Page 1

Package 82 Simultaneous CV

Instruction Manual

Chntains Operating Information

Publication Date: November 1968

Document Number: 5956-901-01 Rev. C

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and

workmanship for a period of 1 year from date of shipment. During the warranty period, we

will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio. You will be given prompt assistance and return instructions. Send the instrument, transportation prepaid, to the indicated service facility. Repairs will be made and the instrument returned, transportation prepaid. Repaired products

are warranted for the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from unauthorized modification or misuse

of any product or part. This warranty also does not apply to fuses, batteries, or damage from

battery leakage.

This warranty is in lieu of all other warranties, expressed or implied, including any implied

warranty of merchantability or fitness for a particular use. Keithley Instruments, Inc. shall

not be liable for any indirect, special or consequential damages.

STATEMENT OF CALIBRATION

This instrument has been inspected and tested in accordance with specifications published

by Keithley Instruments, Inc.

The accuracy and calibration of this instrument are traceable to the National Bureau of Standards through equipment which is calibrated at planned intervals by comparison to certified standards maintained in the Laboratories of Keithley Instruments, Inc.

WEST GERMANY: Kdtldq lnrtrrrmcatr GmbIi / Hdglhok 5 / Mmtdwn 70 I O+3WlOOZ-O I T&C 32-12160 / Tel&~ &35Via?ZS9

GRBATBRlTAINz ~~~U/l~~Rod/~BabhinRG2ONL/o73cB6l287/T~817W/Tddueo13c86J665

FztANcE

-SC ~~~LntrW/A~Wet~/UOZMS~/P.o.BoxU9/UM)ANCcrinchmr

s- Kdtblq InrtmrmntlsA/~.4/3600

AUSTRIA

n-AL*

Keitblq -mUa SARL / 3 Alla du 10 Rue AmbmiseCrdzat / B. P. 60 I 91121 PahisuuKeda l+OllS 13.5 I T&x 600 933 / Tel&c 1-50117726

Kd~~CollnbH/~~huul2/A-l110~/~mp)~~UI/Tdac131671/TJdue~Om)8(JS97

Kdtblq lnstmmmta Sill I Wale B. N 4/A / 20145 Miho / 02420360 or 02-4136!540 / Tdefa 02.4121245’

Dubadaf / 014214444 / T&x 323 VT / Tdohrc 072%315%

I 01330.35333 / T&x 24 684 / Telfax 01&.3MOSZl

Page 3

Instruction Manual

Package 82

Simultaneous CV

@NW, Keithley Instruments, Inc.

Instruments Division

Cleveland, Ohio, U.S.A.

Document Number 5956901-01

Page 4

Hewlett-Packard is a registered trademark of Hewlett-Packard Company.

IBM and AT are registered trademarks of Internation Business Machines, Inc.

Page 5

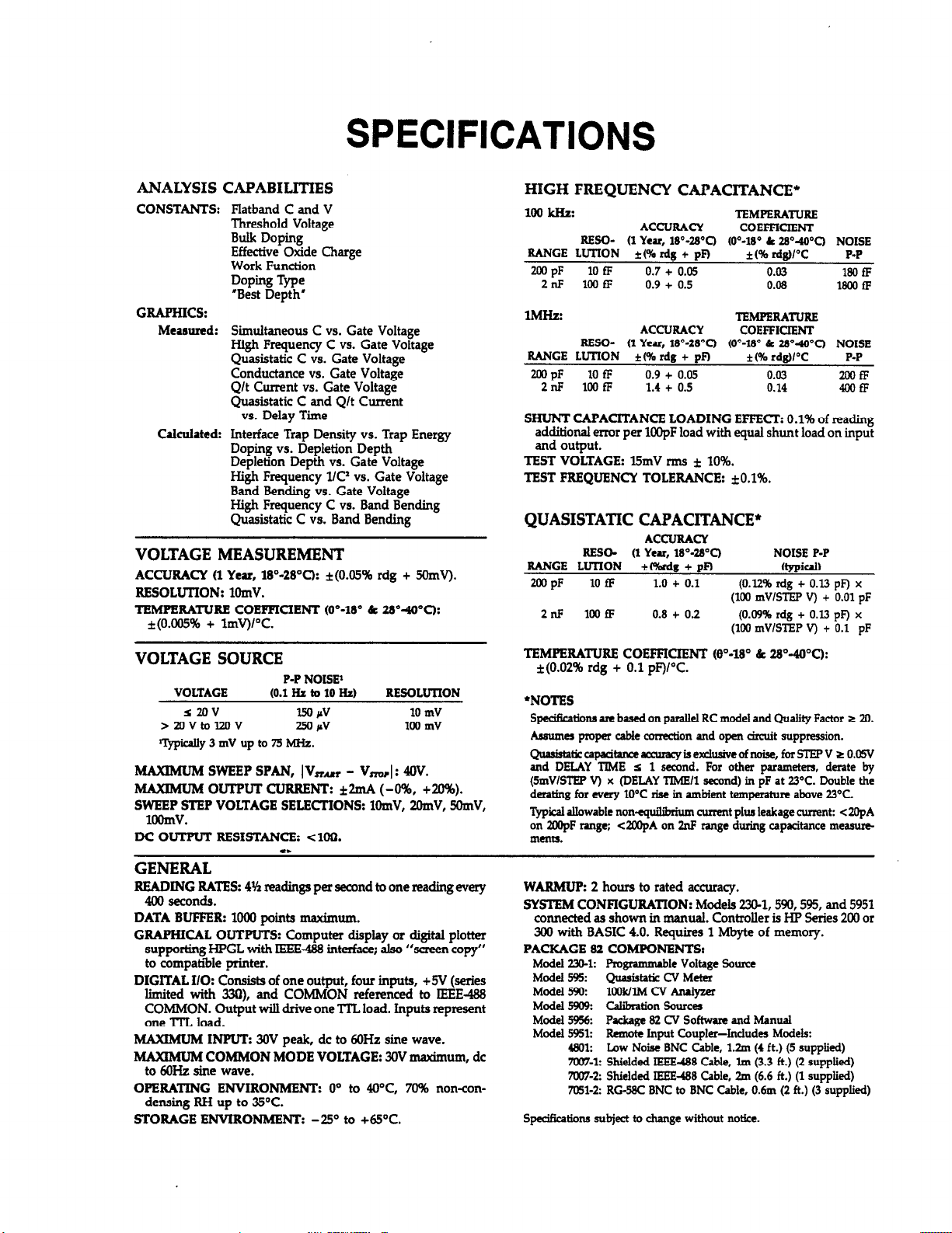

SPECIFICATIONS

ANALYSIS CAPABILITIES

CONSTANTS: Flatband C and V

GRAPHICS:

Measured:

CaIcnIated: Interface Trap Density vs. Trap Energy

Threshold Voltage

Bulk Doping

Effective Oxide Charge

Work Function

Doping Type

‘Best Depth’

Simuitaneous C vs. Gate Voltage

High Frequency C vs. Gate Voltage

Quasistatic C vs. Gate Voltage

Conductance vs. Gate Voltage

Q/t Current vs. Gate Voltage

Quasistatic C and Q/t Current

vs. Delay Time

Doping vs. Depletion Depth

Depletion Depth vs. Gate Voltage

High Frequency l/C’ vs. Gate Voltage

Band Bending vs. Gate Voltage

High Frequency C vs. Band Bending

Quasistatic C vs. Band Bending

VOLTAGE MEASUREMENT

ACCURACY (1Year,18°-280C): *(O.QS% rdg + SOmV).

RESOLUTION: 1OmV.

TEMPERATURECOEFFICIENT (O"-180&2So~oC):

*(O.OOS% + 1mV)K.

HIGH FREQUENCY CAPACITANCE*

1ookHz:

RANGE LUTION i(%rdg+ pF)

mo PF

lMHz:

RANGE LUTION ff%rdg+ pR

~PP

SHUNT CAPACITANCE LOADING EFFECT 0.1% of reading

TEST VOLTAGE: 15mV mu f 10%.

TEST FREQUENCY TOLERANCE: *O.l%.

RESCh QYe~,18~-28~C) too-lS" L 28°-400CJ NOISE

10 a

looa

2nF

RESO- 11 Year, 18"-28°C) (0"-18' (t 28°400C) NOISE

10 fF 0.9 + 0.05

2nF loofF 1.4 + 0.5 0.14

additional error per 1OOpF load with equal shunt load on input

and output.

ACCURACY

0.7 + 0.05 0.03

0.9 + 0.5 0.08

ACCURACY

TEMPERATURE

COEFFICIENT

i (% rdgvc

TEMPERATURE

COERIClENT

k(% rd@l'C

0.03 2cafF

P-P

18ofF

18LMfF

P-P

4lmfF

QUASISTATIC CAPACITANCE*

RANGE LUTION

XIIJ PF

RESO- (1Year,18°-280C)

10 fF 1.0 + 0.1

1mfF

2nP

ACCURACY

rekdg + pm

0.8 + 0.2 (0.09% rdg + 0.13 pF) x

NOISE P-P

(typic&

(0.12% rdg + 0.13 pF) x

(100 mV/STEP V) + 0.01 pF

(100 mV/STEP V) + 0.1 pF

VOLTAGE SOURCE

VOLTAGE (0.1 Hz to 10 Hz) RESOLUTION

S2OV

>iuvtol2ov

ll)@ally 3 mV up to 75 MHz.

MAXIMUM SWEEP SPAN, 1 V,,, - V,r 1: 40V.

MAXIMUM OUTPUT CURRENT: f2mA (-0%. +a%).

SWEEP STEP VOLTAGE SELECMONS: lOmV, 2OmV, SOmV,

1OOHlV.

DC OUTPUT RESISTANCE: Clof.2.

P-PNOISE'

EJl rv

23 rv

10 mV

100 mV

GENERAL

RE&NfN~TES: 444 readings per second to one reading every

DATA BUFFER: 1000 points maximum.

GRAPHICAL OUTPUTS: Computer display or digital plotter

supporting HPGL with IEEE-488 interface; also “screen copy”

to compatiiIe printer.

DIGITAL I/O: Consists of one output, four inputs, +5V (series

limited with 33Q), and COMMON referenced to IEEE-W

COMMON. Output will drive one TI’L load. Inputs represent

one TIL load.

MAXIMUM INPUT: 30V peak, dc to 6oHz sine wave.

MAXIMUM COMMON MODE VOLTAGE: 3OV maximum, dc

to 6OHz sine wave.

OPERATING ENVIRONMENT:

densing RH up to 35°C.

STORAGE ENVIRONMENT: -29’ to +65X

O” to 40°C, 70% non-con-

TEMPERATURECOEFFICIENT @"-lt30&2W'-400C):

*(0.02% rdg + 0.1 pF)K.

*NOTES

Specifkationa are based on parallel RC model and Quality Factor s 20.

Assumes pfopa cable cone&on and open circuit suppression.

~~capsdturerruracyisexdusivcofnoise,for~VrO.OSV

and DEUY TIME s 1 second. For other parameters, derate by

(SmV/STEP V) x (DELAY TIME/l second) in pF at 23OC. Double the

derating for every 10°C rise in ambient temperature above 23°C.

l)pical allowable noniquilbrium current plus leakage current: <ZOpA

on ZOOpF range; cZOOpA on 2nF range during capacitance measurements.

WARMUP: 2 hours to rated accuracy.

SYSTEM CONFIGURATION: Models 22&l, 590,595, and 5951

connected as shown in manual. Controller is HP Series 200 or

300 with BASIC 4.0. Requires 1 Mbyte of memory.

PACRAGE 82 COMPONENTS:

ModeI 230-k Prognmnublc Voltage Source

Model 595:

Model 590:

Model 5909: Calibration Sources

Model 5956:

Model 5951:

Spe&cationa subject to change without notice.

Quaiatatic cv Meter

look/lMcv‘4nalyBer

Packa@? 82 CV Software and Manual

Remote Input Coupler-Includes Models:

Low Noise BNC Cable, 1.2m (4 ft.) (5 supplied)

rllwI1:

7OW1: Shielded IEEEaB Cable, Im (3.3 ft.) (2 supplied)

7007-2: Shielded IEEE488 Cable, Zm (6.6 ft.) (1 supplied)

7051-2: RG-58C BNC to BNC Cable, 0.6m (2 ft.) (3 supplied)

Page 6

Contains information on Package 82 features, specifi-

cations, and supplied accessories.

Gives information to aid in getting your simulta-

neous CV system up and running as quickly as

possible, including hardware and software configuration.

Covers detailed operation including system calibration, correction, and taking data.

SECTION 1 1

General Information j

SECTION 2

Getting Started

SECTION 3 1

Measurement /

Details analysis functions of the Package 82.

Discusses system block diagram, the remote input

coupler, and quasistatic and high-frequency CV

principles.

SECTION 4

SECTION 5

Principles of Operation

Page 7

Table of Contents

SECTION l-GENERAL INFORMATION

1.1

1.2

1.3

1.4

5

i-L

ii2

1.8

1.9

1.9.1

1.9.2

1.10

INTRODUCT’ION ...............................

FEfmJREs

WARRANTY INFORMATION

MANUAL ADDENDA

sm SYMBOLS AND TERMS

SPECIFICAI'IONS

UNPACKING AND INSPECTION

Unpa~gPK>cedure

SuppiiedEquipment

REFACKING FOR SHIPMENT

COMPUTER CONFIGURATION

Series 200 and 300

IBM AT

SERVICE AND CALIBRATION.

...............................

...................................................................

..........................................................................

..............................................................................

.........................................................................

............................................................................

...........................................................................

.....................................................................................

SECTION P-GETTING STARTED

..............................................................................

........................................................................

.:

....

..........................................................................

....................................................................

....................................................................

...........................................................................

...........................................................................

.....................................................................

.............................................................................

.........................................................................

..............................................................................

...........................................................................

.............................................................................

.................................................

...............................................................................

........................................................................

................................................................................

......................................................................

............................................................................

.........................................................................

...................................................................

.........................................................................

.........................................................................

......................................................................

..................................................................................

............................................................................

..........................................................................

i-:.

2:2.1

2.2.2

2.2.3

2.2.4

2.2.5

2.3

2.3.1

2.3.2

2.3.3

2.3.4

2.3.5

2.3.6

2.4

2.4.1

2.4.2

2.4.3

2.4.4

El

2:5:2

2.5.3

2.5.4

2.5.5

2.5.6

2.6

2.6.1

2.6.2

2.7

2.7.1

2.7.2

2.7.3

2.7.4

INTRODUCI’ION

HARDWARE CONFIGURATION

SystemBlockDiagram

RemoteInputCoupler..

SystemConnections

IEEE-483 Bus Connections

Remote Coupler Mounting

SYSTEM POWER UP

Instrument Power Requirements

Power Connections

Environmental Conditions

Warm Up Period

Power Up Procedure

Line Frequency

SOFTWARE CONFIGURAl’ION

Computer Boot Up

Software Backup

Software Initialization

Software Files

SOFIWARE OVERVIEW

System Reset

System Characterization

Cable Correction

C& and Delay Time Determination

Device Measurement

Data Analysis and Plotting

SYSTEM CHECKOUT

Checkout Procedure

System Troubleshooting

USING THE PACKAGE 82 WITH THE IBM AT

Installation

Software Backup

Configuration File Modification

Booting the System

...............................................

.....................................................

...............................................................

...............................................................

..................................................................

................................................................

.................................................................

................................................................

................................................................

...............................................................

.................................................................

............................................................

..................................................

...............................................................

l-1

l-l

l-l

l-1

l-l

l-2

l-2

l-2

l-2

l-2

l-2

l-2

l-2

2-1

2-l

2-l

2-l

2-4

2-6

2-6

2-7

2-7

2-7

2-7

2-a

i:

2-9

2-9

2-9

..- .................... 2-9

;I;

2-9

2-9

2-10

2-11

2-n

2-U

2-11

2-n

2-ll

;I:

2-33

2-l3

2-B

i

Page 8

2.7.5

.......................................................................................................

27.6

Modifyingtheprintpath...................................... . . . . . . . . . . ..*......*........a..

Operational Check. . . . . . .

SECTION 3--MEASUREMENT

. . . . . . . . . . . . . . . . . . ..*............................*.............*....

2-14

2-14

3.1

3.2

3*3

3.4

3.4.1

3.4.2

3.4.3

3.4.4

3.45

3.5

3.5.1

3.5.2

3.5.3

3.54

3.5.5

3.5.6

3.6

3.6.1

36.2

3.6.3

3.6.4

El

3?2

3.7.3

37.4

37.5

3.8

38.1

38.2

3.8.3

3.9

3.9.1

3.9.2

3.9.3

3.9.4

3.9.5

INTRODUCTION

MEASUREMENT SEQUENCE

SYSTEM RESET

TESTING AND CORRECTING FOR SYSTEM LEAKAGES AND !XFWt’S

Test and Correction Menu

.............................................................................. 3-l

...................................................................

...............................................................................

...........................

....................................................................

Parameter Selection

Viewing Leakage Levels

System Leakage Test Sweep

Offset Suppression

CORRECT’ING FOR CABLING EFFECTS

When to Perform Cable Correction.

RecommendedSources

Source Connections

.........................................................................

~oha.re Mciiflcation

Y **

Correction Procedure

Optimizhg Correction Accuracy to Probe Tips

.................................................................................................................................................

...........................................................................................................................................

..

........................................................

...........................................................

......................................................................

.........................................................................

........................................................................

.................................................

DETERMNNG OXIDE CAPACTIXNCE AND EQUILIBRIUM DELAY TIME

& and Delay Time Menu

Running and Analyzing a Diagnostic CV Sweep

...... .... .. .

........... ........

..........

Determining Oxide Capacitance, Oxide Thickness, and Gate Area

Determining Optimum Delay lime

MAKINGCVMF&lIGMEMS

CVMeasurementMenu

....

...........................................................

...............................................................

........................................................................................................................

Programming Measurement Parameters

Manual CV Sweep

......................................................................................................................................................

Auto CV Sweep

Using Corrected Capacitance

LIGHT CONNECX’IONS

Digital I/O Port Tixminals

LED collnectioIls

...........................................................................

Relaycontrol.......................................~

MEASUREMENT CDNSID~ONS

Potential Error Sources

AvoidmgCapacitanceEm>rs

Correcting Residual Errors

Interpreting CV Curves

DynamicRangecOnsideratio~

.................................................................

......................................................................

....................................................................

.......................................

................................................

......................................................................

........

1.

.................................................................

...................................................................

......................................................................

...............................................................

........................

3-3

3-3

g

3-9

3-13

3-13

3-13

3-h

r) -se

zfi

346

3-16

3-X

3-18

3-20

3-22

3-26

322

3-29

3-30

3-33

3-33

3-33

3-34

3-34

g;

3-z

3-39

3-40

SECTION 4-ANALYSIS

4.1

4.2

4.21

INTRODUCTlON

CONSWNTS AND SYMBOLS USED FOR ANALYSIS

constants.

4.2.2 Raw Data Symbols

42.3

4.3

4.3.1

4.3.2

4.4

44.1

4.4.2

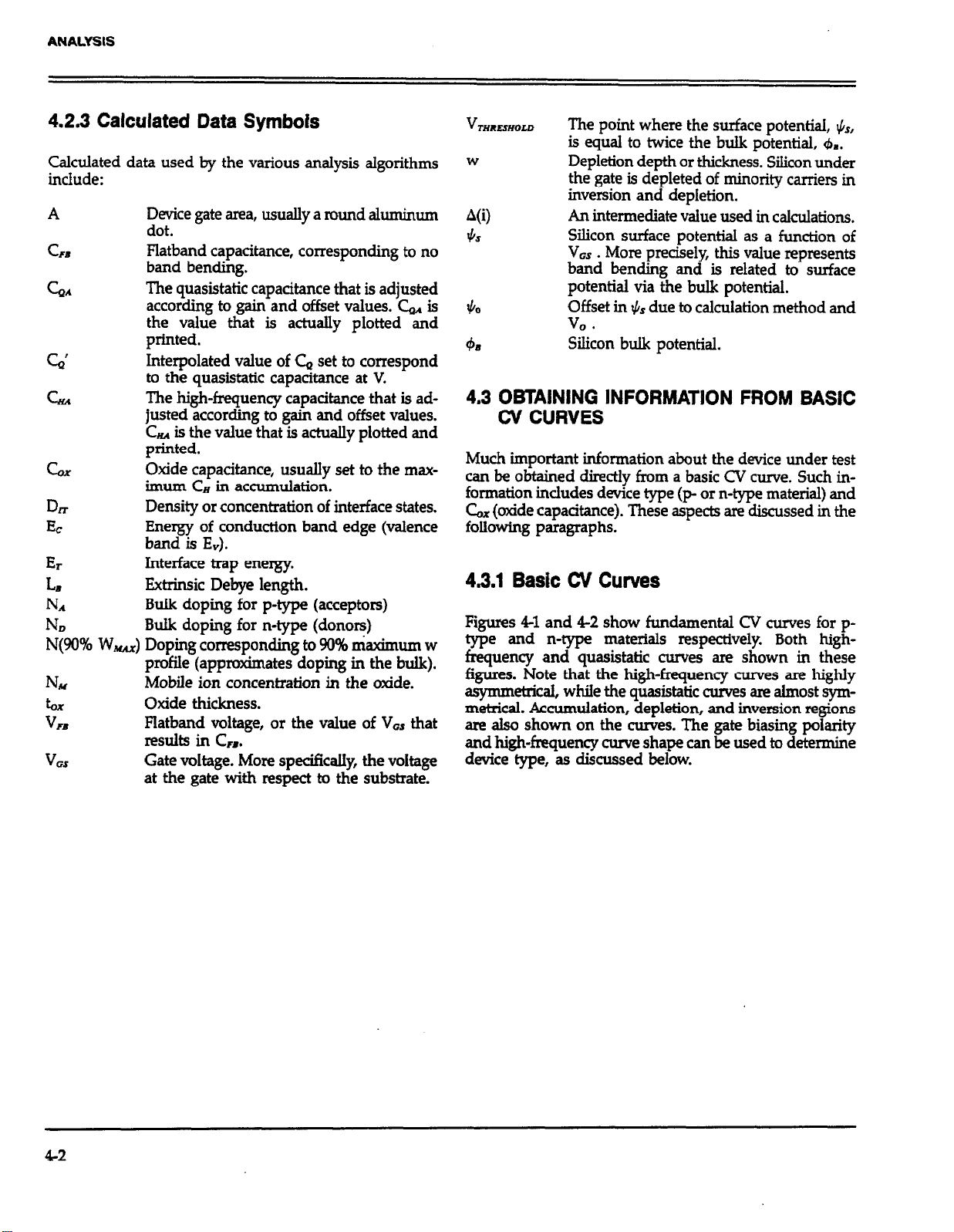

Calculated Data Symbols

OB’UINNG IN-FOlWiAIlON FROM BASIC CV CURVES

Basic CV Curves

Dgtermining Device~e

ANAIXING CV DAIX

PlotterandPxinter Requirements..

Analysis Menu

ii

..............................................................................

.....

..

..........

...........................................................................

....... .....

..................................................................................................

.....................................................................

.............................................................................

.....................................................................

........................................................................

............................................................

..............................................................................

.........................................

41

E;

41

42

42

42

44

44

4-4

45

Page 9

4.4.3

4.4.4

4.4.5

4.4.6

4.4.7

4.4.8

4.4.9

4.4.10

4.4.11

4.4.12

4.4.13

4.4.14

4.5

4.5.1

4.5.2

4.5.3

4.6

4.6.1

4.6.2

Saving andRecalling Data

Displaying and Printing the Reading and Graphics Arrays

Graphing Data

AnalysisTools .............................................................................. 410

Reading Array

Calculated Data Array (Graphics Array)

Constants Used for Analysis

Graphing the Reading Array

Doping Profile

Flatband Capacitance

Interface Trap Density Analysis.

CalculatedAccuracyofNandD~.

MOBIL,E IONIC CHARGE CONCENTTWHON MEASUREMENT .................................

Flatband Voltage Shift Method.

Triangular Voltage Sweep Method

Using Effective Charge to Determine Mobile Ion Drift

REFERENCES AND BIBLIOGRAPHY OF CV MEASUREMENTS AND RELAI’ED TOPICS.

References

Bibliography of CV Measurements and Related Topics

..............................................................................

.............................................................................. 412

..............................................................................

.................................................................................

...................................................................

.................................................................

.................................................................

.......................................................................

.............................................................

...........................................................

..............................................................

........................................................... 430

SECTION 5-PRINCIPLES OF OPERATION

......................................

......................................................

......................................... .433

.........................................

.........

4-6

46

49

413

413

413

419

423

4-23

429

429

4-29

433

433

433

................................................. ............................ 5-l

...................................................................

...................................................................

..............................................................................

........................................................................... 5-2

............................................................................

.................................................................

.......................................................................

.......................................................................

............................................................... 5-5

..........................................................................

::1

El

5:3:2

5.4

5.4.1

5.4.2

5.5

5.5.1

5.5.2

5.6

INTRODUCTION

SYSTEM BLOCK DIAGRAM

REMOTE INPUT COUPLER

Tuned Circuits

Frequency Control

QUASISTATIC CV.

Quasistatic~ Configuration

Measurement Method

HIGH FREQUENCY CV

High Frequency System Configuration

High-Fluency Measurements

SIMUJXWEOUS CV

SECTION 6-REPLACEABLE PARTS

6.1

6.2

E

k5

INTRODUCT’ION

Pm LIST ..................................................................................

ORDERING INFORMAlTON

FACRJRY SERVICE ...........................................................................

COMPONENT LAYOUTS AND

................................................. ............................

........................................ ...........................

s

CHEMAX DIAGRAMS

APPENDICES

Appendix A

Appendix B

Appendix C

AppendixD ..................................................................................

Appendix E

AppendixF

..................................................................................

..................................................................................

..................................................................................

..................................................................................

...................................................................................

........................................................

........................................ 6-l

5-l

5-2

5-2

5-3

5-3

5-3

53

5-5

5-6

:;

z

A-l

g:1

D-l

E-l

F-l

iii/iv

Page 10

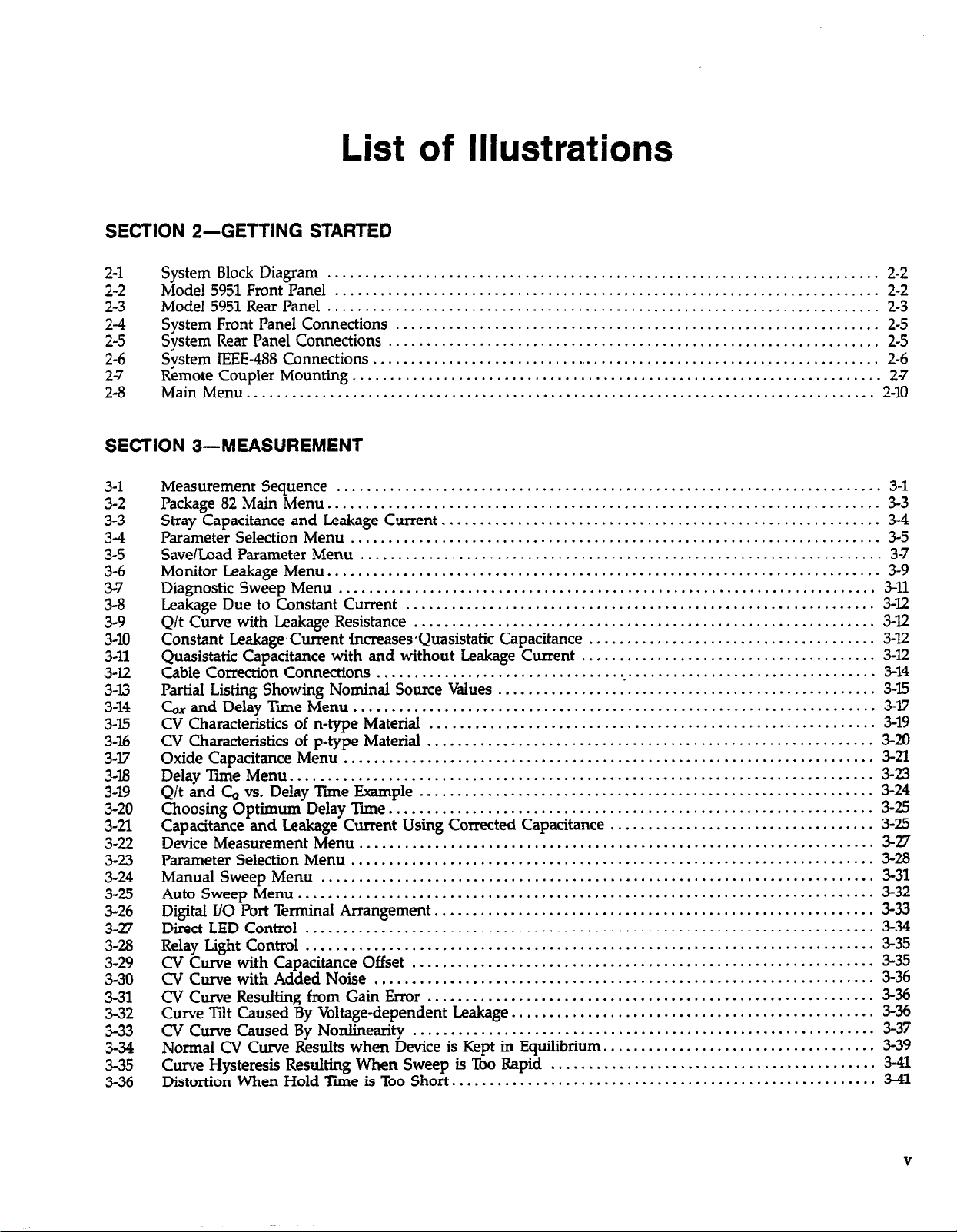

List of Illustrations

SECTION 2-GETTING STARTED

2-l

2-2

2-3

2-4

2-5

2-6

2-7

2-8 Main Menu.

System BlockDiagram

Model5951 Front Panel

Model 5951RearPanel

System Front Panel Connections

System Rear Panel Connections

System IEEE-488 Connections

Remote Coupler Mounting

..................................................................................

.........................................................................

........................................................................

.........................................................................

SECTION 34blEASUREMENT

3-l

3-2

3-3

2

3-6

3-7

3-8

3-9

3-10

3-11

3-22

3-13

3-14

3-15

3-16

3-v

3-18

3-19

3-20

3-21

3-22

3-23

3-24

3-25

3-26

3-27

3-28

3-29

3-30

3-31

3-32

3-33

3-34

3-35

3-36

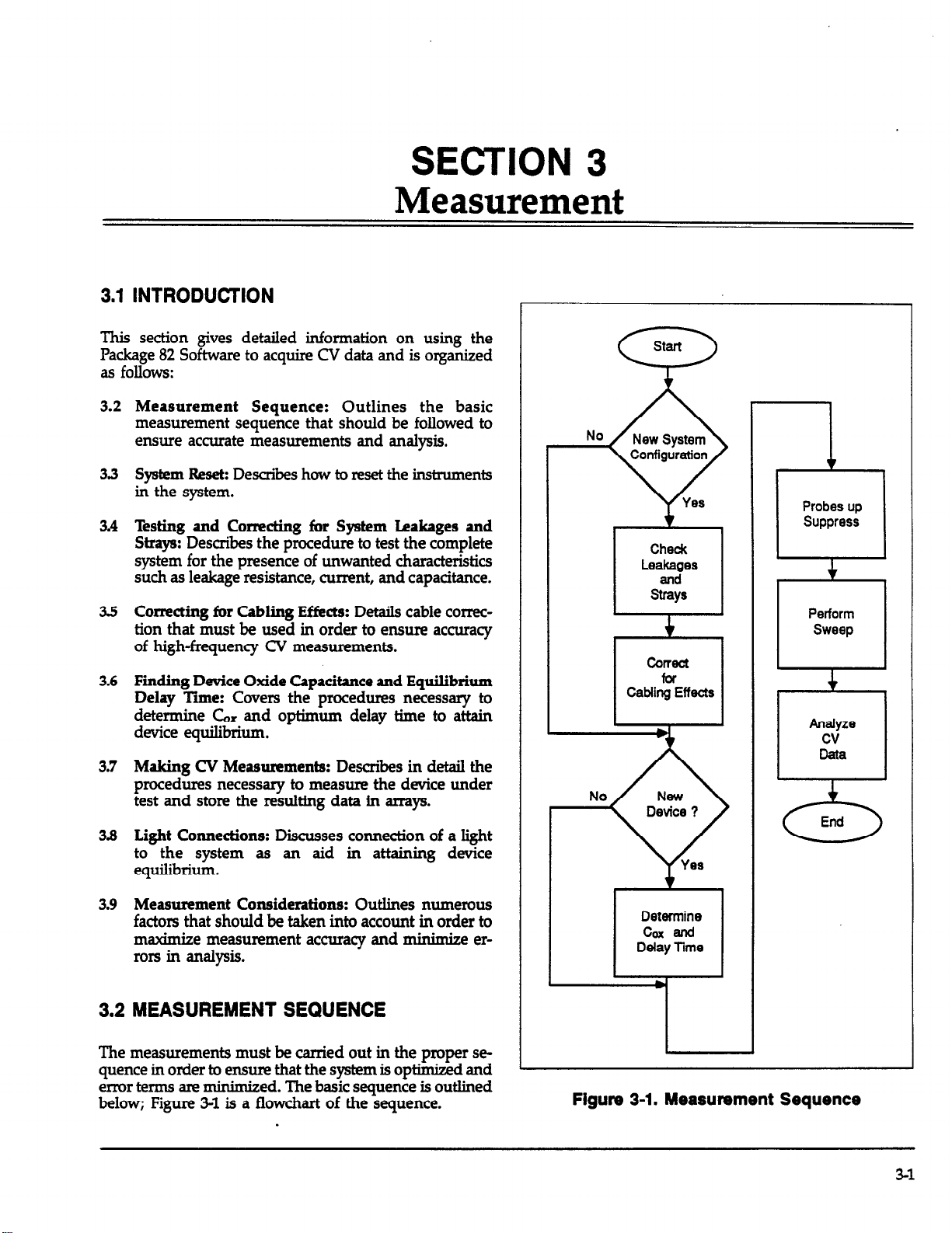

Measurement Sequence

Package 82 Main Menu

Stray Capacitance and Leakage Current.

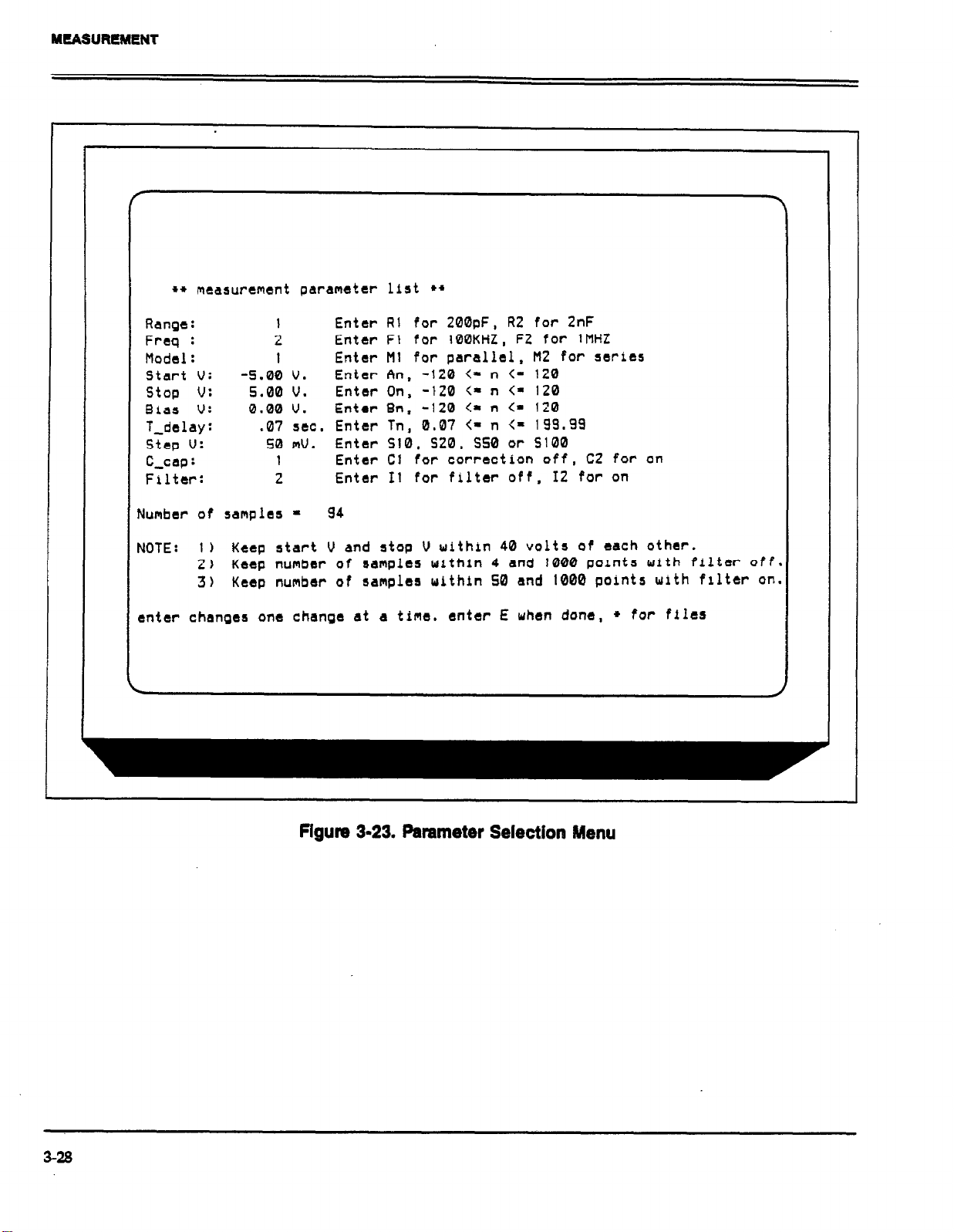

Parameter Selection Menu

Save/Load Parameter Menu

Monitor Leakage Menu

Diagnostic Sweep Menu

Leakage Due to Constant Current

Q/t Curve with Leakage Resistance

Constant Leakage Current .Increases*Quasistatic Capacitance

Quasistatic Capacitance with and without Leakage Current

Cable Correction Connections

Partial Listing Showing Nominal Source Values

X and Delay Time Menu

co

CV Characteristics of n-type Material

CV Characteristics of p-type Material

Oxide Capacitance Menu

Delay Time Menu

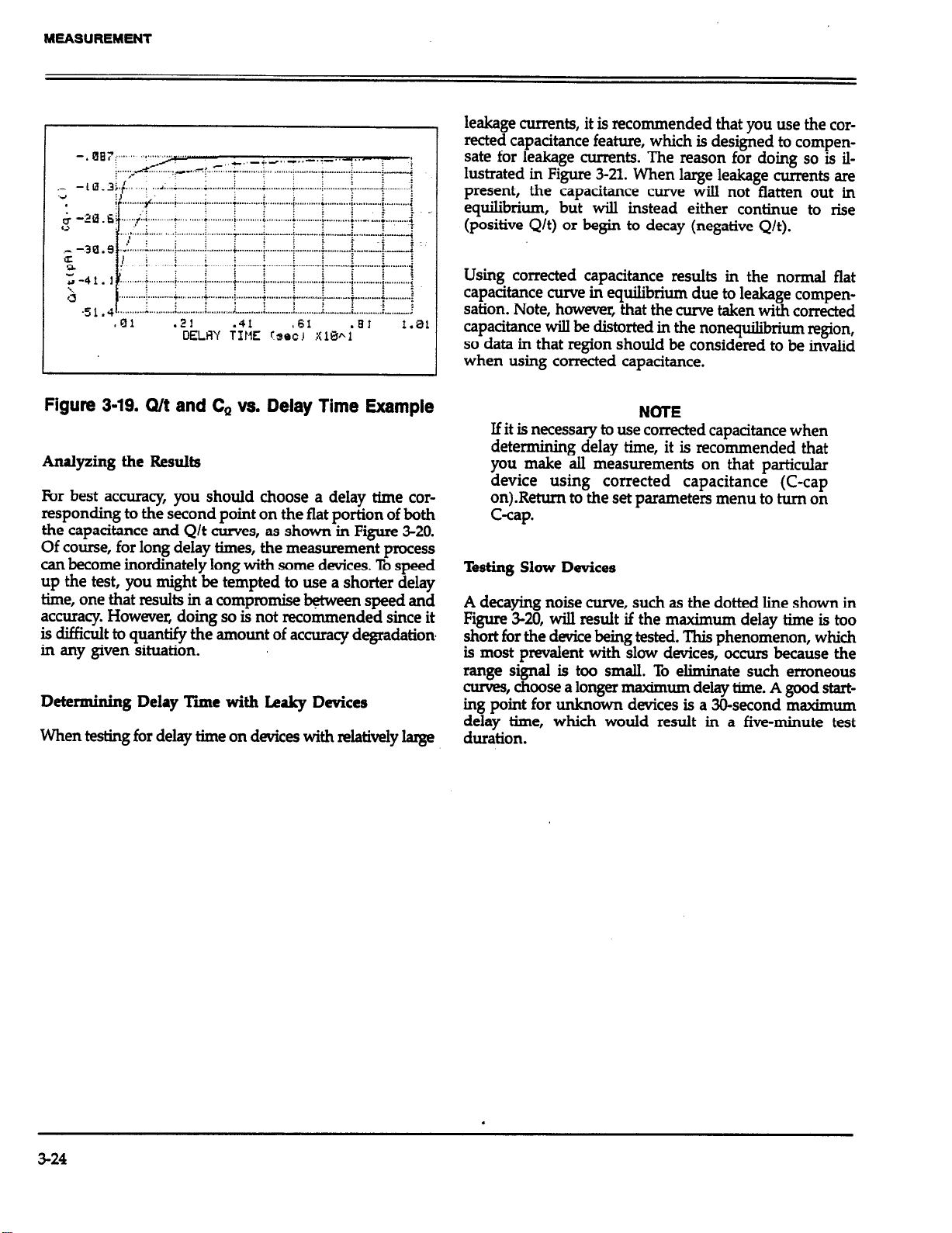

Q/t and C, vs. Delay Time Fixample

Choosing Optimum Delay Time

Capacitance and Leakage Current Using Corrected Capacitance

Device Measurement Menu

Parameter Selection Menu

Manual Sweep Menu

Auto Sweep Menu

Digital 110 Port Terminal Arrangement

Direct LED Control

Relay Light Control

CV Curve with Capacitance Offset

CV Curve with Added Noise

CvCurw Resukingfrom GainError

Curve Tilt Caused By Voltage-dependent Leakage

W Curve Caused By Nonlinearity

Normal~CurveRes&swhenDeviceisKeptinEquiBbrium..

Curve Hysteresis Resulting When Sweep is Too Rapid

DistortionWhenHoldTieisTooShort..

........................................................................

.........................................................................

.........................................................................

.......................................................................

.............................................................................

.........................................................................

............................................................................

...........................................................................

...........................................................................

................................................................

.................................................................

....................................................................

......................................................................

.........................................................

......................................................................

.....................................................................

..............................................................

.............................................................

...................................... 3-12

.......................................

...................................................................

..................................................

.....................................................................

........................................................... 3-19

...........................................................

......................................................................

............................................................

................................................................

...................................

....................................................................

.....................................................................

..........................................................

.............................................................

..................................................................

...........................................................

................................................

.............................................................

..................................

...........................................

......................................................

2-2

2-2

2-3

2-5

2-5

2-6

2-7

2-10

3-l

3-3

3-4

3-5

3-7

3-9

3-11

3-12

3-32

3-12

3-14

3-15

3-17

3-20

3-21

3-23

3-24

3-25

3-25

3-27

3-28

3-31

3-32

3-33

3-34

3-35

3-35

3-36

3-36

3-36

3-37

3-39

3-41

3-41

V

Page 11

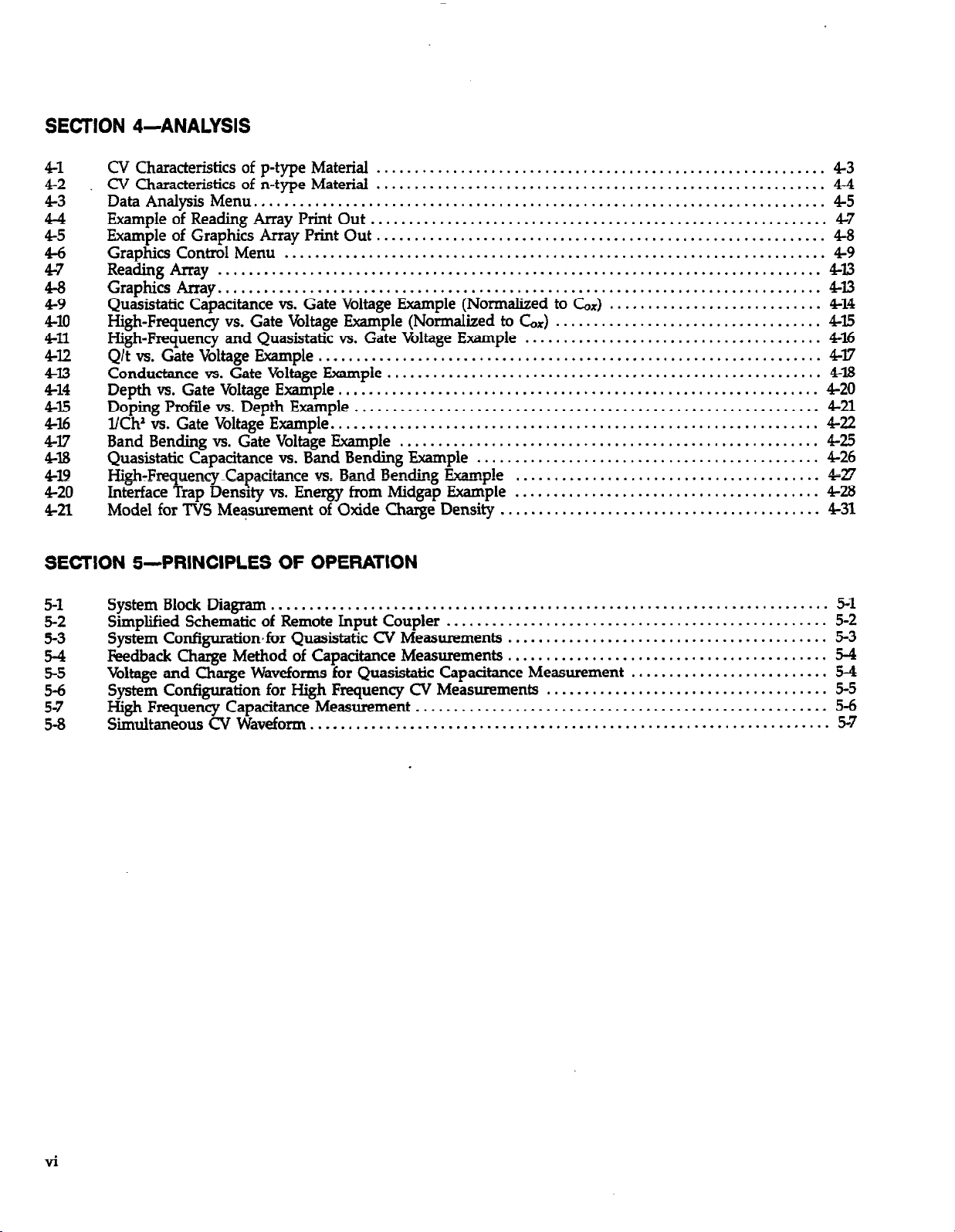

SECTION 4-ANALYSIS

41

42

2

45

2

4-8

4-9

410

Q-11

PI2

413

414

4-15

4-16

417

418

4l9

420

42l

CV Characteristics of p-type Material

CV Characteristics of n-type Material

Data Analysis Menu

........................................................................... z

Example of Reading Array Print Out

Example of Graphics Array Print Out

Graphics Control Menu

Reading Array

Graphics &ray

...............................................................................

............................................................................... 423

....................................................................... 49

Quasistatic Capacitance vs. Gate Voltage Example (Normalized to Lx)

High-Frequency vs. Gate Voltage Example (Nonnaked to 6x)

High-Frequency and Quasistatic vs. Gate Voltage Example

Q/t vs. Gate Voltage Example

..................................................................

Conductance vs. Gate Voltage Example

Depth vs. Gate Voltage Example

Doping Profile vs. Depth Example

Kh’ vs. Gate Voltage Example

Band Bending vs. Gate Voltage Example

Quasistatic Capacitance vs. Band Bending Example

Hligh~FrequencyCapacitance vs Band Bending Examp!e

Interface Trap Density vs. Energy from Midgap Example

Model for TVS Measurement of Oxide Charge Density

...........................................................

...........................................................

............................................................

........................................................... z

.........................................................

............................................................... 420

............................................................. 421

................................................................ 422

....................................................... 425

SEaION S-PRINCIPLES OF OPERATION

5-l

z

5-4

5-5

5-6

El

System Block Diagram

Simplified Schematic of Remote Input Coupler

System Configuration~for Quasistatic CV Measurements

Bxdbaclc Charge Method of Capacitance Measurements

U&age and Charge Waveforms for Quasistatic Capacitance Measurement

System Configuration for High Frequency CV Measurements

High Frequency Capacitance Measurement

Simukmeous CV Waveform.

.........................................................................

...................................................................

............................

................................... 415

....................................... 4%

.............................................

....................................

....

........................................

.......................................... 431

.................................................. 5-2

..........................................

..........................................

..........................

..................................... 5-5

......................................................

43

423

414

417

418

426

A-w

T”

428

5-l

5-3

54

5-4

5-6

57

vi

Page 12

List of Tables

SECTION l-GENERAL INFORMATION

l-1

l-2

l-3

SuppliedEquipment ...........................................................................

Minimum Computer Requirements ..............................................................

Necessary Binary Files

................................................ ..........................

SECTION 2-GETTING STARTED

2-l

;I$

Supplied Cables

Diskette Files

System Troubleshooting Summary

...............................................................................

.................................................................................

SECTON 3-MEASUREMENT

3-l

3-2

Cable Correction Sources

Digital I/O Port Terminal Assignments

......................................................................

SECTION 4-ANALYSIS

41

42 Displayed Constants

43 Analysis Constants

Graphical Analysis

............................................................................ 410

........................................................................... 4-10

............................................................................ 419

..............................................................

.......................................................... 3-33

l-3

l-3

l-3

2-4

;I;

3-14

vii/viii

Page 13

SECTION 1

’ General Information

1.1 INTRODUCTION

This section contains overview information for the Package

82 Simultaneous CV system and is arranged as follows:

1.2 Features

1.3 Warranty Information

1.4 Manual Addenda

1.5 Safety Symbols and Terms

Specifications

1.6

1.7 Unpacking and Inspection

Repacking for Shipment

1.8

1.9 Computer Configurations

Service and Calibration

1.10

1.2 FEATURES

The Package 82 is a computer-controlled system of instruments designed to make simultaneous quasistatic CV

and high frequency (1oOkHz and lMHz) CV measurements

on semiconductors. The package 82 includes a Model 590

CV Analyzer for high-frequency CV measurements, and

a Model 595 Quasistatic CV Meter, along with the

necessary input coupler, connecting and control cables,

and cable calibration sources. A Model 230-l Lbltage Souse

and software for the HP 9000 Series 2(Xl and 300 computers

(or an IBM AT with an HP BASIC language processor card)

running BASIC 4.0 are also included.

l Graphical analysis capabilities allow plotting of data on

the computer display as well as hard copy graphs using

an external digital plotter. Graphical analysis for such

parameters as doping profile and interface trap density

vs. trap energy is provided.

. Supplied external voltage source (Model 230-l) extends

the DC bias capabilities to *l2OV.

0 Supplied calibration capacitors to allow compensation for

cable effects that would otherwise reduce the accuracy

of lOOkHz and lMHz measurements.

l All necessary cables are supplied for easy system hook

UP.

1.3 WARRANTY INFORMATION

Warranty information is located on the inside front cover

of this instruction manual. Should you require warranty

service, contact your Keithley representative or the factory

for further information.

1.4 MANUAL ADDENDA

Any improvements or changes concerning the Package 82

or this instruction manual will be explained on a separate

addendum supplied with the package. Please be sure to

note these changes and incorporate them into the manual

before operating or servicing the system.

Key Package 82 features include:

0 Remote input coupler to simplify connections to the

device under test. Both the Model 595 and the Model

590 are connected to the device under test through the

coupler, allowing simultaneous quasistatic and high frequency measurement of device parameters with negligible interaction between instruments.

l Supplied menu-driven software allows easy collection

of C, G, V, and Q/t data with a minimum of effort. No

computer programming knowledge is necessary to

operate the system.

l Data can be stored on disk for later reference or analysis.

Addenda concerning the Models 250~1,590,595, and 5909

will be packed separately with those instruments.

1.5 SAFETY SYMBOLS AND TERMS

The following safety symbols and terms may be found on

one of the instruments or used in this manual:

symbol on an instrument indicates that you

Q

The ’

should consult the operating instructions in the associated

manual.

l-l

Page 14

GENERAL INFORMATION

The WARNING heading used in this and other manuals

cautions against possible hazards that could lead to personal injury or death. Always read the associated information very carefully before performing the indicated

procedure.

A CAUTION heading outlines dangers that could damage

the instrument. Such damage may invalidate the warranty.

1.6 SPECIFICATIONS

Detailed specifications for the Package 82 system can be

found at the front of this manual. Specifications for the

individual instruments are located in their respective instruction manuals.

1.7 UNPACKING AND INSPECTION

1.7.1 Unpacking Procedure

Upon receiving the Package 82, carefully unpack all instruments and accessories from their respective shipping

cartons, and inspect all items for any obvious physical

damage. Report any such damage to the shipping agent

at once. Save the original packing cartons for possible

future reshipment.

l Advise as to the warranty status of the equipment.

l Write ALTENTION REPAIR DEPARTMENT

on the ship

ping label.

l Fill out and include the service form which is located

at the back of this or one of the other instruction

manuals.

1.9 COMPUTER CONFIGURATIONS

1.9.1 HP Series 200 and 300

The Package 82 is supplied with software intended for use

with the Hewlett Packard HP 9000 Series 200 and 300 computers running under BASIC 4.0. Table l-2 summarizes

minimum requirements for the computer system. Table l-3

summarizes necessary binary files.

1.9.2 IBM AT

The Package 82 can also be used with an IBM AT (or com-

patible) that is equipped with a BASIC-ROM configured

HP-8232lA Language Processor card. Paragraph 23 of this

manual gives an overview of the procedure; see the HP

documentation for detailed information.

1.10 SERVICE AND CALIBRATION

1.7.2 Supplied Equipment

Table l-l summarizes the equipment supplied with the

Package 82 system.

1.8 REPACKING FOR SHIPMENT

Should it become necessary to return any of the instruments for repair, carefully pack them in their original

packing cartons (or the equivalent), and be sure to include

the following information:

The Model 5951 Remote Input Coupler cannot be

calibrated or repaired by the user, so it must be returned

to the factory or authorized service center for repair or

calibration. If the Model 5951 is to be returned, proceed

as folIows:

1. Complete the service form at the back of the manual

and include it with the unit.

2. tZarefdy pack the unit in the original packing carton

or its equivalent.

3. Write AITENTION RJBUR DEl?A#IuENT

on the ship

ping label.

l-2

Page 15

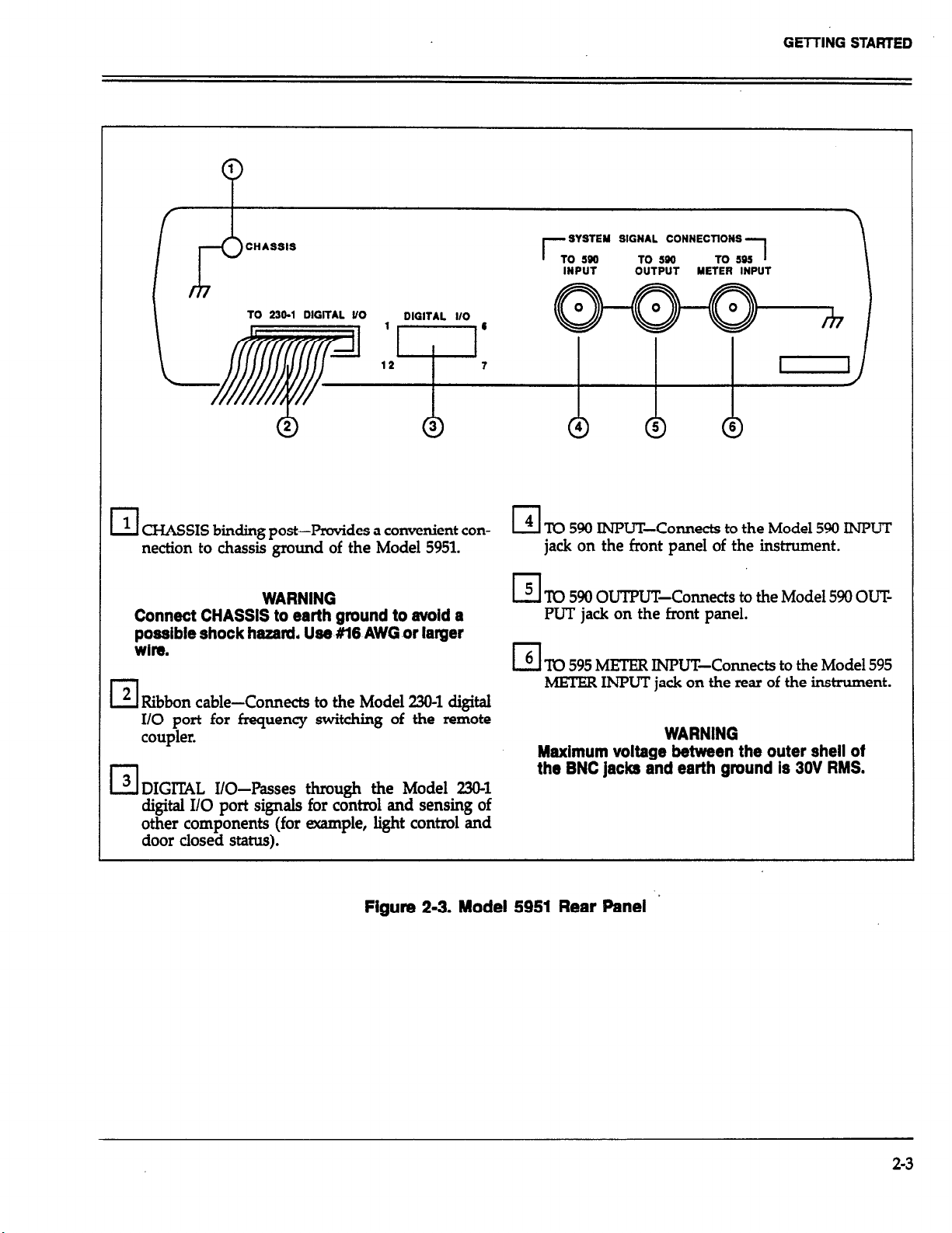

Table l-1. Supplied Equipment

GENERAL INFORMATION

w-------2

1

1

1

1

- ---- ----_

230-l Voltage Source

590 CV Analyzer

595 Quasistatic CV Meter

5951 Remote Input Coupler

5909 Capacitance Sources

:

3

.

2

1

1

4801 Low noise BNC cables (4’)

7051-2 BNC cables

7007-l Shielded IEEE488 cables (lm)

7007-2 Shielded IEEE488 cable (2m) Connect controller to instrument bus

5956 CV Software Package Control Package 82 system.

Table l-2. Minimum Computer Requirements

Hewlett-Packard HP9000

Computer

Minimum FUM

Monitor

Disk Storage

Series 200 or 300**

lM bytes*

Monochrome

HP829Olm (5%“) or

HP&TJ22 (3%“) floppy disk

IEEE-488 Interface

HP-I-B

Programming language BASIC 4.0

-Yp*.~.I”‘.

Supply *lOOV DC offset, control 5951

frequency

Measure lOOkI-&, lMHz C and G

Measure C, Q/t; supply staircase bias

waveform

Connect 590 and 595 to DUT

System configuration/calibration

Connect 5951 to DUT and instruments

Connect instrument control and

voltage signals

Connect instruments to bus

Table 1-3. Necessary Binary Files

Filename

DISC or CS80*

Comments

Depends on disc drive type

I-FIB*

CRTAorCRTB*

Depends on display type

FHPlB*

F!!KHW

IO”

*Only 5I2K bytes required with ROM-based BASIC 4.0

“An IBM-AT equipped with the HP BASIC Language

Processor Card can also be used. See paragraph 2.7.

*Driver

*Language extension

l-311-4

Page 16

SECTION 2

Getting Started

2.1 INTRODUCTION

Section 2 contains introductory information to help you get

your system up and running as quickly as possible. Section 3 contains more detailed information on using the

Package 82 system.

Section 2 contains:

2.2

Hardware Configuration: Details system hardware

configuration, cable co~ections, and remote input

coupler mounting.

2.3

System Power Up: Covers the power up procedure for

the system, environmental conditions, and warm up

periods.

2.4

Software Configuration: Outlines methods for

booting up the computer, making backup copies, and

Package 82 software initialization.

25

Software Ovmiew: Descriks the purpose andoverall

confi8uration of the Package 82 software

2.6

System Checkout: Gives the procedure for checking

out the system to ensure that everything is working

properly.

2.2 HARDWARE CONFIGURATION

The system block diagram and connection procedure are

covered in the following paragraphs.

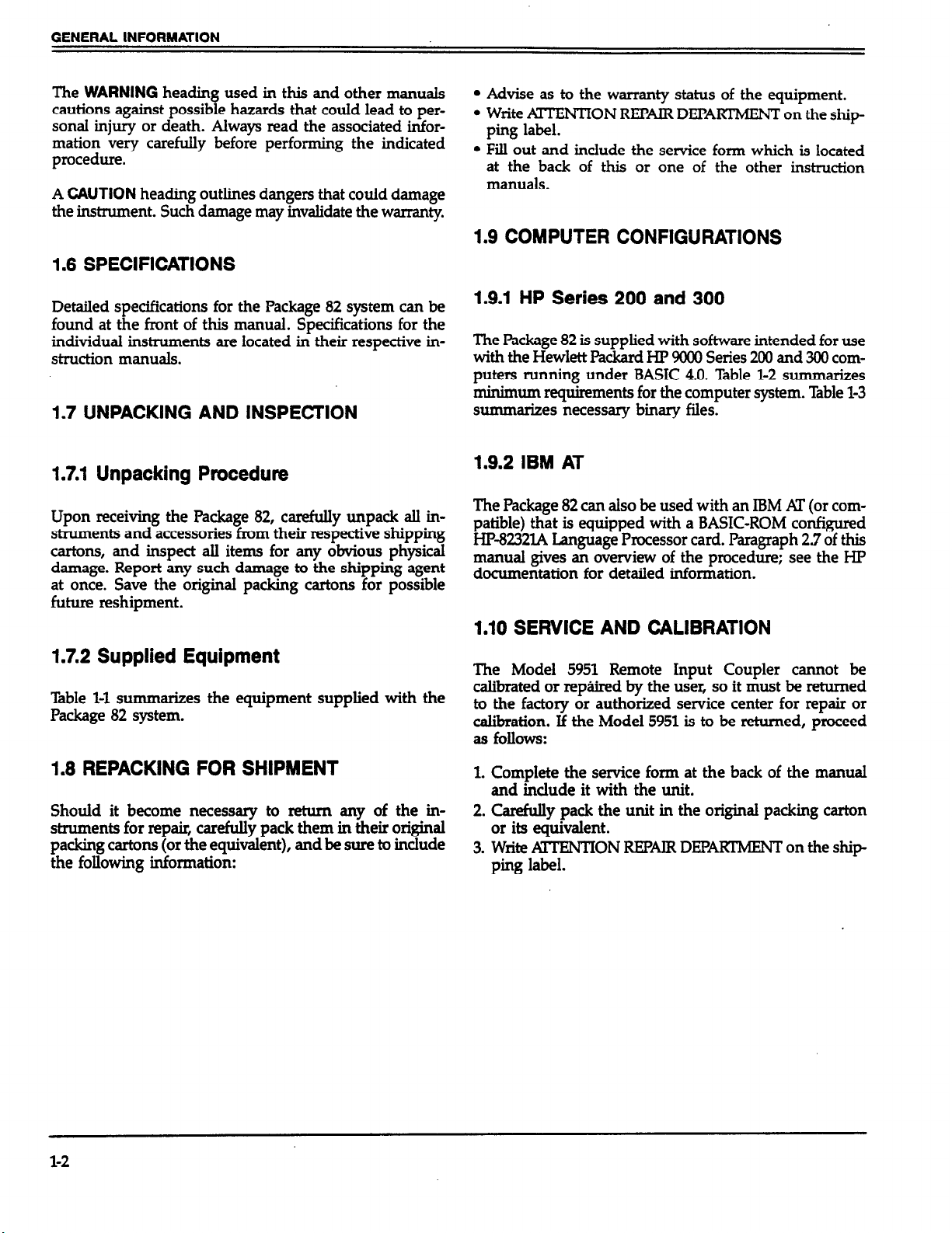

2.2.1 System Block Diagram

An overall block diagram of the Package 82 system is shown

in Fii 2-l. The function of each instrument is as follows:

Model 230-l Voltage Source-Supplies a DC offset voltage

of up to ~XHJV, and also controls operating frequency of

the Model 5951 Remote Input Coupler.

Model 590 CV Analyzer-Supplies a lCHWIz or lMHz test

signal and measures capacitance and conductance when

making high-frequency CV measurements.

Model 595 CV Meter-Measures low-frequency (quasistatic)

capacitance and Q/t, and also supplies the stepped bias

waveform (&2CW maximum) for simultaneous low- and

high-frequency CV measurement sweeps.

Model 5951 Remote Input Coupler-Connects the Model

590 and 595 inputs to the device under test. The input

coupler contains tuned circuits to minimize interaction between low- and high-frequency measurements.

Computer (HP 9000)-Provides the user interface to the

system and controls all instruments over the IEEE-488 bus,

processes data, and allows graphing of results.-

Model 5909 Calibration Set-Provides capacitance reference

somces for cable correcting the system to the test fixture.

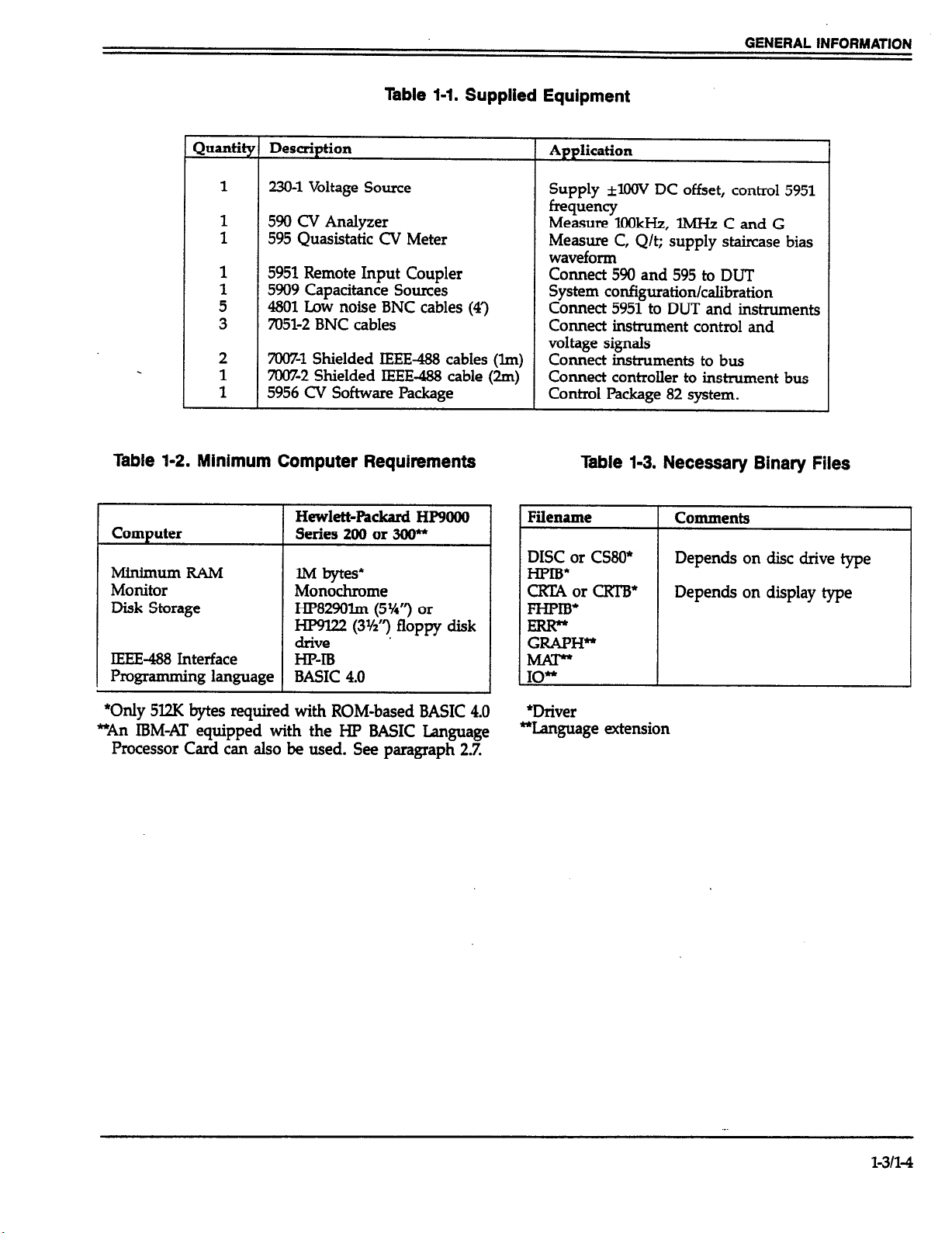

2.2.2 Remote Input Coupler

The Model 5951 Remote Coupler is the link between the

test fixture (which contains the wafer under test) and the

measuring instruments, the Models 590 and 595. The unit

not only simplifies system connections, but also contains

the circuitry necessary to ensure minimal interaction between the low-frequency measurements made by the Model

595, and the high-frequency measurements made by the

Model 590.

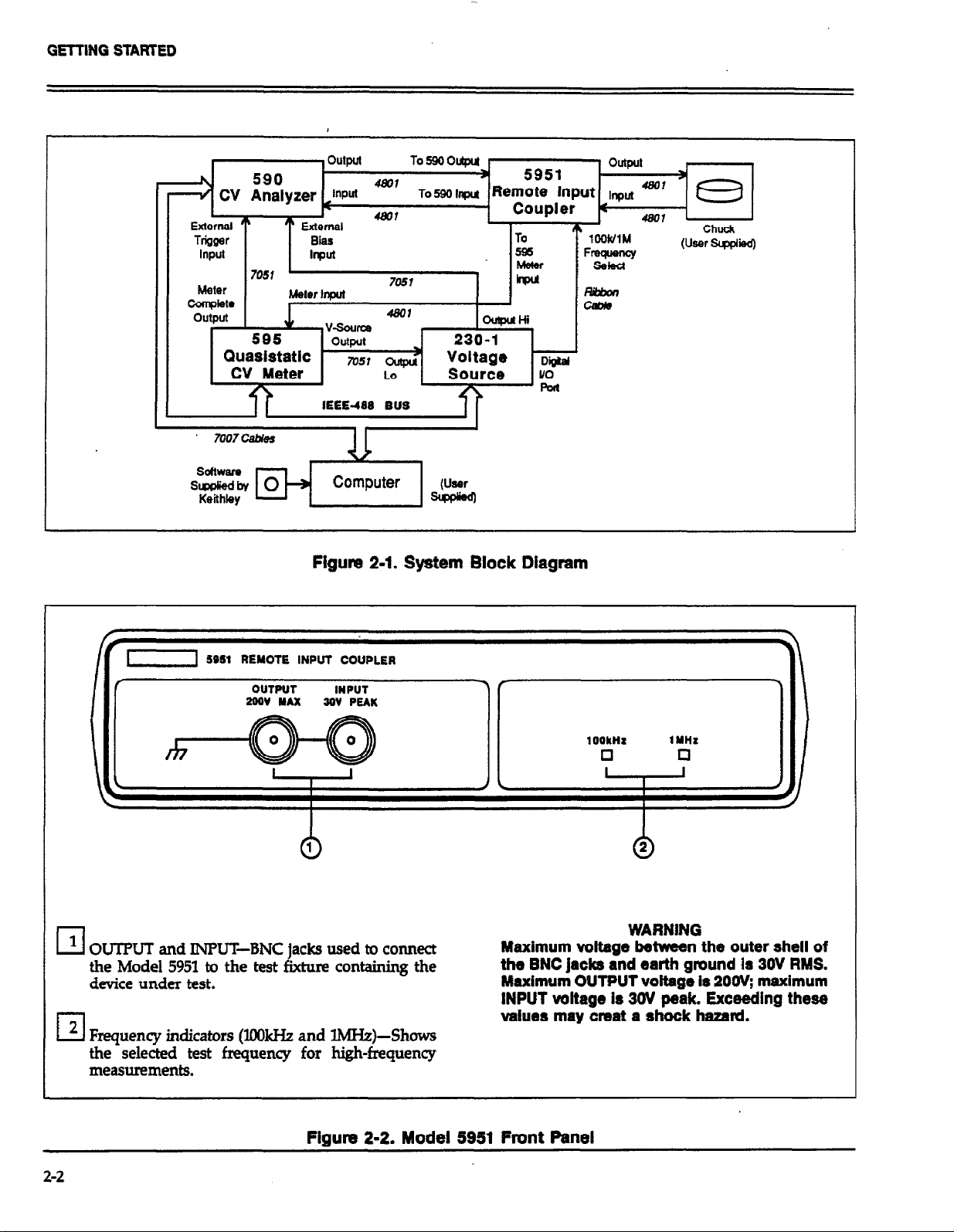

The front and rear panels of the Model.5951 are shown in

Fiis 2-2 and 2-3 respectively. The front panel includes

input and output jacks for connections to the device under

test, as well as indicators that show the selected test frequency (l00kHz or lMI-Iz) for high-frequency measurements. The rear panel includes a binding post for chassis

ground, BNC jacks for connections to the Models 590 and

595, a ribbon cable connector (which co~ects to the Model

230-l digital I/O port), and a digital I/O port edge co~ec-

tar providing one ITL output, four TIL inputs, digital common, and +5V DC.

2-l

Page 17

GETTING STARTED

Meter

7051 ’

‘I ,-

c!cmdElta

I I

Meter Input

IEEE-48S BUS

7051

1 I

I

1

Figure 2-l. System Block Diagram

1 SOS1 REMOTE INPUT COUPLER

f

OUTPUT INPUT

2oov MAX 3oV PEAK

Tf

h5qHp

l

I

’ OUTPUT and INPU’LBNC jacks used to connect

cl

the Model 5951 to the test fixture containing the

device under test.

(7 2 Frequency indicators (X&Hz and lMHz)-Shows

the selected test frequency for high-frequency

measurements.

Figure 2-2. Model 5953 Front Panel

2-2

1 OQkHI

0

I

Maximum voltage between the outer shell of

the EJNC jacks and earth ground Is 3OV RMS.

Maximum OUTPUT voltage Is 200& maximum

INPUT voltage Is 30V peak. Exceeding these

values may &eat a shock hazard.

IYHt

cl

I

I

WARNING

)

-

Page 18

SYSTEM SIGNAL CONNECTIONS

GETTING STARTED

TO 2361 DIGITAL L’O

1

0

CHASSIS binding post-Provides a convenient connection to chassis ground of the Model 5951.

WARNING

Connect CHASSIS to earth ground to avoid a

possible shock hazard, Use #16 AWG or larger

Wh.

2 Ribbon cable-Connects to the Model 230-l digital

Ll

I/O port for frequency switching of the remote

coupler.

3 DIGllAL I/O-Passes through the Model 230-l

LJ

digital I/O port signals for control and sensing of

other components (for example, light control and

door closed status).

DIGITAL l/O

4 To 590 INPUT-Connects to the Model 590 INPUT

cl

jack on the front panel of the instrument.

5 ‘IO 590 OUTPUT-Connects to the Model 590 OUT

cl

PUT jack on the front panel.

6 To 595 METER INPUT-Connects to the Model 595

cl

METER INPUT jack on the rear of the instrument.

WARNING

Maximum voltage between the outer shell of

the BNC jacks and earth ground is 30V RYS.

Figure 2-3. Model 5951 Rear Panel ”

2-3

Page 19

GETTING STARTED

Table 2-l. Supplied Cables

-;

Q

5

3

2

1

1

Model

4801

7051-2

7N%l

7007-2

*

Description

4’ BNC Low Noise

Auriiication

590, 595, 5951

2’ BNC (RG-58) 230-1, 590, 595

lm shielded IEEE-488

IEEE-488 instrument bus

2m shielded IEEE-488 Computer to instruments

Ribbon cable 5951 to 230-l

*Supplied with Model 5951

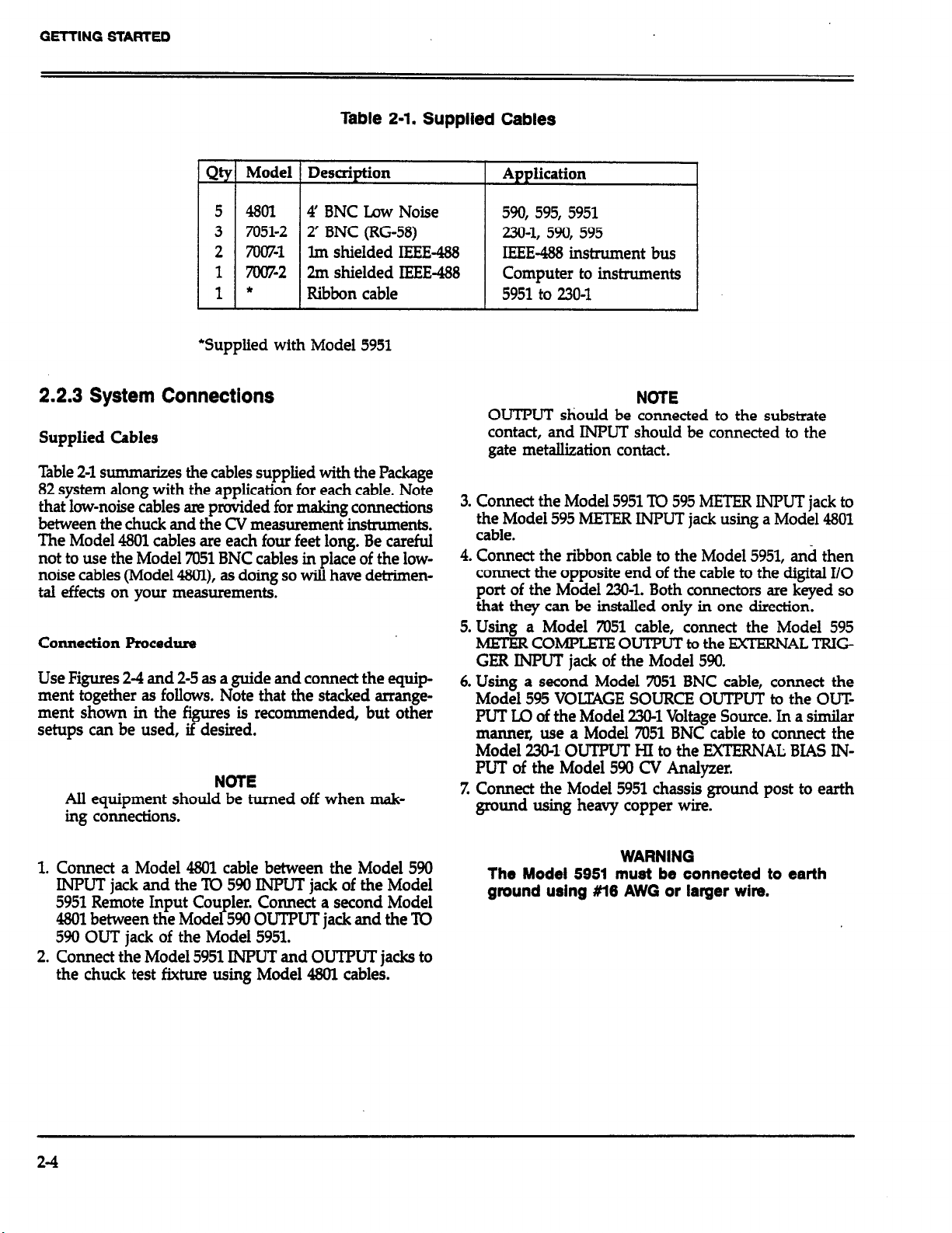

2.2.3 System Connections NOTE

OUTPUT should be connected to the substrate

Supplied Cables

lhble 2-l summarizes the cables supplied with the Package

82 system along with the application for each cable. Note

that low-noise cables am provided for making co~ections

between the chuck and the CV measurement instruments.

The Model 4801 cables are each four feet long. Be careful

not to use the Model 7051 BNC cables in place of the lownoise cables (Model 48Ol), as doing so will have detrimental effects on your measurements.

Connection Procedure

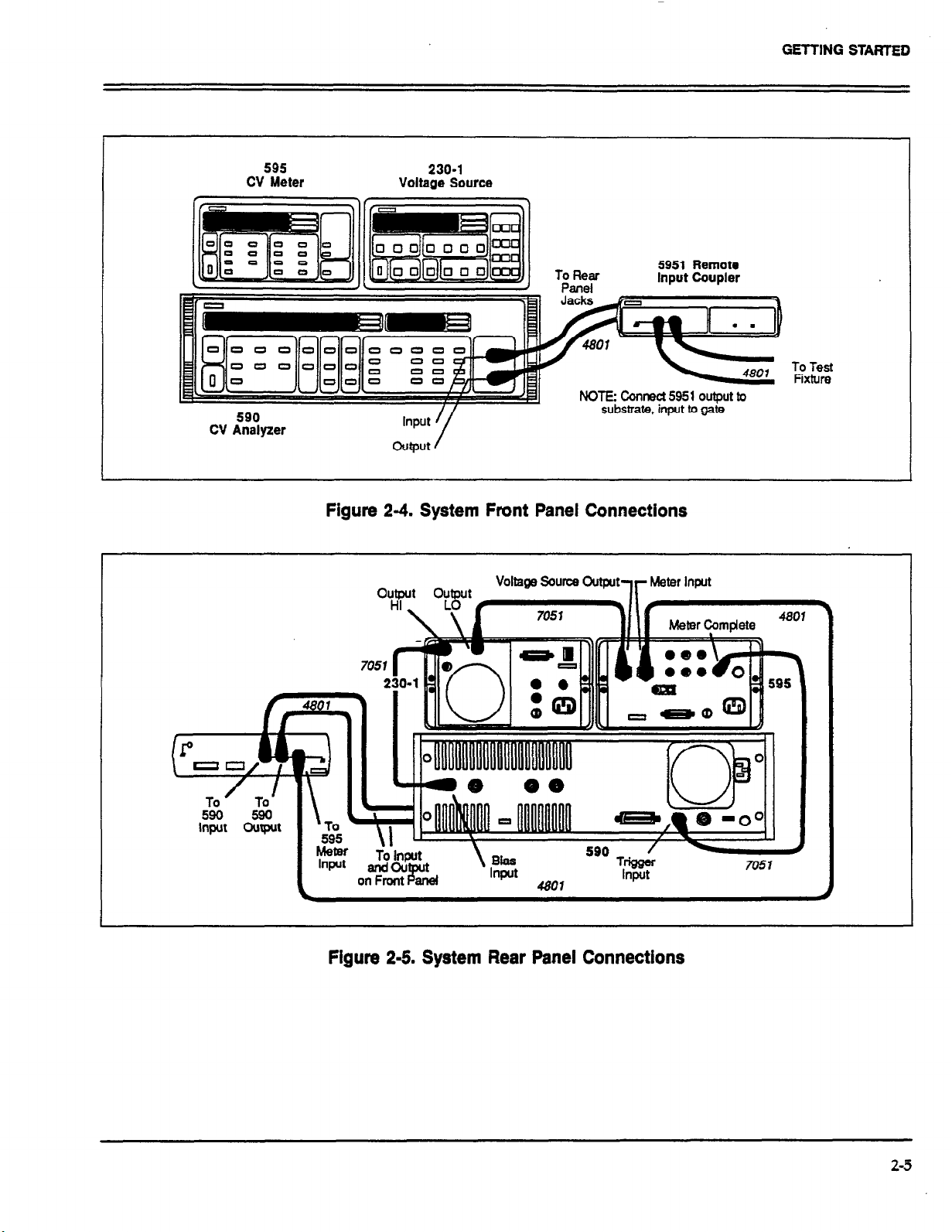

Use Figures 2-4 and 2-5 as a guide and co~ect the equip-

ment together as follows. Note that the stacked arrangement shown in the figures is recommended, but other

setups can be used, if desired.

NOTE

All equipment should be turned off when making coMections.

contact, and INPUT should be connected to the

gate metallization contact.

3. Connect the Model 5951 To 595 METER INPUT jack to

the Model 595 METER INPUT jack using a Model 4801

cable.

4. Connect the ribbon cable to the Model 5951, and then

connect the opposite end of the cable to the digital I/O

port of the Model 230-l. Both connectors are keyed so

that they can be installed only in one direction.

5. Using a Model 7051 cable, connect the Model 595

METERCOMPLEIEOUTPUTtothe EXTERNALTRIG

GER INPUT jack of the Model 590.

6. Using a second Model 7051 BNC cable, connect the

Model 595 VOLEAGE SOURCE OUTPUT to the OUT

PUT LO of the Model 230-l Voltage Source. In a similar

manner, use a Model 7051 BNC cable to connect the

Model 23&l OUTPUT HI to the EXTERNAL BIAS INPUT of the Model 590 CV Analyzer.

Z Connect the Model 5951 chassis ground post to earth

ground using heavy copper wire.

1. Connect a Model 4801 cable between the Model 590

INPUT jack and the To 590 INPUT jack of the Model

5951 Remote Input Coupler. Co~ect a second Model

4801 between the Model 590 OUTF’UT jack and the ‘ID

590 OUT jack of the Model 5951.

2. Connect the Model 5951 INPUT and OUTPUT jacks to

the chuck test fixture using Model 4801 cables.

2-4

WARNING

The Model 5951 must be connected to earth

grwnd using #l6 AWG or larger wire.

Page 20

GETTING STARTED

595

CV Meter

590

CV Analyzer

230-l

Voltage Source

Figure 2-4. System Front Panel Connections

voltl3ga sourcs output

Figure 2-5. System Rear Panel Connections

2-5

Page 21

GETTING SThtlED

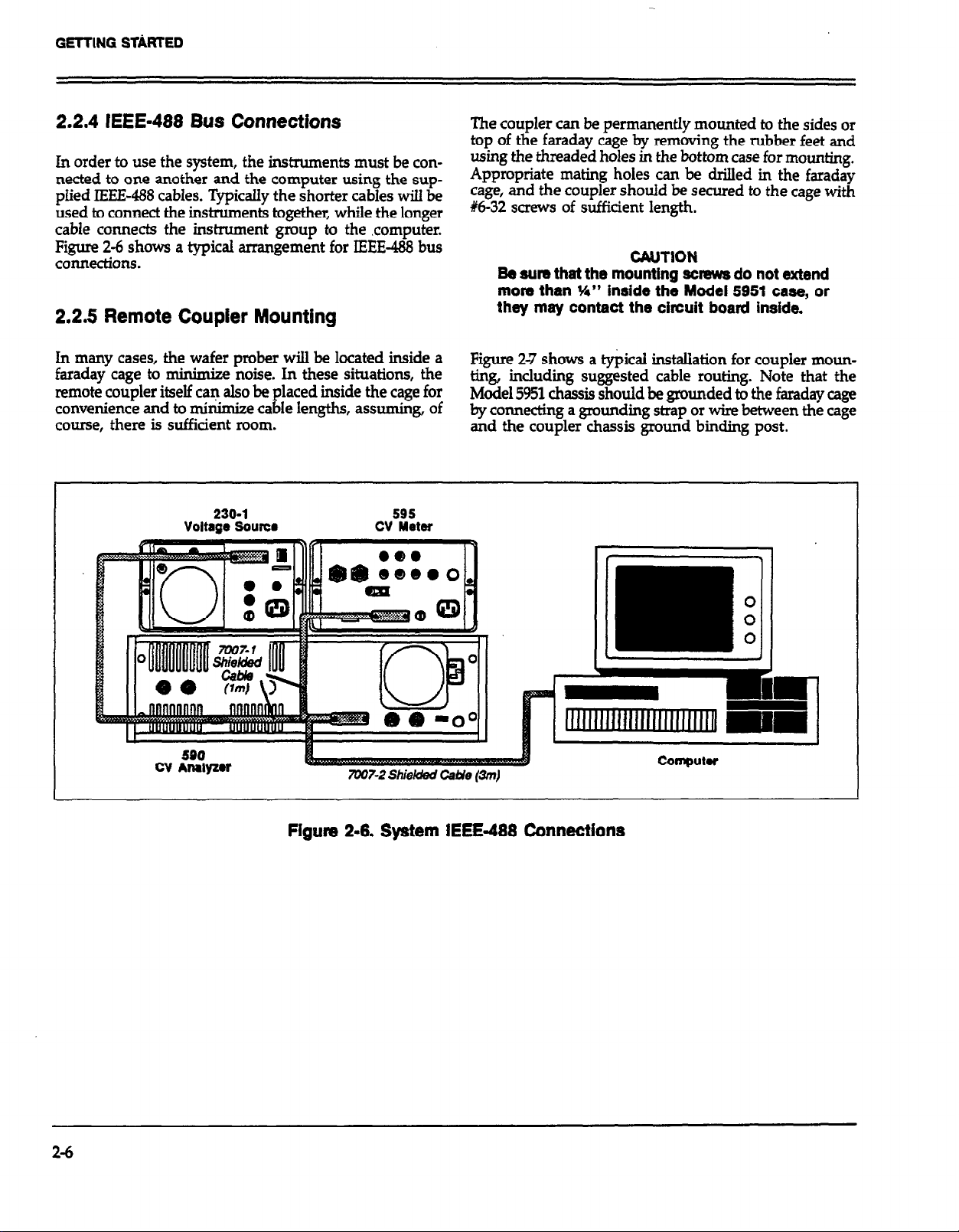

2.2.4 IEEE-488 Bus Connections

In order to use the system, the instruments must be connected to one another and the computer using the supplied IEEE-488 cables. Typically the shorter cables will be

used to connect the instruments together, while the longer

cable connects the instrument group to the computer.

Figure 2-6 shows a typical arrangement for IEEE-488 bus

coM&ions.

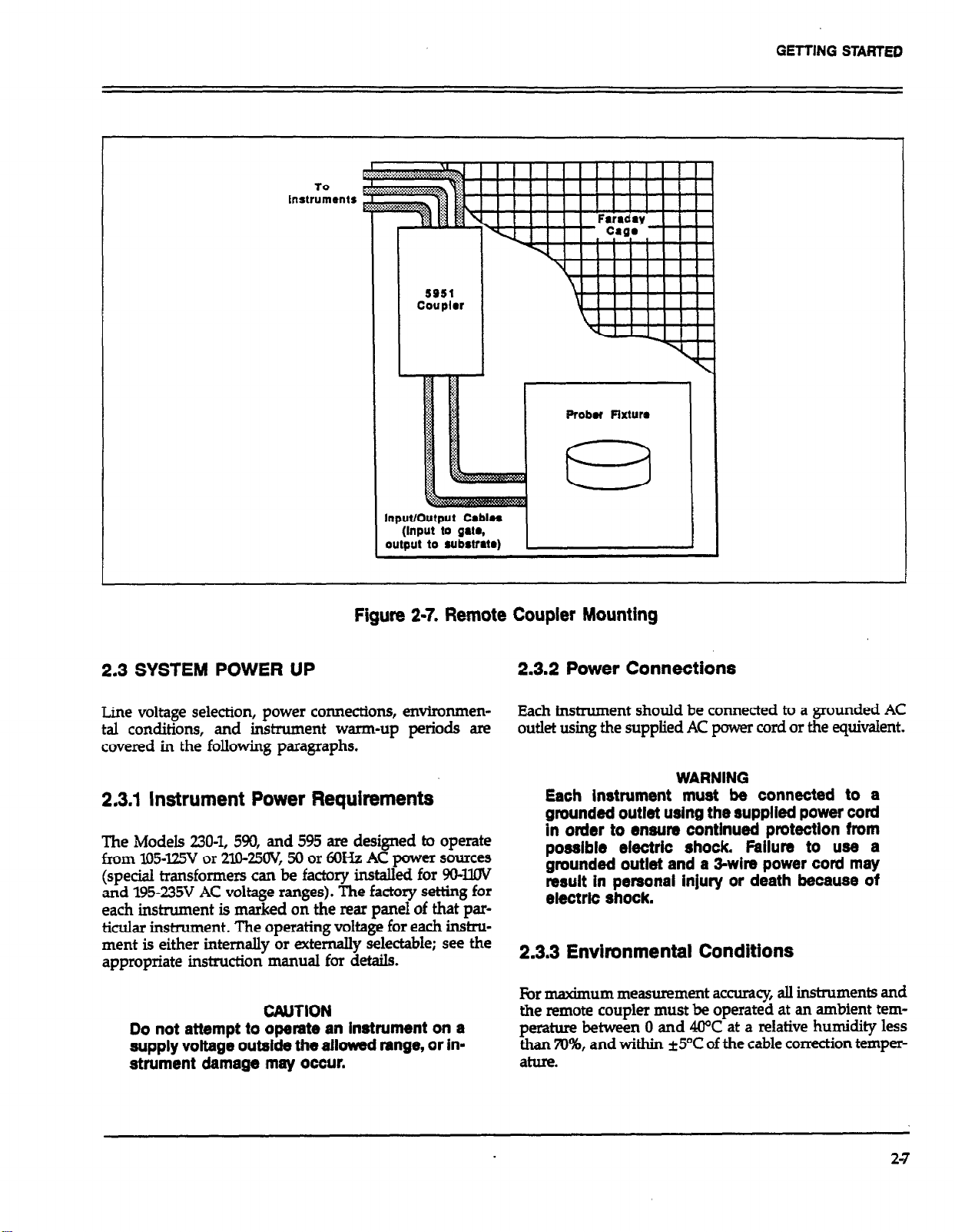

2.2.5 Remote Coupier Mounting

In many cases, the wafer prober will be located inside a

faraday cage to

remote coupler itself can also be placed inside the cage for

convenience and to minimize cable lengths, assuming, of

course, there is sufficient room.

nkimize noise. In these situations, the

230-l

Voltage !3ams

The coupler can be permanently mounted to the sides or

top of the faraday cage by removing the rubber feet and

using the threaded holes in the bottom case for mounting.

Appropriate mating holes can be drilled in the faraday

cage, and the coupler should be secured to the cage with

16-32 screws of sufficient length.

CAUTION

Be sum that the mounting scmws do not extend

more than Y4” inside the Model 5951 case, or

they may contact the circuit board inside.

Figure 2-7 shows a typical installation for coupler mounting, including suggested cable routing. Note that the

Model 5951 chassis should be grounded to the faraday cage

by connecting a grounding strap or wire between the cage

and the coupler chassis ground binding post.

2-4

7UU7-2 Shiekhi Ca#e pm)

Figure 2-6. System IEEE-468 Connections

Page 22

TO

Instruments

GETTING STARTEll

5951

Coupler

Probr Fixturm

Figure 2-7. Remote Coupler Mounting

2.3 SYSTEM POWER UP

Line voltage selection, power connections, environmental conditions, and instrument warm-up periods are

covered in the following paragraphs.

2.3.1 Instrument Power Requirements

The Models 2304, 590, and 595 are designed to operate

from 105425V or 2lO-250X 50 or 6OHz AC power sources

(special transformers can be factory installed for 904.W

and 195~235V AC voltage ranges). The factory setting for

each instrument is marked on the rear panel of that particular instrument. The operating voltage for each in&mment is either internally or externally selectable; see the

appropriate instruction manual for details.

CAUTION

Do not attempt to operate an instrument on a

supply voltage outside the aHowed range, or instrument damage may occur.

2.3.2 Power Connections

Each instrument should be connected to a grounded AC

outlet using the supplied AC power cord or the equivalent.

WARNING

Each instrument must be connected to a

grounded outlet using the supplied power cord

in order to ensure continued protection from

possible electric shock. Failure to use a

grounded outlet and a 3-wire power cord may

result in personal injury or death because of

electric shock.

2.3.3 Environmental Conditions

For maximum measurement accuracy, all instruments and

the remote coupler must be operated at an ambient tem-

perature between 0 and 4CPC at a relative humidity less

than 70%, and within *5T of the cable correction temperature.

2-7

Page 23

GElTING STARTED

2.3.4 Warm Up Period

.

The system can be used immediately when all instruments

are first turned on; however, to achieve rated system accuracy, all instruments should be turned on and allowed

to warm up for at least two hours before use.

2.3.5 Power Up Procedure

Follow the general procedure below to power up the

Package 82 system.

1. Connect the instruments together as outlined in paragraph 2.2.3.

2. Co~ect the instruments to the IEEE-488 bus of the host

?;4puter following the procedure given in paragraph

. . .

3. Turn on the computer and boot up its operating system

in the usual manner. Refer to the computer documentation for complete details for your particular system.

4. Turn on each instrument by pressing in on its liont

panel power switch. Verify that each instrument goes

through its normal power up routine, as described

below.

Model 230-l

1. The instrument first turns on all LEDs ind segments.

2. The software revision level is then displayed as in this

example:

Bl3

3. The unit then displays the primary address:

2. Thh,““‘” then displays the programmed primary

:

IEEE ADDRESS l.5

Verify the address is 15; program it for that value if not.

3. Finally, the unit begins displaying normal readings.

Model 595

1. The instrument first displays the ROM self-test message:

to.

2. The unit then displays normal readings.

3. Press MENU and verify the primary address is 23; set

it to that value if not.

2.3.6 Line Frequency

The Models 230-l and 590 can be operated from either 50

or 6OHz power sources with no further adjustments.

However, for the Model 595 to meet its stated noise

specifications, the unit must be programmed for the line

frequency being used. To set or check the Model 595 line

frequency, proceed as follows:

1. Turn off the Model 595 if it is presently turned on.

2. Press and hold the MENU button and then turn on the

power. Release the MENU button after the display

blanks on power up.

3. Press the MENU button and note .that the frequency

selection prompt is displayed:

IEl.3

4. The unit begins normal display.

Model 590

1. The Model 590 first displays the software revision level

as in this example:

590REVDl3

2-B

Fr - 50

or,

Fr = 60

4. Use one of the ADJUST keys to toggle the unit to the

desired frequency.

5. Press SHIFT EXIT to return to normal operation. Note

that the frequency selection prompt will remain in the

menu until power is removed.

Page 24

GETTING STARTED

2.4 SOFTWARE CONFIGURATION

The folIowing paragraphs discuss booting up the computer, making backup copies of the Package 82 software,

and loading and initializing the software.

2.4.1 Computer Boot Up

Before you can use the Package 82 software, the computer

must be booted up with the proper operating system software. See paragraph 1.9 for further information on computer requirements.

Turn on the computer and boot up BASIC 4.0 (if the com-

puter has ROM-based BASIC, no initialization is

necessary).

2.4.2 Software Backup

Before using the software, it is strongly recommended that

you make a working copy of the software supplied with

the Package 82. Since the software is not copy protected,

you can use the standard copy commands to duplicate

each diskette. After duplication, put the master diskette

away in a safe place and use only the working copy.

you intend to use. A typical example is:

MASS STORAGE IS “:,700,0“

Place the Package 82 software working disk in the

3.

default drive.

4.

Type in LOAD”PKG82CV” and press the EXEC key.

5.

After the program loads, press the RUN key, or type

in RUN and then press the EXEC key The main menu

shown in Figure 2-8 should appear on the computer

display.

2.4.4 Software Files

Package 82 software files that are included with the

distribution diskette are SulTLznarized in ‘Iable 2-2. Note that

“pkg82cal” is created when cable correction is performed

the first time.

2.5 SOFTWARE OVERVIEW

The main sections of the Package 82 software are discussed

in the following paragraphs. These decriptions follow the

order of the main menu shown in Figure 2-8. For detailed

information on using the software to make measurements

and analyze data, refer to Sections 3 and 4.

Use the COPY command to copy the software diskette.

A typical example is:

COPY “:I-lP9895,700,0” ‘IO “:HP9895,7OO,l”

Here, HP9895 represents the type of disk drive, 700 is the

primary address, and 0

Note that the working diskette should be formatted with

the INITIALIZE command before attempting copying.

and 1 are the disk drive numbers.

2.4.3 Software hitialization

Software initiakation is simply a matter of loading and

running a program as you would any other BASIC program, as outlined below.

1. Boot up or enter BASIC 4.0 in the usual manner.

2. If necessary, assign a mass storage specifier to the drive

2.5.1 System Reset

By selecting option I on the main menu, you can easily

reset the instruments and the software to default conditions. DCL (Device Clear) and IFC (Interface Clear) commands are sent over the bus to return the instruments to

their power-on states and remove any talkers or listeners

from the bus.

2.52 System Characterization

Option 2 on the main menu allows you to perform a

“probes up” characterization of the complete system from

the measuring instruments, through the connecting cables

and remote couple& down to the prober level:Characterization is necessary to null out (G, C#, or G), or remedy

leakage

sent in the system that could affect measurement accuracy;

the procedure also allows you to verify connection

problems.

currents, resistances, and stray capacitance pre-

2-9

Page 25

GETTING STARTED

f

l * PfICKflGE 82 MAIN MENU **

1. Reset Package 82 CU System

2. Test and Correct for System Leakages and Strays

3. Correct for Cabling Effects

4. Find Dtv~ct Cox and Equilibrium Delay Time

5. Make CV Measurements

6. halyze CU Data

7. Return to BASIC

Enter number to select from menu

Figure.24. Main Menu

There are two important aspects to systemcharackrktion:

1, Quasistatic capacitance (0, high-frequency capacitance

(C,), conductance (G), and Q/t (current) are measured

at a specified bias voltage to determine system contribution of these factors. Ce, CM, and G can be suppressed

in order to maximize accuracy. If abnormally large error terms are noted, the system should be checked for

poor connections or other factors that could lead to large

erms.

2. Q/t vs. V sweeps can be performed to determine the

presence of leakage resistance and extemal le

rent sources. C vs. V sweeps can be done to test

cur-

r the

7

presence of voltage dependent capacitance in the

system.

System checkout should be performed whenever the configuration, step V, or delay time is changed. Probes-up sup

pression should precede every measurement to achiwe

rated accuracy.

2.5.3 Cable Correction

Cable correction can be performed by selecting option 3

on the main menu. Cable correction is necessary to compensate for transmission line effects of the connecting

cables and is essential for maintaining accuracy of highfrequency CV measurements. In order to cable correct the

system, you must connect the Model 5909 Calibration

Sources to the system. Refer to paragraph 3.5 Correcting

for Cabling Rffects.

Included in the cable correction procedure is a gain correction of the Model 595 CV Meter. Cable correction and

gain unmction parameters are automatically stored on disk

during cable correction and are restored when the softwam

is run ini- so that correction need not be performed

each time the system is used. Note, however, that correction should be performed whenever the ambient temperature changes by more than 5OC, or if the system configuration is changed.

240

Page 26

GETTING STARTED

MOTE

The diskette for storing cable correction parameters

must be in the default drive when correction is

performed.

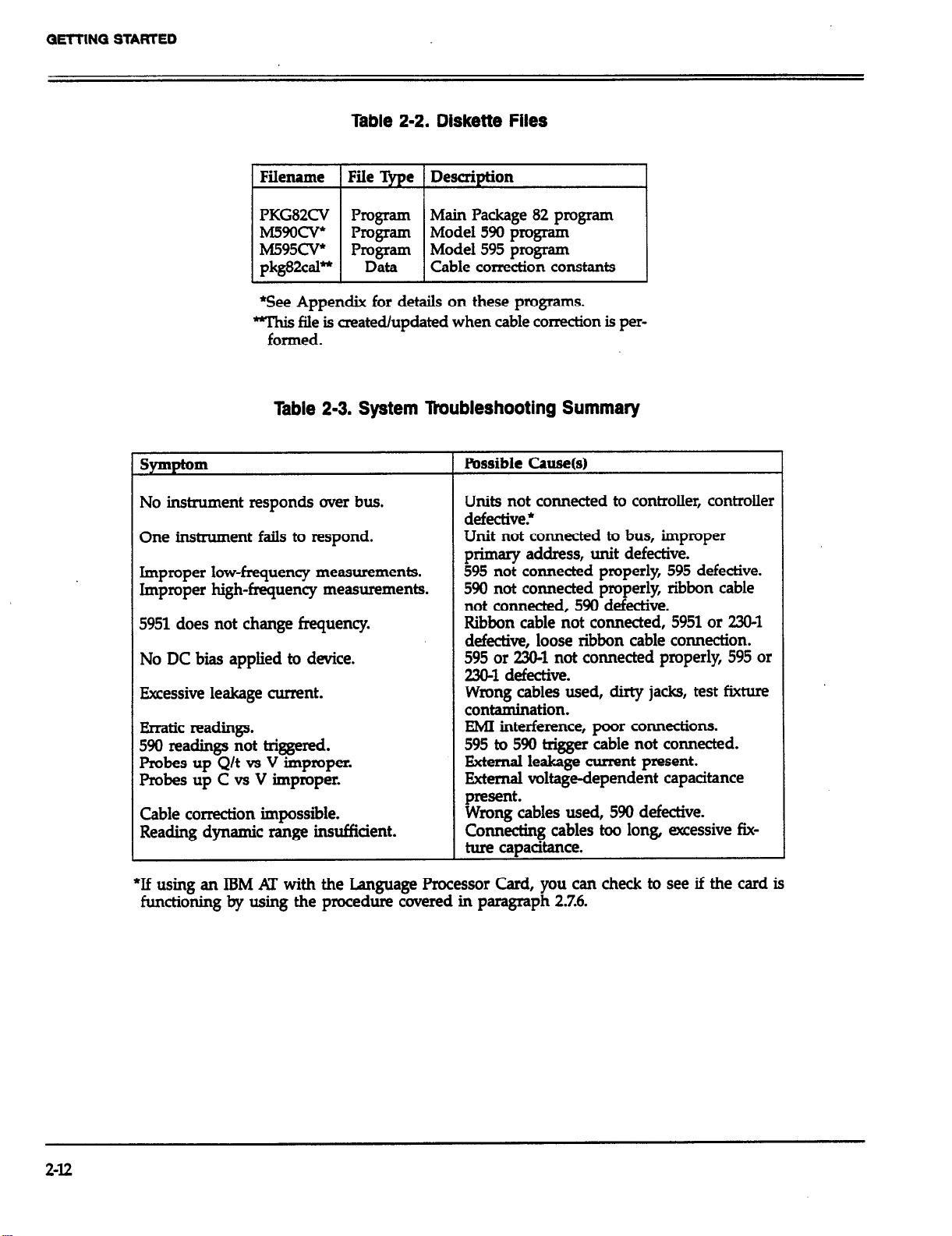

2.5.4 C, and Delay Time Determination

Option 4 allows you to determine optimum parameters for

measuring the device under test. The key areas of this

characterization process are:

1. A CV sweep of the device is used to find accumulation

and inversion voltages.

2. The device is biased in the accumulation region in order

to determine 6x.

3. The device is biased in inversion to determine Model

595 step time. A test for equilibrium can be performed

by monitoring the decay tune of Q/t to the system

leakage level following a step in DC bias voltage. The

user can also control a light on the device to help achieve

equilibrium.

4. A sweep of C and Q/t vs time delay is performed to

determine optimum delay time.

2.5.5 Device Measu@ment

Option 5 on the main menu allows you to perform a

simultaneous CV sweep on the device under test. As

parameters are measured, the data am stored within an

array for plotting or additional analysis, as required.

The two types of sweeps that can be performed include:

1. Accumulation to inversion: Initially, the device is biased

in accumulation, and the bias voltage is held static until Q/t reaches the system leakage level. The sweep is

then performed and the data are stored in the array.

2. inversion to accumulation: In this case, the device is first

biased in inversion, and the sweep is paused until

equilibrium is reached (when Q/t equals the system

leakage levei) . A submenu option allows you to control

a light within the test fixture (using the Model 5951

digital II0 port) as an aid in attaining the equilibrium

point. The sweep is then completed and the data are

stored in an array for further analysis.

the CRT or plotter, graphical analysis, and loading or storing array data on disk. Note that this option can also be

directly selected from menus providing sweep

measurements without having to go through the main

menu.

2.6 SYSTEM CHECKOUT

Use the basic procedure below to check out the Package

82 to determine if the system is operational. The procedure

requires the use of the Model 5909 Calibration Sources,

which are supplied with the package. Note that this pro-

cedure is not intended as an accuracy check, but is in-

cluded to show that all instruments and the system are

functioning normally.

2.6.1 Checkout Procedure

1. Connect the system together, as discussed in paragraph

2.2.

2. Power up the system using the procedure given in

paragraph 2.3.

3. Boot up the computer and load the Package 82 software,

as covered in paragraph 2.4.

4. Select option 2 on the main menu, and then option 2

on the &bsequent menu. Connect the l&F capacitor

and verify that C, is within 1% of the lkHz capacitor

value, and that Q/t is <IpA. Correct any cabling problems before proceeding.

Select the cable correction option on the main menu.

Ebllow the prompts and connect the Model 5909 Calibra-

tion Sources to the Model 5951 INPUT and OUTPUT

cables using the BNC adapters supplied with the Model

5909.

After correction, return to main menu selection 2, then

select option 2 on the submenu. Connect the 1.8nF

capacitor; verify that C, is within 1% of the lkH2

capacitance, and that CB is within 1% of the ICiXHz or

IMHz value (depending on the selected frequency).

Select option 3 on, the leakage and strays menu.

Turn on the sweep and observe the Model 590 voitage

display. Verify that the bias voltage readings step

thmugh the range of -2V to +2V in XhnV increments.

2.6.2 System lkoubleshooting

2.5.6 Data Analysis and Plotting

Option 6 on the main menu provides a window to a

number of analysis and graphing tools. Key options here

include printing out parameters, graphing array data on

Troubleshoot any system problems using the basic procedure shown in Table 2-3. For information on

troubleshooting individual instruments, refer to the respective instruction manual(s).

2-11

Page 27

GE-KING STARTED

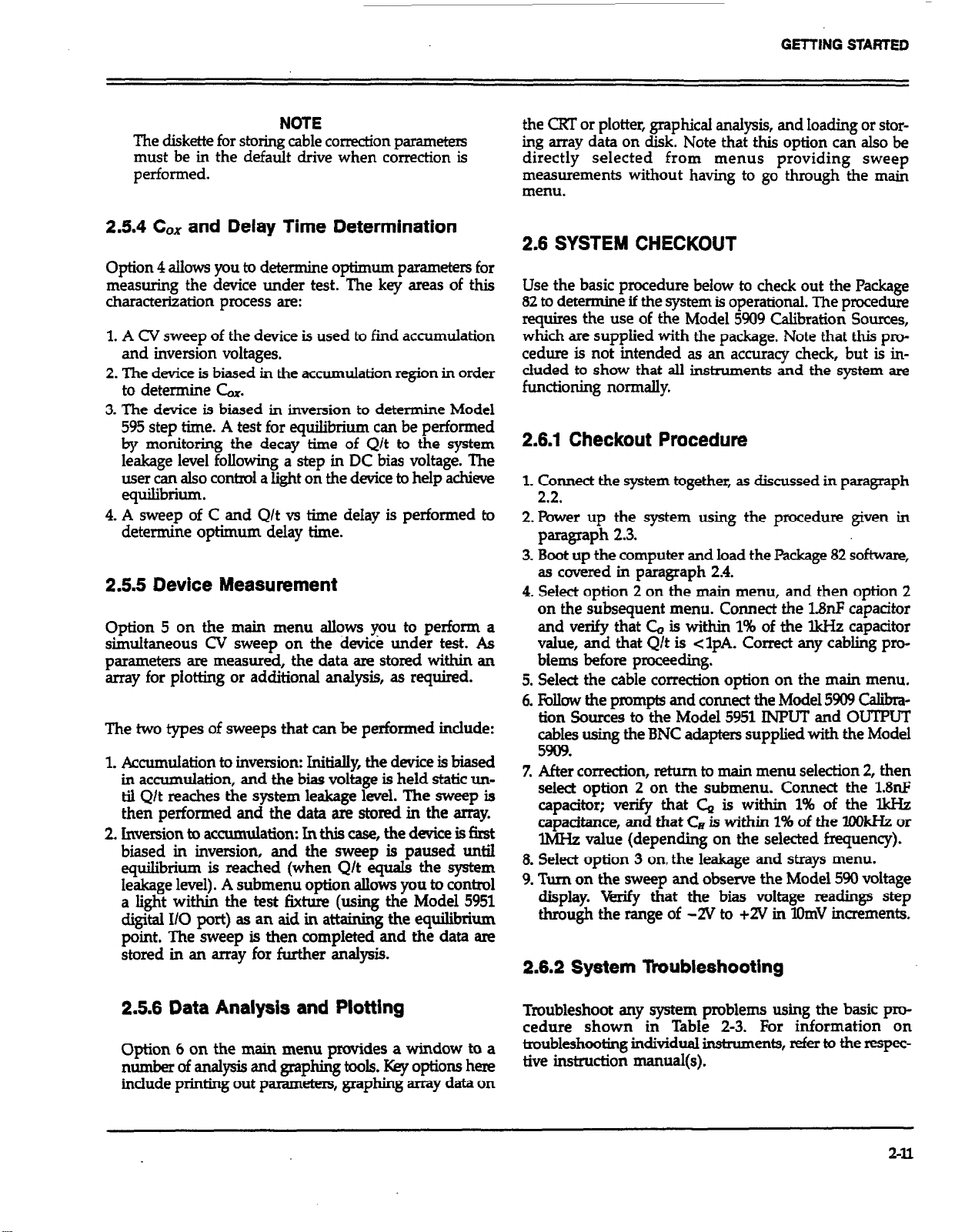

Table 2-2. Diskette Files

Filename File %e Description

PKG82CV Program

M5!3ocv* Program Model 590 program

M595cv*

P~.D~T Model 595 program

pkg82cal*

*See Appendix for details on these programs.

“this file is created/updated when cable correction is per-

formed.

Table 2-3. System liwbleshooting Summary

Symptom

No instrument responds over bus.

One instrument fails to respond.

Improper low-frequency measurements.

Improper high-frequency measurements.

5951 does not change frequency.

No DC bias applied to device.

Excessive leakage current.

Rrratic readings.

590 readings not triggered.

Probes up Q/t vs V improper.

Probes up c -3s v improper.

Main Package 82 program

Cable correction constants

Possible Cause(s)

Units not connected to controller, controller

defective.’

Unit not connected to bus, improper

primary address, unit defective.

595 not connected properly, 595 defective.

590 not connected properly ribbon cable

not cormected, 590 defective.

Ribbon cable not connected, 5951 or 230-l

defective, loose ribbon cable connection.

595 or 230-l not connected properly, 595 or

2304 defective.

Wrong cables used, dirty jacks, test fixture

contamination.

EMI interference, poor connections.

595 to 590 trigger cable not connected.

External leakage current present.

Eternal voltage-dependent capacitance

2-12

Cable correction impossible.

Reading dynamic range insufficient.

Ezt&bles used, 590 defective.

Connecting cables too long, excessive fixture capacitance.

*If using an IBM AT with the Language Processor Card, you can check to see if the card is

functioning by using the procedure covered in paragraph 2.7.6.

Page 28

GETTING STARTED

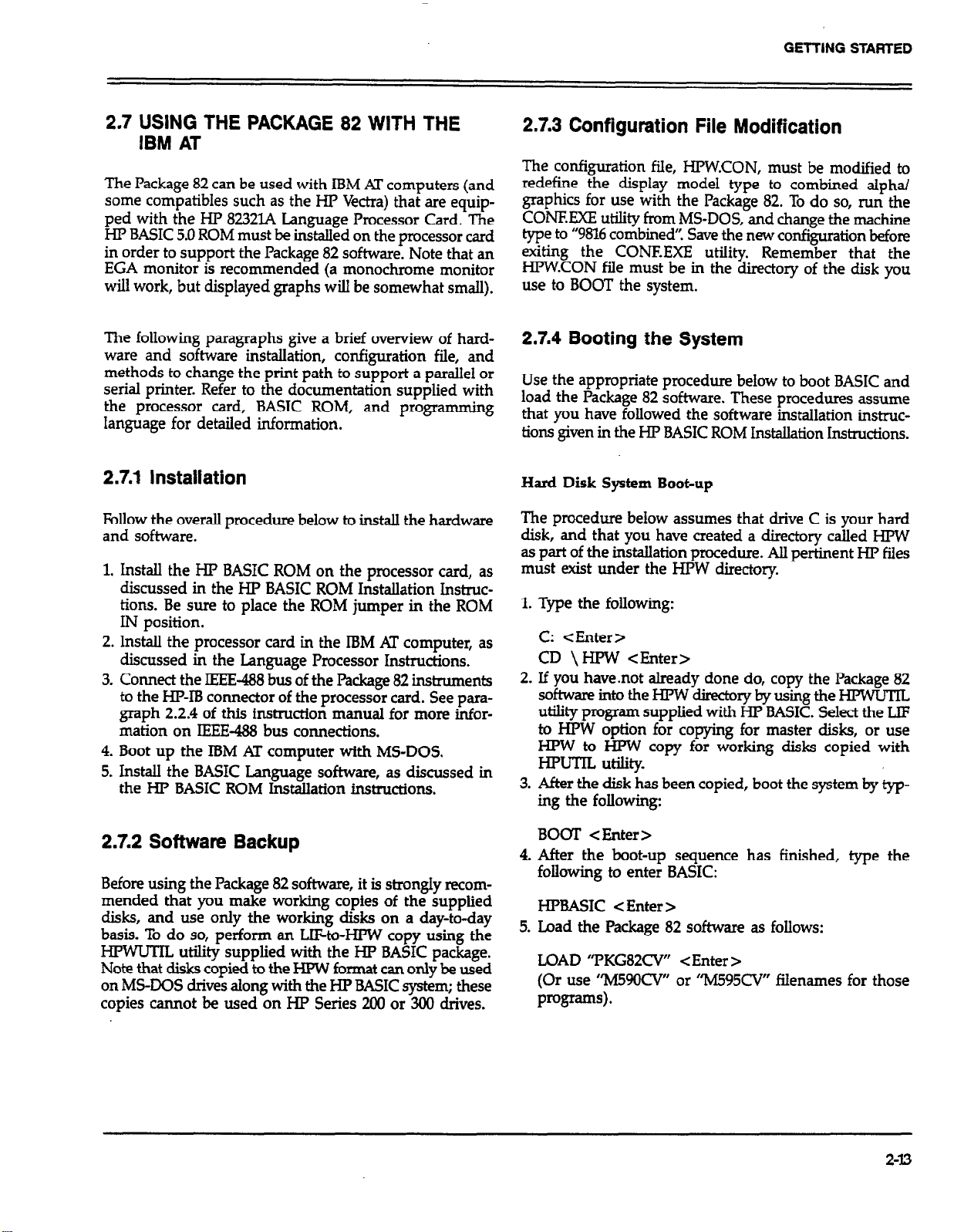

2.7 USlNG THE PACKAGE 82 WITH THE

IBM AT

The Package 82 can be used with IBM AT computers (and

some compatibles such as the HP Vectra) that are equipped with the HP 8232lA Language Processor Card. The

HP BASIC 5.0 ROM must be installed on the processor card

in order to support the Package 82 software. Note that an

EGA monitor is recommended (a monochrome monitor

will work, but displayed graphs will be somewhat small).

The following paragraphs give a brief overview of hardware and software installation, configuration file, and

methods to change the print path to support a parallel or

serial printer. Refer to the documentation supplied with

the processor card, BASIC ROM, and programming

language for detailed information.

2.7.1 Installation

IbIlow the overall procedure below to install the hardware

and software.

1.

Install the HP BASIC ROM on the processor card, as

discussed in the HP BASIC ROM Installation Instructions. Be sure to place the ROM jumper in the RUM

IN position.

2.

Install the processor card in the IBM Al’ computer, as

discussed in the Language Processor Instructions.

3.

Connect the IEEE-488 bus of the Package 82 instruments

to the I-IPlB connector of the processor card. See paragraph 2.2.4 of this instruction manual for more information on IEEE-488 bus connections.

4.

Boot up the IBM AT computer with MS-DOS.

5.

Install the BASIC Language software, as discussed in

the HP BASIC ROM Installation hstructions.

2.7.3 Configuration File Modification

The configuration file, HPW.CON, must be modified to

redefine the display mode1 type to combined alphal

graphics for use with the Package 82. To do so, run the

CONFXXE utility from MS-DOS, and change the machine

type to “9816 combined”, Save the new configuration before

exiting the CONEEXE utility. Remember that the

I-IPW.CON file must be in the directory of the disk you

use to BOOT the system.

2.7.4 Booting the System

Use the appropriate procedure below to boot BASIC and

load the Package 82 software. These procedures assume

that you have followed the software installation instruc-

tions given in the HP BASIC ROM Installation Instructions.

Hard Disk System Boot-up

The procedure below assumes that drive C is your hard

disk, and that you have created a directory called HPW

as part of the installation procedure. All pertinent HP files

must exist under the HPW directory.

1.

Type the following:

C: <Enter>

CD \HPW <Enter>

2.

If you have.not already done do, copy the Package 82

soflwanzintotheI-IPWdirectorybyusingtheHPWUTIL

utility program supplied with HP BASIC. Select the LIP

to HPW option for copying for master disks, or use

HPW to I-IPW copy for working disks copied with

HPUTIL utility.

3.

After the disk has been copied, boot the system by typing the following:

2.7.2 Software Backup

Before using the Package 82 software, it is strongly recommended that you make working copies of the supplied

disks, and use only the working disks on a day-to-day

basis. To do so, perform an LIFto-HPW copy using the

HPWUTIL utility supplied with the HP BASIC package.

Note that disks copied to the HPW format can only be used

on MS-DOS drives along with the HP BASIC system; these

copies cannot be used on HP Series 200 or 300 drives.

BOOT e Enter >

4.

After the boot-up sequence has finished, type the

following to enter BASIC:

HPBASIC <Enter >

5.

Load the Package 82 software as follows:

LOAD ‘TKG82CV” <Enter >

(Or use ‘M59OCV or ‘M595CV filenames for those

Programs).

2-13

Page 29

GE-KING STARTED

6. RUN the program in the usual manner. Refer to the remainder of Section 2, as well as Sections 3 and 4 for

detailed operation information.

Flexible Disk System Boot-up

1. Place the HP BASIC working disk into the default drive,

and type the following:

BOOT <Enter >

2. After the boot-up procedure, enter the following:

HPBASIC <Enter >

3. Place the Package 82 working disk in the default drive,

and type the following:

LOAD “PKG82CV” <Enter>

(Or use “M59OCV” or “M595CV” filenames for those

Programs.)

4. RUN the

3, and 4 or detailed operation information.

rogram in the usual manner. See Sections 2,

4

2.7.5 Modifying the Print Path

As supplied, the Package 82 software supports a printer

connected to the HP-IB bus with a primary address of 1.

The program must be modified to support printers con-

nected to the parallel or serial ports of the IBM AT’ as

outlined below. Note that such printers must emulate HP

Think Jet bit-mapped graphics in order to properly display

graphs generated by the Package 82.

1. Boot up HP BASIC and the ‘PKG82CV” (or “M59OCV’

or “M595CV”) programs, as described above.

2.Type the following in order to locate the Printpath

variable in the program:

Printpath = 26

For the serial port (COMl), modify the Printpath as

follows:

Printpath = 9

(Note: It may also be necessary to modify the configuration file for oroner serial sort oneration. See the HP

BASIC La&rag; Programmer’s Reference Guide.)

Save the modified program under a convenient name.

4.

Use the modified program in order to support the

parallel or serial printers.

2.7.6 Operational Check

After software and hardware installation, the procedure

below can be used to determine if the language processor

card is properly communicating with the instruments.

1. Connect the instruments to the IEEE-488 connector on

the back of the IBM AT computer.

2. Turn on the computer, boot MS-DOS, then boot up HP

BASIC, as described in paragraph 2.7.4.

3. Turn on the instruments; make sure they go through

their normal power-up cycles, and that the primary addresses of the instruments are set to their default values

(2304 X3; 590, W; 595,28). If not, set or program the primary address to the correct value(s).

4. .From the HP BASIC direct mode, type in the following

command, and verify that the Model 230-1 displays XJVz

OUTPUT 7X3 ; ‘VIOXfl <Enter>

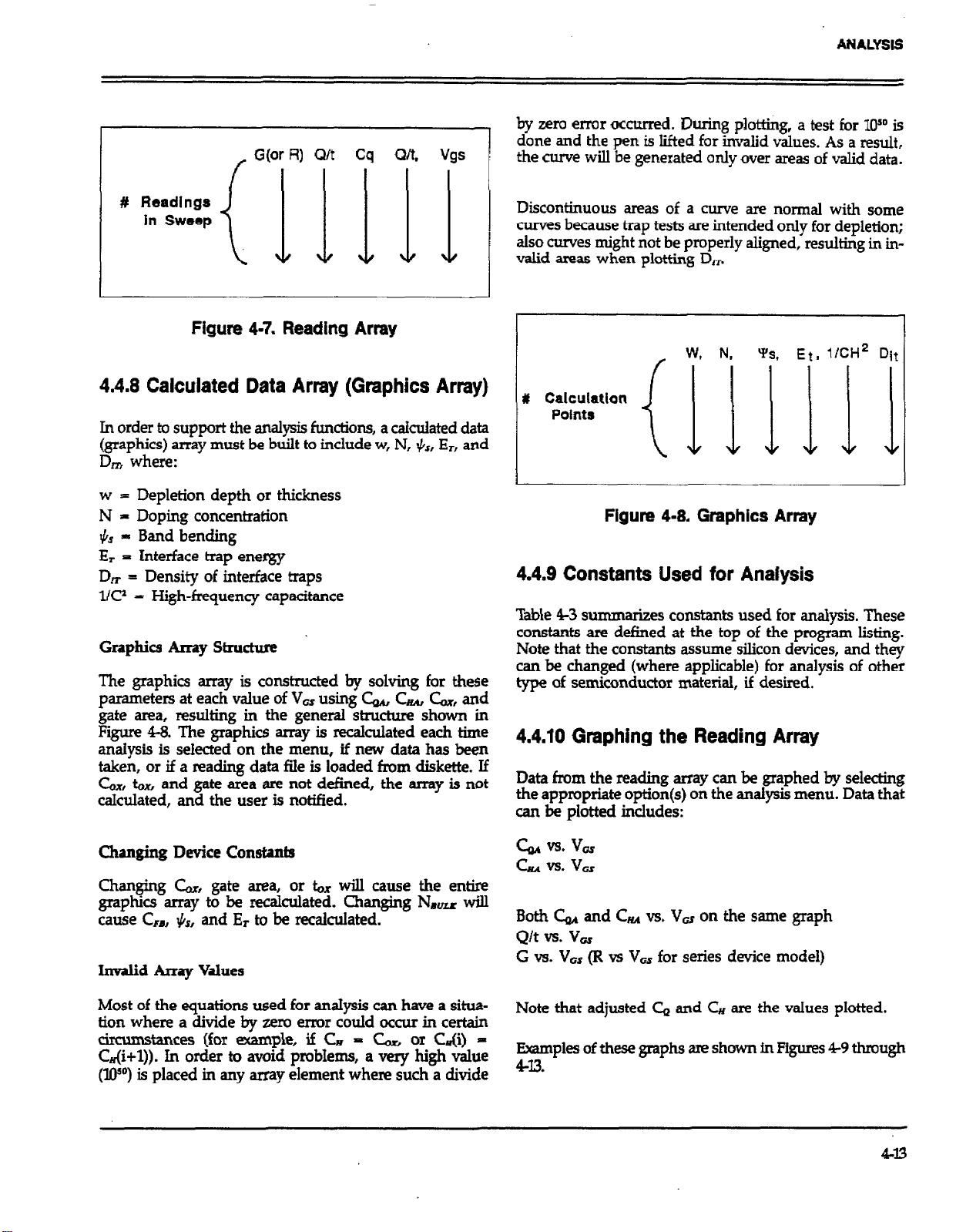

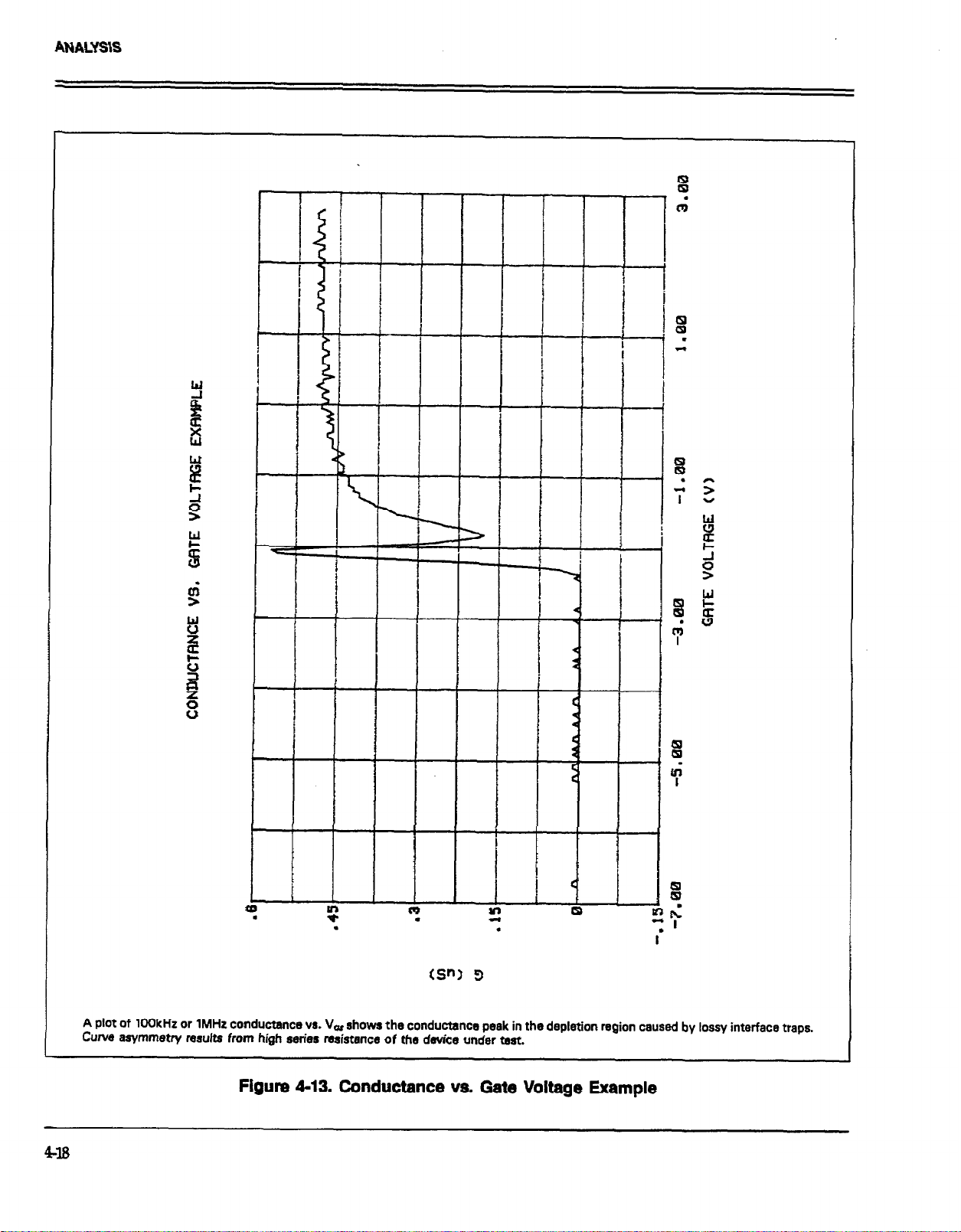

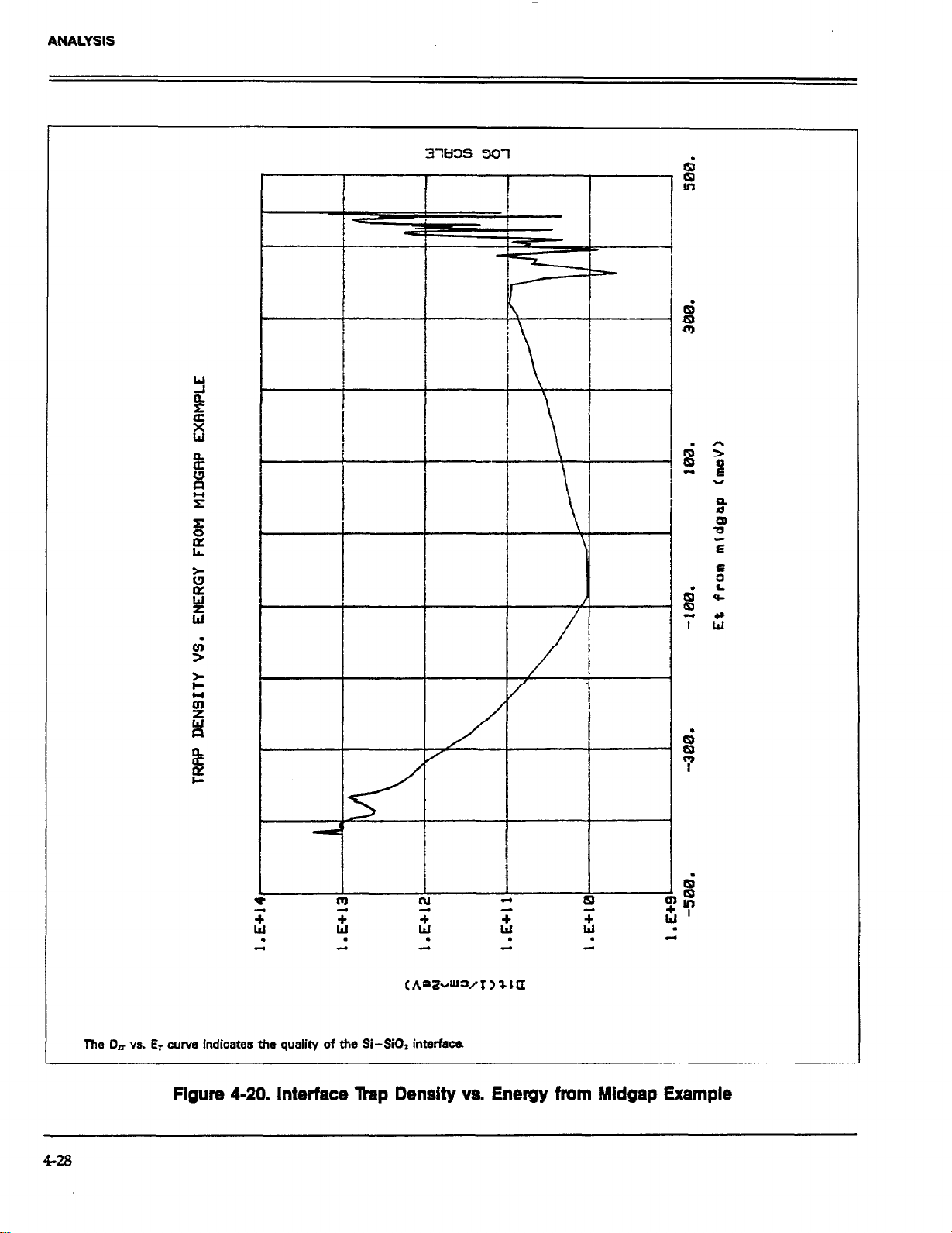

5. Type in the following, and note that the Model 590 goes