Page 1

Instruction Manual

TLA7PG2

Pattern Generator Probes

071-1017-01

This document supports Tektronix Logic Analyzer Family Software Version 4.1 and Tektronix Pattern Generator Software Version 1.3 and above.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

*P071101701*

071101701

Page 2

Copyright Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Page 3

WARRANTY

Tektronix warrants that the products that it manufactures and sells will be free from defects in materials and

workmanship for a period of one (1) year from the date of shipment. If a product proves defective during this

warranty period, Tektronix, at its option, either will repair the defective product without charge for parts and labor,

or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by Tektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the Tektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR

THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

Operating Basics

Reference

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Documentation ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting Tektronix x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Lead Sets and Cables 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the Standard Probes 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the P6475 Probe 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Connectors and Signal Names 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Overview 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Dimensions 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P6475 Installation Requirements 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input/Output Circuits 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Diagrams 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance

Functional Check 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Cleaning 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Static Discharge Information 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Probes 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repackaging 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TLA7PG2 Pattern Generator Probes Instruction Manual

i

Page 6

Table of Contents

List of Figures

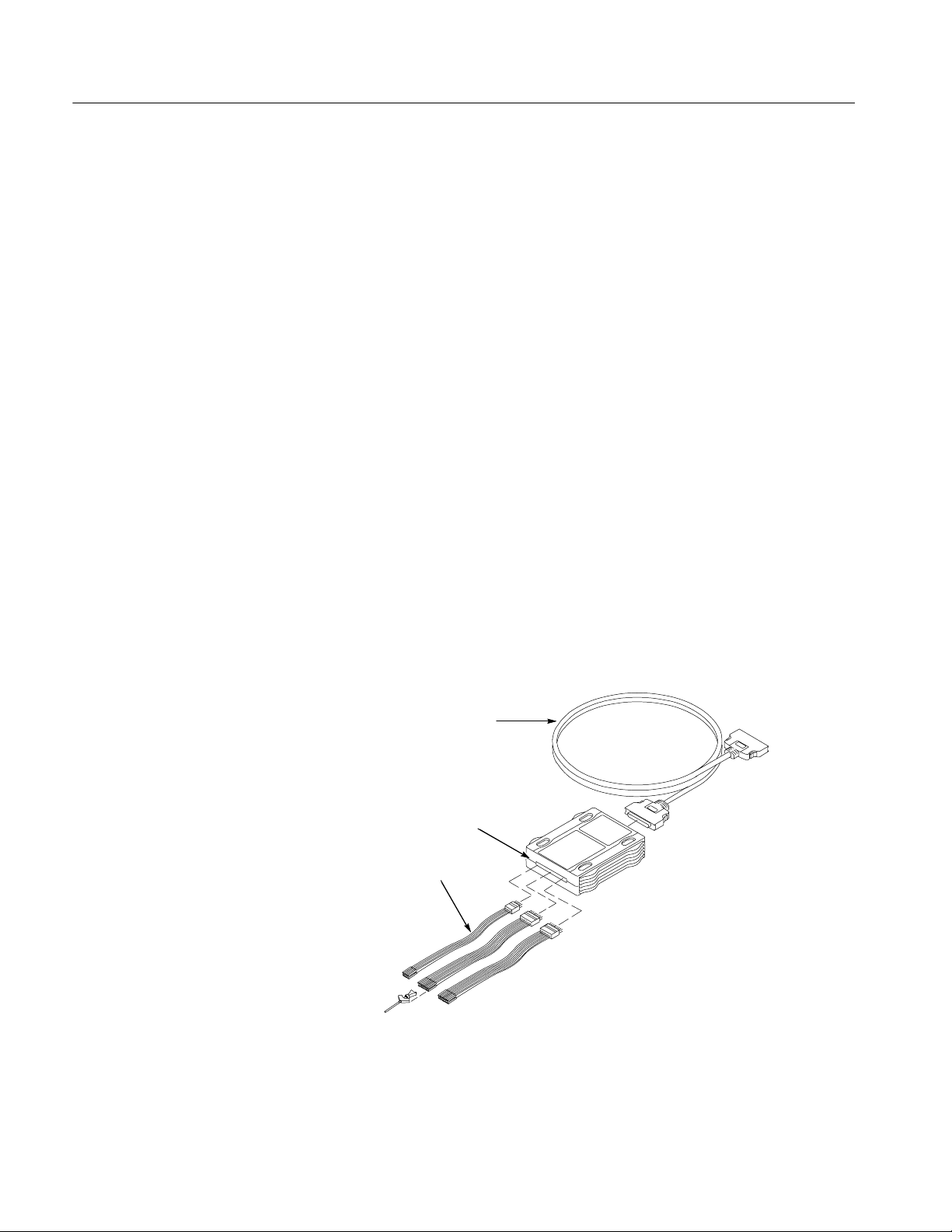

Figure 1: Standard probe, lead sets, and probe cable 2. . . . . . . . . . . .

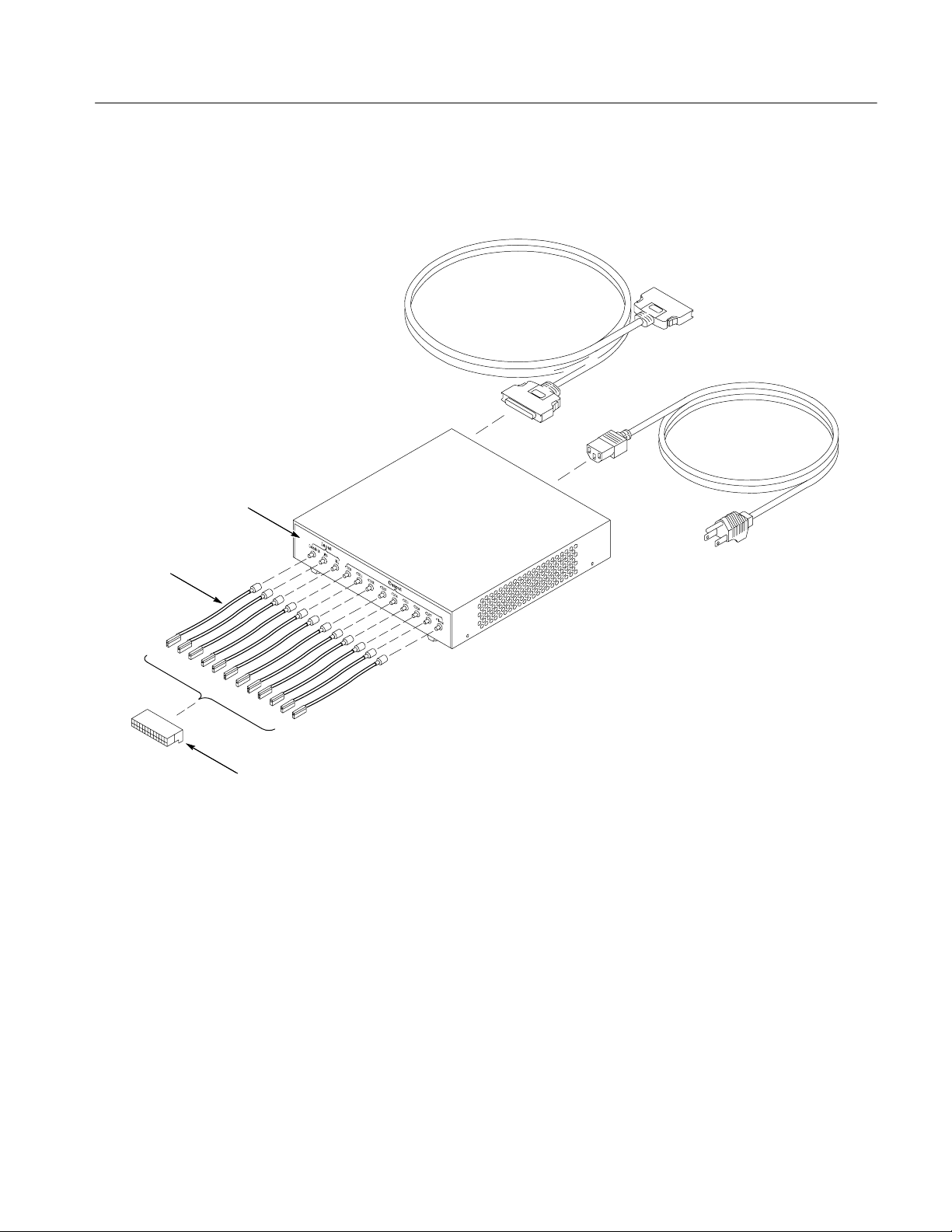

Figure 2: P6475 variable probe, lead sets, power cord,

and probe cable 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3: P6470 and P6474 output connector pin assignments 7. . . . .

Figure 4: P6471 output connector pin assignments 7. . . . . . . . . . . . . .

Figure 5: P6472 output connector pin assignments 8. . . . . . . . . . . . . .

Figure 6: P6473 output connector pin assignments 8. . . . . . . . . . . . . .

Figure 7: P6475 output connector pin assignments 8. . . . . . . . . . . . . .

Figure 8: Strobe output pulse pattern 11. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9: P6475 Variable probe output pulse pattern 11. . . . . . . . . . . .

Figure 10: P6475 CH6 output example 12. . . . . . . . . . . . . . . . . . . . . . . .

Figure 11: P6475 CH6 output mode pulse patterns 13. . . . . . . . . . . . . .

Figure 12: P6470, P6471, P6472, P6473 and P6474

probe dimensions 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 13: P6475 Variable probe dimensions 16. . . . . . . . . . . . . . . . . . .

Figure 14: P6470 input/output circuit 18. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 15: P6471 input/output circuit 19. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 16: P6472 input/output circuit 20. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 17: Signaling sense 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 18: P6474 input/output circuit 22. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 19: Clock and strobe timing diagram 22. . . . . . . . . . . . . . . . . . .

Figure 20: P6470, P6472, P6473, and P6474 inhibit

timing diagram 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 21: P6470, P6472, P6473, and P6474 external event

for inhibit timing diagram 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 22: External event for jump timing diagram 23. . . . . . . . . . . . .

Figure 23: External event for half channel advance

timing diagram 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 24: External event for full channel advance

timing diagram 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 25: External event for delay to data output

for advance diagram 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 7

Table of Contents

Figure 26: Removing the standard probe cover 46. . . . . . . . . . . . . . . . .

Figure 27: P6470 series termination resistors 47. . . . . . . . . . . . . . . . . . .

Figure 28: P6474 series termination resistors 48. . . . . . . . . . . . . . . . . . .

Figure 29: P6472 PECL and LVPECL jumper position 48. . . . . . . . . .

TLA7PG2 Pattern Generator Probes Instruction Manual

iii

Page 8

Table of Contents

List of Tables

Table 1: Inputs and outputs of pattern generator probes 9. . . . . . . .

Table 2: P6475 Variable probe installation requirements 17. . . . . . . . .

Table 3: P6470 TTL/CMOS probe 25. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4: P6471 ECL probe 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5: P6472 PECL/LVPECL probe 30. . . . . . . . . . . . . . . . . . . . . . . .

Table 6: P6473 LVDS probe 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7: P6474 LVCMOS probe 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 8: P6475 Variable probe 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9: Power Supply (P6475 only) 42. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10: Atmospherics 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 11: Dynamics characteristics (P6470, P6471,

P6472, P6473, P6474) 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 12: Dynamics characteristics (P6475) 43. . . . . . . . . . . . . . . . . . . .

Table 13: Probe cables 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 14: Twisted lead set 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 15: Certifications and compliances for P6475 43. . . . . . . . . . . . .

Table 16: P6470 series termination resistors 47. . . . . . . . . . . . . . . . . . .

iv

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the Product. These products (P6470, P6471, P6472, P6473, and P6474)

are indirectly grounded through the grounding conductor of the mainframe

power cord. The P6475 is directly grounded through the grounding conductor of

the probe power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

TLA7PG2 Pattern Generator Probes Instruction Manual

v

Page 10

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

Protective Ground

(Earth) Terminal

vi

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 11

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

TLA7PG2 Pattern Generator Probes Instruction Manual

vii

Page 12

General Safety Summary

viii

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 13

Preface

Related Documentation

This document provides information on using and servicing the TLA7PG2

probes.

In addition to these probe instructions, the following documentation is available

for your Tektronix Logic Analyzer Family:

H The TLA7PG2 Pattern Generator and Probes Service Manual provides

service information for the pattern generator and pattern generator probes.

H The Tektronix Logic Analyzer Family User Manual provides overall user

information for the Tektronix logic analyzers.

H The online help provides information for the probes and pattern generator

user interfaces and the Pattern Generator Programmatic Interface (PPI).

H A series of instruction manuals for microprocessor support provides

operating and service instructions for the individual microprocessor support

packages that are available for use with the logic analyzer.

H Probe instructions accompany the logic analyzer modules to provide

operating and service information.

H The Tektronix Logic Analyzer Family Training Manual provides training

exercises to help you learn key features of the logic analyzer. The training

manual is designed to be used with the TLA7QS training board.

H A series of service manuals are available that provide performance verifica-

tion procedures and board-level service information for major components

of the logic analyzer.

TLA7PG2 Pattern Generator Probes Instruction Manual

ix

Page 14

Preface

Contacting Tektronix

Phone 1Ć800Ć833Ć9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1Ć800Ć833Ć9200, select option 1*

Service support 1Ć800Ć833Ć9200, select option 2*

Technical support Email: TechSupport@tektronix.com

1Ć800Ć833Ć9200, select option 3*

1Ć503Ć627Ć2400

6:00 a.m. - 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

x

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 15

Operating Basics

Product Description

This section provides a brief description of the TLA7PG2 probes and information on connecting the probes from the pattern generator module to the target

system.

The pattern generator probes provide multichannel signals to simulate signals in

a test environment. Following are descriptions of the probes discussed in this

manual:

P6470 TTL/CMOS

P6471 ECL

P6472 PECL/LVPECL

P6473 LVDS

The P6470 provides TTL or CMOS signals to the target system and contains 16

data outputs, 1 clock output, and 1 strobe output. The V

adjustable from 2.0 V to 5.5 V. Figure 14 on page 18 shows the P6470 input/output circuit.

The P6470 probe comes standard with 75 termination resistors packs. You can

change the resistor packs to provide impedance matching for the target system.

Refer to Removing the Probe Cover on page 46 and Changing the Series

Termination Resistors on page 47.

The P6471 ECL pattern generator probe provides ECL signals to the target

system and contains 16 data outputs, 1 clock output, and 1 strobe output. Figure

15 on page 19 shows the P6471 input/output circuit.

The P6472 provides PECL/LVPECL signals to the target system and contains 8

data outputs, 1 clock output, and 1 strobe output. You can select PECL or

LVPECL by moving a jumper in the probe. See Configuring the P6472 for

PECL or LVPECL on page 48. Figure 16 on page 20 shows the P6472 input/output circuit.

The P6473 provides LVDS signals to the target system and contains 16 data

outputs, 1 clock output, and 1 strobe output. All inputs and outputs are LVDS

level.

output driver is

cc

P6474 LVCMOS

TLA7PG2 Pattern Generator Probes Instruction Manual

The P6474 provides LVCMOS signals to the target system and contains 16 data

outputs, 1 clock output and 1 strobe output. Figure 18 on page 22 shows the

P6474 input/output circuit.

V

The

of the output driver is adjustable from 1.2 V to 3.3 V.

cc

1

Page 16

Operating Basics

The P6474 comes standard with 75 termination resistors packs. You can

change the resistor packs to provide impedance matching for the target system.

Refer to Removing Probe the Cover on page 46 and Changing the Series

Termination Resistors on page 47.

P6475 Variable

The P6475 provides logic family signals such as ECL, TTL/CMOS, and

PECL/LVPECL and contains 8 data outputs and one clock output. The P6475

also supports variable delay (0 to 50 ns) for two channels (CH6 and CH7).

When using the P6475 probe with a P6470 (TTL/CMOS), P6473 (LVDS), or

P6474 (LVCMOS) probe, it is recommended that you use a Time Alignment

Cable (P/N 012-A223-00) in conjunction with the TLA7PG2 Pattern Generator

Module. The Time Alignment Cable ensures that the P6475 and the P6470,

P6473, or P6474 probes are time aligned and can be used together. Please order

one Time Alignment Cable (P/N 012-A223-00) for each P6470, P6473, and

P6474 probe.

Probe Lead Sets and Cables

Figure 1 shows a typical pattern generator probe with the lead sets and probe

cable. The probe cable is included with the TLA7PG2 pattern generator module.

Refer to Probe Connectors and Signal Names, beginning on page 7, for probe

connector information.

Probe cable

Front panel

Lead sets

Figure 1: Standard probe, lead sets, and probe cable

2

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 17

Front panel

Operating Basics

Figure 2 shows the P6475 variable probe, lead sets and probe cable. The probe

cable is included with the TLA7PG2 pattern generator module.

Lead sets

Note: The power

Connector

switch is located

on the rear panel

Figure 2: P6475 variable probe, lead sets, power cord, and probe cable

Connecting the Standard Probes

To connect the probes to the logic analyzer and to the target system, do the

following steps:

1. Power off the logic analyzer and the target system before connecting the

pattern generator probes.

2. Connect the lead sets to the target system.

3. Connect the standard probe as shown in Figure 1. The probe cable is

reversible. You can connect the probe cable in either direction.

TLA7PG2 Pattern Generator Probes Instruction Manual

3

Page 18

Operating Basics

4. Connect the probe to the pattern generator module on the logic analyzer.

CAUTION. To prevent damage to the pattern generator module or probe, do not

connect or disconnect the pattern generator cables to or from the pattern

generator module or probe while the logic analyzer is powered on. The

recommended DUT (Device Under Test) and pattern generator power on/off

sequence is as follows:

Power on the DUT first, then power on the pattern generator. Power off the

pattern generator and then power off the DUT.

Although the pattern generator probe cable appears to be a SCSI cable, it is not

compatible with a SCSI cable; do not use a SCSI cable with the pattern

generator module, or use the pattern generator probe cable with a SCSI

instrument.

The probe is fragile; handle it carefully.

Connecting the P6475 Probe

P6475 Connections

Do the following steps to connect the P6475 to the logic analyzer, the target

system, and to the power source:

1. Power off the logic analyzer and the target system before connecting the

pattern generator probes.

2. Connect the lead sets to the target system.

3. Connect the P6475 as shown in Figure 2. The probe cable is reversible;

either end can be connected to the P6475.

4. Connect the P6475 power cord.

5. Connect the probe to the pattern generator module on the logic analyzer.

4

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 19

Operating Basics

Power On/Off

Follow the procedures below to power on and power off the P6475 variable

probe:

1. Power on the DUT

2. Power on the P6475

3. Power on the TLA

1. Power off the TLA

2. Power off the P6475

3. Power off the DUT

TLA7PG2 Pattern Generator Probes Instruction Manual

5

Page 20

Operating Basics

6

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 21

Reference

This section provides reference information and specifications for the TLA7PG2

probes.

Probe Connectors and Signal Names

P6470 and P6474 Pin

Assignments

P6471 Pin Assignments

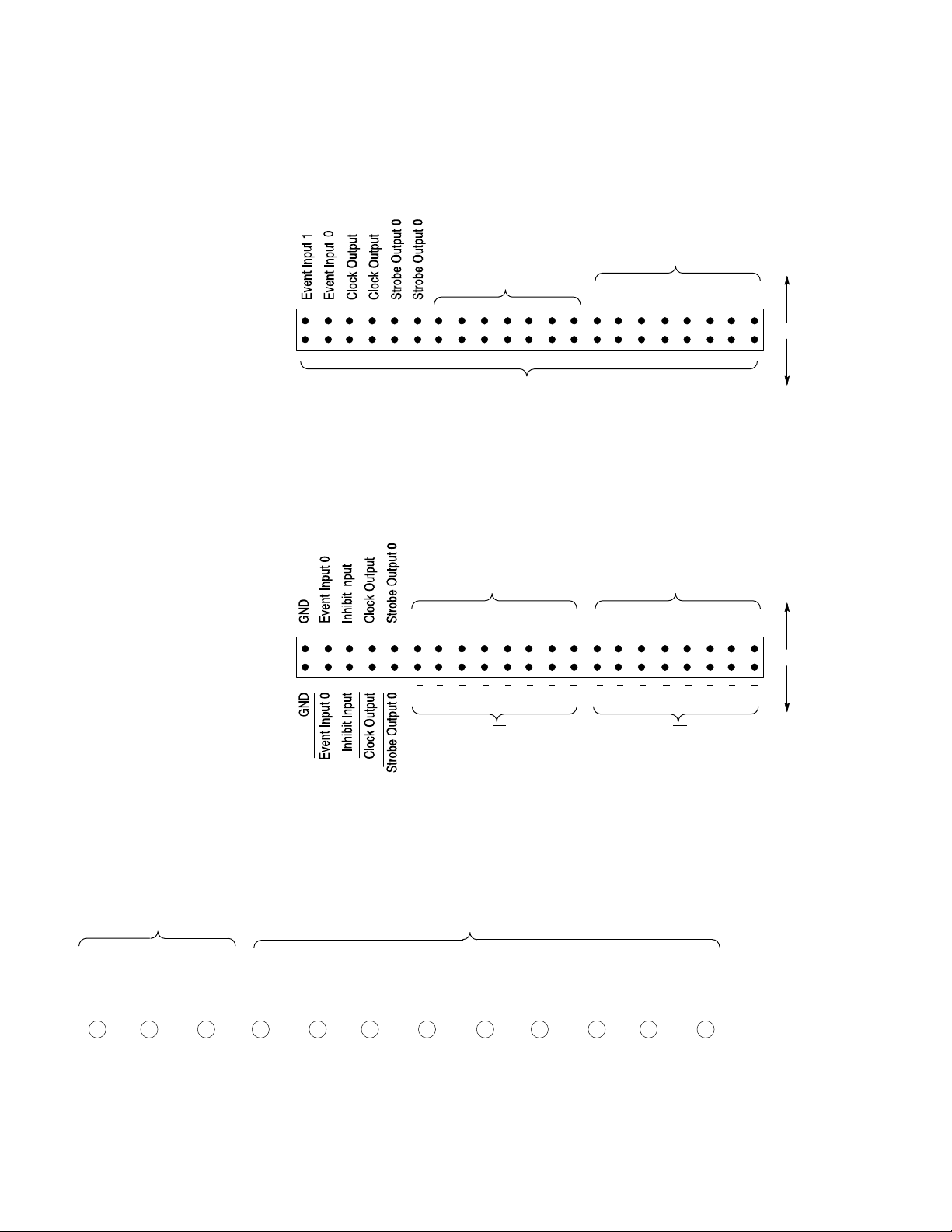

Figure 3 shows the P6470 TTL/CMOS and P6474 LVCMOS pin assignments on

the front panel.

A1 A0

765 43210 765 43210

GND

Top

Bottom

Figure 3: P6470 and P6474 output connector pin assignments

Figure 4 shows the P6471 ECL pin assignments on the front panel.

A1 A0

765 43210 765 43210

Top

Figure 4: P6471 output connector pin assignments

TLA7PG2 Pattern Generator Probes Instruction Manual

GND

Bottom

7

Page 22

Reference

P6472 Pin Assignments

P6473 Pin Assignments

Figure 5 shows the P6472 PECL/LVPECL pin assignments on the front panel.

A0

(not used)

765 43210

GND

Top

Bottom

Figure 5: P6472 output connector pin assignments

Figure 6 shows the P6473 LVDS pin assignments on the front panel.

A1 A0

765 43210 765 43210

Top

7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0

A1 A0

Figure 6: P6473 output connector pin assignments

P6475 Pin Assignments

Input

Inhibit Event 0 Event 1 CH 0 CH 1 CH 2 CH 3 CH 4 CH 5 CH 7

Figure 7 shows the P6475 variable pin assignments on the front panel.

Output

Delay

Figure 7: P6475 output connector pin assignments

Bottom

ClockCH 6

Delay

8

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 23

Probe Overview

Table 1 shows the signal names when used with different probes. These signal

names appear on the probe labels.

You can have up to four probes connected to each PG module. The leftmost

probe will be the master, and the probes to the right of the master are the slaves.

The probes are named Probe A, Probe B, Probe C, and Probe D, respectively.

Refer to Table 1 for input and output names for each probe.

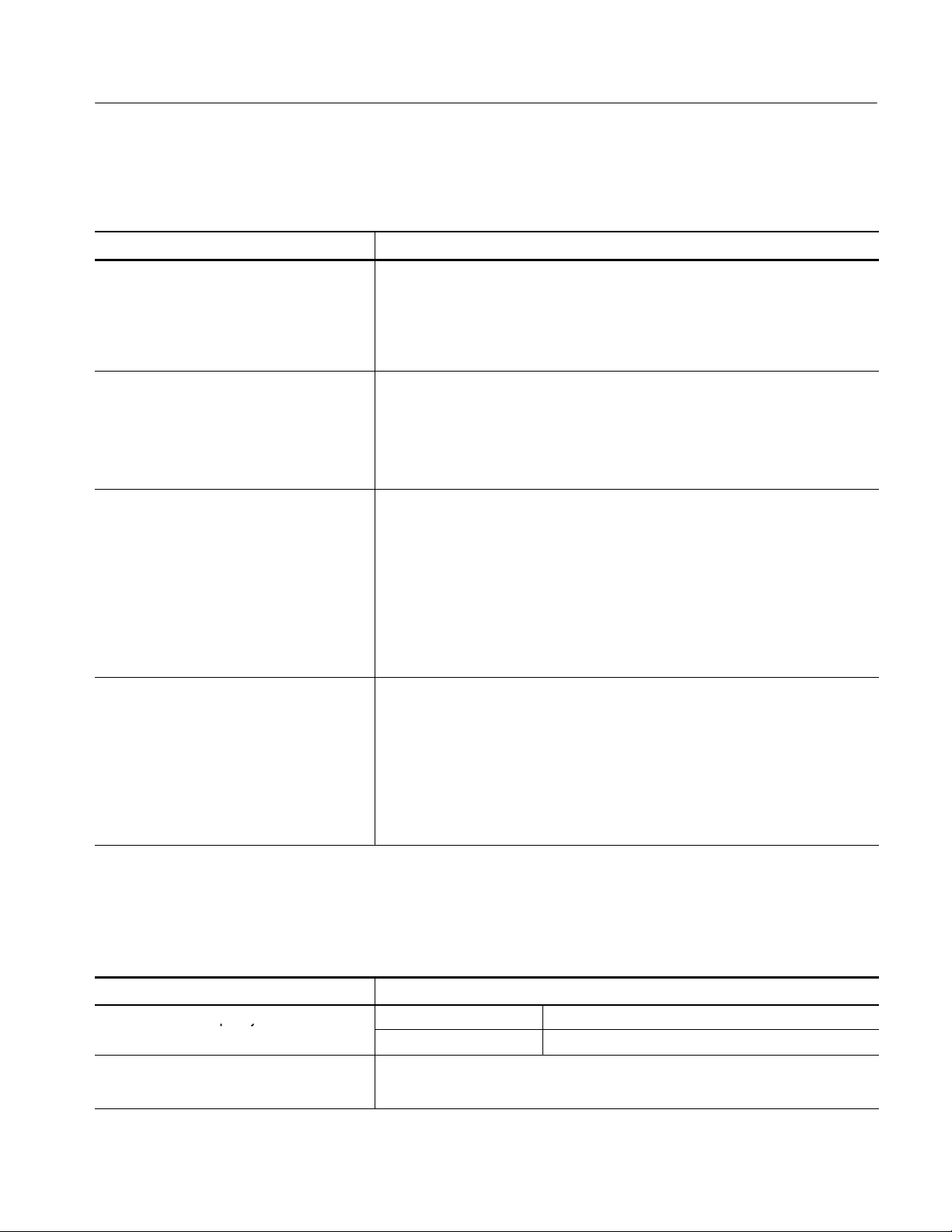

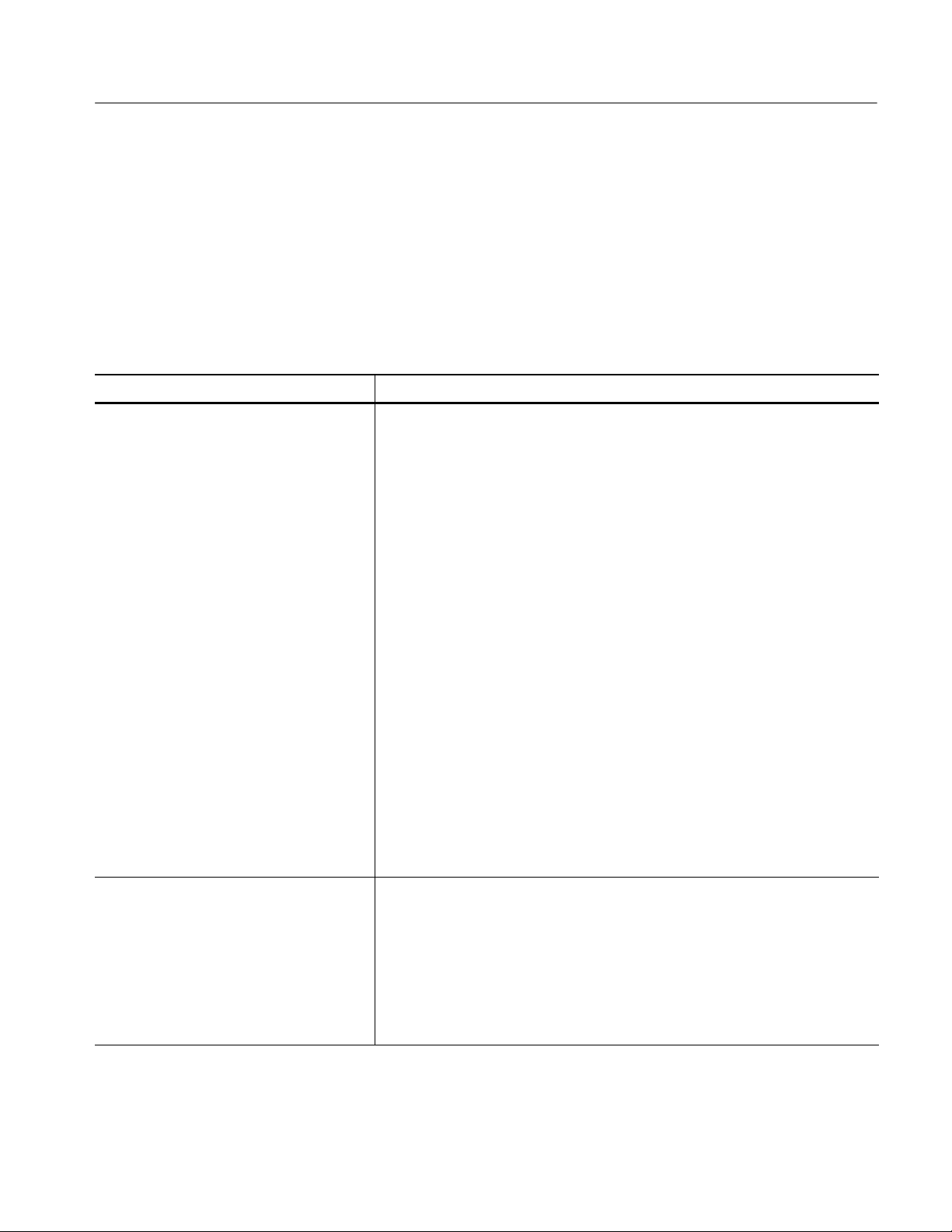

Table 1: Inputs and outputs of pattern generator probes

Reference

P6470 TTL/

Characteristic

Data Output

(Full/Half)

Probe A A0 (0 through 7)

Probe B B0 (0 through 7)

Probe C C0 (0 through 7)

Probe D D0 (0 through 7)

CMOS

16/8 channels 16/8 channels 8/8 channels 16/8 channels 16/8 channels 8/8 channels

A1 (0 through 7)

B1 (0 through 7)

C1 (0 through 7)

P6471 ECL

A0 (0 through 7)

A1 (0 through 7)

B0 (0 through 7)

B1 (0 through 7)

C0 (0 through 7)

C1 (0 through 7)

D0 (0 through 7)

P6472 PECL/

LVPECL

A0 (0 through 7) A0 (0 through 7)

B0 (0 through 7) B0 (0 through 7)

C0 (0 through 7) C0 (0 through 7)

D0 (0 through 7) D0 (0 through 7)

P6473 LVDS P6474 LVCMOS P6475 Variable

A0 (0 through 7)

A1 (0 through 7)

A1 (0 through 7)

B0 (0 through 7)

B1 (0 through 7)

B1 (0 through 7)

C0 (0 through 7)

C1 (0 through 7)

C1 (0 through 7)

A0 (0 through 7)

A1 (0 through 7)

B0 (0 through 7)

B1 (0 through 7)

C0 (0 through 7)

C1 (0 through 7)

D0 (0 through 7)

A0 (0 through 7)

B0 (0 through 7)

C0 (0 through 7)

D0 (0 through 7)

D1 (0 through 7)

Clock Output 1

Probe A CLK CLK CLK, CLK CLK/CLK CLK CLK

Probe B CLK CLK CLK, CLK CLK/CLK CLK CLK

Probe C CLK CLK CLK, CLK CLK/CLK CLK CLK

Probe D CLK CLK CLK, CLK CLK/CLK CLK CLK

1

D1 (0 through 7)

1

1

D0 (0 through 7)

D1 (0 through 7)

D1 (0 through 7)

1

1

1

1

D1 (0 through 7)

1

1

TLA7PG2 Pattern Generator Probes Instruction Manual

1

9

Page 24

Reference

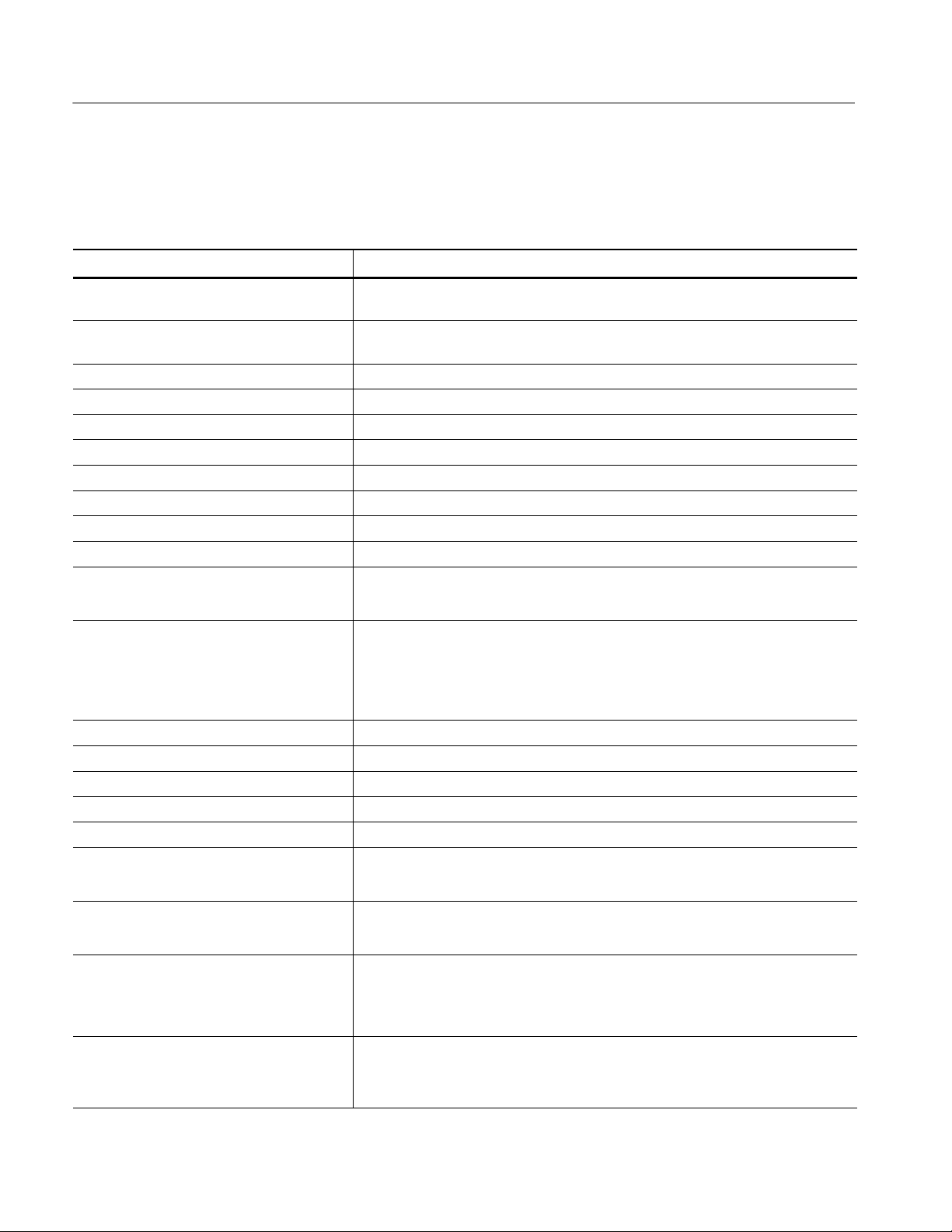

Table 1: Inputs and outputs of pattern generator probes (Cont.)

P6470 TTL/

Characteristic P6475 VariableP6474 LVCMOSP6473 LVDS

Strobe Output 1 1 1 1 1 0

Probe A STRB0 STRB0 STRB0, STRB0 STRB0/STRB0 STRB0

Probe B STRB1 STRB1 STRB1, STRB1 STRB2/STRB2 STRB1

Probe C STRB2 STRB2 STRB2, STRB2 STRB4/STRB4 STRB2

Probe D STRB3 STRB3 STRB3, STRB3 STRB6/STRB6 STRB3

Inhibit Input 1 0 0 1 1 1

Probe A INHB INHB/INHB INHB INHB

Probe B INHB INHB/INHB INHB INHB

Probe C INHB INHB/INHB INHB INHB

Probe D INHB INHB/INHB INHB INHB

Event Input

Probe A EVNT0, EVNT1 EVNT0, EVNT1 EVNT0, EVNT1 EVNT0/EVNT0 EVNT0, EVNT1 EVNT0, EVNT1

Probe B EVNT2, EVNT3 EVNT2, EVNT3 EVNT2, EVNT3 EVNT2/EVNT2 EVNT2, EVNT3 EVNT2, EVNT3

Probe C EVNT4, EVNT5 EVNT4, EVNT5 EVNT4, EVNT5 EVNT4/EVNT4 EVNT4, EVNT5 EVNT4, EVNT5

Probe D EVNT6, EVNT7 EVNT6, EVNT7 EVNT6, EVNT7 EVNT6/EVNT6 EVNT6, EVNT7 EVNT6, EVNT7

1

2

3

3

The Clock Output is disabled when Strobe Output is enabled.

CH6 and CH7 can be used as Strobe Outputs by setting the data format to RZ/R1.

The External Event Input is used to suspend/resume the sequencer (Advance function) or to jump to a

specified line in the sequence or inhibit the output.

CMOS

2 2 2 1 2 2

P6471 ECL

P6472 PECL/

LVPECL

2

10

Descriptions of the probe input and output control signals follow. For more

information on using the probe signals, refer to the online help for the pattern

generator.

Clock Output. Each probe has one clock output signal. The logic level of the

clock output is the same as the data output.

The clock output is disabled when the strobe output is enabled.

Strobe Output. Each probe has a strobe output signal except for the P6475

variable probe. CH 6and CH7 can be used as a strobe signal by setting the data

format to RZ/R1.

The logic level of the strobe output is the same as the data output.

The output format of the strobe is RZ (return to zero). The pulse width is the

same as the first or the second half of the clock cycle. The pulse can be

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 25

Reference

positioned at either first half (Strobe delay: Zero) or second half (Strobe delay:

Trailing Edge) of the clock cycle.

Figure 8 shows the pulse pattern of the strobe output.

01

Strobe Data

Clock

RZ (firstĆhalf)

RZ (secondĆhalf)

Figure 8: Strobe output pulse pattern

P6475 Variable probe Output Format. Figure 9 shows the P6475 output pulse

patterns for various signals. NRZ is the output format for CH0 through CH5.

You can select NRZ, RZ, and R1 from CH6 and CH7. The delay pulse width

using RZ or R1 is equal to half of the clock cycle when using the internal clock

mode. The clock output polarity is selectable from Normal or Invert. Refer to the

TLA7PG2 for more information.

You can delay the CH6 and CH7 output up to 50 ns. Figure 9 shows the P6475

output pulse pattern.

0101

Data

Clock (normal)

Clock (invert)

NRZ

RZ

R1

Figure 9: P6475 Variable probe output pulse pattern

By using the CH6 Output Mode control, it is possible to output a wider or

narrower pulse from the CH6 output connector. Figure 11 shows the CH6 and

CH7 output pulse patterns when using the CH6 Output Mode control.

TLA7PG2 Pattern Generator Probes Instruction Manual

11

Page 26

Reference

For example, if the P6475 is setup as follows:

Clock Frequency: 100 MHz (10 ns period)

CH6: RZ, delay 3 ns

CH7: RZ, delay 5 ns

CH6 Output Mode: CH6 and CH7

The CH6 output will be as shown in Figure 10.

You will see an RZ pulse of 5 ns delay and a 3 ns width at the CH6 output

connector

CH0Ć6

CLK

CH6

CH7

CH6

Output

3 ns 5 ns

5 ns 5 ns

3 ns

Figure 10: P6475 CH6 output example

Figure 11 shows the various CH6 pulse patterns depending on which mode is

setup from the CH6 Output Mode Setup menu. See the TLA7PG2 Online Help

system for more information.

12

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 27

Reference

Normal

CH6 or CH7

CH6 and CH7

CH6

CH7

CH6 Output

CH6

CH7

CH6 Output

CH6

CH7

CH6 Output

CH6 and (NOT CH7)

CH6

CH7

CH6 Output

Figure 11: P6475 CH6 output mode pulse patterns

Inhibit Input. The P6470, P6473, P6474 and P6475 have an inhibit input to set the

output to high impedance. The input polarity is positive true and a High input

will disable the output. Low input or no connection enables the output. The

P6475 input state (High or Low) with no connection will vary according to the

input threshold setting.

External Event Input. All of the probes have one or two event inputs. The pattern

generator detects an event when the external event input is High (True). The

external event input is Low (False) when no signal is detected or when the probe

TLA7PG2 Pattern Generator Probes Instruction Manual

13

Page 28

Reference

is not connected to the pattern generator. The P6475 input state (High or Low)

with no connection will vary according to the input threshold setting.

The external event can be used to Jump or Advance the sequencer or disable the

output. The input polarity is positive true.

Input Logic Level. All inputs are the same logic level as the output except for the

P6475 Variable probe. The V

of the input circuit is the same as the Vcc of the

cc

output driver for the P6470 TTL/CMOS probe and the P6474 LVCMOS probe.

The P6475 Variable probe input threshold level is adjustable within the range of

–2.5 V to +2.5 V.

14

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 29

Probe Dimensions

Reference

Figure 12 shows the dimensions of the standard pattern generator probes. The

physical dimensions are the same for the P6470, P6471, P6472, P6473, and

P6474 probes.

NOTE. There are no ventilation requirements for the standard probes.

137.2 mm

(5.402 in)

114.0 mm

(4.488 in)

130.0 mm

(5.118 in)

33.0 mm

(1.299 in)

Probe weight : 250 g (8.8 oz)

Figure 12: P6470, P6471, P6472, P6473 and P6474 probe dimensions

TLA7PG2 Pattern Generator Probes Instruction Manual

15

Page 30

Reference

Figure 13 shows the dimensions of the P6475 probe.

250.0 mm

(9.843 in)

250.0 mm

(9.843 in)

55.55 mm

(2.185 in)

Figure 13: P6475 Variable probe dimensions

16

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 31

P6475 Installation Requirements

Table 2 provides information for the P6475 Variable probe installation:

Table 2: P6475 Variable probe installation requirements

Characteristics Description

Maximum power dissipation

(fully loaded)

Surge Current Max 57 A peak (25° C) ≤ 5 line cycles after product has been

Clearance for ventilation

Side 10 cm (3.9 in)

35 W max. Maximum line current is 0.6 A

90 V line, with 5 % clipping

turned off for at least 30 s

at 50 Hz,

rms

Reference

TLA7PG2 Pattern Generator Probes Instruction Manual

17

Page 32

Reference

Input/Output Circuits

This subsection shows the input/output circuits for the P6470, P6471, P6472,

P6473. and P6474 probes.

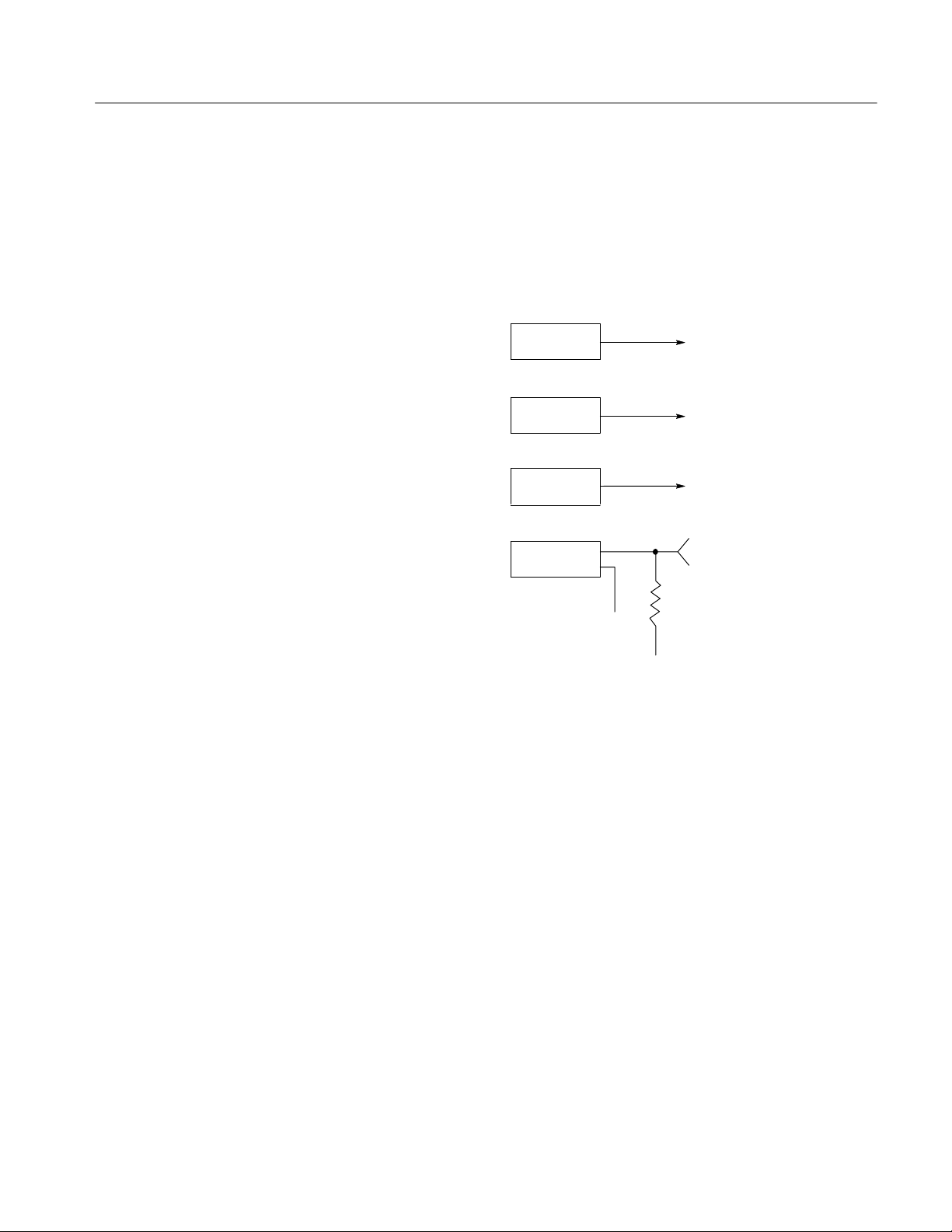

P6470

Figure 14 shows the probe input/output circuit for the P6470 TTL/CMOS pattern

generator probe. The P6470 comes standard with 75

resistor packs. You can

change the resistor packs to provide impedance matching for the target system.

The P6470 provides 16 data outputs, 1 clock output, and 1 strobe output.

75

Data Output

Clock/Strobe Output

Event/Inhibit Input

74LVC541A

75

74LVC244A

74LVC14A

1 k

18

GND

Figure 14: P6470 input/output circuit

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 33

Reference

P6471

Figure 15 shows the probe input/output circuit for the P6471 ECL pattern

generator probe.

The P6471 provides 16 data outputs, 1 clock output, and 1 strobe output.

Data Output

Strobe Output

Clock Output

Event Input

100E151

100EL16

100EL04

10H116

75 k

V

BB

Figure 15: P6471 input/output circuit

-2 V

TLA7PG2 Pattern Generator Probes Instruction Manual

19

Page 34

Reference

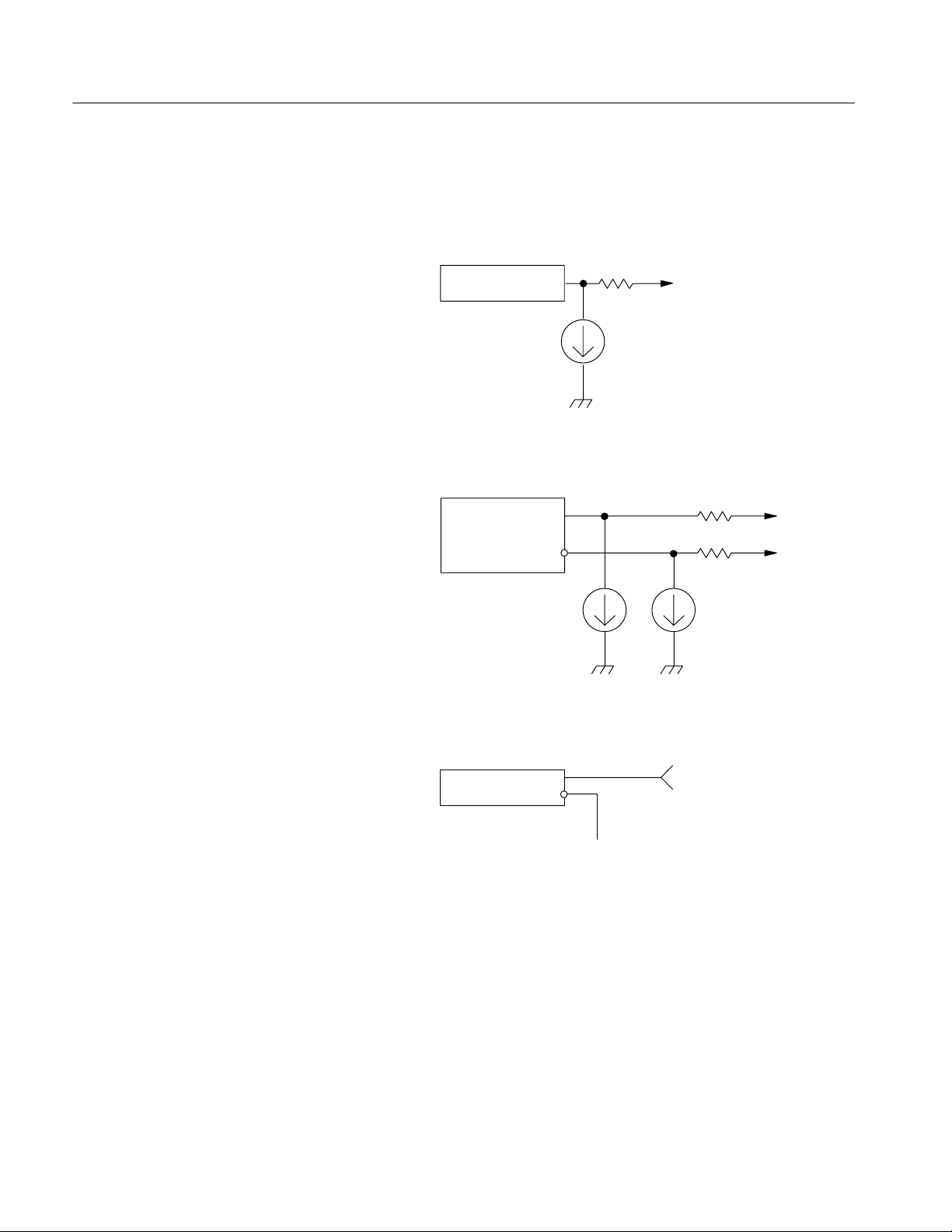

P6472

Figure 16 shows the input/output circuit for the P6472 PECL/LVPECL pattern

generator probe. The P6472 provides PECL/LVPECL signals to the target

system and contains 8 data outputs, 1 clock output, and 1 strobe output.

43

Data Output

100EP90

100EP90Clock/Strobe Output

10 mA

10 mA

43

43

10 mA

20

Event Input

100EL91

Figure 16: P6472 input/output circuit

TLA7PG2 Pattern Generator Probes Instruction Manual

VBB

Page 35

Reference

P6473

The P6473 LVDS is compatible with the TIA/EIA-644 standard.

A generator circuit in the probe produces a balanced source that results in a

differential voltage across a test termination load of 100

in the range of

250 mV to 450 mV.

Figure 17 illustrates the signaling sense of the voltages appearing across the

termination resistor.

H The A terminal of the generator is negative with respect to the B terminal for

a binary 1 or OFF state.

H The A terminal of the generator is positive with respect to the B terminal for

a binary 0 or ON state.

1

OFF

VB

A

B

Z =100

t

G

C

VA

VA ĆVB

ON

0

1

OFF

+1.2 V typical

+250 mV to +400 mV

0 V (Diff)

-250 mV to -400 mV

Figure 17: Signaling sense

TLA7PG2 Pattern Generator Probes Instruction Manual

21

Page 36

Reference

P6474

Figure 18 shows the input/output circuit for the P6474 LVCMOS pattern

generator probe. The P6474 provides LVCMOS signals to the target system and

contains 16 data outputs, one clock output and one strobe output. You can adjust

the V

P6474 comes standard with 75

of the output driver and the input receiver from 1.2 V to 3.3 V. The

cc

resistor packs. You can change the resistor

packs to provide impedance matching for the target system.

The P6474 provides 16 data outputs, 1 clock output and 1 strobe output.

Data/Clock/Strobe Output

Event/Inhibit Input

74AVC16244

74AVC16244

75

1k

Figure 18: P6474 input/output circuit

Timing Diagrams

Figures 19 through 24 show the pattern generator timing diagrams. The diagrams

apply to all probes unless otherwise stated.

External clock Input

Td1

Clock Output

Td2

Data Output

Td3

Strobe Output

(strobe delay = zero)

Figure 19: Clock and strobe timing diagram

22

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 37

Inhibit Input or

Probe D data Output

Td4

Data Output

Figure 20: P6470, P6472, P6473, and P6474 inhibit timing diagram

Reference

Td5

10%

90%

Event

Input

Td6

Clock

Output

Data

Output

Td6

Figure 21: P6470, P6472, P6473, and P6474 external event for inhibit timing diagram

Event Input

Td9

Data Output Current Block Jump Target Block

Figure 22: External event for jump timing diagram

TLA7PG2 Pattern Generator Probes Instruction Manual

23

Page 38

Reference

Event

Input

Td10

Clock

Output

End of previous block

Figure 23: External event for half channel advance timing diagram

Event

Input

Td11

Clock

Output

End of previous block Block Output

Figure 24: External event for full channel advance timing diagram

Block Output

after the event

after the event

24

Event

Input

Td12

Clock

Output

Block Output

after the event

Figure 25: External event for delay to data output for advance diagram

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 39

Specifications

load: 10 k

8

The specifications apply to all versions of the pattern generator unless otherwise

noted.

Table 3: P6470 TTL/CMOS probe

All timing values are specified at the probe connector under the conditions listed below, unless otherwise noted:

Output Voltage setting: +5 V

Series Termination Resistor: 75

Load: 510 + 50 pF

Characteristic Description

Maximum Clock Frequency

(with series termination resistor: 75 )

Output Level (Vcc) Full Channel mode Half Channel mode

Vcc v 3.3 V 134 MHz 268 MHz

3.3 V < Vcc v5 V 62.5 MHz 125 MHz

Vcc > 5 V 52.5 MHz 105 MHz

Reference

Maximum Clock Frequency

(with series termination resistor: 75 ,

+ 15 pf, sample output pattern:

bit counter)

Typical

Output Level (VCC) 2.0 V to 5.5 V, 25 mV step, into 1 M

Maximum Resistive Load 220

Maximum Capacitive Load 50 pF

Output Type 74LVC541A for Data Output

Series Termination Resistor 75 standard. 43, 100 and 150 as optional accessories

Supported Channel Mode Half and Full

Number of External Inhibit Inputs 1

Rise/Fall Time

(20% to 80%

load: 1 M +< 1 pF)

Typical

Rise/Fall Time

(20% to 80%

load: 510 + 51 pF)

Typical

Output Level (Vcc) Full Channel mode Half Channel mode

Vcc v5.5 V 134 MHz 268 MHz

74LVC244A for Clock/Strobe Output

(18 pin DIP socket)

Clock/Strobe Output

Rise 640 ps

Fall 1.1 ns

Data Output

Rise 680 ps

Fall 2.9 ns

Clock/Strobe Output

Rise 6.5 ns

Fall 6.3 ns

Data Output

Rise 5.2 ns

Fall 4.5 ns

TLA7PG2 Pattern Generator Probes Instruction Manual

25

Page 40

Reference

Table 3: P6470 TTL/CMOS probe (Cont.)

All timing values are specified at the probe connector under the conditions listed below, unless otherwise noted:

Output Voltage setting: +5 V

Series Termination Resistor: 75

Load: 510 + 50 pF

Characteristic Description

Data Output Skew

Typical

< 570 ps between all data output pins of all modules in the mainframe after

intermodule skew is adjusted manually

< 480 ps between all data output pins of all probes of single module

< 440 ps between all data output pins of single probe

Data Output to Strobe Output Delay

Typical

Data Output to Clock Output Delay

Typical

External Clock Input to Clock Output Delay

Typical

External Inhibit Input to Output Enable Delay

Typical

External Inhibit Input to Output Disable Delay

Typical

Probe D Data Output to Output Enable Delay

(for Internal Inhibit) Typical

Probe D Data Output to Output Disable Delay

(for Internal Inhibit) Typical

External Event Input to Clock Output Setup

(for inhibit)

(eventĆfilter: off) Typical

External Event Input and Inhibit Input

Input Type

Minimum Pulse Width

External Event Input Delay to Data Output for

Advance

+ 1.7 ns when strobe delay set to zero. (Td3 in Figure 19 on page 22)

+2.4 ns (Td2 in Figure 19 on page 22)

61 ns (Td1 in Figure 19 on page 22)

34 ns for Data Output (Td4 in Figure 20 on page 23)

86 ns for Data Output (Td5 in Figure 20 on page 23)

7 ns for Data Output (Td4 in Figure 20 on page 23)

8 ns for Data Output (Td5 in Figure 20 on page 23)

Full channel mode: 1.5 clocks + 240 ns (Td6 in Figure 21 on page 23)

Half channel mode: 2 clocks + 240 ns

74LVC14A, Positive True, 1 k to GND

200 ns (event filter: off)

230 ns to 330 ns + 1.5 to 2.5 CLK2 (Td12 in Figure 25 on page 24)

(CLK2 is from 2.5 ns to 5 ns when Internal Clock is used. It is the same as one clock

period when the External Clock is used.)

External Event Input

Number of Inputs

Setup Time of Event Typical

Input for Event Jump

26

2

Half Channel Mode

54 to 61 clocks + 240 ns before the next block

Full Channel Mode

27.5 to 31 clocks + 240 ns before the next block

(Td9 in Figure 22 on page 23)

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 41

Table 3: P6470 TTL/CMOS probe (Cont.)

All timing values are specified at the probe connector under the conditions listed below, unless otherwise noted:

Output Voltage setting: +5 V

Series Termination Resistor: 75

Load: 510 + 50 pF

Characteristic Description

Setup Time of Event Input for Event Advance

Typical

Mainframe External Signal Input to PG Probe

data output

for Advance

via Signal 1, 2 Typical

via Signal 3, 4 Typical

for Inhibit

via Signal 1, 2 Typical

In Half Channel Mode, 240 ns before the rising edge of 5th clock output pulse from

the last of the previous block (Td10 in Figure 23 on page 24)

In Full Channel Mode, 240 ns before the rising edge of 3rd clock output pulse from the

last of the previous block (Td11 in Figure 24 on page 24)

200 ns to 300 ns + 1.5 to 2.5 CLK2

230 ns to 330 ns + 1.5 to 2.5 CLK2

(CLK2 is from 2.5 ns to 5 ns when the Internal Clock is used. It is the same as one

clock period when the External Clock is used)

100 ns to 200 ns + 2 to 3 CLK (Half Channel Mode)

100 ns to 200 ns + 1.5 to 2.5 CLK (Full Channel Mode)

Reference

via Signal 3, 4 Typical

PG Probe Clock Output to Mainframe External

Signal Output

via Signal 1, 2 Typical

via Signal 3, 4 Typical

Number of Data Outputs 16 in Full Channel Mode

Number of Clock Outputs 1

Number of Strobe Outputs 1

Number of External Event Inputs 2

Clock Output Polarity Positive

Strobe Type RZ only

130 ns to 230 ns+ 2 to 3 CLK (Half Channel Mode)

130 ns to 230 ns + 1.5 to 2.5 CLK (Full Channel Mode)

18 ns - 5 CLK (Half Channel Mode)

18 ns - 3 CLK (Full Channel Mode)

29 ns - 5 CLK (Half Channel Mode)

29 ns - 3 CLK (Full Channel Mode)

8 in Half Channel Mode

(Only one Clock Output or Strobe Output can be enabled at one time per probe)

TLA7PG2 Pattern Generator Probes Instruction Manual

27

Page 42

Reference

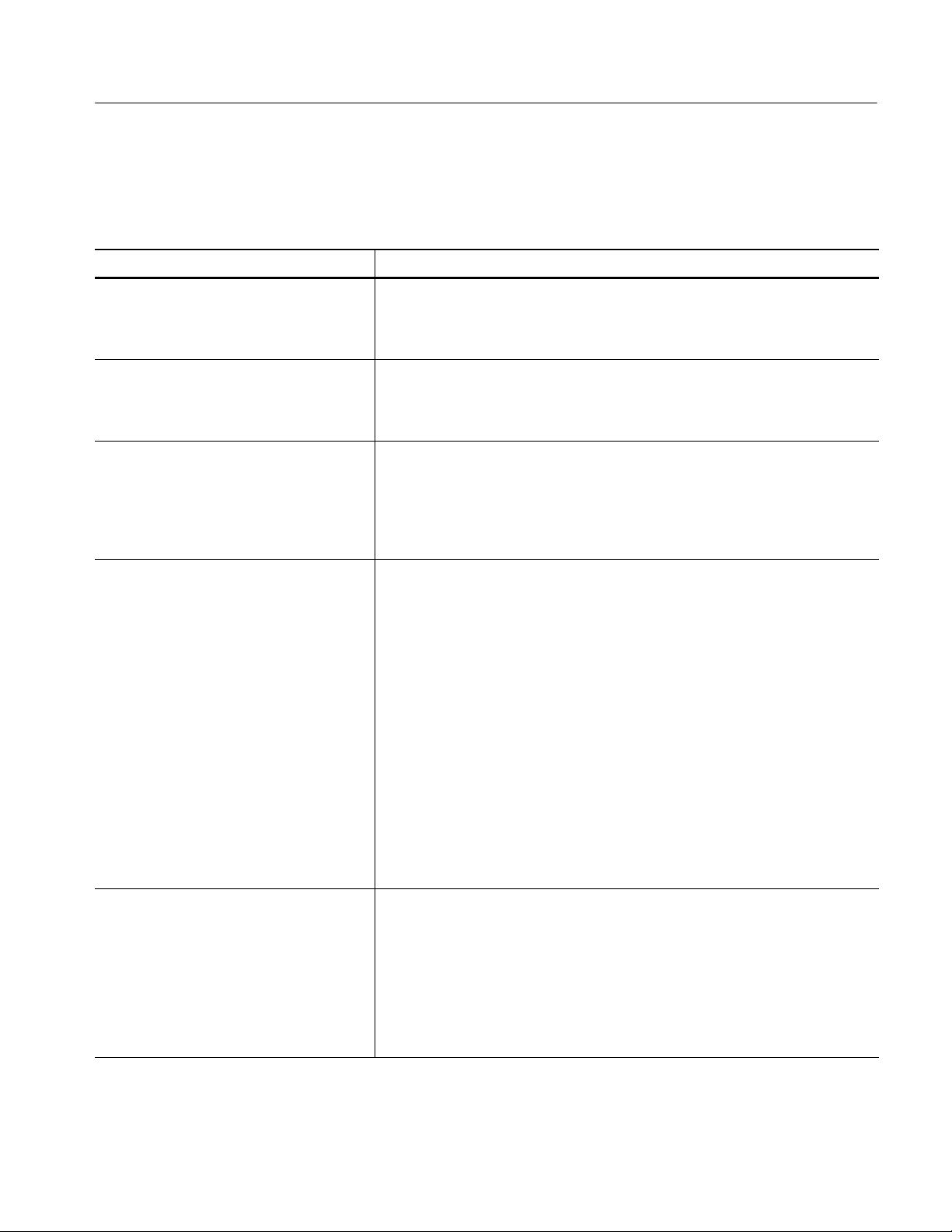

Table 4: P6471 ECL probe

All timing values are specified at the probe connector under the condition listed below, unless otherwise noted:

Load: 51 terminated to -2 V

Characteristic Description

Maximum Clock Frequency 134 MHz in Full Channel mode

268 MHz in Half Channel mode

Output Level ECL

Output Type 100E151 for data output

100EL16 for strobe output

100EL04 for clock output

outputs are unterminated

Supported Channel Mode Half and Full

Rise/Fall Time

(20% to 80%) Typical

Data Output Skew Typical < 255 ps between all data output pins of all modules in the mainframe after

Data Output to Strobe Output Delay

Typical

Data Output to Clock Output Delay

Typical

External Clock Input to Clock Output Delay

Typical

External Event Input Delay to Data Output for

Advance

Clock Output

Rise 320 ps

Fall 330 ps

Data Output

Rise 1,200 ps

Fall 710 ps

Strobe Output

Rise 290 ps

Fall 270 ps

intermodule skew is adjusted manually

< 240 ps between all data output pins of all probes of single module

< 210 ps between all data output pins of a single probe

+2.94 ns when strobe delay set to zero (Td3 in Figure 19 on page 22)

+780 ps (Td2 in Figure 19 on page 22)

50 ns (Td1 in Figure 19 on page 22)

170 ns to 270 ns + 1.5 to 2.5 CLK2 (Td12 in Figure 25 on page 24)

(CLK2 is from 2.5 ns to 5 ns when Internal Clock is used. It is the same as one clock

period when the External Clock is used.)

External Event Input

Input Level

Input Type

Minimum Pulse Width

External Event Input

Number of Inputs

Setup Time of Event

Input for Event Jump

Typical

28

ECL

10H116 with 75 k to -2 V

150 ns (Event filter: off)

2

Half Channel Mode, 54 to 61 clocks + 180 ns before the next block

Full Channel Mode, 27.5 to 31 clocks + 180 ns before the next block (Td9 in Figure 22

on page 23)

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 43

Table 4: P6471 ECL probe (Cont.)

All timing values are specified at the probe connector under the condition listed below, unless otherwise noted:

Load: 51 terminated to -2 V

Characteristic Description

Setup Time of Event

Input for Event Advance

Typical

Mainframe External Signal Input to PG Probe

data output

for Advance

via Signal 1, 2 Typical

via Signal 3, 4 Typical

Half Channel Mode:

80 ns before the rising edge of 5th clock output pulse from the last of the

previous block (Td10 in Figure 23 on page 24)

Full Channel Mode

80 ns before the rising edge of 3rd clock output pulse from the last of the

previous block (Td11 in Figure 24 on page 24)

200 ns to 300 ns + 1.5 to 2.5 CLK2

230 ns to 330 ns + 1.5 to 2.5 CLK2

(CLK2 from 2.5 ns to 5 ns when Internal Clock is used. It is same as one clock period

when External Clock is used.)

Reference

PG Probe Clock Output to Mainframe External

Signal Output

via Signal 1, 2 Typical

via Signal 3, 4 Typical

Number of Data Outputs 16 in Full Channel Mode

Number of Clock Outputs 1

Number of Strobe Outputs 1

Number of External Event Inputs 2

Clock Output Polarity Positive

Strobe Type RZ only

28 ns - 5 CLK (Half Channel Mode)

28 ns - 3 CLK (Full Channel Mode)

38 ns - 5 CLK (Half Channel Mode)

38 ns - 3 CLK (Full Channel Mode)

8 in Half Channel Mode

(Only one Clock Output or one Strobe Output can be enabled at one time per probe)

TLA7PG2 Pattern Generator Probes Instruction Manual

29

Page 44

Reference

qy

Table 5: P6472 PECL/LVPECL probe

All timing values are specified with a load condition of 1 M + ≤ 1 pF with PECL mode.

Characteristic Description

Maximum Clock Frequency Full Channel Mode Half Channel Mode

134 MHz 268 MHz

Number of Data Outputs 8 Full Channel

8 Half Channel

Number of Clock Outputs 1 differential

Number of Strobe Outputs 1 differential

(Only one Clock Output or one Strobe Output can be enabled at one time per probe)

Number of External Event Inputs 2

Clock Output Polarity Positive

Strobe Type RZ (return to zero) only

Strobe Delay Zero or Trailing Edge

Output Level PECL, LVPECL (selectable by moving a jumper in the probe)

Output Type 100EL90 (all outputs are terminated)

Supported Channel Mode Half and Full

Rise/Fall Time (20% to 80%) Rise 430 ps

Fall 970 ps

Data Output Skew < 385 ps between all data output pins of all modules in the mainframe after

intermodule skew is adjusted manually

< 370 ps between all data output pins of all probes of single module

< 340 ps between all data output pins of a single probe

Data Output to Strobe Output Delay + 2.93 ns when strobe delay is set to zero (See Td3 in Figure 19 on page 22)

Data Output to Clock Output Delay + 1.12 ns (Td2 in Figure 19 on page 22)

External Clock Input to Clock Output Delay 50 ns (See Td1 in Figure 19 on page 22)

External Event Input Delay to Data Output for

Advance

External Event Input

Input Level

Input Type

Minimum Pulse Width (event filter: off)

170 ns to 270 ns + 1.5 to 2.5 CLK2 (Td12 in Figure 25 on page 24)

(CLK2 is from 2.5 ns to 5 ns when Internal Clock is used. It is the same as one clock

period when the External Clock is used.)

PECL, LVPECL (selectable by moving a jumper in the probe)

100EL91, unterminated

150 ns

30

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 45

Table 5: P6472 PECL/LVPECL probe (Cont.)

Using signa

Using signal 1 or 2

qy

All timing values are specified with a load condition of 1 M + ≤ 1 pF with PECL mode.

Characteristic Description

External Event Input

Reference

Setup Time of Event Input for Event

Jump

Setup Time of Event Input for Event Advance Half Channel Mode: 180 ns before the rising edge of the 5th clock output pulse from

Mainframe External Signal Input to PG Probe

Data Output

For Advance:

l 1 or 2

Using signal 3 or 4

PG Probe Clock Output to Mainframe External

Signal Output

Using signal 1 or 2

Half Channel Mode: 54 to 61 Clocks + 180 ns before the next block

Full Channel Mode: 27.5 to 31 Clocks + 180 ns before the next block

(see Td9 in Figure 22 on page 23)

the last of the previous block (See Td10 in Figure 23 on page 24)

Full Channel Mode: 180 ns before the rising edge of the 3rd clock output pulse from

the last of the previous block (see Td11 in Figure 24 on page 24)

200 ns to 300 ns + 1.5 to 2.5 CLK2

230 ns to 330 ns + 1.5 to 2.5 CLK2

(CLK2 is from 2.5 ns to 5 ns when Internal Clock is used. It is the same as one clock

period when the External Clock is used.)

31 ns -5 CLK (Half Channel Mode)

31 ns -3 CLK (Full Channel Mode)

Using signal 3 or 4

40 ns -5 CLK (Half Channel Mode)

40 ns -3 CLK (Full Channel Mode)

Table 6: P6473 LVDS probe

All timing values are specified at the probe connector under the condition listed below, unless otherwise noted:

Load: 100 + < 1 pF

Characteristic Description

Maximum Clock Frequency Full Channel Mode Half Channel Mode

134 MHz 268 MHz

Number of Data Outputs 16 Full Channel

8 Half Channel

TLA7PG2 Pattern Generator Probes Instruction Manual

31

Page 46

Reference

Table 6: P6473 LVDS probe (Cont.)

All timing values are specified at the probe connector under the condition listed below, unless otherwise noted:

Load: 100 + < 1 pF

Characteristic Description

Number of Clock Outputs 1 (Only one Clock Output or One Strobe Output can be enabled at one time per

probe.)

Number of Strobe Outputs 1 (Only one Clock Output or One Strobe Output can be enabled at one time per

probe.)

Number of External Event Inputs 1

Number of External Inhibit Inputs 1

Clock Output Polarity Positive

Strobe Type RZ (return to zero) only

Strobe Delay Zero or Trailing Edge

Maximum Capacitive Load 10 pF

Output Type LVDS (TIA/EIA-644 compatible)

Supported Channel Mode Half and Full

Rise/Fall Time

Rise: 910 ps

(20% to 80%)

Data Output Skew < 365 ps between all data output pins of all modules in the mainframe after

Data Output to Strobe Output Delay -280 ns when strobe delay is set to zero (See Td3 in Figure 19 on page 22)

Data Output to Clock Output Delay 1.2 ns (Td2 in Figure 19 on page 22)

External Clock Input to Clock Output Delay 55 ns (See Td1 in Figure 19 on page 22 )

External Inhibit Input to Output Enable Delay 9 ns for Data Output (See Td4 in Figure 20 on page 23)

External Inhibit Input to Output Disable Delay 12 ns for Data Output (See Td5 in Figure 20 on page 23)

Probe D Data Output to Output Enable Delay

(for Internal Inhibit)

Probe D Data Output to Output Disable Delay

(for Internal Inhibit)

External Event Input to Clock Output Setup

(for inhibit) eventĆfilter: off

External Event Input Delay to Data Output for

Advance

Fall: 750 ps

intermodule skew is adjusted manually

< 350 ps between all data output pins of all probes of single module

< 320 ps between all data output pins of a single probe

2 ns for Data Output (See Td4 in Figure 20 on page 23)

5 ns for Data Output (See Td5 in Figure 20 on page 23)

Full Channel mode: 1.5 Clocks + 180 ns

Half Channel mode: 2 Clocks + 180 ns

(See Td6 in Figure 21 on page 23)

170 ns to 270 ns + 1.5 to 2.5 CLK2 (Td12 in Figure 25 on page 24)

(CLK2 is from 2.5 ns to 5 ns when Internal Clock is used. It is the same as one clock

period when the External Clock is used.)

32

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 47

Table 6: P6473 LVDS probe (Cont.)

All timing values are specified at the probe connector under the condition listed below, unless otherwise noted:

Load: 100 + < 1 pF

Characteristic Description

External Event Input and Inhibit Input

Reference

Input Type

Minimum Pulse Width (event filter: off)

External Event Input Setup Time of Event

Input for Event Jump

External Event Input Setup Time for Event

Advance

Mainframe External Signal Input to PG Probe

Data Output

For Advance:

Using signal 1 or 2

Using signal 3 or 4

For Inhibit:

LVDS (TIA/EIA-644 compatible), positive true

150 ns

Half Channel Mode: 54 to 61 Clocks + 180 ns before the next block

Full Channel Mode: 27.5 to 31 Clocks + 180 ns before the next block

(See Td9 in Figure 22 on page 23)

Half Channel Mode: 180 ns before the rising edge of the 5th clock output pulse from

the last of the previous block (See Td10 in Figure 23 on page 24)

Full Channel Mode: 180 ns before the rising edge of the 3rd clock output pulse from

the last of the previous block (See Td11 in Figure 24 on page 24)

200 ns to 300 ns + 1.5 to 2.5 CLK2

230 ns to 330 ns + 1.5 to 2.5 CLK2

(CLK2 is from 2.5 ns to 5 ns when Internal Clock is used. It is the same as one clock

period when the External Clock is used.)

Using signal 1 or 2

Using signal 3 or 4

PG Probe Clock Output to Mainframe External

Signal Output

Using signal 1 or 2

Using signal 3 or 4

100 ns to 200 ns + 2 to 3 CLK (Half Channel Mode)

100 ns to 200 ns +1.5 to 2.5 CLK (Full Channel Mode)

130 ns 230 ns + 2 to 3 CLK (Half Channel Mode)

130 ns to 230 ns + 1.5 to 2.5 CLK (Full Channel Mode)

26 ns -5 CLK (Half Channel Mode)

26 ns -3 CLK (Full Channel Mode)

35 ns -5 CLK (Half Channel Mode)

35 ns -3 CLK (Full Channel Mode)

TLA7PG2 Pattern Generator Probes Instruction Manual

33

Page 48

Reference

qy

Table 7: P6474 LVCMOS probe

All timing values are specified at the probe connector under the conditions listed below, unless otherwise noted:

Output Voltage setting: +3.3 V

Series Termination Resistor: 75

Load: 510 pF

Characteristic Description

Maximum Clock Frequency Full Channel Mode Half Channel Mode

134 MHz 268 MHz

Number of Data Outputs 16 Full Channel

8 Half Channel

Number of Clock Outputs 1 (Only one Clock Output or One Strobe Output can be enabled at one time per

probe.)

Number of Strobe Outputs 1 (Only one Clock Output or One Strobe Output can be enabled at one time per

probe.)

Number of External Event Inputs 2

Number of External Inhibit Inputs 1

Clock Output Polarity Positive

Strobe Type RZ (return to zero) only

Strobe Delay Zero or Trailing Edge

Output Level (Vcc) 1.2 V to 3.3 V, 25 mV step, into 1 M

Maximum Resistive Load 510

Maximum Capacitive Load 20 pF

Output Type 74AVC16244

Series Termination Resistor 75 standard. 43, 100 and 150 as optional accessories

(18 pin DIP socket)

Supported Channel Mode Half and Full

Rise/Fall Time

Rise 1200 ps

(20 % to 80 %, load: 1M < 1 pF)

Rise/Fall Time

(20 % to 80 %, load: 510 50 pF)

Data Output Skew < 590 ps between all data output pins of all modules in the mainframe after

Data Output to Strobe Output Delay 460 ps when strobe delay is set to zero (See Td3 in Figure 19 on page 22)

Data Output to Clock Output Delay 1.84 ns (Td2 in Figure 19 on page 22)

External Clock Input to Clock Output Delay 55 ns (See Td1 in Figure 19 on page 22)

34

Fall 610 ps

Rise 3.4 ns

Fall 3.2 ns

intermodule skew is adjusted manually

< 500 ps between all data output pins of all probes of single module

< 460 ps between all data output pins of a single probe

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 49

Table 7: P6474 LVCMOS probe (Cont.)

All timing values are specified at the probe connector under the conditions listed below, unless otherwise noted:

Output Voltage setting: +3.3 V

Series Termination Resistor: 75

Load: 510 pF

Characteristic Description

External Inhibit Input to Output Enable Delay 36 ns for Data Output (See Td4 in Figure 20 on page 22)

External Inhibit Input to Output Disable Delay 18 ns for Data Output (See Td5 in Figure 20 on page 22)

Probe D Data Output to Output Enable Delay

(for Internal Inhibit)

Probe D Data Output to Output Disable Delay

(for Internal Inhibit)

External Event Input to Clock Output Setup

(for inhibit) eventĆfilter: off

6 ns for Data Output (See Td4 in Figure 20 on page 22)

7 ns for Data Output (See Td5 in Figure 20 on page 22)

Full Channel mode: 1.5 Clocks + 180 ns

Half Channel mode: 2 Clocks + 180 ns

Reference

External Event Input Delay to Data Output for

Advance

External Event Input and Inhibit Input

Input Type

Minimum Pulse Width

External Event Input

Setup Time of Event

Input for Event Jump

External Event Input Setup Time for Event

Advance

(See Td6 in Figure 21 on page 23)

170 ns to 270 ns + 1.5 to 2.5 CLK2 (Td12 in Figure 25 on page 24)

(CLK2 is from 2.5 ns to 5 ns when Internal Clock is used. It is the same as one clock

period when the External Clock is used.)

74AVC16244, Positive True, 1 k to GND

The Vcc of the input receiver is variable and the same as the Vcc of the output driver.

150 ns (event filter: off)

Half Channel Mode: 54 to 61 Clocks + 180 ns before the next block

Full Channel Mode: 27.5 to 31 Clocks + 180 ns before the next block

(See Td9 in Figure 22 on page 23)

Half Channel Mode: 180 ns before the rising edge of the 5th clock output pulse from

the last of the previous block (See Td10 in Figure 23 o n page 24)

Full Channel Mode: 180 ns before the rising edge of the 3rd clock output pulse from

the last of the previous block (See Td11 in Figure 24 on page 24)

TLA7PG2 Pattern Generator Probes Instruction Manual

35

Page 50

Reference

(

(CLK2 is from 2.5 ns to 5 ns when the Internal Clock is used. It is the same as one

Table 7: P6474 LVCMOS probe (Cont.)

All timing values are specified at the probe connector under the conditions listed below, unless otherwise noted:

Output Voltage setting: +3.3 V

Series Termination Resistor: 75

Load: 510 pF

Characteristic Description

Mainframe External Signal Input to PG Probe

Data Output

For Advance:

Using signal 1 or 2

Using signal 3 or 4

For Inhibit:

Using signal 1 or 2

Using signal 3 or 4

PG Probe Clock Output to Mainframe External

Signal Output

Using signal 1 or 2

Using signal 3 or 4

200 ns to 300 ns + 1 to 2 CLK2

230 ns to 330 ns + 1 to 2 CLK2

CLK2 is from 2.5 ns to 5 ns when the Internal Clock is used. It is the same as one

clock period when the External Clock is used.)

100 ns to 200 ns + 2 to 3 CLK (Half Channel Mode)

100 ns to 200 ns + 1.5 to 2.5 CLK (Full Channel Mode)

130 ns to 230 ns + 2 to 3 CLK (Half Channel Mode)

130 ns to 230 ns + 1.5 to 2.5 CLK (Full Channel Mode)

25 ns -5 CLK (Half Channel Mode)

25 ns -3 CLK (Full Channel Mode)

34 ns -5 CLK (Half Channel Mode)

34 ns -3 CLK (Full Channel Mode)

36

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 51

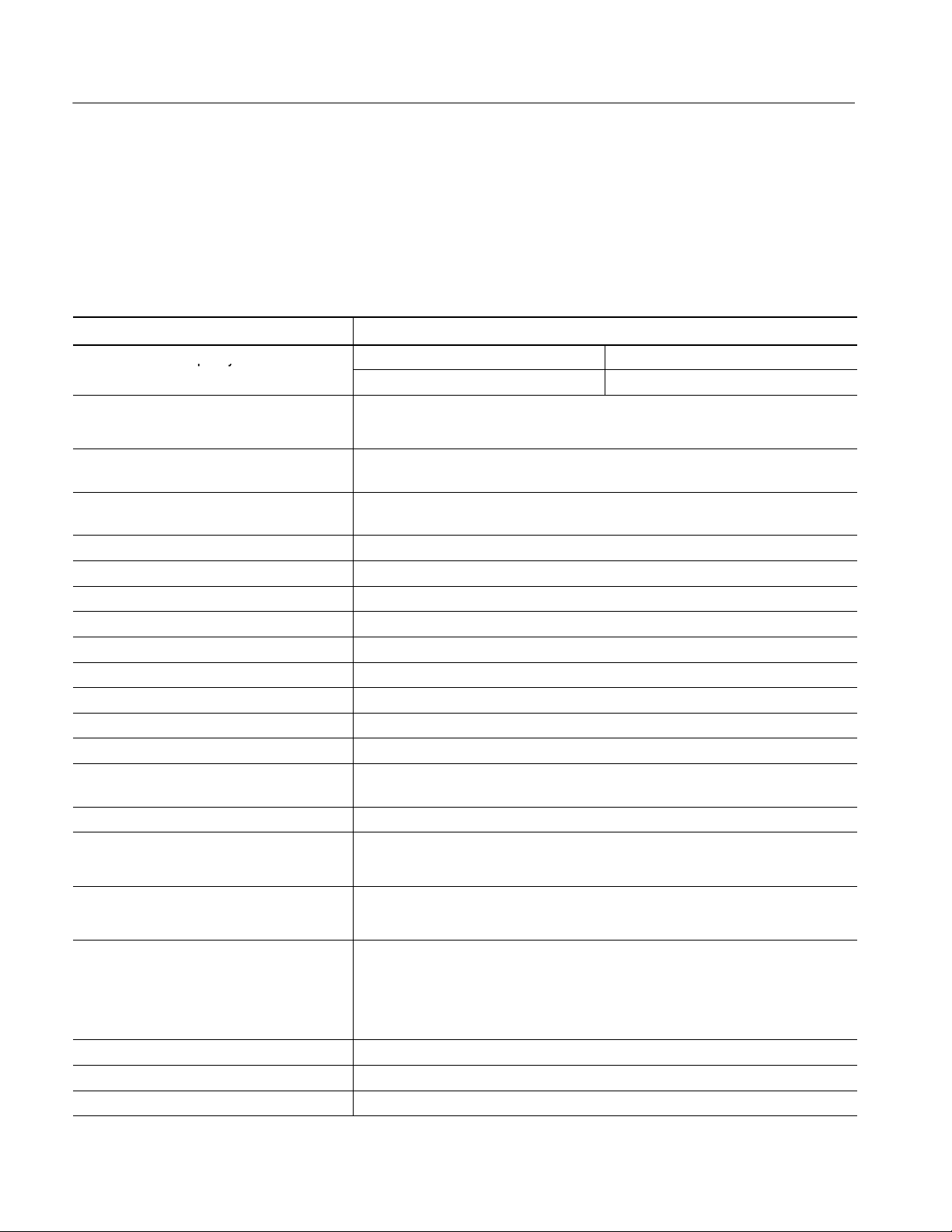

Table 8: P6475 Variable probe

Vol

-3 V to +6.75, 10 mV step, into 1 M

All timing values are specified at the probe connector under the conditions listed below, unless otherwise noted:

Output Voltage setting: Voh +2 V, Vol 0 V

Slew Rate: 2.5 V/ns

Delay Range: 0

Delay Time: 0 ns

Load: 50

Characteristic Description

Reference

Maximum Clock Frequency

Delay Range: 0

Delay v 10 ns

Delay Range: 0

Delay w 10 ns 134 MHz 268 MHz

Delay Range: 1,2,3 30 MHz 30 MHz

Number of Data Outputs 8 (CH0 to CH7)

Number of Clock Outputs 1

Number of Strobe Outputs 0

Number of External Event Inputs 2

Number of External Inhibit Inputs 1

Clock Output Polarity Positive or Negative

Data Format CH0 to CH5: NRZ

CH6 and CH7: NRZ, R1 or RZ (independent)

Output Impedance 50

Output Level

Vol -3 V to +6.75, 10 mV step, into 1 M

Voh

-2.75 V to +7 V, 10 mV step, into 1 M

Full CH Mode Half CH Mode

134 MHz 268 MHz

Voltage Swing

Control

Accuracy

Output Current

Sink

Source

Supported Channel Mode Half and Full

TLA7PG2 Pattern Generator Probes Instruction Manual

250 mV

CH0 to CH5: Common

CH6, CH7, CLK: Independent

$ 3% of value $ 0.1 V

<-30 mA

<+30 mA

pĆp

to 9 V

pĆp

37

Page 52

Reference

Table 8: P6475 Variable probe (Cont.)

All timing values are specified at the probe connector under the conditions listed below, unless otherwise noted:

Output Voltage setting: Voh +2 V, Vol 0 V

Slew Rate: 2.5 V/ns

Delay Range: 0

Delay Time: 0 ns

Load: 50

Characteristic Description

Delay Channel CH6 and CH7 (Independent)

Delay Time Delay Range Minimum Delay Maximum Delay

0 0 ns 20 ns

1 15 ns 30 ns

2 25 ns 40 ns

3 35 ns 50 ns

With reference to CH0, CH6, CH7 independent.

Delay Resolution 10 ps

Delay Accuracy $(3% of Delay Time) $ 0.8 ns (to CH0)

(For delay range of 1, 2, and 3 this is only for rising edge. The falling edge will be

delayed approximately 4 ns from the setting value.)

CH6 Output Mode The following five modes are available:

Normal

CH6 or CH7

CH6 and CH7

CH6 or (not CH7)

CH6 and (not CH7)

Slew Rate Control 0.5 V/ns to 2.5 V/ns, 100 mV step

Rise/Fall Time

20 % to 80 % at maximum slew rate,

load: 1 M + < 10 pF

Rise/Fall Time

Rise 550 ps

Fall 640 ps

Rise 430 ps

20 % to 80 % at maximum slew rate,

load: 50

38

Fall 510 ps

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 53

Table 8: P6475 Variable probe (Cont.)

All timing values are specified at the probe connector under the conditions listed below, unless otherwise noted:

Output Voltage setting: Voh +2 V, Vol 0 V

Slew Rate: 2.5 V/ns

Delay Range: 0

Delay Time: 0 ns

Load: 50

Characteristic Description

Data Output Skew < 295 ps between all data output pins of all modules in the mainframe after

intermodule skew is adjusted manually

< 280 ps between all data output pins of all probes of single module

< 250 ps between all data output pins of a single probe

Data Output to Clock Output Delay 940 ps (See Td2 in Figure 19 on page 22)

External Clock Input to Clock Output Delay 62 ns (See Td1 in Figure 19 on page 22)

External Inhibit Input to Output Enable Delay 30 ns for Data Output (See Td4 in Figure 20 on page 23)

External Inhibit Input to Output Disable Delay 28 ns for Data Output (See Td5 in Figure 19 on page)

Probe D Data Output to Output Enable Delay

-100 ps for Data Output (See Td4 in Figure 20 on page 23)

Reference

(for Internal Inhibit)

Probe D Data Output to Output Disable Delay

(for Internal Inhibit)

External Event Input to Clock Output Setup

(for inhibit) eventĆfilter: off

External Event Input Delay to Data Output for

Advance

External Event Input and Inhibit Input

Polarity

Impedance

Threshold:

Level

Resolution

Minimum Pulse Width

-4.4 ns for Data Output (See Td5 in Figure 20 on page 23)

Full Channel mode: 1.5 Clocks +180 ns

Half Channel mode: 2 Clocks + 180 ns

(See Td6 in Figure 21 on page 23)

170 ns to 270 ns + 1.5 to 2.5 CLK2 (Td12 in Figure 25 on page 24)

(CLK2 is from 2.5 ns to 5 ns when Internal Clock is used. It is the same as one clock

period when the External Clock is used.)

Positive True

1 k to GND

-2.5 V to +2.5 V Event and Inhibit are independent

20 mV

150 ns (event filter: off)

TLA7PG2 Pattern Generator Probes Instruction Manual

39

Page 54

Reference

Table 8: P6475 Variable probe (Cont.)

All timing values are specified at the probe connector under the conditions listed below, unless otherwise noted:

Output Voltage setting: Voh +2 V, Vol 0 V

Slew Rate: 2.5 V/ns

Delay Range: 0

Delay Time: 0 ns

Load: 50

Characteristic Description

External Event Input

Setup Time of Event

Input for Event Jump

Setup Time of Event Input for Event Advance Half Channel Mode: 180 ns before the rising edge of the 5th clock output pulse from

Half Channel Mode: 54 to 61 Clocks + 180 ns before the next block

Full Channel Mode: 27.5 to 31 Clocks + 180 ns before the next block

(See Td9 in Figure 22 on page 23)

the last of the previous block (See Td10 in Figure 23 on page 24 )

Full Channel Mode: 180 ns before the rising edge of the 3rd clock output pulse from

the last of the previous block (See Td11 in Figure 24 on page 24)

40

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 55

Table 8: P6475 Variable probe (Cont.)

Using signal 1 or 2

100 to 200 ns + 2 to 3 CLK (Half Channel Mode)

All timing values are specified at the probe connector under the conditions listed below, unless otherwise noted:

Output Voltage setting: Voh +2 V, Vol 0 V

Slew Rate: 2.5 V/ns

Delay Range: 0

Delay Time: 0 ns

Load: 50

Characteristic Description

Mainframe External Signal Input to PG Probe

Data Output

For Advance:

Reference

Using signal 1 or 2

Using signal 3 or 4

For Inhibit: (Output Enable)

Using signal 3 or 4

For Inhibit: (Output Disable)

Using signal 1 or 2

Using signal 3 or 4

PG Probe Clock Output to Mainframe External

Signal Output Delay

Using signal 1 or 2

200 to 300 ns + 1.5 to 2.5 CLK2

230 to 330 ns + 1.5 to 2.5 CLK2

(CLK2 is from 2.5 ns to 5 ns when the Internal Clock is used. It is the same as one

clock period when the External Clock is used.)

100 to 200 ns +1.5 to 2.5 CLK (Full Channel Mode)

130 to 230 ns + 2 to 3 CLK (Half Channel Mode)

130 to 230 ns + 1.5 to 2.5 CLK (Full Channel Mode)

100 to 200 ns + 2 to 3 CLK (Half Channel Mode)

100 to 200 ns +1.5 to 2.5 CLK (Full Channel Mode)

130 to 230 ns + 2 to 3 CLK (Half Channel Mode)

130 to 230 ns + 1.5 to 2.5 CLK (Full Channel Mode)

19 ns -5 CLK (Half Channel Mode)

Using signal 3 or 4

TLA7PG2 Pattern Generator Probes Instruction Manual

19 ns -3 CLK (Full Channel Mode)

28 ns -5 CLK (Half Channel Mode)

28 ns -3 CLK (Full Channel Mode)

41

Page 56

Reference

Table 9: Power Supply (P6475 only)

Characteristic Description

AC Line Power

Voltage rating 100 - 240 V AC

Voltage range 90 - 250 V AC

Frequency range 50 to 60 Hz

Maximum power 35 W

Maximum current 2 A

Table 10: Atmospherics

Characteristic Description

Temperature

Operating: +0°C to + 50°C

Nonoperating: -20°C to + 60°C

Relative Humidity

Operating: 20% to 80% (No condensation)

Maximum wetĆbulb temperature 29.4°C

Nonoperating: 5% to 90% (No condensation)

Maximum wetĆbulb temperature 40.0°C

Altitude

Operating: Up to 4.5 km (15,000 ft)

Maximum operating temperature decreases 1°C

Nonoperating: Up to 15 km (50,000 ft)

Table 11: Dynamics characteristics (P6470, P6471, P6472, P6473, P6474)

Characteristic Description

Vibration

Operating: 3.038 m/s

Nonoperating: 24.108 m/s

Shock

2

(0.31 G

2

(2.46 G

, 5 Hz to 500 Hz

rms)

), 5 Hz to 500 Hz

rms

Nonoperating: 294 m/s2 (30G), halfĆsine, 11 ms duration,

3 shocks per axis in each direction (18 shocks total)

42

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 57

Table 12: Dynamics characteristics (P6475)

Characteristic Description

Vibration

Operating: 3.038 m/s

Nonoperating: 24.108 m/s

2

(0.31 G

2

(2.46 G

, 5 Hz to 500 Hz

rms)

) , 5 Hz to 500 Hz

rms

Shock (P6475 only)

Nonoperating: 588 m/s2 (60G), halfĆsine, 11 ms duration,

3 shocks per axis in each direction (18 shocks total)

Table 13: Probe cables

Characteristic Description

Dimensions

Length 1.5 m (5 ft) Standard probe cable

Length 3.3 m (10.83 ft) Time alignment cable

Reference

Table 14: Twisted lead set

Characteristic Description

Dimensions

Length 25.4 cm (10 in)

Table 15: Certifications and compliances for P6475

Category Standards or description

Safety

Third party certification UL 3111Ć1

CSA C22.2 No.1010.1

SelfĆDeclaration EN61010Ć1 with second amendment

TLA7PG2 Pattern Generator Probes Instruction Manual

43

Page 58

Reference

44

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 59

Maintenance

The pattern generator probes do not require scheduled or periodic maintenance.

Functional Check

To verify the functionality of the pattern generator probe, you can set up the

pattern generator to output a simple data pattern and use an oscilloscope or a

logic analyzer to verify the data changes at the probe tips. For more extensive

checks, refer to the TLA7PG2 Pattern Generator and Probes Service Manual

Inspection and Cleaning

To maintain good electrical contact, keep the probes free of dirt, dust, and

contaminants. Remove dirt and dust with a soft brush. For more extensive

cleaning use only a damp cloth. Never use abrasive cleaners or organic solvents.

See the TLA7PG2 Pattern Generator and Probes Service Manual for more

extensive cleaning instructions.

Static Discharge Information

Read the General Safety Summary and the Service Safety Summary at the front of

this manual before attempting any procedures in this chapter.

H Minimize handling of static-sensitive circuit boards.

H Discharge the static voltage from your body by wearing a grounded antistatic

wrist strap while handling these circuit boards. Service static-sensitive circuit

boards only at a static-free work station.

H Nothing capable of generating or holding a static charge should be allowed

on the work station surface.

H Avoid handling circuit boards in areas that have a floor or work-surface

covering capable of generating a static charge.

Configuring Probes

This subsection provides instructions for changing the resistor packs on the

P6470 and P6474 and instructions for configuring the P6472 for PECL or

LVPECL.

TLA7PG2 Pattern Generator Probes Instruction Manual

45

Page 60

Maintenance

CAUTION. To prevent possible injury, disconnect the pattern generator and DUT

from the probes prior to removing the probe cover.

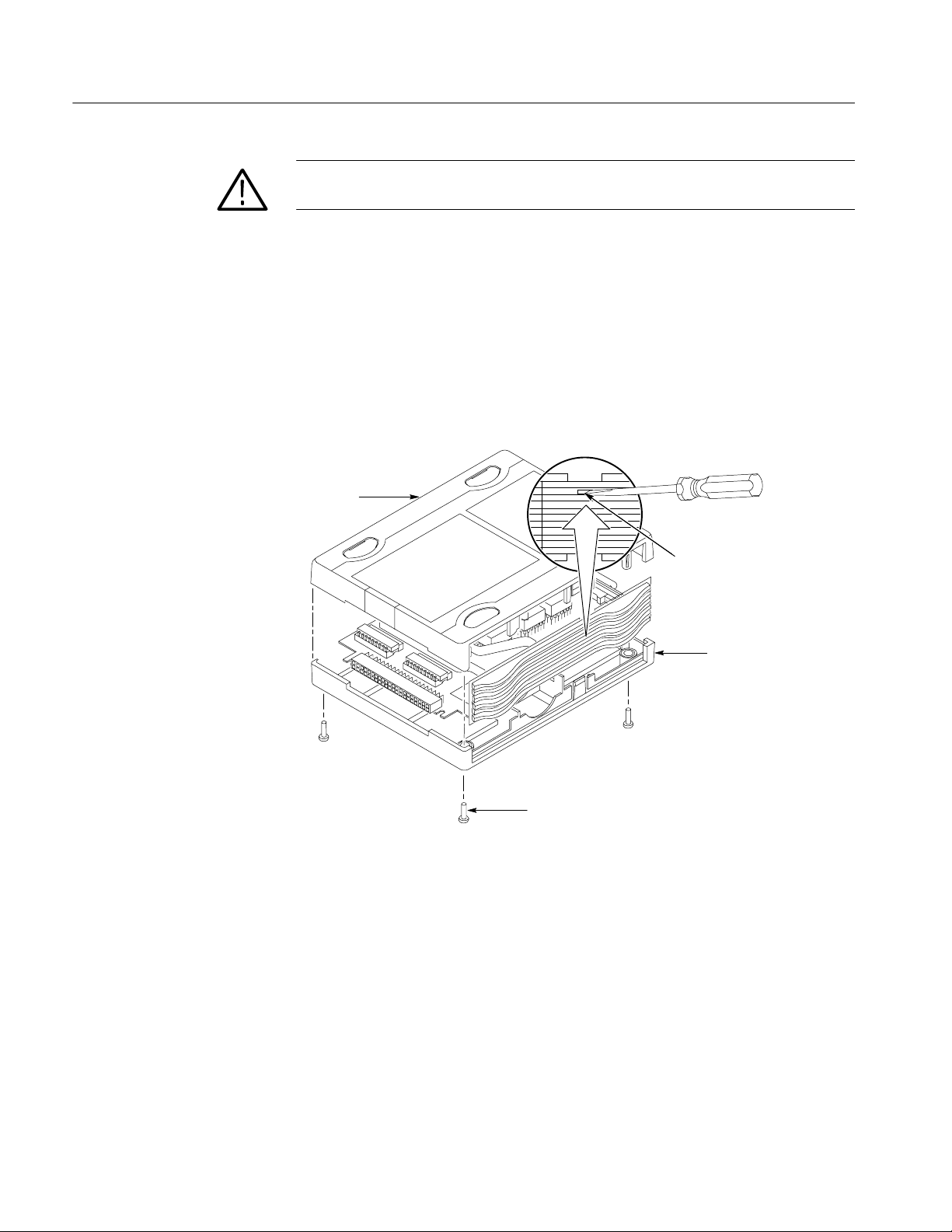

Removing the Probe

Cover

Follow the steps below to remove the probe cover. See Figure 26.

1. Remove the four screws securing the probe cover.

2. Release the cover latches by pushing the tip of a small flat-blade screwdriver

into the cutouts on each side of the probe. Do not pry.

3. Remove the top cover.

Top cover

Push here

Bottom cover

46

Screw (4)

Figure 26: Removing the standard probe cover

TLA7PG2 Pattern Generator Probes Instruction Manual

Page 61

Maintenance

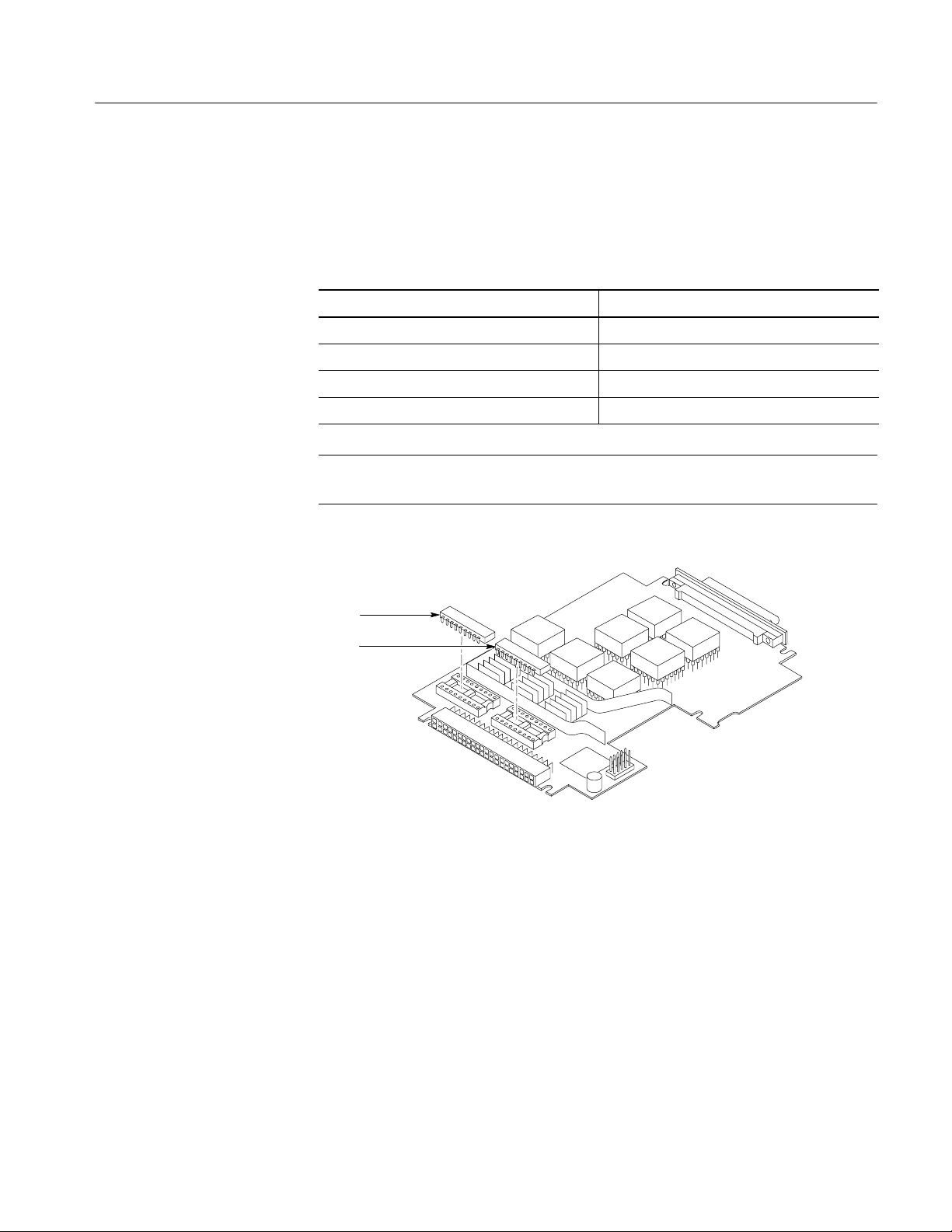

Changing the Series

Termination Resistors

(P6470 and P6474 only)

Table 16 lists the various resistor packs available for the P6470 and P6474

probes (see Figure 27 for the P6470 and Figure 28 for the P6474). These resistor

packs are a subpart of the 015-A095-00 kit.

Table 16: P6470 series termination resistors

Part number Value

307Ć1683Ć00 43

307Ć1684Ć00 75

307Ć1686Ć00 100

307Ć1687Ć00 150

NOTE. Be careful not to bend the resistor pack pins when installing the replacement resistors in sockets.