Page 1

Service Manual

P7240 4 GHz

Active Probe

071-1056-00

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

*P071105600*

071105600

Page 2

Copyright © Tektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and

are protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in T echnical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software – Restricted Rights clause at F AR 52.227-19, as applicable.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

T ektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX, TEK, T ekConnect, and KlipChip are registered trademarks of Tektronix, Inc.

Page 3

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

To Avoid Fire or

Personal Injury

Connect and Disconnect Properly . Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry .

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

P7240 4 GHz Active Probe Service Manual

i

Page 4

General Safety Summary

Symbols and Terms

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

WARNING

High Voltage

Double

Insulated

Protective Ground

(Earth) Terminal

Not suitable for

connection to

the public telecom-

munications network

ii

P7240 4 GHz Active Probe Service Manual

Page 5

Preface

Manual Structure

Related Documentation

This is the service manual for the P7240 4 GHz Active Probe. Read this preface

to learn how this manual is structured and where you can find other information

related to servicing this product.

This manual contains three sections – Description, Performance Verification,

and Adjustment Procedures, and is intended to be used by qualified service

personnel. Replaceable parts are limited to accessories and adapters, and are

described in the Instruction Manual that is shipped with the probe.

Be sure to read the introductions to all procedures. These introductions provide

important information needed to do the service correctly, safely, and efficiently.

The probe is shipped with the following manual:

H

P7240 4 GHz Active Probe Instruction Manual. Tektronix part number

071-0759-XX.

P7240 4 GHz Active Probe Service Manual

iii

Page 6

Preface

Contacting Tektronix

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: support@tektronix.com

1-800-833-9200, select option 3*

6:00 a.m. – 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

iv

P7240 4 GHz Active Probe Service Manual

Page 7

Description

This document describes the Performance Verification and Adjustment Proce-

dures for the P7240 4 GHz Probe. There are no user-replaceable parts inside the

probe. If the probe fails the performance verification procedure, and adjusting the

probe cannot compensate for the failure, contact your Tektronix service center.

Performance Verification

Use the performance verification procedures to verify the warranted specifications of the P7240 probe. The recommended calibration interval is one year. No

software is required to complete a performance verification of the probe.

The performance verification procedures check the following specifications:

H

H

H

Output zero

DC attenuation accuracy

Rise time

Adjustments

The P7240 probe has two electronically-adjusted controls that rarely need

adjusting unless a performance verification yields a specification that is out of

tolerance, or the probe fails an oscilloscope probe calibration utility.

If you must make adjustments to the probe, you need the TekConnect Adjustment Software for the P7240 4 GHz Probe. Refer to Equipment Setup in the

Adjustment Procedures, step 7, for instructions on finding and loading the

adjustment software on your instrument.

The adjustment procedures describe the following adjustments for the probe:

H

Offset zero

H

Offset gain

P7240 4 GHz Active Probe Service Manual

1

Page 8

Description

Equipment Required

Refer to Table 1 for the equipment required to perform the service procedures.

T able 1: Equipment required for performance verification and adjustment procedures

Item description Performance requirement Recommended example

T ekConnect adjustment software

Sampling Oscilloscope ≥12.5 GHz bandwidth T ektronix TDS8000

Sampling head, with extension cable ≥12.5 GHz bandwidth Tektronix 80E0X with 012-1568-00 cable

Oscilloscope T ekConnect Interface T ektronix TDS7404

T ekConnect calibration adapter T ekConnect Interface 067-0422-00

Calibration Step Generator 250 mV step, ≤30ps rise time 067-1338-0X

Adapter TekConnect-to-SMA TCA-SMA

Adapter Probe tip with 50Wterminator 015-0678-00

DC Power Supply 1 VDC at 1 mA T ektronix PS280

DMM (2) with leads 0.05% accuracy, 0.1mV resolution Fluke 87 or equivalent

Feedthrough T ermination 50W ±0.05

BNC-to-BNC coaxial cable (2) 50W coaxial cable 012-0057-01

Coaxial cable Male-to-Male SMA 012-0649-00

Adapter SMA Male-to-Male 015-101 1-00

Adapter SMA Female-to-Female 015-1012-00

Adapter SMA Male-to-BNC Female 015-0554-00

Adapter (2) BNC Female-to-Dual Banana 103-0090-00

Adapter Y -lead adapter 196-3456-00

Adapters (2) KlipChip adapter 206-0364-00

SMA torque wrench 5/16-in, 7 in-lb.

SMA adapter wrench 7/32-in

1

Required for adjustment procedures only

1

P7240 Probe Optional Applications for Windows-Based

Oscilloscopes CD

W

011-0129-00

Special Adapters Required

Some of the adapters listed in Table 1 are custom-made and available only from

Tektronix. The adapters are described on the following pages.

2

P7240 4 GHz Active Probe Service Manual

Page 9

Description

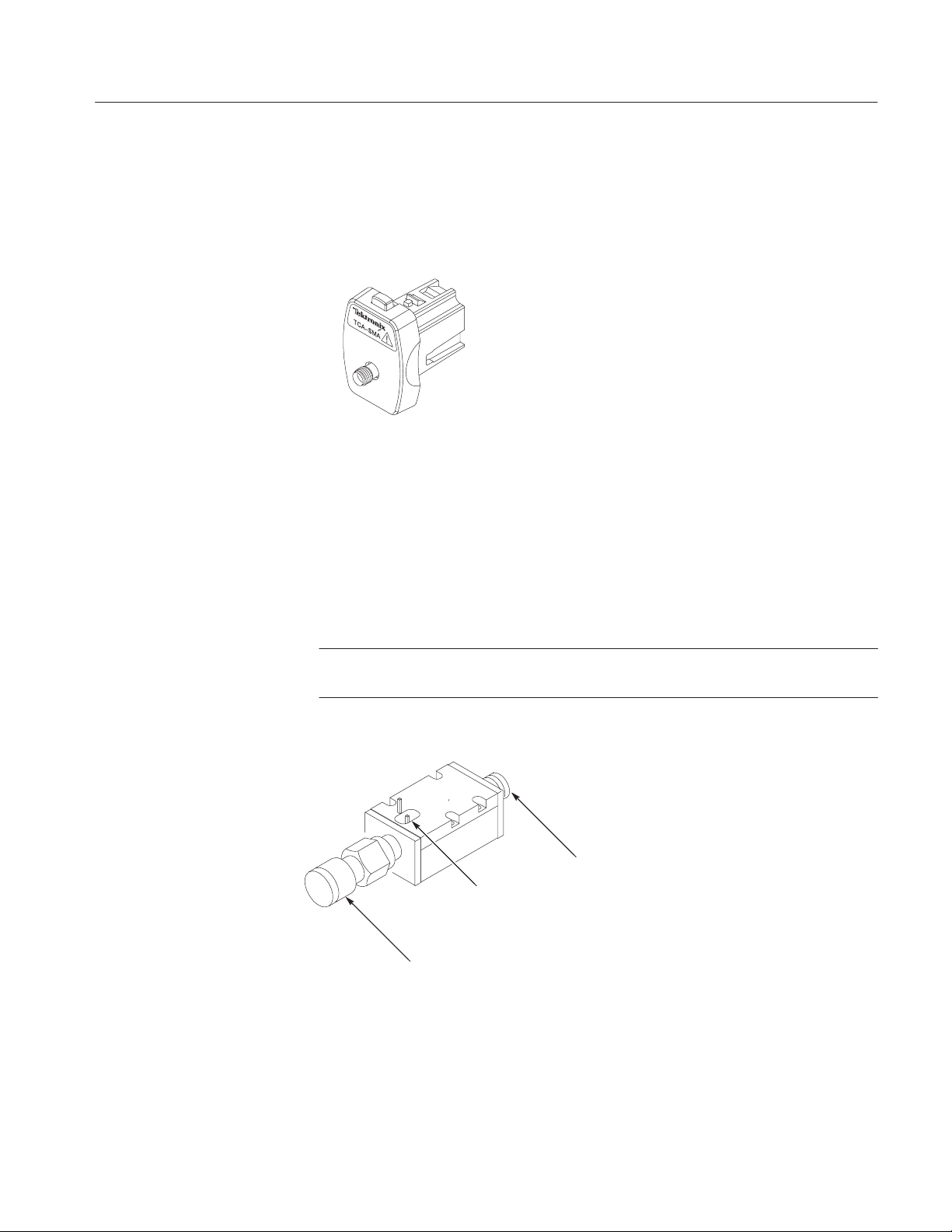

TekConnect-to-SMA

Adapter

Probe Tip Adapter

The TekConnect-to-SMA Adapter, Tektronix part number TCA-SMA, allows

signals from an SMA cable or probe to be connected to a TekConnect input.

See Figure 1. Connect and disconnect the adapter the same way as you do the

P7240 Probe.

Figure 1: TekConnect-to-SMA adapter

The probe tip adapter, Tektronix part number 015-0678-00, provides a low-noise

method for connecting the P7240 to signals present on SMA cables. The adapter

has a test point for the probe and two SMA connectors. A 50 ohm termination is

included with the adapter, and is connected to the SMA connector nearest the

probe test point to minimize relections. Connect the cable from the test circuit to

the other SMA connector. See Figure 2.

NOTE. When taking measurements, do not touch the probe tip adapter. Measurement accuracy is degraded when the probe tip adapter is handled.

SMA connector for test circuit

Probe test point

Terminator

Figure 2: Probe tip adapter

P7240 4 GHz Active Probe Service Manual

3

Page 10

Description

TekConnect Interface

Calibration Adapter

The TekConnect Interface Calibration Adapter, Tektronix part number

067-0422-00, connects between the host instrument and the probe under test, and

provides connectors for probe signal and offset voltage measurements.

See Figure 3.

Figure 3: TekConnect Interface Calibration Adapter

When the adapter is connected to the oscilloscope, the adapter is identified as a

valid calibration device. However, additional power supplies necessary to power

the probe are not enabled until a TekConnect probe is connected to the adapter

and identified by the oscilloscope. When a probe is detected through the adapter,

the Volts/div readout on the oscilloscope displays ##.

Refer to Table 2 on page 5 for features of the calibration adapter.

4

P7240 4 GHz Active Probe Service Manual

Page 11

T able 2: TekConnect Interface Calibration Adapter features

Feature Description

Description

Offset

switch

GND

Latch button

Latch

VAR

Offset

voltage

output

Signal

out

Latch button. The spring-loaded latch mechanically retains the adapter to the oscilloscope. To

release the adapter, grasp the adapter housing, depress the latch button, and pull the adapter

straight out of the oscilloscope.

Offset output select switch. The offset output switch selects between ground and the offset

voltage level from the oscilloscope.

Leave the switch in the ground position for the performance verification procedures.

Move the switch to the variable position for the adjustment procedures.

Offset voltage. The offset voltage of the probe is accessed through the BNC connector.

Measure the offset voltage using a DVM, BNC coaxial cable, and BNC-to-dual-banana jack.

Signal out. The SMA connector on the rear of the box allows for direct monitoring of the probe

signal.

Theory of Operation

Refer to Figure 4 as you read the following information.

There are two adjustments in the P7240 adjustment procedure: Offset Zero and

Offset Gain. These adjustments are made using digitally controlled potentiometers that are controlled by a two-wire serial interface from the host oscilloscope.

Because the adjustments are digitally controlled, the probe does not need to be

disassembled as part of the adjustment procedure. The software application

provides the control needed to make the adjustments to the probe.

P7240 4 GHz Active Probe Service Manual

5

Page 12

Description

Probe tip

Probe head Compensation box Oscilloscope

Probe tip

amplifier

EEPROM

Signal Out

Probe ID Out

Clock In

Offset to probe

+7 V

Offset ampifier

Probe

cable

+V

Offset

Linear

regulator

Offset

zero

–V

gain

T ekConnect

Interface

±1 V Offset

+15 V

–5 V

Ground

Figure 4: P7240 simplified schematic diagram

The offset signal from the oscilloscope extends the dynamic range of the P7240

probe by compensating for some of the DC voltage that may be part of the signal

applied to the probe. Compensation is accomplished by summing the offset

signal with the probe input signal at the probe input attenuator, as shown in

Figure 4. The host oscilloscope supplies the offset signal (with a range of ±1

volt) to the offset amplifier in the probe. Since the offset scale factor of the

P7240 probe is 5X, the effective offset signal range is increased to ±5 V.

The Offset Zero adjustment is used to null out any amplifier voltage offsets in

the offset signal path. With no input signal at the probe input and no offset signal

from the host oscilloscope, the Offset Zero is adjusted to produce 0.0000 V at the

probe output. Since the P7240 probe is designed to operate into a host oscilloscope with a 50 Ω load, a precision 50 Ω feed thru terminator is used in the

adjustment procedure.

The Offset Gain adjustment is used to adjust the offset amplifier gain for a

precise 1X scale factor. Since the P7240 input signal scale factor has been

designed with a 5X scale factor, the Offset Gain is adjusted to null out the

difference between a DC input signal and a 5X-scaled offset signal from the host

oscilloscope.

6

P7240 4 GHz Active Probe Service Manual

Page 13

Performance Verification

Use the following procedures to verify the warranted specifications of the P7240

probe. Before beginning these procedures, refer to page 14 and photocopy the

test record and use it to record the performance test results. The recommended

calibration interval is one year. These procedures test the following specifications:

H

Output zero

H

DC attenuation accuracy

H

Rise time

Equipment Setup

Use this procedure to set up the equipment to test the probe.

1. Connect the probe calibration adapter to the oscilloscope.

2. Connect the probe to the probe calibration adapter.

3. Turn on the oscilloscope, and enable the channel.

4. Verify that the Volts/div readout on the oscilloscope channel displays ##

(the oscilloscope recognizes the probe through the adapter).

5. Set the multimeters to read DC volts.

6. Allow 30 minutes for the equipment to warm up.

P7240 4 GHz Active Probe Service Manual

7

Page 14

Peformance Verification

Output Zero

Use this procedure to verify the probe output zero.

1. Connect the test equipment as shown in Figure 5.

2. Set the offset switch on the calibration adapter to GND.

NOTE. Leave the offset switch in the ground position for all of the performance

verification checks.

3. Ground the probe tip by connecting the probe tip to the probe ground socket.

(Connecting two KlipChip adapters together is recommended.)

4. Observe the multimeter display, and record the results on the test record.

The displayed DC level should be 0.000 V ±10 mV.

TDS7404 Oscilloscope

terminator

BNC-SMA adapter

multimeter

BNC-to-Dual

Banana Adapter

BNC cable

Digital

50W Precision

Figure 5: Setup for output zero

Set offset switch

to GND

KlipChip

adapters

TekConnect

Calibration adapter

Y-lead

adapter

P7240 Probe

8

P7240 4 GHz Active Probe Service Manual

Page 15

DC Attenuation Accuracy

1. Disconnect the KlipChip adapters, and connect the setup as shown in

Peformance Verification

Figure 6.

BNC-to-Dual

Banana Adapter

50W Precision

terminator

BNC-SMA

adapter

P7240

Probe

Digital

multimeter

Black (–)

TDS7404 Oscilloscope

Set offset switch

to GND

BNC cable

TekConnect

calibration

adapter

Digital multimeter

Power supply

–+

KlipChip

adapters

Red (+)

Figure 6: Setup for DC attenuation accuracy

Record the results of steps 2 through 5 separately. Use the results to calculate the

DC accuracy of the probe in step 6.

2. Set the power supply to +1.000 V. Use the multimeter connected to the

power supply to verify that the DC voltage is as close to +1.000 V as

possible. Record this measurement as Vmax.

3. Measure and record the reading of the other multimeter as M1.

4. Set the power supply to –1.000 V. Use the multimeter connected to the

power supply to verify that the DC voltage is as close to –1.000 V as

possible. Record this measurement as Vmin.

5. Measure and record the reading of the other multimeter as M2.

P7240 4 GHz Active Probe Service Manual

Y-lead adapter

9

Page 16

Peformance Verification

6. Determine the percent error by using the formula below:

%Error

+

M1–M2

(Vmax–Vmin) .2

–1 100%

Example:

%Error

0.2028–(–02021)

+

[1.007–(–0.998)] .2

0.4049

+

+

+)

–1 100%

0.4010

1.0097–1 100%

0.97%

–1 100%

The calculated error should be ≤2%.

7. Record the results on the test record.

NOTE. An unacceptable error value may result if a low tolerance termination is

substituted for the recommended termination.

Rise Time

10

This procedure verifies that the probe meets rise time specifications.

The probe rise time is calculated using rise times measured from the test system

separately, and the test system including the probe.

1. Connect the test equipment as shown in Figure 7 on page 11.

CAUTION. To prevent damage, use care when working with SMA connectors:

support equipment to avoid mechanical strain on the connectors, and use a

torque wrench when tightening connections.

P7240 4 GHz Active Probe Service Manual

Page 17

TDS7404 Oscilloscope

Peformance Verification

Set offset switch

to GND

Sampling head

extender cable

80E0X

SMA

M-to-M

adapter

CSA8000/TDS8000

TekConnect

Calibration adapter

TekConnect-toSMA Adapter

Generator remote

head

Calibration

step generator

Trigger input

SMA cable

Internal

clock output

Figure 7: Test system rise time setup

2. Set the oscilloscope trigger to internal clock.

3. Select the channel you have connected to on the 80E0X sampling head, and

then set the oscilloscope vertical scale to 50 mV/div.

NOTE. The output of the step generator rises from a –250 mV level to ground.

4. Adjust the oscilloscope horizontal and vertical position controls to display a

signal similar to that shown in Figure 7.

5. Set the oscilloscope horizontal scale to 50 ps/div and center the waveform.

6. Use the oscilloscope measurement capability to display rise time. Increase

the stability of the pulse edge measurement by using averaging, if available.

Rise time is determined from the 10% and 90% amplitude points on the

waveform. Record the rise time as t

The system rise time (ts) that you measured in step 6 represents the rise time of

the test system without the probe.

P7240 4 GHz Active Probe Service Manual

s.

11

Page 18

Peformance Verification

After you assemble the test setup that includes the probe, as shown in Figure 8,

you will measure the system and probe rise time (t

calculate the probe rise time (t

) in step 14.

p

) in step 13. This is used to

s+p

7. Set the step generator control switch to standby.

8. Remove the TekConnect-SMA adapter from the test setup.

9. Connect the test setup as shown in Figure 8 on page 12.

CAUTION. To prevent damaging the SMA connectors, use a 7/32-inch wrench

when connecting and disconnecting the female-to-female SMA adapter.

TDS7404 Oscilloscope

SMA

Sampling head

extender cable

M-to-M

adapter

80E0X

CSA8000/TDS8000

TekConnect

calibration adapter

P7240 Probe

Trigger input

Internal

clock output

50 W Terminator

Probe tip adapter

SMA F-to-F adapter

Generator remote head

Calibration

step generator

SMA Cable

Figure 8: Test system and probe rise time setup

10. Set the step generator control switch to on.

11. On the TDS8000, expand the horizontal scale to locate the step edge. Set the

vertical scale to 10 mV/div, and adjust horizontal range to 100 ps/div while

maintaining the edge view. For a more stable measurement display, turn

averaging on.

12

P7240 4 GHz Active Probe Service Manual

Page 19

Peformance Verification

12. Adjust the TDS8000 horizontal and vertical position controls to display a

signal similar to that shown in Figure 8.

NOTE. Do not touch the probe tip adapter when making calibration measurements. Measurement accuracy is degraded when the probe tip adapter is

handled.

13. Use the TDS8000 measurement capability to display rise time. Rise time is

determined from the 10% and 90% amplitude points on the waveform.

Record the rise time as t

s+p

.

14. Calculate the probe-only rise time using the following formula:

2

tp+

Ǹ

t

(s)p)

*

2

t

s

15. Check that the calculated rise time meets the probe specification. The rise

time (t

) must be v120 ps.

p

16. Record the results on the test record.

P7240 4 GHz Active Probe Service Manual

13

Page 20

Peformance Verification

T est record

Probe Model:

Serial Number:

Certificate Number:

T emperature:

RH %:

Date of Calibration:

Technician:

Performance test Minimum Incoming Outgoing Maximum

Output zero voltage

(at probe output)

± 10 mV (20_ C to 30_ C)

DC attenuation accuracy (% error) N/A ________ ________ ≤2 %

Rise time N/A ________ ________ ≤120 ps

– 10 mV ________ ________ + 10 mV

14

P7240 4 GHz Active Probe Service Manual

Page 21

Adjustment Procedures

These instructions are for personnel who are familiar with servicing the product.

If you need further details for disassembling or reassembling the product, refer to

the appropriate product manual. Contact your nearest Tektronix, Inc., Service

Center or Tektronix Factory Service for installation assistance.

CAUTION. To prevent static discharge damage, service the product only in a

static-free environment. Observe standard handling precautions for static-sensitive devices when servicing the probe. Always wear a grounded wrist strap,

grounded foot strap, and static resistant apparel when servicing the probe.

Equipment Setup

Use this procedure to set up the equipment to adjust the probe.

1. Turn on the oscilloscope and enable the channel you intend to use.

2. Connect the probe calibration adapter to the oscilloscope.

3. Connect the probe to the probe calibration adapter.

4. Verify that the Volts/div readout on the oscilloscope channel displays ##

(the oscilloscope recognizes the probe through the adapter).

5. Set the multimeters to read DC volts.

6. Allow 30 minutes for the equipment to warm up.

7. While the equipment is warming, verify that the application has been loaded

onto the oscilloscope:

a. Minimize the scope application window by going to File→Minimize.

b. Go to: Start→Programs→Tektronix→TekConnect Adjust

c. If the application is not loaded on the oscilloscope, get the application:

Retreive the application CD that came with the oscilloscope, insert the

CD in the drive, select Start→Run, and then enter D:\setup.exe

Or, download the application from the Tektronix website at:

www.tektronix.com/Software and Drivers/Accessories

8. When the application starts, the display appears as shown in Figure 9.

P7240 4 GHz Active Probe Service Manual

15

Page 22

Adjustment Procedures

Application Setup

Figure 9: TekConnect probe adjustment application

1. Make the following selections in the application dialog box:

a. Select P7240 in the Probe Type to Adjust list.

b. Select the oscilloscope channel that the adapter is connected to in the

Channel to Use list.

c. Select Adjustment in the Task to Perform list.

2. Click Continue.

3. The P7240 Probe Adjustments Dialog Box appears. See Figure 11 on

page 18.

NOTE. An error message appears if one of the following conditions exists:

H

A probe is not connected to the adapter.

H

A probe model other than a P7240 is connected to the adapter.

16

H

The P7240 connected to the adapter is defective (unable to properly

communicate with the adapter).

P7240 4 GHz Active Probe Service Manual

Page 23

Offset Zero

Adjustment Procedures

If an error message appears, click OK, correct the condition that caused the

error message, and then click Continue.

4. Proceed to the Offset Zero procedure.

NOTE. To avoid corrupted test results, do not disconnect the probe under test or

the probe calibration adapter until you have completed the service procedures. If

the probe or adapter are disconnected before completing the procedures, you

must reconnect the probe and adapter, and exit and restart the application.

Use this procedure to adjust the probe offset zero.

1. Connect the test equipment as shown in Figure 10.

TDS7404 Oscilloscope

terminator

BNC-SMA adapter

Set offset switch

to GND

Y-lead

adapter

TekConnect

Calibration adapter

P7240 Probe

KlipChip

adapters

connected

together

BNC-to-Dual

Banana Adapter

50WBNC cable

Digital

multimeter

50W Precision

Figure 10: Setup for offset zero

2. Set the offset switch on the calibration adapter to GND.

3. Click Offset Zero in the application window. See Figure 11 on page 18.

P7240 4 GHz Active Probe Service Manual

17

Page 24

Adjustment Procedures

Adjust slider to set

offset voltage on

DMM to 0.0000 V

Index value covers a

±20 mV range

Click Store Setting

after voltage is set

Channel Offset is

disabled in this step

Figure 11: Offset Zero window

4. Set the offset zero voltage on the DMM to 0.0000 V by adjusting the Offset

Zero Control. The index value in the Offset Zero Control varies from 0 to

3969, and corresponds to approximately ±20 mV of offset voltage range.

Use one of the following methods to make the adjustment:

H

Use your finger or the mouse to drag the on-screen slider up or down.

H

Click or touch the up/down arrow keys above and below the slider.

Each click adjusts the offset voltage by about 10 mV.

H

To increment by ten clicks or about 100 mV, click in the bar above or

below the slider.

18

P7240 4 GHz Active Probe Service Manual

Page 25

Offset Gain

Adjustment Procedures

5. When the offset zero voltage displayed on the voltmeter is 0.0000 V

±0.0001 V, click Store Setting to save the offset zero voltage level.

NOTE. In the Summary Info box, the After field updates with the control value

from step 5. This is a temporary value until Accept is selected later, after all

adjustments have been made.

If you select Accept now, the application requests confirmation: If you click Yes,

the application exits; if you click No, you are able to make further adjustments.

You must complete all adjustments before selecting Accept.

6. Proceed to the Offset Gain procedure.

Use this procedure to adjust the probe offset gain.

1. Set the DC power supply to –2.5 volts. Use a DMM to measure the voltage.

Record this voltage as M1.

Digital

multimeter

#1

BNC-to-Dual

Banana Adapter

BNC cable

50W Precision

terminator

BNC-SMA adapter

Figure 12: Setup for offset gain

2. Connect the test equipment as shown in Figure 12.

TDS7404 Oscilloscope

Set offset switch

to VAR

TekConnect

Calibration adapter

P7240 Probe

Digital

multimeter

BNC cable

#2

BNC-to-Dual

Banana Adapter

DC Power Supply

KlipChip

adapters

3. Set the offset switch on the calibration adapter to VAR.

+–

Y-lead

adapter

4. Click OFFSET GAIN in the application window. See Figure 13 on page 20.

P7240 4 GHz Active Probe Service Manual

19

Page 26

Adjustment Procedures

Adjust slider to set

offset gain on DMM

#1 to value calculated in step 6.

Click Store Setting

after gain and offset

are set.

Adjust slider to set

DMM #2 to 0.5 V.

Figure 13: Offset Gain window

NOTE. Channel offset is multiplied by the 5X attenuator in the probe. The offset

voltage (+ 0.5 V) measured at the BNC connector on the Calibration Adapter

nulls out the –2.5 V applied to the probe input.

5. Set the Channel Offset control to display 0.5 V on DMM #2.

Use one of the following methods:

H

Use your finger or the mouse to drag the on-screen slider up or down.

H

Click or touch the up/down arrow keys above and below the slider.

Each click adjusts the offset voltage by about 1 mV.

H

To increment by ten clicks or 10 mV, click in the bar above or below the

slider.

20

Record this voltage as M2.

P7240 4 GHz Active Probe Service Manual

Page 27

Adjustment Procedures

6. Determine the offset gain target value by using the formula below:

Offset gain target value

+

M1

5

)

M2

7. The Offset Gain voltage is displayed on DMM #1. Adjust the Offset Gain

Control to the offset gain target value, ±1 mV, using one of the following

methods:

H

Use your finger or the mouse to drag the on-screen slider up or down.

H

Click or touch the up/down arrow keys above and below the slider.

Each click adjusts the offset voltage by about 1 mV.

H

To increment by ten clicks or 10 mV, click in the bar above or below the

slider.

8. When the offset gain displayed on DMM #1 is within ±1 mV of the offset

gain target value, click Store Setting to save the offset gain level.

In the Summary Info box, the AFTER field updates with the control value from

step 8. This is a temporary value until Accept is selected.

9. Click Accept to save all the values that you set in these procedures.

10. Click Yes to update the contents.

Verify Operation

This completes the adjustments to the probe.

Do the Performance Verification procedures to verify that the probe meets

specifications.

g

End of document

g

P7240 4 GHz Active Probe Service Manual

21

Page 28

Adjustment Procedures

22

P7240 4 GHz Active Probe Service Manual

Loading...

Loading...