Page 1

TEK

Part No. 070-8356-00

Product Group 3M

&

PS283

WARNING

The following servicing instructions

are for use by qualified service

personnel only. To avoid personal

injury, do not perform any servicing

unless you are qualified to do so.

Refer to the Safety Summary prior

to performing any service.

Please check for CHANGE INFORMATION

at the rear of this manual.

I

LABORATORY DC

POWER SUPPLY

Service Reference

First Printing JUL 1991

Revised AUG 1991

Tektronix

COMMTTCD

TO

EXEa_LB\CE

Page 2

Copyright©

publication may not be reproduced in any form without the written

permission of Tektronix, Inc.

1991

Tektronix, Inc. All rights

reserved.

Contents of this

Products of

and foreign patents issued and pending.

TEKTRONIX, TEK, SCOPE-MOBILE, and W2S are registered

trademarks of Tektronix, Inc.

Printed in

reserved.

Tektronix,

U.S.A.

Inc., and its subsidiaries are covered by U.S.

Specification and price change privileges are

INSTRUMENT SERIAL NUMBERS

Each instrument

stamped on the chassis. The first two digits designate the country of

manufacture. The last five digits

each instrument. The country of manufacture is identified as follows:

B000000 Tektronix, Inc., Beaverton, Oregon,

E200000 Tektronix United Kingdom, Ltd., Marlow

has a

serial number

of

the serial number are unique

on a

panel insert,

U.S.A.

tag, or

to

G100000 Tektronix Guernsey, Ltd., Channel Islands

HKOOOOO Hong Kong

H700000 Tektronix Holland, NV, Heerenveen,

The Netherlands

JPOOOOO Sony/Tektronix, Japan

TWOOOOO Taiwan

Page 3

WBWtfitiAnnnrinn contents

Specifications

Operating Information

Operators and Service Safety Summary

Symbols and Terms

Specific Precautions

Product Description

General

Specifications

General Operating Instructions

Front Panel

Rear Panel

- -|_i

2-1

The Variable Power Supplies

The Fixed Voltage Power Supply

2-4

xi

xii

1.1

1_2

2-1

2-2

X

2-3

i

Theory

of

Operation

Theory

of

Operation

General

Circuit Description

3.1

Master Voltage Output

Slave Voltage Output

5 V Fixed Voltage Output

3.1

3-1

3-1

3-2

3-4

PS280 & PS283 Laboratory DC Power Supply Module-Level Service Manual

REV AUG 1991

Page 4

Performance Verification

Adjustment

Preparation 4-1

Requirements for Performance 4-1

Warm-up Period 4-1

Access 4-1

Test Equipment 4-1

Equipment Required 4-2

Performance Tests 4-3

Constant Current Load Regulation 4-3

Constant Current Ripple and Noise 4-5

Constant Voltage Regulation 4-7

Preparation 5-1

Requirements for Performance 5-1

Personnel 5-1

Warm-up Period 5-1

Access 5-1

Test Equipment 5-1

Maintenance

Adjustment Procedures 5-3

Independent Mode 5-3

Series Tracking Mode . «. 5-5

Parallel Tracking Mode 5-6

5 V Fixed 5-7

Information 6-1

Helpful Procedures 6-1

Preventing ESD 6-1

Inspection and Cleaning 6-5

General Care 6-5

Inspection and Cleaning Procedures 6-5

Inspect Exterior 6-5

Cleaning Procedure - Exterior 6-6

Inspect Interior 6-6

Cleaning Procedure — Interior 6-7

Lubrication 6-8

REV AUG

1991

Contents

Page 5

Options

Removal and Installation Procedures 6-9

Preparation - Please Read 6-9

List of Modules 6-9

General Instructions 6-10

Top Cover Removal 6-10

Slave Circuit Board Removal 6-12

Fuse Circuit Board Removal 6-13

AC Selector Circuit Board Removal 6-14

Master Circuit Board Removal 6-16

Front Panel Display Circuit Boards Assembly Removal 6-17

Front Panel Controls Circuit Board Removal 6-19

Output Connectors Circuit Board Removal 6-21

Power Transistor Circuit Boards Removal 6-23

Options and Accessories 7-1

Power Cord Options 7-1

Standard Accessories 7-1

Optional Accessories 7-1

Parts List

Diagrams

Index

Parts List 8-1

Parts Ordering Information 8-1

Module Replacement 8-1

Using the Parts List 8-2

Item Names 8-2

Indentation System 8-2

Abbreviations 8-2

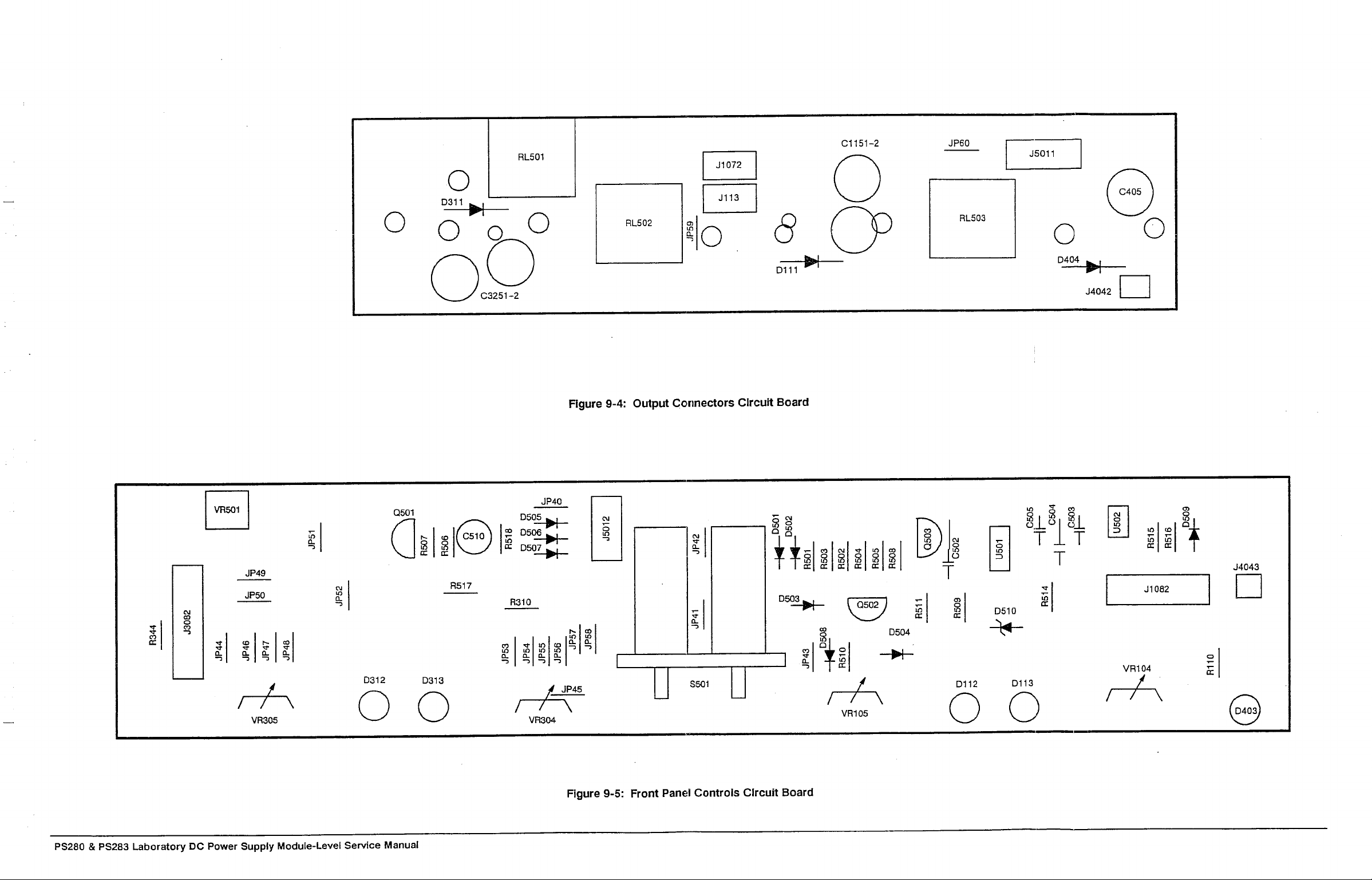

Diagrams and Circuit Board Illustrations 9.1

Component Values g_1

PS280 & PS283 Laboratory DC Power Supply Module-Level Service Manual

REVAUG 1991

Page 6

WM§$XfX¥\rUlJ List of Illustrations

Figure

2-1:

PS280 or PS283 Front Panel 2-1

Figure 2-2: Variable Power Supply Controls 2-2

Figure 2-3: Fixed Power Supply Controls 2-3

Figure 2-4: PS280 or PS283 Rear Panel 2-4

Figure

3-1:

PS280 or PS283 Variable Outputs Block Diagram 3-3

Figure 3-2: PS280 or PS283 5 V Block Diagram 3-4

Figure

4-1:

Constant Current Test Setup 4-3

Figure 4-2: Constant Current Ripple and Noise Test Setup 4-5

Figure 4-3: Constant Voltage Test Setup 4-7

Figure

5-1:

Master Circuit Board Adjustment Locations 5-8

Figure 5-2: Display Assembly Circuit Board Adjustment Locations ... 5-9

Figure 5-3: Front Panel Controls Circuit Board Adjustment Locations . 5-9

Figure

6-1:

Top Cover Removal 6-11

Figure 6-2: Slave and Fuse Circuit Board Removal 6-13

Figure 6r3: AC Selector and Master Circuit Board Removal 6-15

Figure 6^4: Front Panel Display Assembly Removal 6-18

Figure 6-5: Front Panel Controls Assembly 6-20

Figure 6-6: Output Connectors Circuit Board

and Power Switch Location 6-22

Figure 6-7: Power Transistor Circuit Boards Location 6-23

PS280 & PS283

Laboratory

DC

Power Supply

Figure

8-1:

Exploded View A 8-8

Figure 8-2: Exploded View B 8-16

Module-Level Service Manual REV AUG 1991

vii

Page 7

WMMfflfWinnnnj ust

Table 1-1: Operational Characteristics 1-2

Table 1-2: Physical Characteristics 1.3

Table 1-3: Environmental Characteristics 1-3

Table 1-4: Electrical Characteristics 1-3

Table

4-1:

Test Equipment 4-2

Table 4-2: Load Resistor Values for Current Checks 4-4

Table 4-3: Load Resistor Values for Ripple Checks 4-6

Table 4-4: Load Resistor Values for Voltage Checks 4-8

Table

6-1:

Relative Susceptibility to Static-Discharge Damage 6-3

Table 6-2: External Inspection Check List 6-6

Table 6-3: Internal Inspection Check List 6-7

Table 6-4: Tools Required for Module Removal 6-10

of Tables

PS280 & PS2S3 Laboratory DC Power Supply Module-Level Service Manual ;

x

Page 8

Operators and Service Safety Summary

Please take a moment to review these safety precautions. They are provided

for your protection and to prevent damage to the power supply. This safety

information applies to all operators and service personnel.

Symbols and Terms

These two terms

• l^°!L\ statements identify conditions or practices that could result in

damage to the equipment or other property.

ttwwws

•

I

personal injury or loss of life.

These two terms appear on equipment:

•

CAUTION

one reads the marking, or a hazard to property including the equipment

•

DANGER

reads the marking.

This symbol appears in manuals:

appear

* statements identify conditions or practices that could result in

indicates a personal injury hazard not immediately accessible as

indicates a personal injury hazard immediately accessible as one

in

manuals:

®

Static-Sensitive Devices

These symbols appear on equipment:

DANGER

High Voltage

PS280 & F32S3 Laboratory DC Power Supply Module-Level Service Manual xl

Protective

ground (earth)

terminal

ATTENTION

manual

Page 9

Specific Precautions

Observe all of the following precautions to ensure your personal safety and to

prevent damage to either the PS280 or PS283Laboratory DC Power Supply or

equipment connected to it.

Do Not Perform Service While Alone

Do not perform internal service or adjustment of this product unless another

person capable of rendering first aid and resuscitation is present.

Use Care When Servicing With Power On

Dangerous voltages exist at several points in this product. To avoid personal

injury, do not touch exposed connections or components while power is on.

Disconnect power before removing protective panels, soldering, or replacing

components.

Power Source

The PS280 or PS283 Laboratory DC Power Supply is intended to operate from

a power source that will not apply more than 250 V rms between the supply

conductors or between either supply conductor and ground. A protective

ground connection, through the grounding conductor in the power

essential for safe system operation.

cord,

is

Grounding the power supply

The PS280 or PS283 Laboratory DC Power Supply is grounded through the

power

cord.

To avoid electric shock, plug the power cord into a properly wired

receptacle where earth ground has been verified by a qualified service person.

Do this before making connections to the output terminals of the Laboratory DC

Power Supply. -

Without the protective ground connection, all parts of the PS280 or PS283

Laboratory DC Power Supply are potential shock hazards. This includes knobs

and controls that may appear to be insulators.

Use the Proper Power Cord

Use only the power cord and connector specified for your product. Use only a

power cord that is in good condition.

Use the Proper Fuse

To avoid fire hazard, use only the fuse specified in the parts list for your

uct, and which is identical in type, voltage rating, and current rating.

prod-

REV AUG 1991

Operators and Service Safety Summary

Page 10

Do Not Remove Covers or Panels

To avoid personal injury, do not operate the PS280 or PS283 Laboratory DC

Power Supply without the panels or covers.

Do Not Operate in Explosive Atmospheres

ThePS280 or PS283 Laboratory DC Power Supply provides no explosion

protection from static discharges or arcing components. Do not operate in an

atmosphere of explosive gasses.

PS280 & PS283 Laboratory DC Power Supply Module-Level Service Manual

xll!

Page 11

BmMfJWnr Specifications

Page 12

#%f%M_rLTLn Product Description

This subsection begins with a general description of the PS280 or PS283

Power Supply. The Specifications subsection immediately follows.

General

The Tektronix PS280 or PS283 Laboratory DC Power Supply is a multifunction

bench or portable instrument. This regulated power supply provides a fixed 5 V

output for powering logic circuits and two variable outputs for a wide variety of

test and experimental uses. The PS280 or PS283 can be used in any application where three independent power supplies housed in a single package

represent a convenience.

The PS280 or PS283 contains two identical, independently adjustable DC

power supplies that you can vary from 0 to 30

variable power supplies varies from 0 to 2 A. The current on the PS283

able power supplies varies from 0 to 1 A. In all other respects the instruments

are identical. Unless otherwise noted, descriptions and procedures in this

manual apply to both instruments.

Front panel switches select one of three modes of operation: independent,

series, or parallel. In the independent mode, the output voltage and current of

each supply can be controlled independently. In the two tracking modes, the

variable outputs are connected either in series or in parallel. Under these

circumstances, the controls of the master power supply adjust the voltages or

current of both power supplies. Series mode allows the power supplies to be

varied from 0 to 60 V at 0 to 2 A for the PS280, or 0 to 1 A for the PS283.

Parallel mode allows the power supplies to be varied from 0 to 4 A for the

PS280 at 0 to 30

V,

or from 0 to 2 A at 0 to 30 V for the PS283.

V.

The current on the PS280

vari-

PS280 & PS283 Laboratory DC Power Supply Module-Level Service Manual

REV

AUG 1991

f-f

Page 13

Product Description

Specifications

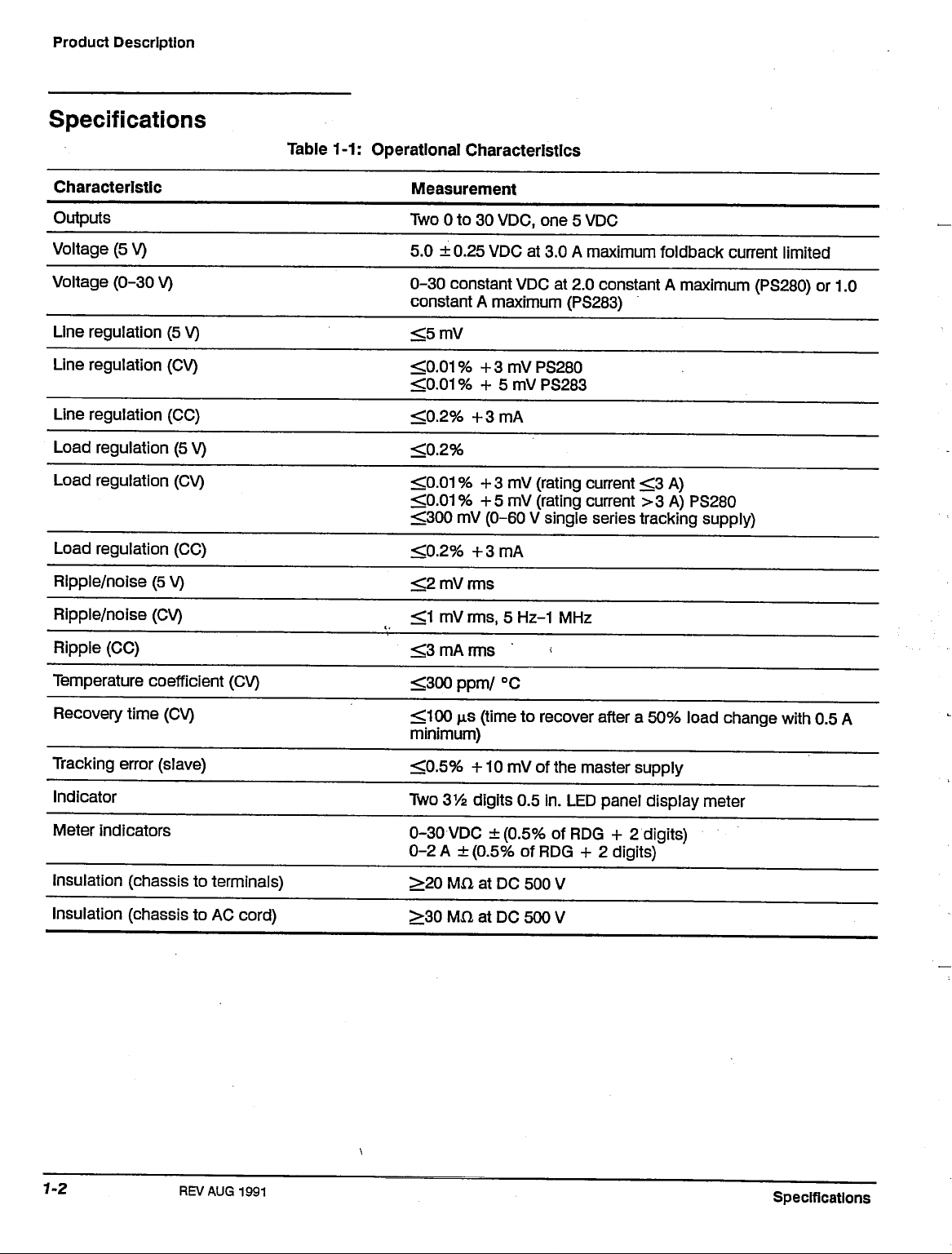

Table 1-1: Operational Characteristics

Characteristic

Outputs

Voltage (5 V)

Voltage (0-30 V)

Line regulation (5 V)

Line regulation (CV)

Line regulation (CC)

Load regulation (5 V)

Load regulation (CV)

Load regulation (CC)

Ripple/noise (5 V)

Ripple/noise (CV)

Ripple (CC)

Measurement

Two 0 to 30

5.0 ±0.25 VDC at 3.0 A maximum foldback current limited

0-30 constant VDC at 2.0 constant A maximum (PS280) or 1.0

constant A maximum (PS283)

<5mV

<0.01%

<0.01%

<0.2%

<0.2%

<0.01 % + 3 mV (rating current <3 A)

<0.01 % +5 mV (rating current >3 A) PS280

<300 mV (0-60 V single series tracking supply)

<0.2%

<2 mV rms

<1 mV

<3 mA rms

VDC,

one 5 VDC

+3mVPS280

+ 5 mV PS283

+3mA

+3mA

rms,

5 Hz-1 MHz

Temperature coefficient (CV)

Recovery time (CV)

Tracking error (slave)

Indicator

Meter indicators

Insulation (chassis to terminals)

Insulation (chassis to AC cord)

<300 ppm/ °C

<100 p.s (time to recover after a 50% load change with 0.5 A

minimum)

<0.5%

-f-10 mV of the master supply

Two 31/2 digits 0.5 in. LED panel display meter

0-30 VDC ±(0.5% of RDG + 2 digits)

0-2 A ±(0.5% of RDG + 2 digits)

>20 MH at DC 500 V

>30 MXl at DC 500 V

REVAUG 1991

Specifications

Page 14

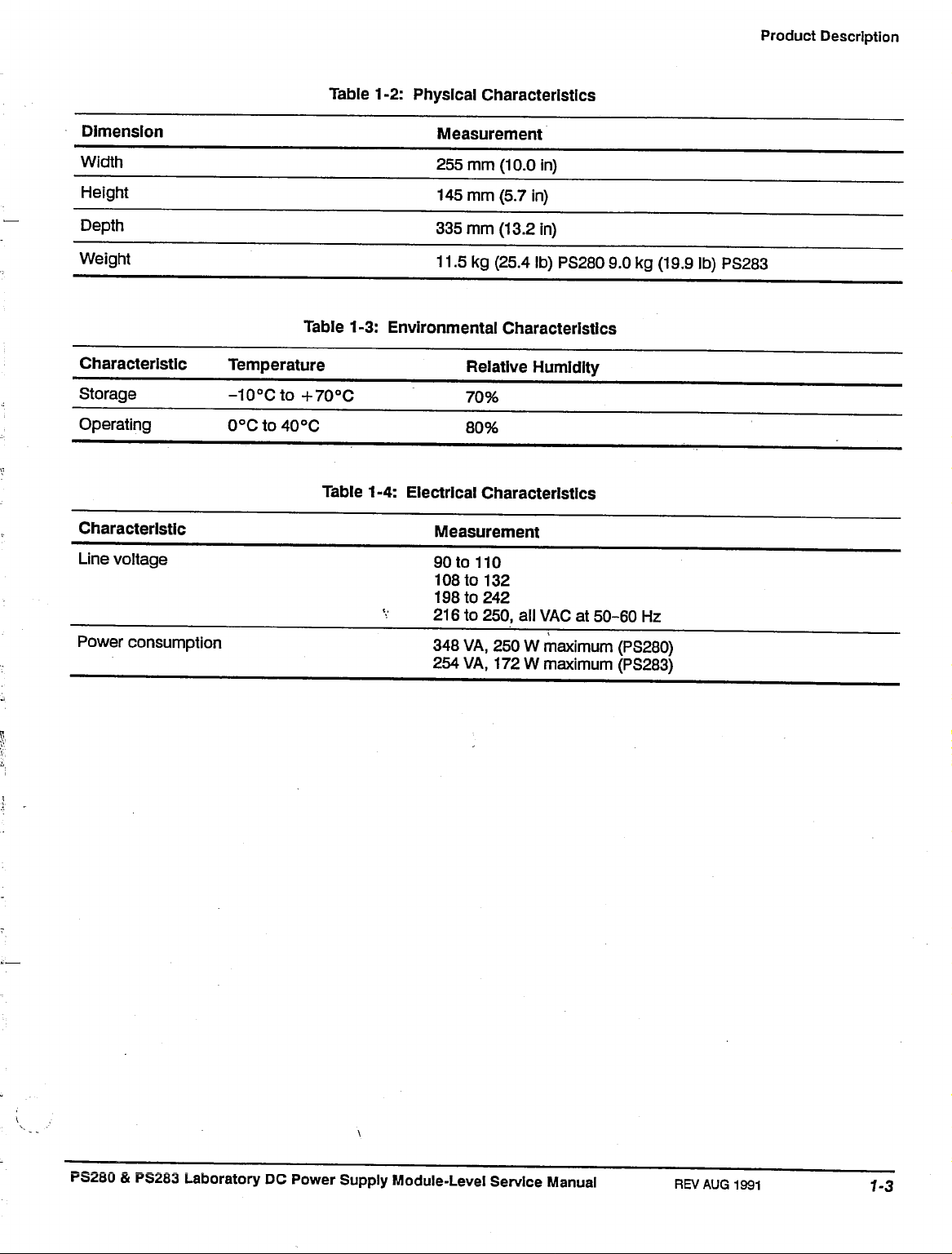

Table 1-2: Physical Characteristics

Product Description

Dimension

Width

Height

Depth

Weight

Characteristic

Storage

Operating

Characteristic

Line voltage

Power consumption

Measurement

255 mm (10.0 in)

145 mm (5.7 in)

335 mm (13.2 in)

11.5 kg (25.4 Ib) PS280 9.0 kg (19.9 Ib) PS283

Table 1-3: Environmental Characteristics

Temperature Relative Humidity

-10°Cto+70°C 70%

0°C to 40 °C 80%

Table 1-4: Electrical Characteristics

Measurement

90 to 110

108 to 132

198 to 242

216 to 250, all VAC at 50-60 Hz

348 VA, 250 W maximum (PS280)

254 VA, 172 W maximum (PS283)

PS2S0 & P5283 Laboratory DC Power Supply Module-Level Service Manual

REV AUG

1991

Page 15

IHF LTOperating Information

Page 16

WWXtX General Operating Instructions

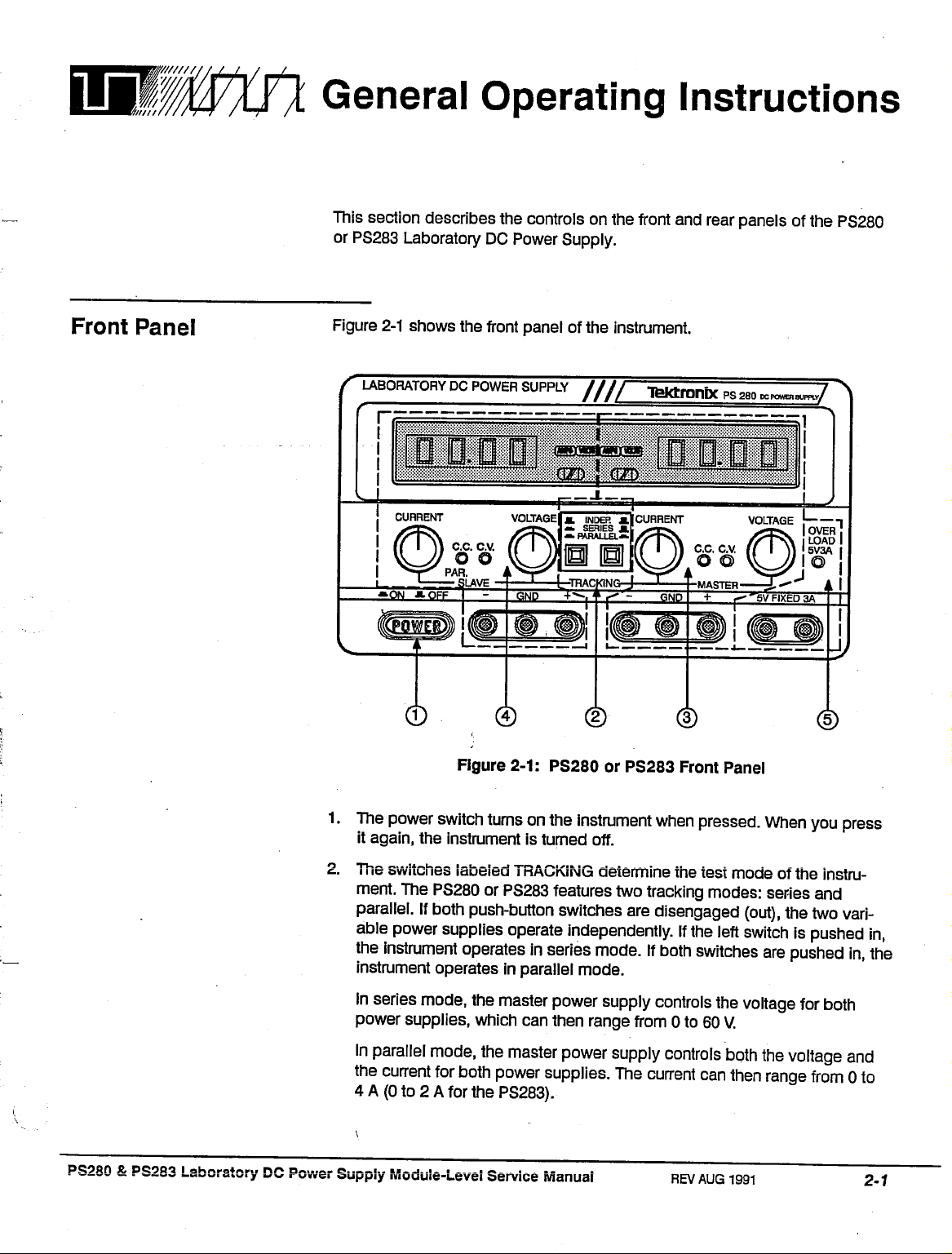

Front Panel

This section describes the controls on the front and rear panels of the PS280

or PS283 Laboratory DC Power Supply.

Figure

2-1

shows the front panel of the instrument.

LABORATORY

1.

The power switch turns on the instrument when pressed. When you press

it again, the instrument is turned off.

DC POWER SUPPLY

Figure

2-1:

PS280 or PS283 Front Panel

//// TWCmniX

PS 280

CC POWER

SUPPLY/

2.

The switches labeled TRACKING determine the test mode of the instru-

ment. The PS280 or PS283 features two tracking modes: series and

parallel.

able power supplies operate independently. If the left switch is pushed in,

the instrument operates in series mode. If both switches are pushed in, the

instrument operates in parallel mode.

In series mode, the master power supply controls the voltage for both

power supplies, which can then range from 0 to 60 V.

In parallel mode, the master power supply controls both the voltage and

the current for both power supplies. The current can then range from 0 to

4A(0to2AforthePS283).

PS2S0 & PS283 Laboratory DC Power Supply Module-Level Service Manual

If both push-button switches are disengaged (out), the two

REV AUG

vari-

1991

Page 17

General Operating Instructions

3. These controls affect the right variable power supply. If the instrument is in

a tracking mode, the right power supply is the master. In a tracking mode,

either or both of the control knobs can affect both variable power supplies.

4.

These controls affect the left variable power supply. If the instrument is in a

tracking mode, the left power supply is the slave. In a tracking mode,

either or both of the control knobs have no effect.

5. These controls affect the fixed 5 V power supply.

The Variable Power Supplies

Figure 2-2 shows the controls for the master variable power supply.

CURRENT

VOLTAGE

Figure 2-2: Variable Power Supply Controls

1.

The output terminals for the power supply allow you to plug in the test

leads.

The red one on the right is the positive polarity output terminal. It is

indicated by a + sign above it.

The black one on the left is the negative polarity output terminal. It is

indicated by a - sign above it.

The green one in the middle is the earth and chassis ground.

2.

The voltage control knob allows you to set the output voltage for the

power supply.

REV AUG

1991

3. The current control knob allows you to set the output current for the power

supply.

4.

If the C.V. light is lighted, the power supply is producing a constant volt-

age.

If the C.C. light is lighted, the power supply is producing a constant

current.

Operating Information

Page 18

General Operating Instructions

5. The LED display lights when the instrument is turned on. The numbers

indicate the voltage or current produced by the variable power supply.

6. The AMPS/VOLTS meter selection switch determines whether the LED

display shows the current or the voltage. If the switch is pushed to the left,

the display shows the current. If the switch is pushed to the right, the

display shows the voltage.

The meter selection switch is to the right of the corresponding display for the

slave variable power supply. All other controls are the same for both variable

power supplies.

The Fixed Voltage Power Supply

Figure 2-3 shows the controls for the fixed voltage power supply.

5V FIXED 3A

Figure 2-3: Fixed Power Supply Controls

1.

The output terminals for the power supply allow you to plug in the test

leads.

The red one on the right is the positive polarity output terminal. The

black one on the left is the negative polarity output terminal.

2.

The overload indicator lights when the current on the 5 V power supply

becomes too large.

PS280 & PS2S3 Laboratory DC Power Supply Module-Level Service Manual

REV

AUG 1991

2-3

Page 19

General Operating Instructions

Rear Panel

Figure

2-4

shows the rear panel

of

the instrument.

Figure 2-4: PS280

1.

These two switches allow you

voltage. Push the top switch

100

to

120

V;

push

it to

the right

•gggss

1

^

S

TEOTRONKINC,

BEAVEHTON.,OH,U.SA

1UKXTAIWAMJI.0.C

or

PS283 Rear Panel

to

set the instrument for the correct line

to

the left

if

the line voltage

If

the line voltage

is in

^

A©

s

is in

the range

y

the range

of

220

of

to

The bottom switch determines whether the line voltage

high end

the low end

voltage

2.

This

holder to ensure that you are using the correct fuse. This

change the fuse.

3. This

of

the voltage range. Push

of

the range-100

is at

the high end

is

the fuse holder. Pull the middle tab down and out

is

the receptacle for the power

of

the

or

220

range

it to

V;

-120

cord.

the left

push

or

it to

is

In the low or the

if

your line voltage

the right

240 V.

if

to

open the fuse

is

also how you

is at

your line

Operating Information

Page 20

BBSftXfTTheory of Operation

Page 21

WMSPXfXVtTirL

Theory

of Operation

General

Circuit Description

The PS280 or PS283 Laboratory DC Power Supply consists of two variable

output supplies and one 5 V fixed output. The circuit elements and their func-

tions are described in the Circuit Description, using the Block Diagram as an

aid in following the circuit description.

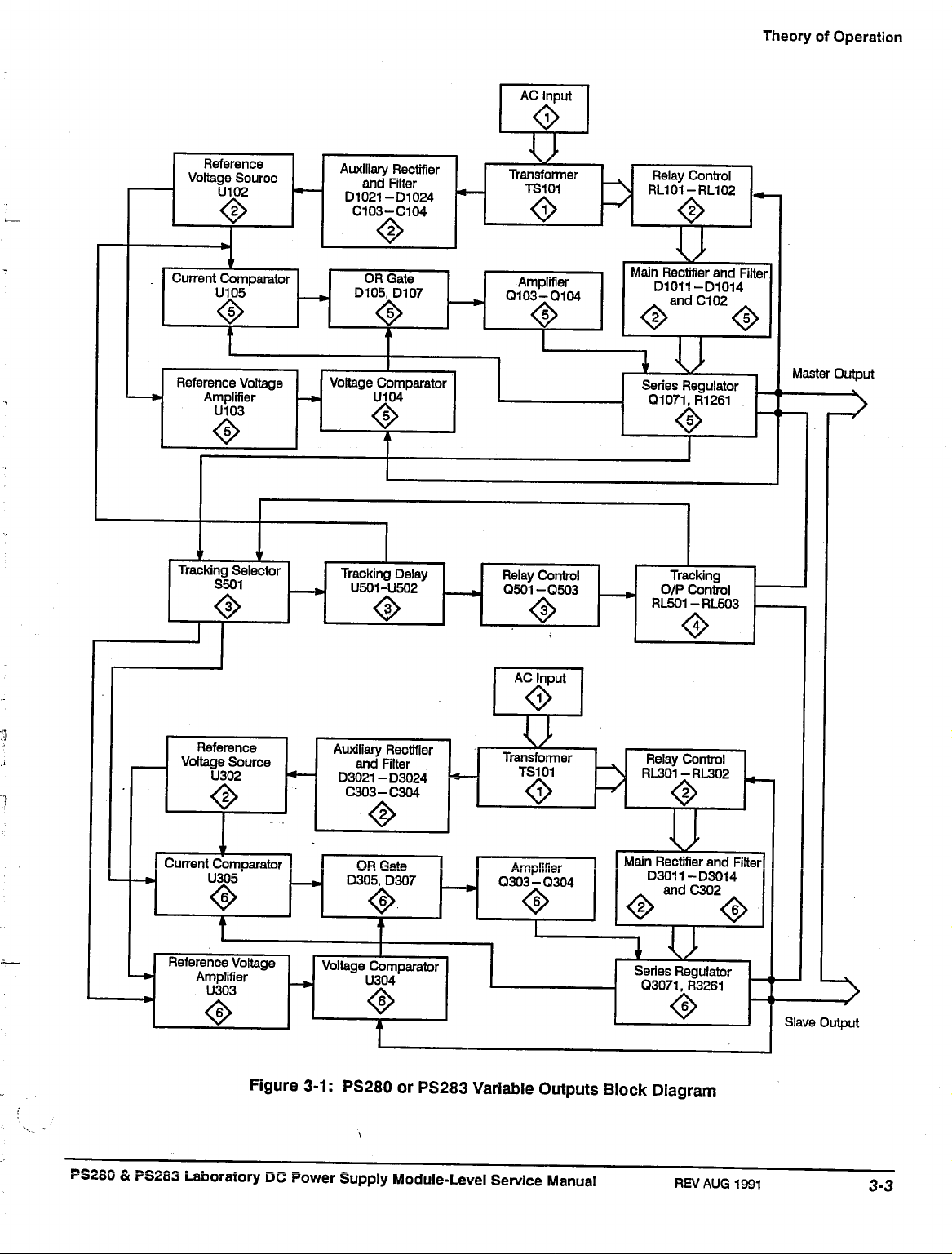

The detailed circuit description uses the block diagram, Figure

for the circuit description. The Block Diagram contains both the circuit component reference designators and lists the appropriate schematic on which they

can be found.

3-1

as a guide

Master Voltage Output

Single phase input power is applied to transformer

The outputs from transformer

relays

RL101

required from the Series Regulator by providing varying voltages to the Main

Rectifier circuit, depending on the output requirements.

The Main Rectifier circuit consists of diodes D1011 through D1014 that form a

full wave bridge rectifier. The output from the bridge rectifier is filtered by

capacitor

circuit.

and RL102. The relay control circuit limits the power dissipation

C102.

The filtered output voltage is applied to the Series Regulator

TS101

are applied to the Main Rectifier circuit by

TS101

through the AC input

The Series Regulator circuit consists mainly of

a regulated voltage to the Laboratory DC Power Supply Master output.

The Auxiliary Rectifier circuit consists of diodes 01021 through D1024 that

form a full wave bridge rectifier. The bias voltage from the bridge rectifier is

filtered by capacitors C103 and C104. This bias voltage is then applied to the

Reference Voltage circuit.

The Reference Voltage circuit consists of

ence circuit provides a regulated +15 V and -15 V to be used by the Current

Comparator circuit and the Reference Voltage Amplifier circuit.

The Current Comparator circuit, consisting of U105, limits the output current of

the Series Regulator circuit through OR gate and Amplifier circuit consisting of

D107,

and Q103 and Q104. Master CURRENT control, VR105, sets the maxi-

mum output current level.

P3280 & PS263 Laboratory DC Power Supply Module-Level Service Manual

U101,

Q1071

Q101,

REV AUG

and

R1261,

and Q102. This Refer-

1991

that deliver

Page 22

Theory of Operation

The Reference Voltage Amplifier circuit consists mainly of U103, and the

Voltage Comparator circuit consists mainly of U104. U104 compares the

voltage from the Reference Voltage Amplifier with feedback from the output

voltage and, through diode D105 and the amplifier circuit of Q103 and Q104,

provides a calibrated output voltage.

The Tracking Selector switches (S501A and S501B), along with the Tracking

Delay circuit (U501 and U502), Relay Control circuit

and the Tracking Relays

(RL501,

RL502, and RL503) set the configuration of

(Q501,

Q502, and Q503),

the Master and Slave outputs.

The TRACKING Mode Switches set the Laboratory DC Power Supply in one of

three modes: INDEPendent Mode, SERIES tracking mode, or PARALLEL

mode.

The on/off conditions of relays

RL501,

RL502, and RL503 are shown

below, according to the operating mode selected.

Tracking Operation

Series Tracking

Parallel Tracking

Independent O/P

Off

On

Off

On

On

Off

Off

On

Off

When in the SERIES Tracking mode, The Master negative output is shorted to

the Slave positive output. Also, the Master output voltage provides the voltage

reference for the Reference Voltage Amplifier circuit, U303.

When in the PARALLEL Tracking mode, both the negative and positive outputs

from the Master outputs are shorted to the negative and positive outputs of the

Slave outputs. A reference voltage for Current Comparator U305 is provided

through R1261 from the Master supply circuit.

U501 and U502 are used to protect the Laboratory DC Power Supply from

instant high voltage/current during the switching time of the relay contacts.

Slave Voltage Output

The Slave output circuitry performs the same as described for the Master

Voltage output. The circuits are the same except for the component names.

Refer to the block diagram for appropriate component names of the Slave

output circuit.

REV

3-2

AUG1991

Theory of Operation

Page 23

AC Input

Theory

of

Operation

Reference

Voltage Source

<2>

Current Comparator

Reference Voltage

Amplifier

Tracking Selector

Auxiliary Rectifier

and Filter

D1021-D1024

C103-C104

D105,

D107

Voltage Comparator

Tracking Delay

U501-U502

u

Transformer

O

Amplifier

Q103-Q104

Relay Control

Q501-Q503

Relay Control

RL101-RL102

JJ

Main Rectifier and Filter

D1011-D1014

u

Series Regulator

Q1071.R1261

Tracking

O/P Control

RL501-RL503

Master Output

Reference

Voltage Source

Current Comparator

Reference Voltage

Amplifier

Figure

Auxiliary Rectifier

and Filter

D3021-D3024

C303-C304

Main Rectifier and Filter

0302.

D307

Amplifier

Q303-Q304

'

A """"A

Voltage Comparator

3-1:

PS280 or PS283 Variable Outputs Block Diagram

3_JJ.

<3>

Relay Control

RL301-RL302

u

D3011-D3014

Series Regulator

Q3071.

R3261

Slave Output

P3280 & PS283 Laboratory

uu

power supply Module-Level Service Manual

REV

AUG

1991

Page 24

Theory of Operation

5 V Fixed Voltage Output

AC Input

u\

Transformer

•

Current Comparator

The 12 V output from transformer

The Rectifier circuit consists of diodes D4011 through D4014 that form a full

wave bridge rectifier. The output from the bridge rectifier is filtered by capacitor

C401.

The filtered output voltage is applied to the Series Regulator circuit.

The Series Regulator circuit consists mainly of Q402 and R407, that deliver a

regulated voltage to the Laboratory DC Power Supply 5 V Fixed output.

The Current Comparator circuit, consisting of

the Series Regulator circuit through Q401.

Rectifier and Filter

D4011-D4014

<>

Series Regulator

andC401

Q402,

R407

TS101

is applied to the Rectifier circuit.

U401,

limits the output current of

5 V Fixed

Output

>

<2>

Figure 3-2: PS280 or PS283 5 V Block Diagram

REVAUG 1991

Theory of Operation

Page 25

SIB Performance Verification

Page 26

WMiMrWinnnnTL Preparation

Purpose - Use this procedure to verify that the Laboratory DC Power Supply

is in conformance with its specifications as listed in Section 1, Specifications.

It can also be used for incoming inspection of the Laboratory DC Power

Supply.

Performance Verification Interval

performed whenever the accuracy or functions of the power supply are

question.

performing the adjustments in Section 5, Adjustments.

Requirements

Performance address the following requirements.

for

Before you perform these performance verification procedures, you need to

Warm-up Period

The Laboratory DC Power Supply requires a 20 minute warm-up time in

20°C to 30°C environment before a performance verification

A performance verification should be used to verify the need for

Access

Cabinet removal is not required to perform any of these procedures

Test Equipment

Table

4-1

lists all the test equipment required to perform both the Performance

Verification procedures and the Adjustment Procedures for the PS280

Laboratory DC Power Supply.

-A

performance verification should be

is

made.

in

a

or

PS283

PS2S0 & P32S3 Laboratory DC rower supply Module-Level Service Manual

REV

AUG 1991

4.7

Page 27

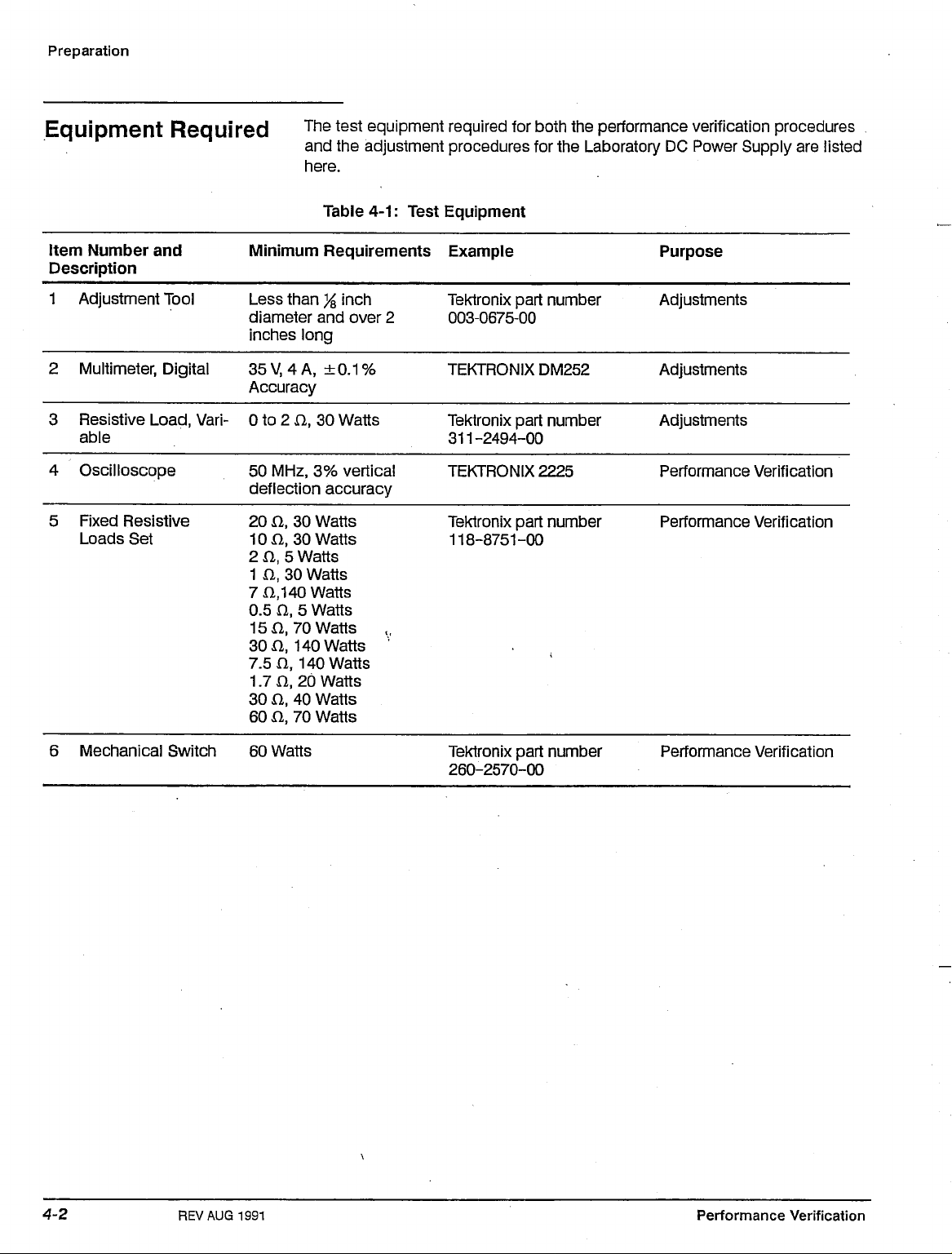

Preparation

Equipment Required

Item Number and

Description

1 Adjustment Tool

2 Multimeter, Digital

3 Resistive Load,

Vari-

4 Oscilloscope

5 Fixed Resistive

Loads Set

Minimum Requirements

Less than % inch

diameter and over 2

inches long

35

Accuracy

0 to 2 n, 30 Watts

50 MHz, 3% vertical

deflection accuracy

20 a, 30 Watts

10 a, 30 Watts

2 fl, 5 Watts

1 a, 30 Watts

7 a, 140 Watts

0.5 a, 5 Watts

15X1,70 Watts

30 a, 140 Watts

7.511,140

1.7 n, 20 Watts

30 a, 40 Watts

60 a, 70 Watts

The test equipment required for both the performance verification procedures

and the adjustment procedures for the Laboratory DC Power Supply are listed

Table

4-1:

Test

Equipment

Example

Tektronix part number

Purpose

Adjustments

003-0675-00

V,

4 A, ±0.1%

TEKTRONIX DM252

Tektronix part number

Adjustments

Adjustments

311-2494-00

TEKTRONIX 2225

Tektronix part number

Performance Verification

Performance Verification

118-8751-00

Watts

6 Mechanical Switch 60 Watts

REV

AUG

1991

Tektronix part number

260-2570-00

Performance Verification

Performance Verification

Page 28

WMMPXfXlftnnr

Performance Tests

Constant Current

Load Regulation

Equipment Required: Digital multimeter and load resistors

Figure

4-1:

Constant Current Test Setup

1.

Check the Master current regulation

a. Set up the equipment:

• Disengage both TRACKING mode switches (both switches out) so

that the power supply is in the INDEPendent operating mode.

(INDEPendent

mode):

•*-i

RL1

• Set the Master AMPS/VOLTS meter selection switch to AMPS.

• Set the digital multimeter to measure a DC voltage of +

• Connect the digital multimeter to the + and - terminals of the

MASTER output.

• Set the Laboratory DC Power Supply MASTER VOLTAGE control

until the multimeter reads +25 V.

• Disconnect the multimeter from the power supply.

• Set the digital multimeter to measure a DC current of at least 1

amp (PS280) or 0.5 amps (PS283).

• Connect the multimeter, load resistors, and test switch to the

+ and - terminals of the Master output as indicated in Figure

See Table 4-2 for the appropriate values of the load resistors.

PS280 & PS283 Laboratory DC Power Supply Module-Level Service Manual

REV AUG

1991

25

volts.

4-1.

Page 29

Performance Tests

b.

Verify

the current regulation:

• Check that the output current level changes less than 0.2%

±3 mA while switching load resistor

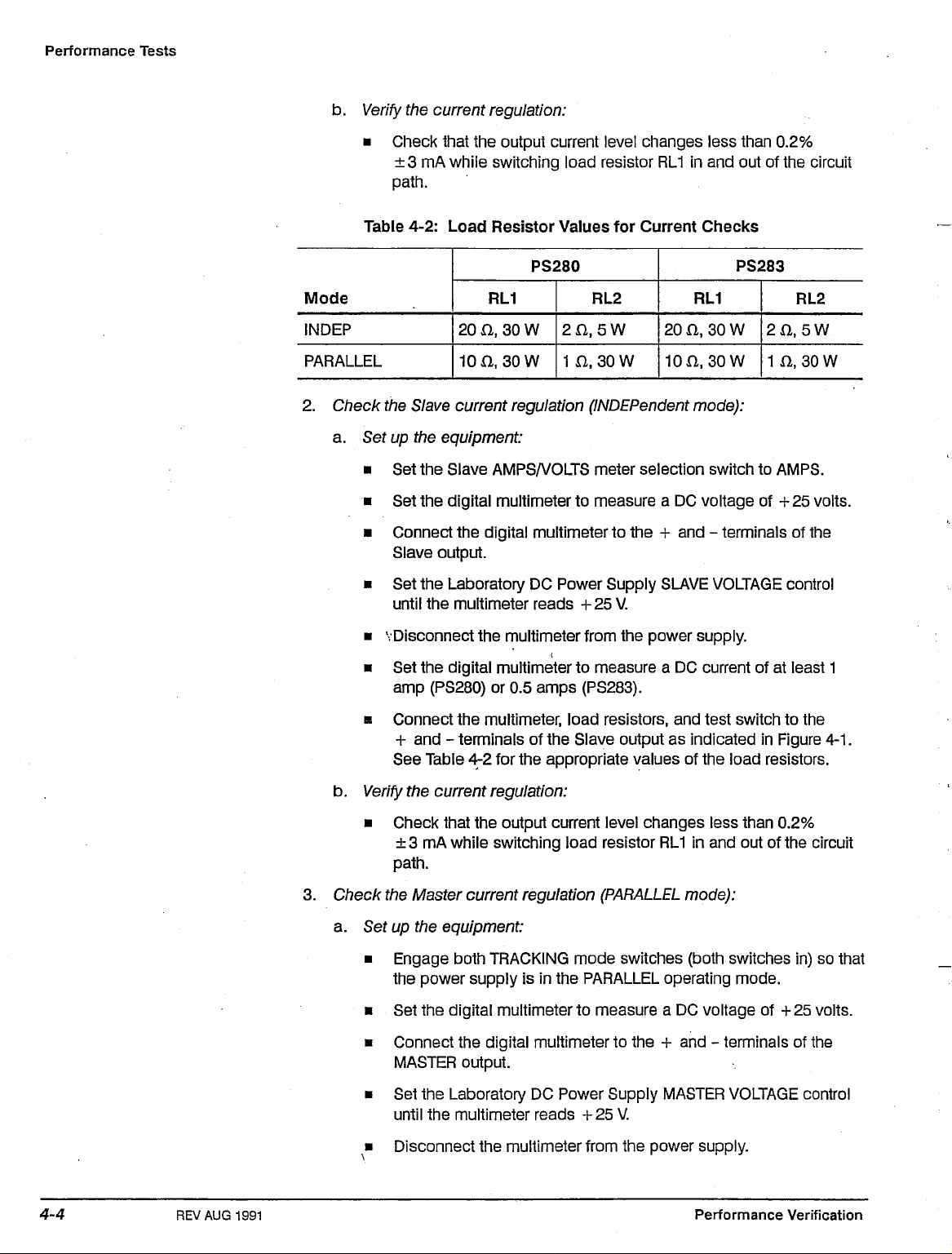

Table 4-2: Load Resistor Values for Current Checks

RL1

in and out of the circuit

PS280

oae

M

INDEP

PARALLEL

2.

Check the Slave current regulation

a. Set up the equipment:

• Set the Slave AMPS/VOLTS meter selection switch to AMPS.

• Set the digital multimeter to measure a DC voltage of + 25 volts.

• Connect the digital multimeter to the + and - terminals of the

Slave output.

• Set the Laboratory DC Power Supply SLAVE VOLTAGE control

until the multimeter reads +25 V.

• 'Disconnect the multimeter from the power supply.

• Set the digital multimeter to measure a DC current of at least 1

amp (PS280) or 0.5 amps (PS283).

a Connect the multimeter, load resistors, and test switch to the

+ and - terminals of the Slave output as indicated in Figure

See Table 4^2 for the appropriate values of the load resistors.

RL1

20

D.,

30

10 a, 30

W

w

RL2

,5W

2O

,30W

in

(INDEPendent

20

10

RL1

a 30

a

so

mode):

PS283

W

w

RL2

2fl.5W

1

a

30

w

4-1.

REV AUG

1991

b.

Verify

3. Check the Master current regulation

a. Set up the equipment:

the current regulation:

• Check that the output current level changes less than 0.2%

±3 mA while switching load resistor

• Engage both TRACKING mode switches (both switches in) so that

the power supply is in the PARALLEL operating mode.

• Set the digital multimeter to measure a DC voltage of +

• Connect the digital multimeter to the + and - terminals of the

MASTER output.

• Set the Laboratory DC Power Supply MASTER VOLTAGE control

until the multimeter reads +25 V.

• Disconnect the multimeter from the power supply.

RL1

(PARALLEL

in and out of the circuit

mode):

25

volts.

Performance Verification

Page 30

Performance Tests

• Set the digital multimeter to measure a DC current of at least

1 amp (PS280) or 0.5 amps (PS283).

• Connect the multimeter, load resistors, and test switch to the

+ and - terminals of the Master output as indicated in Figure

See Table 4-2 for the appropriate values of the load resistors.

b.

Verify

the current regulation:

• Check that the output current level changes less than 0.2%

±5 mA while switching load resistor

RL1

in and out of the circuit

4-1.

Constant Current

Ripple and Noise

Equipment Required: Oscilloscope and load resistors

Figure 4-2: Constant Current Ripple and Noise Test Setup

1.

Check the Master current ripple:

a. Set up the equipment:

• Disengage both TRACKING mode switches (both switches out) so

that the power supply is in the INDEPendent operating mode.

• Set the Master AMPS/VOLTS meter selection switch to VOLTS.

• Set the Laboratory DC Power Supply to+25 volts (using the

digital display).

• Connect the test oscilloscope and load resistors to the + and terminals of the Master output as indicated in Figure 4-2. See

Table 4-3 for the appropriate values of the load resistors.

b.

Verify

PS280 & PS283 Laboratory DC Power Supply Module-Level Service Manual

the current ripple:

• Check that the peak-to-peak ripple viewed with the test oscilloscope is less than 2.5 mV.

REV AUG 1991

Page 31

Performance Tests

c. Set up the

• Engage both TRACKING mode switches (both switches in) so that

d.

Verify

• Check that the peak-to-peak ripple viewed with the test oscillo-

e. Set up the

• Disengage the right TRACKING mode switch (switch out) so that

f.

Verify

• Check that the peak-to-peak ripple viewed with the test oscillo-

Table 4-3: Load Resistor Values for Ripple Checks

Mo,e

INDEP

equipment:

the power supply is in the PARALLEL operating mode.

the current ripple:

scope is less than 2.5 mV.

equipment:

the power supply is in the SERIES operating mode.

the current ripple:

scope is less than 5 mV.

15n,

RL

70W

PS280

0.5 n, 5 W

Rs

30

n, 40

PS283

RL

W

Rs

0.5 n,5W

PARALLEL

2.

Check the Slave current ripple:

7 a 140 W

a. Set up the equipment:

• Disengage both TRACKING mode switches (both switches out) so

that the power supply is in the INDEPendent operating mode.

• Set the Slave AMPS/VOLTS meter selection switch to VOLTS.

• Set the Laboratory DC Power Supply to +

digital display).

• Connect the test oscilloscope and load resistors to the + and -

terminals of the Slave output as indicated in Figure 4-2. See Table

4-3 for the appropriate values of the load resistors.

b.

Verify

the current ripple:

• Check that the peak-to-peak ripple viewed with the test oscilloscope is less than 2.5 mV.

10n,

30w

15

a,70

25

volts (using the

W

0.5 fl,5W

REV AUG

1991

Performance Verification

Page 32

Performance Tests

Constant Voltage

Regulation

Equipment Required: Digital multimeter and load resistors

Figure 4-3: Constant Voltage Test Setup

1.

Check the Master voltage regulation:

a. Set up the equipment:

• Disengage both TRACKING mode switches (both switches out) so

that the power supply is in the INDEPendent operating mode.

v

• Set the digital multimeter to measure a DC voltage of + 60 volts.

• Connect the digital multimeter and load resistors to the + and terminals of the Master output as indicated in Figure 4-3. See

Table 4-4 for the appropriate values of the load resistor.

b.

Verify

c. Set up the equipment:

d.

Verify

e. Set up the equipment:

the voltage output range:

• Check that the Laboratory DC Power Supply can be adjusted from

0 to 30 V.

• Engage the left TRACKING mode switch (switch in) and disengage the right TRACKING mode switch (switch out) so that the

power supply is in the SERIES operating mode.

the voltage output range:

• Check that the Laboratory DC Power Supply can be adjusted from

0 to 60 V.

• Engage both TRACKING mode switches (both switches in) so that

the power supply is in the PARALLEL operating mode.

PS280 & PS283 Laboratory DC Power Supply Module-Level Service Manual

REV AUG

1991

Page 33

Performance Tests

f.

Verify

the voltage output range:

• Check that the Laboratory DC Power Supply can be adjusted from

0 to 30 V.

Table 4-4: Load Resistor Values for Voltage Checks

INDEP

SERIES

PARALLEL

5 V Fixed

2. Check the Slave voltage regulation:

a. Set up the equipment:

• Disengage both TRACKING mode switches (both switches out) so

that the power supply is in the INDEPendent operating mode.

• Set the digital multimeter to measure a DC voltage of +

• Connect the digital multimeter and load resistors to the + and terminals of the Slave output as indicated in Figure 4-3. See Table

•4-4

for the appropriate values of the load resistor.

b.

Verify

the voltage output range:

• Check that the Laboratory DC Power Supply can be adjusted from

0 to 30 V.

15 n,

30

a

7.5 n,

1.7 n,

PS280

RL

70 W

140 W

140 W

20 W

PS283

RL

30 n, 40 W

60 a, 70 W

15n, 70W

1.7 n, 20 W

30

volts.

REVAUG 1991

3. Check the 5 V Fixed voltage regulation:

a. Set up the equipment:

• Set the digital multimeter to measure a DC voltage of +5 volts.

• Connect the digital multimeter and load resistors to the 5 V FIXED

terminals. Use the test setup illustrated in Figure 4-3 and see

Table 4-4 for the appropriate values of the load resistor.

b.

Verify

the voltage output range:

• Check that the Laboratory DC Power Supply maintains an output

of5V, ± 0.25 V.

Performance Verification

Page 34

WKSWXiAnnns Adjustment

Page 35

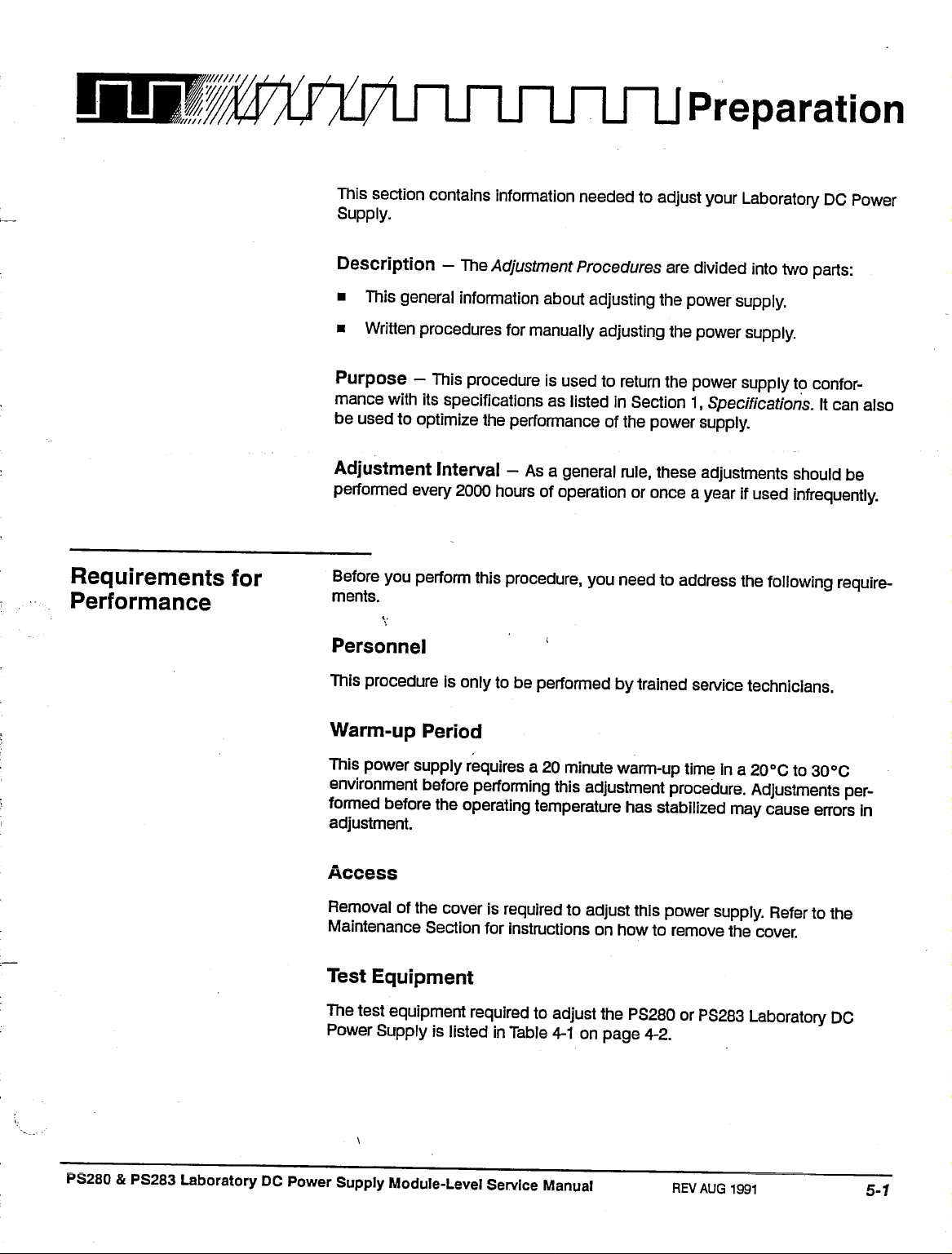

WKSffiyWUinnnni Preparation

Requirements

Performance

This section contains information needed

Supply.

Description - The

• This general information about adjusting

• Written procedures

Purpose — This procedure

mance with

be used

Adjustment Interval - As a

performed every 2000 hours

for

ments

Before you perform this procedure, you need

Personnel

Adjustment Procedures

for

manually adjusting

is

its

specifications

to

optimize the performance

as

of

to

adjust your Laboratory DC Power

are

divided into

the

power supply.

the

power supply.

used

to

return

the

power supply

listed

in

Section 1, Specifications.

of

the power supply.

general rule, these adjustments should

operation

or

once a year

to

address the following require-

two

parts:

to

confor-

It

if

used infrequently.

can also

be

This procedure

is

only

to be

performed

by

trained service technicians.

Warm-up Period

This power supply requires a 20 minute warm-up time

environment before performing this adjustment procedure. Adjustments

formed before the operating temperature

adjustment.

has

stabilized may cause errors

in a

20°C

to

30°C

Access

Removal

Maintenance Section

of

the cover

is

required

for

instructions

to

adjust this power supply. Refer

on

how

to

remove the cover.

to the

Test Equipment

The test equipment required

Power Supply

is

listed in Table

to

adjust the PS280

4-1

on

page

4-2.

or

PS283 Laboratory

per-

in

DC

PS280 & PS283 Laboratory

DC

Power Supply Module-Level Service Manual

REV

AUG 1991

5-f

Page 36

BK#%T%|7tr Adjustment Procedures

Independent Mode Equipment

See Figures 5-1 and 5-2 on pages 5-8 and 5-9 for adjustment locations used

in this procedure.

1.

Adjust the master voltage output:

a. Set up the equipment:

• Disengage both TRACKING mode switches {both switches out) so

• Set the Master AMPS/VOLTS meter selection switch to VOLTS.

• Set the digital multimeter to measure a DC voltage of ±16 mV.

• Set the Laboratory DC Power Supply MASTER VOLTAGE control

• Connect the digital multimeter to the + and - terminals of the

b.,, Make the zero volts adjustment:

• Adjust VR102 for a reading of-15 mV, within ± 15 mV on the

c. Set up the equipment:

Required:

that the power supply is in the INDEPendent operating mode.

to minimum (fully counterclockwise).

Master output.

multimeter.

Digital multimeter

• Set the digital multimeter to measure a DC voltage of ± 35 v.

• Set the MASTER VOLTAGE control to maximum (fully clockwise).

d.

Make the maximum volts adjustments:

• Adjust VR101 for a reading of 31.5 V on the multimeter.

• Adjust VR201 until the Laboratory DC Power Supply meter displays 31.5 V.

2.

Adjust the slave voltage output:

a. Set up the equipment:

• Disengage both TRACKING mode switches (both switches out) so

that the power supply is in the INDEPendent operating mode.

• Set the Slave AMPS/VOLTS meter selection switch to VOLTS.

• Set the digital multimeter to measure a DC voltage of ±16 mV.

• Set the Laboratory DC Power Supply SLAVE VOLTAGE control to

minimum (fully counterclockwise).

PS280 & PS283 Laboratory DC Power Supply Module-Level Service Manual

REV

AUG 1991

5.3

Page 37

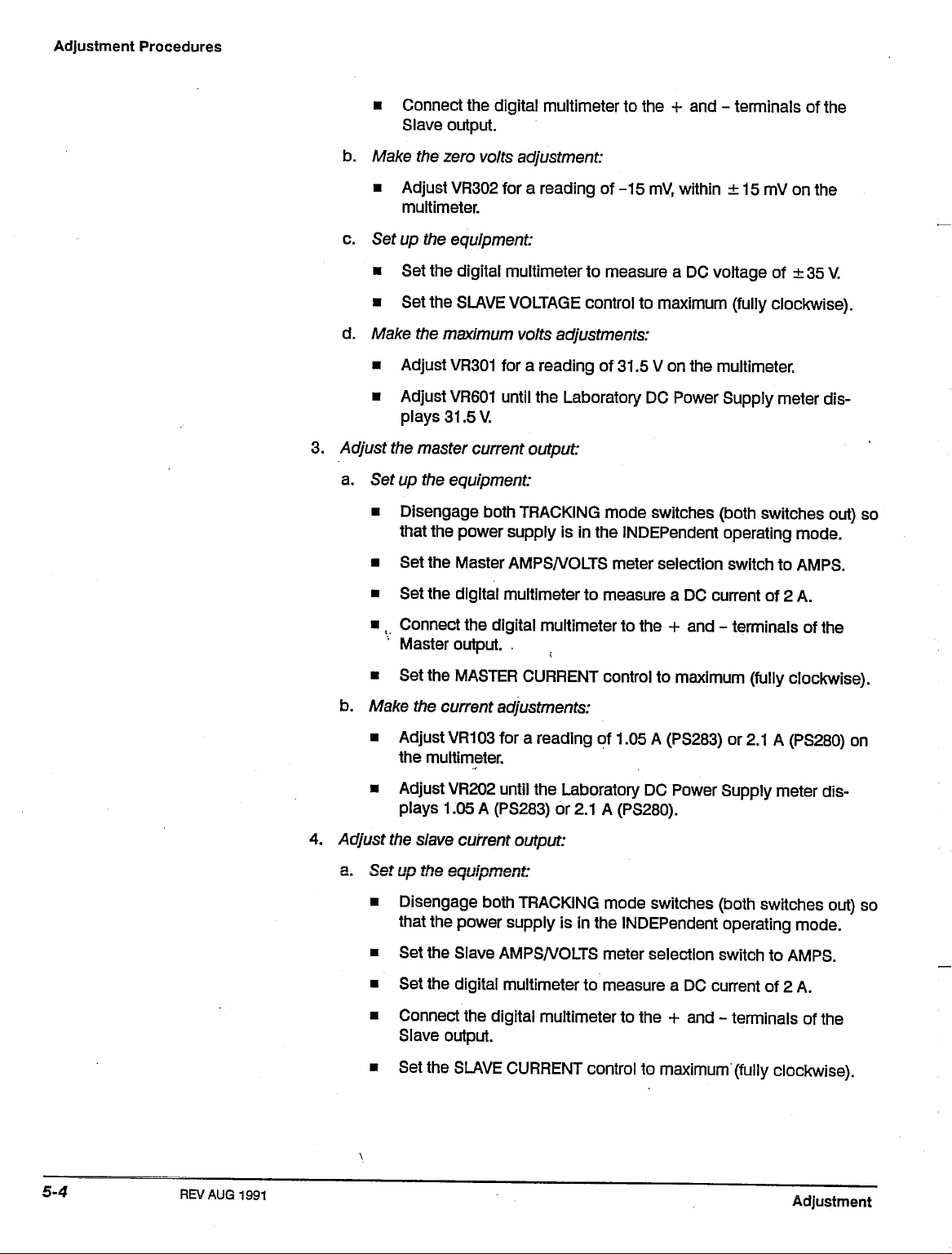

Adjustment Procedures

• Connect the digital multimeter to the + and - terminals of the

Slave output.

b. Make the zero volts adjustment:

• Adjust VR302 for a reading of-15 mV, within ± 15 mV on the

multimeter.

c. Set up the equipment:

• Set the digital multimeter to measure a DC voltage of ± 35 V.

• Set the SLAVE VOLTAGE control to maximum (fully clockwise).

d.

Make the maximum volts adjustments:

• Adjust

• Adjust

VR301

VR601

for a reading of 31.5 V on the multimeter.

until the Laboratory DC Power Supply meter dis-

plays 31.5V.

3. Adjust the master current output:

a. Set up the equipment:

• Disengage both TRACKING mode switches (both switches out) so

that the power supply is in the INDEPendent operating mode.

• Set the Master AMPS/VOLTS meter selection switch to AMPS.

• Set the digital multimeter to measure a DC current of 2 A.

•, Connect the digital multimeter to the + and - terminals of the

Master output. .

• Set the MASTER CURRENT control to maximum (fully clockwise).

b. Make the current adjustments:

• Adjust VR103 for a reading of 1.05 A (PS283) or

the multimeter.

• Adjust VR202 until the Laboratory DC Power Supply meter dis-

plays 1.05 A (PS283) or

2.1

A (PS280).

2.1

A (PS280) on

5-4

REV AUG1991

4.

Adjust the slave current output:

a. Set up the equipment:

• Disengage both TRACKING mode switches (both switches out) so

that the power supply is in the INDEPendent operating mode.

• Set the Slave AMPS/VOLTS meter selection switch to AMPS.

• Set the digital multimeter to measure a DC current of 2 A.

• Connect the digital multimeter to the + and - terminals of the

Slave output.

• Set the SLAVE CURRENT control to maximum (fully clockwise).

Adjustment

Page 38

b. Make the current adjustments:

Adjustment Procedures

Series Tracking

Mode

• Adjust VR303 for a reading of 1.05 A (PS283) or

the multimeter.

• Adjust VR602 until the Laboratory DC Power Supply meter displays 1.05 A (PS283) or

Disconnect the test setup.

Equipment Required: Digital multimeter

See Figures

in this procedure.

1.

Adjust the series tracking Mode:

a. Set up the equipment:

5-1

and 5-3 on pages 5-8 and 5-9 for adjustment locations used

• Engage the left TRACKING mode switch (switch in) and disengage the right TRACKING mode switch (switch out) so that the

power supply is in the SERIES operating mode.

• Set the SLAVE CURRENT control to midrange.

• Set the MASTER VOLTAGE control to minimum (fully

counterclockwise).

2.1

A (PS280).

2.1

A (PS280) on

«. • Set the digital multimeter to measure a DC voltage of ±16 mV.

• Connect the digital multimeter to the + and - terminals of the

Master output and note the reading obtained.

• Connect the digital multimeter to the + and - terminals of the

Slave output.

b. Make the zero voltage tracking adjustment:

• Adjust VR306 until the voltage output of the SLAVE output matches

the reading obtained from the MASTER output.

c. Set up the equipment:

• Set the MASTER VOLTAGE control to maximum (fully clockwise).

• Set the digital multimeter to measure a DC voltage of ± 35 V.

• Connect the digital multimeter to the + and - terminals of the

Master output and note the reading obtained.

• Connect the digital multimeter to the + and - terminals of the

Slave output.

PS280 & PS283 Laboratory DC Power Supply Module-Level Service Manual

REV AUG

1991

Page 39

Adjustment Procedures

d.

Make the maximum voltage tracking adjustment:

• Adjust

Recheck the value of the Master output compared to the value of

the Slave output. Readjust

Disconnect the test setup.

Parallel Tracking Equipment

ModG See Figure

1.

Adjust the parallel tracking Mode:

a. Set up the

• Disengage both TRACKING mode switches (both switches out) so

• Set the MASTER VOLTAGE and CURRENT controls to minimum

VR501

the reading obtained from the Master output.

until the voltage output of the Slave output matches

wore

VR501

Required:

5-1

on page 5-8 for adjustment locations used in this procedure.

that the power supply is in the INDEPendent operating mode.

(fully counterclockwise).

Digital multimeter

equipment:

if the outputs do not match.

• v Set the digital multimeter to measure a DC current of 4 A.

• Connect the digital multimeter to the + and - terminals of the

Master output.

• Set the MASTER VOLTAGE control to midrange and adjust the

MASTER CURRENT control until a reading of 1 A (PS283) or 2 A

(PS280) is displayed on the multimeter.

NOTE

Do not readjust the

of this procedure.

• Engage both TRACKING switches (both switches in) so that the

power supply is in the PARALLEL operating mode.

• Set the SLAVE CURRENT control to maximum (fully clockwise)

and set the SLAVE VOLTAGE control to midrange.

b. Make the parallel tracking adjustment:

• Adjust VR502 until a reading of 2 A (PS283) or 4 A (PS280) is

displayed on the multimeter.

CURRENT

control setting through the remainder

5-6

REV AUG1991

Disconnect the test setup.

Adjustment

Page 40

5 V

Fixed Equipment

See Figure 5-1 on page 5-8 for adjustment locations used in this procedure.

1.

Adjustment Procedures

Required:

Adjust the 5 V fixed output:

a. Setup the equipment:

• Set the digital multimeter to measure a DC voltage of + 5.25 V.

• Connect the digital multimeter to the terminals of the 5 V Fixed

output.

b. Make the 5 V adjustment:

Digital multimeter

and

variable resistive load

• Adjust

c. Set up the equipment:

• Disconnect the multimeter from the Laboratory DC Power Supply.

• Set the digital multimeter to measure a DC current of 3.25 A.

• Adjust VR403 fully counterclockwise.

• Connect a variable load and the multimeter in series to the termi-

• Adjust the variable load until the multimeter displays 3.25 A.

• Disconnect the multimeter from the power supply and reconnect

the 5 V Fixed output.

• Set the digital multimeter to measure a DC voltage of + 5.25 V.

• Connect the digital multimeter to the terminals of the 5 V Fixed

d.

Make the current limit adjustment:

• Slowly adjust VR403 clockwise until the multimeter display shows

a voltage drop of 5 to 6 mV.

e. Set up the equipment:

VR401

nals of the 5 V Fixed output.

the variable load (without changing the setting) to the terminals of

output.

until the multimeter displays 5.00 V (± 0.25 V).

• Disconnect the digital multimeter and the variable load from the

power supply.

• Set the digital multimeter to measure a DC current of 3.25 A.

• Connect a variable load and the multimeter in series to the terminals of the 5 V Fixed output.

• Adjust the variable load until the multimeter displays 3.10 A.

f. Make the overload adjustment:

• Adjust VR402 until the OVERLOAD 5V3A indicator starts to light on

the Laboratory DC Power Supply.

Disconnect the test setup.

P32S0 & PS2S3 Laboratory DC Power Supply Module-Level Service Manual

REV

AUG 1991

5.7

Page 41

Adjustment Procedures

Master

Maximum

Master

Maximum

a'iiliM!!

O

O^

-• 8 = ~

0 I Ill+lfl

oo

+

Master

Minimum

Parallel

5 V Overload

Mi+0+riiJS^

VR303 VR301 VR306 VR302

Slave Slave Serial Slave

Maximum Maximum Minimum Volts Minimum

Amps Volts Volts

Figure

5-1:

Master Circuit Board Adjustment Locations

5V Amps

REV AUG

1991

Adjustment

Page 42

Adjustment Procedures

| J2021 | | J2041

1 1

T

T

-\-

Display Maximum Maximum

Voltage Amps Amps

Tracking

Voltage

J207 J205

L

J20B^-^J206

nup

11

o

1 ^111

1 1

-

t

'

\\\\

VR601 VR602 VR202

Slave Slave Master

Figure 5-2: Display Assembly Circuit Board Adjustment Locations

T T

I T ^r

o

+

L

/-O

Display

Voltage

U

* oo • *r

Figure 5-3: Front Panel Controls Circuit Board Adjustment Locations

1

1

1

1

u-ir-

1

^

PS280 & PS283 Laboratory DC Power Supply Module-Level Service Manual

5-9

Page 43

#%F%M_n_nj Maintenance

Page 44

IHBllWXFlnnnJirL Information

Helpful Procedures

This section contains the information

nance on the Laboratory DC Power Supply. This section of the manual contains information on static-sensitive components, preventive maintenance,

removal and installation procedures.

The following sections contain information/procedures that may be related

doing maintenance.

• Section 2, Operating Information, covers instructions useful when operating the oscilloscope in order to troubleshoot it.

strategy and lists options for obtaining maintenance service and for replacing failed modules.

• Section 3, Theory

ule,

or block level.

• Section 4, Performance Verification, contains procedures that may

useful

in

isolating problems to modules by testing power supply perform-

• Section 5, Adjustment Procedures, addresses after repair adjustment and

thevinterval between periodic adjustments.

adjusting the internal circuits of this power supply.

of

Operation, contains a circuit description at the mod-

to do

periodic and corrective mainte-

It

also details the service

It

contains a procedure for

and

to

be

Preventing ESD

• Section 9, Diagrams, contains the schematics of the individual circuit

boards.

• Section 8, Replaceable

number and contains the exploded views of the power supply.

The following precautions apply when performing any maintenance involving

internal access to the instrument.

Static discharge can damage any semiconductor component in this

instrument.

This instrument contains electrical components that are susceptible to damage from static discharge. Table 6-1 lists the relative susceptibility of various

classes

unprotected environments.

of

semiconductors. Static voltages

Parts,

lists all field replaceable modules by part

of 1 kV to 30 kV are common

in

PS28Q & PS2S3 Laboratory DC Power Supply Module-Level Service Manual

REV AUG

1991

6-1

Page 45

Information

When performing maintenance, observe the following precautions to avoid

component damage:

1.

Minimize handling of static-sensitive components.

2.

Transport and store static-sensitive components or assemblies in their

original containers or on a metal

static-sensitive components or modules.

3. Discharge the static voltage from your body by wearing a grounded

antistatic wrist strap while handling these components. Servicing staticsensitive components or assemblies should be performed only at a

static-free work station by qualified service personnel.

4.

Nothing capable of generating or holding a static charge off the work

station surface.

5. Keep the component leads shorted together whenever possible.

6. Pick up components or modules by their bodies, never by their leads.

7. Do not slide the components or modules over any surface.

8. Avoid handling components or modules in areas that have a floor or

work-surface covering capable of generating a static charge.

rail.

Label any package that contains

9. Use a soldering iron that is connected to earth ground.

10.

Use only approved antistatic, vacuum-type desoldering tools for compo-

nent removal.

G-2 Maintenance

Page 46

Table

6-1:

Relative Susceptibility to Static-discharge Damage

Information

Semiconductor Classes

MOS or CMOS microcircuits or discretes, or linear

microcircuits with MOS inputs (Most Sensitive)

ECL

Schottky signal diodes

Schottky TTL

High-frequency bipolar transistors

JFET

Linear microcircuits

Low-power Schottky TTL

TTL (Least Sensitive)

1

Voltage equivalent for levels (voltage discharged from a 100 pF capacitor through resis-

tance of 100 fl):

1 =

100

to 500 V 6 =

2 = 200 to 500 V 7 =

3 = 250 V 8 =

4 = 500 V 9 = 1200

5 = 400 to 600

V

600

400

900 V

to

800 V

to

1000 V

V

(est)

Relative

Susceptibility

Levels

1

1

2

3

4

5

6

7

8

9

PS280 & PS283 Laboratory DC Power Supply Module-Level Service Manual REVAUG 1991

Page 47

WMMPXlWU~ Inspection and Cleaning

Inspection and Cleaning describes how to inspect for dirt and damage on,

and how to clean the exterior and interior of, the Laboratory DC Power Supply.

Such inspection and cleaning are performed as preventative maintenance.

Preventive maintenance, when performed regularly, may prevent instrument

malfunction and enhance reliability.

Preventive maintenance consists of visually inspecting and cleaning the power

supply and using general care when operating it.

The severity of the environment in which the power supply is used determines

the required frequency of maintenance. An appropriate time to perform preven-

tive maintenance is just before power supply adjustment.

General Care

Inspection

Cleaning Procedures

and The Laboratory DC Power Supply should be visually inspected and cleaned

The cabinet minimizes accumulation of dust inside the Laboratory DC Power

Supply and should normally be in place when operating the power supply.

as Ofte" as

supply can cause overheating and component breakdown. Dirt on components acts as an insulating blanket, preventing efficient heat dissipation. It

also provides an electrical conduction path that could result in instrument

failure,

especially under high-humidity conditions.

Avoid the use of chemical cleaning agents which might damage the

plastics used in this power

cleaning the front

cieaner and rinse with deionized

of

cleaner,

eratin

°P

consult your

9 conditions require. Accumulation of dirt in the power

panel.

supply.

Use a 75% isopropyl alcohol solution as a

Tektronix

Use only deionized water when

water.

Before using any other type

Service Center or representative.

Inspect Exterior

Inspection - Inspect the outside of the power supply for damage, wear, and

missing parts, using Table 6-2 as a guide. Instruments that appear to have

been dropped or otherwise abused should be checked thoroughly to verify

correct operation and performance. Immediately repair deficiencies that could

cause personal injury or lead to further damage to the power supply.

PS280 & PS283 Laboratory DC Power Supply Module-Level Service Manual

REVAUG 1991

Page 48

Inspection and Cleaning

To

prevent getting moisture Inside the power supply during external

cleaning, use only enough liquid to dampen the cloth or

Table 6-2: External Inspection Check List

applicator.

Inspect For

Cabinet and Front

Front-panel Knobs Missing, damaged, or loose knobs.

Connectors

Accessories

Cracks, scratches, deformations,

damaged hardware.

Broken shells, cracked insulation, and

deformed contacts. Dirt in connectors.

Missing items or parts of items, broken or

frayed cables, and damaged connectors.

Cleaning Procedure — Exterior

1.

Remove loose dust on the outside of the power supply with a lint free

2.

Remove remaining dirt with a lint free cloth dampened in a general pur-

pose detergent-and-water solution. Do not use abrasive cleaners.

3. Clean the digital display with a lint-free cloth dampened with either isopropyl alcohol or, preferably, a gentle, general purpose detergent-and-water

solution.

Repair Action

Replace defective module.

Repair or replace missing or defective

knobs.

Replace defective modules. Clear or wash

out dirt.

Replace damaged or missing items, frayed

cables, and defective modules.

REV AUG

1991

Inspect Interior

To access the inside of the power supply for inspection and cleaning, refer to

the Removal and Installation Procedures in this section.

Inspect the internal portions of the power supply for damage and wear, using

Table 6-3 as a guide. Deficiencies found should be repaired immediately.

If any electrical module is replaced, the performance verification procedures

should be used to see If it is necessary to adjust the power supply.

To

prevent damage from electrical arcing, ensure that circuit boards

and components are dry before applying power to the power

supply.

Maintenance

Page 49

Table 6-3: Internal Inspection Check List

Inspection and Cleaning

Inspect For

Circuit Boards

Loose,

broken, or corroded solder

connections. Burned circuit boards.

Burned,

broken, or cracked

circuit-run plating.

Resistors

Burned,

cracked, broken, blistered.

Solder Connections Cold solder or rosin joints.

Capacitors Damaged or leaking cases.

Corroded solder on leads or

terminals.

Semiconductors Loosely inserted in sockets.

Distorted pins.

Wiring and Cables

Chassis

Loose plugs or connectors. Burned,

broken,

or frayed wiring.

Dents, deformations, and damaged

hardware.

Repair Action

Remove failed module and replace with a

fresh module.

Replace failed module and replace with a

fresh module.

Resolder joint and clean with isopropyl

alcohol.

Remove damaged module and replace with a

fresh module from the factory.

Firmly seat loose semiconductors. Remove

devices having distorted pins. Carefully

straighten pins (as required to fit the socket),

using long-nose pliers, and reinsert firmly.

Ensure that straightening action does not

crack pins, causing them to break off.

Firmly seat connectors. Repair or replace

modules with defective wires or cables.

Straighten,

repair,

or replace defective

hardware.

Cleaning Procedure - Interior

If, after doing steps 1 and 2, a module is clean upon inspection, skip

I|J

the remaining steps.

1.

Blow off dust with dry, low-pressure, deionized air (approximately 9 psi).

2.

Remove any remaining dust with a lint free cloth dampened in a 75%

isopropyl alcohol solution and rinse with a warm deionized

cotton-tipped applicator is useful for cleaning in narrow spaces and on

circuit boards.)

3. If steps 1 and 2 do not remove all the dust or dirt, the power supply may

be spray washed using a solution of 75% isopropyl alcohol by doing

steps 4 through 8.

4.

Gain access to the parts to be cleaned by removing easily accessible

shields and panels (see Removal and Installation Procedure).

water.

(A

PS280 & PS283 Laboratory DC Power Supply Module-Level Service Manual

REV AUG

1991

6-7

Page 50

Inspection and Cleaning

5. Spray wash dirty parts with the isopropyl alcohol and wait 60 seconds for

the majority of the alcohol to evaporate.

6. Use hot (120°F to 140°F) deionized water to thoroughly rinse them.

7. Dry all parts with low-pressure, deionized air.

8. Dry all components and assemblies in an oven or drying compartment

using low-temperature (125°Fto 150°F) circulating air.

Lubrication

There is no periodic lubrication required for this power supply.

6"8

Maintenance

Page 51

IHH1 Removal and Installation Procedures

The procedures in this subsection provide instructions on how to remove the

replaceable circuit board modules in the PS280 or PS283Laboratory DC Power

Supply for either cleaning or replacement of a failed module. Replacement

part numbers of each circuit board module can be found In the section 8, Parts

Preparation - , .

Please Read 1

Before performing this or any other procedure in this manual, read

the

Safety

prevent possible injury to service personnel or damage to this

power supplies's components, read Preventing ESD in this section.

This subsection contains the following:

Summary found at the beginning of this manual. Also, to

WARNING

|

• This preparatory information that you need to properly perform the

procedures that follow.

• List of Equipment required to remove and disassemble all modules.

• Disassembly procedures for removal of all the major modules from the

power supply at one time and for reassembly of those modules into the

power supply. Such a complete disassembly is normally only done when

completely cleaning the power supply. (Instructions for doing the actual

cleaning are found under Inspection and Cleaning at the beginning of this

section.)

• Module locator diagrams for finding all the modules in this power supply.

WARNING

Before performing any procedure in this subsection, disconnect the

power cord from the line voltage source. Failure to do so could

cause serious injury or death.

u

List of Modules

Section 8 lists all modules.

PS280 & PS283 Laboratory DC Power Supply Module-Level Service Manual 6-9

Page 52

Removal and Installation Procedures

General Instructions

READ THESE GENERAL INSTRUCTIONS BEFORE REMOVING A

MODULE.

The removal of any internal module first requires the removal of the

top cover. Instructions for the removal of the top cover can be found

on page 6-10.

When unplugging connectors from any circuit board, always label

each one as you unplug them. This will ensure that each connector is

returned to its proper location and avoid damage to the Laboratory DC

Power Supply.

Equipment Required - The modules in this power supply can be removed

with a standard Phillips-head screwdriver. This and other items that are needed for complete disassembly of the instrument are listed in Table 6-4.

Top Cover Removal

Table 6-4: Tools Required for

Name

Module Removal

Description

No"

1

2

3

4

Phillips-head screwdriver

Flat-blade screwdriver

,. Soldering Iron

Solder Wick

Standard tool

Standard tool

Standard tool

Standard tool

The top cover needs to be removed to gain access to all replaceable modules

in the PS280 or PS283 Laboratory DC Power Supply. See Figure 6-1 illustrating

the removal of the top cover.

1.

Remove the two screws attaching the handle to the cover and remove the

handle.

2.

Remove the two screws on the left side and the three screws on the right

side of the power supply.

3. Slide the cover slightly back from the front panel and lift off.

REV

AUG

1991

Maintenance

Page 53

Removal and Installation Procedures

Figure

6-1:

Top Cover Removal

PS280 & PS283 Laboratory DC Power Supply Module-Level Service Manual

REV AUG

1991

Page 54

Removal and Installation Procedures

Slave Circuit Board

Removal

The Slave Circuit board is located on the left side of the power supply when

viewed from the front. See Figure 6-2 for the location of the Slave circuit board.

To aid in locating the connectors referred to in this procedure, see Figure 9-2

in the Diagrams section.The removal of other circuit boards is not necessary

to perform this procedure.

NOTE

Remember to label each connector as you disconnect them.

1.

Unplug J301 from the Slave circuit board.

2.

Unplug J3023 and J1023 from the Slave circuit board.

3. Unplug J1111 from the Slave circuit board.

4.

Unplug J1033 from the Slave circuit board.

5. Unplug J101 from the Slave circuit board.

6. Unplug

7. Remove the two screws, lock washers, and flat washers securing the

circuit board.

8. Tilt the Slave circuit board out slightly and unsolder the two individual

wires at locations

J1101

from the Slave circuit board.

S1

and S2.

9. Tilt thevSlave circuit board further out and unsolder the two individual wires

at locations

10.

Remove the circuit board by lifting it up and out of the bottom chassis

board slots.

11.

Installation of the Slave circuit board is done in the reverse order noting

the following items:

a. Make certain not to pinch any wires underneath the circuit board.

b. The wires from

through the cut-out in the bottom of the board.

c. Make certain that the circuit board is sitting in the circuit board slots in

the bottom chassis.

M1

and M2.

J101

at the bottom of the circuit board should pass

REV AUG

1991

Maintenance

Page 55

Removal and Installation Procedures

Fuse Circuit Board

Removal

PS280 & PS283 Laboratory

DC

Figure 6-2: Slave and Fuse Circuit Board Removal

The Fuse circuit board is located at the left rear of the power supply. See

Figure 6-2 for the location of the Fuse circuit board. To aid in locating the

connectors referred to in this procedure, see Figure 9-7 in the Diagrams sec-

tion.

The removal of other circuit boards is not necessary to perform this

procedure.

NOTE

Remember to label each connector as you disconnect them.

Power Supply Module-Level Service Manual

REV AUG

1991

Page 56

Removal and Installation Procedures

1.

Unplug all connectors from the Fuse circuit board.

2.

Remove the two screws, lock washers, and flat washers securing the top

of the circuit board.

3. Remove the screw, lock washer, and flat washer securing the right bottom

comer of the circuit board. See note below.

wore

Removal of the screw in step 3 may be difficult. Removing the

appropriate screw from the rear of the power

stand-off post between the circuit board and

4.

With a pair of pliers, pinch the board retainer, located at the bottom left, so

that the circuit board can be pulled loose.

supply,

heatsink,

securing the

Is

easier.

AC Selector Circuit

Board Removal

Returning the connectors to Improper locations may damage the

Laboratory DC Power Supply when power is applied.

5. Installation of the Fuse circuit board is done in the reverse order.

The AC Selector circuit board is located at the left rear of the power supply

behind the Fuse circuit board. See Figure 6-3 for the location of the AC Selector circuit board. To aid in locating the connectors referred to In this procedure,

see Figure 9-8 in the Diagrams section. The removal of the Fuse circuit board

is necessary before proceeding with this procedure.

NOTE

Remember to label each wire as you disconnect them.

1.

Remove the four self-tapping screws from the rear panel securing the AC

selector circuit board.

NOTE

REV AUG

1991

The next two steps involve unsoldering eight

colors of the wires are duplicated but are NOT interchangeable.

Make certain that each wire is returned to its proper location. The

colors of the wires mentioned in this procedure are subject to

change due to vendor component manufacturing.

wires.

Some of the

Maintenance

Page 57

Removal and Installation Procedures

2.

Unsolder the four wires located at the top of the circuit board.

• The black wire is soldered to "0"

-AC

Selector Circuit Board

• The gray wire is soldered to "

100"

• The orange wire is soldered to "120"

• The white wire is soldered to "N"

3. Unsolder the four wires located at the bottom of the circuit board.

• The black wire Is soldered to "0"

• The gray wire is soldered to "100"

• The orange wire is soldered to "120"

• The black wire from the power switch is soldered to "TO J601"

4.

Installation of the AC Selector circuit board is done in the reverse order.

Figure 6-3: AC Selector and Master Circuit Board Removal

PS280 & PS283 Laboratory DC Power Supply Module-Level Service Manual

REV AUG

Master Circuit Board

1991

Page 58

Removal and Installation Procedures

Master Circuit Board

Removal

The Master circuit board is located on the right side of the power supply. See

Figure 6-3 for the location of the Master circuit board. To aid in locating the

connectors referred to in this procedure, see Figures

Diagrams section. The removal of other circuit boards is not necessary to

perform this procedure.

NOTE

Remember to label each connector

1.

Unplug J1082 and J3082 from the Front Panel Controls circuit board.

2.

Unplug J3052 and J1102 from the Master circuit board.

3. Unplug

4.

Unplug J106 and J402 from the Master circuit board.

5. Unplug J403 from the Master circuit board.

6. Unplug

7. Unplug J206 and J208 from the Front Panel Display circuit board.

8. Cut the cable ties attached to the wires from

Master circuit board.

J1071,

J1111

J1052,

from the Slave circuit board.

J4041,

and J306 from the Master circuit board.

as

you disconnect them.

9-1,

J1081

9-2, and 9-5 in the

and

J3081

on the

9. Remove the two screws, lock washers, and flat washers securing the top

of the circuit board.

10.

Remove the circuit board by lifting it up and out of the bottom chassis

board slots.

11.

Installation of the Master circuit board is done in the reverse order noting

the following items;

a. Make certain not to pinch any wires underneath the circuit board.

b. Make certain that the circuit board is sitting in the circuit board slots in

the bottom chassis.

REVAUG 1991

Maintenance

Page 59

Removal and Installation Procedures

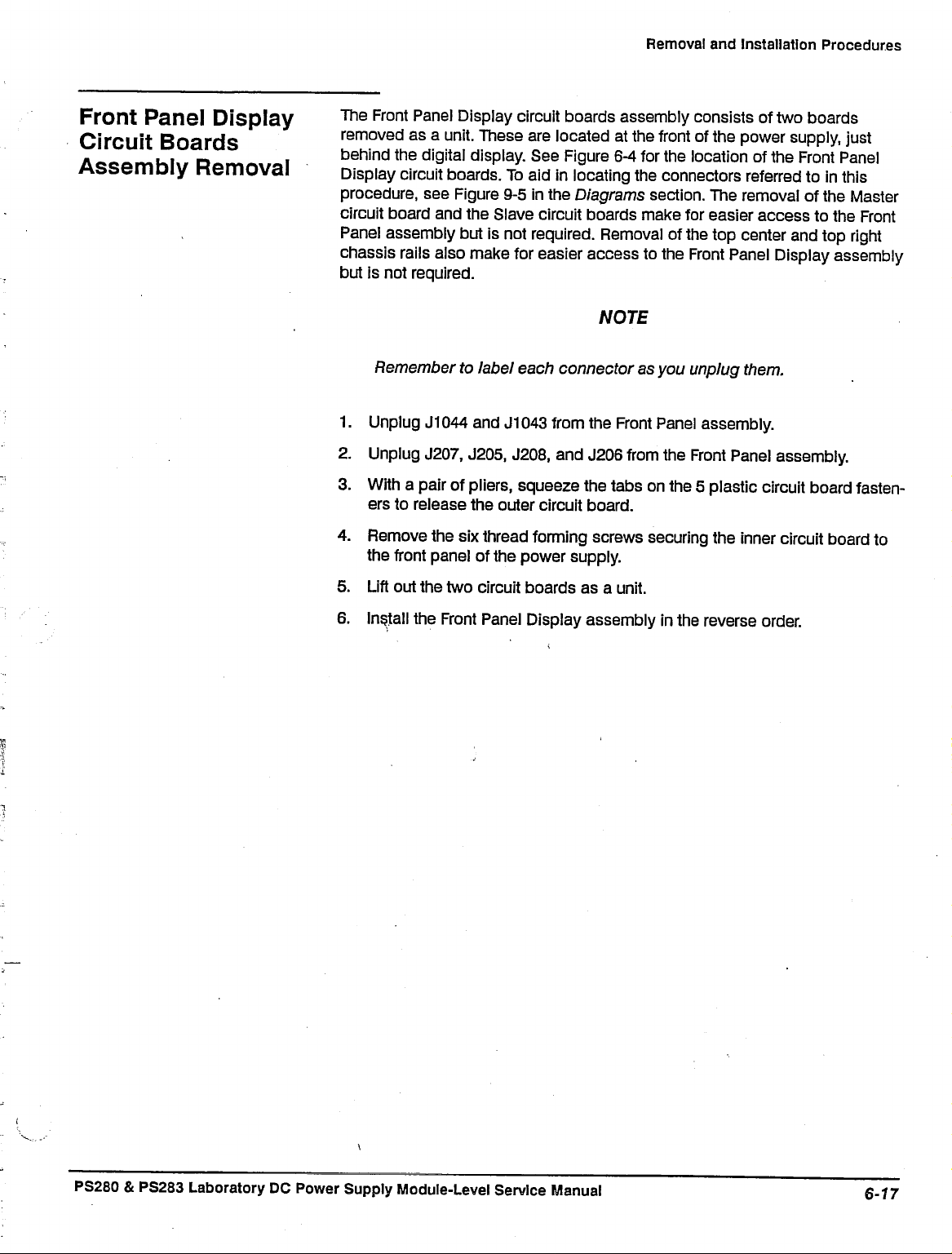

Front Panel Display

Circuit Boards

Assembly Removal

The Front Panel Display circuit boards assembly consists of two boards

removed as a unit. These are located at the front of the power supply, just

behind the digital display. See Figure 6-4 for the location of the Front Panel

Display circuit boards. To aid in locating the connectors referred to in this

procedure, see Figure 9-5 in the Diagrams section. The removal of the Master

circuit board and the Slave circuit boards make for easier access to the Front

Panel assembly but is not required. Removal of the top center and top right

chassis rails also make for easier access to the Front Panel Display assembly

but is not required.

wore