Page 1

Instructions

P6419

Logic Analyzer Probe

071-1303-00

www.tektronix.com

*P071130300*

071130300

Page 2

Copyright © Tektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and

are protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in Technical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software -- Restricted Rights clause at FAR 52.227-19, as applicable.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Tektronix, Inc., 14200 SW Karl Braun Drive, Beaverton, OR 97077

TEKTRONIX, TEK, TLAVu, PatGenVu, and MagniVu are registered trademarks of Tektronix, Inc.

Page 3

HARDWARE WARRANTY

Tektronix warrants that the products that it manufactures and sells will be free from defec ts in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defective during this warranty period, Tektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by Tektronix, with shipping charges prepaid.

Tektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

Tektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligat ed to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than Tektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER W ARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADV ANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Page 5

Table of Contents

Operating Basics

General Safety Summary v...................................

Preface vii...................................................

Related Documentation vii...........................................

Contacting Tektronix viii.............................................

Product Description 1........................................

Mictor-on-PCB to Compression Adapter 2..............................

Compression-on-PCB to P6434 Mictor Adapter 3........................

Attaching Probe Labels 5.....................................

Connecting the Probes to the Logic Analyzer 7...................

Cleaning the P6419 Compression Footprints 8...................

Cleaning the P6419 Probe Heads 8.............................

Storing the P6419 Probe Heads 9..............................

Connecting the Probes to the Target System 10....................

Connecting the P6419 High Density Probes 10...........................

Connecting the Mictor-on-PCB to Compression Adapter 13.................

Connecting the Compression-on-PCB to P6434 Mictor Adapter 13...........

Reference

Maintenance

Designing an Interface Between the P6419 Probe and a Target

System 15................................................

Signal Fixturing Considerations 15.....................................

Signal Names 19...................................................

Land Footprints 27..................................................

Mechanical Considerations 30........................................

Special Considerations 33............................................

Physical Attachment Requirements for P6419 probes 33....................

Physical Attachment Requirements for the Compression-on-PCB to P6434

Mictor and Mictor-on-PCB to Compression Adapters 35................

Electrical Considerations 35..........................................

Transmission Lines 35...............................................

P6419 High-Density Probe Load Model 36..............................

Specifications 38.............................................

Probe Calibration 41.........................................

Functional Check 41..........................................

Inspection and Cleaning 41....................................

P6419 Probe Service Procedures 42.............................

Repackaging Instructions 42...................................

P6419 Logic Analyzer Probe Instructions

i

Page 6

Table of Contents

Replaceable Parts

Index

Parts Ordering Information 43.................................

Using the Replaceable Parts List 43.............................

ii

P6419 Logic Analyzer Probe Instructions

Page 7

List of Figures

Table of Contents

Figure 1: P6419 logic analyzer probe 1..........................

Figure 2: Mictor-on-PCB to Compression adapter 2..............

Figure 3: Compression-on-PCB to P6434 Mictor adapter 3.........

Figure 4: Clearance for probe connection using

Compression-on-PCB to P6434 Mictor adapter 4..............

Figure 5: Attaching labels to the P6419 probe 6..................

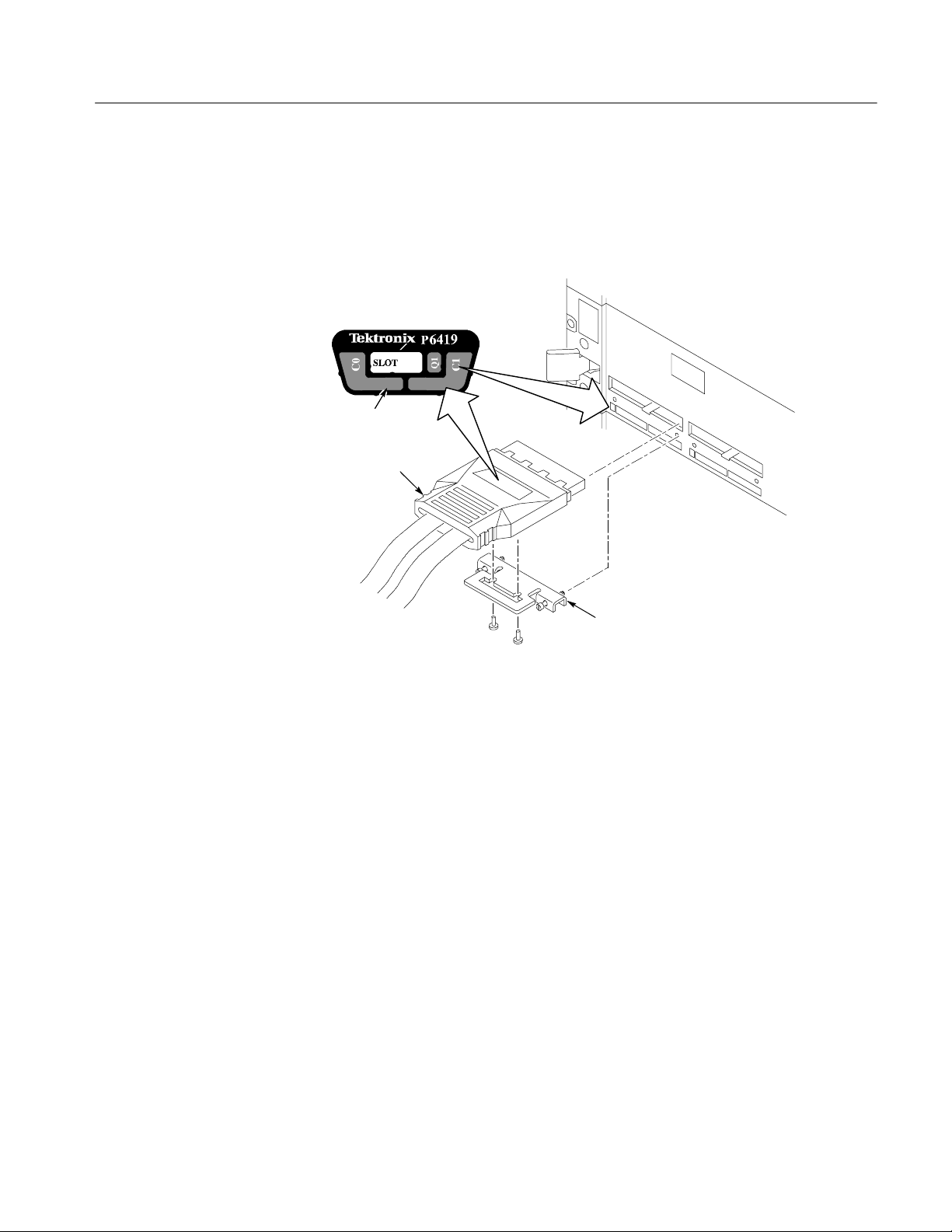

Figure 6: Connecting the probes to the logic analyzer 7............

Figure 7: Cleaning the probe heads 9...........................

Figure 8: Storing the probe heads 10............................

Figure 9: Press-in Nuts installation 11...........................

Figure 10: Connecting the P6419 probe to the target system 12......

Figure 11: P6419 High-Density probe land footprint 28.............

Figure 12: High-Density probe land footprint in a typical

pass-through signal path layout configuration 29..............

Figure 13: Example layout of the High-Density compression

compared to the mictor land footprints 29....................

Figure 14: Land footprint requirements for P6419 probes

(top view) 31.............................................

Figure 15: Land footprint requirements for the

Compression-on-PCB to P6434 Mictor adapter 33..............

Figure 16: Nut Bar design 34...................................

Figure 17: Press-in Nut design 35...............................

Figure 18: High-Density probe load model 36.....................

Figure 19: Mictor-on-PCB to Compression adapter load model 36...

Figure 20: Compression-on-PCB to P6434 Mictor adapter load

model 37................................................

Figure 21: P6419 logic analyzer probe 45.........................

Figure 22: Compression-on-PCB to P6434 Mictor adapter 46........

P6419 Logic Analyzer Probe Instructions

iii

Page 8

Table of Contents

List of Tables

Table 1: Probe section and label combinations 5.................

Table 2: Logic analyzer clock and qu alifier availability 16..........

T able 3: 2X Demultiplexing source-to-destination channel

assignments 17...........................................

T able 4: 4X Demultiplexing source-to-destination channel

assignments 18...........................................

Table 5: P6419 High-Density Probe channel mapping on 136 and

102 channel TLA7Lx/Mx/Nx/Px/Qx modules and both TLA6xx

and TLA520x mainframes 20..............................

Table 6: Recommended Compression-on-PCB to P6434 Mictor

adapter and Mictor-on-PCB to Compression adapter channel

mapping for 136 and 102 channel modules 21................

Table 7: Recommended Compression-on-PCB to P6434 Mictor

adapter and Mictor-on-PCB to Compression adapter channel

mapping for 68 channel module 23.........................

Table 8: Recommended Compression-on-PCB to P6434 Mictor

adapter and Mictor-on-PCB to Compression adapter channel

mapping for 34 channel module 25.........................

T able 9: Electrical and mechanical specifications 38..............

Table 10: Environmental specifications 39.......................

Table 11: Parts list column descriptions 44.......................

Table 12: Manufacturers cross index 44.........................

Table 13: P6419 replaceable parts list 45........................

Table 14: Adapter replaceable parts list 46.......................

iv

P6419 Logic Analyzer Probe Instructions

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Connect and Disconnect Properly. Connect the probe output to the measurement

instrument before connecting the probe to the circuit under test. Disconnect the

probe input and the probe ground from the circuit under test before disconnecting

the probe from the measurement instrument.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Connect the ground lead of the probe to earth ground only.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

P6419 Logic Analyzer Probe Instructions

v

Page 10

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

Breakable.

Do not drop.

vi

P6419 Logic Analyzer Probe Instructions

Page 11

Preface

Related Documentation

This document provides information on using and servicing the P6419 logic

analyzer probe.

In addition to these probe instructions, the following documentation is available

for your Tektronix logic analyzer:

H The Tektronix Logic Analyzer Family User Manual provides overall user

information for the Tektronix logic analyzer family.

H The online help provides information about the TLA user interface and the

TLA Programmatic Interface (TPI). To view the online help, select Help

Topics from the Help menu.

H A series of instruction manuals for microprocessor support that provide

operating and service instructions for the individual microprocessor support

packages that are available for use with the TLA logic analyzer.

H A series of service manuals that provide board-level service information for

major components of the logic analyzer.

P6419 Logic Analyzer Probe Instructions

vii

Page 12

Preface

Contacting Tektronix

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: techsupport@tektronix.com

1-800-833-9200, select option 3*

6:00 a.m. -- 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

viii

P6419 Logic Analyzer Probe Instructions

Page 13

Operating Basics

Product Description

This section provides a brief description of the P6419 logic analyzer probe,

instructions for attaching and using color-coded probe labels, and information

about connecting the probe from between the logic analyzer and your target

system.

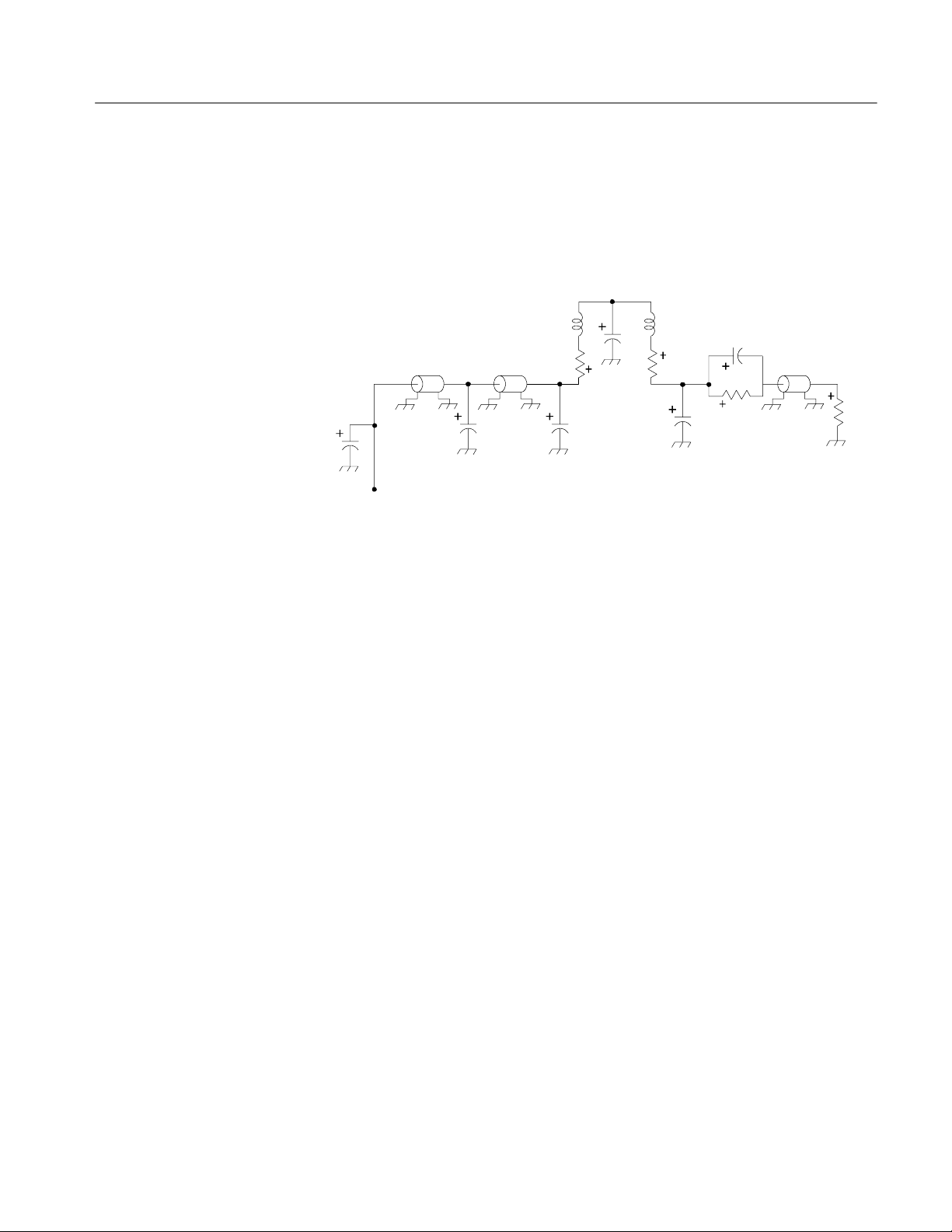

The P6419 logic analyzer probe connects a Tektronix TLA520x mainframe,

TLA6xx mainframe, or a TLA7Lx/Mx/Nx/Px/Qx logic analyzer module to your

target system. The P6419 Probe is a high-density probe (see Figure 1) consisting

of a single independent probe head of 17 channel connectors each (16 data and

1 clock/qual).

Figure 1: P6419 logic analyzer probe

The following list details the capabilities and qualities of the P6419 Probe:

H Single-ended clock and qualification inputs

H Single-ended data inputs

H Compression contact (eliminates need for built-in connector)

H Land pattern (supports direct signal pass-through)

H Supports PCB thickness of 1.27 mm to 6.35 mm (0.050 in to 0.258 in)

P6419 Logic Analyzer Probe Instructions

1

Page 14

Operating Basics

H Narrow 17-channel probe head (for easier placement and layout)

H 2X mode (for example, 1:2 demultiplexing) uses single-probe head

H Approximately 20% less channel density than current Mictor connectors

H Color-coded keyed signal connectors

H Adapter supports Mictor-based connections

H --3.5 V to +6.5 V input operating range

H --2.0 V to +4.5 V threshold range

H 500 mV minimum single-ended signal amplitude

H Minimal loading of < 0.7 pF @ 20 kΩ to ground loading

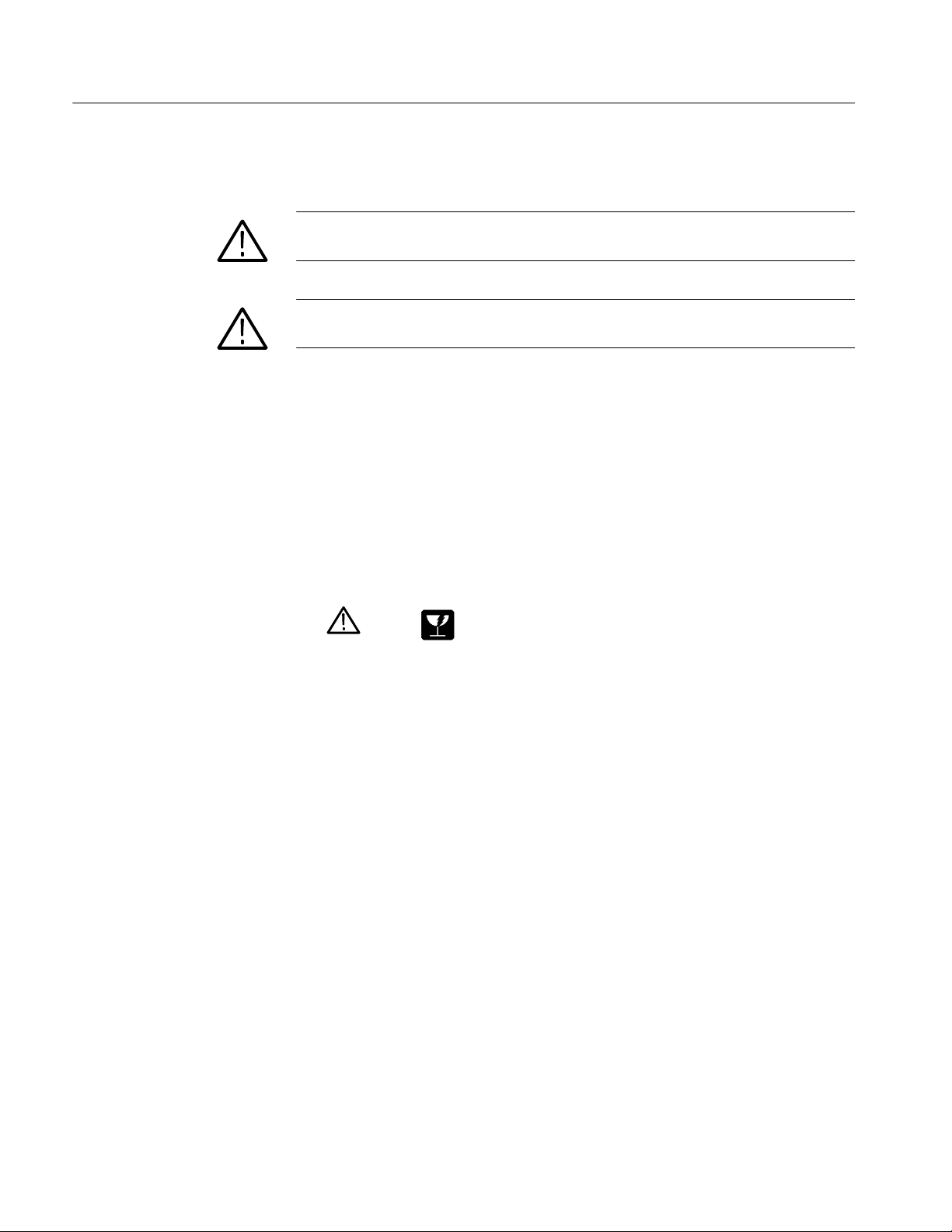

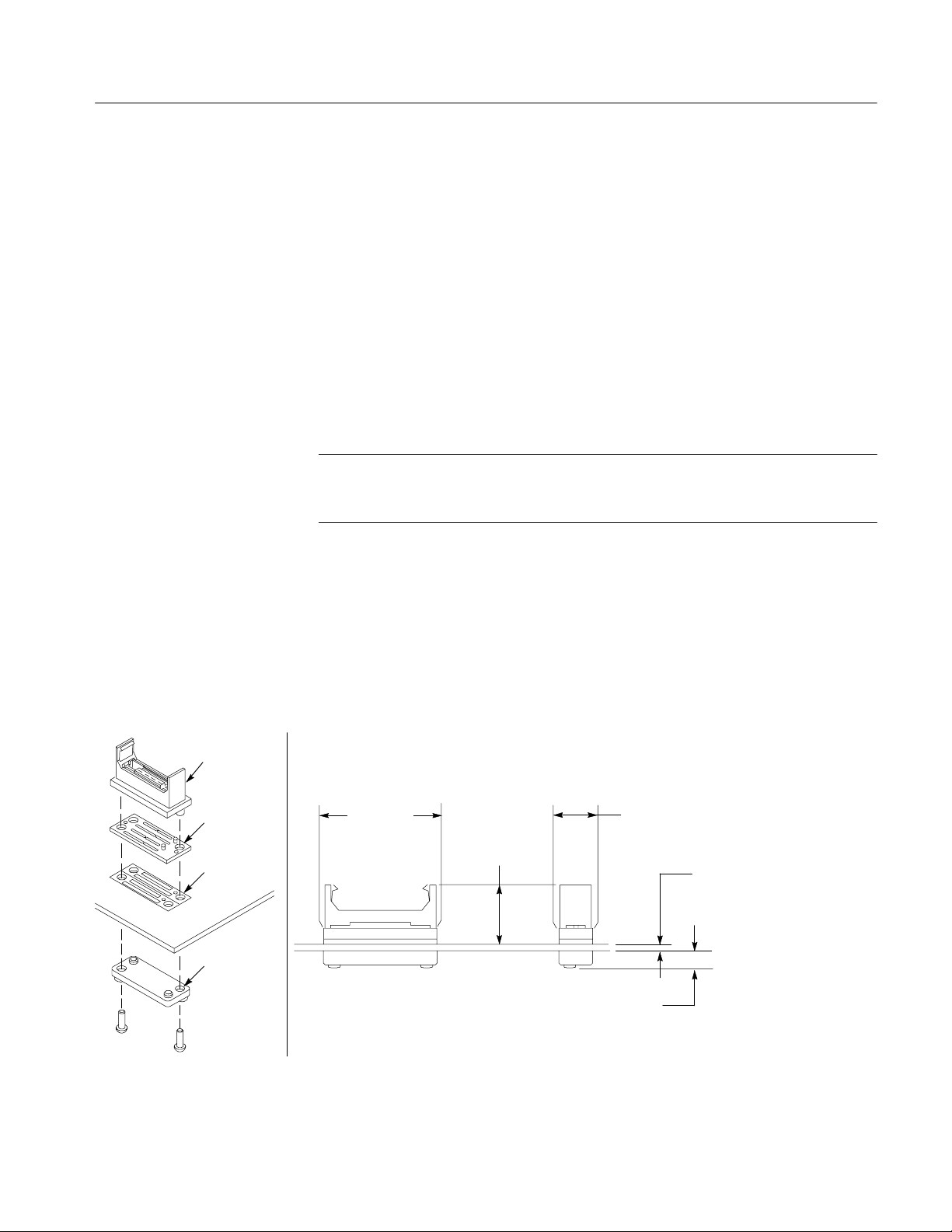

Mictor-on-PCB to

Compression Adapter

Compression

adapter

Mictor adapter

The Mictor-on-PCB to Compression adapter (see Figure NO TAG) allows

existing microprocessor support packages and your hardware designs with

embedded Mictor connectors to be connected to the P6419 High-Density Probe.

32.20 mm

(1.268 in)

58.57 mm

(2.306 in)

20.17 mm

(0.794 in)

Figure 2: Mictor-on-PCB to Compression adapter

2

12.83 mm

(0.505 in)

P6419 Logic Analyzer Probe Instructions

Page 15

Operating Basics

This adapter supports standard Mictor connector footprints and signal connections on older logic analyzer designs.

The Mictor adapter adds 2.7 pF to the high-density compression probe load of

0.7 pF for a combined adapter and probe capacitance load of 3.4 pF.

See Figure 4 on page 4 for comparing the clearances between the P6434 and

compression probe adapters.

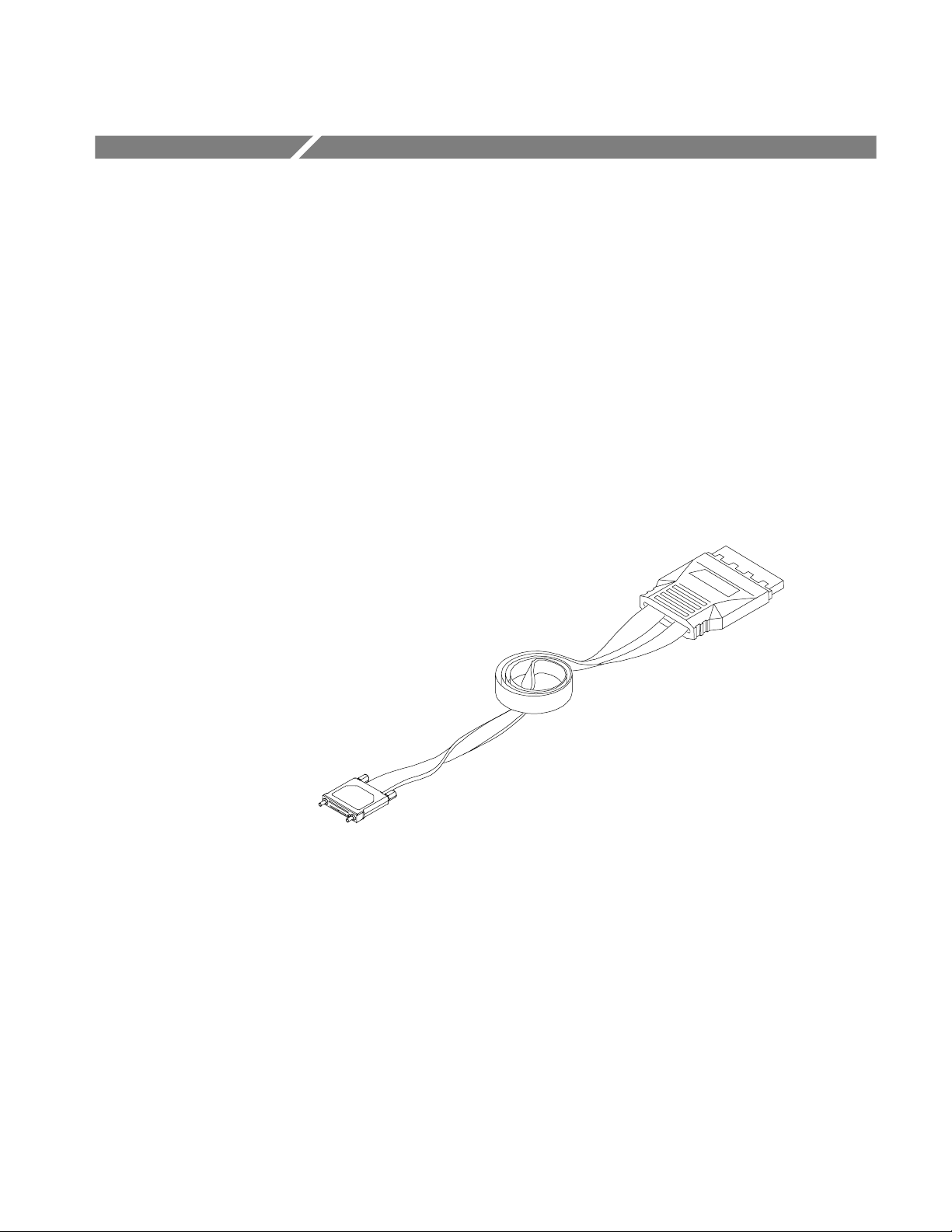

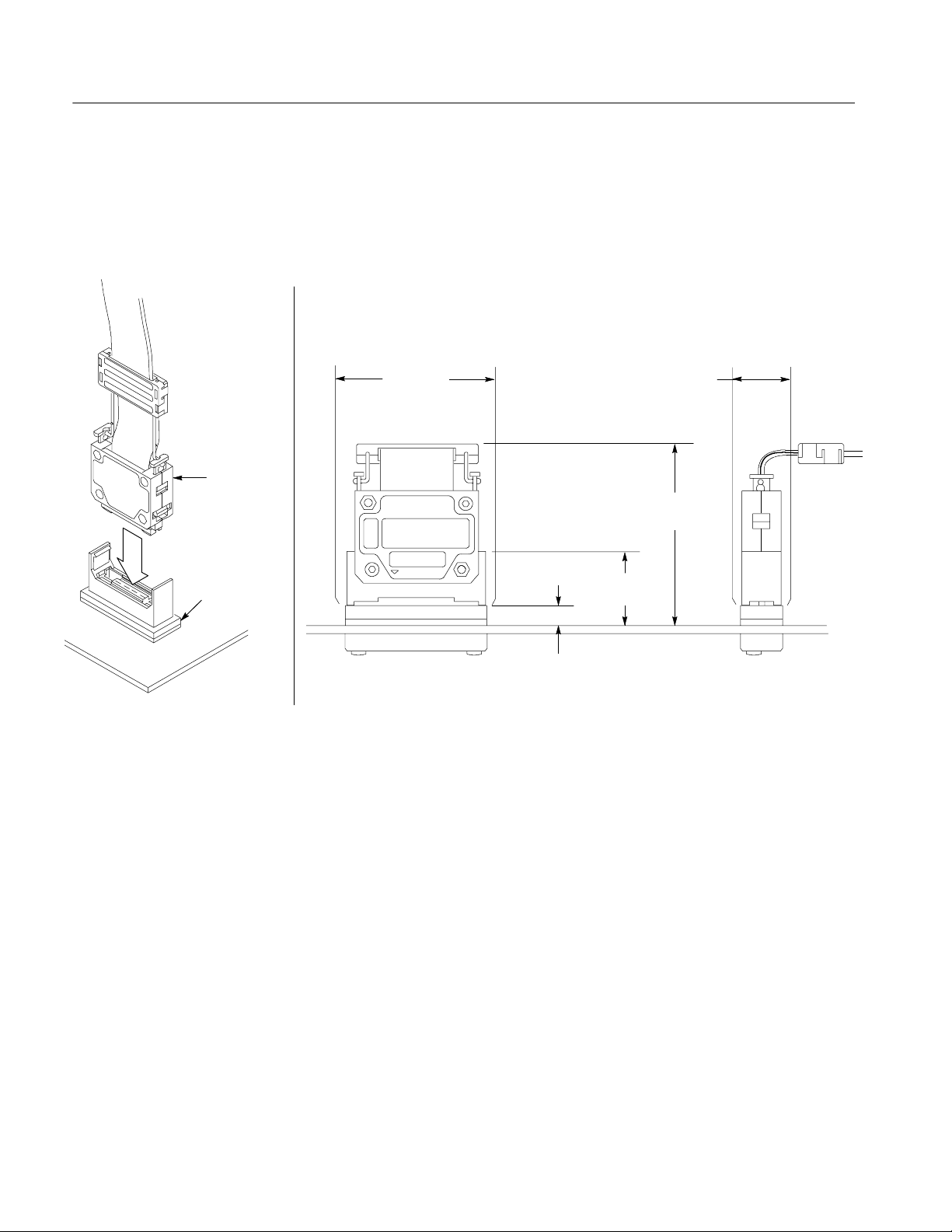

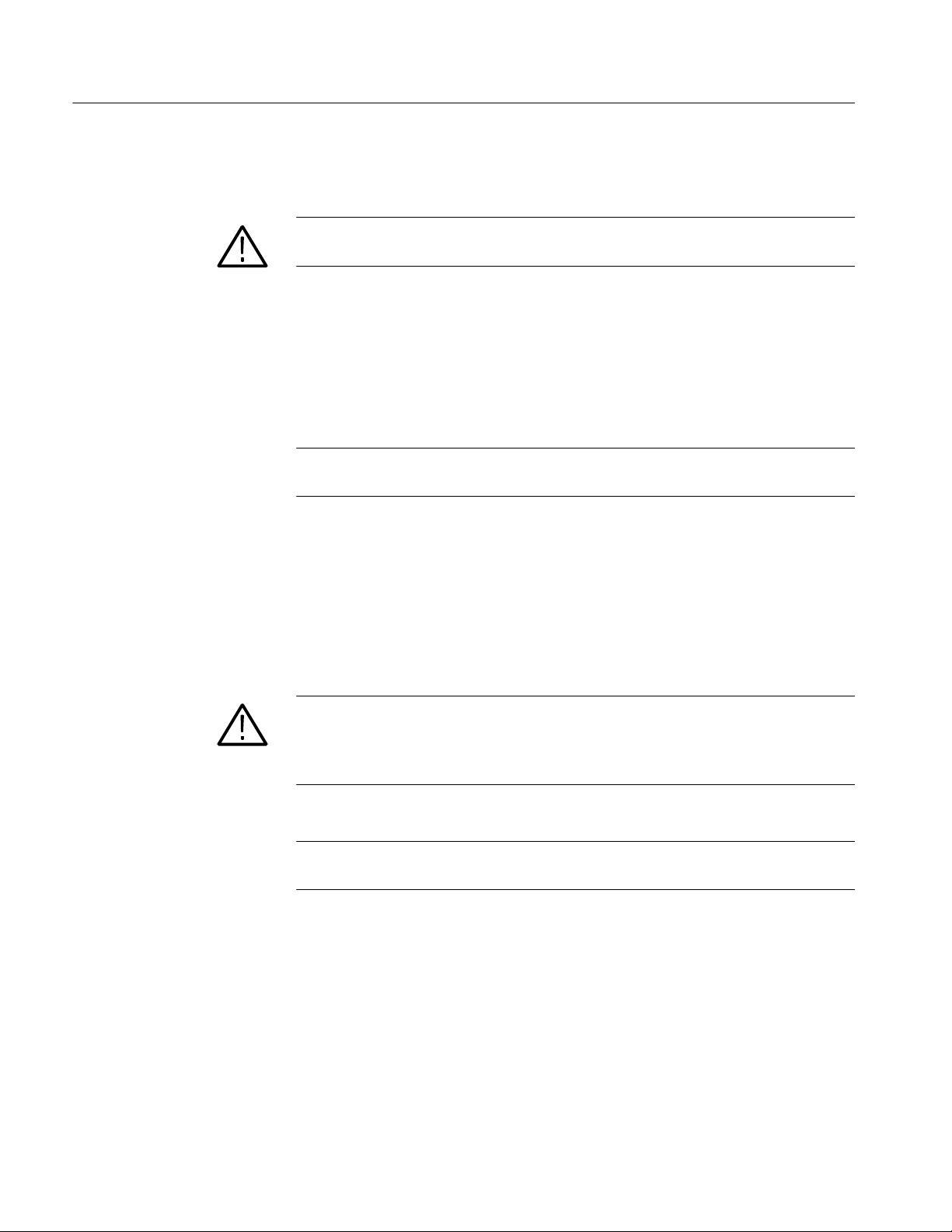

Compression-on-PCB to

P6434 Mictor Adapter

Mictor

adapter

Elastomer

holder

Circuit board

The Compression-on-PCB to P6434 Mictor adapter (see Figure 3) allows the

TLA520x mainframe, the TLA6xx mainframe, and TLA7Lx/Mx/Nx/Px/Qx logic

analyzer modules using a P6434 Probe to take advantage of the new compression

footprint and eliminate the need for Mictor connectors in your target system.

NOTE. To use the P6434 adapter, do not install press-in nuts. However, if board

thickness is > .093 in, you will need to install press-in nuts before migrating to

P6419 probes.

Two different screw lengths are required to accommodate the

1.27 mm to 6.35 mm (0.050 in to 0.250 in) PCB thickness range.

This adapter requires the use of the Compression-on-PCB to P6434 Mictor

adapter land footprint. See Figure 15 on page 33 for further information.

The Compression-on--PCB to Mictor adapter adds 1.5 pF to the P6434 probe

load of 2.0 pF for a combined adapter and probe capacitance load of 3.5 pF.

32.131 mm

(1.265 in)

15.82 mm

(0.623 in)

13.716 mm

(0.540 in)

PCB Thickness

1.27 mm to 6.35 mm

(0.050 in to 0.250 in)

Adapter

backing plate

Figure 3: Compression-on-PCB to P6434 Mictor adapter

P6419 Logic Analyzer Probe Instructions

4.572 mm

(0.180 in)

3

Page 16

Operating Basics

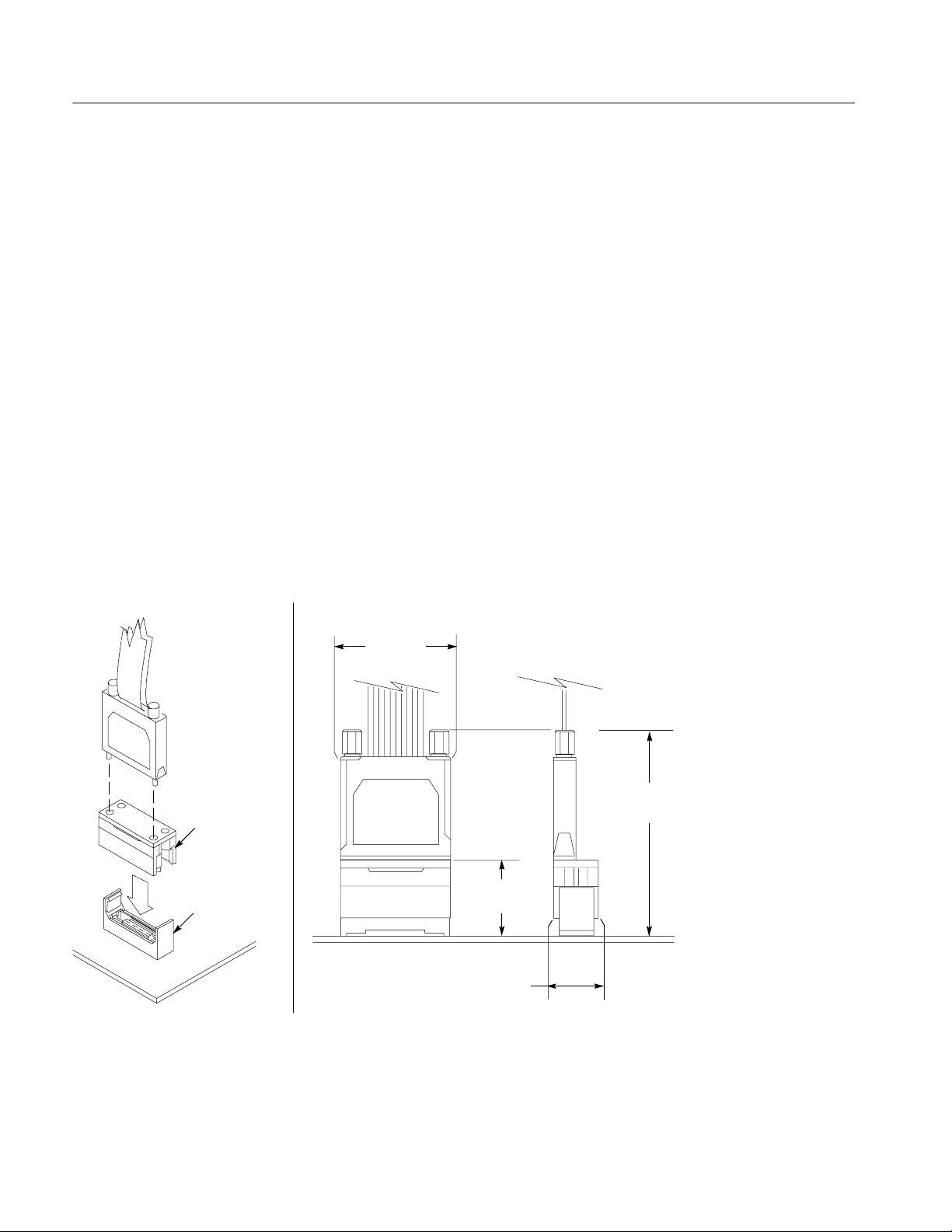

To compare the clearance between the P6434 Probe connection and the P6434

Probe connection via the Compression-on-PCB to P6434 Mictor adapter, refer to

Figure 4. Note that the mictor adapter adds 0.145 inches to the height of the

P6434 probe.

P6434

Mictor adapter

32.131 mm

(1.265 in)

15.82 mm

(0.623 in)

3.68 mm

(0.145 in)

13.716 mm

(0.540 in)

34.93 mm

(1.375 in)

Figure 4: Clearance for probe connection using Compression-on-PCB to P6434 Mictor adapter

4

P6419 Logic Analyzer Probe Instructions

Page 17

Operating Basics

Attaching Probe Labels

When you purchase one or more P6419 logic analyzer probes with a TLA520x

logic analyzer mainframe or TLA7Nx/Px/Qx logic analyzer module, all labels

are already attached. If you purchase the probe seperately from the logic

analyzer, you must apply the color-coded labels as described in this section. The

labels help you identify the probe connections at the logic analyzer end and at

the target system end.

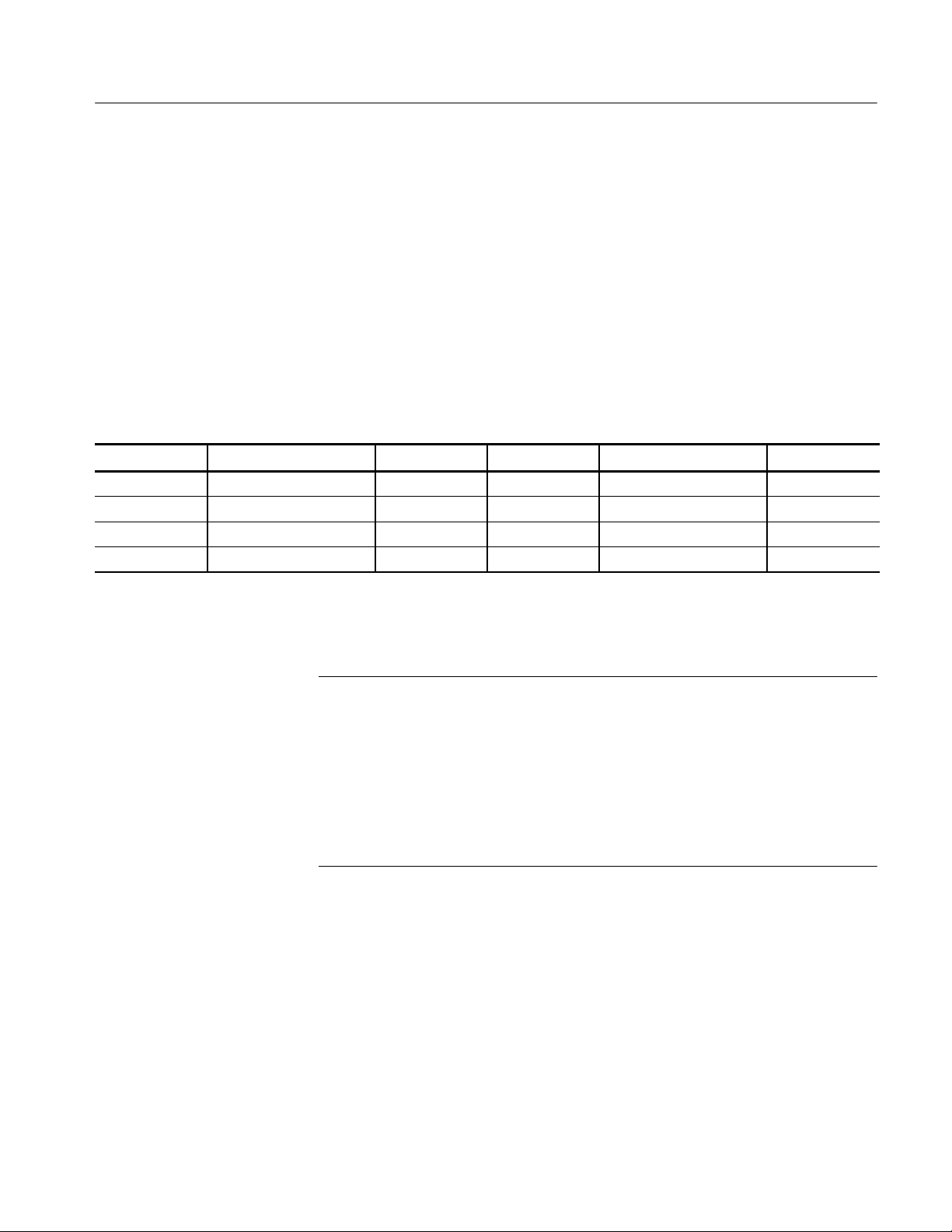

Table 1 lists the probe section and label color combinations. Refer to Table 1 and

to Figure 5 when you attach the probe labels.

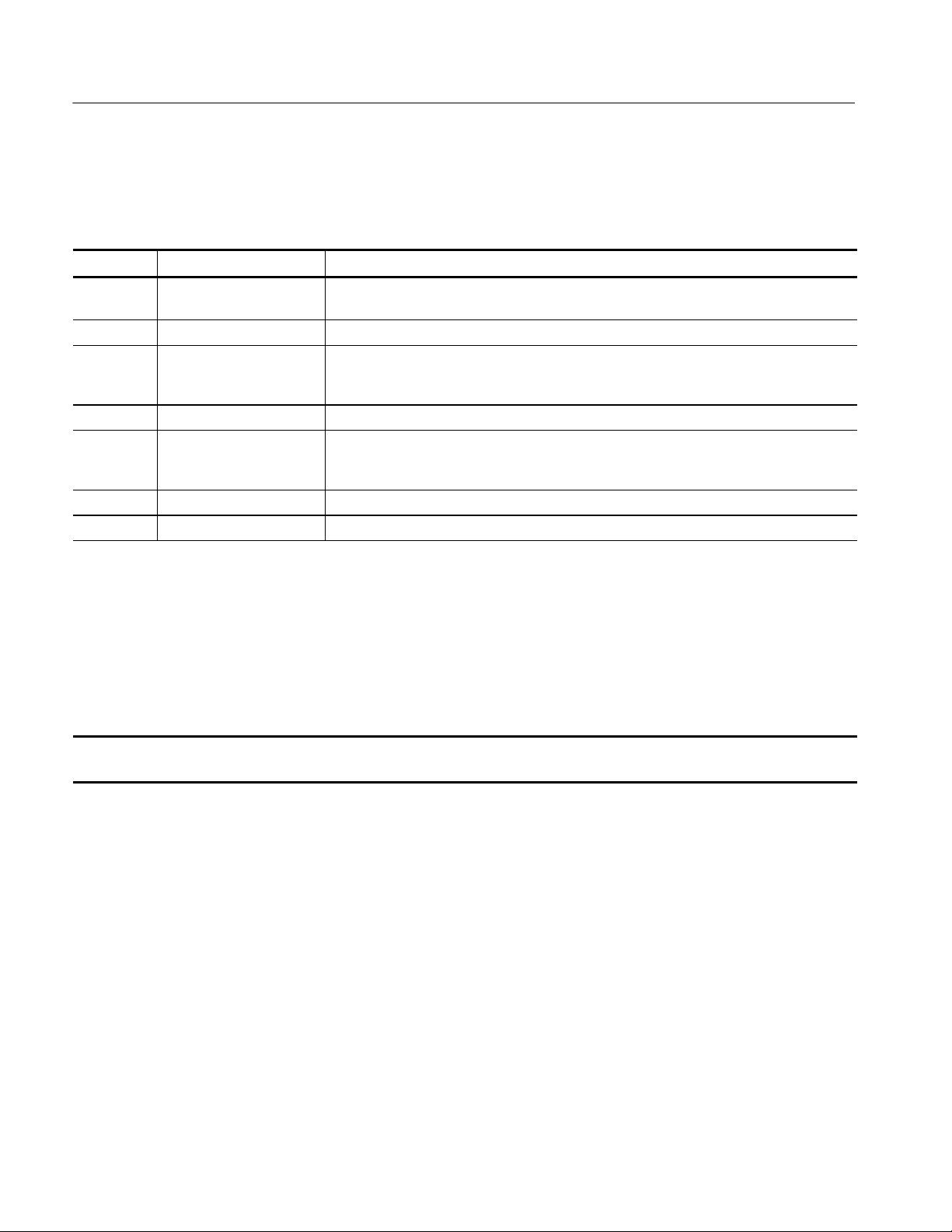

Table 1: Probe section and label combinations

Probe section Channels Label color Probe section Channels Label color

A3-A2 CK0, A3:7--0, A2:7-0 Brown A1-A0 CK1, A1:7-0, A0:7-0 Orange

D3-D2 QUAL0, D3:7-0, D2:7-0 Blue D1-D0 CK2, D1:7-0, D0:7-0 Yellow

C3-C2 CK3, C3:7-0, C2:7-0 White C1-C0 QUAL1, C1:7-0, C0:7-0 Gray

E3-E2 QUAL3, E3:7-0, E2:7-0 Green E1-E0 QUAL2, E1:7-0, E0:7-0 Violet

P6419 Labels

Use the following instructions to attach probe labels to your Tektronix P 6419

Logic Analyzer Probe.

NOTE. Always use flat-nosed tweezers to remove the labels from the sheet of

labels. Never peel labels with your fingers. The labels ar e made of soft vinyl and

can stretch and distort easily. To avoid stretching the label, always grasp it from

the top right corner while removing it from the sheet of labels.

The adhesive on the vinyl labels is extremely strong. Carefully align each label

to the intended outline on the module end and probe head before attaching it to

the probe. Once labels are placed on the probe, they become very difficult to

remove.

You will be attaching labels to the module and and both sides of the probe head.

Refer to Figure 5 and use the following steps to attach the probe labels:

1. Identify the module end of the probe cable.

2. From the sheet of labels, locate the color-coded label for the module end of

the probe cable.

3. Attach the matching colored labels to the probe head on the other end of the

probe cable.

P6419 Logic Analyzer Probe Instructions

5

Page 18

Operating Basics

Module end

Probe head

Figure 5: Attaching labels to the P6419 probe

6

P6419 Logic Analyzer Probe Instructions

Page 19

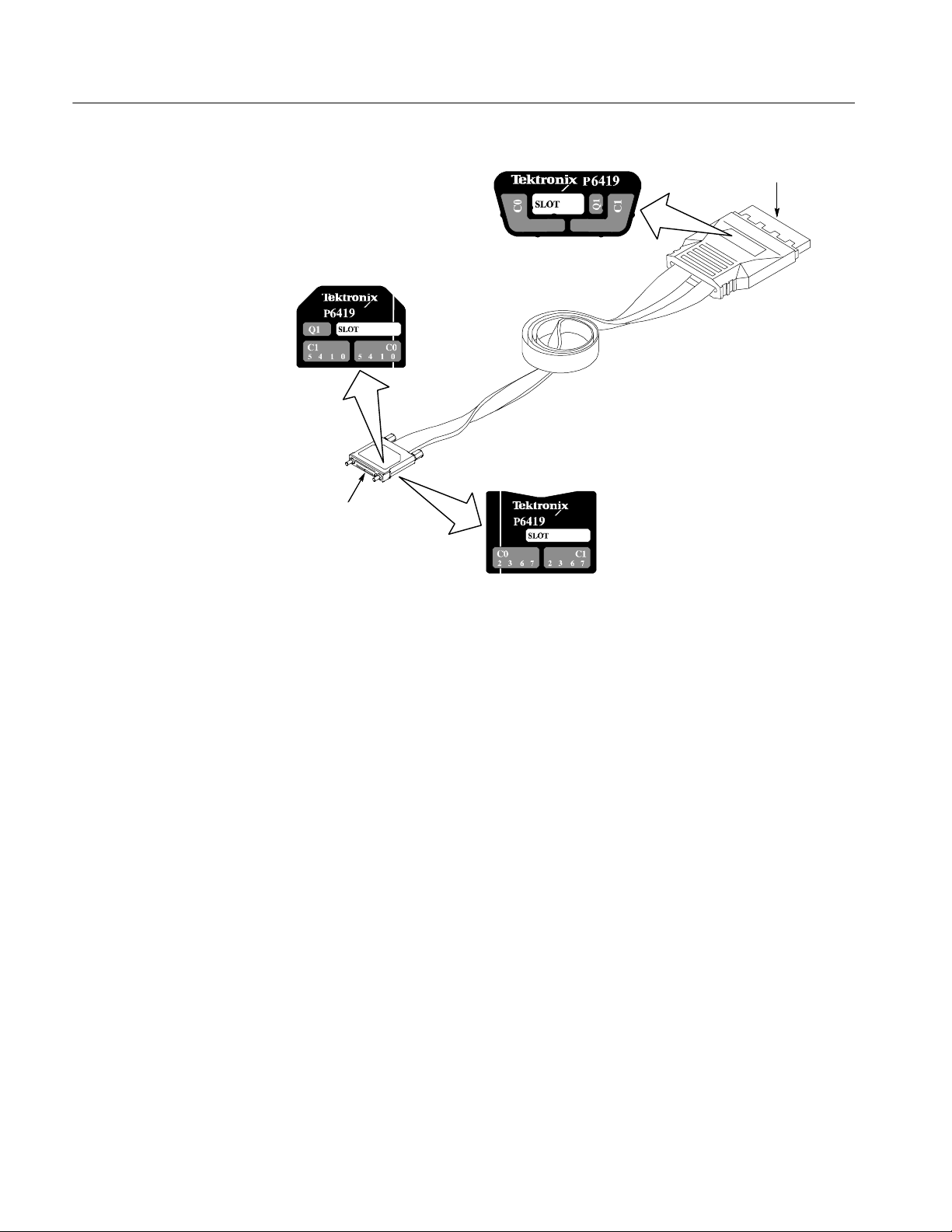

Connecting the Probes to the Logic Analyzer

Connect the logic analyzer probes and the optional retaining brackets as shown

in Figure 6. The retaining brackets and hardware ship with the logic analyzer.

Match color-coded

labels

P6419

Operating Basics

Attach optional probe

retainer brackets

Figure 6: Connecting the probes to the logic analyzer

Refer to Figure 10 and connect the probe to the target system. You can connect

the probes to the target system without turning off the target system.

P6419 Logic Analyzer Probe Instructions

7

Page 20

Operating Basics

Cleaning the P6419 Compression Footprints

CAUTION. To avoid electrical damage, always turn off the power of your target

system before cleaning the compression footprint.

Before connecting the probe to the target system, you must clean the compression footprints on your board according to the following steps:

1. Use a lint-free cloth moistened with isopropyl alcohol and gently wipe the

footprint surface.

2. Remove any remaining lint using a nitrogen air gun.

NOTE. Use alcohol sparingly and be sure that you have removed any remaining

lint or residue with a nitrogen air gun.

Cleaning the P6419 Probe Heads

Before connecting P6419 probes to the target system, ensure that the probe heads

are free from dust, dirt, and contaminants. If necessary, clean the probe heads

according to the following steps.

CAUTION. Static discharge can damage semiconductor components in the probe

head. Always wear a grounded antistatic wrist strap whenever handling the

probe head. Also verify that the probe head is not connected to anything that

carries a static charge.

NOTE. Never clean the elastomers. Always replace them instead. Refer to the

Replaceable Parts section of this manual for information on ordering parts.

To clean probe heads:

1. Remove elastomer holder.

2. Moisten a cotton swab with isopropyl alcohol.

8

P6419 Logic Analyzer Probe Instructions

Page 21

Operating Basics

Elastomer holder

Figure 7: Cleaning the probe heads

3. Gently wipe the edge print pads of the circuit board.

4. Remove any remaining lint using a nitrogen air gun.

5. Put the elastomer holder back in place.

CAUTION. To avoid damaging the probe contacts, do not touch the elastomer. In

addition, do not reverse the elastomer because this will transfer contaminants.

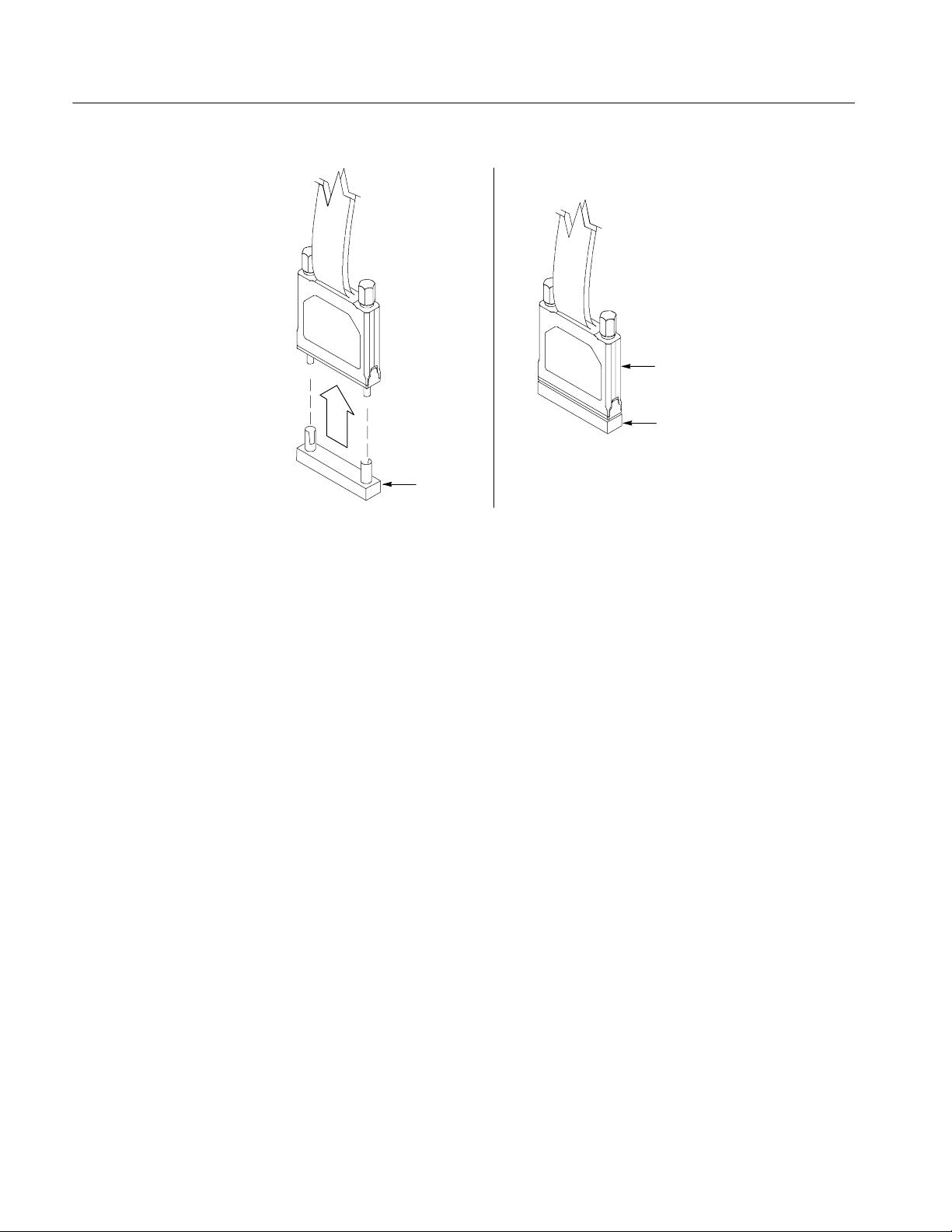

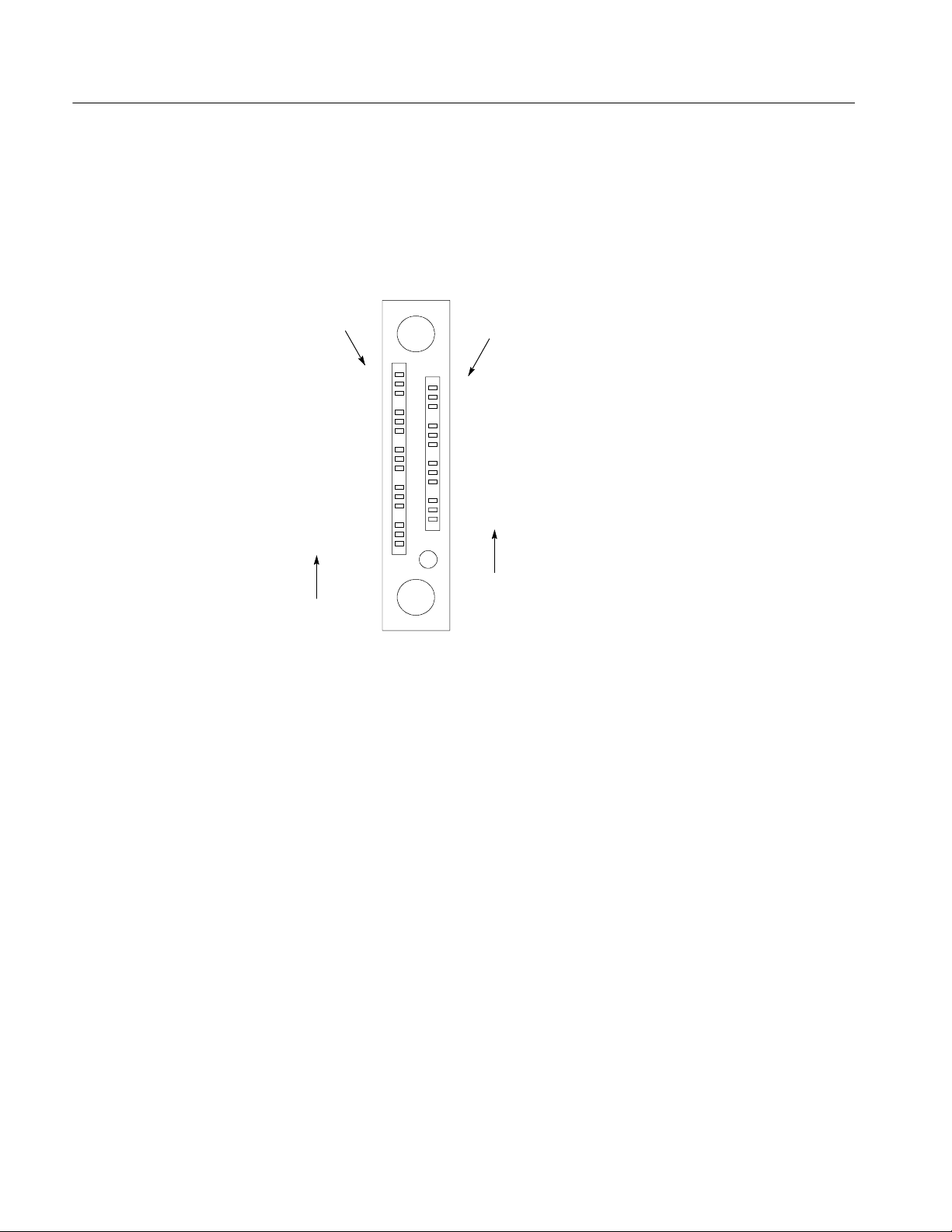

Storing the P6419 Probe Heads

Print pads

To protect the elastomer, it is important to properly store the probe heads when

the probes are not in use. While holding the probe end at a perpendicular angle to

the nut bar, loosely attach both probe head screws. For further details, see

Figure 8.

P6419 Logic Analyzer Probe Instructions

9

Page 22

Operating Basics

Safely store the

probe head

Nut bar

Nut bar

Figure 8: Storing the probe heads

Connecting the Probes to the Target System

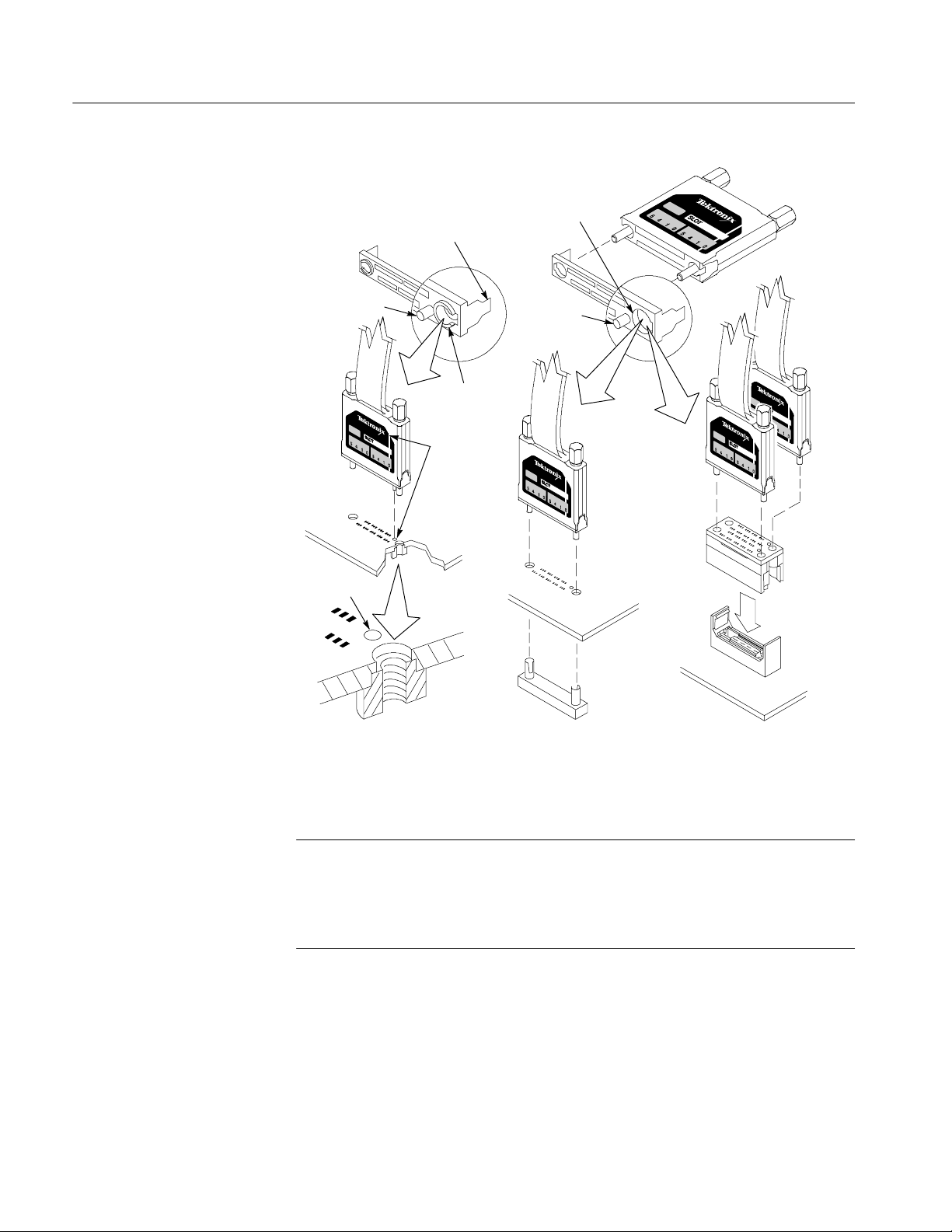

Connecting the P6419

High Density Probes

Connect the P6419 High-Density Probes (see Figure 10 on page 12) to the target

system. You can connect the probes to the target system without turning off the

power to the target system.

Installing the Correct Elastomer Holder. If the PCB is ≤.093 in, use the thin

elastomer holder with a nut bar. If the PCB is > .093, use the thick elastomer

holder with a press-in nut.

1. Nut Bar.

a. Press the nut bar backing plate into the two holes on the underside of the

compression footprint on the PCB.

b. Locate the keying pin on the probe end and align it to the keying pin

hole on the PCB.

c. While holding the probe end at a perpendicular angle to the PCB,

finger-tighten both probe head screws until snug, not to exceed 1 in-lbs.

You are encouraged to use a torque wrench to ensure proper tightness of

the probe head screws.

10

P6419 Logic Analyzer Probe Instructions

Page 23

Operating Basics

CAUTION. When attaching the probe head to the target system, you must use care

to evenly tighten probe head screws until they are snug. First tighten both screws

until the nut bar makes contact with the board surface, then snug each screw to 1

in-lbs (max). Under-tightening the probe head screws can result in intermittence.

Over-tightening can damage the elastomer holder and strip the screws.

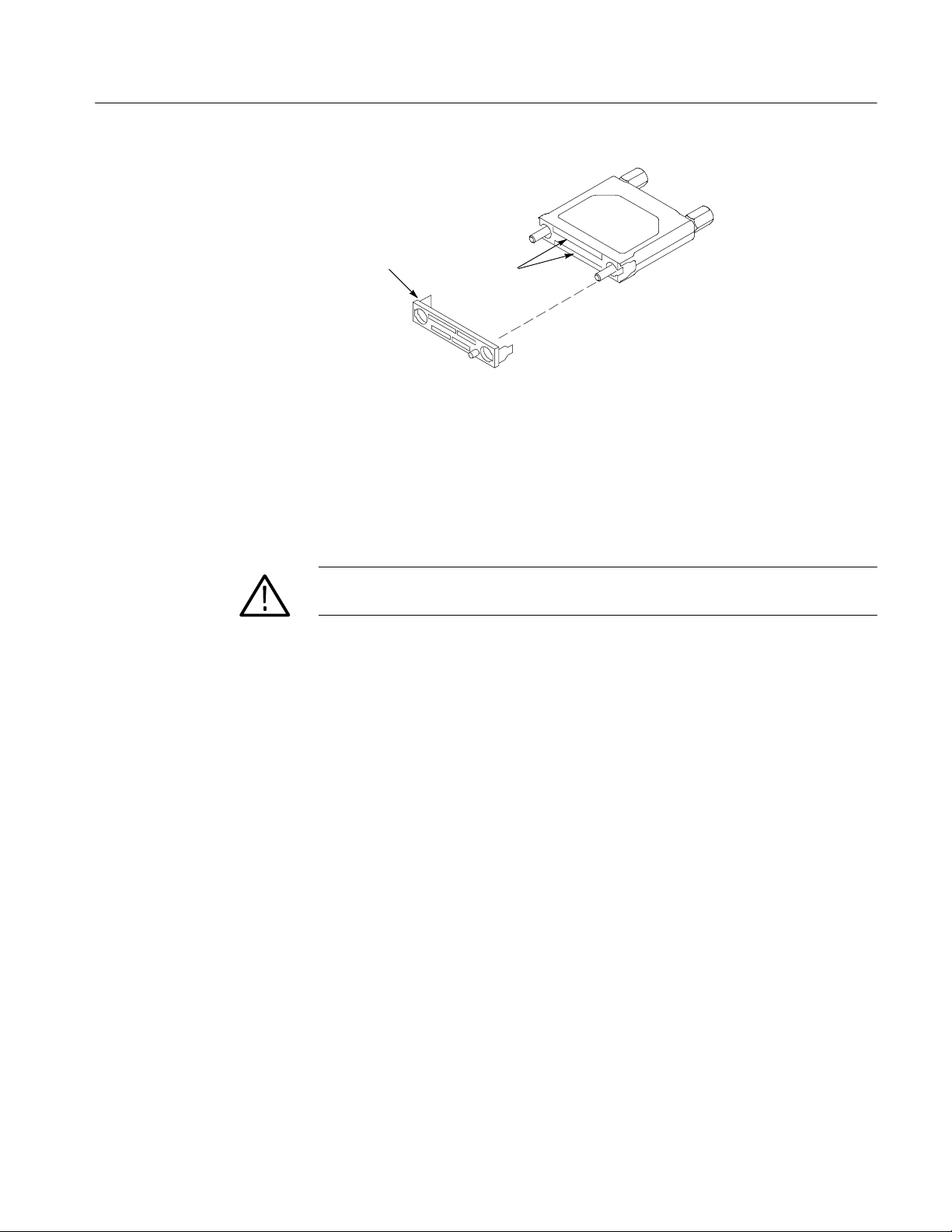

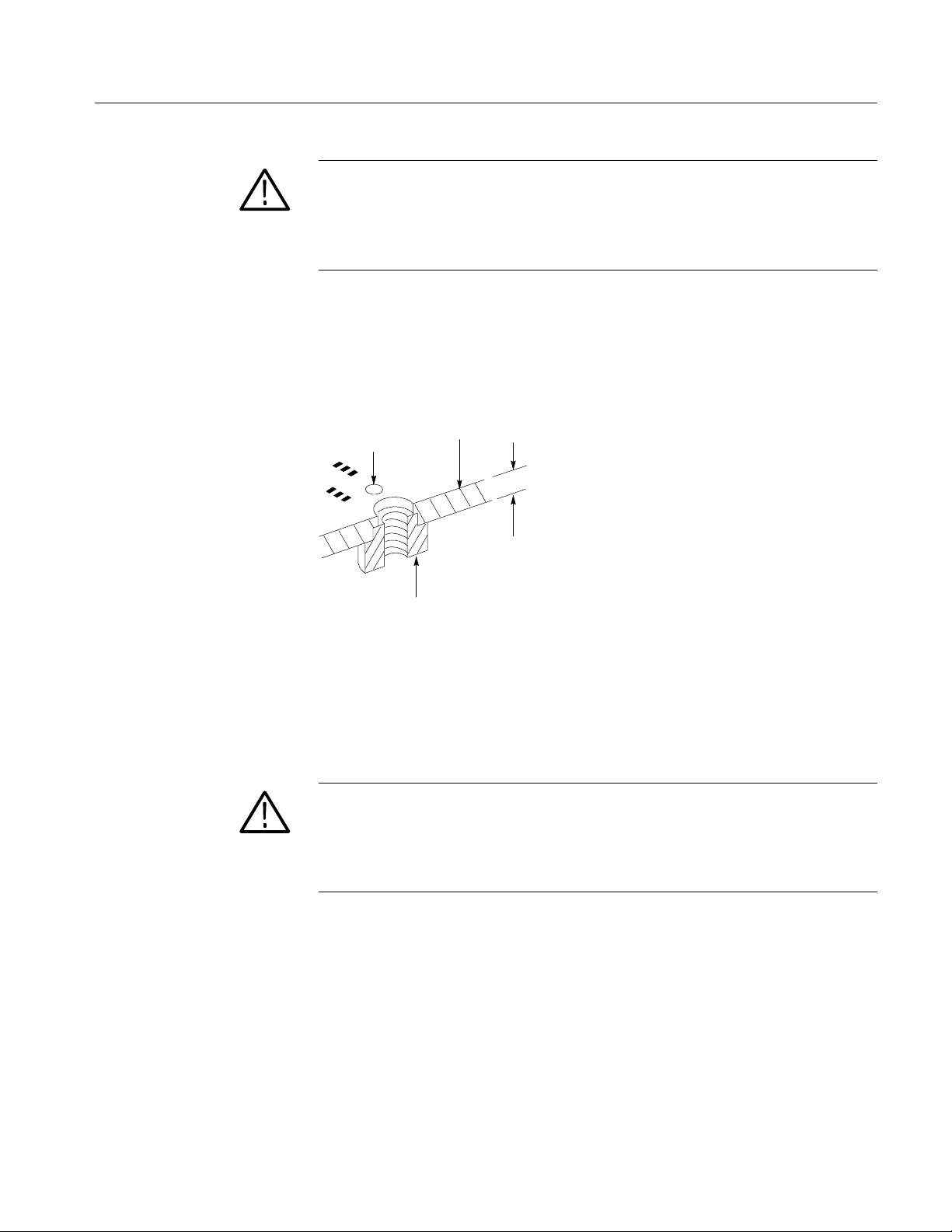

2. Press-in Nut.

a. Install the press-in nuts on the PCB by following the Manufacturer’s

installation procedure. Refer to Figure 9 for press-in nut installation

details.

Keying pin hole

Press--in nuts thread

type (2--56 UNC-2B)

Circuit board

Min 2.362 mm

to Max 6.35 mm

(0.093 in to

0.250 in)

Figure 9: Press-in Nuts installation

b. Locate the keying pin on the probe end and align it to the keying pin

hole on the PCB.

CAUTION. When attaching the probe head to the target system, you must use care

to evenly tighten probe head screws until they are snug. First slightly tighten

both screws, then snug each screw to 1 in-lbs (max). Under-tightening the probe

head screws can result in intermittence. Over-tightening can damage the

elastomer holder and strip the screws.

c. While holding the probe end at a perpendicular angle to the PC B, finger

P6419 Logic Analyzer Probe Instructions

tighten both probe head screws until snug, not to exceed 1 in-lbs. You

are encouraged to use a torque wrench to ensure proper tightness of the

probe head screws.

11

Page 24

Operating Basics

Note that elastomer

holder is keyed

Thin black,

(no rib)

Keying pin

Keying pin hole

Press--in nuts

Thick gray,

(rib)

White thin line

is keying pin

Keying pin

Nut bar

Mictor--on--PCB

12

Figure 10: Connecting the P6419 probe to the target system

NOTE. The Mictor-on-PCB adapter is labeled with J1 and J2 signal identifiers to

assist you with correctly locating each probe head on the adapter. Each probe

head label contains channel information that you compare with information

contained in the Signal Name column of Table 7 on page 23 to determine the

signal to which you connect the probe head.

P6419 Logic Analyzer Probe Instructions

Page 25

Operating Basics

Connecting the

Mictor-on-PCB to

Compression Adapter

The Mictor-on-PCB to compression adapter allows existing applications of older

logic analyzer modules and probes to connect to the compression footprint. You

can connect the adapter to the target system without turning off the target system.

Connect the adapter according to the following steps:

NOTE. Be sure to use a thin elastomer holder. The thin elastomer is black and

does not have the protruding rib (see Figure 10).

1. While holding the first probe end at a perpendicular angle to the adapter,

place the probe end into the adapter and finger-tighten the screws until snug,

not to exceed 1 in-lbs.

2. Connect the second probe end to the adapter in the same manner.

3. Press the connected probe ends and adapter into the existing Mictor

connector on the PCB.

This adapter supports standard Mictor connector footprints and signal connections on older logic analyzer designs.

The Mictor adapter adds 2.7 pF to the high-density compression probe load of

0.7 pF for a combined adapter and probe capacitance load of 3.4 pF.

Connecting the

Compression-on-PCB to

P6434 Mictor Adapter

The Compression-on-PCB to P6434 Mictor adapter (see Figure 3 on page 3)

allows you to connect the compression footprint to the Mictor connector pins

used by the P6434 Probe. You can connect the adapter to the target system

without turning off the target system. Connect the adapter according to the

following steps:

NOTE. To use this adapter, do not install press-in nuts. However if board

thickness is >.093 in, you will need to install press-in nuts before migrating to

P6419 probes.

1. Place the adapter at a perpendicular angle on top of the compression

footprint.

2. Place the backing plate on the underside of the PCB.

3. Connect the backing plate by sliding the two screws into the existing screw

holes from the underside of the PCB and finger-tighten the screws until

snug, not to exceed 1 in-lbs (typically, 1/2 in-lbs. You are encouraged to use

a torque wrench to ensure proper tightness of probe head screws.

P6419 Logic Analyzer Probe Instructions

13

Page 26

Operating Basics

CAUTION. When attaching the probe head to the target system, you must use care

to evenly tighten probe head screws until they are snug. First slightly tighten

both screws, then snug each screw to 1 in-lbs (max). Under-tightening the probe

head screws can result in intermittence. Over-tightening can damage the

elastomer holder and strip the screws.

4. Plug the P6434 Probe into the adapter.

Screws of two different lengths are provided to attach the adapter to your PCB.

The length of screw you need depends on the thickness of the P CB (0.050 in to

0.250 in).

This adapter requires use of the Compression-on-PCB to P6434 Mictor adapter

land footprint. For further dimensional information, refer to the Compression-onPCB to P6434 Mictor adapter land footprint (see Figure 15 on page 33).

14

P6419 Logic Analyzer Probe Instructions

Page 27

Reference

This section provides reference information and specifications for the P6419

high-density probe. Topics include the following:

H Designing an interface between the probe and a target system

H Specifications

Designing an Interface Between the P6419 Probe and a Target System

Once you have determined which probe is required, use the following information to design the appropriate connector into your target system board. The

following topics are in this section:

H Signal fixturing considerations

H Signal connections (signal names and land footprint)

H Mechanical considerations

H Electrical considerations

Signal Fixturing

Considerations

This section contains the following information to consider for signal fixturing:

H Clocks and qualifiers

H Merged modules and source synchronous clocking

H Demultiplexing multiplexed buses

H 2X high resolution timing modes (Internal 2X)

H 4X high resolution timing modes (Internal 4X -- TLA520x logic analyzer

mainframes only)

H Range recognition

Clocks and Qualifiers. Every logic analyzer has some special purpose input

channels. Inputs designated as clocks can cause the analyzer to store data.

Qualifier channels can be logically AND’ed and OR’ed with clocks to further

define when the analyzer should latch data from the system under test. Routing

the appropriate signals from our design to these inputs will ensure that the

analyzer can acquire data correctly.

P6419 Logic Analyzer Probe Instructions

15

Page 28

Reference

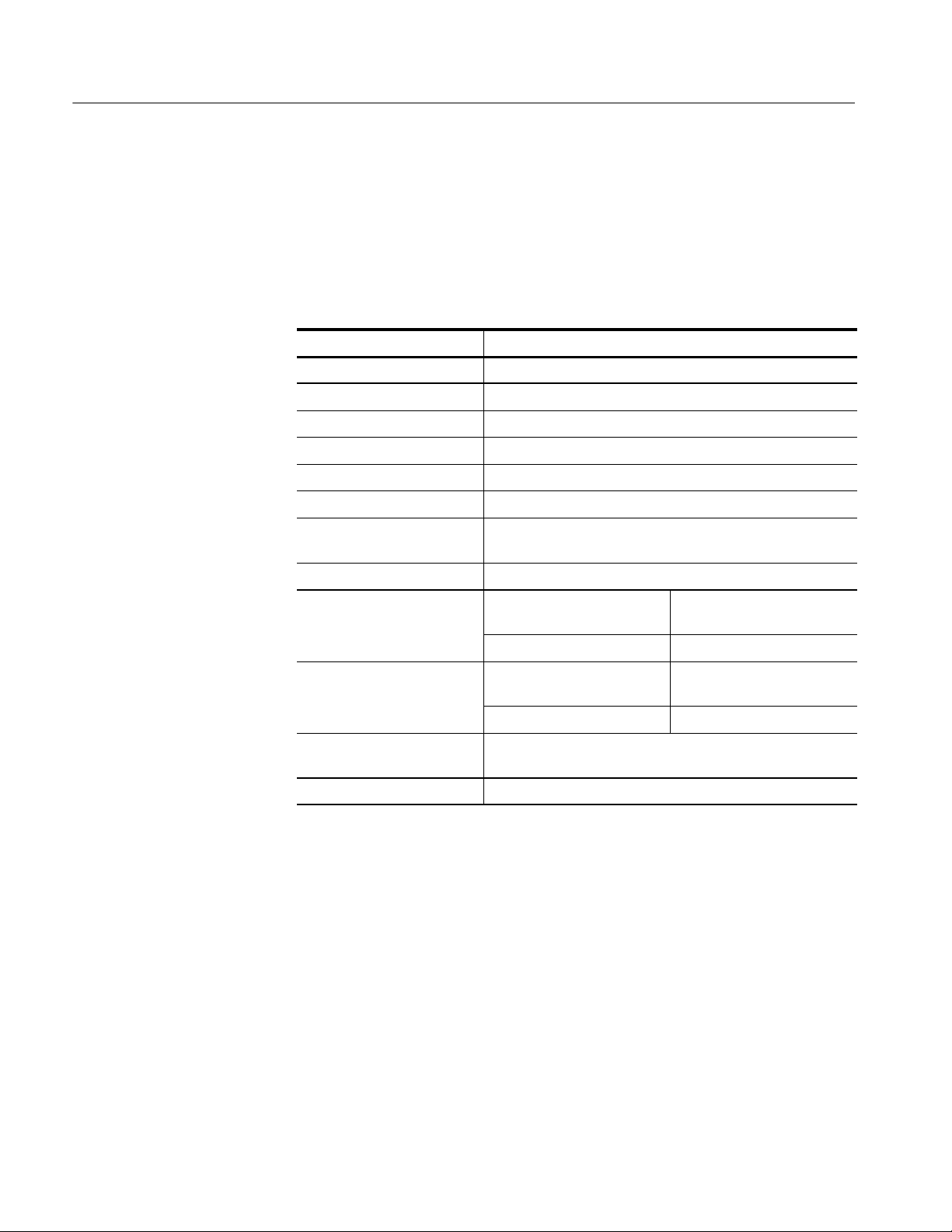

Depending on the channel width, each TLA520x mainframe, TLA6xx mainframe, and TLA7Lx/Mx/Nx/Px/Qx module will have a different set of clock and

qualifier channels. Table 2 shows the clock and qualifier channels available for

each instrument.

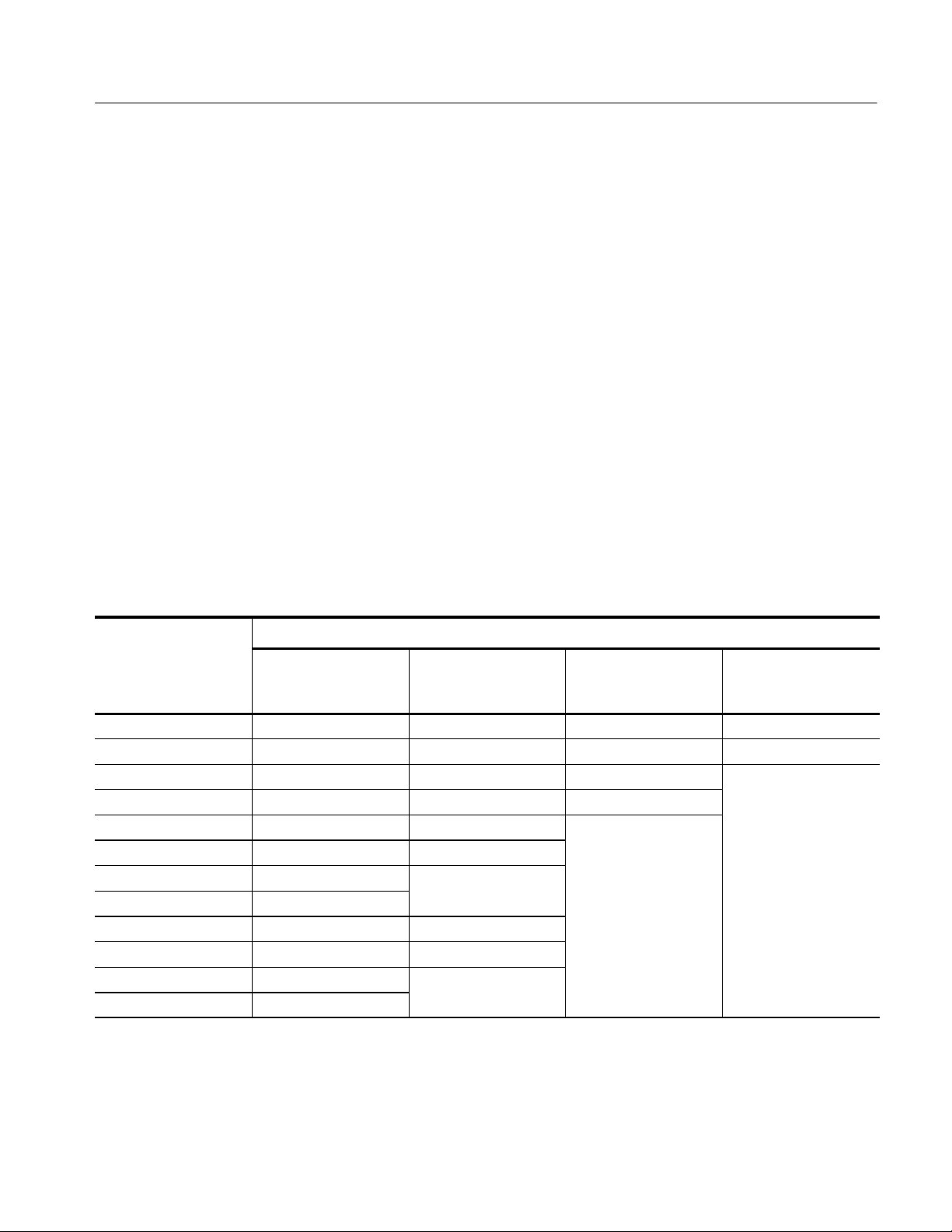

Table 2: Logic analyzer clock and qualifier availability

Clock Inputs Qualifier Inputs

TLA Mainframe

TLA5201

TLA7L1/M1/N1

TLA601/11/21

TLA5202

TLA7L2/M2/N2/P2/Q2

TLA602/12/22

TLA5203

TLA7L3/M3/N3

TLA602/13/23

TLA5204

TLA7L4/M4/N4/P4/Q4

TLA604/14/24

CLK:0

n n

n n n n

n n n n n n

n n n n n n n n

CLK:1 CLK:2 CLK:3 QUAL:0 QUAL:1 QUAL:2 QUAL:3

All clock and qualifier channels are stored. The analyzer stores the logic state of

these channels every time it latches data.

Since clock and qualifier channels are stored in the logic analyzer’smemory,

there is no need to double probe these signals for timing analysis. When

switching from state to timing analysis modes, all of the clock and qualifier

signals are visible. This also allows you to route regular signals, those not

needed for clocking, to these channels when they are not being used for their

special purpose.

16

It is good practice to take advantage of these channels to increase your options

for when you will latch data. Routing several of your design’s clocks and strobes

to the logic analyzer clock inputs provides you with greater flexibility in the

logic analyzer clocking setup menus.

As an example, look at a microprocessor with a master clock, data strobe, and an

address strobe. Routing all three of these signals to analyze clock inputs enables

you to latch data on the processor master clock, only when data is strobes or only

when address is strobed. Some forethought in signal routing can greatly expand

the ways in which you can latch and analyze data.

P6419 Logic Analyzer Probe Instructions

Page 29

Reference

A microprocessor also provides a good example of signals that can be useful as

qualifiers. There are often signals that indicate data reads versus data writes

(R/W), signals that show when alternate bus masters have control of the

processor buses (DMA), and signals that show when various memory devices are

being used (ChipSel). All of these signals are good candidates for assignment to

qualifier channels.

By logically AND’ing the clock with one of these qualifiers, you can program

the analyzer to store only data reads or data writes. Using the DMA signal as a

qualifier provides a means of filtering out alternate bus master cycles. Chip

selects can limit data latching to specific memory banks, I/O ports, or peripheral

devices.

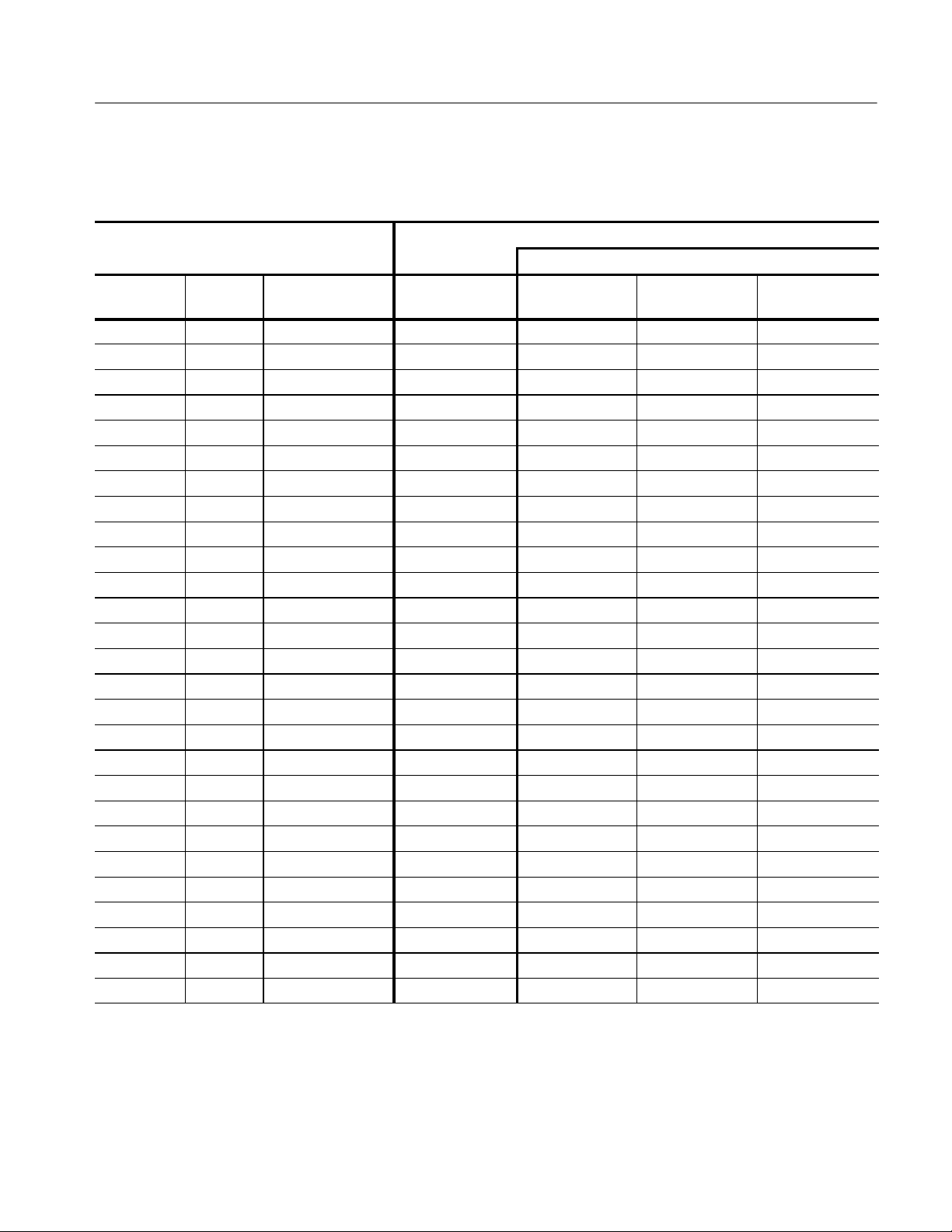

Demultiplexing Multiplexed Buses. TLA7Nx/Px/Qx modules and TLA6xx

mainframes support 2X demultiplexing. However, only TLA520x mainframes

support 4X demultiplexing. Each signal on a dual multiplexed bus can be

demultiplexed into its own logic analyzer channel. See Table 3 and Table 4 to

determine which channel groups to connect to feed channels in the target system

the test data.

Table 3: 2X Demultiplexing source-to-destination channel assignments

Source

connecting channel

groups

A3:7--0 D3:7--0 D3:7--0 C3:7--0 C3:7--0

A2:7--0 D2:7--0 D2:7--0 C2:7--0 C2:7--0

A1:7--0 D1:7--0 D1:7--0 D1:7--0

A0:7--0 D0:7--0 D0:7--0 D0:7--0

C3:7--0 C1:7--0 C1:7--0

C2:7--0 C0:7--0 C0:7--0

E3:7--0 E1:7--0

E2:7--0 E0:7--0

CLK:0 QUAL:1 QUAL:1

CLK:1 QUAL:0 QUAL:0

CLK:2 QUAL:3

CLK:3 QUAL:2

Destination channels receiving target system test data

TLA5204

TLA7N4/P4/Q4

TLA604/14/24

TLA5203

TLA7LN3

TLA602/13/23

TLA5202

TLA7LN2/P2/Q2

TLA602/12/22

TLA5201

TLA7N1

TLA601/11/21

P6419 Logic Analyzer Probe Instructions

17

Page 30

Reference

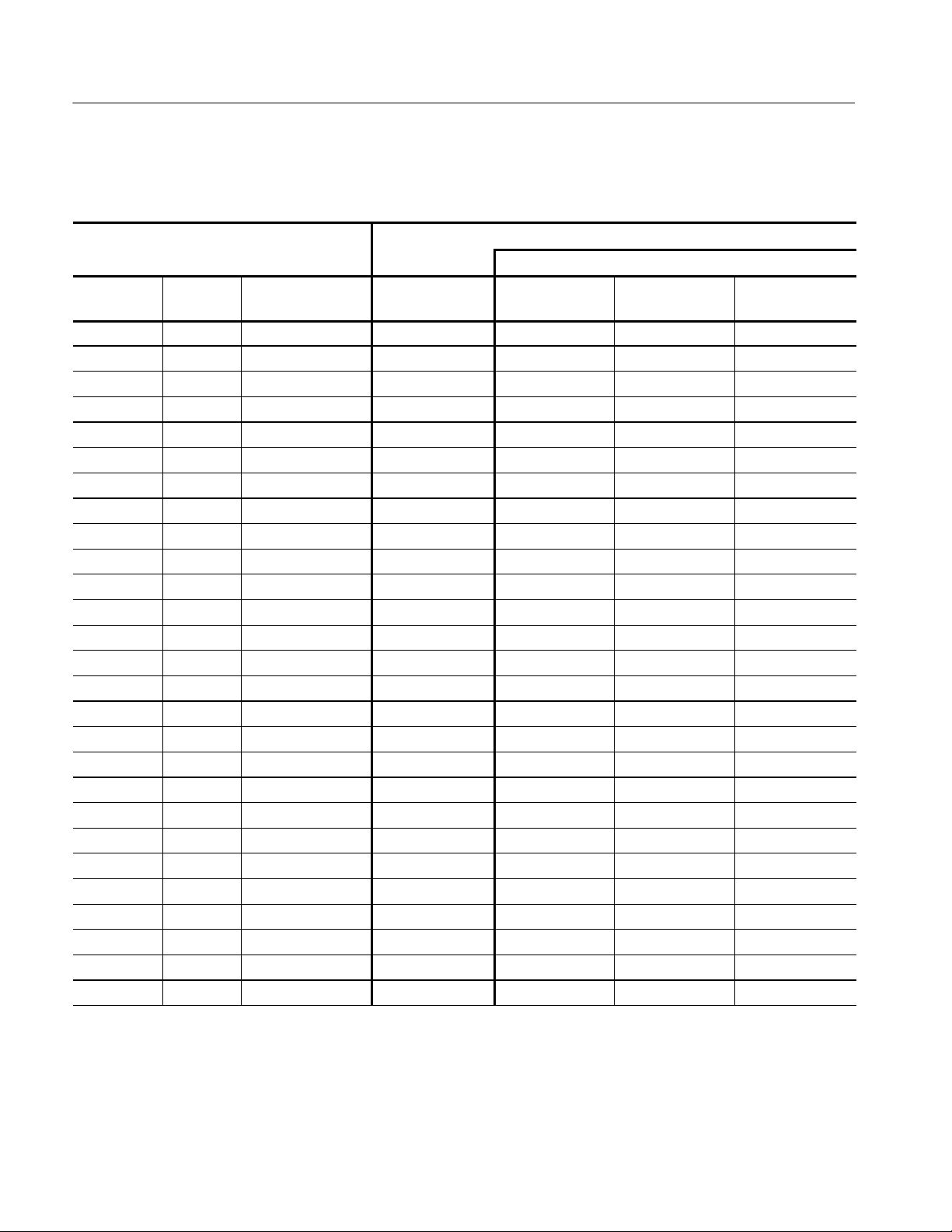

Table 4: 4X Demultiplexing source-to-destination channel assignments

Source

connecting channel

groups

C3:7--0 C2:7--0

A1:7--0 A0:7--0

A3:7--0 A2:7--0

E3:7--0 E2:7--0

CLK:3 CLK:2

CLK:1 CLK:0

Destination channels receiving target system test data

TLA5201

C1:7--0

C0:7--0

D1:7--0

D0:7--0

D3:7--0

D2:7--0

E1:7--0

E0:7--0

QUAL:3

QUAL:2

QUAL:1

QUAL:0

TLA5202 TLA5203 TLA5204

C2:7--0

C1:7--0

C0:7--0

A0:7--0

D1:7--0

D0:7--0

A2:7--0

D3:7--0

D2:7--0

CLK:0

QUAL:1

QUAL:0

A3:7--0

A2:7--0

C2:7--0

A0:7--0

D1:7--0

D0:7--0

A3:7--0

A2:7--0

C2:7--0

When demultiplexing data, there is no need to connect the destination channels

to the multiplexed bus. Data from the source channels are routed to the destination channels internal to the logic analyzer. Table 3 and Table 4 show the

mapping of source channels to destination channels.

18

Demultiplexing affects only the main memory for the destination channels. This

means that the MagniVu memory is filled with data from whatever is connected

to the demultiplexing destination channel probe inputs. This provides an

opportunity to acquire high resolution MagniVu data on a few extra channels.

Connecting the demultiplexing destination channels to other signals will allow

viewing of their activity in the MagniVu memory but not the main memory.

2X and 4X High Resolution Timing Modes. 2X high resolution timing mode

provides double the normal 500 MHz sample rate on one-half of the channels.

By trading half of the analyzers channels, the remaining channels can be sampled

at a 1 GHz rate with double the memory depth. 4X high resolution timing mode

provides quadruple the normal 500 MHz sample rate on one-fourth of the

channels. By trading three-fourths of the analyzer’s channels, the remaining

channels can be sampled at 2 GHz with quadruple the memory depth.

P6419 Logic Analyzer Probe Instructions

Page 31

Reference

Both of the high resolution timing modes use the same demultiplexing channel

routing as shown in Tables 3 and 4. By taking care to assign critical signals to

the demultiplexing source channels, you can obtain extra timing resolution where

most needed. Since demultiplexing affects only the main memory, you will still

have the MagniVu data available for all of the signals that are disconnected from

the main memory when you switch to the high resolution timing modes.

Range Recognition. When using range recognizers, the probe groups and probe

channels must be in hardware order. Probe groups must be used from the

most-significant probe group to the least-significant probe group based on the

following order:

C3 C2 C1 C0 E3 E2 E1 E0 A3 A2 D3 D2 A1 A0 D1 D0 Q3 Q2 Q1 Q0 CK3

CK2 CK1 CK0

Probe channels must be from the most-significant channel to the least-significant

channel, based on the following order:

76543210

Signal Names

The above examples apply to a 136-channel logic analyzer module. The missing

channels in LA modules with fewer than 136 channels are ignored. With merged

modules, range recognition extends across the first three modules: the master

module contains the most-significant channels.

See Tables 5 through 8 for the P6419 probe and adapter signal connections.

P6419 Logic Analyzer Probe Instructions

19

Page 32

Reference

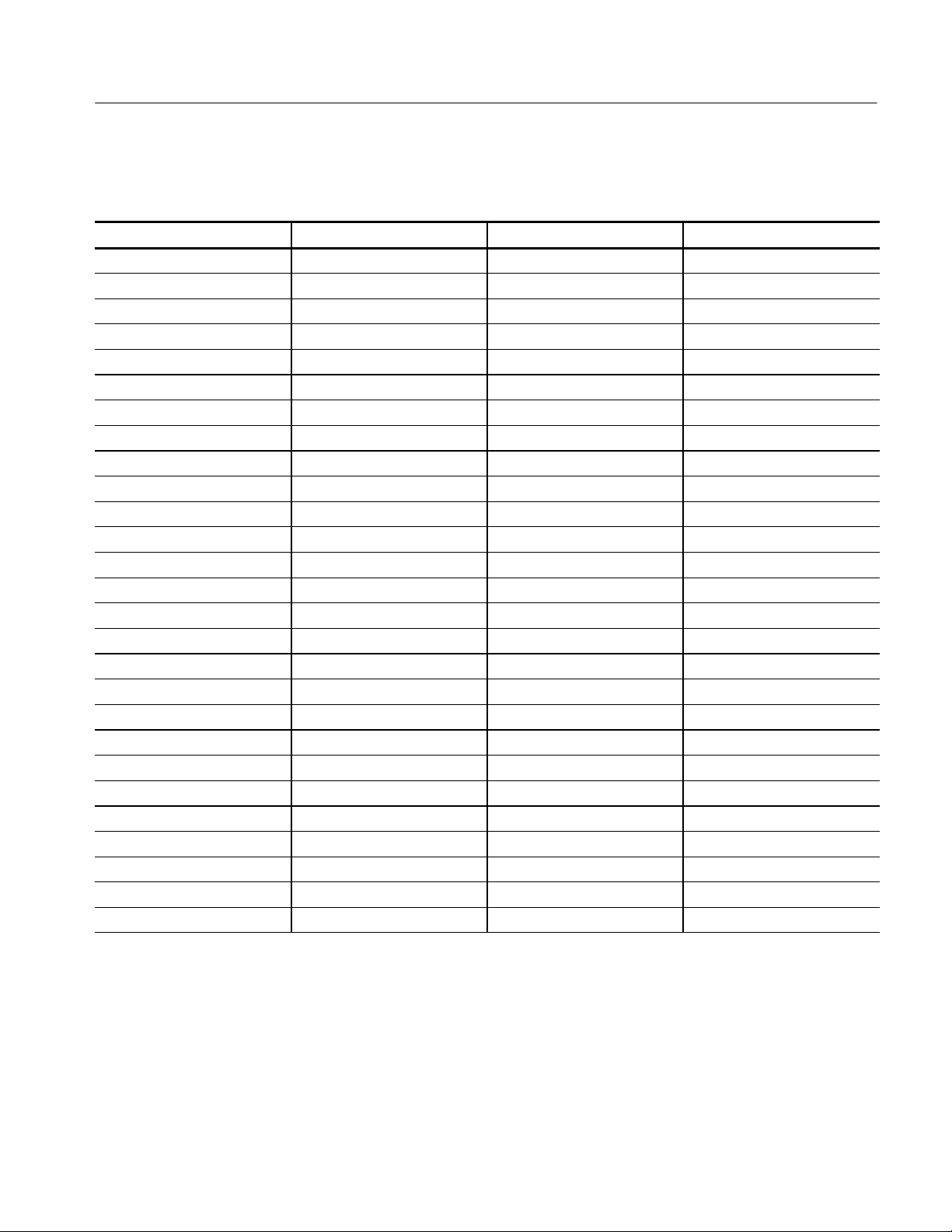

Table 5: P6419 High-Density Probe channel mapping on 136 and 102 channel TLA7Lx/Mx/Nx/Px/Qx modules and

both TLA6xx and TLA520x mainframes

Signal

name

Clk/Qual-- NC NC NC NC NC NC NC NC NC

GND A14 GND GND GND GND GND GND GND GND

Clk/Qual+ A13 Q3+ Q2+ CK0+ Q0+ CK1+ CK2+ CK3+ Q1+

Data 15 B12 E3:7 E1:7 A3:7 D3:7 A1:7 D1:7 C3:7 C1:7

GND B11 GND GND GND GND GND GND GND GND

Data 14 B10 E3:6 E1:6 A3:6 D3:6 A1:6 D1:6 C3:6 C1:6

Data 13 A12 E3:5 E1:5 A3:5 D3:5 A1:5 D1:5 C3:5 C1:5

GND A11 GND GND GND GND GND GND GND GND

Data 12 A10 E3:4 E1:4 A3:4 D3:4 A1:4 D1:4 C3:4 C1:4

Data 11 B9 E3:3 E1:3 A3:3 D3:3 A1:3 D1:3 C3:3 C1:3

GND B8 GND GND GND GND GND GND GND GND

Data 10 B7 E3:2 E1:2 A3:2 D3:2 A1:2 D1:2 C3:2 C1:2

Data 9 A9 E3:1 E1:1 A3:1 D3:1 A1:1 D1:1 C3:1 C1:1

GND A8 GND GND GND GND GND GND GND GND

Data 8 A7 E3:0 E1:0 A3:0 D3:0 A1:0 D1:0 C3:0 C1:0

Data 7 B6 E2:7 E0:7 A2:7 D2:7 A0:7 D0:7 C2:7 C0:7

GND B5 GND GND GND GND GND GND GND GND

Data 6 B4 E2:6 E0:6 A2:6 D2:6 A0:6 D0:6 C2:6 C0:6

Data 5 A6 E2:5 E0:5 A2:5 D2:5 A0:5 D0:5 C2:5 C0:5

GND A5 GND GND GND GND GND GND GND GND

Data 4 A4 E2:4 E0:4 A2:4 D2:4 A0:4 D0:4 C2:4 C0:4

Data 3 B3 E2:3 E0:3 A2:3 D2:3 A0:3 D0:3 C2:3 C0:3

GND B2 GND GND GND GND GND GND GND GND

Data 2 B1 E2:2 E0:2 A2:2 D2:2 A0:2 D0:2 C2:2 C0:2

Data 1 A3 E2:1 E0:1 A2:1 D2:1 A0:1 D0:1 C2:1 C0:1

GND A2 GND GND GND GND GND GND GND GND

Data 0 A1 E2:0 E0:0 A2:0 D2:0 A0:0 D0:0 C2:0 C0:0

Refer to Table 3 on page 17 for 2X demultiplexing channel assignments.

Pad

name

Probe Q3,

E3, E2

Probe Q2,

E1, E0

Probe

CK0, D3,

D2

Probe Q0,

D3, D2

Probe

CK1, A1,

A0

Probe

CK2, D1,

D0

Probe

CK3, C3,

C2

Probe Q1,

C1, C0

20

P6419 Logic Analyzer Probe Instructions

Page 33

Reference

Table 6: Recommended Compression-on-PCB to P6434 Mictor adapter and Mictor-on-PCB to Compression adapter

channel mapping for 136 and 102 channel modules

136 channel module

102 channel module

Signal name Pad name

Mictor pin number

J1 Clk/Qual-- A15 NC NC NC NC NC

GND A14 GND GND GND GND GND

J1 Clk/Qual+ A13 5 Q3 Q0 CK0 CK3

J1 Data 15 B12 7 E3:7 D3:7 A3:7 C3:7

GND B11 GND GND GND GND GND

J1 Data 14 B10 9 E3:6 D3:6 A3:6 C3:6

J1 Data 13 A12 11 E3:5 D3:5 A3:5 C3:5

GND A11 GND GND GND GND GND

J1 Data 12 A10 13 E3:4 D3:4 A3:4 C3:4

J1 Data 11 B9 15 E3:3 D3:3 A3:3 C3:3

GND B8 GND GND GND GND GND

J1 Data 10 B7 17 E3:2 D3:2 A3:2 C3:2

J1 Data 9 A9 19 E3:1 D3:1 A3:1 C3:1

GND A8 GND GND GND GND GND

J1 Data 8 A7 21 E3:0 D3:0 A3:0 C3:0

J1 Data 7 B6 23 E2:7 D2:7 A2:7 C2:7

GND B5 GND GND GND GND GND

J1 Data 6 B4 25 E2:6 D2:6 A2:6 C2:6

J1 Data 5 A6 27 E2:5 D2:5 A2:5 C2:5

GND A5 GND GND GND GND GND

J1 Data 4 A4 29 E2:4 D2:4 A2:4 C2:4

J1 Data 3 B3 31 E2:3 D2:3 A2:3 C2:3

GND B2 GND GND GND GND GND

J1 Data 2 B1 33 E2:2 D2:2 A2:2 C2:2

J1 Data 1 A3 35 E2:1 D2:1 A2:1 C2:1

GND A2 GND GND GND GND GND

J1 Data 0 A1 37 E2:0 D2:0 A2:0 C2:0

Adapter #4/

probe head #4

Adapter #3/

probe head #3

Adapter #2/

probe head #2

Adapter #1/

probe head #1

P6419 Logic Analyzer Probe Instructions

21

Page 34

Reference

Table 6: Recommended Compression-on-PCB to P6434 Mictor adapter and Mictor-on-PCB to Compression adapter

channel mapping for 136 and 102 channel modules (Cont.)

136 channel module

102 channel module

Signal name Adapter #1/

J2 Clk/Qual-- A15 NC NC NC NC NC

GND A14 GND GND GND GND GND

J2 Clk/Qual+ A13 6 Q2 CK2 CK1 Q1

J2 Data 15 B12 8 E1:7 D1:7 A1:7 C1:7

GND B11 GND GND GND GND GND

J2 Data 14 B10 10 E1:6 D1:6 A1:6 C1:6

J2 Data 13 A12 12 E1:5 D1:5 A1:5 C1:5

GND A11 GND GND GND GND GND

J2 Data 12 A10 14 E1:4 D1:4 A1:4 C1:4

J2 Data 11 B9 16 E1:3 D1:3 A1:3 C1:3

GND B8 GND GND GND GND GND

J2 Data 10 B7 18 E1:2 D1:2 A1:2 C1:2

J2 Data 9 A9 20 E1:1 D1:1 A1:1 C1:1

GND A8 GND GND GND GND GND

J2 Data 8 A7 22 E1:0 D1:0 A1:0 C1:0

J2 Data 7 B6 24 E0:7 D0:7 A0:7 C0:7

GND B5 GND GND GND GND GND

J2 Data 6 B4 26 E0:6 D0:6 A0:6 C0:6

J2 Data 5 A6 28 E0:5 D0:5 A0:5 C0:5

GND A5 GND GND GND GND GND

J2 Data 4 A4 30 E0:4 D0:4 A0:4 C0:4

J2 Data 3 B3 32 E0:3 D0:3 A0:3 C0:3

GND B2 GND GND GND GND GND

J2 Data 2 B1 34 E0:2 D0:2 A0:2 C0:2

J2 Data 1 A3 36 E0:1 D0:1 A0:1 C0:1

GND A2 GND GND GND GND GND

J2 Data 0 A1 38 E0:0 D0:0 A0:0 C0:0

Refer to Table 3 on page 17 for 2X demultiplexing channel assignments.

Pad name

Mictor pin number

Adapter #4/

probe head #4

Adapter #3/

probe head #3

Adapter #2/

probe head #2

probe head #1

Any differential input, either the differential clock/qualifiers or the P6419 high-density probe, may have its negative input

pin grounded and be used as a single-ended input.

22

P6419 Logic Analyzer Probe Instructions

Page 35

Reference

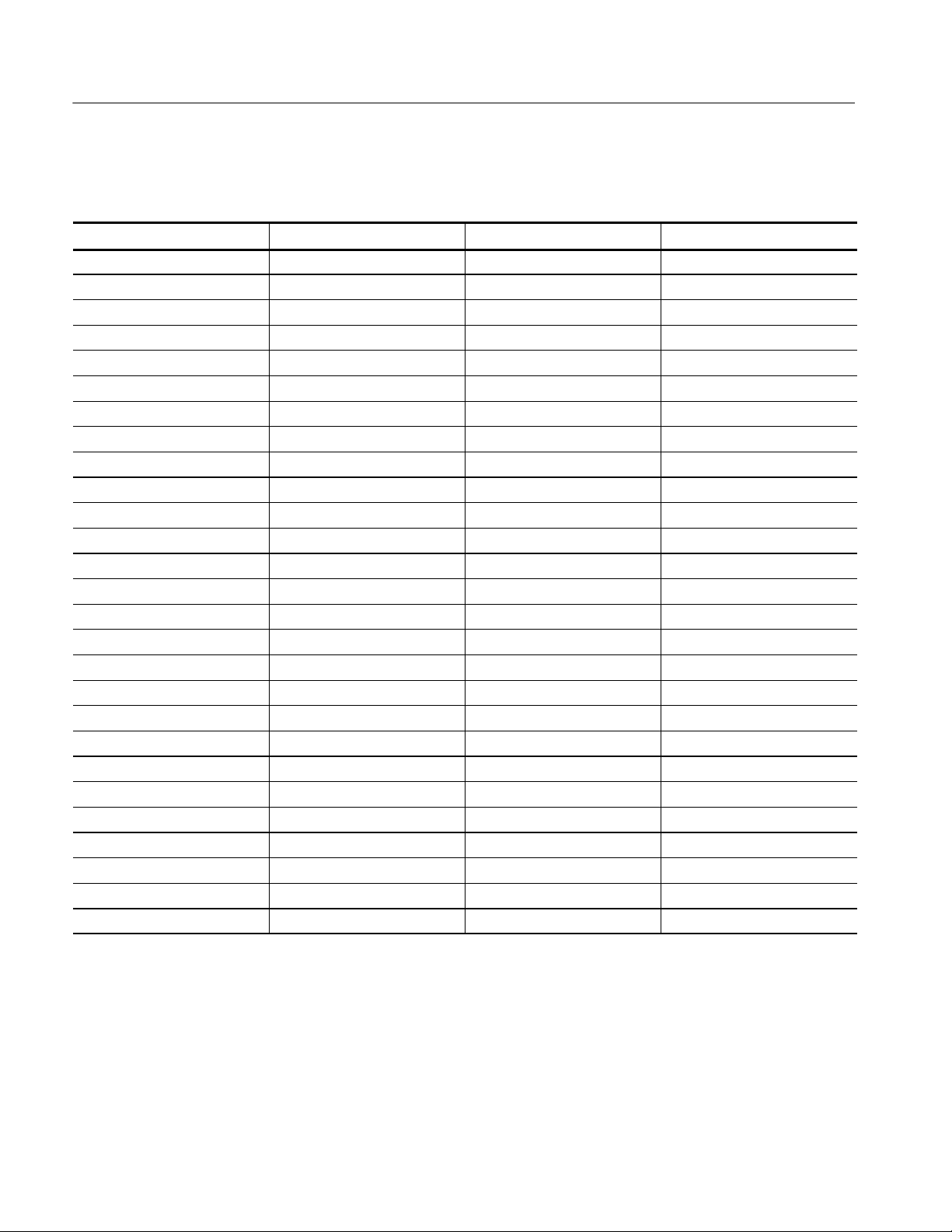

Table 7: Recommended Compression-on-PCB to P6434 Mictor adapter and Mictor-on-PCB to Compression adapter

channel mapping for 68 channel module

Signal name Pad name Mictor pin num ber Adapter #1/

probe head #1

J1 Clk/Qual-- A15 NC NC NC

GND A14 GND GND GND

J1 Clk/Qual+ A13 5 CK0 CK3

J1 Data 15 B12 7 A3:7 C3:7

GND B11 GND GND GND

J1 Data 14 B10 9 A3:6 C3:6

J1 Data 13 A12 11 A3:5 C3:5

GND A11 GND GND GND

J1 Data 12 A10 13 A3:4 C3:4

J1 Data 11 B9 15 A3:3 C3:3

GND B8 GND GND GND

J1 Data 10 B7 17 A3:2 C3:2

J1 Data 9 A9 19 A3:1 C3:1

GND A8 GND GND GND

J1 Data 8 A7 21 A3:0 C3:0

J1 Data 7 B6 23 A2:7 C2:7

GND B5 GND GND GND

J1 Data 6 B4 25 A2:6 C2:6

J1 Data 5 A6 27 A2:5 C2:5

GND A5 GND GND GND

J1 Data 4 A4 29 A2:4 C2:4

J1 Data 3 B3 31 A2:3 C2:3

GND B2 GND GND GND

J1 Data 2 B1 33 A2:2 C2:2

J1 Data 1 A3 35 A2:1 C2:1

GND A2 GND GND GND

J1 Data 0 A1 37 A2:0 C2:0

Adapter #2/

probe head #1

P6419 Logic Analyzer Probe Instructions

23

Page 36

Reference

Table 7: Recommended Compression-on-PCB to P6434 Mictor adapter and Mictor-on-PCB to Compression adapter

channel mapping for 68 channel module (Cont.)

Signal name Adapter #2/

J2 Clk/Qual+ A15 NC NC NC

GND A14 GND GND GND

J2 Clk/Qual+ A13 6 CK1 CK2

J2 Data 15 B12 8 A1:7 D1:7

GND B11 GND GND GND

J2 Data 14 B10 10 A1:6 D1:6

J2 Data 13 A12 12 A1:5 D1:5

GND A11 GND GND GND

J2 Data 12 A10 14 A1:4 D1:4

J2 Data 11 B9 16 A1:3 D1:3

GND B8 GND GND GND

J2 Data 10 B7 18 A1:2 D1:2

J2 Data 9 A9 20 A1:1 D1:1

GND A8 GND GND GND

J2 Data 8 A7 22 A1:0 D1:0

J2 Data 7 B6 24 A0:7 D0:7

GND B5 GND GND GND

J2 Data 6 B4 26 A0:6 D0:6

J2 Data 5 A6 28 A0:5 D0:5

GND A5 GND GND GND

J2 Data 4 A4 30 A0:4 D0:4

J2 Data 3 B3 32 A0:3 D0:3

GND B2 GND GND GND

J2 Data 2 B1 34 A0:2 D0:2

J2 Data 1 A3 36 A0:1 D0:1

GND A2 GND GND GND

J2 Data 0 A1 38 A0:0 D0:0

1/2 channel mode may use Adapter #1 connection signals as source.

Mictor pin numberPad name

Adapter #1/

probe head #1

probe head #1

Refer to Table 3 on page 17 for 2X demultiplexing channel assignments.

Any differential input, either the differential clock/qualifiers or the P6419 high-density probe, may have its negative input

pin grounded and be used as a single-ended input.

24

P6419 Logic Analyzer Probe Instructions

Page 37

Reference

Table 8: Recommended Compression-on-PCB to P6434 Mictor adapter and Mictor-on-PCB to Compression adapter

channel mapping for 34 channel module

Signal name Pad name Mictor pin number Adapter #1/probe head #1

J1 Clk/Qual-- A15 NC NC

GND A14 GND GND

J1 Clk/Qual+ A13 5 CK3

J1 Data 15 B12 7 C3:7

GND B11 GND GND

J1 Data 14 B10 9 C3:6

J1 Data 13 A12 11 C3:5

GND A11 GND GND

J1 Data 12 A10 13 C3:4

J1 Data 11 B9 15 C3:3

GND B8 GND GND

J1 Data 10 B7 17 C3:2

J1 Data 9 A9 19 C3:1

GND A8 GND GND

J1 Data 8 A7 21 C3:0

J1 Data 7 B6 23 C2:7

GND B5 GND GND

J1 Data 6 B4 25 C2:6

J1 Data 5 A6 27 C2:5

GND A5 GND GND

J1 Data 4 A4 29 C2:4

J1 Data 3 B3 31 C2:3

GND B2 GND GND

J1 Data 2 B1 33 C2:2

J1 Data 1 A3 35 C2:1

GND A2 GND GND

J1 Data 0 A1 37 C2:0

P6419 Logic Analyzer Probe Instructions

25

Page 38

Reference

Table 8: Recommended Compression-on-PCB to P6434 Mictor adapter and Mictor-on-PCB to Compression adapter

channel mapping for 34 channel module (Cont.)

Signal name Adapter #1/probe head #1Mictor pin numberPad name

J2 Clk/Qual+ A15 NC NC

GND A14 GND GND

J2 Clk/Qual+ A13 6 CK0

J2 Data 15 B12 8 A3:7

GND B11 GND GND

J2 Data 14 B10 10 A3:6

J2 Data 13 A12 12 A3:5

GND A11 GND GND

J2 Data 12 A10 14 A3:4

J2 Data 11 B9 16 A3:3

GND B8 GND GND

J2 Data 10 B7 18 A3:2

J2 Data 9 A9 20 A3:1

GND A8 GND GND

J2 Data 8 A7 22 A3:0

J2 Data 7 B6 24 A2:7

GND B5 GND GND

J2 Data 6 B4 26 A2:6

J2 Data 5 A6 28 A2:5

GND A5 GND GND

J2 Data 4 A4 30 A2:4

J2 Data 3 B3 32 A2:3

GND B2 GND GND

J2 Data 2 B1 34 A2:2

J2 Data 1 A3 36 A2:1

GND A2 GND GND

J2 Data 0 A1 38 A2:0

Refer to Table 3 on page 17 for 2X demultiplexing channel assignments.

Any differential input, either the differential clock/qualifiers or the P6419 high-density probe, may have its negative input

pin grounded and be used as a single-ended input.

26

P6419 Logic Analyzer Probe Instructions

Page 39

Reference

Special Considerations for the Adapters. Consider the following issue when you

use either the Compression-on-PCB to P6434 Mictor adapter or the Mictor-on-PCB to Compression adapters:

H Use of the Compression-on-PCB to P6434 Mictor and Mictor-on-PCB to

Compression adapters on existing 68 and 34 channel embedded configurations and supports may require exchanging the P6419 Probe heads or P6434

module connector ends to accommodate all older Tektronix logic analyzer

signal connection alternatives.

Land Footprints

The following section shows the land footprints for the P6419 probe. The figures

contain the signal to land pattern assignments.

P6419 Logic Analyzer Probe Instructions

27

Page 40

Reference

P6419 Probe Land Footprint. See Figure 11 for the land footprint for the P6419

High-Density Probe. See Figure 12 for an example of the high-density probe

land footprint in a typical pass-through signal path layout configuration. This

type of configuration optimizes minimal probe loading. Figure 13 contains

example layouts of the high-density compression and mictor land footprints.

Pad

name

N/C

GND

CLK+

D13

GND

D12

D9

GND

D8

D5

GND

D4

D1

GND

D0

A15

A14

A13

A12

A11

A10

A9

A8

A7

A6

A5

A4

A3

A2

A1

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

Pad

name

D15

GND

D14

D11

GND

D10

D7

GND

D6

D3

GND

D2

Signal

Signal

name

name

Probe Head

Figure 11: P6419 High-Density probe land footprint

28

P6419 Logic Analyzer Probe Instructions

Page 41

Reference

Signal Name Pad Name

N/C A15

CLK/Qual+ A13

Data15 B12 GND B11

Data14 B10

Data13 A12 GND A11

Data12 A10

Data11 B9 GND B8

Data10 B7

Data9 A9 GND A8

Data8 A7

Data7 B6 GND B5

Data6 B4

Data5 A6 GND A5

Data4 A4

Data3 B3 GND B2

Data2 B1

Data1 A3 GND A2

Data 0 (LSB) A1

Signal Name Pad Name

GND A14

Figure 12: High-Density probe land footprint in a typical pass-through signal path

layout configuration

Figure 13: Example layout of the High-Density compression compared to the mictor

land footprints

P6419 Logic Analyzer Probe Instructions

29

Page 42

Reference

Mechanical

Considerations

This section provides information on compression land footprint requirements

and physical attachment requirements.

The PCB holes, in general, do not have an impact upon the integrity of your

signals. Signal integrity impact is eliminated when the signals you route around

the holes have the corresponding return current plane immediately below the

signal trace (for the entire signal path from driver to receiver).

NOTE. For optimum signal integrity, there should be a continuous, uninterrupted

ground return plane along the entire signal path.

Land Footprint Requirements for P6419 Probes. See Figure 14 for the compression land footprint requirements for P6419 probes.

30

P6419 Logic Analyzer Probe Instructions

Page 43

32.13 mm

(1.265 in)

Reference

6.25 mm (0.250 in) X 32.13 mm (1.265 in)

Frontside component keepout area

6.35 mm

(0.250 in)

6.25 mm (0.250-in) X 32.13 mm (1.265-in)

backside component keepout area for Nut Bar

version, press-in nut clearance only required

0.25 mm (0.010 in)

4X 1.16 mm (0.046 in)

5X 1.16 mm (0.046 in)

on press--in nut version

3X 0.81 mm (0.032 in)

3X 0.41 mm (0.016 in)

25.65 mm (1.010 in)

22.81 mm (0.898 in)

21.49 mm (0.846 in)

6.50 mm (0.256 in)

3.68 mm (0.145 in)

8.51 mm (0.335 in)

12.17 mm (0.479 in)

15.82 mm (0.623 in)

19.48 mm (0.767 in)

13.49 mm (0.531 in)

9.83 mm (0.387 in)

17.15 mm (0.675 in)

20.80 mm (0.819 in )

6.17 mm (0.243 in)

4.17 mm (0.164 in)

1.70 mm (0.067 in) diameter

2X 3.50 mm (0.138 in) diameter

thin PCB with nut bar

3.18 mm (0.125 in)

1.14 mm (0.045 in)

.000

3.18 mm (0.125 in)

2X 3.73 mm (0.147 in) diameter

thick PCB with press in nut

0.000

3.25 mm (0.128 in)

* 2X 5.72 mm (0.225 in)

diameter external layers

* 2X 4.57 mm (0.180 in)

diameter external layers

0.25 mm (0.010 in)

.000

Position B12

0.91 mm (0.036 in)

All dimensions are per standard IPC

tolerance, which is ᐔ0.004

0.91 mm (0.036 in)

Position A15

Figure 14: Land footprint requirements for P6419 probes (t op view)

P6419 Logic Analyzer Probe Instructions

* The need for additional keepout area depends on

the requirements of both your PCB manufacturer and

your outsourced PCB assembly manufacturer.

Position B1

Via Keepout

White silk--screen bar to indicate

directional keying hole (easier

orientation identification)

Probe body keepout

Position A1

31

Page 44

Reference

Special Considerations

WARNING. To avoid personal injury due to electric shock, always turn off the

power on your target system before cleaning the compression footprint.

H Cleanliness is important for a reliable connection. Refer to Cleaning the

P6419 Compression Footprints, located on page 8.

H Line boxes around the pin groupings are the via keepout areas (not part of

the actual land footprint).

H Solder mask is required between all land pads in the component keepout

area.

H Maintain PCB and solder mask tolerances for all signal runs in the keepout

areas to ensure that no exposed runs or metal exist between pads. This

prevents shorted signal runs.

H Solder mask hardness of at least 8H (pencil hardness) and thickness of at

least 0.0762 mm to 0.1270 mm (0.0003 to 0.0005 in) has been verified for

several hundred cycles without appreciable wear from the compression

contact cycling.

H The compression land footprint design was verified on the immersion gold

process.

Land Footprint Requirements for the Compression-on-PCB to P6434 Mictor

Adapter. See Figure 15 for the land footprint requirements for the Compression-

on-PCB to P6434 Mictor adapter. This compression adapter converts from the

new compression footprint to the existing P6434 Mictor-based 34-channel probe.

Refer to the P6434 Mass Termination Probe Manual for the Mictor land

footprint specification. Refer to Table 6 for the recommended channel mappings

for the Compression-on-PCB to P6434 Mictor adapter and Mictor-on-PCB to

Compression adapter.

32

P6419 Logic Analyzer Probe Instructions

Page 45

32.13 mm

(1.265 in)

Reference

J2

13.72 mm

(0.540 in) Total

Keepout

J1

6.60 mm

(0.260 in)

Figure 15: Land footprint requirements for the Compression-on-PCB to P6434

Mictor adapter

Special Considerations

H Two compression land footprints must be spaced as per the mechanical

dimensions specified to support the compression adapter.

H Placement of the compression land footprints is only constrained with use of

the compression adapter, not in normal usage of the TLA7Nx/Px/Qx logic

analyzer module, the TLA600 series mainframes, or the TLA5000 series

mainframes with a high-density probe.

H The P6434 Probe and older logic analyzer modules do not support differen-

tial signals. Therefore, the compression adapter cannot be used to support

differential signals beyond capturing each side of the differential signal

independently in a single-ended manner. Note that the connection to the

CLK/QUAL signal is only connected to the positive side of the signal.

H The compression adapter will add capacitance to the P6434 probe input

capacitance. The Mictor adapter adds 2.7 pF to the high-density compression

probe load of 0.7 pF for a combined adapter capacitance load of 3.4 pF.

H The TLA7Lx/Mx/Nx/Px/Qx logic analyzer module, TLA600 series

mainframe, and TLA5000 series mainframe with a P6419 High-Density

Probe will connect directly to the compression land footprint to support high

performance data capture and viewing needs.

Physical Attachment Requirements for P6419 probes. The connector-less P6419

High-Density Probe interconnects are designed to accommodate PCB thickness

ranging from 1.27 mm to 6.35 mm (0.050 in to 0.250 in). To accommodate this

range, there are two versions of the design:

H Nut bar

H Press-in nut

P6419 Logic Analyzer Probe Instructions

33

Page 46

Reference

If the PCB thickness is 1.27 mm to 2.36 mm (0.050 in to 0.093 in), use the nut

bar with the thin elastomer (see Figure 16).

If the PCB thickness is 2.36 mm to 6.35 mm (0.093 in to 0.250 in), use the

press-in nut with the thick elastomer (see Figure 17).

38.40 mm

(1.512 in)

2.36 mm (0.093 in)

1.27 mm (0.050 in)

PCB Thickness

4.953 mm

Nut Bar backing

plate

(0.195 in)

Figure 16: Nut bar design

Special Considerations for the Nut Bar Design

H The nut bar backing plate is required to maintain PCB flatness, which

supports the compression connection.

H The nut bar snaps in and out of the PCB without the use of tools.

H Nut bars are reusable and are not required to be a permanent part of the PCB.

H The elastomer is independent and replaceable.

H Additional nut bars and both thick and thin elastomer holders may be

ordered from Tektronix.

34

P6419 Logic Analyzer Probe Instructions

Page 47

1.651 mm

(0.065 in)

Figure 17: Press-in Nut design

Reference

6.35 mm (0.250 in)

2.36 mm (0.093 in)

PCB Thickness

Electrical Considerations

Special Considerations for the Press-in Nut Design

H The PEM

KF2 2-56 or equivalent press-in nut must be inserted into the

PCB.

H The elastomer is independent and replaceable.

Physical Attachment Requirements for the Compression-on-PCB to P6434 Mictor

and Mictor-on-PCB to Compression Adapters. See Figure 3 on page 3 for the

mechanical dimensions of the adapters.

This section provides information on transmission lines and load models for the

P6419 High-Density Probes.

The low frequency model is typically adequate for rise and fall times of 1 ns or

greater in a typical 25 Ω source impedance environment (50 Ω runs with 50 Ω

terminations on the line). For source impedance outside this range, and/or rise

and fall times less than 1 ns, use the high frequency model to determine if a

significant difference is obtained in the modeling result.

The compression land pattern pad is not part of the load model. Make sure that

you include the compression land pad in the modeling.

Transmission Lines. Due to the high performance nature of the interconnect,

ensure that stubs, which are greater than 1/4 length of the signal rise time, are

modeled as transmission lines.

P6419 Logic Analyzer Probe Instructions

35

Page 48

Reference

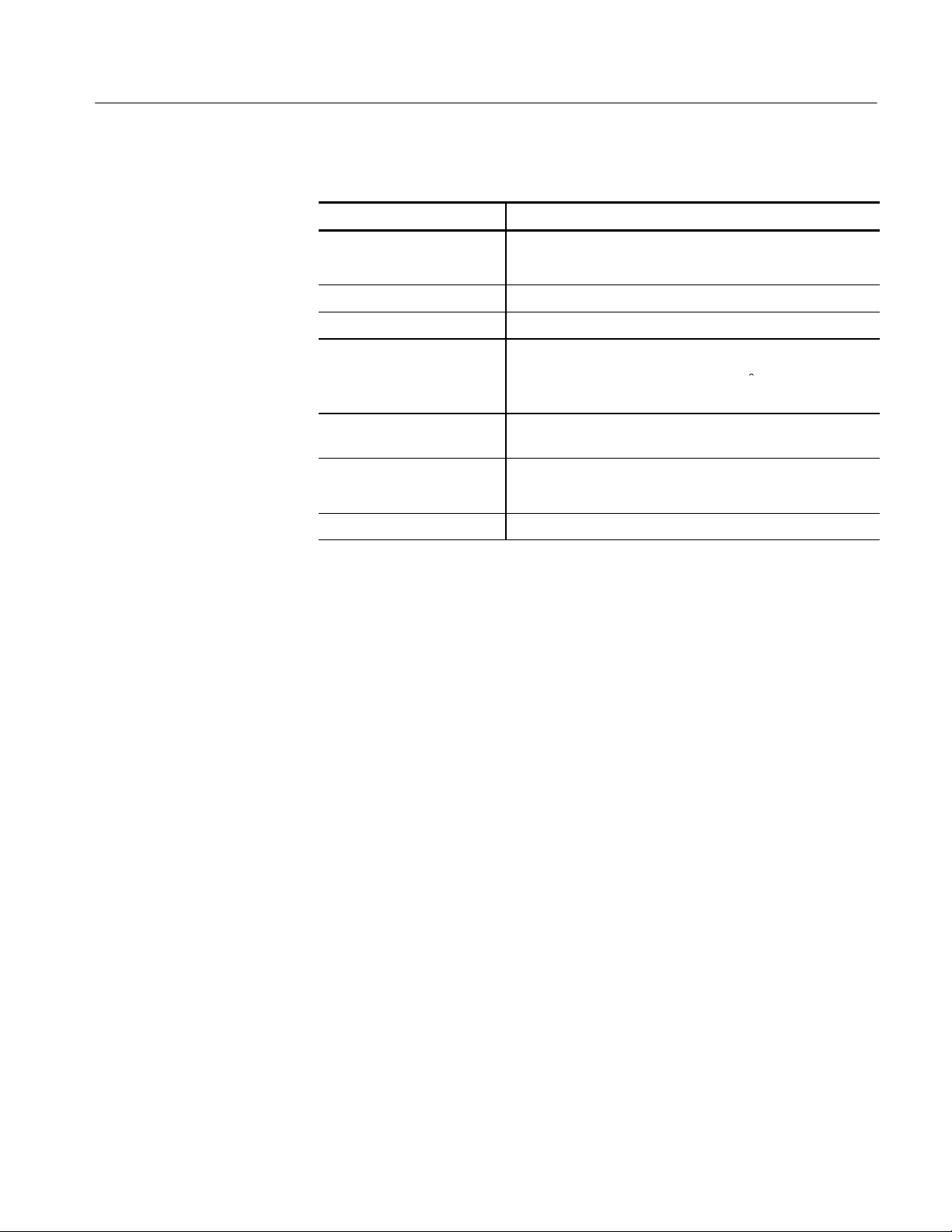

P6419 High-Density Probe Load Model. The following electrical model (see

Figure 18) includes a low-frequency and high-frequency model of the high-density probes.

Low Frequency probe load

0.48 pF

T1 td=17 pS

z0=70 Ω

0.06 pF

T2 td=10 pS

z0=66 Ω

C1

C1

0.22 pF

0.22 pF

High Frequency

probe load

C2

+R1

20k Ω

Ref

Ref - module

GND - TLA520x

2.2 V - TLA7Lx/ Mx/ Nx/ Px/

Qx & TLA6xx

+R1

20k Ω

Ref

Figure 18: High-Density probe load model

Mictor-on-PCB to Compression Adapter Load Model. Refer to Figure 19 for an

electrical model of the Mictor-on-PCB to Compression adapter. The pad cap is

the capacitance of the 0.016 in x 0.032 in pad of the P6419 compression land

footprint. The capacitive load depends upon the distance to the underlying

conductors.

36

td=35 pF

z0=90 Ω

.18 pF .06 pF

.005 Ω

.12 pF

td=17 pF

z0=70 Ω

td=92 pS

z0=57 Ω

.005 Ω

td=10 pF

z0=66 Ω

.22 pF

pad_cap

GND - TLA520x

2.2 V - TLA7Lx/ Mx/ Nx/ Px/

Figure 19: Mictor-on-PCB to Compression adapter load model

P6419 Logic Analyzer Probe Instructions

20K Ω

Ref

Ref - module

Qx & TLA6xx

Page 49

Reference

Compression-on-PCB to P6434 Mictor Adapter Load Model. Refer to Figure 20 for

an electrical model of the Compression-on-PCB to P6434 Mictor adapter. The

pad cap is the capacitance of the 0.016 in x 0.032 in pad of the P6419 compression land footprint. The capacitive load depends upon the distance to the

underlying conductors.

.005 Ω

.12 pF

.7 pF

1.1 pF

1.6 nH

.005 Ω

.23 pF

20K Ω

pad_cap

td=17 pS

z0=70 Ω

1.6 nH

td=35 pS

z0=90 Ω

.18 pF

Figure 20: Compression-on-PCB to P6434 Mictor adapter load model

td = 7 nS

z0 = 75 Ω

75 Ω

P6419 Logic Analyzer Probe Instructions

37

Page 50

Reference

Specifications

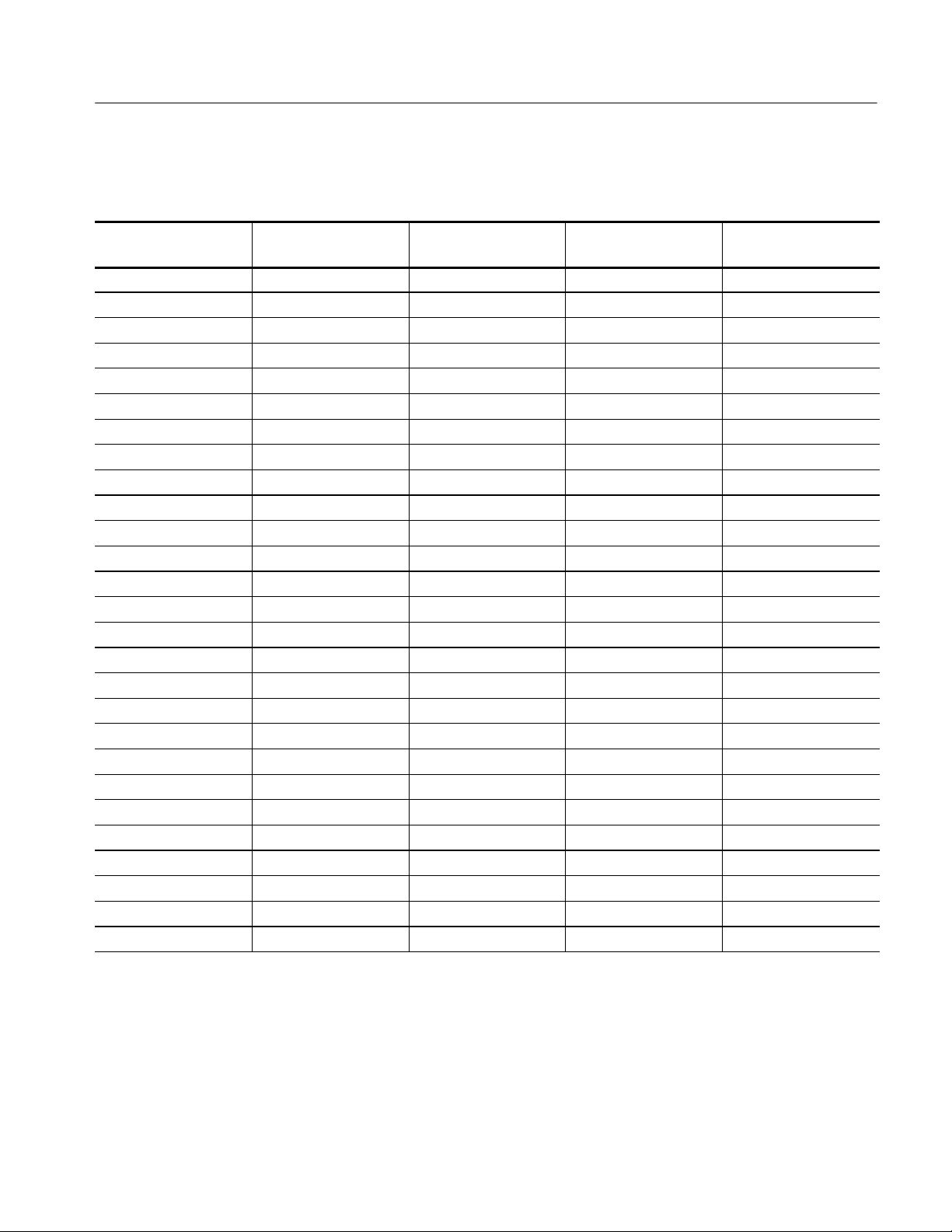

Table 9 lists the electrical and mechanical specifications for the P6419 probe.

The electrical specifications apply when the probe is connected between a

compatible logic analyzer and a target system.

Table 9: Electrical and mechanical specifications

Characteristics Description

Number of input channels 17 (16 data channels, 1 clock/qualifier channel)

Threshold accuracy ± 100 mV

Channel-to-channel skew < 100 ps

Input resistance 20 KΩ

Input capacitance 0.7 pF (typical)

Maximum operating signal 8V

Maximum nondestructive i nput

signal to probe

Probe overdrive ± 300 mV or ± 25% of signal swing, whichever is greater.

Minimum sampling period TLA7Lx,Mx,Nx,Px,Qx and

Maximum synchronous clock

rate

Delay from probe tip to module input connector

Probe length 1.9m(75in)

P-P

± 15 V

TLA520x

TLA60x,61x,62x

4ns 2.22 ns

TLA7Lx,Mx,Nx,Px,Qx and

TLA60x,61x,62x

200 MHz 235 MHz

7.33 ns

TLA520x

Table 10 shows the environmental specifications for the P6419 probe. The probe

is designed to meet Tektronix standard 062-2847-00 class 5.

38

P6419 Logic Analyzer Probe Instructions

Page 51

Table 10: Environmental specifications

y

a

Characteristics Description

Temperature

Reference

Maximum operating

Minimum operating + 0 °C(+ 32 °F)

Non-operating −55 °Cto+75 °C(−67 °Fto+167 °F)

Humidity

Operating 5% to 95% relative humidit

Non-operating 5% to 95% relative humidity at up to +30 °C

Altitude

Operating

Non-operating 4.6 km (15,092 ft)

+ 50 °C 〈+122 °F)

tupto+30 °C

5% to 75% relative humidity above +30 °Cupto+50 °C

5% to 75% relative humidity above +30 °Cupto+60 °C

4.6 km (15,092 ft)

P6419 Logic Analyzer Probe Instructions

39

Page 52

Reference

40

P6419 Logic Analyzer Probe Instructions

Page 53

Maintenance

Probe Calibration

Functional Check

The P6419 probe does not require scheduled or periodic maintenance. Use the

procedures listed under Functional Check to check the basic functionality of the

probe.

To confirm that the probes meet or exceed the performance requirements for

published specifications with a compatible TLA7Lx/Mx/Nx/Px/Qx module,

TLA6xx logic analyzer or TLA520x logic analyzer, refer to the Performance

Verification Procedures in the appropriate logic analyzer service manual.

If performing the probe calibration yourself, refer to the appropriate logic

analyzer service manual for the complete calibration procedure. Otherwise,

return the probe to the local Tektronix service center.

NOTE. For the default setup, if you connect probes to any channels other that the

A2 or A3 groups, you must define the groups and channels in the Setup window

before acquiring data on other probe channels.

Connect the logic analyzer probes to a signal source, start an acquisition, and

verify that the acquired data is displayed in either the Listing or Waveform

windows.

If available, use the TLACAL1 fixture to run the performance verification. For

further details, refer to the performance verification procedure in the appropriate

logic analyzer service manual.

Inspection and Cleaning

CAUTION. To prevent damage during the probe connection process, do not touch

the exposed edge of the elastomer.

To maintain a reliable electrical contact, keep the probes free of dirt, dust, and

contaminants. Remove dirt and dust with a soft brush. For more extensive

cleaning, use only a damp cloth. Never use abrasive cleaners or organic solvents.

P6419 Logic Analyzer Probe Instructions

41

Page 54

Maintenance

P6419 Probe Service Procedures

Except for the elastomer holders, the P6419 probe contains no user-replaceable

parts. If probe failures occur, return the entire probe to your Tektronix service

representative for repair.

Repackaging Instructions

If at all possible, use the original packaging to ship or store the probes. If the

original packaging is not available, use a corrugated cardboard shipping carton.

Add cushioning material to prevent the probes from moving around in the

shipping container.

Enclose the following information when shipping the probe to a Tektronix

Service Center:

H The owner’s address

H Name and phone number of a contact person

H Type of probe

H Reason for returning

H A complete description of the service required

Seal the shipping carton. Mark the address of the Tektronix Service Center and

your own return address on the shipping carton in two prominent locations.

42

P6419 Logic Analyzer Probe Instructions

Page 55

Replaceable Parts

This chapter contains a list of the replaceable components for the P6419 probe.

Use this list to identify and order replacement parts.

Parts Ordering Information

Replacement parts are available through your local Tektronix field office or

representative.

Changes to Tektronix products are sometimes made to accommodate improved

components as they come available and to give you the benefit of the latest

improvements. Therefore, when ordering parts, it is important to include the

following information in your order.

H Part number

H Instrument type or model number

H Instrument serial number

H Instrument modification number, if applicable

If you order a part that has been replaced with a different or improved part, your

local Tektronix field office or representative will contact you concerning any

change in part number.

Using the Replaceable Parts List

Replaceable Parts

The P6419 probe contains only the elastomers and nut block as replaceable parts.

If probe failure occurs, return the entire probe to your Tektronix service

representative for repair.

P6419 Logic Analyzer Probe Instructions

43

Page 56

Replaceable Parts

Refer to the following list for replaceable items:

Table 11: Parts list column descriptions

Column Colum n name Description

1 Figure & index number Items in this section reference figure and index numbers to the exploded view illustrations

that follow.

2 Tektronix part number Use this part number when ordering replacement parts from Tektronix.

3 and 4 Serial number Column three indicates the serial number at which the part was first effective. Column four

indicates teh serial number at which the part was discontinued. No entries indicate the part

is good for all serial numbers.

5 Qty This indicates the quantity of parts used.

6 Name & description An item name is separated from the description by a colon (:). Because of space

limitations, an item name may sometimes appear as incomplete. Use the U.S. Federal

Catalog handbook H6-1 for f urt her item name identification.

7 Mfr. code This indicates the code of the actual manufacturer of the part.

8 Mfr. part number This indicates the actual manufacturer’s or vendor’s part number.

Abbreviations

Mfr. Code to Manufacturer

Cross Index

Abbreviations conform to American National Standard ANSI Y1.1--1972.

The table titled Manufacturers Cross Index shows codes, names, and addresses

of manufacturers or vendors of components listed in the parts list.

Table 12: Manufacturers cross index

Mfr

code

80009 TEKTRONIX 14150 SW KARL BRAUN DR

Manufacturer Address City, state, zip code

PO BOX 500

BEAVERTON, OR 97077-0001

44

P6419 Logic Analyzer Probe Instructions

Page 57

Table 13: P6419 replaceable parts list

Figure &

Index

number

21

-1 010-6419-10 1 P6419 PROBE (INCLUDES SHEET OF LABELS AND

Tektronix

part number

020-2451-00 1 P6419 THIN ELASTOMER HOLDER ASSEMBLY,

020-2452-00 1 P6419 THICK ELASTOMER HOLDER ASSEMBLY,

071-1303-XX 1 MANUAL, TECH:INSTRUCTIONS, P6419 80009 071-1303-XX

335-1007-00 1 P6419 PROBE, SHEET OF LABELS 80009 335-1007-00

061-4254-01 1 DATA SHEET; READ THIS FIRST, PRECAUTIONS

220-0255-00 1 NUT BAR ASSEMBLY 80009 220-0255-00

Serial no

effective

Serial no

discont’d

Qty Name & description

PROBE LABELING INSTRUCTIONS)

P6419 STANDARD ACCESSOR IES

(USED WITH NUT BAR), BAG OF 2 (BLACK) (TOTAL

OF 2 ELASTOM ER ASSEMBLIES)

(USED WITH PRESS-IN NUT), BAG OF 2 (GRAY)

(TOTAL OF 2 ELASTOMER ASSEMBLIES)

FOR HANDLING ELASTOMER BASED COMPRESSION PROBES, GOLDEN ROD;DP

Replaceable Parts

Mfr.

code

80009 010-6419-10

80009 020-2451-00

80009 020-2452-00

80009 061-4252-01

Mfr. part

number

1

Figure 21: P6419 logic analyzer probe

P6419 Logic Analyzer Probe Instructions

45

Page 58

Replaceable Parts

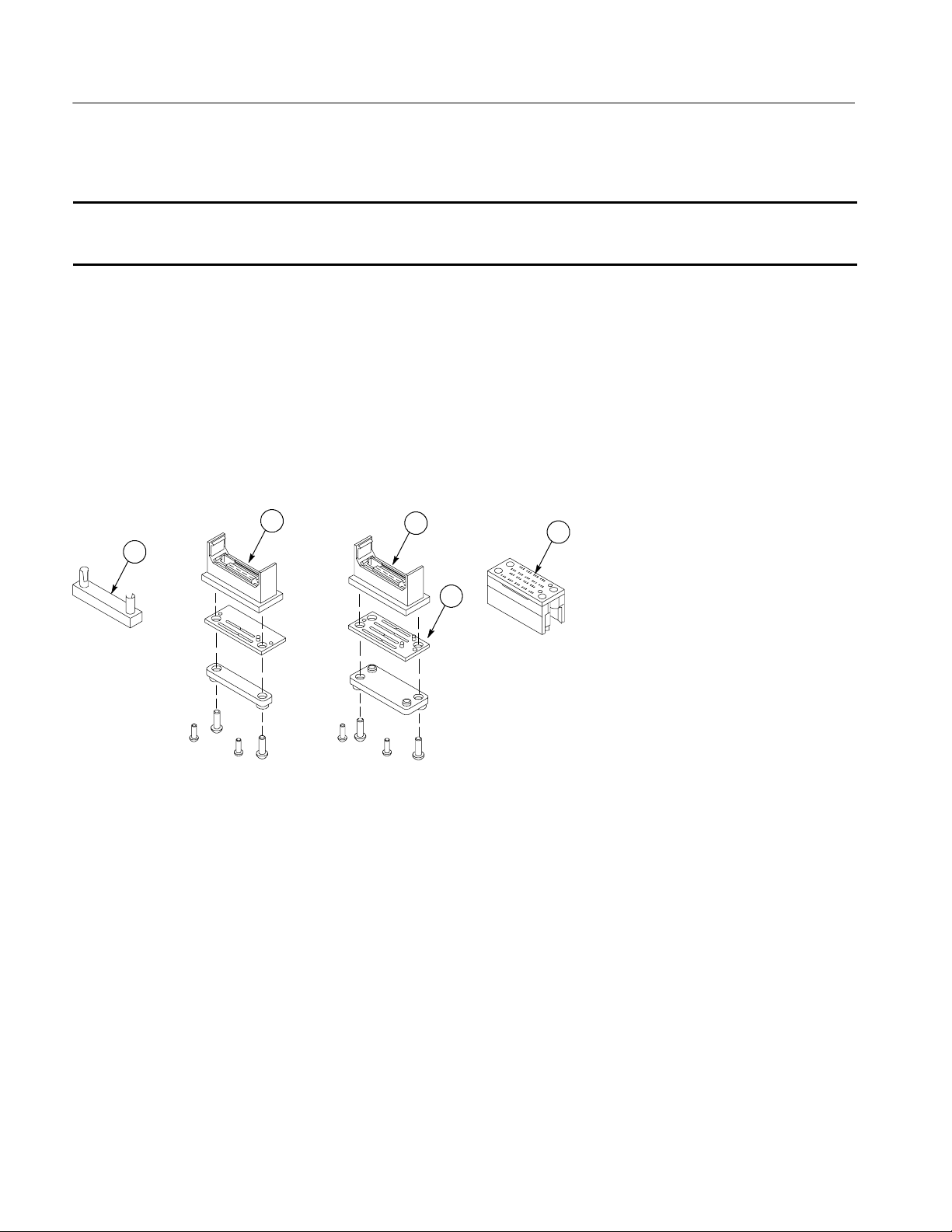

Table 14: Adapter replaceable parts list

Figure &

Index

number

22 P6419 OPTI ONAL ACCESSORI ES

-1 020-2453-00 1 NUT BAR ASSEMBLY, BAG OF 2 80009 020-2453-00

-2 020-2455-00 1 17 CH COMPRESSION-ON-PCB TO P6434 MICTOR

-3 020-2456-00 1 34 CH COMPRESSION-ON-PCB TO P6434 MICTOR

-4 020-2457-00 1 34 CH MICTOR-ON-PCB TO COMPRESSION

-5 352-1095-00 1 ELASTOMER ASSEMBLY 80009 352-1095-00

Tektronix

part number

Serial no

effective

Serial no

discont’d

Qty Name & description

ADAPTER

ADAPTER

ADAPTER

Mfr.

code

80009 020-2455-00

80009 020-2456-00

80009 020-2457-00

Mfr. part

number

2

1

3

5

4

Figure 22: Compression-on-PCB to P6434 Mictor adapter

46

P6419 Logic Analyzer Probe Instructions

Page 59

Index

Page 60

Page 61

Index

A

Adapters

Compression on PCB to Mictor, 3

Mictor on PCB to Compression, 2

Address, Tektronix, viii

C

Cleaning

compression footprints, 8

probe heads, 8

Compression on PCB to Mictor adapter, 3

Connecting

probes to logic analyzer, 7

probes to target system, 10

Contacting Tektronix, viii

D

Designing an interface

electrical considerations, 35

land footprints, 27

mechanical considerations, 30

signal names, 19

L

Labels, attaching to the probe, 5

Land footprints, 27

P6419 High Density Probe, 28

Load model

Compression--on--PCB to P6434 Mictor adapter, 37

Mictor--on-- PCB to Compression adapter, 36

P6419 High Density Probe , 36

Logic analyzer, connecting probes, 7

M

Mechanical considerations

land footprint requirements for P6419 probe, 30

land footprint requirements for the Compression on

PCB to Mictor adapter, 32

physical attachment requirements for P6419 probe,

33

physical attachment requirements for the Compres-

sion on PCB to Mictor and Mictor on PCB to

Compression adapters, 35

Mictor on PCB to Compression adapter, 2

N

E

Elastomer holder, installing Press--in nuts, 11

Electrical considerations

Mictor--on-- PCB to Compression adapter, 36

P6419 High Density Probe load model, 36

Compression--on--PCB to P6434 Mictor adapter, 37

Transmission lines, 35

F

Footprints, land, 27

P6419 High Density Probe, 28

H

High resolution timing modes, 18

K

Keepout area, 31, 33

Nut bar, 10

P

Phone number, Tektronix, viii

Press--in nuts, 11

Probes

cleaning the P6419 Compression footprints, 8

cleaning the P6419 probe head, 8

connecting probes to the logic analyzer, 7

connecting probes to the target system, 10

Product description

Compression on PCB to Mictor adapter, 3

Mictor on PCB to Compression adapter, 2

Product support, contact information, viii

R

Range recognition, 19

Requirements

P6419 Logic Analyzer Probe Instructions

Index- 1

Page 62

Index

land footprint for the Compression on PCB to Mictor

adapter, 32

land footprints for P6419 Probe, 30

physical attachment for the Compression on PCB to

Mictor and Mictor on PCB to Compression

adapters, 35

physical attachment for the P6419 probe, 33