411-XX

RFA300A Measurement Set 8VSB

Page 19

Installation

Check the Shipping List

Read this section before attempting any installation procedures. This section

describes site considerations, power requirements, and ground connections for

your instrument.

Verify that you have received all of the parts of your measurement set. Use the

shipping lists that came with your instrument to compare against the actual

contents of your order. You should also do the following:

H Verify that you have the correct power cord for your geographical area.

H Verify that you have the CD that contains a backup copy of the installed

software. Store the CD in a safe location where you can easily retrieve the

software for maintenance purposes.

H Verify that you have a boot disk in case you reformat the hard drive or

damage operating system files or drivers.

NOTE. Keep the software packaging available. You will need it to enter the

Windows NT software registration number when you first power on the analyzer.

(See step 3 under Powering On and Off on page 1--18.)

H Verify that you have all the other standard and optional accessories that you

ordered.

RFA300A Measurement Set 8VSB

1- 5

Page 20

Installation

Operating Requirements

Table 1--3 lists the operating requirements. Refer to Appendix A: Specifications

for a complete specification list.

Table 1- 3: Operating requirem ents

Requirement Specification

Source voltage 90--250 VAC

Steady State input current 6A

Maximum power consumption 540W

Temperature +5 °Cto+45°C(32°Fto113°F), 30 °C/hr max

Humidity 20% to 80% relative humidity, non-condensing.

maximum, 1.9 A typical

RMS

gradient, non-condensing (derated 1 °C per

1,000 ft. above 5,000 ft. altitude)

Max wet bulb temperature: +31 °C (derates

relative humidity to ~50% @ 50 °C).

,47--63Hz

RMS

Hardware Installation

Altitude To 10,000 ft. (3,040 m), (derated 1 °C per

1,000 ft. above 5,000 ft. altitude).

Before you can operate the product, you must connect the provided power cord.

Refer to Figure 1--10 and connect the power cord to the instrument. Refer to

Table 1--3 for the supply voltage rating and connect the other end of the power

cord to the proper source. Do not connect to any power sources other than those

for which the instrument is rated.

This section deals with hardware installation. To reinstall software, refer to

Appendix C: System Recovery.

The factory installed cabinet is designed to operate in an equipment rack (see

Rackmount Installation on page 1--7). The optional portable cabinet allows you

to operate the instrument on a bench or cart (see Portable Installation on

page 1--12). For proper cooling, at least two inches (5.1 cm) of clearance is

recommended on the rear and sides of the instrument cabinet.

The measurement set is limited to installations where a single, high-amplitude,

8VSB RF signal is available for direct input to the measurement set. Refer to RF

Connections on page 1--14.

1- 6

RFA300A Measurement Set 8VSB

Page 21

Installation

Rackmount Installation

If your instrument has the rackmount cabinet, there is rackmounting hardware on

each side of the cabinet.

CAUTION. For proper cooling in an equipment rack installation, the air

temperature at all air intake vents (inside of the rack) must not exceed 50

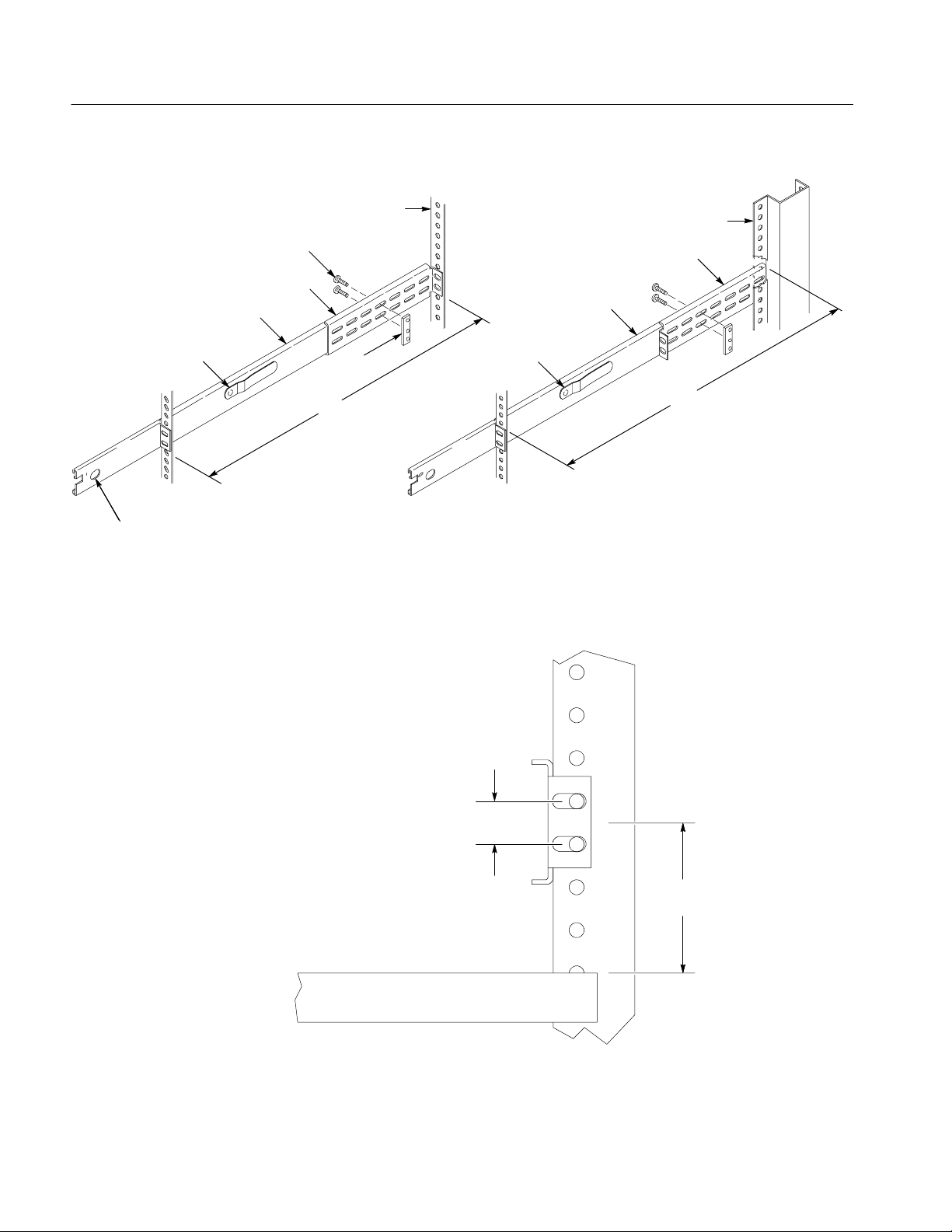

Mounting the Stationary Tracks in the Equipment Rack. The slider kit consists of

left and right stationary tracks that must be installed in the equipment rack. Extra

hardware is provided with the slider assemblies. Since the hardware is intended

to make the sliders compatible with a variety of racks and installation methods,

not all of the hardware will be used for any installation procedure.

1. Attach the extension bracket to the rear of the stationary track.

a. Measure the distance between the front and rear rails of the equipment

rack using method A or method B. Refer to Figure 1--3.

H Method A. If the extension bracket is to be mounted against the front

edge of the rear rail in the equipment rack, measure from the front

edge of the rear rail to the front edge of the front rail.

H Method B. If the extension bracket is to be mounted against the

inside surface of the rear rail in the equipment rack, measure from

the front corner of the rear rail to the front edge of the front rail.

°C.

b. Attach the extension bracket to the rear of the stationary track so that the

length of the combined assembly is approximately that of the measurement taken in step a. above. Use the screws and bar nuts provided with

the chassis tracks. Leave the screws loose.

2. Select the appropriate mounting holes in the front rails of the equipment

rack, observing the clearance measurements shown in Figure 1--4. The front

panel of the rack adapter is designed to fit in an 11-inch high opening.

RFA300A Measurement Set 8VSB

1- 7

Page 22

Installation

Method A Method B

Rear rail

10-32 PNH screw

Extension bracket

Stationary track

Bar

Nut

Use this measurement

Stop latch

hole

Automatic latchAutomatic latch

NOTE: Right-hand and left-hand stationary sections are designated by the

RH and the LH marked on the rails. Stop latch holes should be towards

the bottom when slides are in place. (The right hand rail is shown above.)

Figure 1- 3: Attaching the extension brackets to the stationary tracks

Rear rail

Extension bracket

Stationary track

Use this measurement

1- 8

0.500 in.

1.75 in.

Adjacent equipment

Figure 1- 4: Mounting hole selection on the front rails of the equipment rack

REV SEP 1994

RFA300A Measurement Set 8VSB

Page 23

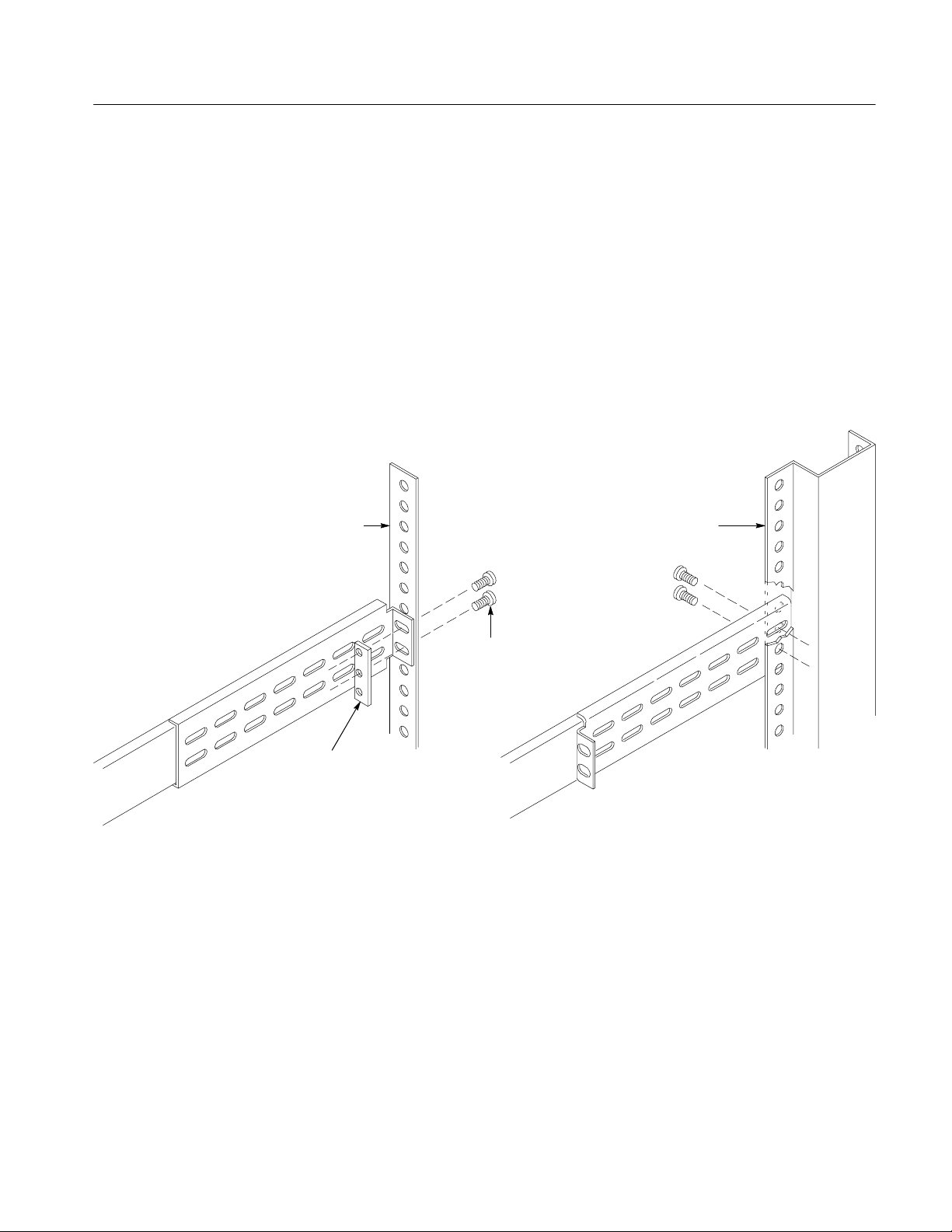

3. Mount the stationary sections (with extension brackets attached) to the front

and rear rails of the equipment rack.

a. Install the rear of the stationary section in front of, behind, or beside the

rear rail of the equipment rack. Use the mounting holes in the rear rails

that correspond to the same level as the front rail holes selected.

If the rear-rail mounting holes are tapped, the bar nut is not used to

attach the extensions. If the rear-rail mounting holes are not tapped, use

the bar nut on the inside of the rail, as shown in Figure 1--5A or use

suitable captive nut clips (not supplied). Figure 1--5B shows the

extension bracket mounted to the inside surface of the rear rail.

Method A Method B

Installation

Rear rail

10-32 PNH

screws

Bar nut (use

if rear rail is

not tapped)

Figure 1- 5: Attaching the extension bracket to the rear rail of the equipment rack

Rear rail

RFA300A Measurement Set 8VSB

1- 9

Page 24

Installation

b. Mount the stationary sections (with the bracket extensions) to the front

rails. If the front rails are not tapped, use the bar nuts. Refer to

Figure 1--6.

Front rail

Bar nut

(use if front rail

is not tapped)

10-32 PNH

screws

Figure 1- 6: Mounting the stationary section to the front rail of the equipment rack

4. Tighten the screws attaching the extension bracket to the stationary section.

Refer to Figure 1--7.

Tighten these screws

1- 10

Figure 1- 7: Stationary bracket, extension bracket, and attaching screws

RFA300A Measurement Set 8VSB

Page 25

Installation

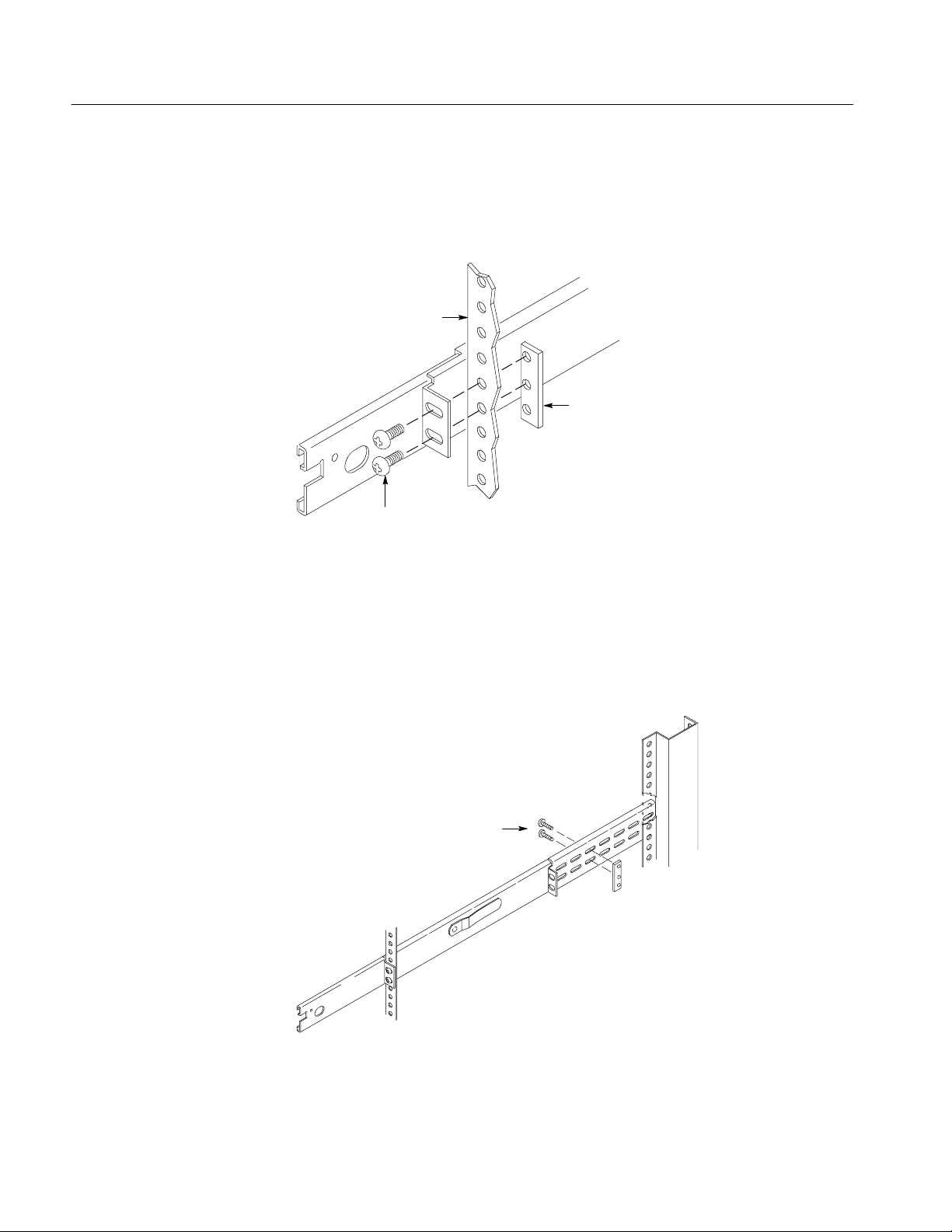

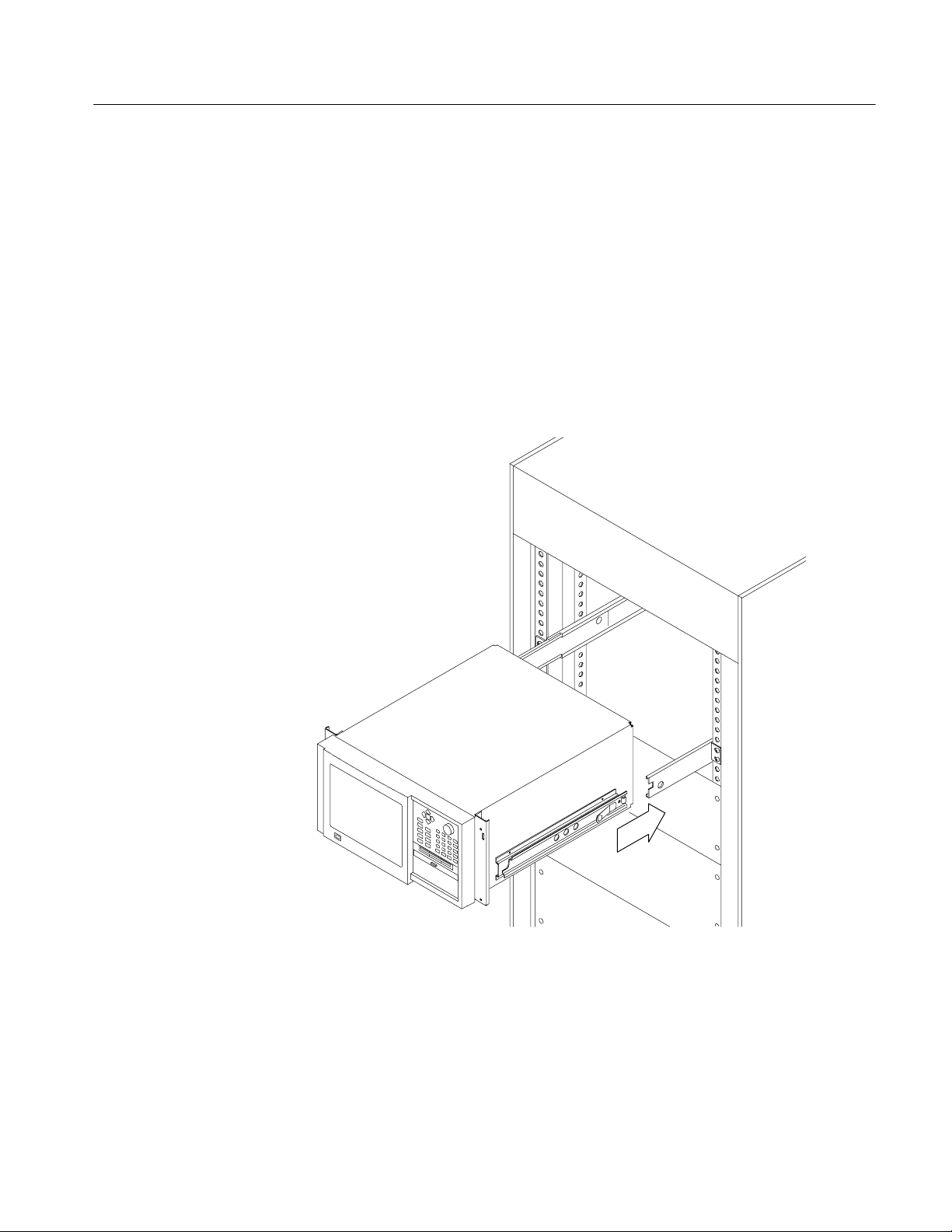

Installing the Instrument in the Equipment Rack. Perform the following steps to

install the instrument in the equipment rack:

1. Pull out the intermediate sections of each slide-out track to the fully

extended position. Refer to Figure 1--8.

2. Insert the tracks of the rack adapter into the slide-out intermediate sections.

3. Press both stop latch releases and push the rack adapter toward the rack until

the latches snap into their holes.

4. Again press the stop latches and push the rack adapter fully into the

equipment rack.

Figure 1- 8: Installing the instrument into the equipment rack

RFA300A Measurement Set 8VSB

1- 11

Page 26

Installation

5. If necessary, adjust the alignment of the stationary sections according to the

following procedure:

a. Loosen the mounting screws at the front of both stationary sections.

b. Allow the tracks to seek their normal positions with the adapter centered

in the rack.

c. Tighten the mounting screws.

Portable Installation

The optional portable cabinet allows you to operate the instrument on a bench or

cart. If you operate the instrument while it rests on the rear feet, make sure that

you properly route any cables coming out of the rear of the instrument to avoid

damaging them. Table 1--2 on page 1--4 lists the part number of the portable

cabinet.

CAUTION. Keep the bottom of the instrument clear of obstructions to ensure

proper cooling.

1- 12

RFA300A Measurement Set 8VSB

Page 27

Creating a Startup Disk

Installation

An RFA300A Windows NT Start Up disk is shipped with the instrument. Use

this disk to restart your measurement set in case of a major hardware or software

failure. This section creates an extra startup disk in case the original becomes

corrupted.

All software is installed at the factory. If you ever need to reinstall, refer to

Appendix C: Software Installation.

NOTE. You cannot reinstall software without a startup disk.

To create a startup disk, do the following:

1. Open My Computer/Control Panel, and double-click on Add/Remove

Programs.

2. Select the Startup Disk tab.

3. Click the Create Disk button and follow instructions.

4. Copy the following files to the startup disk:

H C:REALMODE\MSCDEX.EXE

H C:REALMODE\TEAC_CDI.SYS

H C:WINDOWS\COMMAND\XCOPY.EXE

H C:WINDOWS\COMMAND\XCOPY32.EXE

5. Create a file named AUTOEXEC.BAT in the startup disk. Add the line

MSCDEX.EXE /D:TEAC--CDI/L:D to the file.

6. Open the CONFIG.SYS file in the startup disk and add

DEVICE=TEAC_CDLSYS /D:TEAC--CDI to the end file.

RFA300A Measurement Set 8VSB

1- 13

Page 28

Installation

RF Connections

The quality of the input signal path is critical in obtaining the full-specified

performance of the measurement set. Therefore, you must connect the measurement set to your transmitter using high quality cable and connectors. The

following list provides the requirements needed for the RF connection:

H Hold the nonflatness of the input signal to approximately 0.05 dB peak-to-

peak or less over the width of the channel.

H Keep the station’s radiated signal to at least 63 dB down from the sampled

signal in the line by using appropriate shielding.

H The cable with connectors must have a return loss of at least 26 dB

(VSWR ± 1.10) over the channel width and a loss tilt of less than .02 dB

over the channel width. This assumes that the tap used to obtain the signal

has a return loss of ² 30 dB (VSWR ± 1.065).

High quality cable and connectors are required to meet the listed requirements.

The connectors should be precision grade at both ends of the cable. The best

cable type is dependent on the run length and operating frequency. The return

loss requirement is hardest to meet at high frequencies, and the loss tilt is hardest

to meet at low frequencies. In either case, minimize the difficulties by using only

a few feet for cable length. Longer lengths (50 ft. or more) place extreme

requirements on cable quality specifications.

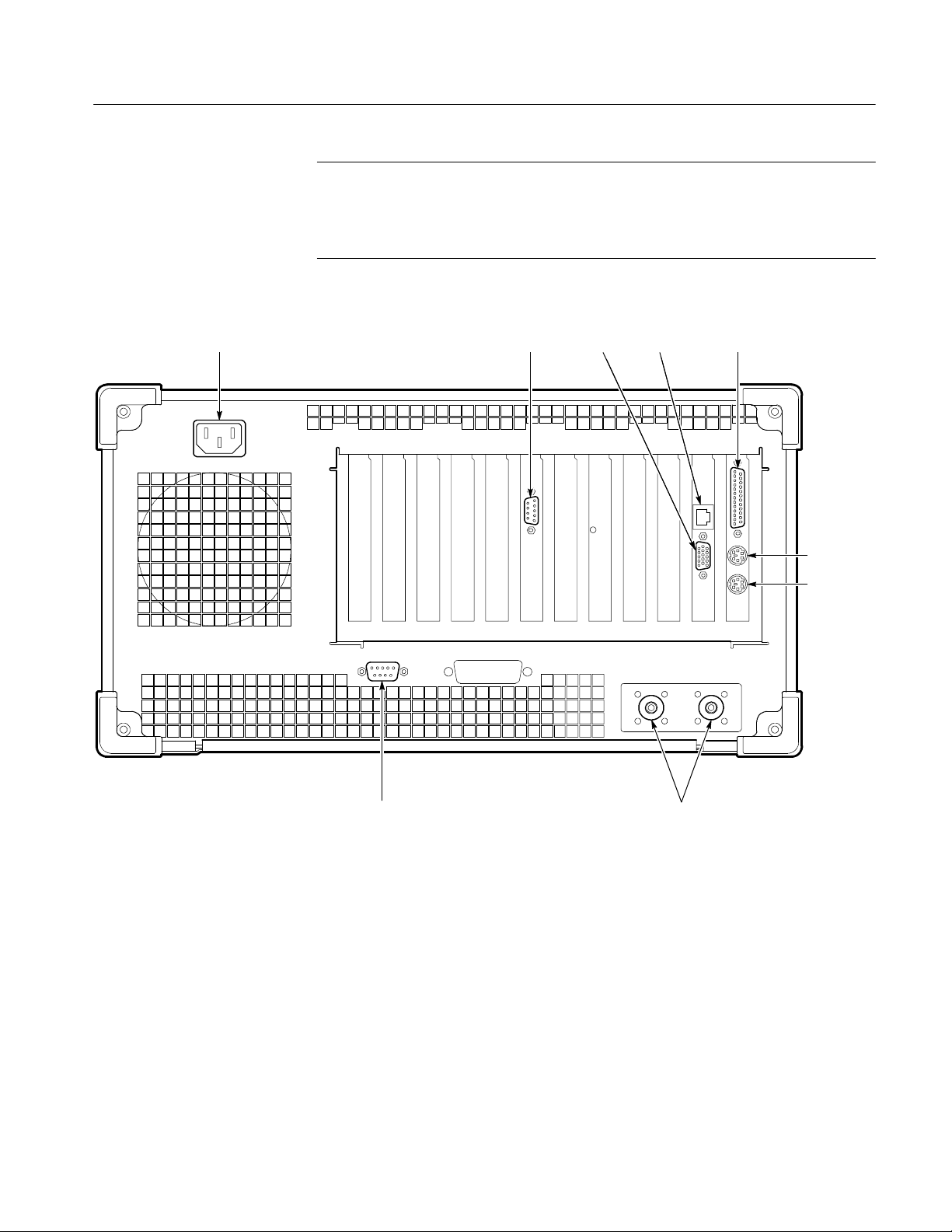

The rear panel provides two RF input connectors for your transmitted signal.

Refer to Figures 1--9 and 1--10 to connect the measurement set to your transmitter and for other connections.

Transmitter Channel filter

Power input

RFA300A

Figure 1- 9: Transmitter connection

Connect the measurement set to your transmitter in a manner that ensures the

instrument will receive only one channel. If the input signal strength is more

than 1 watt, install the external 10 dB attenuator (the input signal strength cannot

be more than 2 watts).

1- 14

RFA300A Measurement Set 8VSB

Page 29

Installation

NOTE. Power to the measurement set must be within the following ranges:

> 1 mW and < 1 W without the external 10 dB attenuator.

> 10 mW and less ≤ 2 W with the external 10 dB attenuator installed.

Power Alarm

SVGA

Ethernet

port

Parallel

port

Keyboard

Mouse

Figure 1- 10: Rear view

RFA300A Measurement Set 8VSB

RS-232

COM port 1

RF

connections

1- 15

Page 30

Installation

Interface Connections

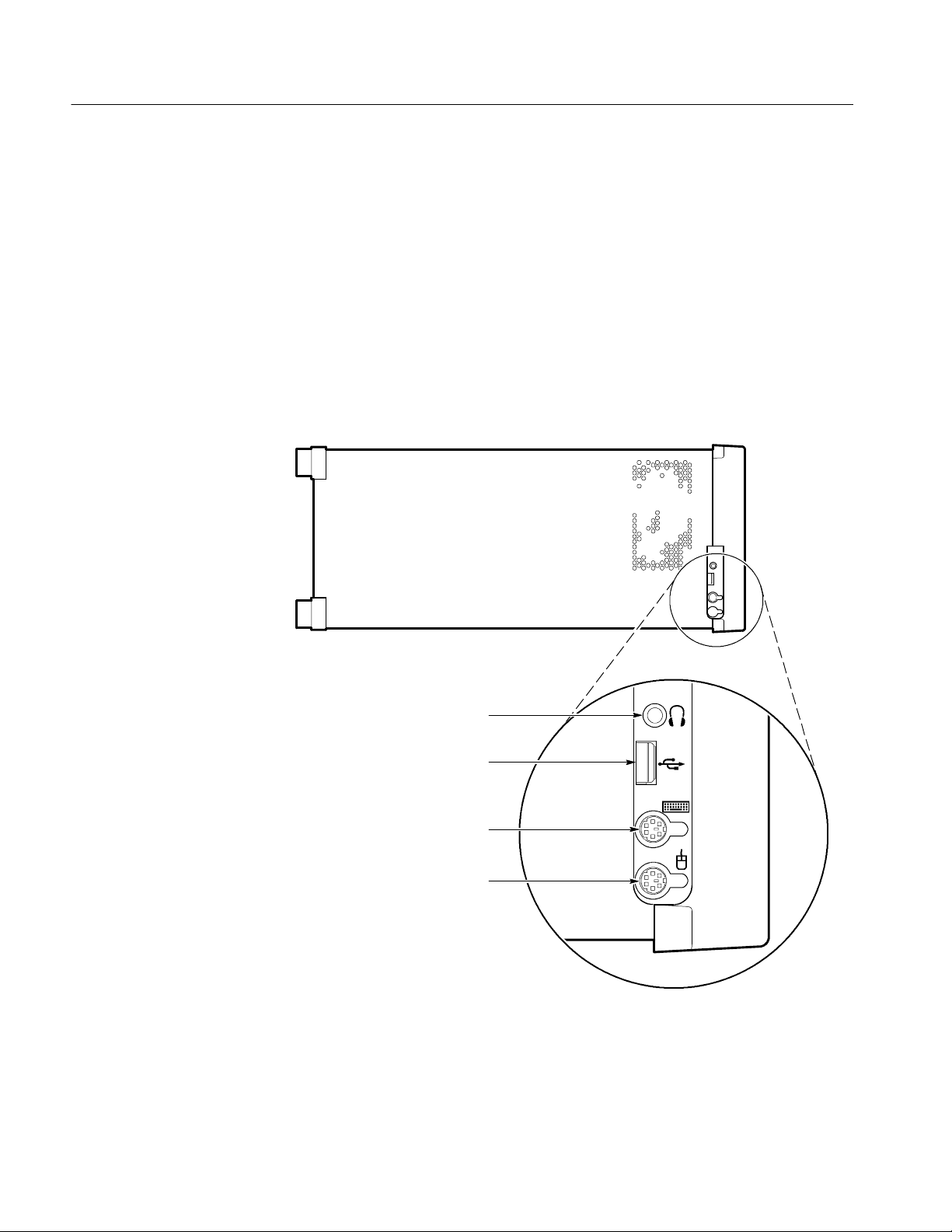

The interface connectors on the rear and side of the RF measurement set, shown

in Figure 1--10 and Figure 1--11, provide the interconnection ports for peripheral

devices and networking. Pin assignments for the rear panel and side panel

connectors are listed in Table A--4 and Table A--5 in Appendix A:Specifications.

Keyboard and Mouse Connections

Connect the keyboard and mouse to the left side of the instrument as shown in

Figure 1--11.

Earphones

(Not used)

USB

Keyboard

Mouse

Figure 1- 11: Keyboard and mouse connections

1- 16

RFA300A Measurement Set 8VSB

Page 31

Powering On and Off

Installation

This section contains the procedure for powering on the instrument for the first

time. To power off the instrument, refer to Powering off on page 1--18.

First Time Power On

On/Standby switch

Power on the measurement set as follows:

1. Press the On/Standby switch to power on the instrument (see Figure 1--12 for

the switch location).

Figure 1- 12: On/Standby switch

2. Wait for the instrument to complete power-on self-tests.

RFA300A Measurement Set 8VSB

The screen displays an Enter Windows Password dialog box prompting you

for a logon name and password. However, if a password is entered then each

time you power on the measurement set you will be prompted for logon

information. To avoid this, do the following steps:

a. Enter a user name (for example, RFA300A) in the Enter Windows

Password dialog box.

b. Click OK, but do not enter a password.

c. Click OK in the Set Windows Password dialog box, but do not enter a

password.

1- 17

Page 32

Installation

3. Follow the instructions on the screen and enter the Windows NT Product

Identification number (located above the bar code) on the Windows NT

software package that came with your instrument. Enter other information as

required.

The internal setup software automatically configures your instrument and

installs all required devices. After the setup software completes configuration, the measurement set application will start.

The next time you power on, the application starts automatically. You do not

need to perform step 3 again.

Powering off

Always power off the instrument using the Windows NT shutdown process and

then press the On/Standby switch.

NOTE. Once a month, power down and restart the instrument. The measurement

set performs an internal calibration as part of the power on procedure. This

ensures the optimum measurement accuracy of the instrument.

Selecting RF Input Channel and Channel Frequency

Use the following procedure to select the RF Input channel, select the channel

frequency, and verify that the RF input signal has sufficient power. Without

sufficient power at the test signal input, the instrument cannot perform accurate

measurements.

1. Connect your transmitter to one of the RF input connectors shown on

page 1--15 (the connectors are internally terminated in 50

termination is needed).

2. If the input signal strength is more than 1 watt (but no greater than 2 watts),

make sure that the external 10 dB attenuator is installed.

Ω, so no external

1- 18

3. Power on the instrument.

4. Click the Setup button on the toolbar.

5. Click on the System tab to display the System page (shown in Figure 1--13).

RFA300A Measurement Set 8VSB

Page 33

Figure 1- 13: System setup

Installation

6. Click on the Input button to select the RF Input channel (Input 1 or Input 2)

to which you connected the transmitter. Only one of these channels can be

input at a time.

7. Enter the desired frequency.

NOTE. The frequency is the pilot frequency, not channel center. Refer to Selecting

channel frequency in the online help.

8. Click Apply, and then click the Input Signal Power button.

9. Check to see if the RF input signal level is in the OK range; if it is not, then

adjust the output of your transmitter accordingly.

10. Close the Input Signal Power dialog box and click OK to close the System

Setup window.

RFA300A Measurement Set 8VSB

1- 19

Page 34

Installation

Incoming Inspection

Incoming inspection consists of verifying basic operation of the measurement

set. The Power-on diagnostics check basic functionality. These diagnostics run

every time you power on the instrument. If a failure is detected, the Power-on

diagnostics dialog box opens with the failed test indicated.

Extended Diagnostics

Signal Power

Measurement

Functionality

Run the extended diagnostics to test functionality in more detail. To run

extended diagnostics, do the following procedure:

1. Go to the Tools menu and select Diagnostics.

2. Click the Extended Diagnostics tab.

3. Select All Modules and Tests and then select One Time.

4. Click Run and observe that a failure does not occur.

If a failure does occur, contact Tektronix using the information provided in the

Preface of this manual or click on Support located under the Help menu.

Perform the procedure on page 1--18 titled Selecting Channel Frequency and

verify that the RF input signal has sufficient power and is connected to the

selected RF input (1 or 2).

Open each measurement window and verify that activity is occurring. For

example, to check Frequency Response and Group Delay do the following

procedure:

1. From the Home window, click on the Frequency Response and Group Delay

icon to open the measurement window.

1- 20

2. Verify that a signal is visible in each waveform graphic within a few

seconds.

3. Verify that the readout for both measurements is updating.

Perform the same procedure for each measurement.

RFA300A Measurement Set 8VSB

Page 35

Operating Basics

Front Panel

This chapter describes the basic operation of the RFA300A Measurement Set

8VSB. For operating details, refer to the online help.

The front panel controls are used to operate the measurement set without the

mouse or keyboard. Figure 2--1 shows the front panel.

Figure 2- 1: Front panel

Keys

RFA300A Measurement Set 8VSB

You can use the front panel keys as an alternative to a keyboard. All keys and

key combinations critical to operating the instrument or for basic Windows tasks

are available via the front panel. To enter letters of the alphabet or special

characters, use the soft keyboard feature (refer to Entering text from the screen in

the online help).

For key combinations, it is unnecessary to hold down more than one key at a

time. For example, you can press SHIFT in the hex keypad, and then press

another key to accomplish a Shift+key combination. The same is true for other

key combinations, such as CTRL and ALT keys. This feature is often referred to

as a locked mode.

Table 2--1 lists front-panel key controls and describes their use.

2- 1

Page 36

Operating Basics

w

Table 2- 1: Front panel-key controls

Control name Mechanism Description

Up Arrow Button Use to navigate and change focus from one

Left Arrow Button

Right Arrow Button

Down Arrow Button

Select Button Same as the space key.

Adjust Knob Rotary encoder Multi-function control, increment/decrement

indow function toanother.

field values or screen element size or position.

Run/Stop Buttonwith3-color

LED

Esc Button Standard Escape key.

Tab Button Standard Tab key.

Print Button Prints current measurement using the same

Touch Button Toggles Touch Screen state on and off. LEDs

Menu (application key) Button Same as mouse button two.

Help Button Opens the Help contents. Standard F1 key

Print Screen Button Copies the screen to the clipboard. Alt plus

START Key Button Opens the Windows Start menu.

Numbers 0 to 9,

period and minus sign

Fctn ButtonwithLED Modifier for numeral keys to create keys F1

Del Button Deletes selected text or object.

Buttons Standard number keys, most have second

Button Backspace key.

Starts or stops a measurement. LED indicates

whether product is in Run or stop state.

print settings as for the previous print.

indicate Touch Screen On/Off state.

Print Screen copies the active window.

(Shift) and third (Function) functions.

through F12. Locked mode key feature. LED

indicates when on.

Button Enter key.

Ctrl ButtonwithLED Control key. LED indicates when keypad is in

control mode. Refer to Table 2--2 for a list of

control functions. Locked mode key feature.

Alt ButtonwithLED Alternate key. LED indicates when keypad is

in alternate mode. Locked mode key feature.

Space Button Space bar or use as mouse button 1

Shift ButtonwithLED Shift key. LED indicates when keypad is in

shift mode. Locked mode key feature.

2- 2

RFA300A Measurement Set 8VSB

Page 37

Table 2- 2: Control key combination functions

Control key Function

Ctrl+A Invokes the AutoScale function

Ctrl+B Opens the previous window (same as the toolbar<<Back)

Ctrl+C COPY

Ctrl+F Opens the following window (same as the toolbar Fwd >>)

Ctrl+H Opens the Home window

Ctrl+K Opens the Keypad dialog box

Ctrl+O Opens the Recal l Results dialog box

Ctrl+P Prints the measurement

Ctrl+S Saves the results of the current measurement

Ctrl+T Toggles the Touchscreen on or off

Ctrl+V PASTE

Ctrl+X CUT

Operating Basics

Touch Screen

Soft Keyboard

Ctrl+Y REPEAT

Ctrl+Z UNDO

The touch screen allows you to use your finger instead of a mouse. Move your

finger around the screen to move the cursor. Tap to select an object and select

ENTER to activate the object.

You can use the soft keyboard with any application. To display the soft keyboard, select My--T--Soft from the Program menu, click the keyboard icon in the

System Setup menu, or click a keyboard icon displayed in an application.

You can configure the keyboard (change the size, for example). To do this, click

the icon shaped like a hand in the upper right corner of the keyboard display to

access a dialog box.

Tutorial. For a tutorial on how to use the soft keyboard, select My--T--Soft

Welcome from the My--T--Soft program group (in Programs in the Windows

startup menu).

Licensing. If the RFA300A software is correctly installed the first time you use

the soft keyboard, the My--T--Soft keyboard registers itself. If the RFA300A is

not installed, the My--T--Soft keyboard will be loaded as a demo version. To

undo this, uninstall the My--T--Soft keyboard, properly install the RFA300A

software, and then reinstall the keyboard.

RFA300A Measurement Set 8VSB

2- 3

Page 38

Operating Basics

Home Window

To display the license status, select Licensing from the My-T-Soft program

group (from Programs in the Start Up menu).

NOTE. The My-T-Soft keyboard must be installed on the same drive letter as the

RFA300A software.

The Home Window is the point-of-entry into the measurement set. From the

home window, you access all measurements by clicking on the appropriate icon.

A measurement begins to run immediately when the window opens. Figure 2--2

shows the Home window. Refer to the Reference chapter for an overview of each

measurement window.

RFA300A -- Home

2- 4

Menus

Toolbar

Figure 2- 2: Home window

Menu selections are available from any measurement window and the Signal

Monitor window. Refer to the online help for a description of each menu selection.

All toolbar selections are available from any measurement window and the

Signal Monitor window. The toolbar provides an easy method for accessing

frequently-used functions. Figure 2--3 shows the toolbar and Table 2--3 lists the

toolbar functions.

RFA300A Measurement Set 8VSB

Page 39

Operating Basics

Recall

Results

Results

Save

Print

Edit

Setup

Smoothing

Selection

Run

Status

Run/Stop

Button

Back & Forward

Home

Figure 2- 3: Toolbar

Table 2- 3: Toolbar functions

Toolbar selection Function

Recall Results Recalls a previously saved measurement.

Save Results Save the results of the current measurement.

Print Prints one copy of the current measurement.

Edit Setup Provides setup controls for the instrument and measurements.

What’s

This?

Smoothing Selection Selects the degree for reducing the variations of the waveform and

results. Smoothing is accomplished differently for each type of

measurement. Refer to the online help for each measurem ent

window to determine how smoothing is accomplished.

Run Status Shows when the measurement is running or stopped. Red is

stopped and green is running.

Run/Stop Button Begins or stops performing measurements.

Back and Forward Back opens the previously opened window. Forward opens the

following window.

Home Returns to the Home window.

What’s This? Provides a brief description of the sel ected control or object.

RFA300A Measurement Set 8VSB

2- 5

Page 40

Operating Basics

Making a Measurement

The following provides a basic overview of how to make and save a measurement. Refer to the online help for details on other operating features. An

explanation of how help works is on page 2--9.

Selecting Frequency

Limits Versus Masks

Limits

Before running measurements you must select your channel frequency and

determine that the input signal has power within the correct range. Refer to

Selecting RF Input Channel and Channel Frequency on page 1--18 for the

procedures on selecting channel frequency and checking input signal power.

Before proceeding, you should understand the differences between limits and

masks. Limits are parameters against which numeric measurement results can be

compared automatically. You can choose the color to highlight results that

violate parameters.

The mask-testing feature allows you to set visual parameters within the graphic

portion of the measurement window. The masks are lines against which you can

compare waveforms.

After selecting your channel frequency and checking input signal power, you can

edit caution and alarm limits. The instrument compares each new result against

the current limits as soon as you enter the measurement window. To edit limits,

do the following:

1. Click the Setup button located in the toolbar.

2. Click the Limits tab.

2- 6

3. Select which results are to be compared against the limits when the

measurement is running.

4. Enter the low value for Alarm. The value must be less than the low Caution

value.

5. Enter the low value for Caution. The value must be less than High Caution

and greater than Low Alarm.

6. Enter the high value for Caution. The value must be less than High Alarm

and greater than Low Caution.

7. Enter the high value for Alarm. The value must be greater than High

Caution.

For some measurements, you cannot enter values for all limits because it would

be counter productive. For example, there is no reason to set a high caution or

alarm value for signal-to-noise when you want the signal-to-noise ratio to be as

high as possible.

RFA300A Measurement Set 8VSB

Page 41

Operating Basics

Masks

Viewing Results

The mask-testing feature is not on when you receive your measurement set. To

turn masks on and off or to select different masks, do the following:

1. Open a measurement window. For example, open the Amplitude and Phase

Error window.

2. Click the Setup button located in the toolbar.

3. Select the appropriate box to enable a mask test. The mask is enabled when

checked.

4. Select the mask you want to use.

5. Click OK to accept your changes and return to your measurement window.

Not all of the measurements need or include a mask test. Those that do not are

the Signal/Noise, Error Vector Magnitude, and Pilot Amplitude Error window

and Peak/Average and Channel Spectrum window.

You can create a mask for those measurements that include mask testing. Refer

to Mask file formatting in the online help.

Once you open a measurement window, notice that the measurement runs and

provides results soon after the window opens. To stop the measurement, press

the Stop button located in the toolbar. To restart, press the Run button.

Saving Results

Signal Monitor

After making a measurement, you can save your results to a database by doing

the following:

1. Go to the File menu and select Save Results As.

2. Enter name, destination, and any notes you want saved with the results.

Results can be printed or exported to other applications using the Report dialog

box selected in the File menu. You can also recall results for further study at any

time.

The Signal Monitor allows you to continuously monitor one or more of the other

measurement’s numeric results in one window. To select the measurements to

monitor, do the following:

1. Open the Signal Monitor window.

2. Click Setup in the Toolbar.

3. Select the measurements you want to monitor.

4. Select how often you want your results to be automatically saved or select

Off to disable the function.

RFA300A Measurement Set 8VSB

2- 7

Page 42

Operating Basics

5. If you selected At Intervals in step 4, enter the amount of hours to save

between AutoSave actions.

NOTE. An indication of how long the instrument can run before running out of

space is provided. Click the File Size button to limit the size of your result

database files. Refer to Limiting the size of a results database file in the online

help.

6. Select when to be notified (under Notification Criteria) if a caution, alarm, or

error occurs. You can also select not to be notified.

7. If you selected to be notified in step 6, select the notification action.

NOTE. Before you can set up Email notification, you must install a Messaging

Application Program Interface (MAPI) compliant Email application.

8. Click the Email Settings button to change Email parameters.

NOTE. Selecting Send Email opens the Email dialog box if the destination is not

yet specified. You can enter the address, include a message, and send the current

results or only results that have violated limits.

9. Click Suspend Actions and select how often you want to be notified.

10. Click OK to close.

11. Click the Setup’s OK button to apply your selections and return to the Signal

Monitor window.

2- 8

RFA300A Measurement Set 8VSB

Page 43

Online Help

Operating Basics

The online help gives detailed information about the operation of the measurement set. Look in the online help for details about user selections and controls

that are not described in this manual.

To access online help, go to the Help menu as shown in Figure 2--4.

Click for Topic help.

Click for What’s This? help on selected object.

Figure 2- 4: Help menu

Help Topics

What’s This? Help

Help topics tell you how to perform tasks and describe software features and

selections shown on the screen. There are two types of help topics, reference

topics and task topics.

Reference topics describe application features, such as the measurement

windows. Reference topics may also describe concepts. Reference topics are

available through the Help menu and through Help buttons in dialog boxes.

From the Help menu, click Help Topics, and locate the topic using the Contents

or Index tab. The Index tab is easier to use. As you enter a word into the text

field, Help searches for and highlights the topic if one can be found. If not, try

the Find tab. Enter a word or phase and help will display all topics that contain

the word or phrase. The Help on Window selection in the Help menu provides

reference help for the current window.

Task topics provide procedure information on how to perform specific tasks.

Task topics are available through the Help menu. From the Help menu, click

Help Topics, and locate the topic using the Contents or Index tab.

What’s This? help provides a short description of the control or screen feature

selected. First, click the What’s This? button on the toolbar as shown in

Figure 2--4, and then click the item of interest.

RFA300A Measurement Set 8VSB

2- 9

Page 44

Operating Basics

Windows NT Online Help

Release Notes

Backing Up Files

Information about Windows features is available through the Windows help

system. Access Windows help as you would with any Windows application:

1. Go to the Windows taskbar and click Start.

2. Select Help from the popup menu.

NOTE. To access Windows NT help using the Touchscreen, press the START key

on the font panel.

The online Release Notes contain information about this release of the RFA300A

application. Check the Release Notes for information such as software compatibility and software version differences from last release.

To access the Release Notes, go to the Windows NT taskbar and click Start, or

press the front panel START key. The Release Notes are at the top of the Start

menu.

You should back up your files on a regular basis. Use the Windows Back Up tool

to back up files stored on the hard disk. The Back Up tool is located in the

following path: Programs\Accessories\System Tools\Back. Start the tool and

determine which files and folders you want to back up. Use the Windows online

help for information on using the Back Up tool.

In particular, you should back up your user-generated masks, setup files, and the

results database files.

2- 10

RFA300A Measurement Set 8VSB

Page 45

Reference

This section gives an overview of each measurement within the measurement set

and the 8VSB transmitter.

Out of Channel Emissions

This section provides an overview of the Out of Channel Emissions measurement window. For more in-depth information, refer to the online help.

Out of Channel Emissions is a vital measurement that is specified by the FCC.

To prevent interference outside of the allotted spectrum, the RF signal must

comply with the specified mask for the transmitter under test.

NOTE. The measurement set is limited to measurements between 0 and -80 dB on

the FCC’s scale.

The measurement set performs the measurement by calculating the power of the

signal that passed through an ¶ 30 kHz filter before being digitized. The

measured values are adjusted to an equivalent 500 kHz noise bandwidth and

divided by the total transmitter output power. This is the FCC measurement

method.

The Out of Channel Emissions measurement window is shown in Figure 3--1.

The measurement window contains the following areas:

H A listing of measurement results.

H A mask test pass or fail indicator.

H Controls for selecting the number of channels to display.

H Controls for resolution.

H Cursor direction controls.

H A listing of each cursor’s position and the difference between the two.

H Graphic showing the spectral waveform with the selected mask overlaid on

the spectrum display, if enabled from the setup (refer to Out of Channel

Emissions Setup next).

RFA300A Measurement Set 8VSB

3- 1

Page 46

Reference

Results listing

Mask indication

Resolution

Channel controls

Cursor position

Cursor directions

Out of Channel

Emissions Setup

Figure 3- 1: Out of Channel Emissions measurement window

Click the Setup button in the toolbar to enable mask testing and select a mask for

the measurement window. The setup dialog box contains the control for turning

masks on and off, plus a list of available masks. You can create your own mask

and place it into the measurement set for use. Refer to Appendix D: Mask File

Formatting in this manual for detailed instructions. Figure 3--2 shows the Out of

Channel Emissions setup.

3- 2

Figure 3- 2: Out of Channel Emissions setup

RFA300A Measurement Set 8VSB

Page 47

S/N, EVM, and Pilot Amplitude Error

This section provides a brief overview of the Signal-to-Noise, Error Vector

Measurement, and Pilot Amplitude Measurement window. For more in-depth

information, refer to the online help.

The S/N, EVM, and Pilot Amplitude Error measurement window provides an

overview of the transmitter’s 8VSB signal quality. Signal-to-Noise (S/N), Error

Vector Magnitude (EVM), and Complex Modulation Error Ratio (MER) are

similar measurements. The calculations for each are slight deviations from each

other. Refer to S/N, EVM, and Complex MER calculations in the online help.

Figure 3--3 shows the measurement window with the constellation display. The

window contains the following areas:

H A listing of measurement results.

H Two display graphics: constellation and eye diagram.

H A control for turning equalization on and off. Equalization removes linear

distortions from the measurements. This allows you to distinguish among

causes of poor signal quality.

Reference

Results listing

Controls

S/N

H A control for subtracting the pilot amplitude from the horizontal axis.

RFA300 A -- Signa l / Noise & EVM

Figure 3- 3: S/N, EVM, and Pilot Amplitude measurement window

The S/N measurement provides a broad measure of impairments in the transmitted signal. S/N is the power ratio between the ideal received signal and the

difference between the ideal and actual received signal as measured along the

real axis during symbol times only. A comparison is made between the deviation

RFA300A Measurement Set 8VSB

3- 3

Page 48

Reference

of the actual digitally modulated television signal and an ideal signal of the same

data. This measurement is the major all-in-one indicator of the transmitter’s

signal quality. The test is an early indication of system problems before they

become bit errors and is more sensitive to modulation errors than Bit Error Ratio

(BER) tests.

Complex MER

Pilot Amplitude Error

Phase Noise

EVM

The EVM (Error Vector Magnitude) measurement also provides a broad analysis

of the transmitted signal. EVM analysis can reveal incorrect filter shaping (see

VSB Modulation on page 3--18) and other modulation quality problems.

Complex MER is a complex form of S/N. The measurement is made by

including Q (quadrature) channel information into the calculation. Refer to

Complex MER calculation in the online help.

This measurement shows any error of the pilot signal amplitude.

This section provides a brief overview of the Phase Noise measurement window.

For more in-depth information, refer to the online help.

This measurement window measures the random low frequency phase deviations

of the entire 8VSB signal. Phase noise is typically added by the transmitter’s

frequency synthesizer system. Phase noise can reduce the S/N ratio.

3- 4

The measurement set performs this measurement by calculating the residual

phase jitter. This jitter is what is left after removing the effects of other transmission errors.

The Phase Noise measurement window is shown in Figure 3--4. The measurement window contains the following areas:

H Listing of measurement results

H A mask test pass or fail indicator

H Cursor direction controls

H Listing of each cursor’s position and the difference between the two

H Graphic showing the pilot’s phase noise spectral density measured in dBc/Hz

versus frequency. The selected mask is overlaid on the display, if you

enabled any in the setup (see Phase Noise Setup next).

RFA300A Measurement Set 8VSB

Page 49

Results listing

Mask indication

Cursor position

Cursor directions

Reference

RFA300A -- Phase Noise

Figure 3- 4: Phase Noise Measurement window

Phase Noise Setup

Click the Setup button in the toolbar to enable and select a mask for the

measurement window. The setup dialog box contains the control for turning

masks on and off, plus a list of available masks. You can create your own mask

and place it into the measurement set for use. Refer to Appendix D: Mask File

Formatting in this manual for detailed instructions. Figure 3--5 shows the Phase

Noise setup.

Figure 3- 5: Phase Noise setup

RFA300A Measurement Set 8VSB

3- 5

Page 50

Reference

Frequency Response and Group Delay

This section provides a brief overview of the Frequency Response and Group

Delay measurement window. For more in-depth information, refer to the online

help.

This measurement measures frequency response and group delay errors. These

errors are the result of linear distortion caused by transmitter imperfections or

possibly small impedance mismatches or both.

The frequency response errors are listed in dB. The frequency at which the

minimum and maximum errors were found is also shown. Group delay errors are

in nanoseconds.

The measurement set calculates these measurements by deriving the amplitude

and time delay response of the channel from the equalizer tap coefficients.

Frequency response and group delay are calculated relative to the pilot frequency

or the center of the channel as selected in the setup.

The Frequency Response and Group Delay measurement window is shown in

Figure 3--6. The measurement window contains the following areas:

H A listing of measurement results.

H Cursor direction controls.

H A mask pass or fail indicator for each measurement.

H A listing of each cursor’s position and the difference between the two.

H Graphics showing frequency response measured in dB versus frequency and

group delay measured in time (nanoseconds) versus frequency. Selected

masks are overlaid on the display, if you enabled any in the setup (refer to

Frequency Response and Group Delay Setup next).

3- 6

RFA300A Measurement Set 8VSB

Page 51

Results listing

Mask indication

Cursor position

Cursor directions

Reference

RFA300 A -- F req uen cy Res ponse & Group Delay

Figure 3- 6: Frequency Response and Group Delay measurement window

Frequency Response and

Group Delay Setup

Click the Setup button in the toolbar to enable and select a mask for each

measurement in the measurement window. In addition, the setup has a reference

point selection for the measurements: either channel center or the pilot. The

setup contains the control for turning masks on and off, plus a list of available

masks. You can create your own mask and place it into the measurement set for

use. Refer to Appendix D: Mask File Formatting in this manual for detailed

instructions. Figure 3--7 shows the Frequency Response and Group Delay setup.

Figure 3- 7: Frequency Response and Group Delay setup

RFA300A Measurement Set 8VSB

3- 7

Page 52

Reference

Amplitude and Phase Errors

This section provides a brief overview of the Amplitude and Phase Errors

measurement window. For more in-depth information, refer to the online help.

This measurement measures amplitude and phase errors, which are nonlinear

distortions. A signal’s phase can shift with amplitude. Transmitters, particularly

high power ones, can exhibit amplitude errors in the form of clipping or

compression when close to full power. These errors decrease a transmitter’s

Signal-to-Noise ratio, thereby reducing the coverage area.

The measurement set performs the measurement by calculating ideal signal

magnitude and phase from the received I/Q signal and comparing it with the

actual signal.

The Amplitude and Phase Errors measurement window is shown in Figure 3--8.

The measurement window contains the following areas:

H A listing of measurement results.

H A mask test pass or fail indicator for each measurement.

H Cursor direction controls.

H A listing of each cursor’s position and the difference between the two.

H Graphics showing signal amplitude error versus ideal signal amplitude

measured in dB versus constellation units (refer to the Glossary) and signal

phase errors versus ideal signal amplitude measured in degrees versus

constellation units. The selected masks are overlaid on the graphics, if

enabled from the setup (refer to Amplitude and Phase Errors Setup next).

3- 8

RFA300A Measurement Set 8VSB

Page 53

Results listing

Mask indication

Cursor position

Cursor directions

Reference

RFA300A -- Amplitude & Phase Errors

Amplitude and Phase

Errors Setup

Figure 3- 8: Amplitude and Phase Errors measurement window

Click the Setup button in the toolbar to enable and select masks for the measurement window. The Setup dialog box contains controls for turning masks on and

off and selections for using different masks. You can create your own mask and

place it into the measurement set for use. Refer to Appendix D: Mask File

Formatting in this manual for detailed instructions. Figure 3--9 shows the

Amplitude and Phase Errors setup.

Figure 3- 9: Amplitude Error and Phase Error setup

RFA300A Measurement Set 8VSB

3- 9

Page 54

Reference

Peak-to-Average and Channel Spectrum

This section provides a brief overview of the Peak-to-Average and Channel

Spectrum measurement window. For more in-depth information, refer to the

online help.

This window measures the cumulative distribution of peak power over time.

Peak power is the maximum value of envelope power that is randomly reached

by the digitally modulated signal. Power amplifiers driven beyond their

capability cause compression of peaks. This distorts the signal causing out of

channel emissions and lower signal-to-noise ratio.

The measurement is calculated by taking the percentage of time that the signal is

greater than the average amplitude. This measurement and the ideal are both

plotted on the Peak-to-Average graph.

The Peak-to-Average and Channel Spectrum measurement window is shown in

Figure 3--10. The measurement window contains the following areas:

H Listing of measurement results.

Results listing

Target operating

point control

H A selection control for setting the target operating point in the peak-to-aver-

age graphic. Select the target operating point method in the setup (refer to

Peak-to-Average Setup next).

H Graphics showing the measured and ideal peak-to-average power curves and

the channel spectrum. The channel spectrum is another tool to assess a

transmitter’s amplitude linearity. To view this graph, click on the Channel

Spectrum tab.

RFA300 A -- Peak / Ave rag e & Ch ann el Spec tru m

3- 10

Figure 3- 10: Peak-to-Average and Channel Spectrum measurement window

RFA300A Measurement Set 8VSB

Page 55

Reference

Peak-to-Average Setup

Click the Setup button in the toolbar to select the target operating point method

for the measurement window. You can select in dB or percentage of time.

Figure 3--11 shows the Peak-to-Average Setup.

Figure 3- 11: Peak-to-Average Setup

RFA300A Measurement Set 8VSB

3- 11

Page 56

Reference

Signal Monitor

This section provides a brief overview of the Signal Monitor measurement

window. For more in-depth information, refer to the online help.

The Signal Monitor allows you to continuously monitor one or more of the other

measurements in one window while the instrument is unattended. You can enter

the setup for each measurement in each measurement’s Setup dialog box. Set all

cautions and alarms in the Limits dialog box (refer to Limits on page 2--6). The

selection of which measurements to monitor is made in the Signal Monitor

Setup. Figure 3--12 shows the Signal Monitor measurement window.

RFA300A -- Amplitude & Phase Errors

3- 12

Figure 3- 12: Signal Monitor measurement window

RFA300A Measurement Set 8VSB

Page 57

Reference

Signal Monitor Setup

Measurement selections

In addition to selecting measurements to monitor, you can also select the

following in the Signal Monitor Setup:

H How often to save your results automatically, if at all.

H Size limit for the results database file.

H When and how to be notified of caution, alarm, and error conditions.

Choices of how to be notified include sound, saving results, email, and by

activation of an external device (see Figure 1--10 on page 1--15 for the alarm

connection location).

H How often or when to be notified.

Figure 3--13 shows the Signal Monitor Setup.

AutoSave controls

Notification controls

Figure 3- 13: Signal Monitor Setup

RFA300A Measurement Set 8VSB

3- 13

Page 58

Reference

8VSB Overview

This section provides an overview of the 8VSB transmitter. For a complete

understanding of the transmitter, refer to Advanced Televisions Systems

Committee (ATSC) Digital Television Standard document A/53. This document

is available from the World Wide Web at ftp://atsc.org/pub/Standards.

The 8VSB standard is a RF modulation format used to broadcast Digital

Television (DTV) to the home. This format was proposed by the ATSC and

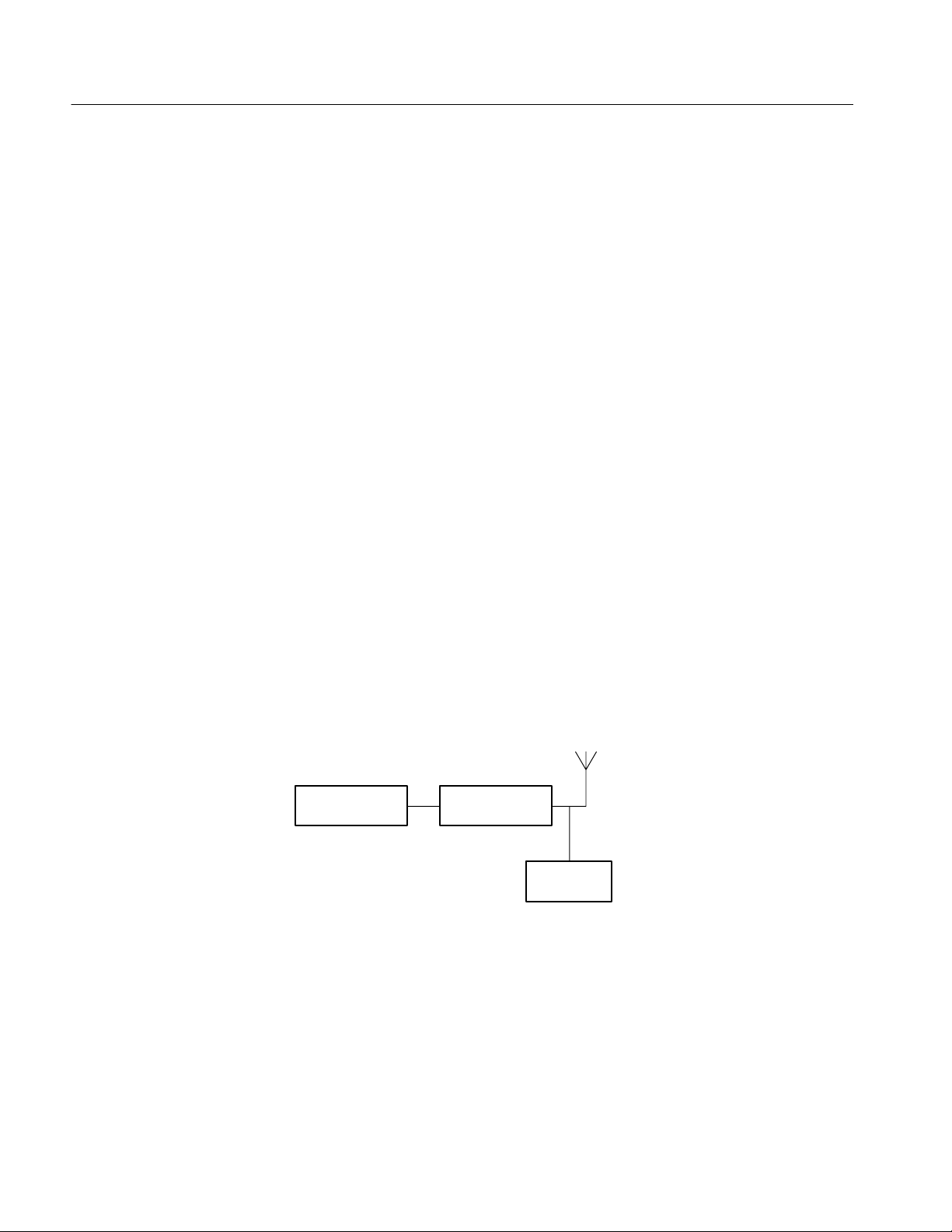

adopted by the FCC. The 8VSB transmitter generates the 8VSB signal as shown

in Figure 3--14. The transmitter must take the bit-stream output from a MPEG II

encoder and transmit it on a 6 MHz RF channel.

Data Randomizer

Data

Randomizer

Pilot

Insertion

Reed-Solomon

Encoder

Modulator

VSB

Data

Interleaver

Upconverter

Segment Sync

RF

Trellis

Encoder

Field Sync

RFA300A

Input Signal

MUX

Figure 3- 14: 8VSB exciter block diagram

To use the 6 MHz channel space with maximum efficiency, the 8VSB bit stream

must be randomized with a pseudo-random bitstream. This ensures a flat

noise-like spectrum and reduces interference to NTSC channels. A recurring

rhythmic pattern causes the RF energy content to cluster at certain areas in the

frequency spectrum. Therefore, without additional processing, certain parts of

the 6 MHz channel could be overused, while other areas are underused. The Data

Randomizer changes each byte value to a known pseudo-random binary

sequence (PRBS). The PRBS process is reversed in the television receiver to

recover the correct data value.

Reed-Solomon Encoder

3- 14

The Reed-Solomon (RS) encoder uses Forward Error Correction (FEC) to

correct received bit errors that can occur during transmission. The RS encoder

takes the 187-byte data block and adds 20 parity bytes. The receiver compares

the 187-byte block to the 20 parity bytes to determine if the data is valid. RS

encoding can correct up to 10 byte errors per one 187-byte data block (packet).

RFA300A Measurement Set 8VSB

Page 59

Reference

Data Interleaver

Some noise burst durations are longer than the RS encoder can manage. For

further protection, a time diversity scheme called data interleaving is used. Refer

to Figure 3--15.

c3, c2, c1, b3, b2, b1, a3, a2, a1

c3, b3, a3, c2, b2, a2, c1, b1, a1

Noise

burst

Non-interleaved

Interleaved

Figure 3- 15: Data interleaving

A noise burst could delete all the b bytes of a non-interleaved signal resulting in

a loss that the RS decoder in a receiver cannot recover. However, if the data is

interleaved, only one byte is lost in each of the a, b and c byte segments of the

interleaved signal. This leaves enough data for the decoder to determine the

correct value. In reality, 8VSB data is interleaved to a depth of 52. This allows

the decoder to determine the correct value of data that has been damaged by a

193 µs noise burst.

Trellis Encoder

A Trellis Encoder is another Forward Error Correction method. However, where

as the RS encoder dealt with the entire data packet as a block, the Trellis encoder

affects the stream of bits as they develop through time. Trellis encoding is

accomplished by Trellis-Coded Modulation (TCM). TCM is a combination of

coding and modulation that does not require additional bandwidth expansion

although there are extra bits for FEC.

The Trellis encoder takes an eight-bit byte and splits it into four two-bit words.

Every two-bit word is compared with previous words. A three-bit code is

assigned to each two-bit word that describes the transition from the previous

word to the current one. Therefore, for every two bits in, the encoder produces

three bits out. The Trellis decoder (Viterbi) in a receiver uses the three bits to

reconstruct the evolution of the data stream from one two-bit word to the next.

The Trellis and Viterbi coding scheme is very effective in managing white noise.

RFA300A Measurement Set 8VSB

3- 15

Page 60

Reference

Multiplexer

Supplementary sync signals are added to a multiplexer to form the 8VSB

baseband signal. Each of the eight levels represents a symbol value. After every

828 symbols, a Segment sync is sent. The Segment sync is two-level binary data

that is 10 constellation units peak-to-peak in amplitude and four symbols long.

This makes each 8VSB data segment 832 symbols long as shown in Figure 3--16. The Segment sync has two roles: it replaces the sync byte that was

removed before the RS encoding, and it increases the signal robustness. It is

easily located by the receiver’s decoder in the presence of noise.

Data

segment

sync

Levels

before

pilot

insertion

+7

+5

+3

+1

Data

segment

sync

-1

-3

-5

Data + FEC

-7

4

Symbols

1byte

828 Symbols = 187 data bytes + 20 parity (R-S) bytes

832 Symbols = 188 byte MPEG data packet + 20 parity bytes

Figure 3- 16: Data segment sync

4

Symbols

1byte

3- 16

RFA300A Measurement Set 8VSB

Page 61

Reference

The other sync signal added to the multiplexer is the Frame synchronizing