Page 1

P7630

xx

ZZZ

TriMode™ Probe

Technical Reference

*P077068001*

077-0680-01

Page 2

Page 3

xx

P7630

ZZZ

TriMode™ Probe

Technical Reference

www.tektronix.com

077-0680-01

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

TriMode is a trademark of Tektronix, Inc.

Velcro is a registered trademark of Velcro Industries B.V.

G3PO is a trademark of Corning Gilbert Inc.

Contacting Tektronix

Tekt roni

14150 SW Karl Braun Drive

P.O . Bo x 5 0 0

Beaverton, OR 97077

USA

For pro

x, Inc.

duct information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldw i d e , visit www.tektronix.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, with shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location w ithin

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other than Tektronix representatives to install, repair or service the product;

Page 6

Page 7

Table of Contents

General safety summary ........ ................................ .................................. ................ iv

Preface ............................................................................................................. vii

Theory of Operation....................... ................................ ................................ ......... 1

Introducti

TriMode Operation ....... .................................. ................................ ................... 6

Operating Voltages............................................................................................. 8

Input Impedance and Probe Loading ....... ................................ ................................ 14

Scale Factor ................................................................................................... 16

Probing Techniques to Maximize Measurement Fidelity . . ... . ... . ... . . ... . ... . ... . ... . ... . ... . ... . ... . . 17

Referen

Single-Ended Measurements Using A and B Modes ......... ................................ ............ 23

Differential Measurements................................................................................... 24

Specifications ................................ ................................ .................................. .... 27

Warranted Characteristics.................................................................................... 27

Typical Characteristics ............. ................................ ................................ .......... 30

Nomi

User Service ........................................................................................................ 35

Error Condition . . ... . ... . ... . ... . ... . ... . ... . ... . ... . ... . ... . ... . ... . ... . ... . ... . ... . ... . ... . ... . .. . . .. . . .. . . . 35

Replaceable Parts ............................................................................................. 35

Preparation for Shipment .............. ................................ ................................ ...... 40

Index

on.............................. ................................ ................................ ....... 1

ce ........................................................................................................... 23

nal Characteristics...................................................................................... 34

P7630 TriMode Probe Technical Reference i

Page 8

Table of Contents

List of Figure

Figure 1: Adapters for the P7630 probe.......................................................................... 3

Figure 2: Pr

Figure 3: TriMode input structure ................................................................................ 7

Figure 4: Typical TriMode Probe Setup screen ......... ................................ ....................... 7

Figure 5: Probe inputs ........................ ................................ ................................ ..... 8

Figure 6: Operating voltage window ............................................................................ 9

Figure 7: Dynamic range versus linearity .......................... ................................ ............ 10

Figure 8:

Figure 9: Probe Setup screen..................................................................................... 12

Figure 10: TriMode probe coaxial input model.... ................................ ............................ 14

Figure 11: P76TA adapter simplified schematic ............................................................... 15

Figure 12: P76TA adapter and P75PST tip equivalent schematic........................ .................... 15

Figure 13: Preventing twist to the coaxial input cables ................... ................................ .... 17

Figur

Figure 15: Solder ramp installed......................... .................................. ...................... 18

Figure 16: Typical wire length from probe tip to circuit ...................................................... 20

Figure 17: P75TLRST solder tip with 0.010 in. of tip wire .................................................. 21

Figure 18: P75TLRST solder tip with 0.050 in. of tip wire .................................................. 21

Figure 19: P75TLRST solder tip with 0.100 in. of tip wire .................................................. 22

gure 20: P75TLRST solder tip with 0.200 in. of tip wire .................................................. 22

Fi

Figure 21: Simplified model of a differential amplifier ....................................................... 24

Figure 22: Typical CMRR ... .................................. ................................ .................. 25

Figure 23: Typical channel isolation ............................................................................ 26

Figure 24: Typical rise time ...................................................................................... 31

Figure 25: Typical frequency response.......................... ................................ ................ 31

Figure 26: Probe body and control box dimensions........................................................... 32

Figure 27: P7630 Probe adapter dimensions .................... .................................. ............ 33

Figure 28: P75PST and P75TLRST solder tip dimensions................................................... 33

Figure 29: Removing the bullets................................................................................. 36

Figure 30: Installing the bullets. . . ... . ... . ... . ... . ... . ... . ... . ... . ... . ... . ... . ... . ... . . .. . . .. . . .. . . .. . . ... . ... . .. 37

obe Tip Selection screen.............................. .................................. ............. 4

Termination voltage operating range ...................... ................................ .......... 11

e 14: P75PST and P75TLRST TriMode Solder Tips.............................. ...................... 18

s

ii P7630 TriMode Probe Technical Reference

Page 9

List of Tables

Table 1: Offset ranges....... ................................ .................................. .................... 23

Tabl e 2: War

Table 3: Warranted environmental characteristics..... ................................ ........................ 29

Table 4: Typical electrical characteristics................. .................................. .................... 30

Table 5: Typical mechanical characteristics .................................................................... 30

Table 6: Nominal electrical characteristics ....... ................................ .............................. 34

Table 7: Nominal adapter electrical characteristics.................. ................................ .......... 34

Tabl e 8: T

Table 9: Required equipment..................... ................................ ................................ 35

ranted electrical characteristics . ................................ ................................ .. 27

riMode probes replaceable parts ....................... ................................ .............. 35

Table of Contents

P7630 TriMode Probe Technical Reference iii

Page 10

General safety summary

General safet

To avoid fire or personal

injury

ysummary

Review the fo

this product or any products connected to it.

To avoid pot

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions r

Connect and disconnect properly. Connect the probe output to the measurement

instrument before connecting the probe to the circuit under test. Connect the

probe reference lead to the circuit under test before connecting the probe input.

Disconnect the probe input and the probe reference lead from the circuit under test

before

Observe all terminal ratings. To avoid fire or shock hazard, observe all ratings

and ma

information before making connections to the product.

Do no

exceeds the maximum rating of that terminal.

disconnecting the probe from the measurement instrument.

t apply a potential to any terminal, including the common terminal, that

llowing safety precautions to avoid injury and prevent damage to

ential hazards, use this product only as specified.

elated to operating the system.

rkings on the product. Consult the product manual for further ratings

ot operate without covers. Do not operate this product with covers or panels

Do n

removed.

ot operate with suspected failures. If you suspect that there is damage to this

Do n

product, have it inspected by qualified service personnel.

oid exposed circuitry. Do not touch exposed connections and components when

Av

power is present.

o not operate in wet/damp conditions.

D

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

iv P7630 TriMode Probe Technical Reference

Page 11

General safety summary

Terms in this manual

Symbols and terms on the

product

These terms may

WAR NING . Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

DANGER in

the marking.

WAR NI NG

read the marking.

CAUTIO

The following symbol(s) may appear on the product:

appear in this manual:

dicates an injury hazard immediately accessible as you read

indicates an injury hazard not immediately accessible as you

N indicates a hazard to property including the product.

P7630 TriMode Probe Technical Reference v

Page 12

General safety summary

vi P7630 TriMode Probe Technical Reference

Page 13

Preface

This manual discusses topics that are not covered in depth in the P7630 TriMode

Probe Quick Start User Manual.

The main sections are:

Theory of Operation — Contains probe details not covered in the user manual.

Reference — Contains information about differential m easurements and how

to increase measurement accuracy.

Specifications — Contains warranted, typical, and nominal characteristics for

the probe, probe adapters and probe tip accessories.

User Service — Describes troubleshooting and probe maintenance.

P7630 TriMode Probe Technical Reference vii

Page 14

Preface

viii P7630 TriMode Probe Technical Reference

Page 15

Theory of Operation

This section discusses operating considerations and probing techniques. For more

detailed information a bout differential measurements and TriMode operation,

refer to Refe

Introduction

rence. (Seepage23.)

Probe Components

The P7630 T

and DPO73304D oscilloscopes. These oscilloscope models feature an

extended-bandwidth version of the TekConnect probe interface designed to

support bandwidths up to 33 GHz. The P7630 probes contain probe-specific

S-parameter data that, when transferred to the host oscilloscope after the initial

connection is made, create unique system DSP filters.

The P7630 TriMode probe is optimized for high bandwidth; it is not a

general-purpose probe. The P7500 Series probe solder tips that can be used

with th

circuitry, and must be handled carefully.

The P7630 probe is comprised of a control box, an active probe head, and an

connect cable that transfers measured signals, power, and control signals

inter

between the control box and probe head. An optional adapter is required on the

probe head to make the final connection to the DUT (device under test).

Control box. The P7630 probe control box assembly mates to the host instrument

through an extended-bandwidth, 33 GHz TekConnect probe interface. The control

includes a membrane toggle switch to select the TriMode input mode:

box

Differential (A–B)

riMode probe is a 30 GHz probe designed for use with DPO72504D

e probe are m iniaturized for electrical characteristics and a ccess to dense

A input (single-ended to ground)

B input (single-ended to ground)

Common-mode (A+B/2 to ground)

The probe input mode can also be selected using the host oscilloscope Probe

Control menu.

LEDs on the control box front and top panels indicate the selected input mode.

Another LED on each panel indicates when an overload condition exists.

Overloads are caused when parameters such as input voltages or termination

voltage driver currents exceed the safe limits of the probe.

P7630 TriMode Probe Technical Reference 1

Page 16

Theory of Operation

A mechanical la

instrument during use. The thumbscrew is only intended to be finger-tightened,

and is machined to prevent tools from being used to over-torque it. To remove

the probe, loosen the thumbscrew counterclockwise, depress the latch button to

release the probe, and then pull out the probe.

CAUTION. To prevent damage to the probe, use care when handling the probe.

Rough or car

Interconnect cable. This cable consists of a low-loss coaxial signal cable that

carries t

includes a 20-conductor bundle of wires that supply probe head power and control

signals from the control box. Some of the wires carry bidirectional data, such as

queries and responses about the type of probe adapter that is attached to the probe

head, and other probe-specific information.

Probe h

and other support circuitry that precondition the acquired signals. It connects to

the optional coaxial and solder tip adapters through a connector that, like the

interconnect cable, carry signal, control and power signals.

The P7630 probe head is intended to be placed close to the DUT test point,

within the final few inches (6 inches or less, for best performance), made with the

optional coaxial and solder tip adapters.

he acquired signal from the probe head to the control box. The cable also

ead. The probe head is an active component that houses an amplifier

tch and retention thumbscrew hold the probe securely to the

eless use can damage the probe.

pters. The P7630 probe requires optional TriMode adapters to complete the

Ada

connection between the probe and your circuit. (See Figure 1 on page 3.) The

adapters connect the P7630 probe to your circuit through 2.92 mm or SMP coaxial

cables. For soldered, in-circuit connections, the connection is made through

P7500 Series solder tips, such as the P75PST Performance Solder Tip.

There are several different coaxial tips available for the probe, which differ only

in the tip connector type or the tip cabling. All of the coaxial tips provide a 50

ohm transmission line signal path from its input connector to the termination

resistor at the probe amplifier input.

The adapter inputs are polarized, with the A input marked in red and the B input

marked in black. All of the adapters are secured to the probe head with a 2 mm

hex screw. Although the adapters can be “hot-plugged” (with the probe connected

to the oscilloscope and powered on), the adapters should first be connected to

the probe before the probe is connected to the instrument. This ensures a good

power-on sequence for both the probe and attached adapter. After the probe

is powered on with an attached adapter, data is transferred from the adapter,

identifying it to the probe and oscilloscope.

2 P7630 TriMode Probe Technical Reference

Page 17

Figure 1: Adapters for the P7630 probe

1. P76CA-292: 2.92 mm Coax Adapter

Theory of Operation

2. P76CA-292C: 2.92 mm Coax Adapter with cables

3. P76CA-S

4. P76TA: P7500 TriMode Solder Tip Adapter (shown with P75PST

Perfor

Use the P76CA-292 adapter with high bandwidth, low skew (<2 ps) cable pairs

ave short (<6 in) lengths and high-quality male 2.92 mm connectors at the

that h

probe end. The other end of the cables can be customized with connectors that

mate to your circuit.

MP: SMP Coax Adapter with cables

mance Solder Tip)

P7630 TriMode Probe Technical Reference 3

Page 18

Theory of Operation

P7500 Series so

soldered connections to the DUT. You must manually choose the solder tip that

you are using in the Probe Tip Selection screen. (See Figure 2.) This enables the

correct DSP filtering to be used for your measurements. Maximum probe solder

tip performance is only provided by the P75PST Performance Solder Tip.

Figure 2

: Probe Tip Selection screen

lder tips. These tips are used with the P76TA adapter to make

4 P7630 TriMode Probe Technical Reference

Page 19

Theory of Operation

Probe Input Architecture

The input struc

tip versions, and are discussed below.

Coaxial Adapters. When a P76CA-xxx coaxial adapter is attached to the P7630

probe, it provides a low VSWR, 50 ohm terminated input for taking TriMode

differential signaling measurements. In order to provide low noise measurement

performanc

attenuation, which results in a relatively low dynamic range limit. The P7630

probe has a quite large Offset Voltage and Termination Voltage adjustment range,

however, which enables optimum placement of the probe dynamic range within

the larger operating voltage window.

Low noise performance is also enhanced in the P7630 probe by the

design of the probe amplifier, which features five step gain settings

(0.25X/0.5X/1.0X/2.0X/4.0X). This step gain control enables lower noise

perform

channel scale factors. The optimum step gain setting is automatically selected by

the host oscilloscope, based on the selected vertical channel scale factor.

Solder Tip Adapter. When a P76TA solder tip adapter and P75PST solder tip

are attached to the P7630 probe, it provides a passive attenuation of the input

signa

structure, which is enhanced by the adjustable termination voltage capability

of the P7630 probe. For the common use case of probing a doubly-terminated

50 ohm transmission line, this results in a 5X broadband attenuation and a 225

ohm loading. (See Figure 12 on page 15.) The signal loss due to this broadband

loading is automatically compensated by boosting the measured signal gain,

as

ance by boosting the signal output amplitude at the more sensitive vertical

l to the probe. This passive attenuation network forms a Z0 probe input

suming a 25 ohm signal source impedance.

ture of the probe adapters differ between the coaxial and solder

e, the coaxial adapters connect the input signal to the probe without

This input attenuation of 5X also expands the single ended dynamic range at the

older tip by the same 5X factor to ±3.0 V. (See Figure 6 on page 9.) The probe

s

noise is also increased by the same 5X factor due to the solder tip attenuation.

CAUTION. To avoid damaging the P75PST and P75TLRST solder tip resistors, do

not allow the termination voltage to differ from either the A or B input voltage by

more than 5 volts. The small size of the solder tip resistors expose them to thermal

damage within the operating conditions of the probe.

P7630 TriMode Probe Technical Reference 5

Page 20

Theory of Operation

TriMode Opera

tion

The TriMode feature of the P7630 probe is designed for improved convenience

and enhanced capability in measuring differential signal quality. Since a

differentia

full characterization of differential signal quality requires more than a simple

differential measurement. A TriMode probe features three Input Modes that allow

a differential signal to be fully characterized with four measurements: differential,

positive polarity and negative polarity single-ended, and common mode.

A TriMode probe provides improved efficiency and convenience by enabling full

differential signal characterization from a pair of coaxial cable connections or a

single soldered connection, depending on the type adapter used.

The P76CA-292C and P76CA-SMP coaxial adapters provide a pair of integral

6-inch coaxial leads with male 2.92 mm or female SMP connectors at the cable

ends. Th

to allow for an off-the-shelf or custom cable connection to the DUT. Coaxial

adapters provide a TriMode signal ground connection through the integral DUT

connector shield connections.

Using a P76TA adapter and one of the P7500 series solder tips available for

the TriMode probes, (for example, the P75PST probe tip), probe connections

are soldered to the two complementary signals (the A signal and the B signal)

and a ground reference. From this single DUT (device under test) connection,

the

of the three probe Input Modes (four measurements) to be selected at a time.

The TriMode probe inputs are routed on the probe ASIC (application-specific

integated circuit) to a set of four independent input amplifiers that perform the

following signal calculations:

l signal is composed o f two complementary single-ended signals,

e P76CA-292 adapter has two female 2.92 mm coaxial connectors

internal electronic switching control of the TriMode probe allows any one

A – B (for differential signal measurement)

A – GND (for positive polarity single-ended measurement)

B – GND (for negative polarity single-ended measurement)

[A+B]/2 - GND (for common mode measurement)

NOTE. In the B – GND Mode, the negative polarity B input is not inverted.

The four input amplifiers are multiplexed together and only the selected Input

Mode function is output to the connected oscilloscope. (See Figure 3 on page 7.)

The figure shows a conceptual view of the TriMode probe input structure, where

the C input provides the probe ground reference and is connected to the probe tip

ground interconnect using the probe tip cable coaxial shields.

6 P7630 TriMode Probe Technical Reference

Page 21

Theory of Operation

Figure 3: TriMode input structure

On oscilloscopes that provide full TriMode support, the oscilloscope-controlled

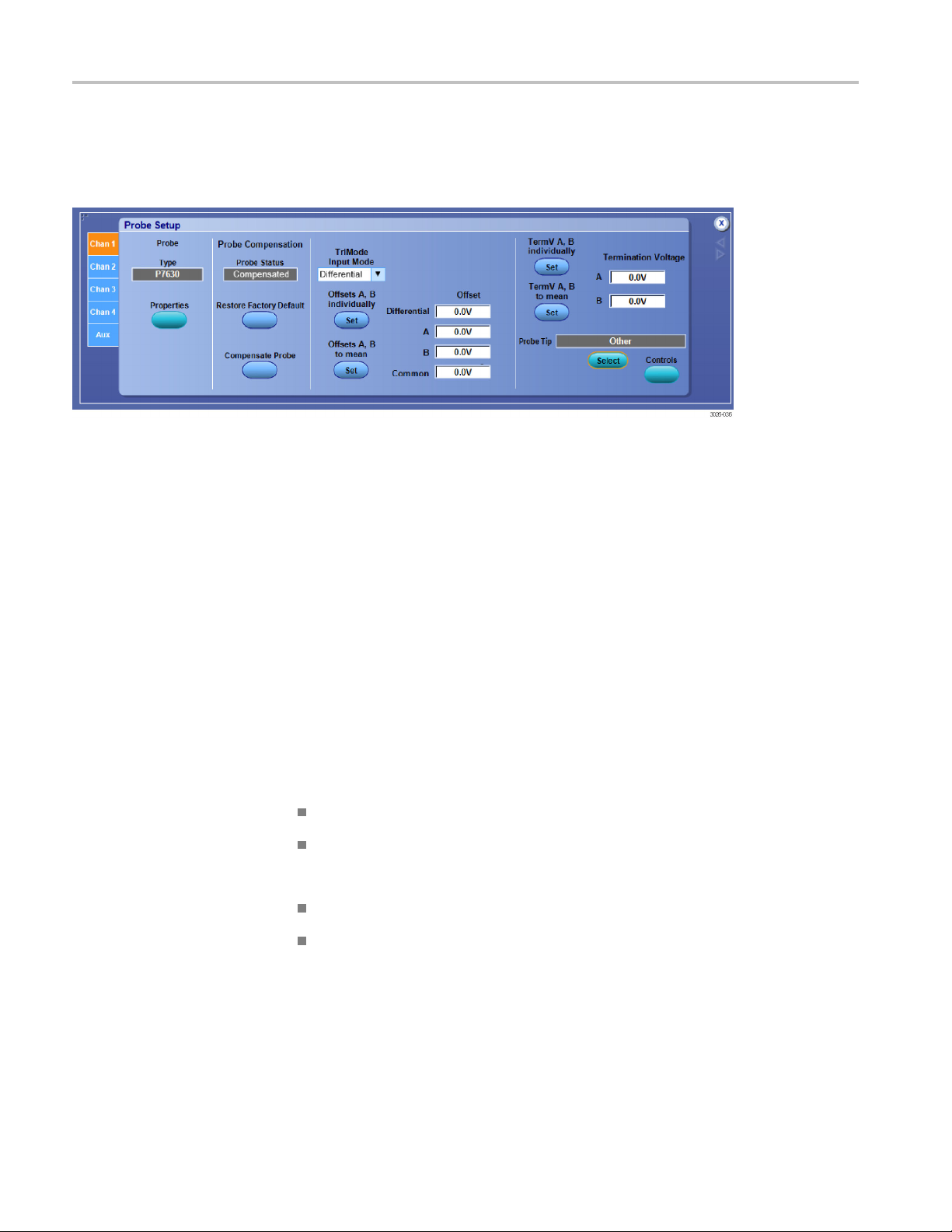

probe G

operation on all Input Modes and Attenuation Settings at once using the Probe

DC Calibration fixture that is supplied with the P7630 probe. (See the P7630

Quick Start User Manual for instructions on running the Probe Cal routine.) Full

TriMode support will also allow storage and automatic recall of relevant settings

like Offset Voltage and Termination Voltage. (See Figure 4.)

Figure 4: Typical TriMode Probe Setup screen

UI (graphical-user interface) can perform a Probe Compensation

P7630 TriMode Probe Technical Reference 7

Page 22

Theory of Operation

Operating Vol

tages

The P7630 TriMode probe is designed to probe low-voltage circuits. Before

probing a circuit, take into account the limits for the operating voltages discussed

in this secti

Input voltage

Operating voltage window

Input signal dynamic range

Offset voltage

Termination voltage

on.

Input

Voltage

Figure 5: Probe inputs

The maximum input voltage is the maximum voltage to ground that the inputs

can withstand without damaging the probe input circuitry. The maximum input

voltage differs between the type of adapter used; the limit for the coaxial adapters

5 V (DC + peak AC). The P76TA solder tip adapter can withstand up to ±8 V

is ±

(DC + peak AC). To avoid damaging the resistors on the P75PST and P75TLRST

solder tips, do not allow the A or B input voltage to differ from the termination

voltage by more than 5 volts. The small size of the solder tip resistors expose

them to thermal damage within the operating conditions of the probe.

CAUTION. To avoid damaging the inputs of the probe, when using the coaxial

dapters, do not apply more than ±5 V (DC + peak AC) between either probe

a

input and ground.

When using the P76TA solder tip adapter, do not apply more than ±8 V (DC +

peak AC) between either probe input and ground.

CAUTION. To avoid ESD damage to the probe, always use an antistatic wrist

strap (provided with your probe), and work at a static-approved workstation when

you handle the probe.

8 P7630 TriMode Probe Technical Reference

Page 23

Theory of Operation

Operating Voltage Window

The operating v

to each input, with respect to earth ground, without saturating the probe input

circuitry. (See Figure 6.) A common-mode voltage that exceeds the operating

voltage window may produce an erroneous output waveform even when the

dynamic range specification is met. The single-ended voltage range (shown as

squares in the figure below) represent the maximum signal swing at the dynamic

range limit

more sensitive on the host oscilloscope.

oltage window defines the maximum voltage that you can apply

s. The squares will shrink in size as the vertical scale factor is made

Figure 6: Operating voltage window

t Signal Dynamic

Inpu

Range

The input signal dynamic range is the maximum voltage difference between the A

and B inputs that the probe can accept without distorting the signal. The distortion

from a voltage that exceeds this maximum can result in a clipped or otherwise

ina

error over the dynamic voltage range of the probe. (See Figure 7.)

Th

as the single-ended signal dynamic range, but this is true only for complementary

A and B input signals. The single-ended A and B dynamic range limits still apply,

even for the case of a maximum differential mode input signal.

ccurate measurement. The graph on the fo llowing p age illustrates the linearity

e differential input mode dynamic range is specified to be almost twice as large

P7630 TriMode Probe Technical Reference 9

Page 24

Theory of Operation

Offset Voltage

The probe A and B

internal circuitry and the sensed values are used by the automatic Offset Voltage

Set control buttons. Two Set control buttons are available; set Individually and

set to Mean.

The Offset Voltage Control, accessible from both the attached oscilloscope

front-panel control and on-screen user interface, allows the probe dynamic range

to be effectively moved up and down within the limits of the offset voltage range

and the operating voltage window. When the offset voltage is set to zero volts and

the input s

signal should be zero volts. If a noticeable zero volt offset is present under the

above conditions, a Probe Compensation operation should be performed. (See the

P7630 Probe Quick Start User Manual).

ignal is zero volts (inputs shorted to ground, not open), the displayed

signal inputs ar e sensed, monitored, and averaged by probe

Figure 7: Dynamic range versus linearity

10 P7630 TriMode Probe Technical Reference

Page 25

Theory of Operation

Termination Voltage

When the probe i

similar to the Tektronix P7313SMA differential probe. Like an SMA-input probe,

the P7630 probe with a coaxial adapter features a user-adjustable termination

voltage, VTERM, which can be controlled independently for both the A and B

probe inputs. Adjustable termination voltage allows greater flexibility than is

possible with the more conventional grounded termination, enabling the user to

minimize DC

The user interface on the oscilloscope allows you to select a preset termination

voltage le

on the A and B inputs. You can also manually enter a value between –4.0 and +

4.0 volts in the on-screen Termination Voltage field.

The diagonal overload limits shown in the figure below are the result of current

limiting the termination voltage drivers to 50 mA. The flat upper and lower input

overload limits are the result of specified voltage limits for the probe amplifier.

vel (mean of both inputs o r independent), based on the voltages sensed

s used with a coaxial tip, i t operates like an SMA-input probe

probe loading from a DUT DC common-mode bias voltage.

Figure 8: Termination voltage operating range

An important limitation of the termination voltage exists when you are using

e P76TA adapter with the P75PST and P75TLRST solder tips. It is possible

th

to damage the solder tips by applying too much voltage to the tips, through a

combination of input and termination voltages.

CAUTION. To prevent exceeding the 62.5 mW power rating of the input resistors

on the solder tips, do not allow the termination voltage to differ from the input

voltage by more than 5 volts.

P7630 TriMode Probe Technical Reference 11

Page 26

Theory of Operation

Autoset of Offset and

Term ination Voltage

Figure 9: Probe Setup screen

You c a n se t b ot h

each input mode. For reference, the TriMode Input Mode field displays the active

input mode in the Offset area of the Probe Setup screen.

Offset Voltage. The offset voltage control sums an adjustable DC voltage with

the probe signal input. It is commonly used to null out an input DC bias voltage

to cente

input. The P7630 A and B probe inputs both have an independent offset voltage

control. Each of the four TriMode input modes also have an independently-stored

pair of offset voltage settings.

r the input signal swing within the linear dynamic range of the probe

the offset and termination voltages to levels that are unique for

Offset voltages may be automatically generated by the probe and can be selected

using the two Set buttons in the Offset section of the Probe Setup screen. You can

also enter specific offset values directly in the Offset fields.

There are four manual Offset Voltage value entry fields which also display the

current Offset Voltage settings. Although all four Offset Voltage value entry fields

are active, only two of the control pairs are independent. The manual controls

eract with each other as follows:

int

Adjusting the A or B settings affects the Differential and Common settings:

Differential = (A – B)

Common = (A + B)/2

Adjusting the Differential or Common settings affects the A and B settings:

A = Common + (Differential/2)

B = Common – (Differential/2)

12 P7630 TriMode Probe Technical Reference

Page 27

Theory of Operation

Termination Vo

voltage which drives the far end of the input termination resistor with a current

limited DC termination voltage. It is generally used to minimize the DC loading

of the probe on the input signal. The P7630 A and B inputs both have an

independent termination voltage control.

Each of the four TriMode input modes also have an independently-stored pair

of termination voltage settings. Termination voltages may be automatically

generated by the probe and can be selected using the two Set buttons in the

Term i nati

values for the A and B inputs directly in the Termination Voltage fields.

In genera

being driven from a relatively low impedance signal source. If the termination

voltage autoset button is activated when either the A or B probe input is open, the

current termination voltage effectively drives the input sense signal used by the

autoset feature. If the termination voltage autoset button is repeatedly actuated

with an open probe input, the termination voltage setting will begin to ramp in the

ion of the accumulated error voltage in the input sense signal path.

direct

ltage. The termination voltage control sets an adjustable DC

on Voltage section of the Probe Setup screen. You can also enter specific

l, the termination voltage autoset feature assumes that the input signal is

P7630 TriMode Probe Technical Reference 13

Page 28

Theory of Operation

Input Impedance and Probe Loading

When you connect the probe inputs to a circuit, you are introducing a new

resistance, capacitance, and inductance into the circuit.

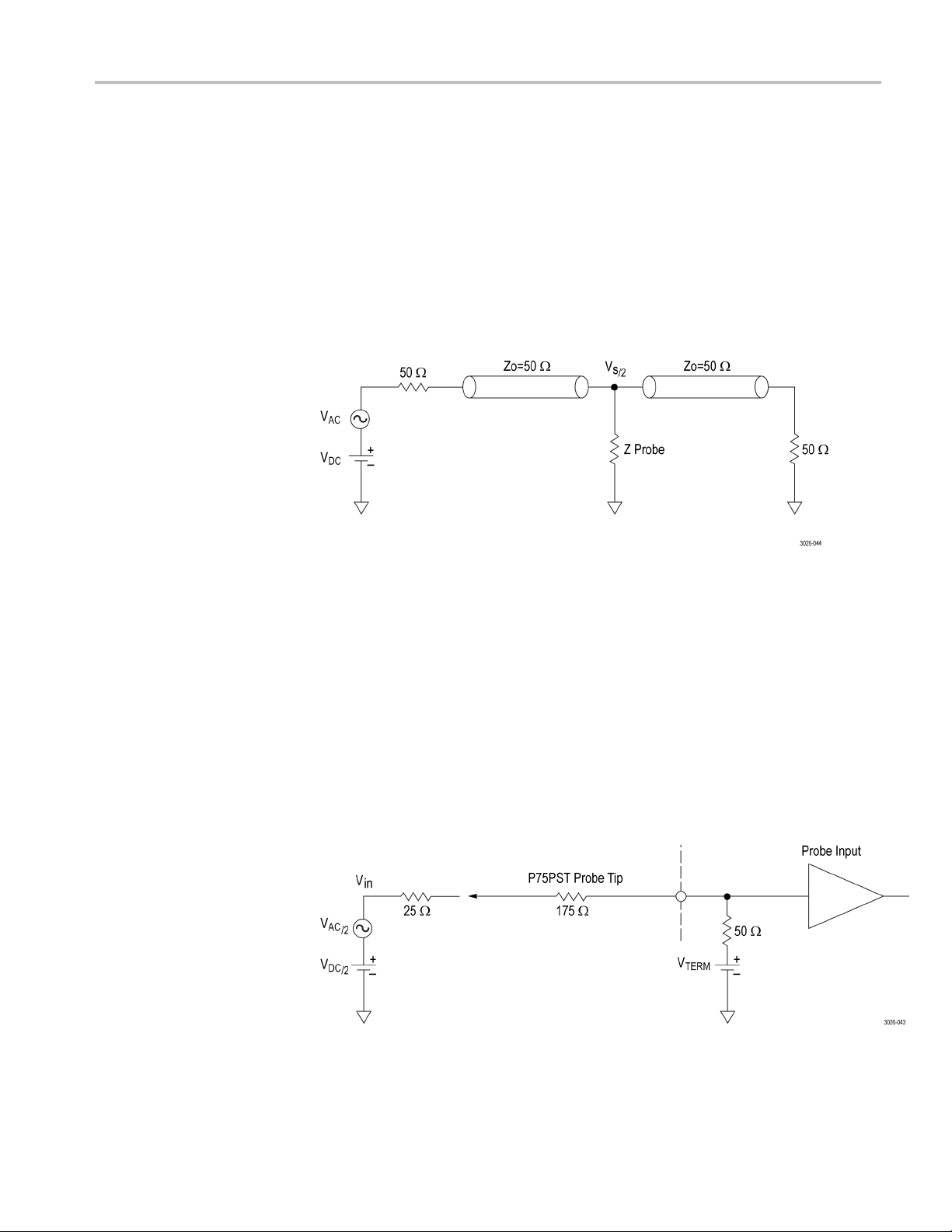

Coaxial Adapters

Each input of the P76CA–xxx adapters provides a 50 Ω transmission line signal

path from its input connector to the termination resistor at the probe amplifier

input. (See Figure 10.) A P7630 probe coaxial tip simplified input schematic

is shown in the figure below.

Figure 10: TriMode probe coaxial input model

The high frequency signals that the P7630 probe is designed to measure typically

have a 50 ohm source impedance, as shown in the above schematic. The DUT

l, V

signa

, is transmitted to the P7630 probe coaxial tip through a 50 ohm

S

transmission line. The P7630 probe input termination resistor is intended to

provide a low discontinuity termination for the DUT signal.

The DUT signal source, V

, is represented in the above schematic as appearing at

S

the input to the P7630 probe coaxial adapter. The P7630 probe coaxial adapters

are calibrated to the adapter connectors for either AC or DC signals and are

compensated for the small DC signal loss in the coaxial adapter signal path.

The signal g ain through the P7630 probe amplifier, when used with a coaxial

adapter, is represented as a unity gain factor multiplied times the selected step

gain. The probe amplifier step gain is selected by the host oscilloscope control

nterface, based on the user-selected vertical scale factor for the vertical channel

i

to which the probe is attached.

14 P7630 TriMode Probe Technical Reference

Page 29

Theory of Operation

Solder Tip Adapter

The P76TA adapt

Series TriMode probe tips to be attached to a P7630 probe. P7500 Series probe

tips have a nominal 5X attenuation structure when used with a 50 Ω input

termination device like the P7630 p robe.

The use of a passive attenuation input pick-off resistor at the P7500 Series probe

tip means that the P7630 probe acts like a Z0 probe when used with a P76TA

adapter and P7500 Series probe tip. This 5X Z0 probe structure reduces probe

loading enough that it is possible to use the P7630 probe and P76TA adapter for

making pro

as shown in the simplified schematic below. (See Figure 11.)

Figure 11: P76TA adapter simplified schematic

er provides a probe tip connection interface that enables P7500

bing measurements anywhere along the signal transmission line path,

The probe diagram above shows a probe measurement being made on a

doubly-terminated signal path. This doubly-terminated signal path is a common

structure for many high frequency signaling standards, since, if implemented

correctly, it p rovides a very low-discontinuity signal path.

The 50 Ω back termination at the signal transmitter absorbs reflected signals

from reverse-path discontinuities on the signal transmission line, including those

due to probe loading. The additional 50 Ω termination resistor at the end of the

ansmission line path also serves to absorb the transmitted signal power and any

tr

forward-path signal reflections from discontinuities on the signal transmission

line. This doubly-terminated signal structure results in an effective 2 5 ohm signal

source impedance. (See Figure 12.)

Figure 12: P76TA adapter and P75PST tip equivalent schematic

P7630 TriMode Probe Technical Reference 15

Page 30

Theory of Operation

Scale Factor

In many of the high-frequency signaling standards that the P7630 probe is

designed for, a 50 Ω termination at the transmitter is in parallel with another 50 Ω

termination

signal source impedance. (See Figure 12.)

at the end of the transmission line path, effectively making a 25 Ω

When the P76

DUT within the transmission line path, this 25 Ω source impedance must be

considered a part of the probe input attenuator structure, and therefore be included

when calculating the probe gain.

Using the formula:

Ext Atten = (Rsource + 225 Ω)/225Ω

where th

differential input, substituting 25 Ω for the Rsource impedance yields an external

attenuation factor of 1.1116.

The probe/oscilloscope signal gain is factory-calibrated at the P76TA probe tips

using this external attenuation factor of 1.1116, and is accurately scaled by the

vertical volts/div control on the host oscilloscope.

For systems with source impedances not equal to 25 Ω, it may be necessary to

adjust the oscilloscope EXT ATTEN scale factor and the offset voltage to optimize

the measurement accuracy. You may also need to adjust the probe termination

voltage control to null out the DC loading effect of the probe.

TA adapter and P75PST or P75TLRST tips are used to probe the

e225Ω represents the input resistance of one half of the solder tip

16 P7630 TriMode Probe Technical Reference

Page 31

Probing Techniques to Maximize Measurement Fidelity

Measurement fidelity is an indication of how accurately a probe represents the

signal being measured. The measurement fidelity of the probe is best when

the probe is connected to the circuit with the P76CA-xxx probe adapters. The

P76CA-292C and P76CA-SMP adapters both include a pair of 6 inch, low-loss,

skew-match

ideally matched high-quality cables to complete the connection to your circuit.

When you use the P76TA adapter with P7500 series probe tips, proper wire lead

length is critical for achieving good measurement results. Recommendations for

connecting the P7500 probe tips a re given in the following section.

The P7630 probe contains S-parameter characterization data for the probe, which

is downloaded to the attached oscilloscope when the probe is first connected. This

probe-specific data is used along with nominal probe adapter data to generate

DSP correction filters that are used for improved high f requency measurement

accuracy. After the probe adapter is attached to the probe, the adapter transfers

identification data which is used as part of the generated filter process.

ed cables. When using the P76CA-292 adapter, only use matched,

Theory of Operation

P76CA-xxx Adapters

P76TA Adapter with P7500

TriMode Solder Tips

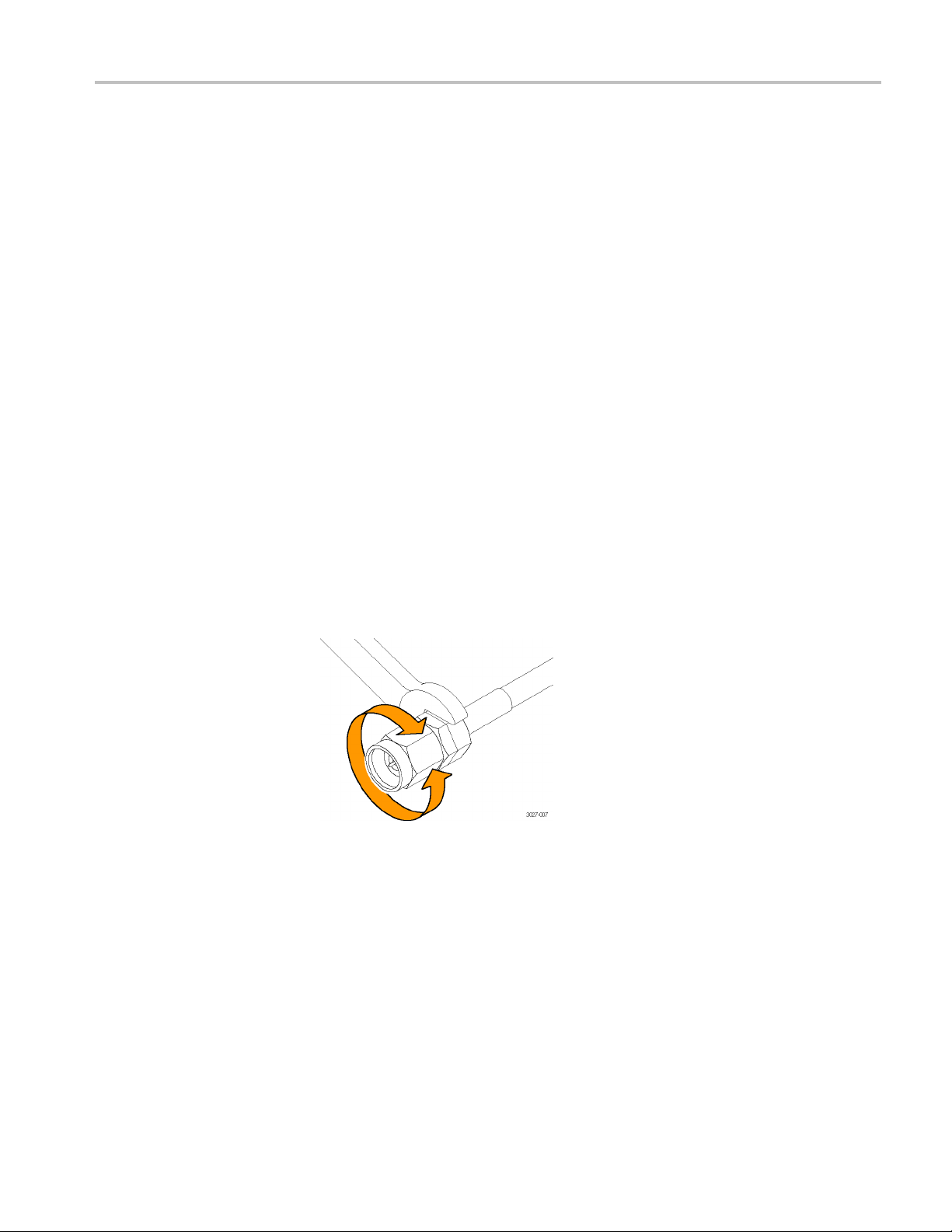

To prevent damage and prolong connector and cable life, the cable and center

conductors must not twist when making connections. Always use a wrench to

minimize the cable twist when you connect and disconnect the 2.92 adapters and

cables. Use a torque wrench to tighten the connectors to 8 in-lbs. Failure to do so

will shorten the service life of the adapters.

Figure 13: Preventing twist to the coaxial input cables

There are several solder tips available for connecting the P7500 Series probes

to your circuit. The P75PST and P75TLRST probe tips solder directly to your

circuit through small wires. (See Figure 14 on page 18.) Two resistor solder tips

are also available; these tips include input resistors that solder to your circuit and

can be replaced if damaged.

P75PST and P75TLRST TriMode Solder Tips. The P75PST and P75TLRST probe

tips are each composed of a small form factor interconnect circuit board with

SMD0402 damping resistors and a set of vias for wire attachment to the DUT

P7630 TriMode Probe Technical Reference 17

Page 32

Theory of Operation

(Device Under T

8 mil wire, and a special high tensile strength wire is supplied as part of the wire

accessory kit. The expanded view of the probe tips shows the location of the A

and B signal inputs as well as the two ground reference connections.

Figure 14: P75PST and P75TLRST TriMode Solder Tips

The recommended wire attachment method is to first solder the wires to the DUT,

being careful to minimize the wire length of the signal and ground connections.

Next, attach a solder ramp to the bottom of the solder tip with hot g lue. A kit of

r ramps are included with the P76TA adapter. A notch on the ramp aligns

solde

with the bottom of the tip.

est). The circuit board vias are designed for both 4 mil and

Figure 15: Solder ramp installed

The solder ramps are designed to point the front of the solder tip downward to

minimize the distance between the solder points on the solder tip and the circuit

st points. For signal frequencies that exceed 25 MHz, this distance must be less

te

than 0.032 in. (0.8 mm) to achieve good results.

nce the solder ramp is secured to the tip, thread the wires through the probe tip

O

board vias, being careful to achieve as symmetrical a wire pattern as possible

between the two signal inputs and a very short ground connection. Secure the

tip/ramp assembly to the DUT with tape or hot glue, and finally, solder the wires

on top of the probe tip circuit board. Any excess wire lead length extending

through the probe tip board should be removed to minimize possible signal

reflection problems.

18 P7630 TriMode Probe Technical Reference

Page 33

Theory of Operation

Because of the l

tip circuit board, the solder-down probe tip should be taped down at the DUT for

strain relief. Although the accessory kit includes adhesive strips that can be used

for the strain relief of the probe tip, the use of mylar tape will generally provide

stronger attachment if room is available at the DUT.

Probe Tip Ca

of very low skew (<1ps) coaxial cables and a polarized G3PO dual connector

block. The 3GPO connectors use a miniature, high frequency design that enables

quick and easy installation of the P7500 Series solder tips. The G3PO connector

block of the probe tip is inserted into the input of the P76TA adapter. The

adapter contains a mating, polarized G3PO connector block with attached G3PO

connecto

The connector bullets are a part of the G3PO connector design, providing a

self-al

connector in the adapter is designed to have higher detent force than the probe

tip connectors, which is intended to ensure that the G3PO bullets remain in the

P76TA adapter connector when disconnected. The adapter, with its integral

spring mechanism, helps to provide a self-aligning mechanism for hand insertion

of the probe tip. The adapter springs also give a secure capture of the probe

tip c

wire-connected cable release holder on the probe tip connec tor. This probe tip

release holder should always be used rather than pulling on the probe tip cables,

which may cause tip cable damage.

r bullets.

igning interconnect mechanism between G3PO connectors. The G3PO

onnector after insertion. Release of the probe tip is assisted by using the

imited mechanical strength of the wire interconnect and probe

bles and Connectors. Attached to the probe tip circuit board is a pair

P7630 TriMode Probe Technical Reference 19

Page 34

Theory of Operation

DUT Connection

between the probe tip board and the DUT must be kept as short as possible to

preserve the integrity of the measured signal. Typical wire lengths range from

0.010 in. to 0.100 in. (See Figure 16.)

s. The lead length of the resistor leads and connection wires

Figure 16: Typical wire length from probe tip to circuit

The following four figures illustrate the signal integrity effect on the P75TLRST

solder tip when used with different lengths of tip wire. Signal fidelity is best when

the wire length is kept as short as possible. The step generator that was used as

a signal source for these screenshots has a 30 ps 10-90% rise time. The table in

each figure contains data for two rise time measurements (10-90% and 20-80%).

These screenshots can be used as a rough guide to gauge the effects of wire length,

but actual results may vary depending on the other factors like characteristics of

e device under test (for example, rise time and impedance), precision of the

th

solder connection, and the model of oscilloscope.

20 P7630 TriMode Probe Technical Reference

Page 35

Figure 17: P75TLRST solder tip with 0.010 in. of tip wire

Theory of Operation

Figure 18: P75TLRST solder tip with 0.050 in. of tip wire

P7630 TriMode Probe Technical Reference 21

Page 36

Theory of Operation

Figure 19: P75TLRST solder tip with 0.100 in. of tip wire

Figure 20: P75TLRST solder tip with 0.200 in. of tip wire

22 P7630 TriMode Probe Technical Reference

Page 37

Reference

This section contains information about taking measurements with the probe

and increasing measurement accuracy.

Single-Ended Measurements Using A and B Modes

A differential probe such as the P7630 TriMode Probe can be used for single-ended

measurements within the limits of its dynamic and offset voltage ranges.

Single-ended probes such as the P7240 typically have a wider offset range than

differential probes, but with much lower bandwidth performance. (See Table 1.)

Table 1: Offset ranges

Probe Attenuation DC offset Dynamic range

P7240 5X

P7513 & P7516 (differential mode)

P7513 & P7516 (single-ended and common-mode)

P7520 (differential mode)

P7520 (single-ended and common-mode)

1

P7630

Coaxial adapters

5X +2.5 V, -1.5 V 1.5 V

5X +3.4 V, -1.8 V 1.5 V

5X +2.5 V, -1.5 V 1.25 V

5X +3.4 V, -1.8 V 1.25 V

1X

1X

Solder tip adapter

5X

5X

1

The P7630 probe has independent A and B input offset controls

ground or the reference level of the measured signal. S et the A signal offset to the DC common-mode voltage of the measured signal.

. To take a single-ended m easurement, use the B input for reference and set the B offset to

+/- 5 V

+/- 4 V 1.2 VPP(single-ended)

+/- 4 V 2.0 V

+/- 4 V 6.0 V

+/- 4 V 10.0 V

4V

PP

PP

PP

PP

PP

(differential)

PP

(single-ended)

PP

(differential)

PP

Differential probes are ideal for a class of single-ended measurements where the

reference voltage is not ground:

SSTL_1,2: VTT,V

PECL: V

=VCC-1.3

REF

REF

=VDD/2

To measure single-ended s ignals in this class, connect the B input of the P7630

Probe to V

REF

.

A differential probe in these applications displays the true signal despite any AC

or DC variation in V

the signal plus the variation in V

from its nominal value. A single-ended probe displays

REF

. Differential probes can also be used to make

REF

ground referenced single-ended measurements o n either single-ended signals or

differential signals like PCI Express or Serial ATA.

Single-ended measurements on differential signals are used to measure common

mode voltage and check for differential signal symmetry. By using a TriMode

probe, you can easily take these measurements with one adapter connection (two

coax cables or a grounded solder tip). Cycle the Input Mode switch to display the

signal that you want to view.

P7630 TriMode Probe Technical Reference 23

Page 38

Reference

Differential

Measurements

A differential probe is optimized to measure high speed differential signals.

Differential signals are formed from two complementary signals with a common

reference vo

Devices designed for differential measurements avoid problems presente d by

single-ended systems. These devices include a variety of differential probes,

differential amplifiers, and isolators.

A differential probe is basically a differential amplifier, which is used to make

differential measurements that reject any voltage that is common to the inputs and

amplifies any difference between the inputs. Voltage that is common to both

inputs is often referred to as the Common-Mode Voltage (V

is different as the Differential-Mode Voltage (V

ltage. (See Figure 21.)

DM

) and voltage that

CM

).

Common-Mode Rejection

Ratio

Figure 21: Simplified model of a differential amplifier

Differential amplifiers cannot reject all of the common-mode signal. The ability

of a differential amplifier to reject the common-mode signal is expressed as the

Common-Mode Rejection Ratio (CMRR).

The DC CMRR is the differential-mode gain (A

gain (A

). It is expressed either as a ratio or in dB:

CM

) divided by the common-mode

DM

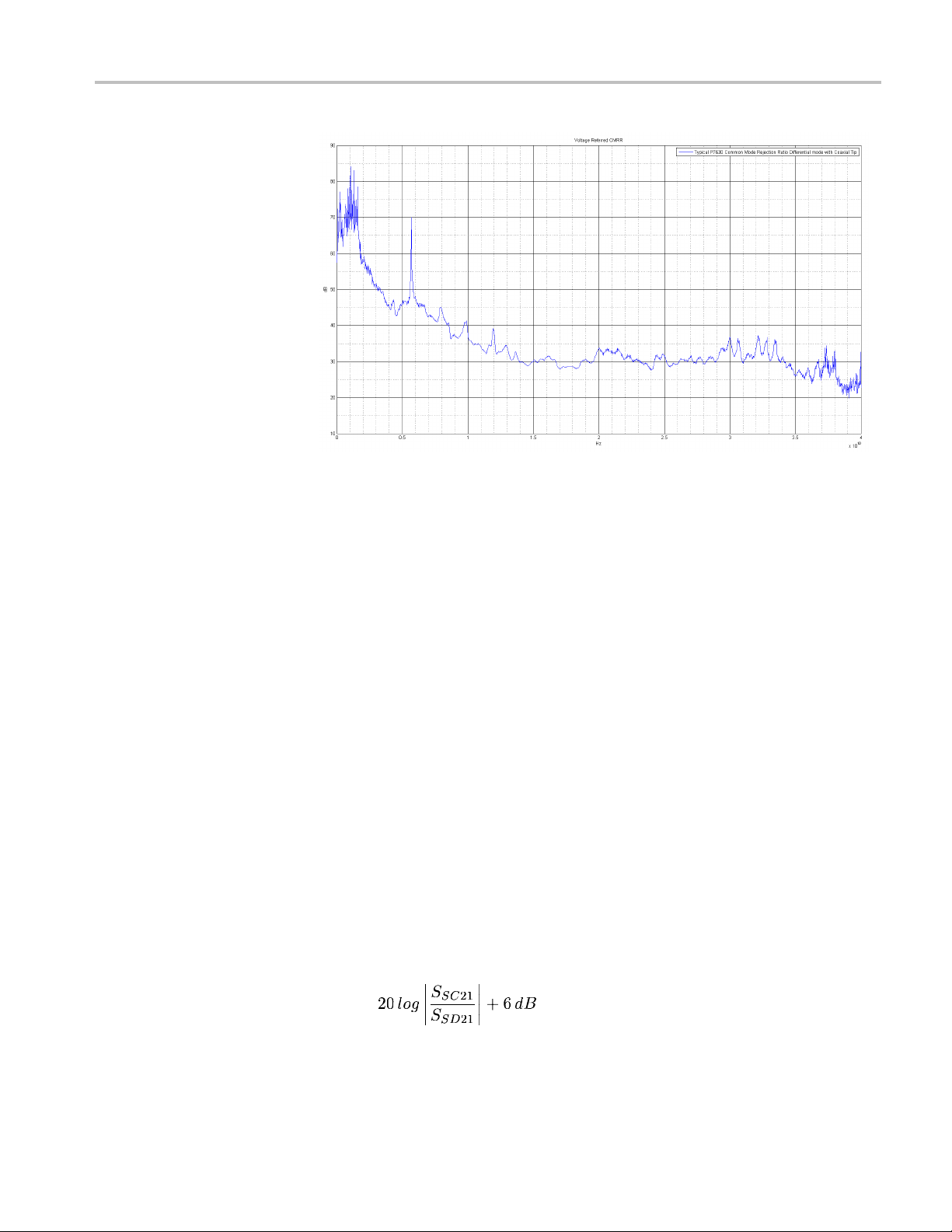

AC CMRR for the P7630 probe is defined using 3-port, mixed-mode S-parameters

as:

for the measured differential mode response, where A input = S1, B input

= S2 and Output = S3. The 6 dB term in the AC CMRR equation gives the

voltage-referenced response. CMRR generally is highest (best) at DC and

degrades with increasing frequency. A typical CMRR plot for the P7630 probe is

shown. (See Figure 22 on page 25.)

24 P7630 TriMode Probe Technical Reference

Page 39

Figure 22: Typical CMRR

Reference

Assessing CMRR Error

Input Imped ance Effects

on CMRR

Differential-Mode

Rejection

The CMRR of the P7630 TriMode Probe is shown in graphs assuming a sinusoidal

common-mode signal. A quick way to assess the magnitude of CMRR error

when the common-mode signal is not sinusoidal is to connect both leads to the

same point in the circuit. The oscilloscope displays only the common-mode

component that is not fully rejected by the probe. While this technique may n ot

yield accurate measurements, it does allow you to determine if the magnitude of

the common-mode error signal is significant. When using the solder-down tips,

keep the tip leads the same length to maximize the probe CMRR.

The lower the input impedance of the probe relative to the source impedance,

thelowertheCMRRforagivensourceimpedance imbalance. Differences

in the source impedance driving the two inputs lowers the CMRR. Note that

single-ended measurements generally result in asymmetric source impedances

which tend to reduce the differential mode CMRR.

When making common-mode signal measurements (A+B/2 – GND) with the

TriMode probe, it is desirable to reject the differential-mode signal present

between the two inputs. This rejection is expressed as the Differential-Mode

Rejection Ratio (DMRR).

AC DMRR for the P7630 probe is defined using 3-port, mixed-mode S-parameters

as:

for the measured common mode response. The 6 dB term in the AC DMRR

equation gives the voltage-referenced response.

P7630 TriMode Probe Technical Reference 25

Page 40

Reference

Channel Isolation

Under ideal con

ditions when taking single-ended measurements with a differential

probe, no part of a signal applied to one input of the probe would appear on the

other input. In reality some portion of the signal on one input does “bleed” over to

the other input, and this effect increases with frequency. Channel isolation is a

measure of how much crosstalk occurs between the two probe inputs. The channel

isolation is defined with S-parameter measurements below, where:

A input = S1, B input = S2, Output = S3

A ISOLATION = 20 log (S

B ISOLATION = 20 log (S

31/S32

32/S31

) | A Mode

)|BMode

A typical isolation plot for the P7630 TriMode probe using a coaxial adapter

is shown below. When the probe is used with the P76TA adapter and solder

tips, note that channel isolation performance is highly dependent on probe tip

attachment lead length. Good channel isolation requires keeping the interconnect

lead length for both signal and ground connections very short. (See Figure 23.)

Figure 23: Typical channel isolation

26 P7630 TriMode Probe Technical Reference

Page 41

Specifications

Specification

s

These specifi

cations apply to the P7630 TriMode Probe when installed on

a DPO/DSA73304D oscilloscope. The probe and oscilloscope must have a

warm-up period of at least 20 minutes and be in an environment that does not

exceed the allowed limits. (See Table 3.)

Specifications for the P7630 TriMode Probe fall into three categories: warranted,

typical, and nominal characteristics.

Warranted Characteristics

Warranted characteristics describe guaranteed performance within tolerance limits

or certain type-tested requirements.

Table 2: Warranted electrical characteristics

Coaxial adapters Solder tip adapter

Characteristic P76CA-292 P76CA-292C P76CA-SMP P76TA

Rise time, system,

DSP corrected

10% – 90%

20% – 80%

DC gain accuracy ±2% ±2% ±2% ±2%

DC output zero

common mode

imbalance

Operating voltage

window

Input signal range

Linearity

Offset voltage range

Offset voltage accuracy

(referred to input)

DC offset drift

(referred to input)

Termination voltage

range

Termination voltage

accuracy

1

Single-ended

Differential

<16 ps <16 ps <16 ps <16 ps

<12 ps <12 ps <12 ps <12 ps

±4 mV ±4 mV ±4 mV ±4 mV

-4.0Vto+4.0V -4.0Vto+4.0V -4.0Vto+4.0V -5.0Vto+5.0V

1.2 Vp-p 1.2 Vp-p 1.2 Vp-p 6.0 Vp-p

2.0 Vp-p 2.0 Vp-p 2.0 Vp-p 10.0 Vp-p

±1% ±1% ±1% ±1%

–4.0 V to +4.0 V –4.0 V to +4.0 V –4.0 V to +4.0 V –4.0 V to +4.0 V

±(2% of FS range +

6mV)

<±0.2 mV/ °C <±0.2 mV/ °C <±0.2 mV/ °C <±0.2 mV/ °C

-4.0Vto+4.0V -4.0Vto+4.0V -4.0Vto+4.0V -4.0Vto+4.0V

<±10 mV <±10 mV <±10 mV <±10 mV

±(2% of FS range +

6mV)

±(2% of FS range +

6mV)

±(2% of FS range +

30 mV) (25 Ω source Z)

P7630 TriMode Probe Technical Reference 27

Page 42

Specifications

Table 2: Warranted electrical characteristics (cont.)

Coaxial adapters Solder tip adapter

Characteristic P76CA-292 P76CA-292C P76CA-SMP P76TA

Maximum

nondestructive input

2

voltage

Input impedance

Differential 450 Ω @1 GHz

Single-ended 225 Ω @1 GHz

Input return loss

Freqto5GHz

Freq to 20 GHz

Freq to 30 GHz

Noise

Probe only (most

sensitive range)

System, DSP

corrected (most

sensitive range)

Overload indicator

range (P76CA-xxx

adapters only)

1

Measured at the output of the probe, relative to the DC output zero common mode voltage reported as the calibrated value in the TekConnect message for

each step gain and input mode combination.

2

Measured between each input or between either probe input and ground.

±5 V

(DC + peak AC)

±5 V

(DC + peak AC)

±5 V

(DC + peak AC)

±8 V

(DC + peak AC)

200 Ω @10 GHz

150 Ω @25 GHz

150 Ω @10 GHz

100 Ω @25 GHz

>20 dB >20 dB >20 dB

>12 dB >12 dB >12 dB

>10 dB >10 dB >10 dB

<0.9 mVrms <0.9 mVrms <0.9 mVrms

<1.0 mVrms <1.0 mVrms <1.0 mVrms <5.0 mVrms

Vterm

Overload off Overload on

–4 V –4.25 <Vin< –1.75 Vin< –4.75 or Vin> –1.00

–3 V –4.25 <Vin< –0.75 Vin< –4.75 or Vin> –0.15

–2 V –4.25 <Vin< +0.25 Vin< –4.75 or Vin> +0.75

–1 V –3.25 <Vin< +1.25 Vin< –3.75 or Vin> +1.75

0 V –2.25 <Vin< +2.25 Vin< –2.75 or Vin> +2.75

+1 V –1.25 <Vin< +3.25 Vin< –1.75 or Vin> +3.75

+2 V +0.25 <Vin< +4.25 Vin< –0.75 or Vin> +4.75

+3 V +0.75 <Vin< +4.25 Vin< +0.25 or Vin> +4.75

+4 V +1.75 <Vin< +4.25 Vin< +1.25 or Vin> +4.75

28 P7630 TriMode Probe Technical Reference

Page 43

Specifications

Table 3: Warran

Characteristic Specification

Temperature

Operating 0 to 40 °C (+32

Nonoperating

Humidity

Operating 20–80% RH, at up to +40 °C (+104 °F)

Nonoperating

Altitude

Operating 3000 meters (10,000 feet)

Nonoper

ted environmental characteristics

ating

to +104 °F)

–20 to +60 °C

12,000 meters (40,000 feet)

(–4 to +140 °F)

5–90% RH

P7630 TriMode Probe Technical Reference 29

Page 44

Specifications

Typical Chara

cteristics

Typical characteristics describe typical but not guaranteed performance.

Table 4: Typical electrical characteristics

Coaxial adapters Solder tip adapter

Characteristic P76CA-292 P76CA-292C P76CA-SMP P76TA

Bandwidth

Rise time, probe only

Input sense voltage

accuracy

Common-mode

rejection ratio,

differential-mode

Differential-mode

rejection ratio,

common-mode

Channel isolation,

single-ended mode

1

2

1

Probe only

System, DSP

corrected

10% –90%

20% –80%

2

Measurements taken @18 to 28 ºC (+64 to +82 °F)

The voltages on the probe inputs are sensed by the probe circuitry, and are used to generate voltages associated with the Set buttons on the oscilloscope

GUI. The Set buttons are used to automatically enter these generated Offset and Termination voltages in the on-screen fields; either Individually or Mean

values can be selected.

>30 GHz

(all input modes)

>30 GHz

(all input modes)

Input sense voltage =

Vin ±24 mV

>40dB@DC >40dB@DC >40dB@DC

>14dBto15GHz >14dBto15GHz >14dBto15GHz

>6 dB to 30 GHz >6 dB to 30 GHz >6 dB to 30 GHz

>26dBto20GHz >26dBto20GHz >26dBto20GHz

>18dBto30GHz >18dBto30GHz >18dBto30GHz

>20dBto20GHz >20dBto20GHz >20dBto20GHz

>12dBto30GHz >12dBto30GHz >12dBto30GHz

>30 GHz

(all input modes)

<16 ps

<12 ps

Input sense voltage

=Vin±24mV

>30 GHz

(all input modes)

Input sense voltage

=Vin±24mV

>30 GHz (A, B, D modes)

>25 GHz (common mode)

Input sense voltage

= Vin ±100 mV

able 5: Typical mechanical characteristics

T

Characteristic Description

imensions, control box

D

Dimensions, probe body

Dimensions, probe main cable length

Unit weight

125.4 mm × 41 mm × 35 mm (4.9 in × 1.6 in × 1.4 in)

101.6 mm × 8.89 mm × 19 mm (4.0 in × 0.350 in × 0.750 in)

1.2 m (47.2 in) (from the front of the probe body to the rear of the

control box; does not include adapter)

1.860 kg (4.1 lbs) (probe, accessories and packaging)

30 P7630 TriMode Probe Technical Reference

Page 45

Specifications

The following fi

probe.

gures show the typical rise time and frequency response of the

Figure 24: Typical rise time

ure 25: Typical frequency response

Fig

P7630 TriMode Probe Technical Reference 31

Page 46

Specifications

igure 26: Probe body and control box dimensions

F

32 P7630 TriMode Probe Technical Reference

Page 47

Specifications

Figure 27: P7630 Probe adapter dimensions

Figure 28: P75PST and P75TLRST solder tip dimensions

P7630 TriMode Probe Technical Reference 33

Page 48

Specifications

Nominal Chara

cteristics

Nominal characteristics describe guaranteed traits, but the traits do not have

tolerance limits.

Table 6: Nom

Characteristic P76CA-292 P76CA-292C P76CA-SMP P76TA

Maximum po

dissipation

Terminat

Probe tip N.A. N.A. N.A. 62.5 mW

Input resistance

Input capacitance N.A. N.A. N.A. 0.1 pF

1

P75PST and P75TLRST solder tips

Table 7

Characteristic Connector type Description

Input configuration

1

User-supplied cables

inal electrical characteristics

Coaxial adapters Solder tip adapter

wer

ion resistor

125 mW 125 mW 125 mW N.A.

50 Ω ±2 Ω 50 Ω ±2 Ω 50 Ω ±2 Ω 225 Ω

: Nominal adapter electrical characteristics

P76CA–292 Adapter 2.92 mm coaxial female

P76CA–292C Adapter 2.92 mm coaxial male (cables)

P76CA–SMP Adapter SMP coaxial female (cables)

TA Adapter with:

P76

PST solder tip

P75

5TLRST solder tip

P7

0.012 in-diameter solder vias

0.012 in-diameter solder vias

1

Differential (two coaxial signal inputs, A and B; outer

cable shields are grounds)

ferential (two signal inputs, A and B; shared with

Dif

single-ended)

Single-ended (one each A and B signal input and

o ground inputs)

tw

1

34 P7630 TriMode Probe Technical Reference

Page 49

User Service

Error Condition

This section covers troubleshooting and probe maintenance. If your probe does

not meet the specifications listed in the Specifications, you can send the probe to

Tektronix fo

r calibration and repair. (See page 40, Preparation for Shipment.)

The LEDs on

the probe alert you to error or status conditions affecting the probe.

When the probe is functioning correctly, there is a quick flash of the LEDs on

the probe just after connecting to the oscilloscope. If the probe LEDs flash or

otherwise appear to be malfunctioning, an error condition may exist. Disconnect

the probe and reconnect it to another channel to isolate the problem. If the

symptoms persist with the probe, call your Tektronix representative for service.

Replaceable Parts

The following parts may need to be replaced due to normal wear and damage.

When yo

to simplify the procedure.

Table 8: TriMode probes replaceable parts

Description Replacement part number

0 probe body bullet contacts

P763

A adapter bullet contacts

P76T

P75PST & P75TLRST solder tip wires

See the user manual for a list of the accessories that are available for your probe.

u replace these components, secure the probe in a small vise or positioner

020-3105-xx, kit of 4

013-0359-xx, kit of 4

-2754-xx, Wire Replacement Kit, includes one bobbin each:

020

4 mil wire, 8 mil wire, and SAC305 solder

Table 9: Required equipment

Description Minimum requirement Recommended example

P7630 probe body bullet removal tool 003-1934-xx

76TA adapter bullet removal tool

P

Probe positioner or bench vise Able to hold probe PPM203B or PPM100

Magnifying glass or microscope Free standing to allow hands-free use

Tweezers

1

Nine-digit part numbers (xxx-xxxx-xx) are Tektronix part numbers.

General purpose

03-1896-xx

0

1

P7630 TriMode Probe Technical Reference 35

Page 50

User Service

Replacing the Bullet

Contacts

The bullet cont

replaced every 200 insertion cycles. The bullet contacts and removal tool differ in

size between the two and cannot be interchanged. The P76TA components are

larger, but the procedures are similar for both the probe and adapter.

To replace the bullets, use the bullets and bullet removal tool listed in the tables

above, and follow the steps below.

Remove.

1. Squeeze the tool plunger to extend the holder tangs.

2. Insert the tool into the probe body or adapter so that the holder tangs surround

one of the bullets.

3. Release the plunger to secure the holder tangs on the bullet.

4. Gently pull the tool outward to remove the bullet.

5. Repeat for the other bullet.

CAUTION. If you cannot extract the bullets with the bullet removal tool, use fine

needle-nosed pliers and a m agnifying glass or microscope. Be careful not to

damage the probe adapter with the pliers.

acts in the P7630 probe head and P76TA adapter should be

Figure 29: Removing the bullets

36 P7630 TriMode Probe Technical Reference

Page 51

User Service

Install. When b

following:

1. Squeeze the to

2. Insert a new bullet into the tool so that the holder tangs surround the bullet.

3. Release the plunger to secure the holder tangs on the bullet.

4. Insert the tool into the probe body or adapter and seat the bullet in the recess.

5. Squeeze the tool plunger to release the bullet.

6. Gently pull the tool out of the probe or adapter.

7. Repeat fo

8. Test that the bullets are installed correctly by connecting and then removing

the P76T

probe adapter. Inspect the probe or adapter and verify that the bullets remain

seated in the probe or adapter (where you installed them).

oth bullets have been removed, install new bullets by doing the

ol plunger to extend the holder tangs.

r the other bullet.

A adapter from the probe, or an accessory solder tip to and from the

Figure 30: Installing the bullets

P7630 TriMode Probe Technical Reference 37

Page 52

User Service

P75PST & P75TLRST

Solder Tip Wires

The solder vias

solder tips are small (0.012 in.), and require small wires to attach to your circuit.

(Use the 4-mil and 8-mil wires included with the Wire Replacement kit to make

the connections.) Because of the small dimensions, the solder tips have a limited

number of solder cycles that the vias can withstand before the Solder Tips become

unusable. If you expect to make frequent soldering changes, consider using the

optional Tr

can accept a higher number of solder cycles and can be replaced when necessary.

NOTE. Axial-leaded tip resistors (included in the TriMode resistor replacement

kit, Tektronix part number 020-2937-xx), should not be used in place of wires

with the P75PST and P75TLRST probe tips unless the surface-mount, SMD0402

resistors are also changed. The total probe tip resistance for the P7500 Series

solder t

CAUTION. To prevent damage to the circuit board or circuit board connections

due to a

you secure the tip to the circuit board using the adhesive tip tape provided in your

accessory kit. You can also use other materials such as Kapton tape or hot glue.

To avoid damage to the tip or the circuit under test, avoid applying excessive heat

from the soldering iron. Use a low wattage, temperature-controlled soldering iron

and appropriately sized soldering iron tip.

ipsisdesignedtobe175Ω.

ccidental movement of the probe and soldered leads, we recommend that

on the circuit board at the end of the P75PST and P75TLRST

iMode Resistor solder tips. The resistors that extend off of these tips

To prolong the life of your solder tips, consider the following points before you

use the solder tips.

Consider the types of measurements that you plan to take. If you are going to take

a few measurements at one location and then move to another, you may be able to

use longer wires. Longer wires may degrade your measurement slightly (which

may not matter), but the wires can then be cut or de-soldered at your circuit and

eused, rather than subjecting the solder tip to a de solde r/solder cycle.

r

At critical test points such as circuit outputs, you might need to keep the wires

as short as possible. If possible, use the solder tip dimensions shown in the

Specifications section to lay out a matching footprint on your circuit board.

38 P7630 TriMode Probe Technical Reference

Page 53

User Service

Use the followi

For best soldering results, use a microscope to examine the quality of the

solder joints

Use a low-wattage, temperature-controlled soldering iron and a small mass

soldering i

possible, while still providing a reliable solder joint.

Use SAC305 s

wires to the circuit under test.

When repla

remove the excess solder from the probe tip circuit board via holes. Be careful

not to overheat the via and damage the board.

The attachment wires should be bent symmetrically to vary the interconnect

spacing. Use care when you solder a tip to a circuit under test to avoid

inadvertently de-soldering either the attachment wires or the damping resistor.

For optimum performance and signal integrity, keep the lead length between

the DUT (Device Under Test) and the tip as short as possible, and the lead

lengths the same length.

ng precautions when you solder the tips:

.

ron tip. The soldering iron temperature should be set as low as

older (included with the wire replacement kit) to attach the tip

cing tip wires or axial-lead resistors, solder wick can be used to

P7630 TriMode Probe Technical Reference 39

Page 54

User Service

Preparation f

or Shipment

If the original packaging is unfit for use or not available, use the following

packaging guidelines:

1. Use a corrugated cardboard shipping carton having inside dimensions at least

2. Put the probe into an antistatic bag or wrap to protect it from dampness.

3. Place the probe into the box and stabilize it with lightweight packing material.

4. Seal the carton with shipping tape.

5. Refer to Contacting Tektronix on the copyright page of this manual for the

one inch greater than the probe dimensions. The box should have a carton

test streng

shipping address.

th of at least 200 pounds.

40 P7630 TriMode Probe Technical Reference

Page 55

Index

A

Autoset, 12

C

Channel iso

Characteristics

Mechanical, 31

nominal, 34

CMRR, 24

assessing CMRR error, 25

Coaxial a

lation, 26

dapters, 14

D

Differential measurements, 24

Differential-Mode Rejection

Ratio, 25

DUT connections, 20

E

Error condition, 35

I

Input impedance, 14

Input signal

Input voltage, 8

dynamic range, 9

O

Offset voltage, 10, 12

Operating voltage window, 9

P

P75PST & P75TLRST

solder tip wires, 38

P75PST a

P76TA, 15

Preparation for Shipment, 40

Probe

Probe input architecture, 5

Probing techniques, 17

nd P75TLRST

TriMode solder tips, 17

replacing the bullet

contacts, 36

components, 1

R

Replaceable parts, 35

Rise time, 31

S

Safety Summary, iv

Scale factor, 16

Single-ended measurements, 23

Specifications

typical, 30

warrante

d, 27

T

Termination voltage, 11, 13

TriMode operation, 6

U

User service, 35

F

quency response, 31

Fre

P7630 TriMode Probe Technical Reference 41

Loading...

Loading...