Page 1

Instruction Manual

P6330

3.5 GHz Differential Probe

071-0757-04

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and

pending. Information in this publication supercedes that in all previously

published material. Specifications and price cha nge privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX, TEK, TEKPROBE, and SureFoot are registered trademarks of

Tektronix, Inc. KlipChip is a trademark of Tektronix, Inc.

Page 3

WARRANTY

Tektronix warrants that the products that it manufactures and sells will be free from defects

in materials and workmanship for a period of one (1) year from the date of shipment. If a

product proves defective during this warranty period, Tektronix, at its option, either will

repair the defective product without charge for parts and labor, or will provide a

replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the

defect before the expiration of the warranty period and make suitable arrangements for the

performance of service. Customer shall be responsible for packaging and shipping the

defective product to the service center designated by Tektronix, with shipping charges

prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to

a location within the country in which the Tektronix service center is located. Customer

shall be responsible for paying all shipping charges, duties, taxes, and any other charges for

products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or

improper or inadequate maintenance and care. Tektronix shall not be obligated to furnish

service under this warranty a) to repair damage resulting from attempts by personnel other

than Tektronix representatives to install, repair or service the product; b) to repair damage

resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a

product that has been modified or integrated with other products when the effect of such

modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER

WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS

DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY

TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF

THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE

FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR

HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

General Safety Summary v..............................

Service Safety Summary vii..............................

Contacting Tektronix viii.................................

Product Features and Accessories 1.....................

Options 2............................................

Features and Standard Accessories 3......................

Optional Accessories 7.................................

Operating Basics 9...................................

Installation 9.........................................

Instruments with the TEKPROBE Interface (Tektronix TDS 400,

500, 600, and 700 Series Oscilloscopes) 10...............

Instruments without the TEKPROBE Interfac e 10............

Input Voltage Limits 10.................................

Maximum Input Voltage 11..............................

Common-Mode Signal Range 11..........................

Differential-Mode Signal Range 11........................

Common-Mode Rejection 11.............................

Probing Techniques to Maximize CMRR 12.................

Electrical Effects of Accessories 13........................

Input Impedance and Probe Loading 14.....................

Probe Grounding 15....................................

Functional Check 17...................................

Reference 19.........................................

Problems with Single-Ended Measurements 19...............

Differential Measurements 19............................

Common-Mode Rejection Ratio 20........................

Assessing CMRR Error 20...............................

Input Impedance Effects on CMRR 21.....................

Extending the Input Leads 21.............................

Extending the Ground Lead 22............................

Extending the Probe Output 22...........................

Terminating the Probe 22................................

Effect of Extending the Output Cable 23....................

Using the Probe with Other Instruments 23..................

P6330 3.5 GHz Differential Probe Instruction Manual

i

Page 6

Table of Contents

Specifications 25......................................

Warranted Characteristics 25.............................

Typical Characteristics 26...............................

Nominal Characteristics 30..............................

Theory of Operation 33................................

Probe Head and Cable Assembly 34.......................

Compensation Box 34...................................

Offset Amplifier 34.....................................

Probe Identification EEPROM 34.........................

TEKPROBE Interface 35................................

Performance Verification 37............................

Equipment Required 37.................................

Equipment Setup 38....................................

Probe Calibration Fixture 39.............................

Using the Probe Calibration Fixture 39.....................

Output Offset Voltage 41................................

DC Gain Accuracy 41...................................

Rise Time 43..........................................

Adjustments 47.......................................

Equipment Required 47.................................

Removing the Compensation Box Cover 48.................

Offset Zero and DC CMRR 50............................

Offset Range 53.......................................

Replacing the Compensation Box Cover 54.................

Maintenance 55.......................................

Replacing TEKPROBE Interface Pins 55...................

Removing and Replacing the TEKPROBE Interface Collar 56..

Inspection and Cleaning 57..............................

Replacement Parts 57...................................

Preparation for Shipment 57..............................

Replaceable Parts 59...................................

Parts Ordering Information 59............................

Using the Replaceable Parts List 60........................

Item Names 60........................................

Indentation System 60..................................

Abbreviations 60.......................................

ii

P6330 3.5 GHz Differential Probe Instruction Manual

Page 7

List of Figures

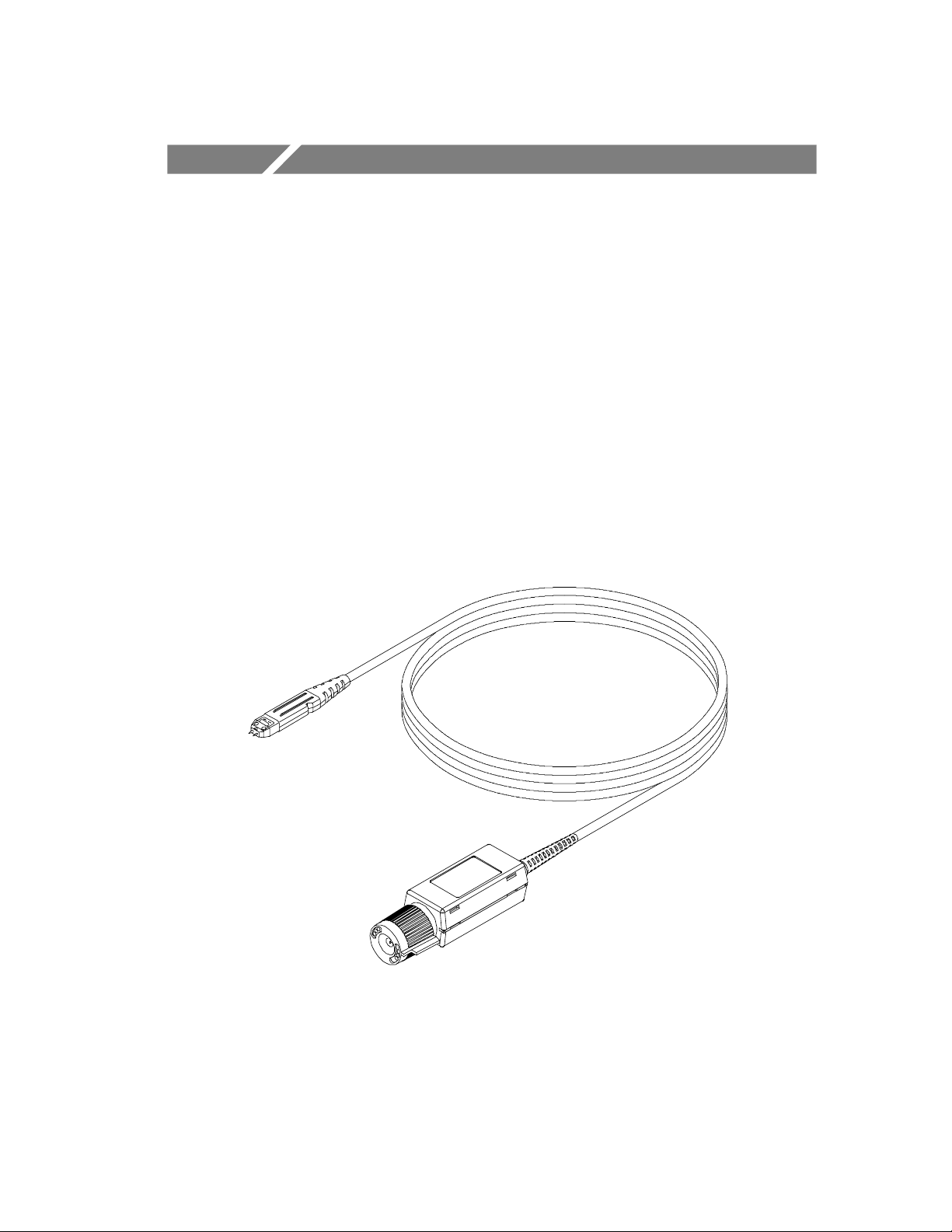

Figure 1: P6330 differential probe 1......................

Figure 2: Input connector of TEKPROBE interface 10.........

Figure 3: Using the variable spacing adapter 12..............

Figure 4: Using the TwinFoot adapter 12....................

Figure 5: Typical effects on a signal using probe tip adapters 13.

Figure 6: Typical probe input model 14.....................

Figure 7: Probe ground input 15...........................

Figure 8: Probe functional check connections 17.............

Figure 9: Simplified model of a differential amplifier 20.......

Figure 10: Twisting the input leads 22......................

Figure 11: Typical common-mode gain 28...................

Figure 12: Typical differential input impedance vs frequenc y 28.

Figure 13: Probe head and compensation box dimensions 29....

Figure 14: Simplified schematic diagram 33.................

Figure 15: TEKPROBE interface 35.......................

Figure 16: Probe Calibration Fixture 39.....................

Figure 17: Probe Calibration Fixture test points 40............

Figure 18: Setup for the output offset voltage test 41..........

Figure 19: DC Gain Accuracy setup 42.....................

Figure 20: Test system rise time setup 43...................

Figure 21: Test system rise time setup with probe 44..........

Figure 22: Verifying both probe pins are contacting the

DM test points 45...................................

Figure 23: Removing the compensation box cover 48..........

Figure 24: Adjustment and test point locations 49.............

Figure 25: Offset zero and DC CMRR setup 51..............

Figure 26: P6330 offset range setup 53.....................

Figure 27: Replacing the compensation box cover 54..........

Figure 28: Replacing TEKPROBE interface pins 55...........

Figure 29: Replacing the TEKPROBE i nterface c ollar 56......

Figure 30: P6330 replaceable parts 61......................

Figure 31: P6330 standard accessories 63...................

Figure 32: P6330 optional accessories 65...................

Table of Contents

P6330 3.5 GHz Differential Probe Instruction Manual

iii

Page 8

Table of Contents

iv

P6330 3.5 GHz Differential Probe Instruction Manual

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent

damage to this product or any products connected to it. To avoid

potential hazards, use this product only as specified.

To Avoid Fire or Personal Injury

Connect and Disconnect Properly. Connect the probe output to the

measurement instrument before connecting the probe to the circuit

under test. Disconnect the probe input and the probe ground from the

circuit under test before disconnecting the probe from the measurement instrument.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all

ratings and markings on the product. Consult the product manual for

further ratings information be fore making connections to the product.

The common terminal is at ground potential. Do not connect the

common terminal to elevated voltages.

Do Not Operate Without Covers. Do not operate this product with

covers or panels removed.

Do Not Operate With Suspected Failures. If you suspect there is damage

to this product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

P6330 3.5 GHz Differential Probe Instruction Manual

v

Page 10

General Safety Summary

Safety Terms and Symbols

Terms in This Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that

could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that

could result in damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you

read the marking.

WARNING indicates an injury hazard not immediately accessible as

you read the marking.

CAUTION indicates a ha zard to property including the product.

Symbols on the Product. These symbols may appear on the product:

CAUTION

Refer to Manual

vi

P6330 3.5 GHz Differential Probe Instruction Manual

Page 11

Service Safety Summary

Only qualified personnel should perform service procedures. Re ad

this Service Safety Summary and the General Safety Summary before

performing any service procedures.

Do Not Service Alone. Do not perform internal service or adjustments

of this product unless another person capabl e of rendering fi rst aid

and resuscitation is present.

P6330 3.5 GHz Differential Probe Instruction Manual

vii

Page 12

Service Safety Summary

Contacting Tektronix

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales

support

Service support

Technical

support

* This phone number is toll free in North America. After office

hours, please l eave a voice mail message.

Outside North America, contact a Tektronix sales office or

distributor; see the Tektronix web site for a list of offices.

1-800-833-9200, select option 1*

1-800-833-9200, select option 2*

Email: techsupport@tektronix.com

1-800-833-9200, select option 3*

6:00 a.m. -- 5:00 p.m. Pacific time

viii

P6330 3.5 GHz Differential Probe Instruction Manual

Page 13

Product F eatures and Accessories

The P6330 is a high-bandwidth (3.5 GHz) active differential probe

with a miniaturized probe head design. The probe has low circuit

loading, high common-mode rejection, and comes with a variety of

accessories for connecting to surface-mount devices and othe r

components.

The P6330 probe uses the TEKPROBE interface, which provides

power, selects the correct display scaling, and automatical ly sets the

50 Ω termination on the oscilloscope input. The TEKPROBE

interface is standard on many Tektronix TDS series oscilloscopes.

The Tektronix 1103 TEKPROBE Power Supply can be used for

instruments without the TEKPROBE interface (refe r to page 7).

Figure 1: P6330 differential probe

P6330 3.5 GHz Differential Probe Instruction Manual

1

Page 14

Product Features and Accessories

Options

The following options are available when ordering the P6330 probe:

H Option D1 -- Calibration Data

H Option C3 -- 3 years Calibration Service

H Option D3 -- 3 years Calibration Data (requires Option C3)

H Option R3 -- 3 years Extended Warranty

2

P6330 3.5 GHz Differential Probe Instruction Manual

Page 15

Product Features and Accessories

Features and Standard Accessories

Table 1 shows the features and standard accessories of the P6330

differential probe.

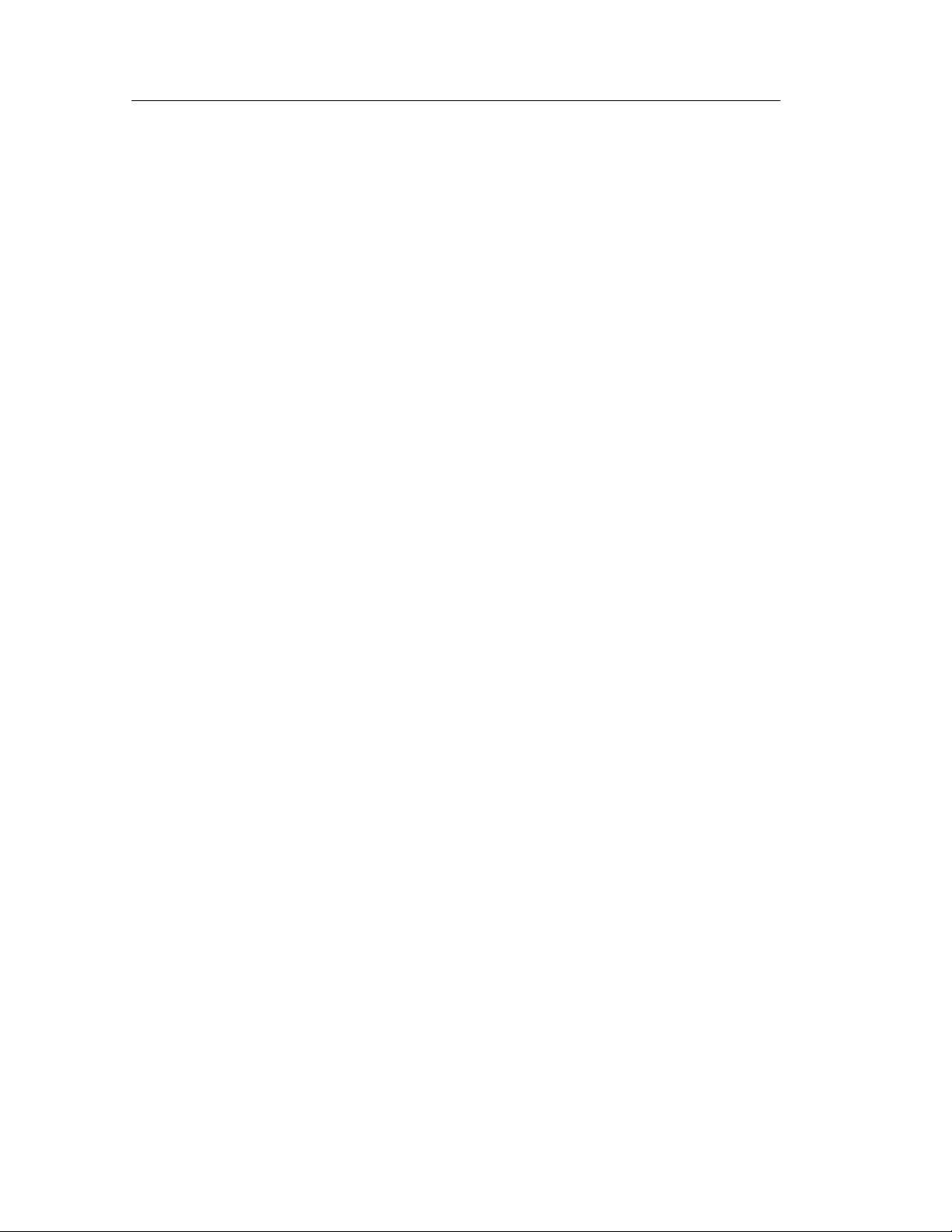

Table 1: P6330 features and standard accessories

Feature/Accessory Description

TEKPROBE interface. The TEKPROBE interface supplies

power to the probe, selects the correct display scaling, and

automatically sets the 50 Ω termination on the oscilloscope input.

If your oscilloscope does not have the TEKPROBE interface, you

can use the optional 1103 power supply (refer to page 7).

Input connections. The plus and minus connections of the probe

head accept the standard and optional probe accessories (some

+

--

Ground

of which connect through the square pin adapter).

WARNING: Skin penetration hazard. To prevent injury, install the

probe tip cover when the probe is not in use. The probe tips are

extremely sharp to ensure good contact and measurement

integrity.

Probe tip cover. The probe tips are extremely sharp to ensure

good contact and measurement integrity. When not using the

probe, slide the probe tip cover over the probe head to prevent

damage to the probe tips and to protect yourself from personal

injury.

Tektronix part number: 200-4236-00

Three-inch ground lead (2 ea). Use the ground lead for

connecting the probe ground to the circuit, if needed. The

socketed end of the lead may be connected to accessories, or

fitted onto 0.025-inch pins.

Tektronix part number: 196-3469-00 (package of 2)

P6330 3.5 GHz Differential Probe Instruction Manual

3

Page 16

Product Features and Accessories

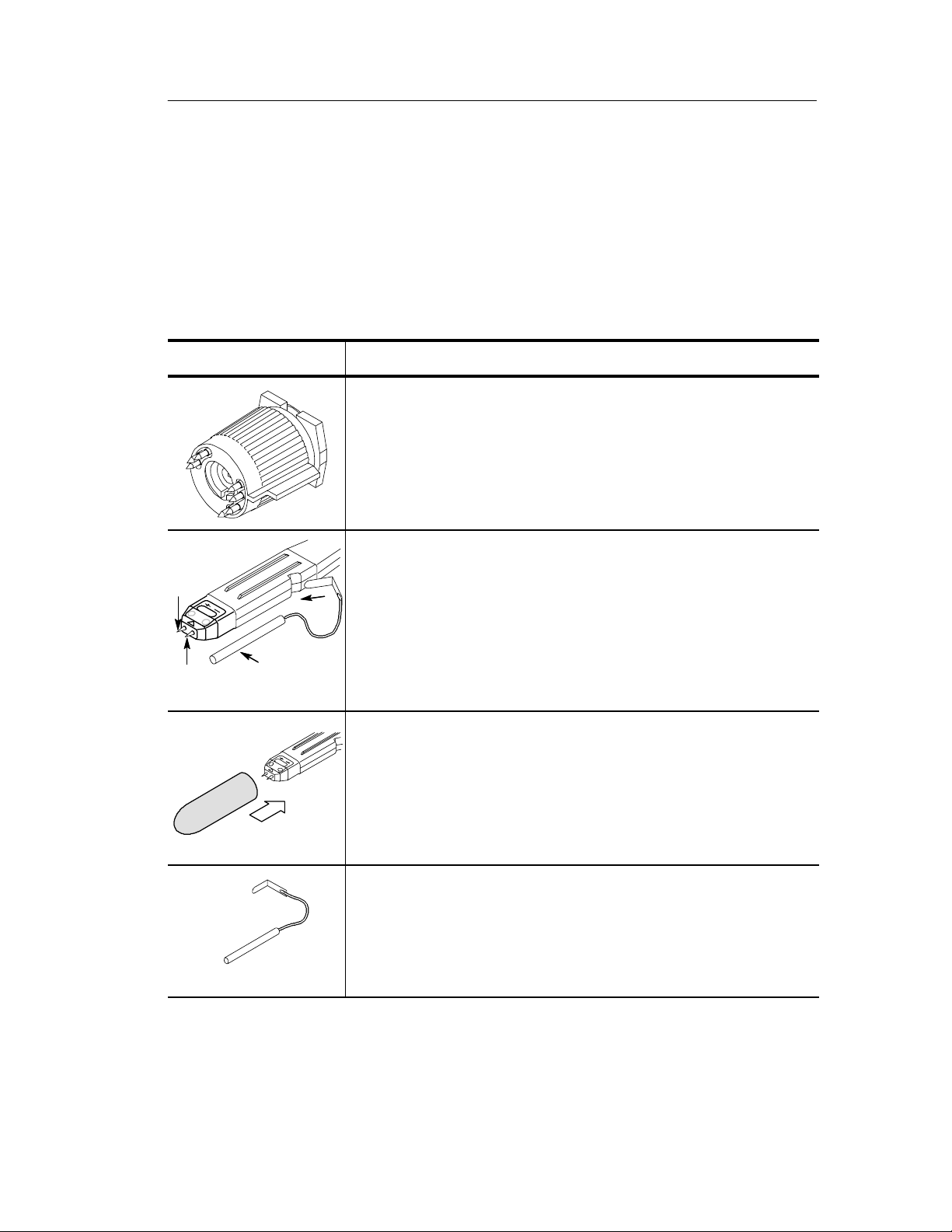

Table 1: P6330 features and standard accessories (Cont.)

Feature/Accessory Description

Variable spacing adapter (4 ea). The variable spacing adapter

fits over the probe tip. Push the adapter onto the probe tip until it

seats against the probe head.

Use the variable spacing adapter to probe any two adjacent leads

or test points spaced between 0.020 and 0.180-inches apart.

Adjust the articulated pins by gently rotating them using a pair of

tweezers.

NOTE: The articulated pins can be bent, but they are fragile. Use

extreme care when bending the pins.

The elastomeric contacts inside the adapter are rated for 50 -- 75

insertion cycles with the probe tip. Replace the adapter after

Seated

against

probe head

exceeding these limits to avoid unreliable operation.

Tektronix part number: 016-1885-00 (package of 4)

Seated

against

probe head

Square pin adapter (4 ea). Push the square pin adapter onto the

probe tip until it seats against the probe head. Use the square pin

adapter to connect the probe to other accessories, such as the

Y-lead adapter or TwinFoot adapter. The inputs on the adapter

are spaced 0.100-inches apart.

CAUTION: To avoid damaging the square pin connectors, do not

insert anything larger than a 0.025-inch square pin into the inputs.

The elastomeric contacts inside the adapter are rated for 50 -- 75

insertion cycles with the probe tip. Replace the adapter after

exceeding these limits to avoid unreliable operation.

Tektronix part number: 016-1884-00 (package of 4)

4

P6330 3.5 GHz Differential Probe Instruction Manual

Page 17

Product Features and Accessories

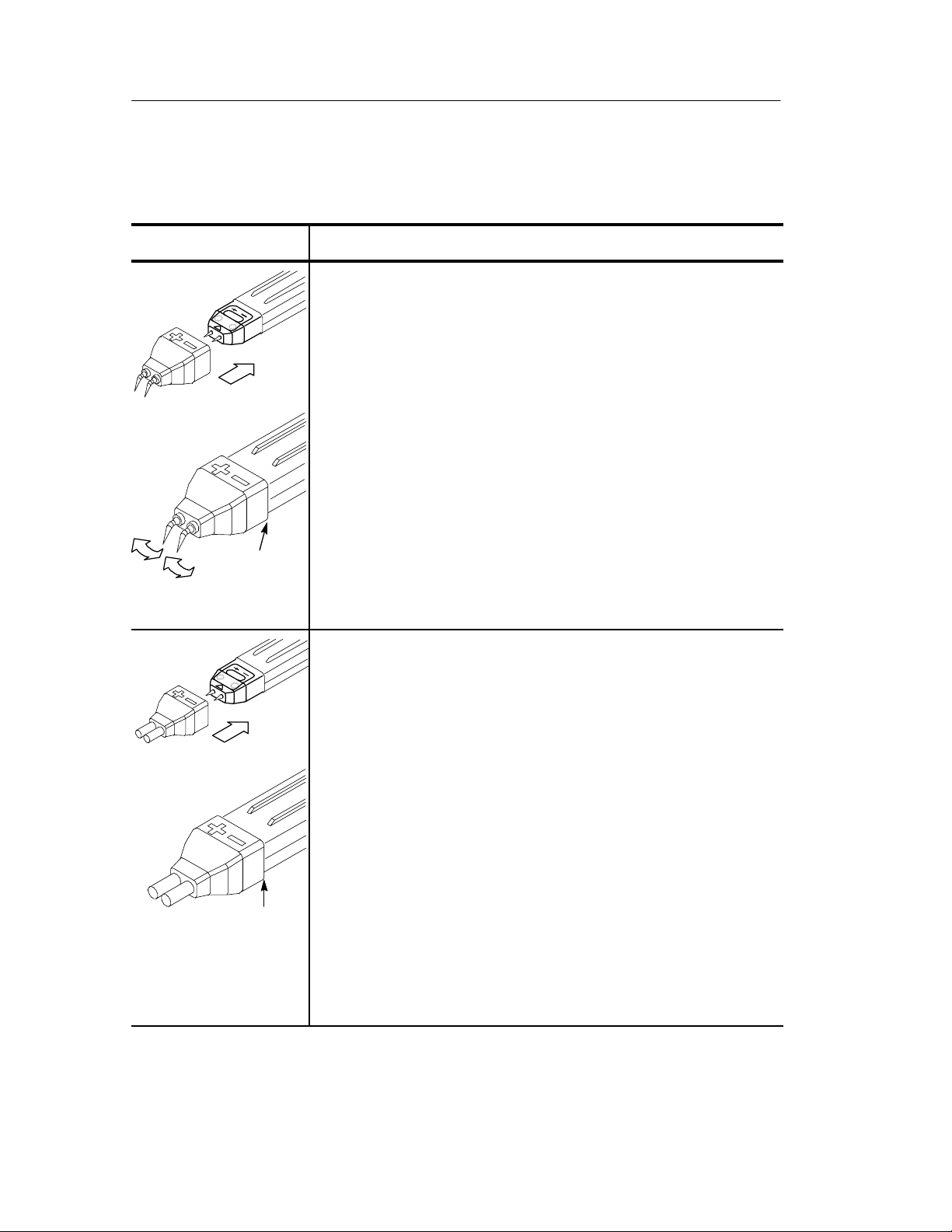

Table 1: P6330 features and standard accessories (Cont.)

Feature/Accessory Description

TwinFoot adapter (4 ea). Use the TwinFoot adapter to probe two

adjacent leads on a surface-mount integrated circuit. The

TwinFoot adapter connects to the probe through the square pin

adapter. Flexible fingers adapt to a range of lead spacings. See

Figure 4 on page 12.

Tektronix part number: 016-1785-00 (package of 4)

Y-lead adapter (2 ea). The Y-lead adapter connects to the probe

through the square pin adapter. The socketed ends of the leads

may be connected to the probe tips and accessories, or fitted onto

0.025-inch pins.

Color marker bands

Tektronix part number: 196-3468-00 (package of 2)

X-lead adapter (2 ea). The X-lead adapter connects between

accessories fitted with 0.025-inch pins, such as the SMT KlipChip

and Micro KlipChip adapters.

You can use the X-lead adapter with the adapters below to make

connections between the probe tip and your circuit under test.

Be aware of the electrical effects of the added lead length of the

adapters, especially as circuit frequencies increase.

Tektronix part number: 196-3473-XX (package of 1)

SMT KlipChip adapter (2 ea). Use this accessory to probe the

leads on dual-in-line packages (DIP). The 0.025-inch pins

recessed in the adapter body may be connected to the X- and

Y-lead adapters, and the 3-inch ground leads.

Tektronix part number: 206-0364-XX (package of 1)

Color marker bands (10 ea). Attach matching pairs of the color

marker bands onto the cable at the head and compensation box

of each probe. The marker bands enable quick verification of

which probe is connected to which instrument channel.

Tektronix part number: 016-1315-00 (package of 10)

P6330 3.5 GHz Differential Probe Instruction Manual

5

Page 18

Product Features and Accessories

Table 1: P6330 features and standard accessories (Cont.)

Feature/Accessory Description

Plastic accessory box. Use the plastic box to store the probe

accessories when not in use.

Tektronix part number: 006-7164-00

Instrument case. The instrument case protects the probe from

harsh environments and provides room for storing optional

accessories.

Tektronix part number: 016-1879-XX

Calibration certificate. A certificate of traceable calibration is

provided with every instrument shipped.

Instruction Manual. Provides instructions for operating the

P6330 differential probe and procedures for verifying the

performance, adjusting, and maintaining the probe.

Tektronix part number: 071-0757-XX

Accessory reorder sheet.

The accessory reorder sheet provides photos and part numbers

for identifying standard and optional accessories that are

compatible with your probe.

Tektronix part number 001-1362-XX

Antistatic wrist strap. When using the probe, always work at an

antistatic work station and wear the antistatic wrist strap.

Tektronix part number: 006-3415-04

6

P6330 3.5 GHz Differential Probe Instruction Manual

Page 19

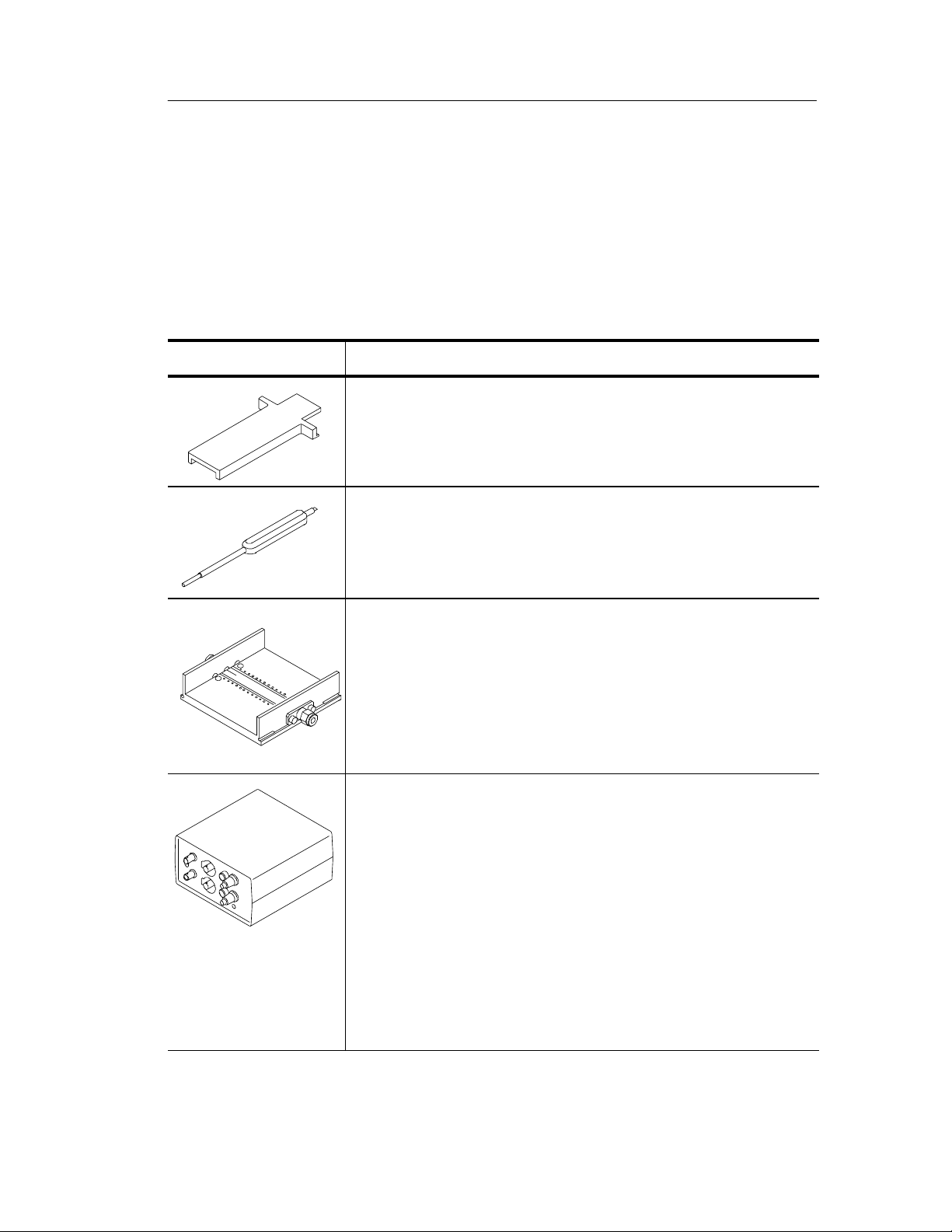

Optional Accessories

Table 2 shows the optional accessories that you can order for the

P6330 differential probe.

Table 2: Optional accessories

Accessory Description

Release tool. Use for opening the compensation box to access

adjustments.

Order Tektronix part number 003-1383-00

Adjustment tool. Use for making internal adjustments to the

probe.

Product Features and Accessories

Order Tektronix part number 003-0675-01

Probe calibration fixture. Use the probe calibration fixture to

perform some of the calibration procedures. The calibration fixture

connects to signal sources used to test the probe characteristics.

Refer to page 39 for details on using the fixture.

Order Tektronix part number 067-0419-XX

1103 Power supply. Order the 1103 power supply for

performance verification procedures, and for instruments that do

not have the TEKPROBE Interface. Power cord options are

available for the following countries or regions.

Standard. North America and Japan

Option A1. European

Option A2. UK

Option A3. Australia

Option A5. Switzerland

P6330 3.5 GHz Differential Probe Instruction Manual

7

Page 20

Product Features and Accessories

Table 2: Optional accessories (Cont.)

Accessory Description

50 Ω termination. Terminates the output of the 1103 power

supply to the required 50 Ω if the oscilloscope does not have a

50 Ω input setting. Order Tektronix part number 011-0049-01.

50 Ω BNC cable. Connects to the 1103 output.

Order Tektronix part number: 012-0076-00

IEEE1394 Adapter. The IEEE1394 Adapter allows you to probe

signals on the bus, external to system enclosures, without

disturbing system operation. The adapter maintains a balanced

55 Ω signal path and can be used in both single-ended and

differential modes.

Order Tektronix part number: 679-5027-00

Micro KlipChip adapters (2 ea). Use the adapters to probe the

leads on integrated circuits that are surface-mounted. The

0.025-inch pin at the back of the adapter may be connected to the

X- and Y-lead adapters, and the 3-inch ground leads.

Order Tektronix part number: SMK4 (package of 4)

8

P6330 3.5 GHz Differential Probe Instruction Manual

Page 21

Operating Basics

This section discusses operating considerations and probing

techniques. For more detailed information about differential

measurements and common-mode rejection ratio (CMRR), see the

Reference sectiononpage19.

The P6330 probe design is optimized for high bandwidth, low

capacitance applications; it is not a general purpose probe. The probe

head and tips are miniaturized for electrical characteristics and

access to dense circuitry, and must be handled carefully. Rough or

careless use will likely damage the probe.

To avoid damaging the probe tips, minimize your lateral pressure on

the tips. Always probe as directly straight onto the circuit (perpe ndicular) as possible. The probe tips are extremel y sharp to ensure good

contact and measurement integrity.

WARNING. Skin penetration hazard. Use care when handling the

probe. To prevent injury and/or probe damage, install the protec tive

cover over the probe tips when the probe is not in use.

Installation

Before you connect the output of the P6330 differential probe,

determine whether or not your oscilloscope has a TEKPROBE

interface. See Figure 2 on page 10.

P6330 3.5 GHz Differential Probe Instruction Manual

9

Page 22

Operating Basics

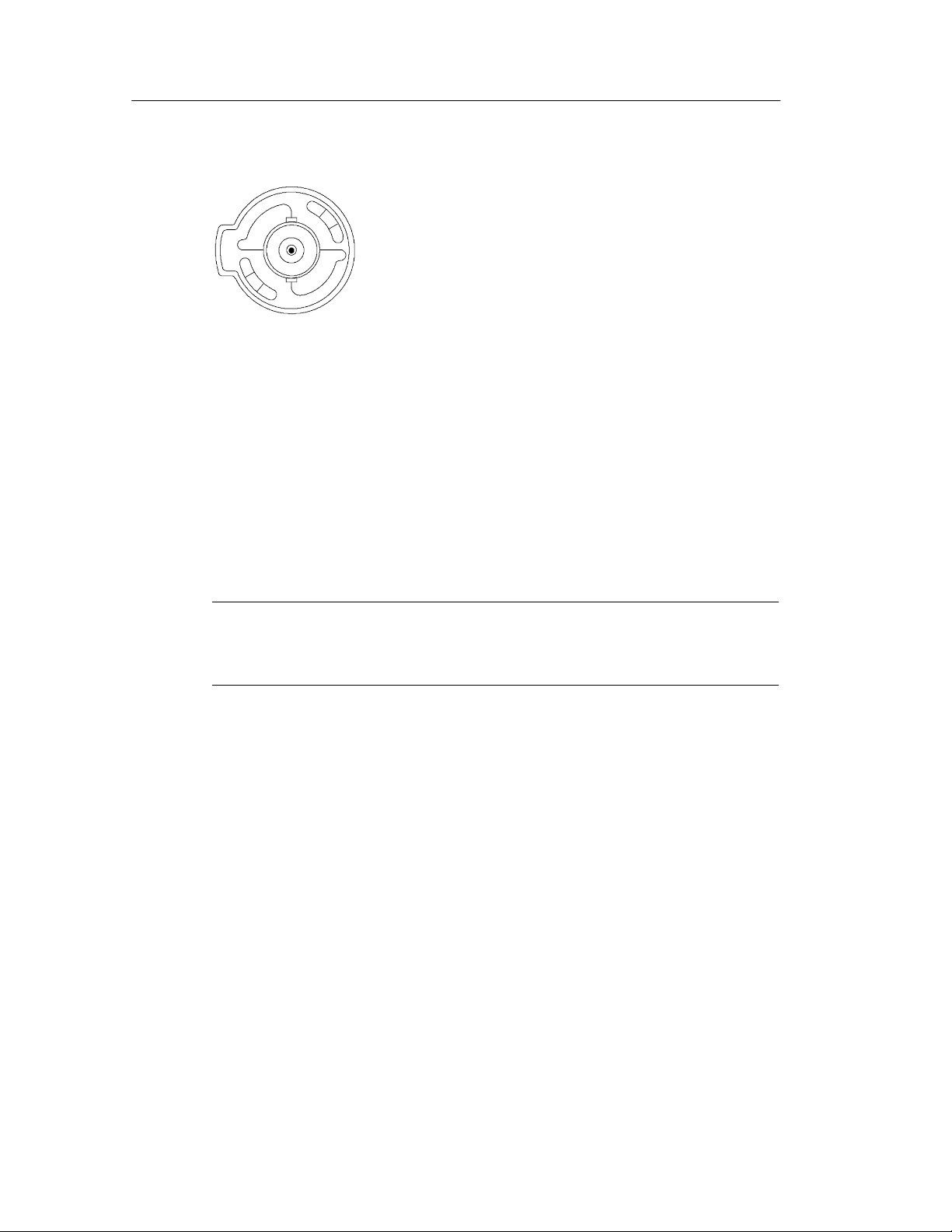

Figure 2: Input connector of TEKPROBE interface

Instruments with the TEKPROBE Interface (Tektronix TDS 400, 500, 600,

and 700 Series Oscilloscopes)

On instruments that have the TEKPROBE interface, simply connect

the probe to the input. The TEKPROBE interface provides power,

selects the correct display scaling, and automatically sets the 50 Ω

termination on the oscilloscope input.

NOTE. TDS 400 and TDS 400A series oscilloscopes do not interpret

the scale factor coding of the P6330 differential probe. To correct for

this problem, divide the measurement (or scale factor) by 5.

Instruments without the TEKPROBE Interface

On instruments that do not have the TEKPROBE interface, you must

order the optional 1103 power supply (refer to page 7). Each 1103

can supply power for two probes. The input of the osc illoscope must

also terminate into 50 Ω. Refer t o page 22 for informat ion on the

effects of extending the output of the probe.

Input Voltage Limits

The P6330 differential probe is designed to probe low-voltage

circuits. Before probing a voltage, take into account the limits for

maximum input voltage, the common-mode signal range, and the

differential-mode signal range. For specific limits, see Specifications

on page 25.

10

P6330 3.5 GHz Differential Probe Instruction Manual

Page 23

Operating Basics

Maximum Input Voltage

The maximum input voltage is the maximum voltage to ground that

the inputs can withstand without damaging the input circuitry of the

probe.

CAUTION. To avoid damaging the inputs of the P6330 differential

probe, do not apply more than ± 15 V (DC + peak AC) between each

input and ground.

Common-Mode Signal Range

The common-mode signal range is the maximum voltage that you

can apply to each input, with respect to earth ground, without

saturating the input circuitry of the probe. A common-mode voltage

that exceeds the common-mode signal range may produce an

erroneous output waveform even when the differential-m ode

specification is met. For Specifications, refer to page 25.

Differential-Mode Signal Range

The differential-mode signal range is the maximum voltage

difference between the plus and minus inputs that the probe can

accept without distorting the signal. The distortion from a volta ge

that is too large can result in a clipped or otherwise distorted and

inaccurate measurement. For Specifications, refer to page 25.

Common-Mode Rejection

The common-mode rejection ratio (CMRR) is the ability of a probe

to reject signals that are common to both inputs. More prec isely,

CMRR is the ratio of the differential gain to the common-mode gain.

The higher the ratio, the greater the ability to reject common-mode

signals.

Common-mode rejection decreases as the i nput frequency increases.

Figure 11 on page 28 is a plot of typical CMRR of the probe versus

input frequency. For additional information about CMRR, see

page 20.

P6330 3.5 GHz Differential Probe Instruction Manual

11

Page 24

Operating Basics

Probing Techniques to Maximize CMRR

The common-mode rejection of the probe is highest when the probe

is applied directly to the circuit, without using adapters. However,

some probing tasks are made easier using accessories incl uded with

the probe. The accessories shown in Figures 3 and 4 achieve a high

CMRR by minimizing the distance between the probe head and the

signal source.

Figure 3: Using the variable spacing adapter

TwinFoot adapter

Square pin adapter

Conductive side

Probe

of probe tip

Insulated side of probe tip

Figure 4: Using the TwinFoot adapter

IC leads being probed

12

P6330 3.5 GHz Differential Probe Instruction Manual

Page 25

Electrical Effects of Accessories

The probe tip accessories included with your probe help connect to

different types of components. While these accessories make

connections easier, be aware tha t the adapter you choose may a ffect

the signal you are measuring, depending on a variety of factors,

including signal frequency, source impedance, and lead length.

Use the probe only (without adapters) to optimize step and frequency

response. Using the probe tip adapters adds inductance and

capacitance, which increases step response and aberrations, and leads

to increased ripples in frequency response. These effects increase as

the source impedance and the measured waveform risetimes

decrease.

The recommended method for hands-free probing is to use the probe

only (without adapters), with a probe positioner such as a Tektronix

PPM203B. If you need a tip space between 0.020 and 0.180 inches

apart, use the variable spacing adapter and the probe positioner. Use

the square pin adapter for test points or component leads spaced

farther than 0.180 inches apart.

Operating Basics

Figure 5 illustrates the typical effects on a given signal using some of

the adapters included with your probe.

Probe only

Variable

spacing

adapter

Square pin

adapter

Figure 5: Typical effects on a signal using probe tip adapters

P6330 3.5 GHz Differential Probe Instruction Manual

13

Page 26

Operating Basics

Input Impedance and Probe Loading

When you connect the probe inputs to a circui t, you are introducing a

new resistance, capacitance, and inductance into the circuit. Each

input of the P6330 differential probe has a characteristic input

impedance of 50 kΩ to ground in parallel with le ss tha n 0.4 pF. See

Figure 6.

For signals with low source impedance and frequency, the 50 kΩ

input impedance on each input is large enough to prevent the inputs

from loading the signal sources. The greater the source impedances

and the higher the signal frequencies, the more you must take these

factors into account.

Input

+

0.4pF 50kΩ

Ground

--

0.1 pF0.4 pF

Input

50 kΩ

Figure 6: Typical probe input model

As the impedance of the signal source on an input increases, the

more the probe loads the source and reduces the signal amplitude.

The frequency of the signal also affects signal measurement. As the

frequency of the signal increases, the input impedance of the probe

decreases. The lower the impedance of the probe relative to that of

the source, the more the probe loads the circuit under test and

reduces the signal amplitude. For a graph of frequency versus input

impedance, refer to Figure 12 on page 28.

14

P6330 3.5 GHz Differential Probe Instruction Manual

Page 27

Probe Grounding

In addition to the plus and minus inputs on the probe head, there is

also a ground (common) input. The ground lead slides into the notch

on the side of the probe. See Figure 7.

+

Operating Basics

-Ground

Figure 7: Probe ground input

CAUTION. To avoid damaging the circuitry under test, connect the

probe ground (common), if used, to a ground-reference point only.

In most applications, the common-mode impedance to ground is

greater than the differential impe dance. Adding the probe ground

lead does not improve the high-frequency performa nce of the

measurement. You can use the probe t o take a di fferential measurement regardless of whether or not the ground (common) is connected.

There are some applications that may require a ground reference

connection to maintain measurement accuracy. Generally this is

necessary when probing circuits which are fully isolated from

ground, such as battery operated devices.

P6330 3.5 GHz Differential Probe Instruction Manual

15

Page 28

Operating Basics

16

P6330 3.5 GHz Differential Probe Instruction Manual

Page 29

Functional Check

After installing the probe on the oscilloscope, a functional check

may be performed using the PROBE COMPENSATION connections

on the front panel of the oscilloscope. See Figure 8.

Figure 8: Probe functional check connections

1. Connect the probe to the oscilloscope.

2. Set the oscilloscope to display the probe channel.

3. Connect the square pin adapter to the probe tip, and connect the

Y-lead adapter to the square pin adapter. Plug the SMT KlipChips

into the Y-lead adapter.

4. Connect the SMT KlipChips to the PROBE COMPENSATION

connections on the oscilloscope.

5. Adjust the oscilloscope to display a stable calibration waveform.

P6330 3.5 GHz Differential Probe Instruction Manual

17

Page 30

Functional Check

NOTE. If your instrument supports probe calibration routines, now is

a good time to perform them.

6. Disconnect the probe from the PROBE COMPENSATION

connector and connect the two KlipChips together.

7. With the probe offset set to 0.0 V, the oscilloscope display should

be at the ground reference.

8. Set the oscilloscope volts/division to 500 mV.

9. Adjust the probe offset. The displayed waveform should vary

between approximately +1.0 V and --1.0 V.

18

P6330 3.5 GHz Differential Probe Instruction Manual

Page 31

Reference

This section contains important referenc e information about

differential measurements and how to increase the accuracy of your

measurements.

Problems with Single-Ended Measurements

While suitable in many applications, single-ended measurements can

present problems in the following situations:

H When the signal is not referenced to eart h ground

H When the signal being measured is distorted or changed by

connecting or disconnecting the probe ground reference lead

Differential Measurements

Devices designed to make differential mea surements avoid the

problems posed by single-ended systems. These devices include a

variety of differential probes, differential amplifiers, and isolators.

The differential amplifier (Figure 9) is at the heart of any device or

system designed to make differential measurements. Ideally, the

differential amplifier rejects any voltage that is common to the inputs

and amplifies any difference between the inputs. Voltage that is

common to both inputs is often referred to as the Comm on-Mode

Voltage (V

Voltage (V

) and voltage that is different as the Differential-Mode

CM

).

DM

P6330 3.5 GHz Differential Probe Instruction Manual

19

Page 32

Reference

+

Differential

mode

Common

mode

+

V

DM

+

V

CM

--

Figure 9: Simplified model of a differential amplifier

V

out

Common-Mode Rejection Ratio

In reality, differential amplifiers cannot reject all of the commonmode signal. The ability of a differential amplifier to reject the

common-mode signal is expressed as the Common-Mode Rejection

Ratio (CMRR). The CMRR is the differential-mode gain (A

divided by the common-mode gain (A

). It is expressed either as a

CM

DM

)

ratio or in dB.

A

DM

A

CM

CMRR =

A

DM

dB = 20 log

A

CM

CMRR generally is highest (best) at DC and degrades with

increasing frequency.

Assessing CMRR Error

Figure 11 on page 28 shows the CMRR of the P6330 differential

probe. This derating chart assumes a common-mode signal that is

sinusoidal.

20

P6330 3.5 GHz Differential Probe Instruction Manual

Page 33

Reference

A quick way to assess the magnitude of CMRR error when the

common-mode signal is not sinusoidal is to connect both leads to the

same point in the circuit. The oscilloscope will display only the

common-mode component which is not fully rejected by the probe.

While this technique may not give you entirely accurate measurements, it does allow you to determine if the magnitude of the

common-mode error signal is significant.

Input Impedance Effects on CMRR

The lower the input impedance of the probe relative to the source

impedance,thelowertheCMRR.SeeFigure12onpage28.

Significant differences in the source impedance driving the two

inputs will also lower the CMRR.

Extending the Input Leads

At times it may be necessary to extend the probe inputs with wires or

a probe tip adapter. When you do this, you should minimize the lead

lengths to optimize common-mode rejection and twist the input leads

together as shown in Figure 10.

Twisting the input leads together does increase capacitance that may

degrade high-frequency performance. You should take into account

any effects caused by the extended leads when you take a measurement.

P6330 3.5 GHz Differential Probe Instruction Manual

21

Page 34

Reference

Square pin

adapter

Figure 10: Twisting the input leads

Extending the Ground Lead

Extending the ground lead will have little, if any, affect on your

measurements. In most circuits, the ground path from the differential

source has sufficiently high impedance to damp out any ringing

caused by lead inductance.

Extending the Probe Output

With the 1103 TEKPROBE power supply, it is possible to extend the

output of the probe to connect the probe to other types of measurement instruments or to connect the probe to a signal source that is

outside the reach of the probe.

Terminating the Probe

The probe must terminate into 50 Ω at the input of the measurement

instrument. Use the 1103 TEKPROBE power supply to adapt the

differential probe and set the input impedance of the measurement

instrument to 50 Ω. If the measurement instrument does not support

50 Ω input termination, connect a 50 Ω coaxial terminator on the

input.

22

P6330 3.5 GHz Differential Probe Instruction Manual

Page 35

Reference

Effect of Extending the Output Cable

As the frequency of a signal increases, current flow concentrates at

the outer edges of the conductor, effectively increasing the

impedance. This effect is known as skin loss. The P6330 probe

contains circuitry to compensate for skin loss.

The compensation provides flat response with the probe cable.

Extending the length of the output cable increases the amount of skin

loss beyond the range of compensation correction. Minimizing the

length of cable extension reduces the attenuation.

In critical applications which require high amplitude accuracy, you

should first characterize the response of the probe with the extension

using a leveled sinewave generator and power meter. Then, you can

factor the characterization results into the measurement.

Using the Probe with Other Instruments

You can use the P6330 differential probe with other types of

measurement instruments, such as spectrum analyzers, time internal

analyzers, and network analyzers.

When using the differential probes with these instruments, you must

use the 1103 TEKPROBE power supply, and normalize the probe

with the instrument before making a measurement.

P6330 3.5 GHz Differential Probe Instruction Manual

23

Page 36

Reference

24

P6330 3.5 GHz Differential Probe Instruction Manual

Page 37

Specifications

The specifications in Tables 3 through 6 apply to a P6330 probe

installed on a TDS8000 oscilloscope. When the probe is used with

another oscilloscope, the oscilloscope must have an input impedance

of 50 Ω. The probe must have a warm-up period of at least

20 minutes and be in an environment that does not exceed the limits

described in Table 3. Specifications for the P6330 differential probe

fall into three categories: warranted, typical, and nominal characteristics.

Warranted Characteristics

Warranted characteristics (Table 3) describe guaranteed performance

within tolerance limits or certain type-tested requirements.

Warranted characteristics that have checks in the Performance

Verification section are marked with the n symbol.

Table 3: Warranted electrical characteristics

Characteristic

n DC gain

n Output offset voltage ± 10 mV (+ 20_ Cto+30_ C,

n Rise time (probe only)

Maximum nondestructive input voltage ± 15 V(DC + peak AC) between signal and

Delay variation (probe-to-probe) 600 ps maximum

Temperature

Description

0.2 ± 2%

+68_ Fto+86_ F)

± 50 mV displayed on screen with

TEKPROBE interface

140 ps (130 ps typical)

common of the same channel.

Operating: 0 to + 40_ C

(+ 32 to + 104_ F)

Nonoperating: -- 55 to + 75_ C

(--131 to + 167 _ F)

1

P6330 3.5 GHz Differential Probe Instruction Manual

25

Page 38

Specifications

Table 3: Warranted electrical characteristics (Cont.)

Characteristic

Humidity Operating: 0--90% RH, tested at

1

See warning that follows.

Description

+30to+40_ C (+ 68 to + 104_ F)

Nonoperating: 0--90% RH, tested at

+30to+60_ C (+ 68 to + 140_ F)

WARNING. To avoid a burn hazard at high ambient temperatures, do

not touch the probe with bare hands at nonoperating temperatures

above + 70_ C. Allow sufficient time for the probe to cool before

handling

.

T ypical Characteristics

Typical characteristics (Tables 4 and 5) describe typical but not

guaranteed performance.

Table 4: Typical electrical characteristics

Characteristic Description

Bandwidth (probe only) DC to ≥ 3.5 GHz (-- 3dB)

Differential signal range ± 2.0 V

Differential offset range ± 1V

Linearity ± 1% or less of dynamic range

Common-mode signal range +5Vto--4V

Common-mode rejection ratio ≥60 dB at DC

≥55 dB at 1 MHz

≥45 dB at 30 MHz

≥25 dB at 1 GHz

26

P6330 3.5 GHz Differential Probe Instruction Manual

Page 39

Table 4: Typical electrical characteristics (Cont.)

Characteristic Description

Delay time 5.4 ns

Specifications

Differential input resistance, DC coupled

Differential input capacitance < 0.3 pF at 100 MHz

Common-mode input resistance, DC

coupled

Common-mode input capacitance < 0.45 pF at 100 MHz (per side)

Input impedance SeeFigure12

Noise, referred to input 35 nV/√Hz

DC Offset Scale Accuracy

(gain of offset signal path)

DC Offset Drift

DC Voltage Measurement Accuracy

(referred to input)

100 kΩ ± 2%

50 kΩ ± 2% (per side)

ᐔ2.0%

150 V/°C or less at output of probe

0.75 mV/°C or less displayed on screen with

TEKPROBE interface

ᐔ[2% of input + (2% of offset) + 50.0 mV +

40.0 mV]

gain error = ᐔ2% of input voltage

offset gain error =ᐔ2% of effective offset at

probe tip

output zero = ᐔ50 mV effective at probe tip

linearity error = ᐔ1.0% of 4.0 V dynamic

range (40.0 mV)

P6330 3.5 GHz Differential Probe Instruction Manual

27

Page 40

Specifications

Figure 11 shows the typical common-mode gain of the probe. The

CMRR can be approximated by subtracting the common-mode gain

from the --14 dB reference level. For example, --80 dB CM gain

equals +66 dB CMRR.

Gain dB

-- 4 4

-- 5 2

-- 6 0

-- 6 8

-- 7 6

-- 8 4

10 MHz1 MHz 100 MHz

Frequency

1GHz

Figure 11: Typical common-mode gain

The graph in Figure 12 represents simulation results of a first order

model of the probe input.

Impedance (Ω)

100 k

10 k

1k

100

28

10

1M

10 M

100 M

Frequency (Hz)

1G

Figure 12: Typical differential input impedance vs frequency

P6330 3.5 GHz Differential Probe Instruction Manual

Page 41

Table 5: Typical mechanical characteristics

Dimensions, input connection 2.5 mm (0.99 in) pins on

2.54 mm (0.100 in) centers

Dimensions, control box 82 mm × 28 mm × 23 mm

(3.2 in × 1.1 in × 0.9 in)

Dimensions, probe head 59 mm × 7.7 mm × 5.1 mm

(2.3 in × 0.3 in × 0.2 in)

Dimensions, output cable 1.3m(51in)

Unit weight (probe only) 160g(5.4oz)

Specifications

0.3 in

2.3 in

0.2 in

0.1 in

1.1 in

3.2 in

Figure 13: Probe head and compensation box dimensions

0.9 in

P6330 3.5 GHz Differential Probe Instruction Manual

29

Page 42

Specifications

Nominal Characteristics

Nominal characteristics (Table 6) describe guaranteed traits, but the

traits do not have tolerance limits.

Table 6: Nominal electrical characteristics

Input configuration Differential (two inputs, + and -- ), with case

ground

Attenuation 5X

Input coupling DC

Termination

Terminate output into 50 Ω

30

P6330 3.5 GHz Differential Probe Instruction Manual

Page 43

WARNING

The following servicing instructions are for use only by

qualified personnel. To avoid injury, do not perform any

servicing other than that stated in the operating instructions

unless you are qualified to do so. Refer to all safety

summaries before performing any service.

Page 44

Page 45

Theory of Operation

There are no user replaceable parts within the probe or the

compensation box; however, this theory of operation is provided to

assist you in isolating failures to either the probe or the host

oscilloscope. Refer to Figure 14 for a simplified schematic of the

probe.

Probe Head Compensation Box Oscilloscope

Probe Tip

IN +

Probe Tip

IN --

Probe Tip

Ampifier

+offset

+

in

--

-- offset

+7 V

EEPROM

Offset Ampifier

Offset

Gain

Signal Out

Probe ID Out

Clock In

±1VOffset

Offset

Zero

+--

Linear

regulator

Probe

Cable

Figure 14: Simplified schematic diagram

P6330 3.5 GHz Differential Probe Instruction Manual

+15 V

+5 V

-- 5 V

Ground

TEKPROBE

Interface

33

Page 46

Theory of Operation

Probe Head and Cable Assembly

The probe head assembly contains an active amplifier circuit that

buffers and amplifies the input signal . The amp lifier receives power

and an offset level from the compensation box assembly via the

cable assembly.

All signal amplification and buffering is performed in the probe head

assembly. No further amplification takes place in the compensation

box.

Compensation Box

The compensation box contains the following circuits:

H Offset amplifier

H Probe identification EEPROM

H TEKPROBE interface

H DC CMRR adjustment circuitry

H V

Offset Amplifier

The offset amplifier is used to offset the DC component of the input

signal so that it stays at the optimal point of the linear dynamic range

of the probe.

The offset amplifier receives offset information as a ±1 VDC voltage

from the oscilloscope. The amplifier then amplifies it to match the

probe characteristics and applies it to the probe hybrid circuit.

The offset amplifier has two adjustments: offset zero and offset gain.

These adjustments rarely need attention; however, detailed

adjustment instructions are in the Adjustments sectiononpage47.

Probe Identification EEPROM

, +7 V linear regulator

CC

34

The probe identification EEPROM is used to configure the

oscilloscope to the probe. The EEPROM receives a c lock input from

the oscilloscope, and information about the probe is passed to the

oscilloscope.

P6330 3.5 GHz Differential Probe Instruction Manual

Page 47

Theory of Operation

TEKPROBE Interface

The TEKPROBE interface provide s a communication path between

the probe and the oscilloscope. Contact pins provide power, signal,

offset, and data transfer for the probe identification EEPROM.

Figure 15 shows the TEKPROBE interface pin functions. Refer to

the service documenation for your oscilloscope for more detailed

specifications.

--15 V

-- 5 V

Offset

Ground

Signal

Figure 15: TEKPROBE interface

Data

Clock

+5 V

+15 V

P6330 3.5 GHz Differential Probe Instruction Manual

35

Page 48

Theory of Operation

36

P6330 3.5 GHz Differential Probe Instruction Manual

Page 49

Performance Verification

Use the following procedures to verify specifications of the P6330

probe. Before beginning these procedures, refer to page 46 and

photocopy the test record, and use it to record t he performanc e test

results. The recommended calibrat ion interval is one year.

These procedures test the following specifications:

H Output offset voltage

H DC gain accuracy

H Rise time

Equipment Required

Refer to Table 7 for a list of the equipment required to verify the

performance of your probe.

Table 7: Equipment required for performance verification

Item description Performance requirement Recommended example

High Speed Sampling

Oscilloscope

Probe Calibration Fixture See page 39 067-0419-00

Probe Positioner Tektronix PPM203B

Power Supply TEKPROBE interface Tektronix 1103

Power Supply 5.0 VDC at 1 mA Tektronix PS280

DMM (2), with leads 0.1 mV resolution Fluke 87 or equivalent

Feedthrough Termination

Coaxial cables (2) Male-to-Male SMA, 20 in 174-1427-00

Coaxial cable

10 GHz bandwidth Tektronix TDS8000 with

80E04 module or 11800 with

SD24 module

BNC, 50 Ω ±0.05 Ω

Male-to-Male BNC, 50 Ω

011-0129-00

012-1342-00

P6330 3.5 GHz Differential Probe Instruction Manual

37

Page 50

Performance Verification

Table 7: Equipment required for performance verification (Cont.)

Item description Recommended examplePerformance requirement

Precision coaxial cable Male-to-Male SMA, 1 ns

delay

Adapter SMA Female-to-Female 015-1012-00

Adapters (2) SMA Female-to-BNC Male 015-0572-00

Adapter SMA Male jack 131-7128-00

Adapter BNC Female-to-Dual

Banana

Adapter Square pin adapter 016-1884-00

Adapter Y-lead adapter 196-3434-00

Adapters (2) KlipChip adapter 206-0364-00

015-0562-00

103-0090-00

Equipment Setup

Use this procedure to set up the equipment to test the probe.

1. Connect the probe to the 1103 power supply.

38

2. Turn on 1103 power supply.

3. Turn on the oscilloscope.

4. Allow 20 minutes for the equipment to warm up.

P6330 3.5 GHz Differential Probe Instruction Manual

Page 51

Probe Calibration Fixture

Some of the procedures in this manual use a probe calibration

fixture, Tektronix part number 067-0419-00.

The calibration fixture provides a me ans to test the probe for both

common mode and differential mode measurements. SMA

connectors allow stimulus signals to connect to the fixt ure and are

located on the front and back of the fixture . The fixt ure is designed

to be used with a probe positioner, such as a Tektronix PPM203B.

Performance Verification

Figure 16: Probe Calibration Fixture

Using the Probe Calibration Fixture

1. Connect the fixture to the test circuit using an SMA cable.

2. Connect the 50 Ω terminator included with the fixture to the

unused SMA connector.

3. Insert and secure the probe in a probe positioner.

4. Position the probe over the fixture, using either the positioner

coarse adjustment or otherwise manipulating the positioner arm

in place.

P6330 3.5 GHz Differential Probe Instruction Manual

39

Page 52

Performance Verification

5. Using the fine position and/or pressure adjust, maneuver the

probe so that the pins contact the CM or DM test points,

depending on which test you are performing. (See Figure 17.)

Common mode Differential mode

Figure 17: Probe Calibration Fixture test points

6. Verify that contact is made on both pins. (You may need to

readjust the fine position and/or pressure adjustment to make

positive contact with the test points.)

7. Proceed with the specific test instructions.

40

P6330 3.5 GHz Differential Probe Instruction Manual

Page 53

Output Offset Voltage

1. Connect the probe as shown in Figure 18.

Digital multimeter

50 Ω precision

terminator

Female BNC-to-male

banana adapter

CH 1

output

1103

Performance Verification

CH 1

input

KlipChip

adapters

Y-lead

adapter

50 Ω BNC cable

Square pin

adapter

Figure 18: Setup for the output offset voltage test

2. Set the Var/0v button on the 1103 power supply to 0v (light off).

3. Verify that the output voltage is 0 V,

DC Gain Accuracy

±10 mV.

1. Connect the probe input to the DC source, as shown in Figure 19

on page 42. Monitor the source voltage with the DMM.

2. Set the input voltage on the DC source to approximately +0.5 V.

Record the actual voltage as V

1.

in

P6330 3.5 GHz Differential Probe Instruction Manual

41

Page 54

Performance Verification

Power supply

-- +

Digital multimeter

KlipChip

adapters

Red (+)

Black (--)

Digital multimeter

Y-lead adapter

Female BNC-to-male

banana adapter

50 Ω precision

terminator

50 Ω BNC cable

Figure 19: DC Gain Accuracy setup

3. Record the output voltage as V

Square pin adapter

1.

out

P6330

CH 1

output

CH 1

input

1103

42

4. Set the input voltage on the DC source to approximately --0.5 V.

Record the actual voltage as V

5. Record the output voltage as V

6. Calculate the gain as follows: (V

in

out

2.

2.

out

1--V

2) ÷ (Vin1--Vin2).

out

7. Verify that the gai n is 0.2, ± 2%.

P6330 3.5 GHz Differential Probe Instruction Manual

Page 55

Rise Time

This procedure verifies that the probe meets rise time specifications.

Two rise times are measured; the test system, and the test system

with the probe included. The probe rise time is calculated using the

two measurements.

1. Connect the test equipment as shown in Figure 20.

Performance Verification

SD24/ 80E04

Oscilloscope

CH1

CH2

BNC-to-SMA adapter

SMA cable 015-0562-00

SMA cable 174-1427-00

Figure 20: Test system rise time setup

2. Adjust the oscilloscope vertical sensitivity to 50 mV/div.

3. Turn on the TDR pulse on the SD-24 or TDS8000 (Ch 2).

4. Adjust the oscilloscope vertical positioning to center the signal on

screen.

015-0572-00

BNC-to-SMA adapter

015-0572-00

CH 1

output

CH 1

input

1103

5. Adjust the oscilloscope horizontal sensitivity to 500 ps/div.

6. Adjust the oscilloscope horizontal positioning to place the rising

edge of the signal where it crosses the second vertical and center

horizontal graticule lines.

7. Use the oscilloscope measurement capability to display rise time.

Rise time is determined from the 10% and 90% amplitude points

on the waveform. Record the rise time as t

P6330 3.5 GHz Differential Probe Instruction Manual

s.

43

Page 56

Performance Verification

If the measurement reading is not stable, use Average mode

(16 Averages) to improve stability.

The system rise time (t

rise time of the test system without the probe. The system rise time is

used to calculate the probe rise time (t

The following steps instruct you to assemble the test setup that

includes the probe, as shown in Figure 21. The system and probe rise

time (t

rise time (t

Oscilloscope

CH1

CH2

) that you measured in step 7 represents the

s

)instep16.

p

)thatyoumeasureinstep15isusedtocalculatetheprobe

s+p

)instep16.

p

BNC-to-SMA

adapter

CH 1

input

1103

SD24/ 80E04

015-0572-00

SMA cable

015-0562-00

CH 1

output

SMA cable

174-1427-00

Probe cal fixture

067-0419-00

P6330

Figure 21: Test system rise time setup with probe

44

P6330 3.5 GHz Differential Probe Instruction Manual

Page 57

Performance Verification

8. Disconnect the BNC-SMA adapter from the CH 1 input of the

1103 power supply and the SMA cable.

9. Connect the SMA cable to one input of the probe cal fixture, and

the terminator to the other input of the probe cal fixture.

10. Connect the probe to the 1103 power supply channel 1 input.

11. Turn off the offset control on channel 1 of the 1103 power supply.

12. Using the probe positioner, probe the DM test points on the probe

calibration fixture. Compare your display to Figure 22 to verify

that you have a valid connection with both pins.

500 ps/div

20% Gain

difference

Both pins in contact

(--) pin not making contact

Figure 22: Verifying both probe pins are contacting the DM test points

13. Adjust the oscilloscope vertical scale to 10 mV/div, averaging on.

14. Adjust the oscilloscope horizontal positioning to place the rising

edge of the signal so that it crosses the second vertical and center

horizontal graticule lines.

15. Use the oscilloscope measurement capability to display rise time.

Rise time is determined from the 10% and 90% amplitude points

on the waveform. Record the rise time as t

s+p.

16. Calculate the probe rise time using the following formula:

Ꭹ

tp= t

2

(s+p)

− t

2

s

17. Record the calculated probe rise time on the test record.

P6330 3.5 GHz Differential Probe Instruction Manual

45

Page 58

Performance Verification

Test record

Probe Model:

Serial Number:

Certificate Number:

Temperature:

RH %:

Date of Calibration:

Technician:

Performance test Minimum Incoming Outgoing Maximum

Output offset voltage

DC gain accuracy -- 2 % ________ ________ +2%

Rise time N/A ________ ________ ≤140 ps

-- 1 0 m V ________ ________ +10mV

46

P6330 3.5 GHz Differential Probe Instruction Manual

Page 59

Adjustments

The P6330 has 3 internal controls: offset zero, offset range, and

DC CMRR. These controls should only be adjusted after a probe

performance verification and functional chec k has been performed

on the oscilloscope, and only if a check fails to meet its specification.

To make adjustments to the probe, the compensation box cover must

be removed and the equipment allowed to warm up for 20 minutes.

Equipment Required

In addition to the equipment required to perform the performance

verification, the adjustment procedures require the equipment listed

in Table 8.

Table 8: Additional equipment required for adjustment

Item description Recommended example

Release tool 003-1383-00

Adjustment tool 003-0675-01

P6330 3.5 GHz Differential Probe Instruction Manual

47

Page 60

Adjustments

Removing the Compensation Box Cover

Follow these steps to open the compensation box.

1. Press the optional release tool pins into the com pensation box

cover catches and gently lift the cover off a small distance. Refer

to Figure 23.

2. Hold the open edge apart, and use the tool to open the other side

of the compensation box.

3. With both sides of the box open, gently separate the two halves of

the compensation box.

Cover

catches

Figure 23: Removing the compensation box cover

Release tool

48

P6330 3.5 GHz Differential Probe Instruction Manual

Page 61

Adjustments

Figure 24 shows the location of the adjustments and test points inside

the compensation box. Refer to Figure 24 when performing the

adjustment procedures in this section.

Offset zero

CMRR

Offset range

Connector

test points

Figure 24: Adjustment and test point locations

NC

NC

Blk -- CMRR

Blu -- Offset

Wht -- 5V

NC

Red + 7V

P6330 3.5 GHz Differential Probe Instruction Manual

49

Page 62

Adjustments

Offset Zero and DC CMRR

Use the following procedures to adjust the offset zero and DC CMRR

characteristics of the probe. Due to the interaction of the two

adjustments, it may be necessary to repeat the procedure to optimize

the adjustments.

NOTE. If your oscilloscope has a probe calibration routine, clear the

probe calibration constants at this time.

If the offset zero is adjusted, perform a functional check of the offset

range before closing the compensation box.

1. Connect the probe tips together using the square pin, Y-lead, and

KlipChip adapters.

2. Connect the probe as shown in Figure 18 on page 41.

3. Set the Var/0v button on the 1103 power supply to 0v (light off).

The output offset voltage is displayed on the DMM.

4. Adjust Offset Zero for 0.00 V ±3mV,displayedontheDMM.

Record the actual value.

5. Connect the probe as shown in Figure 25 on page 51. Monitor the

source voltage with the DMM.

50

P6330 3.5 GHz Differential Probe Instruction Manual

Page 63

Power supply

-- +

Adjustments

Digital multimeter

KlipChip

adapters

Red (+)

Black (--)

Digital multimeter

Y-lead adapter

Female BNC-to-male

banana adapter

50 Ω precision

terminator

50 Ω BNC cable

Square pin adapter

Figure 25: Offset zero and DC CMRR setup

6. Set the input voltage on the DC source to 3.0 V, ±10 mV.

P6330

CH 1

output

CH 1

input

1103

7. Adjust the CMRR control in the probe for an output equal to the

value measured in step 4 on page 50, ±0.1 mV.

8. Set the input voltage on the DC source to approximately +3.0 V.

Record the actual voltage as V

9. Record the output voltage as V

in

out

1.

1.

10. Set the input voltage on the DC source to approximately --3.0 V.

Record the actual voltage as V

11. Record the output voltage as V

in

out

2.

2.

P6330 3.5 GHz Differential Probe Instruction Manual

51

Page 64

Adjustments

12. Calculate the common-mode gain (A

(V

out

1--V

2) ÷ (Vin1--Vin2).

out

13. Calculate the CMRR as follows: 20 log (0.2/|A

) as follows:

CM

CM

|)

14. Reverify that the offset is 0 V, ±3.0 mV (repeat steps 1

through 3). If the offset voltage magnitude is greater than 3.0 mV,

or if the CMRR is less than 60 dB, disconnect the probe from the

test circuit. Repeat the procedure, beginning with step 1 on

page 50, to compensate for the adjustment interaction.

52

P6330 3.5 GHz Differential Probe Instruction Manual

Page 65

Offset Range

Use this procedure to adjust the offset range of the probe. The offset

zero of the probe must be measured before making any adjustment to

the offset range. The offset zero voltage that you measure in the Zero

Offset procedure (step 4 on page 50), is the target value that you

adjust the offset range to. The offset range of the probe is approximately --1.0 to +1.0 volts. Take care not to disturb the power supply

settings as you perform these procedures.

1. Connect the equipment as shown in Figure 26.

2. Power on the 1103 power supply and turn on the offset.

3. RefertoFigure24onpage49forthelocationoftheoffset

voltage test point. Using a second DMM, probe the test point and

adjust the 1103 offset voltage to exactly --0.750 V.

Adjustments

Digital multimeter

BNC-to-dual

Banana adapter

4. Next, use the second DMM to set the DC power supply to exactly

+0.750 V, measured at the output of the power supply.

5. Observe the DC value on the DMM connected to the 1103 power

supply.

1103

50 Ω Precision

terminator

Power supply

Y-lead adapter

Power supply

-- +

KlipChip

adapters

Square-pin adapter

P6330 Probe

Figure 26: P6330 offset range setup

P6330 3.5 GHz Differential Probe Instruction Manual

53

Page 66

Adjustments

6. Adjust Offset Range for a DMM reading equal to the value set in

the Zero Offset procedure (step 4 on page 50), ±3mV.Referto

Figure 24 on page 49 for the location of the offset range

adjustment.

This completes the adjustments to the probe. Replace the compensation box cover and do a performance verification of the probe.

Replacing the Compensation Box Cover

To replace the cover, follow these steps:

1. Align the TEKPROBE interface and the tab notches with the tabs

on the cover. Refer to Figure 27.

2. Press the cover catches in so that the cover can be lowered.

3. Slide the tab into the notch.

4. Firmly press the pieces together until the cover catches snap into

place.

Tab

54

Figure 27: Replacing the compensation box cover

P6330 3.5 GHz Differential Probe Instruction Manual

Page 67

Maintenance

This section details the maintenance and repair procedures for the

P6330 differential probe.

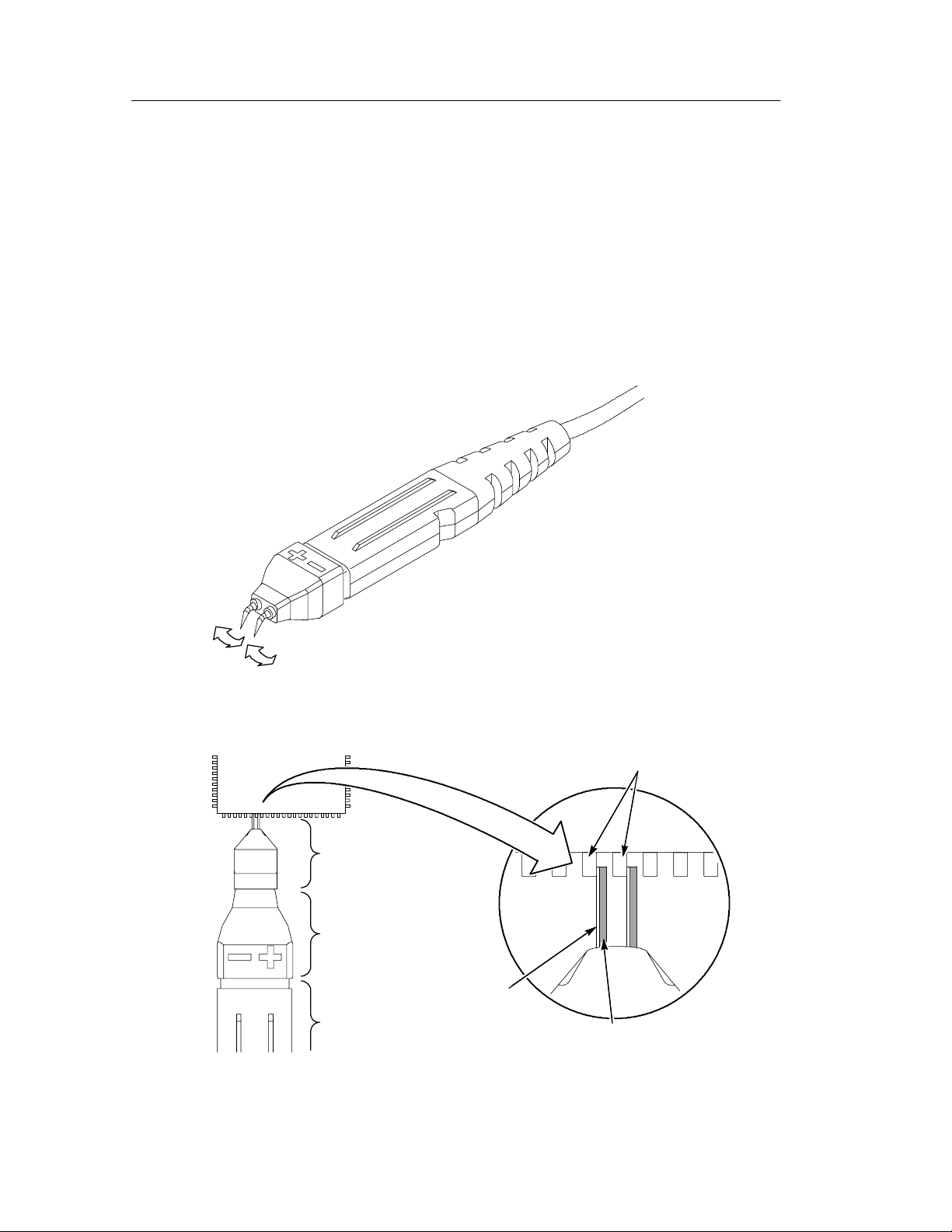

Replacing TEKPROBE Interface Pins

TEKPROBE interface pins can stic k and fail to make contact after

time. Periodically check to see that each of the interface pins move

freely and fully extends out of the interface. If any pin fails to move

freely and fully extend, it should be replaced.

To remove a TEKPROBE interface pin, firmly grasp the pointed tip

with pliers and pull the pin out of the connector. See Figure 28.

No tools are required to install a replacement pin. Insert a new pin

into the connector socket as far as possible using finger pressure. If

necessary, seat the pin into the connector by pressing the tip gently

but firmly against a hard surface, such as a wood block or table top.

Figure 28: Replacing TEKPROBE interface pins

P6330 3.5 GHz Differential Probe Instruction Manual

55

Page 68

Maintenance

Removing and Replacing the TEKPROBE Interface Collar

To remove the TEKPROBE interface collar, firmly grasp the

compensation box body with one hand and the TEKPROBE interface

collar with the other hand. Firmly pull the interface collar off.

To replace the collar, first note the pin configuration on the

compensation box and their holes in the interface collar. The group

of three pins fit through the smaller of the two holes in the inte rface

collar. See Figure 29.

Align the tab to the slot, and gently press the two pieces together.

See Figure 29.

Once installed, the TEKPROBE c ollar should rotate freely to lock

and unlock.

56

Tab

Slot

Figure 29: Replacing the TEKPROBE interface collar

P6330 3.5 GHz Differential Probe Instruction Manual

Page 69

Inspection and Cleaning

To prevent damage to probe materials, avoid using chemicals that

contain benzine, benzene, toluene, xylene, acetone, or similar

solvents.

Do not immerse the probe or use abrasive cleaners.

Dirt may be removed with a soft cloth dampened with a mild

detergent and water solution, or isopropyl alcohol.

Replacement Parts

Refer to the Replaceable Parts section for a list of customer

replacement parts. Due to the sophisticated design of the P6330,

there are no user replaceable parts within the probe.

Maintenance

Preparation for Shipment

If the original packaging is unfit for use or not available, use the

following packaging guidelines:

1. Use a corrugated cardboard shipping carton having inside

dimensions at least one inch greater than the probe dimensions.

The box should have a carton test strength of at least 200 pounds.

2. Put the probe into an antistatic bag or wrap to protect it from

dampness.

3. Place the probe into the box and stabilize it with light packing

material.

4. Seal the carton with shipping tape.

P6330 3.5 GHz Differential Probe Instruction Manual

57

Page 70

Maintenance

58

P6330 3.5 GHz Differential Probe Instruction Manual

Page 71

Replaceable Parts

This section contains a list of replaceable parts for the P6330

differential probe. Use this list to identify and order replacement

parts.

Parts Ordering Information

Replacement parts are available from or through your local

Tektronix, Inc. service center or representative.

Changes to Tektronix instruments are sometimes made to accommodate improved components as they become available and to give you

the benefit of the latest circuit improvements. Therefore, when

ordering parts, it is important to include the following information in

your order:

H Part number

H Instrument type or model number

H Instrument serial number

H Instrument modification number, if applicable

If a part you order has been replac ed with a different or improved

part, your local Tektronix service center or representative will

contact you concerning any change in the part number.

P6330 3.5 GHz Differential Probe Instruction Manual

59

Page 72

Replaceable Parts

Using the Replaceable Parts List

The tabular information in the Repl aceable Parts List is arranged for

quick retrieval. Understanding the structure and features of the list

will help you find the information you need for ordering replacement

parts.

Item Names

In the Replaceable Parts List, an Item Name is separated from the

description by a colon (:). Because of space limitations, an Item

Name may sometimes appear as incomplete. For further Item Name

identification, U.S. Federal Cataloging Handbook H6-1 can be used

where possible.

Indentation System

This parts list is indented to show the relationship between items.

The following example is of the indentation system used in the

Description column:

12345 Name&Description

Assembly and/or Component

Attaching parts for Assembly and/or Component

(END ATTACHING PARTS)

Detail Part of Assembly and/or Component

Attaching parts for Detail Part

(END ATTACHING PARTS)

Parts of Detail Part

Attaching parts for Parts of Detail Part

(END ATTACHING PARTS)

Attaching parts always appear at the same indentation as the item it

mounts, while the detail parts are indented to the right. Indented

items are part of, and included with, the next higher indentation.

Attaching parts must be purchased separately, unless otherwise

specified.

Abbreviations

60

Abbreviations conform to American National Standards Institute

(ANSI) standard Y1.1

P6330 3.5 GHz Differential Probe Instruction Manual

Page 73

Replaceable Parts

5

3

2

4

P6330 3.5 GHz Differential Probe Instruction Manual

1

Figure 30: P6330 replaceable parts

61

Page 74

Replaceable Parts

Mfr. part no.

Mfr.

code

12345 name & description

Qty

Serial no.

Effective Dscont

part no.

Tektronix

010-0640-04 1 PROBE ASSEMBLY:SERVICE REPLACEMENT, SERIALIZ ED 80009 010-0640-04

-2 205-0191-XX 1 SHELL,ELEC CONN:BNC,ABS,DOVE GRAY 80009 205-0191-XX

-3 131-3627-02 1 CONTACT,ELEC:GOLD PLATED TIP 80009 131-3627-02

-4 200-4236-00 1 COVER, PROBE TIP 80009 200-4236-00

Fig. &

index no.

30-1

-5 016-1879-XX 1 CASE,STORAGE:PLASTIC,W/ANTISTAT FOAM TK6108 016-1879-XX

P6330 3.5 GHz Differential Probe Instruction Manual62

Page 75

Replaceable Parts

10

5 6

4

1 2 3

9

8

7

P6330 3.5 GHz Differential Probe Instruction Manual

Figure 31: P6330 standard accessories

63

Page 76

Replaceable Parts

Mfr. part no.

Mfr.

code

060D9 196-3434-00

060D9 196-3473-00

TK0623 RTI 8454001829

CORD

071-0757-XX 1 MANUAL,TECH:INSTRUCTION,P6330 80009 071-0757-XX

-10 006-3415-04 1 STRAP,WRIST:3M TYPE 2214, ADJUSTABLE,6 FT COILED

-2 196-3473-00 2 LEAD,PIN JUMPER:DIFF,FEMALE SQ PIN CONNECTOR

TO FEMALE SQ PIN CONNECTO R,23 AWG,3.0 L

-3 196-3465-00 2 LEAD GROUND:GROUND LEAD 196-3465-00

-4 016-1785-00 1 ADAPTER:DIFFERENTIAL PROBE,PKG OF 4 80009 016-1785-00

-5 016-1884-00 1 ACCESSORY KIT:SQUARE PIN ADAPTER,PKG OF 4 060D9 016-1884-00

-6 016-1885-00 1 ACCESSORY KIT:VARIABLE SPACER ADAPTER,PKG OF 4 060D9 016-1885-00

-7 016-1315-00 1 MARKER KIT,ID:CABLE MARKER BAND,2 EA, VAR COLRS 80009 016-1315-00

-8 006-7164-00 1 BOX,PLASTIC: 4.625 X 2.875 X 1.0 80009 006-7164-00

-9 206-0364-XX 2 TIP,PROBE:MICROCKT TEST,SMT KLIPCHIP 80009 206-0364-XX

STANDARD ACCESSORIES

12345 name & description

Qty

Serial no.

Effective Dscont

part no.

Tektronix

Fig. &

index no.

BLACK,2.300 L,1X2,0.1CTR,0.025 SQ PIN X 2,JACK TIP

31-1 196-3434-00 2 LEAD, ELEC:DESCRETE,CPD,2,22 AWG,RED &

P6330 3.5 GHz Differential Probe Instruction Manual64

Page 77

Replaceable Parts

6

4

3

2

5

1

Figure 32: P6330 optional accessories

P6330 3.5 GHz Differential Probe Instruction Manual

65

Page 78

Replaceable Parts

Mfr. part no.

Mfr.

code

DESCRIPTION

OPTIONAL ACCESSORIES

12345 name & description

Qty

Serial no.

Effective Dscont

part no.

Tektronix

SMG50 1 MICROCKT TEST,SMT KLIPCHIP,PKG OF 20 (SEE 31-9) 80009 SMG50

2 003-1383-00 1 RELEASE TOOL 80009 003-1383-00

3 679-5027-00 1 CKT BD SUBASSY:1394 ADAPTER 80009 679-5027-00

Fig. &

index no.

32-1 003-0675-01 1 ADJUSTMENT TOOL,PLASTIC,BLACK TK2565 003-0675-01

5 1103 1 TEKTRONIX 1103 TEKPROBE POWER SUPPLY 80009 ORDER BY

4 067-0419-00 1 PROBE CALIBRATION FIXTURE 80009 067-0419-00

6 SMK4 1 TIP,PROBE:MICROCKT TEST,PKG OF 4 80009 SMK4

P6330 3.5 GHz Differential Probe Instruction Manual66

Page 79

BEAVERTON, OR 97077-0001

Replaceable Parts

PO BOX 500

CROSS INDEX - MFR. CODE NUMBER TO MANUFACTURER

UNITREK CORPORATION 3000 C O LUMBIA HOUSE BLVD, SUITE 120 VANCOUVER, WA 98661

Mfr. code Manufacturer Address City, state, zip code

060D9