Page 1

Service Manual

P6701B, P6703B & P6723

O/E Converters

070-9892-03

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

*P070989203*

070989203

Page 2

Copyright © Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and pri ce change privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Page 3

WARRANTY

Tektronix warrants that the products that it manufactures and sells will be free from defects in materials and

workmanship for a period of one (1) year from the date of shipment. If a product proves defective during this

warranty period, Tektronix, at its option, either will repair the defective product without charge for parts and labor,

or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by Tektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the Tektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products returned to any other loc ations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompat ible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS W ARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR

THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Service Assurance

If you have not already purchased Service Assurance for this product, you may do so at any time during the

product’s warranty period. Service Assurance provides Repair Protection and Calibration Services to meet your

needs.

Repair Protection extends priori ty repair services beyond the product’s warranty period; you may purchase up to

three years of Repair Protection.

Calibration Services provide annual calibration of your product, standards compliance and required audit

documentation, recall assurance, and reminder notification of scheduled calibration. Coverage begins upon

registration; you may purchase up to five years of Calibration Services.

Service Assurance Advantages

H Priced well below the cost of a single repair or calibration

H Avoid delays for service by eliminating the need for separate purchase authorizations from your company

H Eliminates unexpected service expenses

For Information and Ordering

For more information or to order Service Assurance, contact your Tektronix representative and provide the

information below. Service Assurance may not be available in locations outside the United States of America.

Name VISA or Master Card number and expiration

Company date or purchase order number

Address Repair Protection (1,2, or 3 years)

City, State, Postal code Calibration Services (1,2,3,4, or 5 years)

Country Instrument model and serial number

Phone Instrument purchase date

Page 5

Table of Contents

General Safety Summary iii...................................

Preface v...................................................

Related Manuals v.................................................

Contacting Tektronix v.............................................

P6701B and P6703B Sp ecifications 1...........................

Warranted Characteristics 1..........................................

Typical Characteristics 2............................................

Nominal Characteristics 4...........................................

P6723 Specifications 5.......................................

Warranted Characteristics 5..........................................

Typical Characteristics 6............................................

Nominal Characteristics 6...........................................

P6701B and P6703B Performance Verification 7.................

Equipment Required 7..............................................

Noise Equivalent Power 8...........................................

Output Zero 9.....................................................

DC Conversion Gain 9.............................................

AC Conversion Gain 10.............................................

P6723 Performance Verification 13..............................

Equipment Required 13..............................................

Output Amplitude 14................................................

Maintenance 17..............................................

Cleaning the Optical Connectors 17....................................

Cleaning the External Parts 18........................................

Handling 18.......................................................

Replacing TekProbe Interface Pins 19..................................

Removing and Replacing the TekProbe Interface Collar 20.................

Options 21..................................................

Replaceable Parts 23..........................................

P6701B, P6703B, and P6723 Service Manual

i

Page 6

Table of Contents

ii

P6701B, P6703B, and P6723 Service Manual

Page 7

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

ToAvoidFireor

Personal Injury

Symbols and Terms

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Wear Eye Protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

P6701B, P6703B, and P6723 Service Manual

iii

Page 8

General Safety Summary

Symbols on the Product. The following symbols may appear on the product:

WARNING

High Voltage

Protective Ground

(Earth) Terminal

CAUTION

Refer to Manual

Double

Insulated

iv

P6701B, P6703B, and P6723 Service Manual

Page 9

Preface

Related Manuals

Contacting Tektronix

This manual contains specifications and procedures for servicing the P6701B,

P6703B, and P6723 O/E C onverters.

For operating instructions, refer to the P6701B, P6703B, and P6723 Instruc-

tions (070-9890-XX).

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: techsupport@te ktronix.com

1-800-833-9200, select option 3*

6:00 a.m. -- 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

P6701B, P6703B, and P6723 Service Manual

v

Page 10

Preface

vi

P6701B, P6703B, and P6723 Service Manual

Page 11

P6701B and P6703B Specifications

The specifications in Tables 1 through 3 apply to a P6701B or P6703B O/E

converter. The converter must have a warm-up period of at least 20 minutes and

be in an environment that does not exceed the limits described in Table 1.

Specifications for the P6701B and P6703B O/E converters fall into three

categories: warranted, typical, and nominal characteristics.

Warranted Characteristics

Warranted characteristics (Table 1) describes guaranteed performance within

tolerance limits or certain type-tested requirements. Warranted characteristics

that have checks in the Performance Verification section of the service manual

(070-9892-XX) are marked with the n symbol.

Table 1: P6701B and P6703B warranted electrical characteristics

DC optical input dynamic range DC electrical out will m eet conversion gain specifications up to

11 mW (0 dBm) peak optical power input

Absolute maximum non-destructive optical input 10 mW average power; 20 mW peak power

n DC conversion gain P6701B: 1 V/mW ± 8% at DC, 780 nm

P6703B: 1 V/mW ± 8% at DC, 1310 nm

n AC conversion gain P6701B: 1 V/mW ± 8%, with ≤ 100 W

780 nm

P6703B: 1 V/mW ± 8%, with ≤ 100 W

1310 nm

n Output zero ≤±1mVinto50Ω,20to25_ C

n Noise equivalent power

(with 1 GHz low-pass filter)

Output impedance 50 Ω ± 10%

Temperature Operating: 0 to +50_ C

P6701B: ≤ 0.87 W

(≤ 28 pW Hz)

P6703B: ≤ 0.59 W

(≤ 19 pW Hz

Nonoperating: --40 to +71_ C

RMS

RMS

)

optical modulation,

P-P

optical modulation,

P-P

P6701B, P6703B, and P6723 Service Manual

1

Page 12

P6701B and P6703B Specifications

Table 1: P6701B and P6703B warranted electrical characteristics (cont.)

Humidity Operating: 0--90% RH, tested at

+30to+50_ C

Nonoperating: 0--90% RH, tested at

+30to+60_ C

Altitude Operating: 4,572 m (15,000 ft)

Nonoperating: 15,240 m (50,000 ft)

Typical Characteristics

Typical characteristics (Table 2) describe typical but not guaranteed performance.

Table 2: P6701B and P6703B typical electrical characteristics

Effective wavelength range P6701B: 500 to 950 nm

P6703B: 1100 to 1650 nm

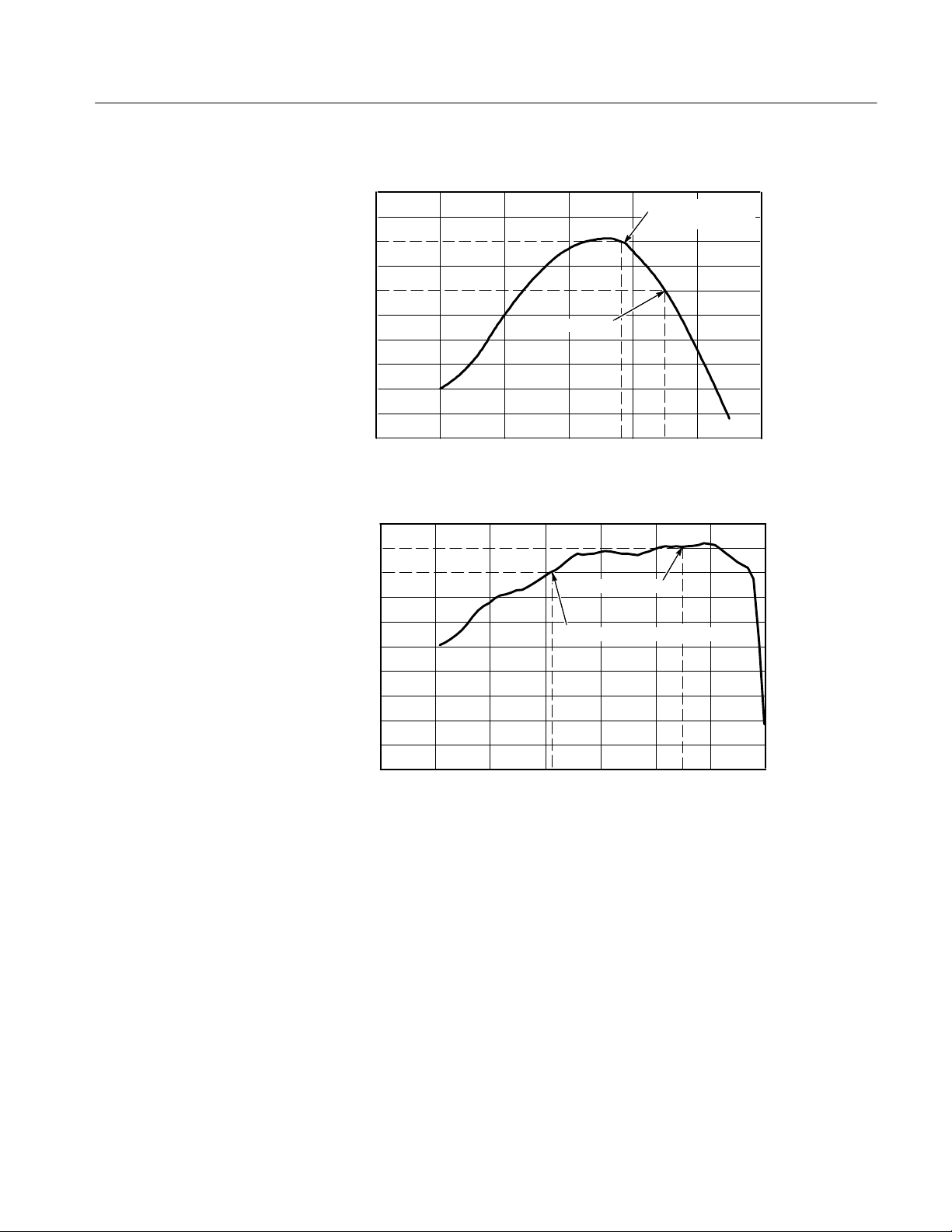

Wavelength dependent gain SeeFigure1

Optical bandwidth P6701B: ≥ 1.0 GHz

P6703B: ≥ 1.2 GHz

Rise time P6701B: ≤ 475 ps

P6703B: ≤ 390 ps

(peak optical signal input < 100 W

Aberrations ≤±15% peak optical signal input < 200 W

P-P

)

P-P

2

P6701B, P6703B, and P6723 Service Manual

Page 13

P6701B and P6703B Specifications

P6701B

1.2

1.1

1.0

0.9

0.8

0.7

0.6

Relative Conversion Gain

0.5

0.4

0.3

0.2

400 500 600 700 800 900 1000

~ 0.8 at 850nm

Wavelength (nm)

P6703B

1.2

1.1

1.0

0.9

0.8

0.7

0.6

Relative Conversion Gain

0.5

0.4

0.3

0.2

1000 1200 1400 1600

Wavelength (nm)

~ 1.1 at 1550 nm

Normalized to 1310nm at 1 V/mW

Normalized to

780nm at 1 V/mW

Figure 1: Typical wavelength dependent gain (25_ C ambient)

P6701B, P6703B, and P6723 Service Manual

3

Page 14

P6701B and P6703B Specifications

Nominal Characteristics

Nominal characteristics (Table 3) describe guaranteed traits, but the traits do not

have tolerance limits.

Table 3: P6701B and P6703B nominal electrical characteristics

Optical input coupling Accepts up to 62.5 m core diameter, Numerical Aperture ≤ 0.29

Optical fiber dressing > 1 inch bend radius, not to exceed a bend radius of < 1 inch to

maintain performance.

Absolute non-destructive fiber bend 0.5 inch bend radius

DC conversion gain linearity < 3% deviation in DC conversion gain from 50 W to 1000 W

average optical input relative to conversion gain with 500 W

average optical power input.

Output zero drift ≤±1.5 mV with output load requirement met for ideally stable

optical input, 0--25_ C

Output load requirement 50 Ω ± 1%

4

P6701B, P6703B, and P6723 Service Manual

Page 15

P6723 Specifications

The specifications in Tables 4 through 6 apply to a P6723 O/E converter. The

converter must have a warm-up period of at least 20 minutes and be in an

environment that does not exceed the limits described in Table 4.

Specifications for the P6723 O/E converter fall into three categories: warranted,

typical, and nominal characteristics.

Warranted Characteristics

Warranted characteristics (Table 4) describes guaranteed performance within

tolerance limits or certain type-tested requirements. Warranted characteristics

that have checks in the Performance Verification section of the service manual

(070-9892-XX) are marked with the n symbol.

Table 4: P6723 warranted electrical characteristics

Optical sensitivity -- 8.0 dBm maximum average optical power,

-- 28 dBm minimum average optical power

Output rise time and fall time ≤ 455 ps

n Output amplitude Minimum: ≥ 690 mV

Maximum: ≤ 1.1 V

Output impedance 50 ± 10%

Output VSWR < 1.5:1 from 10 MHz to 1 GHz

< 2.0:1 from 1 GHz to 2 GHz

Temperature Operating: 0 to +50_ C

Nonoperating: --40 to +71_ C

Humidity Operating: 0--90% RH, tested at

+30to+50_ C

Nonoperating: 0--90% RH, tested at

+30to+60_ C

Altitude Operating: 4,572 m (15,000 ft)

Nonoperating: 15,240 m (50,000 ft)

1

Measured with an optical input using 223- 1 pseudorandom word having a 50% duty cycle.

P-P

P-P

1

P6701B, P6703B, and P6723 Service Manual

5

Page 16

P6723 Specifications

Typical Characteristics

Typical characteristics (Table 5) describe typical but not guaranteed performance.

Table 5: P6723 typical electrical characteristics

Effective wavelength range 1100 to 1570 nm

Aberrations ≤±15%, 20%

P-P

total

Nominal Characteristics

Nominal characteristics (Table 6) describe guaranteed traits, but the traits do not

have tolerance limits.

Table 6: P6723 nominal electrical characteristics

Optical input coupling Accepts up to 62.5 m core diameter, Numerical Aperture ≤ 0.29

Optical data rate 20 MB/s minimum

650 Mb/s maximum

Optical fiber dressing > 1.5-inch bend radius

Absolute non-destructive fiber bend 0.5-inch bend radius

Output load requirement 50 Ω ± 1%, AC or DC coupled

1

Measured with an optical input using 223- 1 pseudorandom word having a 50% duty cycle.

1

1

6

P6701B, P6703B, and P6723 Service Manual

Page 17

P6701B and P6703B Performance Verification

Use the following procedures to verify the warranted specifications of the

P6701B and P6703B O/E converters. Before beginning these procedures, refer to

page 12 and photocopy the test record and use it to record the performance test

results. The recommended calibration interval is one year.

These procedures test the following specifications:

H Noise equivalent power

H Output zero

H DC conversion gain

H AC conversion gain

Equipment Required

Table 7 lists the equipment required to perform the performance verification

procedure. The types and quantities of connectors may vary depending on the

specific equipment you use.

The instrument should be given a 20 minute warm up period and ambient

temperature must be between 20 and 30 degrees C.

Table 7: Test equipment

Description Minimum requirements Example product

Optical power meter with

head and adapters

P6701B only: 780 nm cal

source

P6701B only: 850 nm cal

source

Accuracy > 2.5%, resolution >

5 pW, Max power > 1 mW, calibrated from 700 nm -- 1600 nm

output > 200uW (CW)1,

stability > 0.1 dB over 5 minutes,

modulated square wave @ 10 kHz

with off modulation at zero-light

level

output > 200uW1,

stability > 0.1 dB over 5 minutes,

modulated square wave @ 10 kHz

with off modulation at zero-light

level

HP 8153A with power

sensor HP 81532A and

HP 81531A

P6701B, P6703B, and P6723 Service Manual

7

Page 18

P6701B and P6703B Performance Verification

Table 7: Test equipment (cont.)

Description Example productMinimum requirements

P6703B only: 1310 nm cal

source

output > 200uW1,

stability > 0.1 dB over 5 minutes,

modulated square wave @ 10 kHz

with off modulation at zero-light

level

P6703B only: 1550 nm cal

source

RF power meter noise<.1mV,BW>4GHz HP 437B with power sensor

P6703B only: 1300 nm

impulse generator

P6701B only: 850 nm

impulse generator

Sampling oscilloscope 11K (1140X, CSA40xX, or

Adjustable optical

attenuator

Digital voltmeter 4 1/2 digit Tektronix DMM916

50 ohm termination ± 1% 011-0049-01

Optical cable FC-FC multimode, 62.5um, 2

Inline optical adapter FC female to FC female 131-5039-00

TekProbe Power Supply Tektronix 1103

output > 200uW (CW)1,

stability > 0.1 dB over 5 minutes,

modulated square wave @ 10 kHz

with off modulation at zero-light

level

4 decades, 50um core fiber, FCstyle connectors

meters

HP 8481D

OIG 502

OIG 501

DSA60X)

JDS 5000L with 62 m

fiber with FC connectors

174-2322-00

Noise Equivalent Power

8

Low-pass filter 1GHz Mini Circuits SLP 1000

1

CW and modulated mode available: modulation with OFF level at or below 0.1uW,

optical falltime < 1us

1. Power the P670XB under test using an 1103 Tekprobe power supply.

2. Connect the P670XB output channel from the 1103 power supply to the

power meter input with the 1 GHz filter in series with this connection.

3. With the dust cover on the input to the P670XB, the power meter reading

should be ≤ 15 nW for the P6701B and ≤ 7 nW for the P6703B.

P6701B, P6703B, and P6723 Service Manual

Page 19

Output Zero

DC Conversion Gain

P6701B and P6703B Performance Verification

1. Attach 1103 powered P670XB output to voltmeter with 50 ohm termination.

2. Install optical dust cover on input to P670XB under test.

3. Check that output voltage is ≤ 1mV.

NOTE. Make sure that the optical connector ends of both the fiber jumpers and

the input fiber of the O/E converter under test are well cleaned before performing this step. Use isopropyl alcohol, lint-free lense paper and clean compressed

air to clean the fiber ferrule ends. Refer to page 17 for the recommended

cleaning procedure.

P6701B

1. Connect 780 nm laser to attenuator.

NOTE. The fiber bend radius of the P670XB fiber input should lay with >1-inch

bend radius along the fiber’s entire length. Although this precaution must be

maintained throughout the entire PV procedure, it is especially important for this

step in order to accurately adjust and measure DC-conversion gain of the

P670XB.

2. Connect FC connector of the optical attenuator to FC-receptacle of the

optical power meter using the optical cable. Use the appropriate optical

power meter sensing head with calibrated measurement for a wavelength

span including 780 nm and 850 nm. Be sure the optical power meter

wavelength setting is at 780 nm.

3. Adjust attenuator or the optical source source so that the power meter reads

100 W.

4. Move the FC fiber end (the one now adjusted to 100 W average power)

from the optical power meter and connect to the P670XB input under test by

using the FC-FC inline female-female optical adapter.

5. Attach voltmeter with 50 ohm termination to 1103 powered P670XB output.

6. Check for 100 mV reading on voltmeter, ± 8%. (The 780 nm conversion gain

is 1.00 V/mW.)

P6701B, P6703B, and P6723 Service Manual

9

Page 20

P6701B and P6703B Performance Verification

P6703B

1. Connect 1310 nm laser to attenuator.

NOTE. The longer wavelengths of 1310 nm and especially 1550 nm are more

sensitive to loss in fiber due to bending of the fiber than the short wavelength.

The fiber bend radius of the P670XB fiber input should lay with >1-inch bend

radius along the fiber’s entire length. Although this precaution must be

maintained throughout the entire PV procedure, it is especially important for this

step in order to accurately adjust and measure DC-conversion gain of the

P670XB.

2. Connect FC connector of the optical attenuator to the FC receptacle of the

optical power meter using optical cable; use the appropriate optical power

meter sensing head with calibrated measurement for a wavelength span

including 1310 nm and 1550 nm. Be sure the optical power meter wavelength setting is at 1310 nm.

AC Conversion Gain

3. Adjust the attenuator or optical source so that the power meter reads 100 W.

4. Move the FC fiber end (the one now adjusted to 100 W average power)

from the optical power meter and connect to the P670XB input under test by

using the FC-FC inline female-female optical adapter.

5. Attach voltmeter with 50 ohm termination to 1103 powered P670XB output.

6. Check for 100 mV reading on voltmeter, ± 8%. (The 1310 nm Conversion

Gain is 1.00 V/mW.)

1. Connect the probe under test to the 11K series oscilloscope and to the cal

source.

H If the unit under test is a P6701B, connect the 850 nm modulated laser

source to the optical attenuator input. Connect the output of the optical

attenuator to the P6701B input via an inline adapter.

H If the unit under test is a P6703B, connect the 1310 nm modulated laser

source to the optical attenuator input. Connect the output of the optical

attenuator to the P6703B input via an inline adapter.

10

2. Adjust the laser cal source to provide a 10KHz to 20KHz optical square

wave on the scope. Adjust the optical attenuator so that the total peak-topeak signal from the P670XB is about 200 mV (or 200 W if the vertical

units displayed are “W”).

P6701B, P6703B, and P6723 Service Manual

Page 21

P6701B and P6703B Performance Verification

3. Set the oscilloscope for 5 us/div on the horizontal scale and 5 mV/div (or

5 uW/div) for the vertical scale. Trigger the scope on the negative edge of

the trace and set ground to the middle of the screen. This is equivalent to

1%/div.

4. Check that the OFF level of the square wave at approximately 5 us after the

90% fall time point is within 16 mV (8%) of the ground level (center line).

P6701B, P6703B, and P6723 Service Manual

11

Page 22

P6701B and P6703B Performance Verification

Test record

Probe Model/Serial Number: Certificate Number:

Temperature: RH %:

Date of Calibration: Technician:

Performance test Minimum Incoming Outgoing Maximum

Noise Equivalent Power

Output zero N/A 1mV

DC conversion gain 92 mV 108 mV

AC conversion gain -- 1 6 m V 16 mV

N/A 15 nW (P6701B)

7 nW (P6703B)

12

P6701B, P6703B, and P6723 Service Manual

Page 23

P6723 Performance Verification

Use the following procedure to verify the warranted specification (output

amplitude) of the P6723 O/E converter. Before beginning these procedures, refer

to page 15 and photocopy the test record and use it to record the performance test

results. The recommended calibration interval is one year.

Equipment Required

Table 8 lists the equipment required to perform the performance verification

procedure. The types and quantities of connectors may vary depending on the

specific equipment you use.

The instrument should be tested at an ambient temperature between 20 and 30

degrees C.

Table 8: Test equipment

Description Minimum requirements Example product

Optical power meter with

head and adapters

Accuracy > 2.5%, resolution >

5 pW, Max power > 1 mW, calibrated from 700 nm -- 1600 nm

HP 8153A with power

sensor HP 81530A and

HP 81531A

1310 nm digital optical

signal source

Sampling oscilloscope oscilloscope with Tekprobe II

Adjustable optical

attenuator

Optical cable FC-FC multimode, 62.5 m, 2

52 MHz -- 622 MHz Tektronix CTS710/CTS750

interface

4 decades, 50 m core fiber,

FC-style connectors

meters

Tektronix TDS784x

JDS 5000L with 62 m

fiber with FC connectors

174-2322-00

P6701B, P6703B, and P6723 Service Manual

13

Page 24

P6723 Performance Verification

Output Amplitude

NOTE. Make sure that the optical connector ends of both the fiber jumpers and

the input fiber of the O/E converter under test are well cleaned before performing this step. Use isopropyl alcohol, lint-free lense paper and clean compressed

air to clean the fiber ferrule ends. Refer to page 17 for the recommended

cleaning procedure.

1. Using the fiber jumpers, connect the 1310 nm digital optical source to the

optical attenuator input. Connect the output of the optical attenuator to the

power meter.

2. With the 1310 nm digital optical source transmitting at 155 Mbits/sec (OC3),

adjust the optical attenuator so that the power meter indicates --20 dBm.

3. Disconnect the jumper end from the output of the attenuator and connect the

optical input connector of the P6723 to the output of the attenuator.

4. Connect the output of the P6723 to the input of the TDS784.

5. Set the TDS784 to 5 ns/div, 200 mV/div, triggered on the signal and use the

horizontal cursors to measure the peak-to-peak amplitude.

6. Check that the peak-to-peak output (steady state on to steady state off) is

≤ 1.1 V and ≥ 0.69 V.

14

P6701B, P6703B, and P6723 Service Manual

Page 25

P6723 Performance Verification

Test record

Probe Model/Serial Number: Certificate Number:

Temperature: RH %:

Date of Calibration: Technician:

Performance test Minimum Incoming Outgoing Maximum

Output Amplitude

0.69 V 1.1 V

P6701B, P6703B, and P6723 Service Manual

15

Page 26

P6723 Performance Verification

16

P6701B, P6703B, and P6723 Service Manual

Page 27

Maintenance

To keep the P6701B, P6703B, and P6723 O/E Converters in good operating

condition, observe proper cleaning and handling techniques.

Cleaning the Optical Connectors

Small dust particles and oils can easily contaminate fiber-optic connectors and

reduce or block the signal. Take care to preserve the integrity your connectors by

keeping them free of contamination.

CAUTION. To prevent loss of optical power or damage to the fiber-optic

connectors, keep the connectors clean at all times.

When cleaning the connectors with a swab, use gentle circular motions. Use only

high quality cleaning supplies that are non-abrasive and leave no residue.

To reduce the need for cleaning, immediately replace protective caps on the

fiber-optic connectors when not in use.

Equipment Required

Procedure

Use the following items to clean the fiber-optic connectors:

H clean compressed air

H fiber-optic cleaning swabs

H isopropyl alcohol

Clean the fiber-optic connectors as follows:

1. Hold the can of compressed air upright and spray the can into the air to purge

any propellant.

2. Spray the clean compressed air on the connectors to remove any loose

particles or moisture.

3. Moisten a clean fiber-optic swab with isopropyl alcohol then lightly swab

the surfaces of the connectors.

4. Spray the clean compressed air on the connectors again to remove any loose

particles or isopropyl alcohol.

P6701B, P6703B, and P6723 Service Manual

17

Page 28

Maintenance

NOTE. Cleaning kits for fiber-optic connectors are available from a number of

suppliers.

Cleaning the External Parts

Remove dirt with a soft cloth dampened in a mild detergent and water solution or

isopropyl alcohol.

CAUTION. To avoid damaging the probe, use only a mild detergent and water

solution or isopropyl alcohol; do not use any other solvents or abrasive

cleaners. Do not immerse the probe.

Handling

Even though the fiber-optic cable of the P6701B, P6703B, or P6723 O/E

Converter is protected by a jacket and strain relief, the fiber-optic cable should

be handled carefully at all times.

CAUTION. To avoid damaging the P6701B, P6703B, and P6723 O/E Converters,

take the following precautions:

Do not crush, crimp, or sharply bend the fiber optic cable.

Do not pull or yank the fiber-optic cable.

Do not drop the converter assembly since damage and misalignment of the

photodiode optical assembly can result. Store the converter in a secure location

when not in use.

Replace the protective cap on the connector when the converter is not in use.

The P6701B, P6703B, and P6723 O/E Converters can connect to optical fibers

with a core diameter of up to 62.5 m through one of the FC, ST, SC, or DIN

adapters. Adapter cables that aid in connecting many other popular optical

connectors are also available. (Refer to Optional accessories on page 24.)

18

P6701B, P6703B, and P6723 Service Manual

Page 29

CAUTION. To maintain the high performance (low return loss) of the O/E

converter, connect an adapter and cable between the input of the O/E converter

and the device under test. When you make connections to other devices, leave the

adapter and cable in place to protect the optical connector of the O/E converter

from wear.

If you connect fiber cores larger than 62.5 m, the O/E converters may still

couple light, but the mismatch in core diameter will cause lower conversion gain

andhighinsertionloss.

Replacing TekProbe Interface Pins

1. To remove the interface pin, grasp the pin with a pair of needle-nose pliers

and gently pull the pin out. See Figure 2.

2. To replace the pin, insert the new pin into the socket and press it in against a

hard surface.

Maintenance

Figure 2: Replacing TekProbe interface pins

3. The pin installed in the position shown in Figure 3 is 0.020 inch shorter than

the other pins. Be sure to install the correct pin in this position; instruments

with the TekProbe interface may report errors if a longer pin is in this

position. See the Replaceable Parts List that begins on page 23 for ordering

information

P6701B, P6703B, and P6723 Service Manual

19

Page 30

Maintenance

Short pin

Figure 3: Location of short interface pin

Removing and Replacing the TekProbe Interface Collar

1. To remove the collar, firmly pull the collar off by hand.

2. To replace the collar, align the smaller group of pins with the smaller of the

two holes in the interface collar and align the tabs with the slots. Gently

press the two pieces together. See Figure 4.

Tab

Slot

Figure 4: Replacing the TekProbe collar

20

P6701B, P6703B, and P6723 Service Manual

Page 31

Options

Option 95 documents the measurements taken during calibration.

Option FR documents the frequency response of the O/E converter.

P6701B, P6703B, and P6723 Service Manual

21

Page 32

Options

22

P6701B, P6703B, and P6723 Service Manual

Page 33

Replaceable Parts

3

2

1

Figure 5: Replaceable parts

1

Figure 6: Standard accessories

NOTE: Parts illustrated

with dashed lines are not

replaceable

2

2 3

1 2 3 4

5

6

Figure 7: Optional accessories

P6701B, P6703B, and P6723 Service Manual

7 8 9

23

Page 34

Replaceable Parts

Replaceable parts list

Fig. &

index

number

5--1 131--3627--01 1 CONTACT,ELEC:GOLD PLATED TIP 18359 P--6158--1

--2 131--6353--00 1 CONTACT,ELEC:GOLD PLATED TIP 18359 P--6158--2

--3 205--0191--00 1 SHELL,ELEC CONN:BNC,ABS,DOVE GRAY 80009 205--0191--00

6--1 131--6252--00 1 CONN:FC TO FC SQUARE MOUNT

--2 131--6250--00 1 CONN:FC TO ST ADAPTER W/ZIRCONIA CERAMIC

--3 131--6251--00 1 CONN:SC TO FC SQUARE FLANGE ADAPTER

7--1 174--1497--00 1 CA ASSY,FBR OPT:SINGLE MODE,2M L

--2 174--3737--00 1 FIBER OPTIC:COUPLER, 1 X 2 SPLI TTER,

--3 011--0049--01 1 TERMN ,COAXIAL:50 OHM,2W,BNC 24931 28A123--1

--4 012--0482--00 1 CA ASSY,RF:COAXIAL,RFD,50

--5 015--0554--00 1 ADPTR,SMA,ELEC:FEMALE BNC TO MALE SMA 24931 29JP170-- 1

--6 119--5118-- 00 1 ATTEN,OPTICAL:30MM,L10DBFOR 1310/1550NM,FC

--7 020--2209--00 1 ACCESSORY KIT:CONNECTOR,OPTICAL,DIN TO FC

--8 ------------------ -- 1 1103 TekProbe Power Supply 80009 Order by Description

--9 ------------------ -- 1 FS156 or FS622 SDH/SONET filters 80009 Order by Description

Tektronix

part number

070--9890--XX 1 MANUAL,TECH:INSTRUCTIONS,4 LANGUAGES 80009 070--9890--XX

070--9892--XX 1 MANUAL, TECH:SERVICE,ENGLISH 80009 070-- 9892-- XX

174--1385--00 1 CA ASSY,FBR OPT:SGL MODE, 2M L,FC/PC

174--1386--00 1 CA ASSY,FBR OPT:SINGLE MODE,2M L,FC/PC--ST 80009 174--1386--00

174--1387--00 1 CA ASSY,FBR OPT:SGL MODE, 2M L,FC/PC--FC/PC 80009 174-- 1387-- 00

174--1388--00 1 CA ASSY,FBR OPT:SGL MODE, 2M

174--2322--00 1 CABLE,FIBER OPT:JUMPER,2 METER,62.5

174--2323--00 1 CABLE,FIBER OPT:JUMPER,2 METER,62.5

174--2324--00 1 CABLE,FIBER OPT:JUMPER,2 METER,62.5

Serial no.

effective

Serial no.

discont’d

Qty Name & description Mfr. code Mfr. part number

Standard accessories

ADAPTER,W/ZIRCONIA CERAMIC SLEEVE

SLEEVE

W/ZIRCONIA CERAMIC SLEEVE

0C5R7 CO92290

0C5R7 C032980

0C5R7 C002453

Optional accessories

FC/PC TO DIAMOND 2.5

DIAMOND3.5

L,FC/PC--BICONIC

MICRON,FC/PC TO FC/PC

MICRON,FC/PC TO BICONIC

MICRON,FC/PC TO SMA 906

WAVELENGTH INDEPENDENT, 90/10 RATIO, ATT.

0.1 DB, REFLE

OHM,(175--1455--00),36 L,BNC,MALE,STR,BOTH

ENDS,W/STRAIN RELIEF BO

CONN.FA100--35--10--HP,CTS710

SQUARE MOUNT ADAPTER,

80009 174--1497--00

80009 174--1385--00

80009 174--1388--00

62712 174--2322--00

62712 174--2322--00

62712 PC/SK--20--002A

0C5R7 3--0102--10--B--UFC--0

1-- UFC--01

TK2469 012--0482--00

0LK97 FA100--35--10--HP

80009 020--2209--00

24

P6701B, P6703B, and P6723 Service Manual

Page 35

Replaceable Parts

Manufacturers cross index

Mfr.

code

0C5R7 ALCOA FUJIKURA LTD 150 RIDGEVIEW CIRCLE DUNCAN, SC 29334

0LK97 JDS FITEL INC 570 WEST HUNT CLUB RD NEPEAN, ONTARIO CA ONTARIO K2G 5W8

18359 PYLON CO. INC. 51 NEWCOMB ST ATTLEBORO, MA 02703--1403

24931 BERG ELECTRONICS INC BERG ELECTRONICS RF/COAXIAL DIV

62712 SEIKO INSTRUMENTS USA INC ELECTRONIC COMPONENTS DIV

80009 TEKTRONIX INC 14150 SW KARL BRAUN DR

TK2469 UNITREK CORPORATION 3000 LEWIS & CLARK HWY

Manufacturer Address City , state, zip code

2100 EARLYWOOD DR

PO BOX 547

2990 W LOMITA BLVD

PO BOX 500

SUITE 2

FRANKLIN, IN 46131

TORRANCE, CA 90505

BEAVERTON, OR 97077--0001

VANCOUVER, WA 98661

P6701B, P6703B, and P6723 Service Manual

25

Page 36

Replaceable Parts

26

P6701B, P6703B, and P6723 Service Manual

Page 37

Page 38

Loading...

Loading...