Page 1

PA1000

xx

ZZZ

Power Analyzer

User Manual

*P077091201*

077-0912-01

Page 2

Page 3

xx

PA1000

ZZZ

Power Analyzer

User Manual

Firmware Version 1.003.012 and above

www.tektronix.com

077-0912-01

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges r ese rved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O . Bo x 5 00

Beaverto

USA

For product information, sales, service, and technic al support:

n, OR 97077

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of three

(3) years from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at

its option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts , modules and replacement products used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, m odules and products become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, w ith shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from im proper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE P RO DUC T IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX' RESPONSIB ILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL N OT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVAN CE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W4 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other than Tektronix representatives to install, repair or service the product;

Page 6

Page 7

Table of Contents

Important safety information....... .................................. ................................ ............. v

General safety summary ...................................................................................... v

Service safety summary.............. .................................. ................................ ..... vii

Terms in this manual ............. ................................ .................................. ......... viii

Symbols and terms on the product......................................................................... viii

Compliance information ........................................................................................... x

EMC compliance . .................................. .................................. ......................... x

Safety compliance ............................................................................................ xi

Environmental considerations .............................................................................. xiv

Preface .............................................................................................................. xv

Introduction ......................................................................................................... 1

Basic features................................................................................................... 1

Standard accessories........................................................................................... 2

Optional accessories.............. .................................. ................................ ........... 2

Service options .......................... .................................. .................................. ... 3

Getting started. . ... ... . ... ... . ... ... . ... . . ... ... . ... . . ... ... .. ... ... . ... . . ... ... . ... ... . ... ... . ... .. ... ... . ... ... . ... 4

Before you begin - safety .. .................................. .................................. ............... 4

Power on........................... ................................ .................................. ........... 6

Controls and connectors....................................................................................... 7

Connecting to the product under test ........................................................................ 9

Default measurements........................................................................................ 12

Navigating the menu system................................................................................. 13

Data logging................................................................................................... 14

Unit configuration ............................................................................................ 16

The menu system .................................................................................................. 17

Navigation......... .................................. ................................ .......................... 17

Modes .......................................................................................................... 18

Inputs................. .................................. .................................. ...................... 21

Graphs.. .................................. ................................ .................................. .... 23

Interfaces ...................................................................................................... 24

System configuration... .................................. ................................ .................... 24

User configuration ............................................................................................ 26

View .......................... .................................. .................................. .............. 26

Connecting signals .. .................................. .................................. .......................... 27

Input overview .............. ................................ .................................. ................ 27

To connect a simple current transformer ........... ................................ ........................ 28

To connect an external resistive shunt .................................. .................................. .. 29

To connect a transducer with a voltage output............................................................. 30

To connect a voltage transformer / transducer............................................................. 31

PA1000 Power Analyzer i

Page 8

Table of Contents

Remote operati

Overview .......... ................................ .................................. .......................... 33

Interfacing with USB systems............................................................................... 33

Interfacing with Ethernet systems..................... .................................. .................... 33

Interfacing with GPIB systems.............................................................................. 34

Status reporting ....... .................................. ................................ ...................... 34

Command listing.............................................................................................. 36

IEEE 488.2 standard commands and status commands .................................................. 37

Unit information commands....................... ................................ .......................... 39

Measurement selection and reading commands ........................... ................................ 40

Measurement configuration commands .................................................................... 41

Mode setup commands............... ................................ .................................. ...... 43

Input setup commands ....................................................................................... 45

Graph and waveform commands.......................... .................................. ................ 48

Interface commands ........ .................................. .................................. .............. 49

System configuration commands............................................................................ 51

User configuration commands......................................... .................................. .... 53

View commands ........................ .................................. .................................. .. 53

Sending and receiving commands .......................................................................... 54

Communications examples ........ .................................. .................................. ...... 55

Software ............ .................................. ................................ .............................. 57

PWRVIEW PC software .................................................................................... 57

PA1000 firmware update utility . . ... . . ... ... . ... . . ... ... . ... . . ... ... . ... . . ... ... . ... .. ... ... . ... . . ... ... . ... 58

Applications examples ................ ................................ .................................. .......... 60

IEC 62301 compliance testing and low-power standby measurements ................................ 60

IEC 61000-3-2 pre-compliance current harmonics testing............................. .................. 63

Specifications .................... ................................ .................................. ................ 72

Measurement channel ...................... .................................. ................................ 72

Power input.. .................................. .................................. .............................. 72

Mechanical and environmental.............................................................................. 73

Communication ports......................................................................................... 74

Measured parameters......................................................................................... 76

Power polarity................................................................................................. 77

Digital filter.................................................................................................... 78

Measurement accuracy. .................................. .................................. .................. 78

Appendix A: Input fuse replacement ............................................................................ 81

Check the fuse................................................................................................. 82

Select the proper fuse......................... .................................. .............................. 82

Fuse replacement procedure ................................................................................. 82

Index

on ................................ .................................. ................................ 33

ii PA1000 Power Analyzer

Page 9

List of Figures

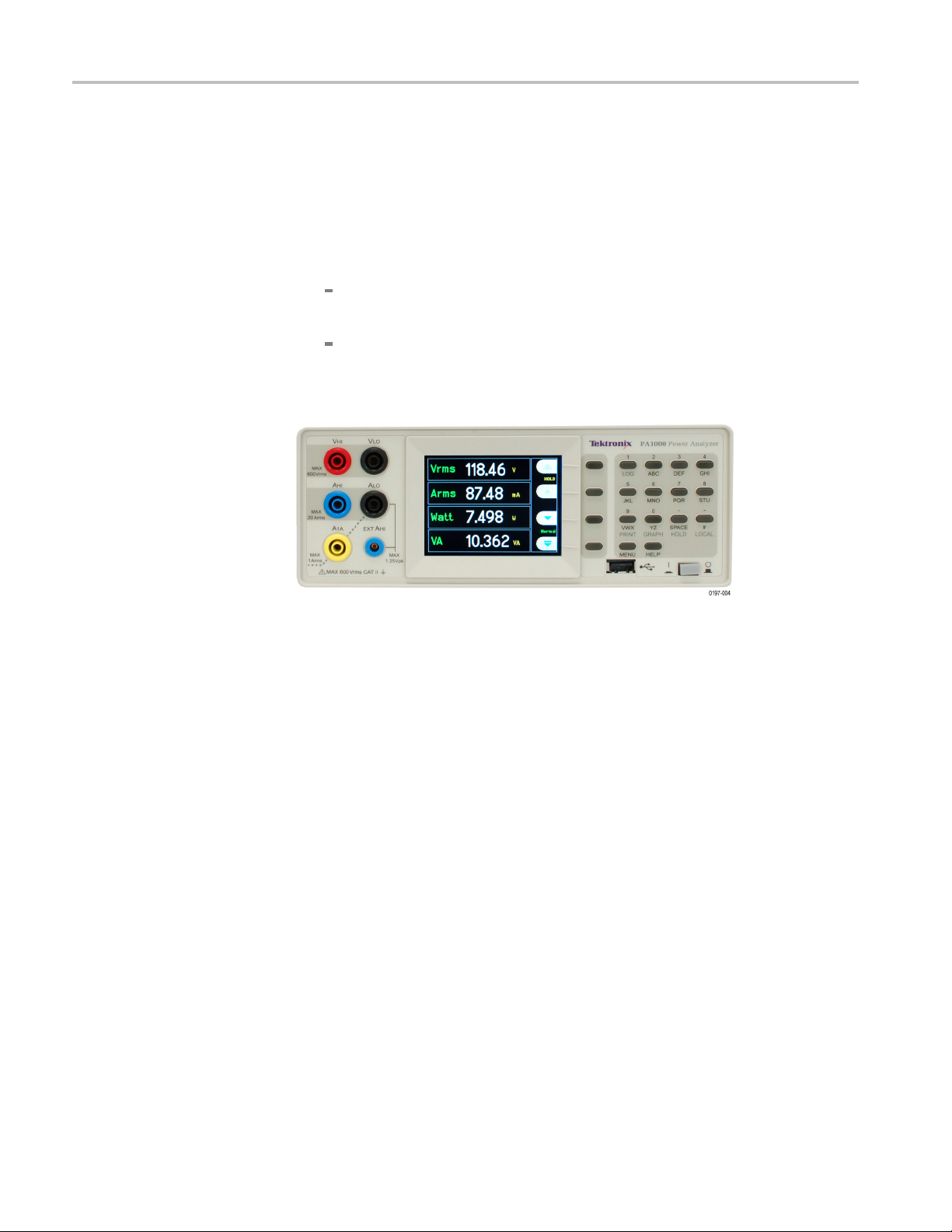

Figure 1: PA1000 Power Analyzer .............. ................................ ................................. 1

Figure 2: Initial power-on d isplay . . ... . ... . . ... . . ... .. ... . . ... .. ... . . ... . . ... . . ... .. ... . . ... .. ... . . ... .. ... ... . .. 6

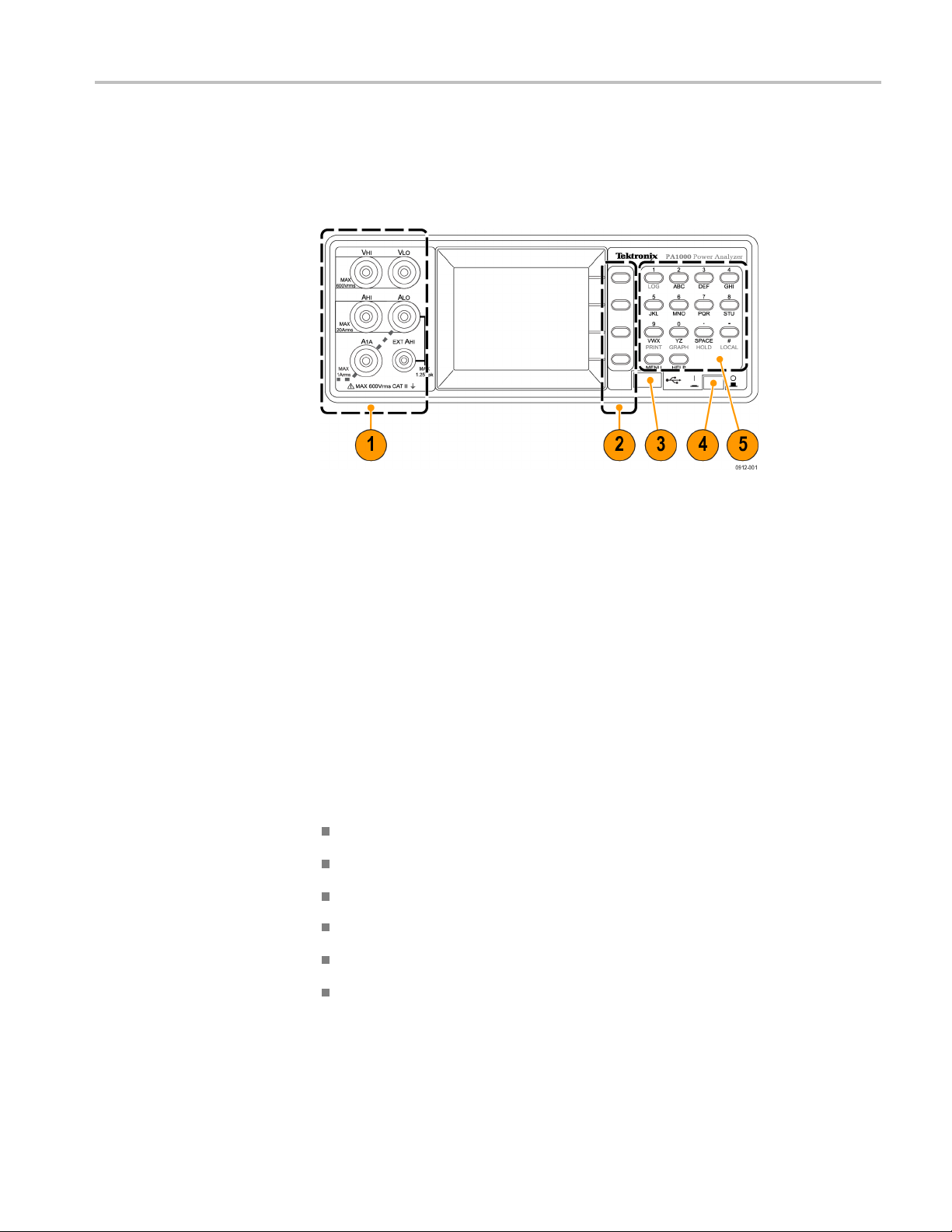

Figure 3: PA1000 front panel ..................................................................................... 7

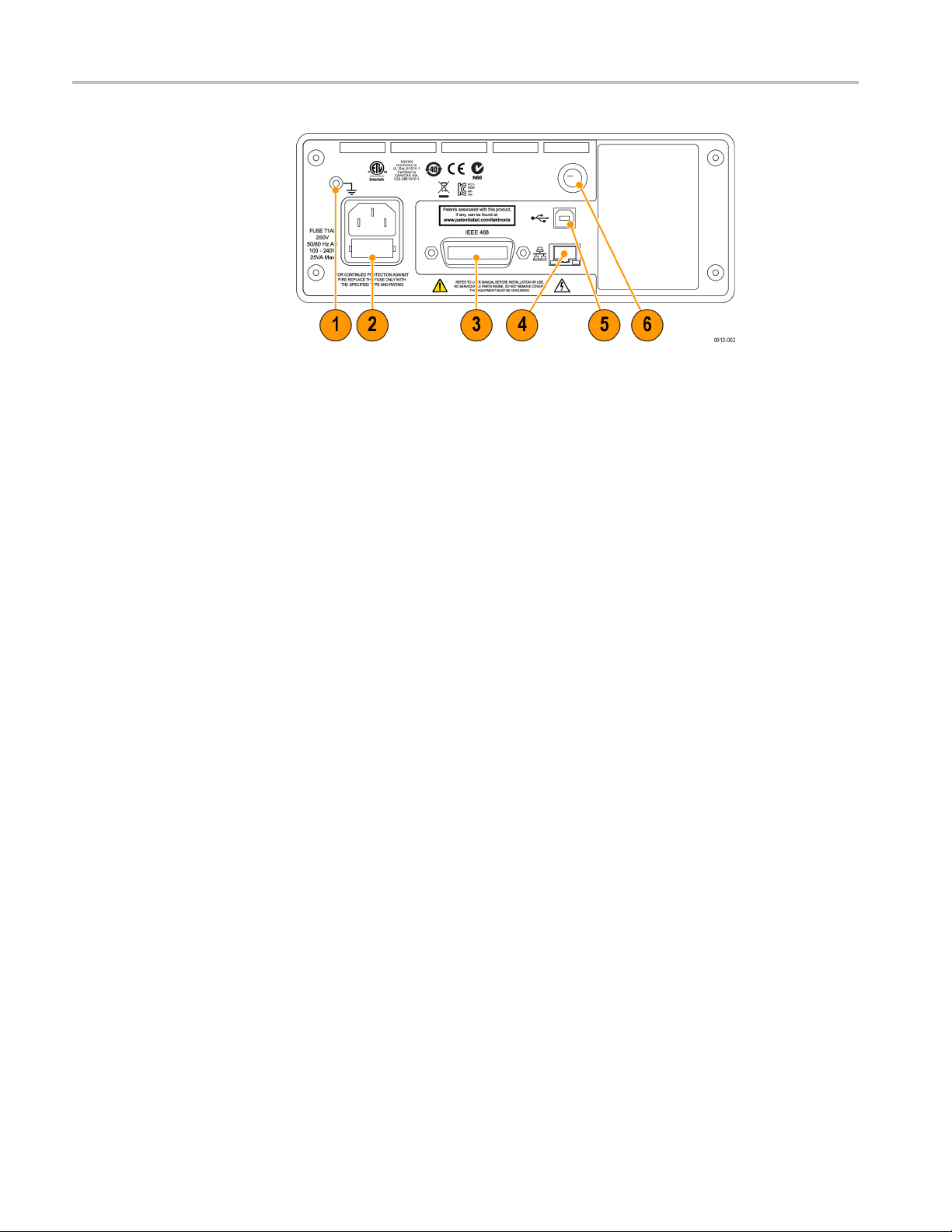

Figure 4: PA

Figure 5: Typical PA1000 input connections.................................................................... 9

Figure 6: Breakout box ........................................................................................... 10

Figure 7: Typical breakout box connections.......................... ................................ .......... 11

Figure 8: Default measurement display......................................................................... 12

Figure 9: Display soft keys....................................................................................... 12

Figure 1

Figure 11: PA1000 logged data .................................................................................. 15

Figure 12: Current transformer connections.................... .................................. .............. 28

Figure 13: External resistive shunt connections ............................................................... 29

Figure 14: Transducer with voltage output connections ........................ .............................. 31

Figure 15: Voltage transformer / transducer connections ..................................................... 32

re 16: Communication ports .............. ................................ .................................. 33

Figu

Figure 17: PWRVIEW application .............................................................................. 58

Figure 18: Laptop charger full-compliance standby power test with PWRVIEW software. ... . ... . . ... .. 61

Figure 19: PA1000 measuring 5 mW in front-panel standby mode.................. ........................ 62

Figure 20: Standby power measurement connections ......................................................... 62

Figure 21: IEC 61000-3-2 pre-compliance test running on PWRVIEW software ............. ............ 65

gure 22: Connection diagram for IEC 61000-3-2 pre-compliance current harmonics test.. ... . ... . ... . 66

Fi

Figure 23: Connecting a power analyzer for the first time using the PWRVIEW software ............... 67

Figure 24: Pre-compliance harmonics test setup......................................... ...................... 67

Figure 25: Test environment and other important information setup ............ ............................ 68

Figure 26: Select load class based on IEC standard ........................................................... 68

Figure 27: IEC 61000-3-2 pre-compliance test ................................................................ 69

Figure 28: Table view for IEC 61000-3-2 pre-compliance test .............................................. 69

Figure 29: Results summary for IEC 61000-3-2 pre-compliance test ....................... ................ 70

Figure 30: Harmonics results with scroll bars for time and amplitude ... . . ... . . ... ... . ... .. ... ... . ... .. ... . 70

Figure 31: PDF report for IEC61000-3-2 pre-compliance test........... .................................. .. 71

Figure 32: Input fuse rating ...................................................................................... 81

Figure 33: Input fuse location ....... .................................. ................................ .......... 82

1000 rear panel ...................................................................................... 8

0: Menu keys............................................................................................. 13

PA1000 Power Analyzer iii

Page 10

Table of Contents

List of Tables

Table 1: Standard accessories .............. .................................. .................................. ... 2

Table 2: Opt

Table 3: Service options .......... .................................. ................................ ............... 3

Table 4: Available measurements per mode........ .................................. .......................... 19

Table 5: Phase measurements.... ................................ .................................. .............. 76

Table 6: Power polarity ........................................................................................... 77

ional accessories .......... .................................. .................................. ....... 2

iv PA1000 Power Analyzer

Page 11

Important safety information

This manual contains information and warnings that must be followed by the user

for safe operation and to keep the product in a safe condition.

To safely perform service on this product, additional information is provided at

the end of this section. (See page vii, Service safety summary.)

General safety summary

Use the product only as specifi ed. Review the following safety precautions to

avoid inj

Carefully read all instructions. Retain these instructions for future reference.

ury and prevent damage to this product or any products connected to it.

Comply wi

For correct and safe operation of the product, it is essential that you follow

general

in this m anual.

The pro

Only qualified personnel who are aware of the hazards involved should remove

the co

Before use, always check the product with a known source to be sure it is

oper

This product is not intended for detection of hazardous voltages.

Use personal protective equipment to prevent shock and arc blast injury where

hazardous live conductors are exposed.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

autions related to operating the system.

c

When incorporating this equipment into a system, the safety of that system is the

esponsibility of the assembler of the system.

r

th local and national safety codes.

ly accepted safety procedures in addition to the safety precautions specified

duct is designed to be used by trained personnel only.

ver for repair, maintenance, or adjustment.

ating corr ectly.

To avoid fire or personal

injury

PA1000 Power Analyzer v

Use proper power cord. Use only the power cord specified for this product and

certified for the country of use.

Do not use the provided power cord for other products.

Ground the product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, make sure that the product is properly grounded.

Page 12

Important safety information

Power disconne

source. See instructions for the location. Do not position the equipment so that it

is difficult to disconnect the power switch; it must remain accessible to the user at

all times to allow for quick disconnection if needed.

Connect and disconnect properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Use only insulated voltage probes, test leads, and adapters supplied with the

product, or indicated by Tektronix to be suitable for the product.

Observe all terminal ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before m aking connections to the product. Do not exceed the

Measurement Category (CAT) rating and voltage or current rating of the lowest

rated individual com ponent of a product, probe, o r accessory. Use caution when

using 1:1 test leads because the probe tip voltage is directly transmitted to the

product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do not float the common terminal above the rated voltage for that terminal.

Do not operate without covers. Do not operate this product with covers or panels

removed, or with the case open. Hazardous voltage exposure is possible.

ct. The power switch disconnects the product from the power

Avoid exposed circuitry. Do not touch exposed connections and components

when power is p resent.

Do not operate with suspected failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Disable the product if it is damaged. Do not use the product if it is damaged

or operates incorrectly. If in doubt about safety of the product, turn it off and

disconnect the power cord. Clearly mark the product to prevent its further

operation.

Before use, inspect voltage probes, test leads, and ac cessories for mechanical

damage and replace when damaged. Do not use probes or test leads if they are

damaged, if there is exposed metal, or if a wear indicator shows.

Examine the exterior of the product before you use it. Look for cracks or missing

pieces.

Use only specified replacement parts.

Use proper fuse. Useonlythefusetypeandratingspecified for this product.

Do not operate in wet/damp conditions. Be aware that condensation may occur if

a unit is moved from a cold to a warm environment.

vi PA1000 Power Analyzer

Page 13

Important safety information

Probes and test leads

Do not operate i

Keep product surfaces clean and dry. Remove the input signals before you clean

the product.

Provide proper ventilation. Refer to the installation instructions in the manual for

details on installing the product so it has proper ventilation.

Slots and openings are provided for ventilation and should never be covered or

otherwise obstructed. Do not push objects into any of the openings.

Provide a safe working environment. Always place the product in a location

convenient for viewing the display and indicators.

Avoid improper or prolonged use of keyboards, pointers, and button pads.

Improper or prolonged keyboard or pointer use may result in s erious injury.

Be sure your work area meets applicable ergonomic standards. Consult with an

ergonomics professional to avoid stress injuries.

Before connecting probes or test leads, connect the power cord from the power

connector to a properly grounded power outlet.

Remove all probes, test leads and accessories that are not in use.

n an explosive atmosphere.

Use only correct Measurement Category (CAT), voltage, temperature, altitude,

and amperage rated probes, test leads, and adapters for any measurement.

Connect and disconnect properly. De-energize the circuit under test before

connecting or disconnecting the current probe.

Connect the probe reference lead to earth ground only.

Do not connect a current probe to a ny wire that carries voltages above the current

probe voltage rating.

Inspect the probe and accessories. Before each use, inspect probe and accessories

for damage (cuts, tears, or defects in the probe body, acc ess ories, or cable jacket).

Do not use if damaged.

Servicesafetysummary

The Service safety summary section contains additional information required to

safely perform service on t

service procedures. Read this Service safety summary and the General safety

summary before performing any service procedures.

To avoid electric shock. Do not touch ex posed connections.

he product. Only qualified personnel should perform

PA1000 Power Analyzer vii

Page 14

Important safety information

Termsinthismanual

Do not service a

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect power. To avoid electric shock, switch off the product power and

disconnect the power cord from the mains power before removing any covers or

panels, or o

Use care when servicing with power on. Dangerous voltages or currents may exist

in this product. Disconnect power, remove battery (if applicable), and disconnect

test leads before removing protective panels, soldering, or replacing components.

Verify sa

strength after performing a repair.

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

fety after repair. Always recheck ground continuity and mains dielectric

lone. Do not perform internal service or adjustm ents of this

pening the case for servicing.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

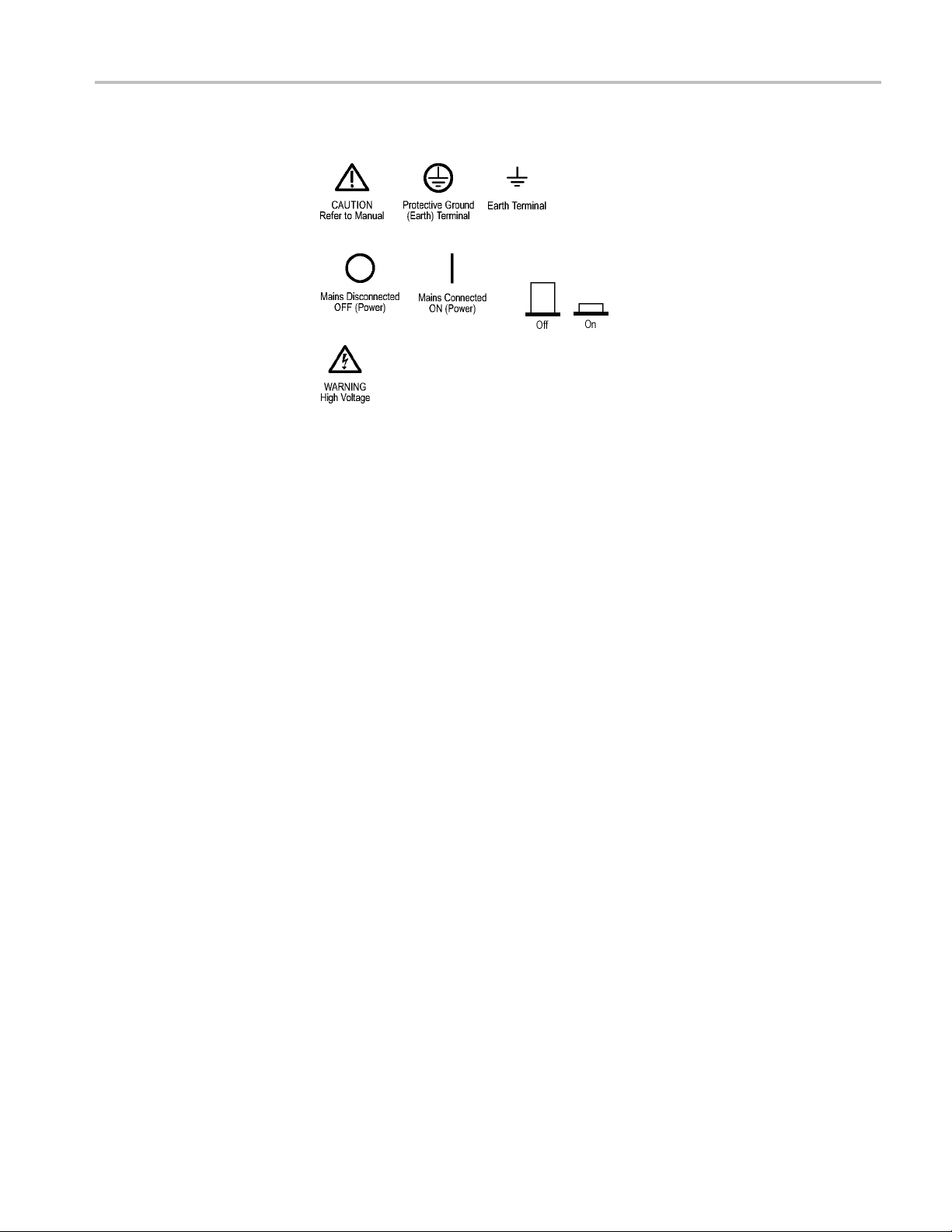

Symbols and terms on the product

These terms may a ppear on the product:

DANGER indicates an injury hazard immediately accessible as you read

the marking.

WARNING indicates an injury hazard not immediately accessible as you

read the marking.

CAUTION indicates a hazard to property including the product.

When this symbol is marked on the product, be sure to consult the manual

to find out the nature of the potential hazards and any actions which have to

betakentoavoidthem. (Thissymbolmayalsobeusedtorefertheuserto

ratings in the manual.)

viii PA1000 Power Analyzer

Page 15

Important safety information

The following s

ymbol(s) may appear on the product:

PA1000 Power Analyzer ix

Page 16

Compliance information

Compliance in

EMC compliance

EC Declaration of

conformity – EMC

formation

This section

environmental standards with which the instrument complies.

Meets intent of Directive 2004/108/EC for Electromagnetic Compatibility.

Compliance was demonstrated to the following specifications as listed in the

Official Journal of the European Communities:

EN 61326-1:2006, EN 61326-2-1:2006. EMC requirements for electrical equipment

for meas

CISPR 11:2003. Radiated and conducted emissions, Group 1, Class A

IEC 61000-4-2:2001. Electrostatic discharge immunity

IEC 61000-4-3:2002. RF electromagnetic field immunity

IEC 61000-4-4:2004. Electrical fast transient/burst immunity

IEC 61000-4-5:2001. Power line surge immunity

lists the EMC (electrom agnetic compliance), safety, and

urement, control, and laboratory use.

123

1000-4-6:2003. Conducted RF immunity

IEC 6

IEC 61000-4-11:2004. Voltage dips and interruptions immunity

EN 61000-3-2:2006. AC power line harmonic emissions

EN 61000-3-3:1995. Voltage changes, fluctuations, and flicker

European contact.

ektronix UK, Ltd.

T

One Thames Valley

Wokingham Road

Bracknell, RG42 1NG

United Kingdom

x PA1000 Power Analyzer

Page 17

Compliance information

EMC compliance

Australia / New Zealand

Declaration of Conformity

–EMC

Meets the inten

t of Directive 2004/108/EC for Electromagnetic C omp atibility

when it is used with the product(s) stated in the specifications table. Refer to the

EMC specification published for the stated products. May not meet the intent of

the directive if used with other products.

European contact.

Tektronix U

K, Ltd.

One Thames Valley

Wokingham Road

Bracknell, RG42 1NG

United Kingdom

1

This product is intended for u se in nonresidential areas only. Use in residential areas may cause electromagnetic

interference.

2

Emissions which exceed the levels required by this standard may occur when this equipment is connected to a

test object.

3

For compliance with the EMC standards listed here, high quality shielded interface cables should be used.

Complies with the EMC provision of the Radiocommunications Act per the

following standard, in accordance with ACMA:

CISPR 11:2003. Radiated and conducted emissions, Group 1, Class A, in

accordance with EN 61326- 1:2006 and EN 61326-2-1:2006.

Safety compliance

EU declaration of

conformity – low voltage

Australia / New Zealand contact.

Baker & McKenzie

l 2 7, AMP Centre

Leve

50 Bridge Street

Sydney NSW 2000, Australia

This section lists the safety standards with which the product complies a nd other

safety com p liance information.

Compliance was dem onstrated to the following specification as listed in the

Official Journal of the European Union:

Low Voltage Directive 2006/95/EC.

EN 61010-1. Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use – Part 1: General Requirements.

EN 61010-2-030. Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use – Part 2-030: Particular

requirements for testing and measuring circuits.

PA1000 Power Analyzer xi

Page 18

Compliance information

U.S. nationally recognized

testing laboratory listing

Canadian certification

Additional compliances

UL 61010-1. Saf

Control, and Laboratory Use – Part 1 : General Requirements.

UL 61010-2-030. Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use – Part 2-030: Particular

requirements for testing and measuring circuits.

CAN/CSA-C22.2 No. 61010-1. Safety Requirements for Electrical

Equipment for Measurement, Control, and Laboratory Use – Part 1: General

Requirements.

CAN/CSA-C22.2 No. 61010-2-030. Safety Requirements for Electrical

Equipment for Measurement, Control, and Laboratory Use – Part 2-030:

Particular requirements for testing and measuring circuits.

IEC 61010-1. Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use – Part 1: General Requirements.

IEC 61010-2-030. Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use – Part 2-030: Particular

requirements for testing and measuring circuits.

ety Requirements for Electrical Equipment for Measurement,

Equipment type

Safety class

Pollution degree

descriptions

Test and measuring equipment.

Class 1 – grounded product.

A measure of the contaminants that could occur in the environment around

and within a product. Typically the internal environment inside a product is

considered to be the same as the external. Products should be used only in the

environment for which they are rated.

Pollution degree 1. No pollution or only d ry, nonconductive pollution occurs.

Products in this category are generally encapsulated, hermetically se aled, or

located in clean rooms.

Pollution degree 2. Normally only dry, nonconductive pollution occurs.

Occasionally a temporary conductivity that is caused by condensation must

be expected. This location is a typical office/home environment. Temporary

condensation occurs only when the product is out of service.

Pollution degree 3. Conductive pollution, or dry, nonconductive pollution

that becomes conductive due to condensation. These are sheltered locations

where neither temperature nor humidity is controlled. The area is protected

from direct sunshine, rain, or direct wind.

Pollution degree 4. Pollution that generates persistent conductivity through

conductive dust, rain, or snow. Typical outdoor locations.

xii PA1000 Power Analyzer

Page 19

Compliance information

Pollution degree rating

Measurement and

overvoltage

category

descriptions

Mains overvoltage

category rating

Pollution degr

use only.

Measurement terminals on this product may be rated for measuring mains voltages

from one or mo

the product and in the manual).

Category II

points (socket outlets and similar points).

Category I

Category IV. At the source of the electrical supply to the building.

NOTE. On

Only measurement circuits have a measurement category rating. Other circuits

within the product do not have either rating.

Overvoltage category II (as defined in IEC 61010-1).

ee 2 (as defined in IEC 61010-1). Rated for indoor, dry location

re of the following categories (see specific ratings marked on

. Circuits directly connected to the building wiring at utilization

II. In the building wiring and distribution system.

ly mains power supply circuits have an overvoltage category rating.

PA1000 Power Analyzer xiii

Page 20

Compliance information

Environmental considerations

This section provides information about the environmental impact of the product.

Product end-of-life

handling

Restriction o f hazardous

substances

Observe the f

Equipment recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could be

harmful to the environment or human health if improperly handled at the product’s

end of life. To avoid release of such substances into the environment and to

reduce the

an appropriate system that will ensure that most of the materials are reuse d or

recycled appropriately.

This pr

and is not required to comply with the substance restrictions of the recast RoHS

Directive 2011/65/EU until July 22, 2017.

ollowing guidelines when recycling an instrument or component:

use of natural resour ces, we encourage you to recycle this product in

This symbol indicates that this product complies with the applicable European

Union re

on waste electrical and electronic equipment (WEEE) and batteries. For

information about recycling options, check the Support/Service section of the

Tek t ro n

oduct is classified as an industrial monitoring and control instrument,

quirements according to Directives 2002/96/EC and 2006/66/EC

ixWebsite(www.tektronix.com).

xiv PA1000 Power Analyzer

Page 21

Preface

Preface

This manual c

Specifications and remote operation, including p rogramm ing commands, are

included in later chapters.

overs the setup and use of the PA1000 Power Analyzer.

PA1000 Power Analyzer xv

Page 22

Preface

xvi PA1000 Power Analyzer

Page 23

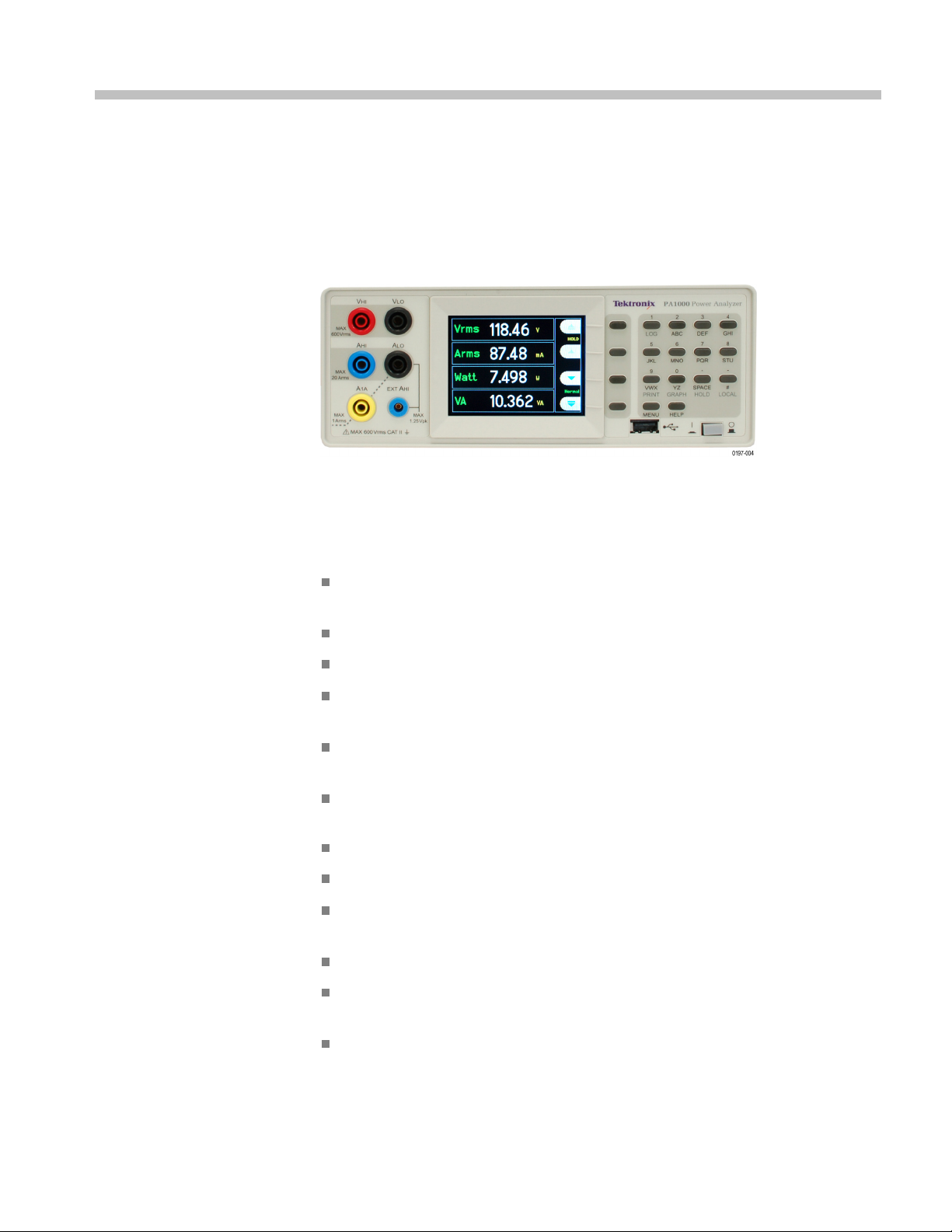

Introduction

Basic features

The Tektronix PA1000 is a powerful and versatile precision power analyzer.

Designed to provide clear and accurate measurements of electrical power and

energy on all single-phase electrical products, the PA1000 is an easy-to-use

bench instrument with capability for remote control, data transfer and regulatory

compliance

Figure 1: PA1000 Power Analyzer

Measures Watts, Volts, A mps, Volt-Amperes and Power Factor. Always

accurate, even on distorted waveforms.

testing.

Range of measurement from milliwatts to megawatts.

Quick access to results, graphing and menus.

Built-in energy analyzer (watt-hour integrator) for measuring energy

consumption over time.

Built-in 20 A and 1 A shunts to allow the easy measurement of a wide

dynamic range of currents.

Standby power measurement mode for fast and accurate low power

measurements.

IEC 62301 Compliance testing available with PWRVIEW software

Harmonic analyzer with built in spectrum display.

IEC Current Harmonics mode (requires PWRVIEW PC software) for IEC

61000-3-2 pre-compliance testing.

Bright color TFT display.

Compre

USB as standard.

Inrush current measurement mode for measuring switch-on and other transient

peak currents.

hensive range of computer interfaces including GPIB, Ethernet and

PA1000 Power Analyzer 1

Page 24

Introduction

Standard accessories

Ballast mode fo

r measuring the tube power of electronic ballasts.

Easy-to-use menu system with context-sensitive help.

Table 1: Standard accessories

Accessory Tektronix part number

Voltage lead set

USB 2.0 cable, A to B, 6 ft. length

Documentation CD

Power Cord

Country-specific power cord

One of the following:

North America

Universal Euro

United Kingdom

Australia

Switzerland (Option A5)

Japan

China (Option A10)

India

Brazil

No power cord or AC adapter (Option A99)

PA LEADSET

174-6053-xx

063-4519-xx

(Option A0)

(Option A1)

(Option A2)

(Option A3)

(Option A6)

(Option A11)

(Option A12)

Optional accessories

Table 2: Optional accessories

Accessory Tektronix part number

Breakout box (North America plug configuration)

Breakout box (Euro plug confi guration)

Breakout box (United Kingdom plug configuration)

Specialty current transducer for lamp ballast testing BALLAST-CT

Current clamp, 1 A - 200 A, for Tektronix Power Analyzers CL200

Current clamp, 0.1 A - 1200 A, for Tektronix Power Analyzers CL1200

Replacement lead set for Tektronix Power Analyzers (one

channel leadset)

2 PA1000 Power Analyzer

BB1000-NA

BB1000-EU

BB1000-UK

PA-LEADSET

Page 25

Introduction

Service optio

ns

Table 3: Service options

Option Description

Opt. C3 Calibration

Opt. C5 Calibratio

Opt. D1 Calibrati

Opt. D3 Calibrati

Opt. D5 Calibrat

n Service 5 Years

on Data Report

on Data Report 3 Years (with Option C3)

ion Data R eport 5 Years (with Option C5)

Service 3 Years

PA1000 Power Analyzer 3

Page 26

Getting started

Getting start

ed

Before you begin - safety

Carefully r

the Power Analyzer.

WARNING. To avoid possible electric shock or personal injury:

• By connecting the Power Analyzer to active circuits, the terminals and certain

parts inside the Power Analyzer are live.

• If possible, open the circuit before establishing a connection to the Power

Analyzer.

• Before connecting the circuits, ensure that the maximum measuring voltage and

maximum

• Do not use leads and accessories that do not comply with relevant safety

standards, as this could lead to serious injury or death from electric shock.

• Shunts and conductors can generate heat when in use and surfaces may burn

the skin.

Qualified personnel

This

persons who are familiar with the installation, assembly, connection, inspection

of connections, and operation of the analyzer and who have been trained in the

following areas:

ead and adhere to the following warning statements before you connect

voltage to earth g round (600 V

product may be operated only by qualified personnel. This means only

, CAT II) is not exceeded.

RMS

Installation

Switching on/off, enabling, earth-grounding and identification of electrical

circuits and services/sys tem s according to the applicable safety standards.

Maintenance and operation of appropriate safety gear, in accordance with the

applicable safety standards.

First aid.

Ensure that all perso ns using the de vice have read an d fully understood the

Operators Manual and safety instructions.

Mains connection m ust conform to these ranges/values: 100 – 240 V,

50/60 Hz.

The device may only be used under certain ambient conditions. Ensure that

the actual ambient conditions conform to the admissible conditions specified

in this manual.

Ensure this product is installed in such a way that its power cable is accessible

at all times and can easily be disconnected.

4 PA1000 Power Analyzer

Page 27

Getting started

Before each use

Connection sequence

Ensure that the

power and connecting cables as well as all acces sories and

connected devices used in conjunction with this product are in proper working

order and clean.

Ensure that any third-party accessories used in conjunction with the device

conform to the applicable IEC61010-031 / IEC61010-2-032 standards and are

suitable for the respective measuring voltage range.

WAR N ING. To avoid possible electric shock or personal injury:

When the measuring circuit is used to measure MAINS, the voltage to earth may

not exceed 600 V

in a CAT II environment.

RMS

For safety reasons, when connecting a circuit to the Power Analyzer, proceed

in the sequence outlined as follows:

1. Connect the Power Analyzer power cord to a properly grounded mains outlet.

The Power Analyzer is now connecte d to the protective earth ground wire.

2. Power on the Power Analyzer.

During use

3. Conne

ct the measuring circuit according to all instructions and as shown in

the connection diagrams in this manual.

For connection work, work in teams of at least two persons.

If you detect any damage to the housing, controls, power cable, connecting

leads, or connected devices, immediately disconnect the unit from the power

ply.

sup

you are in doubt as regards the safe operation of the device, immediate l y

If

shut down the unit and the respective accessories, s ecure them against

inadvertent switching on, and have them serviced by a qualified service

person.

PA1000 Power Analyzer 5

Page 28

Getting started

Power on

1. Check that the power analyzer is in good condition, with no signs of damage.

2. Follow the Connection Sequence described in the Before you begin - safety

section. (See page 4.)

3. After pressing the power switch at the front to on:

The PA1000 w

5–10 seconds.

During pow

version.

4. The instr

Figure 2: Initial power-on display

ument is now ready for use.

ill start its power-on sequence. This takes approximately

er on, you will see the PA1000 serial number and firmware

6 PA1000 Power Analyzer

Page 29

Getting started

Controls and c

Front panel

onnectors

Use this section to help familiarize yourself with the instrument operation.

Figure 3:

1. Input ba

PA1000 front panel

nana jacks – For safe operation, use o nly the test lead set supplied

with the instrument. Typical connections for the power analyzer are shown

later in this section. (See Figure 5 on page 9.)

2. Soft keys – These push buttons control the screen -specific functions that

appear on the instrument display. (See Figure 9 on page 12.)

3. USB connection – Use this front-panel USB jack for saving instrument data

to your flash drive.

4. Power switch – Push button switch turns on the instrument power.

5. Alp

Key shortcuts.

hanumeric keypad – Use these keys to input alphanumeric information

and to perform functions such as displaying graphs. See Key shortcuts below:

Display main menu: Press MENU (toggle on/off)

isplay system help: Press HELP (toggle on/off)

D

Display hold: Press SPACE (toggle on/off)

Display graph: Press YZ (toggle betwee n graph and results)

Local control (from remote): Press #

Toggle Data Logging: Press STU or 1

PA1000 Power Analyzer 7

Page 30

Getting started

Rear panel

Figure 4: PA1000 rear panel

1. Ground lug – Attach the ground connection from the device under test (DUT)

to this rear-panel connector.

2. Power cord connector and line fuse – This connector accepts the

country-specific line cords that are available for the instrument. The line fuse

is replaceable; see Specifications for the correct fuse type.

mware upgrade

Fir

3. IEEE.488 (GPIB) connector – Use this connection to communicate to the

instrument over a GPIB bus.

4. RJ-45 (Ethernet) connector – Use this connection to communicate to the

instrument through an E thernet connection.

5. USB B connector – Use this connection to communicate to the instrument

through a USB connection.

6. Front-panel inputs fuse – The input circuitry is protected by this fuse. Refer

to Specifications for the proper replacement type.

For the best performance and compliance to the specifications and features

described in this manual, please ensure that the latest firmware is installed on your

PA1000. The firmware version of your PA1000 is displayed during power-on.

e latest version is available on our website at www.tek.com and installs over

Th

USB from a PC utility in less than 15 minutes. To locate the latest version of

the firmware (and PC software), go to ww w.tek.com, and browse to the "Power

Analyzers" "PA1000" page and then click on the software link or tab. (See

page 58, PA1000 firmware update utility.)

8 PA1000 Power Analyzer

Page 31

Getting started

Connecting to

the product under test

The PA1000 can m eas ure up to 600 V

4 mm terminals on the front panel. For measurements outside the range (low or

high power),

page 27, Connecting signals.)

To measure p

with the supply voltage and in series with the load current as shown below.

WAR N ING. To avoid injury always use good quality safety cables as supplied and

check that they are not damaged before use.

WAR N ING. If the peak voltage or current exc eeds the measurement capability of

the instrument, the results screen will be replaced with Over Range. At this point,

the input levels should be reduced ensure accurate measurements.

see the information on using current and voltage transducers. (See

ower, connect the measuring terminals of the PA1000 in parallel

and20A

RMS

RMS

or 1 A

directly using the

RMS

Figure 5: Typical PA1000 input connections

PA1000 Power Analyzer 9

Page 32

Getting started

Breakout Box

The simplest an

use a Tektronix Breakout Box. This provides a line socket for connection of the

product and 5 x 4 mm sockets for direct connection to the PA1000 terminals as

described above.

Figure 6: Breakout box

There are three versions of the breakout box, differing by the type of line socket:

120 V North America, 230 V Europe and 230 V United Kingdom. See Optional

accessories for ordering information. (See Table 2 on page 2.)

d safest way to make a connection to the product under test is to

10 PA1000 Power Analyzer

Page 33

Getting started

Connecting the

1. Using the test leads provided with the PA1000, make the voltage and current

connections between the breakout box and the input jacks on the PA1000.

(See Figure 7

NOTE. The VLO Source jack on the breakout box is designed for taking

measurements in low power, standby applications.

breakout box.

.)

e 7: Typical breakout box connections

Figur

2. Plug

3. Con

4. Po

For other information about the breakout box, refer to the BB1000 Instructions

at are included with the breakout box.

th

PA1000 Power Analyzer 11

the power cord from the unit under test into the receptacle on the

breakout box.

nect a power cord from the line source to the breakout box Line In

connector.

wer on the unit under test and begin taking measurements.

Page 34

Getting started

Default measu

rements

After you switch on the supply to the load, the PA1000 is ready to take

measurements. Note that it is not necessary to switch the PA1000 either off or

on when the lo

ad is being connected.

Figure 8: Default measurement display

The default display shows 4 values at one time. Each line clearly shows the

rement type ‘V

measu

’, the measured value, ‘118.46’ and the measurement

RMS

units, ‘V’. Normal engineering notationisusedtodescribeunits,e.g. mV=

milli-volts (10

The default measurements are V

–3

) and MW = mega-Watts (10+6).

RMS,ARMS

, Watts, Frequency and Power Factor.

To scroll through the measurements, use the 4 keys to the right of the display:

Figure 9: Display soft keys

12 PA1000 Power Analyzer

Page 35

Navigating the menu system

The menu system provides complete access to all settings of the PA1000. To

access the menu system, press the MENU key.

To return to the measurement display at any tim e, simply press the MENU key

again. With the menu system active, the 4 soft keys to the right of the display may

be used to navigate and select options.

Menu k eys

Getting started

Choosing measurements

to display

Figure 10: Menu keys

To choose the measurements on the display:

1. Press MENU to show the menu.

2. Press

displayed in the order s hown.

3. Use the

4. The measurement will be highlighted in red. To move the measurement use

the

5. Press

To remove a selected measurement, select it and press

Hint: To restore the default list, see the User Configuration Menu. (See page 26,

User configuration.)

to see the list of measurements. Measureme

and keys to select a measurement to display and press .

and keys.

to select the measurement.

nts with a

.

will be

PA1000 Power Analyzer 13

Page 36

Getting started

Data logging

The PA1000 can log data to a USB flash drive. The unit will log all selected

measurements into a comma separated values (CSV) formatted file that is stored

on the connected USB flash drive. Results will be logged approximately once

per second. The exact logging time interval will differ based on selected mode,

number of me

Prior to enabling data logging, insert a USB flash drive into the USB host port on

the front o

WARNING. If the U SB flash drive is removed while data logging is enabled, data

corruption will occur.

asurements and other settings.

f the PA1000.

Logging data

Data storage and format

To start

indicated by the current mode text flashing every second. To stop data logging,

press the 1 key on the PA1000 keypad.

The da

drive. The directory structure c reated will contain the last five digits of the serial

number of the PA1000 used and the date at the start of data logging. The file nam e

will reflect the time at the start of data logging in 24 hr format and will have a

.CSV extension.

For example, if a PA1000 with the serial number B010100 begins data logging on

28 June 2013 at 3:10:56 PM, the directory tree will be as shown below:

The first portion of the file will contain a header identifying the instrument used by

serial number and the time data logging began. The second portion of the file will

contain column headers for every measurement currently selected. Subsequent

lines will contain an indexed set of the measurements c urrently selected, in the

rder disp layed on the PA1000 screen.

o

data logging, press the 1 key on the PA1000 keypad. Data logging is

ta will be logged in a directory created by the PA1000 on the USB fl ash

Root Dir\PA1000\10100\20130628\15-10-56.csv

14 PA1000 Power Analyzer

Page 37

Getting started

The basic forma

year, month, day (YYYYMMDD) format respectively.

Figure 1

USB Fla

1: PA1000 logged data

sh Drive Requirements:

t of the data is shown below. Time and date will be in 24 hr and

Printing

The USB flash drive must be formatted with FAT12, FAT16 or FAT32 fi le

ms.

syste

Sector size must be 512 bytes. Cluster size up to 32 kB.

Only Bulk Only Mass Storage (BOMS) devices which support the SCSI or

AT command sets are supported. For more information on BOMS devices

rtoUniversalSerialBusMassStorageClass–BulkOnlyTransportRev.

refe

1.0, published by the USB Implementers Forum.

t USB memory devices meet the above requirements.

Mos

Printing directly from the PA1000 is not currently supported, but may be

implemented in a future software release.

PA1000 Power Analyzer 15

Page 38

Getting started

Unit configura

tion

Explanation of adjustment

(calibration) type

To view unit configuration data including hardware revision, firmware revision,

serial number, date of last adjustment (calibration), a nd verification, select:

System Configuration → Unit Configuration

On the unit configuration s creen there are 2 dates related to calibration. They are:

Last Verified – This is the date the PA1000 was last checked against

specification without any adjustments being made.

Last Adjusted – This is the date calibration information was last changed in

the PA1000.

16 PA1000 Power Analyzer

Page 39

The menu system

Navigation

The menu in the PA1000 is a powerful yet easy-to-use system for control of the

analyzer. See the Quick Start section of this manual for an overview of how to

access and use the menu system. (See page 13, Navigating the menu system.)

For help at any time while using the PA1000 press the HELP key at any time.

Menu items

Main menu

Measure

ments

To switch the display of the menu system off or on, press the MENU key at any

time.

To select a menu, press the key.

Choose the measurements to display.

To add a new measurement:

1. Select it

2. (Optional) Move the measurement

3. Press O K.

To remove a measurement, select it and press

Hint: To restore the default list, see the User Configuration Menu.

nformation on setup for harmonics and distortion factor, see System

For i

Configuration.

and and press .

and (does not apply to harmonics).

.

PA1000 Power Analyzer 17

Page 40

The menu system

Modes

Select mode

Choose this option to set the PA1000 into one of its operating modes. Each mode

is indicated on the front panel measurement display once set. The modes are:

Normal. Ideal for most general measurements.

Ballast. For measuring the output of electronic ballasts. See www.tektronix.com

for application notes on this subject. The frequency displayed is the ballast

switching frequency.

Inrush. For measuring the peak current during any event. Typically this is used to

measure t

keytosettheinrushcurrenttozero.

Standby power. A special mode in the analyzer that allows the user to set

a time window over which to accumulate pow er measurements. When set,

power measurements will update after each time window period, other available

measur

The currently displayed power measurement represents the amount of power

accumulated over the last time window only.

Integrator. For energy consumption (W-h) measurements over time. Ideal for

rating products whose energy consumption is not constant like washing machines

and

he peak current when a product is first switched on. Press the Reset soft

ements will update at the normal display update rate of 0.5 seconds.

refrigerators.

otes on changing mode

N

IEC current harmonics. This mode can be accessed using the PWRVIEW PC

software only. It enables pre-compliant current harmonic measurements to

be made consistent with IEC61000-3-2:2014 Ed.4 and IEC61000-4-7:2002 +

A1:2009.

When you change modes, the measurements that are displayed will change.

Adding a measurement to the display will only apply to the currently selected

mode. The number of available measurements a re different, depending on which

mode you are in. The same applies for remote communications since the "FRD?"

command,whichisusedtoreturnresults, only returns the results displayed on

the screen, in the order in which they are displayed.

The following table lists which m easurements are available in which mode, along

with which measurements are displayed by default for the selected mode . (See

Table 4 on page 19.)

18 PA1000 Power Analyzer

Page 41

The menu system

Table 4: Availa

ble measurements per mode

Mode

Measurement Normal Ballast Inrush Standby Power Integrator

V

RMS

A

RMS

Watts

X* X*

X* X* X* X*

X* X* X*

X

X* X*

X

VA X X X X

Var X X X X

Freq

PF

X* X*

X* X* X* X*

Vpk+ X X

Vpk– X X

Apk+ X X

Apk– X X

X

X*

X*

X*

X*

X* X*

Vdc X X

Vac X X

Vcf

Acf

XX X

XX

Vthd X X X

d

Ath

XX

ZX

RX

XX

Hr X

Whr

X*

VAhrs X

VArhr X

Ahr X

V-harm X X X

A-harm X X

V range X X X X X

A range X X X X X

X = Measurement available

X* = Displayed as default

PA1000 Power Analyzer 19

Page 42

The menu system

Setup mode

Also, dependin

g on which mode you change to, other settings may be changed:

When you change to any mode except Inrush mode, the voltage and the

current range

s will be set to auto range.

When you change to Inrush mode, the voltage and current ranges will be set

to the defau

lts set up under the Inrush mode setup.

Choose the mode that you want to set up.

Inrush set

up. Choose the default starting current range and the default starting

voltage range. Start with the maxim um range and then set the mode and make

measurements. Choose a lower range with the soft keys for more accuracy once

you begin to make measurements. The reset soft key sets the inrush current to zero.

Standby power setup. The time window is the time over which the PA1000

will ave

period specified in the time window, with the exception of V

rage the samples. Note that the measurements will only update at the

,Vcf,Frequency,

RMS

Vthd, and Vharmonics magnitude and phase which will continue to update every

0.5 seconds.

Integrator setup. The Integrator on the PA1000 operates in two methods, the

al Start Method and the Clock Start Method. In the Manual Start Method the

Manu

integrator will start and stop when the user presses the start/stop button and will

reset when the user presses the reset button.

In the Clock Start Method the PA1000 will use its real time clock to start the

integrator based on the date and time set up by the user. The user will also

configure a duration for the Clock Start Method that will stop the integrator at the

appropriate time.

The desired Start Method is configured in the Integrator Setup, Start Method

menu. Select Manual or Clock using the

key.

If Manual Start M ethod is selected, nothing more needs to be configured to run the

integrator. After the mode is selected, the user will use the start/stop

start and stop the integrator and the reset key (

Note: Use of the reset key (

) requires the integrator to be stopped. The Clock

) to reset the accumulated values.

key to

Start Method is configured in the Integrator Setup m enu. Here the user can

configure the start date and tim e and the duration. The starting time and the

starting date are entered in the current format of the PA1000, as shown at the

time they are entered. The duration is entered in minutes in the range shown on

the data entry screen.

20 PA1000 Power Analyzer

Page 43

Inputs

The menu system

Set up the measurement inputs – range , scale and low value blanking.

This menu may be used to set up the physical inputs of the PA1000. For normal

operation, (20 mA to 20 A

andupto600V

RMS

), it is not necessary to change

RMS

these settings from default.

Fixed/Auto ranging

Scaling

To select an Inputs menu item, use the

keys and then press for detailed

options.

For most me

asurements, auto-ranging is the best choice. Choosing a fixed range

may be useful if the voltage or current is changing continuously or has large peaks

that make the analyzer spend excessive tim e changing range.

Select

ltsorAmpsandpress

Vo

to choose the range. Changing the

measurement mode will often reset the voltage and current range to auto.

Scaling

can be used to adjust the PA1000 values to account for the transducer

ratio. The scaling factor will affect every measured value related to the input

to which it is applied.

When the 600 V and 20 A and 1 A inputs are used directly, then the default setting

for Volts and Amps scaling is 1.

To use the PA1000 with external voltage or current transducers, enter a sca le

factor to make the PA1000 display measurements with proper scaling, accounting

for the transducer ratio.

Select

Volts or Amps and press to enter the scale factor. See the Chapter

Using External Voltage and Current Transducers for further information.

Frequency source

To make accurate rms measurements, the PA1000 must first determine frequency.

Normally the PA1000 detects frequency from the voltage signal using proprietary

algorithms. If no voltage signal is present, or it is a chopped waveform, then it

may be necessary to select Amps as the frequency source. Select Volts or A mps

Bandwidth

Frequency Source using the

The default bandwidth of 1 MHz is ideal for most measurements. Choose 'High'

keys and press to confirm.

to set the 1 MHz bandwidth. The measurement bandwidth may be reduced to

10 kHz or 50 kHz by choosing the respective setting. This setting introduces

a 10 kHz or 50 kHz digital FIR filter, depending on the selection, and may be

used to reduce unwanted high-frequency noise. Choose 10 kHz or 50 kHz

bandwidth when making low power standby measurements or for compatibility

with low -bandw idth instrumentation.

PA1000 Power Analyzer 21

Page 44

The menu system

Frequency filter

Shunts

For optimal fre

quency measurement perform ance when measuring volta ge signals

below 20 kHz, the Low Pass frequency filter can be engaged. If the signal level on

the voltage signal is less than 10% of range and the frequency is known to be less

than 20 kHz, the Low Pass frequency filter is recommended. Select Auto or Low

Pass using the

keys and press to confirm.

NOTE. The frequency filter does not affect the voltage measurement. The filter

is for the frequency detection.

The PA1000 is fitted with two internal shunts. The 20 A shunt is suitable for

measurements from 20 mA to 20 A

from 20 μA

to 1 A. These ranges may be extended by the use of suitable current

. The 1 A shunt is suitable for measurements

RMS

transducers from μAtoMA.

Some cur

rent transducers (including simple resistive shunts) produce a voltage

that is proportional to current. External Shunt Inputs are provided on the PA1000

for use with current transducers that provide a voltage output. Because the 0 V is

common to both the internal and external shunts, only one type may be connected

at any time.

Select Internal (20 A), Internal (1 A) or External Shunt using the

and press

to confirm.

keys

Blanking

Averaging

Further information is available. (See page 27, Connecting signals.)

mally enabled. Select Disable to measure voltage or current that are small.

Nor

If blanking operates on either voltage or current then all related measurements

would be blanked including W, VA and PF. S elect Disable or Enable using the

keys and press to confirm.

rmally disabled. Select Enable to allow the PA1000 to average results, for

No

more stable measurements of fluctuating signals. Averaging depth is set at four

when enabled. All results, including harmonic magnitude and phase, are averaged

except for ranges (when selected for display) and cumulative measurements

(Whrs, VAhrs, VArHrs, Ahrs, and Hrs). Select Disable or Enable using the

keys and press to confirm.

22 PA1000 Power Analyzer

Page 45

Graphs

The menu system

To set up the graphical displays of the PA1000, select the graph type using the

keys and press for options.

Hint: Use the YZ key to toggle between graphic and numeric displays.

Waveform graph

Harmon

ic bar chart

This will display the voltage, current and (optionally) the Watts waveform. The

scale of the graph is set automatically according to the selected range and scaling.

Display of the Watts graph may be disabled.

Use the

Graph. Select ‘Watts’ to add the instantaneous watts waveform to the display.

NOTE. Waveforms will only be displayed when there is a valid frequency. DC

waveforms will not be displayed.

Select Voltage or Current harm onic bar chart using the keys and press

for details.

The scale is the maximum amplitude that will be displayed. Set the scale to be

similar to the rms value to see an overview of the spectrum. To view smaller

harmonics in more detail a smaller scale may be set.

If the harmonic exceeds the set scale it will be shown with a white cap on the

top of the bar.

The scale only applies when the harmonic format is absolute measurements. If

percentage measurements are used, then the scale is automatically set to 100%.

The fundamental harmonic (H1) will be displayed as 100%.

keys to select Show and then press to display the Waveform

The right

amplitude and phase are shown at the top of the screen. The selected harmonic

is shown in yellow. Select

bar chart (voltage or current).

Integration graph

PA1000 Power Analyzer 23

elect Integration g raph using the

S

The Integration Graph menu allows the user to select what value to display on

the graph and the vertical scale of the graph (in units of the value selected). The

horizontal scale of the graph is only for display purposes. The integration will

continue until stopped by the user using the start/stop button

key

NOTE. Useoftheresetkey

and left arrow keys may be used to select the harmonic whose

Show and press to display the harmonic

keys, press to configure.

.Thereset

can be used to reset the accumulated values.

requires the integrator to be stopped.

Page 46

The menu system

Interfaces

Ethernet configure

GPIB address

When the graph i

PA1000 must be in Integrator mode for the graph to start.

This menu may be used to set up the interfaces of the PA1000.

To select set up an interface, use the

options.

Enter the GPIB address and press OK.

Default address is 6. The address is unchanged after a “*RST” or “:DVC”

command.

The PA1000 offers Ethernet communications through an Ethernet port using

TCP/IP.

The Ethernet port will make a TCP/IP connection on port 5025. Port 5025 is

designated by the Internet Assigned Numbers Authority (IANA) to be a SCPI port.

Use the IP Selection Method menu, and the

assigned IP address, by selecting “Set IP using DHCP”, or a fixed/static IP address

by selecting “Fix IP Address” with the

sconfigured, select Show to view the graph. Note: The

keys, and then press for detailed

keys to opt for a dynamically

button.

System configuration

Harmonics setup

To view the current IP settings, choose “Current IP Settings” in the Ethernet

Setup menu. This allows you to view the current IP address, subnet mask, and

default gateway.

To configure the static IP address, choose “Static IP Settings” in the Ethernet

Setup menu. This allows you to enter the IP address, the subnet mask and the

default gateway. After entering the relevant data, press the OK button in each

nu to apply.

me

The Ethernet m ode (Static/DHCP), IP address, default gateway and subnet mask

reunchangedaftera“*RST”or“:DVC”command.

a

Set up harmonics, distortion, the clock and auto zero.

To select a menu item, use the

For both voltage and current harmonics, a number of different parameters can be

set. These setting are independent of the m ode that is currently selected:

keys and then press for detailed options.

24 PA1000 Power Analyzer

Page 47

The menu system

Distortion setup

Sequence: All o

Range: The maximum harmonic (up to 50)

Format: Displa y harmonics as absolute values or as a percentage of the

fundamental (1st) harmonic.

For both voltage and current harmonics, a number of different parameters can be

set. These settings are independent of the mode that is currently selected. Four

following settings can be made for distortion:

Formula: Series (Total Harmonic Distortion) or difference (Distortion Factor).

(The default = series formula)

Sequence: Include all harmonics or only odd harmonics in the series formula.

(default = all harmonics)

Range: The maximum harmonic to be included in the series formula. (default

=7)

DC (H0): Include or exclude D C in the series formula. (default = exclude)

Reference: rms or 1st harmonic. (default = rms)

For details of the actual equations used, (See page 76, Measured parameters.)

r odd harmonics only

Auto and Manual Zero

Normally the PA1000 will cancel any small dc offsets in the m easurement

automatically. This feature i

Auto Zero. Auto Zero should always be enabled except in certain applications

such as Inrush current measurement.

Select

Manual Zero. Manual zero is a procedure normally carried out during periodic

calibration of the PA1000. The procedure cancels dc offsets in the measurement

system by making measur

We recommend a manual zero is performed:

During routine service (calibration or repair).

After firmware upgrade.

Before very low-level measurements (for example below 100 uA).

To perform a manual zero:

1. Allow the PA1000 to warm up for 1 hour.

2. Remove all voltage and current inputs.

3. Select Run Manual Zero Offset and press

prompt you after a few seconds when the process is complete.

Disable and Enable and press to confirm.

sreferredtoasAutoZero.

ements with nothing connected to the input terminals.

to confirm. The analyzer will

PA1000 Power Analyzer 25

Page 48

The menu system

Unit configu

User confi

Clock setup

ration

guration

These options m

menu item, use

Set Time - Enter the time using the format shown and press OK to confirm.

Set Date - Enter the date using the format shown and press OK to confirm.

Time Format - Selec t

Date Format - Select

The Unit Configuration menu displays the hardware revision, firmware revision,

serial number, date of last adjustment and verification.

The PA1000 has the ability to store and recall up to 5 different setups.

To select a menu item, use the

The first option is to ‘Load Default’. Choosing this option sets every menu option

of the PA1000 to its factory default.

ay be used to che ck or set the PA1000 i nternal clock. To select a

the

keys and then press for detailed options.

12 Hour or 24 Hour and press to confirm.

the required date format and press to confirm.

keys and then press for detailed options.

V

iew

Zoom

The other menu items (Default ‘CONFIGURATION n’) may be used to store

and recall all settings of the PA1000.

For each User Configuration you can go into a sub menu and you may:

Apply

Rename – give the configuration a meaningful name. A name can be up to

Save Current – save a configuration. This is always the com plete setting o f

NOTE. Loading a configuration that has never been saved will result in an error

message. The current configuration of the unit will not be changed.

To select a menu item, use the keys and then press for detailed options.

Use the Zoom function to select the number of measurement results that are

displayed on the instrument screen. The selections are either 4 or 14. Select

— either 4 results or 14 results display and press to confirm.

– apply the saved configuration.

aracters.

16 ch

PA1000 at the time you choose this option.

the

26 PA1000 Power Analyzer

Page 49

Connecting signals

Connecting si

Input overview

Voltage

Curren

gnals

WAR N ING. To avoid possible electric shock o r personal injury:

· Do not touch connections, internal circuits or measuring devices that are not

connected to earth ground.

· Always ad

page 5, Connection sequence.)

Signal le

Voltagesofupto600V

VHI and VLO safety sockets at the front of the PA1000.

Currentsofupto20A

t

AHI and ALO safety sockets at the front of the PA1000 Alternatively, if you

are making measurements of less than 1 A

measu

here to the instructions regarding the sequence of connection. (See

ads are connected on the front of the PA1000.

may be connected directly to the red and black 4 mm

RMS

may be connected directly to the blue and black 4 mm

RMS

,2Apk, connect the current to be

RMS

red between the yellow A1A and black ALO connections.

External current input

The external current input, EXT AHI, accepts voltages up to 1.25 V

proportional to the current being measured. This input allows a very wide range

xternal current transducers to be connected, from low -milliamp current shunts

of e

to mega-Amp current transformers. For each type of transducer, the PA1000 may

be scaled to read the correct current. (See page 21, Inputs.)

The choice of current transducer will depend on:

he current being measured, including peaks and transients

T

The accuracy required

The bandwidth required: Unless the waveforms are purely sinusoidal, a

bandwidth in excess of the fundamental frequency will be required.

Whether there is DC current present

Convenience of connection – that is, using a clamp-on current transformer,

with jaws that open, for quick connection in a fixed wiring loom.

The effect of the transducer on the circuit

peak

that are

PA1000 Power Analyzer 27

Page 50

Connecting signals

To connect a si

mple current transformer

To use a conventional current transformer (CT) like the Tektronix CL series

(or any other transducer with a current output), connect the normal AHI and

ALO inputs of

manufacturer’s instructions for the safe use and installation of the transducer.

Normally th

point of an arrow or a + symbol. Connect this terminal to the a ppropriate AHI