Tektronix PCI Express Reference manual

Reference

PCI Express

Methods of Implementation (MOI)

071-1772-00

www.tektronix.com

Copyright © Tektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its

suppliers and are protected by United States copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supercedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX, TEK and RT-Eye are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive or P.O. Box 500

Beaverton, OR 97077 USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

Table of Contents

1 Introduction to the RT-Eye PCI Express Compliance Module.............1

2 PCI Express Compliance Specifications..................................................2

2.1 Differential Transmitter (TX) Output Specifications............................. 3

2.2 Differential Transmitter (TX) Compliance Eye Diagrams ....................4

2.3 Differential Receiver (RX) Input Specifications ..................................... 5

2.4 Differential Receiver (RX) Compliance Eye Diagrams.......................... 5

2.5 Add-In Card Transmitter Path Compliance Specifications .................. 6

2.6 Add-In Card Compliance Eye Diagrams ................................................7

2.7 System Board Transmitter Path Compliance Eye Diagrams ................ 7

2.8 System Board Compliance Eye Diagrams............................................... 8

2.9 PCI ExpressModule™ Compliance Specifications................................. 9

2.9.1 ExpressModule Add-In Card Transmitter Path

Specifications................................................................................... 9

Table of Contents

2.9.2 ExpressModule System Board Transmitter Path ..........................

Compliance Eye Diagrams ........................................................... 10

2.9.3 Express Module System Board Compliance Eye Diagrams...... 10

2.10 PCI Express External Cabling Specifications....................................... 11

2.10.1 External Cabling Transmitter Path Specifications ................... 11

2.10.2 Cable (Transmitter Side) Eye Diagrams.................................... 11

2.10.3 External Cabling Receiver Path Specifications .........................12

2.10.4 Cable (Receive Side) Eye Diagrams............................................ 12

2.11 Reference Clock Compliance Specifications .........................................13

3 Preparing to Take Measurements..........................................................14

3.1 Required Equipment ............................................................................... 14

3.2 Probing Options for Transmitter Testing .............................................14

3.2.1 SMA Input Connection................................................................. 15

3.2.2 ECB pad connection...................................................................... 16

3.3 Initial Oscilloscope Setup........................................................................ 17

3.4 Running the RT-Eye Software ...............................................................17

3.5 Configuring the Software to take measurements..................................18

3.5.1 Select Standard.............................................................................. 18

3.5.2 Select Test Point ............................................................................18

3.5.3 Select Probe Type.......................................................................... 19

PCI Express i

Table of Contents

4 PCI Express Transmitter Compliance Testing.....................................24

4.1 Probing the link for TX compliance.......................................................24

4.2 TX Compliance Test Load ......................................................................24

4.3 Running a Transmitter (TX) Compliance Test..................................... 24

3.5.4 Select Measurements..................................................................... 19

3.5.5 Configure Source of Waveforms.................................................. 20

3.5.6 Configure Clock Recovery ...........................................................21

3.5.7 Configure Plots .............................................................................. 23

4.3.1 TX Unit Interval Measurement MOI ..........................................26

4.3.2 TX Differential Pk-Pk Output Voltage MOI.............................. 27

4.3.3 TX De-Emphasized Differential Output Voltage (Ratio)

MOI....................................................................................................... 29

4.3.4 Minimum TX Eye Width MOI ....................................................30

4.3.5 TX Median-to-Max Jitter MOI.................................................... 31

4.3.6 TX Output Rise/Fall Time MOI ..................................................32

4.3.7 TX AC Common Mode Output Voltage MOI ............................34

4.3.8 TX Delta DC Common Mode Voltage MOI ...............................35

4.3.9 TX Total Jitter@BER MOI .........................................................36

4.3.10 Spectrum Analysis Based Rj/Dj Separation on ............................

Repeating Pattern ........................................................................36

4.3.11 Arbitrary Pattern Analysis Based Rj/Dj Separation ................38

4.3.12 TX Deterministic MOI (Using Dual-Dirac Model) ...................39

4.3.13 Rj/Dj Separation Based on Dual Dirac Model .......................... 39

4.3.14 TX Waveform Eye Diagram Mask Test MOI ...........................40

5 PCI Express Receiver (RX) Compliance Testing..................................41

5.1 Probing the Link for RX Compliance.................................................... 41

5.2 Running a Complete RX Compliance Test ...........................................41

5.2.1 RX Unit Interval Measurement MOI.......................................... 42

5.2.2 RX Differential Pk-Pk Input Voltage MOI................................. 42

5.2.3 Minimum RX Eye Width MOI .................................................... 43

5.2.4 RX Median-to-Max Jitter MOI ...................................................44

5.2.5 RX Total Jitter@BER MOI ......................................................... 45

5.2.6 RX Deterministic Jitter@BER using Dual-Dirac model ........... 46

5.2.7 RX Waveform Eye Diagram Mask Test MOI ............................47

ii PCI Express

Table of Contents

6 PCI Express Interconnect Test Point Testing .......................................48

6.1 Unit Interval Measurement MOI ........................................................... 49

6.2 Transition and Non-Transition Bit Eye Height Measurement MOI ..49

6.3 Eye Width Measurement MOI ............................................................... 50

6.4 Interconnect Median-to-Max Jitter and Total Jitter@BER MOI ...... 52

7 PCI Express Reference Clock Compliance Measurements .................53

7.1 Probing the Link for Reference Clock Compliance .............................53

7.2 Running a Complete Reference Clock Compliance Test ..................... 53

7.2.1 Reference Clock Frequency Measurement Test MOI ...............54

7.2.2 Reference Clock Differential Voltage Hi and Lo Test MOI...... 55

7.2.3 Reference Clock Differential rise and fall edge rates test MOI 56

7.2.4 Reference clock Duty cycle test MOI........................................... 57

7.2.5 Reference Clock Jitter Test MOI................................................. 58

8 Using SigTest............................................................................................59

9 Using Dynamic Test Points .....................................................................62

9.1 Test Point File Syntax.............................................................................. 63

9.2 Creating the new Test Point ...................................................................65

9.3 Running a test with the new DTP........................................................... 66

10 Giving a Device an ID..............................................................................67

11 Creating a Compliance Report...............................................................67

12 Further Analysis Techniques..................................................................67

13 Ensuring Compliance over specified population ..................................68

PCI Express iii

Table of Contents

iv PCI Express

Methods of Implementation

1 Introduction to the RT-Eye PCI Express Compliance Module1

This document provides the procedures for making PCI Express compliance measurements with Tektronix

TDS6000 Series and TDS7704B, real time oscilloscopes (6 GHz models and above) and probing solutions.

The PCI Express (PCI-E) Compliance Module Version 2.0 (Opt. PCE) is an optional software plug-in to the

RT-Eye Serial Data Compliance and Analysis software (Opt. RTE). The PCI Express Compliance module

provides transmitter path measurements (amplitude, timing, and jitter), waveform mask testing, and

Reference Clock (RefClk) compliance measurements described in multiple variants of the PCI Express

specifications. Specifications covered in this document and the PCE module includes a total of eighteen data

and reference clock test points defined in the following specifications.

Additional test points can also be added by the user, or provided by Tektronix representatives, using

Dynamic Test Point (DTP) definition, described in detail in Section 9.

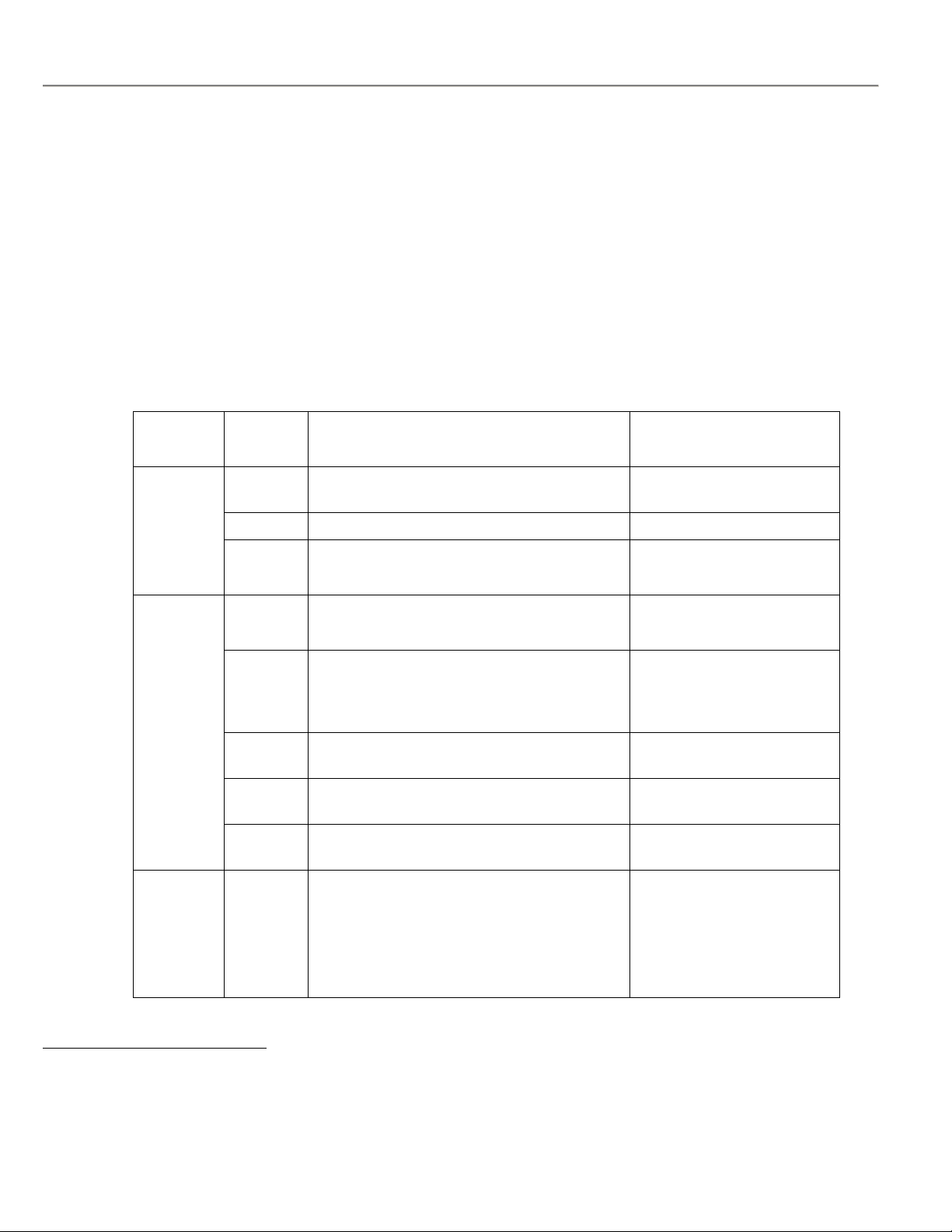

Table 1 – Supported Specifications

Test Methods Spec

Revision

Rev1.0a

Rev1.1

Rev1.0a Base Specification Transmitter and Receiver

Rev 1.0 Mobile Graphics Lower Power Addendum Transmitter (Section 2.2)

Rev1.0a CEM (Card Electro-Mechanical) Specification System and Add-In Card

Rev1.1 Base Specification Transmitter & Receiver

Rev1.1 CEM Specification System and Add-In Card

Rev1.0 Express Module Specification Transmitter Path and System

Rev0.4C External Cabling Specification Transmitter and Receiver Path

TBD Future 2.5 Gb/s Variants Dynamic Test Points as

PCI Express Specification Title Test Points Defined

(Section 4.3)

(Section 4.7)

(Section 4.3)

(Section 4.7)

Reference Clock (Section 2.1)

Board (Section 5.4)

(Section 3.3)

specifications are defined

Gen2 Rev0.3 Base Specification Transmitter & Receiver

(Section 4.4)

Mobile Low Power Transmitter

(Section 4.4)

Reference Clock (Section 4.4)

1

Disclaimer: The tests provided in the PCI Express compliance module (which are described in this document) do not guarantee PCI Express

compliance. The test results should be considered “Pre-Compliance”. Official PCI Express compliance and PCI-SIG Integrator List qualification

is governed by the PCI-SIG (Special Interest Group) and can be achieved only through official PCI-SIG sanctioned testing.

PCI Express 1

Methods of Implementation

Test Methods Spec

Revision

TBD Future 5 Gb/s Variants Dynamic Test Points as

PCI Express Specification Title Test Points Defined

specifications are defined

Refer to http://www.pcisig.com/specifications/pciexpress/ for the latest specifications.

The PCE module can also be used to automate setup procedures for SigTest by using its SigTest Import

feature (Refer to Section 8).

In this document, for all references to the PCI Express Base Specification and Card Electrical Mechanical

(CEM) specification, refer to all versions of the Spec. (Rev 1.0a, 1.1, and Gen2). Differences between the

specifications are specifically called out when appropriate.

In the subsequent sections, step-by-step procedures are described to help you perform PCI Express

measurements. Each measurement is described as a Method of Implementation (MOI). For further reference,

consult the Compliance checklists offered to PCI-SIG members at www.pcisig.com

.

2 PCI Express Compliance Specifications

As shown in Table 1, Electrical Specifications for PCI Express are provided in multiple documents. This

section provides a summary of the measurement parameters measured in the RT-Eye PCE module and how

they are related to the symbol and test limits in the specification.

2 PCI Express

Methods of Implementation

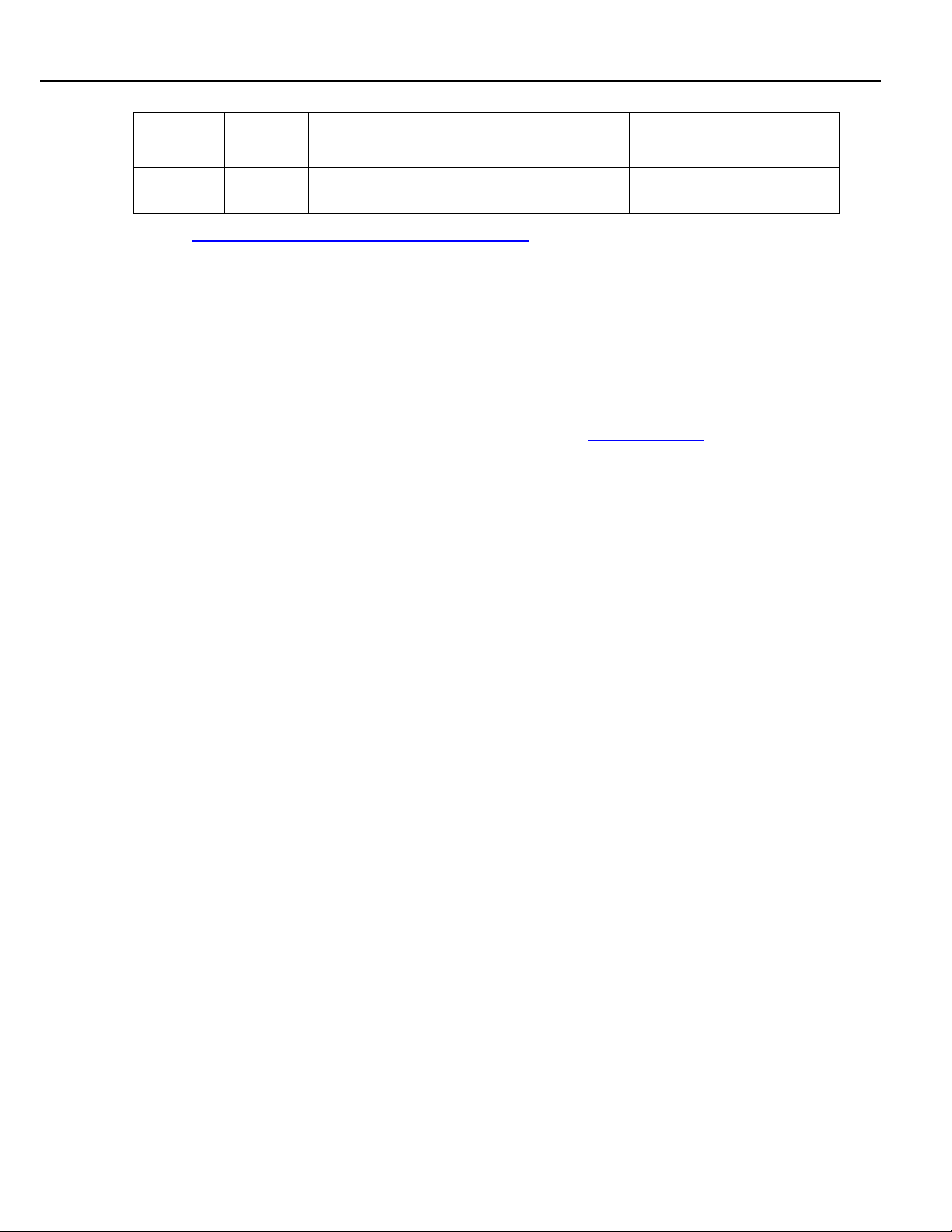

2.1 Differential Transmitter (TX) Output Specifications

The following table shows the available measurements in the PCE Module and their test limits defined in

each of the Base specifications.

Table 2- Supported base specification transmitter measurements

Specification Parameter Symbol(s)

Gen1

Rev1.0a

Unit interval UI 400 ps

+/- 300 ppm

Differential p-p TX

voltage swing

Low power differential

V

V

TX-SWING

V

TX-SWING-LOW

pDIFFpTX

−−

Not Specfied Not Specfied

0.8 V (min)

1.2 V (max)

p-p TX voltage swing

De-emphasized output

voltage ratio

Transmitter eye

including all jitter

sources

Maximum time

between the jitter

median and maximum

RATIODETXV−−

EYETXT−

t

TX-EYE_TJ

T

TX-EYEMEDIAN-to-MAXJITTER

-3.0 dB (min)

-4.0 dB (max)

.70 UI (min) .75 UI (min) .75 UI (min)

.125 UI (max) .125 UI (max) Not Spec’d

deviation from the

median

Deterministic jitter

T

TX-DJ-DD

0.15 UI (max)

Gen1

Rev1.1

400 ps

+/- 300 ppm

0.8 V (min)

1.2 V (max)

-3.0 dB (min)

-4.0 dB (max)

Gen2

Rev0.3

200 ps

+/- 300 ppm

0.8 V (min)

1.2 V (max)

0.4 V (min)

0.6 V (max)

-5.5 dB (min)

-6.5 dB (max)

D+/D- TX output

rise/fall Time

AC RMS common

mode output voltage

Absolute delta of DC

common mode voltage

between D+ and D-

RISETXT−

V

FALLTXT−

ACpCMTXV−−

DELTALINEDCCMTX

−−−−

0.125 UI (min) 0.125 UI (min) 0.15 UI (min)

20 mV (max) Not Specfied Not Specfied

0 V (min)

25 mV (max)

0 V (min)

25 mV (max)

0 V (min)

25 mV (max)

PCI Express 3

Methods of Implementation

2.2 Differential Transmitter (TX) Compliance Eye Diagrams

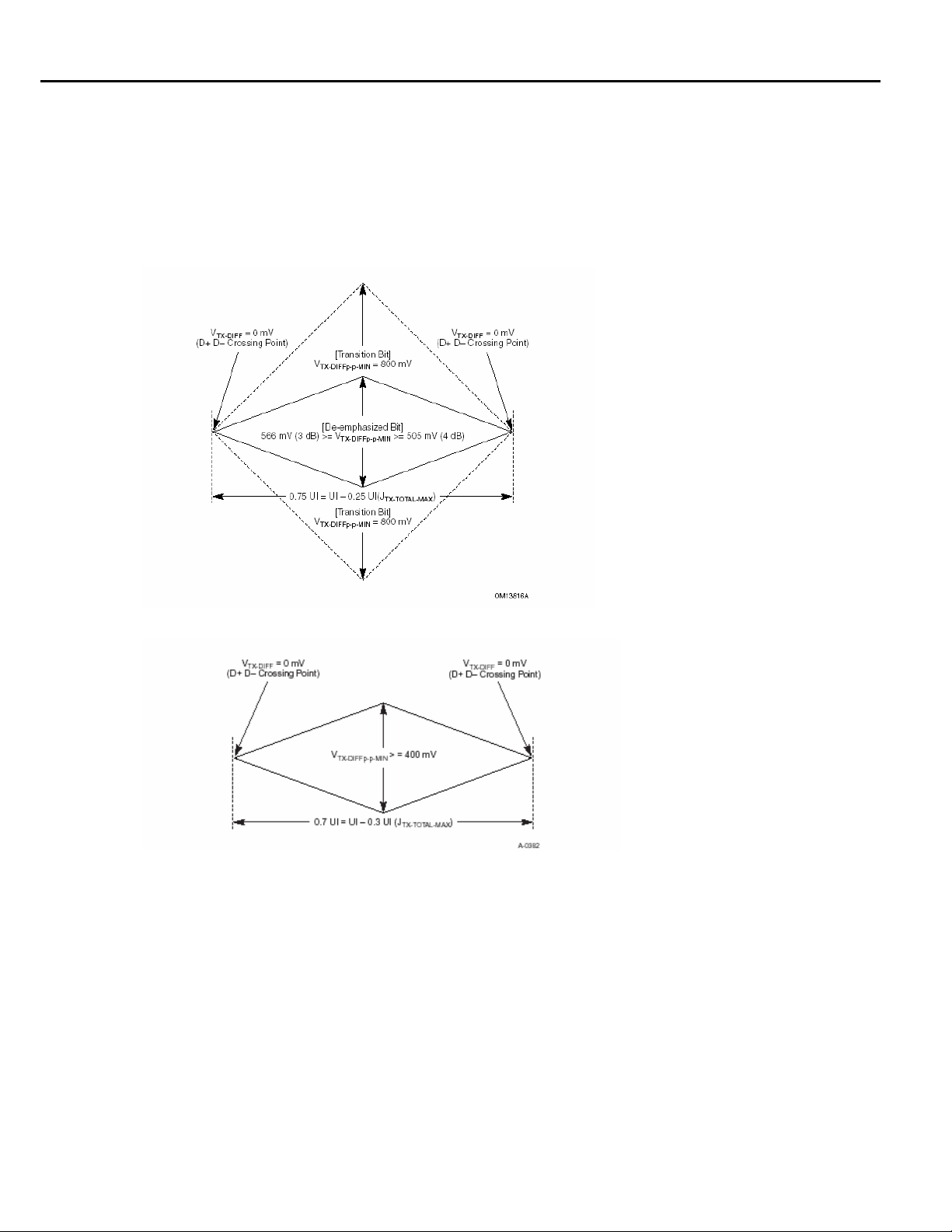

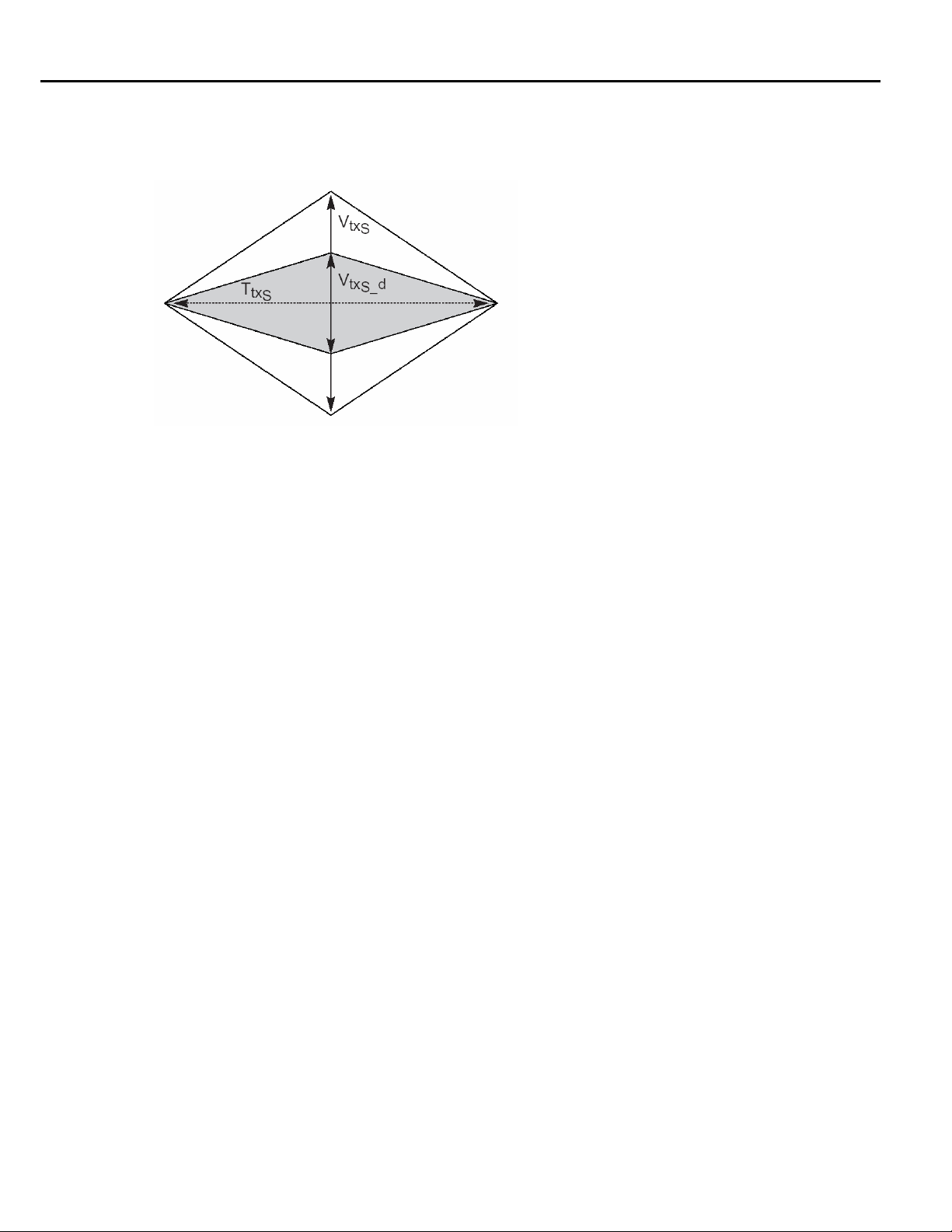

Figure 1a shows the eye mask definitions for the Rev1.1 Base specification. It provides an example of a

transmitter mask for a signal with de-emphasis. Transition and non-transition bits must be separated to

perform the mask testing. The amplitude and jitter mask geometries are derived from the amplitude and

jitter specifications. Low power transmitter variants in both Gen1 and Gen2 do not use de-emphasis (This

is shown in Figure 1b).

Figure 1a: Transmitter eye masks for transition and non-transition bits

Figure 1b: Transmitter eye mask for low power variant where de-emphasis is not used

4 PCI Express

Methods of Implementation

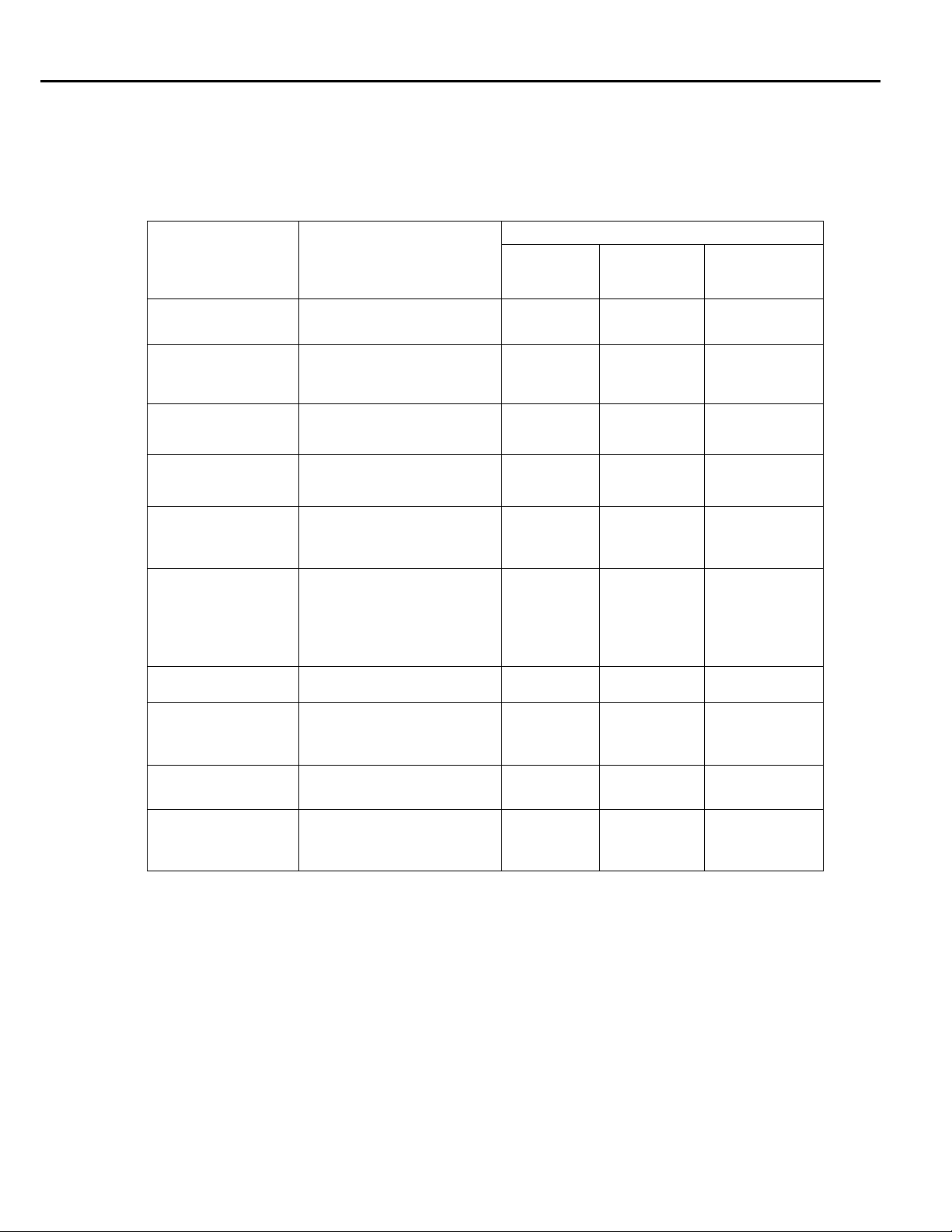

2.3 Differential Receiver (RX) Input Specifications

The following table shows the available measurements in the PCE Module and their test limits defined in

each of the Base specifications.

Table 3 – Supported base specification receiver measurements

Parameter Symbol

Unit interval UI 400 ps

Gen1

Rev1.0a

Gen1

Rev1.1

400 ps

Gen2

Rev0.3

200 ps

Minimum receiver eye height

Minimum receiver eye width

Receiver deterministic jitter –

V

RX_EYE

T

RX_DJ_DD

+/- 300 ppm

.175 V (min)

1.2 V (max)

EYERXT−

.40 UI (min) .40 UI (min) .40 UI (min)

Not Specfied Not Specfied .44 UI (max)

+/- 300 ppm

.175 V (min)

1.2 V (max)

+/- 300 ppm

.120 V (min)

1.2 V (max)

Dj

Maximum time between the

jitter median and maximum

deviation from the median.

T

TX-EYEMEDIAN-to-MAXJITTER

.30 UI (max) .30 UI (max)

Not

Specified

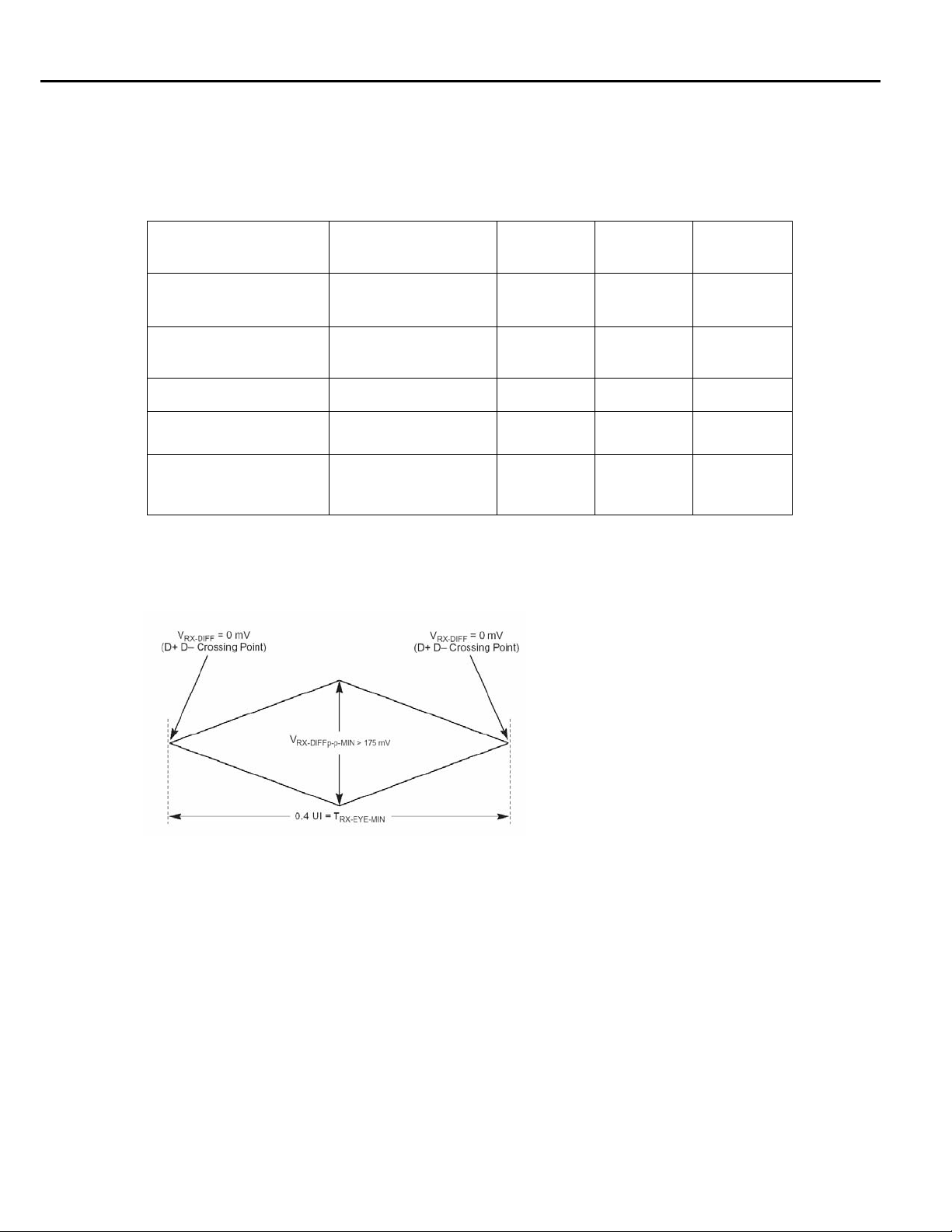

2.4 Differential Receiver (RX) Compliance Eye Diagrams

Figure 2 shows the receiver eye mask definitions for the Rev1.1 Base specification. The amplitude and

jitter mask geometries are derived from the amplitude and jitter specifications.

Figure 2: Receiver input eye mask

PCI Express 5

Methods of Implementation

2.5 Add-In Card Transmitter Path Compliance Specifications

Table 5 is derived from the Electrical Mechanical Specifications (CEM). See the CEM Specification for

additional notes and test definitions.

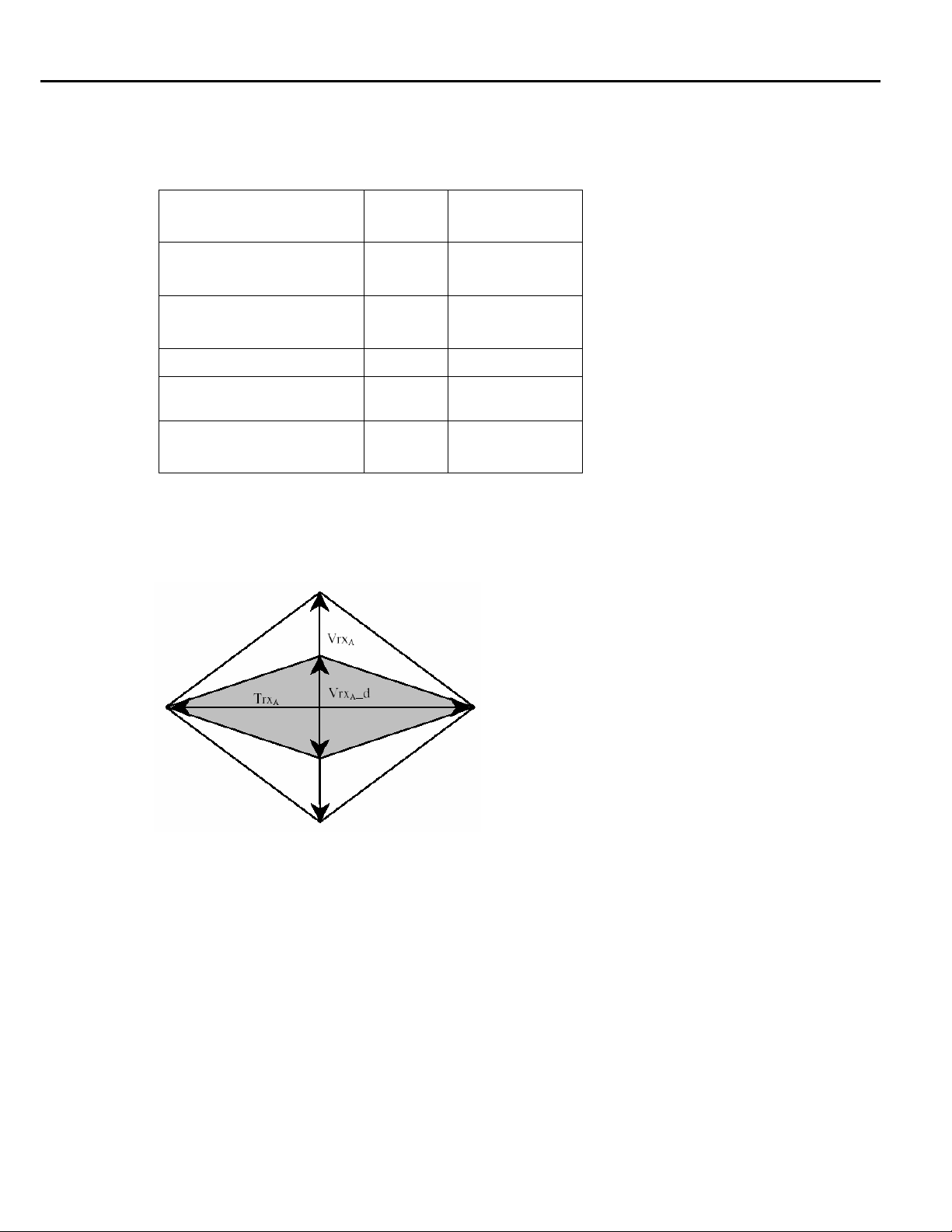

Table 4 – Supported CEM add-in card measurements

Parameter Symbol Gen1

Gen1

Gen2

Rev1.0a

Unit interval UI 400 ps

+/- 300 ppm

V

V

TXA

TXA_d

.514 V (min)

1.2 V (max)

.360 V (min) .360 V (min) TBD

Eye height of transition

bits

Eye height of non-

Rev1.1

400 ps

+/- 300 ppm

.514 V (min)

1.2 V (max)

Rev0.3

200 ps

+/- 300 ppm

TBD

transition bits

T

Eye width across any

250 UIs

Eye width with sample

size of 10

6

UI

Jitter eye opening at

-12

BER 10

Maximum median-max

TXA

In Rev1.0a

T

TXA

In Rev1.1

J

TXA-MEDIAN-to-MAX-JITTER

237 ps (min) Not

Specified

Not Specfied 287 ps (min) TBD

Not Specfied 274 ps (min)

Not Specfied 56.5 ps (max) TBD

TBD

TBD

jitter outlier with sample

size of 10

Maximum median-max

jitter outlier with sample

size of 10

6

6

UI

UI

Not Specfied 63 ps (max)

TBD

6 PCI Express

Methods of Implementation

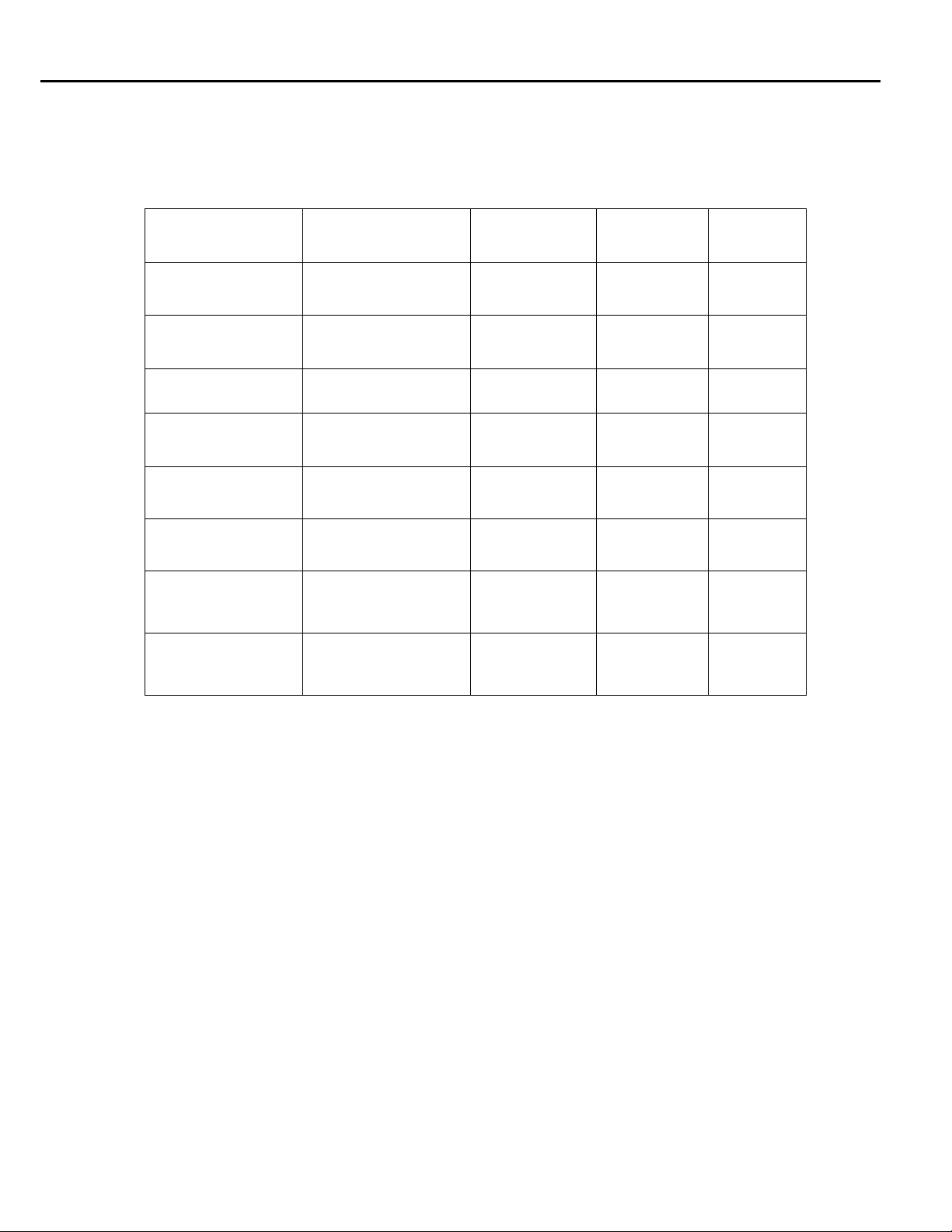

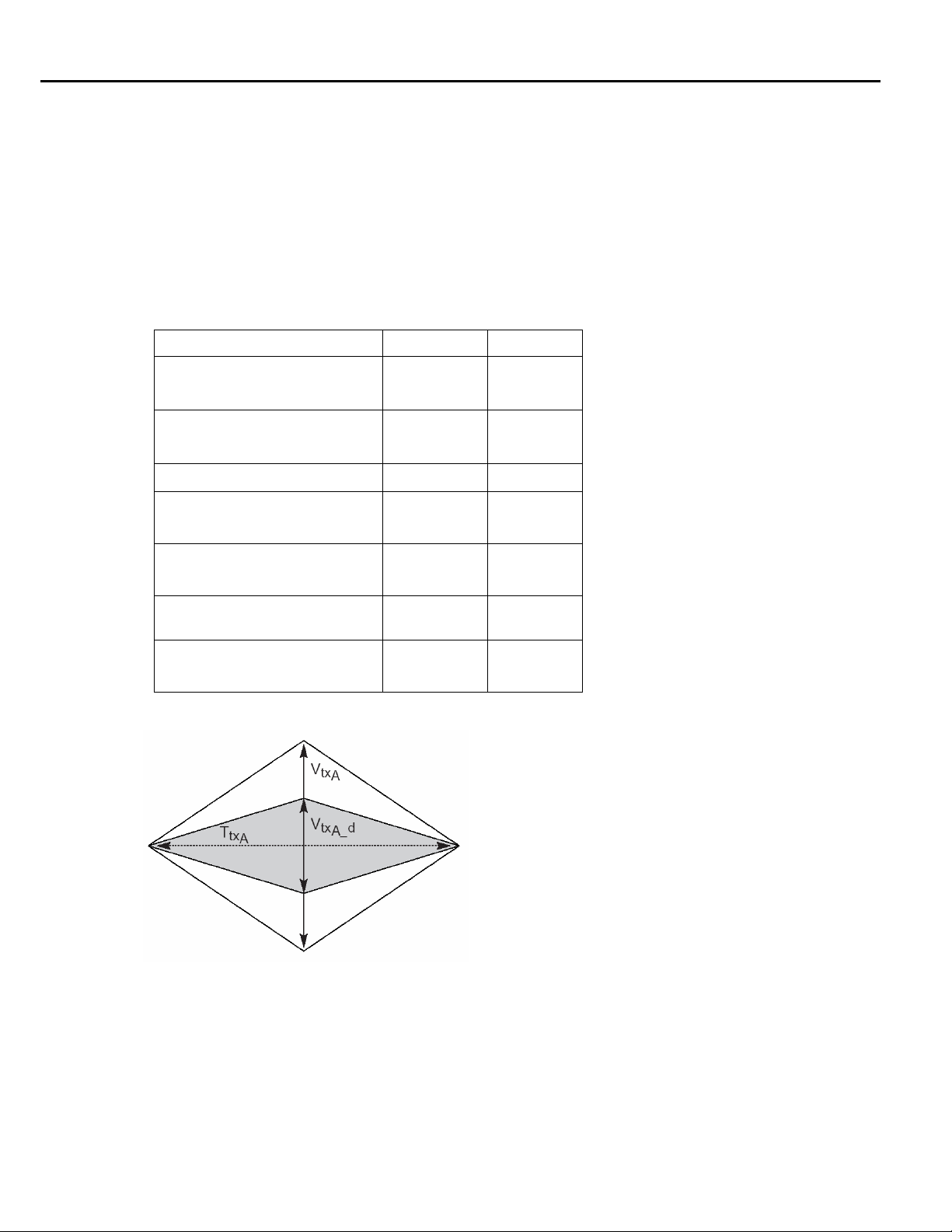

2.6 Add-In Card Compliance Eye Diagrams

The amplitude and jitter masks are derived from the amplitude and jitter specifications in Table 4.

Figure 3: Add-in card compliance eye masks

2.7 System Board Transmitter Path Compliance Eye Diagrams

Table 6 is derived from the Electrical Mechanical Specifications (CEM). See the CEM Specification for

additional notes and test definitions.

Table 5 – Supported CEM System Board Measurements

Parameter Symbol Gen1

Gen1

Gen2

Rev1.0a

Unit interval UI 400 ps

+/- 300 ppm

V

Eye height of transition bits

TXS

.274 V (min)

1.2 V (max)

V

Eye height of non-transition

TXS_d

.253 V (min) .253 V (min) TBD

Rev1.1

400 ps

+/- 300 ppm

.274 V (min)

1.2 V (max)

Rev0.3

200 ps

+/- 300 ppm

TBD

bits

T

Eye width across any 250

UIs

Eye width with sample size of

6

10

UI

Jitter eye opening at BER 10

12

Maximum median-max jitter

outlier with sample size of

6

10

UI

Maximum median-max jitter

outlier with sample size of

6

10

UI

-

TXS

18 ps (min) Not Specfied TBD

In Rev1.0a

T

TXS

Not Specfied 246 ps (min) TBD

In Rev1.1

Not Specfied 233 ps (min)

J

TXA-MEDIAN-to-MAX-

JITTER

Not Specfied 77 ps (max) TBD

Not Specfied 83.5 ps (max)

TBD

TBD

PCI Express 7

Methods of Implementation

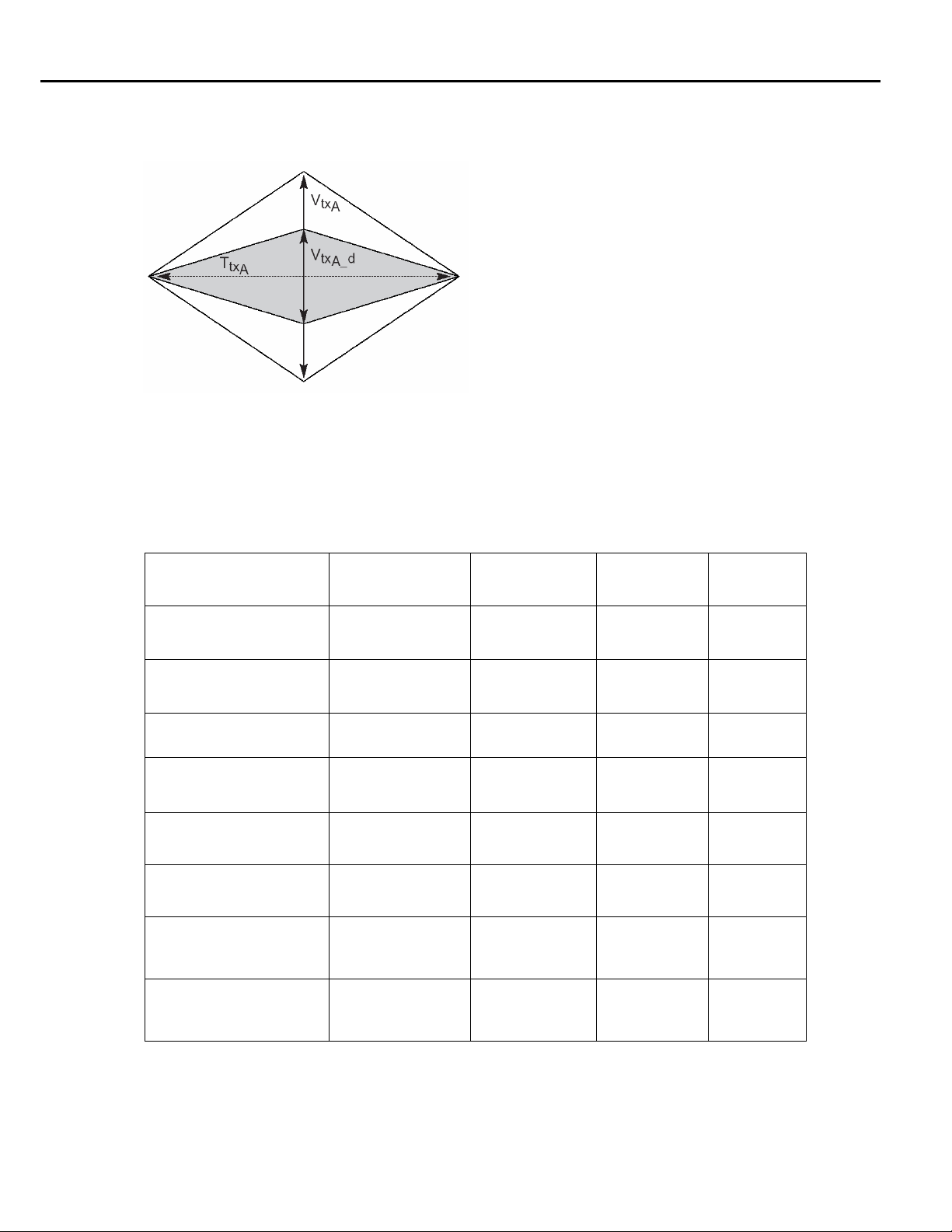

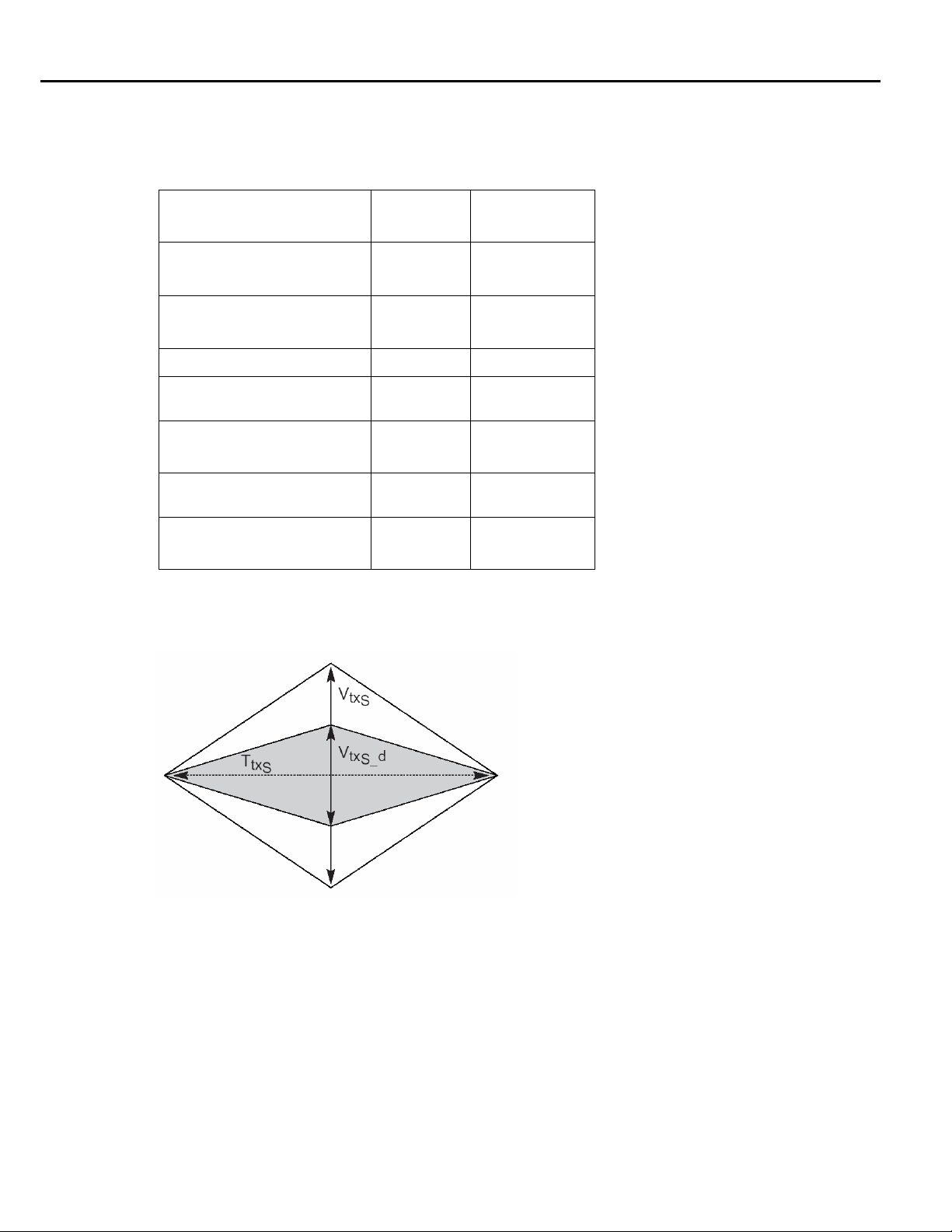

2.8 System Board Compliance Eye Diagrams

The amplitude and jitter masks are derived from the amplitude and jitter specifications in Table 5.

Figure 4: System Board Compliance Eye Masks

8 PCI Express

Methods of Implementation

2.9 PCI ExpressModule™ Compliance Specifications

The specifications in this section are taken from the PCI Express ExpressModule™ specification, which is

a companion specification to the PCI Express Base specification. Its primary focus is the implementation

of a modular I/O form factor that is focused on the needs of workstations and servers. Measurements in the

PCE module support add-in card and system transmitter path measurements at the PCI Express connector.

2.9.1 ExpressModule Add-In Card Transmitter Path Specifications

Table 6 is derived from Section 5.4.1 of the ExpressModule Electro-Mechanical Specifications Rev. 1.0.

Table 6 – Supported ExpressModule Add-In Card Measurements

Parameter Symbol Rev1.0

Unit interval UI 400 ps

+/- 300 ppm

V

Eye height of transition Bits

Eye height of non-transition Bits

Eye width with sample size of 106 UI

Jitter eye opening at BER 10

-12

Maximum median-max jitter outlier

with sample size of 10

6

UI

Maximum median-max jitter outlier

with sample size of 10

6

UI

TXA

V

TXA_d

T

TXA

In Rev1.1

J

TXA-MEDIAN-to-

MAX-JITTER

.514 V (min)

1.2 V (max)

.360 V (min)

287 ps (min)

274 ps (min)

56.5 ps (max)

63 ps (max)

Figure 5: ExpressModule add-in card compliance eye masks

PCI Express 9

Methods of Implementation

2.9.2 ExpressModule System Board Transmitter Path Compliance Eye Diagrams

Table 7 is derived from Section 5.4.3 of the ExpressModule Electro-Mechanical Specifications Rev. 1.0.

Table 7 – Supported ExpressModule system board measurements

Parameter Symbol Gen1

Unit interval UI 400 ps

Eye height of transition bits

Eye height of non-transition bits

Eye width with sample size of 106

UI

Jitter eye opening at BER 10

Maximum median-max jitter outlier

with sample size of 10

Maximum median-max jitter outlier

with sample size of 10

6

6

V

TXS

V

TXS_d

T

246 ps (min)

TXS

-12

233 ps (min)

J

TXA-MEDIAN-

UI

to-MAX-JITTER

UI

Rev1.0

+/- 300 ppm

.274 V (min)

1.2 V (max)

.253 V (min)

77 ps (max)

83.5 ps (max)

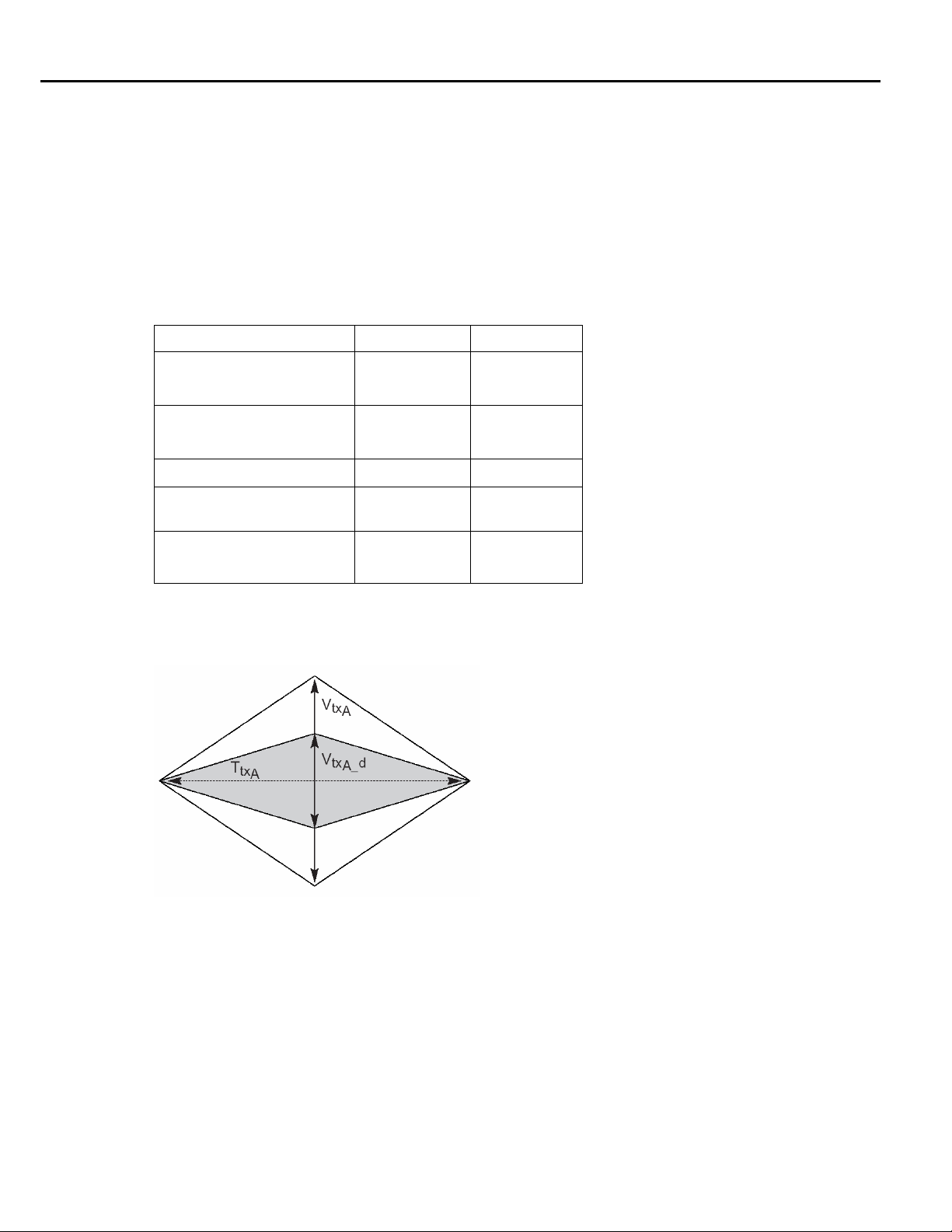

2.9.3 Express Module System Board Compliance Eye Diagrams

The amplitude and jitter masks are derived from the amplitude and jitter specifications in Table 7.

Figure 6: ExpressModule system board compliance eye masks

10 PCI Express

Methods of Implementation

2.10 PCI Express External Cabling Specifications

The specifications in this section are taken from the PCI Express External Cabling Specification. Its

primary focus is the implementation of a cabled interconnect. Measurements in the PCE module support

transmitter path and receiver path measurements. These measurements represent the test points at the

transmitter end of the cable and the receiver end of the cable respectively.

2.10.1 External Cabling Transmitter Path Specifications

Table 8 is derived from Section 3.3.1 of the External Cabling Specification Rev. 0.4C.

Table 8 – Supported external cabling transmitter path measurements

Parameter Symbol Rev0.4C

Unit interval UI 400 ps

+/- 300 ppm

V

V

T

TXA

TXA_d

TXA

.659 V (min)

1.2 V (max)

.456 V (min)

309 ps (min)

296 ps (min)

Eye height of transition bits

Eye height of non-transition bits

Eye width with sample size of

6

10

UI

Jitter eye opening at BER 10

-12

2.10.2 Cable (Transmitter Side) Eye Diagrams

The amplitude and jitter masks are derived from the amplitude and jitter specifications in Table 8.

Figure 7: Cable (transmitter side) compliance eye masks

PCI Express 11

Methods of Implementation

2.10.3 External Cabling Receiver Path Specifications

Table 9 is derived from Section 3.3.2 of the External Cabling Specification Rev. 0.4C.

Table 9 – Supported CEM System Board Measurements

Parameter Symbol Gen1

Unit interval UI 400 ps

Eye height of transition bits

Eye height of non-transition bits

Eye width with sample size of 106

UI

Jitter eye opening at BER 10

2.10.4 Cable (Receive Side) Eye Diagrams

Rev1.0

+/- 300 ppm

V

RXA

.219 V (min)

1.2 V (max)

V

RXA_d

T

247 ps (min)

RXA

-12

234 ps (min)

.200 V (min)

The amplitude and jitter masks are derived from the amplitude and jitter specifications in Table 9.

Figure 8: Cable (receiver side) compliance eye masks

12 PCI Express

Methods of Implementation

2.11 Reference Clock Compliance Specifications

Table 10 is derived from section 2.1 of the Gen1 Rev1.1 Electrical Mechanical Specifications (CEM) and

Gen2 Base specifications.

Table 10 – Supported reference clock measurements

Parameter Symbol Gen1

Rev1.1

Rise edge rate

Rise Edge Rate

0.6 V/ns (min)

4.0 V/ns (max)

Fall edge rate

Fall Edge Rate 0.6 V/ns (min)

4.0 V/ns (max)

Differential input high voltage

V

IH

150 mV (max) 150 mV (max)

Differential input low voltage VIL -150 mV (min) -150 mV (min)

Absolute period (including jitter

and spread spectrum)

T

PERIOD_ABS

9.847 ns (min)

10.203 ns (max)

Duty cycle Duty Cycle 40% (min)

60% (max)

Maximum peak-peak filtered

Jitter @ 10

-12

BER 108 ps (max) Not

phase jitter

Gen2

Rev0.3

0.6 V/ns (min)

4.0 V/ns (max)

0.6 V/ns (min)

4.0 V/ns (max)

9.997 ns (min)

10.053 ns (max)

40% (min)

60% (max)

Specified

Maximum peak-peak filtered

phase jitter

RMS jitter T

Jitter @ 10-6 BER 86 ps (max) Not

Specified

3.1 ps (max)

CLK_RJ

PCI Express 13

Methods of Implementation

3 Preparing to Take Measurements

3.1 Required Equipment

The following equipment is required to take the measurements:

• Oscilloscope Selection:

ο Gen1 (2.5 Gb/s) – The PCI-SIG recommends a minimum of 6 GHz system BW for Gen1

Measurements. Tektronix models that meet this recommendation are: All the TDS6000B/C Series

instruments and the TDS7704B.

ο Gen2 (5 Gb/s) – It is recommended that >12 GHz system BW is used for Gen2. This ensures the

th

5

harmonic is represented in the measurements. Tektronix models that meet this

recommendation are TDS6000C models.

• RT-Eye software (Opt. RTE) and PCI Express Compliance Module (PCE) installed.

• Probes – probing configuration is MOI specific. Refer to each MOI for proper probe configuration.

• Test fixture breakout from transmitter to differential SMA connectors. A Compliance Base Board

(CBB) used for add-in card compliance tests and a Compliance Load Board (CLB) used for system

compliance tests are available through the PCI-SIG at the following URL:

http://www.pcisig.com/specifications/ordering_information/ordering_information

• Test fixtures for notebook testing are available from the following URL:

http://www.expresscard.org/web/site/testtools.jsp

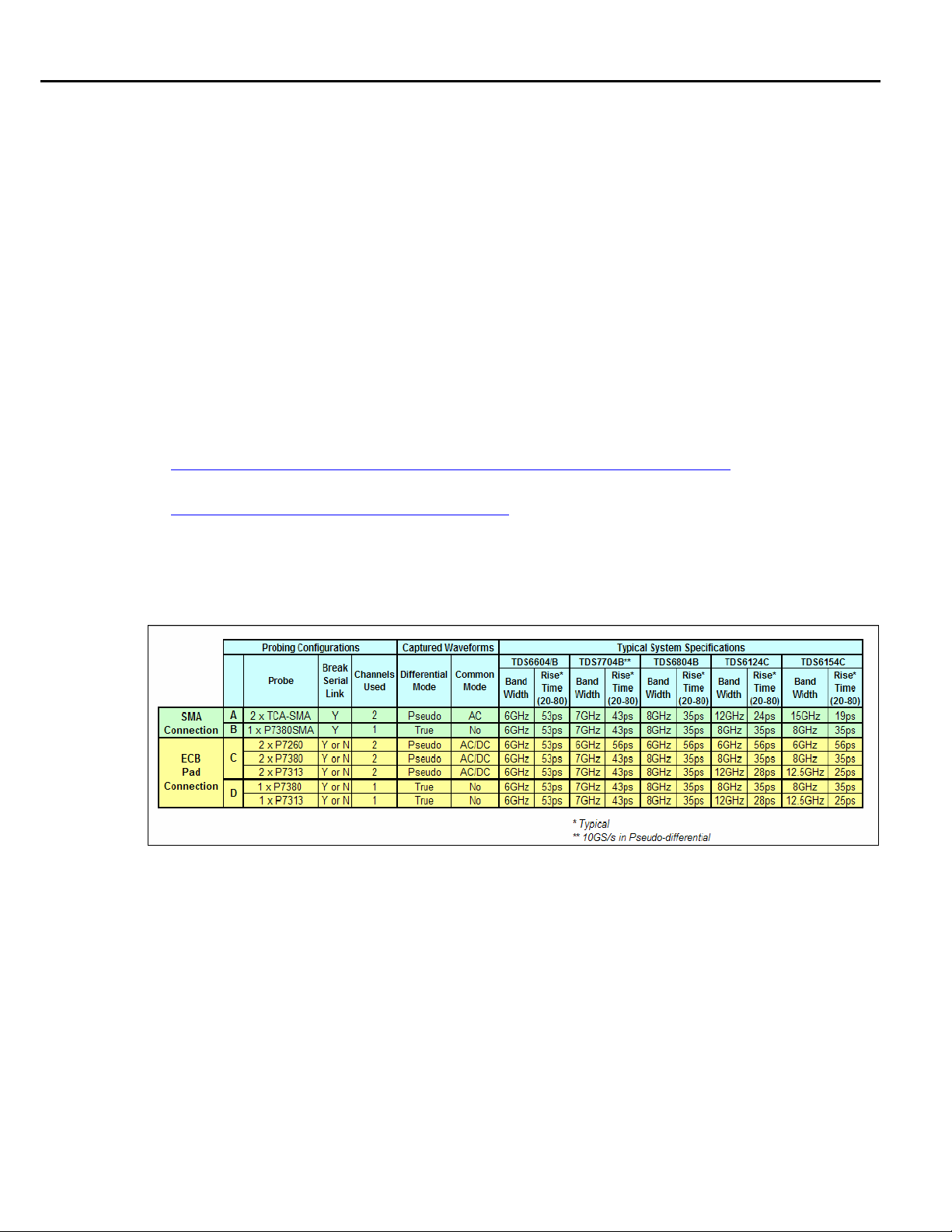

3.2 Probing Options for Transmitter Testing

The first step is to probe the link. Use one of the following four methods to connect probes to the link.

Table 11 – Probing configurations for a PCI express link

14 PCI Express

Methods of Implementation

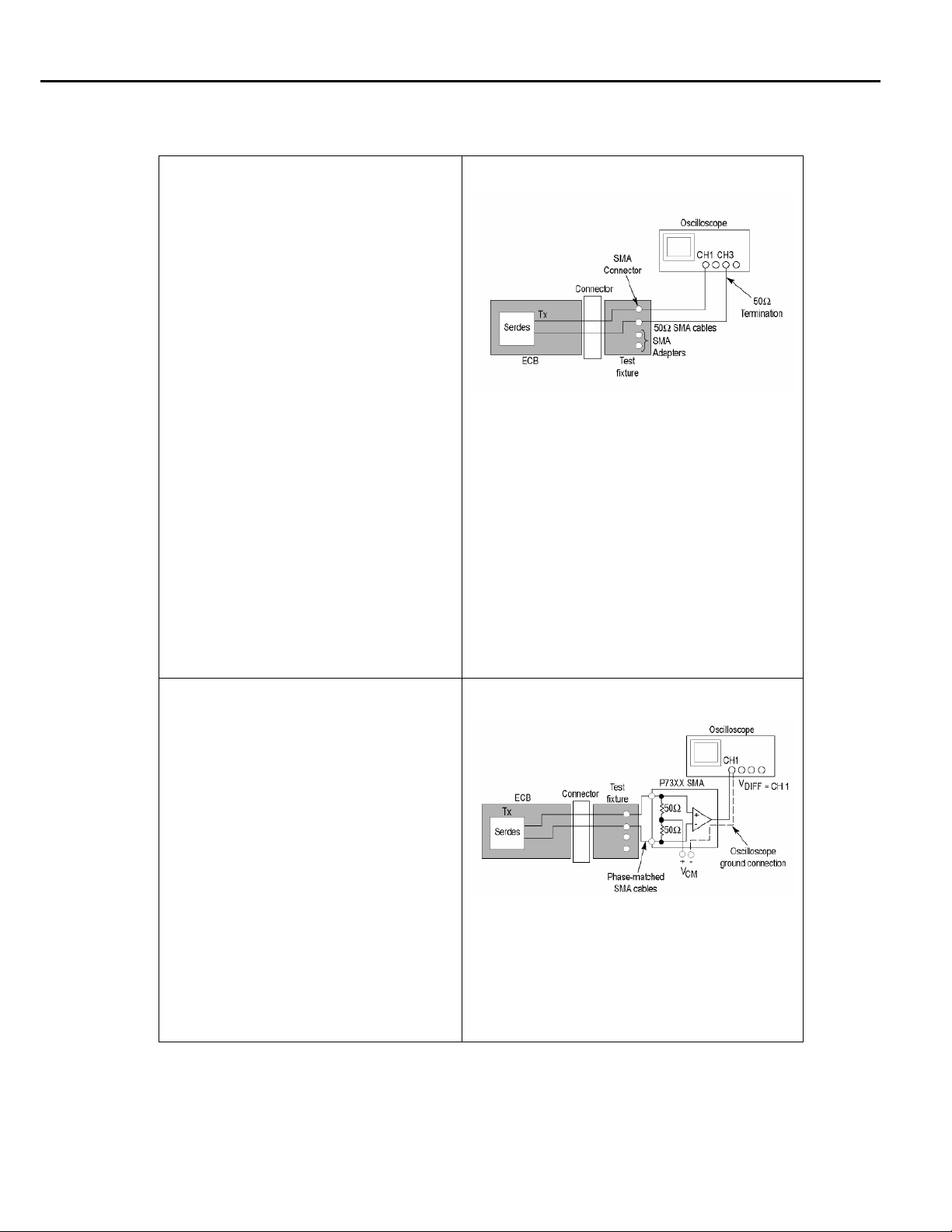

3.2.1 SMA Input Connection

1. Two TCA-SMA inputs using SMA

cables (Ch1) and (Ch3)

The differential signal is created by

the RT-Eye software from the math

waveform Ch1-Ch3. The Common

mode AC measurement is also

available in this configuration from

the common mode waveform

(Ch1+Ch3)/2. This probing technique

requires breaking the link and

terminating into a 50 Ω/side

termination of the oscilloscope.

While in this mode, the PCI Express

SerDes will transmit the compliance

test pattern. Ch-Ch de-skew is

required using this technique because

two channels are used. This

configuration does not compensate

for cable loss in the SMA cables. The

measurement reference plane is at the

input of the TCA-SMA connectors

on the oscilloscope. Any cable loss

should be measured and entered into

the vertical attenuation menu for

accurate measurements at the SMA

cable attachment point.

Probe Configuration A

SMA Psuedo-differential

2. One P7380SMA differential active

probe (Ch1)

The differential signal is measured

across the termination resistors inside

the P7380SMA probe. This probing

technique requires breaking the link.

While in this mode, the PCI Express

SerDes will transmit the compliance

test pattern. Matched cables are

provided with the P7380 probe to

avoid introducing de-skew into the

system. Only one channel of the

oscilloscope is used. The P7380SMA

provides a calibrated system at the

Probe Configuration B

SMA Input Differential Probe

Test Fixture attachment point,

eliminating the need to compensate

for cable loss associated with the

probe configuration A.

PCI Express 15

Methods of Implementation

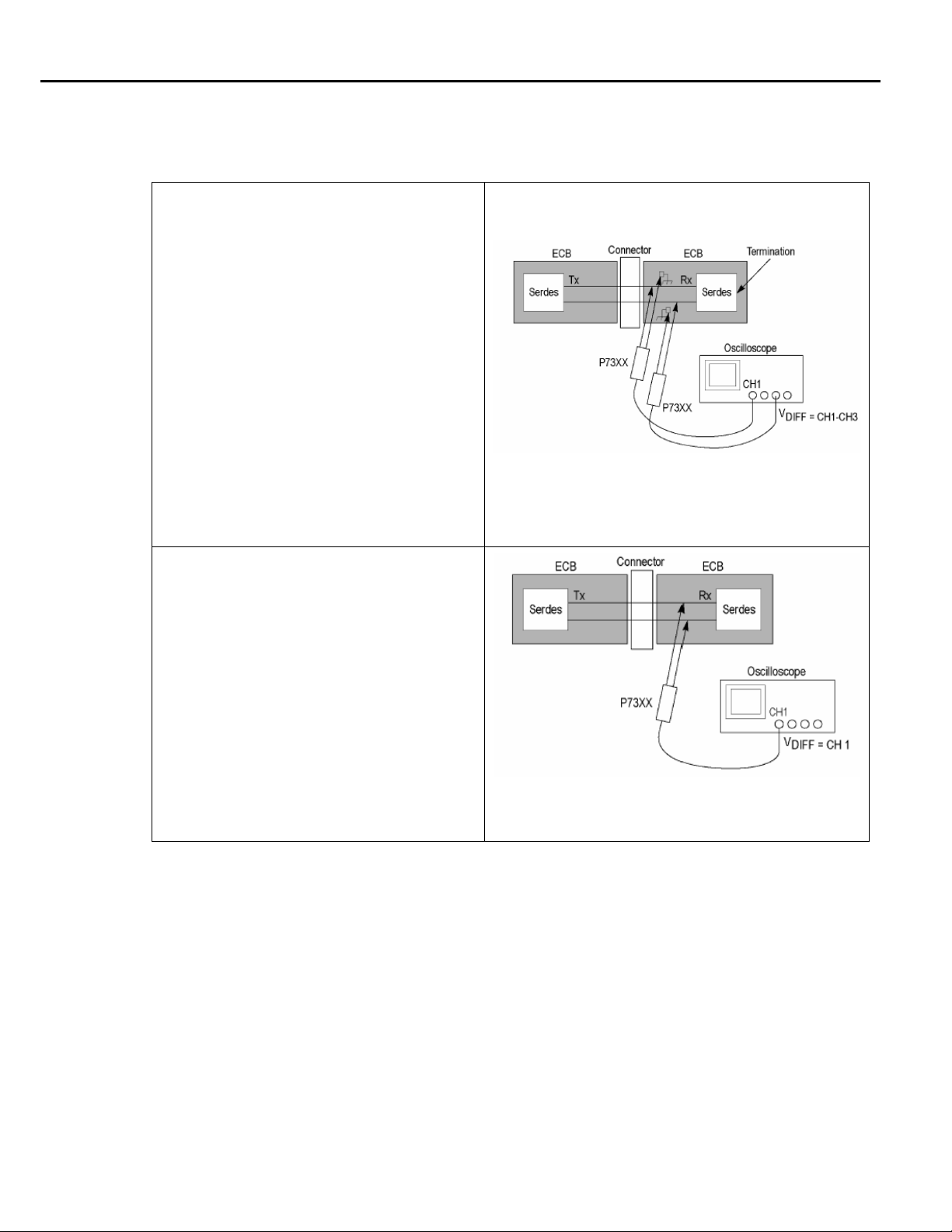

3.2.2 ECB pad connection

3. Two P7300 or P7260 active probes

(Ch1) and (Ch3)

The differential signal is created by the

RT-Eye software from the math

waveform Ch1-Ch3. The Common mode

AC measurement is also available in this

configuration from the common mode

waveform (Ch1+Ch3)/2. This probing

technique can be used for either a live

link that is transmitting data, or a link that

has terminated into a “dummy load.” In

both cases, the single-ended signals

should be probed as close as possible to

the termination resistors on both sides

with the shortest ground connection

possible. Ch-Ch de-skew is required

using this technique because two

channels are used.

Probe Configuration C

Two Single-Ended Active Probes

4. One P7380 Differential probe (Ch1)

The differential signal is measured

directly across the termination resistors.

This probing technique can be used for

either a live link that is transmitting data,

or a link that is terminated into a “dummy

load.” In both cases, the signals should be

probed as close as possible to the

termination resistors. De-skew is not

necessary because a single channel of the

oscilloscope is used.

Probe Configuration D

One Differential Active Probe

16 PCI Express

Methods of Implementation

3.3 Initial Oscilloscope Setup

After connecting the DUT by following the proper probing configuration for the test, click DEFAULT

SETUP and then Autoset to display the serial data bit stream.

3.4 Running the RT-Eye Software

1. On non-B or non-C model oscilloscopes (Example: TDS6604), Go to File > Run Application > RT-

Eye Serial Compliance and Analysis. For B and C models (Example: TDS7704B, TDS6154C), go to

App > RT-Eye Serial Compliance and Analysis.

Figure 9: Default menu of the RT-Eye software

Figure 9 shows the oscilloscope display. The default mode of the software is the Serial Analysis module

(Opt.RTE). This software is intended for generalized Serial Data analysis on 8B/10B encoded copper

links.

2. Select the PCI Express Compliance Module from the Modules pull-down list.

Figure 10: Choosing PCI Express Compliance Module.

PCI Express 17

Loading...

Loading...