Page 1

P7500 Series

TriMode™ Probes

Technical Reference

www.tektronix.com

071-2161-00

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Velcro is a registered trademark of Velcro Industries B.V.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. B o x 5 0 0

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worl dwid e, vis it www.tektronix.com to find contacts in your area.

Page 3

Warranty 2

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be ne

the property of Tektronix.

w or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, with shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulti

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTR

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ng from attempts by personnel other than Tektronix representatives to install, repair or service the product;

ONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

Page 4

Page 5

Table of Contents

General Safety Summary .......................................................................................... v

Introduction ......................................................................................................... 1

Theory of Operation......... ................................ ................................ ....................... 3

Input Voltage

TriMode Operation ................... ................................ ................................ ......... 6

Probing Techniques to Maximize Signal Fidelity ..................... ................................ ..... 8

Input Impedance and Probe Loading ............... .................................. ...................... 15

Reference ....... ................................ .................................. ................................ .. 17

Single-Ended Measurements Using A and B Modes ..................... ................................ 17

Differentia

Serial Bus Standards...................................... ................................ .................... 21

Specifications ...... .................................. ................................ .............................. 22

Warranted Characteristics.................................................................................... 22

Typical Characteristics ....................... ................................ ................................ 23

Nominal Characteristics...................................................................................... 25

Tip Specifica

User Service ........................................................................................................ 35

Error Condition . . . ..... . ..... . ..... . ..... . ..... . ..... . ..... . .... . . .... . . .... . ..... . ..... . ..... . ..... . ..... . ... 35

Replaceable Parts ............................................................................................. 36

Preparation for Shipment .................. ................................ .................................. 48

Limits.................................... .................................. ..................... 3

l Measurements................................................................................... 19

tions............................................................................................. 26

P7500 TriMode Probe Family Technical Reference i

Page 6

Table of Contents

List of Figure

Figure 1: Operating voltage window ...................... ................................ ....................... 4

Figure 2: Dynamic range versus linearity, 5X range ........................ ................................ ... 5

Figure 3: Dynamic range versus linearity, 12.5X range........................... ............................. 5

Figure 4: TriMode input structure ................................................................................ 7

Figure 5: P75TLRST TriMode Long Reach Solder Tip. .................................. ..................... 8

Figure 6: Typical wire length from probe tip to circuit......................................................... 9

Figure 7: P75TLRST solder tip with 0.010 in. of tip wire.................. .................................. 10

Figure 8: P75TLRST solder tip with 0.050 in

Figure 9: P75TLRST solder tip with 0.100 in. of tip wire.................. .................................. 11

Figure 10: P75TLRST solder tip with 0.200 in. of tip wire .................................................. 11

Figure 11: P75PDPM Precision Differential Probing Module ............................................... 12

Figure 12: P75PDPM with short ground spring, 0.030 in. spacing.......................................... 13

Figure 13: P75PDPM with short ground spring, 0.050 in. spacing.......................................... 13

Figure 14: P75PDPM with short ground spring, 0.090 in. spacing.......................................... 14

Figure 15: P75PDPM with short ground spring, 0.180 in. spacing.......................................... 14

Figure 16: TriMode probe input model ......................................................................... 15

Figure 17: Embedded probe fixture ....................... ................................ ...................... 16

Figure 18: Typical channel isolation for P7500 Series TriMode probes .................................... 18

Figure 19: Simplified model of a differential amplifier ....................................................... 19

Figure 20: Typical CMRR for P7500 Series TriMode probes................................................ 20

Figure 21: Probe body and control box dimensions ........................................................... 24

Figure 22: P75TLRST TriMode Long Reach Solder Tip dimensions....................................... 26

Figure 23: P7513 probe with the P75TLRST solder tip....................................................... 27

Figure 24: P7516 probe with the P75TLRST solder tip....................................................... 27

Figure 25: P75TLRST differential impedance versus lump-element equivalent........................... 28

Figure 26: P75TLRST common-mode impedance ............................................................ 28

Figure 27: P75TLRST bandwidth

Figure 28: P75TLRST bandwidth on a P7516 probe.......................... ................................ 29

Figure 29: P75PDPM Precision Differential Probing Module dimensions ................................. 30

Figure 30: P7513 probe with the P75PDPM probing module................................................ 31

Figure 31: P7516 probe with the P75PDPM probing module................................................ 31

Figure 32: P75PDPM differential impedance versus lump-element equivalent.. .......................... 32

Figure 33: P75PDPM bandwidth on a P7513 probe........................................................... 32

Figure 34: P75PDPM bandwidth on a P7516 probe........................................................... 33

Figure 35: Removing the bullets................................................................................. 37

Figure 36: Installing the bullets.. . . ..... . ..... . ..... . ... . . . .... . ..... . ..... . ..... . ..... ..... . ..... . ..... . ..... . .. 38

Figure 37: Large and small springs installed ..................... ................................ .............. 40

Figure 38: Set the gap....................... ................................ ................................ ...... 41

s

. of tip wire...................................... .............. 10

on a P7513 probe.......................... ................................ 29

ii P7500 TriMode Probe Family Technical Reference

Page 7

Table of Contents

Figure 39: Inse

Figure 40: Transfer spring from tip to tool ..................................................................... 42

Figure 41: Place spring on tool .................................................................................. 43

Figure 42: Set spring in front seat ............................................................................... 43

Figure 43: Set the spring in the rear seats....................................................................... 44

Figure 44: Properly seated spring................................................................................ 44

Figure 45: Dis

Figure 46: Probing module tips.................................................................................. 45

Figure 47: Removing the tip ..................................................................................... 46

Figure 48: Separating the tip board pair ........................................................................ 46

Figure 49: Seating the tip in the top tabs.................................. .................................. .... 47

Figure 50: Snapping the tip into the bottom tabs .............................................................. 47

rt tool beneath spring............................................................................ 41

connecting the tip cable.............................. ................................ ............ 45

P7500 TriMode Probe Family Technical Reference iii

Page 8

Table of Contents

List of Tables

Table 1: Offset ranges....................... .................................. ................................ .... 17

Table 2: Seri

Table 3: Warranted electrical characteristics ... .................................. .............................. 22

Table 4: Typical electrical characteristics. ................................ .................................. .... 23

Table 5: Typical mechanical characteristics.................................................................... 24

Table 6: Nominal electrical characteristics ........................... .................................. ........ 25

Table 7: TriMode probes replaceable parts ..................................................................... 36

Table 8: Requ

al bus standards with dynamic range requirements............................................. 21

ired equipment....................... ................................ .............................. 36

iv P7500 TriMode Probe Family Technical Reference

Page 9

General Safety Summary

General Safet

To Avoid Fire or Personal

Injury

ySummary

Review the fol

this product or any products connected to it.

To avoid pote

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions re

Connect and Disconnect Properly. Connect the probe output to the measurement

instrument before connecting the probe to the circuit under test. Connect the

probe reference lead to the circuit under test before connecting the probe input.

Disconnect the probe input and the probe reference lead from the circuit under test

before d

Observe All Terminal Ratings. To avo id fire or shock hazard, observe all ratings

and mark

information before making connections to the product.

Do not a

exceeds the maximum rating of that terminal.

lowing safety precautions to avoid injury and prevent damage to

ntial hazards, use this product only as specified.

lated to operating the system.

isconnecting the probe from the measurement instrument.

ings on the product. Consult the product manual for further ratings

pply a potential to any terminal, including the common terminal, that

Do Not O

removed.

Do Not

product, have it inspected by qualified service personnel.

Avoid

when power is present.

Do No

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

perate Without Covers. Do not operate this product with covers or panels

Operate With Suspected Failures. If you suspec t that there is damage to this

Exposed Circuitry. Do not touch exposed connections and components

t Operate in Wet/Damp Conditions.

P7500 TriMode Probe Family Technical Reference v

Page 10

General Safety Summary

TermsinthisManual

Symbols and Terms on the

Product

These terms may

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may a ppear on the product:

DANGER ind

the marking.

WARNING i

read the marking.

CAUTION i

The following symbol(s) may appear on the product:

appear in this manual:

icates an injury hazard immediately accessible as you read

ndicates an injury hazard not immediately accessible as you

ndicates a hazard to property including the product.

vi P7500 TriMode Probe Family Technical Reference

Page 11

Introduction

This manual discusses topics that are not covered in depth in the P7500 Series

TriMode Probes Quick Start User Manual.

The main sections are:

Theory of Operation — Contains probe details not covered in the user manual.

Reference — Co

to increase measurement accuracy.

Specificatio

the probe and probe tip accessories.

User Servic

ntains information about differential measurements and how

ns — Contains warranted, typical, and nominal characteristics for

e — Describes troubleshooting and probe maintenance.

P7500 TriMode Probe Family Technical Reference 1

Page 12

Introduction

2 P7500 TriMode Probe Family Technical Reference

Page 13

Theory of Operation

This section discusses operating considerations and probing techniques. For more

detailed information a bout differential measurements and TriMode operation,

refer to Refe

The P7500 Series TriMode probes are optimized for high bandwidth; they

are not gener

characteristics and access to dense circuitry, and must be handled carefully.

CAUTION. To prevent damage to the probe, use care when handling the probe.

Rough or careless use can damage the probe.

Input Voltage Limits

The P7500 Series TriMode probes are designed to probe low-voltage circuits.

Before pr

the operating voltage window, and the differential-mode signal range. (See

Table 4 on page 23.)

rence. (Seepage17.)

al-purpose probes. The probe tips are miniaturized for electrical

obing a circuit, take into account the limits for maximum input voltage,

Maximum Input Voltage

The max

withstand without damaging the probe input circuitry.

CAUTION. To avoid damaging the inputs of the probes, do not apply more than

±15 V (DC + peak AC) between each input or between either probe input and

ground.

CAUTION. To avoid ESD damage to the probe, always use an antistatic wrist

strap (provided with your probe), and work at a static-approved workstation when

you handle the probe.

imum input voltage is the maximum voltage to ground that the inputs can

P7500 TriMode Probe Family Technical Reference 3

Page 14

Theory of Operation

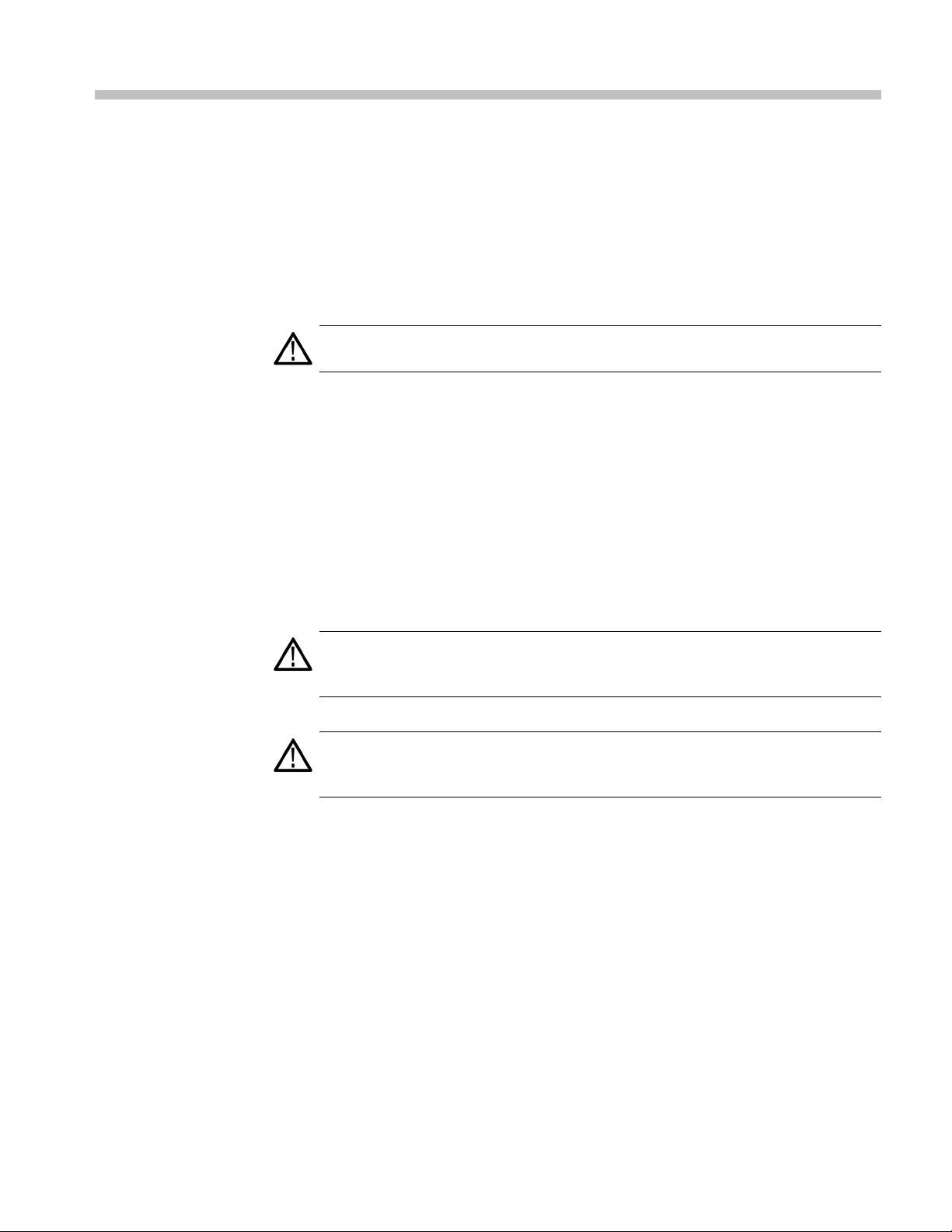

Operating Voltage Window

The operating v

to each input, with respect to earth ground, without saturating the probe input

circuitry. (See Figure 1.) A common-mode voltage that exceeds the operating

voltage window may produce an erroneous output waveform even when the

differential-mode specification is met.

Figure 1: Operating voltage window

oltage window defines the maximum voltage that you can apply

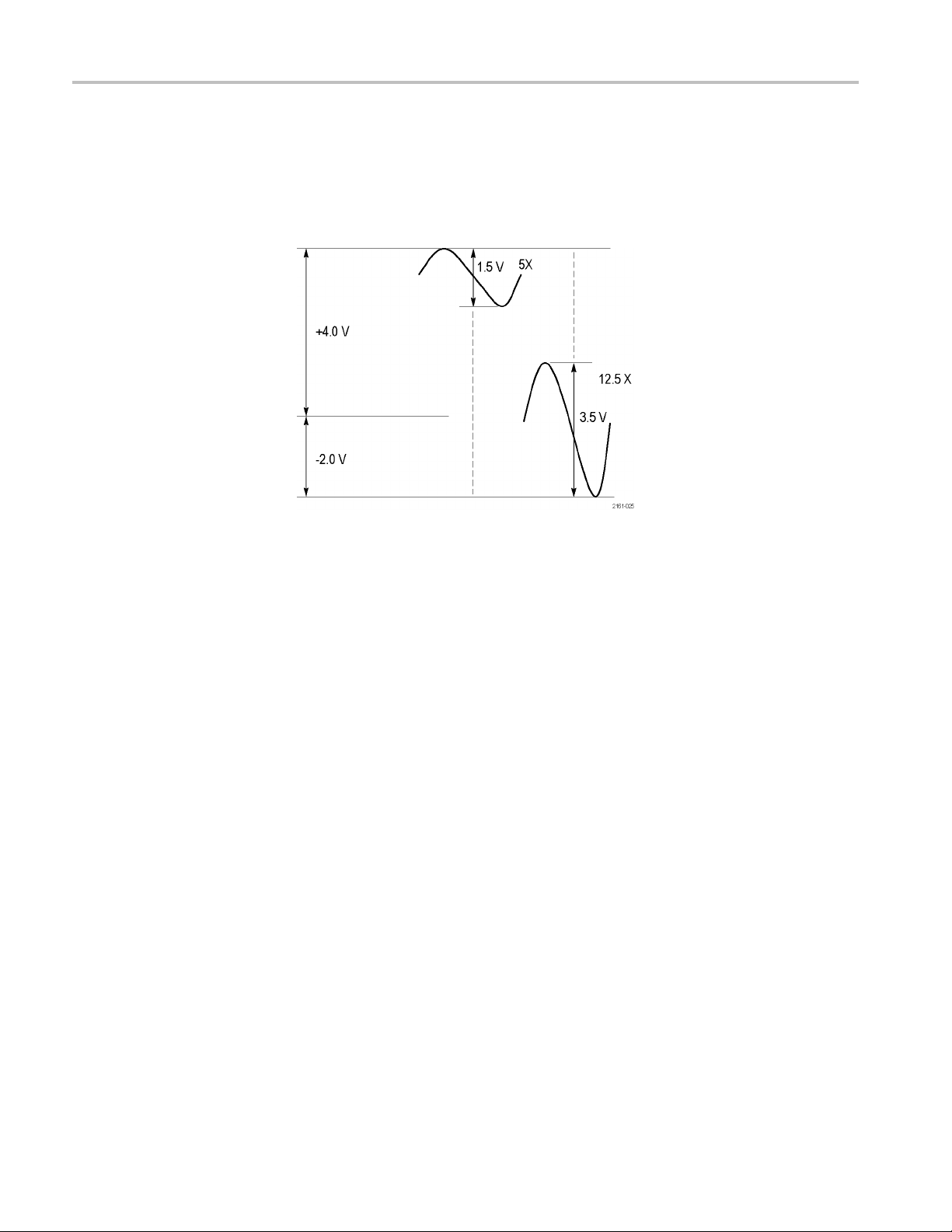

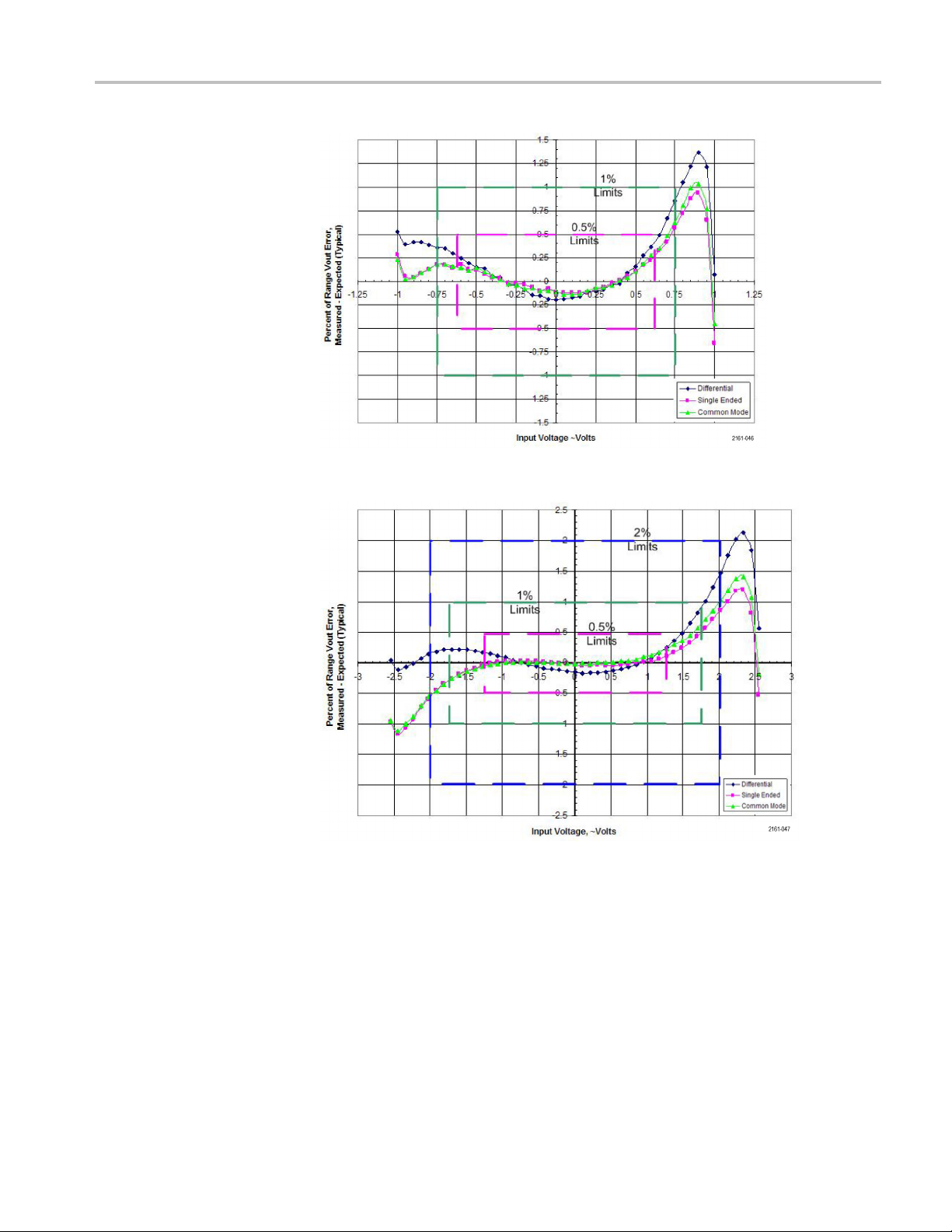

Differential-Mode Signal

Range

Offset Voltage Range

The differential-mode signal range is the maximum voltage difference between

the A and B inputs that the probe can accept without distorting the signal. The

distortion from a voltage that exceeds this maximum can result in a clipped or

otherwise inaccurate measurement. The P7500 Series probes have two attenuation

ngs, 5X and 12.5X, that allow dynamic range to be traded off against signal

setti

noise. The 12.5X attenuator setting has the largest dynamic range; the 5X

attenuator setting has the lowest noise. The following two graphs illustrate the

linearity error over the dynamic voltage range of the probes in both attenuation

settings.

The Offset Voltage Control, accessible from the attached oscilloscope user

interface, allows the probe dynamic range to be effectively moved up and down

within the limits of the offset voltage range and the operating voltage window.

When the offset voltage is set to zero volts and the input signal is zero volts

nputs shorted to ground, not open), the displayed signal should be zero volts.

(i

If a noticeable zero volt offset is present under the a bove conditions, a Probe

Cal operation should be performed. (See the P7500 Series Probes Quick Start

User Manual).

4 P7500 TriMode Probe Family Technical Reference

Page 15

Figure 2: Dynamic range versus linearity, 5X range

Theory of Operation

Figure 3: Dynamic range versus linearity, 12.5X range

P7500 TriMode Probe Family Technical Reference 5

Page 16

Theory of Operation

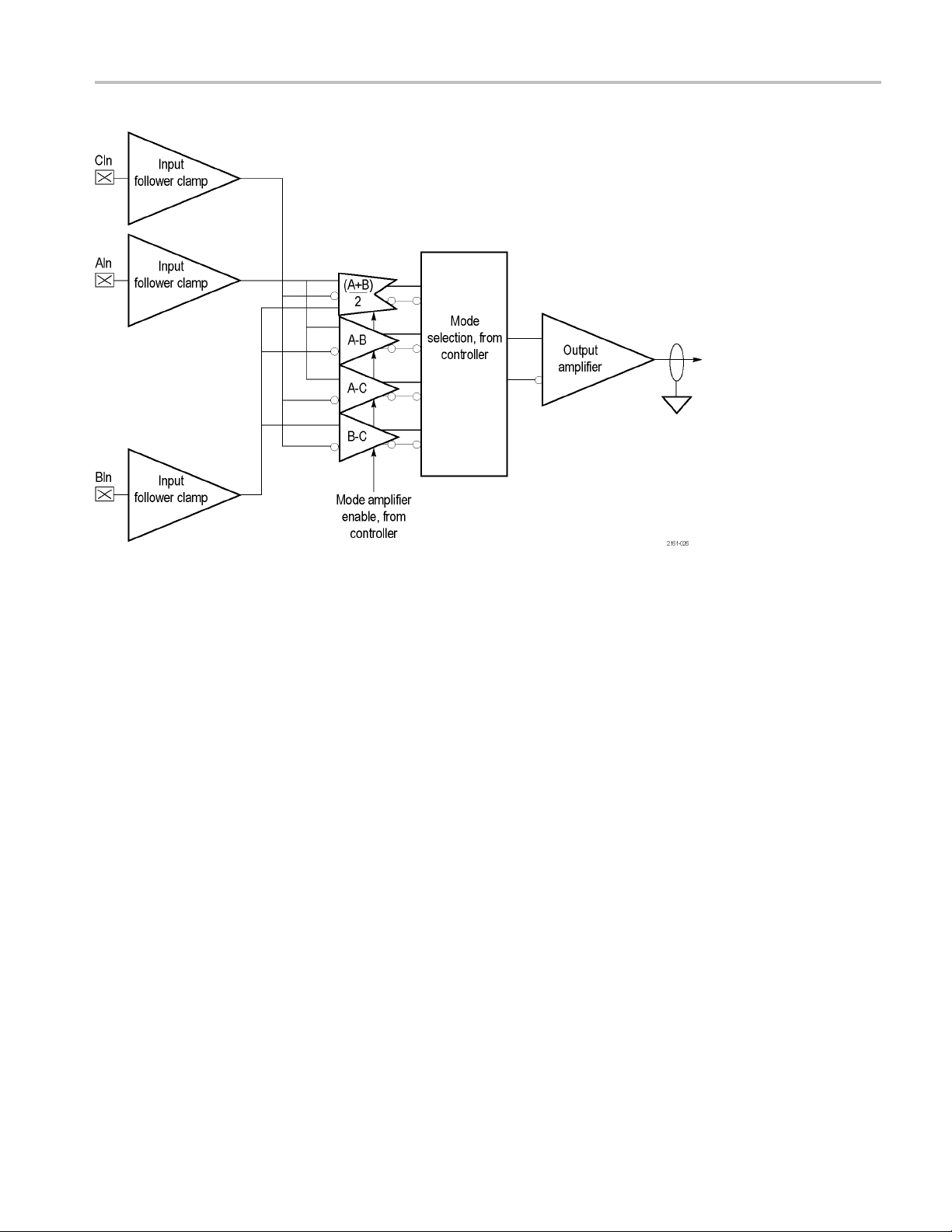

TriMode Opera

tion

The TriMode feature of the new P7500 Series probe family is designed for

improved convenience and enhanced capability in measuring differential

signal quali

single-ended signals, full characterization of differential signal quality requires

more than a simple differential measurement. A TriMode probe features three

Input Modes that allow a differential signal to be fully characterized with four

measurements: differential, positive polarity and negative polarity single-ended,

and common mode.

A TriMode probe provides improved efficiency and convenience by enabling full

differential signal characterization from a single soldered connection. Using the

P75TLRST

signals (the A signal and the B signal) and a ground reference. From this single

DUT (device under test) connection, the internal electronic switching control

of the TriMode probe allows any one of the three probe Input Modes (four

measurements) to be selected at a time. The TriMode probe inputs are routed on

the probe ASIC (application-specific integated circuit) to a set of four independent

input a

A – B (for differential signal measurement)

A – GND (for positive polarity single-ended measurement)

ty. Since a differential signal is composed of two complementary

probe tip, probe connections are soldered to the two c omplementary

mplifiers that perform the following signal calculations:

B – GND (for negative polarity single-ended measurement)

[A+B]/2 - GND (for common mode measurement)

The four input amplifiers are multiplexed together and only the selected Input

Mode function is output to the connected scope. (See Figure 4 on page 7.) The

figure shows a conceptual view of the TriMode probe input structure, where the

C input provides the probe ground reference and is connected to the probe tip

ground interconnect using the probe tip cable coaxial shields.

6 P7500 TriMode Probe Family Technical Reference

Page 17

Theory of Operation

Figure 4: TriMode input structure

The TriMode features are controlled by the probe Control Box switches, which

allow os

probe Input Mode.

On futur

probe GUI can perform a Probe Cal operation on all Input Modes and Attenuation

Settings at once using the TriMode Probe Cal fixture that is supplied with P7500

Series probes. Full TriMode support will also allow storage and automatic recall

of relevant settings like Offset. For more information about oscilloscopes that

feature full TriMode support, contact Tektronix.

cilloscope features like Probe Cal to be exercised only for the selected

e oscilloscopes that provide full TriMode support, the scope-controlled

P7500 TriMode Probe Family Technical Reference 7

Page 18

Theory of Operation

Probing Techn

iques to Maximize Signal Fidelity

P7500 TriMode Long Reach

Solder Tip (P75TLRST)

Signal fidelity is an indication of how accurately a probe represents the signal

being measured. The signal fidelity of the probe is best when the probe is

applied prop

connecting the P7500 probe tips are given in the following section.

The P75TLRST probe tip is designed for solder-down probing applications. It

is composed of a small form factor interconnect circuit board with SMD0402

damping resistors and a set of vias for wire attachment to the DUT. The circuit

board vias are designed for both 4 mil and 8 mil wire and a special high tensile

strength wire is supplied as part of the wire accessory kit. The expanded view of

the probe tip shows the location of the A and B signal inputs as well as the two

ground reference connections. (See Figure 5.)

erly to the circuit with the P7500 probe tips. Recommendations for

Figure 5: P75TLRST TriMode Long Reach Solder Ti

Attached to the circuit board are a pair of very low skew (<1ps) coaxial cables and

a polarized G3PO dual connector block. The G3PO connector block of the probe

tip is inserted into the input nose piece on the end of the probe body of the P7500

family probes. The probe body contains a mating, polarized G3PO connector

block with attached G3PO connector b ullets.

The connector bullets are a part of the G3PO connector design, providing a

self-aligning interconnect mechanism between G3PO connectors. The G3PO

connector in the probe body is designed to have higher detent force than the probe

tip connectors, which is intended to ensure that the G3PO bullets remain in the

probe body connector when disconnected. The probe body nose piece, with its

integral spring mechanism, helps to provide a self-aligning mechanism for hand

insertion of the probe tip. The probe body nose springs also give a secure capture

of the probe tip connector after insertion. Release of the probe tip is assisted by

using the wire-connected cable release holder on the probe tip connector. This

probe tip release holder should always be used rather than pulling on the probe tip

cables, which may cause tip cable damage.

The recommended wire attachment method is to first solder the wires to the DUT,

being careful to minimize the wire length of the signal and ground connections.

This is followed by threading the wires through the probe tip board vias, being

p

8 P7500 TriMode Probe Family Technical Reference

Page 19

Theory of Operation

careful to achi

inputs and a very short ground connection. Finally, the attachment is completed

by soldering the wires on top of the probe tip circuit board. Any excess wire lead

length extending through the probe tip board should be removed to minimize

possible signal reflection problems. Because of the limited mechanical strength

of the wire interconnect and probe tip circuit board, the solder-down probe tip

should be ta

includes adhesive strips that can be used for the strain relief of the probe tip, the

use of mylar tape will generally provide stronger attachment if room is available

at the DUT.

The lead length of the connection wires between the probe tip board and the DUT

must be kept as short as possible to preserve the integrity of the measured signal.

Typical wire lengths range from 0.010 in. to 0.100 in. (See Figure 6.)

eve as symmetrical a wire pattern as possible betweenthetwosignal

ped down at the DUT for strain relief. Although the accessory kit

Figure 6: Typical wire length from probe tip to circuit

The following four figures illustrate the signal integrity effect on the P75TLRST

solder tip when used with different lengths of tip wire. Signal fidelity is best when

the wire length is k ept as short as possible. The step generator that was u sed as a

signal source for thes e screenshots has a 30 ps 10-90% rise time. The table in each

re contains data for two rise time measurements (10-90% and 20-80%). These

figu

screenshots can be used as a rough guide to gauge the effects of wire length, but

actual results may vary depending on the other factors like characteristics of the

device under test (for example, rise time and impedance), precision of the solder

connection, and the model of oscilloscope.

P7500 TriMode Probe Family Technical Reference 9

Page 20

Theory of Operation

Figure 7: P75TLRST solder tip with 0.010 in. of tip wire

Figure 8: P75TLRST solder tip with 0.050 in. of tip wire

10 P7500 TriMode Probe Family Technical Reference

Page 21

Figure 9: P75TLRST solder tip with 0.100 in. of tip wire

Theory of Operation

Figure 10: P75TLRST solder tip with 0.200 in. of tip wire

P75PD

PM Precision

Differential Probing

Module

P7500 TriMode Probe Family Technical Reference 11

The P75PDPM Probing Module is designed for handheld and fixtured probing

applications. The P75PDPM probe tip is composed of two replaceable probe tip

circuit boards with a pin on one end and a G3PO socket connector on the other.

ing resistors on the tip boards near the input pins and a 50 Ω transmission

Damp

line on the board transmit the signal from the input pin to the G3PO socket

connector. The probe tip boards are connected to the P7500 probe body with a

very low skew (<1 ps) cable assembly (P75TC).

Page 22

Theory of Operation

The left-side a

adjustment housing. The probe tip spacing is adjustable from 0.030 – 0.180 in.

(0.76 – 4.57 mm) using the thumb-operated screw. Because of the variable spacing

between the two probe tip boards, a gold-plated ground spring is connected

between the probe tip boards to ensure a good common mode ground return n ear

the probe tip pins.

Figure 11: P75PDPM Precision Differential Probing Module

The P75PDPM probe tip circuit boards mount in an articulating metal housing

that also supports the variable spacing control. The angle of the probe tip housing

can be adjusted and locked in place using an articulation screw in the probe holder

bar. The probe holder bar contains mechanical details for retaining the probe tip

cable assembly as well as a retaining clamp for the probe body. The probe holder

bar can be held manually or can be mounted for fixtured probing on an articulating

probe arm using mechanical features in the holder bar.

nd right-side probe tip boards mount at an angle in the P75PDPM

The P75PDPM design features improved mechanical compliance in probe

tip attachment to the DUT. Mechanical compliance is a significant issue for

differential probes because of the difficulty in making reliable contact with two

DUT connections at the same time. The reliability in making this dual point

connection can be improved by a tip structure with good mechanical compliance,

in which there is sufficient give in the probe tips to absorb interconnect surface

irregularity.

The P75PDPM does not have a local DUT ground connection because of the

great difficulty in making a good three-point interconnect without soldering. As a

result, the only low-noise TriMode Input Mode available with the P75PDPM is

the A-B (DIFF) mode, since for differential signals, there is an inherent virtual

ground present in the measurement circuit.

The following four figures illustrate the signal integrity effect of changing the

spacing on the P75PDPM Probing Module. Signal fidelity is best with the tips at

the smallest spacing. The step generator tha t was used as a signal sour ce for the

screenshots has a 30ps 10-90% rise time. The table in each figure contains data

for two rise time m easurements (10-90% and 20-80%). These screenshots can be

used as a rough guide to gauge the effects of probe tip spacing, but actual results

may vary depending on the other factors like characteristics of the device under

test (for example, rise time and impedance) and the model of oscilloscope.

se

12 P7500 TriMode Probe Family Technical Reference

Page 23

Figure 12: P75PDPM with short ground spring, 0.030 in. spacing

Theory of Operation

Figure 13: P75PDPM with short ground spring, 0.050 in. spacing

P7500 TriMode Probe Family Technical Reference 13

Page 24

Theory of Operation

Figure 14: P75PDPM with short ground spring, 0.090 in. spacing

Figure 15: P75PDPM with short ground spring, 0.180 in. spacing

14 P7500 TriMode Probe Family Technical Reference

Page 25

Input Impedance and Probe Loading

When you connect the probe inputs to a circuit, you are introducing a new

resistance, capacitance, and inductance into the c ircuit. Each input of the

differential probe has a characteristic input impedance of 50 kΩ to ground. (See

Figure 16.)

Figure 16: TriMode probe input model

For signals with low source impedance and frequency, the 50 kΩ input impedance

on each input is large enough to prevent the inputs from loading the signal

sources. The more the signal source impedance on an input increases, the more

the probe

source impedances and the higher the signal frequencies, the more you must

take these factors into account.

loads the source and reduces the signal amplitude. The greater the

Theory of Operation

The frequency of the signal also affects signal measurement. As the frequency of

the signal increases, the input impedance of the probe decreases. The lower the

impedance of the probe relative to that of the source, the more the probe loads the

circuit under test and reduces the signal amplitude.

P7500 TriMode Probe Family Technical Reference 15

Page 26

Theory of Operation

Embedded Probe

It is possible t

an embedded connection in your circuit. (See Figure 17.) Connectors that mate to

the P75TC Tip Cable can be incorporated in the circuit board design and carefully

placed to balance any reflections or other characteristics that may affect the

circuit or measurement. An embedded probe connection will generally provide

optimum probe performance because the signal interconnect lead length can be

minimized i

connections, contact Tektronix.

o acquire signals with the P7500 Series TriMode probes by including

f implemented correctly. For more information about embedded probe

Figure

17: Embedded probe fixture

16 P7500 TriMode Probe Family Technical Reference

Page 27

Reference

This section contains information about taking measurements with the TriMode

probes and increasing measurement accuracy.

Single-Ended Measurements Using A and B Modes

A differential probe such as the P7516 TriMode Probe can be used for single-ended

measurement

Single-ended probes such as the P7240 typically have a wider offset range than

differential probes, but with much lower bandwidth performance. (See Table 1.)

Table 1: Offset ranges

s within the limits of its dynamic and offset voltage ranges.

Probe DC Offset, 5X

P7240

P7516 TriMode Probe

(differential mode)

P7516 TriMode Probe

(Single-ended and common-mode)

+/- 5 V

+1.5 V, -1.5 V 1.5 V

+2.0 V, -2.0 V 1.5 V

Differential probes are ideal for a class of single-ended measurements where the

reference voltage is not ground:

SSTL_1,2: VTT,V

PECL: V

To measur

e single-ended signals in this class, connect the negative input of the

=VCC-1.3

REF

P7500 TriMode Probe to V

Adiffer

or DC variation in V

ential probe in these applications displays the true signal despite any AC

REF

the signal plus the variation in V

Differential probes can also be used to make ground referenced single-ended

measurements on either single-ended signals or differential signals like PCI

Express or Serial ATA. To measure ground referenced single-ended signals with

the handheld module, connect the negative input of the P7500 TriMode Probe to

ground.

REF

Dynamic

Range, 5X

4V

=VDD/2

.

REF

PP

PP

PP

DC Offset,

12.5X

–

+1.5 V, -1.5 V 3.5 V

+2.0 V, -2.0 V 3.5 V

Dynamic

Range, 12.5X

—

PP

PP

from its nominal value. A single-ended probe displays

.

REF

Single-ended measurements on differential signals are used to measure common

mode voltage and check for d ifferential signal symmetry. By using the TriMode

er tip, you can easily take these measurements with one connection. Cycle the

sold

Input Mode switch to display the signal that you want to view.

P7500 TriMode Probe Family Technical Reference 17

Page 28

Reference

Channel Isolation

Under ideal con

probe, no part of a signal applied to one input of the probe would appear on the

other input. In reality some portion of the signal on one input does “bleed” over to

the other input, and this effect increases with frequency. Channel isolation is a

measure of how much crosstalk occurs between the two probe inputs. The channel

isolation is defined with S-parameter measurements below, where:

A input = S1, B input = S2, Output = S3

A ISOLATION = 20 log (S32 / S31) | A Mode

B ISOLATION = 20 log (S31 / S32) | B Mode

A typical isolation plot for the P7500 series TriMode probes using an embedded

probe with zero-ground lead length is shown. Channel isolation performance is

highly dependent on probe tip attachment lead length. Good channel isolation

requires keeping the interconnect lead length for both signal and ground

connections very short. (See Figure 18.)

ditions when taking single-ended measurements with a differential

Figure 18: Typical channel isolation for P7500 Series TriMode probes

18 P7500 TriMode Probe Family Technical Reference

Page 29

Reference

Differential

Measurements

A differential probe is optimized to measure high speed differential signals.

Differential signals are formed from two complementary signals with a common

reference vo

Devices designed for differential measurements avoid problems presented by

single-ende

differential amplifiers, and isolators.

A different

differential measurements that reject any voltage that is common to the inputs and

amplifies any difference between the inputs. Voltage that is common to both

inputs is often referred to as the Common-Mode Voltage (V

is different as the Differential-Mode Voltage (V

ltage. (See Figure 19.)

d systems. These devices include a variety of differential probes,

ial probe is basically a differential amplifier, which is used to make

) and voltage that

CM

).

DM

Common

-Mode Rejection

Ratio

Figure 19: Simplified model of a differential amplifier

Differential amplifiers cannot reject all of the common-mode signal. The ability

of a differential amplifier to reject the common-mode signal is expressed as the

Commo

gain (A

n-Mode Rejection Ratio (CMRR). The CMRR is the differential-mode

) divided by the common-mode gain (ACM). It is expressed either as

DM

a ratio or in dB.

CMRR generally is highest (best) at DC and degrades with increasing frequency.

A typical CMRR plot for the P7500 Series TriMode probes is shown. (See

Figure 20 on page 20.)

P7500 TriMode Probe Family Technical Reference 19

Page 30

Reference

Figure 20: Typical CMRR for P7500 Series TriMode probes

Assessing CMRR Error

Input Impedance Effects

on CMRR

Differential-Mode

Rejection

The CMRR of the P7500 Series TriMode Probes is shown in graphs assuming a

sinusoidal common-mode signal.

A quick way to a ssess the magnitude of CMRR error when the common-mode

signal is not sinusoidal is to connect both leads to the same point in the circuit. The

oscilloscope displays only the common-mode component that is not fully rejected

by the probe. While this technique may not give you accurate measurements, it

does allow you to determine if the magnitude of the common-mode error signal

is significant. Make the probe tip wires the same length to maximize the probe

CMRR.

The lower the input impedance of the probe relative to the source impedance,

thelowertheCMRRforagivensourceimpedance imbalance. Differences

in the source impedance driving the two inputs lowers the CMRR. Note that

single-ended measurements generally result in asymmetric source impedances

which tend to reduce the differential mode CMRR.

When making common-mode signal measurements (A+B/2 -GND) with the

TriMode probe, it is desirable to reject the differential-mode signal p resent

between the two inputs. This rejection is expressed as the Differential-Mode

Rejection Ratio (DMRR), and is defined as the common-mode gain (A

by the differential-m

ode gain (A

). It is expressed either as a ratio or in dB, and

DM

) divided

CM

degrades at higher frequencies.

20 P7500 TriMode Probe Family Technical Reference

Page 31

Reference

Serial Bus Sta

ndards

The table below lists some popular high-speed data communication standards that

can be measured with the P7500 Series TriMode Probes.

Table 2: Seri

Standard Data Rate Vdm_max Vdm_min Vcm_max Vcm_min

HDMI/DVI 1.65 Gb/s

InfiniBand TX 2.5 Gb/s

InfiniBand RX 2.5 Gb/s

PCI Express TX 2.5 Gb/s

PCI Express RX 2.5 Gb/s

Serial ATA TX 1.5 Gb/s

Serial ATA RX 1.5 Gb/s

XAUI TX 3.125 Gb/s

XAUI RX 3.125 Gb/s

OIF-SxI-5 TX 3.125 Gb/s

OIF-SxI-5 RX 3.125 Gb/s

LV PECL (std ECL) >12 GHz

LV PE CL (RSECL) >12 GHz

al bus standards with dynamic range requirements

800 mV 150 mV 3.3 V 2.8 V

1.6 V 1.0 V 1.0 V 0.5 V

1.6 V 0.175 V 1.0 V 0.5 V

1.2 V 0.8 V

1.2 V 0.175 V

0.6 V 0.4 V 0.3 V 0.2 V

0.6 V 0.325 V 0.3 V 0.2 V

0.4 V

0.1 V

1.0 V 0.5 V 1.23 V 0.72 V

1.0 V 0.175 V 1.30 V 1.10 V

1.66 V

(typ)

1.05 V 0.70 V

1.48 V

AC AC

AC AC

1.3 V (vt) 0.5 V (vt)

1.3 V (vt) 0.5 V (vt)

P7500 TriMode Probe Family Technical Reference 21

Page 32

Specifications

Specification

s

These specific

ations apply to the P7500 Series TriMode Probes installed on an

oscilloscope with a TekConnect interface. When the probe is used with another

oscilloscope, the oscilloscope must have an input impedance of 50 Ω. The probe

must have a warm-up period of at least 20 minutes and be in an environment that

does not exceed the allowed limits. (See Table 3.)

Specifications for the P7500 Series TriMode Probes fall into three categories:

warranted, typical, and nominal characteristics.

Warranted

Characteristics

Warranted characteristics describe guaranteed performance within tolerance limits

or certain type-tested requirements.

Table 3: W

Characteristic Specification (applies to all models unless specified otherwise.)

Rise time

Usinga25

(18 to28ºC+64to+82°F)

DC attenuation accuracy 0.2125 ±2% (5X)

Output O ffset Zero ±3 mV (+20 to +30 °C, +68 to +86 °F) (5X) ±14.1 mV on oscilloscope

Temperature

Humidity

Altitude

1

Measurements taken using an embedded probe fixture

arranted electrical characteristics

1

10–90%

20–80%

0mVstep

P7513 P7516

<40 ps <32 ps

<28 ps <24 ps

0.0833 ±2% (12.5X)

±3 mV (+20

Operatin

Nonoperating: –20 to +71 °C (-4 to +160 °F)

Operating: 20–80% RH, at up to +40 °C (+104 °F)

Nonoperating: 5–90% RH

Operating: 3000 meters (10,000 feet)

Nonopera

to +30 °C, +68 to +86 °F) (12.5X) ±36 mV on oscilloscope

g: 0 to +40 °C (+32 to +104 °F),

ting: 12,000 meters (40,000 feet)

22 P7500 TriMode Probe Family Technical Reference

Page 33

Specifications

Typical Chara

cteristics

Typical characteristics describe typical but not guaranteed performance.

Table 4: Typical electrical characteristics

Characteristic Specification (applies to all models unless specified otherwise.)

Differential input resistance, DC coupled 100 kΩ ±6 kΩ

Input resistance matching

Common-mode input resistance, DC

coupled

Offset voltage range, differential-mode

Offset voltage range, single-ended and

common-mode (ground-referenced)

Offset scale accuracy, differential-mode 0.10 ±2%, referred to input

Offset scale accuracy, single-ended and

common-mode (ground-referenced)

Noise, differential-mode

Noise, single-ended and common-mode

(ground-referenced)

Delay time 4.4 ns ±0.1 ns

Input impedance

(See page 26, Tip Specifications.)

Common-mode rejection ratio,

differential-mode

(See page 26, Tip Specifications.)

Differential-mode rejection ratio,

common-mode

(See page 26, Tip Specifications.)

Channel isolation, single-ended mode

(See page 26, Tip Specifications.)

Maximum non destructive input voltage ±15 V

Differential signal range (DC coupled) ±0.750 V at attenuation setting of 5X

±250Ω side-to-side with respect to ground

50 kΩ ±3 kΩ

–1.5Vto+1.5V

–2.0Vto+2.0V

0.20 ±2%, referred to input

<33 nV/ (5X)

<48 nV/

<38 nV/ (5X)

<52 nV/

(See page 26, Tip Specifications.)

P7513 P7516Bandwidth

13 GHz 16 GHz

>60 dB at DC

>40dBto50MHz(5X)

>35dBto50MHz(12.5X)

>30dBto1GHz

>20dBto7GHz

>15dBto13GHz

>40dBto50MHz(5X)

>35dBto50MHz(12.5X)

>30dBto1GHz

>20dBto7GHz

>15dBto13GHz

>40dBto50MHz(5X)

>35dBto50MHz(12.5X)

>30dBto1GHz

>20dBto7GHz

>15dBto13GHz

(DC + peak AC)

±1.75 V at attenuation setting of 12.5X

(12.5X)

(12.5X)

>60 dB at DC

>40dBto50MHz(5X)

>35 dB to 50 MHz (12.5X)

>30dBto1GHz

>20dBto8GHz

>15dBto16GHz

>40dBto50MHz(5X)

>35 dB to 50 MHz (12.5X)

>30dBto1GHz

>20dBto8GHz

>15dBto16GHz

>40dBto50MHz(5X)

>35 dB to 50 MHz (12.5X)

>30dBto1GHz

>20dBto8GHz

>15dBto16GHz

between each input or between either probe inputs and ground

P7500 TriMode Probe Family Technical Reference 23

Page 34

Specifications

Characteristic Specification (applies to all models unless specified otherwise.)

Operating Voltage Window

Linearity

DC offset drift, differential-mode –0.47 mV/ °C (5X, referred to input)

DC offset drif

common-mode (ground-referenced)

DC voltage measurement accuracy ±2% of input + (2% of offset) + 15 mV + 4.7 mV) 5X

t, single-ended and

-2.0Vto+4.0V

±1% over a dynamic range of –0.75 V to +0.75 V for 5X

±1% over a dynamic range of –1.75 V to +1.75 V for 12.5X

–0.72 mV/ °C (1

+0.47 mV/ °C (5

+0.24 mV/ °C (12.5X, referred to input)

±2% of input + (2% of offset) + 75 mV + 20 mV) 12.5X

2.5X, referred to input)

X, referred to input)

Table 5: Typical mechanical characteristics

Characteristic Description

Dimensions, control box

Dimensions, probe body

Dimensions, cable length

Unit weight

125.4 mm × 41 mm × 35 mm (4.9 in × 1.6 in × 1.4 in)

101.6 mm × 8.89 mm × 19 mm (4.0 in × 0.350 in × 0.750 in)

1.0 m (39.3 i n) (from the probe body to the control box)

1.550 g (3.1 lbs) (probe, accessories and packaging)

Figure 21: Probe body and control box dimensions

24 P7500 TriMode Probe Family Technical Reference

Page 35

Specifications

Nominal Chara

cteristics

Nominal characteristics describe guaranteed traits, but the traits do not have

tolerance limits.

Table 6: Nomi

Characteristic Description

Input configuration

Output coupling DC

Attenuation settings 5X and 12.5X

Terminatio

nal electrical characteristics

n

P75TLRST solder tip: Differential (two signal

inputs, + and –; shared with single-ended))

Single-ende

and two ground inputs)

P75PDPM handheld: Differential (two inputs,

+ and –)

Terminate output into 50 Ω

d (one each + and – signal input

P7500 TriMode Probe Family Technical Reference 25

Page 36

Specifications

Tip Specificat

ions

This section lists specifications that are applicable to the probe when used with

the accessory tips available for the TriMode probes.

P75TLRST Tri

Mode Long

Reach Solder Tip

Probe model

(bandwidth) Rise time CMRR DMRR Channel Isolation

P7513 (>13.0 GHz) 10%–90%:

<40 ps

20%–80%:

<32 ps

P7516 (>16.0

GHz)

10%–90%:

<28 ps

20%–80%:

<24 ps

Specifications are typical and apply to all ranges and input modes unless specified

otherwise.

>60 dB at DC

>40dBat50MHz(5X)

>35dBat50M

>30 dB at 1 GHz

>20 dB at 7 GHz

>15 dB at 13 GH

>60 dB at DC

>40dBat50MHz(5X)

>35 dB at 50 MHz (12.5X)

>30 dB at 1 GHz

>20 dB at 8 GHz

>15 dB at 16 G Hz

Hz (12.5X)

z

>40dBat50MHz(5X)

>35 dB at 50 MHz (12.5X)

>30 dB at 1 GH

>20 dB at 7 GHz

>15 dB at 13 GHz

>40dBat50MH

>35 dB at 50 MHz (12.5X)

>30 dB at 1 GHz

>20 dB at 8 GHz

>15 dB at 16 GHz

z

z (5X)

>40dBat50M

>30 dB at 1 GHz

>20 dB at 7 GHz

>10dBat13GH

>40dBat50MHz

>30 dB at 1 GHz

>20 dB at 8 GHz

>6 dB at 16 GHz

Hz

z

Figure 22:

P75TLRST TriMode Long Reach Solder Tip dimensions

26 P7500 TriMode Probe Family Technical Reference

Page 37

Specifications

The following fi

the P75TLRST solder tip.

Figure 23: P7513 probe with the P75TLRST solder tip

gures show the typical step response of the TriMode probes with

Figure 24: P7516 probe with the P75TLRST solder tip

P7500 TriMode Probe Family Technical Reference 27

Page 38

Specifications

The following fi

TriMode probes with the P75TLRST solder tip.

Figure 25: P75TLRST differential impedance versus lump-element equivalent

gures show the typical impedance and bandwidth plots of the

Figure 26: P75TLRST common-mode impedance

28 P7500 TriMode Probe Family Technical Reference

Page 39

Specifications

Figure 27:

Figure 28: P75TLRST bandwidth on a P7516 probe

P75TLRST bandwidth on a P7513 probe

P7500 TriMode Probe Family Technical Reference 29

Page 40

Specifications

P75PDPM Precision

Differential Probing

Module

Specifications

are typical and apply to all ranges and input modes unless specified

otherwise.

Probe model (bandwidth) Rise time CMRR

P7513 (>13.0 GHz ) 10%–90%: <40 ps

20%–80%: <32 ps

P7516 (>16.0 GHz) 10%–90%: <28 ps

20%–80%: <24 ps

>60dBatDC

>40dBat50MHz(5X)

>35 dB at 50 MHz (12.5X)

>30 dB at 1 GHz

>20 dB at 7 GHz

>15dBat13GHz

>60dBatDC

>40dBat50MHz(5X)

>35 dB at 50 MHz (12.5X)

>30 dB at 1 GHz

>20 dB at 8 GHz

>15dBat16GHz

Figure 29: P75PDPM Precision Differential Probing Module dimensions

30 P7500 TriMode Probe Family Technical Reference

Page 41

Specifications

The following fi

the P75PDPM probing module.

Figure 30: P7513 probe with the P75PDPM probing module

gures show the typical step response of the TriMode probes with

Figure 31: P7516 probe with the P75PDPM probing module

P7500 TriMode Probe Family Technical Reference 31

Page 42

Specifications

The following fi

the TriMode probes with the P75PDPM probing module.

Figure 32: P75PDPM differential impedance versus lump-element equivalent

gures show the typical differential impedance and bandwidth of

Figure 33: P75PDPM bandwidth on a P7513 probe

32 P7500 TriMode Probe Family Technical Reference

Page 43

Specifications

Figure 34:

P75PDPM bandwidth on a P7516 probe

P7500 TriMode Probe Family Technical Reference 33

Page 44

Specifications

34 P7500 TriMode Probe Family Technical Reference

Page 45

User Service

This section covers troubleshooting and probe maintenance.

If your probe does not meet the specifications listed in the Specifications,youcan

send the probe to Tektronix for repair. (See page 48, Preparation for Shipment.)

Error Condit

ion

The LEDs on the probe alert you to error or status conditions affecting the probe.

When the probe is functioning correctly, there is a quick flash of the LEDs on

the probe ju

otherwise appear to be malfunctioning, an error condition may exist. Disconnect

the probe and reconnect it to another channel to isolate the problem. If the

symptoms persist with the probe, call your Tektronix representative for service.

st after connecting to the oscilloscope. If the probe LEDs flash or

P7500 TriMode Probe Family Technical Reference 35

Page 46

User Service

Replaceable Parts

The following parts may need to be replaced due to normal wear and damage.

When you repla ce these components, secure the probe in a small vise or positioner

to simplify the procedure.

Table 7: TriMode probes replaceable parts

Description Replacement part number

Probe body bullet contacts

P75TLRST Solder Tip wires

P75PDPM Probing Module

springs

P75PMT Probing Module

tips (left and right)

P75TC Probing Module Tip

Cable

013-0359-xx, kit of 4

020-2754-xx, Wire Replacement Kit, includes one bobbin

each: 4 mil wire, 8 mil wire, and SAC305 solder

016-1998-xx, kit of 4 (large springs)

016-1999-xx, kit of 4 (small springs)

P75PMT, one pair

P75TC, qty. 1

Refer to the user manual for a list of the accessories that are available for your

probe.

Table 8: Re

Descripti

Connecto

Ground sp

Tweezers

Magnifyi

microscope

Probe pos

vise

1

Nine-digit part numbers (xxx-xxxx-xx) are Tektronix part numbers.

quired equipment

on

r separator tool

ring tool

ng glass or

itioner or bench

Minimum re

Custom to

Custom to

General p

Free standing to allow

hands-fr

Abletoho

quirement

ol

ol

urpose

ee use

ld probe

Recommend

003-1897-xx

003-1900-xx

PPM203B o

ed example

r PPM100

1

36 P7500 TriMode Probe Family Technical Reference

Page 47

User Service

Replacing probe body

bullet contacts

The bullet cont

cycles. Follow these steps to replace the bullets by using the removal tool:

Remove.

1. Squeeze the tool plunger to extend the holder tangs.

2. Insert the tool into the probe body so that the holder tangs surround one of the

bullets.

3. Release the plunger to secure the holder tangs on the bullet.

4. Gently pull the tool outward to remove the bullet.

5. Repeat for the other bullet.

CAUTION. If you cannot extract the bullets with the bullet removal tool, use fine

needle-nosed pliers and a magnifying glass or microscope. Be careful not to

damage the probe body with the pliers.

acts in the probe body should be replaced every 200 insertion

Figure 35: Removing the bullets

P7500 TriMode Probe Family Technical Reference 37

Page 48

User Service

Install. When b

following:

1. Squeeze the to

2. Insert a new bullet into the tool so that the holder tangs surround the bullet.

3. Release the plunger to secure the holder tangs on the bullet.

4. Insert the tool into the probe body and seat the bullet in the recess.

5. Squeeze the tool plunger to release the bullet.

6. Gently pull the tool out of the probe body.

7. Repeat for th

oth bullets have been removed, install new bullets by doing the

ol plunger to extend the holder tangs

e other bullet.

Figure 36: Installing the bullets

38 P7500 TriMode Probe Family Technical Reference

Page 49

User Service

P75TLRST Solder Tip

Wires

The solder vias

small (0.012 in.), and require small wires to attach to your circuit. (Use the 4-mil

and 8-mil wires included with the Wire Replacement kit to make the connections.)

Because of the small dimensions, the solder tips have a limited number of solder

cycles that the vias can withstand before the Solder Tips become unusable.

Therefore, to prolong the life of your solder tips, consider the following points

before you u

CAUTION. To prevent damage to the c ircuit board or circuit board connections

due to accidental movement of the probe and soldered leads, we recommend that

you secure the tip to the circuit board using the adhesive tip tape provided in your

accessory kit. You can also use other materials such as Kapton tape or hot glue.

To avoid damage to the tip or the circuit under test, avoid applying excessive heat

from the soldering iron. Use a low wattage, temperature-controlled soldering iron

and appropriately sized soldering iron tip.

Consider the types of measurements that you plan to take. If you are going to take

a few measurements at one location and then move to another, you may be able to

use lon

may not matter), but the wires can then be cut o r desoldered a t your circuit and

reused, rather than subjecting the solder tip to a desolder/solder cycle.

ger wires. Longer wires may degrade your measurement slightly (which

on the circuit board at the end of the P75TLRST Solder Tip are

se the solder tips.

Perhaps the optional P75PDPM Precision Differential Probing Module is a better

choice for the test points that you do not measure as often. The probing module

can take both single-ended and differential measurements, and when used with

a probe positioner, can provide hands-free access to tight spaces. Depending

on your measurement requirements and circuit geometries, the probing module

ht be a preferable a lternative.

mig

At critical test points such as circuit outputs, you might need to keep the wires

hort as possible. If possible, use the solder tip dimensions shown in the

as s

Specifications section to lay out a matching footprint on your circuit board.

P7500 TriMode Probe Family Technical Reference 39

Page 50

User Service

P75PDPM Probing Module

Springs

Use the followi

Use a low-wattage, temperature-controlled soldering iron and a small mass

soldering iro

possible, while still providing a reliable solder joint.

Use SAC305 so

wires to the circuit under test.

The attachme

spacing. Use care when you solder a tip to a circuit under test to avoid

inadvertently desoldering either the attachment wires or the damping resistor.

For optimum performance and signal integrity, keep the lead length between

the DUT (Device Under Test) and the tip as short as possible, and the lead

lengths the same length.

Equipment Required: ground spring tool, magnifying glass or microscope,

tweezers, probe holder

ng precautions when you solder the tips:

n tip. The soldering iron temperature should be set as low as

lder (included with the wire replacement kit) to attach the tip

nt wires should be bent symmetrically to vary the interconnect

Figure 37: Large and small springs installed

40 P7500 TriMode Probe Family Technical Reference

Page 51

User Service

Remove.

1. Adjust the tip gap using the gap measurement tab on the spring tool. Set the

tool between the tip circuit boards, not the tips.

Figure 38

2. Insert th

Figure 39: Insert tool beneath spring

: Set the gap

e ground spring tool under the top of the spring.

P7500 TriMode Probe Family Technical Reference 41

Page 52

User Service

3. Rock the tool aw

ay from the tips so that the spring clears the seat edge.

Figure 40: Transfer spring from tip to tool

4. Gently pull the tool away; the spring should come away with the tool.

5. Put the spring in the accessory container or a safe place to avoid losing the

spring.

42 P7500 TriMode Probe Family Technical Reference

Page 53

User Service

Install.

1. Two spring sizes are available: the small spring allows 0.030 – 0.090 in.

(0.76 – 2.28 mm) tip span, the large spring allows 0.050 – 0.180 in.

(1.27–4.57mm

2. Check that the tip gap is .032 in. using the gap measurement tab on the spring

tool. Adjust

3. Using tweezers, install the spring on the tool. The tool has a large and small

side, one fo

of the tool as shown.

) tip span.

if necessary.

r each size spring. Make sure the gap in the spring is on the top

Figure 41: Place spring on tool

4. Set the bottom of the spring in the front seats (those c losest to the tip ends).

Maintain a slight pressure on the spring to keep it in the front seats.

Figure 42: Set spring in front seat

P7500 TriMode Probe Family Technical Reference 43

Page 54

User Service

5. Set the top of th

the rear seat with the top of the spring.

e spring in the rear seats by lifting the tool to clear the edge of

Figure 43: Set the spring in the rear seats

6. Gently retract the tool from the spring. Verify that the spring is seated as

shown.

Figure 44: Properly seated spring

44 P7500 TriMode Probe Family Technical Reference

Page 55

User Service

P75TC Probing Module Tip

Cable

Equipment Requ

1. Disconnect the Cable Tip by the inserting the tool between the connectors.

The tapered ed

tip connector.

Figure 45: Disconnecting the tip c able

ired: connector separator tool

ges of the tool gently separate the cable connector from the

P75PMT Probing Module

Tips (Left and Right)

2. Repeat for the other cable and then pull both cables away from the tip

connectors.

Equipment Required: connector separator tool, magnifying glass or microscope

(preferred), tweezers, and probe holder.

NOTE. The probing module tips are electrically matched pairs and should be

replaced together. Failure to do so may degrade the performance of your probe.

Figure 46: Probing module tips

P7500 TriMode Probe Family Technical Reference 45

Page 56

User Service

Remove.

1. DisconnecttheCableTips. (Seepage45,P75TC Probing Module Tip Cable.)

2. Remove the spring. (See page 40, P75PDPM Probing Module Springs.)

3. Adjust the tip gap to maximum width.

4. Use the connector separator tool or a small screwdriver to pry the board up

from the bottom. The bottom tabs are designed to flex; the top tabs are not.

Figure 47: Removing the tip

5. Repeat for the other tip.

Install.

6. Separate the new tip board pair by snapping the board against a sharp edge.

Figure 48: Separating the tip board pair

46 P7500 TriMode Probe Family Technical Reference

Page 57

User Service

7. Select the corr

board is notched to align it to the tip body.

Figure 49: Seating the tip in the top tabs

8. Press the bottom of the board to snap it past the bottom tabs.

ect board (left or right), and seat the board in the top tabs. The

Figure 50: Snapping the tip into the bottom tabs

9. Repeat steps 7 and 8 for the other tip.

10. Attach the spring. (See page 40, P75PDPM Probing Module Springs.)

11. Reattach the cable pair.

P7500 TriMode Probe Family Technical Reference 47

Page 58

User Service

Preparation f

or Shipment

If the original packaging is unfit for use or not available, use the following

packaging guidelines:

1. Use a corrugated cardboard shipping carton having inside dimensions at least

2. Put the probe into an antistatic bag or wrap to protect it from d ampness.

3. Place the probe into the box and stabilize it with light-weight packing material.

4. Seal the carton with shipping tape.

5. Refer to Contacting Tektronix on the copyright page of this manual for the

one inch greater than the probe dimensions. The box should have a carton

test strengt

shipping address.

h of at least 200 pounds.

48 P7500 TriMode Probe Family Technical Reference

Loading...

Loading...