Page 1

TM 11-6625-1722-15

TECHNICAL MANUAL

OPE R A TOR ’ S , OR GA N I Z A TI ON A L , D I R E C T S U PPOR T

GE N E R A L S U PPOR T , A N D D E POT M A I N TE N A N CE

MANUAL

OSCI L LOSCOP E AN / U SM - 2 7 3

(NSN 6625-00-930-6637)

This copy is a reprint which includes current

pages from Changes 1.

HEADQUARTERS,

DEPARTMENT OF THE ARMY

JANUARY 1972

Page 2

THIS MANUAL IS AN AUTHENTICATION OF THE MANUFACTURER’S COMMERCIAL LITERATURE WHICH,

THROUGH USAGE, HAS BEEN FOUND TO COVER THE

DATA REQUIRED TO OPERATE AND MAINTAIN THIS

EQUIPMENT. SINCE THE MANIJAL WAS NOT PREPARED

IN ACCORDANCE WITH MILITARY SPECIFICATION, THE

FORMAT HAS NOT BEEN STRUCTURED TO CONSIDER

LEVEL OF MAINTENANCE NOR TO INCLUDE A FORMAL SECTION ON DEPOT MAINTENANCE STANDARDS.

WARNING

DANGEROUS VOLTAGES

EXIST IN THIS EQUIPMENT

DON’T TAKE CHANCES!

CAUTION

Special 3% silver solder is required on the ceramic terminal

strips in this equipment. A 40- to 75-watt soldering iron

should be used and it should be tinned with the same special

solder. Additional quantities of the solder may be procured

under FSN 3439-912-8698. Ordinary solder may be used

only in dire emergency.

Page 3

This Manual Contains Copyrighted Material Reproduced

Tektronix, Inc. All Rights Reserved

Permission Of

By

TM 11-6625-1722-15

T

ECHNICAL M ANUAL

HEADQUARTERS

DEPARTMENT OF THE ARMY

NO. 11–6625–1722–15

ASHINGTON

, D.C., 10 January 1972

W

Operator’s Organizational, Direct Support, General Support, and Depot

Maintenance Manual Including Repair Parts and Special Tools Lists

OSCILLOSCOPE AN/USM–273

S

ECTION A.

INRODUCTION

1.

CHARACTERISTICS

2.

OPERATING INSTRUCTIONS . .. . . . . . . . . . . . . . . . . . . . .

CIRCUIT DESCRIPTION . . . . . . . . . . . . . . . . . .

3.

4.

MAINTENANCE

PERFOR0MANCE CHECK . . . . . . . . . . . . . . . . . . . . .

5.

Page

A-1

1-1

2–1

3–1

4–1

5-1

6.

7.

8.

9.

10,

APPENDIX A .

B.

C.

D.

CALIBRATION

PREVENTIVE MAINTENANCE INSTRUCTIONS . . . . . . . . . . . . . . . . .

MECHNICAL PARTS IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . .

DIAGRAMS

RACKMOUNTING

REFERENCES

ITEMS COMPRISING AN OPERABLE EQUIPMENT . . . . . . . . . . . . . . . .

MAINTENANCE ALLOCATION . . . . . . . . . . . . . . .

REPAIR PARTS AND SPECIAL TOOLS LIST . . . . . . . . . . . . . .

6–1

7–1

8-1

9-1

10-1

A–1

B–1

C-1

D-1

Page 4

Page 5

TM 11-6625-1722-15

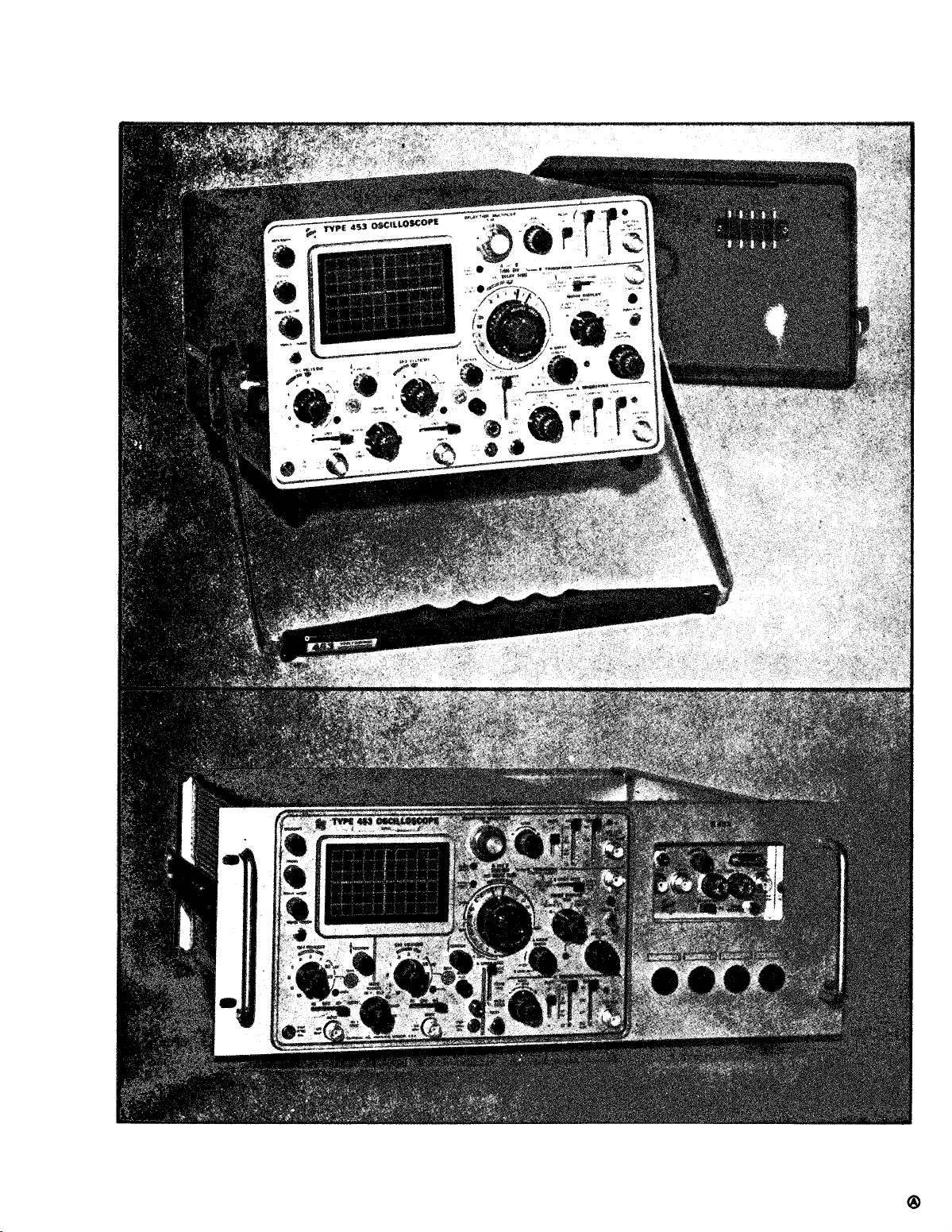

Fig. 1-1. Top; the Type 453 Oscilloscope. Bottom; the Type R453 Oscilloscope.

A-O

Page 6

Page 7

SECTION 0

INSTRUCTIONS

TM 11-6625-1722-15

0-1.

maintenance instructions.

Scope

This manual describes Oscilloscope

Throughout this manual, the AN/USM-273 is re-

AN/USM-273 (fig. 1-1) and provides

ferred to as the Tektronix Type 453 Oscilloscope. The maintenance allo-

cation chart appears in appendix C.

Repair parts and special tools lists

are contained in TM-6625-1722-24P.

0-2.

Indexes of Publications

a. DA Pam 310-4.

Refer to the latest issue of DA Pam 310-4 to deter-

mine whether there are new editions, changes, or additional publications

pertaining to the equipment.

DA Pam 310-7.

b .

Refer to DA Pam 310-7 to determine whether there

are modification work orders (MWO’S) pertaining to the equipment.

0-3.

Maintenance Forms, Records, and Reports

Reports of Maintenance and Unsatisfactory

a.

Equipment.

Department

of the Army forms and procedures used for equipment maintenance will be

those prescribed by TM 38-750, The Army Maintenance Management System.

Report of Packaging and Handling Deficiencies.

b.

Fill out and for-

ward DD Form 6 (Packaging Improvement Report) as prescribed in AR 700-58/

NAVSUPINST 4030.29/AFR 71-13/MCO P4030.29A, and DLAR 4145.8.

Discrepancy

c.

in Shipment Report (DISREP) (SF 361). Fill out and

forward Discrepancy in Shipment Report (DISREP) (SF 361) as prescribed in

AR 55-38/NAVSUPINST 4610.33B/AFR 75-18/MCO P4610.19C and DLAR 4500.15.

0-1

Page 8

TM 11-6625-1722-15

0-4.

Reporting Equipment Improvement Recommendations (EIR)

If your Oscilloscope AN/USM-273 needs improvement, let us know.

You,

us an EIR.

the user,

don’t like about your equipment.

design.

Tell us why a procedure is hard to perform.

(Quality Deficiency Report).

and Electronics Materiel Readiness Command, ATTN:

Monmouth, NJ 07703.

0-5.

Administrative Storage

We’ll send you a reply.

are the only one who can tell us what you

Let us know why you don’t like the

Put it on an SF 368

Mail it to Commander, US Army Communications

DRSEL-ME-MQ, Fort

Administrative storage of equipment issued to and used by Army activi-

ties shall be in accordance with TM 740-90–1.

0-6

Destruction of Army Electronics Materiel

Destruction of Army electronics materiel to prevent enemy use shall be

Send

in accordance with TM 750-244-2.

0-7.

Reporting Errors and Recommending Improvements

You can help improve this manual. If you find any mistakes or if you

know of a way to improve the procedures, please let us know. Mail your

letter or DA Form 2028 (Recommended Changes to Publications and Blank

Forms) to

Readiness Command, ATTN:

either case,

Commander, US Army Communications and Electronics Materiel

DRSEL-ME-MQ, Fort Monmouth, NJ 07703. In

a reply will be furnished direct to you.

0-2

Change 1

Page 9

SECTION 1

CHARACTERISTICS

TM 11-6625-1722-15

Introduction

The Tektronix Type 453 Oscilloscope is a transistorized

portable oscilloscope designed to operate in a wide range

of environmental conditions. The light weight of the Type

453 allows it to be easily transported, while providing the

performance necessary for accurate high-frequency measurements.

provides calibrated deflection factors from 5 millivolts to

10 volts/division. Channels 1 and 2 can be cascaded using

an external cable to provide a one millivolt minimum defection factor (both VOLTS/DIV switches set to 5 mV).

The trigger circuits provide stable triggering over the full

range of vertical frequency response. Separate trigger controls are provided to select the desired triggering for the A

and B sweeps. One of three sweep modes can be selected

for the A sweep; automatic, normal or single sweep. The

horizontal sweep provides a maximum sweep rate of 0.1

microsecond/division (10 nanosecond/division using 10X

magnifier) along with a delayed sweep feature for accurate

relative-time measurements.

can be made with Channel 2 providing the vertical deflection,

and Channel 1 providing the horizontal [deflection. (TRIGGER

switch set to CH 1 ONLY, HORIZ DISPLAY switch set to EXT

HORIZ). The regulated DC power supplies maintain con-

The dual-channel DC-to-50 MHz vertical system

Accurate X-Y measurements

ELEC TRI C A L C H A RA C TERI STI C S

VERTICAL DEFLECTlON SYSTEM

stant output over a wide variation of line voltages and frequencies.

approximately 90 watts.

Information given in this instruction monual applies to the

Type R453 also unless otherwise noted. The Type R453 is

electrically identical to the Type 453 but is mechanically

adapted for mounting in a standard 19-inch rack. Rackmounting instructions, a mechanical parts list and a dimensional drawing for the Type R453 are provided in Section

10 of this manual.

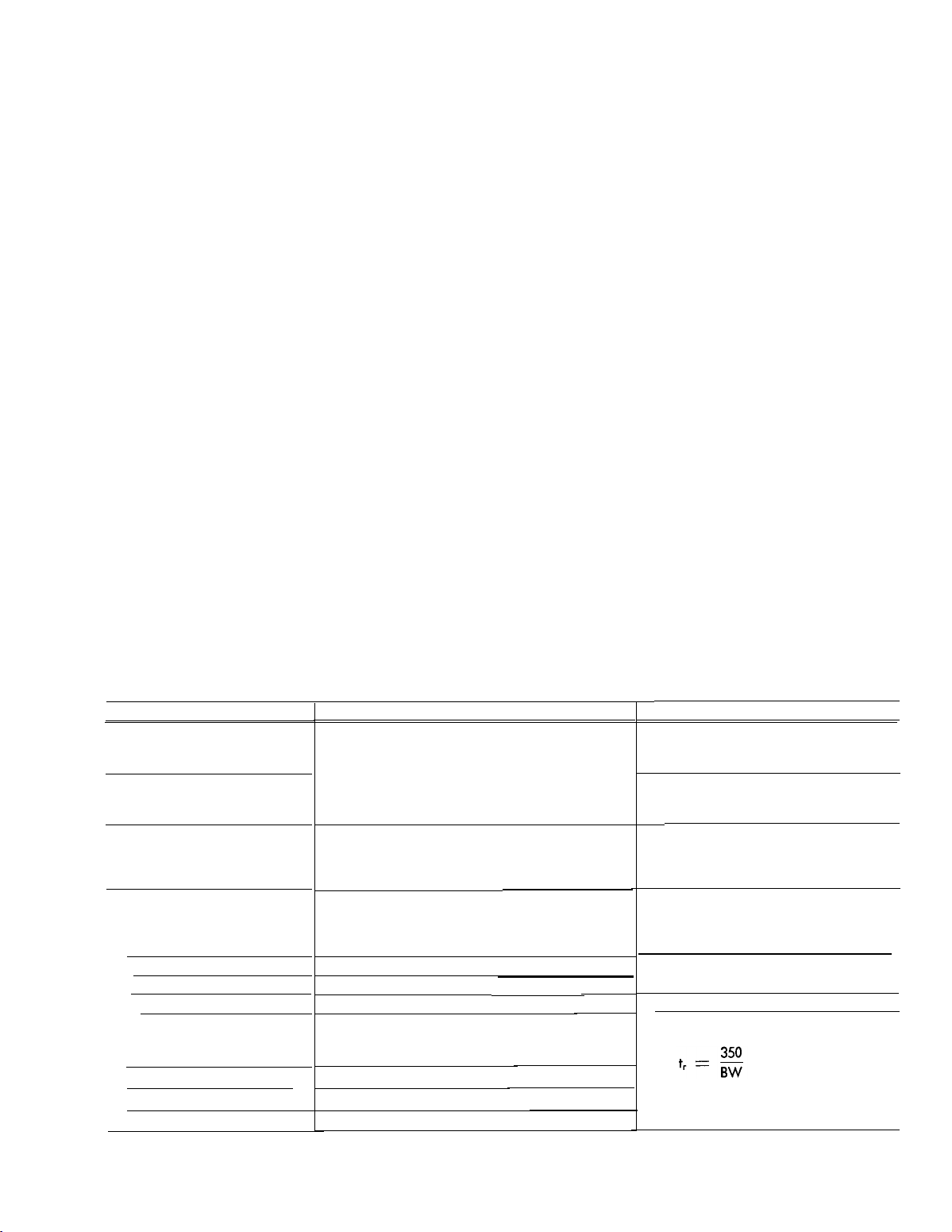

The electrical characteristics which follow are divided

into two categories. Characteristics listed in the Performance

Requirement column are checked in the Performance Check

and Calibration sections of this manual. Items listed in the

Operational Information column are provided for reference

use and do not directly reflect the measurement capabilities of this instrument. The Performance Check procedure

given in Section 5 of this manual provides a convenient

method of checking the items listed in the Performance

Requirement column. The following electrical characteristics

apply over a calibration interval of 1000 hours at an ambient temperature range of -15°C to +55°C, except as

otherwise indicated. Warm-up time for given accuracy is

20 minutes.

Total power consumption of the instrument is

. .

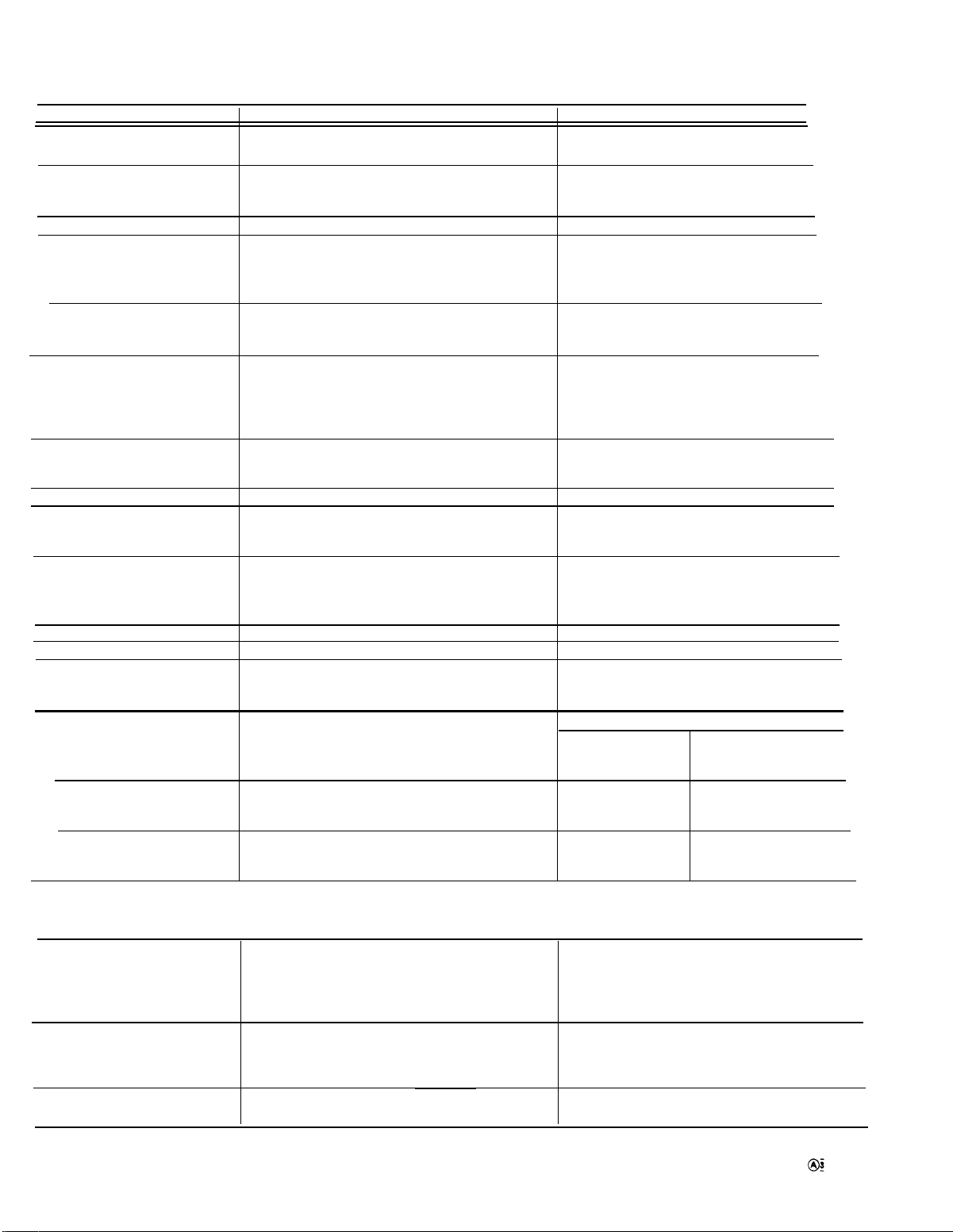

Characteristic

Deflection Factor

Deflection Accuracy

Variable Deflection Factor

Bandwidth at Upper -3 dB

point (with or without P6010

Probe)

20 mV to 10 VOLTS/DIV

10 mV/DIV

5 mV/DIV

Channels land 2 cascaded

Risetime (calculated). With or

without P6010 Probe.

20 mV to 10 VOLTS/DIV

10 mV/DIV

5 mV/DIV

Channels 1 and 2 cascaded

Performance Requirement

5 millivolts/division to 10 volts/division in 11

calibrated steps for each channel. One millivolt/

division when Channel 1 and 2 are cascaded.

Within ±3Y% of indicated deflection with VARlABLE control set to CAL. Cascaded deflection

factor uncalibrated.

Uncalibrated deflection factor at least 2.5 times

the VOLTS/DIV switch indication. This provides

a maximum uncalibrated deflection factor of 25

volts/division in the 10 volts position.

DC to 50 MHz or greater

DC to 45 MHz or greater

DC to 40 MHz or greater

DC to 25 MHz or greater

Less than 7 nanoseconds

Less than 7.8 nanoseconds

Less than 8.75 nanoseconds

Less than 14 nanoseconds

Operational Information

Steps in 1-2-5 sequence

With gain correct at 20 mV

Driven from 25-ohm source

Measured at one millivolt/division

Risetime calculated from bandwidth

measurement using the formula:

Where:

= Risetime in nanoseconds.

t

r

BW = Bandwidth in megahertz.

1-1

Page 10

TM 11-6625-1722-15

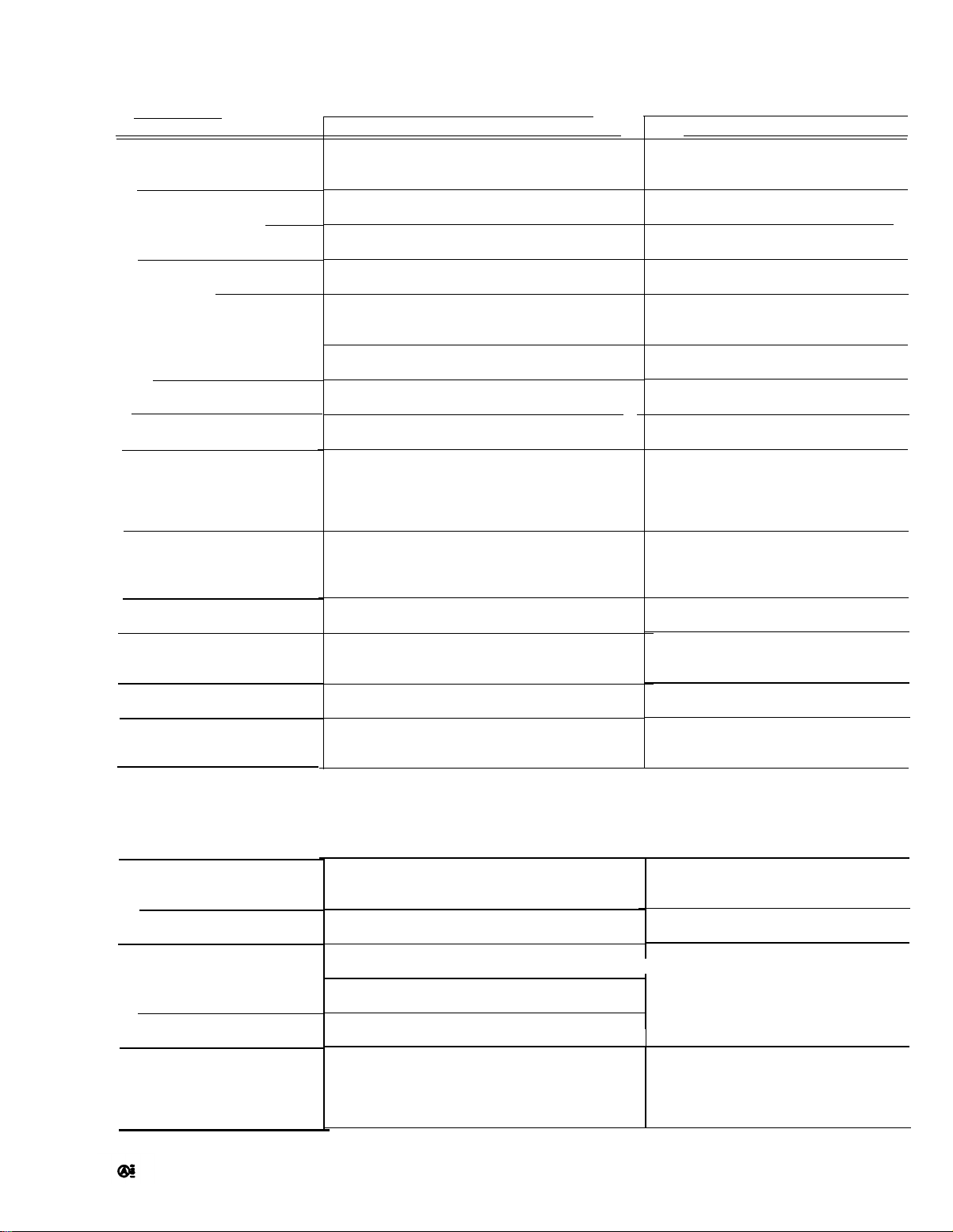

Characteristic

Input RC Characteristics

Maximum lnput Voltage

lnput Coupling Modes

AC Low-Frequency Response

(lower -3 dB point)

Without probe

With P6010 Probe

Trace Shift Due to Input Gate

Current (at 25°C)

Vertical Display Modes

Chopped Repetition Rate

Attenuator Isolation

Common Mode Rejection Ratio

Linear Dynamic Range Useful

for Common-Mode Relection

in ADD Mode

Polarity Inversion

Signal Delay Line

Low-Frequency

Vertical Linearity

Trace Drift (after 20 minute

warm up)

20 mV to 10 VOLTS/DIV

10 mV/DIV

5 mV/DIV

VERTICAL (cont)

Performance Requirement

AC or DC, selected by front-panel switch

Negligible

Channel 1 only

Channel 2 only

Dual-troce, alternate between channels

Dual-trace, chopped between channels

Added algebraically

Approximately one-microsecond segments from

each channel dispiayed at repetition rate of 500

kHz, ±20%.

Greater than 10,000:1, DC to 20 MHz

Greater than 20:1 at 20 MHz for common-mode

signals less than eight times VOLTS/DIV switch

setting.

Signal on Channel 2 can be inverted

Less than 0.15 division compression or expansion

of two division signal when positioned to vertical

extremes of display area

Operational Information

Typically 1 megohm (±2%), paralleled

by 20 pF (±3%)

600 volts DC + peak AC (one kilohertz

or less). Peak-to-peak AC not to exceed

600 volts.

Typicaily 1.6 Hz, Input Coupling switch

set to AC

Typically 0.16 Hz

With optimum GAIN

frequency

Less than 10% incremental signal dis-

tortion for instantaneous input voltage

-10 or +10 times VOLTS/DIV

of

switch setting

Approximately 140 nanoseconds

Includes CRT linearity. Measured with

one-kilohertz square wave.

Time

Typically less than Typically less than

0.03 division/hour

Typically less than

0.05 division/hour

Typically less than

0.08 division/hour

adjustment at low

Temperature

0.0075 division/degree C

Typically less than

0.0125 division/degree C

Typically less than

0.02 division/de-

gree C

Source

Coupling

Polarity

1-2

TRIGGERING (A AND B SWEEP)

Internal from displayed channel or from Channel

1 only

Internal from AC power source

External

External divide by 10

AC

AC low-frequency reject

AC high-frequency reject

DC

Sweep can be triggered from positive-going or

negative-going portion of trigger signal

Page 11

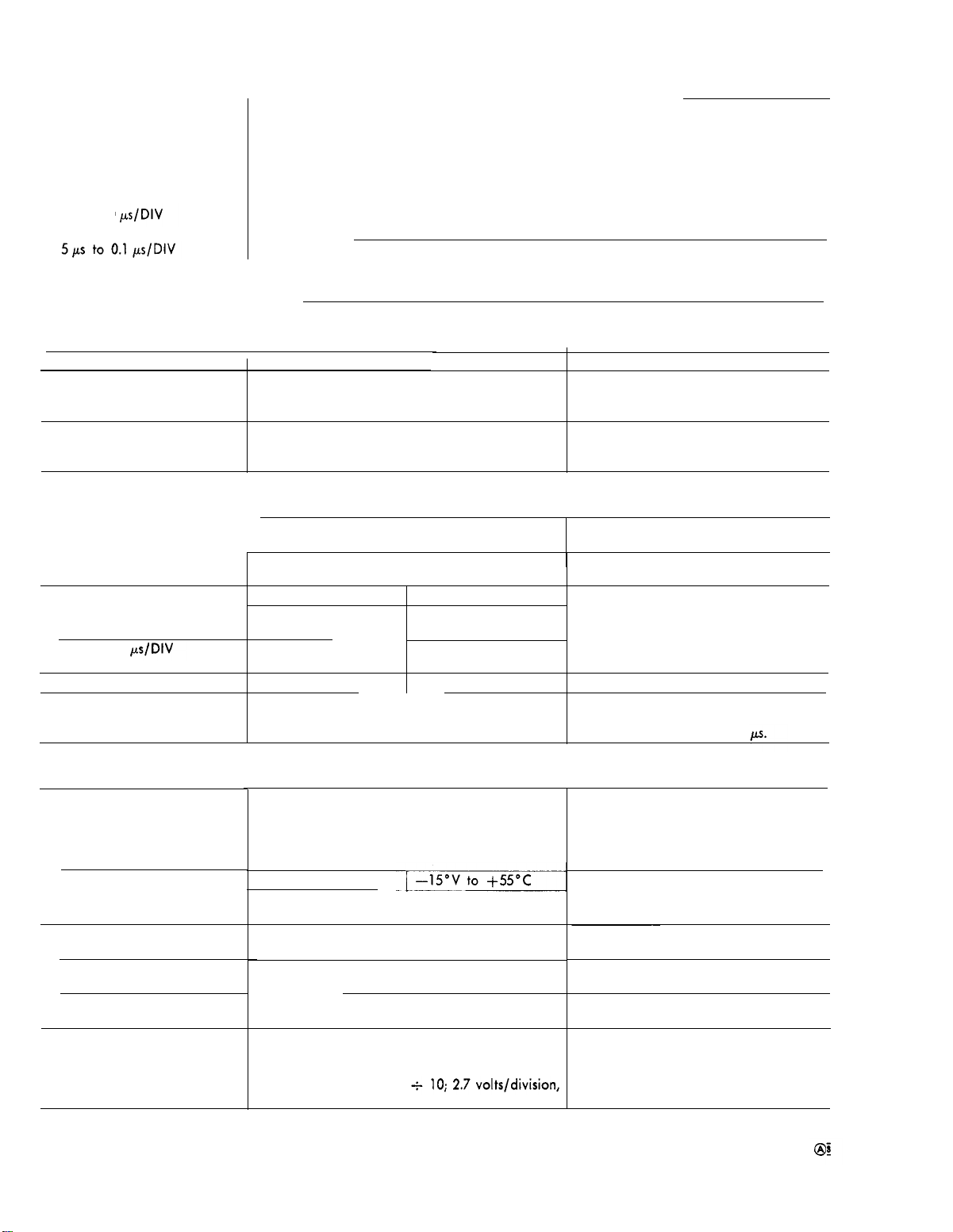

TRIGGERING (cont)

TM 11-6625-1722-15

Characteristic

Internal Trigger Sensitivity

AC

LF REJ

HF REJ

DC

External Trigger Sensitivity

AC

LF REJ

HF REJ

DC

Auto Triggering (A sweep only)

Single Sweep (A sweep only)

Display Jitter

Maximum Input Voltage

External Trigger Input RC

Characteristics (approximate)

LEVEL Control Range

Performance Requirement

0.2 division of deflection, minimum, 30 Hz to 10

MHz; increasing to 1 division at 50 MHz

0.2 division of deflection, minimum, 30 Hz to 10

0.2 division of deflection, minimum, 30 kHz to 10

0.2 division of deflection, minimum, 30 Hz to 50

kHz

0.2 division of deflection, minimum, DC to 10

MHz; increasing to 1 division at 50 MHz

50 millivolts, minimum, 30 Hz to 10 MHz; increasing to 200 millivolts at 50 MHz

50 millivolts, minimum, 30 kHz to 10 MHz; increasing to 200 millivolts at 50 MHz

50 millivolts, minimum, 30 Hz to 50 kHz

50 millivolts, minimum, DC to 10 MHz; increas-

ing to 200 millivolts at 50 MHz

Stable display presented with signal amplitudes

given under Internal and External Trigger Sensitivity above 20 Hz. Presents a free-running sweep

for lower frequencies or in absence of trigger

signal.

A Sweep Generator produces only one sweep

when triggered. Further sweeps are locked out

until RESET button is pressed. Trigger sensitivity

same as given above.

Less than 1 nanosecond at 10 nanoseconds/division sweep rate (MAG switch set to X10)

At least ±2 volts, SOURCE switch in EXT position. At least ±20 volts, SOURCE switch in EXT

÷10 position

Operational Information

Typical -3 dB point, 16 Hz

Typical -3 dB point, 16 kHz

Typical -3 dB points, 16 Hz and 100

kHz

Typical -3 dB point, 16 Hz

Typical -3 dB point, 16 kHz

Typical -3 dB points, 16 Hz and 100

kHz

600 volts DC + peak AC (one kilohertz

or less). Peak-to-peak AC not to exceed

600 volts.

1 Megohm paralleled by 20 pF, except

in LF REJ

Sweep Rates

A Sweep

B sweep

Sweep Accuracy-A and B

Sweep

5 s to 0.1 s/DIV

50 ms to 0.1 µs/ DIV

Variable Sweep Rate

HORIZONTAL DEFLECTION SYSTEM

A and B Sweep Generator

0.1 microsecond/division to 5 seconds/division in

24 calibrated stem

0.1 microsecond/division to 0.5 second/division

in 21 calibrated steps

0°C to +40°C

Within ±3% of indi- Within ±5% of indi-

cated sweep rate

Within ±3% of indi- Within ±4% of indi-

cated sweep rate

Uncalibrated sweep rate to at least 2.5 times the

TIME/DIV indication, or a maximum of at least

12.5 seconds/division in the 5 s position (B sweep,

maximum of 1.25 seconds/division in the .5 s

position.

-15°C to +55°C

cated sweep rate

cated sweep rate

A sweep is main and delaying sweep

B sweep is delayed sweep

A VARIABLE and B TIME/DiV VARlABLE controls set to CAL

1-3

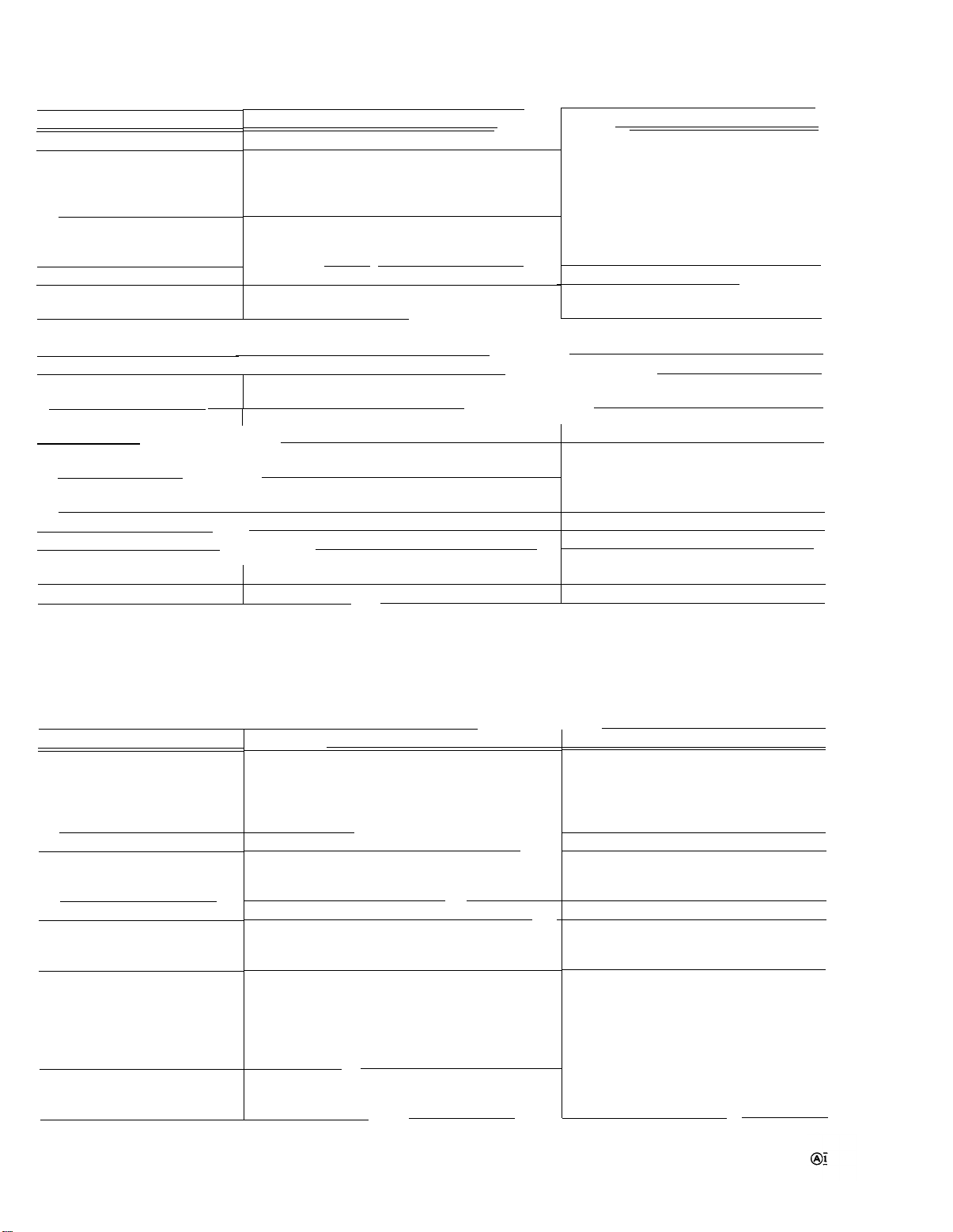

Page 12

TM 11-6625-1722-15

A and B Sweep Generotor

Characteristic

Sweep Length

A sweep

B sweep

Sweep Hold-off-A sweep

5s to 10

Sweep Magnification

Magnified Sweep Accuracy 1% tolerance added to speclfled sweep accuracy

Magnified Sweep Linearity

Normal/Magnified Registration

Calibrated Delay Time Range

DELAY-TIME MULTIPLIER

Dial Range

Delay Time Accuracy

5s to 0.1 s/DIV

50 ms to 1

Incremental Multiplier Linearity

Delay Time Jitter

Variable from less than 4 divisions to 11.0, ±0.5

division

11.0 divisions, ±0.5 division

Less than one times the A TIME/DIV switch set-

ting

Less than 2.5 microseconds

Each sweep rate can be increased 10 times the Extends fastest sweep rate to 10 nano-

indicated sweep rate by horizontally expanding seconds/division

the center division of display

±1.5% for any eight division portion of the

total magnified sweep length (excluding first

and last 60 nanoseconds of magnified sweep)

±0.2 division, or less, trace shift at graticuie

center when switching MAG switch from X10

to OFF

Continuous from 50 seconds to 1 microsecond A VARIABLE control set to CAL for indi-

0.20 to 10.20

0°C to +40°C -15° C to +55° C

Within ±2.5% of indicated delay cated delay Includes incremental multiplier linearity

Within ±1.5% of indicated delay cated delay

±0.2%

Less than 1 part in 20,000 of 10 times A TIME/

DIV switch setting

Performance Requirement

Sweep Magnifier

Sweep Delay

Within ±3.5% of indi-

‘Within ±2% of indi-

±0.3%.

Operational Information

A TIME/DIV switch set to 1 ms

B TIME/DIV switch set to 1 ms

cated delay

Equal to 0.5 division, or less, with the A

TIME/DIV switch set to 1 ms and the B

TIME/DIV switch set to 1

Input to Channel 1 (TRIGGER

switch in CH 1 ONLY)

Deflection factor

Accuracy

X Bandwidth at Upper -3 dB

Point

Input RC characteristics

Phase difference between X

and Y amplifiers at 50 kHz

Input to EXT HORIZ Connector

Deflection factor

1-4

External Horizontal Amplifier

5 millivolts/division to 10 volts/division in 11 calibrated steps

0°C to +40°C

Within ±5% of indi- Within ±8% of indi-

cated deflection

5 MHz or greater

Less than 3°

B SOURCE switch in EXT; 270 millivolts/division,

±15%.

B SOURCE switch in EXT

±20%

cated deflection

Steps in 1-2-5 sequence.

Channel 1 VARIABLE control does not

affect horizontal deflection

With external horizontal gain correct

at 20 mV

Typically 1 megohm (±2%), paralleled

by 20 pF (±3%)

Page 13

Ex t e r na l H o r iz o n ta l A m p l i fi e r (c ont)

X Ba nd w id th a t Up p er -3 5 M Hz o r g re a te r

TM 11-6625-1722-15

Operational Information

—

Input RC c h ara c te ristic s

(approxima te]

Ph a se d if fe re n c e b etw e e n X

and Y amplifiers at 50kHz

CALIBRATOR

Waveshap e

Po la rit y

Output Voltage

Output Current

Sq u a r e w a v e

Po sit ive g o in g w it h b a se line a t ze ro v o lt s

0.1 vo lt o r 1 volt, p ea k to p eak

5-milliamp ere s through PROBE LOO P on side

Re p e t i t i o n Ra t e

Volta ge Accuracy

Current Accuracy

Re p e t it i o n Ra t e A c c u r a c y

Ri se t im e

Duty C ycIe

.-

±1.5%

±0.5%

Le ss t ha n 1 m ic r o se c o n d

49% to 51%

Output Resistance

Z A XI S I NPUT

Se n s i t i v i t y

5 v olt p ea k-to-p ea k signal p rod uc e s no tic e able

modulation

Usa b le Freq ue n c y Ra ng e D C t o g re ate r t ha n 50 M Hz

Input Re sista nc e a t DC

Input C o up ling DC coupled

Po la rity o f O p e ra tio n

1 me gohm, para llele d by 20 pF

Le ss t h a n 3 °

Selected by CALIBRATOR switch on side

panel

Approximately 200 ohms in 1 V position.

Approximately 20 ohms in .1 V position.

Approximately 47 kilohms

Po sitiv e-g o in g inp u t sig n a l d e c re a se s

trac e intensity

Neg ative-g oing signal inc rea ses trace

Maximum Input Voltage

A and B Ga te

Waveshap e

Amplitude

Po la rity

Duration

Output resistance

Vertica l Signal Out (CH 1 only)

Output voltage

Ba n d w id t h

Output coupling

Output resistance

O UTPUT SIGN ALS

—

Re c t a n g u l a r p u l se

Po slt lve-g o in g w it h b a se line a t a b o u t - 0.7 v o lt s.

I Same d ura tio n a s the re sp ec t ive sw eep

I

25 m illivo lts, o r g rea ter/ division o f CRT d isplay

int o 1 meg oh m load .

DC to 25 MHz or g rea te r when ca sca ded with

Channel 2 or into 50-ohm load.

DC coup led

200 vo lts c om bined DC and pea k AC

A GATE duration variable between

about 4 and 11 times the A TIME/DIV

sw i tc h se t t in g

with the A SWEEP

LENG TH c o n t ro l .

Approximately 1.5 kilohms

Approximately 50 ohms

1-5

Page 14

TM 11-6625-1722-15

Characteristic

Line Voltage

Voltage Ranges (AC, RMS)

115-volts nominal

230-volts nominal

Line Frequency

Maximum Power Consumption

at 115 Volts, 60 Hz

Tube Type

Phosphor

Accelerating Potential

Graticule

Type

Area

Illumination

Unblinking

Raster Distortion

Trace Finder

POWER SUPPLY

Performance Requirement

115 volts nominal or 230 volts nominal

90 to 110 volts

104 to 126 volts

112 to 136 volts

180 to 220 volts

208 to 252 volts

224 to 272 volts

———

48 to 440 Hz

CATHODE-RAY TUBE (CRT)

I

Internal

Six divisions vertical by 10 divisions horizontal.

Each division equals 0.8 centimeter.

0.1 division or less total

Limits display within graticule area when pressed.

Operational Information

.—

Line voltage and range selected by Line

Voltage Selector assembly on rear

panel. Voltage ranges apply for waveform distortion which does not reduce

the peak line voltage more than 5%

below the true sine-wave peak value.

92 watts (105 volt-amperes)

Tektronix T4530-31-1 rectangular

P31 standard. Others available on

special order.

Approximately 10 kV total (cathode

potential -1.95 kV).

Variable edge lighting

Bias-type, DC coupled to CRT grid.

Adjustable with Geometry and Y Axis

Align adjustments.

Characteristic

Temperature

Operating

Non-operating

Altitude

Operating

Non-operating

Humidity

Non-operating

Vibration

Operating and

non-operating

Shock

Operating and

non-operating

ENVIRONMENTAL CHARACTERISTICS

The following environmental test limits apply when tested in accordance with the recommended test procedure. This instrument will meet the electrical characteristics given in this

section following environmental test.

including failure criteria, etc., may be obtained from Tektronix, Inc. Contact your local

Tektronix Field Office or representative.

Performance Requirement

-15°C to +55°c

-55° to +75°C

15,000 feet maximum

50,000 feet maximum

Five cycles (120 hours) of Mil-Std-202C, Method

106B

15 minutes along each of the three major axes

at a total displacement of 0.025-inch peak to peak

(4 g at 55 c/s) with frequency varied from 10-5510 c/s in one-minute cycles. Hold at 55 c/s for

three minutes on each axis.

Two shocks of 30 g, one-half sine, 11 millisecond

duration each direction along each major axis.

Complete details on environmental test procedures,

Supplemental Information

Fan at rear circulates air throughout instrument.

cutout protects instrument from overheating.

Derate maximum operating tempera-

ture by 1°C/1000 feet change in altitude

above 5000 feet.

Exclude freezing and vibration

Instrument secured to vibration platform

during test. Total vibration time, about

55 minutes.

Guillotine-type shocks.

Total of 12 shocks

Automatic resetting thermal

1-6

Page 15

EN V I RO N M EN TA L C HARAC TERI STIC S (c ont)

TM 11-6625-1722-15

Characteristic

Tr a n s p o r t a t i o n

Pa c ka g e v ib ra t io n

Pa c ka g e d ro p

Ty p e 4 5 3

Ty p e R 4 5 3

MECHANICAL CHARACTERISTICS

Characteristic

Construction

Chassis

Pa n el

Cabinet

Circuit boards

Overall Dimensions, Type

453 (m easured ot m aximum points)

He ig ht

Width

Le n g t h

Overall Dimensions, Type

R4 53 ( m e a su r e d a t m a x imum points)

He ig ht

Pe rf orm a nc e Re q u ire m e nt

Meets National Safe Transit type of test when

packaged as shipped from Tektronix, Inc.

One hour vibration slightly in excess of 1 g.

30-inc h drop o n any corne r, e dge o r fla t surface.

18-inc h drop on a ny c orner, e d ge or fla t surface.

Width

Info rmation

Le n g t h

Aluminum alloy

Aluminum alloy with ano-

dized finish

Blu e v in y l- c o a t e d a l um i n um

Glass-epoxy laminate

Connectors

Z A XIS I NP UT

All other connec tors

Net Weight

Ty p e 4 5 3 ( i n c l u d e s f r o n t

cover without accessor-

Ty p e R 4 5 3 ( w i t h o u t a c -

hand le positioned for ca rrying .

St a n d a r d a c c e s so r i e s s u p p l i e d w i t h t h e Ty p e 4 5 3 a n d R4 5 3

are listed on the last pullout page of the Mechanical Parts

List illu st ra t io ns.

7 inches

Operational Information

Pa c ka ge sho uld just l ea ve vib ra t io n surface

19 inc hes

panel;

Bin d i ng p o st

BN C

Approximately 29 pounds.

ies)

Approximately 32 pounds.

cessories)

STANDA RD A C C ESSO RIES

1-7

Page 16

Page 17

SECTION 2

OPERATING INSTRUCT IONS

General

O effectively use the Type 453, the operation and capa-

T

bilities of the instrument must be known. This section describes the operation of the front-, side- and rear-panel

controls and connectors, gives first time and general operating information and lists some basic applications for this

instrument.

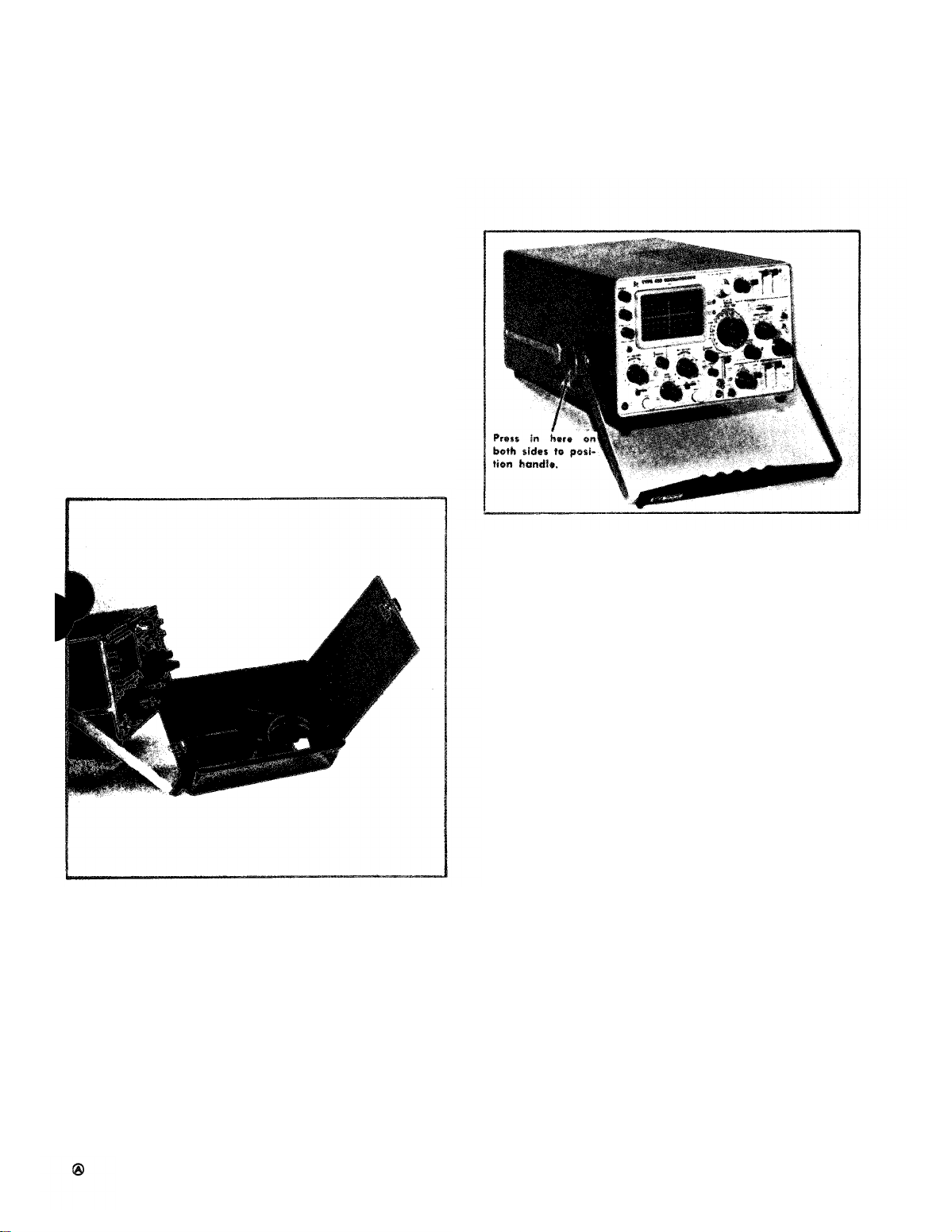

Front Cover and Handle

The front cover furnished with the Type 453 provides a

dust-tight seal around the front panel. Use the cover to

protect the front panel when storing or transporting the

instrument. The cover also provides storage space for probes

and other accessories (see Fig. 2-1).

TM 11-6625-1722-15

Fig. 2-1. Accessory storage provided in front cover.

The handle af the Type 453 can be positioned for carrying

or as a tilt-stand for the instrument. To position the handle,

press in at both pivot points (see Fig. 2-2) and turn the

handle to the desired position. Several positions are provided for convenient carrying or viewing. The instrument

may also be set an the rear-panel feet for operation or

storage.

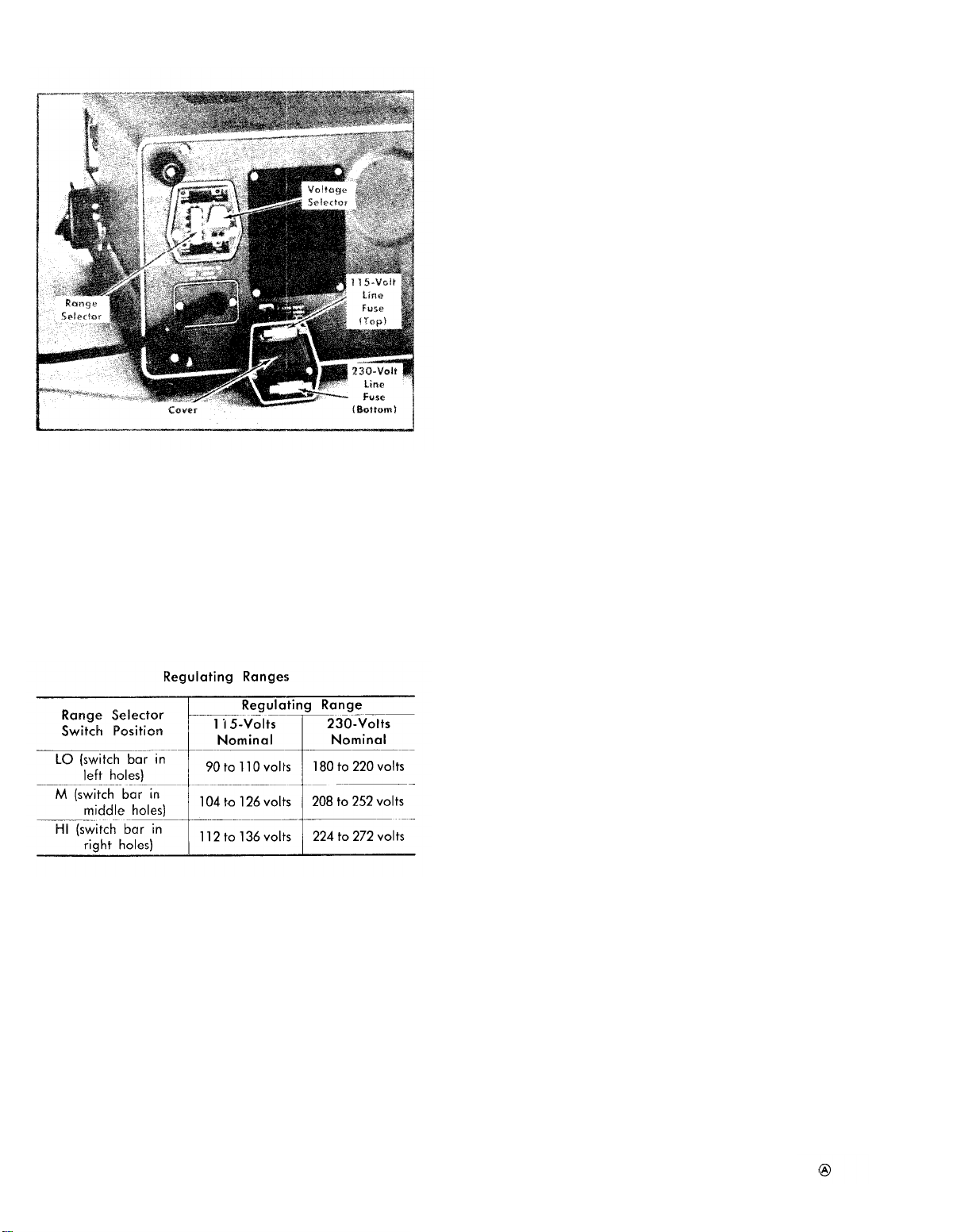

Operating Voltage

The Type 453 can be operated from either a 115-volt or

a 230-volt nominal line-voltage source. The Line Voltage

Fig. 2 -2 . Handle positione d to provide a sta nd for t he instrum ent

Selector assembly on the rear panel converts the instrument

from one operating range to the other. In addition, this

assembly changes the primary connections of the power

transformer to allow selection of one of three regulating

ranges. The assembly also includes the two line fuses. When

the instrument is converted from 115-volt to 230-volt nominal

operation, or vice versa, the assembly connects or disconnects one of the fuses to provide the correct protection for

the instrument. Use the following procedure to convert this

instrument between nominal line voltages or regulating

ranges.

1. Disconnect the instrument from the power source.

2. Loosen the two captive screws which hold the cover

onto the voltage selector assembly; then pull to remove the

cover.

3. To convert from 115-volts nominal to 230-volts nominal line voltage, pull out the Voltage Selector switch bar

(see Fig. 2-3]; turn it around 180° and plug it back into the

remaining holes. Change the line-cord power plug to match

the power-source receptacle or use a 115- to 230-volt

adapter.

4. To change regulating ranges, pull out the Range

Selector switch bar (see Fig. 2-3); slide it to the desired

position and plug it back in. Select a range which is centered about the average line voltage to which the instrument is to be connected (see Table 2-1).

5. Re-install the cover and tighten the two captive screws.

6. Before applying power to the instrument, check that

the indicating tabs on the switch bars are protruding through

the correct holes for the desired nominal line voltage and

regulating range.

2-1

Page 18

TM 11-6625-1722-15

Fig. 2-3. Line Voltage Selector assembly on the rear panel (shown

with cover removed).

CAUTION

The Type 453 should not be operated with the

Voltage Selector or Range Selector switches in the

wrong positions for the line voltage applied.

Operation of the instrument with the switches in

the wrong positions may either provide incorrect

aperotion or damage the instrument.

TABLE 2-1

more frequently. The air filter should be cleaned occasion-

ally to aII

OW the maximum amount of cooling air to enter

the instrument. Cleaning instructions are given in Section 4.

The Type 453 can be operated where the ambient air

temperature is between

-15°C and +55°C. Derate the

maximum operating temperature 1°C for each additional

1000 feet of altitude above 5000 feet. This instrument can

be stored in ambient temperatures between –55°C and

+75°C. After storage at temperatures beyond the operating

limits, allow the chassis temperature to come within the

operating limits before power is applied.

Rackmounting

Complete information for mounting the Type R453 in a

cabinet rack is given in Section 10 of this manual.

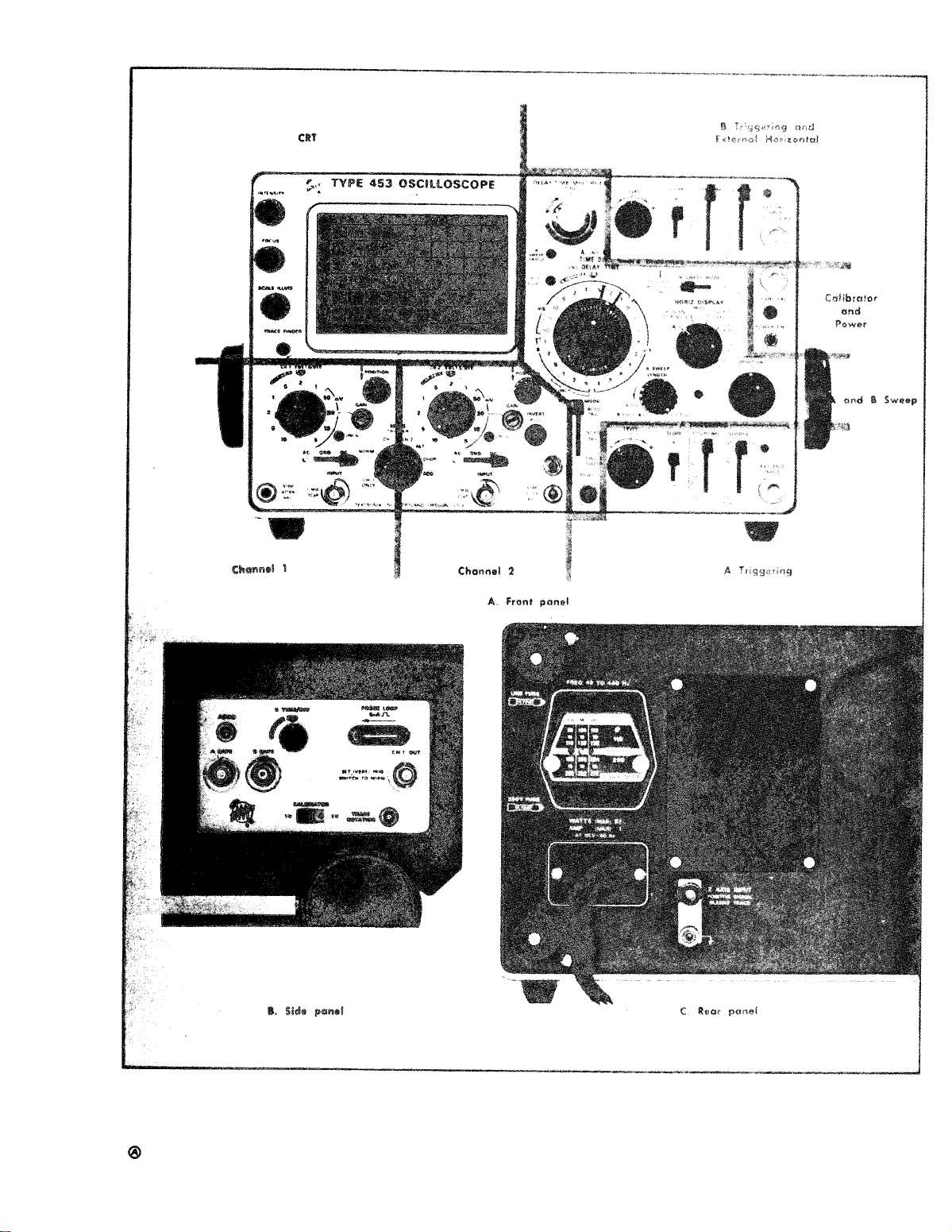

CONTROLS AND CONNECTORS

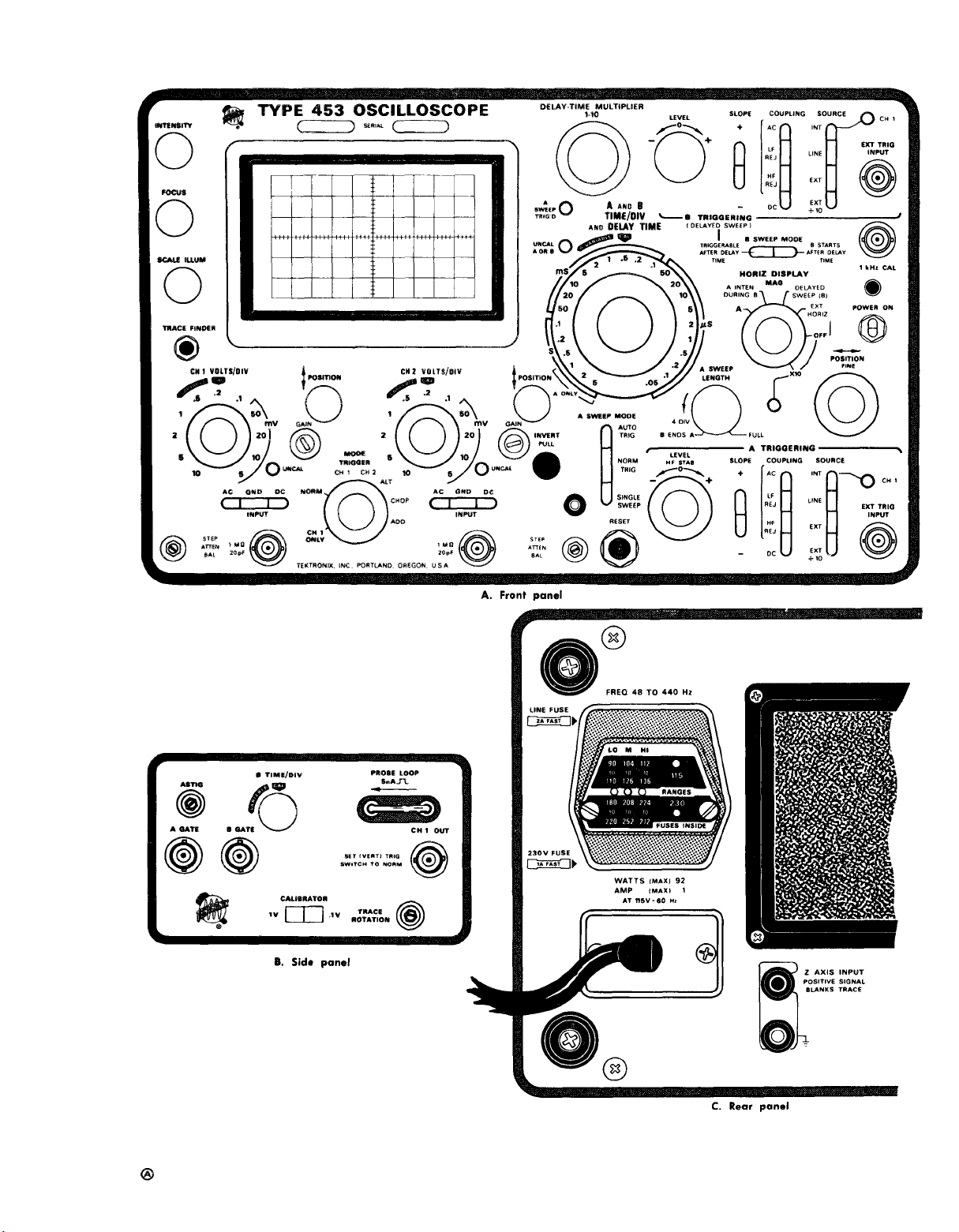

A brief description of the function or operation

front-, side- and rear-panel controls and connectors

(see Fig. 2-4). More detailed information is given

of the

follows

in this

section under General Operating Information.

Cathode-Ray Tube

INTENSITY

FOCUS

Controls brightness of display.

Provides adjustment for a well-defined display.

SCALE ILLUM

TRACE FINDER

Controls graticule illumination.

Compresses display within graticule area

independent of display position or applied signals.

Operating Temperature

The Type 453 is cooled by air drawn in at the rear and

blown out through holes in the top and bottom covers. Adequate clearance on the top, bottom and rear must be provided to allow heat to be dissipated away from the instru-

ment. The clearance provided by the feet at the bottom and

rear should be maintained. If possible, allow about one

inch of clearance on the top. Do not block or restrict the air

flow from the air-escape holes in the cabinet.

A thermal cutout in this instrument provides thermal protection and disconnects the power to the instrument if the

internal temperature exceeds a safe operating level. Operation of the instrument for extended periods without the covers

may cause it to overheat and the thermal cutout to open

Vertical (both

VOLTS/DIV

VARIABLE

UNCAL

POSITION

GAIN

Input Coupling

(AC GND DC)

channels except as noted)

Selects vertical deflection factor (VARlABLE control must be in CAL position for

indicated deflection factor).

Provides continuously variable deflection

factor between the calibrated settings of

the VOLTS/DIV switch.

Light indicates that the VARIABLE control

is not in the CAL position.

Controls vertical position of trace.

Screwdriver adjustment to set gain of the

Vertical Preamp. Line between adjustment and 20 mV VOLTS/DIV position indicates that gain should be set with

VOLTS/DIV switch in this position.

Selects method of coupling input signal

to Vertical Deflection System.

AC: DC component of input signal is

blocked. Low frequency limit -3 dB

point) is about 1.6 hertz.

GND: Input circuit is grounded (does not

ground applied signal).

2-2

Page 19

TM 11-6625-1722-15

Fig. 2-4. Front-, side- and rear-panel controls and connectors.

2-3

Page 20

TM 11-6625-1722-15

DC: All components of the input signal are

passed to the Vertical Deflection System.

STEP ATTEN

BAL

INPUT

MODE

TRIGGER

INVERT (CH 2

only)

A and B Triggering (both where applicable)

EXT TRIG

INPUT

SOURCE

Screwdriver adjustment to balance Vertical Deflection System in the 5, 10 and 20

mV positions of the VOLTS/DIV switch.

Vertical input connector for signal.

Selects vertical mode of operation.

CH 1: The Channel 1 signal is displayed.

CH 2: The Channel 2 signal is displayed.

ALT: Dual trace display of signal on both

channels. Display switched at end of

each sweep.

CHOP: Dual trace display of signal on

both channels. Approximately one-microsecond segmerlts from each channel

displayed at a repetition rate of about

500 kilohertz.

ADD: Channel 1 and 2 signals are alge-

braically added and the algebraic sum

is displayed on the CRT.

Selects saurce of internal trigger signal

from vertical system.

NORM: Sweep circuits triggered from dis-

played channel(s). Channel 1 signal

available at CH 1 OUT connector.

CH 1 ONLY: Sweep circuits triggered only

from signal applied to the Channel 1

INPUT connector. No signal available

at CH 1 OUT connector. CH 1 lights,

located beside A and B SOURCE switches indicate when the TRIGGER switch is

in the CH 1 ONLY position.

Inverts the Channel 2 signal when pulled

out.

Input connector for external trigger signal.

Connector in B Triggering section of front

panel also serves as external horizontal

input when HORIZ DISPLAY switch is in

EXT HORIZ position and B SOURCE switch

is in EXT position.

Selects source of trigger signal.

INT: Internal trigger signal obtained from

Vertical Deflection System. When CH

1 light is on, trigger signal is obtained

only from the Channel 1 input signal;

when the light is off, the trigger signal

is abtained from the displayed chan-

nel(s). Source of internal trigger signal

is selected by the TRIGGER switch.

LINE: Trigger signal obtained from a sam-

ple of the line voltage applied to this

instrument.

EXT: Trigger signal obtained from an ex-

ternal signal applied to the EXT TRIG

INPUT connector.

nal approximately 10 times.

CH 1

COUPLING

SLOPE

LEVEL

HF STAB Decreases display jitter for high-frequency

(A Triggering only) sweep rates.

A and B Sweep

DELAY-TIME

MULTIPLIER

A SWEEP

TRIG’D

UNCAL A

OR B

A AND B

TIME/DIV

AND DELAY

TIME

Light indicates that the internal trigger signal is abtained only from the signal connected to the Channel 1 INPUT connector

(see TRIGGER switch).

Determines method of coupling trigger

signal to trigger circuit.

AC: Rejects DC and attenuates signals be-

low about 30 hertz. Accepts signals

between abaut 30 hertz and 50 megahertz.

LF REJ: Rejects DC and attenuates signals

below about 30 kilohertz. Accepts signals between about 30 kilohertz and 50

megahertz.

HF REJ: Accepts signals between about 30

hertz and 50 kilohertz; rejects DC and

attenuates signals outside the above

range.

DC: Accepts all trigger signals from DC to

50 megahertz or greater.

Selects portion of trigger signal which

starts the sweep.

+: Sweep can be triggered from positive-

going portion of trigger signal.

-: Sweep can be triggered from negativegoing portion of trigger signal.

Selects amplitude point on trigger signal

at which sweep is triggered.

signals. Has negligible effect at lower

Provides variable sweep delay between

0.20 and 10.20 times the delay time indi-

cated by the A TIME/DIV switch.

Light indicates that A sweep is triggered

and will produce a stable display with

correct INTENSITY and POSITION control

settings.

Light indicates that either the A or B

VARIABLE control is not in the CAL posi-

tion.

A TIME/DIV switch (clear plastic flange)

selects the sweep rate of the A sweep

circuit for A sweep only operatian and

selects the basic delay time (to be multi-

plied by DELAY-TIME MULTIPLIER dial

setting) for delayed sweep operation.

B TIME/DIV (DELAYED SWEEP) switch

selects sweep rate of the B sweep circuit

Attenuates external trigger sig-

2-4

Page 21

TM 11-6625-1722-15

A VARIABLE

B SWEEP

MODE

HORIZ

DISPLAY

MAG

A SWEEP

MODE

for delayed sweep operation only. VARlABLE controls must be in CAL positions for

calibrated sweep rates.

Provides continuously variable A sweep

rate to at least 2.5 times setting of the

A TIME/DIV switch. A sweep rate is calibrated when control is set fully clockwise

to CAL.

Selects B sweep operation mode.

TRIGGERABLE AFTER DELAY TIME: B

sweep circuit will not produce a sweep

until a trigger pulse is received following the delay time selected by the

DELAY TIME (A TIME/DIV) switch and

the DELAY-TIME MULTIPLIER dial.

B STARTS AFTER DELAY TIME: B sweep

circuit runs immediately following delay

time selected by the DELAY TIME switch

and DELAY-TIME MULTIPLIER dial.

Selects horizontal mode of operation.

A: Horizontal deflection provided by A

sweep.

B sweep inoperative.

A INTEN DURING B: Sweep rate deter-

mined by A TIME/DIV switch. An intensified portion appears on the sweep

during the B sweep time. This position

provides a check of the duration and

position of the delayed sweep (B) with

respect to the delaying sweep (A).

DELAYED SWEEP (B): Sweep rate deter-

mined by B TIME/DIV switch with the

delay time determined by the setting of

the DELAY TIME (A TIME/DIV) switch

and the DELAY-TIME MULTIPLIER dial.

Sweep mode determined by B SWEEP

MODE switch.

EXT HORIZ: Horizontal deflection pro-

vided by an external signal.

Increases sweep rate to ten times setting

of A or B TIME/DIV switch by horizontally

expanding the center division of the display. Light indicates when magnifier is

on.

Determines the operating mode for A

sweep.

AUTO TRIG: Sweep initiated by the ap-

plied trigger signal using the A Trig-

gering controls when the trigger signal

repetition rate is above about 20 hertz.

For lower repetition rates or when there

is no trigger signal, the sweep free runs

at the sweep rate selected by the A

TIME/DIV switch to produce a bright

reference trace.

NORM TRIG: Sweep initiated by the ap-

plied trigger signal using the A Trig-

gering controls. No trace is displayed

when there is no trigger signal.

RESET

A SWEEP

LENGTH

POSITION

FINE

1 kHz CAL

POWER ON

Side Panel

ASTIG

B TiME/DIVVARIABLE

PROBE LOOP

A GATE

B GATE

CH 1 OUT

SINGLE SWEEP: After a sweep is display-

ed, further sweeps cannot be presented

until the RESET button is pressed. Display is triggered as for NORM operation using the A Triggering controls.

When the RESET button is pressed (SINGLE SWEEP mode), a single display will

be presented (with correct triggering) when

the next trigger pulse is received. RESET

light (inside RESET button) remains on

until a trigger is received and the sweep is

completed. RESET button must be pressed

before another sweep can be presented.

Adiusts length of A sweep. In the FULL

position (clockwise detent), the sweep is

about 11 divisions long. As the control is

rotated counterclockwise, the length of A

sweep is reduced until it is less than four

divisions long iust before the detent in

the fully-counterclockwise position is reached. In the B ENDS A position (counterclockwise detent), the A sweep is reset

at the end of the B sweep to provide the

fastest possible sweep repetition rate for

delayed sweep displays.

Controls horizontal position of trace.

Provides more precise horizontal position

adjustment.

Calibrator output connector.

Light: Indicates that POWER switch is

on and the instrument is connected to

a line voltage source.

Switch: Controls power to the instrument.

Screwdriver adjustment used in conjunction with the FOCUS control to obtain a

well-defined display. Does not require

readjustment in normal use.

Provides continuously variable sweep rate

to at least 2.5 times setting of B TIME/DIV

switch. B sweep rate is calibrated when

control is set fully clockwise to CAL.

Current loop providing five-milliampere

square-wave current from calibrator circuit.

Output connector providing a rectangular

pulse coincident with A sweep.

Output connector providing a rectangular

pulse coincident with B sweep.

Output connector providing a sample of

the signal applied to the Channel 1 lN-

PUT connector when the TRIGGER switch

is in the NORM position.

2-5

Page 22

TM 11-6625-1722-15

CALIBRATOR

TRACE

ROTATION

Rear Panel

Z AXIS INPUT

Line Voltage

Selector

The following steps will demonstrate the use of the controls and connectors of the Type 453. It is recommended

that this procedure be followed completely for familiarization with this instrument.

Setup Information

1. Set the front-panel controls as follows:

CRT Controls

INTENSITY

FOCUS

SCALE ILLUM Counterclockwise

Vertical Controls (both channels if applicable)

VOLTS/DIV 20 mV

VARIABLE

POSITION Midrange

INPUT COUPLING

MODE

TRIGGER

INVERT

Triggering Controls (both A and B if applicable)

LEVEL

SLOPE

COUPLING

SOURCE

Sweep Controls

DELAY-TIME

MULTIPLIER

A and B TIME/DIV

A VARIABLE

B SWEEP MODE

Switch selects output voltoge of Calibrator.

1-volt or 0.1-volt square wave available.

Screwdriver adjustment to align trace with

horizontal graticule lines.

Input connector for intensity modulation

of the CRT display.

Switching assembly to select the nominal

operating voltage and the line voltage

range.

line fuses.

Voltage Selector: Selects nominal operat-

Range Selector: Selects line voltage range

FIRST-TIME OPERATION

The assembly also includes the

ing voltage range (115V or 230V).

(low, medium, high).

Counterclockwise

Midrange

CAL

D C

CH 1

NORM

Pushed in

Clockwise (+)

+

AC

INT

0.20

.5 ms

CAL

B STARTS AFTER

DELAY TIME

HORIZ DISPLAY

MAG

POSITION

A SWEEP LENGTH

A SWEEP MODE

POWER

Side-Panel Controls

B TIME/DIV VARIABLE

CALIBRATOR

2. Connect the Type 453 to a power source that meets

the voltage and frequency requirements of the instrument.

If the available line voltage is outside the limits of the Line

Voltage Selector assembly position (on rear panel), see

Operating Voltage in this section.

3. Set the POWER switch to ON. Allow about five minutes

warmup so the instrument reaches a normal operating temperature before proceeding.

CRT Controls

4. Advance the INTENSITY control until the trace is at

the desired viewing level (near midrange).

5. Connect the 1 kHz CAL connector to the Channel 1

INPUT connector with a BNC cable.

6. Turn the A LEVEL control toward 0 until the display

becomes stable. Note that the A SWEEP TRIG’D light is on

when the display is stable.

7. Adiust the FOCUS control for a sharp, well-defined

display over the entire trace length. (If focused display can-

not be obtained, see Astigmatism Adjustment in this section.)

8. Disconnect the input signal and move the trace with

the Channel 1 POSITION control so it coincides with one of

the horizontal graticule lines.

the graticule line, see Trace Alignment Adjustment in this

section.

9. Rotate the SCALE ILLUM control throughout its range

and notice that the graticule lines are illuminated as the

control is turned clockwise (most obvious with mesh or smokegray filter installed). Set control so graticule lines are

illuminated as desired.

Vertical Controls

10. Change the CH 1 VOLTS/DIV switch from 20 mV to 5

mV. If the vertical position of the trace shifts, see Step

Attenuator Balance in this section.

11. Set the CH 1 VOLTS/DIV switch to 20 mV and set the

Channel 1 Input Coupling switch to AC. Connect the 1 kHz

CAL connector to both the Channel 1 and 2 INPUT connectors with two BNC cables and a BNC T connector.

If the BNC cables and BNC T connector are not

available, make the following changes in the procedure. Place the BNC jack post (supplied accessory) on the 1 kHz CAL connector and connect

A

OFF

Midrange

FULL

AUTO TRIG

OFF

CAL

.1 V

If the trace is not parallel with

NOTE

2-6

Page 23

TM 11-6625-1722-15

the Channel 1 and 2 INPUT connectors. Connect

the probe tips to the BNC jack post. Set the CALIBRATOR switch (on side-panel) to 1 V.

12. Turn the Channel 1 POSITION control to center the

display. The display is a square wave, five divisions in

amplitude with about five cycles displayed on the screen. If

the display is not five divisions in amplitude, see Vertical

Gain Adjustment in this section.

13. Set the Channel 1 Input Coupling switch to GND ond

position the trace to the center horizontal line.

14. Set the Channel 1 Input Coupling switch to DC. Note

that the baseline of the waveform remains at the center

horizontal line (ground reference).

15. Set the Channel 1 Input Coupling switch to AC. Note

that the waveform is centered about the center horizontal

line.

16. Turn the Channel 1 VARIABLE control throughout its

range. Note that the UNCAL light comes on when the VARl-

ABLE control is moved from the CAL position (fully clockwise). The deflection should be reduced to about two divisions. Return the VARIABLE control to CAL.

17. Set the MODE switch to CH 2.

18. Turn the Channel 2 POSITION control to center the

display. The display will be similar to the previous display

for Channel 1. Check Channel 2 step attenuator balance and

gain as described in steps 10 through 12. The Channel 2

input Coupling switch and VARIABLE control operate as

described in steps 13 through 16.

19. Set both VOLTS/DIV switches to 50 mV.

20. Set the MODE switch to ALT and position the Channel

1 waveform to the top of the graticule area and the Chan-

nel 2 waveform to the bottom of the graticule area. Turn

the A TIME/DIV switch throughout its range. Note that the

display alternates between channels at all sweep rates.

Triggering

25. Set the CALIBRATOR switch to 1 V. Rotate the A LEVEL

control throughout its range. The display free runs at the

extremes of rotation. Note that the A SWEEP TRIG'D light

is on only when the display is triggered.

26. Set the A SWEEP MODE switch to NORM TRIG. Again

rotate the A LEVEL control throughout its range. A display

is presented only when correctly triggered. The A SWEEP

TRIG'D light operates as in AUTO TRIG. Return the A SWEEP

MODE switch to AUTO TRIG.

27. Set the A SLOPE switch to -. The trace starts on the

negative part of the square wave. Return the switch to +;

the trace starts with the positive part of the square wave.

28. Set the A COUPLING switch to DC. Turn the Channel 1 POSITION control until the display becomes unstable

(only part of square wave visible). Return the A COUPLING

switch to AC; the display is again stable. Since changing

trace position changes DC level, this shows how DC level

changes affect DC trigger coupling. Return the display to

the center of the screen.

29. Set the MODE switch to CH 2; the display should be

stable. Remove the signal connected to Channel 1; the dis-

play free runs.

Set the TRIGGER switch to NORM; the dis-

play is again stable. Note that the CH 1 lights in A and B

Triggering go out when the TRIGGER switch is changed to

NORM.

30. Connect the Calibrator signal to both the Channel 2

INPUT and A EXT TRIG INPUT connectors. Set the A

SOURCE switch to EXT. Operation of the LEVEL, SLOPE

and COUPLING controls for external triggering are the same

as described in steps 25 through 28.

31. Set the A SOURCE switch to EXT

is the same as for EXT. Note that the A LEVEL control has

less range in this position, indicating trigger signal attenuation. Return the A SOURCE switch to INT.

32. Operation of the B Triggering controls is similar to

A Triggering.

21. Set the MODE switch to CHOP and the A TIME/DIV

Note the switching between channels as

shown by the segmented trace. Set the TRIGGER switch to

CH 1 ONLY; the trace should appear more solid, since it is

no longer triggered on the between-channel switching trans-

ients. Turn the A TIME/DIV switch throughout its range. A

dual-trace display is presented at all sweep rates, but unlike

ALT, both channels are displayed on each trace on a timesharing basis. Return the A TIME/DIV switch to .5 ms.

22. Set the MODE switch to ADD. The display should be

four divisions in amplitude. Note that either POSITION control moves the display.

23. Pull the INVERT switch. The display is a straight line

indicating that the algebraic sum of the two signals is zero

(if the Channel 1 and 2 gain is correct).

24. Set either VOLTS/DIV switch to 20 mV. The square-

wave display indicates that the algebraic sum of the two

signals is no longer zero.

Return the MODE switch to CH 1

and both VOLTS/DIV switches to .2 (if using 10X probes,

set both VOLTS/DIV switches to 20 mV). Push in the INVERT

switch.

Normal and Magnified Sweep

33. Set the A TIME/DIV switch to 5 ms and the MAG

switch to X10. The display should be similar to that obtained with the A TIME/DIV switch set to .5 ms and the MAG

switch to OFF.

34. Turn the horizontal POSITION control throughout its

range; it should be possible to position the display across

the complete graticule area. Now turn the FINE control. The

display moves a smaller amount and allows more precise

positioning. Return the A TIME/DIV switch to .5 ms, the

MAG switch to OFF and return the start of the trace to the

left graticule line.

Delayed Sweep

36. Pull the DELAYED SWEEP knob out and turn it to 50

(DELAY TIME remains at .5 ms). Set the HORIZ DISPLAY

switch to A INTEN DURING B. An intensified portion, about

one division in length, should be shown at the start of the

trace. Rotate the DELAY-TIME MULTIPLIER dial throughout

its range; the intensified portion should move along the display.

2-7

Page 24

TM 11-6625-1722-15

37. Set the B SWEEP MODE switch to TRIGGERABLE

AFTER DELAY TIME. Again rolate the DELAY-TIME MULTI-

PLIER dial throughout its range and note that the intensified

portion appears to jump between posltive slopes of the display. Set the B SLOPE switch to -;

begins on the negative slope.

the intensified portion

Rotate the B LEVEL control;

the intensified portion of the display disappears when the B

LEVEL control is out of the trlggerable range. Return the

B LEVEL control to 0.

38. Set the HORIZ DISPLAY switch to DELAYED SWEEP

(B). Rotate the DELAY-TIME MULTIPLIER dial througout its

range; about one-half cycle of the waveform should be

displayed on the screen (Ieading edge visible only at high

INTENSITY control setting). The display remains stable on

the screen, indicating that the B sweep is triggered.

39. Set the B SWEEP MODE switch to B STARTS AFTER

DELAY TIME. Rotate the DELAY-TIME MULTIPLIER dial

throughout its range; the display moves continously across

the screen as the control is rotated.

40. Rotate the DELAYTIME MIULTIPLIER dial fully counter-

clockwise and set the HORIZ DISPLAY switch to A INTEN

DURING B. Rotate the A SWEEP LENGTH control counter-

clockwise; the Iength of the display decreases. Set the con-

trol to the B ENDS A position; now the display ends after

the intensified portion. Rotate the DELAY-TIME MULTIPLIER

dial ond note that the sweep length increases as the display

moves across the screen. Return the A SWEEP LENGTH con-

trol to FULL and the HORIZ DISPLAY switch to A.

Single Sweep

41. Set the A SWEEP MODE switch to SINGLE SWEEP.

Remove the Calibrator signal from the Channel 2 INPUT

connector. Press the RESET button; the RESET light should

come on and remain on. Again apply the signal to the Channel 2 INPUT connector; a single trace should be presented

and the RESET light should go out. Return the A SWEEP

MODE switch to AUTO TRIG.

External Horizontal

42. Connect the Calibrator signal to both the Channel 2

INPUT and EXT HORIZ (B EXT TRIG lNPUT] connectors. Set

the B SOURCE switch to EXT, B COUPLING switch to DC

and the HORIZ DISPLAY switch to EXT HORIZ. lncrease the

INTENSITY control setting until the display is visible (two dots

displayed diagonally). The display should be five divisions

vertically and about 3.7 divisions horizontally. Set the B

10. The display should be reduced

ten times horizontally. The display can be positioned horizontally with the horizontal POSITION or FINE control and

vertically with the Channel 2 POSITION control.

43. Connect the Calibrator signal to both the Channel 1

and 2 INPUT connectors. Set the TRIGGER switch to CH 1

ONLY and the B SOURCE switch to INT.

44. The display should be five divisions vertically and

horizontally.

The display can be postioned horizontally

with the Channel 1 POSITION control and vertically with the

Channel 2 POSITION control.

45. Change the CH1 VOLTS/DIV switch to 5. The display

play is reduced to two divisions horizontally. Now set the

CH 2 VOLTS/DIV switch to 5. The display is reduced to two

divisions vertically.

Trace Finder

46. Set the CH 1 and CH 2 VOLTS/DlV switches to 10

mv. The display i

S not visible since it exceeds the scan area

of the CRT.

47. Press the TRACE FINDER button. Note that the disis returned to the display area. While holding the

play

TRACE FINDER button depressed, increase the vertical and

horizontal deflection factors until the display is reduced to

about two divisions vertically ond horizontally. Adjust the

Channel 1 and 2 POSITION controls to center the display

about the center lines of the graticule. Release the TRACE

FINDER and note that the display remains within the viewing

area. Disconnect the applied signal.

48. Reduce the INTENSITY control setting to normal, B

SOURCE switch to INT and set the HORIZ DISPLAY switch

to A.

Z-Axis Input

49. If an, External signal is available (five volts peak to

peak minimum] the function of tlhe Z AXIS INPUT circuit can

be demonstrated. Connect the external signal to both the

Channel 2 INPUT connector and the Z AXIS INPUT binding

posts. Set the A TIME/DIV switch to display about five

cycles of the waveform. The positive peaks of the waveform

should be blanked and the negative peaks intensified, indi-

cating intensify modulation.

50. This completes the basic operating procedure for the

Type 453. lnstrument operation not explained here, or operations which need further explanation are discussed under

General Operating Information.

CONTROL SETUP CHART

Fig. 2-5 shows the front, side and rear panels of the Type

453. This chart can, be reproduced and used as a test-setup

record for special measurements, applications or procedures,

or it may be used as a training aid for familiarization with

this instrument.

GENERAL OPERATING INFORMATION

Intensify Control

The setting of the INTENSITY control may affect the correct focus of the display. Slight readjustment of the FOCUS

control may be necessary when the intensity level is changed.

To protect the CRT phosphor, do not turn the INTENSITY

control higher than necessary to provide a satisfactory dis-

play. The light filters reduce the observed light output from

the CRT. When using these filters, avoid odvancing the

INTENSITY control to a setting that may bum the phosphor.

When Ihe highest intensity display is desired, remove the

filters and use the clear faceplate protector. Also, be careful that the INTENSITY control is not set too high when

changing the TIME/DlV switch front a fast to a slow sweep

rate, or when changing the HORIZ DISPLAY switch from EXT

HORIZ operation to the norrmal sweep mode.

Astigmatism Adjustment

If a well-defined trace cannot be obtained with the FOCUS

control, adjust the ASTIG adjustment (side panel) as fol-

lows.

2-8

Page 25

TM 11-6625-1722-15

Fig. 2-5. Control setup chart for the Type 453.

2-9

Page 26

TM 11-6625-1722-15

NOTE

To c h e c k f o r p r o p e r s e t t i n g o f t h e A STI G a d j u st ment, slowly turn the FOCUS control through the

optimum setting. If the ASTIG adjustment is cor-

re c tly set, the vert ic a l a n d h orizo nt a l p o rtio ns

of the trace will come into sharpest focus at the

sa m e p o si t io n o f t h e FO C US c o n t ro l . This se t t ing

of the ASTIG adjustment should be correct for any

display. However, it may be necessary to reset

the FOCUS control slightly when the INTENSITY

control is changed.

1. Co nnec t a 1 V Ca libra tor sig na l to e ithe r channe l a nd

se t t h e V O LTS/ D IV sw i t c h o f t h a t c h a n n e l t o p r e se n t a t w o division display. Set the MODE switch to display the chan-

nel selec ted.

2. Set the TIME/DIV sw itc h to .2 ms

3. With the FOCUS c ontro l an d ASTIG a d just me nt set to

midra ng e, a djust the INTENSITY c ontro l so the rising portio n

of the display c an be seen.

4. Set the ASTIG ad justment so the ho rizo ntal a nd vertical portions of the display are equally focused, but not

nec essarily well focused.

5. Se t the FOCUS c ontrol so the vertic al p ortion of the

trac e is as thin as possible.

6. Repe a t step s 4 an d 5 fo r b est overa ll foc us. Make fina l

check at normal intensity.

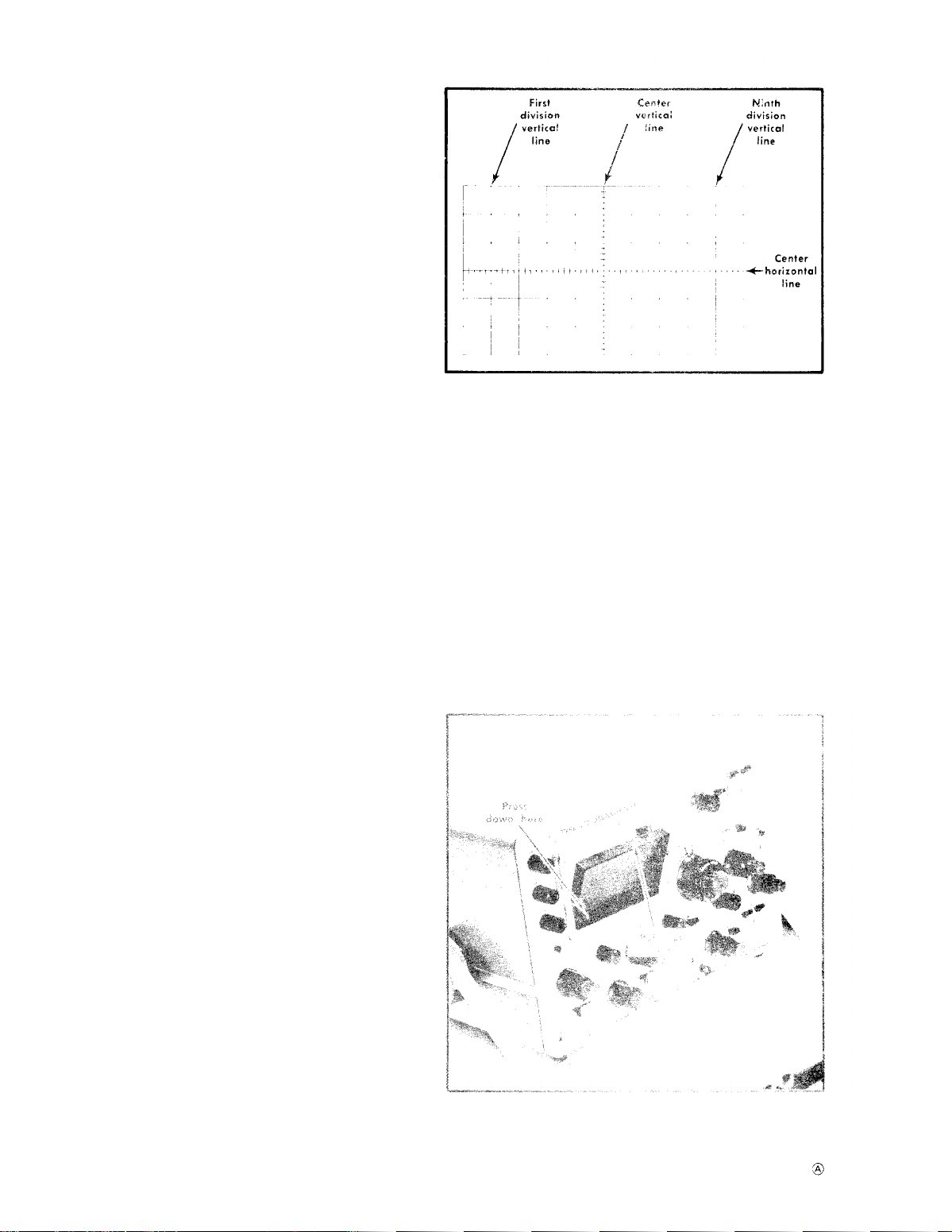

Graticule

Th e g r a t i c u l e o f t h e Ty p e 4 5 3 i s i n t e r n a l l y m a r k e d o n t h e

faceplate of the CRT to p rovid e acc urate, no -para lla x measurements. The graticule is marked with six vertic al and 10

horizontal divisions. Each division is 0.8 centimeter sq uare.

In a d dition, e ac h m a jo r d iv ision is d iv id ed int a five m inor

divisions at the center vertical and horizontal lines. The

vertic al gain and horizonta l timing are calibrated to the

graticule so accurate measurements can be made from the

CRT. The illumination of the graticule lines can be varied

with the SCALE ILLUM control.

Fi g . 2 - 6 sh o w s t h e g r a t i c u l e o f t h e Typ e 4 53 a n d d e f i n e s

the various mea surement lines. The terminology defined here

will be used in all discussions involving graticule measurements.

Fi g . 2 - 6 . D e f i n i t i o n o f m e a s u re m e n t l in e s o n Ty p e 4 5 3 g r a t i c u l e .

re mov e the f ilte r, p ress

down at the bottom of the frame

and pull the top of the filter away from the CRT faceplate

(see Fig. 2-7).

Th e t i n t e d l i g h t f i l t e r m i n i m i z e s l i g h t r e f l e c t i o n s f r o m t h e

face of the CRT to imp ro ve c ontrast when viewing the display under high ambient light conditions. A clear plastic

faceplate protector is a lso p rovided w ith this instrument for

use when neither the me sh nor the tinted filter is used. The

clear faceplate protector provides the best display for waveform p hotographs. It is a lso preferable for view ing high

writing rate displays.

A filter or the facepla te protector should be used at all

times ta protec t the CRT fac eplate from scratc hes. The faceplate protector and the tinted filter mount in the same holder.

Tra c e A l i g n m e n t A d j u st m e n t

If a free-runn ing t ra c e is not p a ra lle l t o the ho rizo nt a l

graticule lines, set the TRACE ROTATION adjustment as fol-

lows. Positio n the tro ce to th e c en te r ho rizonta l line . Ad just

the TRACE ROTATION adjustment (side panel) so the trace

is para llel w ith th e ho rizonta l grat ic ule line s.

Li g ht Fi lte r

Th e m e sh f i l t e r p r o v i d e d w i t h t h e Ty p e 4 5 3 p r o v i d e s s h i e l d ing a gain st ra d iate d EM I (e lectro-mag ne tic int erferen c e) fro m

the face of the CRT. It also serves as a light filter to make

the trace more visible und er ambient light conditions. To

2-10

Fi g . 2 - 7. Re m o v i n g t h e f i lt e r o r f a c e p l a t e p r o t e c t o r .

Page 27

TM 11-6625-1722-15

To r e m o v e t h e l i g h t f i l t e r o r f a c e p l a t e p r o t e c t o r f r o m t h e

holder, press it out to the rear. They can be replaced by

sn a p p i n g t h e m b a c k i n t o t h e h o l d e r.

Tr a c e Find e r

Th e TR A C E FI N D ER p r o v i d e s a m e a n s a f l o c a t i n g a d i s p l a y

which overscans the viewing area either vertically or horizo nta l ly. W he n t h e TRA CE FIND ER b u t to n is p re sse d , t he

display is compressed within the graticule area. T

O locate

and reposition an overscanned display, use the following

procedure.

1. Pre ss the TRA CE FINDER button.

2. While the TRACE FINDER b ut to n is held d epre ssed ,

inc rease the vertic al a nd ho rizo nta l deflec tio n facto rs until

the vertic al deflection is reduced to a bout two divisions and

the horizontal d eflection is reduced to about four d ivisions

(the horizo ntal deflec tion need s to be reduced o nly when in

the external horizontal mode of op eration).

3. Adjust t he v ertic al a nd horizonta l POSITION c ontrols

to c enter the d isp la y ab out the vertical and horizontal c en-

ter lines.

4. Re lea se the TRA CE FINDER button; the displa y sho uld

re main within the view ing area .

Vertical Channel Se lection

Ei t h e r o f t h e i n p u t c h a n n e l s c a n b e u se d f o r si n g l e - t r a c e

displays. Apply the signal to the desired INPUT connector

and set the MODE switch to display the channel used. However, since CH 1 ONLY triggering is provided only in Chan-

nel 1 and the invert feature only in Cha nnel 2, the correct

channel must be selected to take advantage of these features. For d ual-trace displays, c onnect the signals to both

INPUT c onn ec t ors a nd se t t he M ODE switc h to o ne o f the

dual-trace positions.

Vertical Ga in Adjustment

To c h e c k t h e g a i n o f e i t h e r c h a n n e l , s e t t h e V O L TS/ D I V

sw i t c h t o 2 0 m V . Se t t h e C A L IBRA TO R sw i t c h t o . 1 V a n d

connect the 1 kHz CAL connector to the INPUT of the chan-

nel used . The vertica l deflec tion should be exac tly five

divisions.

If not, a d just t he f ront -p ane l G AIN a d just m ent

for exac tly five divisions of d eflec tion.

NOTE

If t he g a in o f the t wo c ha nne ls m ust b e c lo se ly

matched (such as for ADD mode operation), the

ADJUSTMENT p roc edure given in the Calibration

se c t i o n sh o u ld b e u se d .

Th e b e s t m e a s u r e m e n t a c c u r a c y w h e n u s i n g p r o b e s i s p r o vided if the GAIN adjustment is made with the p robes inst a l l e d ( se t t h e C A LIB RA TO R sw i t c h t o 1 V ) . A l so , t o p r o v id e

the most accurate measurements, ca librate the vertical g ain

of the Type 453 at the temperature at which the measurement

is to be ma de.

Ste p A tt e nua t o r Ba l a nc e

To c h e c k t h e s t e p a t t e n u a t o r b a l a n c e o f e i t h e r c h a n n e l ,

se t t h e In p u t C o u p l i n g sw i t c h t o G N D a n d se t t h e A SW EEP

MODE swic h to AUTO TRIG to provide a free-running trace.

Change the VOLTS/DIV switc h from 20 mV to 5 mV. If the

trac e moves vertically, adjust the front-panel STEP ATTEN

BA L a d j u st m e n t a s f o ll o w s ( a llo w a t l e a st 1 0 m i nut e s w a rm

up b efore performing this a djustment].

1. With th e Inp ut Coupling switch se t to GND a nd the

VOLTS/ DIV sw itc h set to 20 mV, m ove the tra ce to the center

horizontal line of the graticule with the vertica l POSITION

control.

2. Se t the VOLTS/ DIV switc h to 5 m V a nd a djust t he

STEP A TTEN B A L a d j u st m e n t t o r e t u r n t h e t r a c e t o t h e c e n t e r

horizonal line.

3. Re c he ck step a ttenuator bala nc e and rep eat adjustm ent

until no trac e shift oc curs a s the VOLTS/ DIV switc h is cha nged from 20 mV to 5 mV.

Sig na l C o nn e c ti o ns

In gen era l, p rob es o ff er th e m o st c on ve nient me a ns o f c o nnec ting a signal to the input of the Type 453. The Tektronix

probes are shielded to prevent pickup of electrostatic interferenc e. A 10X a ttenuator probe offe rs a high input imped ance and allows the circuit under test to perform very close

to normal operating c onditions. However, a 10X p robe

also attenuates the input signal 10 times.

Th e Te k t r o n i x

P60 45 Fie ld Ef fe c t Tra n sisto r p ro b e a n d a c c e ssory p o w er

su p p l y o f f e r t h e sa m e h i g h - i n p u t i m p e d a n c e a s t h e 1 0 X

probes. However, it is particularly useful since it provides

wide-band operatian while presenting no attenuation (1X

gain) and a low input capacitance. To obtain maximum

bandwidth when using the probes, observe the grounding

considerations given in the probe manual. The probe-toconnector adapters and the bayonet-ground tip provide the

best frequency response. Remember that a ground strap

only a few inches in length can produc e several percent of

ringing wh en opera ting at th e hig he r fre q ue nc y lim it o f this

sy st e m . Se e y o u r Te kt r o n i x, I n c . c a t a l o g f o r c h a r a c t e ri st i c s

and compatibility of probes for use with this system.

In hig h-freque nc y a p p lic a tions re q uiring ma ximu m ove ra ll

bandwidth, use coaxial cables terminated at both ends in

their characteristic impedanc e. See the discussion on coa xia l cab les in th is sec tio n fo r more info rma tio n.

Hig h-lev el, lo w-fre que nc y sig na ls c a n b e c onnec ted directly

to the Type 453 INPUT connectors with short unshield ed

leads. Th is c ou p ling m et ho d w orks b est fo r sig na ls b elow

about one kilohertz and deflection foctors above one volt/

division. When this method is used, establish a common

ground between the Type 453 and the equipment under test.

Attempt to position the leads away from any source of interferenc e to avoid errors in the display. If interference is

excessive with unshielded leads, use a coaxial cable or a

probe.

Lo a d in g Ef fe c t o f t he Ty p e 4 5 3

As nearly as possible, simulate actual operating c onditions in the equipment under test. Otherwise, the equipment

under test may not produce a normal signa l. The 10X

attenuator probe and field effect transistor probe mentioned

previously offer the least circuit loading. See the probe

instru c tio n man ua l fo r load ing cha ra c te ristics o f t he ind ividual probes.

2-11

Page 28

TM 11-6625-1722-15

When the sig nal is c oupled directly to the input of the

Ty p e 4 5 3 , t h e i n p u t i m p e d a n c e i s a b o u t o n e m e g o h m

paralleled by about 20 pF. When the signal is coupled to

the input through a c oaxia l c ab le, the effeclive input capacitance depends upon the type and Iength of cable used.

Se e t h e f o l l o w i n g d i s c u ss i o n f o r

inf orrna tio n o n obt a ining

maximum frequency responspe with coaxial cables.

Th e s i g n a l c a b l e s u s e d t o c o n n e c t t h e s i g n a l 1 0 t h e t y p e

453 INPUT conn ec tors ha ve a Ia rg e effec t on t he ac curac y

of the displayed high-frequency waveform.

To m a i t a i n t h e

high-frequenc y characteristics of the app lied signal, highquality low-loss coaxial cable should be used. The cable

sh o u l d b e t e r m i n a t e d a t t h e Ty p e 4 5 3 IN PU T c o n n e c t o r in i t s

characteristic impedonce.

with differing characteristic impedances,

If it is n ec e ssary t o u se c a b les

use suitab le imped-

ance-matching devices to provide the correct transition, with

minimum loss, from one impedance to the other.

Th e c h a r a c t e r i s t i c i m p e d a n c e , v e l o c i t y o f p r o p a g a t i o n a n d

nature of signa l lOSSeS in a c oa xial c ab le a re det ermined

by the physical and electrical characteristics of the cable.

Lo sse s c a u se d b y e n e rg y d i ssip a t i o n in t h e d i e le c t ric a re

proportional to the signal frequency. Therefore, much of

the high-frequency information in a fast-rise p ulse can be

lost in o nly a few fee t of intercon ne c tin g c able if it is no t

the c orrec t type. To be sure of the high-frequency resp onse

of the system when using cables longer than about five feet,

observe the transient response of the Type 453 and the

int ercon ne c tin g c ab le with a fast-rise

pulse generator (gen-

erator risetime Iess than 0.5 nanoseconds).

DC c om po nents. The pre -charging ne twork inco rpora te d

in this u nit a II

OWS the inp ut-c oupling cap ac itor to charge to

the DC source voltage level when the Inp ut Coupling switc h

is se t to G ND. Th e p ro c ed ure f or using this fe ature is a s

follows:

1. Be fore c onn ec ting the signa l c ontaining a DC c om ponent to the Typ e 453 INPUT connector, set the Input Coupling

sw i tc h t o G N D. Th e n c o n n e c t t h e si g n a l t o t h e IN PUT

connector.

2. Wa it a bout one se c ond for the coupling c apa citor to

charge.

3. Se t the In put C ouplin g switc h to A C. Th e t rac e (display) will remain on the screen and the AC component of

the signal c an be measured in the normal ma nner.

Deflection Fa c tor

Th e a m o u n t o f v e r t i c a l d e f l e c t i o n p r o d u c e d b y a si g n a l

is d eterm ined by the sig na l a m plitude , th e attenua tio n fac to r

of the probe (if used), the setting of the VOLTS/DIV switch

and the setting of the VARIABLE VOLTS/DIV control. The

calibrated deflection factors indicated by the VOLTS/DIV

sw i t c h e s a p p l y o n l y w h e n t h e V A RI A BLE c o n t r o l i s se t t o

the CAL position.

Th e V A R I A B L E V O L TS/ D I V c o n t r o l p r o v i d e s v a r i a b l e

(unc alibrated) vertical deflection between the c alibrated

se t t i n g s o f t h e V O LTS/ D IV sw i t c h . Th e V A RIA BLE c o n t r o l

extends the maximum vertical deflec tion factor of the Type

453 to a t lea st 25 volts/ divisio n (10 volts po sition).

Input Coupling

Th e C h a n n e l 1 a n d 2 l n p u t C o u p l i n g sw i t c h e s a l l o w a

choice of input caupling. The type of display desired will

determine the coupling used.

Th e D C p o s i t i o n c a n b e u s e d f o r m o st a p p l i c a t i o n s . H o w ever, if the DC component of the signal is much larger than

the AC component, the AC p osition vvill probab ly provide a

better display. DC coupling should be used to display AC

si g n a l s b e l o w a b o u t 1 6 h e l t z a s t h e y w i l l b e a t t e n u a t e d i n

the AC position.

In t he A C p o sitio n, t he D C c o mpone nt o f t he sig nal is

blocked by a capacitor in the input circuit. The low-frequency response in the AC position is about 1.6 hertz (–3 dB

point). Therefore,

so m e l o w - f re q u e n c y d i st o rt i o n c a n b e

expected near this frequency limit. Distortion will also

appear

in sq ua re w aves w hic h hav e low-f req ue nc y c om-

ponents.

Th e G N D p o s i t i o n p r o v i d e s a g r o u n d r e f e r e n c e a t t h e

inp ut of the Typ e 453. The sig na l app lied to the inp ut con-

nec tor is internally disc onnec ted but not grounded. The

inp ut c irc uit is he ld at g rou nd p ote nt ial, e limina tin g th e ne ed

to externally ground the input to establish a DC ground

re fe renc e.

Th e G N D p o s i t i o n c a n a l s o b e u se d t o p r e - c h a r g e t h e

coupling capacitor to the average voltage level of the signal

applied to the INPUT connector. This allows measurement

of only the AC component of signals having both AC and

Dua l-Tra ce O pe ration

Alte rnate Mode. Th e A L T p o s i t i o n o f t h e M O D E s w i t c h

produces a disploy which alternates between Channel 1 and

2 w ith eac h swe ep of t he CRT. A ltho ug h the ALT mod e

can be used at all sweep rates, the CHOP mode provides

a more satisfactory display at sweep rates below about 50

microseconds/division. At these slower sweep rates, alternate

mode switching becomes visually perceptible.

Pro p e r in t erna l trig g e rin g in t h e A LT m o d e c a n b e o b -

tained in either the NORM or CH 1 ONLY positions of the

TRI G G E R s w i t c h . W h e n i n t h e N O R M p o si t i o n , t h e s w e e p i s

triggered from the signal on each channel. This provid es a

st a b l e d i sp l a y o f t w o u n re l a t e d sig n a l s, b u t d o e s n o t in d i c a t e

the time relationship between the signals. In the CH 1 ONLY

position, the two signals are displayed showing true time

re la tio nship . If the sig na ls a re n ot tim e relate d , th e Ch a nn el

2 wa ve fo rm will b e unsta ble in the CH 1 ONLY po sition.

Chopped Mode. Th e C H O P p o si t i o n o f t h e M O D E sw i t c h

produces a display which is electronically switched between

channels. In general, the CHOP mode provides the best