x

PSM3000, PSM4000, and PSM5000 Series

RF and Microwave Power Sensors/Meters

ZZZ

Programmer Manual

*P077065100*

077-0651-00

xx

PSM3000, PSM4000, and PSM5000 Series

RF and Microwave Power Sensors/Meters

ZZZ

Programmer Manual

www.tektronix.com

077-0651-00

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are

protected by na

tional copyright laws and international treaty provisions.

Tektronix pro

previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

ducts are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

Table of Contents

Preface ................................................................................................................................ vii

Getting Started......................................................................................................................... 1

Commands Common to all Models. .... . . .... . . ... . . . .... . . ... . . . ... . . . .... . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . .... . . ... . . . ... 2

Pulse Measurements ............................................................................................................ 2

Pulse Profiling.................................................................................................................... 2

Addressing and Communicating with Sensors.. . . . ..... . . .... . . ... . . . ... . . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . . 3

Identify the Instrument. . . ..... . ..... . . ... . . . ..... . . ... . . . ..... . . .... . . ..... . . .... . . ..... . . .... . . ..... . . ... . . . ..... . ..... . . .. 3

Set the Instrument Address .. . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . .. 4

Make a CW Measurement....................................................................................................... 5

VB 6.0 Code ................................................................................................................ 6

VB.NET Code (Visual Studio 2005)........................................................................................ 7

C# Code (Visual Studio 2005) . . ..... . . .... . . ..... . ..... . . ... . . . ... . . . ..... . . .... . . ..... . . .... . . ..... . ..... . . ... . . . ... . . . .. 8

Command Groups . . . .... . . .... . . .... . . .... . . .... . . .... . . .... . . .... . . .... . . .... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ... . .. 10

CW Measurement Command Group........................................................................................... 10

Initialization and Identification Command Group .............................................................................. 10

Pulse Measurement Command Group......................................................................................... 12

Pulse Setup Command Group.................................................................................................. 12

Pulse Profiling Gate Command Group......................................................................................... 12

Pulse Profiling Marker Command Group....................................................................................... 14

Pulse Profiling Setup Command Group........................................................................................ 15

Pulse Profiling Status Command Group ....................................................................................... 16

Pulse Profiling Trace Command Group........................................................................................ 16

Pulse Profiling Trigger Command Group.... . . .... . . ... . . . ... . . . .... . . ... . . . ... . . . .... . . ... . . . ... . . . .... . . ... . . . ... . . . .... . . ... 18

Save/Recall Command Group.................................................................................................. 18

Service Command Group....................................................................................................... 19

Setup Command Group......................................................................................................... 19

Trigger Command Group ... . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . .. 21

Commands Listed in Alphabetical Order ..... . . .... . . ... . . . ..... . . .... . . ... . . . ..... . . .... . . ..... . ..... . . .... . . ..... . . .... . . ... . . . ... 22

LB_AddressConflictExists ...................................................................................................... 23

LB_BlinkLED_Addr (and related commands)

linkLED_Idx .......................................................................................................... 24

LB_B

LB_BlinkLED_SN ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... 24

LB_ChangeAddress. . ... . . . ..... . ..... . . ... . . . ..... . . ... . . . ... . . . ..... . . ... . . . ... . . . ..... . ..... . . ... . . . ..... . . .... . . ..... . . ... . . 26

LB_DriverVersion. . . . ..... . . ... . . . ..... . . ... . . . ..... . . ..... . . ... . . . ..... . . .... . . ..... . . ..... . . ... . . . ..... . . .... . . ..... . . ..... . . ..27

LB_GetFirmwareVersion. . ... . . . ..... . . .... . . ..... . ..... . . ... . . . ..... . . .... . . ..... . . .... . . ..... . ..... . . ... . . . ..... . . ... . . . ... . . . 28

LB_GetIndex_Addr (and related commands) ..... . . .... . . ... . . . ..... . . .... . . ..... . ..... . . .... . . ..... . . .... . . ... . . . ..... . . .... . 29

LB_GetIndex_SN . . ..... . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . . 29

LB_GetModelNumber_Addr (and related commands) . ..... . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . 31

LB_GetModelNumber_Idx. .... . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . 31

LB_GetModelNumber_SN .... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . 31

LB_GetSerNo_Addr (and related commands) . .... . . ..... . ..... . . .... . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . 35

LB_GetSerNo_Idx ... . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . 35

Table of Content

.................................................................................. 24

s

PSM3000, PSM4000, and PSM5000 Series i

Table of Content

s

LB_InitializeSensor_Addr (and related commands) . . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ..... . . .... . . ... . . . .. 37

LB_InitializeSensor_Idx . . ... . . . ... . . . ..... . . ... . . . ..... . . ... . . . ... . . . ..... . . .... . . ..... . . .... . . ..... . . ... . . . ..... . ..... . . . 37

LB_InitializeSensor_SN .... . . ... . . . ..... . . ... . . . ... . . . ..... . ..... . . ... . . . ..... . . ... . . . ... . . . ..... . . ... . . . ... . . . ..... . ..... 37

LB_IsDeviceInUse_Addr (and related commands) ..... . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . 40

LB_IsDeviceInUse_Idx .................................................................................................... 40

LB_IsDeviceInUse_SN . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ... . . . ... . . . ..... . . ... 40

LB_IsSensorConnected_Addr (and related commands) . . . .... . ..... . ..... . ... . . . .... . . .... . ..... . ... . . . .... . . .... . ... . . . .... 42

LB_IsSensorConnected_SN ... . . . ..... . . .... . . ..... . . ... . . . ... . . . ..... . ..... . . ... . . . ..... . . .... . . ..... . . ... . . . ..... . ..... 42

LB_MeasureBurst_DBM . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . 44

LB_MeasureCW. . ..... . . .... . . ... . . . ... . . . ..... . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . 46

LB_MeasureCW_PF .. . . ... . . . .... . . ... . . . .... . . ... . . . .... . . ... . . . ... . . . .... . . ... . . . .... . . ... . . . .... . . ... . . . ... . . . .... . . ... . . . . 48

LB_MeasurePulse. .... . . ..... . ..... . . .... . . ..... . . .... . . ..... . . ... . . . ... . . . ..... . ..... . . ... . . . ... . . . ..... . . .... . . ..... . . .... . . .. 51

LB_MeasurePulse_PF . . .... . . ..... . ..... . . .... . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . 53

LB_ResetRegStates (and related commands).... . . .... . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ..... . ..... . . . 55

LB_ResetCurrentState .................................................................................................... 55

LB_ReadStateFromINI (and related commands).. . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . 56

LB_WriteStateToINI........................................................................................................ 56

LB_SensorCnt. . . ... . . . .... . . ... . . . .... . . ... . . . .... . . ... . . . .... . . ... . . . ... . . . .... . . ... . . . .... . . ... . . . .... . . ... . . . ... . . . .... . . ... . 57

LB_SensorList. . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . .... . . ....58

LB_Set75OhmsEnabled (and related commands) . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . .. 60

LB_Get75OhmsEnabled . . . ... . . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . . .... . . ... . . . ..... . ..... . . . 60

LB_SetAddress_Idx (and related commands) . . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ..... . ..... 61

LB_GetAddress_Idx ....................................................................................................... 61

LB_SetAddress_SN (and related commands) . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . .. 63

LB_GetAddress_SN....................................................................................................... 63

LB_SetAntiAliasingEnabled (and related commands). . . ..... . . .... . . ... . . . ..... . . .... . . ..... . ..... . . .... . . ..... . . .... . . ... . . . 65

LB_GetAntiAliasingEnabled... . . ..... . . ... . . . ..... . . .... . . ..... . . ..... . . ... . . . ..... . . .... . . ..... . . ... . . . ..... . . ..... . ..... 65

LB_SetAutoPulseEnabled (and related commands) . . ..... . . .... . . ..... . ..... . . .... . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... 67

LB_GetAutoPulseEnabled ... . . . ..... . . ... . . . ..... . ..... . . ... . . . ..... . . ... . . . ..... . . ... . . . ..... . ..... . . ..... . . .... . . ..... . 67

LB_SetAverages (and related commands) . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... 69

LB_GetAverages .... . . ... . . . ... . . . ..... . . .... . . ..... . . .... . . ..... . ..... . . ... . . . ... . . . ..... . . .... . . ..... . . .... . . ..... . ..... 69

LB_SetCalDueDate (and related commands) . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . 71

LB_GetCalDueDate ....................................................................................................... 71

LB_SetCWReference (and related commands) ... . . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . . 74

LB_GetCWReference ..................................................................................................... 74

LB_SetDutyCycleEnabled (and related commands) . . ..... . . .... . . ..... . ..... . . .... . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... 76

LB_GetDutyCycleEnabled .. . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . 76

LB_SetDutyCyclePerCent. . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... 76

LB_GetDutyCyclePerCent .. . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ..... . ..... . . .... 76

LB_SetExtendedAveraging (and related commands) . . . . ..... . . .... . . ... . . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . 79

LB_GetExtendedAveraging .... . . .... . . ... . . . ..... . ..... . . .... . . ..... . . .... . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ..... . . 79

LB_SetExtendedAveragingEnabled . .... . . ..... . . .... . . ... . . . ... . . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . ... 79

LB_GetExtendedAveragingEnabled . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ..... . . .... . . ... . . . .. 79

LB_ResetExtendedAveraging. . ..... . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ..... . ..... . . .... 79

LB_SetFrequency (and related commands) . . . . ... . . . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . ..... . . .... . . ... . . . .... 82

ii PSM3000, PSM4000, and PSM5000 Series

Table of Content

LB_GetFrequency ... . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . 82

LB_SetLimitEnabled (and related commands). ..... . . . ..... . . . ...... . . ...... . . . ..... . . . ..... . . . ...... . . ...... . . . ..... . . . .... . . 84

LB_GetLimitEnabled..... . . ... . . . ... . . . ..... . . .... . . ..... . ..... . . ... . . . ... . . . ..... . . .... . . ..... . . .... . . ..... . ..... . . ... . . . . 84

LB_SetSingleSidedLimit . . . ..... . ..... . . .... . . ..... . . .... . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ..... . . .... . . ..... . . .... . 84

LB_GetSingleSidedLimit . . ..... . . ... . . . ..... . ..... . . ... . . . ... . . . ..... . . .... . . ..... . . .... . . ..... . ..... . . ... . . . ... . . . ..... . . 84

LB_SetDoubleSidedLimit. . . .... . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . ..... . . . 84

LB_GetDoubleSidedLimit . . . .... . . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . 84

LB_SetMaxHoldEnabled (and related commands) ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . ..... . . . 9

LB_GetMaxHoldEnabled . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ..... . . .... . . .. 93

LB_ResetMaxHold. . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . . 93

LB_SetMeasurementPowerUnits (and related commands) ..... . . .... . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ... 95

LB_GetMeasurementPowerUnits . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . .. 95

LB_SetOffset (and related commands) ..... . . .... . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . 97

LB_GetOffset . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . 97

LB_SetOffsetEnabled .... . . .... . . ... . . . ..... . ..... . . .... . . ..... . . .... . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ..... . . .... . . 97

LB_GetOffsetEnabled ... . . ... . . . ... . . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ..... . . .... . . ..... . . .... . . ... . . . ..... . ..... . . . 97

LB_SetPulseCriteria (and related commands) .... . . ... . . . ..... . ..... . . ... . . . ..... . . .... . . ..... . . ... . . . ..... . ..... . . ... . . . .. 100

LB_GetPulseCriteria. . . ..... . . .... . . ..... . . ..... . ..... . . ... . . . ..... . . ... . . . ..... . . ..... . ..... . . ... . . . ..... . . ..... . . .... . . 100

LB_SetPulseReference (and related commands) ... . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... 103

LB_GetPulseReference .... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . 103

LB_SetResponseEnabled (and related commands).... . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . 106

LB_GetResponseEnabled. .... . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . 106

LB_SetResponse . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . 106

LB_GetResponse . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . .... . . ... . . . ... . . . .... . . ... . . . ... . . . .... . . ... . . 106

LB_SetTTLTriggerInEnabled (and related commands). ..... . ..... . . .... . . ..... . . .... . . ... . . . ... . . . ..... . . .... . . ... . . . ..... . 110

LB_GetTTLTriggerInEnabled. . ..... . . ... . . . ..... . . .... . . ..... . . ... . . . ..... . ..... . . ... . . . ..... . . ... . . . ..... . . .... . . ..... . 110

LB_SetTTLTriggerInInverted . . . ..... . . ... . . . ..... . . .... . . ..... . ..... . . ... . . . ..... . . ... . . . ..... . . ... . . . ..... . ..... . . ... . . 110

LB_GetTTLTriggerInInverted... . . ... . . . ..... . ..... . . ... . . . ..... . . ... . . . ..... . . .... . . ..... . ..... . . ..... . . .... . . ..... . . ... 110

LB_SetTTLTriggerInTimeOut.... . . ... . . . ... . . . ..... . . .... . . ... . . . ..... . . .... . . ..... . ..... . . .... . . ..... . . .... . . ... . . . .... 110

LB_GetTTLTriggerInTimeOut ... . . . ... . . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ..... . . .... . . ..... . . .... . . ... . . . ..... . ... 110

LB_SetTTLTriggerOutEnabled (and related commands). . . .... . . ..... . . .... . . ..... . . ... . . . ... . . . ..... . ..... . . ... . . . ..... . . . 114

LB_GetTTLTriggerOutEnabled.. . ..... . . ... . . . ..... . . ... . . . ..... . . ... . . . ... . . . ..... . . .... . . ..... . . .... . . ..... . . ... . . . ... 114

LB_SetTTLTriggerOutInverted ... . . ... . . . ..... . . ... . . . ..... . . .... . . ..... . . ... . . . ..... . . ..... . ..... . . ... . . . ..... . . ..... . . 114

LB_GetTTLTriggerOutInverted .... . . ..... . ..... . . ... . . . ..... . . ... . . . ... . . . ..... . . ... . . . ..... . ..... . . ... . . . ..... . . ... . . . . 114

LB_StoreReg (and related commands) ... . . ... . . . ... . . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . . .... . . 118

LB_RecallReg ..... . . .... . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ... . . . ... . . . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . 118

LB_WillAddressConflict....................................................................................................... 120

PP_AnalysisTraceIsValid . .... . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ..... . ..... . . .... . . ... . . . ... . . . ... . . . ..... . . . 121

PP_CheckTrigger ..... . . .... . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . ..... . . .... . . .. 122

PP_CnvtTrace.. . . ..... . . ... . . . ..... . ..... . . ..... . . .... . . ..... . . ..... . ..... . . ... . . . ..... . . ..... . . .... . . ..... . . .... . . ..... . . ... . 123

PP_CurrTrace2AnalysisTrace . .... . . ..... . . .... . . ..... . ..... . . ... . . . ... . . . ..... . . .... . . ..... . . .... . . ..... . ..... . . ... . . . ... . . 125

PP_GatePositionIsValid .... . . .... . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . ..... . . .. 126

PP_GetAnalysisTraceLength ... . . . ..... . ..... . . .... . . ..... . . .... . . ... . . . ..... . . .... . . ..... . ..... . . .... . . ..... . . .... . . ... . . . . 127

PP_GetGateCrestFactor.. . . ..... . . .... . . ..... . . .... . . ..... . ..... . . .... . . ..... . . .... . . ..... . . .... . . ..... . ..... . . ... . . . ..... . . . 128

PP_GetGateDroop . . ..... . . .... . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . ..... . . .... . . ... . . 129

s

3

PSM3000, PSM4000, and PSM5000 Series iii

Table of Content

s

PP_GetGateDutyCycle .... . . ... . . . ..... . . .... . . ..... . ..... . . ... . . . ..... . . .... . . ..... . . .... . . ..... . ..... . . ... . . . ..... . . .... . . . 130

PP_GetGateEndPosition ..... . . .... . . ..... . . .... . . ..... . ..... . . ... . . . ..... . . .... . . ..... . . ... . . . ... . . . ..... . ..... . . ... . . . ..... 132

PP_GetGateFallTime ... . . . ... . . . ... . . . ... . . . ..... . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . . 133

PP_GetGateOverShoot .... . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . . .... . . ... . . . ..... . ..... . . .... . . .. 135

PP_GetGatePeakPower . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . . 136

PP_GetGatePRF... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... 137

PP_GetGatePRT.. . . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . .... 139

PP_GetGatePulsePower ... . . . ..... . . .... . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ..... . . .... . . ..... . . .... . . ... . . . ..... . ..... . 141

PP_GetGatePulseWidth ... . . . ... . . . ..... . . .... . . ..... . . .... . . ..... . ..... . . ... . . . ... . . . ..... . . .... . . ..... . . .... . . ..... . ..... . 143

PP_GetGateRiseTime ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . 145

PP_GetMarkerAmp . ... . . . .... . . ... . . . .... . . ... . . . ... . . . .... . . ... . . . .... . . ... . . . .... . . ... . . . ... . . . .... . . ... . . . .... . . ... . . . .... 146

PP_GetMarkerDeltaAmp .... . . .... . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . .... . 147

PP_GetPeaks_Val (and related commands) . . ..... . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . 148

PP_GetPeaks_Idx .. . ..... . . ... . . . ... . . . ..... . ..... . . ... . . . ... . . . ..... . . .... . . ..... . . .... . . ..... . ..... . . ... . . . ... . . . ..... 148

PP_GetPeaksFromTr_Val.... . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . ..... . . .... . . ... . . . .. 148

PP_GetPeaksFromTr_Idx ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . . 148

PP_GetPeaks_VEE_Idx. . . .... . . ..... . . .... . . ..... . ..... . . .... . . ..... . . .... . . ... . . . ..... . . .... . . ..... . ..... . . .... . . ..... 148

PP_GetPeaks_VEE_Val.. . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . ..... . . .... . . ... . . 148

PP_GetPulseEdgesTime (and related commands).... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . . 152

PP_GetPulseEdgesPosition . ... . . . ..... . . ... . . . ..... . ..... . . ..... . . .... . . ..... . . ... . . . ..... . ..... . . ..... . . .... . . ..... . . 152

PP_GetTrace.... . . ... . . . ... . . . ..... . ..... . . .... . . ..... . . .... . . ... . . . ..... . . .... . . ..... . ..... . . .... . . ..... . . .... . . ... . . . ..... . . 155

PP_GetTraceAvgPower (and related commands) . . ..... . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . 158

PP_GetTraceCrestFactor . ... . . . ... . . . ..... . . .... . . ..... . ..... . . ... . . . ... . . . ..... . . .... . . ..... . . .... . . ..... . ..... . . ... . . 158

PP_GetTraceDC . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . . 158

PP_GetTracePkPwr ... . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ..... . ... 158

PP_GetTracePulsePower . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... 158

PP_GetTraceLength .... . . .... . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ..... . . .... . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ..... 160

PP_MarkerPosIsValid. . . .... . . ... . . . ..... . ..... . . .... . . ..... . . .... . . ... . . . ..... . . .... . . ..... . ..... . . .... . . ..... . . .... . . ... . . . . 162

PP_MarkerToPk (and related commands) . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ..... . ..... . . .... . . ... . . . ... . . . ... . . . ... . . 163

PP_MarkerToLowestPk ..... . . .... . . ... . . . ..... . ..... . . ... . . . ... . . . ... . . . ..... . . .... . . ..... . . .... . . ... . . . ..... . ..... . . .. 163

PP_MarkerToFirstPk..... . . .... . . ..... . . .... . . ..... . ..... . . .... . . ..... . . .... . . ..... . . .... . . ..... . ..... . . ... . . . ... . . . ..... 163

PP_MarkerToLastPk. . . ... . . . ... . . . ..... . . ... . . . ... . . . ..... . . ... . . . ... . . . ..... . ..... . . ... . . . ..... . . .... . . ..... . . ... . . . ... 163

PP_MarkerPrevPk . ... . . . ..... . . ..... . . ... . . . ..... . . .... . . ..... . . ... . . . ..... . . ..... . ..... . . ..... . . ... . . . ..... . . ... . . . ... 163

PP_MarkerNextPk . .... . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ... . . . .. 163

PP_MarkerPkHigher. . . ... . . . ..... . . .... . . ..... . . .... . . ..... . ..... . . ... . . . ... . . . ..... . . .... . . ..... . . .... . . ..... . ..... . . .. 163

PP_MarkerPkLower ... . . . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . . 163

PP_SetAnalysisTrace (and related commands) . . .... . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . . .... . . ... . . . 167

PP_SetAvgMode (and related commands) . . . . ... . . . ... . . . ... . . . ..... . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . 169

PP_GetTraceAvgs... . . .... . . ... . . . ..... . . .... . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ..... . . .... . . ..... . . .... . . ... . . . ... 169

PP_GetAvgMode ... . . ... . . . .... . . ... . . . ... . . . .... . . ... . . . ... . . . .... . . ... . . . ... . . . .... . . ... . . . ... . . . .... . . ... . . . ... . . . ... 169

PP_ResetTraceAveraging. .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . 169

PP_SetAvgResetSens (and related commands) ... . ..... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . 172

PP_GetAvgResetSens .... . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . . . 172

PP_SetClosestSweepTimeUSEC . . ..... . . .... . . .... . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . 173

PP_SetFilter (and related commands) .. . . . ..... . ..... . . ... . . . ... . . . ..... . . .... . . ..... . . .... . . ..... . ..... . . ... . . . ... . . . ..... 174

iv PSM3000, PSM4000, and P SM5000 Series

Table of Content

PP_GetFilter .... . . ... . . . ... . . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . . .... . . ... . . . ..... . ..... . . .. 174

PP_SetGateMode (and related commands) . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . 177

PP_GetGateMode . . . ... . . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . 177

PP_SetGateStartEndPosition (and related commands). . ... . . . ..... . . .... . . ..... . ..... . . .... . . ..... . . .... . . ... . . . ..... . . ... 179

PP_GetGateStartEndPosition ..... . . ..... . . ... . . . ..... . . ... . . . ..... . ..... . . ..... . . ... . . . ..... . . ... . . . ..... . . .... . . ..... 179

PP_SetGateStartEndTime . ..... . . ... . . . ..... . . ... . . . ... . . . ..... . . ... . . . ... . . . ..... . ..... . . ... . . . ..... . . .... . . ..... . . ... 179

PP_GetGateStartEndTime . . . ..... . ..... . . ... . . . ..... . . ... . . . ..... . . .... . . ..... . . .... . . ..... . . .... . . ..... . . ... . . . ..... . 179

PP_SetGateStartPosition .... . . .... . . ..... . . ... . . . ..... . . ..... . ..... . . ... . . . ..... . . ... . . . ..... . . ..... . ..... . . ... . . . ..... 179

PP_GetGateStartPosition .. . . . ..... . ..... . . ..... . . ... . . . ..... . . ... . . . ..... . . ... . . . ..... . . ... . . . ..... . . ... . . . ..... . . .... . 179

PP_SetGateEndPosition ..... . . .... . . ... . . . ..... . . .... . . ..... . . .... . . ..... . ..... . . ... . . . ... . . . ..... . . .... . . ..... . . .... . . 179

PP_GetGateEndPosition . . .... . . ..... . ..... . . ... . . . ..... . . .... . . ..... . . ... . . . ..... . ..... . . ... . . . ... . . . ..... . . ... . . . ... . 179

PP_SetGateStartTime. . . . ..... . . ... . . . ..... . . ... . . . ..... . ..... . . ... . . . ..... . . ... . . . ..... . . ... . . . ..... . ..... . . ..... . . .... 179

PP_GetGateStartTime ..... . . ..... . . ... . . . ..... . ..... . . ..... . . ... . . . ..... . . ... . . . ..... . ..... . . ..... . . ... . . . ..... . . ... . . . 179

PP_SetGateEndTime. .... . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... 179

PP_GetGateEndTime . ..... . . .... . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ... . . . ... . . . ..... . . .... . . ... . . . ..... . . .... . . ... 179

PP_SetMarkerDeltaTime (and related commands) . ... . . . ..... . ..... . . .... . . ..... . . .... . . ... . . . ..... . . .... . . ..... . ..... . . .. 184

PP_GetMarkerDeltaTime..... . ..... . . .... . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . 184

PP_SetMarkerMode (and related commands) . . . ..... . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . . 186

PP_GetMarkerMode. . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . .. 186

PP_SetMarkerPosition (and related commands) . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . . .... . . ... . . . ..... . ..... . . .... . 188

PP_GetMarkerPosition . . . .... . . ... . . . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . .... . . . 188

PP_SetMarkerPositionTime... . . ... . . . ... . . . ..... . . ... . . . ... . . . ..... . ..... . . ... . . . ..... . . .... . . ..... . . ... . . . ... . . . ..... . 188

PP_GetMarkerPositionTime.. . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... 188

PP_SetMeasurementThreshold (and related commands) ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . 190

PP_GetMeasurementThreshold . ..... . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . .. 190

PP_SetPoles (and related commands) . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . . .... 192

PP_GetPoles ..... . ..... . . ... . . . ..... . . ... . . . ... . . . ..... . . ... . . . ... . . . ..... . ..... . . ... . . . ..... . . .... . . ..... . . ... . . . ..... . 192

PP_SetSweepDelay (and related commands). ..... . . .... . . .... . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . 194

PP_GetSweepDelay ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ..... . ..... . . .... . . .. 194

PP_SetSweepDelayMode (and related commands) . . . .... . . .... . . ... . . . ... . . . .... . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... 196

PP_GetSweetDelayMode ... . . .... . . ..... . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . .... 196

PP_SetSweepHoldOff (and related commands)..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . 197

PP_GetSweepHoldOff . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . 197

PP_SetSweepTime (and related commands).. . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... 198

PP_GetSweepTime..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . . . ... . . . ..... . ... 198

PP_SetTimeOut (and related commands) . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . .. 200

PP_GetTimeOut . . . . .... . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . . ... . . . ... . . . ... . . . .... . . ... . . 200

PP_SetTriggerEdge (and related commands) ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . ... . . . 201

PP_GetTriggerEdge . . .... . . ..... . . ... . . . ... . . . ..... . . ... . . . ... . . . ..... . ..... . . ... . . . ..... . . .... . . ..... . . ... . . . ..... . ... 201

PP_SetTriggerLevel (and related commands) . . .... . . ... . . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ... . . . ..... . . .... . . ... . . . . 203

PP_GetTriggerLevel.. . . . ..... . ..... . . .... . . ..... . . .... . . ..... . . .... . . ... . . . ..... . ..... . . .... . . ..... . . .... . . ..... . . .... . . 203

PP_SetTriggerOut (and related commands) . . . ... . . . ... . . . ..... . ..... . . .... . . ... . . . ... . . . ... . . . ... . . . ..... . . .... . . ... . . . ... . 205

PP_GetTriggerOut . . ..... . . ... . . . ..... . ..... . . ... . . . ..... . . ... . . . ..... . . ... . . . ..... . ..... . . ..... . . .... . . ..... . . ... . . . ... 205

PP_SetTriggerSource (and related commands).... . ..... . . ... . . . ... . . . ..... . . .... . . ... . . . ..... . . .... . . ..... . ..... . . .... . . .. 207

PP_GetTriggerSource . ... . . . ..... . . ..... . ..... . . ..... . . ... . . . ..... . . ..... . ..... . . ..... . . ... . . . ..... . . ..... . . .... . . ..... 207

s

PSM3000, PSM4000, and PSM5000 Series v

Table of Content

Index

s

vi PSM3000, PSM4000, and P SM5000 Series

Preface

This manual provides programming information for remotely controlling the following Tektronix products:

Product Description

PSM3110 10MHz-8GHz (3.5mm-male)

PSM3120 10MHz-8GHz (N-Type male)

PSM3310 10MHz-18GHz (3.5mm-male)

PSM3320 10MHz-18GHz (N-Type male)

PSM3510 10MHz-26.5GHz (3.5mm-male)

PSM4110 10MHz-8GHz (3.5mm-male)

PSM4120 10MHz-8GHz (N-Type male)

PSM4320 50MHz-18GHz (N-Type male)

PSM4410 50MHz-20GHz (3.5mm-male)

PSM5110 100MHz-8GHz (3.5mm-male)

PSM5120 100MHz-8GHz (N-Type male)

PSM5320 50MHz-18GHz (N-Type male)

PSM5410 50MHz-20GHz (3.5mm-male)

Preface

This manual consists of the following sections:

Getting Started describes how to make simple measurements using commands, provides command naming conventions,

and describes how to communicate with the instrument. (See page 1, Getting Started.)

Command Groups provides lists of commands by function and includes command descriptions. (See page 10,

Command Groups.)

Commands Listed in Alphabetical Order provides a list of commands that includes arguments, related commands, and

programming examples. (See page 22, Commands Listed in Alphabetical Order .)

Index provides an indexed list of the contents of this manual.

PSM3000, PSM4000, and PSM5000 Series vii

Preface

viii PSM3000, PSM4000, and PSM5000 Series

Getting Started

Getting Start

Most of the commands documented in this manual correspond directly to setup and measurement functions in the Power

Meter and Pulse Profiling applications. Explanations of setup and measurement techniques are provided in the PSM3000,

PSM4000, and PSM5000 Series RF and Microwave Power Sensors/Meters User Manual. Commands that correspond to

the Power Meter application begin with the prefix "LB". Commands that correspond to the Pulse Profiling application

begin with the prefix "PP".

The programmatic interface for these instruments consists of a dynamic link library (DLL). The name of the DLL is

LB_API2.DLL. This library uses the WinAPI or "_stdcall" calling convention. The DLL is located in the Tektronix application

directory. The name of the default application directory is "C:\Program Files\Tektronix\Tektronix Power Sensor Applications".

Included in the installation are the following files, which will help you become familiar with the available function calls. These

files can be found in "C:\Program Files\Tektronix\Tektronix Power Sensor Applications\Sample C ode":

C# Pulse Profiling sample code

C# Power Meter sample code

VB Power Meter sample code

C# High Speed Logger sample code

Driver Installation Files

Three test harness programs are also included in the sample code installation. These executable programs are designed

to exercise instrument functions and generate code that demonstrates correct syntax for commands. They can be found

in subdirectories within the Sample Code directory. The different versions support different programming languages and

instrument applications:

ed

C# Power Meter Applications

C# Pulse Profiling Applications

VB Power Meter Applications

NOTE. See the README.txt file and test harness documentation in the Sample Code directory for more information

about test harnesses.

PSM3000, PSM4000, and PSM5000 Series 1

Getting Started

Commands Common to all Models

Some commands only apply to certain instrument models and their corresponding measurement capabilities. Other

commands, called common commands, apply to all instrument models. These commands all begin with the prefix “LB”.

This common command group includes commands to:

Detect, identify, and address an instrument

Initialize an instrument

Manage communications and exceptions with an instru

Set the center frequency

Perform average power measurements

Configure and perform pass/fail limit testing on continuous wave (CW) power

Set averaging parameters

Set trigger conditions

Configure offsets and relative measurements

Save and recall setups

Pulse Measurements

The PSM4000 and PSM5000 Series instruments can measure power contained within pulses. These measurements include

average pulse power, peak pulse power, crest factor, duty cycle, and average continuous wave (CW) power. Commands

related to these measurement types begin with the prefix “LB”.

These instrument models support additional commands to:

Set the criteria for distinguishing pulses

Perform average pulse power, pulse power, crest factor, and duty cycle

ment

Configure and perform pass/fail limit testing on pulse power

Pulse Profiling

The PSM5000 Series instruments can perform pulse profiling measurements. Commands related to these measurement

types begin with the prefix “PP”, and are used to:

Configure and manage pulse profile triggers

Perform gated measurements of pulse characteristics

Manipulate markers and read back measurements

Set filters

Transfer the trace to the computer

Perform power measurements on the trace

Perform pulse measurements like rise/fall time, overshoot and droop

2 PSM3000, PSM4000, and PSM5000 Series

Addressing and Communicating with Sensors

You can use an instrument identifier and a series of function commands to establish a connection with the correct instrument.

Function commands are provided for the following tasks:

Collect all instrument identification information, including index, serial number, and address

Obtain the address via serial number or index

Set/change the address using the index, serial number, or current address

Retrieve the serial number using the index or address

Retrieve the index using the serial number or address

Blink the LED on a specific instrument

Determine if an address conflict exists

Determine if changing an address will cause an address conflict

Identify the Instrument

Getting Started

You must fi

rst identify the instrument before you can use the function commands. You can do this in one of the following ways:

Address. A user-set identifier stored in the instrument's memory. The user has complete control over the address, and

can assign any legitimate address (1-255) to any instrument.

Using the address is the recommended way to identify an instrument, because this eliminates the need to change the

programming code if the original instrument is being replaced. More importantly, almost all commands require the

instrument’s address, including getting, setting measurement attributes and making measurements (over 80 of them). The

address is stored in non-volatile memory, so it is not lost when the instrument is disconnected or the system is powered

down. Note that address conflicts may arise during the process of reassigning instrument addresses.

Serial Number. This number is permanent and determined by the factory. It is stamped into the back of the instrument.

The address or index can be retrieved using the serial number. You can also use the serial number to change the address

use the LED to blink.

and ca

Index. A temporary logical descriptor determined by the system driver when the instrument is connected.

This is an arbitrary number that is assigned by order of identification. The index of the first instrument detected by the system

is 1. The index of the second instrument is 2 and so on. Typically, the index is less useful than the address and serial number.

The index is most useful when coupled with the function call LB_SensorCnt. For instance, when LB_SensorCnt is called, if

the instrument count is three, the first instrument discovered will have an index of 1; the second instrument will have an

index of 2; and the third instrument will have an index of 3.

PSM3000, PSM4000, and PSM5000 Series 3

Getting Started

Set the Instrument Address

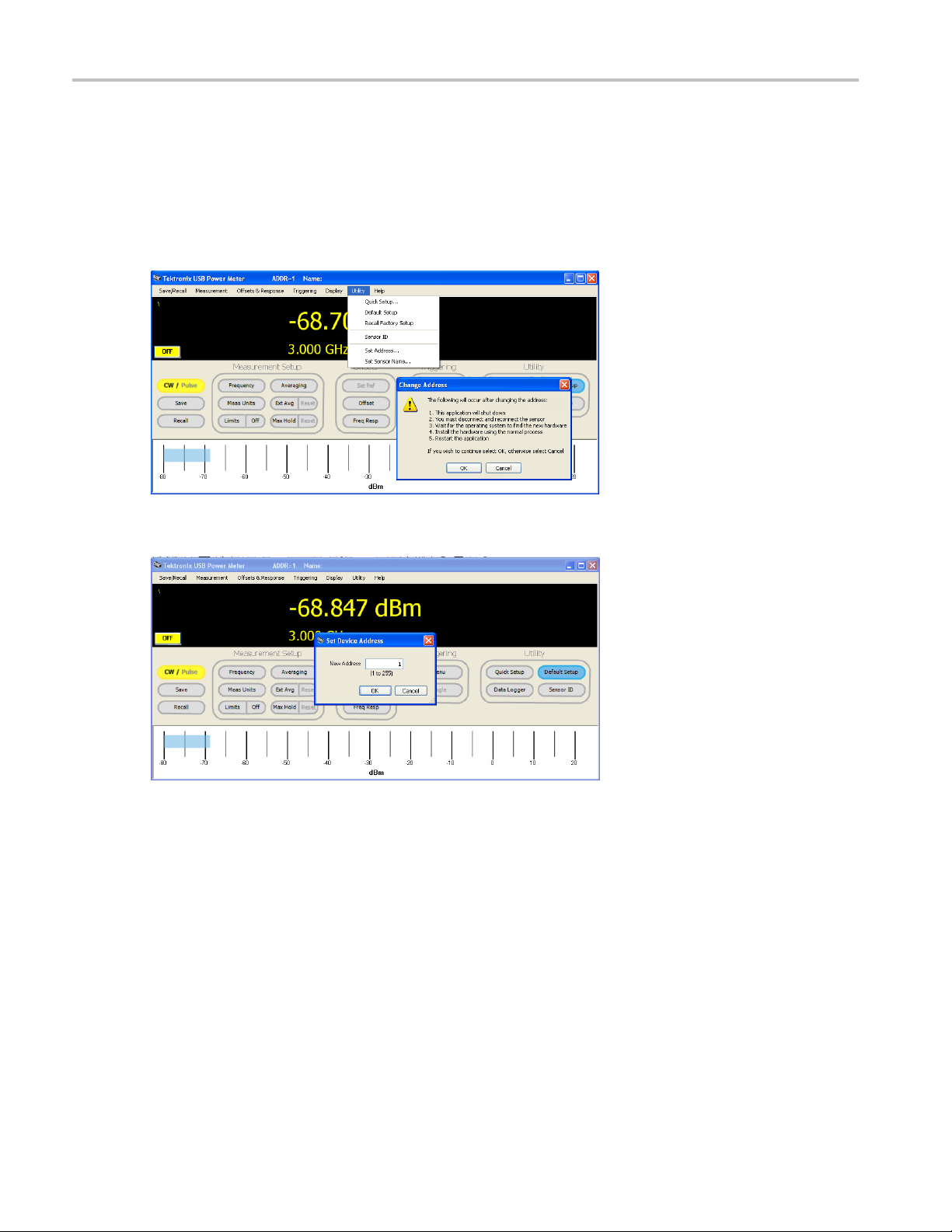

Next, you’ll need to set the instrument address:

1. Open the Power Meter application, which should be visible in the Tektronix menu (Start > Tektronix > Power Meter

2. After the Power Meter application opens, select the "Set Address" command found under the Utility menu tab. A window

3. After pressing "Ok", set the new address of the device and press "Ok", as shown below. Then allow the application to

Application > P ower Meter Application.

will open that lists the steps to follow in order to change the instrument address as shown below.

shut down.

4. Disconnect and reconnect the instrument.

5. Wait for the operating system to find the new hardware.

6. Restart the Power Meter application.

7. Confirm that the instrument address shown at the top of the Power Meter window is the correct address.

8. Close the Power Meter application.

4 PSM3000, PSM4000, and PSM5000 Series

Make a CW Measurement

When creating an application for making a simple continuous wave (CW) measurement, a similar approach is taken whether

you are using VB 6.0, VB .Net, or C#. The VB .NET and C# examples in this section were created using Microsoft Visual

Studio 2005. Thfor taking a measurementis code assumes that a single instrument has been connected to the computer and

has proven functional. If an earlier version of Visual Studio.NET is being used, the VB.NET and C# code may need minor

modification, as a direct copy and paste may not work.

NOTE. Before performing the following procedures, make sure you have installed the Sample Code application on

your PC and that the instrument and PC are communicating properly. For installation and functional check procedures,

see the Installation and Safety Instructions that shipped with your instrument. You can also download the manual from

www.tektronix.com.manuals.

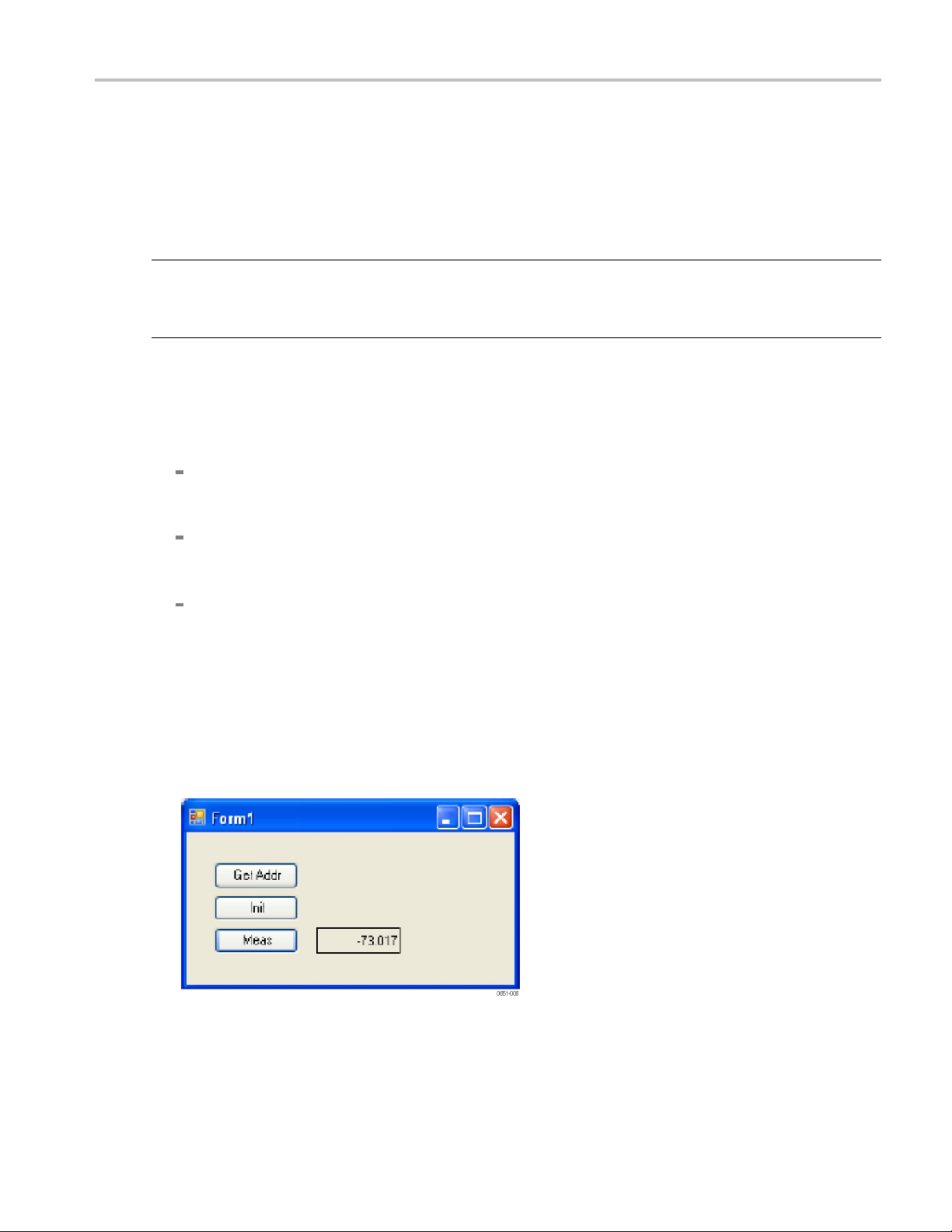

1. Start the code by creating a default Windows application.

2. Place three buttons and one label on the window or form.

3. Name the buttons as follows:

cmdGetAddress: Clicking this button uses the "LB_GetAddress_Idx" command. The name of this command can

be interpreted as "get the address using the index." In this case, the first instrument is used, or the instrument

with an index of 1.

Getting Started

cmdInitialize: Clicking this button uses the "LB_InitializeSensor_Addr" command. The name of this command can

be interpreted as "initialize the instrument using the address". Initialization causes the calibration constants and other

information for the instrument to be transferred to the PC.

cmdMeasure: Clicking this button uses the "LB_CWMeasure" command. The name of this command can be

interpreted as “make a measurement”. The result of the m easurement is converted to text and placed in the label.

This command requires the address acquired in the first button click. It also requires that the instrument be initialized,

as done in the second button click. In this API, most commands are designed for use with the address.

4. Name the label lblCW. The result of the measurement taken when the cmdMeasure command is used is converted to

text and placed in this label.

5. Copy the appropriate portions of code from the following pages.

6. Compile the application you have just coded. The window may look similar to the one shown here.

PSM3000, PSM4000, and PSM5000 Series 5

Getting Started

7. Run the application as follows:

a. Click the “Get Addr” or cmdGetAddress button.

b. Click the “Init” or cmdInitialize button. Wait for the message indicating initialization is complete. This typically

takes about 5 s

econds.

c. Click the “Mea

been initialized, this button can be clicked repeatedly for as many measurements as you would like.

s” or cmdMeasure button and a measurement should appear in the label. Now that the instrument has

Tips

A few items that may be of interest to some programmers are:

“Long” in VB 6.0 is equivalent to an “Integer” in VB.NET and “int” in C#.

The default ByRef/ByVal are switched when going from VB 6.0 to VB.NET and C#. We have taken the approach of

explicitly including the ByRef/ByVal declarations in all code. We highly recommend this practice.

Structures in VB 6.0 allowed the embedding of fixed arrays. This is/was commonly used for transferring complex

data types. The exact capability has not been duplicated in VB.NET and C#. VB.NET does have the following type

of declaration, which can be used inside a structure. However, it seems able to be passed via a_stdcall for simple

structures only.

<VBFixedArray(6)>Dim SerialNumber() As Byte

NOTE. If you are using an earlier version of Visual Studio.NET, the code may need some modification.

VB 6.0 Code

Option Explicit

e Declare Function LB_SensorCnt Lib _

Privat

"LB_API2.dll" () _

As Long

Private Declare Function LB_GetAddress_Idx _

Lib "LB_API2.dll" ( _

l addr As Long) _

ByVa

As Long

ate Declare Function LB_InitializeSensor_Addr _

Priv

Lib "LB_API2.dll" ( _

ByVal addr As Long) _

ong

As L

Private Declare Function LB_MeasureCW _

"LB_API2.dll" ( _

Lib

ByVal addr As Long, _

ByRef CW As Double) As Long

Dim m_Addr As Long

ivate Sub cmdG etAddress_Click()

Pr

6 PSM3000, PSM4000, and PSM5000 Series

If LB_SensorCnt() > 0 Then

m_Addr = LB_Get

End If

End Sub

Private Sub cmdInitialize_Click()

If LB_InitializeSensor_Addr(m_Addr) > 0 Then

MsgBox ("Ini

End If

End Sub

Private Sub cmdMeasure_Click()

Dim CW As Double, rslt As Long

rslt = LB_Me

If rslt > 0 Then lblCW.Caption = Format(CW, "###0.0###")

End Sub

asureCW(m_Addr, CW)

Address_Idx(1)

tialization OK")

Getting Started

VB.NET Cod

Public Class Form1

Public Declare Function LB_SensorCnt Lib _

Public Declare Function LB_GetAddress_Idx _

Public Declare Function LB_InitializeSensor_Addr _

Public Declare Function LB_MeasureCW _

Dim m_Addr As Integer

Private Sub cmdGetAddress_Click(ByVal sender As System.Object, _

End Sub

e (Visual Studio 2005)

"LB_API2.dll" () _

As Integer

Lib "LB_API2.dll" ( _

ByVal addr As Integer) _

As Integer

Lib "LB_API2.dll" ( _

ByVal addr As Integer) _

As Integer

Lib "LB_API2.dll" ( _

ByVal addr As Integer, _

ByRef CW As Double) As Integer

ByVal e As System.EventArgs) Handles cmdGetAddress.Click

If LB_SensorCnt() > 0 Then

m_Addr = LB_GetAddress_Idx(1)

End If

Private Sub cmdInitialize_Click(ByVal sender As System.Object, _

ByVal e As System.EventArgs) Handles cmdInitialize.Click

If LB_InitializeSensor_Addr(m_Addr) > 0 Then

PSM3000, PSM4000, and PSM5000 Series 7

Getting Started

MsgBox("Initialization OK")

End If

End Sub

Private Sub cm

Dim CW As Doub

rslt = LB_MeasureCW(m_Addr, CW)

If rslt > 0 The

End Sub

End Class

C# Code (Vi

using Microsoft.VisualBasic;

using System;

using System.Collections;

using System.Collections.Generic;

using System.Data;

using System.Drawing;

using System.Diagnostics;

using System.Windows.Forms;

namespace SimpleMeasurement

{

public partial class Form1

{

public Form1()

{

}

dMeasure_Click(ByVal sender As System.Object, _

ByVal e As System.EventArgs) Handles cmdMeasure.Click

le, rslt As Long

n lblCW.Text = Format(CW, "###0.0###")

sual Studio 2005)

InitializeComponent();

cmdGetAddress.Click += new System.EventHandler( cmdGetAddress_Click );

cmdInitialize.Click += new System.EventHandler( cmdInitialize_Click );

cmdMeasure.Click += new System.EventHandler( cmdMeasure_Click );

[System.Runtime.InteropServices.DllImport("LB_API2.dll")]

public static extern int LB_SensorCnt();

[System.Runtime.InteropServices.DllImport("LB_API2.dll")]

public static extern int LB_GetAddress_Idx( int addr );

[System.Runtime.InteropServices.DllImport("LB_API2.dll")]

public static extern int LB_InitializeSensor_Addr( int addr );

[System.Runtime.InteropServices.DllImport("LB_API2.dll")]

public static extern int LB_MeasureCW( int addr, ref double CW );

public int m _Addr;

private void cmdGetAddress_Click( System.Object sender, System.EventArgs e )

{

8 PSM3000, PSM4000, and PSM5000 Series

if ( LB_SensorCnt() > 0 )

{

m_Addr = LB_GetAddress_Idx( 1 );

}

}

private void cmdInitialize_Click( System.Object sender, System.EventArgs e )

{

if ( LB_InitializeSensor_Addr( m_Addr)>0)

{

Interaction

(Microsoft.VisualBasic.MsgBoxStyle)(0), null );

}

}

private void cmdMeasure_Click( System.Object sender, System.EventArgs e )

{

double CW = 0; long rslt = 0;

.MsgBox( "Initialization OK",

Getting Started

rslt = LB_M

if ( rslt > 0 )

{

}

}

}

}

easureCW( m_Addr, ref CW );

lblCW.Te

xt = Strings.Format( CW, "###0.0###" );

PSM3000, PSM4000, and PSM5000 Series 9

Command Groups

Command Group

The following command group tables organize commands together by functionality and link each command to the individual

command, located in the Commands Listed in Alphabetical Order section of this manual. (See page 22, Commands

Listed in Alphabetical Order.)

If a command has related commands, the related commands are indented to the primary command in the table. Primary

commands are listed in the Commands Listed in Alphabetical Order section, and in the table of contents.

NOTE. Unless otherwise noted the following commands are valid for all instrument models.

s

CW Measurement C om mand Group

Command

LB_MeasureCW

(See page 46, LB_MeasureCW.)

LB_MeasureCW_PF

(See page 48, LB_MeasureCW_PF .)

Description

Makes continuous wave (CW) measurements. The value returned is in

the units currently selected.

Makes continuous wave (CW) measurements and evaluates the

measurement relative to the current limit. The value returned is in the

units currently selected.

Initialization and Identification Com mand Group

Command

LB_AddressConflictExists

(See page 23, LB_AddressConflictExists.)

LB_BlinkLED_Addr

LB_BlinkLED_Idx

LB_BlinkLED_SN

(See page 24, LB_BlinkLED_Addr (and

related commands).)

LB_ChangeAddress

(See page 26, LB_ChangeAddress.)

LB_IsDeviceInUse_Addr

LB_IsDeviceInUse_Idx

LB_IsDeviceInUse_SN

(See page 40, LB_IsDeviceInUse_Addr

(and related commands).)

LB_DriverVersion

(See page 27, LB_DriverVersion.)

LB_GetFirmwareVersion

(See page 28, LB_GetFirmwareVersion.)

Description

Checks the address of all instruments that are connected to the system.

If any of the addresses match, a conflict is deemed to exist. If all the

addresses are unique to the system, a conflict is deemed not to exist.

Cause the instrument LED to blink four times.

Changes the address of the device. The address is changed from

“currentAddr” to “newAddr”.

Return a 1 if the device has been initialized and a 0 if the device has not

been initialized by the calling program or any other program.

Returns a 32 bit integer indicating the version of LB_API2.dll.

Returns a null-terminated string of chars indicating the firmware version.

10 PSM3000, PSM4000, and PSM5000 Series

Command Groups

Command

LB_GetIndex_

LB_GetIndex_SN

(See page 29, LB_GetIndex_Addr (and

related comma

LB_GetModel

LB_GetModelNumber_Idx

LB_GetModelNumber_SN

(See page 31, L

(and related commands).)

LB_GetSerNo_Addr

LB_GetSerNo_Idx

(See page 35,

related commands).)

LB_InitializeSensor_Addr

LB_InitializeSensor_Idx

LB_Init

(See page 37, LB_InitializeSensor_Addr

(and related commands) .)

LB_IsSensorConnected_Addr

LB_IsS

(See page 42, LB_IsSensorConnected_Addr (and related commands).)

LB_SensorCnt

(See p

etAddress_Idx

LB_S

LB_GetAddress_Idx

(See page 61, LB_SetAddress_Idx (and

ated commands).)

rel

SetAddress_SN

LB_

LB_GetAddress_SN

(See page 63, LB_S etAddress_SN (and

lated commands).)

re

_WillAddressConflict

LB

(See page 120, LB_WillAddressConflict.)

Addr

nds).)

Number_Addr

B_GetModelNumber_Addr

LB_GetSerNo_Addr (and

ializeSensor_SN

ensorConnected_SN

age 57, LB_SensorCnt.)

Description

Return the index given to the serial number or address.

Return a value equating to a model number enumeration.

Return the

Cause the instrument to be initialized.

Determine if the specified instrument is connected. The query is based

on the s

Returns the number of instruments currently connected to the computer.

Return the address, given the index and vice versa. The index is

assi

Return the address, given the serial number and vice versa.

ecks the address of all instruments connected to the system. If any of

Ch

the addresses match, a conflict is deemed to exist.

serial number given the index or address.

erial number or address.

gned by the OS when the unit is plugged in.

PSM3000, PSM4000, and PSM5000 Series 11

Command Groups

Pulse Measurement Command Group

NOTE. These co

Command

LB_MeasureBurst_DBM

(See page 44, LB_MeasureBurst_DBM.)

LB_MeasurePulse

(See page 51, L

LB_Measur

(See page 53, LB_MeasurePulse_PF.)

mmands are only valid for PSM4000 and PSM5000 Series instruments.

B_MeasurePulse.)

ePulse_PF

Pulse Setup Command Group

NOTE. These commands are only valid for PSM4000 and PSM5000 Series instruments.

Command

LB_SetAutoPulseEnabled

LB_GetAutoPulseEnabled

age 67, LB_SetAutoPulseEnabled

(See p

(and related commands) .)

LB_SetPulseCriteria

LB_GetPulseCriteria

page 100, LB_SetPulseCriteria (and

(See

related commands) .)

LB_SetPulseReference

LB_GetPulseReference

e page 103, LB_SetPulseReference

(Se

(and related commands) .)

Description

Measures the peak power, minimum power and average power over a

specified measurement interval or burst. The measurement is made

relative to

Makes pulse measurements. The measurement returns pulse power

(average po

averge power; and duty cycle.

Makes puls

the pulse power (instead of peak or average) is evaluated against the

selected limit.

Descrip

Enable or disable the default or automatic pulse measurement criteria.

Set or get the pulse measurement criteria.

Configure the instrument for relative measurements during pulse

measurements. (Other commands set a reference for CW

mea

a trigger.

wer in the pulse); peak power (highest sample measured);

e measurements just as LBMeasurePulse does, except that

tion

surements.)

lse Profiling Gate Command Group

Pu

NOTE. These commands are valid only for the PSM5000 Series instrument.

12 PSM3000, PSM4000, and PSM5000 Series

Command Groups

Command

PP_GatePosit

ionIsValid

(See page 126, PP_GatePositionIsValid .)

PP_GetGateCrestFactor

(See page 128, PP_GetGateCrestFactor.)

PP_GetGateDroop

(See page 129, P

P_GetGateDroop.)

PP_GetGateDutyCycle

(See page 130, PP_GetGateDutyCycle .)

PP_GetGateEndPosition

(See page

PP_GetGa

132, PP_GetGateEndPosition .)

teFallTime

(See page 133, PP_GetGateFallTime .)

PP_GetGateOverShoot

(See page 135, PP_GetGateOverShoot .)

PP_GetGatePeakPower

ge 136, PP_GetGatePeakPower .)

(See pa

tGatePRF

PP_Ge

(See page 137, PP_GetGatePRF.)

PP_GetGatePRT

page 139, PP_GetGatePRT.)

(See

PP_GetGatePulsePower

(See page 141, PP_GetGatePulsePower .)

PP_GetGatePulseWidth

ee page 143, PP_GetGatePulseWidth .)

(S

_GetGateRiseTime

PP

(See page 145, PP_GetGateRiseTime .)

PP_SetGateStartEndPosition

PP_SetGateStartEndTime

PP_GetGateStartEndTime

PP_SetGateStartPosition

PP_GetGateStartPosition

PP_SetGateEndPosition

PP_GetGateEndPosition

PP_SetGateStartTime

PP_GetGateStartTime

PP_SetGateEndTime

PP_GetGateEndTime

(See page 179, PP_SetGateStartEndPosition (and related commands).)

Description

Determines wh

ether the specified gate is valid. The gate index may

be 0..4.

Returns the create factor (in dB) of the span in the analysis trace

specified by the gate.

Returns the droop of the span in the analysis trace specified by the gate.

The droop wi

ll be the difference in power between the area at beginning

and end of the gate edges.

Returns the duty cycle (as a decimal) of span in the analysis trace

specified by the gate.

Returns the location, as an index in the analysis trace, of the right side

of the spe

Returns t

cified gate.

he fall time in microseconds of the pulse delineated by the

selected gate.

Returns

the overshoot in dB.

Returns the peak power measured of the analysis trace as defined by

e edges.

the gat

ns the pulse repetition frequency (PRF) in Hertz, as defined by the

Retur

inverse of the time between the rising edges of the first two complete

pulses present in the span defined by the gate (gateIdx).

Returns the pulse repetition time (PRT) in microseconds using the same

rithm defined for PRF. The sole difference is that time instead of

algo

frequency is returned.

urns average pulse power.

Ret

Measures the pulse width in microseconds.

Returns rise time in microseconds.

Sets or gets the gate start (left side) and/or end (right side) in terms of

trace index or time.

PSM3000, PSM4000, and PSM5000 Series 13

Command Groups

Pulse Profiling Marker Command Group

NOTE. These co

Command

PP_GetMarkerAmp

(See page 146, P

PP_GetMark

(See page 147, PP_GetMarkerDeltaAmp .)

PP_Marker

(See page 162, PP_MarkerPosIsValid.)

PP_Marke

PP_MarkerToLowestPk

PP_MarkerToFirstPk

PP_Marke

PP_MarkerPrevPk

PP_MarkerNextPk

PP_Mark

PP_MarkerPkLower

(See page 163, PP_MarkerToPk (and

relate

tMarkerDeltaTime

PP_Se

PP_GetMarkerDeltaTime

(See page 184, PP_SetMarkerDeltaTime

(and r

etMarkerMode

PP_S

PP_GetMarkerMode

(See page 186, PP_SetMarkerMode (and

ted commands) .)

rela

SetMarkerPosition

PP_

PP_GetMarkerPosition

PP_SetMarkerPositionTime

_GetMarkerPositionTime

PP

(See page 188, PP_SetMarkerPosition

(and related commands).)

mmands are valid only for the PSM5000 Series instrument.

P_GetMarkerAmp .)

erDeltaAmp

PosIsValid

rToPk

rToLastPk

erPkHigher

d commands) .)

elated commands) .)

Description

Returns the amplitude of the trace at the point indicated by the marker.

Returns the

delta marker in dBm.

Returns the state of the selected marker.

Set one of five markers (0<=mrkIdx<=4) to the position specified in the

command.

Sets o

Sets

s or gets the position of the normal or delta marker depending on

Set

the marker mode.

difference in amplitude between the normal marker and the

r gets the positions the selected marker in microseconds.

or gets the marker mode to on, normal or delta marker.

14 PSM3000, PSM4000, and PSM5000 Series

Pulse ProfilingSetupCommandGroup

Command Groups

NOTE. These co

Command

PP_GetPulseEdgesTime

PP_GetPuls

(See page 152, PP_GetPulseEdgesTime

(and related commands).)

PP_SetAvgMode

PP_GetAvg

PP_GetTraceAvgs

PP_ResetTraceAveraging

(See page

related commands).)

PP_SetAvgResetSens

PP_GetAvgResetSens

(See pag

related commands).)

PP_SetClosestSweepTimeUSEC

(See page 173, PP_SetClosestSweepTimeUSE

tFilter

PP_Se

PP_GetFilter

(See page 174, PP_SetFilter (and related

comm

etGateMode

PP_S

PP_GetGateMode

(See page 177, P P_SetGateMode (and

ated commands) .)

rel

SetMeasurementThreshold

PP_

PP_GetMeasurementThreshold

(See page 190, PP_SetMeasurement-

reshold (and related commands).)

Th

P_SetPoles

P

PP_GetPoles

(See page 192, PP_S etPoles (and related

ommands) .)

c

PP_SetSweepDelay

PP_GetSweepDelay

(See page 194, PP_SetSweepDelay (and

related commands).)

mmands are valid only for the PSM5000 Series instrument.

eEdgesPosition

Mode

169, PP_SetAvgMode (and

e 172, PP_SetAvgResetSens (and

C.)

ands) .)

Description

Return the index of the leading and trailing edges of the pulse

containing

Set, auto-set or manual reset the averaging mode.

Set or get the criteria used to reset the averaging when the

averaging mode is AVG_AUTO_RESET (see PP_SetAvgMode and

PP_GetA

Sets the sweep time to the fixed sweep time closest to the sweep time

sent (in microseconds) to the command.

Sets o

Sets

Set

along with the peak criteria, affects a number of measurement

commands, especially the peak commands.

ets or gets the number of poles in the current filter.

S

Sets or gets the sweep delay in microseconds. Sweep delay is the

time between the trigger and the start of data acquisition.

the peak defined by pkTime or pkIdx.

vgMode).

r gets the enumeration associated with the current filter settings.

or gets the gate mode.

s or gets the measurement threshold. The measurement threshold,

PSM3000, PSM4000, and PSM5000 Series 15

Command Groups

Command

PP_SetSweepD

PP_GetSweetDelayMode

(See page 196, PP_SetSweepDelayMode

(and related c

PP_SetSweep

PP_GetSweepHoldOff

(See page 197, PP_SetSweepHoldOff (and

related com

PP_SetSwe

PP_GetSweepTime

(See page 198, PP_SetSweepTime (and

related co

PP_SetTi

PP_GetTimeOut

(See page 200, PP_SetTimeOut (and related

command

elayMode

ommands).)

HoldOff

mands).)

epTime

mmands).)

meOut

s).)

Description

Turns the swee

unchanged.

Specifies the

trace is taken.

Sets or get

taken. Sweep time is a 1, 2, 5 sequence starting with 10 μsec and

ending with 1 second.

Sets or ge

Pulse Profiling Status Command Group

p delay on or off. The sweep delay parameter remains

length of time (in microseconds) to wait after a sweep or

s the sweep time (in microseconds) for the next sweep

ts the timeout used while taking a trace.

NOTE. T

Command

PP_AnalysisTraceIsValid

PP_CheckTrigger

hese commands are valid only for the PSM5000 Series instrument.

Description

Checks to ensure that the current analysis trace is valid. If the analysis

(See page 121, PP_AnalysisTraceIsValid .)

page 122, PP_CheckTrigger .)

(See

trace

Checks the trigger source for an active trigger. If a trigger is detected, a

valu

Pulse Profiling Trace Command Group

E. These commands are valid only for the PSM5000 Series instrument.

NOT

mmand

Co

PP_CnvtTrace

See page 123, PP_CnvtTrace.)

(

PP_CurrTrace2AnalysisTrace

See page 125, PP_CurrTrace2AnalysisTrace

(

.)

Description

Converts a trace (trIn) from one unit to another, and stores the converted

v

Copies the current trace to the analysis trace and returns a copy of that

race.

t

is valid, a 1 is returned; if it is not valid, a 0 or less is returned.

e > 0 is returned; if a trigger is not detected, a value <= 0 is returned.

alues in a new trace (trOut).

16 PSM3000, PSM4000, and PSM5000 Series

Command Groups

Command

PP_GetAnalys

(See page 127, PP_GetAnalysisTraceLength

.)

PP_GetPeaks_Val

PP_GetPeaks_Idx

PP_GetPeak

PP_GetPeaksFromTr_Idx

PP_GetPeaks_VEE_Idx

PP_GetPeak

(See page 148, PP_GetPeaks_Val (and

related commands) .)

PP_GetPulseEdgesTime

PP_GetPulseEdgesPosition

(See page

(and related commands).)

PP_GetT

(See page 155, PP_GetTrace.)

PP_Get

PP_GetTraceCrestFactor

PP_GetTraceDC

PP_Ge

PP_GetTracePulsePower

(See page 158, PP_GetTraceAvgPower (and

relat

isTraceLength

sFromTr_Val

s_VEE_Val

152, PP_GetPulseEdgesTime

race

TraceAvgPower

tTracePkPwr

ed commands) .)

Description

Returns a 32 bi

Return a set of peaks from either the analysis trace (PP_GetPeaks_Val

and PP_GetPeaks_Idx) or from a trace passed to the command.

Returns the index of the leading and trailing edges of the pulse containing

the peak defined by pkTime or pkIdx.

Causes t

trace is an array of equally spaced (in time) samples, in dBm.

Make a n

commands, but operate on a single trace instead of a set of random

samples.

t integer indicating the length of the analysis trace.

he instrument to take a trace and return the resultant data. The

umber of measurements similar to the power meter measurement

PP_GetTraceLength

page 160, PP_GetTraceLength.)

(See

PP_SetAnalysisTrace

GetAnalysisTrace

PP_

(See page 167, P P_SetAnalysisTrace (and

related commands).)

Returns the number of trace points associated with the current sweep time.

Enable the user to get and set the analysis trace directly. These are

companions to PP_CurrTrace2AnalysisTrace.

PSM3000, PSM4000, and PSM5000 Series 17

Command Groups

Pulse ProfilingTriggerCommandGroup

NOTE. These co

Command

PP_SetTriggerEdge

PP_GetTrig

(See page 201, PP_SetTriggerEdge (and

related commands).)

PP_SetTriggerLevel

PP_GetTri

(See page 203, PP_SetTriggerLevel (and

related commands) .)

PP_SetTriggerOut

PP_GetTr

(See page 205, PP_SetTriggerOut (and

related commands).)

PP_SetTriggerSource

PP_Get

(See page 207, PP_SetTriggerSource (and

related commands).)

mmands are valid only for the PSM5000 Series instrument.

gerEdge

ggerLevel

iggerOut

TriggerSource

Description

Sets or gets the trigger signal edge on which the beginning of the trace

will occur.

Sets or gets the trigger level for internal triggering (manual or automatic),

in dBm.

Sets or gets the trigger out mode. The trigger out can be off (no trigger

out)orit

relative to the input trigger).

Sets or gets the trigger source. Trigger source can be internal or external.

The values are positive edge or negative edge.

can be normal (same polarity as the input trigger or inverted

Save/Recall Command Group

Command

LB_ReadStateFromINI

LB_WriteStateToINI

page 56, LB_ReadStateFromINI (and

(See

related commands).)

LB_ResetRegStates

LB_ResetCurrentState

ee page 55, LB_ResetRegStates (and

(S

related commands).)

LB_StoreReg

LB_RecallReg

See page 118, LB_StoreReg (and related

(

commands).)

iption

Descr

Cause the current state, including all numbered registers to be written

to an INI file.

Enable the user to cause either the current state or the state information

held in the save/recall registers to be reset.

Store/recall register commands. There are 20 registers and each

register holds an entire state.

18 PSM3000, PSM4000, and PSM5000 Series

Loading...

Loading...