Page 1

xx

P6700 Series

ZZZ

Serial Analyzer Probes

Instruction Manual

*P077011500*

077-0115-00

Page 2

Page 3

xx

P6700 Series

ZZZ

Serial Analyzer Probes

Instruction Manual

Revision B

www.tektronix.com

077-0115-00

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are c overed by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

RT-Eye is a registered trademark of Tektronix, Inc.

PCI Express is a registered trademark of PCI-SIG®.

G3PO is a trademark of Corning Gilbert Inc.

Contacting Tektronix

Tektroni

14200 SW Karl Braun Drive

P.O . Bo x 50 0

Beaverton, OR 97077

USA

For pro

x, Inc.

duct information, sales, service, and t echnical support:

In North America, call 1-800-833-9200.

Worl d wide, vi sit www.tektronix.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, with shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other than Tektronix representatives to install, repair or service the product;

Page 6

Page 7

Table of Contents

General Safety Summary .......................................................................................... v

Service Safety Summary........................ ................................ ................................ . vii

Environmental Considerations .................................................................................. viii

Preface.............................................................................................................. ix

Related Documentation ...................................................................................... ix

List of Terms ................................................................................................... x

Getting Started . . . .. . ... ... . .. . ... ... . ... ... . . .. . ... ... . ... ... ... . ... ... . ... ... ... . ... ... . .. . ... ... . ... ... ... . ... ... . 1

Product Description....................................... ................................ ..................... 1

Serial Analyzer Configurations........................ .................................. ..................... 4

Operating Basics.................................................................................................... 5

Preparing for Installation of the Midbus Retention Mechanism.......................................... 5

Installing the Midbus Retention Mechanism . ... . ... ... ... . ... ... . .. . ... ... . ... ... ... . ... ... . ... ... ... . ... . 5

Connecting the Midbus Probe..... ................................ .................................. ......... 7

Arranging the Midbus Probe Cables......................................................................... 9

Connecting a Slot Interposer Probe......................................................................... 10

Connecting the Solder-Down Probe ................ ................................ ........................ 14

Reference ................... .................................. ................................ ...................... 19

Probe Dimensions ............................................................................................ 19

Circuit Board Design......................................................................................... 23

Midbus Footprint Pin and Probe Channel Assignments........ ................................ .......... 40

Rearranging Wires in the Probe Connector ................................................................ 57

Adding Probes to the P6701SD Probe Connector........................... .............................. 60

Specifications .... .................................. ................................ ................................ 61

Environmental. ................................ .................................. .............................. 61

Maintenance........................................................................................................ 63

Inspection and Cleaning.......................................... ................................ ............ 67

Storing the Probe.................................... .................................. ........................ 67

Repackaging Instructions ...... ................................ .................................. ............ 67

Appendix A: PCI Express System Design Review Checklist ................................................ 69

General Consideratio

Midbus Probe Configuration ................................................................................ 69

Mechanical Considerations .......... .................................. ................................ ...... 69

Electrical Considerations .... ................................ .................................. .............. 71

Appendix B: Reference Files................................... ................................ .................. 73

Index

ns .... .................................. ................................ ................ 69

P6700 Series Serial Analyzer Probes Instruction Manual i

Page 8

Table of Contents

List of Figure

Figure 1: P6716 16-Channel Midbus probe .............. ................................ ....................... 1

Figure 2: P6708S Slot interposer probe.......................................................................... 2

Figure 3: P6701SD Solder-Down probe ......................................................................... 3

Figure 4: 16-Channel footprint..................................... ................................ ............... 5

Figure 5: Installing the retention mechanism. . ... ... . .. . ... ... . ... ... ... . ... ... . . .. . ... ... . .. . ... ... . .. . ... ... . . 6

Figure 6: Soldering the anchoring posts to the PCB............................................................ 6

Figure 7: Connecting a probe to the retention mechanism.................................... ................. 8

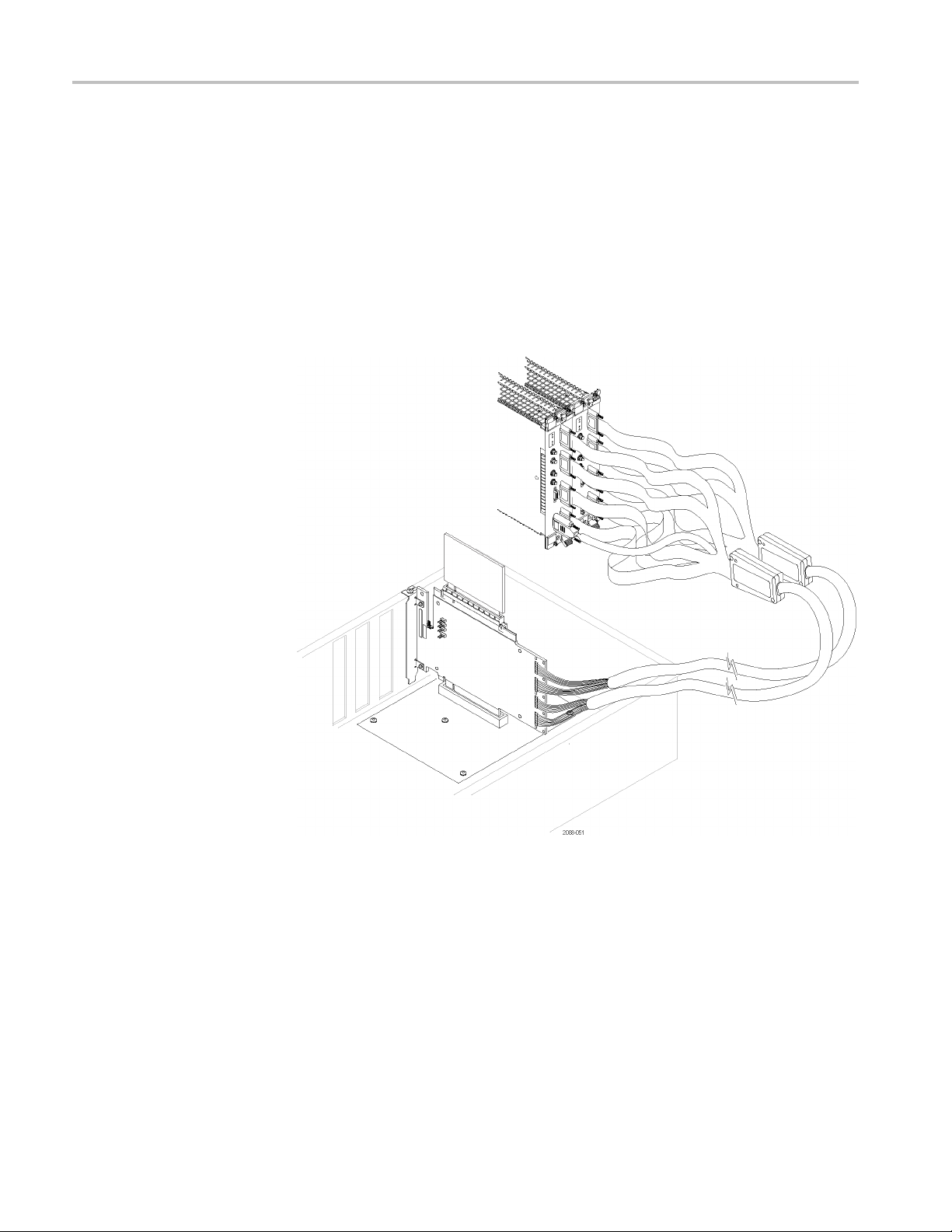

Figure 8: Arranging the midbus probe cables ................................................................... 9

Figure 9: Connecting a slot interposer probe......... ................................ .......................... 11

Figure 10: Installing the P6701SD probe ... ... . .. . ... ... . ... ... . ... ... . .. . ... ... . ... ... . ... ... . .. . ... ... . ... ... 14

Figure 11: Connecting the P75TLRST tip to the probe head................................................. 15

Figure 12: Connecting wires to the circuit.......... ................................ ............................ 16

Figure 13: Connecting the tip to the circuit............... ................................ ...................... 17

Figure 14: P6716S dimensions................................... ................................ ................ 19

Figure 15: P6716 cable length dimensions ..................................................................... 20

Figure 16: P6716S cable length dimensions...... ................................ .............................. 20

Figure 17: P6701S, P6704S, and P6708S dimensions .............. ................................ .......... 21

Figure 18: P6701SD dimensions ............ ................................ .................................. .. 22

Figure 19: P75TLRST Solder Tip dimensions................................................................. 22

Figure 20: 8-Channel midbus footprint dimensions and keep-out area ..................................... 24

Figure 21: 16-Channel midbus footprint dimensions and keep-out area .................................... 25

Figure 22: Recommended trace routing on primary surface layer ............. .............................. 26

Figure 23: Via and trace keep-out areas for the P6708 8-Channel probe ................................... 27

Figure 24: Via and trace keep-out areas for the P6716 16-Channel probe ................ .................. 27

Figure 25: Recomme nded trace routing on inner or secondary surface layer (prima

shown) ......................................................................................................... 27

Figure 26: Recommended trace routing on inner or secondary surface layer (primary layer pads not

shown) ......................................................................................................... 28

Figure 27: Clock cable connector dimensions ................................................................. 29

Figure 28: P75TLRST TriMode Long Reach Solder Tip ..................................................... 30

Figure 29: Typical wire length from probe tip to circuit...................................................... 31

Figure 30: P75TLRST solder tip with 0.010 inch of tip wire ................................ ................ 32

Figure 31: P75TLRST solder tip with 0.050 inch of tip wire ................................ ................ 32

Figure 32: P75TLRST solder tip with 0.100 inch of tip wire ................................ ................ 33

Figure 33: P75TLRST solder tip with 0.200 inch of tip wire ................................ ................ 33

Figure 34: P75TLRST TriMode Long Reach Solder Tip dimensions ....................................... 34

Figure 35: Signal eye measurements (time versus voltage) .................................................. 34

Figure 36: Periodic jitter gain function ... ... ... . ... ... ... . ... ... ... . ... ... . .. . ... ... . .. . ... ... . ... ... ... . ... ... 36

s

ry layer pads

ii P6700 Series Serial Analyzer Probes Instruction Manual

Page 9

Table of Contents

Figure 37: S-pa

Figure 38: S-parameter data of retention mechanism plus P6700 Series midbus probe................... 37

Figure 39: S-parameter data of P6701SD Solder-Down probe................................... ............ 38

Figure 40: Slot Interposer probe with a clock cable connected .. .................................. .......... 39

Figure 41: P6708 8-Channel probe footprint pin assignments ............................................... 40

Figure 42: P6716 16-Channel probe footprint pin assignments.............................................. 40

Figure 43: 8

Figure 44: 16-Channel midbus footprint connection module connector .................................... 41

Figure 45: Opening the probe connector........................................................................ 58

Figure 46: Removing the probe sleeve.......................................................................... 58

Figure 47: Probe labels ........................................................................................... 59

Figure 48: Removing individual wires.......................................................................... 59

Figure 4

Figure 50: Replaceable bullets and tool... ................................ ................................ ...... 63

Figure 51: Removing the bullet contacts ... .................................. ................................ .. 64

Figure 52: Inspect the bullet contacts ........................................................................... 65

Figure 53: Installing the bullet contacts. ... . .. . ... ... . .. . ... ... . .. . ... ... . ... ... ... . ... ... ... . ... ... ... . ... ... .. 66

9: Inserting additional probe wires . ... ... ... . .. . ... ... ... . ... ... ... . .. . ... ... . .. . ... ... ... . ... ... ... . . 60

rameter data of retention mechanism only ................................................... 37

-Channel midbus footprint connection module connector...................................... 40

P6700 Series Serial Analyzer Probes Instruction Manual iii

Page 10

Table of Contents

List of Tables

Table i: Terms used in this document ............................................................................ x

Table 1: Ser

Table 2: Recommended circuit board design criteria.......................................................... 23

Table 3: Via and trace characteristics ....... ................................ .................................. .. 26

Table 4: Clock cable three-pin connector pin assignments ................................................... 28

Table 5: Probe Eye Requirements ............... .................................. .............................. 35

Table 6: Reference clock electrical requirements .............................................................. 39

Table 7: X

Table 8: X8 bidirectional link.................................................................................... 44

Table 9: X8 (2) unidirectional links ............................................................................. 45

Table 10: X4 bidirectional link .................................................................................. 46

Table 11: X4 (2) unidirectional links................................ ................................ ............ 47

Table 12: X2 bidirectional link .................................................................................. 48

Table

Table 14: X1 bidirectional link .................................................................................. 50

Table 15: X1 (2) unidirectional links.......................... ................................ .................. 51

Table 16: X8 unidirectional link ............................. ................................ .................... 52

Table 17: X4 bidirectional link .................................................................................. 52

Table 18: X4 (2) unidirectional links.......................... ................................ .................. 53

ble 19: X4 unidirectional link and a X2 unidirectional link ................... ............................ 53

Ta

Table 20: X4 unidirectional link and a X1 unidirectional link . .................................. ............ 54

Table 21: X2 bidirectional link .................................................................................. 54

Table 22: X2 (2) unidirectional links.......................... ................................ .................. 55

Table 23: X1 bidirectional link .................................................................................. 55

Table 24: X1 (2) unidirectional links.......................... ................................ .................. 56

Table 25: Atmospheric characteristics .......................................................................... 61

Table 26: Midbus Probe Configuration ..... .................................. ................................ .. 69

Table 27: Midbus Probe .......................................................................................... 69

Table 28: Slot Interposer Probe .................................................................................. 70

Table 29: Reference Clock Connector .............................. .................................. .......... 70

Table 30: Midbus Probe .......................................................................................... 71

Table 31: Slot Interposer Probe .................................................................................. 71

Table 32: Reference Clock Connector .............................. .................................. .......... 72

ial analyzer configuration............................. ................................ ............... 4

16 unidirectional link ................. .................................. .............................. 43

13: X2 (2) unidirectional links............................................ ................................ 49

iv P6700 Series Serial Analyzer Probes Instruction Manual

Page 11

General Safety Summary

General Safet

To Avoid Fire or Personal

Injury

ySummary

Review the fo

this product or any products connected to it.

To avoid pot

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions r

Connect and Disconnect Properly. Connect the probe output to the measurement

instrument before connecting the probe to the circuit under test. Connect the

probe reference lead to the circuit under test before connecting the probe input.

Disconnect the probe input and the probe reference lead from the circuit under test

before

Ground the Product. This product is indirectly grounded through the grounding

condu

conductor must be connected to earth ground. Before making connections to

the input or output terminals of the product, ensure that the product is properly

grounded.

disconnecting the probe from the measurement instrument.

ctor of the mainframe power cord. To avoid electric shock, the grounding

llowing safety precautions to avoid injury and prevent damage to

ential hazards, use this product only as specified.

elated to operating the system.

Observe All Terminal Ratings. To a v o i d fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

The inputs are not rated for connection to mains or Category II, III, or IV circuits.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Power Disconnect. The power cord disconnects the product from the power source.

Do not block the power cord; it must remain accessible to the user at all times.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Do Not Operate With Suspected Failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

P6700 Series Serial Analyzer Probes Instruction Manual v

Page 12

General Safety Summary

TermsinthisManual

Symbols and Terms on the

Product

Do Not Operate i

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Prop

details on installing the product so it has proper ventilation.

These terms may appear in this manual:

WARNING.

in injury or loss of life.

CAUTION

damage to this product or other property.

These t

. Caution statements identify conditions or practices that could result in

erms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read

the ma

n Wet/Damp Conditions.

er Ventilation. Refer to the manual’s installation instructions for

Warning statements identify conditions or practices that could result

rking.

WARNING indicates an injury hazard not immediately accessible as you

the marking.

read

CAUTION indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

vi P6700 Series Serial Analyzer Probes Instruction Manual

Page 13

Service Safety Summary

Service Safet

y Summary

Only qualifie

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

UseCareWhenServicingWithPowerOn. Dangerousvoltagesorcurrentsmay

exist in

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

d personnel should perform service procedures. Read this Service

this product. Disconnect power, remove battery (if applicable), and

P6700 Series Serial Analyzer Probes Instruction Manual vii

Page 14

Environmental Considerations

Environmenta

Product End-of-Life

Handling

Restriction of Hazardous

Substances

l Considerations

This section

Observe the following guidelines when recycling an instrument or component:

Equipment R

use of natural resources. The equipment may contain substances that could be

harmful to the environment or human health if improperly handled at the product’s

end of life. In order to avoid release of such substances into the environment and

to reduce the use of natural resources, we encourage you to recycle this product

in an appropriate system that will ensure that most of the materials are reused or

recycle

This product has been classified as Monitoring and Control equipment, and is

outside the scope of the 2002/95/EC RoHS Directive.

provides information about the environmental impact of the product.

ecycling. Production of this equipment required the extraction and

d appropriately.

This symbol indicates that this product complies with the European Union’s

requirements according to Directive 2002/96/EC on waste electrical and

nic equipment (WEEE). For information about recycling options, check

electro

the S upport/Service section of the Tektronix Web site (www.tektronix.com).

viii P6700 Series Serial Analyzer Probes Instruction Manual

Page 15

Preface

Preface

This manual c

ontains information needed to install and use a P6700 Series probe

with a TLA7S08 or TLA7S16 Serial Analyzer module to debug, validate, and

verify computer and embedded systems.

Related Documentation

The following table lists related documentation available for your instrument. The

documentation is available on the TLA Documentation CD and on the Tektronix

Web site (www.Tektronix.com/manuals).

For documentation not specified in the table, contact your local Tektronix

representative.

Related Documentation

Item Purpose Location

TLA Quick Start User Manuals

eHelp

Onlin

Installation Quick Reference Cards High-level installation information

High-level operational overview

In-depth operation and UI help

Installation Manuals

XYZs of Logic Analyzers

Declassification and Securities

tructions

ins

Application notes

Product Specifications & Performance

Verification Procedures

TPI.NET Documentation

iled first-tim e installation information

Deta

Logic analyzer basics

Data security concerns specificto

itizing or removing m emory devices

san

from Te ktronix products

Collection of logic analyzer application

specific notes

TLA Product specifications and

performance verification procedures

Detailed information for controlling the

logic analyzer using .NET

P6700 Series Serial Analyzer Probes Instruction Manual ix

Page 16

Preface

Related Documentation (cont.)

Item Purpose Location

Field upgrade kits

Optional Service Manuals Self-service documentation for modules

Upgrade information for your logic

analyzer

and mainfr

ames

List of Terms

The following is a list of terms that appear in this manual. You may want to

review this list if you are unfamiliar with some of the terms. For a list of PCI

Express®-specific terms, refer to the PCI Express Base Specification.

Table i: Terms used in this document

Term Description

Footprint

tion Mechanism

Reten

Probe Head

Full-width

Half-width 8-Channel

Link

Differential Pair A set of two signals, positive and negative, transmitting data

Lane

PCB

SUT System under test. This is the system/circuit board(s) you intend

An arrangement of pads built into the board as specified in the

PCI Exp

retention mechanism.

The mechanism that connects the probe head to the PCB. It fits

on the footprint and must be soldered to the PCB.

The end of the probe that connects to the retention mechanism.

16-Channel

A connection between two PCI Express devices. A link consists

of

of a number (N) lanes.

from one device to another.

A single differential pair (two signals) that transmit data in one

d

Printed circuit board

to test with the serial analyzer.

ress Base Specification. It is the contact point for the

a number of lanes. A link described as by-N (or xN) consists

irection of a PCI Express Link. A unidirectional lane.

x P6700 Series Serial Analyzer Probes Instruction Manual

Page 17

Getting Started

Product Descr

Midbus Probes

iption

Tektronix offers three types of probes for the TLA7S08 and TLA7S16 Serial

Analyzer modules:

Midbus probes

Slot interposer probes

Solder-down probes

A midbus p

You must install the retention mechanism to either a PCI Express Gen1 or Gen2

footprint on your circuit board.

Tektronix offers the following midbus probes:

P6708 8

P6716 16-Channel Midbus probe

robe connects to a retention mechanism installed on your circuit board.

-Channel Midbus probe

Figure 1: P6716 16-Channel Midbus probe

P6700 Series Serial Analyzer Probes Instruction Manual 1

Page 18

Getting Started

Slot Interposer Probes

A slot interpos

has a x16 connector for a PCI Express card device.

Tektronix off

P6701S PCI Express x1 Slot Interposer probe

P6704S PCI Express x4 Slot Interposer probe

P6708S PCI Express x8 Slot Interposer probe

P6716S PCI Express x16 Slot Interposer probe

er probe connects to a PCI Express slot on your SUT. Each probe

ers the following (bidirectional) slot interposer probes:

Figure 2: P6708S Slot interposer probe

2 P6700 Series Serial Analyzer Probes Instruction Manual

Page 19

Getting Started

P6701SD Solder-Down

Probe

The P6701SD pro

tip (P75TLRST). Up to four probes (one differential pair each) can be installed in

each signal connector to the serial module. (See page 60, Adding Probes to the

P6701SD Probe Connector.)

be connects to your SUT through the differential solder-down

Figure 3: P6701SD Solder-Down probe

P6700 Series Serial Analyzer Probes Instruction Manual 3

Page 20

Getting Started

Serial Analyz

er Configurations

The following table lists the minimum serial analyzer configuration required by

link widths.

Table 1: Ser

Link width

X11111

X41111

X81112

X16 1 2 2 2

1

The link width can be supported with either a P6716P Slot Interposer probe or a P6708 Slot Interposer probe.

Choose one or the other, based on the footprint on your platform.

To capture signals from a bidirectional X16 link, you will need two serial analyzer

modules connected to a slot interposer probe. (See page 12, Connecting a Probe

to a Bidirectional X16 Link.)

ial analyzer configuration

TLA7S16

TLA7012

or TLA7016

mainframe

Serial

Analyzer

module P6716 probe

1

P6708 probe

1

4 P6700 Series Serial Analyzer Probes Instruction Manual

Page 21

Operating Basics

Preparing for Installation of the Midbus Retention Mechanism

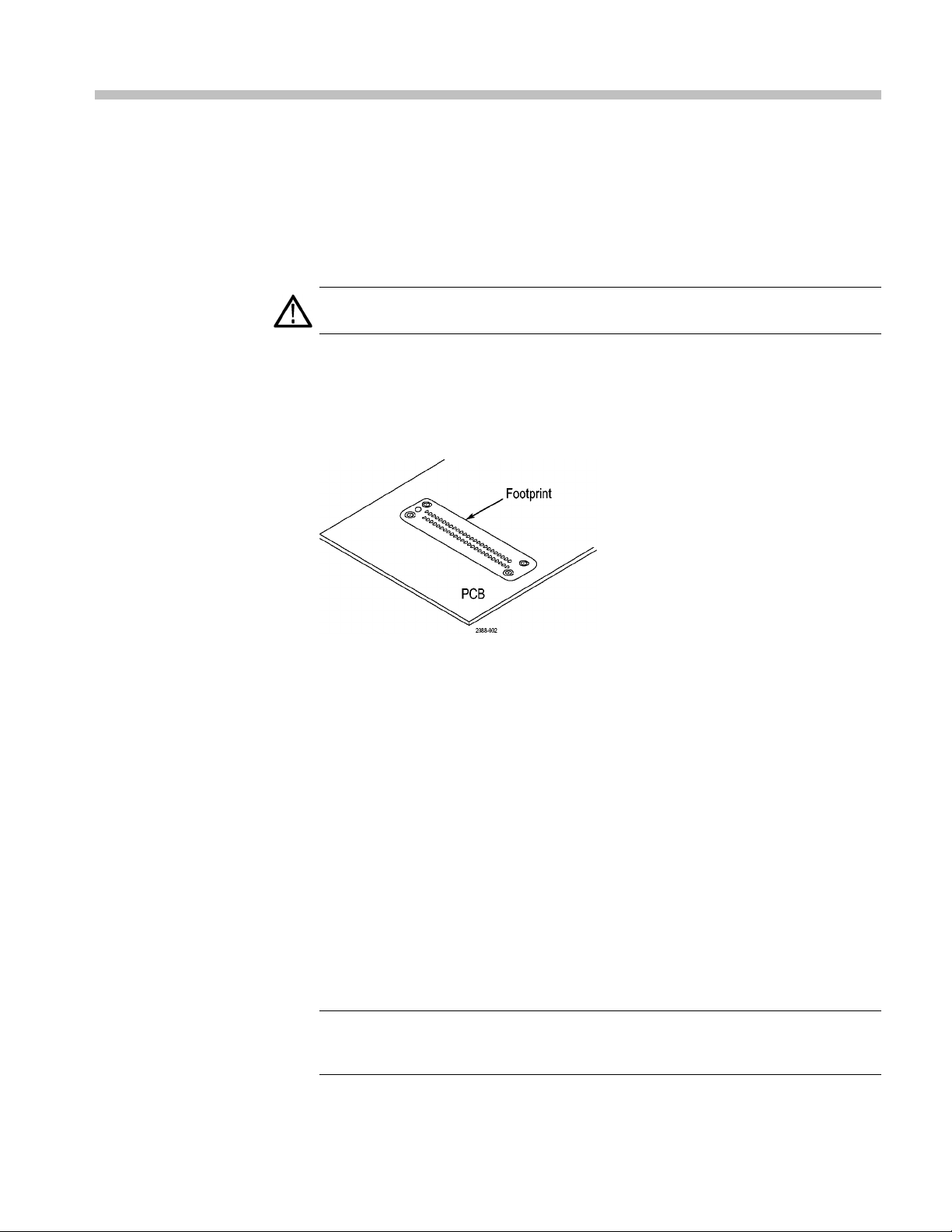

Cleaning the Footprint

Inspect the footprint for lint, oil, or fingerprints. If the footprint is dirty, clean it by

following these steps:

CAUTION. To avoid electrical damage, always power off your system under test

before cleaning the footprint.

1. Use a lint-free, clean-room cloth lightly moistened with electronic/reagent

grade isopropyl alcohol, and gently wipe the surface of the footprint.

2. Remove any remaining lint using a nitrogen air gun or clean, oil-free dry air.

Figure 4: 16-Channel footprint

Installing the Midbus Retention Mechanism

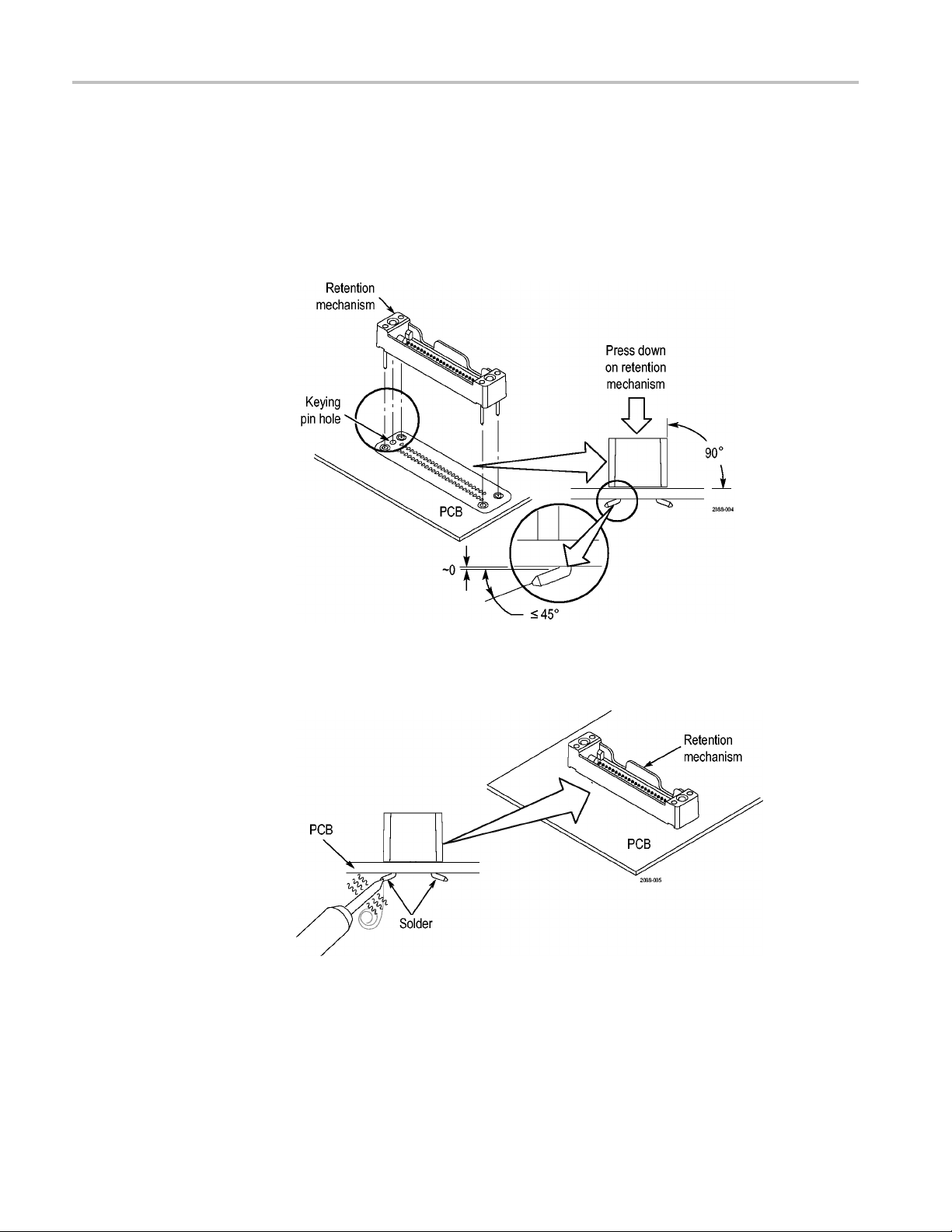

Before connecting a midbus probe, you must install the retention mechanism.

The retention m echanism connects the probe head to your circuit board (PCB).

It fits on the footprint and must be soldered to the PCB. To install the retention

mechanism on the circuit board, do the following:

1. Locate the correct footprint. If you intend to use multiple probes, your PCB

has multiple footprints. Be careful to select the correct one.

2. Align the retention mechanism over the footprint so that the keying pin on

the retention mechanism l

(See Figure 5.)

3. Insert the retention mechanism into the holes in the footprint on the PCB.

NOTE. The following two steps are important to ensure that the retention

mechanism is correctly mounted and that the probe makes proper contact with

the PCB.

P6700 Series Serial Analyzer Probes Instruction Manual 5

ines up with the k eying pin hole on the footprint.

Page 22

Operating Basics

4. Hold the retent

the footprint, and the four anchoring posts extend through the circuit board

to the opposite side.

5. Using a pair of needle-nose pliers, grasp one of the posts. Using the circuit

board hole as a fulcrum, bend the post outward so that it secures the

mechanism to the PCB. Bend the other three posts in the same manner.

ion mechanism so that it is firmly flush with the surface of

e 5: Installing the retention mechanism

Figur

6. Solde

Figure 6: Soldering the anchoring posts to the PCB

r the anchoring posts to the PCB.

6 P6700 Series Serial Analyzer Probes Instruction Manual

Page 23

Operating Basics

Connecting th

Handling the

Connect the Probe

Probe Head

eMidbusProbe

After you have installed the retention mechanism, you are ready to connect the

midbus probe.

Handle the probe head with care. Keep the following points in mind:

Handle the probe head by the outer plastic casing. Do not touch the contacts

in the center with fingers, tools, wipes, or any other devices.

Do not expose the connector to liquids or dry chemicals.

When connecting the probe, be careful not to touch the probe head contacts to

any other surfaces or components on your circuit board.

Connect

1. Locate the correct retention mechanism. If you intend to use multiple probes,

your PC

one.

2. Align

the probe can only be inserted one way.

the probe by following these steps:

B has multiple retention mechanisms. Be careful to select the correct

the probe head with the retention mechanism. Both are keyed so that

3. Pres

s the probe head into the retention mechanism.

P6700 Series Serial Analyzer Probes Instruction Manual 7

Page 24

Operating Basics

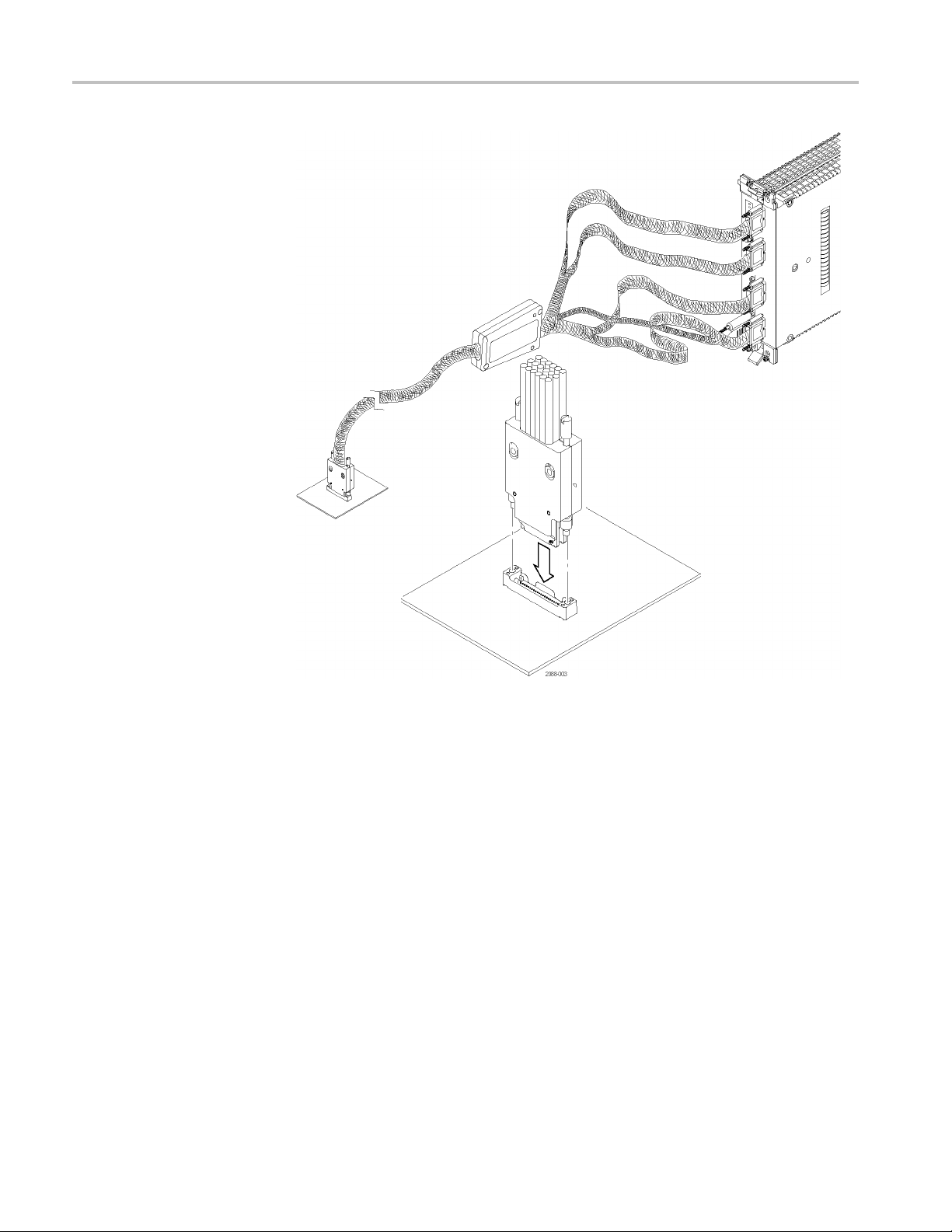

Figure 7: Connecting a probe to the retention mechanism

4. Start both mounting screws in the posts, and tighten them evenly to ensure

that the probe approaches and mates squarely to the PCB. If acc ess is limited,

use the adjustment tool included with your probe. The probe is completely

ened to the PCB when both mounting screws are seated.

fast

5. Refer to the TLA7S08 & TLA7S16 Serial Analyzer Modules Instruction

ual to verify that all channels are acquiring data. If you suspect that

Man

a p oor probe connection may be the source of a problem, refer to the

troubleshooting section of the TLA7S08 & TLA7S16 Serial Analyzer Modules

Instruction Manual.

8 P6700 Series Serial Analyzer Probes Instruction Manual

Page 25

Operating Basics

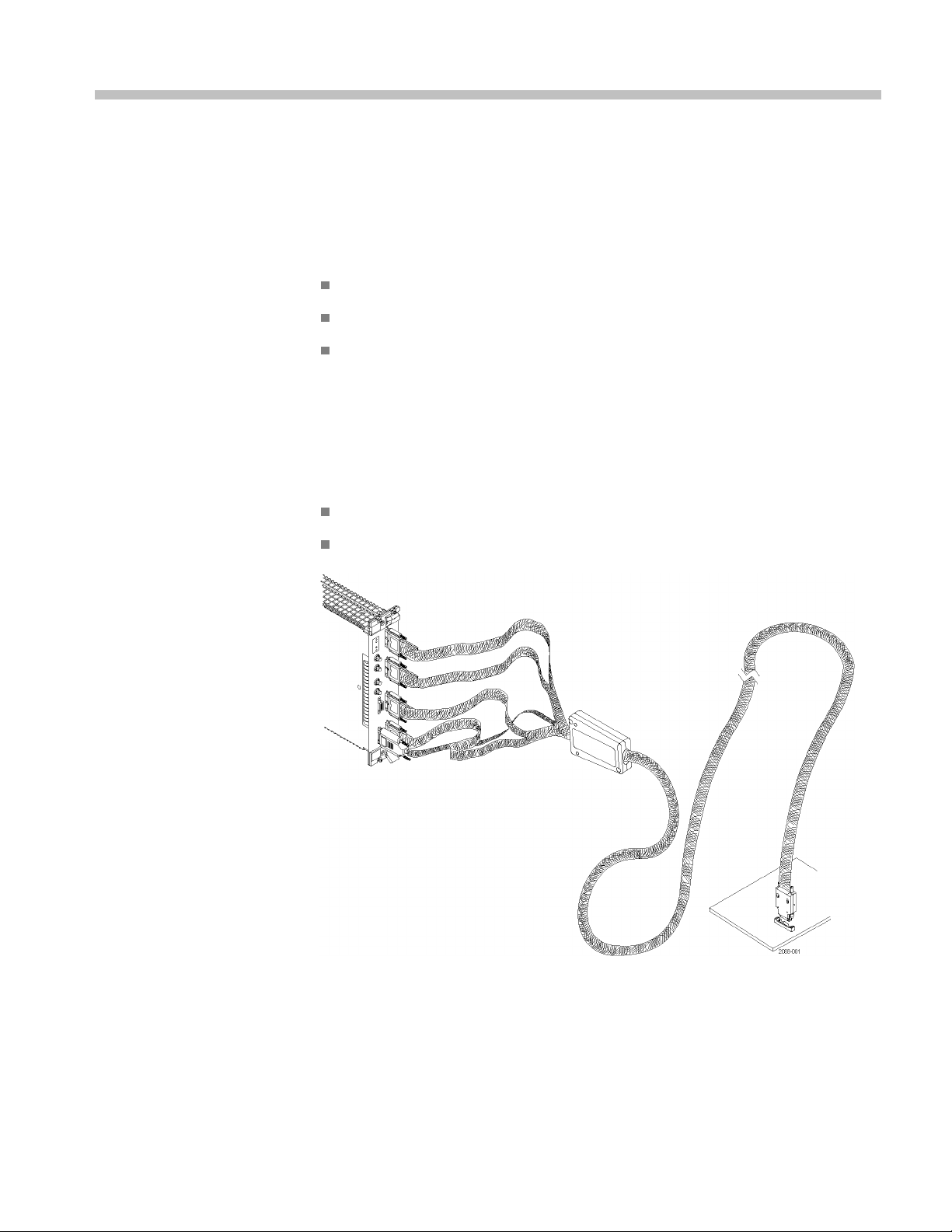

Arranging the

Midbus Probe Cables

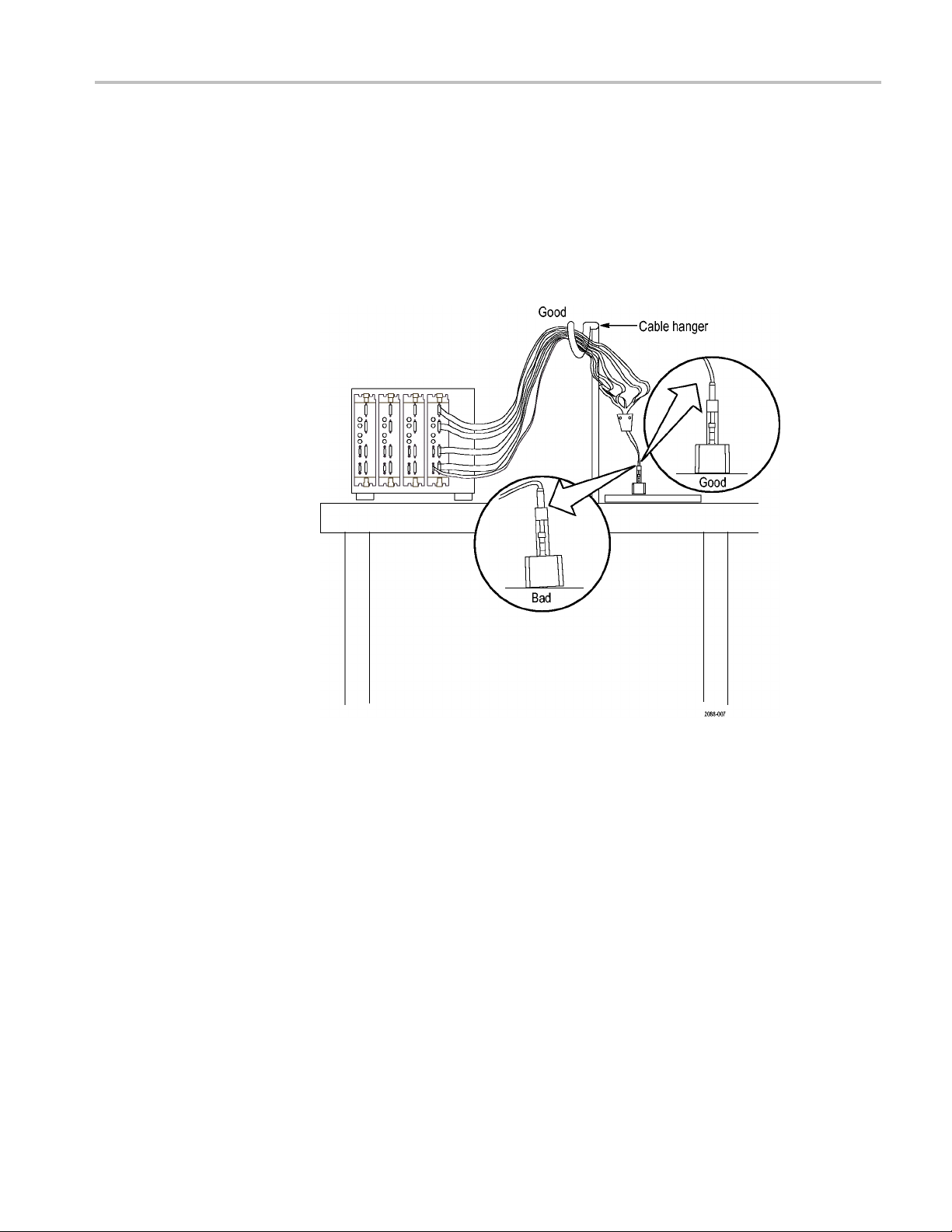

Arrange and hang the probe cables so that the probe head is perpendicular to the

circuit board, and tension on the retention mechanism is minimized. Route the

cables as str

degree bend does not occur within three inches of the circuit board surface. (See

Figure 8.) You can route a hanger through the two holes in the cable transition

housing as well.

aight as possible, maximizing the bend radius, and make sure that a 90

Figure 8: Arranging the midbus probe cables

P6700 Series Serial Analyzer Probes Instruction Manual 9

Page 26

Operating Basics

Connecting a S

lot Interposer Probe

Handling the Probe Head

Connect the Probe

Handle the probe head with care. Keep the following points in mind:

Handle the probe head by the outer casing. Do not touch the contacts with

fingers, tools, wipes, or any other devices.

Do not expose the connector to liquids or dry chemicals.

When connecting the probe, be careful not to touch the probe head contacts to

any other surfaces or components on your circuit board.

CAUTION. Static discharge can damage the probe head. Always wear a grounded

antistatic wrist strap whenever handling the probe head. Also verify that anything

to which

Connect the probe by following these steps:

1. Disconnect the power supply to your SUT. Unplug the PC power supply if

2. Locate the correct PCI Express slot.

3. Align the probe with the slot.

the probe head is connected does not carry a static charge.

your SUT is connected to one.

10 P6700 Series Serial Analyzer Probes Instruction Manual

Page 27

Operating Basics

4. Press the probe

head into the slot.

Figure 9: Connecting a slot interposer probe

5. Position the mounting bracket and attach the screws.

6. Press your PCI Express card device into the probe.

NOTE. When the slot interposer is installed, you must connect the power

ector to the module and the module must be powered on whenever the SUT is

conn

powered on.

7. Refer to the TLA7S08 & TLA7S16 Serial Analyzer Modules Instruction

ual to verify that all channels are recognizing signals. If y ou suspect

Man

that a poor probe connection may be the source of a problem, refer to the

troubleshooting section of the TLA7S08 & TLA7S16 Serial Analyzer Modules

Instruction Manual.

P6700 Series Serial Analyzer Probes Instruction Manual 11

Page 28

Operating Basics

Connecting a Probe to a

Bidirectional X16 Link

To c a p t u r e s i g n

serial analyzer modules to a single slot interposer probe. Connect the probe by

following these steps:

1. Disconnect the power supply to your SUT. If your SUT is connected to a PC

power supply, unplug the power supply..

2. Locate the correct PCI Express slot.

3. Align the pr

4. Press the probe head into the slot.

als from a bidirectional X16 link you need to connect two

obe with the s lot.

5. Pos

6. Press your PCI Express card device into the probe.

7. Connect the probe to the two serial analyzer modules; connect the probe

12 P6700 Series Serial Analyzer Probes Instruction Manual

ition the mounting bracket and attach the screws.

power connector to either serial analyzer module.

Page 29

Operating Basics

NOTE. When the s

connector to either module and the modules must be powered on whenever the

SUT is powered on.

8. Refer to the T

Manual to verify that all channels are recognizing signals. If you suspect

that a poor probe connection may be the source of a problem, refer to the

troubleshooting section of the TLA7S08 & TLA7S16 Serial Analyzer Modules

Instruction Manual.

lot interposer is installed, you must connect the power

LA7S08 & TLA7S16 Serial Analyzer Modules Instruction

P6700 Series Serial Analyzer Probes Instruction Manual 13

Page 30

Operating Basics

Connecting th

Connect to th

Analyzer Module

e Solder-Down Probe

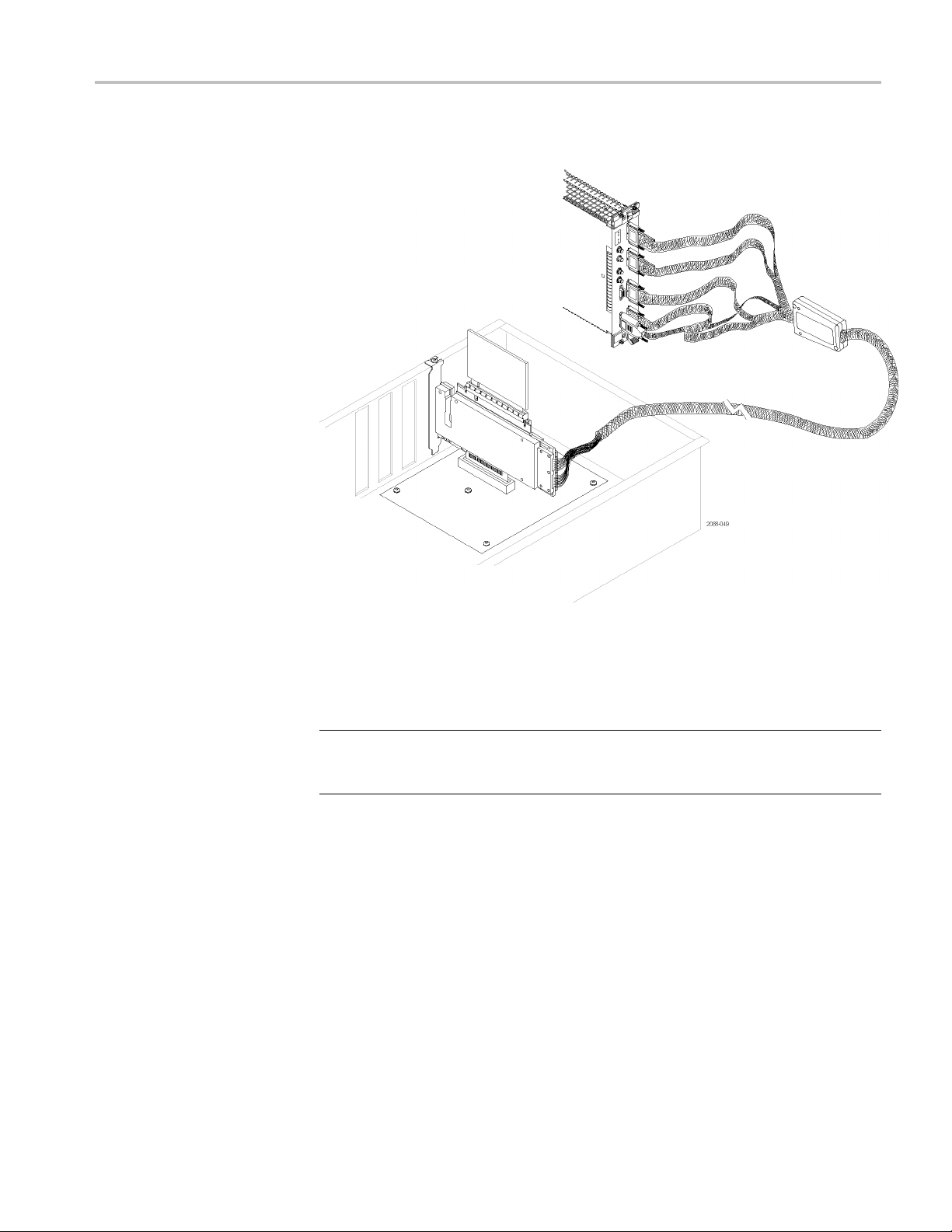

The probe connects to the module and to the probe tip, and the probe tip is

soldered to the circuit. Install the probe by following these steps:

eSerial

1. Plug the signal connector into the module and tighten the hold-down screws.

2. Plug the Power Adapter into the module and tighten the hold-down screws.

3. Plug the power connector into any one of the receptacles on the Power

Adapter.

gure 10: Installing the P6701SD probe

Fi

14 P6700 Series Serial Analyzer Probes Instruction Manual

Page 31

Operating Basics

P75TLRST Solder Tip

Install the pro

NOTE. This tip is very small and must be handled carefully. The following

procedures describe the proper techniques for using the tip.

Connect to the Probe Head. The probe body and tip cable ends a re keyed to

ensure correct installation.

1. Orient the probe body with the + and – inputs on top.

2. Align the tip cable lead with the red band to the + input.

be tip by following these steps:

Figure

3. Grasp

4. To remove the tip, pull the cable tab straight out from the probe body.

CAUTION. Pull only on the cable tab when removing the tip. You can damage the

tip or probe if you pull on the cables.

11: Connecting the P75TLRST tip to the probe head

the cable connector by hand and push the cable into the probe body

until you feel a click. The cable housing is fully seated when it is flush with

the edge of the probe body.

P6700 Series Serial Analyzer Probes Instruction Manual 15

Page 32

Operating Basics

Connect to the C

in this manual for reference. (See Figure 34 on page 34.) You can also design the

tip footprint into your circuit board layout for easier test connections.

To connect the probe tip to your circuit, use the wire and solder that are provided

in the wire replacement kit. The kit includes:

0.004 in (0.1016 mm) wire

0.008 in (0.

SAC305 solder (RoHS compliant)

1. Identify a location where the tip can b e placed, soldered, and secured to your

circuit. You can work with long wires (~1 inch), but keep the finished wire

lengths o

2. Lay the wires against a circuit board pad, trace, or other conductive feature. (If

vias or t

3. Solder the wires to your circuit.

ircuit. The dimensions of the solder tip connections are provided

2032 mm) wire

f the signal and ground connections as short as possible.

hrough-holes are very close, you can thread the wires through them.)

Figure 12: Connecting wires to the circuit

16 P6700 Series Serial Analyzer Probes Instruction Manual

Page 33

Operating Basics

4. Attach tip tape

5. Clean out the tip vias with a solder-wicking material if you are reusing the

tip. Thread th

6. Press the tip to the circuit board and quickly solder the wires to the tip. Keep

all finished

7. Clip off the excess wire from all of the solder joints.

8. Push the end of the tip into the probe head until it seats in the probe head.

to the bottom of the tip.

e wires through the tip.

wire lengths as short as possible.

Figure 13: Connecting the tip to the circuit

9. Secure the probe to the circuit board with tape or with the hook-and-loop

ips and dots that are included with the probe.

str

P6700 Series Serial Analyzer Probes Instruction Manual 17

Page 34

Operating Basics

18 P6700 Series Serial Analyzer Probes Instruction Manual

Page 35

Reference

Probe Dimensions

This section provides guidelines for designing a system to b e tested with a P6700

series probe(s).

The following figure shows dimensions of the P6700 series probes. Both the

P6708 and P

6716 have the same cable lengths.

Figure 14: P6716S dimensions

P6700 Series Serial Analyzer Probes Instruction Manual 19

Page 36

Reference

Figure 15: P6716 cable length dimensions

The following figures show the dimensions of the P6700S slot interposer probes.

re 16: P6716S cable length dimensions

Figu

20 P6700 Series Serial Analyzer Probes Instruction Manual

Page 37

Reference

Figure 17: P6701S, P6704S, and P6708S dimensions

P6700 Series Serial Analyzer Probes Instruction Manual 21

Page 38

Reference

Figure 18: P6701SD dimensions

Figure 19: P75TLRST Solder Tip dimensions

22 P6700 Series Serial Analyzer Probes Instruction Manual

Page 39

Reference

Circuit Board

Mechanical D

Design

esign

Use the following mechanical and electrical guidelines when designing your

system.

This section provides mechanical design details for the midbus probe, including

footprint dimensions, footprint keep-out areas, and trace and via size, and routing

requirements.

Table 2: Re

Paramete

Maximum circuit board

thicknes

Footprint type

Pad finis

commended circuit board design criteria

r

s

h

Descript

3.81 mm (0

PCI Expr

Immersi

level (HASL) also acceptable)

ion

.150 in)

ess Gen1 or Gen2

on gold over nickel (immersion silver and hot air solder

NOTE. Tektronix recommends that the holes made for the retention mechanism

remain unconnected to a ground plane. This prevents overheating the

posts

ground plane and promotes quicker soldering of the retention posts to your PCB.

print dimensions and keep-out area. Design your circuit board layout using

Foot

the following footprint dimensions so that a probe retention mechanism will fit

properly and make good electrical contact with your system. (See Figure 20 on

page 24.) The space around the footprint (keep-out area) represents the area that

will be covered by the retention mechanism.

P6700 Series Serial Analyzer Probes Instruction Manual 23

Page 40

Reference

Figure 20: 8-Channel midbus footprint dimensions and keep-out area

24 P6700 Series Serial Analyzer Probes Instruction Manual

Page 41

Reference

e 21: 16-Channel midbus footprint dimensions and keep-out area

Figur

Routing Considerations for the Midbus Probe Footprint. Routing and simulation

studies have been performed near and through the PCI Express midbus footprint

to determine a best known method for maintaining integrity of the system

nel as well as provide an adequate signal to the serial a nalyzer. However,

chan

the following information does not imply that superior routing techniques do not

exist. It is mandatory that you closely monitor and simulate the routing near and

through the midbus probe to insure that integrity of the system and midbus signal

eye are maximized. Some dimensional details concluded from these simulations

and studies are provided in the following table.

OTE. The via hole size in the following table is a minimum size, based on the

N

assumption that the circuit board is 2.36 mm (0.093-inch) thick.

P6700 Series Serial Analyzer Probes Instruction Manual 25

Page 42

Reference

Table 3: Via and

Parameter Size

Via hole 10 mil

Via annular ring 20 mil

Via antipad 33 mil

Minimum spac

and pad

Trace width 14 mil

Microtrace width 5 mil

Space between traces (before and after

footprint

Space bet

footprint negotiation)

Primary

negotiation)

ween microtraces (before and after

Surface Layer Routing. The following figure shows recommended trace

trace characteristics

e between via annular ring

5mil

14 mil

5mil

routing on the primary surface layer (the surface where the midbus footprint will

be). The solid white pads shown in the diagram are the ground pads.

Figure 22: Recommended trace routing on primary surface layer

Tektronix recommends that you design your footprint so that there are no traces

or vias in the two spaces designated in the following diagram. If your design

requires the use of these two spaces, Tektronix recommends that you fully solder

mask these areas.

26 P6700 Series Serial Analyzer Probes Instruction Manual

Page 43

Figure 23: Via and trace keep-out areas for the P6708 8-Channel probe

Reference

Figure 24: Via and trace keep-out areas for the P6716 16-Channel probe

Inner Layer or Secondary Surface Layer Routing. The following figures show

suggested trace routing on the inner layer, and the secondary surface layer (the

surface opposite from where the midbus footprint will be). The solid white pads

shown in the diagram a re the ground pads.

Figure 25: Recommended trace routing on inner or secondary surface layer (primary

layer pads shown)

P6700 Series Serial Analyzer Probes Instruction Manual 27

Page 44

Reference

Figure 26: Recommended trace routing on inner or secondary surface layer (primary

layer pads not shown)

Clock Cable Three-Pin

Connector

If you intend to use a midbus probe and a clock cable, a three-pin micro-terminal

strip connector must be installed on your SUT. A non-intrusive clock cable

(Tektro

nix part number, 672-6285-00) has two SMA connectors on one end

(+ and –), and a small circuit board with a mating three-pin connector on the other.

Only one connector is needed, even if more than one TLA7S08 or TLA7S16

module is used. In this case, a “jumper” clock cable with SMA connectors on

each end (+ and –) can connect the two modules and share the clock signal.

Tektronix suggests installing the following three-pin connector (or similar):

Through hole: Samtec® TMS 103-02-S-S

(1x3,0.05centerspacing)

face mount: Samtec® FTR 103-02-S-S

Sur

(1x3,0.05centerspacing)

ble 4: Clock cable three-pin connector pin assignments

Ta

Signal Pin number

REFCLKp 1 (or 3)

GND

REFCLKn 3 (or 1)

1

The serial analyzer module is not sensitive to the polarity of the reference clock signal. The clock cable connector

can be attached in either orientation.

1

2

1

28 P6700 Series Serial Analyzer Probes Instruction Manual

Page 45

Reference

Figure 27: Clock cable connector dimensions

For more specific information on keep-out volumes for particular system

configurations, contact your local Tektronix representative.

P6700 Series Serial Analyzer Probes Instruction Manual 29

Page 46

Reference

P6701SD Probe Solder Tip

(P75TLRST)

The P75TLRST pr

is composed of a small form factor interconnect circuit board with SMD0402

damping resistors and a set of vias for wire attachment to the SUT. The circuit

board vias are designed for both 4 mil and 8 mil wire and a special high tensile

strength wire is supplied as part of the wire accessory kit. The expanded v iew of

the probe tip shows the location of the + and – signal inputs as well as the two

ground refe

Figure 2

Attach

a polarized G3PO dual connector block. The 3GPO connectors use a miniature,

high frequency design that enables quick and easy installation of the P75TLRST

solder tip. The G3PO connector block of the probe tip is inserted into the input

nose piece on the end of the P6701SD Serial Analyzer probe body. The probe

body contains a mating, polarized G3PO connector block with attached G3PO

ector bullets.

conn

rence connections. (See Figure 28.)

8: P75TLRST TriMode Long Reach Solder Tip

ed to the circuit board a re a pair of very low skew (<1ps) coaxial cables and

obe tip is designed for solder-down probing applications. It

The connector bullets are a part of the G3PO connector design, providing a

f-aligning interconnect mechanism between G3PO connectors. The G3PO

sel

connector in the probe body is designed to have higher detent force than the probe

tip connectors, which is intended to ensure that the G3PO bullets remain in the

probe body connector when disconnected.

The probe body nose piece, with its integral spring mechanism, helps to provide a

self-aligning mechanism for hand insertion of the probe tip. The probe body nose

springs also give a secure capture of the probe tip connector after insertion.

Release of the probe tip is assisted by using the wire-connected cable release

holder on the probe tip connector. This probe tip release holder should always be

used rather than pulling on the probe tip cables, which may cause tip cable damage.

The recommended wire attachment method is to first solder the wires to the SUT,

being careful to minimize the wire length of the signal and ground connections.

This is followed by threading the wires through the probe tip board vias, being

careful to achieve as symmetrical a wire pattern as possible between the two

signal inputs and a very short ground connection.

30 P6700 Series Serial Analyzer Probes Instruction Manual

Page 47

Reference

Finally, the at

circuit board. Any excess wire lead length extending through the probe tip board

should be removed to minimize possible signal reflection problems. Because of

the limited mechanical strength of the wire interconnect and probe tip circuit

board, the solder-down probe tip should be taped down at the SUT for strain

relief. Although the accessory kit includes adhesive strips that can be used for the

strain reli

attachment if room is available at the SUT.

The lead le

must be kept as short as possible to preserve the integrity of the measured signal.

Typical wire lengths range from 0.010 in. to 0.100 in. (See Figure 29.)

tachment is completed by soldering the wires on top of the probe tip

ef of the probe tip, the use of mylar tape will generally provide stronger

ngth of the connection wires between the probe tip board and the SUT

ure 29: Typical wire length from probe tip to circuit

Fig

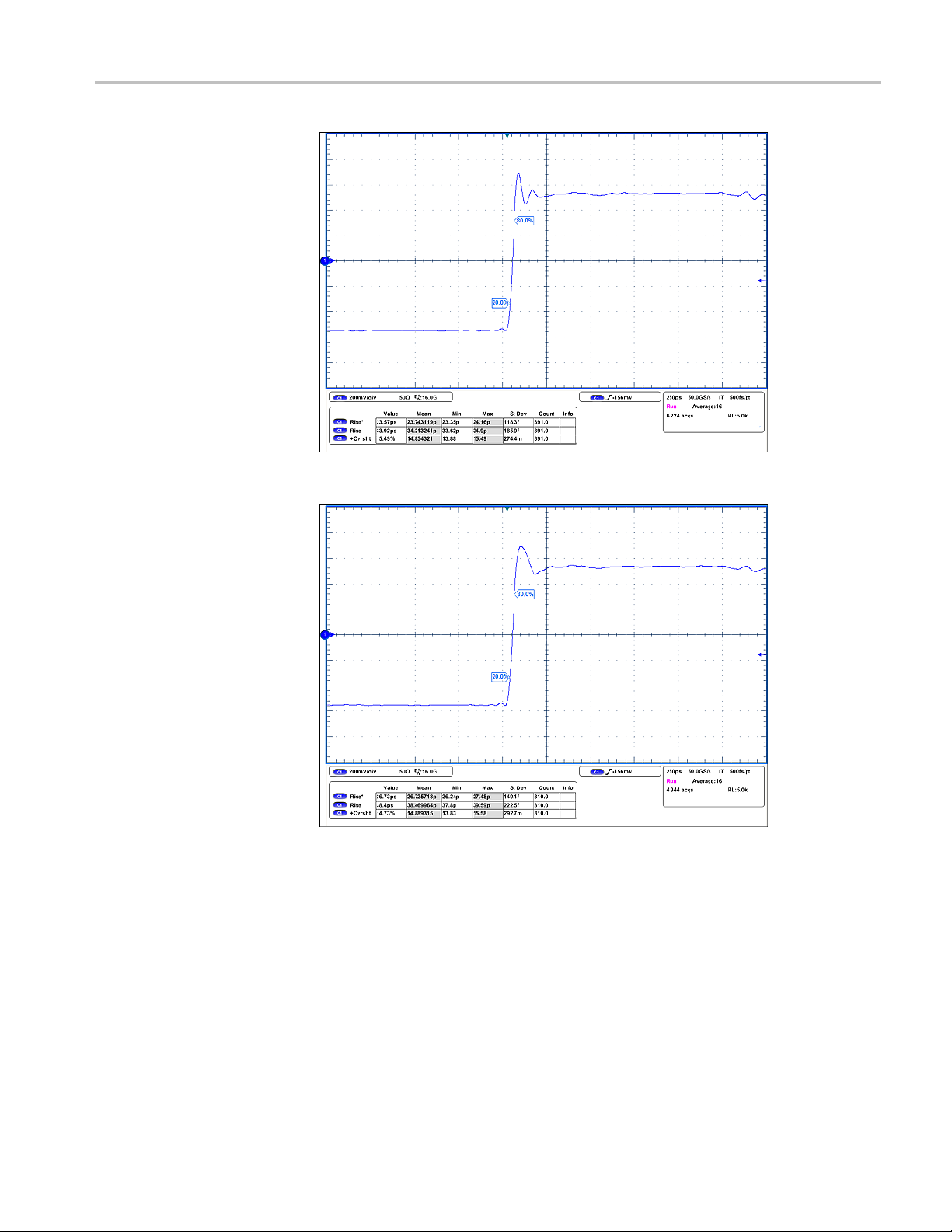

following four figures illustrate the signal integrity effect on the P75TLRST

The

solder tip when used with different lengths of tip wire. Signal fidelity is best when

the wire length is kept as short as possible. The step generator that was used as

a signal source for these screenshots has a 30 ps 10-90% rise time. The table in

each figure contains data for two rise time m easurements (10-90% and 20-80%).

These screenshots can be used as a guide to gauge the effects of wire length, but

actual results may vary depending on the other factors like characteristics of the

device under test (for example, rise time and impedance), and the precision of

the solder connection.

P6700 Series Serial Analyzer Probes Instruction Manual 31

Page 48

Reference

Figure 30: P75TLRST solder tip with 0.010 inch of tip wire

Figure 31: P75TLRST solder tip with 0.050 inch of tip wire

32 P6700 Series Serial Analyzer Probes Instruction Manual

Page 49

Figure 32: P75TLRST solder tip with 0.100 inch of tip wire

Reference

Figure 33: P75TLRST solder tip with 0.200 inch of tip wire

P6700 Series Serial Analyzer Probes Instruction Manual 33

Page 50

Reference

The following fi

Figure 34: P75TLRST TriMode Long Reach Solder Tip dimensions

Electric

al Design

For the serial analyzer module to reliably capture logical transactions on the bus,

adequate signal eye must be available at the point of probing while the probe is

connected. This can be verified by electrical simulation using the load model of

the P67

00 Series probe.

gure shows the dimensions of the P75TLRST Solder Tip.

Eye requirements are defined at the point of probing (midbus footprint, solder tip

for the solder-down probe, or the slot connector for the slot interposer probe)

input

and are measured by eye height and eye width, forming a diamond shape.

Figure 35: Signal eye measurements (time versus voltage)

The following specifications limit the electrical distance between the driver

pin and the point of probing. When analyzing both directions of an electrically

ong PCI Express link, you might need to design your system with two separate

l

footprints to maintain adequate signal eye. Eye requirements apply regardless of

circuit board material and infrastructure.

34 P6700 Series Serial Analyzer Probes Instruction Manual

Page 51

Reference

Table 5: Probe E

ye Requirements

Parameter Description

Midbus probe

Minimum eye height

1

at footprint p

ad

Minimum eye width

at footprint

pad

30 mV (single-

0.53 UI if jit

≤ 40 MHz are not present

If jitter frequency components of ≤ 40 MHz are

present, th

in the graph to the jitter of the signal. (See

Figure 36 on page 36.)

probe

Minimum eye height

at solder tip input

Minimum eye width

at solder tip input

30 mV (single-ended)Solder-down

1

0.53 UI if jitter frequency components of

≤ 40 MHz are

If jitter frequency components of ≤ 40 MHz are

present, then apply the filter function described

in the gra

ph to the jitter of the signal. (See

Figure 36 on page 36.)

probe

Minimum

at probe connection

point

Minimum eye width

at probe connection

point

1

eye height

60 mV (single-ended)Slot interposer

0.58 UI if jitter frequency components of

≤ 40 MHz

If jitter frequency components of ≤ 40 MHz are

present, then apply the filter function described

raph to the jitter of the signal. (See

in the g

Figure 36 on page 36.)

Unit Interval Gen1

Unit Interval Gen2

1

Eye Height/Width values apply to both data rates.

2

irements valid for 10

Requ

information, contact your local Tektronix representative.

–12

BER. Refer to the following graphs for probe input jitter tolerances. For further

400 ps

200 p

s

1

ended)

ter frequency components of

2

en apply the filter function described

not present

are not present

2

2

P6700 Series Serial Analyzer Probes Instruction Manual 35

Page 52

Reference

Figure 36: Periodic jitter gain function

Measuring signal eye. Tektronix recommends using a Tektronix DPO70000 series

or DSA70000 series oscilloscope with a P7500 series probe with solder-down tips

for most accurate results. If your system does not allow you to use solder-down

tips, use the handheld Precision Differential Probing Module (Tektronix part

r P75PDPM). Tektronix recommends using TDSJIT3 Advanced software

numbe

to take signal eye measurements. Tektronix RT-Eye software is also acceptable.

For instructions on using TDSJIT3 Advanced and RT Eye software, go t o

Tektronix.com/manuals, or contact your local Tektronix representative.

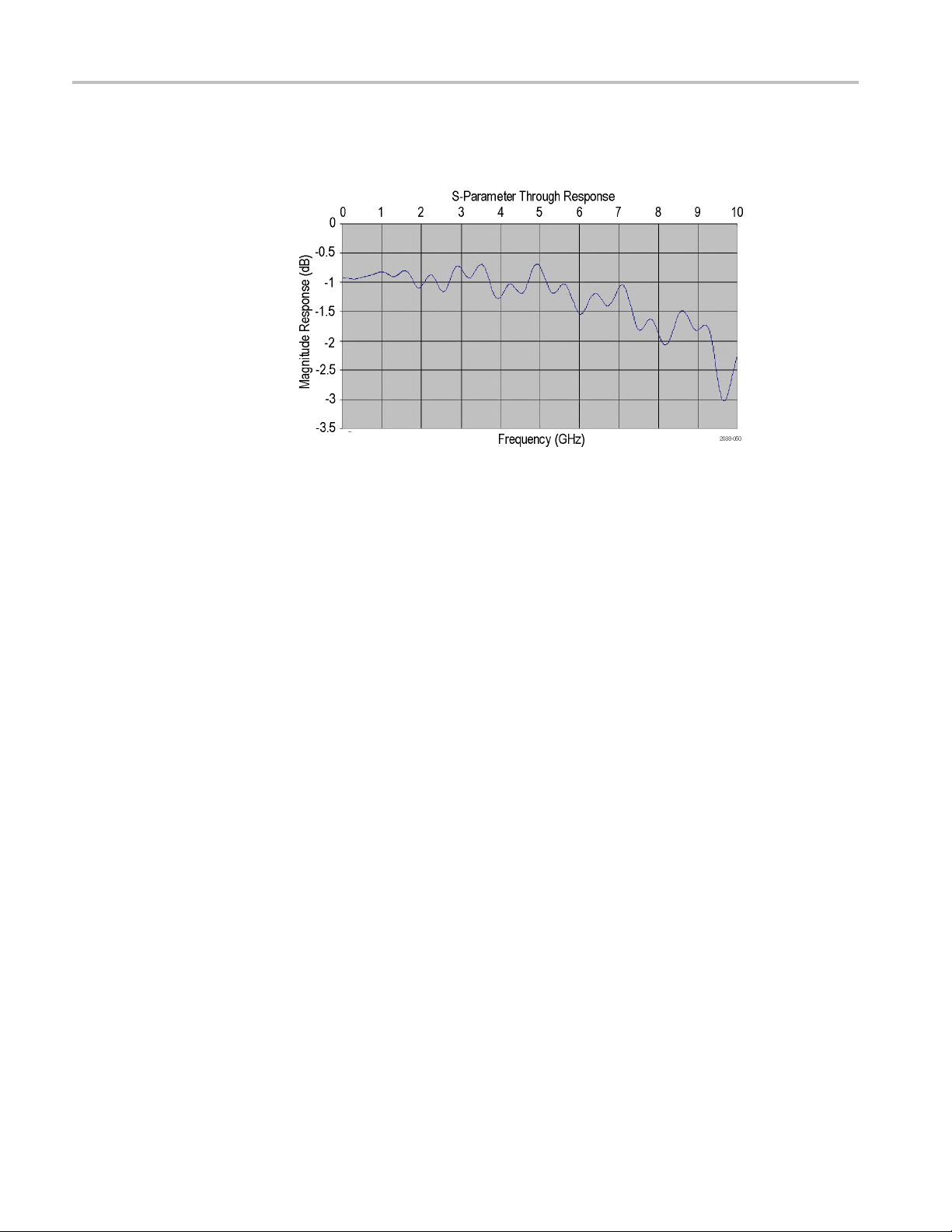

P6700 Series midbus probe circuit impact. Tektronix has provided two

chstone® models (sdd12wop.dat and sdd12wp.dat). (See page 73, Reference

Tou

Files.) These models simulate the impact of the P6700 Series midbus probe (8

or 16 channel) retention mechanisms with and without the probe installed. This

is actual S-parameter measured data using real probes and retentions. Graphical

representation of the data is provided in the next two graphs.

The first graph shows the frequency response of a transmission line loaded with a

P6700 midbus probe retention. (See Figure 37 on page 37.)

36 P6700 Series Serial Analyzer Probes Instruction Manual

Page 53

Reference

Figure 37: S-parameter data of retention mechanism only

The second graph shows the frequency response of a transmission line loaded

with a P6700 midbus probe retention and a probe. (See Figure 39.)

Figure 38: S-parameter data of retention mechanism plus P6700 Series midbus probe

P6700S Series Slot Interposer Probe circuit impact. Tektronix has provided

Touchstone® models to simulate the impact of a P6700S Series slot interposer

probe. (See page 73, Reference Files.) This is actual S-parameter measured data

using a real P6700S interposer probe.

P6701SD Solder-Down Probe circuit impact. Tektronix has provided a

Touchstone® model (P6701SD.dat) to simulate the impact o f a P6701SD

solder-down probe and P75TLRST solder tip. (See page 73, Reference Files.)

This is actual S-parameter measured data using a real P6701SD solder-down

probe. Graphical representation of the data is provided in the following graph.

P6700 Series Serial Analyzer Probes Instruction Manual 37

Page 54

Reference

Reference Clock Signal

It shows the fre

solder-down probe and P75TLRST solder tip.

Figure 39

The TLA7S08 & TLA7S16 Serial Analyzer modules can recognize a clock

signal f

embedded in the data.

rom a cable connection to the SUT, or by recovering the clock signal

quency response of a transmission line loaded with a P6701SD

: S-parameter data of P6701SD Solder-Down probe

Recognize the clock signal embedded in the data stream. A stable reference

signal is generated by the serial analyzer and synchronized with the embedded

clock signal. A clock cable connection is not required, since the logic analyzer

gnizes the embedded signal from the probe.

reco

The transfer rate of the serial link must be 2.5 GT/s ± 300 ppm (PCI Express

) or 5.0 GT/s ± 300 ppm (PCI Express Gen 2). If the transfer rate is not

Gen 1

within this range, the module will not capture the data reliably.

SC (spread spectrum clocking) is enabled, and your PCI Express link uses

If S

power management states, you must connect a clock cable to the SUT and set the

reference clock source to SUT so that the module will capture data reliably.

Recognize the clock signal by directly connecting to the SUT with a clock

cable. Tektronix recommends connecting a clock cable to ensure that data is

ccurately synchronized with the clock signal.

a

If you intend to use a midbus probe, you must install a three-pin connector on

your SUT to connect to the clock cable. (See page 28, Clock Cable Three-Pin

Connector.) Slot interposer probes already have this connector installed on the

probe.

38 P6700 Series Serial Analyzer Probes Instruction Manual

Page 55

Reference

Figure 4

0: Slot Interposer probe with a clock cable connected

Table 6: Reference clock electrical requirements

module requirement

Serial

Differential Voltage at Ref Clock Attach Point Vdiff

Absolute Voltage Limit at Ref Clock Attach Point

rence Clock Frequency –100 MHz

Refe

Reference Clock Frequency –100 MHz + 10%

Reference Clock Frequency –100 MHz - 10%

ference Clock Frequency –125 MHz

Re

1

Reference Clock Total Jitter RefClkJitter

1

With SSC (spread spectrum clocking) enabled or disabled

2

Vdiff= |2*(Vrefclockp - Vrefclockn)|

Symbol Minimu

2

Vabs 0 V

Freq100

1

Freq100 +10% - 110 MHz +/-300 ppm -

1

Freq100 -10% - 90 MHz +/-300 ppm -

Freq125

m

0.8 V

- 100 M

-12

-

-

l

Typica

-

-

Hz +/-300 ppm

5 MHz +/-300 ppm

<1 MHz: 25 ps p-p

>1 MHz: 200 ps p-p

Maximu

2.0 V

3.3 V

m

-

-

-

-

P6700 Series Serial Analyzer Probes Instruction Manual 39

Page 56

Reference

Midbus Footpr

int Pin and Probe Channel Assignments

The following figure shows the standard pin assignments for a PCI Express

8-channel footprint.

Figure 41: P6708 8-Channel probe footprint pin assignments

The following figure shows the standard pin assignments for a PCI Express

16-channel footprint.

General Guidelines for

Pin-Channel Assignment

Figure 42: P6716 16-Channel probe footprint pin assignments

Tektronix strongly recommends that you design your system so that pins are

assigned to channels according to the following guidelines and the standard

formats listed in the tables. The formats listed in the tables were created so

that each module-end probe connector contains the wires c onnected to adjacent

differential pairs on the footprint.

Figure 43: 8-Channel midbus footprint connection module connector

40 P6700 Series Serial Analyzer Probes Instruction Manual

Page 57

Figure 44: 16-Channel midbus footprint connection module connector

Reference

The serial analyzer software is designed to be easily configured based on these

standard formats. If your system design does not allow you to follow these

guideli

rewire the connector at the module end of the probe. (See page 57, Rearranging

Wires in the Probe Connector.)

nes, or if a footprint is incorrectly wired, you may have to disassemble and

The differential pairs that make up a PCI Express link must be connected to

specific pads (pins) on the footprint

The polarity of the differential pairs can be swapped, if required, for routing

ream and downstream channels can be swapped on a footprint, if

Upst

required, for routing

ire links can be reversed compared to the suggested routing

Ent

P6700 Series Serial Analyzer Probes Instruction Manual 41

Page 58

Reference

Key concepts fo

Each channel is connected to either an upstream or downstream differential

pair.

Signal name = C[number][p (positive) or n (negative)]

Example: C3p = the positive signal of the differential pair connected to

channel three

Channels are grouped together in sets of four in probe-to-module connectors.

All channels in the probe-to-module connector must come from the same

direction.

To ensure that all lanes from one direction of the link are connected to the top

two connectors on a TLA7S16 or to the top connector of a TLA7S08, refer

to the connector illustrations. (See Figure 43 on page 40.) (See Figure 44

on page 41.) Ensure that all lanes going to the bottom two connectors of

the TLA

direction.

llowing tables show footprint p in-channel assignments for PCI Express

The fo

links of various standard recommended configurations.

r the channel mapping tables.

7S16 (or the bottom connector of the TLA7S08) are from the same

42 P6700 Series Serial Analyzer Probes Instruction Manual

Page 59

Reference

16-Channel PC

I Ex press

Midbus Pin Assignments

Table 7: X16 uni

Pin # Signal name Pin # Signal name

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

6

3

8

3

40

42

44

46

48

G2 GND

directional link

GND

C1p

C1n

GND

C3p

C3n

GND

C5p

C5n

GND

C7p

C7n

GND

C9p

C9n

GND

C11p

C11n

GND

C13p

C13n

GND

C15p

C15n

G1 GND

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

3

3

39

41

43

45

47

5

7

C0p

C0n

GND

C2p

C2n

GND

C4p

C4n

GND

C6p

C6n

GND

C8p

C8n

GND

C10p

C10n

GND

C12p

C12n

GND

C14p

C14n

GND

P6700 Series Serial Analyzer Probes Instruction Manual 43

Page 60

Reference

Table 8: X8 bidi

Pin # Signal name Pin # Signal name

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

6

3

8

3

40

42

44

46

48

G2 GND

rectional link

GND

C0p- Downstream

C0n- Downstream

GND

C1p- Downstream

C1n- Downstream

GND

C2p- Downstream

C2n- Downstream

GND

C3p- Downstream

C3n- Downstream

GND

C4p- Downstream

C4n- Downstream

GND

C5p- Downstream

C5n- Downstream

GND

C6p- Downstream

C6n- Downstream

GND

C7p- Downstream

C7n- Downstream

G1 GND

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

3

3

39

41

43

45

47

5

7

C0p- Upstream

C0n- Upstream

GND

C1p- Upstream

C1n- Upstream

GND

C2p- Upstream

C2n- Upstream

GND

C3p- Upstream

C3n- Upstream

GND

C4p- Upstream

C4n- Upstream

GND

C5p- Upstream

C5n- Upstream

GND

C6p- Upstream

C6n- Upstream

GND

C7p- Upstream

C7n- Upstream

GND

44 P6700 Series Serial Analyzer Probes Instruction Manual

Page 61

Reference

Table 9 : X8 (2) u

Pin # Signal name Pin # Signal name

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

6

3

8

3

40

42

44

46

48

G2 GND

nidirectional links

GND

C1p- DirectionA

C1n- DirectionA

GND

C3p- DirectionA

C3n- DirectionA

GND

C5p- DirectionA

C5n- DirectionA

GND

C7p- DirectionA

C7n- DirectionA

GND

C1p- DirectionB

C1n- DirectionB

GND

C3p- DirectionB

C3n- DirectionB

GND

C5p- DirectionB

C5n- DirectionB

GND

C7p- DirectionB

C7n- DirectionB

G1 GND

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

3

3

39

41

43

45

47

5

7

C0p- DirectionA

C0n- DirectionA

GND

C2p- DirectionA

C2n- DirectionA

GND

C4p- DirectionA

C4n- DirectionA

GND

C6p- DirectionA

C6n- DirectionA

GND

C0p- DirectionB

C0n- DirectionB

GND

C2p- DirectionB

C2n- DirectionB

GND

C4p- DirectionB

C4n- DirectionB

GND

C6p- DirectionB

C6n- DirectionB

GND

P6700 Series Serial Analyzer Probes Instruction Manual 45

Page 62

Reference

Table 10: X4 bid

Pin # Signal name Pin # Signal name

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

6

3

8

3

40

42

44

46

48

G2 GND

irectional link

GND

C0p- Downstream1

C0n- Downstream1

GND

C1p- Downstream1

C1n- Downstream1

GND

C2p- Downstream1

C2n- Downstream1

GND

C3p- Downstream1

C3n- Downstream1

GND

C0p- Downstream2

C0n- Downstream2

GND

C1p- Downstream2

C1n- Downstream2

GND

C2p- Downstream2

C2n- Downstream2

GND

C3p- Downstream2

C3n- Downstream2

G1 GND

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

3

3

39

41

43

45

47

5

7

C0p- Upstream1

C0n- Upstream1

GND

C1p- Upstream1

C1n- Upstream1

GND

C2p- Upstream1

C2n- Upstream1

GND

C3p- Upstream1

C3n- Upstream1

GND

C0p- Upstream2

C0n- Upstream2

GND

C1p- Upstream2

C1n- Upstream2

GND

C2p- Upstream2

C2n- Upstream2

GND

C3p- Upstream2

C3n- Upstream2

GND

46 P6700 Series Serial Analyzer Probes Instruction Manual

Page 63

Reference

Table 11: X 4 (2)

Pin # Signal name Pin # Signal name

2

4

6

8

10

12

14

16 Not conn

18 Not connected 17

20

22 Not connected 21 Not connected

24 Not connected 23

26

28

30

32

34

36

38

40 Not connected 39 Not connected

42 Not connected 41

44

46 Not connected 45 Not connected

48 Not connected 47

G2 GND

unidirectional links

GND

C1p- DirectionA

C1n- DirectionA

GND

C3p- DirectionA

C3n- DirectionA

GND

ected

GND

GND

C1p- DirectionB

C1n- DirectionB

GND

C3p- DirectionB

C3n- DirectionB

GND

GND

G1 GND

1

3

5

7

9

11

13 Not conn

15 Not conn

19 Not connected

25

27

29

31

33

35

37 Not connected

43 Not connected

C0p- DirectionA

C0n- DirectionA

GND

C2p- DirectionA

C2n- DirectionA

GND

ected

ected

GND

GND

C0p- DirectionB

C0n- DirectionB

GND

C2p- DirectionB

C2n- DirectionB

GND

GND

GND

P6700 Series Serial Analyzer Probes Instruction Manual 47

Page 64

Reference

Table 12: X2 bid

Pin # Signal name Pin # Signal name

2

4

6

8

10

12

14

16 Not conn

18 Not connected 17

20

22 Not connected 21 Not connected

24 Not connected 23

26

28

30

32

34

36

38

40 Not connected 39 Not connected

42 Not connected 41

44

46 Not connected 45 Not connected

48 Not connected 47

G2 GND

irectional link

GND

C0p- Downstream1

C0n- Downstream1

GND

C1p- Downstream1

C1n- Downstream1

GND

ected

GND

GND

C0p- Downstream2

C0n- Downstream2

GND

C1p- Downstream2

C1n- Downstream2

GND

GND

G1 GND

1

3

5

7

9

11

13 Not conn

15 Not conn

19 Not connected

25

27

29

31

33

35

37 Not connected

43 Not connected

C0p- Upstream1

C0n- Upstream1

GND

C1p- Upstream1

C1n- Upstream1

GND

ected

ected

GND

GND

C0p- Upstream2

C0n- Upstream2

GND

C1p- Upstream2

C1n- Upstream2

GND

GND

GND

48 P6700 Series Serial Analyzer Probes Instruction Manual

Page 65

Reference

Table 13: X2 (2)

Pin # Signal name Pin # Signal name

2

4

6

8

10 Not connec

12 Not connected 11

14

16 Not connected 15 Not connected

18 Not connected 17

20

22 Not connected 21 Not connected

24 Not co

26

28

30

32

34 No

36 Not connected 35

38

40 Not connected 39 Not connected

42 Not connected 41

44

46 Not connected 45 Not connected

48 Not connected 47

G2 GND

unidirectional links

GND

C1p- DirectionA

C1n- DirectionA

GND

ted

GND

GND

nnected

GND

C1p- DirectionB

C1n- DirectionB

GND

t connected

ND

G

GND

G1 GND

1

3

5

7

9 Not connec

13 Not connected

19 Not connected

23

25

27

29

31 Not

33 No

37 Not connected

43 Not connected

C0p- DirectionA

C0n- DirectionA

GND

Not connec

GND

GND

GND

C0p- DirectionB

C0n- DirectionB

GND

t connected

GN

GND

GND

ted

ted

connected

D

P6700 Series Serial Analyzer Probes Instruction Manual 49

Page 66

Reference

Table 14: X1 bid

Pin # Signal name Pin # Signal name

2

4

6

8

10 Not connec

12 Not connected 11

14

16 Not connected 15 Not connected

18 Not connected 17

20

22 Not connected 21 Not connected

24 Not co

26

28

30

32

34 No

36 Not connected 35

38

40 Not connected 39 Not connected

42 Not connected 41

44

46 Not connected 45 Not connected

48 Not connected 47

G2 GND

irectional link

GND

C0p- Downstream1

C0n- Downstream1

GND

ted

GND

GND

nnected

GND

C0p- Downstream2

C0n- Downstream2

GND

t connected

ND

G

GND

G1 GND

1

3

5

7

9 Not connec

13 Not connected

19 Not connected

23

25

27

29

31 Not

33 No

37 Not connected