Page 1

Instruction Manual

P6339A

500 MHz Buffered Passive Probe

071-0178-01

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and

pending. Information in this publication supercedes that in all previously

published material. Specifications and price change privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX, TEK, TEKPROBE, and SureFoot are registered trademarks of

Tektronix, Inc. KlipChip is a trademark of Tektronix, Inc.

Copyright © Tektronix, Inc. All rights reserved.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects

in materials and workmanship for a period of one (1) year from the date of shipment. If a

product proves defective during this warranty period, Tektronix, at its option, either will

repair the defective product without charge for parts and labor, or will provide a

replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the

defect before the expiration of the warranty period and make suitable arrangements for the

performance of service. Customer shall be responsible for packaging and shipping the

defective product to the service center designated by Tektronix, with shipping charges

prepaid. T ektronix shall pay for the return of the product to Customer if the shipment is to

a location within the country in which the Tektronix service center is located. Customer

shall be responsible for paying all shipping charges, duties, taxes, and any other charges for

products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or

improper or inadequate maintenance and care. Tektronix shall not be obligated to furnish

service under this warranty a) to repair damage resulting from attempts by personnel other

than Tektronix representatives to install, repair or service the product; b) to repair damage

resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a

product that has been modified or integrated with other products when the effect of such

modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER

WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS

DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY

TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF

THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE

FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR

HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting Tektronix ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Started 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features and Accessories 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Accessories 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Check 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ekProbe Communication 5. . . . . . . . . . . . . . . . . . . . . . . . . .

DC Offset 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Gain and Attenuation 6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Basics 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Compensation 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Input Voltage 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High-Frequency Probe Connections 8. . . . . . . . . . . . . . . . . . . . .

Specifications 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment and Verification Procedures 15. . . . . . . . . . . . . . .

Equipment Required 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove the Top Cover 17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prepare the Equipment 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Locations 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedures 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HF Adjust 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compensate the Probe 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rise Time and Aberrations 21. . . . . . . . . . . . . . . . . . . . . . . . .

Output Zero Adjust 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Attenuation Accuracy 22. . . . . . . . . . . . . . . . . . . . . . . . . .

Rise Time Check 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reset DIP Switches and Install Cover 26. . . . . . . . . . . . . . . . .

Test Record 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P6339A Instruction Manual

i

Page 6

Table of Contents

Maintenance 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing TekProbe Interface Pins 32. . . . . . . . . . . . . . . . . . . . . .

Removing and Replacing the TekProbe Interface Collar 33. . . . .

Removing and Replacing the Cable Assembly 34. . . . . . . . . . . . .

Replaceable Parts 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

P6339A Instruction Manual

Page 7

List of Figures

Figure 1: SMK4 Micro KlipChip adapter 4. . . . . . . . . . . . . . .

Figure 2: Probe compensation waveforms 7. . . . . . . . . . . . . .

Figure 3: Ground lead effects 8. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4: Voltage derating, typical 1 1. . . . . . . . . . . . . . . . . . . . .

Figure 5: Input impedance, typical 12. . . . . . . . . . . . . . . . . . . .

Figure 6: Input phase, typical 12. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7: Location adjustments and DIP switches 18. . . . . . . .

Figure 8: Setup for probe compensation and high fr equency

adjustment 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Figure 9: Probe compensation waveforms 20. . . . . . . . . . . . . .

Figure 10: Setup for rise time and aberrations 21. . . . . . . . . . .

Figure 11: Setup for the output offset adjustment 22. . . . . . . .

Figure 12: Setup for DC attenuation accuracy 23. . . . . . . . . . .

Figure 13: Setup for rise time check 25. . . . . . . . . . . . . . . . . . .

Figure 14: Replacing TekProbe interface pins 32. . . . . . . . . . .

Figure 15: Replacing the TekProbe collar 33. . . . . . . . . . . . . . .

Figure 16: Replacing the cable assembly 34. . . . . . . . . . . . . . . .

Figure 17: P6339A replaceable parts and standard

accessories 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P6339A Instruction Manual

iii

Page 8

Table of Contents

List of Tables

Table 1: Features and accessories 2. . . . . . . . . . . . . . . . . . . . .

Table 2: Electrical specifications 9. . . . . . . . . . . . . . . . . . . . . .

Table 3: Environmental characteristics 11. . . . . . . . . . . . . . . .

Table 4: Physical characteristics 13. . . . . . . . . . . . . . . . . . . . . .

Table 5: Certifications and compliances 13. . . . . . . . . . . . . . . .

Table 6: Test equipment 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7: DIP switch/attenuation settings 19. . . . . . . . . . . . . . .

Table 8: Input voltages for DC attenuation accuracy

adjustment 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9: Settings for rise time check 26. . . . . . . . . . . . . . . . . . .

iv

P6339A Instruction Manual

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent

damage to this product or any products connected to it. To avoid

potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or Personal Injury

Connect and Disconnect Properly. Connect the probe output to the

measurement instrument before connecting the probe to the circuit

under test. Disconnect the probe input and the probe ground from the

circuit under test before disconnecting the probe from the measurement instrument.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all

ratings and markings on the product. Consult the product manual for

further ratings information before making connections to the product.

The common terminal is at ground potential. Do not connect the

common terminal to elevated voltages.

Do Not Operate Without Covers. Do not operate this product with

covers or panels removed.

Do Not Operate With Suspected Failures. If you suspect there is damage

to this product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

P6339A Instruction Manual

v

Page 10

General Safety Summary

Safety Terms and Symbols

Terms in This Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that

could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that

could result in damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you

read the marking.

WARNING indicates an injury hazard not immediately accessible as

you read the marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. These symbols may appear on the product:

CAUTION

Refer to Manual

WARNING

High Voltage

Double

Insulated

Protective Ground

(Earth) Terminal

vi

P6339A Instruction Manual

Page 11

Service Safety Summary

Only qualified personnel should perform service procedures. Read

this Service Safety Summary and the General Safety Summary before

performing any service procedures.

Do Not Service Alone. Do not perform internal service or adjustments

of this product unless another person capable of rendering first aid

and resuscitation is present.

Use Care When Servicing with Power On. Dangerous voltages or currents

may exist in this product. Disconnect power, remove battery (if

applicable), and disconnect test leads before removing protective

panels, soldering, or replacing components.

To avoid electric shock, do not touch exposed connections.

P6339A Instruction Manual

vii

Page 12

Service Safety Summary

viii

P6339A Instruction Manual

Page 13

Contacting Tektronix

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales

support

Service

support

Technical

support

* This phone number is toll free in North America. After office

hours, please leave a voice mail message.

Outside North America, contact a T ektronix sales office or

distributor; see the Tektronix web site for a list of offices.

1-800-833-9200, select option 1*

1-800-833-9200, select option 2*

Email: techsupport@tektronix.com

1-800-833-9200, select option 3*

1-503-627-2400

6:00 a.m. – 5:00 p.m. Pacific time

P6339A Instruction Manual

ix

Page 14

Contacting Tektronix

x

P6339A Instruction Manual

Page 15

Getting Started

The P6339A Buffered Passive Probe is specifically designed for

Tektronix oscilloscopes such as the TDS 794D. Each high-bandwidth

input of these oscilloscopes has a fixed 50 W impedance and a

TekProbe III interface. To allow a broader range of measurement

applications, the P6339A probe passively attenuates and then

actively buffers the signal to match the 50 W input impedance.

Key probe specifications include the following:

H 500 MHz bandwidth

H 8 pF input capacitance

H 10 MW passive input (10X)

The oscilloscope settings control the following parameters of the

buffered probe output:

H Attenuation and gain

H AC/DC coupling

H Bandwidth limit

H DC offset

For a complete list of specifications, refer to page 9.

Features and Accessories

Table 1 illustrates the user features of the P6339A Buffered Passive

Probe and standard accessories. In addition to those items shown, the

standard accessories also include the following:

H Adjustment tool for probe compensation

H Accessory pouch

H Instructions (this manual)

P6339A Instruction Manual

1

Page 16

Getting Started

Table 1: Features and accessories

Feature/Accessory Description Applications/Notes

Marker bands Color codes the probe to the

oscilloscope input when more

than one probe is in use. Clip

one band around the strain relief

of the probe head and the

matching band on the strain

relief of the probe compensation

box.

Ground collar

Ground lead

Ridged probe cover

Short ground

lead

Retractable

hook tip

SMT KlipChip

and ground

lead

Connects the probe ground to a

ground reference close to the

signal source.

To install, slip the ground collar

onto the probe head then screw

the ridged probe cover down

over the probe tip. Insert the

socket end of the ground lead

into the hole of the ground

collar.

Connects the probe tip to wires

and component leads for handsfree measurement.

NOTE. For a solid connection,

firmly push and twist the hook

tip onto the probe tip before

using.

Connects the probe ground to

small or hard to reach ground

reference points. The ground

lead also connects to a variety

of optional accessories.

2

P6339A Instruction Manual

Page 17

T able 1: Features and accessories (cont.)

Feature/Accessory Applications/NotesDescription

Getting Started

Ground lead

with insulated

alligator clip

SureFoot

probe tip set

Guard Keeps fingers away from the

Guard

Connects the probe ground to

ground reference.

Provides fault-free probing of

SMD packages that have lead

spacings of 0.50 mm/20 mil

(red), 0.65 mm/25 mil (blue), or

50 mil (orange).

probe tip for protection against

electric shock.

WARNING. To avoid electric shock when using the probe, keep fingers

behind the guard on the probe body.

Ordering information for replaceable parts and standard accessories

begins on page 35.

P6339A Instruction Manual

3

Page 18

Getting Started

Optional Accessories

Recommended optional accessories include the SMK4 shown in

Figure 1. This adapter enables connections to very small leads.

Figure 1: SMK4 Micro KlipChip adapter

The P6339A probe is fully compatible with the entire line of 3.5 mm

(compact) accessories.

Ordering information for optional accessories begins on page 35.

Functional Check

Use the functional check procedures in this section to verify basic

probe operation with Tektronix oscilloscopes such as the TDS 794D.

Because this is a functional check, no tolerances are given for the

measured values.

NOTE. To verify warranted specifications and to adjust the probe,

qualified service personnel may use the adjustment and verification

procedures that begin on page 15.

4

P6339A Instruction Manual

Page 19

Getting Started

T ekProbe Communication

This procedure verifies the operation of the TekProbe III interface.

1. Turn on the oscilloscope. Wait for the power up self test to

complete.

2. Disconnect all cables or probes from the inputs.

3. Press the Autoset button.

4. Press the CH 1 button.

5. Use the Vertical Scale knob to set the vertical scale factor to

100 mV/div.

6. Press the Vertical Menu button.

7. Attach the probe to the CH 1 input.

8. Select the Coupling menu.

9. Verify that AC and DC coupling and GND are selectable by

switching between them.

10.Verify that the channel 1 scale factor is selectable from 10mV/div

to 100V/div.

11. Verify that the Bandwidth is selectable between Full, 20MHz and

150MHz (2nd button along lower bezel).

DC Offset

This procedure verifies that the oscilloscope can compensate for the

DC offset of each volts/division range of the the P6339A probe.

1. With the probe attached to channel 1, set the oscilloscope to the

lowest volts/division setting (10 mV/div).

2. Set the input coupling to GND and set the ground reference to

center screen.

3. Install a retractable hook tip and ground lead on the probe head.

4. Short the input of the probe to probe ground by connecting a

short jumper from the hook tip to the ground lead.

5. Set the coupling to DC.

P6339A Instruction Manual

5

Page 20

Getting Started

6. Check that the ground reference for each volts per division range

DC Gain and Attenuation

This procedure verifies the correct gain and attenuation of each

volts/division range of the probe.

1. With the probe attached to channel 1, set the oscilloscope to the

2. Connect the output of a standard amplitude calibration generator

3. Set the oscilloscope to DC coupling.

4. For each volts per division range from 10mV/div to 100V/div,

from 10mV/div to 100V/div stays near center screen.

lowest volts/division setting (10 mV/div).

or calibrated DC source to the input of the probe.

adjust the generator or DC source to display four or five divisions

of vertical deflection and check that the measured value of the

input agrees with the output of the generator or DC source.

This completes the functional check procedure.

6

P6339A Instruction Manual

Page 21

Operating Basics

To obtain the best performance from the P6339A probe, compensate

the probe as needed, observe the maximum input voltage and make

appropriate probe connections.

Probe Compensation

Due to variations in oscilloscope input characteristics, probe

low-frequency compensation may need adjustment after moving the

probe from one oscilloscope to another . If a 1 kHz calibrated square

wave displayed at 1 ms/division shows significant differences

between the leading and trailing edges, perform the following steps

to optimize low-frequency compensation.

1. Connect the probe to the calibration signal on the oscilloscope

front panel.

2. Press AUTOSET or otherwise adjust your digitizing oscilloscope

to display a meaningful waveform.

3. Adjust the trimmer in the probe (accessible through the

compensation box) until you see a perfectly flat-top square wave

on the display. See Figure 2.

Undercompensated Overcompensated Properly compensated

Figure 2: Probe compensation waveforms

P6339A Instruction Manual

7

Page 22

Operating Basics

Maximum Input Voltage

Estimate the RMS voltage of a pulse signal before measurement. The

combination of pulse width, duty factor, and DC level determine the

RMS signal voltage. Depending on the application or “installation

category,” this voltage must not exceed the ratings listed in the

Specifications section on page 10.

WARNING. To avoid electric shock when using the probe, do not

touch the metallic portions of the probe head while connected to a

voltage source.

High-Frequency Probe Connections

To minimize inductive effects that cause ringing at high frequencies,

keep all signal and ground leads as short as possible (see Figure 3).

Accessories are included with the probe that provide convenient

means to make short connections (see page 2).

100

90

10

0%

Short ground lead

3“ Ground lead

Figure 3: Ground lead effects

8

P6339A Instruction Manual

Page 23

Specifications

All specifications in Table 2 apply to the probe only unless marked

as system. The system specifications apply when the P6339A probe

is operated with a TDS 794D in an environment that does not exceed

the limits described in Table 3 on page 11.

All specifications are warranted unless marked as typical. The

n symbol indicates warranted specifications that have checks in the

Adjustment Procedures section.

T able 2: Electrical specifications

System input resistance, typical

System input capacitance, typical 8.0 pF at 1 kHz (DC coupled), see Figure 5

System bandwidth, calculated DC to 500 MHz at 50 mV/div

System dynamic range, typical ± 10 divisions at each V/div setting except

System offset range, typical ± 10 divisions

System output zero, typical ± 0.6 division or less displayed on screen

Aberrations, typical (probe only) +8%, –6% at 10 mV/div

10 MW at DC (DC coupled), see Figure 5

50 V and 100 V/div

after probe cal

+16%, –6% at 20 mV, 50 mV, 0.1 V, and

0.2 V/div

+18%, –6% at 0.5 V/div

+21%, –6% at 1 V/div

+22%, –6% at 2 V/div

+24%, –6% at 5 V/div

1

+35%, –17% at 10 V/div

AC coupling, typical lower bandwidth < 10 Hz

P6339A Instruction Manual

9

Page 24

Specifications

T able 2: Electrical specifications (cont.)

n

Output zero (probe only)

± 20 mV at 10 mV/div,

± 10 mV at 20 mV/div,

± 5 mV at all other V/div settings

n DC attenuation accuracy (probe only)

± 2.0 % at 10 mV, 20 mV, 50 mV, 0.1 V,

0.2 V, 0.5 V, 1 V, 2 V, 5 V, 10 V, 20 V, and

50 V/div

± 4.0 % at 100 V/div

n Rise time (probe only)

1.4 ns at 10 mV/div

875 ps at 20 mV/div

700 ps at 50 mV, 0.1 V, 0.2 V, 0.5 V, 1 V,

2 V, and 5 V/div

870 ps at 10 V/div

Required output termination

50 W

Bandwidth limit frequencies (–3 dB), typical 20 MHz and 150 MHz

Time delay, typical 7.8 ns ± 1 ns

Maximum rated input voltage, probe tip to

earth ground

Overvoltage category I:

600 V

(DC + peak AC)

PK

Overvoltage category II:

300 V

RMS

Category III:

150 V

RMS

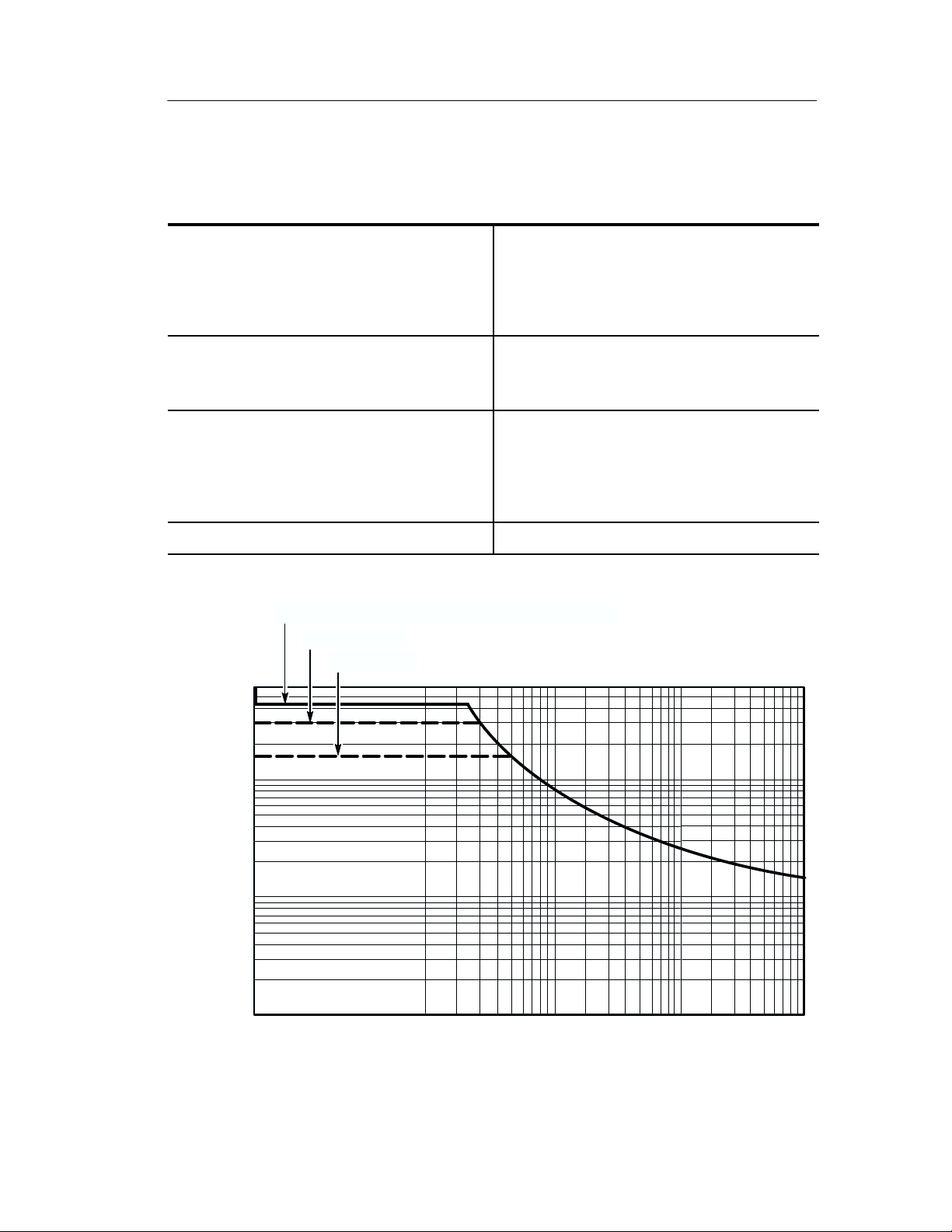

Voltage derating, typical See Figure 4

Input impedance, typical See Figure 5

Input phase, typical See Figure 6

1

Full dynamic range at 50 V and 100 V/div would exceed the safety rating of

the probe.

10

P6339A Instruction Manual

Page 25

Specifications

T able 3: Environmental characteristics

Temperature Operating:

+10_ C to + 50_ C (+50_ F to +122_ F)

Nonoperating

–22_ C to +60_ C (–7.6_ F to +140_ F)

Humidity Operating and Nonoperating:

Five cycles (120 hr total) at 80% to 85%

relative humidity

Altitude, operating < 2000 m (< 6,562 ft), rated ranges

2000 to 5000 m (6,562 to 16,404 ft) voltage

ratings reduced to 300 V CAT I and 150 V

CAT II

Altitude, non-operating < 15,240 meters (50,000 ft)

Category I, 420 V

and 600 V

RMS

(DC + peak AC

)

Category II

Category III

600V

400V

300V

200V

100V

AC

RMS

Voltage

10V

0

Figure 4: Voltage derating, typical

P6339A Instruction Manual

5M 50M

10M 100M1M

Frequency (Hz)

1G

11

Page 26

Specifications

10 MW

1MW

100 kW

10 kW

1 kW

100 W

1 k100

10 k 100 k 1 M 10 M 100 M

Figure 5: Input impedance, typical

0_

-10_

-20_

-30_

-40_

-50_

-60_

-70_

-80_

1 G

Frequency (Hz)

-90_

100

Figure 6: Input phase, typical

12

10 k 100 k 1 M 10 M 100 M1 k10

Frequency (Hz)

1 G

P6339A Instruction Manual

Page 27

Specifications

Table 4 lists the physical characteristics of the P6339A probe.

T able 4: Physical characteristics

Weight, typical Shipping weight: 515 g (1.2 lbs) including

shipping materials

Net weight: 185 g (0.41 lbs), probe only

Cable length, typical 1.3 m (51.18 in)

Table 5 lists the certifications and compliances.

T able 5: Certifications and compliances

EC Declaration of

Conformity – Low

Voltage

U.S. Nationally

Recognized Testing

Laboratory Listing

Canadian

Certification

Compliance was demonstrated to the following specification as

listed in the Official Journal of the European Union:

Low Voltage Directive 73/23/EEC, amended by 93/69/EEC

EN 61010-2-031:1994

Particular requirements for hand-held probe assemblies

for electrical measurement and test equipment.

UL3111-1

Standard for electrical measuring and test equipment.

IEC61010-2-031:1994

Particular requirements for hand-held probe assemblies

for electrical measurement and test equipment.

CAN/CSA C22.2 No. 1010.1

Safety requirements for electrical equipment for

measurement, control, and laboratory use.

CAN/CSA C22.2 No. 1010.2.031:1994

Particular requirements for hand-held probe assemblies

for electrical measurement and test equipment.

Additional

Compliance

IEC61010-1/A2

P6339A Instruction Manual

Safety requirements for electrical equipment for

measurement, control, and laboratory use.

13

Page 28

Specifications

T able 5: Certifications and compliances (cont.)

Installation

(Overvoltage)

Category

Pollution Degree A measure of the contaminates that could occur in the environment

Terminals on this product may have different installation

(overvoltage) category designations. The installation categories are:

CAT III Distribution-level mains (usually permanently connected).

Equipment at this level is typically in a fixed industrial

location.

CAT II Local-level mains (wall sockets). Equipment at this level

includes appliances, portable tools, and similar products.

Equipment is usually cord-connected.

CAT I Secondary (signal level) or battery operated circuits of

electronic equipment.

around and within a product. Typically the internal environment

inside a product is considered to be the same as the external.

Products should be used only in the environment for which they are

rated.

Pollution Degree 2

Normally only dry, nonconductive pollution occurs.

Occasionally a temporary conductivity that is caused by

condensation must be expected. This location is a

typical office/home environment. Temporary

condensation occurs only when the product is out of

service.

14

P6339A Instruction Manual

Page 29

WARNING

The following servicing instructions are for use only by

qualified personnel. To avoid injury, do not perform any

servicing other than that stated in the operating instructions

unless you are qualified to do so. Refer to all safety

summaries before performing any service.

Page 30

Page 31

Adjustment and Verification Procedures

Use the following procedures to adjust and verify the P6339A

Buffered Passive Probe to warranted specifications. Before beginning

these procedures, photocopy the test record on pages 27 through 29

and use it to record test results. The recommended adjustment and

verification interval is one year .

These procedures adjust and/or verify the following:

H High frequency (adjust)

H Probe compensation (adjust)

H Rise time and aberrations (adjust)

H Output zero (adjust and/or verify)

H DC attenuation accuracy (adjust and verify)

H Rise time (verify)

WARNING. These procedures are for use by qualified service

personnel only .

P6339A Instruction Manual

15

Page 32

Adjustment and Verification Procedures

Equipment Required

Table 6 lists the equipment required to perform these procedures.

The types and quantities of connectors may vary depending on the

specific equipment you use.

Table 6: Test equipment

Description Minimum requirements Example product

Oscilloscope TekProbe interface,

≤ 267 ps risetime

Probe power supply Compatible with the Tek-

Probe interface

Calibrated DC voltage

source

Digital multimeter DC Accuracy ≤ 0.1%,

High amplitude pulse

generator

Male BNC to probe tip

adapter

Male BNC to 50 W

probe tip adapter

BNC cable

Dual-male-banana-to-

female BNC adapter

Adjustable from 0 V to

400 V with accuracy

≤ 0.05%.

≤ 400 mV range

0 to 50 V pulse, ≤ 250 ps

rise time

Straight-thru 013-0226-00

50 W nominal

50 W, 1%, precision

As per description 103-0090-00

Tektronix TDS694C

Tektronix Type 1103

Wavetek 9100

Fluke 87 or equivalent

Picosecond Pulse Labs

2700C or 2700B

013-0227-00

012-0482-00

16

Precision inline BNC

terminator

Probe tip shorting

connector

In-line attenuator

50 W ± 0.1%

As per description

50 W, 10X

011-0129-00

011-0059-02

P6339A Instruction Manual

Page 33

Preparation

Prepare the probe for adjustment as follows:

Remove the Top Cover

1. Remove the four screws that attach the top cover to the

compensation box.

2. Remove the top cover .

Prepare the Equipment

1. Connect the male BNC to probe tip adapter (013-0226-00) to the

input of the probe.

2. Attach the probe to the 1103 TekProbe Power Supply.

Adjustment and Verification Procedures

3. If necessary, set the line selector to the correct voltage.

4. Turn on the 1103 power supply.

5. Set the offset button to the off position (button not illuminated).

6. Allow at least 20 minutes for the equipment to warm up.

NOTE. Ambient temperature must be within 20_ C to 30_ C when you

adjust the probe.

P6339A Instruction Manual

17

Page 34

Adjustment and Verification Procedures

Adjustment Locations

Figure 7 shows the locations of the adjustments and the DIP switches

(S1) that manually set the probe attenuation (gain) range.

R1 C4

C7

R3

S1

X1

X10

A1

A0

S1

G3

G2

G1

G0

HF

1

0

HF AdjustLF COMP

10m 20m 50m .2 .5 100

10m 20m 50m .2 .5 100

1251020

TP2

50

GAIN

Offset,

X1

DIP switches shown in

“1” position

Offset, X10

Figure 7: Location adjustments and DIP switches

18

Offset, X100

P6339A Instruction Manual

Page 35

Because some of these procedures use the TekProbe 1103 Power

Supply, there is no automatic control of the probe attenuation. You

must manually set the required attenuation for these procedures

according to Table 7.

Table 7: DIP switch/attenuation settings

Adjustment and Verification Procedures

Atten.

setting

10 mV 0 1 0 1 0 0 0 1 1 1.0000

20 mV 0 0 1 0 2 0.5000

50 mV

0.2 V 0 1 0 0 10 0.1000

0.5 V 0 1 0 1 25 0.04000

1 V 1 0 0 0 0 0 1 1 50 0.02000

2 V 0 1 0 0 100 0.01000

5 V 0 1 0 1 250 0.00400

10 V 1 0 1 0 0 0 1 1 500 0.00200

20 V 0 1 0 0 1000 0.00100

50 V 0 1 0 1 2500 0.000400

100 V 1 1 0 1 5000 0.000200

1

X10 X1 A1 A0

1

G3 G2 G1 G0

0 0 1 1 5 0.2000

During normal operation, the probe attenuation for 50 mV/div is the same

System

atten.

System

gain

as 0.1 V/div and the oscilloscope automatically displays the correct

waveform. With the 1103, there are no adjustments for 0.1 V/div.

Procedures

Perform the adjustment and verification procedures in order .

HF Adjust

1. Setup the equipment as shown in Figure 8 on page 20. (For this

procedure, the probe tip does not have to be connected to the

probe compensation signal.)

P6339A Instruction Manual

19

Page 36

Adjustment and Verification Procedures

2. Measure the voltage on TP2 with a DMM and set the HF Adjust

potentiometer until the voltage at TP2 is –0.50 ± 0.05 VDC.

Compensate the Probe

1. Set up the equipment as shown in Figure 8.

2. With the P6339A probe installed on the 1103 power supply, set

all the DIP switches to the “0” position. See Figure 7 on page 18.

3. Using Table 7 on page 19, set the DIP switches for 50 mV/div.

CH 1

output

1103

Test oscilloscope

CH 1 input

Signal

P6339A

Probe compensation

([0.5 V

, 1 kHz square wave)

p-p

Gnd

50 W BNC cable

Figure 8: Setup for probe compensation and high frequency adjustment

4. Press AUTOSET or otherwise adjust your digitizing oscilloscope

to display a meaningful waveform.

5. Adjust the LF COMP trimmer, C7 (Figure 7 on page 18), until

you see a perfectly flat-top square wave on the display (Figure 9).

CH 1 input

Under compensated Overcompensated Properly compensated

Figure 9: Probe compensation waveforms

20

P6339A Instruction Manual

Page 37

Adjustment and Verification Procedures

Rise Time and Aberrations

1. Set up the equipment as shown in Figure 10.

2. Set all the DIP switches to the “1” position.

3. Set the oscilloscope vertical to 50 mV.

4. Set the pulse generator to 250 mV.

5. Adjust R1 and R3 for a flat response with minimum rise time

(≤ 700 ps).

6. Adjust C4 for minimum aberrations in the first 3 ns.

TDS 694C Digitizing Oscilloscope

High Amplitude Pulse Generator

Figure 10: Setup for rise time and aberrations

P6339A Instruction Manual

BNC-to-probe tip adapter

013-0227-00

P6339A

21

Page 38

Adjustment and Verification Procedures

Output Zero Adjust

1. Connect the probe as shown in Figure 11.

Digital multimeter

BNC cable

–+

Female BNC-tomale banana

adapter

50 W precision

terminator

Short

Figure 11: Setup for the output offset adjustment

50 W

P6339A

CH 1

output

CH 1

input

1103

22

2. Set the DMM to the mV range.

3. Set all the DIP switches to the “0” position.

4. Set the DIP switches for an attenuation of 10 mV as shown in

Table 7.

5. If necessary, adjust the offset potentiometer marked “10m” for a

DMM reading of 0.0 mV ± 1 mV.

6. Set the DIP switches for each attenuation range listed in Table 7

and adjust the corresponding offset potentiometer for a DMM

reading of 0.0 mV ± 0.5 mV.

P6339A Instruction Manual

Page 39

Adjustment and Verification Procedures

DC Attenuation Accuracy

1. Connect the probe as shown in Figure 12.

Digital multimeter

–+

Female BNC-to-male

banana adapter

50 W precision

terminator

DC Source

CH 1

output

50 W

BNC cable

BNC-to-probe tip adapter

013-0226-00

P6339A

CH 1

input

1103

Figure 12: Setup for DC attenuation accuracy

2. Set the DMM to the mV range.

3. Set all the DIP switches to the “0” position.

4. Set the DIP switches for an attenuation of 10 mV and adjust the

gain potentiometer marked 10m (top row, left) for the best

compromise that produces an output reading on the DMM within

the limits listed in Table 8 on page 24 for both positive and

negative voltage inputs.

P6339A Instruction Manual

23

Page 40

Adjustment and Verification Procedures

5. In similar fashion, apply the voltages for each subsequent

attenuation range listed in Table 8 and check the DMM reading.

Adjust the appropriate potentiometer for each range. Note that

some ranges do not have an adjustment.

Table 8: Input voltages for DC attenuation accuracy adjustment

Attenuation setting DCV in DMM reading

10mV

(0 1 0 1 0 0 0 1)

20mV

(0 1 0 1 0 0 1 0)

50mV

(0 1 0 1 0 0 1 1)

0.2 V

(0 1 0 1 0 1 0 0)

0.5 V

(0 1 0 1 0 1 0 1)

1 V1

(1 0 0 0 0 0 1 1)

1

2 V

(1 0 0 0 0 1 0 0)

+100.00 mV 98.0 mV to 102.0 mV

–100.00 mV

+200.00 mV 98.0 mV to 102.0 mV

–200.00 mV

+500.00 mV 98.0 mV to 102.0 mV

–500.00 mV

+1.000 V 98.0 mV to 102.0 mV

–1.000 V

+2.500 V 98.0 mV to 102.0 mV

–2.500 V

+5.000 V 98.0 mV to 102.0 mV

–5.000 V

+10.00 V 98.0 mV to 102.0 mV

–10.00 V

–102.0 mV to –98.0 mV

–102.0 mV to –98.0 mV

–102.0 mV to –98.0 mV

–102.0 mV to –98.0 mV

–102.0 mV to –98.0 mV

–102.0 mV to –98.0 mV

–102.0 mV to –98.0 mV

24

1

5 V

(1 0 0 0 0 1 0 1)

10 V1

(1 0 1 0 0 0 1 1)

20 V1

(1 0 1 0 0 1 0 0)

+25.00 V 98.0 mV to 102.0 mV

–25.00 V

+50.00 V 98.0 mV to 102.0 mV

–50.00 V

+100.0 V 98.0 mV to 102.0 mV

–100.0 V –102.0 mV to –98.0 mV

–102.0 mV to –98.0 mV

–102.0 mV to –98.0 mV

P6339A Instruction Manual

Page 41

Adjustment and Verification Procedures

T able 8: Input voltages for DC attenuation accuracy adjustment (cont.)

Attenuation setting DMM readingDCV in

1

50 V

+250.0 V 98.0 mV to 102.0 mV

(1 0 1 0 0 1 0 1)

–250.0 V

–102.0 mV to –98.0 mV

100 V

+400.0 V 76.8 mV to 83.2 mV

(1 0 1 0 1 1 0 1)

–400.0 V

1

These ranges do not have adjustments

Rise Time Check

1. Connect the probe as shown in Figure 13.

TDS 694C Digitizing Oscilloscope

–83.2 mV to –76.8 mV

High Amplitude Pulse Generator

Figure 13: Setup for rise time check

2. Set all the DIP switches to the “1” position.

P6339A Instruction Manual

BNC-to-probe tip adapter

013-0227-00

P6339A

25

Page 42

Adjustment and Verification Procedures

3. Set the pulse generator and check the rise for each attenuation

setting listed in Table 9.

Table 9: Settings for rise time check

TDS694C attenuation

setting

10 mV 50 mV ≤ 1.4 ns

20 mV 100 mV ≤ 875 ps

50 mV 250 mV ≤ 700 ps

0.2 V 1 V ≤ 700 ps

0.5 V 2.5 V ≤ 700 ps

Pulse generator Rise time

1 V 5 V ≤ 700 ps

2 V 10 V ≤ 700 ps

5 V 25 V ≤ 700 ps

10 V 50 V ≤ 870 ps

Reset DIP Switches and Install Cover

1. Return all DIP switches to the “1” position as shown in Figure 7

on page 18.

2. Place the top cover back onto the compensation box and secure

the cover with the four screws removed earlier .

This completes the adjustment and verification procedures.

26

P6339A Instruction Manual

Page 43

Test Record

Photocopy the following test record and use it to record test results.

P6339A Test Record, Page 1 of 3

Serial

Number

Oscilloscope tests Low limit Test result High limit

Output zero

Adjustment and Verification Procedures

Procedure performed by Date

1

10 mV –20 mV +20 mV

20 mV –10 mV +10 mV

50 mV –5 mV +5 mV

0.2 V –5 mV +5 mV

5 V –5 mV +5 mV

1 V –5 mV +5 mV

2 V –5 mV +5 mV

5 V –5 mV +5 mV

10 V –5 mV +5 mV

20 V –5 mV +5 mV

50 V –5 mV +5 mV

100 V –5 mV +5 mV

1

The high and low limits for output zero represent the acceptable

limits over time. When making the adjustments, set the

10 mV/div adjustment to 0.00 mV ± 1.0 mV and all other

adjustments to 0.00 mV ± 0.5 mV.

P6339A Instruction Manual

27

Page 44

Adjustment and Verification Procedures

P6339A Test Record, Page 2 of 3

Oscilloscope tests Low limit Test result High limit

DC 10 mV

attenuation

accuracy

(±100 mV in)

20 mV

(±200 mV in)

50 mV

(±500 mV in)

0.2 V

(±1.000 V in)

0.5 V

(±2.500 V in)

1 V

(±100 mV in)

2 V

(±200 mV in)

+98.0 mV +102.0 mV

–102.0 mV –98.0 mV

+98.0 mV +102.0 mV

–102.0 mV –98.0 mV

+98.0 mV +102.0 mV

–102.0 mV –98.0 mV

+98.0 mV +102.0 mV

–102.0 mV –98.0 mV

+98.0 mV +102.0 mV

–102.0 mV –98.0 mV

+98.0 mV +102.0 mV

–102.0 mV –98.0 mV

+98.0 mV +102.0 mV

–102.0 mV –98.0 mV

28

5 V

(±500 mV in)

10 V

(±1.000 V in)

20 V

(±2.500 V in)

50 V

(±250.0 V in)

100 V

(±400.0 V in)

+98.0 mV +102.0 mV

–102.0 mV –98.0 mV

+98.0 mV +102.0 mV

–102.0 mV –98.0 mV

+98.0 mV +102.0 mV

–102.0 mV –98.0 mV

+98.0 mV +102.0 mV

–102.0 mV –98.0 mV

+76.8 mV +83.2 mV

–83.2 mV –76.8 mV

P6339A Instruction Manual

Page 45

Adjustment and Verification Procedures

P6339A Test Record Page 3 of 3

Oscilloscope tests Low limit Test result High limit

Rise time

10 mV N/A 1.4 ns

20 mV N/A 875 ps

50 mV N/A 700 ps

0.2 V N/A 700 ps

0.5 V N/A 700 ps

1 V N/A 700 ps

2 V N/A 700 ps

5 V N/A 700 ps

10 V N/A 870 ps

NOTE. Return all DIP switches to the “1” position before installing

the top cover on the compensation box.

P6339A Instruction Manual

29

Page 46

Adjustment and Verification Procedures

30

P6339A Instruction Manual

Page 47

Maintenance

The procedures in this section describe how to maintain and repair

the P6339A Buffered Passive Probe.

Cleaning

Remove dirt with a soft cloth dampened in a mild detergent and

water solution or isopropyl alcohol.

CAUTION. To avoid damaging the probe, use only a mild detergent

and water solution or isopropyl alcohol; do not use any other

solvents or abrasive cleaners. Do not immerse the probe.

P6339A Instruction Manual

31

Page 48

Maintenance

Replacing TekProbe Interface Pins

1. To remove the interface pin, grasp the pin with a pair of

needle-nose pliers and gently pull the pin out. See Figure 14.

2. To replace the pin, insert the new pin into the socket and press it

in against a hard surface.

32

Figure 14: Replacing TekProbe interface pins

P6339A Instruction Manual

Page 49

Maintenance

Removing and Replacing the TekProbe Interface Collar

1. To remove the collar, firmly pull the collar off by hand.

2. To replace the collar, align the smaller group of pins with the

smaller of the two holes in the interface collar and align the tabs

with the slots. Gently press the two pieces together . See

Figure 15.

Tab

Slot

Figure 15: Replacing the TekProbe collar

P6339A Instruction Manual

33

Page 50

Maintenance

Removing and Replacing the Cable Assembly

1. Unscrew the retaining nut and slide it back on the cable.

2. Firmly grasp the cable close to the threaded housing and pull it

straight out.

3. Remove the nut from the old cable and place it onto the new

cable.

4. Insert the new cable into the housing until it snaps into place.

5. Tighten the retaining nut (approximately 30 inch-lbs).

Cable

Retaining nut

Figure 16: Replacing the cable assembly

Threading housing

34

P6339A Instruction Manual

Page 51

Replaceable Parts

1

2

14

15

16

17

13

18

5

6

3

4

7

101112

9

8

Figure 17: P6339A replaceable parts and standard accessories

P6339A Instruction Manual

35

Page 52

Replaceable Parts

Accessories

80009 See Optional

2 EA 0.50 mm/20 mil (red), 0.65 mm/25 mil (blue), and

Qty Name & description Mfr. code Mfr. part number

Serial no.

discont’d

Serial no.

effective

Tektronix

part number

Fig. &

index

number

17–1 206–0485–00 1 COMP BOX ASSY:P6339A 80009 206–0485–00

–2 174–0978–00 1 CABLE ASSY,RF:65 OHM COAX PER FT ,1.3M 060D9 174–0978–00

–3 196–3305–00 1 LEAD,ELECTRICAL:22 AWG,6.0 L,W/CLIP 060D9 196–3305–00

–4 206–0441–00 1 PROBE TIP ASSY:10X,8.0PF,9M OHM, 80009 206–0441–00

P6339A and replaceable parts and accessories

–5 204–1049–00 1 BODY SHELL:TIP COVER TK2565 204–1049–00

1 ADAPTER,SMD KIT

Accessories

–6 013–0107–07 1 TIP,PROBE:MINIATURE/COMPACT SIZE TK2565 013–0107–07

–7 See Optional

50 mil (orange)

–8 206–0364–00 1 TIP,PROBE:MICROCKT TEST,0.05 CTR 80009 206–0364–00

–9 ––––––––––– 1 POUCH (not replaceable)

–10 003–1433–03 1 SCREWDRIVER:ADJUSTMENT TOOL,METAL TIP TK2565 003–1433–03

–11 016–0633–00 1 MARKER SET,CA:2 EA VARIOUS COLORS 80009 016–0633–00

–12 196–3113–02 1 LEAD,ELECTRICAL:STRD,22 AWG,6.0 L,8–N 060D9 196–3113–02

–13 195–4240–00 1 LEAD,ELECTRICAL:0.025 DIA,COPPER,2.3 L 060D9 195–4240–00

–14 343–1003–01 1 COLLAR,GND:P6130 TK2565 343–1003–01

–15 205–0191–01 1 SHELL,ELEC CONN:BNC,ABS,DOVE GRAY 80009 205–0191–01

–16 131–3627–02 1 CONTACT,ELEC:SPRING LOADED,GOLD PLATED TK2565 131–3627–02

–17 211–0001–00 1 SCREW,MACHINE:2–56 X 0.25,PNH,STL CD PL,POZ 93907 ORDER BY DESCRIP

36 P6339A Instructions

Page 53

Mfr. part numberMfr. codeName & descriptionQty

Replaceable Parts

Serial no.

discont’d

Serial no.

effective

Tektronix

part number

OPTIONAL ACCESSORIES

071–0178–01 1 MANUAL,TECH:INSTRUCTIONS,P6339A TK2548 071–0178–01

SF202A 12 INSULATOR: ADAPTER, SMD, BLUE, 0.65 mm/25 mil 80009 SF202A

SF203A 12 INSULATOR: ADAPTER, SMD, RED, 0.50 mm/20 mil 80009 SF203A

Fig. &

index

number

P6339A and replaceable parts and accessories (Cont.)

–18 200–3018–00 1 COVER,CABLE NIP:COMP BOX 0J260 ORDER BY DESCRIP

17–8 SF201A 12 INSULATOR: ADAPTER, SMD, ORANGE, 50 MIL 80009 SF201A

P6339A Instructions

37

Page 54

Replaceable Parts

VANCOUVER, W A 98661

20

BEAVER T ON, OR 970764200

M/S 16–207

ROCKFORD, IL 611045181

BEAVER T ON, OR 97077–0001

PO BOX 500

516 18TH AVE

Manufacturer Address City, state, zip code

93907 CAMCAR DIV OF TEXTRON INC ATTN: ALICIA SANFORD

TK2548 XEROX CORPORATION 14181 SW MILLIKAN WAY BEAVERTON, OR 97005

Mfr.

Manufacturers cross index

code

060D9 UNITREK CORPORATION 3000 COLUMBIA HOUSE BLVD, SUITE 1

0J260 COMTEK MANUFACTURING OF OREGON P O BOX 4200

80009 TEKTRONIX INC 14150 SW KARL BRAUN DR

TK2565 VISION PLASTICS INC 26000 SW PARKW AY CENTER DRIVE WILSONVILLE, OR 97070

38 P6339A Instructions

Loading...

Loading...