Page 1

REL-16 Series

User’s Guide

®

A GREATER MEASURE OF CONFIDENCE

Page 2

WARRANTY

Hardware

Keithley Instruments, Inc. warrants that, for a period of one (1) year from the date of shipment (3 years for Models 2000,

2001, 2002, 2010 and 2700), the Keithley Hardware product will be free from defects in materials or workmanship. This

warranty will be honored provided the defect has not been caused by use of the Keithley Hardware not in accordance with

the instructions for the product. This warranty shall be null and void upon: (1) any modification of Keithley Hardware that

is made by other than Keithley and not approved in writing by Keithley or (2) operation of the Keithley Hardware outside

of the environmental specifications therefore.

Upon receiving notification of a defect in the Keithley Hardware during the warranty period, Keithley will, at its option,

either repair or replace such Keithley Hardware. During the first ninety days of the warranty period, Keithley will, at its

option, supply the necessary on site labor to return the product to the condition prior to the notification of a defect. Failure

to notify Keithley of a defect during the warranty shall relieve Keithley of its obligations and liabilities under this

warranty.

Other Hardware

The portion of the product that is not manufactured by Keithley (Other Hardware) shall not be covered by this warranty,

and Keithley shall have no duty of obligation to enforce any manufacturers' warranties on behalf of the customer. On those

other manufacturers’ products that Keithley purchases for resale, Keithley shall have no duty of obligation to enforce any

manufacturers’ warranties on behalf of the customer.

Software

Keithley warrants that for a period of one (1) year from date of shipment, the Keithley produced portion of the software or

firmware (Keithley Software) will conform in all material respects with the published specifications provided such Keithley

Software is used on the product for which it is intended and otherwise in accordance with the instructions therefore.

Keithley does not warrant that operation of the Keithley Software will be uninterrupted or error-free and/or that the Keithley

Software will be adequate for the customer's intended application and/or use. This warranty shall be null and void upon any

modification of the Keithley Software that is made by other than Keithley and not approved in writing by Keithley.

If Keithley receives notification of a Keithley Software nonconformity that is covered by this warranty during the warranty

period, Keithley will review the conditions described in such notice. Such notice must state the published specification(s)

to which the Keithley Software fails to conform and the manner in which the Keithley Software fails to conform to such

published specification(s) with sufficient specificity to permit Keithley to correct such nonconformity. If Keithley determines that the Keithley Software does not conform with the published specifications, Keithley will, at its option, provide

either the programming services necessary to correct such nonconformity or develop a program change to bypass such

nonconformity in the Keithley Software. Failure to notify Keithley of a nonconformity during the warranty shall relieve

Keithley of its obligations and liabilities under this warranty.

Other Software

OEM software that is not produced by Keithley (Other Software) shall not be covered by this warranty, and Keithley shall

have no duty or obligation to enforce any OEM's warranties on behalf of the customer.

Other Items

Keithley warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries, diskettes,

and documentation.

Items not Covered under Warranty

This warranty does not apply to fuses, non-rechargeable batteries, damage from battery leakage, or problems arising from

normal wear or failure to follow instructions.

Limitation of Warranty

This warranty does not apply to defects resulting from product modification made by Purchaser without Keithley's express

written consent, or by misuse of any product or part.

Page 3

Disclaimer of Warranties

EXCEPT FOR THE EXPRESS WARRANTIES ABOVE KEITHLEY DISCLAIMS ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION, ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. KEITHLEY DISCLAIMS ALL WARRANTIES WITH

RESPECT TO THE OTHER HARDWARE AND OTHER SOFTWARE.

Limitation of Liability

KEITHLEY INSTRUMENTS SHALL IN NO EVENT, REGARDLESS OF CAUSE, ASSUME RESPONSIBILITY FOR

OR BE LIABLE FOR: (1) ECONOMICAL, INCIDENTAL, CONSEQUENTIAL, INDIRECT, SPECIAL, PUNITIVE OR

EXEMPLARY DAMAGES, WHETHER CLAIMED UNDER CONTRACT, TORT OR ANY OTHER LEGAL THEORY,

(2) LOSS OF OR DAMAGE TO THE CUSTOMER'S DATA OR PROGRAMMING, OR (3) PENALTIES OR PENALTY

CLAUSES OF ANY DESCRIPTION OR INDEMNIFICATION OF THE CUSTOMER OR OTHERS FOR COSTS, DAMAGES, OR EXPENSES RELATED TO THE GOODS OR SERVICES PROVIDED UNDER THIS WARRANTY.

Keithley Instruments, Inc.

Sales Offices: BELGIUM: Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02-363 00 40 • Fax: 02/363 00 64

CHINA: Yuan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-6202-2886 • Fax: 8610-6202-2892

FINLAND: Tietäjäntie 2 • 02130 Espoo • Phone: 09-54 75 08 10 • Fax: 09-25 10 51 00

FRANCE: 3, allée des Garays • 91127 Palaiseau Cédex • 01-64 53 20 20 • Fax: 01-60 11 77 26

GERMANY: Landsberger Strasse 65 • 82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

GREAT BRITAIN: Unit 2 Commerce Park, Brunel Road • Theale • Berkshire RG7 4AB • 0118 929 7500 • Fax: 0118 929 7519

INDIA: Flat 2B, Willocrissa • 14, Rest House Crescent • Bangalore 560 001 • 91-80-509-1320/21 • Fax: 91-80-509-1322

ITALY: Viale San Gimignano, 38 • 20146 Milano • 02-48 39 16 01 • Fax: 02-48 30 22 74

JAPAN: New Pier Takeshiba North Tower 13F • 11-1, Kaigan 1-chome • Minato-ku, Tokyo 105-0022 • 81-3-5733-7555 • Fax: 81-3-5733-7556

KOREA: 2FL., URI Building • 2-14 Yangjae-Dong • Seocho-Gu, Seoul 137-888 • 82-2-574-7778 • Fax: 82-2-574-7838

NETHERLANDS: Postbus 559 • 4200 AN Gorinchem • 0183-635333 • Fax: 0183-630821

SWEDEN: c/o Regus Business Centre • Frosundaviks Allé 15, 4tr • 169 70 Solna • 08-509 04 679 • Fax: 08-655 26 10

SWITZERLAND: Kriesbachstrasse 4 • 8600 Dübendorf • 01-821 94 44 • Fax: 01-820 30 81

TAIWAN: 1FL., 85 Po Ai Street • Hsinchu, Taiwan, R.O.C. • 886-3-572-9077• Fax: 886-3-572-9031

28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax: 440-248-6168

1-888-KEITHLEY (534-8453) • www.keithley.com

4/02

Page 4

The information contained in this manual is believed to be accurate and reliable. However, Keithley

Instruments, Inc., assumes no responsibility for its use or for any infringements of patents or other rights

of third parties that may result from its use. No license is granted by implication or otherwise under any

patent rights of Keithley Instruments, Inc.

KEITHLEY INSTRUMENTS, INC., SHALL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES RELATED TO THE USE OF THIS PRODUCT. THIS

PRODUCT IS NOT DESIGNED WITH COMPONENTS OF A LEVEL OF RELIABILITY

SUITABLE FOR USE IN LIFE SUPPORT OR CRITICAL APPLICATIONS.

Refer to your Keithley Instruments license agreement and Conditions of Sale document for specific

warranty and liability information.

MetraByte is a trademark of Keithley Instruments, Inc. All other brand and product names are

trademarks or registered trademarks of their respective companies.

© Copyright Keithley Instruments, Inc., 1994, 1998, 1999.

All rights reserved. Reproduction or adaptation of any part of this documentation beyond that permitted

by Section 117 of the 1976 United States Copyright Act without permission of the Copyright owner is

unlawful.

Keithley Instruments, Inc.

28775 Aurora Road, Cleveland, OH 44139

Page 5

REL-16 Series User’s Guide

Revision E - April 2001

Part Number: 79360

Page 6

S

The following safety precautions should be observed before using this product and any associated instrumentation.

Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations

where hazardous conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety

precautions required to avoid possible injury. Read and follow all installation, operation, and maintenance information

carefully before using the product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body

the equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately

trained.

Operators

of the instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel

the line voltage or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel

properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are rated Installation Category I and Installation

Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most measurement, control, and data I/O signals are Installation Category I and must not be directly connected to mains voltage

or to voltage sources with high transient over-voltages. Installation Category II connections require protection for high

transient over-voltages often associated with local AC mains connections. Assume all measurement, control, and data

I/O connections are for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or

test fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels

greater than 30V RMS, 42.4V peak, or 60VDC are present.

age is present in any unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that

operators are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential human contact. Product operators in these circumstances must be trained to protect themselves from

the risk of electric shock. If the circuit is capable of operating at or above 1000 volts,

may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance

limited sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards,

install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect

the connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

is the individual or group responsible for the use and maintenance of equipment, for ensuring that

use the product for its intended function. They must be trained in electrical safety procedures and proper use

perform routine procedures on the product to keep it operating properly, for example, setting

are trained to work on live circuits, and perform safe installations and repairs of products. Only

afety Precautions

A good safety practice is to expect that hazardous volt-

no conductive part of the circuit

5/02

Page 7

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main

input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the

operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting

or disconnecting cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions or the

safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a lid interlock.

If or is present, connect it to safety earth ground using the wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined

effect of normal and common mode voltages. Use standard safety precautions to avoid personal contact with these

voltages.

The

WARNING

associated information very carefully before performing the indicated procedure.

The

CAUTION

the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits, including the power

transformer, test leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable

national safety approvals, may be used if the rating and type are the same. Other components that are not safety related

may be purchased from other suppliers as long as they are equivalent to the original component. (Note that selected parts

should be purchased only through Keithley Instruments to maintain accuracy and functionality of the product.) If you

are unsure about the applicability of a replacement component, call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based cleaner. Clean the exterior of the instrument only. Do

not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist

of a circuit board with no case or chassis (e.g., data acquisition board for installation into a computer) should never

require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected,

the board should be returned to the factory for proper cleaning/servicing.

heading in a manual explains dangers that might result in personal injury or death. Always read the

heading in a manual explains hazards that could damage the instrument. Such damage may invalidate

Page 8

Table of Contents

Preface

Overview

1

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Supporting Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Installation

2

Inventorying Required Installation Resources . . . . . . . . . . . . . 2-2

Installing DriverLINX Software and Documentation . . . . . . . . 2-2

Configuring Your Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Preparing and Installing Your Board . . . . . . . . . . . . . . . . . . . . . 2-6

Unpacking and Inspecting . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Setting the Base Address . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Installing the Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Checking Your Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

I/O Bit Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Output Set Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Input Read Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Using Power from a REL-16 Series Board . . . . . . . . . . . . . . . 2-20

3

Cabling and Wiring

Attaching an STA-U or STP-37/FC Accessory . . . . . . . . . . . . . 3-2

Attaching an STC-37 Accessory . . . . . . . . . . . . . . . . . . . . . . . . 3-3

4

Programming

5

Troubleshooting

Problem Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Identifying Symptoms and Possible Causes . . . . . . . . . . . . 5-1

Testing the Board and Host Computer . . . . . . . . . . . . . . . . . 5-3

Testing the Accessory Slot and I/O Connections . . . . . . . . . 5-4

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

i

Page 9

A

Specifications

B

Connector Pin Assignments

C

Register Maps

Index

List of Figures

Figure 1-1 Block Diagram of the REL-16 and

REL-16/W Boards . . . . . . . . . . . . . . . . . . . . . . 1-2

Figure 2-1 Base Address Switch Location . . . . . . . . . . . . . . 2-8

Figure 2-2 An AIO Panel example . . . . . . . . . . . . . . . . . . . 2-11

Figure 2-3 DIO channel tab example . . . . . . . . . . . . . . . . . 2-12

Figure 2-4 Configuring the digital I/O channels as inputs

and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Figure 2-5 Configuring channel 0 for output

bit pattern A . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Figure 2-6 An AIO Panel example . . . . . . . . . . . . . . . . . . . 2-16

Figure 2-7 Configuring the digital I/O channels as

inputs and outputs . . . . . . . . . . . . . . . . . . . . . 2-17

Figure 2-8 Configuring channel 0 for output

bit pattern A . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Figure 2-9 Configuring channel 0 for output

bit pattern B . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Figure 3-1 Pin Assignments for the Main I/O Connector . . 3-1

Figure 3-2 Attaching an STA-U or STP-37/FC to an

REL-16 Series Board . . . . . . . . . . . . . . . . . . . . 3-2

Figure 3-3 Layout of STC-37 Screw Terminal

Connector Panel . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Figure 3-4 Attaching an STC-37 Accessory . . . . . . . . . . . . 3-4

Figure B-1 Main I/O Connector Pin Assignments . . . . . . . . B-1

ii

Page 10

List of Tables

Table 2-1 Values of Base Address Switch Positions . . . . . 2-8

Table 5-1 Troubleshooting Information . . . . . . . . . . . . . . . 5-2

Table A-1 General Output Specifications . . . . . . . . . . . . . . A-1

Table A-2 REL-16 Contact Ratings . . . . . . . . . . . . . . . . . . . A-1

Table A-3 REL-16/W Contact Ratings . . . . . . . . . . . . . . . . A-2

Table A-4 Environmental Specifications . . . . . . . . . . . . . . . A-2

Table A-5 Power Consumption Specifications . . . . . . . . . . A-2

Table C-1 I/O Map and Functions . . . . . . . . . . . . . . . . . . . . C-1

Table C-2 Relay Addresses for Ports A and B . . . . . . . . . . C-2

iii

Page 11

Preface

The

REL-16 Series User’s Guide

and installation, use of wiring accessories, included-software

characteristics and installation, and combined board and software

configuration. There is also a section on troubleshooting.

This guide serves data acquisition system designers, engineers,

programmers, and other users responsible for setting up, cabling, and

wiring signals to REL-16 Series boards. To follow the information and

instructions contained in this manual, you must be familiar with data

acquisition principles, with the Windows

and with your application.

The

REL-16 Series User’s Guide

●

Section 1 provides an overview of the hardware, a block diagram, a

description of the included DriverLINX software, and a description of

accessories.

Section 2 describes how to install the DriverLINX software and

●

documentation, how to unpack, set up, and install the board, and how

to configure and check the installation.

describes board capabilities, board setup

®

95/98/NT operating system,

is organized as follows:

●

Section 3 describes how to attach the accessories used for wiring

signals to the board.

Section 4 briefly describes the need to program through the

●

DriverLINX interface provided with your board, and tells how to

access the extensive DriverLINX documentation.

●

Section 5 describes common problems and solutions, troubleshooting

procedures, and instructions for obtaining technical support.

v

Page 12

Appendix A contains specifications for REL-16 Series boards.

●

Appendix B contains pin assignments for the main connector of

●

REL-16 Series boards.

●

Appendix C provides register maps, for background reference only

(you program REL-16 Series boards through the DriverLINX

interface, not at the register level).

An index completes the manual.

●

vi

Page 13

This chapter describes the REL-16 Series boards, supporting software,

and applicable accessories. Also included is a block diagram of REL-16

Series boards.

General Description

REL-16 Series boards are 16-channel, electromechanical-relay boards

containing a Form A (SPST) relay module for each channel. Applications

for the boards include control switching, analog multiplexing, lighting

control, alarm control, and motor starter control. The combined REL-16

Series board and supplied software installs and runs in any IBM

PC-compatible computer that runs the Microsoft Windows® 95/98/NT

operating system (Pentium®-series processor recommended).

1

Overview

The boards are available in two versions: the REL-16 and the REL-16/W.

Differences between the two versions are in their relays. Relays on the

REL-16 are rhodium plated with a rating to 500mA (resistive). Relays on

the REL-16/W are mercury wetted with a rating to 1A (resistive).

Note:

board can therefore be oriented in any direction. Mercury wetted

relays are sensitive to position; an REL-16/W board must therefore

be oriented vertically.

Port configuration for the REL-16 provides two independent, 8-bit ports

(A and B). Control of the relays requires an 8-bit word to be written to

each of the ports.

Mercury amalgam relays are insensitive to position; an REL-16

1-1

Page 14

The boards use a power-up reset to put all relays in their power-off

(normally open) state when power is applied to the host computer.

I/O connections are made through a 37-pin, type D connector. A +5V

power connection at this connector is brought out from the computer to

power external devices.

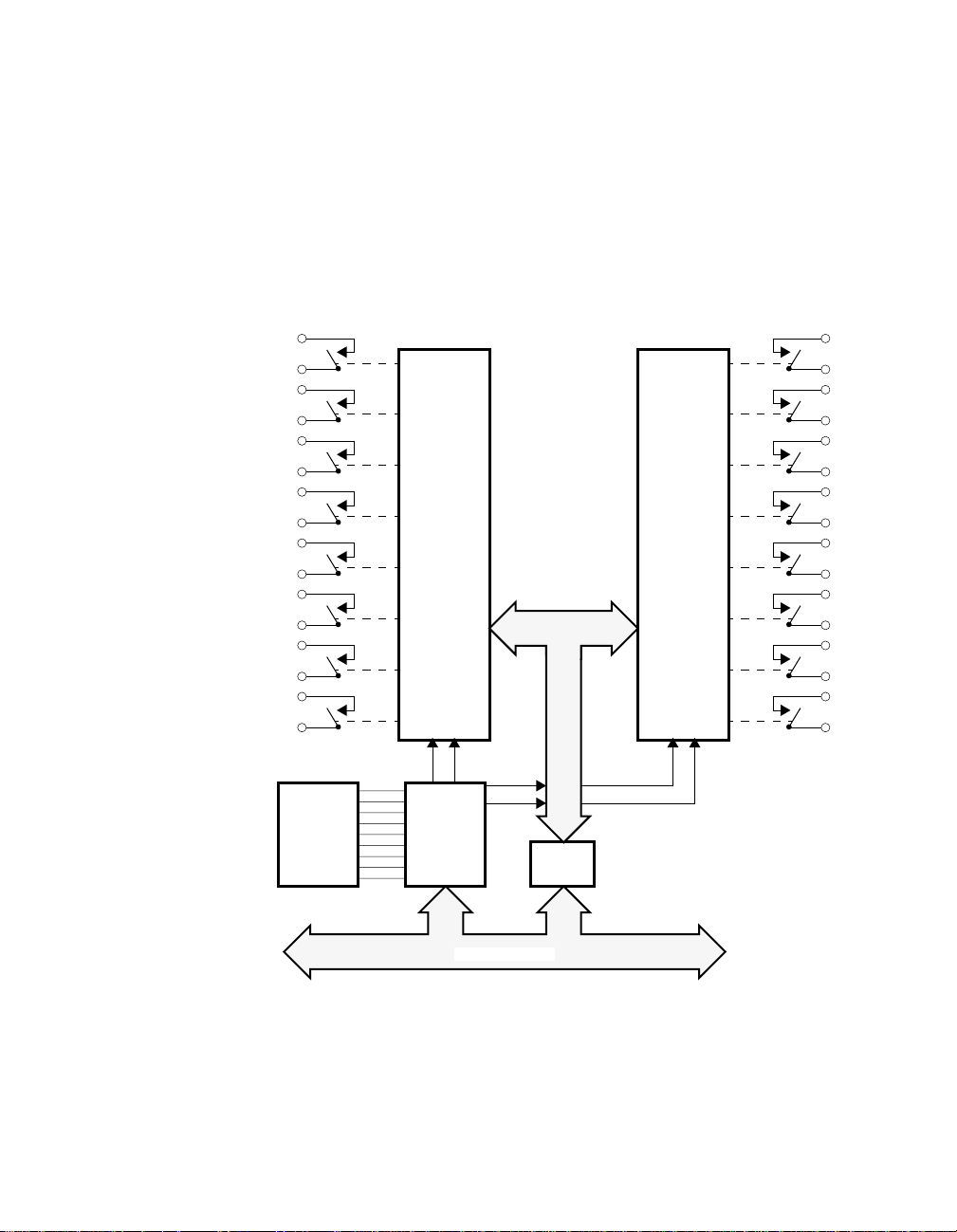

Figure 1-1 shows a block diagram of the REL-16 Series boards.

B0

B1

B2

B3

B4

B5

B6

B7

Address

Switch

Base

Port B Relay Outputs Port A Relay Outputs

Bit 0

Bit 1

Bit 2

Bit 3

Bit 4

Bit 5

Bit 6

Bit 7

Address

Decode

and R/W

Logic

Output Register with Readback

Bus

Buffers

Bit 0

Bit 1

Output Register with Readback

Bit 2

Bit 3

Bit 4

Bit 5

Bit 6

Bit 7

A0

A1

A2

A3

A4

A5

A6

A7

Computer Bus

Figure 1-1. Block Diagram of the REL-16 and REL-16/W Boards

1-2 Overview

Page 15

Supporting Software

DriverLINX software is supplied by Keithley with the REL-16 Series

boards. DriverLINX provides convenient interfaces to configure and set

I/O bits without register-level programming.

Most importantly, however, DriverLINX supports those programmers

who wish to create custom applications using Visual C/C++, Visual Basic,

or Delphi. DriverLINX accomplishes foreground and background tasks to

perform data acquisition. The software includes memory and data buffer

management, event triggering, extensive error checking, and context

sensitive online help.

More specifically, DriverLINX provides application developers a

standardized interface to over 100 services for creating foreground and

background tasks for the following:

●

Analog input and output

Digital input and output

●

●

Time and frequency measurement

●

Event counting

Pulse output

●

Period measurement

●

In addition to basic I/O support, DriverLINX also provides:

●

Built-in capabilities to handle memory and data buffer management

●

A selection of starting and stopping trigger events, including

pre-triggering, mid-point triggering and post-triggering protocols

●

Extensive error checking

●

Context-sensitive on-line help system

DriverLINX is essentially hardware independent, because its portable

APIs work across various operating systems. This capability eliminates

unnecessary programming when changing operating system platforms.

1-3

Page 16

Accessories

The following accessories are available for use with REL-16 Series

boards at voltages up to 30V RMS, 42.4V peak, or 60VDC, only.

●

SFC-37

— connector for the main I/O connector of REL-16 Series

boards. This accessory allows you to wire directly to the I/O of the

boards.

●

STA-U

— screw terminal panel. This accessory connects to the main

I/O connector of a board through a C1800 cable to connect all I/O

lines to labeled screw terminals.

●

STC-37

— screw terminal connector panel. This accessory connects

directly to the main I/O connector of a board to provide

general-purpose, screw-terminal connections in a compact form

factor.

STP-37/FC

●

— screw terminal panel. This accessory connects to the

main I/O connector of REL-16 Series boards through a C-1800/M

cable. The printed-circuit area of this accessory is covered to provide

extra protection against personal or tool contact with signals.

●

C1800

— cable. The C1800 is an 18-inch ribbon cable terminated at

both ends with 37-pin, D-type connectors.

C-1800/M

●

— cable. The C-1800/M is an 18-inch ribbon cable

terminated at one end with a connector to fit the main I/O connector

of an REL-16 Series board and terminated at the other end with a

connector to fit the I/O connector of an STP-37/FC accessory.

Warning

Do not use the STA-U, STC-37, STP-37/FC, C1800, and C-1800/M

accessories at voltages above 30V RMS, 42.4V peak, or 60VDC. These

accessories are rated for 30V RMS, 42.4V peak, or 60VDC maximum.

Use at higher voltages may result in shock hazard.

Refer to Section 3 for information on connecting these accessories to

REL-16 Series boards.

1-4 Overview

Page 17

Important Safety Instructions

REL-16 Series boards are prominently labeled to warn of shock hazard.

Before you install your REL-16 Series board, perform the following

steps:

1. Read the warnings in this section.

2. When installing, cabling, and wiring your board, pay close attention

to the warnings on the board labels and those described in this

section, and follow the instructions in Sections 2 and 3.

3. When using the board, do not exceed the ratings specified in

Appendix A.

Warning

Because you can connect the relay contacts of an REL-16 Series board to

high voltage, you can turn some areas of the board surface into a shock

hazard. A shock hazard can exist on those board areas even when your

computer is powered off. To protect you from exposure to areas of shock

hazard, Keithley furnishes REL-16 Series boards only with fully installed

protective covers (front and rear), attached to the board on each side by

nylon screws. While you can remove the covers to service an REL-16

Series board,

In addition, you must disconnect all cables and wiring before servicing

this board.

you must never use this board with its covers removed!

1-5

Page 18

2

Installation

Warning

The procedures in the section are intended for qualified service personnel.

Do not perform these procedures unless you are qualified to do so.

This section contains the following procedures, in the order in which they

are to be performed:

Inventorying installation resources

●

●

Installing the DriverLINX software needed to operate your REL-16

Series board

●

Configuring the installation in software

Unpacking and inspecting the board, setting the base address of the

●

board, and installing the board in your computer

●

Checking the installation

If you encounter any problems with the installation, refer to Section 5 for

troubleshooting information.

Note:

Series board. Otherwise, the device drivers will be more difficult to

install.

Install the DriverLINX software before installing the REL-16

2-1

Page 19

Inventorying Required Installation Resources

Before installing DriverLINX and the board, do the following:

1. Inventory your REL-16 Series board’s configuration settings.

2. Determine the resources your REL-16 Series board requires.

3. Inventory your computer’s resources already allocated to other

installed devices.

4. Determine whether your computer has sufficient resources for your

REL-16 Series board.

5. Determine whether your REL-16 Series board can use your

computer’s free resources.

6. Continue with the next section, “Installing DriverLINX Software and

Documentation.”

Note:

amplifies the inventory process in checklist items 1-5. (Disregard the rest

of the checklist items for now.) To display this manual from your

DriverLINX PIO Series CD-ROM, open the Windows Explorer, then

double click on

the CD-ROM drive. Acrobat Reader must already be installed on the other

system. If necessary, you can first install Acrobat Reader directly from the

CD-ROM by double clicking

The DriverLINX Installation and Configuration Guide

X:\Drvlinx4\Docs\Instconf.pdf

X:\Acrobat\setup.exe

, where X = the letter of

.

, Section 1,

Installing DriverLINX Software and Documentation

Note:

already installed on your system, you must also install the PIO Series

DriverLINX version. In the process, some DriverLINX capabilities shared

by all boards may be upgraded (test utilities, for example).

2-2 Installation

Even if DriverLINX versions other than the PIO Series version are

Page 20

This section discusses installation of drivers, interfaces, and

documentation. The component installation options provided by the

DriverLINX setup program are as follows:

●

Install Drivers

— This required component installs only the files you

need for configuring your hardware and running third-party

data-acquisition applications that require DriverLINX.

Install Interfaces

●

— This optional component installs the files and

example programs that you will need to develop custom applications

for DriverLINX using C/C++, Visual Basic, and Delphi.

Install Documentation

●

— This optional component installs

electronic documentation for DriverLINX that you can read, search,

and print using the Adobe Acrobat Reader.

●

Install Acrobat

— This optional component installs the Adobe

Acrobat Reader for the DriverLINX electronic documentation.

Install the DriverLINX software and board as follows:

1. Place the DriverLINX PIO Series CD-ROM in your drive and wait a

few seconds. On most systems, setup starts automatically. If not, run

the setup.exe file, found in the root directory of the CD-ROM.

A DriverLINX Browser Introduction screen appears. Thereafter, the

DriverLINX CD Navigator screen appears automatically after waiting

a few seconds or after clicking

Note:

On the DriverLINX CD Navigator and other DriverLINX Browser

Next

.

screens, place the cursor over a menu item to see an explanation. A star

next to a menu item means that it was selected previously.

Before continuing with this installation, Keithley suggests clicking

Me First

on the DriverLINX CD Navigator and reviewing the brief

information that appears.

2. On the DriverLINX CD Navigator screen, click

Install DriverLINX

An Install These DriverLINX Components screen appears.

Read

.

2-3

Page 21

3. Click

Install Drivers

, and then follow the series of on-screen

instructions. When done, the Install These DriverLINX Components

screen reappears.

4. If you do not plan to develop custom application software for your

REL-16 Series board, then skip to Step 5. If you do plan to develop

custom application software, you must install DriverLINX interfaces

before writing the software. Install them now by clicking

Interfaces

and following the series of on-screen instructions. When

Install

done, the Install These DriverLINX Components screen reappears.

5. Click

Install Documentation

and follow the series of on-screen

instructions. This step installs the manuals. When done, the Install

These DriverLINX Components screen reappears.

6. If Acrobat Reader is not already installed on your system, install it

now. You need Acrobat Reader to read the manuals, a section of

which you must access in step 9. Click on

Install Acrobat

and follow

the series of on-screen instructions. When done, the Install These

DriverLINX Components screen reappears.

7. Click

Exit.

Then, on the screen that appears saying “Thank you for

using DriverLINX,” click

Done

. The System Settings Changed dialog

box appears.

8. On the System Settings Changed dialog box, click

No. (The system

will be rebooted and configured later under “Configuring Your

Installation” on page 2-5.) The screen returns to the Windows

desktop.

9. Print out one section of a DriverLINX manual that you will briefly

review later during system configuration. Proceed as follows:

a. In the Start menu under Programs

→ DriverLINX, click

On-line Manuals. A menu document appears.

b. In the menu document, scroll until you find the major category

Configuration.

c. Under Configuration click Hardware References. A list of

documents appears.

2-4 Installation

Page 22

d. In the list of documents, click Keithley PIO Series. Acrobat

Reader opens and the manual entitled Using DriverLINX with

Your Hardware—Keithley PIO Series appears.

e. Print the following section from the Using DriverLINX with Your

Hardware—Keithley PIO Series manual: “Configuring the PIO

Series.”

Note: If your data acquisition system is not connected to a printer, you

can display and print the Using DriverLINX with Your Hardware—

Keithley PIO Series manual sections from another system, directly from

the CD-ROM (without installing anything). To display the manual, open

the Windows Explorer, then double click on

X:\Drvlinx4\Docs\Notes\kmbpio.pdf, where X = the letter of the

CD-ROM drive. Acrobat Reader must already be installed on the other

system. If necessary, you can first install Acrobat Reader directly from the

CD-ROM by double clicking X:\Acrobat\setup.exe.

10. Continue with the next section, “Checking Your Installation.”

Configuring Y our Installation

Configure the installation as follows:

1. Locate and briefly review the DriverLINX manual section,

“Configuring the PIO Series,” that you printed earlier during step 9 of

“Installing DriverLINX Software and Documentation.” Reviewing

this section will help prepare you to input information and select

options when configuring your installation.

Note: Be sure to note and follow all configuration differences between

installations for Windows NT and Windows 95/98.

2. Reboot your computer. The DriverLINX Plug and Play Wizard

appears on your screen automatically at the end of the boot cycle.

2-5

Page 23

Note: If you do not run the DriverLINX Plug and Play Wizard now, it

will not reappear during the current computer session, although it may

appear after a subsequent reboot. If you wish to configure your board

sometime later, you can start the Plug and Play Wizard manually from a

batch file. In the Windows Explorer, double click

X:\Drvlinx4\Help\kmbpio.bat, where X is the letter of the drive on

which DriverLINX is installed.

3. On the Plug and Play Wizard, click Wizard and follow the series of

on-screen instructions that appear. The wizard will first lead you

through the steps of installing your hardware—from a software

viewpoint—and configuring it.

Note: If your operating system is Windows NT, use Windows NT

Diagnostics to find the free resources that the Plug and Play Wizard asks

you to assign. However, if your board requires an interrupt, to reliably

find a free ISA interrupt you may need to 1) configure your computer as

having as a non-Plug and Play operating system, using BIOS setup, and

then 2) individually assign the interrupt to the ISA bus.

4. Continue with the next section, “Preparing and Installing Your

Board.”

Preparing and Installing Your Board

Caution: Ensure that the computer is turned OFF before installing or

removing a board. Installing or removing a board while power is ON can

damage your computer, the board, or both.

Handle the board in a static-controlled workstation; wear a grounded

wrist strap. Discharge static voltage differences between the wrapped

board and the handling environment before removing the board from its

protective wrapper. Failure to discharge static electricity before and

during handling may damage semiconductor circuits on the board.

Handle the board using the mounting bracket. Do not touch the circuit

traces or connector contacts when handling the board.

2-6 Installation

Page 24

Unpacking and Inspecting

Caution: A discharge of static electricity from your hands can seriously

damage certain electrical components on any circuit board. Before

handling any board, discharge static electricity from yourself by touching

a grounded conductor such as your computer chassis (your computer must

be turned OFF).

Use the following procedure to unwrap and inspect an REL-16 Series

board.

1. Factory packaging of the REL-16 Series board includes a final wrap

of protective, anti-static material. Remove the board from its

anti-static wrapping material. You may wish to store the wrapping

material for possible future use.

2. Inspect the board for signs of damage. If damage is apparent, arrange

to return the board to the factory (see “Technical Support” on page

5-5).

3. Check the remaining contents of your package against the packing

list to be sure your order is complete. Report any missing items

immediately.

4. When you are satisfied with the inspection, proceed with the next

procedure, “Setting the Base Address.”

Setting the Base Address

The base address is specified through switch settings. The location and

factory default setting of this switch is shown in Figure 2-1.

2-7

Page 25

Base Address

1 2 3 4 5 6 7 8

O

N

9

Switch

Figure 2-1. Base Address Switch Location

The base address switch is preset at the factory for 300h (see Figure 2-1).

If 300h was also assigned to the board when you ran the DriverLINX Plug

and Play Wizard, you do not need to reset the address switch. Otherwise,

reset the base address switch to conform to the base address assigned

when you ran the Wizard. The address you specify must be within the

range of 200h to 3FCh (512 to 1020 decimal) and on a 2-byte boundary.

Table 2-1 lists the values of individual base address switches. Use this

table as a guide when selecting a base address.

Table 2-1. Values of Base Address Switch Positions

Value When Switch Is OFF

Switch

Position

Address

Line

Decimal Hexadecimal

1 A9 512 200

2 A8 256 100

3 A7 128 80

4A6 64 40

5 A5 32 20

2-8 Installation

Page 26

Table 2-1. Values of Base Address Switch Positions (cont.)

When you have finished setting the base address, continue with the next

procedure, “Installing the Board.”

Installing the Board

Warning Because you can connect the relay contacts of an REL-16 Series board to

high voltage, you can turn some areas of the board surface into a shock

hazard. A shock hazard can exist on those board areas even when your

computer is powered off. To protect you from exposure to areas of shock

hazard, Keithley furnishes REL-16 Series boards only with fully installed

protective covers (front and rear), attached to the board on each side by

nylon screws. While you can remove the covers to service an REL-16

Series board, you must never use this board with its covers removed!

In addition, you must disconnect all cables and wiring before servicing

this board.

Value When Switch Is OFF

Switch

Position

6A4 16 10

7 A3 8 8

8A2 4 4

9 A1 2 2

Address

Line

Decimal Hexadecimal

Caution: Installing or removing a board while power is on can damage

your computer.

Before installing a board, check its base address switch for proper

settings. Then, use the following steps to install a REL-16 Series board in

an accessory slot of your computer:

1. Turn off power to the computer and all attached equipment.

2. Remove the computer chassis cover.

2-9

Page 27

3. Select an unoccupied accessory slot, and remove the corresponding

blank plate from the I/O connector panel.

4. Insert and secure the board in the selected slot.

5. Replace the computer cover.

6. Continue with the next section, “Checking Your Installation.”

Checking Y our Installation

The ability to start the DriverLINX AIO Panel utility, which is available

after you install DriverLINX, verifies that DriverLINX and the board are

installed and configured satisfactorily.

You can also test the functions of the REL-16 Series board, without

needing to write an application program, by connecting appropriate

digital signals and observing the responses with the DriverLINX AIO

Panel. Before connecting signals, first read the next section, “Cabling and

Wiring.”

After you configure and check your installation, read the next section,

“Using Power from a REL-16 Series Board.”

Note: Refer also to the DriverLINX Installation and Configuration Guide

and Using DriverLINX with Your Hardware—Keithley PIO Series

manuals.

I/O Bit Tests

General Information

1. Start the AIO Panel as follows:

a. In the Start menu, click Programs.

b. Find the DriverLINX ➧ Test Panels folder, under which you

should find the AIO Panel entry.

2-10 Installation

Page 28

c. Click on the AIO Panel entry. The Analog I/O Panel should

appear, similar to the example in Figure 2-2. (If you have other

DriverLINX devices installed in addition to the digital

input/output card you are testing, they will also be listed. In that

case, select the desired digital I/O card and the proper device

number before proceeding.)

Figure 2-2. An AIO Panel example

Note: The “Driver Selection” column will show the actual DriverLINX

driver(s) you have installed.

2-11

Page 29

2. On the AIO Control Panel, click the DIO tab.

Figure 2-3. DIO channel tab example

2-12 Installation

Page 30

Note: The on-screen digital I/O controller works as follows:

● Channels 0 to 15 refer to the 8-bit general-purpose registers of

your digital input-output card. (Depending on which card is

used, the number of valid 8-bit registers will vary.) Bits

displayed on the Digital Input Panel and the Digital Output

Panel are numbered 0-7 for every channel. Refer elsewhere in

this manual for a description of the available ports and their

direction.

● Invalid channels and settings appear as dark gray squares. For

example:

- Non-existent channels always appear as dark gray squares.

- Channels configured as inputs will appear as dark gray

squares on the output panel.

● Valid channels and settings appear as white squares when OFF

and green squares when ON. (When the manual is printed in

black and white, valid channels and settings appear as white

squares when OFF and as light gray squares when ON.)

● The two-digit numeric displays under Input Bits and Output

Bits show the hexadecimal values of the adjacent bit patterns.

● To configure a valid channel either for input or output, use the

Digital Channel Configuration Panel. Click on either the

Input or Output square below the channel number. Note: this

selection will be disabled for channels which are fixed as input

or output by hardware design.

● To turn ON output-channel bits, use the Digital Output Panel.

First select the channel number of the bits to be turned on by

clicking on the appropriate square under Channels. Then, turn

ON a bit by clicking the appropriate square under Output Bits.

Turn OFF a bit in the same way.

● To read an input-channel bit, use the Digital Input Panel. First

select the channel number to be checked by clicking the

appropriate square under Channels. Then, read the numbered

bit under Input Bits. OFF input bits appear as black dots and

ON input bits appear as green dots. (When the manual is

printed in black and white, OFF input bits appear as black dots

and ON input bits appear as light gray dots.)

2-13

Page 31

3. Under Digital I/O Configuration Panel, configure channels as

shown in Figure 2-4. (Actual channels available will vary according

to your hardware.)

KEITHLEY

Channel Configuration

0

Input

Output

123456789101112131415

Digital I/O Configuration Panel

Figure 2-4. Configuring the digital I/O channels as inputs and outputs

Note: For clarity when the manual is printed in black and white, the

control colors in Figure 2-4 and subsequent drawings will be shown as

follows:

Color on

Illustration

Actual Panel Function

BLACK DARK GRAY Invalid

WHITE LIGHT GRAY OFF

GRAY GREEN ON

4. In the Digital Output Panel under Channels, click on a channel

(here, channel 0) as shown in Figure 2-5.

KEITHLEY

Channels

1234567

0

8 9 10 11 12 13 14 15

Output Bits

76543210

Digital Output Panel

55

Figure 2-5. Configuring channel 0 for output bit pattern A

2-14 Installation

Page 32

5. In the Digital Output Panel under Output Bits, set the bits of the

6. In the Digital Input Panel under Channels, click on a channel to

Output Set Test

The output set test checks whether logic levels measured at all output pins

agree with output bit patterns set by software, using a DriverLINX

graphical interface (AIO Panel).

Note: This test is performed without user circuits being connected to the

outputs.

Perform the output set test as follows:

1. Ready the following equipment:

channel as desired as shown in Figure 2-5. (Click on each bit position

to turn it ON or OFF.)

select it and display the logical state of its input lines.

● A digital voltmeter (DVM) or a digital multimeter (DMM) set to

measure voltages, or a logic probe capable of reading TTL logic

levels.

● A suitable accessory and cable for the board being tested.

2. Turn OFF the host computer.

3. Connect the cable and accessory to your board.

4. Turn ON the host computer and boot Windows 95/98/NT.

5. Click the Windows 95/98/NT Start tab.

2-15

Page 33

6. Start the AIO Panel as follows:

a. In the Start menu, click Programs.

b. Find the DriverLINX ➧ Test Panels folder, under which you

should find the AIO Panel entry.

c. Click on the AIO Panel entry. The Analog I/O Panel should

appear, similar to the example in Figure 2-6. (If you have other

DriverLINX devices installed in addition to the digital

input/output card you are testing, they will also be listed. In that

case, select the desired digital I/O card and the proper device

number before proceeding.)

Figure 2-6. An AIO Panel example

2-16 Installation

Page 34

7. On the AIO Panel, click the DIO tab.

Note: To read an input-channel bit, use the Digital Input Panel. First,

select the channel number to be checked by clicking the appropriate

square under Channels. Then, read the numbered bit under Input Bits.

OFF input bits appear as black dots and ON input bits appear as green

dots. (When the manual is printed in black and white, OFF input bits

appear as black dots and ON input bits appear as light gray dots.) Further

information about this panel, how to make changes, and how to interpret

displays, is given in “I/O Bit Tests” of this section.

8. Under Digital I/O Configuration Panel, configure the output

channels to be tested as shown in Figure 2-7. (Actual output channels

available will vary according to your hardware.)

KEITHLEY

Channel Configuration

0

Input

Output

123456789101112131415

Digital I/O Configuration Panel

Figure 2-7. Configuring the digital I/O channels as inputs and outputs

Note: In Figure 2-7 and subsequent drawings of digital I/O controller

panels, the squares below invalid channels are colored black instead of

dark gray—for clarity when the manual is printed in black and white.

2-17

Page 35

9. In the Digital Output Panel under Channels, click on an output

channel (channel 0 in this example) as shown in Figure 2-8.

KEITHLEY

Channels

1234567

0

8 9 10 11 12 13 14 15

Figure 2-8. Configuring channel 0 for output bit pattern A

10. In the Digital Output Panel under Output Bits, set the bits of

channel 0 for bit pattern A as shown in Figure 2-8.

11. Measure the voltage between signal ground and each bit of the output

port with a DMM or DVM. Make measurements at the cabled mating

connector of your accessory.

12. Each bit set to ON in the AIO Panel should output a logic-high signal

at the corresponding I/O terminal, reading typically about 4 volts

(minimum of 2.2 volts) at a DMM/DVM. Each bit set to OFF in the

AIO Panel should output a logic-low signal at the corresponding I/O

terminal, reading typically about 0 volts (maximum of 0.8 volts) at a

DMM/DVM. Do one of the following:

Digital Output Panel

Output Bits

76543210

55

Note: The typical values shown are valid for boards with TTL

compatible outputs. For boards with relay outputs (REL-16, PDISO-8,

and PIO-32) the output will be a relay contact closure. For boards with

open collector outputs (PIO-HV) use a pull up resistor to an appropriate

voltage to detect output state. Refer to the hardware description in this

user’s guide for more details on the output’s electrical specification.

● If the bit patterns set on the AIO Panel do not agree with the

logic levels measured at the I/O terminals, the board is not

functioning properly. Stop here, and determine why.

● If the bit patterns set on the AIO Panel agree with the logic levels

measured at the I/O terminals, then repeat steps 9, 10, and 11 for

remaining output channels.

2-18 Installation

Page 36

13. In the Digital Output Panel under Channels, click on the output

channel to test (channel 0 in this example) as shown in Figure 2-9.

KEITHLEY

Channels

1234567

0

8 9 10 11 12 13 14 15

Figure 2-9. Configuring channel 1 for output bit pattern B

14. In the Digital Output Panel under Output Bits, set the bits of

channel 0 for bit pattern B as shown in Figure 2-9.

15. Measure the voltage between signal ground and each bit of the output

port with a DMM or DVM. Make measurements at the STA-50

terminals or the cabled mating connector that is connected to the

selected CONN-3160-D1 50-pin connector.

16. Again, each bit set to ON in the AIO Panel should output a logichigh signal at the corresponding I/O terminal, reading typically about

4 volts (minimum of 2.2 volts) at a DMM/DVM. Each bit set to OFF

in the AIO Panel should output a logic-low signal at the corresponding I/O terminal, reading typically about 0 volts (maximum of 0.8

volts) at a DMM/DVM.

Digital Output Panel

Output Bits

76543210

AA

Note: The typical values shown are valid for boards with TTL

compatible outputs. For boards with relay outputs (REL-16, PDISO-8,

and PIO-32) the output will be a relay contact closure. For boards with

open collector outputs (PIO-HV) use a pull up resistor to an appropriate

voltage to detect output state. Refer to the hardware description in this

user’s guide for more details on the output’s electrical specification.

● If the bit patterns set on the AIO Panel do not agree with the

logic levels measured at the I/O terminals, the board is not

functioning properly. Stop here, and determine why.

● If the bit patterns set on the AIO Panel do agree with the logic

levels measured at the I/O terminals, and you have performed an

output set test for all ports, the board is functioning properly.

17. Repeat steps 13, 14, and 15 for additional output channels.

2-19

Page 37

Input Read Test

A similar test of input circuitry can be performed by applying an input

signal of suitable type to each input line and verifying that the appropriate

input indicator changes state. Refer to the hardware description in this

user’s guide for more details on the input’s electrical specifications.

Using Power from a REL-16 Series Board

Power from the computer supply is available on the main I/O connector of

the REL-16 Series board. In situations where the board is used with a

dedicated peripheral (for example, a switch pad) and the cabling and

design loads are fixed, you may find it more appropriate to use the

REL-16 power outputs. In most other cases, however, you are advised to

power external devices from their own supplies.

In general, you are advised not to use computer power unless you can

safely avoid the following conditions:

● Short circuits, overloads, or the application of other external voltages.

All of these conditions may damage the PC system board and result in

costly repairs. The PC power supply is designed to shut down on a

short circuit, but you should not rely on this characteristic to protect

your system.

● A power draw that exceeds the capacity of the computer power

supply and its internal loads (see the technical reference manual for

your computer). Because of computer board connector and trace

width limitations, it is recommended that you limit power draw to 1A

from the +5V.

You are now ready to attach accessories as needed and wire the external

signals to the board. Refer to Section 3, “Cabling and Wiring,” for

instructions.

2-20 Installation

Page 38

Cabling and Wiring

Warning The procedures in this section are intended for qualified service

personnel. Do not perform these procedures unless you are qualified

to do so.

Users of this product must be protected from electric shock at all times.

The responsible body must ensure that users are prevented access and/or

insulated from every connection point. In some cases, connections must

be exposed to potential human contact. Product users in these

circumstances must be trained to protect themselves from the risk of

electric shock.

This section shows the cabling and connections required for attaching

accessories and I/O lines to the main I/O connector of your REL-16 Series

boards. The main I/O connector is a male, 37-pin, D-type. Pin

assignments for this connector are shown in Figure 3-1.

3

REL A0 - 19

REL A1 - 18

REL A2 - 17

REL A3 - 16

REL A4 - 15

REL A5 - 14

REL A6 - 13

REL A7 - 12

REL B0 - 11

REL B1 - 10

REL B2 - 09

REL B3 - 08

REL B4 - 07

REL B5 - 06

REL B6 - 05

REL B7 - 04

N/C - 03

N/C - 02

N/C - 01

37 - REL A0

36 - REL A1

35 - REL A2

34 - REL A3

33 - REL A4

32 - REL A5

31 - REL A6

30 - REL A7

29 - REL B0

28 - REL B1

27 - REL B2

26 - REL B3

25 - REL B4

24 - REL B5

23 - REL B6

22 - REL B7

21 - Pwr. Com.

20 - +5V

Figure 3-1. Pin Assignments for the Main I/O Connector

3-1

Page 39

Caution: To avoid electrical damage, turn off power to the computer and

any attached accessories before making connections to REL-16 Series

boards.

Attaching an STA-U or STP-37/FC Accessory

Warning Do not use the STA-U, STP-37/FC, C1800, and C-1800/M accessories at

voltages above 30V RMS, 42.4V peak, or 60VDC. These accessories are

rated for 30V RMS, 42.4V peak, or 60VDC maximum. Use at higher

voltages may result in shock hazard.

When connecting voltages up to 30V RMS, 42.4V peak, or 60VDC, only,

you may attach the REL-16 board to an STA-U or STP-37/FC screw

terminal accessory as follows:

● When attaching an STA-U accessory, use a C1800 cable.

● When attaching an STP-37/FC accessory, use a C-1800/M cable.

You may make these connections as shown in Figure 3-2.

REL-16 Series board

C1800 cable for STA-U;

C-1800/M cable for

STP-37/FC

Figure 3-2. Attaching an STA-U or STP-37/FC to an

REL-16 Series Board

3-2 Cabling and Wiring

STA-U or

STP-37/FC

Page 40

Note: Use the STP-37/FC accessory with a C-1800/M cable for extra

protection against the possibility of personal or tool contact with signals.

Attaching an STC-37 Accessory

Warning Do not use the STC-37/FC accessory at voltages above 30V RMS, 42.4V

peak, or 60VDC. This accessory is rated for 30V RMS, 42.4V peak, or

60VDC maximum. Use at higher voltages may result in shock hazard.

The STC-37, shown in Figure 3-3, is a directly connected screw terminal

panel for use at voltages up to 30V RMS, 42.4V peak, or 60VDC.

35

363734

31

32

33

30

28

29

25

26

22

23

24

27

Cable Clamp

56789

432

2120191817

10

11

12

13

14

15

16

1

D-Connector that connects

to the main I/O connector of

an REL-16 Series board

Figure 3-3. Layout of STC-37 Screw Terminal Connector Panel

The STC-37 connects to the main I/O connector on an REL-16 Series

board as shown in Figure 3-4. The screw terminal numbers of the STC-37

correspond to the pin numbers of the main I/O connector.

3-3

Page 41

REL-16 Series board

Figure 3-4. Attaching an STC-37 Accessory

STC-37

3-4 Cabling and Wiring

Page 42

4

Programming

You do not program the registers of your REL-16 Series board directly

through Windows 95/98/NT. Instead, you program register changes

through the application programming interface (API) of DriverLINX.

DriverLINX is provided on the CD-ROM that comes with your board and

should now be installed on your system. (Refer to Section 2,

“Installation.”) Using DriverLINX, you can program the board in Visual

C/C++, Visual Basic, and Delphi.

DriverLINX features are summarized in Section 1, under “Supporting

Software” on page 1-3. For detailed information about DriverLINX in

general and about programming with DriverLINX specifically, refer to

your DriverLINX documentation.

Note: To access the DriverLINX documents on-line, Acrobat Reader

(version 3.0 or greater) must be installed on your computer.

To access the DriverLINX documentation after you have installed it on

your computer, do the following:

1. Click the Windows 95/98/NT Start tab.

2. In the Start menu, click Programs.

3. Find the DriverLINX entry, under which you should find the On-line

Manuals entry.

4. Click on the On-line Manuals entry. The DriverLINX Printable

Documentation table of contents opens via Acrobat Reader.

4-1

Page 43

5. Scroll through the DriverLINX Printable Documentation table of

contents and find the document or document category that you want.

6. Click on the wanted document or document category. Either the

selected document appears or a list of documents that fit the selected

category appears.

7. If a list appears, click on the title of the document that you want. The

desired document appears.

To access the DriverLINX documentation from the CD-ROM that came

with your board, do the following:

1. In Windows Explorer, double click on X:\Drvlinx4\Docs\Toc.pdf,

where X is the drive letter of your CD-ROM drive. The DriverLINX

Printable Documentation table of contents opens via Acrobat Reader.

2. Scroll through the DriverLINX Printable Documentation table of

contents and find the document or document category that you want.

3. Click on the wanted document or document category. Either the

selected document appears or a list of documents that fit the selected

category appears.

4. If a list appears, click on the title of the document that you want.

The desired document appears.

4-2 Programming

Page 44

Warning The procedures in this section are intended for qualified service

personnel. Do not perform these procedures unless you are qualified

to do so.

If your REL-16 Series board is not operating properly, use the

information in this section to isolate the problem. If the problem appears

serious enough to warrant technical support, refer to “Technical Support”

on page 5-5 for information on how to contact an applications engineer.

Problem Isolation

5

Troubleshooting

If you encounter a problem with an REL-16 Series board, use the

instructions in this section to isolate the cause of the problem before

calling Keithley Hardware Applications Engineering.

Identifying Symptoms and Possible Causes

Use the troubleshooting information in Table 5-1 to try to isolate the

problem. Table 5-1 lists general symptoms and possible solutions for

problems with REL-16 Series boards.

5-1

Page 45

Table 5-1. Troubleshooting Information

Symptom Possible Cause Possible Solution

Board does not

respond

DriverLINX is not installed

correctly or the combined

DriverLINX/board installation is

not properly configured.

Base address is incorrect or not

consistent with what the program

is addressing.

The board configuration is

incorrect.

The board is incorrectly aligned

in the accessory slot.

The board is damaged. Contact the Keithley Hardware

Reinstall and/or reconfigure DriverLINX

if necessary. Refer to “Configuring Your

Installation” on page 2-5 and to

“Configuring the PIO Series” in the

manual Using DriverLINX With Your

Hardware—Keithley PIO Series.

Check the base address switch setting. If

the base address is set correctly, make

sure no other computer device is using

any of the I/O locations beginning at the

specified base address. If necessary,

reconfigure the base address. Refer to

“Setting the Base Address” on page 2-7

for instructions on setting the base

address.

Check the remaining settings.

Check the board for proper seating.

Applications Engineering Department;

see “Technical Support” on page 5-5.

Intermittent

operation

5-2 Troubleshooting

The most common cause of this

problem is that the I/O bus speed

is in excess of 8MHz.

Vibrations or loose connections

exist.

The board is overheating. Check environmental and ambient

Electrical noise exists. Provide better shielding or reroute

Reduce I/O bus speed to a maximum of

8MHz (to change the I/O bus speed, run

BIOS setup). See your computer

documentation for instructions on

running BIOS setup.

Cushion source of vibration and tighten

connections.

temperature. See the documentation for

your computer.

unshielded wiring.

Page 46

Table 5-1. Troubleshooting Information (cont.)

Symptom Possible Cause Possible Solution

Data appears to be

invalid

Computer does not

boot

The most common cause of this

problem is that the I/O bus speed

is in excess of 8MHz.

An open connection exists. Check wiring to screw terminal and to

Another system resource is using

the specified base address.

Board not seated properly. Check the installation of the board.

The base address setting of the

REL-16 board conflicts with that

of another system resource.

The power supply of the host

computer is too small to handle

all the system resources.

Reduce I/O bus speed to a maximum of

8MHz (to change the I/O bus speed, run

BIOS setup). See the documentation for

your computer for instructions on

running BIOS setup.

REL-16 Series board.

Reconfigure the base address of the

REL-16 board; refer to “Setting the

Base Address” on page 2-7 for more

information. Check the I/O assignments

of other system resources and

reconfigure, if necessary.

Check the base address settings of your

system resources; each address must be

unique.

Check the needs of all system resources

and obtain a larger power supply.

If your board is not operating properly after using the information in

Table 5-1, continue with the next two sections to further isolate the

problem.

Testing the Board and Host Computer

To isolate the problem to an REL-16 Series board or to the host computer,

use the following steps:

1. Turn the power to the host computer OFF, and remove power

connections to the computer.

5-3

Page 47

Caution: Removing a board with the power ON can cause damage to

your board and/or computer.

2. While keeping connections to accessory board intact, unplug the

accessory connector or cable from the REL-16 Series board.

3. Remove the REL-16 Series board from the computer and visually

check for damage. If a board is obviously damaged, refer to

“Technical Support” on page 5-5 for information on returning the

board.

4. With the REL-16 Series board out of the computer, check the

computer for proper operation. Power up the computer and perform

any necessary diagnostics.

At this point, if you have another REL-16 Series board that you know is

functional, you can test the slot and I/O connections using the instructions

in the next section. If you do not have another board, refer to the

instructions on “Technical Support” on page 5-5 before calling Keithley

Technical Support.

Testing the Accessory Slot and I/O Connections

When you are sure that the computer is operating properly, test the

computer accessory slot and I/O connections using another REL-16

Series board that you know is functional. To test the computer accessory

slot and the I/O connections, follow these steps:

1. Remove computer power again, and install an REL-16 Series board

that you know is functional. Do not make any I/O connections.

2. Turn computer power ON and check operation with the functional

board in place. This test checks the computer accessory slot. If you

were using more than one REL-16 Series board when the problem

occurred, use the functional board to test the other slot, as well.

3. If the accessory slots are functional, use the functional board to check

the I/O connections. Reconnect and check the operation of the I/O

connections, one at a time.

4. If operation fails for an I/O connection, check the individual inputs

one at a time for shorts and opens.

5-4 Troubleshooting

Page 48

5. If operation remains normal to this point, the problem is in the

REL-16 Series board(s) originally in the computer. If you were using

more than one board, try each board one at a time in the computer to

determine which is faulty.

6. If you cannot isolate the problem, refer to the next section for

instructions on obtaining assistance.

Technical Support

Before returning any equipment for repair, call the Keithley Hardware

Applications Engineering Department at:

1-888-KEITHLEY

Monday - Friday, 8:00 a.m. - 5:00 p.m., Eastern Time

An applications engineer will help you diagnose and resolve your

problem over the telephone.

Please make sure that you have the following information page available

before you call:

REL-16 Series Board

Configuration

Computer Manufacturer

Operating System Windows version ___________________

Compiler

(if applicable)

Accessories Type

Model

Serial #

Revision code

Base address setting

CPU type

Clock speed (MHz)

MB of RAM

Video system

BIOS type

Language

Manufacturer

Version

Type

Type

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

___________________

5-5

Page 49

If a telephone resolution is not possible, the applications engineer will

issue you a Return Material Authorization (RMA) number and ask you to

return the equipment. Include the RMA number with any documentation

regarding the equipment.

When returning equipment for repair, include the following information:

● Your name, address, and telephone number.

● The invoice or order number and date of equipment purchase.

● A description of the problem or its symptoms.

● The RMA number on the outside of the package.

Repackage the equipment, using the original anti-static wrapping, if

possible, and handling it with ground protection. Ship the equipment to:

ATTN: RMA #_______

Repair Department

Keithley Instruments, Inc.

28775 Aurora Road

Cleveland, Ohio 44139

Telephone 1-888-KEITHLEY

FAX (440) 248-6168

Notes: If you are submitting your equipment for repair under warranty,

you must include the invoice number and date of purchase.

To enable Keithley to respond as quickly as possible, you must include

the RMA number on the outside of the package.

5-6 Troubleshooting

Page 50

A

Specifications

This appendix provides specifications for the REL-16 Series relay boards.

Table A-1. General Output Specifications

Feature Specification

Number of outputs 16 SPST (Form A) relays

Operation time 2.0ms maximum

Relay isolation resistance

Table A-2. REL-16 Contact Ratings

Feature Specification

Contact type Rhodium plated

Contact rating 10W @ 0.5A or 125V RMS

Contact resistance 100mΩ maximum, initial

Contact life

*Do not connect to mains or unlimited power circuits.

109Ω @ 100VDC

(resistive), Installation Category I*

107 operations at rated load

A-1

Page 51

Table A-3. REL-16/W Contact Ratings

Feature Specification

Contact type Mercury wetted (position-sensitive;

board must be mounted within ±30˚ of

vertical)

Contact rating 50W @ 1A or 125V RMS (resistive),

Installation Category I*

Contact resistance 50mΩ maximum, initial

Contact life

*Do not connect to mains or unlimited power circuits.

107 operations at rated load

Table A-4. Environmental Specifications

Feature Specification

Operating temperature 0˚ to 60˚C

Storage temperature −40˚ to 100˚C

Humidity 0 to 90%, non-condensing

Mounting The REL-16/W must be mounted

within 30˚ of vertical. The REL-16

can be mounted at any angle.

Dimensions 9.0 x 4.25 x 0.85 in.

(22.9 × 10.8 × 2.2 cm)

Table A-5. Power Consumption Specifications

Feature Specification

+5V 510mA plus 22mA maximum for each

activated relay

±12V Not used

A-2 Specifications

Page 52

B

Connector Pin Assignments

The connection between an external I/O device and an REL-16 Series

board is made at the main I/O connector, which is a standard 37-pin,

D-type male connector. The mating connector is a 37-pin, D-type female

connector (part# SFC-37). Figure B-1 illustrates pin assignments of the

main I/O connector.

REL A0 - 19

REL A1 - 18

REL A2 - 17

REL A3 - 16

REL A4 - 15

REL A5 - 14

REL A6 - 13

REL A7 - 12

REL B0 - 11

REL B1 - 10

REL B2 - 09

REL B3 - 08

REL B4 - 07

REL B5 - 06

REL B6 - 05

REL B7 - 04

N/C - 03

N/C - 02

N/C - 01

37 - REL A0

36 - REL A1

35 - REL A2

34 - REL A3

33 - REL A4

32 - REL A5

31 - REL A6

30 - REL A7

29 - REL B0

28 - REL B1

27 - REL B2

26 - REL B3

25 - REL B4

24 - REL B5

23 - REL B6

22 - REL B7

21 - Pwr. Com.

20 - +5V

Figure B-1. Main I/O Connector Pin Assignments

B-1

Page 53

C

Register Maps

Note: Register maps are provided here only for background reference

purposes. You do not program registers directly in Windows 95/98/NT.