Page 1

PCIP-DMM/A

User’s Manual

Page 2

Part Number: 24423

First Printing: July 1991

Copyright 0 1991

bY

Keithley MetraByte Corporation

440 Myles Standish Boulevard

Taunton, Massachusetts 02780

WARNING

Keithley MetraByte Corporation assumes no liability for damages consequent to the use of this

product. This product is not designed with components of a level of reliability suitable for use

in life support or critical applications.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system,

or transmitted, in any form by any means, electronic, mechanical, photocopying, recording, or

otherwise, without the express prior written permission of MetraByte Corporation.

Information furnished by Keithley MetraByte Corporation is believed to be accurate and reliable.

However, no responsibility is assumed by MetraByte Corporation for its use; nor for any

infringements of

Keithley MetraByte TM

atents or other rights of third parties which ma result from its use. No license

Y is granted by imp

ication or otherwise under any patent rights of x

eithley MetraByte Corporation.

(hereinafter referred to as MetraByte) is a trademark of Keithley MetraByte

Corporation.

BASICTM is a trademark of Dartmouth College.

IBM8 is a registered trademark of International Business Machines Corporation.

PC, XT, and AT@ are trademarks of International Business Machines Corporation.

Microsoft@ is a registered trademark of Microsoft Corporation.

. . .

III

Page 3

New Contact Information

Keithley Instruments, Inc.

28775 Aurora Road

Cleveland, OH 44139

Technical Support: 1-888-KEITHLEY

Monday – Friday 8:00 a.m. to 5:00 p.m (EST)

Fax: (440) 248-6168

Visit our website at http://www.keithley.com

Page 4

WARRANTY

Hardware

Keithley Instruments, Inc. warrants that, for a period of one (1) year from the date of shipment (3 years for Models 2000,

2001, 2002, 2010 and 2700), the Keithley Hardware product will be free from defects in materials or workmanship. This

warranty will be honored provided the defect has not been caused by use of the Keithley Hardware not in accordance with

the instructions for the product. This warranty shall be null and void upon: (1) any modification of Keithley Hardware that

is made by other than Keithley and not approved in writing by Keithley or (2) operation of the Keithley Hardware outside

of the environmental specifications therefore.

Upon receiving notification of a defect in the Keithley Hardware during the warranty period, Keithley will, at its option,

either repair or replace such Keithley Hardware. During the first ninety days of the warranty period, Keithley will, at its

option, supply the necessary on site labor to return the product to the condition prior to the notification of a defect. Failure

to notify Keithley of a defect during the warranty shall relieve Keithley of its obligations and liabilities under this

warranty.

Other Hardware

The portion of the product that is not manufactured by Keithley (Other Hardware) shall not be covered by this warranty,

and Keithley shall have no duty of obligation to enforce any manufacturers' warranties on behalf of the customer. On those

other manufacturers’ products that Keithley purchases for resale, Keithley shall have no duty of obligation to enforce any

manufacturers’ warranties on behalf of the customer.

Software

Keithley warrants that for a period of one (1) year from date of shipment, the Keithley produced portion of the software or

firmware (Keithley Software) will conform in all material respects with the published specifications provided such Keithley

Software is used on the product for which it is intended and otherwise in accordance with the instructions therefore.

Keithley does not warrant that operation of the Keithley Software will be uninterrupted or error-free and/or that the Keithley

Software will be adequate for the customer's intended application and/or use. This warranty shall be null and void upon any

modification of the Keithley Software that is made by other than Keithley and not approved in writing by Keithley.

If Keithley receives notification of a Keithley Software nonconformity that is covered by this warranty during the warranty

period, Keithley will review the conditions described in such notice. Such notice must state the published specification(s)

to which the Keithley Software fails to conform and the manner in which the Keithley Software fails to conform to such

published specification(s) with sufficient specificity to permit Keithley to correct such nonconformity. If Keithley determines that the Keithley Software does not conform with the published specifications, Keithley will, at its option, provide

either the programming services necessary to correct such nonconformity or develop a program change to bypass such

nonconformity in the Keithley Software. Failure to notify Keithley of a nonconformity during the warranty shall relieve

Keithley of its obligations and liabilities under this warranty.

Other Software

OEM software that is not produced by Keithley (Other Software) shall not be covered by this warranty, and Keithley shall

have no duty or obligation to enforce any OEM's warranties on behalf of the customer.

Other Items

Keithley warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries, diskettes,

and documentation.

Items not Covered under Warranty

This warranty does not apply to fuses, non-rechargeable batteries, damage from battery leakage, or problems arising from

normal wear or failure to follow instructions.

Limitation of Warranty

This warranty does not apply to defects resulting from product modification made by Purchaser without Keithley's express

written consent, or by misuse of any product or part.

Page 5

Disclaimer of Warranties

EXCEPT FOR THE EXPRESS WARRANTIES ABOVE KEITHLEY DISCLAIMS ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION, ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. KEITHLEY DISCLAIMS ALL WARRANTIES WITH

RESPECT TO THE OTHER HARDWARE AND OTHER SOFTWARE.

Limitation of Liability

KEITHLEY INSTRUMENTS SHALL IN NO EVENT, REGARDLESS OF CAUSE, ASSUME RESPONSIBILITY FOR

OR BE LIABLE FOR: (1) ECONOMICAL, INCIDENTAL, CONSEQUENTIAL, INDIRECT, SPECIAL, PUNITIVE OR

EXEMPLARY DAMAGES, WHETHER CLAIMED UNDER CONTRACT, TORT OR ANY OTHER LEGAL THEORY,

(2) LOSS OF OR DAMAGE TO THE CUSTOMER'S DATA OR PROGRAMMING, OR (3) PENALTIES OR PENALTY

CLAUSES OF ANY DESCRIPTION OR INDEMNIFICATION OF THE CUSTOMER OR OTHERS FOR COSTS, DAMAGES, OR EXPENSES RELATED TO THE GOODS OR SERVICES PROVIDED UNDER THIS WARRANTY.

Keithley Instruments, Inc.

Sales Offices: BELGIUM: Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02-363 00 40 • Fax: 02/363 00 64

CHINA: Yuan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-6202-2886 • Fax: 8610-6202-2892

FINLAND: Tietäjäntie 2 • 02130 Espoo • Phone: 09-54 75 08 10 • Fax: 09-25 10 51 00

FRANCE: 3, allée des Garays • 91127 Palaiseau Cédex • 01-64 53 20 20 • Fax: 01-60 11 77 26

GERMANY: Landsberger Strasse 65 • 82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

GREAT BRITAIN: Unit 2 Commerce Park, Brunel Road • Theale • Berkshire RG7 4AB • 0118 929 7500 • Fax: 0118 929 7519

INDIA: Flat 2B, Willocrissa • 14, Rest House Crescent • Bangalore 560 001 • 91-80-509-1320/21 • Fax: 91-80-509-1322

ITALY: Viale San Gimignano, 38 • 20146 Milano • 02-48 39 16 01 • Fax: 02-48 30 22 74

JAPAN: New Pier Takeshiba North Tower 13F • 11-1, Kaigan 1-chome • Minato-ku, Tokyo 105-0022 • 81-3-5733-7555 • Fax: 81-3-5733-7556

KOREA: 2FL., URI Building • 2-14 Yangjae-Dong • Seocho-Gu, Seoul 137-888 • 82-2-574-7778 • Fax: 82-2-574-7838

NETHERLANDS: Postbus 559 • 4200 AN Gorinchem • 0183-635333 • Fax: 0183-630821

SWEDEN: c/o Regus Business Centre • Frosundaviks Allé 15, 4tr • 169 70 Solna • 08-509 04 679 • Fax: 08-655 26 10

SWITZERLAND: Kriesbachstrasse 4 • 8600 Dübendorf • 01-821 94 44 • Fax: 01-820 30 81

TAIWAN: 1FL., 85 Po Ai Street • Hsinchu, Taiwan, R.O.C. • 886-3-572-9077• Fax: 886-3-572-9031

28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax: 440-248-6168

1-888-KEITHLEY (534-8453) • www.keithley.com

4/02

Page 6

S

The following safety precautions should be observed before using this product and any associated instrumentation.

Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations

where hazardous conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety

precautions required to avoid possible injury. Read and follow all installation, operation, and maintenance information

carefully before using the product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that

the equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately

trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use

of the instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting

the line voltage or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, and perform safe installations and repairs of products. Only

properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are rated Installation Category I and Installation

Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most measurement, control, and data I/O signals are Installation Category I and must not be directly connected to mains voltage

or to voltage sources with high transient over-voltages. Installation Category II connections require protection for high

transient over-voltages often associated with local AC mains connections. Assume all measurement, control, and data

I/O connections are for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or

test fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels

greater than 30V RMS, 42.4V peak, or 60VDC are present.

age is present in any unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that

operators are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential human contact. Product operators in these circumstances must be trained to protect themselves from

the risk of electric shock. If the circuit is capable of operating at or above 1000 volts,

may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance

limited sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards,

install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect

the connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

afety Precautions

A good safety practice is to expect that hazardous volt-

no conductive part of the circuit

5/02

Page 7

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main

input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the

operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting

or disconnecting cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions or the

safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground con-

nections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation re-

quires the use of a lid interlock.

If or is present, connect it to safety earth ground using the wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined

effect of normal and common mode voltages. Use standard safety precautions to avoid personal contact with these

voltages.

The

WARNING

associated information very carefully before performing the indicated procedure.

The

CAUTION

the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits, including the power

transformer, test leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable

national safety approvals, may be used if the rating and type are the same. Other components that are not safety related

may be purchased from other suppliers as long as they are equivalent to the original component. (Note that selected parts

should be purchased only through Keithley Instruments to maintain accuracy and functionality of the product.) If you

are unsure about the applicability of a replacement component, call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based cleaner. Clean the exterior of the instrument only. Do

not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist

of a circuit board with no case or chassis (e.g., data acquisition board for installation into a computer) should never

require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected,

the board should be returned to the factory for proper cleaning/servicing.

heading in a manual explains dangers that might result in personal injury or death. Always read the

heading in a manual explains hazards that could damage the instrument. Such damage may invalidate

Page 8

-.

<

Page 9

TABLE OF CONTENTS

CHARTER 1

INTRODUCTION

1.1 GENERAL INTRODUCTION.. ............................................................................................

1.2 FUNCTIONAL DESCRIPTION.. ..........................................................................................

1.3 FILES ON THE

1.4 SPECIFICATIONS ...................................................................................................................

1.5 ORDERING

1.6 HOW TO USE THIS MANUAL..

CHARTER 2

PCIP-DMM UTILITY DISK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . l-3

INFORMATION.. .............................................................................................

..........................................................................................

.1-l

l-2

l-3

l-7

l-8

2.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........ 2-l

2.2 UNPACKING

AND INSPECTION.. ...................................................................................

2.3 BASE ADDRESS SWITCH..

2.4 BOARD

INSTALLATION ....................................................................................................

2.5 SYSTEM CONNECTIONS

..................................................................................................

....................................................................................................

.2-l

.2-2

..2- 3

.2-5

CHAPTER 3

GETTING STARTED

3.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........ 3-l

3.2 MAKING A BACKUP COPY OF THE SOFTWARE

3.3 INSTALLING THE PCIP-DMM SOFTWARE

3.4 ADDING ANSLSYS TO CONFIGSYS

3.5 INSTALLING THE DEVICE

3.6 ADDITIONAL PCIP-DMM

DRIVERS.. ............................................................................

PROGRAMS ..........................................................................

................................................................................

................................................................... .3-2

.........................................................

.3-l

.3-2

.3-3

.3-23

CHARTER 4

OPERATING THE PCIP-DMM

4.1 GENERAL..

...........................................................................................................................

4.2 USING A MOUSE.. .................................................................................................................

4.3 USING A KEYBOARD..

.........................................................................................................

4.4 ON-LINE HELP.. ....................................................................................................................

4.5 THE SETUP PANEL.. .............................................................................................................

4.6 THE DATA LOGGING

4.7 LOGGING

DATA..

PANEL.. ..........................................................................................

.................................................................................................................

...4-1

4-l

4-l

.4-2

4-2

4-4

.4-6

CHAPTER 5

DATA FILE STRUCTURE

5.1 GENERAL

.............................................................................................................................

5.2 COMMENTS.. ..........................................................................................................................

5.3 DATA FILES

............................................................................................................................

5.4 DATA-SET FILE (SAMPLE). ................................................................................................

...5-1

5-1

5-l

.5-5

CHARTER 6

PROGRAMMING

6.1 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........ 6-l

6.2 LANGUAGE INDEPENDENT

INTERFACE COMMANDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-l

6.3 DIRECT SCREEN I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

6.4 PROGRAMMING HINTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27

V

Page 10

CHAPTER 7

MAINTENANCE AND REPAIR

7.1 GENERAL.. ..............................................................................................................................

7.2 TEST EQUIPMENT.. ..............................................................................................................

7.3 PERFORMANCE VERIFICATION ......................................................................................

7.4 CALIBRATION

7.5 FUSE REPLACEMENT.. .......................................................................................................

7.6 WARRANTY INFORMATION..

7.7 RETURN TO FACTORY INFORMATION

APPENDIX A - INSTALLING MULTIPLE PCIP-TYPE INSTRUMENTS

APPENDIX B - REGISTER DESCRIPTIONS

.......................................................................................................................

.......................................................................................... .7-10

........................................................................ ..7-11

7-1

.7-l

.7-2

.7-9

..7-10

vi

Page 11

LIST OF TABLES

Table

l-l. Ordering

2-l. Connectors..

6-l. Language Interface Commands..

7- 1. Test Equipment Specifications..

7-2. DC Voltage Readings.. ..........................................................................................

7-3. PCIP-DMM AC Voltage Range.. .............................................................................

7-4. Resistance Readings ............................................................................................

7-5. AC Current Values..

7-6. DC Current Values.. .............................................................................................

Information.. ..........................................................................................

........................................................................................................

..........................................................................

...........................................................................

..............................................................................................

TABLE OF FIGURES

Figure

Location of Switches .............................................................................................

;I;*

Example

2-3:

Utility Program

Start-up Screen ...................................................................................................

;I;*

Selecting the

3-3:

Generating the Path Name to VISYS.. ..................................................................

3-4.

Specifying the Type of Monitor..

3-5.

Defining the .........................................................................................

3-6.

Defining the

3-7.

Defining the

3-8.

Confhming the

3-9.

Generating the DMM.SYS Path

3- 10. Pop-Up Key Def’mittion .........................................................................................

3- 11. Selecting a Base Address .....................................................................................

3-12. Confirmin the PCIP-DMM Setup..

3-13. f Creation o

3-14. CONFIGBAK already exists..

3- 15. Utility Program Start-Up Screen ..........................................................................

4-l. Setup Panel.. ........................................................................................................

4-2. The Data Logging Panel.. ......................................................................................

5- 1. Data File Header.. ................................................................................................

5-2. Data Section of the Data File.. ..............................................................................

6- 1. Opening the Language Interface File in BASIC ......................................................

6-2. Opening the Language Interface File in C..

7- 1. Connection of DC Calibrator to PCIP-DMM ...........................................................

7-2. Connection of AC Calibrator to PCIP-DMM..

7-3. Connection of Calibration Resistor..

7-4. Connection of AC Current Calibrator to PCIP-DMM.. ............................................

7-5. CALDMM Start-up Screen.. ..................................................................................

Base Address Switch ..................................................................

Start-Up

Boot Drive..

Help Key..

Mode Select

Instrument Select ......................................................................

System Setup

the new CONFIG.SYS.. ......................................................................

Setting

Screen.. .........................................................................

.....................................................................................

............................................................................ .3-8

.............................................................................. 3-l 1

Key..

Key

............................................................................... .3- 13

............................................................................. .3- 14

...................................................................... .3- 17

............................................................................... .3-18

...........................................................

..................................................................... .7-5

.........................................................

Page

l-7

.2-5

.6-4

.7- 1

.7-4

.7-5

..7- 6

7-7

.7-8

Page

.2-2

.2-3

.2-4

..3- 6

.3-7

.3-8

.3- 10

.3- 12

.3- 15

.3- 16

.3-18

.3-24

.4-2

.4-4

.5-2

.5-3

.6-2

.6-3

.7-2

.7-4

.7-6

.7-10

vii

Page 12

PCIP-DMM/A User’s

Manual

Introduction

CHAPTER 7

INTRODUCTION

7.7 GENERAL INTRODUCTiON

Keithley MetraByte’s PCIP-DMM/A is a 4 l/2 digit multimeter that plugs directly into any

I/O slot of an IBM 8 PC/XT/AT or IBM I’S/2 model 25/30 or compatible. The board provides all the features and accuracy you would expect from a standard bench-top multimeter.

However, instead of LED’s or LCD’s, the PCF-DMM/A uses the computer screen as its

display which is programmed by using the computer keyboard or a “mouse”. The display

operates in a “pop-up” mode. When activated, the DMM display takes up approximately

one-third of the screen. When the DMM display is deactivated, the screen returns to its

original display.

The PCIP-DMM/A also features automatic or manual data-logging. This records PCIPDMM/A readings to a user-specified ASCII file. This file may be used as input to popular

spread-sheet programs for plotting. When automatic logging is selected, the PUP-DMM/A

can be programmed to record up to 999999 readings at a rate of l/2 seconds to 99.9 minutes

between readings. Automatic logging may be setup to run in the background while the PC

is used for other tasks.

The PCIP-DMM/A is fully isolated from the computer and line power. The voltage and

current input protection assures that board will not be damaged by intentional or inadvertent connections to 120 Vat power. All connections are made through three IEC approved

recessed safety jacks. The terminals are spaced at the standard 3/4 inches, and compatible

with a wide variety of interconnecting and cabling schemes.

For users who have sophisticated applications, MetraByte provides a library of Language

Independent Interface commands. These ASCII commands are incorporated into a userdesigned application program. For example, to set the board to the 20 Vdc range, you

would use the command

SET 20 volt DC .

Application programs can be programmed in

several languages including: BASIC 8, PASCAL, C, and FORTRAN.

l-l

Page 13

Introduction

PCIP-DMM/A User’s

Manual

7.2 FUNCTIONAL DESCRIPTION

This section provides an overall functional description of the PCIP-DMM/A.

The inputs to the PCIP-DMM/A are isolated (400 V) from the computer. This protects the

computer in the event that there are high voltages present at the PCIP-DMM/A inputs.

Power is supplied to the isolated side of the PCIP-DMM/A by a transformer-coupled DC to

DC converter. A group of opto-couplers are used to isolate the various control signals travelling between the computer and these signals.

Voltuge Measurements

Voltage measurements are made between the VOLT-OHM and COMMON connectors on

the PCIP-DMM/A. There are four voltage ranges: 2OOmV, 2 V, 2OV, and 200 V. A programmable resistor divider network scales the input voltage signal and also provides 10 MOhm

input impedance. The signal is then buffered. AC signals are routed to a true RMS (TRMS)

converter which is set to give an output DC voltage equal to the RMS value of a signal

applied to its input. The signal is then routed to

the

analog to digital (A/D) converter. DC

signals are routed directly to the A/D converter.

Current Measurements

Current Measurements are made between the MA and COMMON connectors

on the

PCIPDMM/A. The PCIP-DMM/A is capable of measuring AC or DC current. The current

develops a voltage across a programmable shunt resistance on the PCIP-DMM/A. This

voltage signal is then routed to either the AC or DC converter and X10 amplifier used for

voltage measurements.

Resistance Measurements

Resistance Measurements are made by a ratio technique. A reference voltage is connected

to a voltage divider formed by a known programmable reference resistor and the resistance

to be measured. The reference voltage is measured at a convenient time, typically when a

resistance range is first selected. Then the voltage across the unknown resistance is measured. The value of the unknown resistance is related to the reference voltage and reference

resistor as follows:

Unknown Resistance = Rx

Voltage across Rx = Vx

Reference Resistor = Rref

Reference Voltage = Vref

l-2

Page 14

PCIP-DMM/A User’s

Manual

Introduction

Rx = (Vx x Rref)/(Vref - Vx)

Range selection is accomplished by switching in the appropriate provided reference resistor.

7.3 PC/P-DMM/A DlSTRlBUTlON DISKETTES

The PCIP-DMM/A is shipped with a complete set of software drivers, support utilities, and

examples. Refer to the file FILESJJOC for a complete listing of the files supplied. The Software is normally provided on 5 l/4” diskettes. It is optionally available on 3 1 /Z” diskettes.

7.4 SPEClFICATlONS

This section lists

the

operating specifications for the PCIP-DMM/A board.

DC Voltage

Range

200 mV 1opv

2v 1oOjlV

2ov

I

2oov

I

Resolution Accuracy

1mV

I

1OmV

I

+/- (% of reading + digits)

(With zero set by REL function)

1 Year

0.03 + Id

0.03 + Id

0.03 + Id

0.03 + Id

Settling Time: 1 set to within 3 counts of final reading on range.

Overload: 250 Vdc or peak AC

Input

Impedance

>lO&IMOhm I

>1003 MOhm

10 MOhm

10 MOhm

I

l-3

Page 15

Introduction PCIP-DMM/A User’s

Manual

AC Voltage (True MS, AC Coupled)

Range Resolution Accuracy

+/- (% of reading + digits)

6oHz

1 Year

I

200 mV

I

1OlV

I

1+ Id

I

fylj+-

lOOOH

1 year

1 + Id

1 + Id

1OKHz

1 year

I

3+ld

I

3+ld

I

EEA-K-

Input

Impedance

>lO MOhm I I 1OOpF

>looO MOhm I I clOOPf

>l MOhm I I <lOOPf

>l MOhm I I clOOPf

Overload: 250 Vdc or peak AC

NOTE:

Accuracy is %FS and applies above 200 counts (1% of FS) and to the stated percent +

30 counts (0.15%) crest factor (ratio of peak to RhG) up to 3:l allowable, add + 0.1% for 3:l

crest factor.

Resistance

Range

2ccl ohm

2 KOhm

20 KOhm

200 KOhm

2 MOhm

Resolution

0.01 Ohm

0.1 Ohm

1 Ohm

1oohm

loo ohm

Accuracy

+/- (% of reading + digits)

(With zero set by REL function)

1 Year

0.03 + Id

0.03 + Id

0.03 + Id

0.03 + Id

0.03 + Id

Settling time: 2 sec. to within 3 counts of final value.

Overload: 250 V continuous

Open Circuit Voltage: ~3.5V all ranges

l-4

Page 16

PCIP-DMM/A User’s

Manual

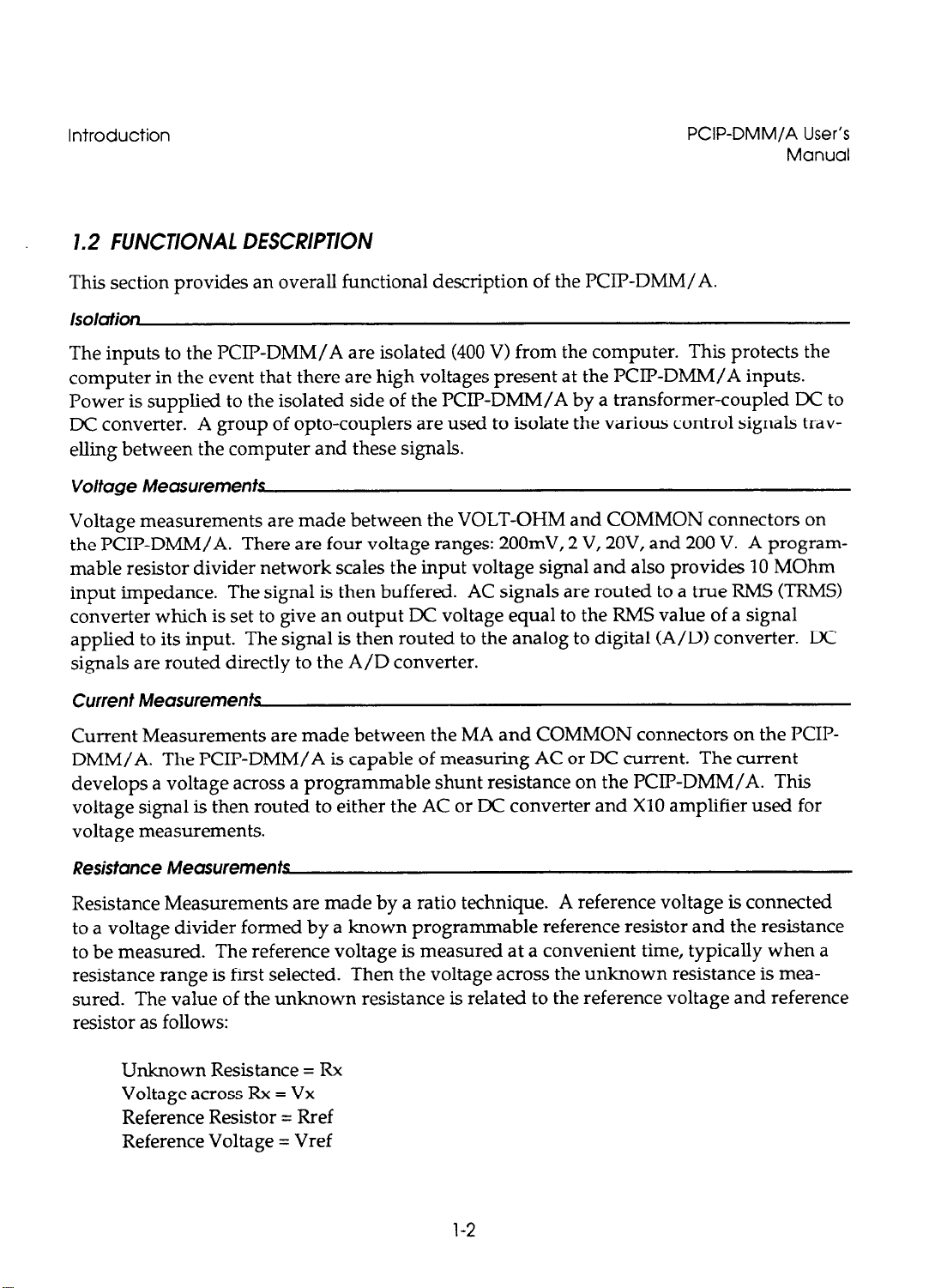

DC Current

Introduction

Range Resolution Accuracy

2mA

2omA

200 mA

0.1 /.L4

1clA

lOti

+/- (% of reading + digits)

(With zero set by REL function)

1 Year

0.03 + Id

0.03 + Id

0.03 + Id

Overload Protection: 0.5A, 100 Volts

AC Current

(above 1% of full scale)

Range

2mA

/

IzomA

1200mA

Resolution Accuracy

0.1 pA

Iti I

+/- (% of reading + digits)

1 Year

1 + Id

I

1 + Id

Overload: 0.5 A, 100 Volts

Burden

Voltage

03v

0.2 v

0.2 v

02v

I

-1

Conversion Rate

2.5 Readings/set.

Isolation

Input COM to computer ground, greater than 100 MOhm shunted by approx. 250pF. Max

input, COM to computer ground, 400 Vdc.

1-5

Page 17

Introduction

PCIP-DMM/A User’s

Manual

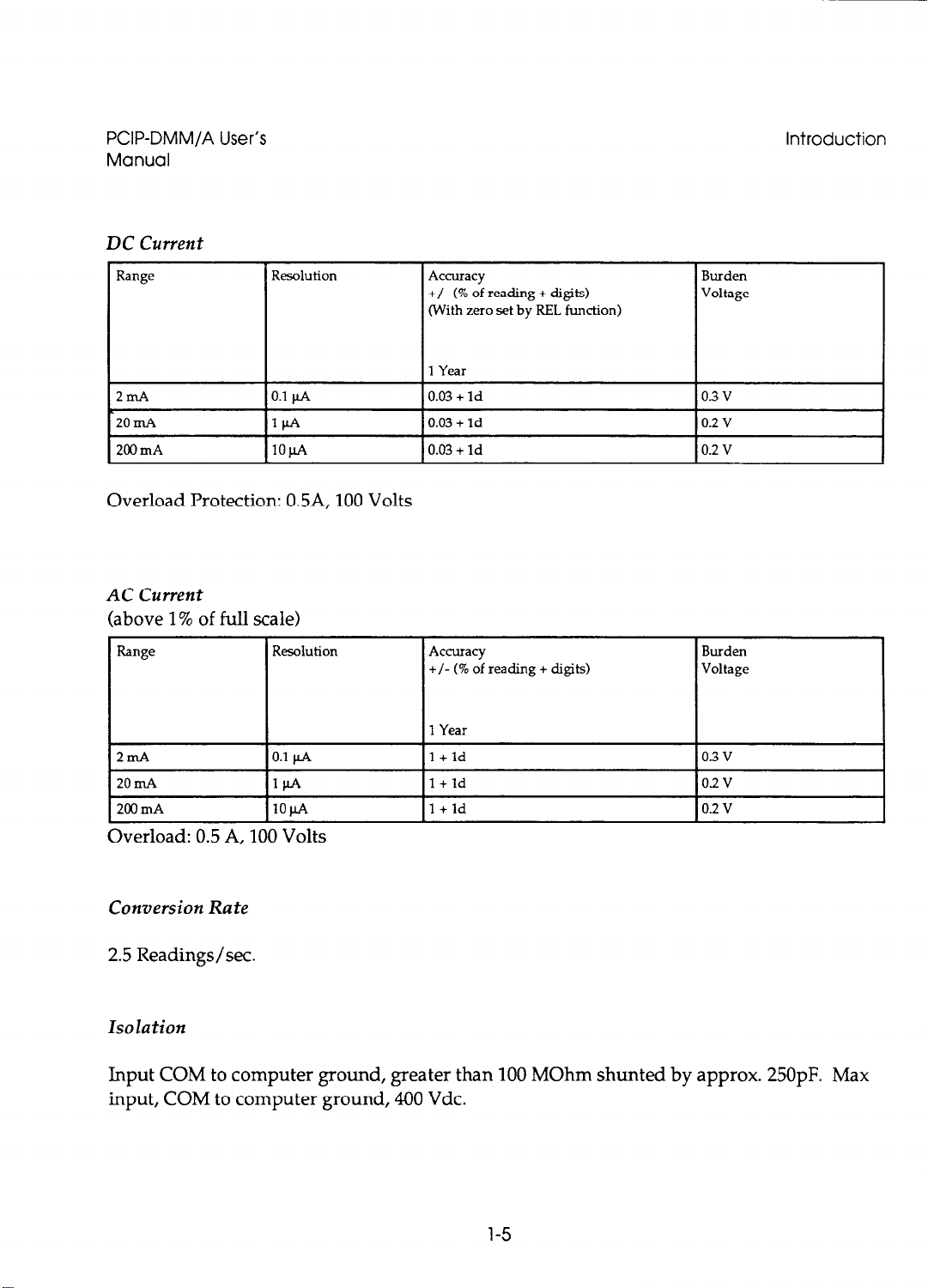

Power Drawn

from

the PC

+5 Volts - 985 mA typical, 1245 mA max.

Fuse Type

5 x 20 mm, Bussman GMA -l/2

BUS

XT/AT or compatible

Physical

Size:

13.25” X 4.20 ”

Weight: 11 oz.

Environmental

Operating Temperature Range: 0 to 50 o C

Storage Temperature Range: -20 to 70” C

Humidity: 0 to 90%, non-condensing

l-6

Page 18

Introduction PCIP-DMM/A User’s

Manual

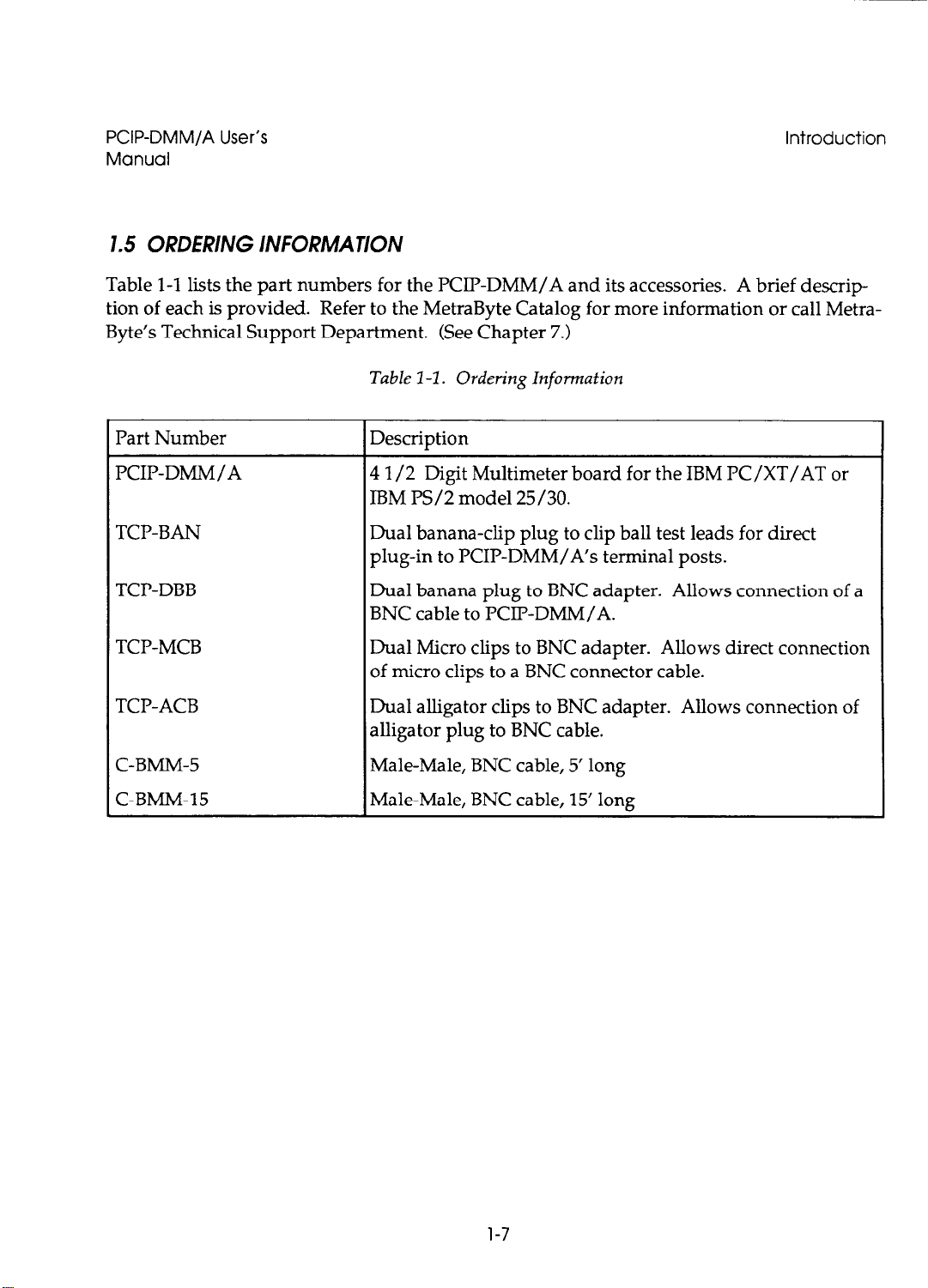

1.5 ORDERING INFORMATlON

Table l-1 lists the part numbers for the PUP-DMM/A and its accessories. A brief description of each is provided. Refer to the MetraByte Catalog for more information or call Metra-

Byte’s Technical Support Department. (See Chapter 7.)

Table l-l. Ordering Information

Part Number

PCIP-DMM/A

TCP-BAN

TCP-DBB

TCP-MCB

TCP-ACB

C-BMM-5

C-BMM-15

Description

4 l/2 Digit Multimeter board for the IBM PC/XT/AT or

IBM E/2 model 25/30.

Dual banana-clip plug to clip ball test leads for direct

plug-in to PCIP-DMM/A’s terminal posts.

Dual banana plug to BNC adapter. Allows connection of a

BNC cable to PCIP-DMM/A.

Dual Micro clips to BNC adapter. Allows direct connection

of micro clips to a BNC connector cable.

Dual alligator clips to BNC adapter. Allows connection of

alligator plug to BNC cable.

Male-Male, BNC cable, 5’ long

Male-Male, BNC cable, 15’ long

l-7

Page 19

Introduction

PCIP-DMM/A User’s

Manual

7.6 HOW TO USE THIS MANUAL

This manual is designed for a knowledgeable computer user. It assumes that the user is

familiar with the PC and its operation. At times, it may be necessary to refer to the Operator’s Manual provided with the computer and a reference manual for

the

language used in

custom application programs. Be sure to have these handy.

You may also find it useful to print out the example programs and the file

READMEDOC.

This file provides additional information which may not be included in this manual.

Chapter 2,“Installation” describes unpacking and inspection procedures, setting the base

address and memory configuration switches, installation of the board, and how to connect

peripherals.

Chapter 3, “Getting Started” tells you how to make copies of the PCIP-DMM/A Distribution

Diskettes. Additionally, the chapter describes how to install the device drivers and modify

your CONFIG.SYS file. This chapter also describes how to use the PCIP-DMM/A’s Setup

Panel to set the operating parameters.

Chapter 4, “Operating the PUP-DMM/A”, describes how to use the Setup and Data Logging

Panels.

Chapter 5, “Data File Structure”, describes the format of the file to which data is logged.

Chapter 6, “Programming”, describes the

Language

Independent Interface Commands and

gives other programming information.

Chapter 7, “Maintenance and Repair” gives a procedure for calibrating the PCIP-DMM/A.

Warranty information and Return-to-Factory instructions are also provided.

Appendix A gives instructions for the

PCIPMOD

program, used when installing multiple

PCIP-type instruments. Appendix B provides register descriptions.

l-8

Page 20

PCIP-DMM/A User’s

Manual

Installation

CHAPTER 2

INSTALLATION

2.7 GENERAL

This chapter describes how to install your PUP-DMM/A. The following information is

provided: unpacking and inspection procedures, setting of the base address switch, installation of the board, and system connections.

If you have installed optional peripheral boards in your PC before, you may want to skip

this chapter. Be sure however, that the base address switch has been set according to the

instructions in section 2.3. The PCIP-DMM/A is factory-calibrated and should be recalibrated when necessary. Calibration procedures are given in section 7.4.

2.2 UNPACKlNG AND INSPECTION

After you unpack the board from its outer shipping material:

1.

Remove the item from its packing material, while placing one hand

firmly on a metal portion of the system chassis. This will prevent any

damage to the board components due to possible static electricity

build-up during transit.

2. After allowing a moment for static electricity discharge, carefully

unwrap the board from the anti-static material.

3. Inspect the board for any possible damage. If any sign of damage is

detected, return the board to the factory as described in section 7.7.

Confirm that each item on the packing list has been shipped. It is a good idea to retain the

packing material in the event that the board must be returned to the factory for repair.

2-l

Page 21

Installation PCIP-DMM/A User’s

Manual

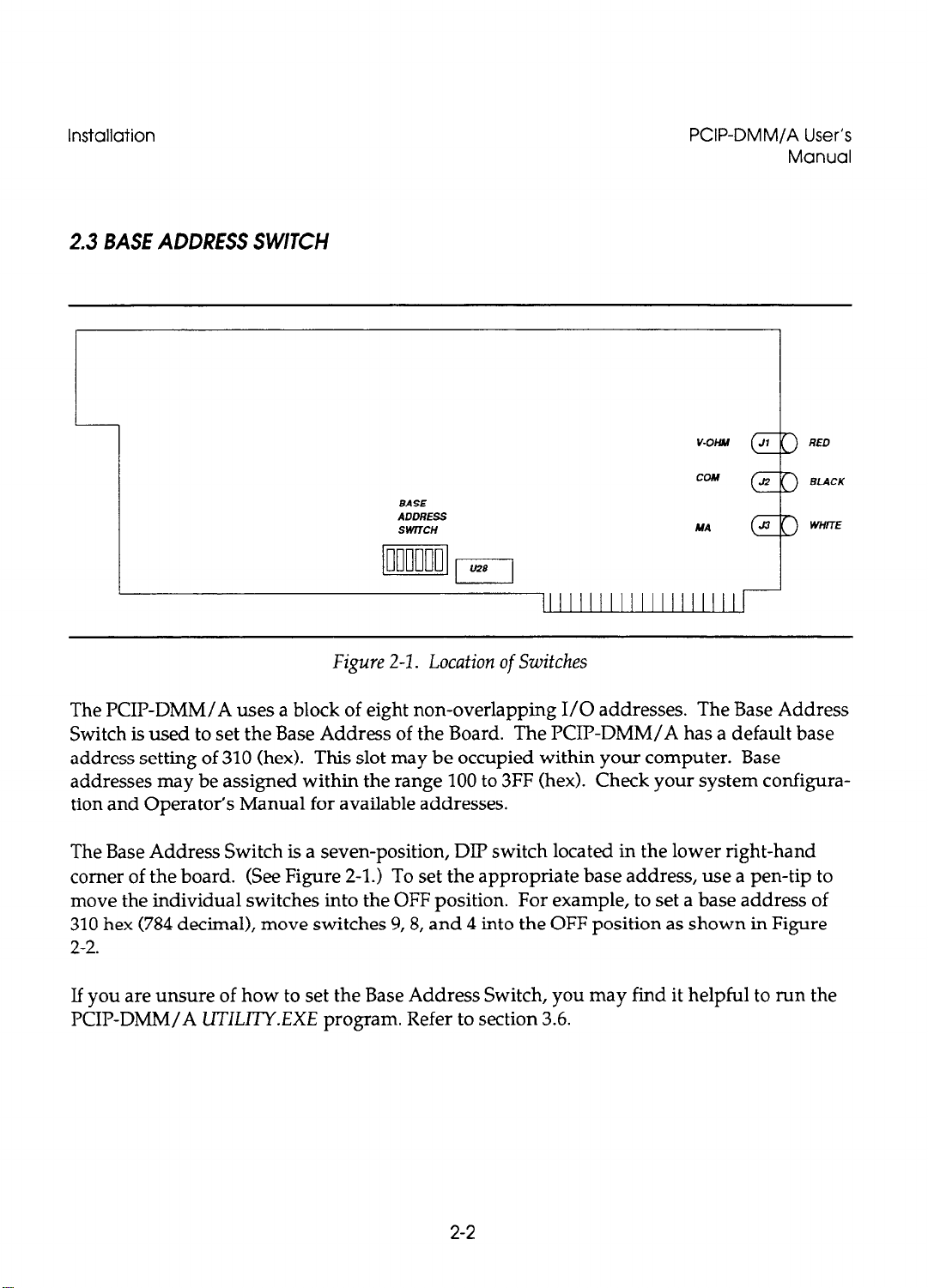

2.3 BASE ADDRESS SWITCH

RED

BASE

ADDRESS

SW7TCH

COh4

MA

BLACK

WHITE

Figure 2-1. Location of Switches

The PCIP-DMM/A uses a block of eight non-overlapping I/O addresses. The Base Address

Switch is used to set the Base Address of the Board. The PCIP-DMM/A has a default base

address setting of 310 (hex). This slot may be occupied within your computer. Base

addresses may be assigned within the range 100 to 3FF (hex). Check your system configura-

tion and Operator’s Manual for available addresses.

The Base Address Switch is a seven-position, DIP switch located in the lower right-hand

comer of the board. (See Figure 2-l.) To set the appropriate base address, use a pen-tip to

move the individual switches into the OFF position. For example, to set a base address of

310 hex (784 decimal), move switches 9,8, and 4 into the OFF position as shown in Figure

2-2.

If you are unsure of how to set the Base Address Switch, you may find it helpful to run the

PCIP-DMM/A U7’1LJTY.EXE program. Refer to section 3.6.

2-2

Page 22

installation PCIP-DMM/A User’s

Manual

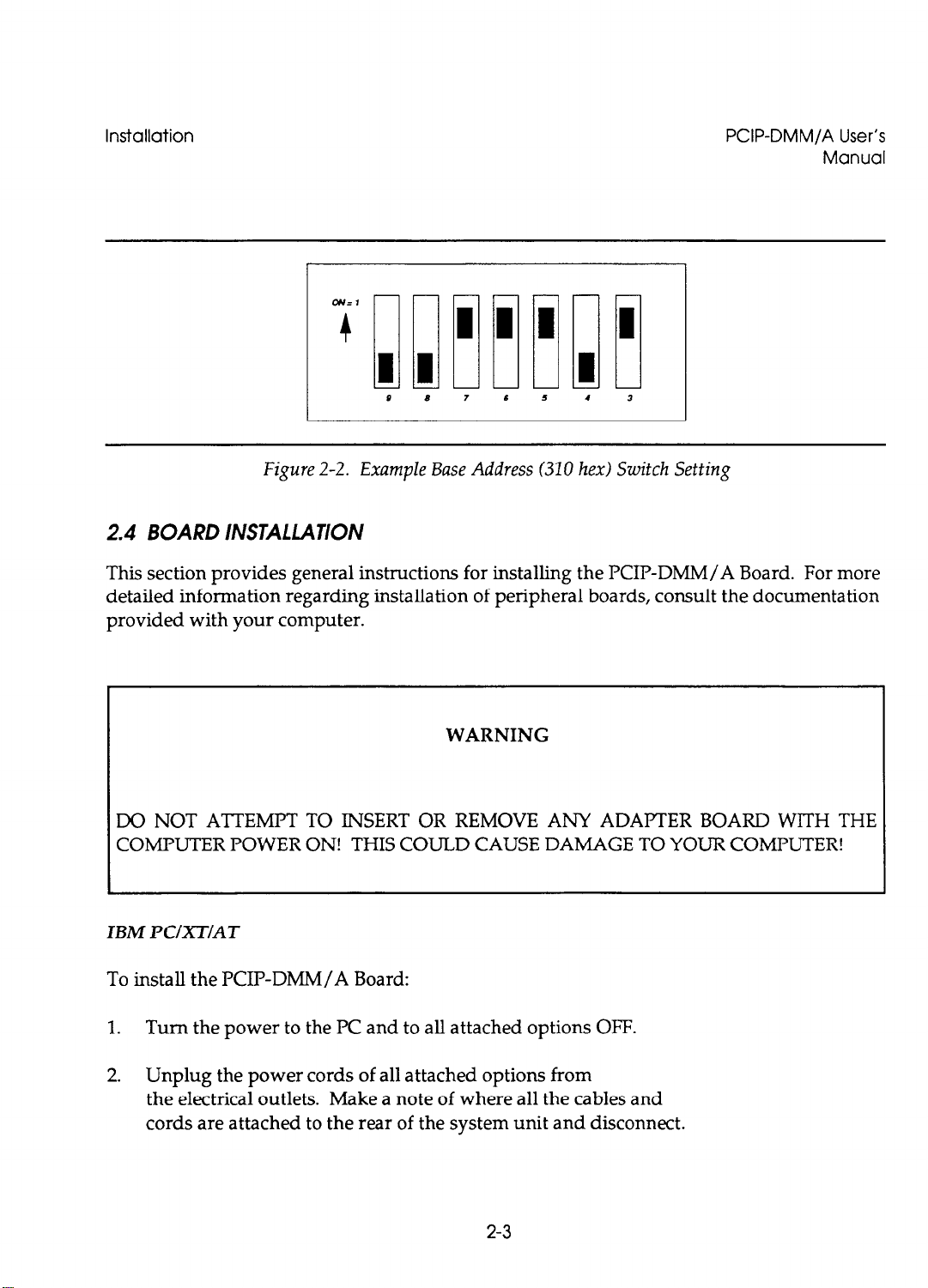

Figure 2-2. Example Base Address (310 hex) Switch Setting

2.4 BOARD INSTALLATION

This section provides general instructions for installing the PCIP-DMM/A Board. For more

detailed information regarding installation of peripheral boards, consult the documentation

provided with your computer.

WARNING

DO NOT ATTEMPT TO INSERT OR REMOVE ANY ADAPTER BOARD WITH THE

COMPUTER POWER ON! THIS COULD CAUSE DAMAGE TO YOUR COMPUTER!

IBM PC/XT/AT

To install the PCIP-DMM/A Board:

1. Turn the power to the PC and to all attached options OFF.

2. Unplug the power cords of all attached options from

the electrical outlets. Make a note of where all the cables and

cords are attached to the rear of the system unit and disconnect.

2-3

Page 23

Installation

3.

Remove the cover of the PC. To do this, first remove the five cover

mounting screws on the rear panel of the computer. Then, slide the

cover of the computer about 3/4 of the way forward.

Tilt the cover upwards

to remove.

4.

Choose an available option slot. Loosen and remove the screw at the top of

the blank adapter plate. Then slide the plate up and out to remove.

5.

Hold the PCIP-DMM/A in one hand. With the other hand, touch any metallic

part of the PC/AT cabinet. This will safely discharge any static

electricity which has built-up in your body.

6.

Set the desired Base Address as described in section 2.3.

7.

Align the gold edge connector with the edge socket and the back adapter

place with the adapter plate screw. Gently press the board downward into

the socket. Re-install the adapter plate screw.

PCIP-DMM/A User’s

Manual

8.

Replace the computer’s cover. Tilt the cover up and slide it onto the

system’s base, making sure the front of the cover is under the rail along

the front of the frame. Install the mounting screws.

9.

Plug in all cords and cables. Turn the power to the computer back on.

IBM PSI2 Models 2930

This installation procedure is similar to the one outlined above. For specific information,

refer to your operator’s manual.

You are now ready to make any necessary system connections and install the software.

2-4

Page 24

installation

PCIP-DMM/A User’s

Manual

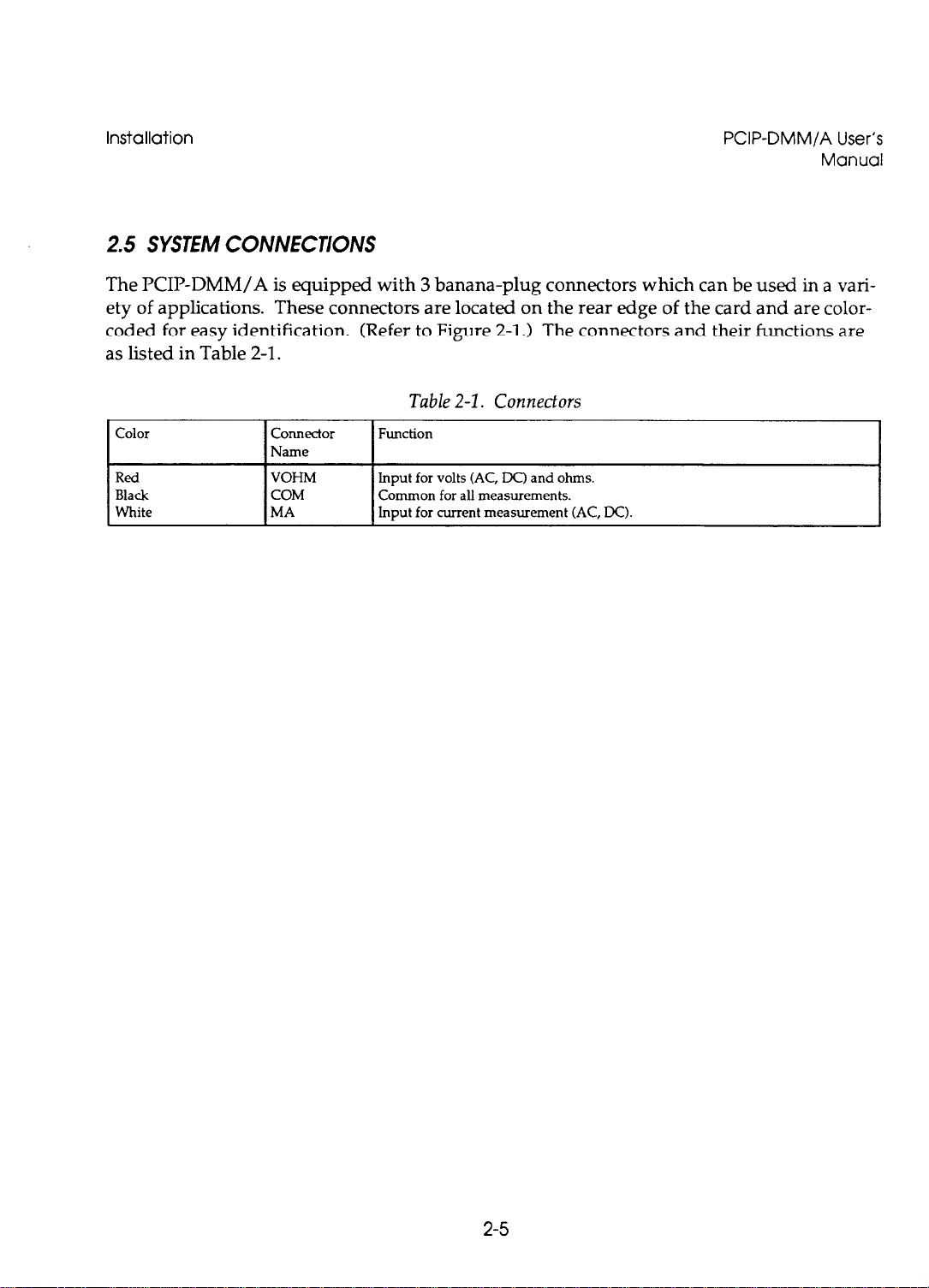

2.5 SYSTEM CONNECTIONS

The PCIP-DMM/A is equipped with 3 banana-plug connectors which can be used in a variety of applications. These connectors are located on the rear edge of the card and are colorcoded for easy identification. (Refer to Figure 2-l.) The connectors and their functions are

as listed in Table 2-1.

Table 2-1. Connectors

Color

I

Red

Black

White

Connector

Name I

I

Function

I

Input for volts (AC, DC) and ohms.

Common for all measurements.

Input for current measurement (AC, DC).

2-5

Page 25

PCIP-DMM/A User’s

Manual

Getting Started

CHAPTER 3

GETTING STARTED

3.7 GENERAL

This chapter describes the information necessary to begin operating the PCIP-DMM/A.

Instructions for making back-up copies of the PCIP-DMM/A Diskette, and modifying the

CONFIG.SYS file to include the necessary drivers are included. Also provided in this chapter are instructions for using the Pop-Up Menu to set the PCIP-DMM/A’s operating parameters.

3.2 MAKJI’VG A BACK-UP COPY OF THE SOFWARE

Before installing the PCF-DMM/A software, first create a back-up copy of the PCIPDMM/A Diskette(s). Follow the general procedure outlined below:

1.

Turn on your computer and display.

2.

Switch to the directory containing your

3.

At the DOS prompt, type:

DISKCOPY {source drive

4.

The system will prompt you through the disk copying process. Insert the

designator)

DISKCOPY.EXE

:

{copy drive

DO!3 utility.

designator

source diskette into the specified drive. Then, it will ask you to

insert the target disk into the other drive. This is a blank, formatted

disk which is to be your back-up disk. When the copying process

completed, the computer will ask

5.

When your copy has been completed, put the original disk is a safe place.

copy another (Y/N)

?. Enter N .

Label the back-up copy “PCIP-DMM/A Disk Back-Up Copy”. Use this disk

to install the software.

has

I:

been

3-1

Page 26

Getting Started

PCIP-DMM/A User’s

Manual

3.3 INSTALLlNG THE PCIP-DMM/A SOFTWARE

If at all possible, the PCIP-DMM/A software should be installed on your computer’s hard

drive. Installing the PCIP-DMM/A software in this manner requires the use of the DOS

COPY

command. To install the PCIP-DMM/A software:

1.

Turn on your PC and its display. You should see a prompt which indicates

you are at the DOS level.

2.

The following instructions create a special directory for the PCIP-DMM/A

Disk files and assumes this directory is called

DOS prompt, change to the root directory (or other directory you want

the PCIP-DMM/A directory to be branched off from), i.e. type:

cd \

3.

Next, create the DMM directory. Type:

DMM.

At the

mmir \dxtun OR md \dmm

Change to the dmm directory by typing:

cd \dmm

Place the PCIP-DMM/A Disk into the floppy drive (assume this is drive a:> and type:

3.

copy a:*.*

Repeat as needed.

You are now ready to install the driver software.

3.4 ADDING ANSLSYS to CONFIG.SYS

The PCIP-DMM/A software requires that ANSLSYS be loaded from your CONFIG.SYS. Be

sure to add the following instruction to your CONFIG.SYS file:

DEVICEi = {path}ANSI.SYS

3-2

Page 27

PCIP-DMM/A User’s

Manual

Getting Started

If the device drivers are installed from the CONFIG.SYS file, the ANSI.SYS instruction must

precede the device driver instructions (See 3.5.1 and 3.5.2.).

3.5 INSTALLING THE DEVICE DRIVERS

Before operating your PCIP-DMM/A, you must load its driver files

DMM.SYS).

This can be done in one of two ways: either by loading the drivers from your

(VI.SYS

and

CONFIG.SYS or by loading them directly from DOS using the Load/Unload Utility.

If you choose to load the drivers from your COiVFIG.SYS, they will be automatically loaded

every time your computer is booted up. This keeps the drivers memory-resident, allowing

the PCIP-DMM/A to be used at any time. There are two ways to modify your CONFIG.SYS

file: (1) Editing your COIVFIG.SYS file (See section 3.5.1.) and (2) Using the DMMSETUP

Program (See section 3.5.2).

If unoccupied memory is limited in your computer, you will probably want to manually

load and unload the drivers from the DOS command line. After the drivers have been

unloaded using this technique, 500 bytes will remain memory resident. We suggest creating

batch files to invoke the load and unload options quickly. Section 3.5.3 discusses how to

load the device drivers from the command line.

NOTE: If you have more than one PCIP-DMM/A installed in the same computer - or if you

have an additional MetraByte PCIP family Virtual Instrument Products, refer to Appendix

A for Driver Installation procedure.

Syntax Notes

The following syntax is used in this section:

{ } - Anything enclosed within curly brackets is optional. Do not include the curly brackets

in the command. Choices are separated by commas.

3.5.7 Editing the CONFIGSYS File

If you do not want to run the PCIP-DMM/A Set-Up Program and are familiar with your

CONFIG.SYS file, you may want to edit the existing CONRG.SYS file with a standard

wordprocessor which handles ASCII input. Start by bringing the CONFIG.SYS file into the

editor. Then, add the following two instructions (after the

3-3

DEVICE = ANSI. SYS

instruction).

Page 28

Getting Started PCIP-DMM/A User’s

Manual

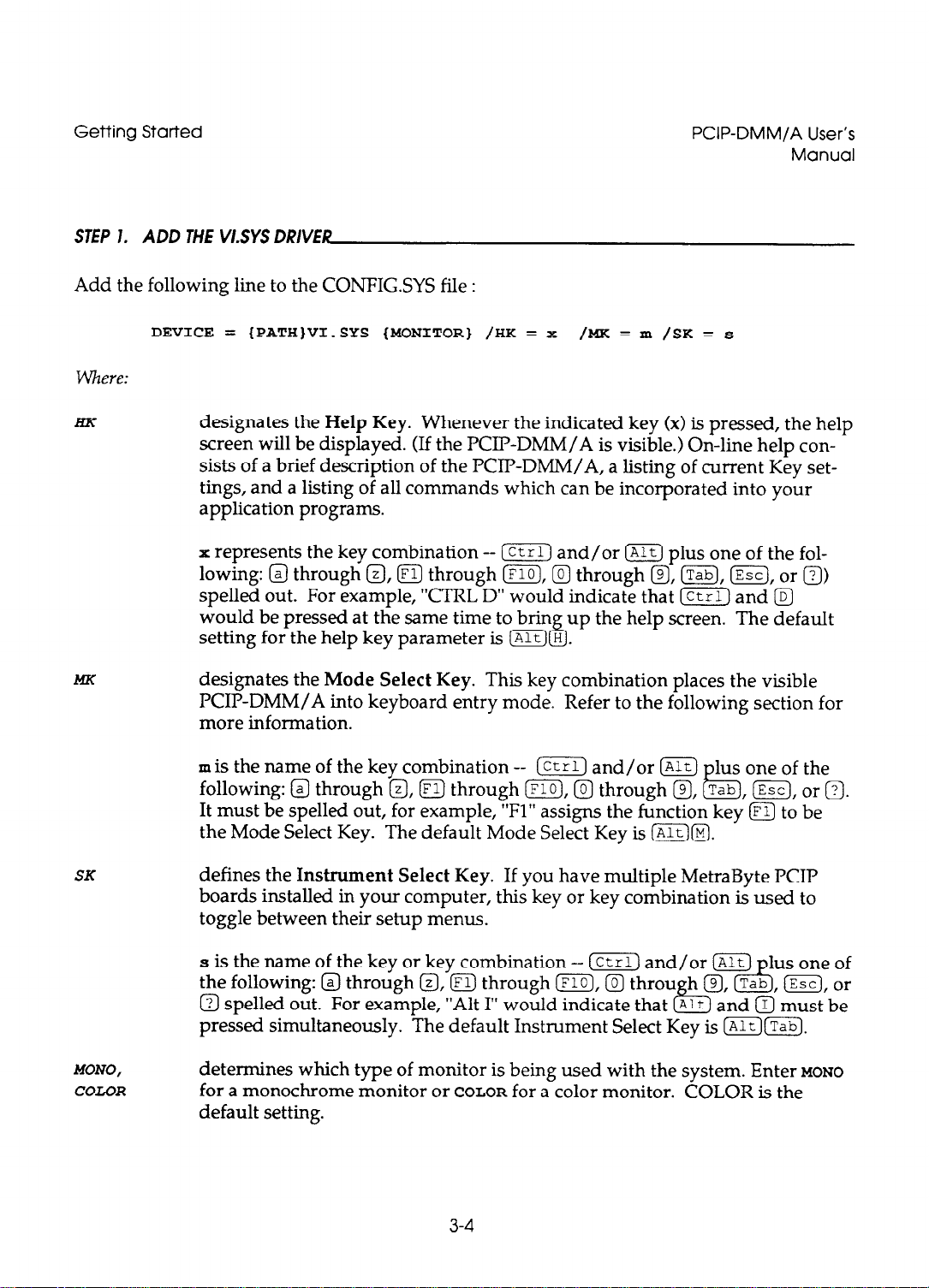

STEP 1. ADD THE VISYS DRIVER

Add the following line to the CONEIG.SYS file :

DEVICE = {PATH}VI.SYS {MONITOR} /HK = x /MK = m /SK = s

Where:

HK

MK

SK

designates the Help Key. Whenever the indicated key (x) is pressed, the help

screen will be displayed. (If the PCIP-DMM/A is visible.) On-line help consists of a brief description of the PCIP-DMM/A, a listing of current Key settings, and a listing of all commands which can be incorporated into your

application programs.

x represents the key combination -- (Ctrl) and/or (Alt) plus one of the fol-

lowing: 8 through 0, (F1) through @I, @ through @, (Tab], (Esc), or a)

spelled out. For example, “CTRL D” would indicate that m and @

would be pressed at the same time to brin up the help screen. The default

setting for the help key parameter is IAlt) H .

?I

designates the Mode Select Key. This key combination places the visible

PCIP-DMM/A into keyboard entry mode. Refer to the following section for

more information.

mis the name of the key combination -- (Ctrlj and/or (Alt)

following: @ through 0, a through (F10), @J through @I, Tab

lus one of the

, (Esc), or Q.

b

It must be spelled out, for example, “Fl” assigns the function key (F1) to be

the Mode Select Key. The default Mode Select Key is (Alt)@.

defines the Instrument Select Key. If you have multiple MetraByte PCIP

boards installed in your computer, this key or key combination is used to

toggle between their setup menus.

MONO,

COLOR

s is the name of the key or key combination - (-1 and/or (Alt) lus one of

the following: @ through 0, (F1) through (F10), @ throu h @, Tab , (Esc), or

a spelled out. For example, “Alt I” would indicate that Alt and Q must be

b

c5

pressed simultaneously. The default Instrument Select Key is (Alt)lTab).

determines which type of monitor is being used with the system. Enter

for a monochrome monitor or

COLOR

for a color monitor. COLOR is the

MONO

default setting.

3-4

Page 29

PCIP-DMM/A User’s

Manual

Getting Started

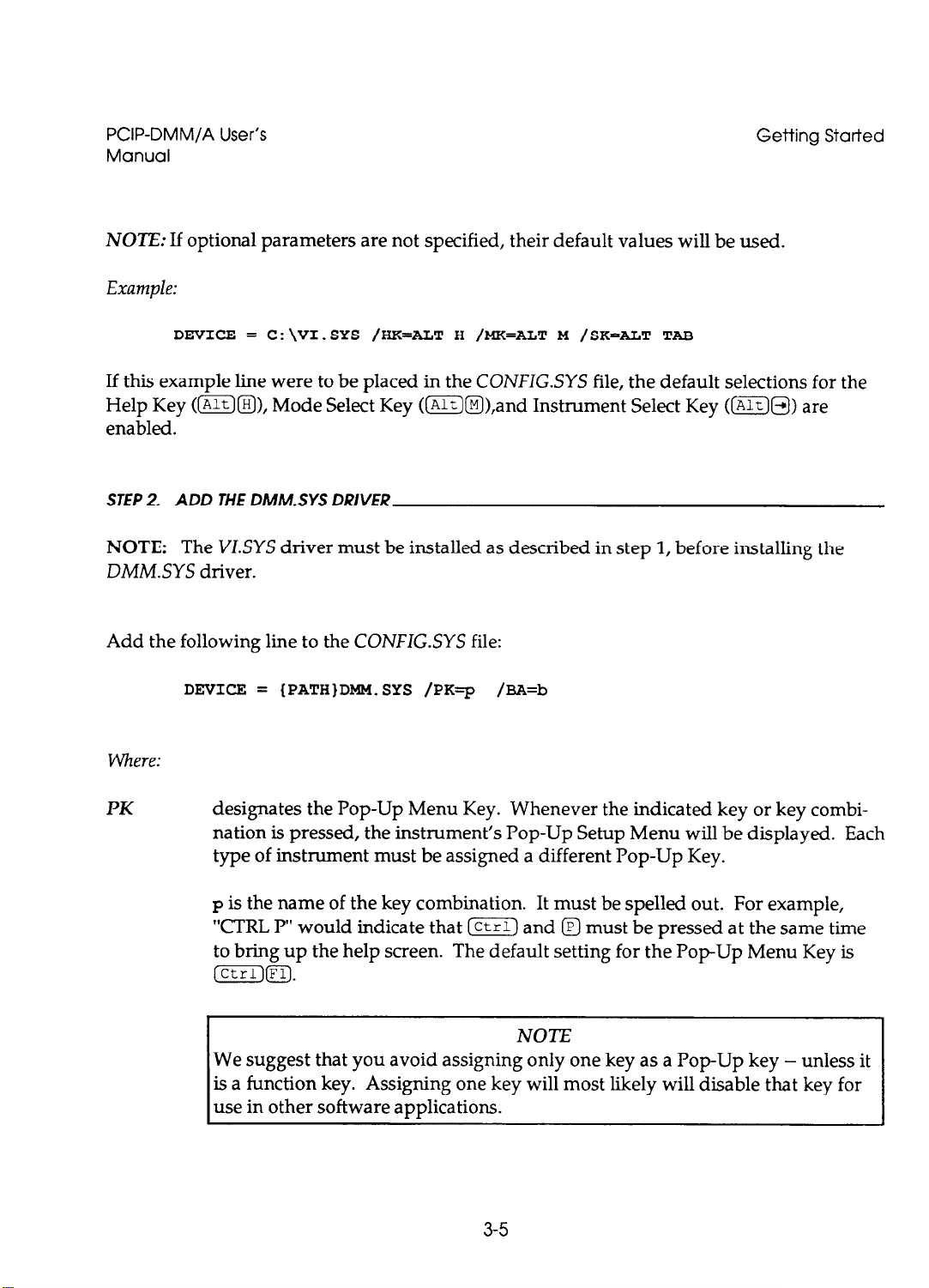

NOTE: If optional parameters are not specified, their default values will be used.

Example:

DEVICE = C:\VI.SYS /HK=ALT H /MK=ALT M

If this example line were to be placed in the CONFIG.SYS file, the default selections for

/SK=ALT

TAB

the

Help Key ([XlIIi)), Mode Select Key ((=1@1),and Instrument Select Key ((E)@) are

enabled.

STEP 2. ADD THE DMMSYS DRIVER

NOTE: The VLSYS driver must be installed as described in step 1, before installing the

DMM.SYS driver.

Add the following line to the CONFIG.SYS file:

DEVICE = {PATH)DMM.SYS /PK=p /EA=b

Where:

PK designates the Pop-Up Menu Key. Whenever the indicated key or key combi-

nation is pressed, the instrument’s Pop-Up Setup Menu will be displayed. Each

type of instrument must be assigned a different Pop-Up Key.

p

is the name of the key combination. It must be spelled out. For example,

“CTRL P” would indicate that [K) and @ must be pressed at the same time

to bring up the help screen. The default setting for the PopUp Menu Key is

(ct,l)(Fi].

NOTE

We suggest that you avoid assigning only one key as a Pop-Up key - unless it

is a function key. Assigning

one

key will most likely will disable that key for

use in other software applications.

3-5

Page 30

Getting Started

POP-DMM/A User’s

Manual

23A

defines the base address setting for the PCIP-DMM/A. If this parameter is not

given, the default base address of &H310 (784 decimal) will be used.

b

is the value of the base address. Base address values may be given in either

hex or decimal; however, if they are given in hex they must be preceded by an

ampersand and an H (i.e., &H). Make certain that

the

base address you give

has not been already assigned to another peripheral.

NOTE: If optional parameters are not specified, their default values will be used.

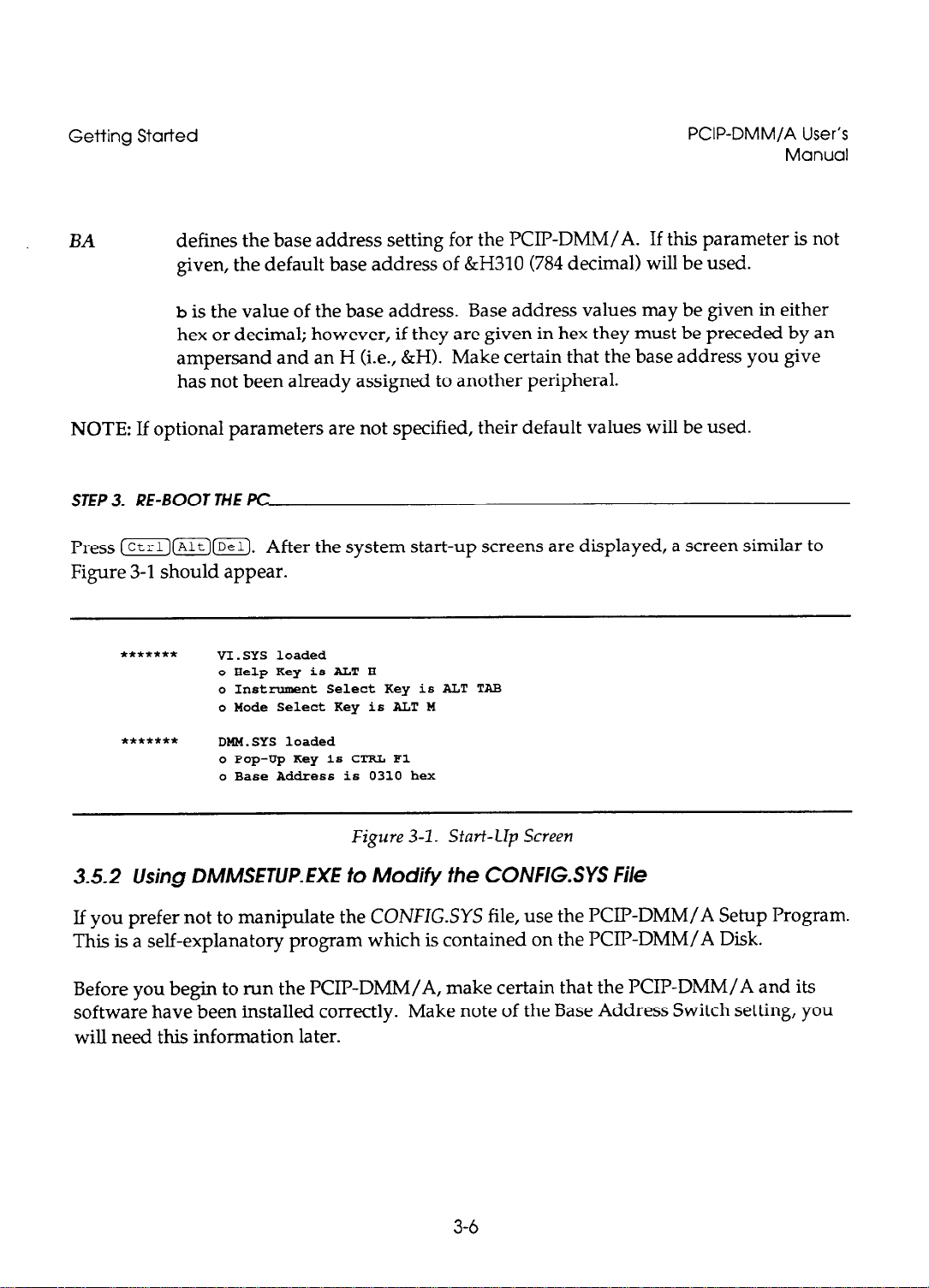

STEP 3. RE-BOOT THE PC

Press (m)(E)(Del). After the system start-up screens are displayed, a screen similar to

Figure 3-1 should appear.

t******

*******

VI. SYS loaded

o Help Key is ALT H

o Instrument Select Key is ALT TAB

o Mode Select Key is ALT M

DMM.SYS loaded

o Pop-Up Key is CTRL Fl

o Base Address is 0310 hex

Figure 3-1. Start-Up Screen

3.5.2 Using DMMSETUP.EXE to Modify the CONFIG.SYS File

If you prefer not to manipulate the CONFIGSYS file, use the PCIP-DMM/A Setup Program.

This is a self-explanatory program which is contained on the PCIP-DMM/A Disk.

Before you begin to run the PCIP-DMM/A, make certain that the PCIP-DMM/A and its

software have been installed correctly. Make

note

of the Base Address Switch setting, you

will need this information later.

3-6

Page 31

PCIP-DMM/A User’s

Manual

1.

Then, change to the directory where your PCIP-DMM/A software has been loaded.

Getting Started

At the DOS prompt, type:

DMMSE!l’UP

The program will then prompt you for the information required by the

system driver (VLSYS). Follow the instructions given. Sample screen

dialogue is provided in Figures 3-2 through Figure 3-8.

First, you will be asked to specify the drive where you want the

CONFIG.SYS file to reside. Enter the appropriate letter (i.e., C).

PCIP-DMM Setup Program

I

Drive letter for CONFIG.SYS file : C

Select Boot Drive

Enter a drive letter where New/Revised CONFIG.SYS is to be placed. Then hit 'ENTER'.

Hitting ‘ESC' will exit program.

Figure 3-2. Selecting fhe Boof Drive

2.

You will then be asked for the fuIl path name to the VLSYS file. If you

are unsure of what a path name is, refer to the operator’s manual provide with your

PC. Otherwise, provide the path name, being certain to include the correct drive specifier and directory name(s). See Figure 3-3.

3-7

Page 32

Getting Started PCIP-DMM/A User’s

Manual

PCIP-Dt4.M Setup Program

Drive letter for CONFIG.SYS file : C

Full path name to VI.SYS: C:\DMM

Generate the path name to VI.SYS

The default path is . .._ ( C:\ )

The path in the current CORFIG.SYS is . . . . ( C:\DMM\ )

Enter one of the following..

0

The complete path to VI.SYS followed by 'ENTER'

'ENTER' to use default path

0

0

'ESC' to exit Setup

Figure 3-3. Generating the Path Name to VLSYS

3. Specify the type of monitor you are using: MONO or COLOR.

PCIP-DMM Setup Program

Drive letter for CONFIG.SYS file : C

Full path name to VI.SYS: C:\DMM

Declare type of monitor: COLOR

Specify the type of monitor in system

The default monitor is __._ ( COLOR )

The current monitor is . . . . ( COLOR )

Enter one of the following..

o The word COLOR or MONO followed by 'ENTER'

0

'ENTER' to default monitor

0

'ESC' to exit setup

.

Figure 3-4. Specifying the type of Monitor

3-8

Page 33

PCIP-DMM/A User’s

Manual

3. Set the Help Select Key, Mode Select Key, and Instrument Select Key as

illustrated in Figures 3-5 through 3-7.

Getting Started

Whenever the

Help

Key is pressed and the instrument is visible, the help

screen will be displayed. On-line help consists of a brief description

of the IUP-DMM/A, a listing of current key settings, and a listing of all

commands which can be incorporated into your application programs. The

default setting for the help key is [Alt)@].

The Mode S&d Key is used to toggle between the mouse and

keyboard setup modes. Refer to the following section for more

information. The default Mode Select Key is (x)[E].

If you have other PCIF boards installed in your computer, the Insfrument

Select Key is used to toggle between their setup menus. The currently

selected instrument’s menu will appear first in the sequence. The

default Instrument Select Key is [z)(%].

Keys may be a single function key (Fl through FlO) or a combination

of keys (Ctrl or Alt with another valid key). Hot keys are specified by

“spelling out” the key(s) used. For example:

“Alt I” means that (Alt) and 0 are pressed simultaneously.

“Fl” indicates a.

“Ctrl I” is (ml and 0 pressed together.

If an invalid key or key combination is entered, the following error message

will appear:

The Definition for the

Strike any key to try another.

Key

is not valid.

3-9

Page 34

Getting Started PCIP-DMM/A User’s

Manual

CAUTION

Single keystrokes may be defined as Keys; however, it is suggested that only function

keys be assigned in this manner. If the CONFIG.SYS file resides in the root directory,

assigning a single keystroke will disable that key from being used in other software applications.

PCIP-DMM Setup Program

Drive letter for CONFIG.SYS file : C

Full path name to VI.SYS: C:\DMM

Declare type of monitor: COLOR

HELP KEY definition: ALT ?

Help Key Definition

The Help Key is defined by spelling out either or both the legal

SHIFT KEYS (CTPL and ALT) plus 1 of the following character keys.

A through 2, Fl through FlO, 0 through 9

TAB, ESC, ?

The default HELP KEY is....( ALT H )

The current HELP KEY is....( ALT ? )

Enter one of the following..

0

The definition for Help Key followed by ‘ENTER'

0

'ENTER' to use default HELP KEY

0

'ESC' to end entry

Figure 3-5. Defining the Help Key

3-10

Page 35

PCIP-DMM/A User’s

Manual

Drive letter for CONFIG.SYS file : C

Full path name to VI:.SYS: C:\DMM

Declare type of monitor: COLOR

HELP KEY definition: ALT ?

MODE SELECT KEY definition: F2

The Mode Select Key is defined by spelling out either or both the

legal SHIFT KEYS (CTRL and UT) plus 1 of the following character keys.

PCIP-DMM Setup Program

Mode Select Key Definition

A through 2, Fl through FlO, 0 through 9

TAB. ESC, ?

Getting Started

The default MODE SELECT KEY is....( ALT M )

The current MODE SELECT KEY is....( F2 )

Enter one of the following..

o The definition for Mode Select Key followed by 'ENTER'

0

'ENTER' to use default HELP KEY

0

‘ESC' to end entry

Figure 3-6. Defining the Mode Select Key

3-11

Page 36

Getting Started PCIP-DMM/A User’s

Manual

PCIP-DMM Setup Program

Drive letter for CONFIG.SYS file : C

Full path name to VI.SYS:

Declare type of monitor: COLOR

HELP KEY definition: A.LT ?

MODE SELECT KEY definition: F2

INSTRUMENT SELECT KEY definition: CTRL I

The Instrument Select Key is defined by spelling out either or both the legal

SHIFT KEYS (CTRL and ALT) plus 1 of the following character keys.

A through 2, Fl through FlO, 0 through 9

The default INSTRUMENT SELECT KEY is....( ALT TAR )

The current INSTRUMENT SELEXT KEY is....( CTRD I )

Enter one of the following..

0

The definition for INSTRUMENT SELECT KEY followed by 'ENTER'

0

'ENTER' to use default INSTRUMENT SELECT KEY

0

'ESC' to end

entry

C:\DMM

Instrument Select Key Definition

TAB, ESC, ?

Figure 3-7. Defining fhe lnsfrument Select Key

4. You will now be asked to confirm your selections. (See Figure 3-8.)

If you wish to change an entry, press @I and the program will return

to the Boot Drive Selection Screen. To return to DOS, press (Esc),

Otherwise, press @I.

3-12

Page 37

PCIP-DMM/A User’s

Manual

Drive letter for CONFIG.SYS file : C

Full path name to VI.SYS: C:\DMM

Declare type of monitor: COLOR

HELP KEY definition: ALT ?

MODE SELECT KEY definition: F2

INSTRUMENT SELECT KEY definition: CTRL I

Enter one of the following..

0 IN' if above entries are NOT OK

'ENTER' to continue

0

0 'ESC' to exit setup

Getting Started

PCIP-DMM Setup Program

VI Setup CONFIRMATION

Figure 3-8. Confirming the System Setup

Next, the program will ask you for the information required to setup the

5.

PCIP-DMM/A driver. It first prompts you for the path name to

DMM.SYS. (See Figure 3-9.)

the

file

3-13

Page 38

Getting Started PCIP-DMM/A User’s

Manual

PCIP-DMM Setup Program

Pull path name to vI.SYS: C:\DMM

I

Generate the path name to DMM.SYS

The default path is . . . . ( C:\ )

The path in the current CONF'IG.SYS is . . . . ( C:\DMM\ )

Enter one of the following..

o The complete path to DMM.SYS followed by 'ENTER'

0

‘ENTER’ to use default path

0

'Esc' to exit Setup

Figure 3-9. Generating the DMM.SYS Path

6. The program then asks you to select a Pop-Up Menu Key as shown in

Figure 3-10. Whenever the

Pop-Up Menu Key

is pressed, the

instrument’s Pop-Up Setup Menu will be displayed. It is suggested that

each type of instrument be assigned a different Pop-Up Key. The default

setting for the Pop-Up Menu Key is (m)[E].

Keys may be a single function key (Fl through FlO) or a combination

of keys (Ctrl or Alt with another valid key). Hot keys are specified by

“spelling out” the key(s) used. (See Step #3 for specifics.)

3-14

Page 39

PCIP-DMM/A User’s

Manual

PCIP-DMM Setup Program

I

Full path name to DMM.SYS: C:\DMM

POP UP MENU KEY definition: ALT P I

POP UP Key Definition

The Pop Up Key is defined by spelling out either or both the legal

SHIFT KEYS (CTPL and ALT) plus 1 of the following character keys.

A through 2, Fl through FlO, 0 through 9

The default POP UP KEY is....( CTRL Fl )

The current POP UP KEY is....( ALT P )

Enter one of the following..

0

The definition for POP UP KEY followed by ‘ENTER'

‘ENTER' to use default POP UP KEY

0

0

'ESC' to end entrv

TAB, ESC, ?

Getting Started

Figure 3-10. Pop Up Key Definition

7.

You now will be asked for the Base Address of the PCIP-DMM/A. Base address

values may be given in either hex or decimal; however, if they are given

in hex they must be preceded by an ampersand and an H (i.e., &HI. Make

certain that the base address you give has not been already assigned to

another peripheral and agrees with the Base Address Switch setting on

the PCIP-DMM/A.

3-15

Page 40

Getting Started

Full path name to DMM.SYS: C:\DKM

POP UP MENU KEY definition: ALT P

I

Base Address for PCIP-DMM: CHnter> I

The Base Address can be entered in either decimal or hex.

If entered in hex, the number must be preceded by LB

(i.e., hH310 is the same as 784)

The default PCIP-DMM Base Address is ( LB310 ).

The current PCIP-DMM Ease Address is ( hH310 ).

Enter one of the following..

o The BASE ADDRESS to use for the PCIP-DKM followed by 'ENTER'

'ENTER' to use default BASE ADDRESS

0

0

'ESC' to exit Setup

PCIP-DMM/A User’s

Manual

PCIP-DMM Setup Program

PCIP-DMM I/O Base Address Selection

Figure 3-11. Selecting a Base Address

8.

You will now be asked to confirm your selections. (See Figure 3-12.)

If you wish to change an entry, press @I and the program will return

to the screen requesting a path name for the PCIP-DMM/A driver. To return

to DOS, press (Esc). Otherwise, press @.

3-16

Page 41

PCIP-DMM/A User’s

Manual

Full path name to DMM.SYS:

POP UP KEY definition: ALT P

Ease Address for the PCIP-DMM:SH310

Enter one of the following..

‘N' if above entries are NOT OK

0

0

‘ENTER' to continue

0

'ESC' to exit setup

Getting Started

PCIP-DMM Setup Program

C:\DMM

PCIP-DMM Setup CONFIRMATION

Figure 3-12. Confirming the PCIP-DMM/A Setup

9. The program will back-up your present CONFIG.SYS file to the file

CONFIG.BAK and write the new set-up information to the CONFIG.SYS

File. The CONFIGSYS file is displayed. An example is given in

Figure 3-13. If your system already has a CONFIGBAK file, you will

be asked if it should be deleted as shown in Figure 3-14.

3-17

Page 42

Getting Started

Backing old CONFIG.SYS file to CONF1G.U

and creating new CONPIG.SYS

DEVICE = C:\SYS\ANSI.SYS

DEVICE = C:\vI:..SYS /HX=ALT B /MX=ALT H /SX=ALT TAB

DEVICE = C:\DMM.SYS /PX= CTRL Fl /BA = 68310

files = 20

buffers = 10

PCIP-DMM/A User’s

Manual

Figure 3-13. Creation

Backing old CONFIG.SYS file to CONFIG.BAX

and creating new CONFIG.SYS

Backup file already exists

Delete it? (Y/N)

DEVICE = C:\SYS\ANSI.SYS

DEVICE = c:\v~.sYS /HX=ALT H /MX=ALT M /SX=A.LT TAB

DEVICE = C:\DMM.SYS /PX= CTRL Fl /BA = hH310

files = 20

buffers = 10

of

the new CONFZG.SYS

Figure 3-24. CONFIG.BAK Already Exists

3-18

Page 43

PCIP-DMM/A User’s

Manual

In order to activate the CONFIGSYS file that was created, press (~l(~](~)

10.

Getting Started

simultaneously to re-boot the system.

3.5.3 Loading/Unloading the Drivers from DOS

The VI.SYS and DMM.SYS drivers can be “manually” loaded from the DOS command line,

if desired. This is useful if you frequently run memory-resident programs. Using this technique, a maximum of 500 driver file bytes will remain memory resident once the drivers

have been unloaded. You can create batch files which will alleviate the tediousness of this

method. See Notes for specifics on batch files.

NOTE: Both of these drivers must be loaded for the PCIP-DMM/A to operate. Be sure

that

ANSLSYS has been loaded. Refer to Appendix A if you have multiple PCF-DMM/A’s or

another MetraByte PCIP instrument installed.

Syntax Conventions

The following syntax conventions are used in this section:

1.

{ ) - Anything enclosed within curly brackets is optional. Do not

include the curly brackets in the command.

Loading the Drivers

The LS.COM utility lets you load the PCIP-DMM/A driver files from the DOS command

line. Help is available for this utility. The help screen briefly describes the function of, syn-

tax for, and a sample usage for LS.COM. To access help, type

LS

at the DOS prompt.

VI.SYS

To load the VI.SYS driver, type the following at the DOS prompt:

LS {Path) VI.SYS {/HK = x) {/MK = m) {/SK = s}

Where

HK

designates the Help Key. Whenever the indicated key (x) is pressed, the help

screen will be displayed if the PCIP-DMM/A is visible. On-line help consists

3-19

Page 44

Getting Started

PCIP-DMM/A User’s

Manual

of a brief description of the PCIP-DMM/A, a listing of current Key settings,

and a listing of all commands which can be incorporated into your application programs.

MK

SK

x represents the key combination - (x) and/or (Alt)) plus one of

the fol-

lowing: @ through @, @I through (F10), @I through 8, (Tab), (Esc), or a>,

spelled out. For example, “CTRL D” would indicate that

(m) and @I

would be pressed at the same time to brin up the help screen. The default

setting for the help key parameter is (Alto H . ?I

designates the

Mode Select Key.

This key combination places the visible

PCIP-DMM/A into keyboard entry mode. Refer to the following section for

more information.

m

is the name of the key combination

following: @ through 0, (F through

It must be spelled out, for example, “Fl” assigns the function key @I to be

the Mode Select Key. The default Mode Select Key is (Alt)[@.

defines the

Instrument Select Key.

If you have multiple MetraByte PCIP

boards installed in your computer, this key or key combination is used to

toggle between their setup menus.

s is the name of the key or key combination - (m] and/or (Alt) lus one of

the following: @ through @, (F through (FlOj, @ throu h @, Tab , m, or

0 spelled out. For example, “Alt I” would indicate that .Qt and 0 must be

b

?I

pressed simultaneously. The default Instrument Select Key is (E)lTab’.

Examples

LS VI.SYS /HK=ALT H /MK=ALT M /SK=ALT TAB

LS VI.SYS

LS c:\PcIP\vI.sYs /HK=?

DMM.SYS DRIVER

To load the

VI.SYS

LS {PATH} DMM.SYS {/PK=p} I /BA=bl

driver, type the following at the DOS prompt:

3-20

Page 45

PCIP-DMM/A User’s

Manual

Where:

Getting Started

PK

BA

designates the Pop-Up Menu Key. Whenever the indicated key or key combination is pressed, the instrument’s Pop-Up Setup Menu will be displayed. Each

type of PCIP or PCIP-DMM/A instrument must be assigned a different Pop-Up

Key.

p is the name of the key combination. It must be spelled out. For example,

“CTRL I”’ would indicate that (m] and @ must be pressed at the same time

to bring up the help screen. The default setting for the Pop-Up Menu Key is

(ctrl)(Z].

NOTE

We suggest that you avoid assigning only one key as a Pop-Up key - unless it

is a function key. Assigning one key will most likely wilI disable that key for

use in other software applications.

defines the base address setting for the PCIP-DMM/A. If this parameter is not

given, the default base address of &H310 (784 decimal) will be used.

b is the value of the base address. Base address values may be given in either

hex or decimal; however, if they are given in hex they must be preceded by an

ampersand and an H (i.e., &HI. Make certain that the base address you give

has not been already assigned to another peripheral.

NOTE:

If optional parameters are not specified, their default values will be used.

Examples

LS D:\DMM\DMM.SYS /PK= CTFG

LS C:\PCIP\DMM.SYS /aA=

LS DMM.SYS

Fl

/BA = 6H310

3-21

Page 46

Getting Started

Unloading the Drivers

PCIP-DMM/A User’s

Manual

The USLOM utility lets you unload the PCIP-DMM/A driver files from the DO!3 command

line. Each driver must be unloaded separately. Help is available for this utility. The help

screen briefly describes the function of, syntax for, and a sample usage for US.COM. To

access help, type us at the DOS prompt.

To unload a driver, at the DOS prompt, type:

US {PATH} DRIVER-FILENAME

Where:

DRIVER~FILENAME

Examples

US D:\PCIP\VI.SYS

US C:\DMM\DMM.SYS

.

VLSYS loads into memory in two portions: a resident portion and a transient portion. The resident portion occupies about 500 bytes of memory and stays resident

until the computer is rebooted or turned OFF. VI.SYS should be uninstalled after

DMM. SYS.

.

When loading VLSYS from a batch file, load it twice, i.e.:

LS {path)VI.SYS

LS {path)VI.SYS

. . .

This is necessary because VI.SYS loads in two portions. Normally, this

occurs automatically; however batch files do not allow this.

is VLSYS or DMM.SYS.

3-22

Page 47

PCIP-DMM/A User’s

Manual

Getting Started

l

Load VI.SYS as soon as possible after power-up and then unload it if you do not

need it. This action locates the resident portion as low as possible in memory,

avoiding the creation of memory “holes”. (DOS has no mechanism for recovering

fragmented memory.)

.

When LS.COM loads a .SYS file, it displays an Amount of xemory statement. The

amount indicated may exceed the actual SYS file size, because additional memory

is allocated to the .SYS file as “working” space.

.

In some instances, the LS.COM utility can be used to load non-MetraByte drivers for example MSMOUSE.SYS. However, in general, MetraByte does not suggest this

practice. Not all non-MetraByte drivers work and those that do cannot be unloaded

without disrupting certain interrupt vectors. If you choose to experiment with this

procedure, the VLSYS driver must be loaded first.

.

It is important that you specify the path to the driver files when calling LS.COM

from the command line. If no path is specified, LS.COM will search the current

directory and then the paths listed in the CONFIG.SYS file (using the

PATH

= command). lS.COM will load the first file it finds in the specified path, displaying the

filename and path as well as the load destination.

.

If two instrument drivers are installed, you must have two boards installed. DO

NOT install two drivers at the same base address.

3.6 ADDITIONAL PC/P-DMM/A PROGRAMS

The PCIP-DMM/A Software has several programs which you may find useful to refer to.

These are:

.

UTILITY.EXE - aids in setting the Base Address Switch

.

Various demo programs - (Refer to FILESDOC on the diskette for a

complete list.)

.

DEMOBAT - creates executable versions of the demo files

3-23

Page 48

Getting Started

PCIP-DMM/A User’s

Manual

The Base Address UtMy Program

This program pictorially describes the appropriate base address switch setting for any given

Base Address. You can exit from this program at any time by pressing [Esc).

1. To invoke the Utility Program, first be certain that you are in the

correct directory. Then, at the DOS prompt, type:

2.

The program will respond with by displaying the first 2 lines of

UTILITY .

Figure 3-15. Enter the appropriate Base Address setting using the appropriate format.

Only Base Addresses greater than or equal to 256 decimal (100 hex) are valid. If an

invalid base address is entered, a beep sounds and a base address is prompted for

again. If a hex value is given in an unrecognizable format (Valid format is &H???.),

the following error message appears:

?F&do from start

Enter the Base Address Setting

This is the PCIP-DMM Utility Program

Enter the Base Address Switch setting (decimal or &H---):

For address 800(Hex 320), set switch as shown

BASE ADDRESS

ON

PCIP-DMM not responding at selected base address.

9876543

Press ‘Enter to continue’

Figure 3-15 Uf ility Program Start-Up Screen

3-24