Page 1

xx

P6910

ZZZ

General Purpose Logic Analyzer Probe

Instruction Manual

www.tektronix.com

P077063000*

*

077-0630-00

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 500

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

Worl dwid e, visi t www.tektronix.com to find contacts in your area.

Page 3

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, with shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from improper use or connection t o incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other than Tektronix representatives to install, repair or service the product;

Page 4

Page 5

Table of Contents

General Safety Summary ......................................................................................... iii

Service Safety Summary.............. .................................. ................................ ........... v

Compliance information .......................................................................................... vi

Safety comp

Environmental considerations .............................................................................. vii

Preface .............................................................................................................. ix

Related documentation......................... ................................ .............................. ix

Operating basics ..................... ................................ ................................ ............... 1

Product description ..................... ................................ ................................ ....... 1

P6910 pr

Probe label overview ................. .................................. ................................ ....... 2

Apply the labels to the probe .............. ................................ .................................. . 4

Connect the probe to the instrument................ .................................. ....................... 6

Connect the probe directly to the SUT ...................................................................... 7

Option 1K accessories.................................. ................................ ....................... 9

on 2K accessories.................... ................................ ................................ .... 10

Opti

Reference ............... .................................. ................................ .......................... 17

Clock and qualifiers .......................................................................................... 17

Multiplexed buses .... ..... . ..... . ... . . . .... . ..... . ..... ..... . ..... . ... . . . .... . ..... . ..... ..... . ..... . ... . . . .. 18

Range recognizers ...................... .................................. ................................ .... 19

Probe signal names ........................................................................................... 20

obe footprints ............................................................................................... 23

Pr

Load models................................................................................................... 24

Specifications........................ ................................ ................................ .......... 24

Maintenance........................................................................................................ 27

Probe calibration information ........... .................................. ................................ .. 27

Probe service strategy information.......................................................................... 27

Perform the functional check .................... ................................ ............................ 27

Inspect or clean the probe................ .................................. ................................ .. 28

Repackage the probe ......................................................................................... 28

Replaceable parts .................................................................................................. 29

Parts ordering information ................................................................................... 29

Glossary

Index

liance ............................................................................................ vi

obe accessory information ......................................................................... 1

P6910 General Purpose Probe Instruction Manual i

Page 6

Table of Contents

List of Figure

Figure 1: Example of a sheet of P6910 probe labels .............. .................................. ........... 3

Figure 2: At

Figure 3: Connect the probe to the logic analyzer . ................................ ............................. 7

Figure 4: Option 1K accessories.................................................................................. 9

Figure 5: Option 2K accessory kit contents ........ .................................. .......................... 11

Figure 6: Installing the standard adapter on the PCB. . .... . ..... . ..... . ... . . ..... . ..... . ... . . . .... . ..... . ..... 11

Figure 7: Install the wide body adapter on the PCB ........................................................... 12

Figure 8:

Figure 9: Install the adapter holder by gluing it to the circuit board......................................... 14

Figure 10: Insert the lead set into the hand browser....................... ................................ .... 14

Figure 11: Use the grouper to hold the lead sets together..................................................... 15

Figure 12: Clearance and insertion force information for the lead sets ....................... .............. 16

Figure 13: P6910 General-Purpose probe land footprint...................................................... 23

e 14: Single podlet load model ............................................................................ 24

Figur

taching the probe labels ........ ................................ .................................. ... 5

Install the adapter to the SUT with the insulated wire............................................. 13

s

List of Tables

Table 1: Logic analyzer clock and qualifier availability .... . ..... . ..... ..... . ..... . ..... . ..... . ..... . ..... . .. 17

Table 2: 2X demultiplexing source-to channel assignments.. . . ..... . ..... . ..... . ... . . . .... . ..... . ..... . ..... 18

Table 3: 4X demultiplexing source-to channel assignments.. . . ..... . ..... . ..... . ... . . . .... . ..... . ..... . ..... 19

Table 4: Signal c onnections on 136- and 102-channel instruments for probe 4 and probe 3 .... . ..... . .. 20

Table 5: Signal c onnections on 102- and 136-channel instruments for probe 2 and probe 1 .... . ..... . .. 21

able 6: Signal connections on 68- and 34-channel instruments............................................. 22

T

Table 7: Mechanical and electrical specifications............................................ .................. 24

Table 8: Environmental specifications ........ ................................ .................................. 25

Table 9: Service options ............ ................................ ................................ .............. 27

ii P6910 General Purpose Probe Instruction Manual

Page 7

General Safety Summary

General Safet

To Avoid Fire or Personal

Injury

ySummary

Review the fo

this product or any products connected to it.

To avoid pot

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions r

Ground the product. This product is indirectly grounded through the grounding

conductor of the mainframe power cord. To avoid electric shock, the grounding

conductor must be connected to earth ground. Before making connections to

the input or output terminals of the product, ensure that the product is properly

ground

Observe all terminal ratings. To avoid fire or shock hazard, observe all ratings

and ma

information before making connections to the product.

The i

ed.

nputs are not rated for connection to mains or Category II, III, or IV circuits.

llowing safety precautions to avoid injury and prevent damage to

ential hazards, use this product only as specified.

elated to operating the system.

rkings on the product. Consult the product manual for further ratings

Connect the probe reference lead to earth ground only.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do not operate without covers. Do not operate this product with covers or panels

removed.

Do not operate with suspected failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Avoid exposed circuitry. Do not touch exposed connections and components when

power is present.

P6910 General Purpose Probe Instruction Manual iii

Page 8

General Safety Summary

TermsinThisManual

Symbols and Terms on the

Product

Do not operate i

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

These terms

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

DANGER

the marking.

WARNI

read the marking.

CAUT

n wet/damp conditions.

may appear in this manual:

indicates an injury hazard immediately accessible as you read

NG indicates an injury hazard not immediately accessible as you

ION indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

iv P6910 General Purpose Probe Instruction Manual

Page 9

Service Safety Summary

Service Safet

y Summary

Only qualifie

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

UseCareWhenServicingWithPowerOn. Dangerousvoltagesorcurrentsmay

exist in

disconnect test leads before removing protective p anels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

d personnel should perform service procedures. Read this Service

this product. Disconnect power, remove battery (if applicable), and

P6910 General Purpose Probe Instruction Manual v

Page 10

Compliance information

Compliance in

Safety compliance

Equipment type

Safety class

Pollution

degree

description

formation

This section

instrument complies.

Test and measuring equipment.

Class 1 – grounded product.

A measure of the contaminants that could occur in the environment around

and within a product. Typically the internal environment inside a product is

considered to be the same as the external. Products should be used only in the

environ

Pollution Degree 1. No pollution or only dry, nonconductive pollution occurs.

Produc

located in clean rooms.

lists the safety and environmental standards with which the

ment for which they are rated.

ts in this category are generally encapsulated, hermetically sealed, or

ollution degree

P

tion Degree 2. Normally only dry, nonconductive pollution occurs.

Pollu

Occasionally a temporary conductivity that is caused by condensation must

be expected. This location is a typical office/home environment. Temporary

condensation occurs only when the product is out of service.

Pollution Degree 3. Conductive pollution, or dry, nonconductive pollution

that becomes conductive due to condensation. These are sheltered locations

where neither temperature nor humidity is controlled. The area is protected

from direct sunshine, rain, or direct wind.

Pollution Degree 4. Pollution that generates persistent conductivity through

conductive dust, rain, o r snow. Typical outdoor locations.

Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor use only.

vi P6910 General Purpose Probe Instruction Manual

Page 11

Environmental considerations

This section provides information about the environmental impact of the product.

Compliance information

Product End-of-Life

handling

Restriction of hazardous

substances

Observe the f

Equipment recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could be

harmful to the environment or human health if improperly handled at the product’s

end of life. To avoid release of such substances into the environment and to

reduce the

an appropriate system that will ensure that most of the materials are reused or

recycled appropriately.

This pr

scope of the 2002/95/EC RoHS Directive.

ollowing guidelines when recycling an instrument or component:

use of natural resources, we encourage you to recycle this product in

This symbol indicates that this product complies with the applicable European

Union re

on waste electrical and electronic equipment (WEEE) and batteries. For

information about recycling options, check the Support/Service section of the

Tekt r on

oduct is classified as Monitoring and Control equipment, and is outside the

quirements according to Directives 2002/96/EC and 2006/66/EC

ixWebsite(www.tektronix.com).

P6910 General Purpose Probe Instruction Manual vii

Page 12

Compliance information

viii P6910 General Purpose Probe Instruction Manual

Page 13

Preface

Related documentation

Preface

The followi

ng list and table provide information on the related documentation

available for your Tektronix product. For additional information, refer to the

Tektronix Web site (www.tektronix.com/manuals).

Related documentation

Item Purpose

TLA Quick Start User Manuals

Online Help

Installation Reference Sheets High-level installation information

Installation Manuals

XYZs of Logic Analyzers

Declassification and Securities instructions Data security concerns specific to sanitizing

Application notes

Product Specifications & Performance

Verification Procedures

TPI.NET Documentation

Field upgrade kits

Optional Service Manuals Self-service documentation for modules and

High-level operational overview

In-depth operation and UI help

Detailed first-time installation information

Logic analyzer basics

or removing memory devices from Tektronix

products

Collection of logic analyzer application

specific notes

TLA Product specifications and performance

verification procedures

Detailed information for controlling the logic

analyzer using .NET

Upgrade information for your logic analyzer

mainframes

P6910 General Purpose Probe Instruction Manual ix

Page 14

Preface

x P6910 General Purpose Probe Instruction Manual

Page 15

Operating basics

Product description

This section provides a brief description o f the Tektronix P6910 General Purpose

Logic Analyzer Probe, probe accessories, probe labels, and probe accessory

connection i

nstructions.

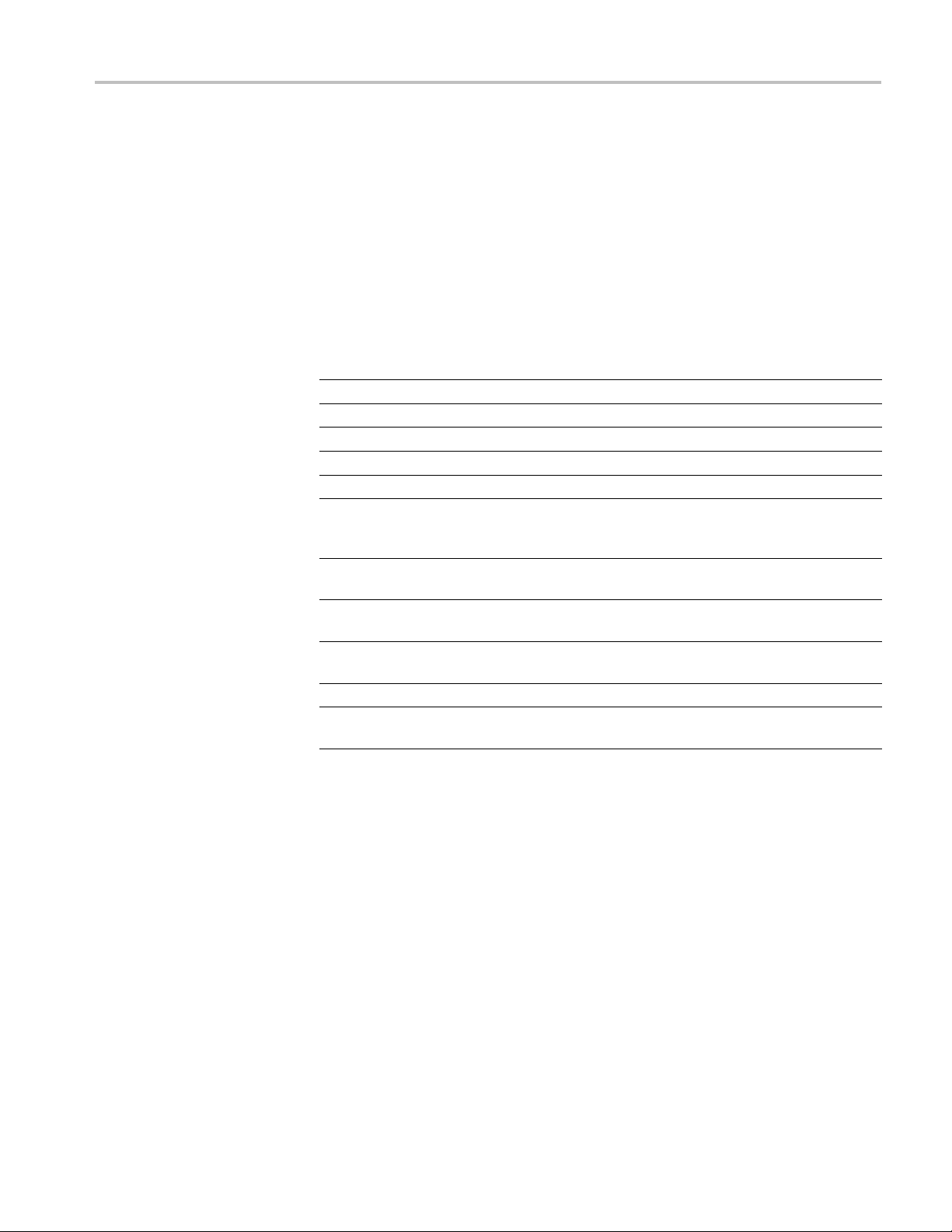

The P6910 p

from a Tektronix logic analyzer to the SUT (system-under-test).

The follo

34 individual active channel connections

Differential and single-ended data, clock and qualification inputs

Lead set support for both single-ended and differential applications

Holder for 8-channel applications

Color-coded signal connectors

–2.5 V

Minimal loading of <1 pF and 20 kΩ to ground

Operation in normal or inverted polarity is acceptable

Any common mode voltage is acceptable as long as the maximum positive

voltage does not exceed +5 V and the maximum negative voltage does not

exceed –2.5 V

robe is a 34-channel, general purpose probe that provides connections

wing list details the capabilities and qualities of the P6910 probe:

to +5 V input operating range

P6910 probe accessory information

The P6910 probe includes accessories to connect the logic analyzer to the SUT.

The following accessories are available for the P6910 probe:

Option 1K provides accessories for probing applications for less than

100 MHz. Tektronix recommends ordering two of each of the accessories

for a 34-channel probe. Details on the accessories are provided later in this

document. (See page 9, Option 1K accessories.)

Option 2K provides a probe accessory kit (Tektronix part number,

020-2973-01 or higher) for high-performance probing applications; provides

different means to connect the logic analyzer to the SUT. Tektronix

recommends ordering two accessory kits for a 34-channel probe. Details on

the accessory kit contents are provided later in this document. (See page 10,

Option 2K accessories.)

P6910 General Purpose Probe Instruction Manual 1

Page 16

Operating basics

Probe label overview

Probe labels, o

P6910 General Purpose Logic Analyzer Probe Instruction Manual (Tektronix

part number, 0

downloadable from the Tektronix Web site: www.tektronix.com/manuals)

The logic analyzer probe comes with a shee t of labels to apply to the probe before

connecting the probe to the instrument and SUT.

Tektronix provides a sheet of color-coded labels to apply to the probe to help

identify the connections to the logic analyzer and to the SUT. The label color is

designed to match the color of the probe connections on the logic analyzer. A set

of custom labels is also available for custom applications.

NOTE. If you are labeling probes for either 34- or 68-channel logic analyzers, use

a combi

this probe are grouped within a dashed red line. (See Figure 1 on page 3.)

nation of two sets of probe labels for one of your probes. The labels for

ne sheet

77-0630-xx, available on the TLA Documentation CD or

2 P6910 General Purpose Probe Instruction Manual

Page 17

Operating basics

Figure 1: Example of a sheet of P6910 probe labels

P6910 General Purpose Probe Instruction Manual 3

Page 18

Operating basics

Apply the labels to the p robe

Attach the labels to logic analyzer-end of the probe and to each of the four way

stations.

Attach the color-coded labels to the probe to help you identify the logic analyzer

and probe connections when connecting the probe to the SUT.

1. Determine the channel groups that you plan to use on your logic analyzer and

identify the matching labels.

Refer to the logic analyzer to identify the number of probe connections

(dependent on the number of channels on the instrument) and the channel

color-coding that corresponds to the provided sheet of probe labels.

2. Identify the logic analyzer end of the probe. (See Figure 2 on page 5.)

3. Using a pair of flat-nosed tweezers, place the tip of the tweezers under the

upper right corner of the logic analyzer-end label.

This will be the largest label of the five labels. Grasp the corner of the label

and lift the label up and toward you.

4. Carefully align the label to the label indent located on the top of the logic

analyzer-end and apply the label.

5. Identify the four way stations. (See Figure 2 on page 5.)

Note that the logic analyzer end label contains two colors. From the logic

analyzer end follow one of the two colors down the length of the cable to

the way station.

6. Using a pair of flat-nosed tweezers, place the tip of the tweezers under the

upper right corner of the matching color-coded way station.

Grasp the corner of the label and lift the label up a nd toward you.

7. Carefully align the label to the label indent located on the top of the way

station and apply the label.

8. Repeat step 7 for the second way station of the same color (but different label

shape).

9. Repeat the above steps for the other logic analyzer-end label colors .

After applying the labels to the probes, you are ready to connect the probes to

the logic analyzer.

4 P6910 General Purpose Probe Instruction Manual

Page 19

Operating basics

Figure 2: Attaching the probe labels

P6910 General Purpose Probe Instruction Manual 5

Page 20

Operating basics

Connect the pr

obe to the instrument

The P6910 probe connects a TLA6200 Series logic analyzer or TLA7000 Series

logic analyzer with TLA7Axx or TLA7Bxx logic analyzer modules to the SUT.

Apply the labels to the probes before connecting the probes to the instrument

and to the SUT.

Connect the probes to the logic analyzer using the following steps:

1. Match the color-coded labels of the probe to the same color-coded connector

on the logic analyzer. (See Figure 3 on page 7.)

2. Identify the beveled edges of the connector inside the logic analyzer end

of the probe.

3. Align the beveled edges of the connector to its mating connector on the logic

analyzer and press into place.

4. Evenly tighten both screws on the logic analyzer end of the probe until they

are snug.

Tighten each screw to 4 in-lbs (max).

CAUTION. When attaching the probe to the logic analyzer, use care to evenly

tighten probe screws until they are snug. Under-tightening the probe screws can

lt in intermittent operation. Over-tightening can result in stripped screws.

resu

NOTE. The P6910 probe can be connected to the logic analyzer when it is

ered on. The probe head can also be connected to the SUT without turning

pow

the power off.

6 P6910 General Purpose Probe Instruction Manual

Page 21

Operating basics

Figure 3: Connect the probe to the logic analyzer

Connect the probe directly to the SUT

Connect the probe directly to square pin connectors on the SUT.

CAUTION. The probe can be damaged by incorrectly connecting the probe to

the SUT. Incorrect handling of the probe while connecting it to the SUT can

damage the probe or the mating connector on the SUT. Always position the probe

endicularly to the mating connector and then connect the probe.

perp

P6910 General Purpose Probe Instruction Manual 7

Page 22

Operating basics

1. Connect the pro

The probe is compatible with differential and single-ended signals. The (-)

lead can be con

NOTE. Connect lead sets in groups or to individual locations on the SUT. If

necessary, use the grouper from the accessories kit to hold the lead set together.

2. ConnectthewaystationgroundconnectortoagroundontheSUT.

NOTE. The lead sets have true differential inputs. For single-ended use, the

negative input of the lead set can be connected to ground. However, the ground

lead from each way station is provided to connect the probe ground to the SUT

ground.

be to the square pins on the SUT.

nected to the (-) side of a differential signal or to ground.

8 P6910 General Purpose Probe Instruction Manual

Page 23

Operating basics

Option 1K acce

ssories

Option 1K provides probe accessories to connect the P6910 probe to the SUT for

applications for less than 100 MHz. The following table and illustration show

the probe acc

Ref

number Item Quantity

1 8-channel lead set 2 ea 196-3470-01

2 1-channel lead set 1 ea 196-3471-01

3

4 Probe grabber tips 2 ea

1

Instructions for installing the probe grouper are provided later in this manual. (See page 15, Install the probe

grouper (Option 1K and 2K).)

essories.

Probe Grouper kit

Header, 2 X 8 pin

2ea

1ea

1 package of 10 tips

Tektronix

part number

020-3042-

020-2896-00

00

Figure 4: Option 1K accessories

P6910 General Purpose Probe Instruction Manual 9

Page 24

Operating basics

Option 2K acce

ssories

Option 2K provides probe accessories with different means to connect the P6910

probe to the SUT.

Determine which method meets your particular needs. For some cases, you may

need to either glue or solder the adapters to the SUT before connecting the probe.

Not all of th

e accessories in the kit are needed for use with this probe.

The accessory kit is identical to the one used with the P6780 MSO probe. Either

the P6780 o

r P6910 probes can connect to any of the accessories in the kit. The

accessories enable users to share accessories between either probe as well as

switching between logic analyzer and oscilloscope probing applications.

The following table describes the contents of the accessory kit.

Tektronix part

Item Quantity

Standard Adapter Kit of 17 ea

Wire Tubing

Ferrite Bead

Wide Body Adapter

Flex Adapter

Insulated Wire

25°/55° Holder Kit of 17 ea

Lead set Ground Kit of 2 ea

Hand Browser

Probe Grouper

Header, 2 X 8 pin

Kitof34ea

Kitof17ea

Kitof17ea

Kitof17ea

15 ft. (4.57 m)

Kit of 2 ea

2ea

1ea

number

020-3035-01

020-3037-01

020-3034-01

020-3036-01

020-3033-01

020-3021-00

020-3032-01

020-3038-00

020-3031-00

020-3042-00

10 P6910 General Purpose Probe Instruction Manual

Page 25

Operating basics

Install the standard adapter

The following fi

Figure 5: Option 2K accessory kit contents

Use the general purpose standard adapters for soldering to the com

vias on the SUT.

gure shows the individual contents of the accessory kit.

ponent pins or

Install adapters on the PCB as n eeded to connect the probe to the SUT.

1. Locate the standard adapter in the accessory kit and trim the length according

to your needs.

2. Trim the wire tubing to the desired length and slide it over the adapter leads.

(SeeFigure6onpage11.)

Figure 6: Installing the standard adapter on the PCB

P6910 General Purpose Probe Instruction Manual 11

Page 26

Operating basics

Install the wide body

adapter

3. Attach the ferr

4. Insert the ends of the adapter onto the PCB.

5. Solder the adapter to the PCB.

6. Connect the probe lead set to the adapter.

Use the wide body adapter to firmly hold the probe lead set in place on the PCB.

The adapters can be stacked or grouped together depending on the connection

needs.

Install the wide body adapter on the PCB after installing the wire tubing and

ferrite bead:

1. Locate the wide body adapter in the accessory kit and trim the length

according to your needs.

2. Trim the wire tubing to the desired length, attach the ferrite bead (if needed

to improve the signal quality), and slide the ferrite bead and tubing over the

adapter leads.

3. Insert the ends of the adapter onto the PCB.

4. Solder the adapter to the PCB.

ite bead as needed to improve the signal quality. (See Figure 6.)

5. Identify where to place the wide body adapter on the PCB and glue it into

place. (See Figure 7 on page 12.)

Figure 7: Install the wide body adapter on the PCB

6. Connect the probe lead set to the adapter.

12 P6910 General Purpose Probe Instruction Manual

Page 27

Operating basics

Install the flex adapter

Use the flexible

1. Determine the location for the flex adapter on the circuit board.

The adapter connects to the SUT through the insulated wire provided with

the accessory kit.

2. Use a soldering iron to melt the insulation on the wire to connect the adapter

totheSUT.(SeeFigure8onpage13.)

Use two wires to connect differential signals from the probe to the SUT.

tip to connect to circuit board vias on the SUT.

Install the 25° /55° holder

Figure 8: Install the adapter to the SUT with the insulated wire

3. Solder one end of the wire to the circuit board as shown. (See Figure 8.)

Install the second wire in the same manner.

4. Install the flex adapter over the two wires and solder it in place.

5. Connect the probe lead set to the adapter.

Use the holders to provide strain relief for the flex adapter and standard adapter

a 25° or 55° angle.

at

1. Determine if you want to use the holder with the adapters at a 25° or 55° angle

n the circuit board.

o

Rotate the holder to work at either angle.

2. Position the holder so that the leads of the flex adapter or standard adapter

align to the connections on the circuit board and glue the holder into place.

(See Figure 9.)

P6910 General Purpose Probe Instruction Manual 13

Page 28

Operating basics

Install the hand browser

Figure 9: I

3. Install t

Use the hand browser to temporarily connect to signals o f interest on the SUT.

1. Insert the lead set into the hand browser. (See Figure 1 0.)

nstall the adapter holder by gluing it to the circuit board

he lead set and the adapter in the holder.

Figure 10: Insert the lead set into the hand browser

2. Position the probe tips as needed to connect to the signal of interest on the

SUT.

Theprobetipsswivel360°.

14 P6910 General Purpose Probe Instruction Manual

Page 29

Operating basics

Install the probe grouper

(Option 1K and

2K)

Use the probe gr

pins on the SUT.

1. Connect the le

The header te

grouper.

Figure 1

2. Place t

3. Remove the header from the lead sets.

1: Use the grouper to hold the lead sets together

ouper to group lead sets together for connections to adjacent

ad sets to the header. (See Figure 11.)

mporarily holds the lead sets in place while you install the

he grouper around the lead sets and close it in place.

4. Connect the assembly to the SUT.

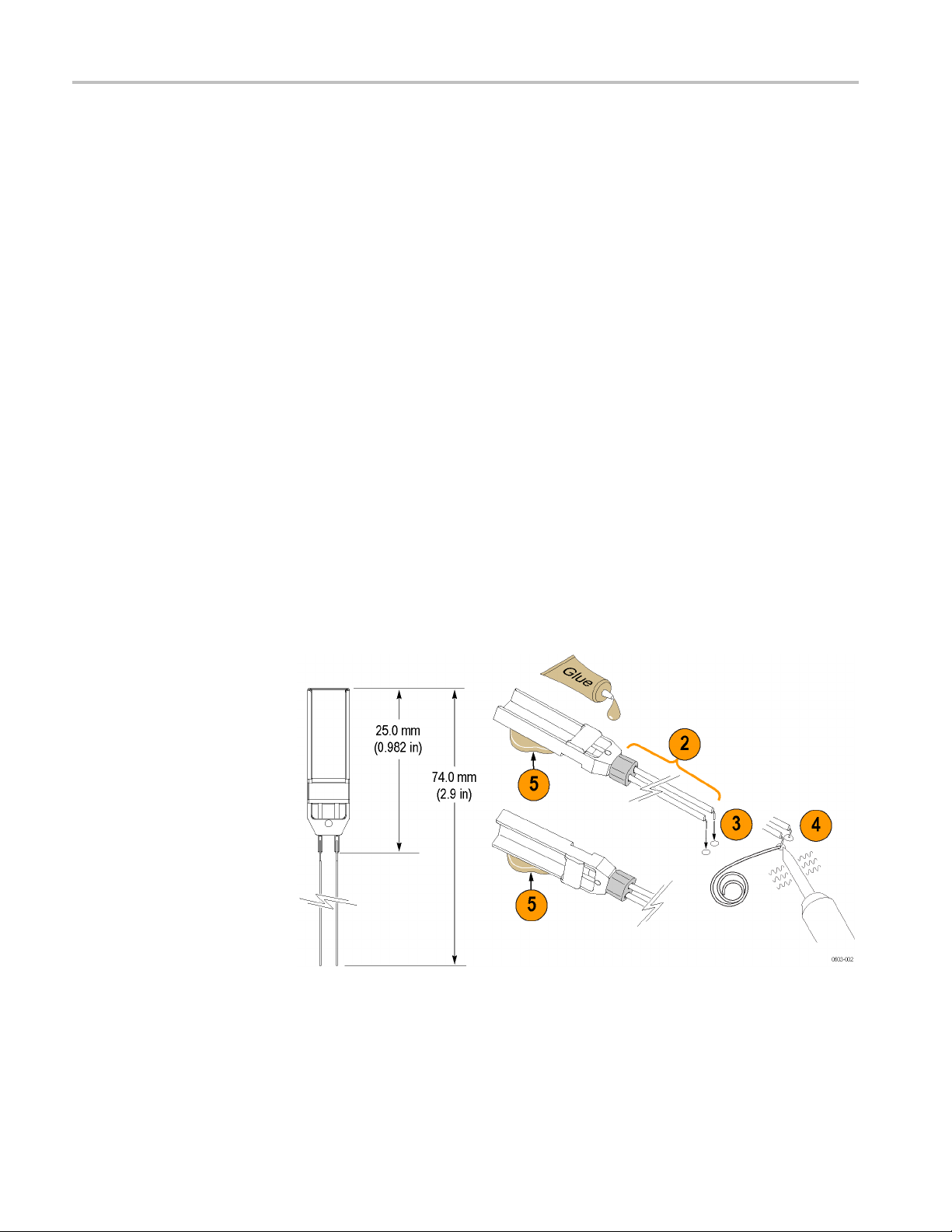

Note the insertion force and clearance guidelines when connecting the probe

to the SUT. (See Figure 12 on page 16.)

P6910 General Purpose Probe Instruction Manual 15

Page 30

Operating basics

WARNING. To avoid damaging the lead sets, do not exceed the clearances or

insertion for

for clearance and insertion force information.

ce for the lead sets and square pins. Refer to the following illustration

Figure 1

2: Clearance and insertion force information for the lead sets

16 P6910 General Purpose Probe Instruction Manual

Page 31

Reference

Clock and qual

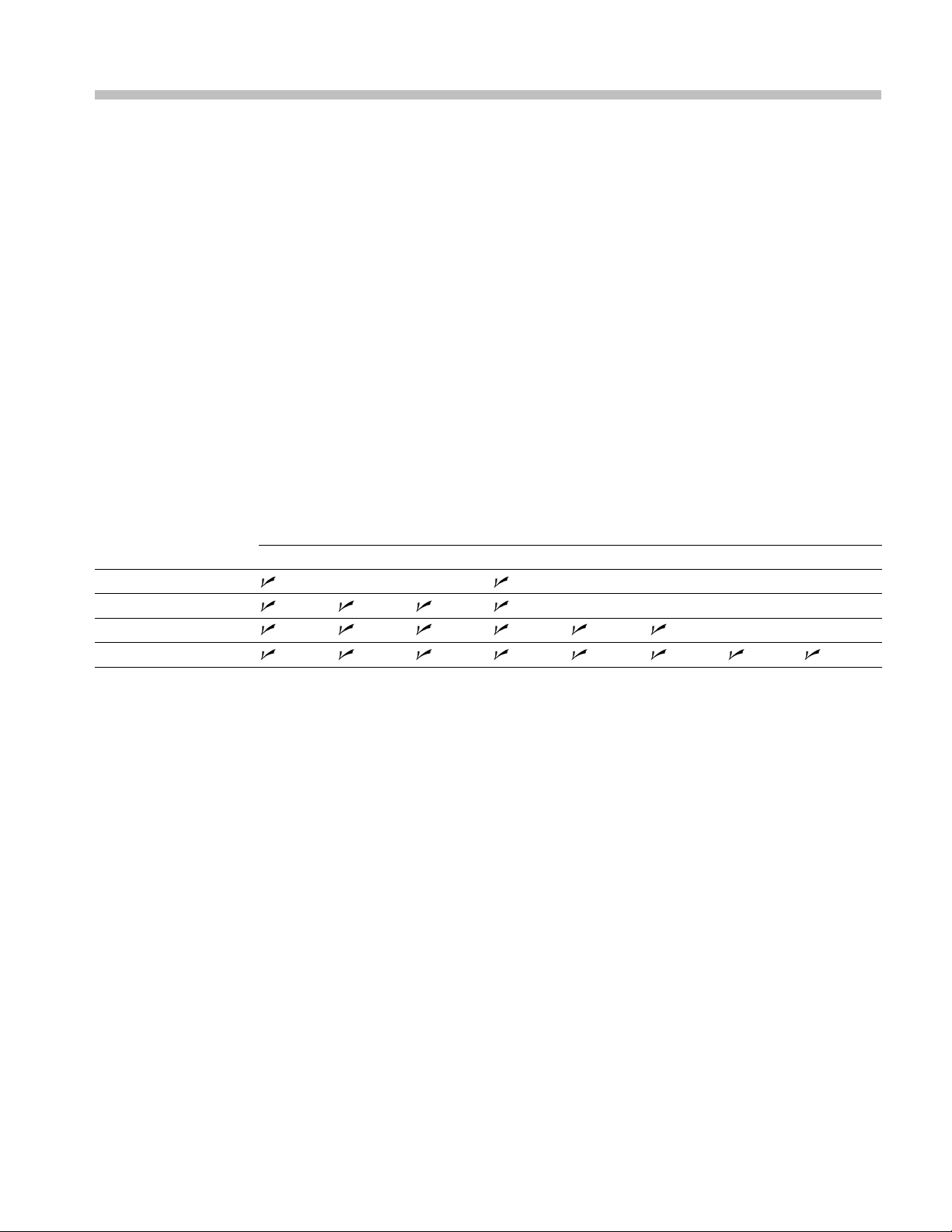

Table 1: Logic analyzer clock and qualifier availability

Logic analyzer width

34-channel

annel

68-ch

102-channel

136-channel

ifiers

Use the clock and qualifier probe connections from the SUT to define how the

logic analyzer stores data.

Every logic analyzer has some-special purpose input channels. Inputs designated

as clocks can cause the logic analyzer to store data. Qualifier channels can be

logically

from the SUT. Routing the appropriate signals from the design to these inputs

ensures that the logic analyzer can acquire data correctly. Unused clocks can be

used as qualifier signals.

Depending on the channel width, each logic analyzer will have a different set of

clock and qualifier channels. The following table shows the availability of the

clock and qualifier channels.

Clock inputs Qualifier inputs

CLK:0 CLK:1 CLK:2 CLK:3 QUAL:0 QUAL:1 QUAL:2 QUAL:3

AND’ed and OR’ed with clocks to further define when to latch data

lock and qualifier channels are stored. The logic analyzer always stores the

All c

logic state of these channels every time it latches data.

ce clock and qualifier channels are stored in memory there is no need to

Sin

double-probe these signals for timing analysis. When switching from state to

timing analysis modes, all of the clock and qualifier signals will be visible. This

also allows you to route regular signals, those not needed for clocking, to these

channels when they are not being used for their special purpose.

It is a good practice to take advantage of these channels to increase your options

for when you will latch data. Routing several of your design's clocks and strobes

to the logic analyzer clock inputs will provide you with a greater flexibility in the

logic analyzer clocking setup menus.

As an example, look at a processor with a ma ster clock, a data strobe, and an

address strobe. Routing all three of these signals to the logic analyzer clock inputs

will enable you to latch data on the processor master clock, only when data is

strobed, or only when address is strobed. Some forethought in signal routing can

greatly expand the ways to latch and analyze data.

P6910 General Purpose Probe Instruction Manual 17

Page 32

Reference

A processor als

o provides a good example of signals that can be useful as

qualifiers. There are often signals that indicate data reads versus data writes

(R/W), signals that show when alternate bus masters have control of the processor

buses (DMA), and signals that show when various memory devices are being

used (ChipSel). All of these signals are good candidates for assignment to

qualifier channels.

By logically AND'ing the clock with one of these qualifiers you can program the

logic analyzer to store only data reads or data writes. Using the DMA signal as a

qualifier p

rovides a means of filtering out alternate bus master cycles. Chip selects

can limit data latching to specific memory banks, I/O ports, or peripheral devices.

Multiplexed buses

The logic analyzer can demultiplex data from multiplexed buses.

Each sig

logic analyzer channel. Refer to the following tables to determine which channel

groups to connect to feed the test data to channels on the SUT.

Table 2: 2X demultiplexing source-to channel assignments

Prime channels receiving SUT test data

136-channel logic

Base connecting channel groups

A3:7-0 D3:7-0 D3:7-0

A2:7-0 D2:7-0 D2:7-0

A1:7-0 D1:7-0 D1:7-0 D1:7-0

A0:7-0 D0:7-0 D0:7-0 D0:7-0

C3:7-0 C1:7-0 C1:7-0

C2:7-0 C0:7-0 C0:7-0

E3:7-0 E1:7-0

E2:7-0 E0:7-0

CLK:0 QUAL:1 QUAL:1

CLK:1 QUAL:0 QUAL:0

CLK:2 QUAL:3

CLK:3 QUAL:2

analyzer

nal on a dual- or quad-multiplexed bus can be demultiplexed into its own

102-channel logic

analyzer

———

———

———

———

68-channel logic

analyzer

C3:7-0 C3:7-0

C2:7-0 C2:7-0

——

——

——

——

34-channel logic

analyzer

—

—

18 P6910 General Purpose Probe Instruction Manual

Page 33

Reference

Table 3: 4X demu

Base connecting channel groups

C3:7-0 C2:7-0 C1:7-0

A1:7-0 A0:7-0 D1:7-0

A3:7-0 A2:7-0 D3:7-0

E3:7-0 E2:7-0 E1:7-0

CLK:3 CLK:2 QUAL:3

CLK:1 CLK:0 QUA

ltiplexing source-to channel assignments

Prime channels receiving SUT test data

136-channel l

analyzer

C0:7-0

D0:7-0

D2:7-0

E0:7-0

QUAL:2

L:1

QUAL:0

When demultiplexing data there is no need to connect the destination channels to

the multiplexed bus. Data from the source channels are routed to the d estination

channels internal to the logic analyzer.

Demultiplexing affects only the main memory for the destination channels. This

means that the MagniVu memory is filled with data from whatever is connected to

the demultiplexing destination channel probe inputs. This provides an opportunity

to acquire high resolution MagniVu data on a few extra channels. Connecting the

demultiplexing destination channels to other signals will allow viewing of their

activity in the MagniVu memory but not the main memory.

ogic

102-channel l

analyzer

C2:7-0 C1:7-0

C0:7-0

A0:7-0 D1:7-0

D0:7-0

A2:7-0 D3:7-0

D2:7-0

———

———

CLK:0 Q UA

QUAL:0

ogic

L:1

68-channel lo

analyzer

A3:7-0 A2:7C2:7-0

A0:7-0 D1:7-0

D0:7-0

——

——

gic

0

34-channel lo

analyzer

A3:7-0 A2:7C2:7-0

—

gic

0

Range recognizers

When using range recognizers, probe groups and probe channels must be in

hardware order.

Probe groups must be used from the most-significant probe group to the

least-significant probe group based on the following order:

C3 C2 C1 C0 E3 E2 E1 E0 A3 A2 D3 D2 A1 A0 D1 D0 Q3 Q2 Q1 Q0

CK3 CK2 CK1 CK0

Probe channels must be from the most-significant channel to the least-significant

channel based on the following order:

76543210

The above example assumes a 136-channel logic analyzer. The missing channels

in instruments with fewer than 136 channels are ignored. With merged modules,

range recognition extends across the first three modules: the master module

contains the most-significant channels.

P6910 General Purpose Probe Instruction Manual 19

Page 34

Reference

Probe signal names

Use signal names to simplify probe connections to the logic analyzer.

Refer to the following tables for information on signal connections. Match the

alpha character that precedes the channel identifier (for example, E3:7) to the

probe head label.

All differential data and clock/qualifiers on the probe may have the negative input

pin grounded and be used as a single-ended input.

You can find more information on 2X and 4X demultiplexing channel assignments

in the Demultiplexing Information section. (See Table 2 on page 18.) (See Table 3

on page 19.)

Table 4: Signal connections on 136- and 102-channel instruments for probe 4 and probe 3

Signal

name Podlet

Clk/Qual Clk/Qual Q3- Q2- CK0- Q0-

Clk/Qual+ Clk/Qual Q3+ Q2+ CK0+ Q0+

Data 7-

Data 7+

Data 6- 6 E3:6- E2:6- E1:6- E0:6- A3:6- A2:6- D3:6- D2:6-

Data 6+ 6 E3:6+ E2:6+ E1:6+ E0:6+ A3:6+ A2:6+ D3:6+ D2:6+

Data 5-

Data 5+

Data 4- 4 E3:4- E2:4- E1:4- E0:4- A3:4- A2:4- D3:4- D2:4-

Data 4+ 4 E3:4+ E2:4+ E1:4+ E0:4+ A3:4+ A2:4+ D3:4+ D2:4+

Data 3- 3 E3:3- E2:3- E1:3- E0:3- A3:3- A2:3- D3:3- D2:3-

Data 3+ 3 E3:3+ E2:3+ E1:3+ E0:3+ A3:3+ A2:3+ D3:3+ D2:3+

Data 2- 2 E3:2- E2:2- E1:2- E0:2- A3:2- A2:2- D3:2- D2:2-

Data 2+ 2 E3:2+ E2:2+ E1:2+ E0:2+ A3:2+ A2:2+ D3:2+ D2:2+

Data 1- 1 E3:1- E2:1- E1:1- E0:1- A3:1- A2:1- D3:1- D2:1-

Data 1+ 1 E3:1+ E2:1+ E1:1+ E0:1+ A3:1+ A2:1+ D3:1+ D2:1+

Data 0- 0 E3:0- E2:0- E1:0- E0:0- A3:0- A2:0- D3:0- D2:0-

Data 0+ 0 E3:0+ E2:0+ E1:0+ E0:0+ A3:0+ A2:0+ D3:0+ D2:0+

7

7

5

5

Probe 4 way station for 136-channel instrument

only

E3:7- E2:7- E1:7- E0:7- A3:7- A2:7- D3:7- D2:7-

E3:7+ E2:7+ E1:7+ E0:7+ A3:7+ A2:7+ D3:7+ D2:7+

E3:5- E2:5- E1:5- E0:5- A3:5- A2:5- D3:5- D2:5-

E3:5+ E2:5+ E1:5+ E0:5+ A3:5+ A2:5+ D3:5+ D2:5+

Probe 3 way station for 136- and 102-channel

instruments

20 P6910 General Purpose Probe Instruction Manual

Page 35

Reference

Table 5: Signal

Signal

name

Clk/Qual- Clk/Qual- CK1- CK2- CK3- Q1-

Clk/Qual+ Clk/Qual+ CK1+ CK2+ CK3+ Q1+

Data 7-

Data 7+

Data 6- 6 A1:6- A0:6- D1:6- D0:6-

Data 6+ 6 A1:6+ A0:6+ D1:6+ D0:6+

Data 5-

Data 5+

Data 4- 4 A1:4- A0:4- D1:4- D0:4-

Data 4+ 4 A1:4+ A0:4+ D1:4+ D0:4+

Data 2+ 2 A1:2+ A0:2+ D1:2+ D0:2+

Data 3- 3 A1:3- A0:3- D1:3- D0:3-

Data 3+ 3 A1:3+ A0:3+ D1:3+ D0:3+

Data 2- 2 A1:2- A0:2- D1:2- D0:2-

Data 1- 1 A1:1- A0:1- D1:1- D0:1-

Data 1+ 1 A1:1+ A0:1+ D1:1+ D0:1+

Data 0- 0 A1:0- A0:0- D1:0- D0:0-

Data 0+ 0 A1:0+ A0:0+ D1:0+ D0:0+

connections on 102- and 136-channel instruments for probe 2 and probe 1

Podlet

7

7

5

5

Probe 2 way station for 136- and 102-channel

instruments

A1:7- A0:7- D1:7- D0:7-

A1:7+ A0:7+ D1:7+ D0:7+

A1:5- A0:5- D1:5- D0:5-

A1:5+ A0:5+ D1:5+ D0:5+

Probe 1 way station for 136- and 102-channel

instruments

C3:7- C2:7- C1:7- C0:7-

C3:7+ C2:7+ C1:7+ C0:7+

C3:6- C2:6- C1:6- C0:6-

C3:6+ C2:6+ C1:6+ C0:6+

C3:5- C2:5- C1:5- C0:5-

C3:5+ C2:5+ C1:5+ C0:5+

C3:4- C2:4- C1:4- C0:4-

C3:4+ C2:4+ C1:4+ C0:4+

C3:2+ C2:2+ C1:2+ C0:2+

C3:3- C2:3- C1:3- C0:3-

C3:3+ C2:3+ C1:3+ C0:3+

C3:2- C2:2- C1:2- C0:2-

C3:1- C2:1- C1:1- C0:1-

C3:1+ C2:1+ C1:1+ C0:1+

C3:0- C2:0- C1:0- C0:0-

C3:0+ C2:0+ C1:0+ C0:0+

P6910 General Purpose Probe Instruction Manual 21

Page 36

Reference

Table 6: Signal

Signal

name

Clk/Qual Clk/Qual CK1- CK2- CK3-

Clk/Qual+ Clk/Qual CK1+ CK2+ CK3+

Data 7-

Data 7+

Data 6- 6 A1:6- A0:6- D1:6- D0:6-

Data 6+ 6 A1:6+ A0:6+ D1:6+ D0:6+

Data 5-

Data 5+

Data 4- 4 A1:4- A0:4- D1:4- D0:4-

Data 4+ 4 A1:4+ A0:4+ D1:4+ D0:4+

Data 3- 3 A1:3- A0:3- D1:3- D0:3-

Data 3+ 3 A1:3+ A0:3+ D1:3+ D0:3+

Data 2- 2 A1:2- A0:2- D1:2- D0:2-

Data 2+ 2 A1:2+ A0:2+ D1:2+ D0:2+

Data 1- 1 A1:1- A0:1- D1:1- D0:1-

Data 1+ 1 A1:1+ A0:1+ D1:1+ D0:1+

Data 0- 0 A1:0- A0:0- D1:0- D0:0-

Data 0+ 0 A1:0+ A0:0+ D1:0+ D0:0+

connections on 68- and 34-channel instruments

Podlet

7

7

5

5

Probe 2 way station for 68-channel instrument only Probe 1 way station for 34-channel

A1:7- A0:7- D1:7- D0:7-

A1:7+ A0:7+ D1:7+ D0:7+

A1:5- A0:5- D1:5- D0:5-

A1:5+ A0:5+ D1:5+ D0:5+

instrument only

C3:7- C2:7-

C3:7+ C2:7+

C3:6- C2:6-

C3:6+ C2:6+

C3:5- C2:5-

C3:5+ C2:5+

C3:4- C2:4-

C3:4+ C2:4+

C3:3- C2:3-

C3:3+ C2:3+

C3:2- C2:2-

C3:2+ C2:2+

C3:1- C2:1-

C3:1+ C2:1+

C3:0- C2:0-

C3:0+ C2:0+

A2:7-

A2:7+

A2:6-

A2:6+

A2:5-

A2:5+

A2:4-

A2:4+

A2:3-

A2:3+

A2:2-

A2:2+

A2:1-

A2:1+

A2:0-

A2:0+

22 P6910 General Purpose Probe Instruction Manual

Page 37

Reference

Probe footpri

nts

Pin spacing allows for space tolerances between the podlet holder and the

clock/qualifier configurations.

Refer to the following figure for footprint information. (See Figure 13.) Negative

inputs of differential signals can be grounded to support single-ended signal inputs.

Figure 13: P6910 General-Purpose probe land footprint

P6910 General Purpose Probe Instruction Manual 23

Page 38

Reference

Load models

Load models are important electrical considerations when working with the

P6910 probe.

The low frequency model is typically adequate for rise and fall times of 1 ns

or greater in a typical 25 Ω source impedance environment (50 Ω runs with a

pass-through connection). For source impedance outside this range, and/or rise

and fall times less than 1 ns, use the high frequency model to determine if a

significan

t difference is obtained in the modeling result.

The following electrical model displays a single podlet load model of the probe.

(See Figu

re 14.)

Specifications

Figure 14: Single podlet load model

The following tables list the electrical and environmental specifications for the

P6910 probe.

The electrical specifications apply when the probe is connected between a

compatible logic analyzer and a SUT. Refer to the Tektronix Logic Analyzer Series

Product Specifications & Performance Verification Technical Reference Manual

(available on the TLA Documentation CD or downloadable from the Tektronix

Web site) for a complete list of system and module specifications. The probes are

designed to meet Tektronix standard 062-2847-00 class 5.

Table 7: Mechanical and electrical specifications

Characteristic Description

Threshold accuracy

Input resistance

Input capacitance <1.0 pF

Minimum digital signal swing 300 mV single-ended

Maximum nondestructive input signal to

probe

Delay from probe tip to input connector

±(35 mV ±1% of setting)

20 kΩ ±1%

1

±15 V

7.70 ns ±80 ps

24 P6910 General Purpose Probe Instruction Manual

Page 39

Table 7: Mechanical and electrical specifications (cont.)

Characteristic Description

Probe length

Operating range

1

P6910 single podlet input capacitance is 0.7 pF, but podlets in a g roup will have <1 pF input capacitance.

1.8 m (6 ft)

+5 V to –2.5 V

Table 8: Environmental speci fi cations

Characteristic Description

Temperature

Operating 0 °C to 50 °C (32 °F to 122 °F) with 5 °C/hour maximum

gradient, noncondensing

Nonoperating

Humidity

Operating 5% to 95% relative humidity ≤ 30 °C (86 °F)

Nonoperating

Altitude

Operating Up to 4600 m (15,092 ft)

Nonoperating

–55 °C to 75 °C (–67 ° to 167°F) with 5 °C/hour maximum

gradient, no media in instrument drive

5% to 75% relative humidity 30 °C to 60 °C (86 °F to 140 °F)

Non condensing

5% to 95% relative humidity ≤ 30 °C (86 °F)

5% to 75% relative humidity 30 °C to 50 °C (86 °F to 122 °F)

Non condensing

Up to 4600 m (15,092 ft)

Reference

P6910 General Purpose Probe Instruction Manual 25

Page 40

Reference

26 P6910 General Purpose Probe Instruction Manual

Page 41

Maintenance

Probe calibration information

The probe does not require calibration. If a probe failure occurs, return the entire

probe to your Tektronix representative for repair.

Probe service strategy information

The following service options are available when you order your Tektronix

product:

Table 9: Service options

Option Description

C3 Calibration Service 3 Years

C5 Calibration Service 5 Years

R3

R5

R3DW

R5DW

Includes initial certifications plus two annual calibrations

Includes initial certifications plus four annual calibrations

Repair Service 3 Years

Return product to Tektronix for servicing

Repair Service 5 Years

Return product to Tektronix for servicing

Repair Service Coverage 3 Years

(includes product warranty period). 3-year period starts at time of

instrument purchase

Repair Service Coverage 5 Years

(includes product warranty period). 5-year period starts at time of

instrument purchase

Perform the functional check

A functional check verifies basic functionality of the probe.

onnect the probe to the logic analyzer and to an a ctive signal source.

1.C

2. Open the Setup window where the probes are attached to the logic analyzer.

If your logic analyzer is a TLA7000 Series mainframe with multiple modules,

open the Setup window for the module where the probes are attached.

3. Check for signal activity in the Setup window for the attached probe.

P6910 General Purpose Probe Instruction Manual 27

Page 42

Maintenance

Inspect or clean the probe

Inspect and clean the probe as often as operating conditions require. Dirt acts as

an insulating blanket, preventing efficient heat dissipation. Dirt also provides an

electrical conduction path that can cause failures, especially under high-humidity

conditions.

Perform the following steps to c lean the probe:

1. Keep the probes free of dirt, dust, and contaminants to maintain a reliable

2. Remove dirt and dust with a soft brush.

3. Use only a damp cloth for more extensive cleaning.

Repackage the probe

The following information describes how to repackage the probe, to store the

probe, or to return the probes to the factory.

electrical probe connection.

Never use abrasive cleaners or organic solvents.

1. Use the original packaging, if possible.

original packaging is not available, use a corrugated cardboard shipping

If the

carton.

2. Add c

3. Enc

ushioning material to prevent the probes from moving inside the

shipping container.

lose the following information when shipping the probe to a Tektronix

Center:

ner’s address

Ow

Name and phone number of a contact person

Type of probe

Reason for return

Full description of the service required

28 P6910 General Purpose Probe Instruction Manual

Page 43

Replaceable parts

Replaceable parts

Parts orderin

g information

Replacement parts are available through your local Tektronix field office or

representative.

The P6910 probe contains no user-replaceable parts. However, probe accessories

can be replaced. (See page 1, P6910 probe accessory information.) Contact your

local Tekt

Changes to Tektronix products are sometimes made to accommodate improved

componen

improvements. When ordering parts, include the following information in your

order:

If you order a part that has been replaced with a different or improved part, your

local Tektronix field office or representative will contact you concerning any

change in the part number.

ronix representative for replacement information.

ts as they become available and to give you the benefit of the latest

Part number

ment type or model number

Instru

Instrument serial number

Instrument modification n umber, if applicable

P6910 General Purpose Probe Instruction Manual 29

Page 44

Replaceable parts

30 P6910 General Purpose Probe Instruction Manual

Page 45

Glossary

Functional check procedure

Functional check procedures verify the basic functionality of the probes by

confirming that the probes recognize signal activity at the probe tips.

Keep out area

Theareaof

be mounted.

Logic analyzer-end

The end of the probe which connects to the logic analyzer.

Module

The unit that plugs into a TLA7000 series mainframe which provides

instru

Podlet

A circuit contained in a flex lead and attached to a probe which provides

square-pin connections to the circuit under test for one data acquisition

channel and a reference pin.

Podlet holder

movable clip that groups eight individual podlets into a single 8-wide

Are

P6910 probe assembly. This provides ease when connecting to a row of 2 x

8 2.54 mm (0.100 in) square pins.

PCB

the printed circuit board in which only probe components m ay

ment capabilities such as logic analysis.

An acronym for Printed Circuit Board.

Probe head

The end of the probe that connects to the SUT.

SUT

System-Under-Test. Also known as the target system. The logic analyzer

connects to the SUT through the probe.

Way station

An intermediate probe part is u sed to connect the heads of the P6910 probes

to a single ribbon cable.

P6910 General Purpose Probe Instruction Manual 31

Page 46

Glossary

32 P6910 General Purpose Probe Instruction Manual

Page 47

Index

A

accessories, 1

option 1K, 9

option 2K, 10

adapter holder, 13

attaching labels, 4

C

calibration, 27

channel groups, 4

channel w

cleaning, 28

clearances

clock channels, 17

clocks, 17

conne

idth, 17

lead set, 16

cting

probes to logic analyzer, 6

probes to the SUT, 7

D

demultiplex data, 18

destination channels, 19

differential data, 20

ble probing signals, 17

dou

E

electrical considerations, 24

electrical model, 24

electrical specifications, 24

environmental specifications, 25

F

ferrite bead, 11, 12

flex adapter, 13

footprint, 23

functional check, 27

H

hand browser, 14

hardware order, 19

I

insertion force

lead set, 16

inspection and cleaning, 28

L

label

installation, 4

labels, 2

lead set

clearances, 16

insertion force, 16

load mo

logic analyzer

del, 24

connecting probes, 6

M

MagniVu memory, 19

maintenance

functional check, 27

pection and cleaning, 28

ins

probe calibration, 27

probe repackaging, 28

service strategy, 27

mechanical specifications, 24

multiplexed buses, 18

O

Option 1K accessories, 9

Option 2K accessory kit

contents, 10

ordering parts, 29

P

P6910 footprint, 23

podlet holder, 23

probe

clearances, 16

connecting probes to the

SUT, 7

descriptio

grouper, 15

labels, 2

repackaging, 28

probe connections

to the instrument, 6

to the log

n, 1

ic analyzer, 6

Q

qualifier channels, 17

R

range recognizers, 19

related documentation, ix

repackage the probe, 28

replacement parts, 29

S

ety Summary, iii

Saf

service options, 27

signal connections, 20

source channels, 19

source impedance, 24

space tolerances, 23

pecifications

s

electrical, 24

environmental, 25

mechanical, 24

standard adapter, 11

strain relief, 13

SUT

connecting probes, 7

T

timing analysis, 17

P6910 General Purpose Probe Instruction Manual 33

Page 48

Index

W

way stations, 4

wide body adapter, 12

wire tubing, 11, 12

34 P6910 General Purpose Probe Instruction Manual

Loading...

Loading...