Page 1

Safety symbols on the product

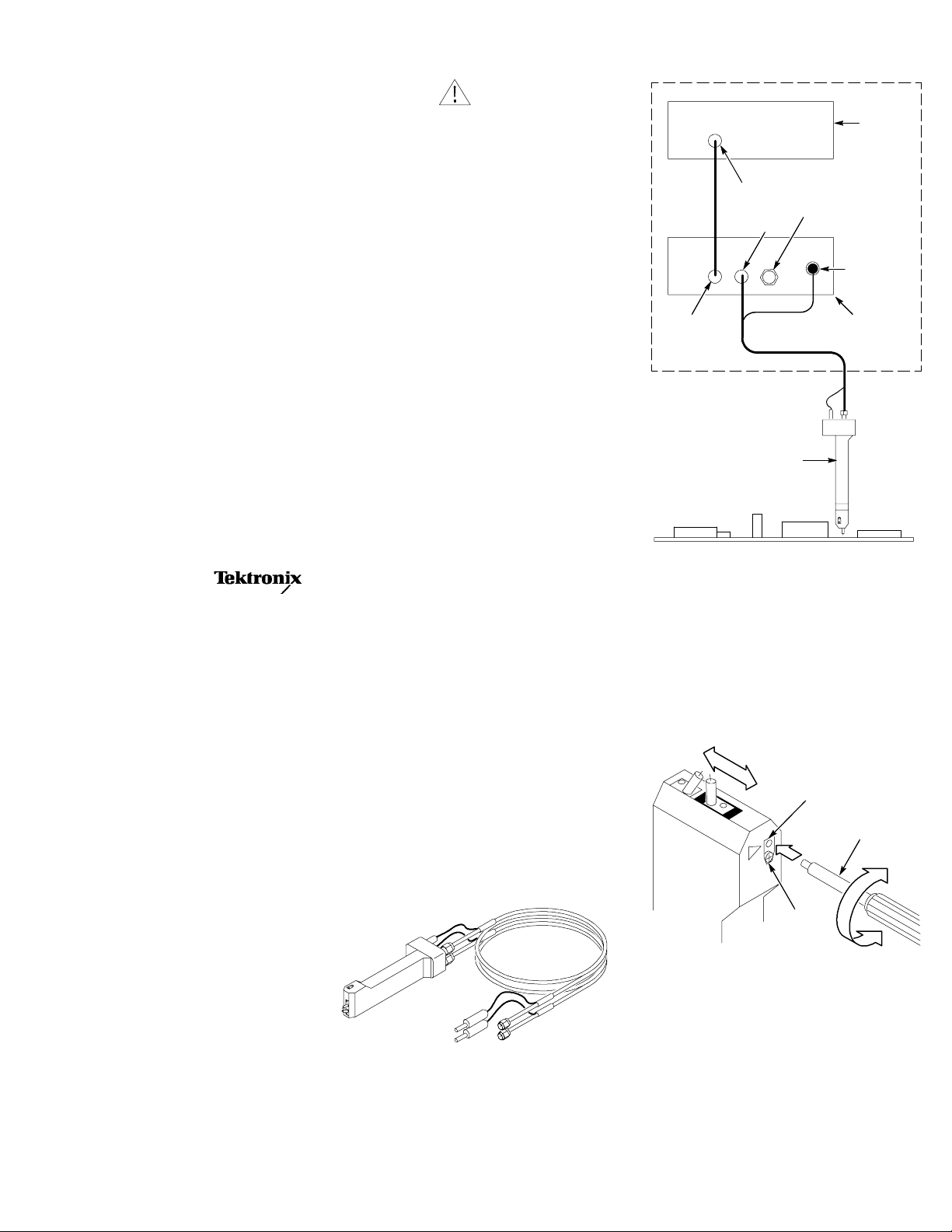

Connecting the Probe

P80318

Handheld Differential

Impedance Probe

Instructions

www.tektronix.com

*P071177501*

071-1775-01

Safety Summary

To avoid potential hazards, use this product only

as specified.

To avoid fire or personal injury

Ground the product. This product is indirectly

grounded through the grounding conductor of

the mainframe power cord. To avoid electric

shock, the grounding conductor must be connected to earth ground. Before making connections to the input or output terminals of the

product, ensure that the product is properly

grounded.

Connect and disconnect properly. Do not connect

or disconnect probes or test leads while they are

connected to a voltage source.

Observe all terminal ratings. To avoid fire or shock

hazard, observe all ratings and markings on the

product. Consult the host instrument documentation for further ratings information before making connections to the host instrument.

Do not apply a potential to any terminal,

including the common terminal, that exceeds the

maximum rating of that terminal.

Do not operate with suspected failures. If you

suspect there is damage to this product, have it

inspected by qualified service personnel.

Do not operate in wet/damp conditions.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

Copyright E Tektronix. All rights reserved.

CAUTION

Refer to Product Manual

Product End-of-Life Handling. Observe the following guidelines when recycling an instrument

or component:

Equipment Recycling. This product complies

with the European Union’s requirements according to Directive 2002/96/EC on waste electrical

and electronic equipment (WEEE). For information about recycling options, check the Support/

Service section of the Tektronix Web site

(www.tektronix.com).

Restriction of Hazardous Substances. This

product has been classified as Monitoring and

Control equipment, and is outside the scope of

the 2002/95/EC RoHS Directive. This product is

known to contain lead and hexavalent chromium.

Warranty Information

For warranty information, go to

www.tektronix.com, click Support, and then

select Look Up Tektronix Warranty.

Probe tips and the ground wires are consumable

items and are not covered by the warranty.

Standard Accessories

The P80318 probe includes the following items:

H 2 one-meter SMA cables, each

with a parallel control line

H 3 ground wires (1 installed, 2 spares)

H Adjustment tool

H Vinyl probe tip protection cap

H 2 strap sets for fastening together the cables.

Product Description

The P80318 High Performance 100 Ohm

Differential Impedance Hand Probe provides

users a differential hand probe with adjustable

spacing tips, EOS/ESD protection (with the

Tektronix 80A02 EOS/ESD Protection Module),

and a unique double spring mechanism that

provides physical feedback to optimize probing

contact pressure. The probe is suitable for

probing differential runs on circuit boards, IC

package pins, and other devices that have a

0.5 mm to 4 mm pitch.

The P80318 probe is designed to be used with

the Tektronix 80A02 EOS/ESD Protection

Module. Together, they protect sensitive

instrument-input stages, such as the sampling

bridge of Tektronix electrical sampling modules,

from electro-overstress (EOS) and electrostatic

discharge (ESD) damage due to static charges

stored in the device under test (DUT).

Sampling

module

Input

Input

Output

Repeat for second cable

P80318 probe

DUT

50 Ω

termination

Control

80A02 Module

Connector Care

Use extra care when attaching or removing the

cable SMA connectors from the probe. Turn only

the nut, not the cable. When attaching the cable,

align the connectors carefully before turning the

nut. Use light finger pressure to make this initial

connection. Then tighten the nut lightly with a

wrench. Ideally, tighten the SMA connectors to

56 N-cm (5 in-lb) with a torque wrench.

Adjusting Probe Tip Gap

Adjustment hole

Adjustment tool

Adjustment

tension

Probing Guidelines

H The P80318 uses a unique double spring

mechanism that provides physical feedback

to optimize probing contact pressure. When

applying pressure after the initial contact to

the DUT, the first spring engages and the

probe tips retract with the first spring pressure. As you apply more pressure, the second

spring engages, increasing the probe compression resistance. This sudden increase in

stiffness is the correct operation zone. In-

Page 2

creasing pressure beyond this point accelerates probe tip wear and is not recommended.

Optimum probe tip

pressure

Probe tip pressure

Probe tip travel

H When the probe engages the second spring,

the probe sends a control signal to the 80A02

EOS/ESD protection module to enable the

signal path.

H Do not scrape or otherwise drag the probe

tips on the board traces or DUT leads in an

attempt to improve signal contact. Make

sure that the contact area is clean before

using the probe.

H Do not bend or shape the ground wire.

Improper bending of the wire can reduce

signal acquisition bandwidth or accuracy.

H Cover the probe tip when not in use with the

vinyl probe cover.

H When using the P80318 probe with auto-

mated probing stations, do not exceed

0.040 inches travel from initial DUT contact.

Removing/Installing the Ground Wire

Step 1

Set probe tips to maximum gap

Useknifetiptolift

end of wire

Step

2

Pull out old

wire with

tweezers

Step 3

Use tweezers to hold the new

wire. Insert the wire end ~1/3

length into the small hole

Step 4

1

Apply light pressure

against the wire to

keep in position

2

Pivot wire to position it on top of the support block.

Then use flat blade end of adjustment tool to push

wire down between block and probe tip.

Step 5

Push end of wire down

into hole. Insert screw

after wire is positioned

Ground wire is under tension during

installation and can easily spring away

Clamping the Probe for Fixtured Probing

Clamp

zone

Specifications

Table 1: Electrical

Characteristic

Probe impedance

Probe delay 1 ns typical from the female

Attenuation 1X

Risetime, probe head

and cable

Bandwidth, probe head

and cable, calculated

Maximum voltage input

RF input connector Precision 26 GHz SMA female

Control signal connector

type

Table 2: Environmental mechanics

Characteristic

Probe dimensions

Length 127.0 mm (5.0 in)

Height 33.0 mm (1.30 in)

Width 28.0 mm (1.10 in)

Weight (probe only) 0.075 kg (0.165 lbs)

Altitude

Operating 3,000 m (9,843 ft)

Non-operating 12,190 m (40,000 ft)

Ambient temperature

Operating --15 _C to +55 _C

Non-operating -- 6 2 _C to +85 _C

Humidity

Operating 20% to 80% relative humidity

Specification

50 Ω ±1.5 Ω, single ended,

each polarity.

SMA connector end to the

probe tip.

19.4 ps or better, one-way

transit, differential drive, with

minimum probe tip spacing (for

a 100 ps window with 50%

threshold crossing at center of

screen).

18 GHz or better, using above

risetime calculation and

assuming 0.35 product of

risetime and bandwidth.

±5.0 V (DC + AC

connector

Audio mono phone mini-jack

Specification

(+5 _F to +131 _F)

(--80 _F to +185 _F)

with a maximum wet bulb

temperature of +29 _Cator

below +40 _C,

non-condensing. (Upper limit

derates to 45% relative

humidity at +40 _C.)

p-- p

)

Loading...

Loading...