Page 1

xx

PSM3000, PSM4000,

and PSM5000 Series

ZZZ

RF and Microwave Po wer Sensors/Meters

User Manual

*P077059201*

077-0592-01

Page 2

Page 3

xx

PSM3000, PSM4000,

and PSM5000 Series

ZZZ

RF and Microwave Power Sensors/Meters

User Manual

www.tektronix.com

077-0592-01

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. B o x 5 0 0

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

Worl dwid e, vis it www.tektronix.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of three

(3) years from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at

its option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, with shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused b y improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has b een modified or

integrated with other products when the effect of such modification or integration i ncreases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FO R BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W4 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other than Tektronix representatives to install, repair or service the product;

Page 6

Page 7

Table of Contents

Preface ............................................................................................................... v

Safety Information............................................................................................. v

About This Manual ............................. .................................. ............................. v

Products.......... ................................ ................................ .............................. vi

Key Features .................................................................................................. vi

Where To Find More Information ......................................................................... vii

Getting Started ..... . ... . . ..... . ..... . ... . . . .... . ..... . ..... . ... . . ..... . ..... . ... . . . .... . ..... . ..... . ... . . ..... . ..... 1

Install the Software ............................................................................................ 1

Connect to a Computer........................................................................................ 6

Start An

Functional Check ............................................................................................. 10

Operating Basics................................................................................................... 13

Measurement Capabilities . . ..... . .... . ..... . ..... . ..... . .... . . .... . ..... . ..... . ..... . .... . ..... . ..... . ..... . 14

CW (Average) Measurements ............... .................................. .............................. 14

Pulse Measurements.......................................................................................... 15

Puls

Configure Instrument for Measurements ................................................................... 17

Power Meter Application... .................................. ................................ .................... 19

Front Panel Elements......................................................................................... 19

Make an Average Power (CW) Measurement ................... ................................ .......... 27

Make a Pulse Measurement Using Duty Cycle........................ ................................ .... 28

Ma

Pulse Profiling Application................. .................................. ................................ .... 31

Menu Features................................................................................................. 31

Toolbar Functions............................................................................................. 36

Make a Marker Measurement ..................... ................................ .......................... 48

Make a Gated Measurement ....................... ................................ .......................... 49

High Speed Logger Application ..... ................................ .................................. .......... 52

Menu Functions............................................................................................... 53

Make a Simple Measurement................................................................................ 58

Troubleshooting........... ................................ ................................ .................... 59

Index

Application.......................................................................................... 10

eProfiling..................... ................................ .................................. .......... 16

ke a Pulse Power Measurement ................... ................................ ...................... 29

RF and Microwave Power Sensors/Met ers i

Page 8

Table of Contents

List of Figure

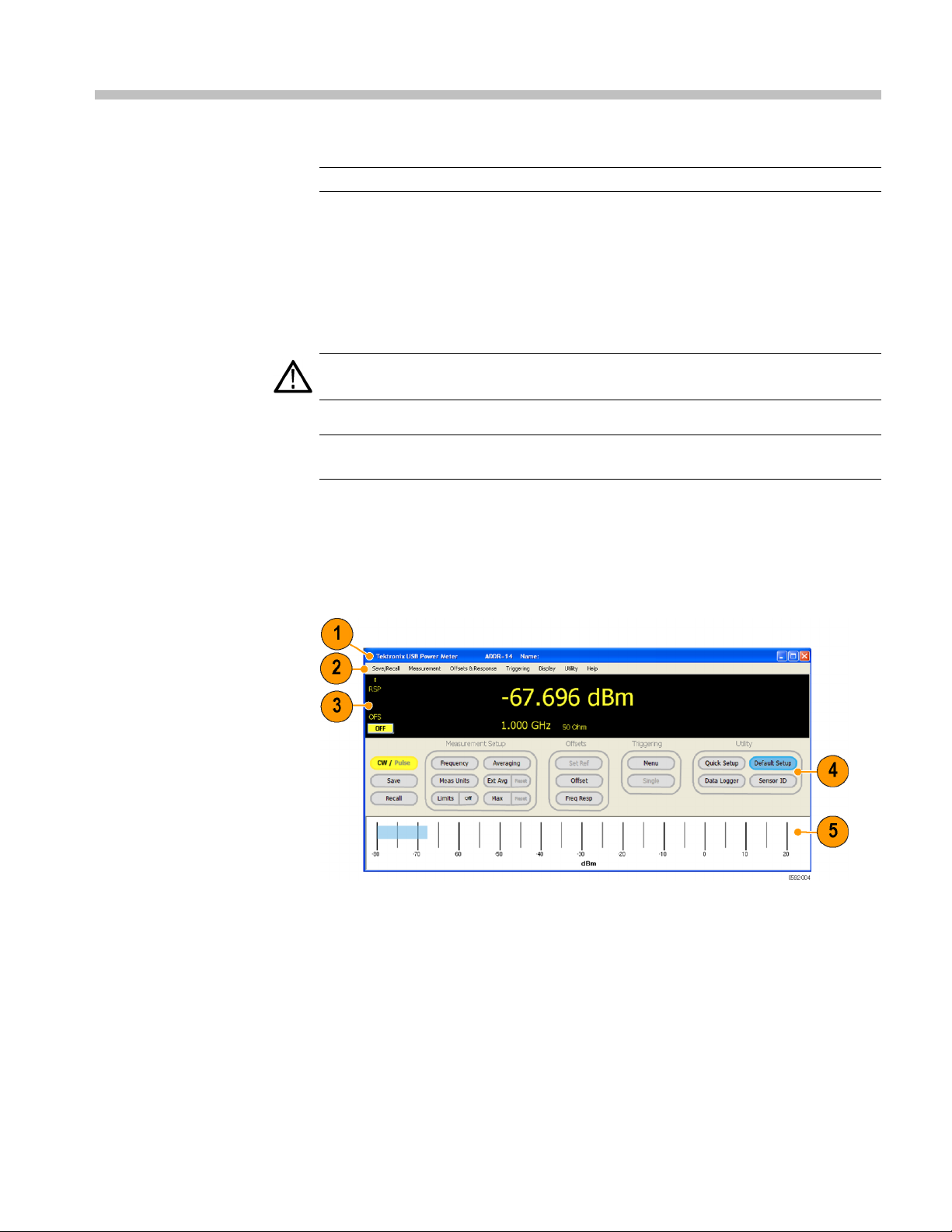

Figure 1: Power Meter application interface using a PSM5120........................................ ...... 19

Figure 2: Di

Figure 3: Pulse Profiling application interface ................................................................. 31

Figure 4: Gate positioning diagram ... .................................. ................................ ........ 44

Figure 5: Position of gates for measurement . . ..... . ... . . ..... . ..... . .... . . .... . ..... . ..... . .... . ..... . ..... . .. 51

Figure 6: High Speed Logger application window ...................... .................................. .... 52

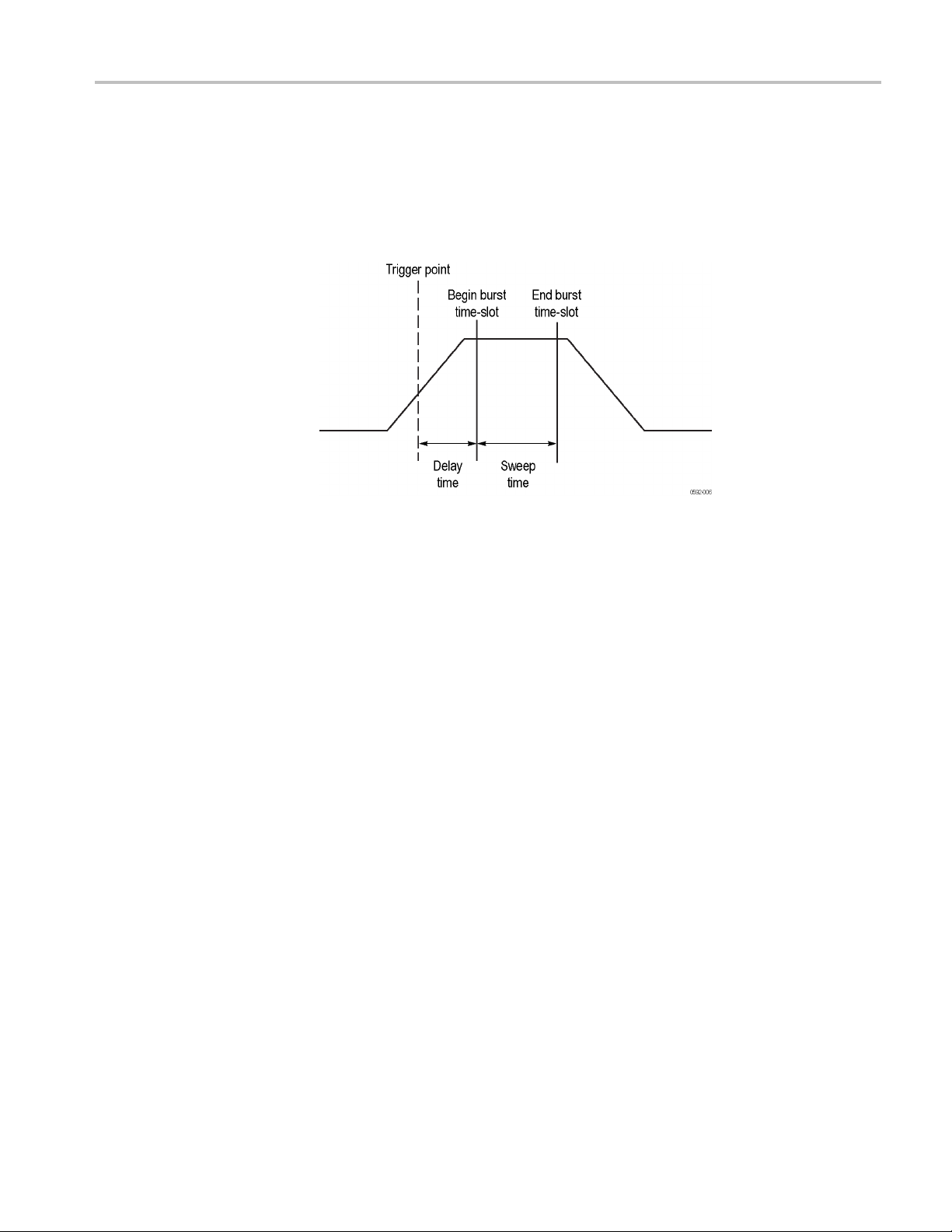

agram of a burst time slot .......................................................................... 23

s

ii RF and Microwave Power Sensors/Meters

Page 9

List of Tables

Table i: Product documentation................................................................................. vii

Table 1 : F un

Table 2: Power Meter default values ................................ ................................ ............ 25

Table 3: Sweep time values ...................................................................................... 37

ctions by instrument model........................................................................ 13

Table of Contents

RF and Microwave Power Sensors/Meters iii

Page 10

Table of Contents

iv RF and Microwave Power Sensors/Meters

Page 11

Preface

Safety Information

Preface

About This Manual

Product gen

environmental compliance information for the products discussed in this manual

are located in the Installation and Safety Instructions. You can find this document

in print form in the box that shipped with your product, in electronic form on

the USB memory device in the box that shipped with your product, or online at

www.tektronix.com/manuals. Please refer to that document b efore installing

and using

This doc

Series, PSM4000 Series, and PSM5000 Series RF and Microwave Power

Sensors/Meters:

The Getting Started chapter provides an overview of instrument features,

installation instructions, and a functional check procedure. (See page 1.)

The Operating Basics chapter provides information about how measurements

work, how to configure the instrument for making measurements, and

information about averaging, pulse measurements, CW measurements, and

pulse profiling. (See page 13.)

The Power Meter Application chapter provides information about using this

application. (See page 19.)

eral safety information, EMC and safety compliance, and

this product.

ument contains the following information about the Tektronix PSM3000

The Pulse Profiling Application chapter provides information about using this

application. (See page 31.)

The High Speed Logger Application chapter provides information about using

this application. (See page 52.)

RF and Microwave Power Sensors/Met ers v

Page 12

Preface

Products

The Tektronix PSM3000 Series, PSM4000 Series, and PSM5000 Series RF

and Microwave Power Sensors/Meters convert radio frequency (RF) and

microwave power into digital data at the point of measurement. They are ideal

for troubleshooting and characterization in the lab, and can be used for radio

frequency (

RF) component testing. These products connect d irectly to a desktop

or laptop computer with a USB 2.0 port and cable.

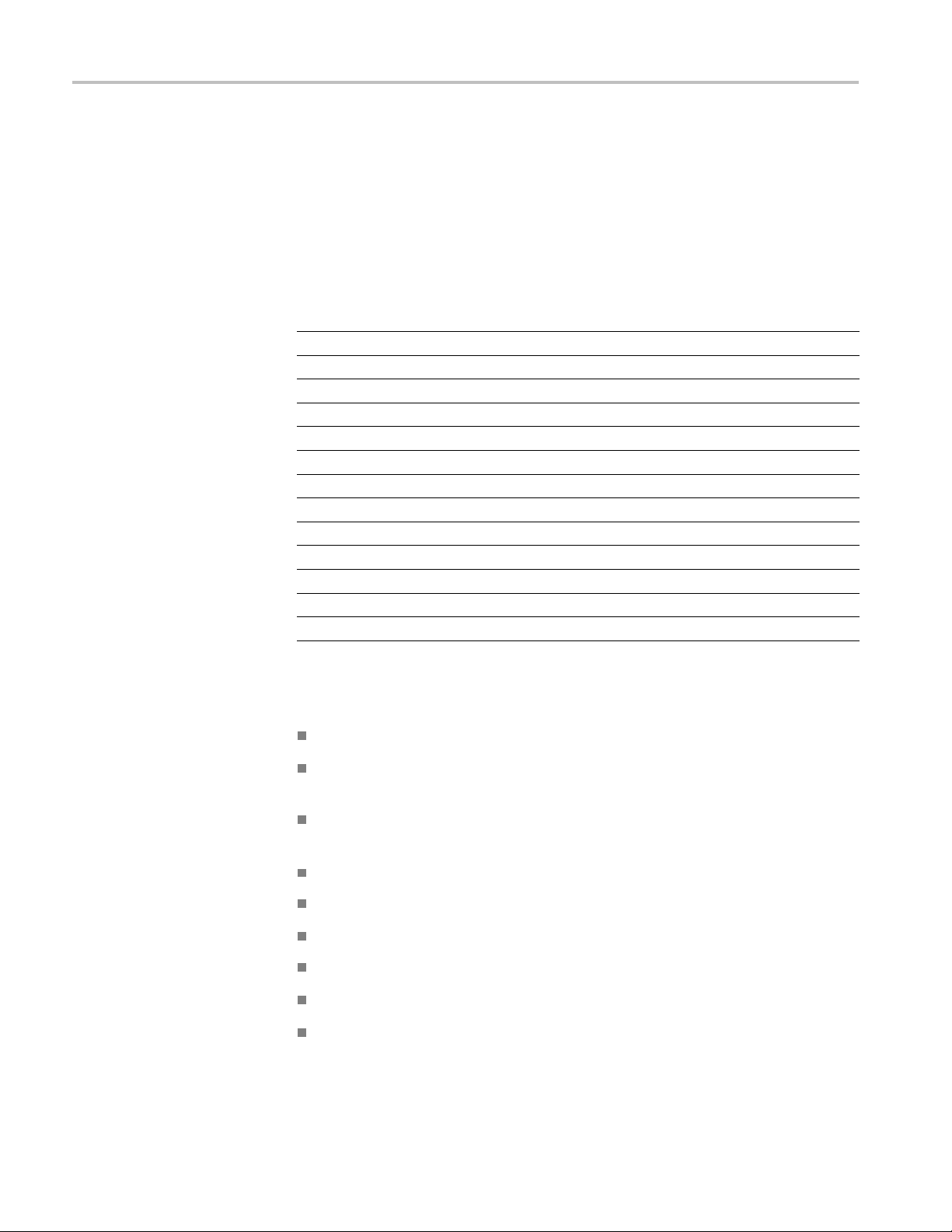

Product Description Connector type

PSM3110 10MHz-8GHz

PSM3120 10MHz-8GHz

PSM3310 10MHz-18GHz

PSM3320 10MHz-18GHz

PSM3510 10MHz-26.5GHz

PSM4110 10MHz-8GHz

PSM4120 10MHz-8GHz

PSM4320 50MHz-18GHz

PSM4410 50MHz-20GHz

PSM5110 100MHz-8GHz

PSM5120 100MHz-8GHz

PSM5320 50MHz-18GHz

PSM5410 50MHz-20GHz

3.5mm-male

N-Type male

3.5mm-male

N-Type male

3.5mm-male

3.5mm-male

N-Type male

N-Type male

3.5mm-male

3.5mm-male

N-Type male

N-Type male

3.5mm-male

Key Features

Reading rates up to 2000 readings per second

Meters are calibrated over full temperature range: No zero or cal needed

before making measurements, saving time and avoiding poor-quality data

Average power, duty cycle corrected pulse power, and measurement logging

on all models

Max hold and relative measurement modes

Offset, frequency response, and 75 Ω minimum loss pad correction

Flexible averaging modes for quick, stable measurements

TTL trigger input and output allow synchronization with external instruments

Pass/Fail limit mode

The PSM3000 series offers True Average power measurements that give

accurate results re gardless of signal shape or modulation

vi RF and Microwave Power Sen sors/Meters

Page 13

Preface

The PSM4000 and

PSM5000 series offer average power, pulse power, duty

cycle, peak power, and crest factor measurements

The PSM5000 se

ries includes a Pulse Profiling application for making

measurements on repetitive, pulsed signals

Where To Find More Information

You c a n find more information about your instrument in the following

documents. These documents can be found on the Tektronix Web site at

www.tektronix.com/manuals, on the product documentation USB device that

shipped with your instrument, or both.

Table i: Product documentation

To read about Use these documents

Product compliance, safety, and

set up and installation information

Operation, configuration, and

application information

Specifications and field verification

procedures

Declassification and security Declassification and Security Instructions available for download at www.tektronix.com/manuals.

Programming information Programmer’s M anual available on the product documentation USB device that shipped with

Online help Online help is available in the SW application you load onto your computer when you first

Installation and Safety Instructions available printed, on the product documentation USB device

that shipped with your instrument, and for download at www.tektronix.com/manuals.

User manual (this manual) available in English, German, French, Spanish, Italian, P ortuguese,

Russian, Korean, Japanese, Simplified Chinese, and Traditional Chinese on the product

documentation USB device that shipped with your instrument and for download at

www.tektronix.com/manuals.

Specifications and Field Verification Technical Reference available on the product

documentation USB device that shipped with your instrument, and for download at

www.tektronix.com/manuals.

your instrument, and for download at www.tektronix.com/manuals.

install the instrument.

RF and Microwave Power Sensors/Meters vii

Page 14

Preface

viii RF and Microwave Power Sensors/Meters

Page 15

Getting Started

Install the Software

This section provides the following information:

How to install the software

How to install the U SB driver and connect to a computer

How to start and application and perform a functional check

Before connecting the instrument to a computer, you need to first load

the software provided on the USB memory device that shipped with your

instrument. You can also find the latest software on the Tektronix Web site at

www.tektronix.com/software.

Computer, System, and

USB Requirements

Compute

the instrument software must have at least 2 GB RAM and a USB 2.0 port that

supplies more than 450 mA at 5 V.

Power requirements. This instrument is powered through the USB cable when

connected to a computer. The USB 2.0 port of the computer must supply more

than

this product. The supplied cable has 20 AWG power conductors that are a heavier

gauge than most USB cables.

NOTE. Refer to the Specifications section of the PSM3000, PSM4000, and

PSM5000 Series RF and Microwave Power Sensors/Meters Specifications and

Field Verification Technical Reference for additional information on electrical

quirements.

re

Hub recommendations. A USB host port on a computer will provide adequate

power for the instrument under normal circumstances. However, if you use a

SB cable longer than 3 to 5 meters, are connecting multiple instruments, or

U

are using a portable computer that runs on battery power, you will need to use

an active or self-powered hub.

The instrument typically draws 450 mA at a nominal 5 VDC. An active hub

compensates for the DC voltage drop in a USB cable longer than 3 to 5 meters.

It also conserves battery life in a portable computer.

r hardware requirements. The computer onto which you are downloading

450 mA at 5 V. Tektronix recommends using the USB cable supplied with

System Requirements. The instrument software you are downloading is

compatible with the following operating systems:

RF and Microwave Power Sensors/Met ers 1

Page 16

Getting Started

Software Installation

Procedure

Windows XP, Ser

Windows Vista

Windows 7 (32 or 64-bit, or XP mode)

This procedure allows you to install one or more of the following software

applications or programs:

Power Meter application: provides a virtual power meter front panel for your

instrument. Use the application software to make power meter measurements.

High-speed Logging application: allows you to take raw, high-speed

readings from your instrument.

Pulse Profiling application: (PSM5000 series only) provides the tools for

complete characterization of a modulated signal.

Sample Code: provides programming examples for remote control of

the instrument. You can read more about remote programming in the

PSM3000, PSM4000, and PSM5000 Series RF and Microwave Power

Sensors/Meters Programming Manual available on the Tektronix Web site at

www.tektronix.com/manuals.

vice Pack 3

2 RF and Microwave Power Sensors/Meters

Page 17

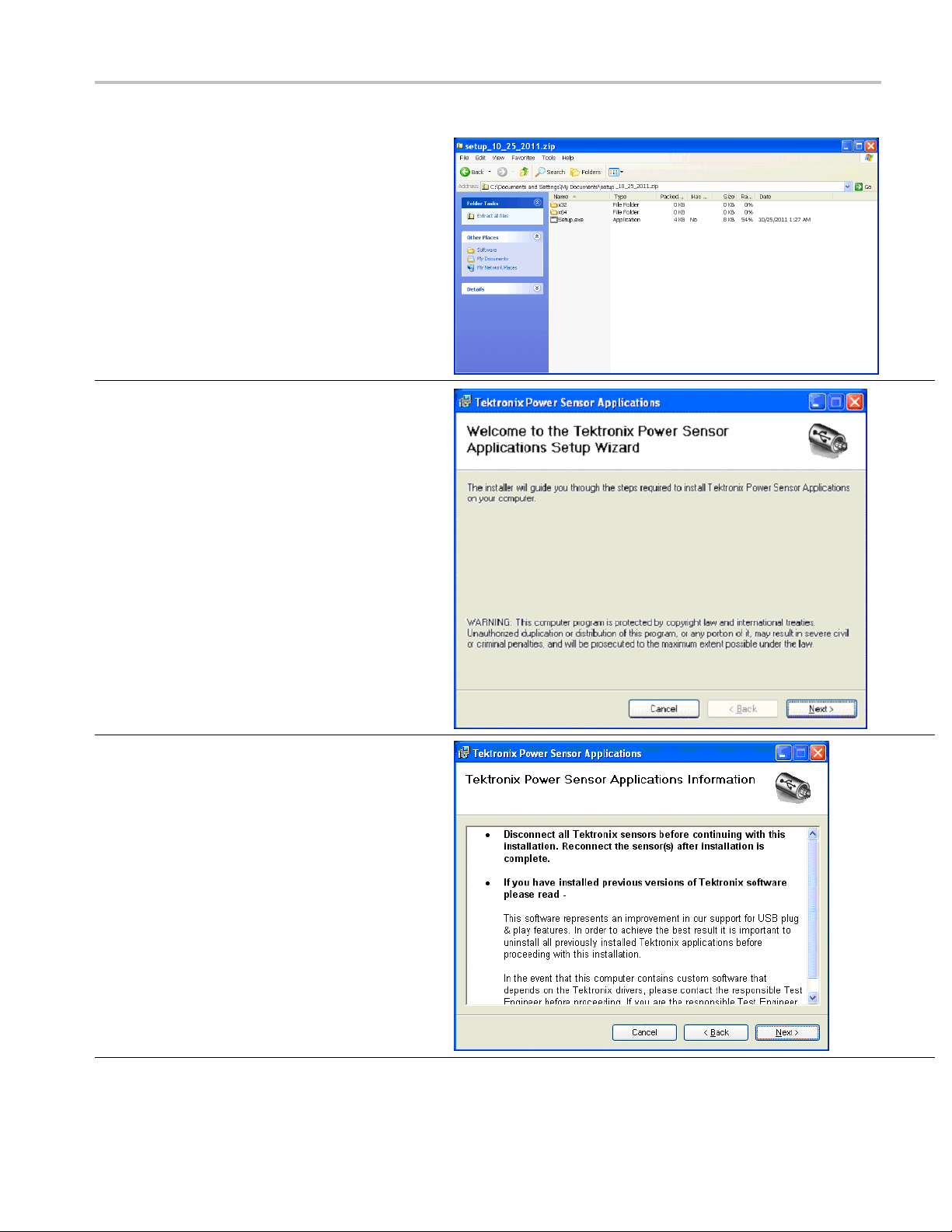

1

Go to www.tektronix.com and search for the most

recent software version for this product and download

it to your comp

the .exe file to start installation.

uter. Once downloaded, double click on

NOTE. You can also insert the USB memory device

that shipped

USB drive. The installation should start automatically.

If the installation does not start automatically, select

Start > Run and the media drive and a semicolon (D:

for example

setup.exe file you downloaded from the Tektronix Web

site, and then press OK.

2 The installer will open and guide you through the

installation procedure. Select Next to continue.

with your instrument into the computer

), and then \setup.exe or the location of the

Getting Started

3

If you have a previous version of the instrument

software, uninstall it before proceeding.

If you are ready to continue installation, click Next.

RF and Microwave Power Sensors/Met ers 3

Page 18

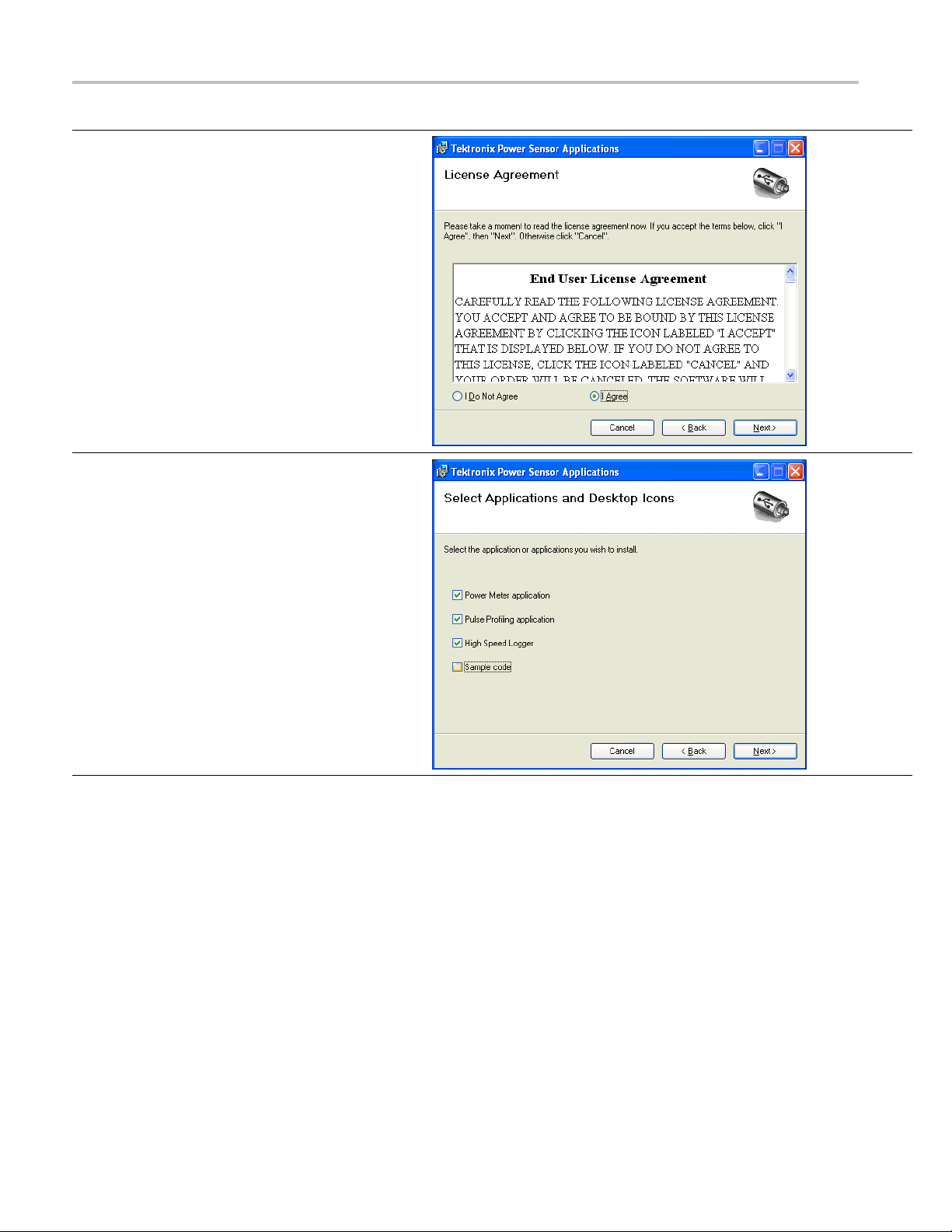

Getting Started

4 Read the licen

then click Next to continue.

5

The installer is ready to install the following software

on your computer (this will vary depending on options

and instrument model):

Power Meter application

Pulse Profiling application

High Speed Logger

Sample Code

Click Next to continue.

se agreement and select Iagreeand

4 RF and Microwave Power Sensors/Meters

Page 19

6

Confirm location for download or provide a location,

and then click Next.

7

When prompted, confirm installation by selecting Next.

Getting Started

RF and Microwave Power Sensors/Met ers 5

Page 20

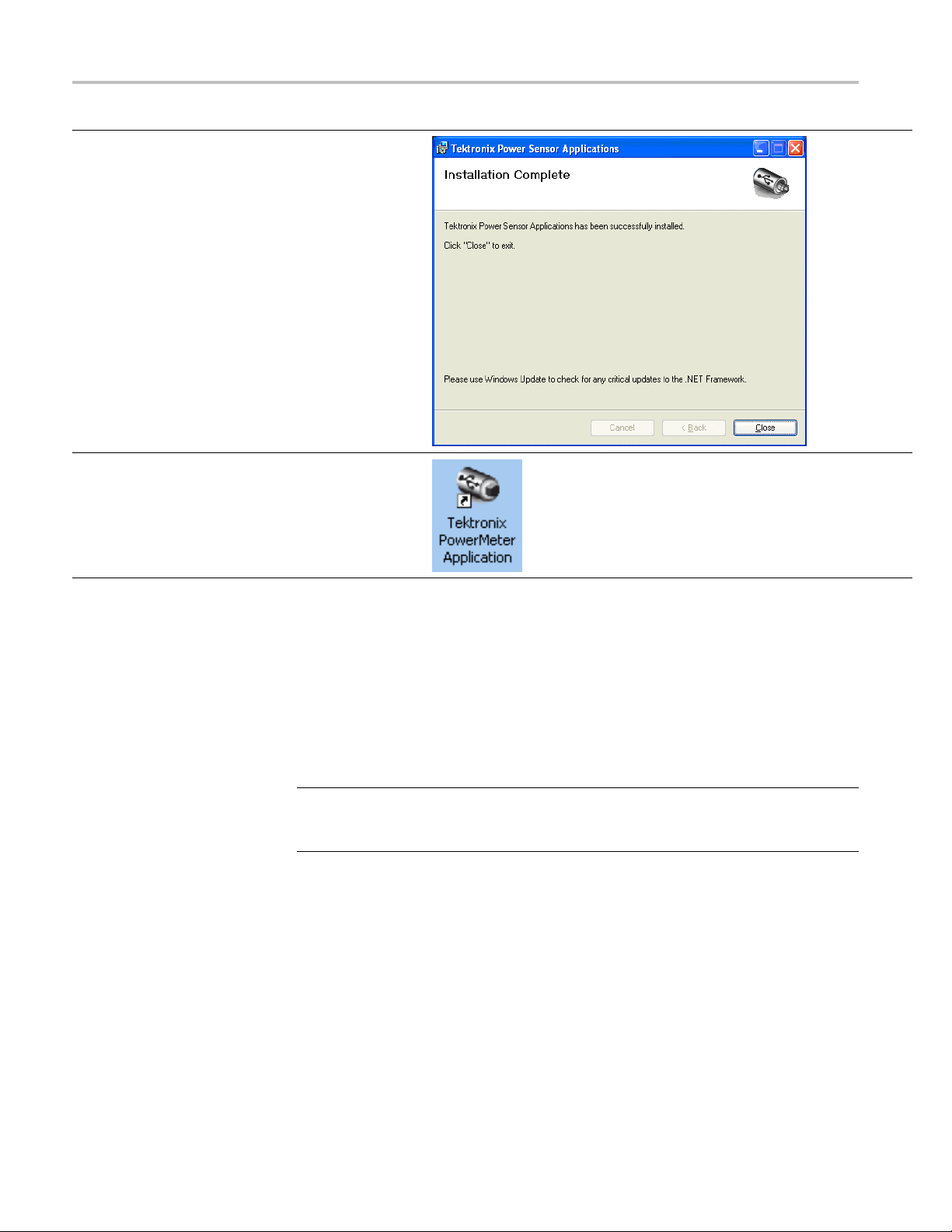

Getting Started

8 When the insta

appear stating that the software was successfully

installed. Select Close to exit.

9 Each downloaded application will now have an

associated icon on the Desktop of your computer.

Before opening the application, connect the instrument

to your computer. (See page 6, Connect to a

Computer.)

llation is complete, a dialog box will

Connect to a Computer

Install the USB Driver

This in

strument is powered through a USB cable that you attach to a computer.

Use the following procedure to install the USB driver so that the computer can

communicate with the instrument. Once the driver is installed, you can start the

Power Meter application software and any other instrument applications that

were installed.

NOTE. Tektronix recommends using the USB cable supplied with this product.

upplied cable has 20 AWG power conductors that are a heavier gauge than

The s

most USB cables.

6 RF and Microwave Power Sensors/Meters

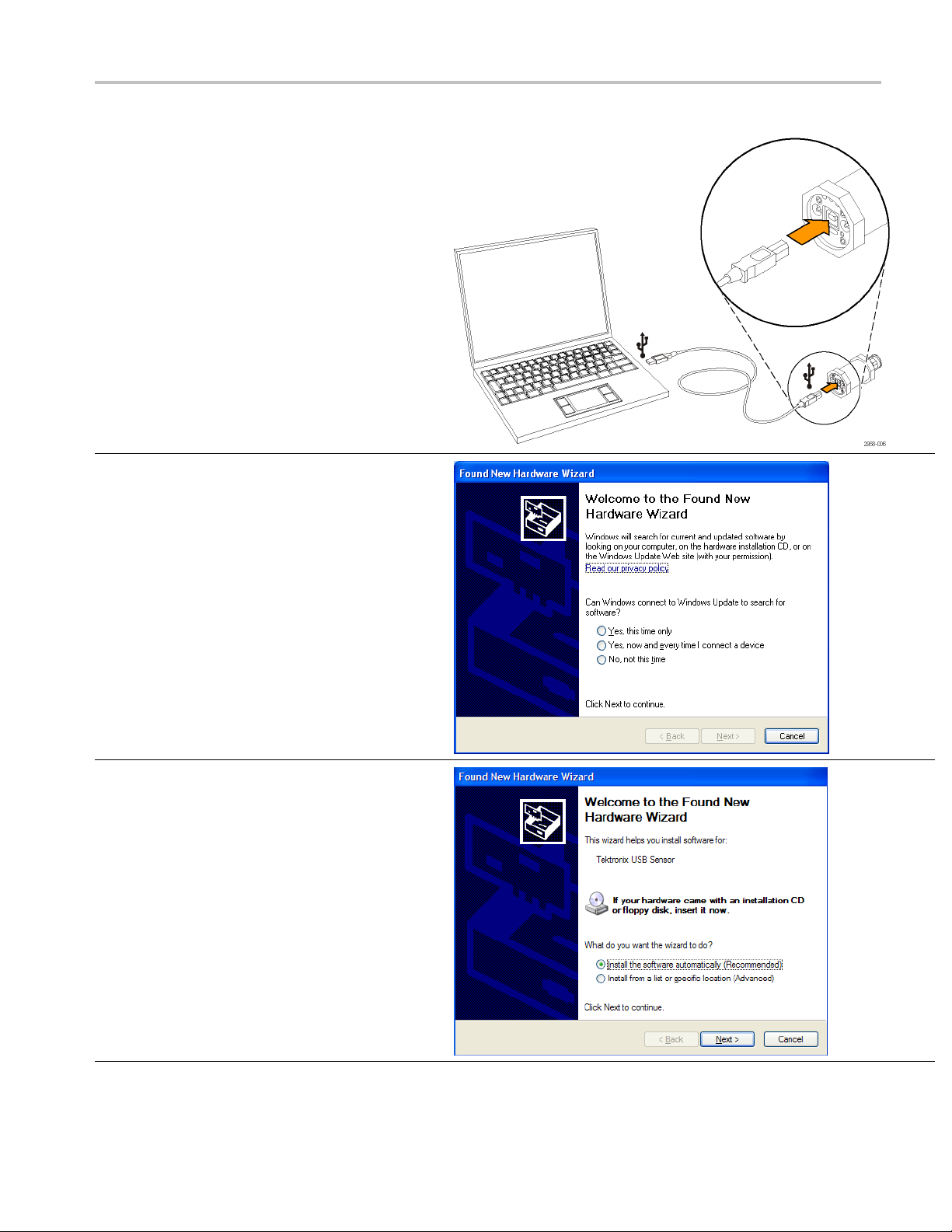

Page 21

1

Use a USB-A to USB-B interface cable to connect the

instrument to the computer.

2 A Welcome to the Found New Hardware Wizard dialog

box will appear. Select Yes, this time only and then

select Next to continue.

Getting Started

3

Select Install the software automatically

(Recommended) and then select Next to continue.

RF and Microwave Power Sensors/Met ers 7

Page 22

Getting Started

4

The W izard will search for the appropriate software.

Once found, the driver will install.

5

The Wizard will show you when the installation is

complete. Select Fin ish.

You can now open the Power Meter application or

other instrument applications that were installed.

8 RF and Microwave Power Sensors/Meters

Page 23

Getting Started

Connect Multiple

Instruments

LED Indicator

If you are conne

The USB port or hub must supply more than 450 mA at 5 VDC for power

instrument operation. Read more about USB power requirements. (See page 1,

Computer, System, and USB Requirements.)

There is a green LED located below the trigger out (TO) connector on the

ment. This LED indicates instrument status as follows:

instru

cting more than one instrument to a computer, use a USB hub.

Dim green and steady: This shows power is being supplied to the instrument

at the instrument has not yet been recognized by the computer.

but th

Bright green and steady: This is the state for normal operation and shows that

r is being supplied to the instrument and that the instrument has been

powe

recognized.

ght green and blinking: This state shows that the instrument is not getting

Bri

enough current from the USB port. This usually means that the USB port

is not a high current USB 2.0 port.

Bright green and blinks a few times: This state is activated when you have

requested the software to identify the instrument. This is useful when you have

multiple instruments connected at once. (See page 10, Start An Application.)

RF and Microwave Power Sensors/Met ers 9

Page 24

Getting Started

Start An Appli

cation

Functional Check

To start an application, double-click the appropriate icon on the Desktop of your

computer, or select it from its program location on your computer (for example,

through the S

NOTE. An application will not launch unless the instrument is connected to the

computer.

If you are u

application software for each instrument. Each instance of the software identifies

its corresponding instrument by displaying the model, serial number, and port

address in the software window title bar.

To identify which instrument corresponds to which software window, compare

the serial number displayed in the software to the serial number stamped on the

instrument body below the USB port. Or, click Sensor ID in the application,

which causes the instrument LED to blink four times.

tart menu).

sing multiple instruments, you must open a new instance of the

After you have installed the software and connected the instrument to a computer,

orm this functional check to verify that your instrument is operating correctly.

perf

You will need the following equipment to perform the functional check:

Equipment Part number

RF/Microwave Source

Windows PC, with Power Meter application

installed

USB cable

Adapters, as needed, to connect RF source

to instrument

Agilent N5183A or equivalent

—

174-6150-00

—

10 RF and Microwave Power Sensors/Meters

Page 25

Getting Started

Warm Up Procedure

Functional Check

Procedure

1. For 24 hours pri

instrument must be stored in a stable laboratory environment. In addition, the

instrument should be powered for at least 20 minutes before starting the test.

Stable environmental conditions are defined as:

Temperature: 20 °C to 30 °C (68 °F to 86 °F)

Humidity: 15% to 95% noncondensing

Altitude: S

2. All equipment requiring power should be connected to mains and warmed up

according

1. Connect the instrument to the computer with a USB cable if you have not

already done so.

2. Turn on and preset a signal source.

3. Turn the source RF output off.

4. Connect the source to the instrument input connector. (Use adapters as

required. Use of cables may skew results so direct connection to the source is

recommended.)

or to and during execution of this test procedure, the

ea Level to 3,000 meters (9,850 feet)

to the recommendations of the manufacturer .

5. Start the Power Meter Application.

6. After the application starts, click the Default Setup button.

7. Vary the input power to prove the instrument is functioning properly. Use

the procedure below.

a. Set the SOURCE frequency to 1 GHz.

t the SOURCE power to 0 dBm.

b. Se

c. Turn the SOURCE RF output on.

d. Read the instrument power.

e. Set the SOURCE power to -20 dBm.

f. With a high quality SOURCE and adapters, the SOURCE and instrument

power readings should agree within ±1 dB. You may see larger

disagreement with some sources.

g. The functional check is successful if the instrument is within ±1 dB of

the SOURCE power.

RF and Microwave Power Sensors/Met ers 11

Page 26

Getting Started

12 RF and Microwave Power Sensors/Meters

Page 27

Operating Basics

This section contains discussions of the following topics, which apply to all

instrument models:

Measurement capabilities

Pulse power and pulse profiling measurements

Procedures for setting center frequency and making measurements

All instruments models can use the Power Meter application. Some measurement

functions, however, are only available on specific models . (See Table 1.)

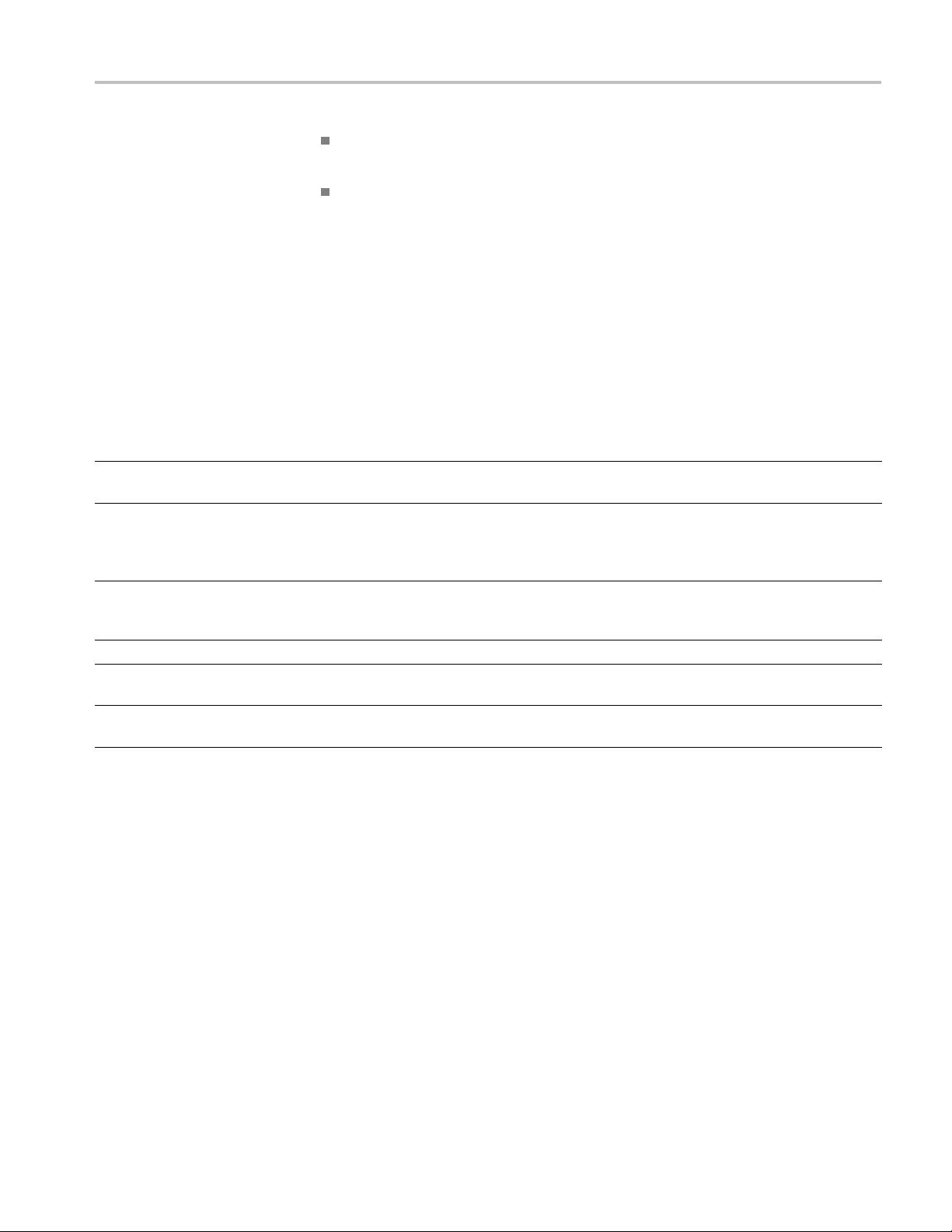

Table 1: Functions by instrument model

Function Model Description

Average

Peak and Pulse

Pulse Profili ng

PSM3110 10 MHz - 8 GHz

(-55 to +20 dBm)

PSM3120 10 MHz - 8 GHz

(-55 to +20 dBm)

PSM3310 10 MHz - 18 GHz

(-55 to +20 dBm)

PSM3320 10 MHz - 18 GHz

(-55 to +20 dBm)

PSM3510 10 MHz - 26.5 GHz

(-55 to +20 dBm)

PSM4110 10 MHz - 8 GHz

(-60 to +20 dBm)

PSM4120 10 MHz - 8 GHz

(-60 to +20 dBm)

PSM4320 50 MHz - 18 GHz

(-40 to +20 dBm)

PSM4410 50 MHz - 20 GHz

(-40 to +20 dBm)

PSM5110 100 MHz - 8 GHz

(-60 to +20 dBm)

PSM5120 100 MHz - 8 GHz

(-60 to +20 dBm)

PSM5320 50 MHz - 18 GHz

(-40 to +20 dBm)

PSM5410 50 MHz - 20 GHz

(-40 to +20 dBm)

RF and Microwave Power Sensors/Met ers 13

Page 28

Operating Basics

Measurement C

apabilities

Measurement capabilities differ between different models. All of the instruments

accept RF or microwave signals, detect the envelope, convert the power into

digital v alu

are capable of producing 2000 settled measurements per second.

The PSM3000

for making accurate average power measurements on both narrowband and

wideband signals. There are two applications that work with the PSM3000 series

instruments: the Power Meter application and the High Speed Logger application.

When these instruments are used with those applications, only CW (average)

measurements are available.

The PSM4000 and PSM5000 series instruments also measure average power,

but are intended for use primarily on pulsed repetitive signals with modulation

bandwid

the average power and peak power contai ned within RF and microwave pulses.

These models can both be used with the Power Meter and the High Speed Logger

applications. In both applications, you can select between CW (average) and

Pulse measurements.

In addition to pulse power measurements, PSM5000 series instruments are

designed for time domain analysis of pulse and other modulated signal formats.

The Pulse Profiling application that is included with these instruments can be used

to b

on the pulse envelope.

es, and send measurements to a PC over a USB connection. All models

series instruments are true average instruments that are well-suited

th less than or equal to 10 MHz. These instruments can also measure

uild a trace of a pulsed RF envelope and make 13 different measurements

CW (Average) Measurements

Average power measurements provide the average power contained in an RF or

microwave signal during a measurement window.

Each PSM3000 series instrument is referre d to as a “true average sensor”,

which means it integrates the broadband power contained in the signal under

test. Although the measurement hardware is different, the results are similar to

a thermal sensor. A PSM3000 series instrument works well on modulation that

falls anywhere within the bandwidth of the sensor.

Average power can also be m easured accurately on the PSM4000 and PSM5000

series; however, the sampling technology that enables pulse measurements also

limits the modulation bandwidth to 10 MHz.

14 RF and Microwave Power Sensors/Meters

Page 29

Pulse Measurements

Operating Basics

NOTE. This information applies to the PSM4000 and PSM5000 series instruments

only.

The PSM4000 and PSM5000 series instruments use a detector, sampling system,

and signal p

addition to overall average power, these instruments can measure the following:

rocessing to detect RF puls es and perform measurements on them. In

Average po

Peak power within the pulse

Duty cycle

Crest factor (which is also called peak to average power ratio)

The undersampling technique used to perform pulse measurements relies on

the pulses being repetitive. That is, these instruments will not perform “single

shot measurements”, nor will they operate well on signals in which modulation

constantly varies. Averaging and extended averaging can be used to increase

asurement window, improve the quality of low-level measurements, and

the me

increase the probability of sampling peak power.

etection and sampling system in these instruments make it possible to

The d

measure signals with modulation rates up to 10 MHz.

eal-time sampling rate of PSM4000 and PSM5000 series instruments is

The r

500 kS/s, w hich is much lower than the video bandwidth of 10 MHz. Aliasing

may affect accuracy o n signals with modulation bandwidth greater than 200

kHz. An anti-aliasing feature is provided to eliminate the effect of aliasing for

signals greater than 200 kHz. The anti-aliasing feature requires some additional

processing power and may s low down the measurement rate when it is active.

In order to perform pulse measurements, criteria for recognizing pulses have to be

established. This involves setting a threshold. The points at which the envelope

rosses this threshold determine the beginning and end of the pulse. The method

c

for setting the criteria differs somewhat between the Power Meter and the Pulse

Profiling applications, so consult the appropriate sections of this manual for

details. Both applications allow you to select an automatic setting that will work

for most applications.

wer within the pulse

RF and Microwave Power Sensors/Met ers 15

Page 30

Operating Basics

Pulse Profilin

g

NOTE. This information applies to the PSM5000 series instruments only.

The PSM5000

equivalent-time sampling to build a trace of the envelope of repetitive input

signals. Theequivalent-timesamplerateis48MS/s.

A wide variety of measurements are available in the Pulse Profiling application.

These include:

Rise Time (RT)

Fall Time (FT)

Pulse Width (PW)

Pulse Repetition Time (PRT)

Pulse Repetition Frequency (PRF)

Duty Cycle (DC)

Pulse Power (Pls)

Peak Power (Pk)

series instruments using the Pulse Profiling application use

Average Power (Avg)

Crest Factor (CF or CrF)

Overshoot (OvSh)

Droop

On/Off Ratio

You can set trigger levels and conditions, apply digital filters to the envelope, and

set the software to average traces together.

The overall trace is shown in the Panoramic Trace window. Pan and zoom

functions let you select a subset of the trace, which is displayed in the

Measurement Trace window. All measurements are taken on the Measurement

window data. These measurements can be further qual

and gates.

An Auto Measurements feature allows all measurements to be taken on the first

two pulses in the Measurement trace with the click of a button.

Statistics can be taken on the Measurement Trace window data, including CDF,

CCDF, and PDF. (See page 33, CDF, CCDF, and PDF Display.)

You can read more about this application. (See page 31, Pulse Profiling

Application.) (See page 42, Gate Measurement Types in Gates Toolbar.)

ified by using m arkers

16 RF and Microwave Power Sensors/Meters

Page 31

Operating Basics

Configure Inst

Set the Cente

Change the Sensor

Zero and Calibration

r Frequency

rument for Measurements

The following information will help you configure the instrument to make

measurements.

You must set the center frequency when the incoming signal frequency changes.

Measurement accuracy requires that the frequency be set. Not doing so can be a

significant source of errors. Each applicationprovidesabuttonormenuoptionfor

e frequency of the incoming signal.

ents connected to a computer. After you change the address to an

Address

setting th

Each application provides a button or menu option enabling you to change

an instrument address. This function is most useful when you have multiple

instrum

instrument, the software application will close. Disconnect and then reconnect

the instrument before reopening the application. The new address will appear

for that instrument.

These power sensors are stable over a wide range of temperatures. You do not

need to zero or calibrate these instruments before using them, or if the temperature

changes. A factory calibration is required once a year to maintain traceability

to national standards.

Measurement Resolution

CAUTION. The PSM3000 series instruments require time to thermally stabilize.

tle, if any, warm up time is required for measurements above -40.0 dBm.

Lit

However, to make accurate measurements below -40.0 dBm, allow the PSM3000

series instrument to thermally stabilize for one hour.

The amplitude resolution is fixed to a thousandth of a measurement unit.

Frequency is selectable in MHz or GHz ranges.

RF and Microwave Power Sensors/Met ers 17

Page 32

Operating Basics

18 RF and Microwave Power Sensors/Meters

Page 33

Power Meter Application

NOTE. This application is available for all instrument models.

The Power Meter application software allows you to make power meter

measurements from a display that emulates a typical bench power meter. Double

click the Power Meter application icon on your D esktop to start the application.

The control panel will appear with default settings applied. You can always return

the softwa

CAUTION. Do not exceed +23 dBm, 200 mW, or 3.15 VRMS. Ensure that the RF

input connector on the sensor and the mating connector are clean and undamaged.

NOTE. Using more than one type of application at a time can result in errors. It is

recommended that you use only one type of application at a time.

re to the default settings state by clicking the Default Settings button.

Front P

anel Elements

The main elements of the Power Meter application interface are shown here with

no signal applied to the instrument.

Figure 1: Power Meter application interface using a PSM5120

The main elements of the interface are:

1. Banner: the unit address and the unit name

2. Menus: drop down menus allow you to adjust various settings; many of these

settings are also accessible using the settings panel buttons

RF and Microwave Power Sensors/Met ers 19

Page 34

Power Meter Application

CW/Pulse

Save

Recall

3. Digital Readou

fail, low, high, or off

4. Settings Pane

utility functions by clicking on the related button

5. Power Meter

can be enabled in the Display drop down menu

Switch between CW and Pulse measurements.

Call the Sa

setup as a register or as a named state. This function is also accessible from the

Save/Recall drop down menu.

There are 10 Save/Recall registers and each register holds an entire state. The

states are not held in the instrument but reside on the local PC.

Call th

a state. This function is also accessible from the Save/Recall drop down menu.

ve Named State window. In this window, you can save your test

e Recall Named State window. In this window, you can recall a register or

t: shows measurements in digital format; shows limits as pass,

l: access measurement setups, offset setups, trigger setups and

Bar: provides an analog view of the meter reading; this view

Manage Named States

Frequency

Meas Units

Limits (On/Off)

This menu item is found in the Save/Recall drop down menu. It calls a Manage

Named

Select the frequency units (MHz or GHz). The center frequency must be updated

when the incoming signal frequency changes as this frequency setting is used

to d

frequency to be set and not doing so can be a significant source of error.

Yo

Select the power units (dBm, dBW, dBkW, dBuV, dBmV, dBV, W, V, dB Relative).

Set measurement limit specifications with pass or fail (High/Low) indicators

shown on the digital display panel.

From the Display drop down menu, you can establish a single test limit or upper

and lower test limits. Limits are fixed values against which a measured value

is compared. A n evaluation is done during a measurement and is expressed as

pass or fail.

For the single limit, the value can be below, equal to, or above this limit and you

may specify any of these conditions as pass or fail.

states window from which you can delete and view n amed states.

etermine calibration factors. The best measurement accuracy requires the

u can also find this item in the Measurement drop down menu.

20 RF and Microwave Power Sensors/Meters

Page 35

Power Meter Application

Averaging

For the upper an

between the limit, or equal to one of the limits. Any condition may be specified as

pass or fail.

Two t ypes of a

improve the stability of measurements, especially at low-levels: Averaging and

Extended Averaging.

The Averaging function averages some number of measurements and then

displays the averaged value. You can change the number of measurements that

are averaged from 1 to 100,000. By default, 75 measurements are averaged for

each displayed reading.

Averaging also has the effect of expanding the measurement interval. This

increases the amount of data used to determine peak pulse power, crest factor, and

duty cycle. For signals with narrow pulses or fast peaks, increase averaging to

e stable peak power, crest factor and duty cycle measurements.

achiev

For example, each raw measurement takes about 250 μs. Setting the averaging

000 would result in a 250 μs x 10,000 = 2.5 s delay between displayed

to 10,

readings. The average is calculated before each reading is displayed. If averaging

is set high, then the display updates slowly.

d lower limit, the value can be equal outside the limit, equal

veraging are available to use in the Power Meter application to

Extended Averaging /

Reset

Max / Reset

an combine Averaging and Extended Averaging to balance stability and

You c

responsiveness for your application and preference.

h the Ext Avg / Reset button and Measurement drop down m enu, you can set,

Wit

enable, and reset extended averaging. Extended averaging should be seen as an

adjunct to averaging: it may be used to further smooth readings and does not slow

down the display update rate as does averaging.

Since extended averaging applies a running exponential average of the last n

readings, where n is the number of extended averages, the display updates quickly

but the measurements respond to changes more slowly. The Reset button resets or

restarts both the max hold and extended averaging functions.

An xAvg indicator will appear in the digital display when extended averaging is

enabled and set greater than 1.

Retains the maximum measured value until reset or deactivated. For pulse

measurements, each reading (Pulse, Peak, CrF, Avg, DC) is held at its maximum

value independent of the other readings. You can reset or restart this function by

clicking on Reset. You can also find this item in the Measurement drop down

menu.

A MAX indicator will appear in the digital display when Max hold is enabled.

RF and Microwave Power Sensors/Met ers 21

Page 36

Power Meter Application

Set Ref

Offset

Freq Resp

Set the referen

to the power measurement on the display. When Ref Offset is activated, the REL

indicator will show in the digital readout display and the power units will change

to “dB relative”.

You can enable this setting from the Offsets & Response drop down menu item

called Relative Units On/Off.

Set gain or loss offsets to be applied to all measurements. You can also find this

item in the Offsets & Response drop down menu.

An OFS indicator will appear on the digital display when Offset is enabled.

Set frequency dependent gain or loss offsets to be applied to measurements. This

is a freq

response changes accordingly. Response amplitude is always expressed in dB

and the frequency is expressed in Hz. The interpolation is linear with respect to

frequency and dB. The frequency response feature must be enabled before it will

have an effect. A frequency response (RSP) indicator will appear on the digital

display readout when response correction is enabled.

The frequency response correction factors are specified as frequency and

amplitude pairs. To load the correction factors go to the Frequency Response

et window. Click Add after each frequency and offset entry to build the table.

Offs

Then select Show Graph to get a graphical presentation of the frequency offsets

that were entered in the table. The Response setup allows up to 201 points to be

entered.

ce value so that a subsequent power level can be measured relative

uency sensitive offset, so as you change the measurement frequency the

Anti-alias Control

Measured Pulse Setup

You can also find this item in the Offsets & Response drop down menu.

is function randomizes the sampling pattern to eliminate the effect of aliasing

Th

due to undersampling. The real-time sample rate of the instrument is 500 kS/s.

As the baseband signals approach the Nyquist criteria (about 200 kHz in this

case) anti-aliasing can occur. If you are measuring signals that have baseband

content greater than about 200 kHz, enable anti-aliasing for the best measurement

accuracy. Anti-aliasing slows down measurements, so for faster reading rates on

signals with modulation bandwidth below 200 kHz, disable anti-aliasing.

This function is found in the Measurement drop down menu.

This value determines the portion of the pulse to be used to measure pulse power.

The default or automatic value is 3 dB below the measured peak value or the

50% down points.

This function is found in the Measurement drop down menu.

22 RF and Microwave Power Sensors/Meters

Page 37

Power Meter Application

Burst Measurements

The PSM4000 and

on RF bursts. To access this measurement, select Burst Measurement... from the

Measurement drop down menu. From the window that appears, you can specify a

trigger, a delay relative to the trigger, and the sweep time over which the power

measurement is taken. The instrument will then display the peak power, average

power, and minimum power measured during the qualified duration.

Figure 2: Diagram of a burst time slot

Trigger. The measurement c an be triggered by the incoming RF signal, or from

an external TTL source. When using the Internal Auto Level setting, the trigger

level is automatically set to approximately half the pulse amplitude.

PSM5000 series instruments allow you to make measurements

Meas Update Rate

Delay. The delay time determines how long after the trigger the sweep time

begins.

Sweep Time. The sweep time defines the duration of the measurement.

Resolution. The power measurement data is taken at the real-time sample rate of

the instrument, which is 500 kS/s. This results in a fixed resolution of 2 μs.

Measure. The measurements consist of peak power, average power, and minimum

power observed during the specified sweep time. Measurements can be set to

update continuously by selecting the Continuous check box. Deselect the check

box to stop taking measurements. For a single set of measurements, click on the

Start button. The Copy button transfers the three measurements to the clipboard

so you can paste them into a document.

Data Logging. Burst measurements can be logged to a text file. To do this, type in

or browse to a file, and then enable logging by selecting the Log Measurements

check box.

The measurement update rate determines how quickly measurements are updated.

Options are S

This function is found in the Measurement drop down menu.

lowest, Slow, Medium, Fast, and Fastest.

RF and Microwave Power Sensors/Met ers 23

Page 38

Power Meter Application

Minimum Loss Pad

Menu (Triggering)

The instrument

a75Ω input impedance, you may attach a 75 Ω minimum loss pad (MLP) to the

input. You can correct for the pad by selecting 75 ohm MLP from the Offsets &

Response menu. The instrument will adjust its measurements accordingly and

the display will indicate “75ohm-MLP”, if selected.

This button calls the Triggering setup menu. From here you can set triggering to

internal or external continuous, and internal or external single. You can also set

the TTL trigger in/out, inverted trigger, and trigger timeout.

NOTE. When the trigger timeout is set to long and triggers occur slowly, the

Power Met

Trigger In. The external trigger input is assumed to be a TTL level and positive

edge tri

is detected, the measurement will commence and will continue for the specified

number of averages. In External Single mode, the system will wait for you to

click the Single button and then it will monitor the trigger in port. If a trigger is

not detected in the allotted time, the system will time out and return an ext trig?

indicator.

gger. Trigger in can be e nabled, disabled, or inverted. After the trigger

hasa50Ω input impedance. However, for applications requiring

er interface will respond slowly to mouse clicks.

Single

When the trigger in is inverted, the system will look for a negative edge (instead

of a positive edge) and begin the measurement when a negative edge is detected.

an set a trigger timeout period for an external trigger input, up to 30 seconds.

You c

Trigger Out. The trigger output is compatible with TTL levels. It can be enabled,

disabled, and inverted. A trigger out pulse occurs at the beginning of each

measurement. Even if the external trigger is disabled and trigger out is enabled, a

trigger will be produced each time a measurement is made.

By default, the trigger output is normally low. The start of the trigger is indicated

by a rising edge on the output. The output stays at a TTL high level for a few

icroseconds and then returns to a low level. If the trigger out is inverted, it will

m

transition from a high to a low TTL level to indicate when a trigger has occurred.

NOTE. When multiple Power Meter instances are running, the absence of a

trigger in one instance of the Power Meter application will cause other instances

to update at a slower rate or even time out. This would occur, for example, if an

instrument lost its external trigger source.

Enable this button from the Triggering drop down menu by selecting internal or

external single triggering. Click the button to initiate a single measurement.

24 RF and Microwave Power Sensors/Meters

Page 39

Power Meter Application

Quick Setup

Data Logger

Select to call a

window that allows you to set the mode (CW or Pulse), frequency,

power units, averages, and offsets all from one window.

You can also find this item in the Utility drop down menu.

This function allows you to plot measurement trends on the display or record a

measurement in a file. Use the Logging Setup menu item in the Measurement

drop down menu to set the following data logging options:

Turn off storage

Specify a file name

Settoappenddatatotheendofthefile

Set to overwrite data in a file

Click the Data Logger button to display the logging graph and start logging data

to a file once logging is set up.

The logger will start graphing from 0 to 300 readings (bottom scale, right to left).

The duty cycle is scaled v ertically from 0 to 10% (1% per divisio

n). Crest Factor

is scaled vertically from 0 to 20 dB (2 dB per division).

NOTE. There is a separate High Speed Logger application available for logging

high-speed measurements directly to a file. (See page 52, High Speed Logger

Application.)

Default Setup

Click this button to return all measurement parameters to their default settings,

but not user defined settings, such as display color or window size. When you

start the application for the first time, all parameters are in their d efault settings.

Unless you change one or more parameters, they will remain at their default

values. (See Table 2.)

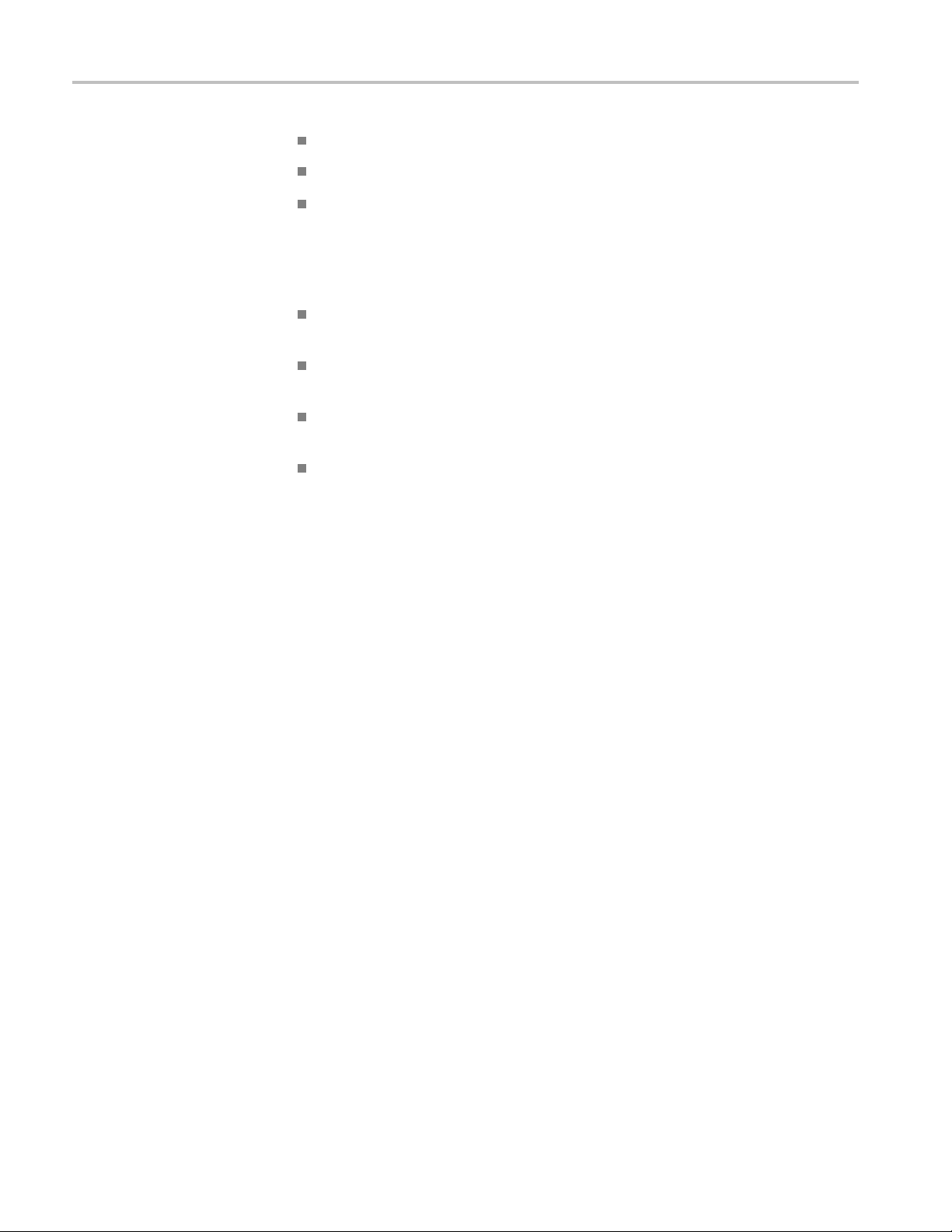

Table 2: Power Meter default values

Parameter Default value

Mode

Frequency

Power units dBm

Averaging

Measured Pulse Setup 3 dB (PSM4000 and PSM5000 series only)

Measurement Update Rate Medium

Display

Sweep Time

Offset

CW

1GHz

75

Default

1ms

0 dB, disabled

RF and Microwave Power Sensors/Met ers 25

Page 40

Power Meter Application

Table 2: Power Meter default values (cont.)

Parameter Default value

Response 0 dB, disabled

Duty Cycle 10%, disabled

Minimum Loss Pad (75 ohm) Not selected. The Default Setup button will not

change the input impedance if this value is selected

(enabled). Application launch sets the input to 50 Ω.

Trigger Mode

Trigger Out

Internal Continuous

Disabled

Recall Factory Setup

Sensor ID

Set Address

Set Sensor Name

Select this menu item from the Utility drop down menu to reset all measurement

parameters and user preferences, such as display color and window size, to default

settings.

Click this button to identify an instrument. The LED on the identified instrument

will blink four times. This is particularly useful when multiple instruments are

connected.

You can als o find this item in the Utility drop down menu.

s item is located in the Utility drop down menu. Use it to set an instrument

Thi

address. This is particularly useful when multiple instruments are connected.

NOTE. Changing the address requires re-initialization of the USB connection.

After changing the instrument address, the application will close and must be

reopened.

This item is located in the Utility drop down menu. Use it to set an instrument

name for the current session only. This is particularly useful when multiple

instruments are connected.

Error Messages

Various error windows will appear if there is a hardware or software problem or

conflict. Follow the message instructions to correct the problem.

26 RF and Microwave Power Sensors/Meters

Page 41

Power Meter Application

Make an Averag

e Power (CW) Measurement

This example procedure applies to all instrument models and assumes a signal

source with the following parameters:

CW Frequency: 1 GHz

Power Level: 0dBM(1mW)

Modulation: off

RF Power: off

CAUTION. Do not exceed +23 dBm, 200 mW, or 3.15 VRMS.

1. For PSM4000 and P

on the Settings Panel to activate CW mode. Yo u can also enable CW from the

Measurement menu.

NOTE. For PSM3000 series instruments, the software is always in CW mode,

so the button is not available.

SM5000 series instruments, click the Pulse/CW button

2. Click Measur

will open.

3. Enter 1 GHz,

4. Confirm that the instrument is set to continuously trigger, and then click

Triggerin

5. Connect the instrument to the RF source and turn on RF power.

The display indicates approximately0dBmat1GHz. Thesoftwaretracks

changes as you vary the source power.

ement > Set Frequency and the Set Frequency dialog box

and click OK.

g > Internal Continuous.

RF and Microwave Power Sensors/Met ers 27

Page 42

Power Meter Application

MakeaPulseMe

asurement Using Duty Cycle

This method of measuring average pulse power is available with all instrument

models. However, this is the only method for measuring average pulse power on

PSM3000 seri

adjustment to the indicated power. This type of measurement is more prone to

error than the signal processing pulse power measurements available on PSM4000

and PSM5000 series instruments. However, this a useful measurement approach

when using PSM3000 series instruments.

The duty cycle correction calculation is:

Pulse Power = Measured Power + Duty Cycle Adjustment

The duty cycle adjustment is:

-(10log

For instance, if you measured an average power of -20 dBm and assumed a duty

cycle o

f 10% (0.10), then the pulse power would be calculated as:

Pulse Power = -20 dBm + -(10log

NOTE.

cycle measurement.

es instruments. This measurement uses an assumed duty cycle as an

(Duty Cycle))

10

The instrument must be in CW Power mode to access this method of duty

(Duty Cycle)) = -20 dBm + (10 dB) = -10dBm

10

t the instrument to measure average pulse power on a signal with 10% duty

To se

cycle, do the following:

1. For

PSM4000 and PSM5000 series instruments, click the Pulse/CW button

on the toolbar to activate CW mode. You can also enable CW from the

Measurement menu.

NOTE. For PSM3000 series instruments, the software is always in CW mode,

so the button is not available.

2. Click Offsets&Response>DutyCycle>Setup.

The Measurement Duty Cycle dialog box opens.

3. Enter 10.0 (the duty cycle percentage), and click OK.

4. Click Offsets & Response > Dut y Cycle > Enabled.

The software shows source pulse power in the CW configuration, and the

DC annunciator activates. You can use the duty cycle pulse power method

down to approximately 0.1%.

28 RF and Microwave Power Sensors/Meters

Page 43

Make a Pulse Power Measurement

This example procedure applies to the PSM4000 and PSM5000 series instruments

only. It assumes an RF signal source for a pulse-modulated output with the

following parameters:

CW Frequency: 1 GHz

Power Level: 0dBM(1mW)

PRF: 10 kHz (or a PRI of 0.1 ms)

Power Meter Application

Pulse Modu

RF Power: off

CAUTION.

1. Click Measurement > Pulse Power.

Or, click the Pulse/CW button o n the toolbar to activate Pulse mode.

2. Click Measurement > Set Frequency.

The Set Frequency dialog box opens.

3. Enter 1 GHz, a

4. Confirm that the instrument is set to continuously trigger, and then click

Triggering

In Pulse Power mode, the software shows these measurements at the right of

the displa

DC: duty cycle

lation: 50% Duty Cycle (or a pulse width of 50 μs)

Do not exceed + 23 dBm, 200 mW, or 3.15 VRMS.

nd click OK.

> Internal Continuous.

y:

Pk: peak power

Avg: average power

CrF: crest factor (also known a s peak-to-average power ratio (PAR))

The large number in the center of the software display shows the pulse

power. The default pulse threshold is Automatic 50% or 3 dB below peak

check box in the Pulse Setup dialog box (Measurement > Measured

Pulse Setup). If you know the s pecifi c pulse characteristics, you can

change this by selecting Measured Pulse Setup in the Measurement drop

down m

RF and Microwave Power Sensors/Met ers 29

enu.

Page 44

Power Meter Application

5. Connect the ins

The software should indicate these approximate values:

1 GHz

0 dBm pulse power

50% duty cycle

0dBmpeak

-3 dBm aver

3 dB crest factor (the ratio between peak and average power)

The measurement changes as you vary the source power.

trument to the RF source and turn on RF power.

age

30 RF and Microwave Power Sensors/Meters

Page 45

Pulse Profiling Application

Pulse Profilin

Menu Features

gApplication

NOTE. This application is only available for PSM5000 series instruments.

For basic CW

To perform detailed measurements on repetitive, pulsed RF and microwave

signals with PSM5000 series instruments, use the Pulse Profiling application.

This application displays a trace of the pulse envelope and allows you to take

measurements at any point on the trace.

CAUTION. Do not exceed +23 dBm, 200 mW, or 3.15 VRMS. Ensure that the RF

input co

NOTE. Using more than one type of application at a time can result in errors. It is

recomm

ThemainelementsofthePulseProfiling application interface are shown here.

and pulse power measureme nts, use the Power Meter application.

nnector on the sensor and the mating connector are clean and undamaged.

ended that you use only one type of application at a time.

Figure 3: Pulse Profiling application interface

RF and Microwave Power Sensors/Met ers 31

Page 46

Pulse Profiling Application

Highlight Span

The main elemen

1. Banner: unit address and the unit name

2. Toolbar: Allows you to configure the instrument for measurements, control

the display, access Help, and perform other tasks. (See page 36, Toolbar

Functions.)

3. Panoramic Trace: The Panoramic Trace is displayed on a grid with 10 vertical

divisions that indicate power, and 10 horizontal divisions that indicate time.

You can highlight a portion of the Panoramic trace by clicking and dragging

the cursor directly on the Panoramic trace. Current tra ce parameters are also

listed above the grid.

4. Measurement Trace: The highlighted time segment from the panoramic trace

will appear in this view, allowing for a more detailed examination of the

signal using time markers and time gates. The Measurement trace is displayed

on a grid with 10 vertical divisions that indicate power, and 10 horizontal

divisions that indicate time.

5. Auto Measure Panel (Results and Auto Measure windows): This panel

contains the Auto Measure and Results windows and a display control toolbar.

(See page 34, Auto Measure Panel.)

The Panoramic Trace and the Measurement Trace windows are designed to work

in tandem to help you identify a nd investigate areas of interest easily and q uickly.

To view a portion of the Panoramic trace in more detail, highlight the portion of

the trace in which you are interested. The highlighted portion will appear in the

Measurement Trace window.

ts of the display are:

You can highlight or select a portion of the trace using the following techniques:

1. Click and drag the mouse over a portion of the Panoramic trace. Only the

portion selected by the mouse movement will be viewed in the Measurement

Trace window .

2. Click and drag the mouse over a portion of t he Measurement trace. Only the

portion selected by the mouse movement will be viewed in the Measurement

Trace window. This technique allows you to zoom in on the trace. The mouse

pointer must be in Highlight mode.

3. Click the Highlight Span drop down on the Results pane (or Display Control

toolbar) and then select the percentage of interest. The selected portion will

be viewable in the Measurement Trace window. If a portion of the Panoramic

trace is currently selected, then the percentage will be centered on the current

selection. If a portion of the trace is not selected, then the percentage will be

centered around the middle of the Panoramic trace.

4. To select a precise portion of the trace, click the Highlight Span drop down

and then select Set Start. Enter the beginning of the measurement trace in

microseconds.

32 RF and Microwave Power Sensors/Meters

Page 47

Pulse Profiling Application

CDF, CCDF, and PDF

Display

5. Click the Zoom I

current viewing area. These buttons are available in the Results window and

in the Display Control toolbar.

6. Click the Reset button. This resets the Measurement Trace window to include

the entire Panoramic trace.

7. Use the scroll and nudge controls in the Results window. These controls allow

you to scroll the area of interest left or right. The nudge controls move the

area one small step at a time.

You can select to print CDF (Cumulative Distribution Function), CCDF

(Complementary Cumulative Distribution Function), or PDF (Probability Density

Function) displays from the Print toolbar. All displays are printable in black and

white or color (depending on the capabilities of your printer). For all of these

displays, you can set the resolution, data source (trace or gates), minimum and

maximum

Pulse Profiling.)

The CDF

level.

The CC

average power level (expressed in dB relative to the avera ge power). The

percentage of time the signal spends at or above each line defines the probability

for that particular power level. A CCDF curve is a plot of relative power levels

versus probability.

power, and the number of data sets or runs with counter. (See page 16,

display shows the probability that a signal is below the average power

DF display shows how much time the signal spends at or above the

n or Zoom Out buttons. These buttons double or halve the

Power (CCDF) curves provide critical information about the signals encountered

in 3G systems. These c urves also provide the peak-to-average power (crest factor)

data needed by component designers.

The PDF shows the distribution of the average power level.

NOTE. Read more about the Print toolbar. (See page 46, Print.)

RF and Microwave Power Sensors/Met ers 33

Page 48

Pulse Profiling Application

Auto Measure Panel

The Auto Measur

window. Click the Start Measurement button to start the automatic measurement

feature and get a complete characterization of the pulse based on the selected

sweep time.

Results Window. This window allows you to set up markers and ga tes for specific

measuremen

values, marker values, and gate values.

e panel consists of the Results window and the Auto Measure

ts. It also shows the measurement values that include current trace

34 RF and Microwave Power Sensors/Meters

Page 49

Pulse Profiling Application

Auto Measure Wi

of measurements based on the Measurement Trace window by clicking the

Start Measurement button. A toolbar also allows you to select Gates, Markers,

or Highlight functions; to select the percentage of h ighlight; to reset the

Measurement Trace window to include the entire Panoramic trace; and to zoom

in and out on the Measurement trace.

In addition to the gate measurements, the Auto Measurement feature performs

an On/Off Ratio measurement. This measurement returns the difference in dB

between th

pulse is off during the first complete cycle.

ndow. This window allows you to make a comprehensive list

e average power while the pulse is on to the average power while the

NOTE. The Auto Measurement feature requires at least two complete cycles of

the pulse to be viewable in the Measurement Trace window in order to make

accurate measurements.

Start Measurement. Click Start Measurement to capture the instantaneous

values shown above. The readings will not continuously update, but will make a

single sweep of the trace. You must click Start Measurement each time to update

the measured readings. A description of each measurement is shown at the bottom

of the pane when you click on the measurement label.

Copy Data. Click Copy Data to copy the measurement results to the clipboard

and then paste it to your document of choice.

RF and Microwave Power Sensors/Met ers 35

Page 50

Pulse Profiling Application

Customize the Display

The display is c

display using Microsoft drag and drop tools.

Moving menu tabs. You can rearrange the menus in the menu p anel. Just click

on the menu you want to move and then drag it the desired location in the menu

panel. When you release the mouse button, the menu will be in the new location.

Moving windows. The Panoramic Trace, Measurement Trace, Results, and Auto

Measure windows can be moved and placed anywhere on the display using the

docking popup or by clicking and dragging.

To activate the docking popup and move a window, do the following:

1. Click and hold on one of the four windows in the display.

2. Drag the window until you see the docking popup appear.

3. Place the window you are moving over one of the positions (top, bottom,

center, right, left) on the popup. This position represents how the window will

be docked on the display and that area of the display will become highlighted.

NOTE. You can also place a window anywhere on the display without using the

docking popup. Simply click and drag the window to the desired location and

then release the mouse button.

omposed of five movable windows that can be rearranged on the

Toolbar Functions

Main

4. Release the mouse button and the move will be completed.

The toolbar functions allow you to set the following parameters.

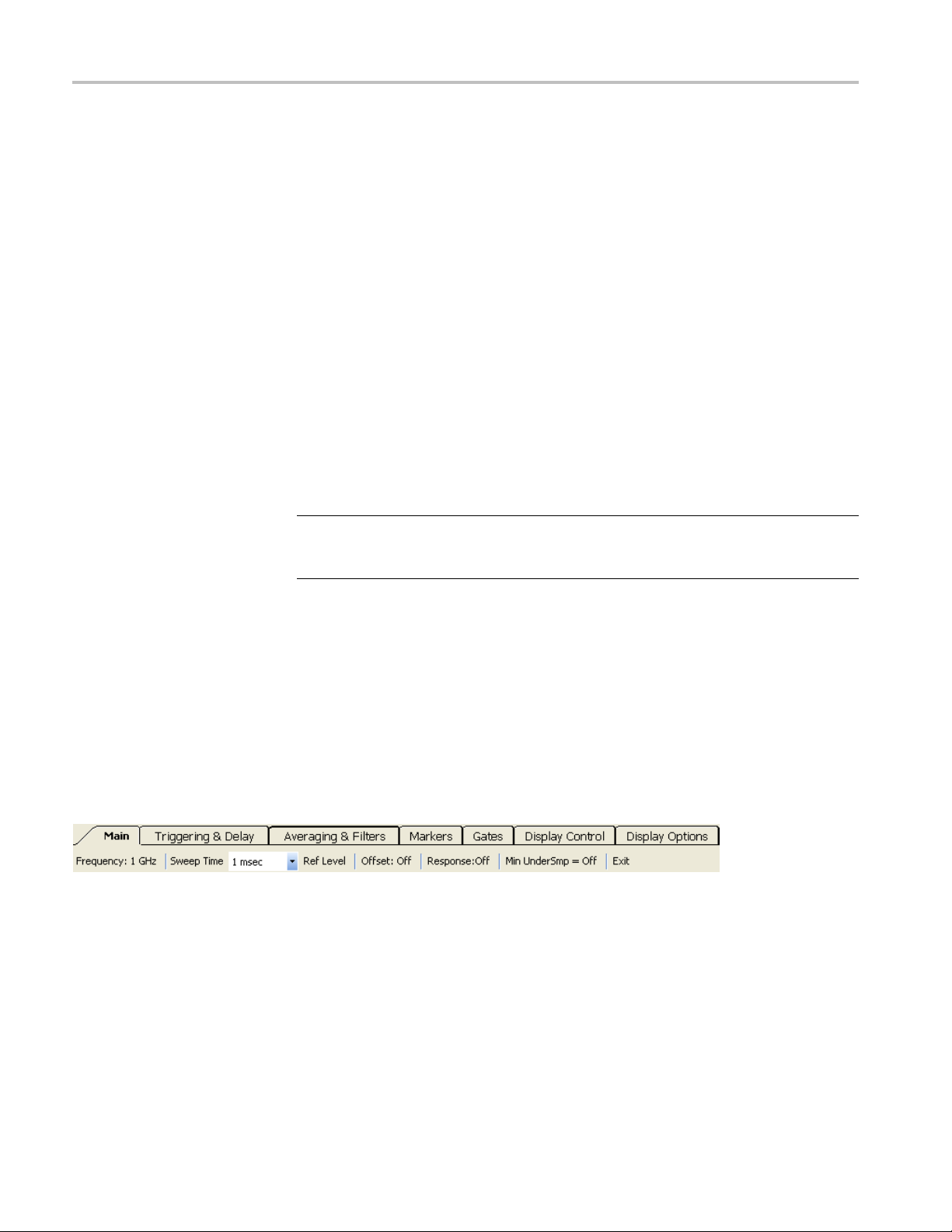

The Main toolbar allows setting of the measurement Frequency; Sweep Time;

Reference Level and Resolution; Offset and (frequency) Response.

Frequency. The frequency setting must match the signal carrier frequency to

achieve the most accurate measurements. Setting the frequency is essential to

making accurate measurements because readings are corrected based on frequency

(calibration factors). Significant errors can occur if you do not set the frequency

properly, especially at the upper end of the frequency range.

Sweep Time. The following table shows the relationship between sweep time,

sample rate, and total number of samples. Notice that the resolution of most

computer displays is limited to somewhere between 1000 and 2000 points.

36 RF and Microwave Power Sensors/Meters

Page 51

Pulse Profiling Application

However, the tr

ace data has much higher resolution. If you want to see more

detail on a 10,000 point trace, for example, you can use the zoom icons on the

Display Control toolbar. (See page 44, Zoom In and Out.)

Table 3: Sweep time values

Sweep time Time between samples Length of trace

10 μs 0.0208 μs 480 points

20 μs 0.0208 μs 960 points

50 μs 0.0208 μs 2400 points

100 μs 0.0208 μs 4800 points

200 μs 0.0208 μs 9600 points

500 μs0.05μs 10,000 points

1ms 0.1μs 10,000 points

2ms 0.2μs 10,000 points

5ms

10 ms 1.0 μs 10,000 points

20 ms 2.0 μs 10,000 points

50 ms 5.0 μs 10,000 points

100 ms 10.0 μs 10,000 points

200 ms 20.0 μs 10,000 points

500 ms 50.0 μs 10,000 points

1 s 100.0 μs 10,000 points

0.5 μs 10,000 points

Reference Level. The Reference Level allows you to change the maximum value

displayed in the Panoramic and Measurement windows. It also allows you to

change the vertical scale in the Measurement window.

The vertical scale setting only applies to the Measurement window.

NOTE. The reference level and resolution settings are display functions that

change the formatting of the data that is presented, whereas offset and response

modify the measured values.

Offset. This function applies a constant offset to all measured data. It shifts the

actual values of the measured data. Simple offsets can be useful, but they are

limited in that they are not sensitive to frequency. If there is a frequency sensitive

device in the measurement path, then every frequency change requires a change in

offset. In this case, the Response function may be more appropriate.

The Offset function must be enabled to affect measurements. The Offset

annunciator is visible above and to the right of the measurement trace when the

Offset function is enabled.

RF and Microwave Power Sensors/Met ers 37

Page 52

Pulse Profiling Application

Response. Use t

devices like directional couplers. The Response function allows you to enter a set

of amplitude and frequency pairs. As you change the frequency of measurement,

the application automatically adjusts the offset based on the frequency you

selected.

The Response function must be enabled to affect measurements. The Response

annunciator is visible above and to the right of the measurement trace when the

Response function is enabled.

Minimize Undersampling. For sweep times of 10 ms or less, equivalent-time

sampling (undersampling) is used to provide adequate time resolution and fill

the trace memory. The Minimize Undersampling function has no effect at these

sweep time settings.

For sweep times of 20 ms, 50 ms, and 100 ms, undersampling provides more

samples than are needed to fill the trace memory. When Minimize Undersampling

is turned off, samples are averaged together to fit into the 10,000 point trace. When

the Minimize Undersampling function is turned on, equivalent-time samples that

do not fit into the trace are not averaged, but are discarded. Activating this function

will tend to increase the noise on the trace, but it improves the ability to see peaks.

For sweep times of 200 ms or more, real-time sampling provides enough samples

to fill the trace memory and to give adequate time resolution. Undersampling is

not used and the Minimize Undersampling function has no effect at these sweep

settings.

he Response function for correcting measurements through

Triggering & Delay

NOTE. You can read more about sweep time values. (See Table 3.)

Exit. Select to exit the application.

The Triggering and Delay toolbar allows you to set trigger and delay parameters.

Trigger Source. You have three options for trigger source settings. All of

these options allow you to use positive or negative Edge triggering, as well as

Continuous or Single Sweep.

Internal Auto Level: The trigger is based on the input signal. As the input varies,

the auto trigger level will be adjusted accordingly. This trigger mode always

returns a trace. A trigger pulse is sent out the TTL trigger output each time a

sweep starts. If a signal is not present, then it will return a noise trace. This trigger

source is not recommended when peak input levels fall below approximately

-50 dBm. In these cases, use Internal Manual Level.

38 RF and Microwave Power Sensors/Meters

Page 53

Pulse Profiling Application

Internal Manua

based on the input signal as it crosses the level you s pecify. If you set the trigger

level too high, then you will not get a trace. Instead, you will get a “Trigger?”

message in the middle top of the Mea surement grid. This message indicates that a

trigger was not found. If the trigger is set too low, then the system will trigger on

noise. A trigger pulse is sent out the TTL trigger output each time a sweep starts.

External TTL: The instrument will take a measurement after it senses a transition

on the TTL trigger input (TI). To use this trigger function, connect an SMB

cable to a TTL trigger source. Use this capability to trigger on very low signal

levels approaching the noise floor of the instrument. For measuring very low

signal levels, use the Averagi

Filters.)

NOTE. An incoming pulse for an external TTL trigger must be on at least 0.20 μs

followed by at least 1 μs of off time for the sensor to properly trigger.

Trigger Level. Usethismenufunctiontosetthetrigger level when the trigger

source is set to Internal Manual Level.

Edge. Use this menu function to set the instrument to trigger on a positive or

negative edge.

l Level: You must set the trigger level manually. The trigger is

ng and Filters functions. (See page 40, Averaging &

Continuous. Use this menu function to set the instrument to continuously provide

a new trace with each new trigger event.

Single Sweep. Use this menu function to set the instrument for a single sweep.

The instrument will then wait for a trigger each time the Single button is clicked.

Single. This button is blue when Single Sweep trigger is active. Click this button

to initiate a trigger sequence.

Delay Trigger. Use this menu function to delay the beginning of a trace

triggereventforupto10ms. Thismaybeusedtocapturehighresolutiontraces

long after the trigger e vent.

Trigger Out. Use this menu function to enable the TTL trigger output (TO) signal

and invert it.

Timeout. Use this menu function to set a timeout period for an external trigger

input (up to 10 seconds). If a trigger event is not detected in the allotted time, the

system will time out and the Tr igge r? indicator w ill appear at the top center of

the Measurement Trace window.

NOTE. If the trigger timeout is set long, and triggers occur slowly, the meter

display will appear sluggish as the instrument waits for triggers.

from the

RF and Microwave Power Sensors/Met ers 39

Page 54

Pulse Profiling Application

Averaging & Filters

You can use aver

near the noise floor of the instrument. Increasing the number of averages

maintainswaveshapebutslowsdowntheupdaterateofthetrace. Alower

low-pass filter setting will provide faster trace updates, but results in a rounded

pulse shape with longer rise and fall times.

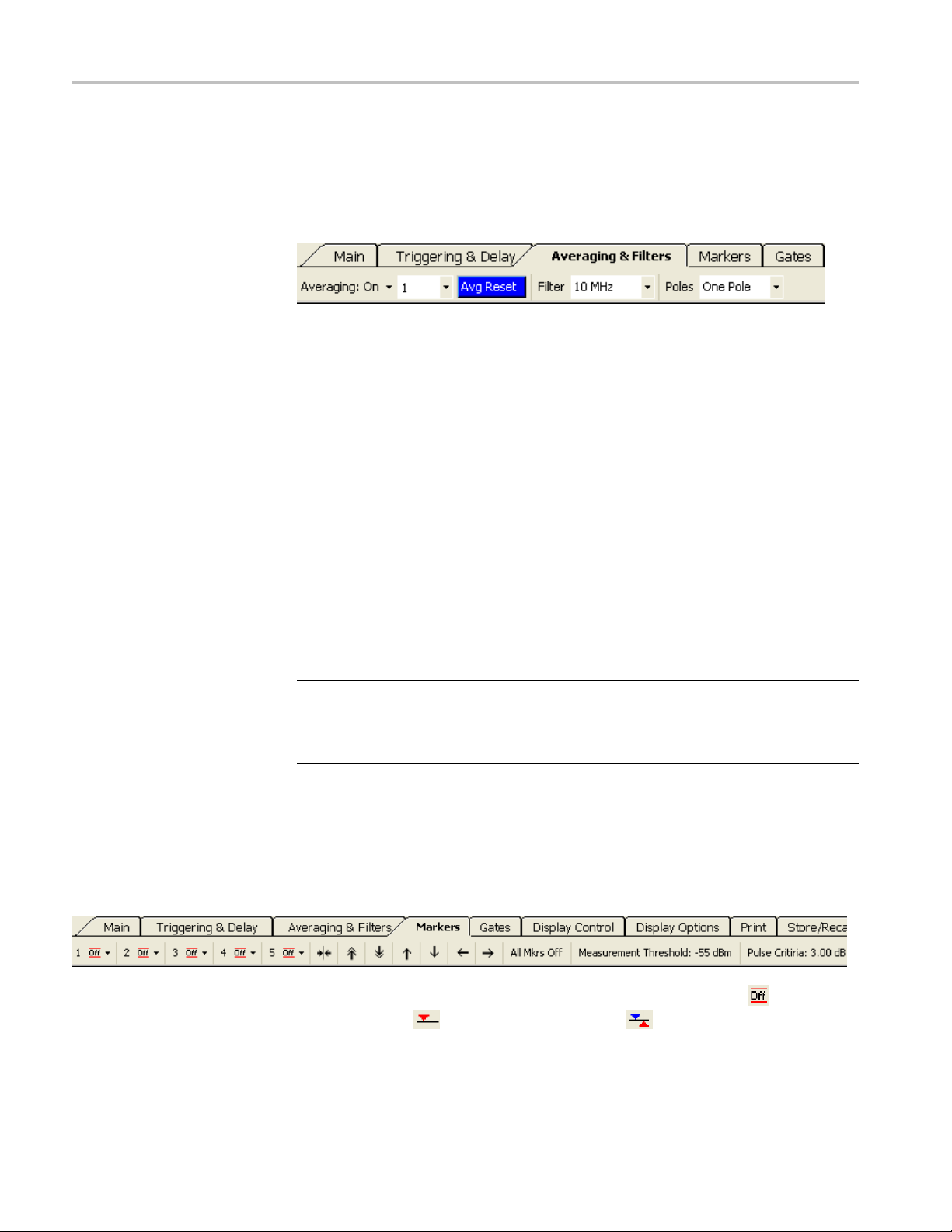

Averaging. Select to turn averaging on or off. When this function is turned on,

you can s elect the number of traces to be averaged from the drop down m enu. The

number of averages c an be set from 1 to 100. It takes 0.3 to 1.0 ms to collect

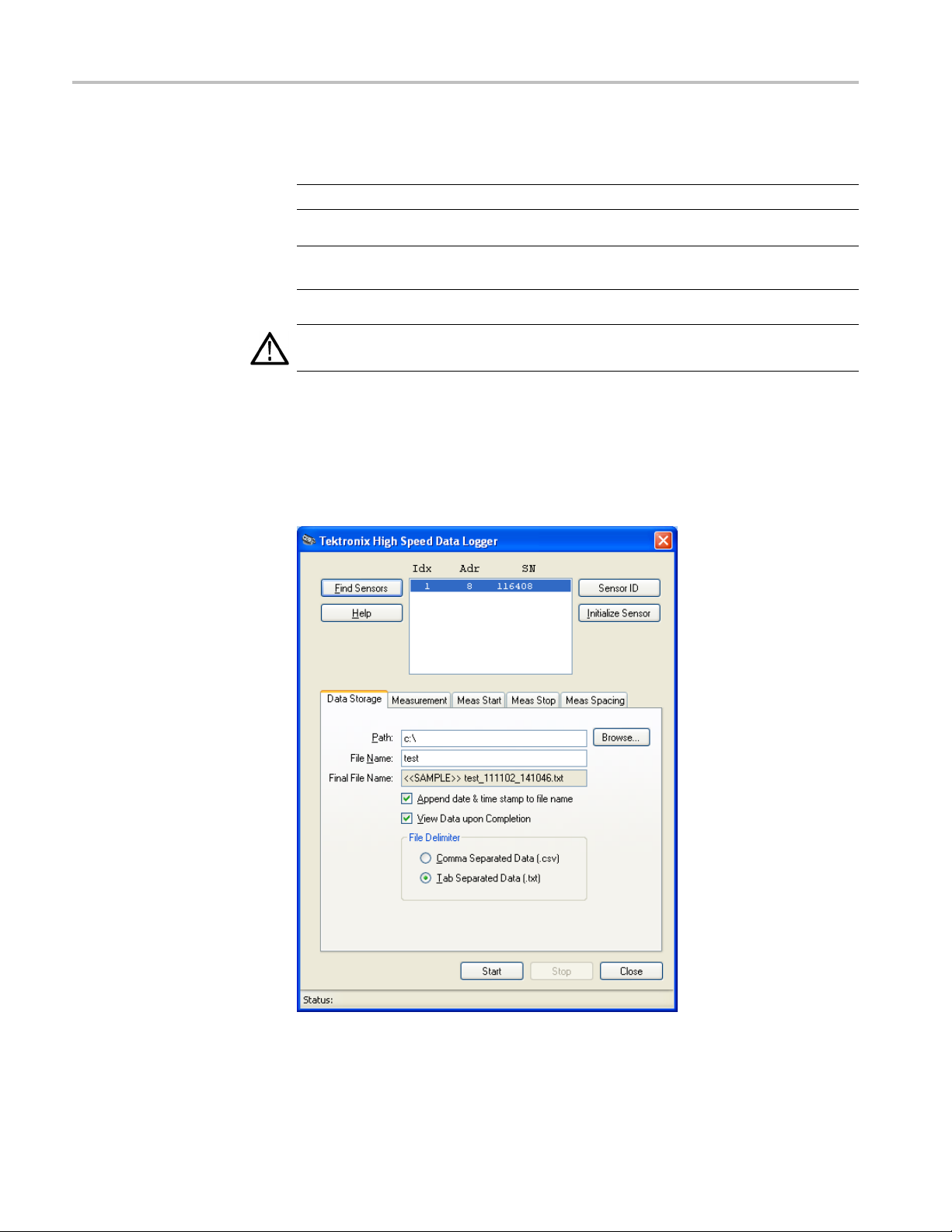

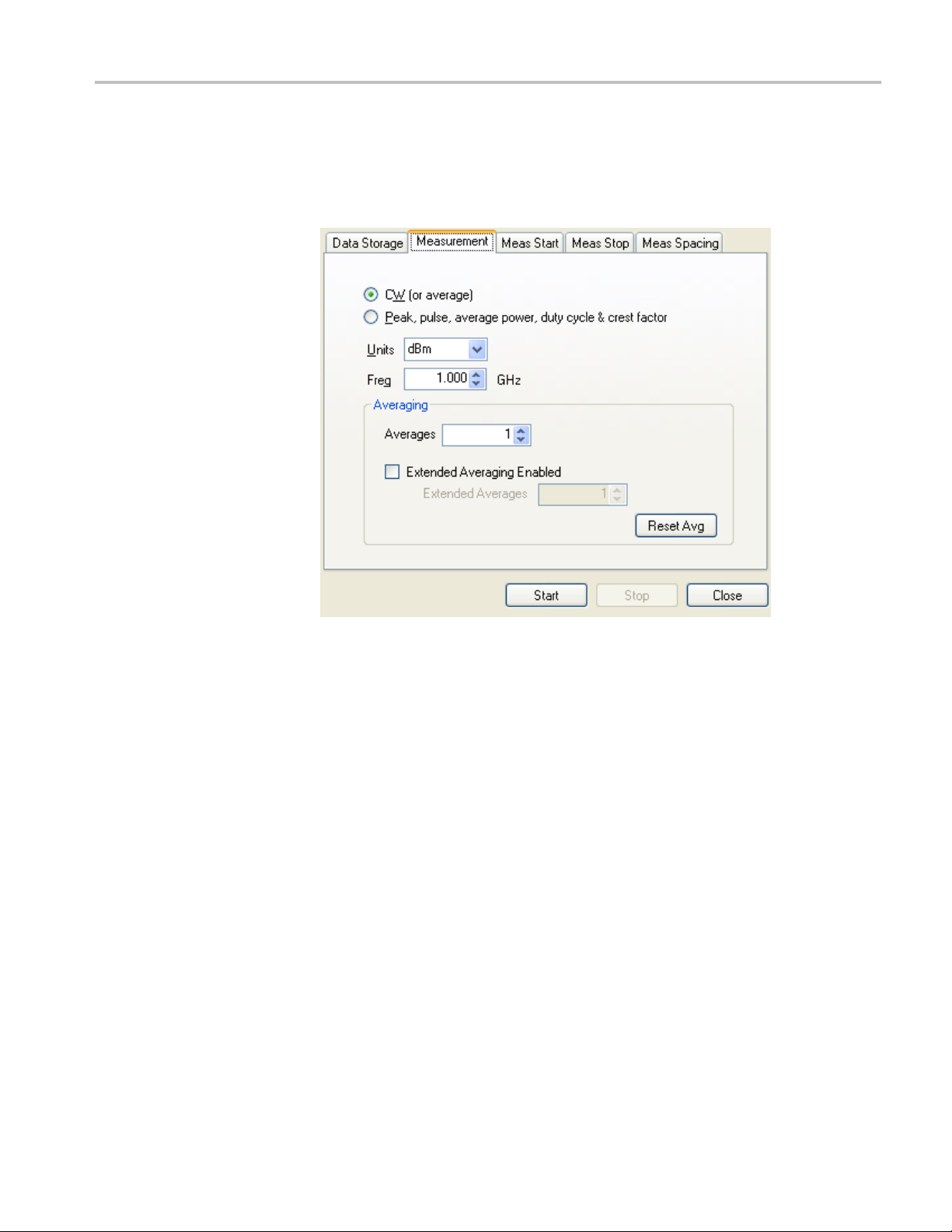

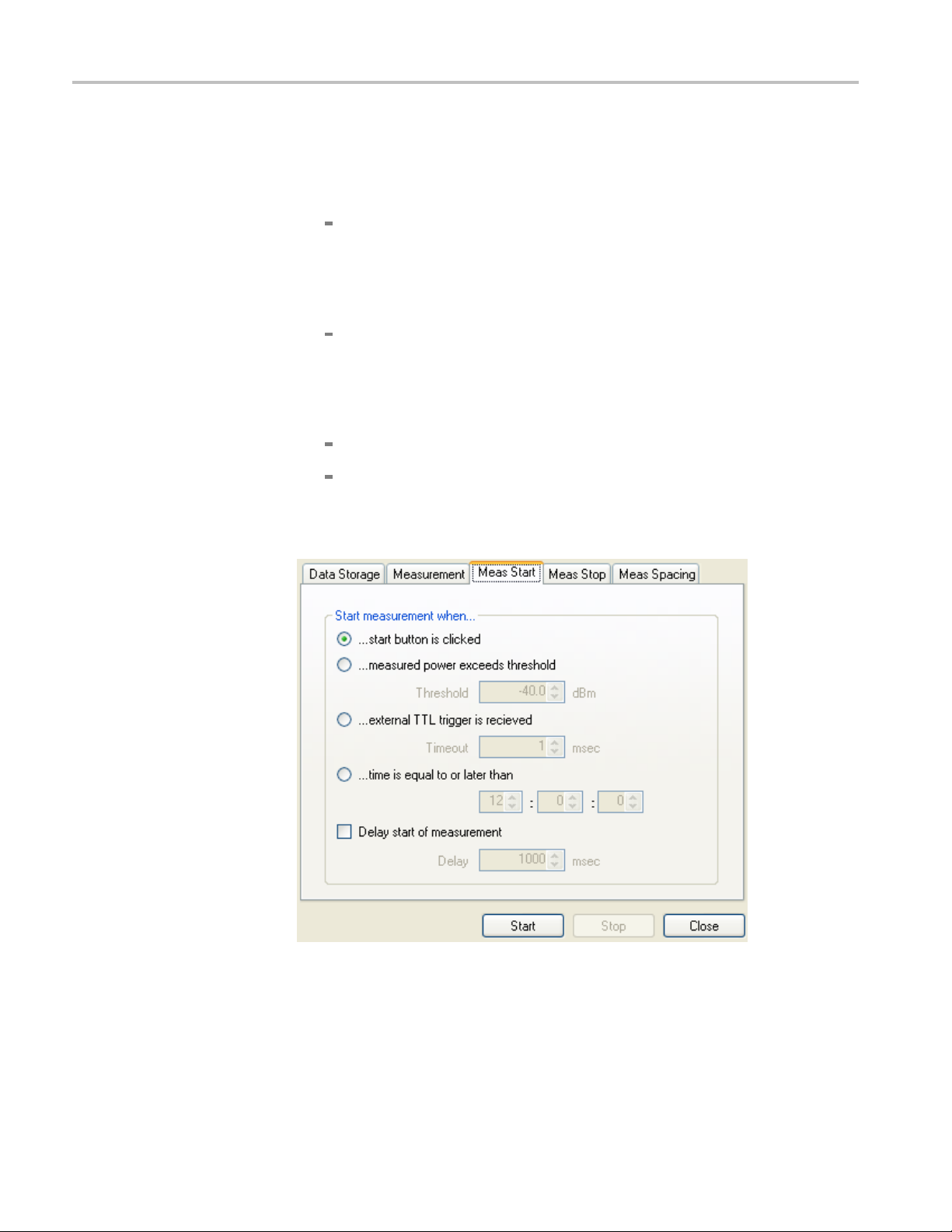

each trace.