Page 1

xx

ZZZ

PWRVIEW

Online Help

*P077116500*

077-1165-00

Page 2

Page 3

PWRVIEW

ZZZ

Online Help

w.tek.com

ww

077-1165-00

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its

subsidiaries or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this

publication supersedes that in all previously published material. Specifications and price change privileges

reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

077-1165-00 Printed version of the 076–0386–00 PWRVIEW Online Help, March, 2016.

Contactin

Tektronix, Inc.

14150 SW Karl Braun Drive

P. O . B o x 50 0

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

g Tektronix

In North America, call 1-800-833-9200.

Worldwide, visit www.tek.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of

one (1) year from the date of shipment. If any such product proves defective during this warranty period,

Tektronix, at its option, either will repair the defective product without charge for parts and labor, or will

provide a rep

by Tektronix for warranty work may be new or reconditioned to like new performance. A ll replaced parts,

modules and products become the property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the

expiration of the warranty period and make suitable arrangements for the performance of service. Customer

shall be responsible for packaging and shipping the defective product to the service center designated by

Tektronix, with shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if

the shipment is to a location within the country in which the Tektronix service center is located. Customer

shall be r

to any other locations.

lacement in exchange for the defective product. Parts, modules and replacement products used

esponsible for paying all shipping charges, duties, taxes, and any other charges for products returned

This war

inadequate maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to

repair damage resulting from attempts by personnel other than Tektronix representatives to install, repair or

service the product; b) to repair damage resulting from improper use or connection to incompatible equipment;

c) to repair any damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a product

that has been modified or integrated with other products when the effect of such modification or integration

incr

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHE

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR

HE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

T

[W2 – 15AUG04]

ranty shall not apply to any defect, failure or damage caused by improper use or improper or

eases the time or difficulty of servicing the product.

R WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

Page 6

Page 7

Table of Contents

Welcome

Introduction ......................................................................................................... 1

Quick start................ ................................ ................................ ........................... 2

File menu

File menu ............................................................................................................ 7

Projects .............................................................................................................. 7

Default Project...................................................................................................... 9

Open / recent project .................. .................................. ................................ .......... 10

Save / Save As ....... ................................ .................................. ............................ 11

About................................................................................................................ 11

Setup

Setup ................................................................................................................ 13

Instrument add/remove

Instrument add/remove....................................................................................... 14

Add... .................................. ................................ ................................ ........ 15

Remove .................... .................................. ................................ .................. 16

Network........................................................................................................ 17

Application Mode ....................... ................................ .................................. ........ 17

Efficiency........................................................................................................... 18

Limits ............................................................................................................... 18

Upload ........................ .................................. ................................ .................... 20

Instrument setup panel

Instrument Setup panel....................................................................................... 20

Applications/tests panel

Applications/Tests panel ................................................................................ 21

Apply button.............................................................................................. 22

Applications wizard

Applications wizard................................................................................. 23

General

AC Power ............................................................................................ 24

LED Driver

LED Driver ...... ................................ ................................ .................... 24

LED Driver Input ................................... .................................. .............. 24

LED Driver Output ................................................................................. 25

LED Driver Efficiency........................ ................................ ...................... 26

Ballast

Table of Contents

PWRVIEW Online Help i

Page 8

Table of Contents

Instrument information panel.................. .................................. ............................ 37

Instrument wiring/setup

Wiring configuration

Ballast ........ ................................ ................................ ........................ 27

Ballast Input ... ................................ .................................. .................... 27

Ballast Output ....................................................................................... 28

Ballast Efficiency.......................................... ................................ .......... 29

PWM Motor Drive

PWM Motor Drive .................................................................................. 29

PWM Motor Drive Output ......................................................................... 30

PWM Motor Drive Efficiency ..................................................................... 31

Energy Me asurements

Energy Measurements .............................................................................. 32

Energy Consumption ..................................... ................................ .......... 32

Standby Power Measurements

Standby Power Measurements..................................................................... 32

Standby Power....................................................................................... 33

Compliance tests

Compliance tests ........ .................................. ................................ .......... 34

IEC 62301 Standby Power....... ................................ .................................. 34

MIL-1399 Current Harmonics ..................... ................................ ................ 36

IEC 61000-3-2 Current Harmonics (Pre-compliance) .......................................... 36

Wiring Instructions...................... ................................ ............................ 36

Wiring configuration..................................................................................... 37

Wiring type ............................................................................................... 39

Group names.............................................................................................. 39

Group configuration

Group configuration................................... ................................ .............. 40

Mode

Mode.................................. ................................ ................................ 41

Normal mode .................. ................................ ................................ ...... 42

Ballast mode......................................................................................... 43

Standby mode.................................... ................................ .................... 44

PWM mode .................................... ................................ ...................... 45

Integrator mode.............................. ................................ ........................ 45

Inrush mode................ .................................. ................................ ........ 46

IEC 62301 mode ........................................ .................................. .......... 46

MIL-1399 mode..................................................................................... 47

IEC 61000-3-2 mode ............................................................................... 47

Filter . . .................................... .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...... 48

Frequency source.................................................................................... 49

Frequency range..................................................................................... 50

ii PWRVIEW Online Help

Page 9

Measure

Measure..................................... ................................ .................................. ...... 63

Start ... .................................. ................................ ................................ ............ 63

Stop ................................................................................................................. 64

Reset ................................................................................................................ 65

Significant figures ............. .................................. ................................ .................. 65

Averaging....................... ................................ ................................ .................... 66

Zero Blanking.............................. .................................. ................................ ...... 66

Integration .......................................................................................................... 67

Data logging

Measurement results and charts

Table of Contents

Voltage channel...................................................................................... 51

Current Channel............... ................................ ................................ ...... 51

Measurement selection

Measurement selections .......... ................................ ................................ .. 53

Sum results

Sum results........................................................................................... 53

1P3W Sum formulas................................................................................ 54

3P3W Sum formulas................................................................................ 56

3P4W Sum formulas................................................................................ 57

Harmonics................................ ................................ ............................ 58

Total harmonic distortion................... ................................ ........................ 59

Distortion factor ............... ................................ .................................. .... 60

Auxiliary inputs

Auxiliary inputs .............................. .................................. .......................... 60

Equation guidelines ........................ ................................ .............................. 61

Data logging................................................................................................... 67

Snapshot ....................................................................................................... 67

Record............................ ................................ .................................. ............ 68

Measurement results and charts............... ................................ .............................. 71

Results grid.............. ................................ .................................. .................... 71

Formulas and text......................... ................................ ................................ .... 72

Charts

Charts............................ .................................. ................................ ........ 72

Harmonic bar charts ..................................................................................... 73

Waveform charts ......................................................................................... 74

Trend charts............................. ................................ .................................. 75

Test

Test tab.............................................................................................................. 77

Test .... .................................. ................................ ................................ ............ 77

PWRVIEW Online Help iii

Page 10

Table of Contents

Test details

Test details..................................................................................................... 79

Laboratory..... ................................ .................................. .............................. 79

Customer....................................................................................................... 80

Product

Test info.... .................................. ................................ ................................ .. 82

IEC 62301 Standby power test

IEC 62301 Standby power test .............................. ................................ ................ 82

Power plot ... ................................ ................................ .................................. 83

Voltage quality . . . . . . . . . . . . . . . . . . . . . . . . .................... . . . . . . . . . . . . . . . . . . . . . . . . . . .................... . . . . . . 84

Power stability . . . . . . . . . . . . .......................... .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .................... 85

Uncertainty .................................................................................................... 85

Test status.................................... ................................ .................................. 86

MIL-1399 Current Harmonics test

MIL-1399 Current Harmonics test............................................ .............................. 86

Test limits.................................... ................................ .................................. 88

Harmonics graph/table . ................................ ................................ ...................... 89

Test status.................................... ................................ .................................. 90

IEC 61000-3-2 Current Harmonics

IEC 61000-3-2 Current Harmonics (pre-compliance) test ............................................... 91

Limit class types .............................................................................................. 93

Rated parameters.............................................................................................. 96

Harmonics graph/table . ................................ ................................ ...................... 98

Test results................................................................................................... 100

Product .................................................................................................... 80

Manufacturer ..................... ................................ ................................ ........ 81

Results

Results tab........................................................................................................ 101

Measurement results............................................................................................. 101

Test results.................. .................................. ................................ .................... 103

Standby power results

Standby power results .......... ................................ ................................ ............ 104

Results Summary tab ....................................................................................... 104

Power Readings tab......................................................................................... 105

MIL-1399 results

MIL-1399 results ........................................................................................... 105

Results Summary tab ....................................................................................... 106

Harmonics Results tab ............... ................................ .................................. .... 107

Current harmonic results

Current harmonic results................................................................................... 108

Results Summary tab ....................................................................................... 109

iv PWRVIEW Online Help

Page 11

Index

Table of Contents

Harmonics results tab ...................................................................................... 111

Reports

Reports ....................................................................................................... 112

PDF reports.. ................................ .................................. .............................. 113

Spreadsheet reports......................................................................................... 114

PWRVIEW Online Help v

Page 12

Table of Contents

vi PWRVIEW Online Help

Page 13

Welc o me Introduction

Introduction

Welcome to the PWRVIEW online help for the Tektronix power analyzers.

PWRVIEW has been designed to make power measurement and a nalysis as simple as possible using

Tektronix power analyzers.

Measure efficiency, energy consumption, standby power, harmonics, and other power parameters for

single and three phase applications

Remotely monitor, control and log power measurements

Take measurements simultaneously from multiple power analyzers

View voltage, current and power waveforms

Chart har

Set custom measurement limits to monitor when measurements have exceeded a user specified

thresho

Trend measurements by plotting their values over time

Save measurement snapshots

Record results for future analysis in spread sheets or comma separated value files

Run, compliance and pre-compliance tests for various regulatory standards such as IEC 62301

(Standby Power), IEC 61000-3-2 (Current Harmonics) or MIL-1399 (Current Harmonics)

monics to instantly visualize a voltage or current frequency spectrum

ld

Minimum system requirements

The minimum system requirements for running PWRVIEW are:

Microsoft Windows 7 or 8.1

2 GHz or faster 32-bit (x86) or 64-bit (x64) processor

2 GB RAM (minimum), 4 GB RAM (recommended)

inimum display resolution of XGA (1024 x 768)

M

PWRVIEW also supports "Virtual" instruments; these instruments can be used to learn the features of

ither product without a physical instrument being present.

e

Use the Setup

Setup Wizards make the most complex measurement settings simple by taking you step by step through

your unique requirements.

Use the Measure

all the selected measurement can be viewed in a grid. Harmonics, waveforms, and trend plots can also be

enabled on this screen.

PWRVIEW Online Help 1

(see page 13) screentoconfigure instruments and switch between Measure and Test modes.

(see page 63) screen to monitor and analyze measurement results. This s creen is where

Page 14

Welc o me Quick start

Use the Test (see page 77) screen to perform Regulatory Standards testing based on measured results.

IEC 62301 (Low Power Standby), IEC 61000-3-2 (Current Harmonics) and MIL-1399 (Current

Harmonics) st

andards testing is supported.

Use the Results

Use the File Menu

See the Quick Start

Quick start

This section provides a step-by-step guide for setting up and measuring results. This section uses a

single four-channel PA3000; if you have a single-channel instrument or multiple instruments, some

of the screens will differ from the ones shown.

1. Connect your power analyzer to the computer using your preferred communications method.

Communications are possible using USB, Ethernet, and GPIB. Not all instrument models have all

types of communication port available, and some may be optional. Please consult the documentation

for you

2. If using USB or GPIB, instruments are automatically detected. If using Ethernet, make sure the

instr

(see page 101) screen to export recorded data or to analyze and report the test results.

(see page 7) to save and manage measurement projects.

(see page 2) guide to quickly begin m aking measurements.

r model.

uments IP Addresses are configured in the Network Setup.

2 PWRVIEW Online Help

Page 15

Welc o me Quick start

3. Press the Add button to detect and add your instrument. The following dialog box will appear:

4. Click the Connect button to connect your instrument to PWRVIEW.

If desired, check the “Include Virtual Instruments” box to add demonstration instruments to the list and

then select one or more instruments before clicking the Connect button.

5. After closing the Add dialog box, the Setup tab will be displayed with the newly selected instruments.

The following figure shows the Setup tab with the w iring configuration for the PA3000.

If you have a single-channel instrument such as a PA1000, the Setup tab will show the settings

configuration.

PWRVIEW Online Help 3

Page 16

Welc o me Quick start

6. By default, the General/AC Power Application is applied to each instrument. This is used to make

general power measurements.

7. To start gathering measurement results, go to Measure tab on the top and click the Start button. The

settings will be automatically uploaded to the instrument. The measurements will be updated and

results will be shown in the results grid:

4 PWRVIEW Online Help

Page 17

Welc o me Quick start

8. Click the Stop button to stop the measurements.

PWRVIEW Online Help 5

Page 18

Welc o me Quick start

6 PWRVIEW Online Help

Page 19

File menu File menu

File menu

The File menu contains all functionality to manage project files.

Default Project (see page 9) returns PWRVIEW to a default state.

Open (see page 10) opens an existing project.

Save / Save As (see page 11) saves the current PWRVIEW configurationtoafile.

age

About (see p

Exit closes the application.

A Recent Projects list conveniently shows a list of the most recently used projects to open with a click of

the mouse.

11) provides information about PWRVIEW.

Projects

The current settings of the PWRVIEW application can be stored in a project file. The file suffix is .vpm.

The file includes:

A list of all the instruments currently added to PWRVIEW

wiring setup for each instrument

The

The configuration for each instrument group including the mode, Voltage channel, Current channel,

d measurement selections for all groups

an

The Auxiliary input configuration for an instrument (applicable to PA3000 or PA4000 instruments)

The Efficiency measurement settings

All limits definitions

PWRVIEW Online Help 7

Page 20

File menu Projects

All values that can be set from the Measurement tab:

Significant figures setting

Averaging setting

Zero blanking

The number o

The logging setup

If a test is active, all values associated with that test. The details vary per test.

Project files can be saved and recalled anywhere within the file system. Saving a project file has no impact

on the current PWRVIEW setup. Recalling a project file replaces the current PWRVIEW setup.

PWRVIEW automatically prompts you to save any changes you made to the setup settings before exiting.

This allows you to continue working with the same configuration setting when you restart PWRVIEW.

PWRVIEW provides a Default Project option to remove all instruments and return all settings to default

values w

hen desired.

f charts that are displayed

8 PWRVIEW Online Help

Page 21

File menu Default Project

Default Project

Default Project resets PWRVIEW to a default state. All instruments and defined formulas will be removed,

averaging, blanking, significant digits, and logging settings will be returned to default settings.

NOTE. Defaul

Default Project does not affect database or recorded test results.

1. Click the blue tab with white arrow below to expand the File Menu (see page 7),thenselectthe

Default Project entry.

2. Upon cl

of values.

t Project does not affect the current settings on the power analyzer.

icking Default Project you will be asked to confirm the removal of instruments and resetting

er confirmation, PWRVIEW will be returned to default settings: all instruments and defined

Aft

formulas will be removed, averaging, blanking, significant digits, and logging settings will be returned

to default settings.

PWRVIEW Online Help 9

Page 22

File menu Open / recent project

Open / recent project

Open

The Open button allows you to open previously saved project files.

1. Click the blue tab with white arrow to expand the File Menu

a saved project.

2. Select a

file as shown below with a .vpm extension and click Open.

(see page 7) andclickOpentoopen

PWRVIEW will be set based on the settings within the opened file.

Recent Projects

e Recent Projects area is a list of recently Saved/Saved As proje ct files. A new entry will appear after

Th

saving a project to file. Selecting an entry in this area opens that project file (it is equivalent to pressing the

Open selection and browsing to the project file path). Hovering the mouse over one of the recent projects

shows the full path of the project file.

10 PWRVIEW Online Help

Page 23

File menu Save / Save As

Save / Save As

Use the Save or Save As buttons to save the current PWRVIEW configuration to file.

About

The About dialog box shows information about the PWRVIEW software.

PWRVIEW Online Help 11

Page 24

File menu About

12 PWRVIEW Online Help

Page 25

Setup Setup

Setup

The Setup ribbon provides the ability to add and remove instruments as well as the ability to configure

instruments to make the desired me asurements. It contains the following areas:

Instruments (see page 14): Adds and removes power analyzers to and from PWRVIEW

Application Mode (see page 17): Switches between Measure and Test mode s

Efficiency (see page 18):Configures the Efficiency measurement

Limits (see page 18):Configures user defined limits for Measurement, Auxiliary inputs, and Formulas

Settings (

The Instrument Setup Panel (see page 20) has a dedicated tab for each instrument. Each instrument tab

has the fo

see page

llowing sub panels:

Applications / Tests Panel (see page 21) is used to configure instruments for specific applications

includi

Information Panel (see page 37) showing instrument details.

Wiring and Group panel which is used to setupaninstrument(see page 20) for various wiring

configurations.

ng enabling tests.

20): Uploads the current PWRVIEW settings to each added instrument

PWRVIEW Online Help 13

Page 26

Setup Instrument add/remove

Instrument add/remove

The setup ribbon provides the user with functionality that:

Adds (see page 15) new instruments

Removes (see page 16) currently added instruments

Network (see page 17) configures the IP addresses over which to communicate

PWRVIEW interacts with one or more power analyz ers to send setup information and receive measurement

results. Communication is achieved using TekVISA software which is available from www.tek.com

VISA system manages all communications links allowing PWRVIEW to use a common framework

regardless of the physical communication layer chosen. NI-VISA, National Instruments VISA, is also

supported.

Communication is possible u sing USB, Ethernet, and GPIB. All three buses are always available on the

PA1000 products. GPIB is optional for PA3000 products.

.The

USB connections

Using the Universal Serial Bus is the simplest way to connect your instrument to the computer. Just plug

a cable into any USB port on the computer running PWRVIEW and the square USB port (Standard

B) on the rear of the instrument. The computer should automatically detect and install an appropriate

communication driver. After driver installation, the attached power analyzer will be shown in the list of

available instruments.

Ethernet (Network) connections

Unlike USB and GPIB, an Ethernet enabled instruments are not automatically detected by VISA. The

IP address of each instrument must be entered into the Network address dialog box

approach eliminates long VISA Ethernet search times.

First connect both the PWRVIEW host computer and power analyzer onto the same Ethernet network.

The power analyzer will, by default, obtain an IP address automatically from the DHCP server. The IP

address can be accessed on PA1000 front panel by selecting Menu → Interfaces → Ethernet → Current IP

Settings. On the PA3000, the IP addresses can be accessed on the instrument front panel by pressing the

Setup button and then scrolling to the bottom of the screen.

Once the correct network IP address is entered into the Network dialog box, the instrument will be added

to the list of available instruments.

(see page 17).This

GPIB connections (IEEE 488.1)

General Purpose Instrument Bus connections require the addition of a GPIB controller to the host

computer. GPIB controllers come in a variety of formats from PCI cards that require installation inside

desktop computers to USB-GPIB converters that can simply be attached to the USB port of the computer.

14 PWRVIEW Online Help

Page 27

Setup Add

Whichever option is used the manufacturer must supply drivers that interface with the VISA system.

Connect the instrument to the GPIB controller using a GPIB cable and the instrument should be shown in

the list of ava

ilable instruments.

Add

The Add button activates the Add An Instrument dialog box. When this dialog is activated, PWRVIEW

will search

the Network dialog box

for instruments attached to the computer on USB, GPIB, and the Ethernet addresses defined in

(see page 17).

1. Click Add t

2. Upon clicking Add the following dialog box displays. It shows the instruments available for

connection. Click the box next to an instrument to add it to PWRVIEW.

o detect and add an instrument.

Clicking the Refresh button will initiate a new search for connected instruments.

Checking "Include Virtual Instruments" adds Virtual Instruments to the list of available instruments.

Virtual instruments can be used to learn the features of either product without a physical instrument

being present.

PWRVIEW Online Help 15

Page 28

Setup Remove

Remove

Remove opens a dialog box that can b e used to remove instruments from PWRVIEW.

1. Click Remove for removing already added instrument.

2. Select the instrument to remove.

3. All selected instruments will be removed from the project.

16 PWRVIEW Online Help

Page 29

Setup Network

Network

The Network dialog box specifies instrument IP addresses. PWRVIEW will only searc h the Ethernet

for addresses in this list.

The Add area allows you to enter new addresses to be searched. To remove an address, select it from the

list and click Remove.

The addresses in the list will be searched when the Add instrument function is performed.

The IP address list will be searched each time instruments are added. Therefore this list should be kept as

small as possible. Addresses that are not valid extend the search time.

Application Mode

Use the Application Mode to select either the Measure or Test modes. The Applications / Test (see

page 21) area on the left side of the screen provides a list of preset applications and tests. The selections in

the list depend on the instrument; The PA3000 and PA4000 have different tests than the PA1000. The

application mode selection helps set up the measurements or tests for your particular application.

Depending on the application mode, some selections are grayed out and are not active until you change the

mode. For example Compliance Tests are not available in Measure mode, but only in Test mode.

Use Measure to select the measurements, such as AC Power or LED Driver Input, and then click either the

Wizard button or the Apply button. After selecting the measurement, the configuration details appear on

the right side of the screen. When you select the Measure applicat

available where you can start or stop measurements and display the results using different tools such as

Harmonics

Use Test to select compliance tests for your instrument, such as IEC 62301 Standby Power. Click either

the Wizard button or the Apply button to apply the test setups on the right side of the screen. When you

select the Test application mode, the Test tab is available where you can start or stop the test.

PWRVIEW Online Help 17

(see page 98), Wavef o rms (see page 74),orTrend (see page 75) charts.

ion mode, the Measure tab becomes

Page 30

Setup Efficiency

Efficiency

The Efficiency Configure check box allows for configuring the Efficiency measurement. This feature

requires at least two groups added in PWRVIEW. Click the Configure check box to bring up the Efficiency

Setup tab to c

Click the Measure Efficiency check box to enable selected efficiency calculations on the measure grid.

onfigure the input and output instruments and groups.

Limits

Use the Limits setup to configure user defined limits for various measurement parameters.

its can be set for different categories (Standard, Harmonics, Sum, Aux and Formulas).

Lim

Click the down arrow for more options such as setting up limit values, saving limits to a file, recalling

its from a file, and clearing all limits. The limits file is independent of the PWRVIEW configuration

lim

file and can be saved and recalled independently.

18 PWRVIEW Online Help

Page 31

Setup Limits

Select Setup from the menu to open the Limits Setup dialog box for configuring limit values.

its will show up on the Measurement grid as an individual tab. Hovering over the results cell displays

Lim

the set Limit Function, Limit Value, Relative Value, and Pass-Fail Status in r eal-time.

PWRVIEW Online Help 19

Page 32

Setup Upload

Upload

Use the Upload button to remotely control and change settings on the power analyzer.

Upload sends the commands necessary to configure the power analyzer to measure the selected parameters.

The use of this button is not mandatory as the uploads take place automatically when trying to take

measurements; but it can be used for controlling the instrument remotely and for diagnostic purposes.

Instrument Setup panel

All instruments added to the configuration using the Add (see page 15) button will appear as a series of

tabs in the Instrument Setup panel. Select the instrument to configure by clicking the tab. Information to

allow simple identification of the instrument is shown in the Information Panel

and tests can be configured using Applications / Tests Panel

using the Wiring

(see page 37) and Group Configuration (see page 40) panels.

(see page 37). Applications

(see page 21). Other parameters are configured

20 PWRVIEW Online Help

Page 33

Setup Applications/Tests panel

Applications/Tests panel

The Applications / Tests selector provides a list of preset applications and tests. These suggest the

parameters for the applications and tests; when applied they can be modified to suit the application or test.

Select from the list of available applications and tests and then use the Wizard

page 22) button to quickly generate an instrument setup. The following figure shows the applications and

tests available for a PA3000; other test are available with other power analyzers.

NOTE. Some items in the list are grayed out depending on the whether the Application Mode is Measure

t. In the following figure, the Compliance Tests are grayed out because the Application Mode

or Tes

is Measure.

(see page 23) or Apply (see

PWRVIEW Online Help 21

Page 34

Setup Apply button

Apply button

The Apply button applies the default setup for the selected application / test.

After clicking Apply, the instrument configuration is generated. You can then make any necessary changes

before saving and u ploading the configuration.

22 PWRVIEW Online Help

Page 35

Setup Applications wizard

Appli

NOTE. The Apply button does not upload the settings to the power analyzer, it just configures the settings

of PWRVIEW. Click either the Upload button or the Start button under the Measure or Test tab to send

all the settings to the power analyzer.

cations wizard

pplications wizard launches a series of prompts that ask questions about the measurement application

The A

before automatically generating an instrument configuration. It can also provide help and wiring diagrams

to connect the instrument. The available applications vary depending on which power analyzer is being

used and the number of available channels.

1. Click the wizard button and follow the screen prompts.

PWRVIEW Online Help 23

Page 36

Setup AC Power

Available w iza

LED Driver Inpu

LED Driver Out

LED driver effi

Ballast Inpu

Ballast Outp

Ballast Effic

Standby Pow

PWM Drive Ou

PWM Drive E

Energy Con

Full Compl

rds (depending on instrument) are:

tWizard

put Wizard

ciency wizard

t

(see page 27)

ut

(see page 28)

iency

er

(see page 33)

tput

fficiency

sumption

iance Standby

(see page 24)

(see page 25)

(see page 26)

(see page 29)

(see page 30)

(see page 31)

(see page 32)

(see page 34)

xxx

AC Power

AC Power does not have a wizard; but is used to apply a default configuration for making general AC power

measurements in Normal mode. This configuration will expect steady st ate power for each line cycle.

LED Dr

iver

LED - L

ight Emitting Diode - applications are those that involve making AC-DC LED drive measurements.

An LED drive is the supply unit used to drive LED devices. They typically take line power in and produce

a constant current DC output.

LED Driver Input

LED Driver Input

The LED Driver Input wizard provides a wiring diagram showing how to connect the input of an LED

driver to the mains. The last page of the wizard presents a wiring summary showing a schematic with

wiring instruction

(see page 24),Output (see page 25),andEfficiency (see page 26) wizards are available.

(see page 36).

24 PWRVIEW Online Help

Page 37

Setup LED Driver Output

LED Driver Output

The LED Driver Output wizard provides a wiring diagram showing how to connect the Output of an LED

Driver to the LED module. The last page of the wizard pres ents a wiring summary showing a schematic

with wiring instructions.

(see page 36)

PWRVIEW Online Help 25

Page 38

Setup LED Driver Efficiency

LED Driver Efficiency

The LED Driver Efficiency wizard generates a configuration suitable for measuring the efficiency of

LED

(see page 24) Drive systems. Prompts are generatedthesameasthoseoftheLED Driver Input

(see page 24) an

(see page 36) shown.

d LED Driver Output

(see page 25) wizards before presenting the wiring instructions

26 PWRVIEW Online Help

Page 39

Setup Ballast

Ballast

Ballast applications involve measurements of lighting ballast systems. A typical ballast system will

take the line input and convert it to high frequency signals that can be heavily amplitude-modulated at

line frequen

cies.

Ballast Input

guide you th

Ballast Input

This wizard generates a suitable configuration for measuring the power input of ballast systems.

The maximum expected peak current is requested to determine which shunt (1 A or 30 A) should be used.

The last page of the wizard provides a wiring summary showing a schematic with wiring instructions

e

(see pag

36).

(see page 27), Output (see page 28),andEfficiency (see page 29) wizards are available to

rough the measurement application and apply an appropriate configuration.

PWRVIEW Online Help 27

Page 40

Setup Ballast Output

Ballast Output

This wizard generates a suitable configuration for measuring the output power of ballast systems. The

wizard requests the maximum expected peak current to determine which shunt (1 A or 30 A) should be

used. The lin

to the fundamental power frequency. Selecting a tube with a filament presents the required schematic

diagram. The last page of the wizard provides a wiring summary showing a schematic with wiring

instructions. (see page 36)

e frequency is requested and used by the power analyzer to synchronize the measurements

NOTE. The image shows the use of the Tektronix Ballast CT accessory for measuring output power and

tube current in h igh frequency electronic lighting ballast applications.

28 PWRVIEW Online Help

Page 41

Setup Ballast Efficiency

Ballast Efficiency

This wizard generates a suitable configuration for measuring the efficiency of ballast systems. Prompts are

generated the same as those of the ballast input

before creat

ing the wiring instructions

(see page 36) shown below.

(see page 27) and ballast output (see page 28) wizards

NOTE. The image demonstrates the use of the Tektronix Ballast CT accessory for measuring output power

and tube current in high frequency electronic lighting ballast application.

PWM Motor Drive

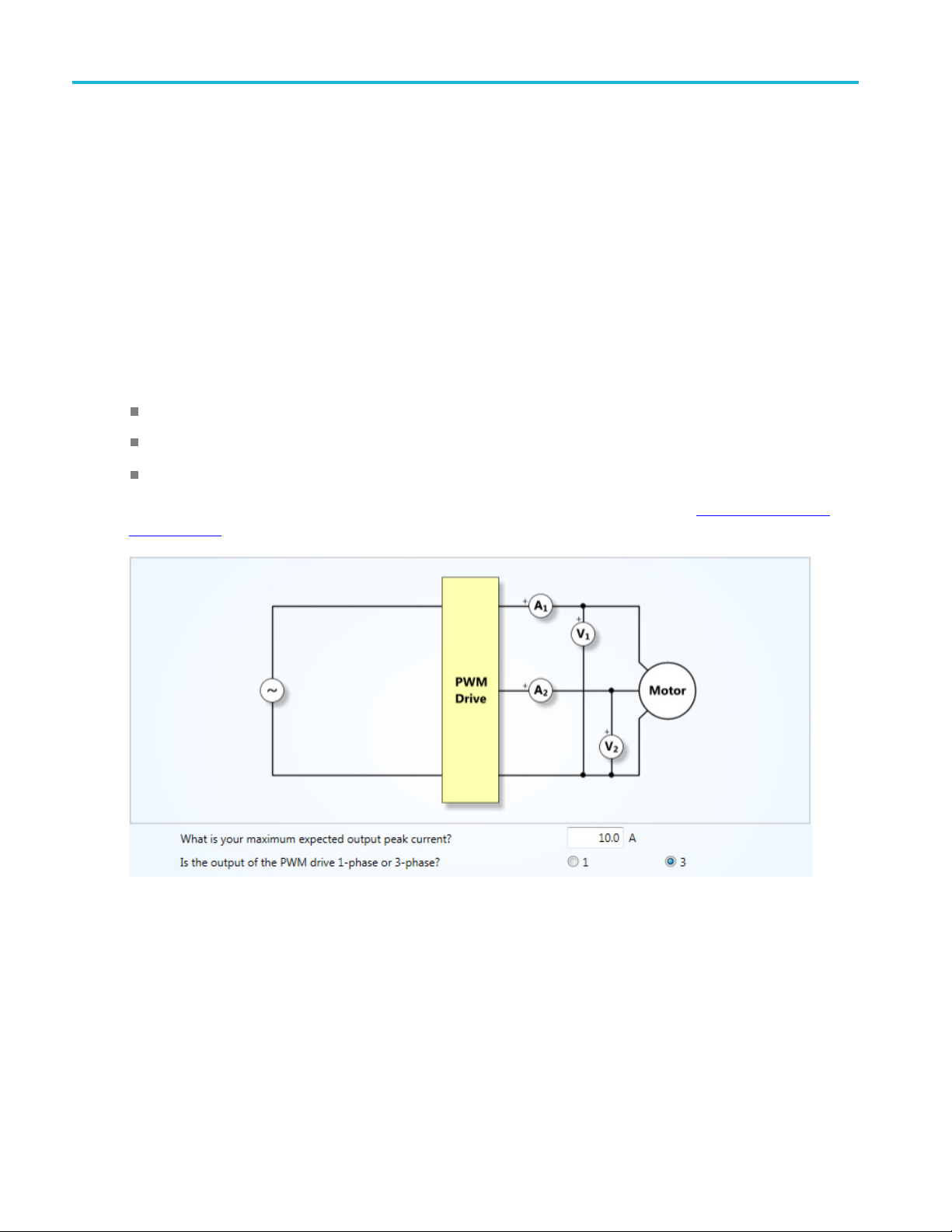

PWM (Pulse Width Modulation) motor d rive applications are those involved with measuring the power

consumption and efficiency of PWM motor inverter systems.

A typical PWM motor drive operates from a single or a three phase supply and converts the output voltage

to a high frequency pulse width modulated signal to accurately control a three phase motor. The resultant

output current is at motor frequency and represents the fundamental frequency for output power but can

often be highly distorted and not fit for frequency detection. The PWM mode

(see page 45) digitally filters

PWRVIEW Online Help 29

Page 42

Setup PWM Motor Drive Output

and demodulates the output voltage to accurately detect the fundamental power frequency. The digital filter

in PWM mode is only used for frequency detection and does not affect the actual RMS readings of voltage.

PWM Motor Drive Output

This wizard generates a suitable configuration for measuring the output power of PWM motor drive

systems using the two watt meter method.

The maximum expected peak current is requested to determine which shunt (1 A or 30 A) should be used.

The number of phases might be requested to determine the number of channels to use.

The following current measurement options are presented:

Direct Measurement

Current Transformer

Voltage Output Transducer

The las

(see page 36)

t page of the wizard provides a wiring summary showing a schematic with wiring instructions.

30 PWRVIEW Online Help

Page 43

Setup PWM Motor Drive Efficiency

PWM Motor Drive Efficiency

This wizard generates a suitable configuration for measuring the efficiency of PWM m otor drive systems

using the two watt meter method. Prompts are generated to ask questions about the power into the inverter,

followedbyq

Questions are asked about peak current (to determine the s hunt selection) and number of input phases. The

following i

Direct Measurement

Current Transformer

Voltage Output Transducer

The las t page of the wizard provides a wiring summary showing a schematic with wiring instructions.

(see page 36)

uestions similar to those of the PWM Drive Output

nput current measurement options are presented:

(see page 30) wizard.

PWRVIEW Online Help 31

Page 44

Setup Energy Measurements

Energy Measurements

Energy consumption measurements require power integration over long periods of time to determine the

energy used (in kilowatt hours, for example). Integrator mode is used for these measurements.

Energy Consumption

This wizard generates a suitable configuration for measuring energy consumption of a device. The

maximum expected peak current is requested to determine which shunt (1 A or 30 A) should be used. The

number of input phases is requested. The software can also compute the Correction VArs (CVArs) based

on the target power factor for this measurement.

Thelastpageofthewizardprovidesawiring summary showing a schematic with wiring instructions.

(see page 36)

Standby Power Measurements

Standby power is generally defined as power consumption when the device under test is operating in a no

load or a low load scenario.

Standby power is usually very low and highly distorted. The signal normally has very low power factor

and high irregular peaks. Such signals require wide dynamic measuring range and long averaging to obtain

a stable power measurement.

32 PWRVIEW Online Help

Page 45

Setup Standby Power

PWRVIEW provides default application modes to measure or test standby power either for quick

measurement checks or for full compliance tests to the IEC 62301 standard.

Standby power

IEC 62301 Standby Power (Full Compliance Test)

Standby Power

This wizard generates a suitable configuration for measuring the input power of devices operating in

standby mode

r 30 A) and range should be used. The power analyzer is then set in Auto-up-only range setting,

(1 A o

where the range is set to increase every time a peak is detected but never switches down. This helps power

analyzer determine the optimum range for a given signal and not miss any irregular current peaks. The

operating c ycle time is also requested so that an integration time of three times the cycle time can be

set. An integration time of 10 seconds is used as default. The last page of the wizard provides a wiring

summary showing a schematic with wiring instructions.

PWRVIEW Online Help 33

(see page 44). The maximum expected peak current is requested to determine which shunt

(see page 36)

Page 46

Setup Compliance tests

NOTE. The image demonstrates the use of the Tektronix Breakout box (BB1000) for measuring input

AC standby power.

Compliance tests

The Compliance tests are available when the Application Mode is Test; none of these tests are available

under Measure. If you are in the Measure mode, you need to change the Application Mode to Test to

enable the compliance tests.

PWRVIEW will only run one test at a time on a single channel on a single instrument.

IEC 62301 Standby Power

This wizard generates a s uitable configuration for testing the standby power of devices according to

IEC 62301 ED 2.0 standard.

The instrument will be configured to use the IEC 62301 mode which uses the auto-up ranging system.

The auto-up ranging system allows the maximum test current to be measured a nd the range to be fixed so

that no range changes occur during the main test. Thelastpageofthewizardprovidesawiringsummary

showing a schematic with wiring instructions.

(see page 36)

After applying this wizard the IEC 62301 Standby Power Test can be controlled from the Test (see

page 77) tab.

34 PWRVIEW Online Help

Page 47

Setup IEC 62301 Standby Power

NOTE. The image demonstrates the use of the Tektronix Breakout box (BB1000) for measuring input

AC standby power.

PWRVIEW Online Help 35

Page 48

Setup MIL-1399 Current Harmonics

MIL-1399 Current Harmonics

The MIL-1399 Current Harmonics test is available with PA3000 and PA4000 instruments. This test does

not have a wizard. Click the Apply button to apply the test.

IEC 61000-3-2 Current Harmonics (Pre-compliance)

The IEC 61000-3-2 Current Harmonics (Pre-compliance) test is available with PA1000 instruments. This

test does not have a wizard. Click the Apply button to apply the test.

Wiring Instructions

Wiring instructions on the last page of each wizard summarize the wiring configuration and shunt selection

for each channel based on the application and user inputs. In the following example, the power analyzer is

setup in a 3p3w configuration using two watt meter method on input and output. Current Transducers

(CTs) are selected for each channel based on the user input. 1 A current shunts are used to connect the

output (secondary) of the current transducers as indicated by t

page. The voltage and current connections are shown in the schematic as V

channel number. A "+" indication denotes the "Hi" side connection.

he instruction on the bottom of the wizard

and Ansymbols where n is the

n

36 PWRVIEW Online Help

Page 49

Setup Instrument information panel

Instrument information panel

The Instrument Information Panel shows the following:

Instrument type

Connection details including:

Connection type used for communication

VISA vendor

Instrument serial number

Instrument firmware version

and version number

Wiring configuration

The wiring configuration is only present for a multi-channel instrument and is used to set up the channels

n a group. The wiring type

used i

required will be generated. Group tabs are shown to allow further group configuration.

Group names

(see page 39) can be changed by editing the values shown.

(see page 39) can be set for each channel and the number of groups

(see page 40).

PWRVIEW Online Help 37

Page 50

Setup Wiring configuration

NOTE. In Test mode, the wiring type is fixed at 1p2w and cannot be changed. Use the radio button in

the front of each channel to select which channel to run the test on.

38 PWRVIEW Online Help

Page 51

Setup Wiring type

Wiring type

The wiring type groups channels together as required by the application and specifies the wiring

configuration for the group.

Wiring type Number of channels in group

1p2w - 1 phase 2 wire 1

d]

se3wire

2

None – cha

nnel not used

1p3w - 1 pha

3p3w - 3 phase 3 wire 2

3p4w - 3 phase 4 wire 3

[Disable

xxx

Group names

Group names can be edited to allow for simple identification. Use a group a name that describes its purpose.

PWRVIEW Online Help 39

Page 52

Setup Group configuration

Group configuration

The group configuration section, shown for each group tab, allows configuration of a group of channels

with the following information:

Modes (see page 41)

Filtering (see page 48)

Frequency Source (see page 49)

Frequency Range (see page 50)

annel

Voltage Ch

Current Channel (see page 51)

Measurement selections (see page 53)

(see page 51)

40 PWRVIEW Online Help

Page 53

Setup Mode

Mode

The mode setting configures the instrument to operate in the manner required by certain measurement

ications. The available modes differ depending on the type of instrument. On changing the mode the

appl

available measurement selections

The following modes are available when the Application Mode is set to Measure:

Normal Mode (see page 42)

Ballast Mode (see page 43)

Standby Mode (see page 44)

PWM Mode [Applicable only for the PA3000] (see page 45)

PWRVIEW Online Help 41

(see page 53) and other setup options can change.

Page 54

Setup Normal mode

Integrator Mode (see page 45)

Inrush Mode [Applicable only for the PA1000] (see page 46)

List of modes available in the PA3000 are:

List of modes available in the PA1000 are:

Mode is set to one of the following tests when the Application Mode is set to Test:

IEC 62301 Standby Power (see page 46)

MIL 1399 Current Harmonics (see page 47), applicable only for the PA3000 and PA4000

IEC 61000-3-2 Curren

t Harmonics (Pre-compliance)

(see page 47), applicable only for the PA1000

Normal mode

Normal mode is the most common operating mode of the instrument. It can measure all available

measurement parameters and detects the frequency of the signals from the zero crossings of the waveforms.

42 PWRVIEW Online Help

Page 55

Setup Ballast mode

PA3000 Normal mode

PA1000 Normal mode

Ballast mode

Ballast mode is required to measure parameters of an AM (Amplitude Modulated) waveform typical of the

voltage outputs of ballast systems. The Tektronix power analyzers use a p roprietary dynamic frequency

detection technique for tracking periodic modulation frequency as zero crossing can be unreliable for

such applications.

PA3000 Ballast mode

PA1000 Ballast mode

On selecting ballast mode, any filter settings will normally be fixed to high bandwidth (to capture the faster

switching frequencies of the ballast) and a prompt for the line frequency will be given.

PWRVIEW Online Help 43

Page 56

Setup Standby mode

Standby mode

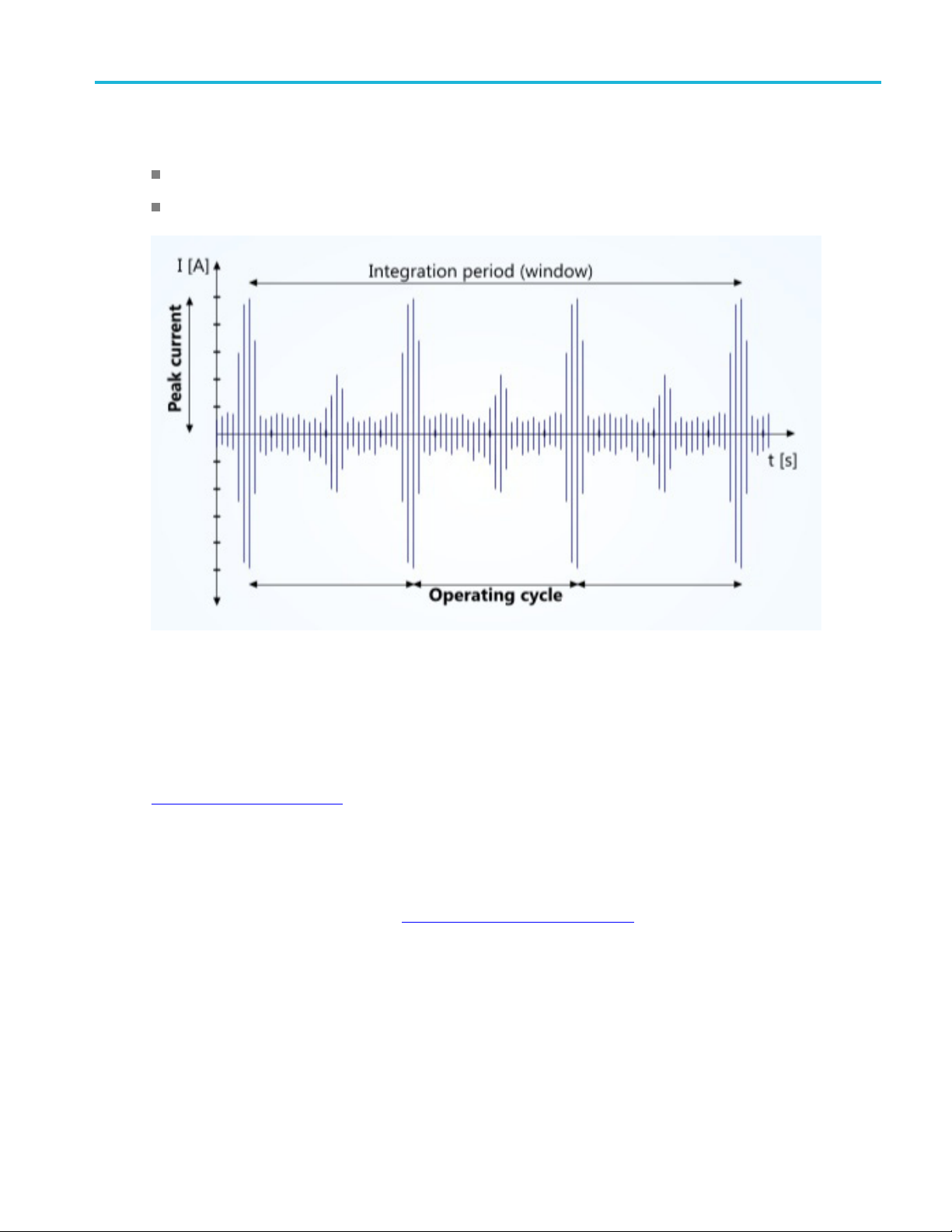

Standby mode is required when the current drawn by a load is low, very intermittent and irregular, such as

with modern power supplies running under no load conditions. Measurements are integrated over long

periods of ti

PA3000 Standby mode

PA1000 Standby mode

me to ensure that accurate average values can be determined.

On selecting Standby mode, the filter frequency is locked on High Bandwidth and a time period is

sted over which to integrate the measurement. The default value of 10 seconds is recommended for

reque

most applications, but if the unit under test draws variable power over a longer cycle time, this integration

period should be set to at least three times the longest cycle time.

All integrated measurement results will not be further averaged by PWRVIEW so the result is unaffected

by the averaging setting

(see page 66).

44 PWRVIEW Online Help

Page 57

Setup PWM mode

PWM mode

PWM mode is designed to demodulate a pulse width modulated voltage signal to determine the modulation

frequency without affecting the RMS values. This allows the power analyzer to synchronize measurements

to the modula

P3000 and PA4000 PWM Mode

tion frequency and get the most stable readings possible.

Integrator mode

Integrator mode is used for energy consumption measurements where the power is integrated over

time to produce measurements such as watt-hours or average watts. In the Integrator mode the energy

consumption measurements will become available in the measurement selections

to start and stop the integrator

PA3000 and PA4000 Integrator mode

PA1000 Integrator mode

(see page 67) will be available in the Measurement tab. (see page 63)

(see page 53) and options

On some instruments a targ

PWRVIEW Online Help 45

et power factor value can be entered here to compute the value of CVArs.

Page 58

Setup Inrush mode

Inrush mode

Inrush mode is used to measure the peak current drawn by a load, normally at mains power on. This mode

tells the power analyzer to continuously sample using fixedrangesontheVoltage Channel

and Current C

uploading

available in inrush mode with Filter

Click Reset

PA1000 Inrush mode

hannel

(see page 20) the configuration. A smaller subset of measurement selections (see page 53) are

(see page 65) in the Measurement tab (see page 63) to restart an inrush measurement.

(see page 51) so that a peak event is not missed. Select the correct range before

(see page 48) and Frequency Source (see page 49) settings unavailable.

(see page 51)

IEC 62301 mode

In IEC 62301 mode the test group is configured to perform low power standby tests suitable for full

compliance testing to IEC 62301 using the Sampling test method. The IEC 62301

become available under the Te st

and the auto-up only current ranging

allows the maximum test current to be measured and the range to be fixed so that n o range changes occur

during the main test. A range change would break the conditions defined in IEC 62301 which require

continuous measurements.

PA3000 IEC 62301 mode

PA1000 IEC 62301 mode

(see page 82) test will

(see page 77) tab, the minimum measurement parameters will be fixed

(see page 51) will be preselected. The auto-up ranging system

46 PWRVIEW Online Help

Page 59

Setup MIL-1399 mode

MIL-1399 mode

In MIL-1399 mode the test group is configured to test current harmonics according to MIL-STD-1399 –

Section 300B as published by Department of Defense Interface Standard – Electric Power, Alternating

Current.The

page 77) tab and the minimum measurement parameters and auto current ranging will be fixed.

MIL-1399 Current Harmonics

(see page 86) test will become available under the Test (see

MIL-1399 mo

PA3000andPA4000MIL-1399mode

de is available when interacting with PA3000 and PA4000 instruments.

IEC 61000-3-2 mode

In IEC 61000-3-2 mode the measurement group is configured to perform current harmonics measurements

le for pre-compliance testing to IEC 61000-3-2 standard. The IEC 61000-3-2 Current Harmonics

suitab

(Pre-compliance) (see page 91) test will become available under the Test (see page 77) tab and the minimum

measurement parameters along with auto-up only current ranging

The IEC 61000-3-2 mode is available w hen interacting with PA1000 instruments.

00 IEC 61000-3-2 mode

PA10

(see page 51) will be pre-selected.

PWRVIEW Online Help 47

Page 60

Setup Filter

Filter

Depending on the connected instrument a number of filter selections will be available. These are all low

pass filters designed to remove high frequency components. See the instrument user manual for more

information

The PA3000 and PA4000 have the following filter selections.

The PA1000 has the following filter selections.

.

48 PWRVIEW Online Help

Page 61

Setup Frequency source

Frequency source

To a ccurately measure most measurement parameters the frequency of the s ignals must be determined.

The frequency source selects the method by which this frequency is measured. The mode

selection af

is used to detect the frequency by looking at the zero crossings of the waveform. The voltage channel is

used by default, but current should be used if only measuring current or if the current waveform is less

distorted than the voltage so that the frequency can be determined more accurately. The PA3000 and

PA4000 also offer an external frequency option.

When Test is selected in the Application Mode, Voltage is the only available frequency source.

The PA3000 and PA4000 have the following frequency source selections.

fects the frequency detection operation, but generally either the voltage or the current channel

(see page 41)

The PA1000 has the following frequency source selections.

PWRVIEW Online Help 49

Page 62

Setup Frequency range

Frequency range

When the PA3000 Application Mode is set to Measure, the frequency range setting configures the

fundamental frequencies that can be measured. Normally this is only needed when making very low

frequency me

frequency range is fixed at > 10 Hz.

asurements, probably in PWM mode. When the application mode is set to Test, the

DC can be mea

The frequency range is only available for the PA3000 and PA4000.

sured in all ranges.

50 PWRVIEW Online Help

Page 63

Setup Voltage channel

Voltage channel

The Voltage Channel section allows the set up of ranging and scaling as shown below.

1. Use the Range selection to select auto range (when available) or to select fixed individual ranges

applicable to the connected instrument.

For example, if the PA3000 is connected, the following ranges are applicable:

2. Use Scaling to provide a method to adjust the measured value where voltage probes or voltage

transformers are used.

The Scaling value entered is multiplied by the applied voltage to give the correct scaled voltage value.

Current Channel

The Current Channel section allows the set up of ranging and scaling as well as the current shunt selection.

1. Use the Range selection to select auto range (when available) or to select fixed individual ranges

applicable to the connected instrument.

For example, if the PA3000 is connected, the following ranges are applicable:

PWRVIEW Online Help 51

Page 64

Setup Current Channel

2. Use Scaling to provide a method to adjust the measured value where current transformer, current

clamps, or specific custom shunts are being used. The value entered as Scaling is multiplied by the

applied current to give the correct scaled current value.

3. Use the Shunt selection to select a shunt to use for current measurements. Make sure the selection

matches the location where the current is connected on the instrument.

The PA3000 has the following shunt selections.

The PA1000 has the following shunt selections.

52 PWRVIEW Online Help

Page 65

Setup Measurement selections

Measurement selections

The Measurement selections allow the required measurements to be checked for inclusion in the

measurement results returned by the instrument. The available options depend on the type of instrument

and the measu

available in Integrator mode

Sum results

rement mode. In the figure below, a number of options grayed out because they are results

(see page 45) only and Normal mode (see page 42) is selected. Enabling t he

(see page 53) adds an extra Sum column to the group in the measurement results.

Volts Harmonics, Amp, and Watts Harmonics

Distortion Factor

(see page 60) automatically expand to give further options.

(see page 58), Total Harmonic Distortion (see page 59),and

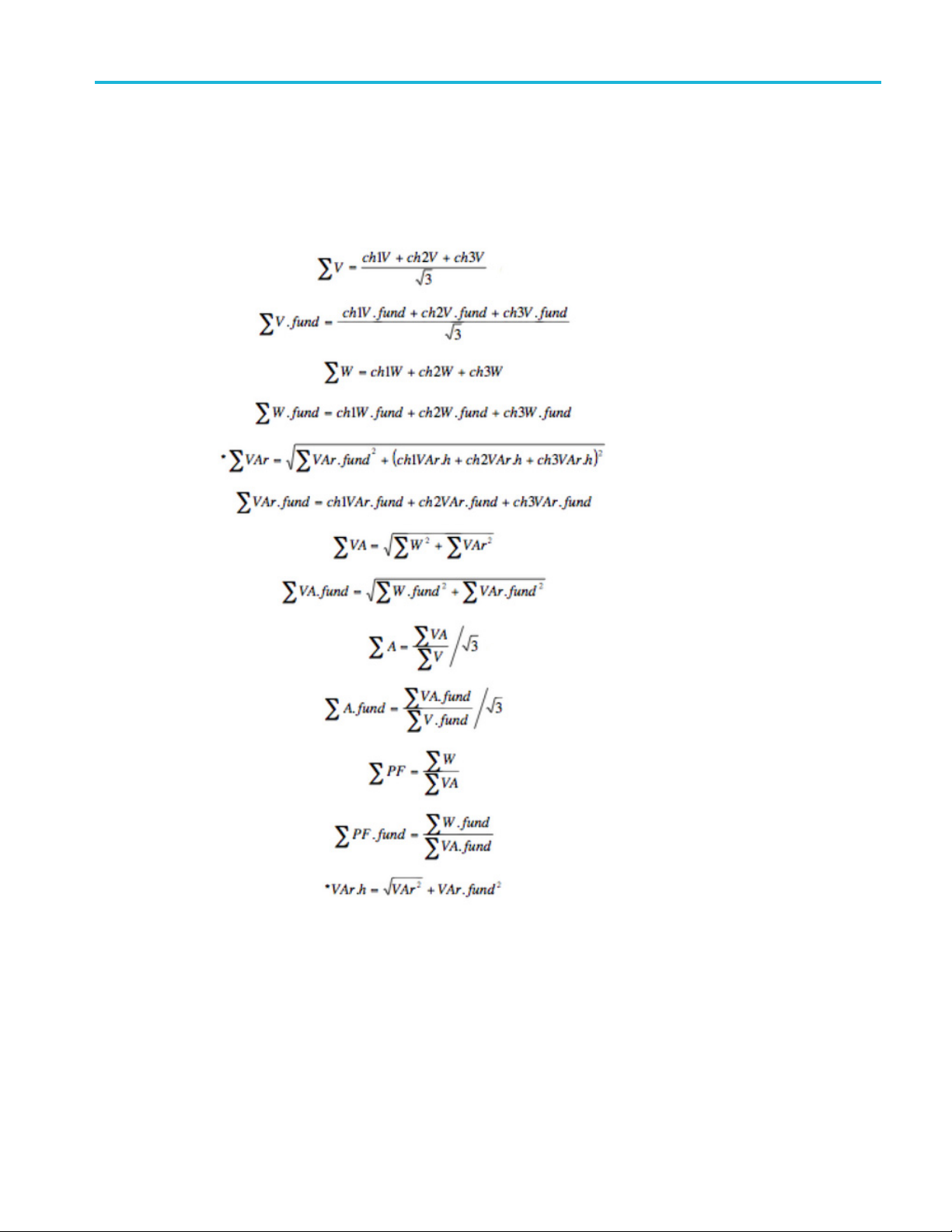

Sum results

Selecting Sum results creates an extra column in the measurement results that shows the Sum values

computed according to the wiring type of the group. The formulas or equations used to calculate the

results are shown in the following links:

PWRVIEW Online Help 53

Page 66

Setup 1P3W Sum formulas

1P3W Sum formulas (see page 54)

3P3W Sum formulas (see page 56)

3P4W Sum formulas (see page 57)

For additional information on using Sum formulas or Sum equations, refer to the Sum Equations section

in the PA3000 User Manual.

NOTE. The Sum results are not available when selecting the 1p2W wiring type.

1P3W Sum formulas

The formulas used to compute the Sum results for 1P3W measurements are as follows:

54 PWRVIEW Online Help

Page 67

Setup 1P3W Sum formulas

PWRVIEW Online Help 55

Page 68

Setup 3P3W Sum formulas

3P3W Sum formulas

The formulas used to compute the Sum results for 3P3W measurements are as follows:

56 PWRVIEW Online Help

Page 69

Setup 3P4W Sum formulas

3P4W Sum formulas

The formulas used to compute the Sum results for 3P4W measurements are as follows:

PWRVIEW Online Help 57

Page 70

Setup Harmonics

Harmonics

Depending on the power analyzer, either 50 or 100 harmonics are available. The PA1000 supports 50 and

the PA3000 and the PA4000 support 100 harmonics.

You can view only odd harmonics or both odd and even harmonics.

The h armonic results can be selected as the absolute values (the actual reading) or as a percentage of

the fundamental (harmonic 1).

58 PWRVIEW Online Help

Page 71

Setup Total harmonic distortion

Total harmonic distortion

THD (Total Harmonic Distortion) is a measure of the distortion of a waveform.

Voltage and Current (Vthd & Athd) are available as separate selections. The minimum & maximum

harmonics to use for the computation are shown. The maximum is adjustable. Odd and Even or Odd

Only harmonics can be selected .

You can choose whether to include DC in the formula, and whether the measurement is expressed as a

percentage of the fundamental or the RMS value.

The selection of harmonics used in the THD measurement is independent of Volts Harmonics and Amp

Harmonics (see page 58) results. However the selections for the THD measurement must be a subset of

the Volts and Amps Harmonics selection. For example, the THD measurement could include odd only

harmonics 2 through 21, yet the Volts and Amps Harmonics could be configured for odd and even 1

through 50. If necessary, PWRVIEW will automatically adjust the Volts and Amps Harmonics selections

to accommodate THD selections.

The formulas for voltage and current THD are:

PWRVIEW Online Help 59

Page 72

Setup Distortion factor

The Total Harmonic Distortion formula (sometimes referred to as the series formula) will produce more

accurate results when the THD is less than 5%. It is important to set the maximum harmonic setting to

cover the majo

theharmoniccount,themoreaccuratetheresult.

rity of the harmonic components contained in the signal being measured. The higher

Distortion factor

Distortion Factor is a measure of the distortion of a waveform. Voltage and Current (Vdf & Adf) are

available as separate selections. You can choose whether the measurement is expressed as a percentage

of the fundamental or the RMS value.

The formulas for voltage and current Distortion Factor are:

Auxiliary inputs

The PA3000 and PA4000 have four analog inputs on the rear of the instrument. Each of the four inputs

can be used to measure signals from a device such as a torque sensor. Each of the four inputs has two

differentranges. Therangesare±10Vand±1V.

The PA3000 and PA4000 also h ave two counter inputs on the Auxiliary Inputs connector on the rear of the

instrument. Either of these can be used as an external frequency source for signals where there is too much

noise or speed sensors. Each of the two counter inputs accepts TTL-compatible square wave signals.

60 PWRVIEW Online Help

Page 73

Setup Equation guidelines

The Auxiliary Inputs option on the Instrument Tab must be enabled as shown in the following figure to

view and configure the auxiliary inputs.

NOTE. The Auxi

After the Auxiliary Inputs option is enabled, the Auxiliary Inputs tab becomes available as shown in the

following figure.

You can configure the label, units, and equation to be calculated from the measurement read from each

of the auxiliary inputs. You can also set the range for each of the four analog inputs and select which

ry inputs are enabled.

auxilia

liary Inputs option is not available for the PA1000.

Equation guidelines

Here is a brief explanation on the configurable columns in the Auxiliary Inputs screen:

Label. While measuring the auxiliary input, you can name a custom equation that is being configured.

For example: Torque.

PWRVIEW Online Help 61

Page 74

Setup Equation guidelines

Units. Specify the unit in which the measurement should be read, such as NM or RPM.

Equation. The

details.

Range. 1 V or 10 V c an be selected based on the Auxiliary input Volts Range of the physical input

being provided.

Enabled. If

displayed in the Measure tab.

Use the following guidelines to help configure the equation.

Equations can be a scaling number, expression, or empty.

Scaling numbers can be either integers or simple floating point values.

Expressions must contain the base name for the specific input source. Expressions can also contain

arithmetic operators and numbers. Parenthesis are also supported.

The defined base names are: ANA1, ANA2, ANA3, ANA4, COUNT1, COUNT2. They are not case

sensitive.

Arithmetic operators include operators and simple numbers.

Supportedoperators: +,–,/,*,(,)charactersareallowed.

formula o r equation to be calculated from the measurement read. See below for more

the check box is selected, the Auxiliary input will be considered for measurement and will be

ers include integers and simple floating point values such as 20, -35, 0.23, 100.15, -0.5

Numb

62 PWRVIEW Online Help

Page 75

Measure Measure

Measure

Use the Measure tab to control, log, monitor, and chart measurements. The Me asure tab is only available

when Application mode under the Setup tab is set to Measure. The Measure tab allows you to perform the

following ta

Start (see page 63) the measurements

Stop (see page 64) the measurements

Reset (see page 65) averaging and Min and Max values

Setup Limits (see page 18) for different limit categories

Set the Significant Figures (see page 65) or number format shown in the results grid (see page 71)

sks:

Set the Av

Turn on/off Zero Blanking (see page 66)

Enable/disable Efficiency (see page 18) measurement

Control Integration (see page 67)

Chart (see page 72) measurement results

Perform data logging (see page 67)

Monit

Ribbon options available on the Measure tab:

eraging

or measurement results in the results grid

(see page 66) depth

(see page 71)

Start

The Start button starts the measurement process to list the results into the results grid as shown below:

PWRVIEW Online Help 63

Page 76

Measure Stop

Stop

The Stop button stops the current measurement cycle.

64 PWRVIEW Online Help

Page 77

Measure Reset

Reset

Use the Reset button to reset the averaging (see page 66), all Min and Max results, and inrush

measurements when in inrush mode

start averag

ing the results again. Large averaging values can take a long time to show changes.

(see page 46).Thisisusefultofind new Min and Max values and to

Significant figures

The significant figures affect the results and determine the number of digits displayed.

The foll

owing figure specifies five significant figures to give a fixed width of five digits.

PWRVIEW Online Help 65

Page 78

Measure Aver aging

Averaging

Averaging is a function that smooths out results to improve the readability of varying quantities. The

higher the averaging, the more stable the result will be. You can specify an averaging depth up to 64. The

default aver

response to large step changes. Normally leave the setting to Auto. Click the Reset

restart the averaging process.

aging is Auto, which is effectively an averaging of eight with an algorithm that improves the

(see page 65) button to

Zero Blanking

Turn off Zero Blanking to see very small readings that would normally show up as zero.

66 PWRVIEW Online Help

Page 79

Measure Integration

Integration

Integration can be controlled using the Integrator Start/Stop/Reset buttons available on the Measurement

ribbon. On pressing Start, the integrator will start running on the instrument and integrator results will

begintoaccu

Reset clears the integrator results to zero. These controls are only visible when at least one group is

configured for the Integrator Mode.

xxx

mulate. The button will also change to a S top button which is used to stop the integrator.

(see page 45)

or

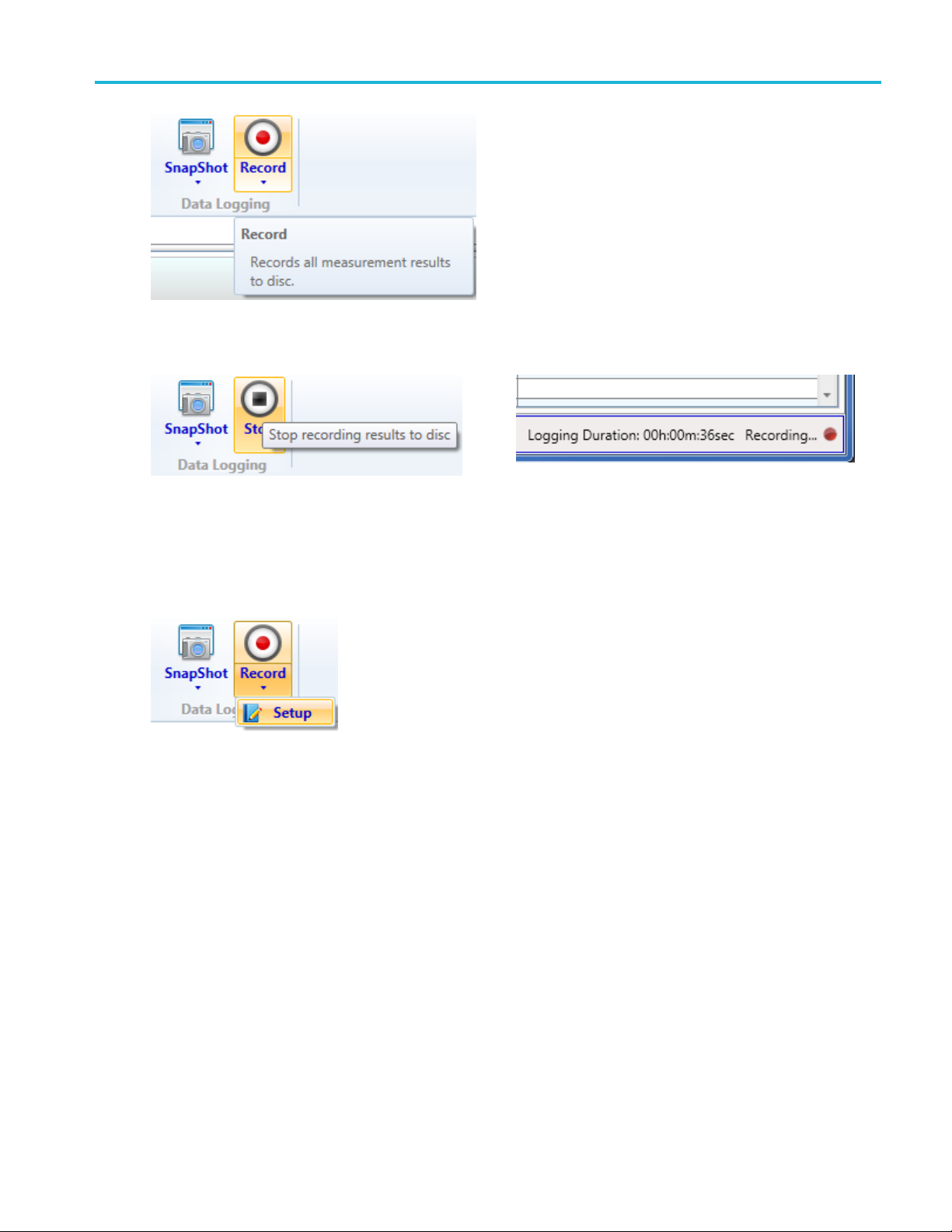

Data logg

Data logg

Snapshot (see page 67) takes the results as shown in the results grid (see page 71) and saves them to

a file.

Record (see page 68) saves all measurement results continuously to a database system for later

exporting and analysis.

Snapshot

Snapshot saves a copy of the results grid in CSV format for reading into spread sheet applications.

ing

ing allows recording and exporting measurement results.

Click the down arrow f or more snapshot options such as view after creation:

PWRVIEW Online Help 67

Page 80

Measure Record

Upon clicking Snapshot all listed results are exported to the CSV format. A Save As dialog box prompts

you for a location and file name for saving the file. When View after creation is checked, the file will

be automatically opened for viewing.

Record

Click Record at any time to immediately start recording all measurement results to the PWRVIEW

database system.

68 PWRVIEW Online Help

Page 81

Measure Record

The Status Bar indicates that results are b eing recorded and the Record button will change to Stop.

xxx

The minimal amount of data to represent all measurement results is stored to the database to save space

- not the

results shown on the results grid. This means that results that can be computed from the other

results are not stored in the database.