Page 1

User Manual

PS2520, PS2520G, PS2521 & PS2521G

Programmable Power Supplies

070-9196-01

Page 2

Copyright T ektronix, Inc. 1995. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and

pending. Information in this publication supercedes that in all previously

published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

Tektronix warrants that this product will be free from defects in materials and

workmanship for a period of one (1) year from the date of shipment. If any such product

proves defective during this warranty period, Tektronix, at its option, either will repair the

defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect

before the expiration of the warranty period and make suitable arrangements for the

performance of service. Customer shall be responsible for packaging and shipping the

defective product to the service center designated by Tektronix, with shipping charges

prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to

a location within the country in which the Tektronix service center is located. Customer

shall be responsible for paying all shipping charges, duties, taxes, and any other charges for

products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or

improper or inadequate maintenance and care. Tektronix shall not be obligated to furnish

service under this warranty a) to repair damage resulting from attempts by personnel other

than Tektronix representatives to install, repair or service the product; b) to repair damage

resulting from improper use or connection to incompatible equipment; or c) to service a

product that has been modified or integrated with other products when the effect of such

modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS

PRODUCT IN LIEU OF ANY OTHER WARRANTIES, EXPRESSED OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE

DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY

PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

EC Declaration of Conformity

We

Tektronix Holland N.V.

Marktweg 73A

8444 AB Heerenveen

The Netherlands

declare under sole responsibility that the

PS2520G Programmable Power Supply

meets the intent of Directive 89/336/EEC for Electromagnetic

Compatibility and Low Voltage Directive 73/23/ECC for Product Safety.

Compliance was demonstrated to the following specifications as listed

in the Official Journal of the European Communities:

EMC Directive 89/336/EEC:

EN 55011 Class B Radiated and Conducted Emissions

EN 50081-1 Emissions:

EN 60555-2 AC Power Line Harmonic Emissions

EN 50082-1 Immunity:

IEC 801-2 Electrostatic Discharge Immunity

IEC 801-3 RF Electromagnetic Field Immunity

IEC 801-4 Electrical Fast Transient/Burst Immunity

IEC 801-5 Power Line Surge Immunity

“...conformity with the following standards:

following the provisions of the Directives of the Council of the

European Union:

Low Voltage Directive 73/23/EEC: Amended by 93/68/EEC.”

Page 6

EC Declaration of Conformity

We

Tektronix Holland N.V.

Marktweg 73A

8444 AB Heerenveen

The Netherlands

declare under sole responsibility that the

PS2521G Programmable Power Supply

meets the intent of Directive 89/336/EEC for Electromagnetic

Compatibility and Low Voltage Directive 73/23/ECC for Product Safety.

Compliance was demonstrated to the following specifications as listed

in the Official Journal of the European Communities:

EMC Directive 89/336/EEC:

EN 55011 Class A Radiated and Conducted Emissions

EN 50081-1 Emissions:

EN 60555-2 AC Power Line Harmonic Emissions

EN 50082-1 Immunity:

IEC 801-2 Electrostatic Discharge Immunity

IEC 801-3 RF Electromagnetic Field Immunity

IEC 801-4 Electrical Fast Transient/Burst Immunity

IEC 801-5 Power Line Surge Immunity

“...conformity with the following standards:

following the provisions of the Directives of the Council of the

European Union:

Low Voltage Directive 73/23/EEC: Amended by 93/68/EEC.”

Page 7

Table of Contents

General Safety Summary iii. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Started 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Procedure 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Basics 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Overview 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Making a Control Setting 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting the Output 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Protection Levels 8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the OVP 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resetting the OVP 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the OCP 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Voltage and Current Limits 9. . . . . . . . . . . . . . . . . . . . . .

Using the Keypad to Set Limits 9. . . . . . . . . . . . . . . . . . . . . .

Setting Voltage and Current Steps 10. . . . . . . . . . . . . . . . . . . .

Connecting the Outputs 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Referencing Outputs to Ground 11. . . . . . . . . . . . . . . . . . . . . .

Independent Operation 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Master/Slave Operation 18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enabling the Outputs 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sensing the Output Level 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storing and Recalling Settings 21. . . . . . . . . . . . . . . . . . . . . . . . . .

Storing a Setting 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recalling an Individual Setting 22. . . . . . . . . . . . . . . . . . . . . .

Storing and Recalling a Sequence of Settings 22. . . . . . . . . . .

Setting the GPIB Address 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A: Specifications 27. . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B: Maintenance 31. . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C: Replaceable Parts 37. . . . . . . . . . . . . . . . . . . . . . .

Index 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PS2520, PS2520G, PS2521 & PS2521G User Manual

i

Page 8

T able of Contents

List of Figures

Figure 1: Changing the Line Voltage Setting 2. . . . . . . . . . . .

Figure 2: Replacing the Line Fuse 3. . . . . . . . . . . . . . . . . . . . .

Figure 3: Front Panel Features 5. . . . . . . . . . . . . . . . . . . . . . . .

Figure 4: Rear Panel Features 6. . . . . . . . . . . . . . . . . . . . . . . .

Figure 5: SHIFT control 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6: Isolated-Ground Connection 11. . . . . . . . . . . . . . . . .

Figure 7: Examples of Independent Output Connections 13. .

Figure 8: Connecting Power Supplies in Series 14. . . . . . . . . .

Figure 9: Examples of External Series Connections 15. . . . . .

Figure 10: Connecting Power Supplies in Parallel 16. . . . . . . .

Figure 11: Examples of External Parallel Connections 17. . . .

Figure 12: Series-Tracking Operation 19. . . . . . . . . . . . . . . . . .

Figure 13: Parallel-Tracking Operation 19. . . . . . . . . . . . . . . .

Figure 14: Output On/Off Button 20. . . . . . . . . . . . . . . . . . . . .

Figure 15: Connecting the Auxiliary Sense Inputs 21. . . . . . . .

List of Tables

Table 1: Maximum Output in Series and Para Modes 18. . . .

Table 2: Operating Characteristics 27. . . . . . . . . . . . . . . . . . . .

Table 3: Electrical Characteristics 29. . . . . . . . . . . . . . . . . . . .

Table 4: Environmental Characteristics 30. . . . . . . . . . . . . . . .

Table 5: Physical Characteristics 30. . . . . . . . . . . . . . . . . . . . .

Table 6: Troubleshooting Steps 33. . . . . . . . . . . . . . . . . . . . . . .

Table 7: Error Messages 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 8: Standard Accessories 37. . . . . . . . . . . . . . . . . . . . . . . .

Table 9: Optional Accessories 37. . . . . . . . . . . . . . . . . . . . . . . .

Table 10: Accessory Power Cords 38. . . . . . . . . . . . . . . . . . . . .

ii

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent

damage to this product or any products connected to it.

Only qualified personnel should perform service procedures.

Injury Precautions

Use Proper Power Cord

T o avoid fire hazard, use only the power cord specified for this

product.

Avoid Electric Overload

T o avoid electric shock or fire hazard, do not apply a voltage to a

terminal that is outside the range specified for that terminal.

Ground the Product

This product is grounded through the grounding conductor of the

power cord. T o avoid electric shock, the grounding conductor must

be connected to earth ground. Before making connections to the

input or output terminals of the product, ensure that the product is

properly grounded.

Do Not Operate Without Covers

T o avoid electric shock or fire hazard, do not operate this product

with covers or panels removed.

Use Proper Fuse

T o avoid fire hazard, use only the fuse type and rating specified for

this product.

PS2520, PS2520G, PS2521 & PS2521G User Manual

iii

Page 10

General Safety Summary

Do Not Operate in Wet/Damp Conditions

T o avoid electric shock, do not operate this product in wet or damp

conditions.

Do Not Operate in Explosive Atmosphere

T o avoid injury or fire hazard, do not operate this product in an

explosive atmosphere.

Avoid Exposed Circuitry

T o avoid injury, remove jewelry such as rings, watches, and other

metallic objects. Do not touch exposed connections and components

when power is present.

Product Damage Precautions

Use Proper Power Source

Do not operate this product from a power source that applies more

than the voltage specified.

Use Proper V oltage Setting

Before applying power, ensure that the line selector is in the proper

position for the power source being used.

Provide Proper Ventilation

T o prevent product overheating, provide proper ventilation.

Do Not Operate With Suspected Failures

If you suspect there is damage to this product, have it inspected by

qualified service personnel.

iv

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 11

Safety Terms and Symbols

Terms in This Manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that

could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that

could result in damage to this product or other property.

Terms on the Product

These terms may appear on the product:

General Safety Summary

DANGER indicates an injury hazard immediately accessible as you

read the marking.

WARNING indicates an injury hazard not immediately accessible as

you read the marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product

The following symbols may appear on the product:

DANGER

High Voltage

Protective Ground

(Earth) T erminal

ATTENTION

Refer to

Manual

PS2520, PS2520G, PS2521 & PS2521G User Manual

Double

Insulated

v

Page 12

General Safety Summary

Certifications and Compliances

CSA Certified Power Cords

CSA Certification includes the products and power cords appropriate

for use in the North America power network. All other power cords

supplied are approved for the country of use.

vi

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 13

Preface

This manual provides installation and operating instructions for the

PS2520, PS2520G, PS2521, and PS2521G Programmable Power

Supplies. The manual is organized as follows:

H Getting Started lists the product features, and describes how to

H Operating Basics provides an overview of the front and rear

H The Appendices list product specifications and other reference

Refer to the PS2520G and PS2521G Programmer Manual

(070-9197-XX) for information on how to set up and use the

PS2520G and PS2521G Programmable Power Supplies over the

IEEE-488 General Purpose Interface Bus (GPIB).

install the power supply.

panel and details each operating task step by step. This section

also provides a practical example of each control setting.

information.

PS2520, PS2520G, PS2521 & PS2521G User Manual

vii

Page 14

Preface

viii

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 15

Getting Started

This section describes the features of the PS2520, PS2520G, PS2521,

and PS2521G Programmable Power Supplies.

Be sure to set up your power supply using the installation instructions at the end of this section.

Product Description

The PS2520, PS2520G, PS2521, and PS2521G are programmable

DC power supplies. All four power supplies have the following

features:

H Three outputs allow independent, series, or parallel operation

H Automatic series or parallel tracking

H Easy to set, push-button controls

H Data entry using the keypad, up/down keys

H Four-digit displays for both voltage and current

H Overvoltage and overcurrent protection

H Display readouts for memory, output, and error code display

H Precision digital-to-analog converter for high resolution

H High stability, low drift output

H Memory storage and recall

H Automatic sequencing with timer

H Diagnostic self-test at power on

In addition, the PS2520G and PS2521G power supplies include a

GPIB interface that allows you to program and operate the power

supply from a remote location over the General Purpose Interface

Bus (GPIB).

For a complete list of specifications, refer to Appendix A: Specifica-

tions on page 27.

PS2520, PS2520G, PS2521 & PS2521G User Manual

1

Page 16

Getting Started

Installation

Use the following installation procedure to properly configure and

turn on the power supply for the first time:

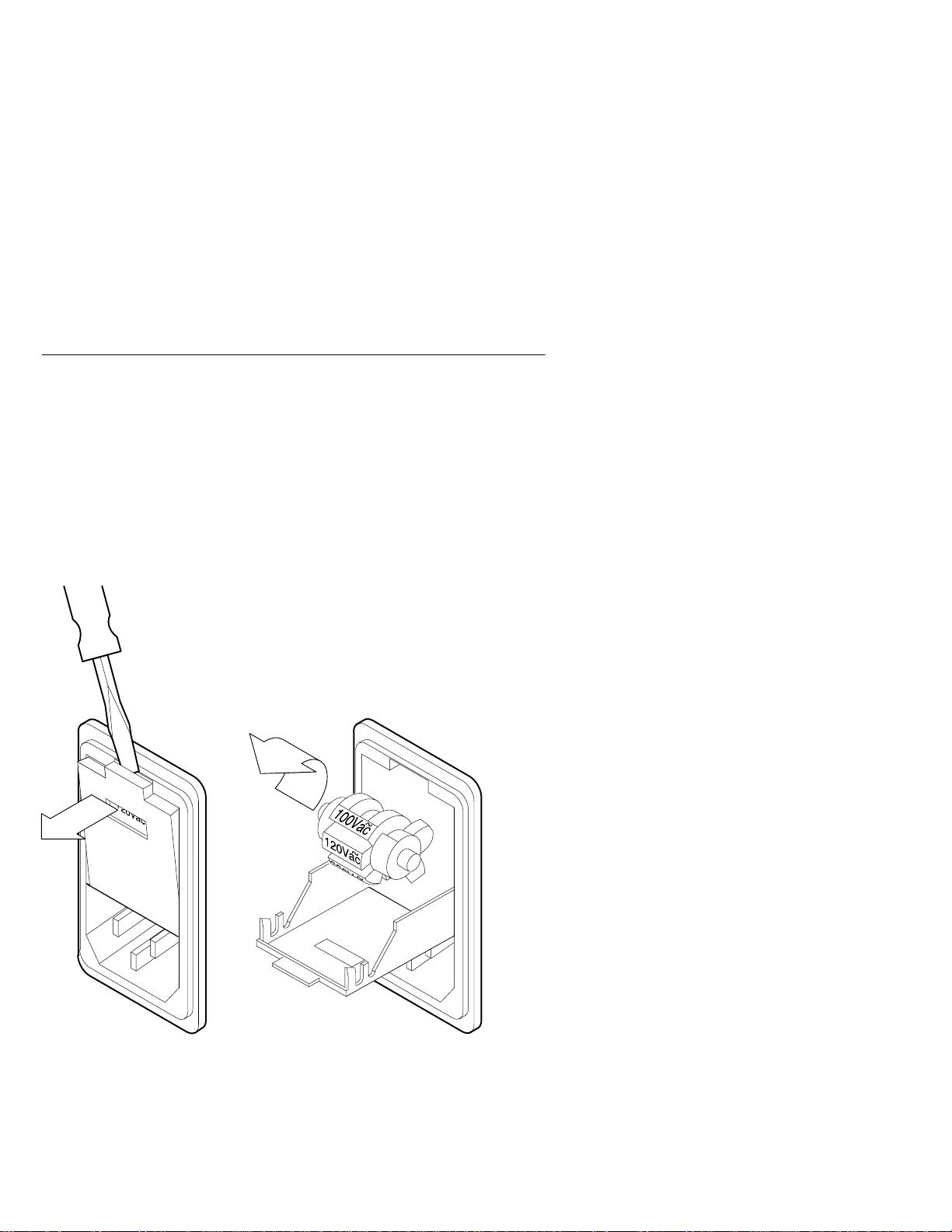

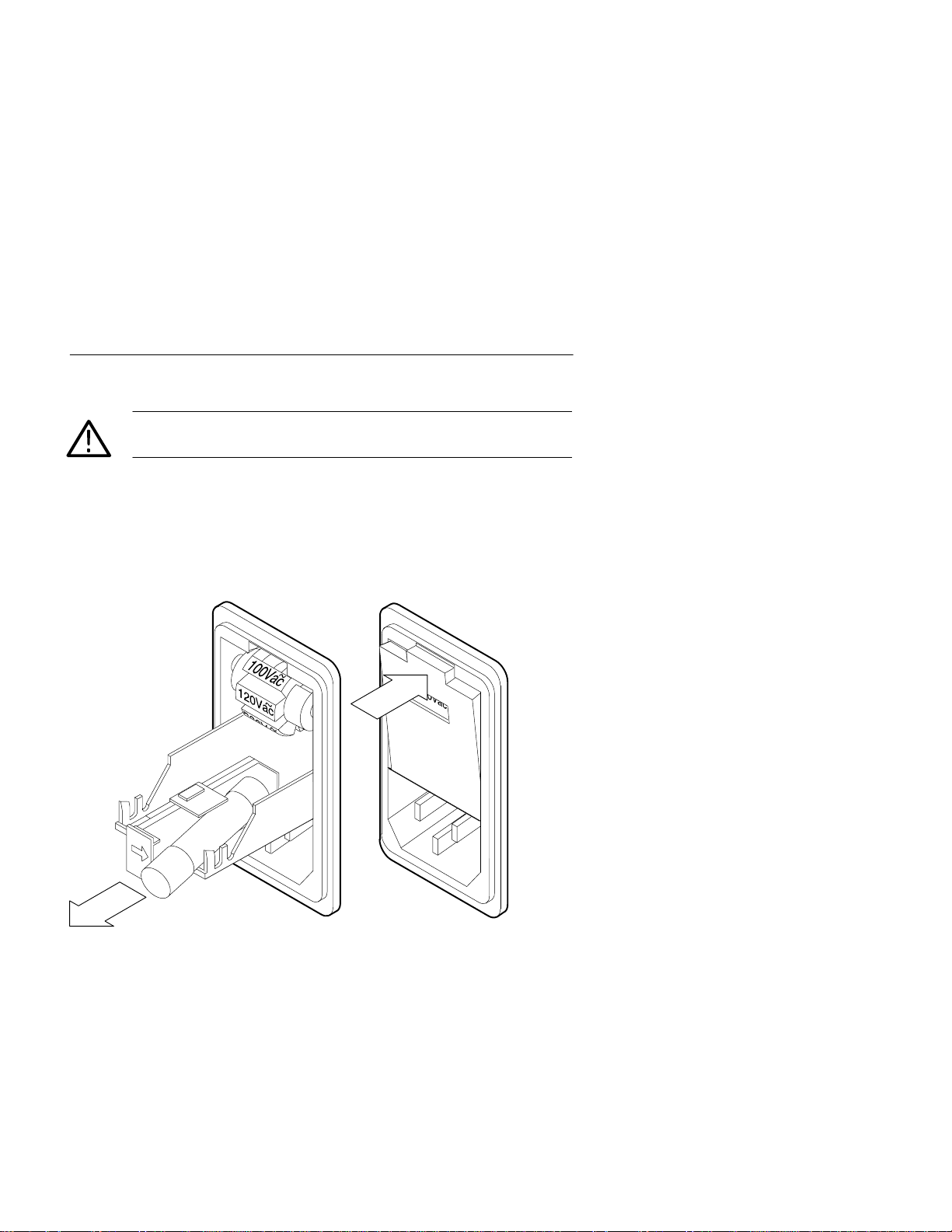

1. Check the line voltage setting on the rear panel. If the line

voltage setting does not match the line voltage of your area,

change the line voltage setting as shown in Figure 1.

Pry open cover with

flat-blade screwdriver.

Figure 1: Changing the Line V oltage Setting

Remove cam drum,

rotate to correct

selection, and reinsert.

2

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 17

Getting Started

CAUTION. To avoid damaging the instrument, make sure the line

voltage setting and fuse type match the line voltage of your area.

2. Identify the fuse and replace it if necessary with the type

specified in Appendix C: Replaceable Parts on page 37. See

Figure 2 to replace the fuse.

Reinsert drawer and

close cover.

Pull fuse drawer out and

replace fuse.

Figure 2: Replacing the Line Fuse

3. Place the power supply on a level surface. Leave at least 10 cm

(4 in) clearance around the cabinet for cooling.

4. Connect the power cord to the connector on the rear of the power

supply and plug the other end into a wall receptacle.

PS2520, PS2520G, PS2521 & PS2521G User Manual

3

Page 18

Getting Started

5. Turn the power on. The display indicators will flash briefly. The

voltage and current readouts show the output settings. You should

also hear the cooling fan running whenever the power is on.

The power supply performs a diagnostic self test at power on. If the

diagnostic self test detects a problem, the unit displays an error code

number in the form “Err –xxx.” If you encounter an error code, refer

to Troubleshooting on page 32.

General Procedure

Use the following general procedure to connect one or more of the

power supply outputs to a load. This procedure allows you to use the

power supply safely. More information about each step is in

Operating Basics on page 5.

1. Turn the power supply off and remove any connections on the

outputs.

2. Turn the power supply on.

3. Select the output you want to configure. Refer to Selecting the

Output on page 7.

4. Set the protection levels for the selected output. Refer to Setting

the Protection Levels on page 8.

5. Set the voltage and current limit for the selected output. Refer to

Setting Voltage and Current Limits on page 9.

6. Repeat steps 3 through 5 for the remaining outputs.

7. Turn the power supply supply off.

8. Connect the output(s) to the load(s). Refer to Connecting the

Outputs on page 11.

9. Turn the power supply on.

10.Enable the outputs. Refer to Enabling the Outputs on page 20.

4

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 19

Operating Basics

This section describes how to use the front panel controls and how to

make connections to the power supply.

Functional Overview

Figure 3 illustrates the front panel features of the PS2520, PS2520G,

PS2521, and PS2521G Programmable Power Supplies.

Amperes

Memory

Power

switch

Figure 3: Front Panel Features

readout

Output

connectors

Volts

readout

KeypadOutput

controls

PS2520, PS2520G, PS2521 & PS2521G User Manual

5

Page 20

Operating Basics

Figure 4 illustrates the rear panel features.

Sense

selector

GPIB

interface

(PS2520G and

PS2521G only)

Power output and sense

input connectors

Cooling

fan

Line voltage

setting

Fuse

access

Power

connector

Figure 4: Rear Panel Features

Making a Control Setting

The front-panel controls allow you to set or program the amount of

voltage, current, and protection for each output. T o make a control

setting you must press specific control buttons in the correct

sequence. To enter a number, for example, you must select the

function, enter the number, and then press return (

presents an entry sequence of this type in the following form:

Press (function) → (number) → (return

6

PS2520, PS2520G, PS2521 & PS2521G User Manual

). This manual

)

Page 21

Operating Basics

Items that compose the sequence appear in order from left to right

with arrows separating each item.

An example follows each sequence string to help reinforce your

understanding. Examples look like this:

Example: Set the voltage to 2.34 volts.

VOLTS SET → 2.34 → (return

T o select functions that have nomenclature above the output control

buttons, you must first press the SHIFT button (see Figure 5). The

shift indicator appears and remains active until you enter the

function.

Example: Reset the OVP.

SHIFT → OVP RESET

Figure 5: SHIFT control

Selecting the Output

You must select the output before you can set the voltage, current,

and protection levels for that output.

Press SHIFT → OUT(n) to select the output.

Example: Select Output 2.

)

SHIFT → OUT2

The output indicator for Output 2 lights, and you can set the output

levels.

PS2520, PS2520G, PS2521 & PS2521G User Manual

7

Page 22

Operating Basics

Setting the Protection Levels

The OVP (overvoltage protection) and OCP (overcurrent protection)

settings protect against supplying excessive voltage or current to an

output load. If voltage or current reaches the protection level setting,

the power supply disables the outputs.

CAUTION. To prevent damaging a circuit under test, set protection

levels before you apply power to the circuit.

Setting the OVP

The OVP (overvoltage protection) circuit automatically disables the

output when the voltage on the output reaches the set level.

Press OVP SET → (number) → (return

Example: Set the overvoltage protection for Output 1 to 6 volts:

1. SHIFT → OUT1

2. OVP SET → 6 → (return

Pressing the OVP SET again momentarily displays the OVP level

and allows you to confirm the setting.

Resetting the OVP

Using the previous example, if the Output 1 voltage reaches 6 volts,

the power supply automatically disables the output and displays the

message “Err –013.”

T o reset the OVP, correct the condition causing the overvoltage and

press SHIFT → OVP RESET

Setting the OCP

Pressing OCP

automatically disable the outputs upon reaching the current limit.

The OCP indicator appears on the display when the OCP is on.

ON (overcurrent protection on) sets the power supply to

)

) to enter the OVP level.

8

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 23

When the OCP circuit disables the output, it displays the message

“Err –012”. When this happens, correct the setup and remove the

error message by toggling OCP off and then on again.

When the OCP is not on, the power supply still limits the current to

the set level and reduces the voltage as necessary to control the

power. Refer to the following section for instructions on how to set

the current limit.

Setting Voltage and Current Limits

The power supplies provide either constant voltage or constant

current to a load. The voltage limit, current limit, and the size of the

load connected to the output determines whether the power supply

holds the voltage constant or the current constant. The appropriate

indicator appears on the display to indicate whether constant voltage

(C.V.) or constant current (C.C.) is active.

Using the Keypad to Set Limits

Operating Basics

Press VOLTS SET → (number) → (return

limit.

Press CURRENT SET → (number) → (return

current limit.

Example: Set the voltage of Output 3 to 4.2 volts with a maximum

current of 0.3 amperes.

1. Select Output 3:

SHIFT → OUT3

2. Set the voltage level of the output to 4.2 V:

VOLTS SET → 4.2 → (return

3. Set the current limit of the output to 0.3 A:

CURRENT SET → .3 → (return

The power supply keeps the voltage constant if the load does not

require more than 0.3 amperes. The power supply indicates C.V. on

the display.

PS2520, PS2520G, PS2521 & PS2521G User Manual

)

)

) to enter the voltage

) to enter the

9

Page 24

Operating Basics

Once the load tries to draw more than 0.3 amperes, however, the

supply holds the current to 0.3 amperes (unless OCP is on) and

allows the voltage level to vary accordingly. The power supply then

indicates C.C. on the display.

Setting Voltage and Current Steps

The CURRENT and VOL TS

keys allow you to make minor adjustments to the current and voltage

settings.

The STEP SET function determines the amount that the arrow keys

increment or decrement the setting when you press them.

Press STEP SET → VOLTS SET → (number) → (return

the amount of each voltage step increment and decrement.

Press STEP SET → CURRENT SET → (number) → (return

set the amount of each current step increment and decrement.

NOTE. The power supplies permit voltage steps up to 2.000 V and

current steps up to 0.200 A.

Example: Set voltage steps to 0.5 V and current steps to 0.1 A.

1. Set voltage steps to 0.5 V:

STEP SET → VOLTS SET → .5 → (return

2. Set current steps to 0.1 A:

STEP SET → CURRENT SET → .1 → (return

Press VOLTS

voltage limit by steps of 0.5 V.

to increase (and press VOLTS to decrease) the

(step up) and (step down) arrow

) to set

) to

)

)

10

Press CURRENT

decrease) the current limit by steps of 0.1 A.

Press and hold the arrow key to increase the selection speed.

to increase (and press CURRENT to

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 25

Connecting the Outputs

After setting the voltage and current limits, turn the power off and

connect the outputs to one or more loads. The binding posts on the

front outputs accept wires, spade lugs, or banana plugs. The rear

output terminals provide additional output connections. You can

make connections with or without reference to ground to each supply

independently, in series or in parallel.

WARNING. To avoid electrical shock and damage to circuits

connected to the outputs, make sure that you turn the power supply

off before making or changing output connections.

Referencing Outputs to Ground

There are two types of power supply connections in relation to

ground: isolated ground or ground referenced. Figure 6 shows both

types of connections.

Operating Basics

Voltage Voltage Voltage

or

Isolated ground Ground referenced

Figure 6: Isolated-Ground Connection

Use an isolated-ground connection when it is unnecessary or

undesirable to connect one of the outputs to ground.

T o reference an output connection to ground, do one of the

following:

H Connect the positive output to the ground terminal to supply a

negative voltage across the load.

PS2520, PS2520G, PS2521 & PS2521G User Manual

11

Page 26

Operating Basics

H Connect the negative output to the ground terminal to supply a

positive voltage across the load.

NOTE. The ground post on the power supply internally connects to

earth ground through the power supply chassis and line cord.

Independent Operation

Independent operation allows you connect each of the three outputs

to separate loads or to connect the outputs in series or in parallel with

external connections. When the outputs are in the independent mode

of operation, the SERIES and PARA indicators are not lighted. See

Figure 7 for examples of independent output connections.

12

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 27

Isolated-gro

und connec

tions

Operating Basics

OUTPUT 1 OUTPUT 2

–+

V

1

GND

–+

Load 1

Negative-ground connections

OUTPUT 1 OUTPUT 2

–+

+V

1

GND

–+

Load 1

Positive-ground and negative-ground connections

OUTPUT 1 OUTPUT 2

–+

–V

1

GND

–+

Load 1

V

2

Load 2

+V

2

Load 2

+V

2

Load 2

OUTPUT 3

–+

V

3

Load 3

OUTPUT 3

–+

+V

3

Load 3

OUTPUT 3

–+

–V

3

Load 3

Figure 7: Examples of Independent Output Connections

PS2520, PS2520G, PS2521 & PS2521G User Manual

13

Page 28

Operating Basics

External Series Connections. To achieve a potential across the load

that exceeds the output of a single power supply, connect two or

more power supplies in series. Figure 8 illustrates two independent

power supplies connected in series. Note that the voltages of the

power supplies add together but the currents do not.

20 V, 1 A 15 V, 1 A

–+–+

Figure 8: Connecting Power Supplies in Series

WARNING. Voltages more than 60 VDC are a lethal shock hazard to

the user. Be careful when connecting power supplies in series to

achieve voltages higher than 60 VDC total or 60 VDC between any

connection and earth ground.

35 V, 1 A

14

Refer to Figure 9 for examples of different types of series connections using the three outputs.

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 29

Isolated-gro

und

Operating Basics

OUTPUT 1 OUTPUT 2

–+

V

1

GND

V

Total

Negative-ground

OUTPUT 1 OUTPUT 2

–+

V

1

GND

Positive-ground

OUTPUT 1 OUTPUT 2

–+

V

1

GND

V

= –(V1 + V2 + V3)

T otal

–+

V

2

= V1 = V2 + V

3

Load

–+

V

2

V

= V2 + V

T otal

Load

–+

V

2

Load

OUTPUT 3

–+

V

3

OUTPUT 3

–+

V

3

3

OUTPUT 3

–+

+V

3

Figure 9: Examples of External Series Connections

PS2520, PS2520G, PS2521 & PS2521G User Manual

15

Page 30

Operating Basics

External Parallel Connections. To supply more current than any one

supply can provide individually, connect two or more power supplies

in parallel. Figure 10 illustrates two power supplies externally

connected in parallel. Note that the currents add together but the

voltages do not. For this example the power supplies are set to

independent and the SERIES and PARA indicators are not lighted.

20 V, 1 A 20 V, 1 A

–+–+

Figure 10: Connecting Power Supplies in Parallel

20 V, 2 A

16

CAUTION. To avoid damaging the output circuitry of the power

supply, do not apply a voltage across an output that exceeds the

voltage rating of that output.

Refer to Figure 11 for examples of different types of parallel

connections using the three outputs.

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 31

Isolated-ground

Operating Basics

OUTPUT 1 OUTPUT 2

–+

I

1

GND

Negative-ground

OUTPUT 1 OUTPUT 2

–+

GND

Positive-ground

OUTPUT 1 OUTPUT 2

–+

GND

–+

I

I

2

I

Load

Maximum

= I

1Max

–+

I

I

2

I

Maximum

Load

–+

OUTPUT 3

–+

3

+ I

+ I

2Max

3Max

OUTPUT 3

–+

3

= I

+ I

2Max

3Max

OUTPUT 3

–+

I

I

1

Load

I

2

I

Maximum

= I

1Max

Figure 11: Examples of External Parallel Connections

PS2520, PS2520G, PS2521 & PS2521G User Manual

+ I

2Max

+ I

3Max

3

17

Page 32

Operating Basics

Master/Slave Operation

The SERIES and PARA controls on the front panel allow you to

internally connect Output 1 and Output 2 in series or parallel. When

you do this, Output 2 (the master output) sets Output 1 (the slave

output) to the same level as the Output 2 setting. These modes of

operation are also called series tracking and parallel tracking.

Output 3 is always independent. You can connect Output 3 in series

or parallel with the other outputs by using external connections only.

T able 1 shows the maximum output available for the power supplies

in SERIES and PARA operation

Table 1: Maximum Output in Series and Para Modes

Model

PS2520, PS2520G 40 V, 2.5 A 20 V, 5 A

PS2521, PS2521G 72 V, 1.5 A 36 V, 3 A

Series Para

Series Tracking. Select SERIES to internally connect Output 1 and

Output 2 in series. Output 2 is the master.

Press SHIFT → SERIES

The SERIES indicator lights.

Use the Output 2 settings to control the power to the load. The

Output 2 voltage setting should be one half of the total output

voltage desired. (The voltage across Output 1 and Output 2 in series

is twice that of Output 2.) The current setting for Output 2 controls

the maximum current available to the load. See Figure 12.

18

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 33

Operating Basics

–+

Slave

GND

–+–+

Master

Internal connection

V

Total

= V

Master

I

× 2

Maximum

= I

Master

Figure 12: Series-Tracking Operation

Parallel Tracking. Select PARA to internally connect Output 1 and

Output 2 in parallel. Output 2 is the master.

Press SHIFT → PARA

The PARA indicator lights.

Use the Output 2 settings to control the power to the load. The

voltage across Output 1 and Output 2 in parallel is the same as the

Output 2 setting. The current available from Output 1 and Output 2

in parallel is twice that of the Output 2 setting. See Figure 13.

–+

Slave

GND

–+–+

Master

Internal connection

Internal connection

= V

V

Total

Master

I

Maximum

= I

Master

× 2

Figure 13: Parallel-Tracking Operation

PS2520, PS2520G, PS2521 & PS2521G User Manual

19

Page 34

Operating Basics

Enabling the Outputs

Press the OUTPUT ON/OFF button (Figure 14) to enable the power to

all outputs.

Press to enable power to the outputs.

Figure 14: Output On/Off Button

The OUT indicator appears and all outputs are active.

Press the OUTPUT

remove power from the load or loads connected to the output

terminals.

ON/OFF button again to disable the outputs and

Sensing the Output Level

Although the front and rear output terminals simultaneously supply

power, the power supply senses the voltage level internally from

either the front or rear terminals. Use the SENSE selector located on

the rear panel to select the appropriate sense input. See Figure 15.

As the length of the output leads or the amount of output current

increases, the amount of voltage drop across the output leads also

increases. In this case, the internal sense connection does not

accurately measure the voltage across the load. T o compensate for

20

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 35

this problem the power supply has auxiliary sense inputs on the rear

panel. Using these inputs, as illustrated in Figure 15, bypasses the

voltage dropped across the output leads and senses the voltage

directly across the load. It is best to use a shielded two-wire cable for

this connection to prevent extraneous noise from affecting the sense

measurement.

Remove shorting bars.

Load

Connect sense inputs across load.

Figure 15: Connecting the Auxiliary Sense Inputs

Operating Basics

Storing and Recalling Settings

The power supplies allow you to store voltage and current settings in

as many as 50 different memory locations (00 – 49). Each location

stores the settings for all three outputs. You can recall the settings of

any location individually or you can step through the settings for

each memory location in sequence.

Storing a Setting

The Store function saves the front panel settings for OVP, voltage

limit, current limit, and delay timer in a specific memory location.

(The section that describes the delay timer operation begins on

page 24.)

Press SHIFT → STORE → (memory location number) →

(return

PS2520, PS2520G, PS2521 & PS2521G User Manual

) to store the settings in memory.

21

Page 36

Operating Basics

Example: Store the power supply settings for all three outputs in

memory location 01:

SHIFT → STORE → 1 → (return )

Recalling an Individual Setting

The Recall function recalls the settings stored in a specific memory

location.

Press SHIFT → RECALL → (memory location number) →

(return

Example: Recall the settings for all three outputs from memory

location 01:

) to recall a particular setting from memory.

SHIFT → RECALL → 1 → (return

Storing and Recalling a Sequence of Settings

T o create an automatic test routine, you can program the power

supply to sequence through the settings stored in two or more

consecutive memory locations. You can recall the sequence of stored

settings either manually or automatically.

Manual Sequencing. Manual sequencing allows you to step through

the stored settings one at a time by pressing the RECALL NEXT or

RECALL LAST buttons.

1. Press SHIFT → STORE → (memory location number) →

(return

consecutive memory location for each setting.

2. Press SHIFT → RECALL → (first memory location) →

(decimal point) → (last memory location) → (return

specify the first through last memory locations in the sequence.

3. Press RECALL NEXT to recall the next memory location in the

sequence. Press RECALL LAST to recall the previous memory

location in the sequence.

) to store a setting. Repeat for each new setting, using a

)

) to

22

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 37

Operating Basics

Example: Store three new settings for Output 1 and manually recall

the settings in sequence:

H Store 1 V, 0.1 A in memory location 01.

H Store 2 V, 0.15 A in memory location 02.

H Store 3 V, 0.15 A in memory location 03.

H Recall the settings of each memory location in order (01 – 03).

1. Select Output 1:

SHIFT → OUT1

2. Set the voltage limit to 1 V and the current limit to 0.1 A:

VOLTS SET → 1 → (return

CURRENT SET → .1 → (return

3. Store this setting in memory location 01:

SHIFT → STORE → 1 → (return

4. Set the voltage limit to 2 V and the current limit to 0.15 A:

VOLTS SET → 2 → (return

CURRENT SET → .15 → (return

5. Store this setting in memory location 02:

SHIFT → STORE → 2 → (return

6. Store 3 V, 0.15 A in memory location 03:

VOLTS SET → 3 → (return

SHIFT → STORE → 3 → (return

Note the current limit setting for location 03 is the same as

location 02; therefore, you do not have to re-enter the current

limit setting.

7. Set the sequence for memory locations 01 through 03:

SHIFT → RECALL → 1.3 → (return

)

)

)

)

)

)

)

)

)

PS2520, PS2520G, PS2521 & PS2521G User Manual

23

Page 38

Operating Basics

8. Recall the settings in memory locations 01, 02, and 03 in that

order:

SHIFT → RECALL → 1 → (return

)

RECALL NEXT → RECALL NEXT

Pressing RECALL NEXT recalls the next memory location in the

sequence. (RECALL LAST recalls the previous memory location.)

Automatic Sequencing. To automatically output a sequence of stored

settings, you must store the delay time along with the other settings

for each memory location. The minimum delay time setting is

1 second; the maximum is 65535 seconds.

1. Press DELAY → (seconds) → (return

) to specify the delay

time for a sequence step.

2. Press SHIFT → STORE → (memory location number) →

(return

) to store a setting.

3. Repeat steps 1 and 2 for each new setting, using a consecutive

memory location for each setting.

4. Press SHIFT → RECALL → (first memory location) →

(decimal point) → (last memory location) → (return

) to

specify the first through last memory locations in the sequence.

5. Press AUTO SEQ

ON → OUTPUT ON to automatically output

the settings in sequence.

Example: Recall the previously stored memory locations 01 and

02 and set the delay times for each as follows:

01: 3 seconds

02: 7 seconds

Set the test loop for memory locations 01 and 02.

24

1. Recall the settings in memory location 01:

SHIFT → RECALL → 1 → (return

2. Set the delay time to 3 seconds:

DELAY → 3 → (return

)

PS2520, PS2520G, PS2521 & PS2521G User Manual

)

Page 39

3. Store this setting back into memory location 01:

Operating Basics

SHIFT → STORE → 1 → (return

4. Recall the settings in memory location 02:

SHIFT → RECALL → 2 → (return

5. Set the delay time for memory location 02:

DELAY → 7 → (return

6. Store this setting back into memory location 02:

SHIFT → STORE → 2 → (return

7. Specify the sequence to contain only locations 01 through 02:

SHIFT → RECALL → 1.2 → (return

8. Set the power supply to automatically output and repeat this

sequence starting with memory location 01:

AUTO SEQ

The AUTO and OUT indicators appear and the sequence starts

running.

ON → OUTPUT ON

Setting the GPIB Address

If you have a PS2520G or PS2521G Programmable Power Supply,

use the ADDRESS/LOCAL control to set or read the GPIB address

of the power supply. Refer to the PS2520G and PS2521G Program-

mer Manual for more details.

)

)

)

)

)

PS2520, PS2520G, PS2521 & PS2521G User Manual

25

Page 40

Operating Basics

26

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 41

Appendix A: Specifications

T ables 2 through 5 list the specifications of the PS2520, PS2520G,

PS2521, and PS2521G Programmable Power Supplies.

Table 2: Operating Characteristics

Name

Independent Output

Ratings

Series Tracking Output

Rating

Parallel Tracking Output

Rating

Maximum OVP PS2520 and PS2520G:

Load Effect Voltage: ≤ 3 mV, rear output; ≤ 6 mV, front output

Source Effect Voltage: ≤ 3 mV

Resolution Voltage: 10 mV (20 mV if rating voltage 36 V)

Characteristic

PS2520 and PS2520G:

two outputs 0 to 36 V, 0 to 1.5 A and

one output 0 to 6 V, 3 A

PS2521 and PS2521G:

two outputs 0 to 20 V, 0 to 2.5 A

one output 0 to 6 V, 0 to 5 A

PS2520 and PS2520G: 0 to 72 V, 0 to 1.5 A

PS2521 and PS2521G: 0 to 40 V, 0 to 2.5 A

PS2520 and PS2520G: 0 to 36 V, 0 to 3 A

PS2521 and PS2521G: 0 to 20 V, 0 to 5 A

38.5 V on 36 V outputs

7.0 V on 6 V output

PS2521 and PS2521G:

22.5 V on 20 V outputs

7.0 V on 6 V output

Current: ≤ 3 mA (≤ 6 mA if rating current 3.5 A)

Current: ≤ 3 mA

Current: 1 mA (2 mA if rating current 3.5 A)

OVP: 10 mV (20 mV if rating voltage 36 V)

PS2520, PS2520G, PS2521 & PS2521G User Manual

27

Page 42

Appendix A: Specifications

Table 2: Operating Characteristics (Cont.)

Name Characteristic

Program Accuracy

(25 ± 5_ C)

Ripple and Noise

20 Hz to 20 MHz

Temperature Coefficient

(0_ C to 40_ C)

Readback Resolution

Readback Accuracy

(25 ± 5_ C)

Voltage: ≤ 0.05% + 25 mV (+50 mV if rating voltage

36 V)

Current: ≤ 0.2% + 10 mA

OVP: ≤ 2% + 0.6 V

Voltage Ripple: 1 mV

Voltage Noise: 2 mV

Current: ≤ 3 mA

RMS

/3 mV

RMS

/30 mV

RMS

(≤ 5 mA

p-p

p-p

if rating current

RMS

3.5 A)

Voltage: ≤ 100 ppm + 3 mV

Current: ≤ 150 ppm + 3 mA

Voltage: 10 mV (20 mV if rating voltage 36 V)

Current: 1 mA (2 mA if rating current 3.5 A)

Voltage: ≤ 0.05% + 25 mV (+50 mV if rating voltage

36 V)

28

Current: ≤ 0.2% + 10 mA

Response Time 10% to 90% (up): ≤ 100 ms

90% to 10% (down): ≤ 100 ms (≥ 10% rating load)

Readback Temperature

Coefficient

Voltage: ≤ 100 ppm + 10 mV (+20 mV if rating

voltage 36 V)

Current: ≤ 150 ppm + 10 mA

1

Drift

Voltage: ≤ 0.03% + 6 mV

Current: ≤ 0.1% + 6 mA

Series Tracking

tracking error

load effect

source effect

Voltage: ≤ 0.1% + 50 mV

Voltage: ≤ 50 mV

Voltage: ≤ 3 mV

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 43

Table 2: Operating Characteristics (Cont.)

Name Characteristic

Parallel Tracking

Appendix A: Specifications

program accuracy

(25 ± 5_ C)

load effect

source effect

GPIB Capability

IEEE-488.2 (optional)

Memory Locations

(Store and Recall)

Timer Setting Time: 1 to 65535 seconds

1

Change in output over an 8-hour interval under constant line, load,

and ambient temperature following a 30-minute warmup.

Voltage: ≤ 0.05% + 25 mV

(+50 mV if rating voltage > 36 V)

Current:: ≤ 0.2% + 20 mA

OVP: ≤ 2% + 0.6 V

Voltage: ≤ 3 mV rear output (≤ 6 mV front output)

Current: ≤ 6 mA (≤ 12 mA if rating current > 3.5 A)

Voltage: ≤ 3 mV

Current: ≤ 6 mA

SH1, AH1, T6, L4, SR1, RL1, PP0, DC1, DT0, C0,

E1

00 – 49 (50 locations)

Resolution: 1 second

Table 3: Electrical Characteristics

Name Description

Power Source 100, 120, and 220 VAC, ± 10% 50 – 60 Hz

240 VAC –10% + 4.2% 50 – 60 Hz

Safety ETL listed to UL 1244

Certified to CSA–C22.2 No 231–M89

PS2520, PS2520G, PS2521 & PS2521G User Manual

29

Page 44

Appendix A: Specifications

Table 4: Environmental Characteristics

Name

Storage Temperature

Operating Temperature

Description

–10_ C to +70_ C (+14_ F to +158_ F)

0_ C to +40_ C (+32_ F to +104_ F)

Table 5: Physical Characteristics

Name

Overall Dimensions Width: 255 mm (10.0 in)

Weight 10 kg (22 lbs)

Description

Height: 145 mm (5.7 in)

Depth: 346 mm (13.6 in)

30

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 45

Appendix B: Maintenance

This appendix provides information for the basic maintenance of the

power supply . Electronic maintenance on the power supply must be

performed by a trained technician. However, an operator can perform

some basic and routine maintenance.

Cleaning

T o clean the power supply, use a soft cloth dampened in a solution of

mild detergent and water. Do not spray cleaner directly onto the

instrument, since it may leak into the cabinet and cause damage.

Do not use chemicals containing benzine, benzene, toluene, xylene,

acetone, or similar solvents.

Do not use abrasive cleaners on any portion of the frequency counter.

Warranty Service

The power supplies are covered by a standard T ektronix one-year

warranty . The warranty statement appears at the front of this manual.

If the power supply fails during the warranty period, return it to

T ektronix for free servicing (subject to conditions of the warranty

statement).

T o arrange for warranty service or to get an estimate on a product

that is out of warranty, call your local Tektronix office. If you are

within the continental U.S., you may call 1-800-TEK-WIDE

(1-800-835-9433) for assistance. When you call, have the serial

number of the power supply available. The serial number is located

on the left side of the rear panel.

PS2520, PS2520G, PS2521 & PS2521G User Manual

31

Page 46

Appendix B: Maintenance

Repackaging for Shipment

If your instrument must be returned for servicing, use the original

packing materials if possible. If the original materials are unfit or

unavailable, repackage the power supply in the following manner:

1. Use a sturdy shipping carton made of corrugated cardboard that

has an interior size of at least 15 cm (6 in) greater than the

instrument size in all directions.

2. Enclose the following information:

H Owner’s name and address

H Name and phone number of a person that T ektronix should

contact

H Serial number of the instrument

H Description of the problem

3. Completely wrap the power supply with polyethylene sheeting

(or equivalent material) to protect the outside finish and keep

harmful substances out of the power supply.

4. Cushion the instrument on all sides with 8 cm (3 in) of padding

material or urethane foam tightly packed between the carton and

the instrument.

5. Seal the shipping carton with an industrial stapler or strapping

tape.

6. Call your local Tektronix office for shipping instructions. If you

are within the continental U.S., you may call 1-800-TEK-WIDE

(1-800-835–9433) for assistance.

Troubleshooting

If the power supply does not function properly, refer to Table 6 to

eliminate operating faults.

32

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 47

Appendix B: Maintenance

WARNING. To prevent electrical shock, unplug the power cord and

disconnect the outputs before changing the line fuse or line voltage

setting.

Table 6: Troubleshooting Steps

Symptom

Supply does not power on H Power cord not connected properly; check

No output or incorrect

output

Error Message (“Err...”) H Setup error; check error number against error

Possible Causes

connections.

H Line voltage selection not correct; check

setting.

H Fuse blown; disconnect line cord and see

page 2 to open cover and replace fuse. Use

the proper fuse for the line voltage setting.

See page 37 for fuse part numbers.

H Leads not properly connected to the positive

and negative outputs.

H The output is not enabled (“OUT” indicator is

not lighted); press the OUTPUT button.

H The power supply settings are not appropriate

for the output load. The power supply is

functioning normally by limiting either current

or voltage. Check load or disconnect output to

verify.

description in Table 7 on page 34.

H Overvoltage protection tripped; correct the

cause and clear error (OVP RESET). Set

overvoltage protection to a higher value if

necessary.

H Overcurrent protection tripped; correct the

cause and clear the error (OCP

The power supply indicates an error in setup or operation by

displaying the message “Err –xxx” on the front panel. T able 7 lists

each message number and explains what the error code means.

PS2520, PS2520G, PS2521 & PS2521G User Manual

OFF).

33

Page 48

Appendix B: Maintenance

Table 7: Error Messages

Front Panel

Error Code

0 “No error”

–001 “Self-test failed; CPU test error”

–002 “Self-test failed; RAM test error”

–003 “Self-test failed; ROM test error”

–005 “Self-test failed; DAC/ADC test error”

–012 “Device-specific error; Overcurrent protection error”

–013 “Device-specific error; Overvoltage protection error”

–016 “Data out of range; Voltage too large”

–017 “Data out of range; Current too large”

–018 “Data out of range; Voltage too small”

–019 “Data out of range; Current too small”

Description

34

–064 “Setting conflict; Timer setting error”

–065 “Setting conflict; Overvoltage protection setting error”

–066 “Setting conflict; Address setting error”

–067 “Setting conflict; Voltage setting error”

–068 “Setting conflict; Current setting error”

–069 “Setting conflict; Recall setting error”

–070 “Setting conflict; Store setting error”

–091 “Device-specific error; Calibration current full-scale error”

–092 “Device-specific error; Calibration voltage full-scale error”

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 49

Appendix B: Maintenance

Table 7: Error Messages (Cont.)

Front Panel

Error Code

–093 “Device-specific error; Calibration overvoltage protection

–094 “Device-specific error; Calibration overvoltage protection

Description

full-scale error”

offset error”

PS2520, PS2520G, PS2521 & PS2521G User Manual

35

Page 50

Appendix B: Maintenance

36

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 51

Appendix C: Replaceable Parts

Replaceable parts may be ordered directly from your authorized

T ektronix dealer.

Standard Accessories

The items listed in T able 8 are shipped with the power supply:

Table 8: Standard Accessories

Accessory

Fuse,3AG, 4A, 250V,SB

(90 – 132 V operation)

User Manual 070-9196-XX

Programmer Manual (PS2520G and

PS2521G only)

Three sets of test leads 196-3384-XX

115V Power Cord Refer to Table 10

Optional Accessories

The items listed in T able 9 are available as optional accessories:

Table 9: Optional Accessories

Accessory

Fuse,3AG, 2A, 250V,SB

(198 – 250 V operation)

230V Power Cords Refer to Table 10

Tektronix Part Number

159-0149-00

070-9197-XX

Tektronix Part Number

159–0023–00

PS2520, PS2520G, PS2521 & PS2521G User Manual

37

Page 52

Appendix C: Replaceable Parts

The following power cords are available.

Table 10: Accessory Power Cords

Plug Configuration

Normal Usage

North America

115 V

Tektronix Part

Number

161-0104-00

Europe

230 V

United Kingdom

230 V

Australia

230 V

North America

230 V

Switzerland

230 V

161-0104-06

161-0104-07

161-0104-05

161-0104-08

161-0167-00

38

PS2520, PS2520G, PS2521 & PS2521G User Manual

Page 53

Index

A

accessories

optional, 37

standard, 37

amperes readout, depicted, 5

automatic tracking, 18

C

C.C., definition of, 9

C.V., definition of, 9

characteristics

electrical, 29

environmental, 30

operating, 27

physical, 30

cleaning, 31

connection

external parallel, 16

external series, 14

ground referenced, 11

isolated ground, 11

parallel, depicted, 16

controls

See also indicators

ADDRESS, 25

AUTO SEQ, 25

CURRENT (step), 10

CURRENT SET, 9

DELAY, 24

entry sequence, 6

front panel, 5

keypad, use of, 9

LOCAL, 25

OCP, 8

OUTPUT, 20

output selection, 7

OVP RESET, 8

OVP SET, 8

power switch, 5

rear panel, 6

RECALL, 22

RECALL LAST, 22, 24

RECALL NEXT, 22, 24

return key, 6

sense selector, 20

SHIFT, 7

STEP SET, 10

STORE, 21, 22

VOLTS (step), 10

VOLTS SET, 9

cooling, clearance, 3

cooling fan, depicted, 6

current limit, setting level of, 9

CURRENT steps, setting, 10

D

data entry, 6

data entry keypad, depicted, 5

diagnostics, 4

dimensions, physical, 30

E

error messages, 34

F

features

front panel, 5

product, 1

rear panel, 6

fuse, replacement, 3

PS2520, PS2520G, PS2521 & PS2521G User Manual

39

Page 54

Index

fuse access, depicted, 3, 6

G

GPIB connector, depicted, 6

GPIB option, 1

I

indicators

AUTO, 25

C.C., 9

C.V., 9

front panel depicted, 5

GPIB status, 5

OCP, 8

OUT, 7, 25

output, 5

PARA, 19

SERIES, 18

SHIFT, 7

installation

fuse, 3

power cord, 3

K

recalling from, 21, 22

storing to, 21, 22

O

OCP

definition of, 8

reset, 8

setting level of, 8

optional accessories, 37

output

enabling, 20

rating, 27

sensing level of, 20

output connectors

depicted, 5, 6

methods for connecting, 11

output controls, depicted, 5

output modes, independent, 12

overcurrent protection, setting level

of, 8

overvoltage protection, setting

level of, 8

OVP

definition, 8

maximum level, 27

reset, 8

keypad, depicted, 5

L

line voltage selector, depicted, 2, 6

M

maintenance, 31

master/slave operation, 18

memory indicator, depicted, 5

memory locations

40

PS2520, PS2520G, PS2521 & PS2521G User Manual

P

para operation, depicted, 19

parallel tracking, 19

power connector, depicted, 6

power cord, installation, 3

power switch, depicted, 5

procedure, general operation, 4

R

recalling stored settings, 22

Page 55

Index

repackaging, 32

replaceable parts, 37

S

selector, line voltage, 2

sense inputs, depicted, 6

sense selector, depicted, 6

sensing output level, procedure for,

20

sequence

RECALL, 22

STORE, 22

sequencing, automatic, 24

series tracking, 18

shipment, repackaging for, 32

specifications, 27

standard accessories, 37

status indicators, depicted, 5

STEP SET function, procedure for,

10

storing a sequence, 22

storing instrument settings, 21

T

telephone numbers, TEK WIDE,

31, 32

tracking, automatic, 18

troubleshooting, 32

V

voltage, setting limit of, 9

VOLTS readout, depicted, 5

VOLTS steps, setting, 10

W

warranty service, 31

weight, 30

PS2520, PS2520G, PS2521 & PS2521G User Manual

41

Page 56

Index

42

PS2520, PS2520G, PS2521 & PS2521G User Manual

Loading...

Loading...