Page 1

Instruction Manual

P6249

4 GHz 5X Active Probe

071-0538-03

www.tektronix.com

Page 2

Copyright © Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and

pending. Information in this publication supercedes that in all previously

published material. Specifications and price change privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

TEKTRONIX, TEK, TEKPROBE, and SureFoot are registered trademarks,

and SureToe, FlexLead, and KlipChip are trademarks of Tektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects

in materials and workmanship for a period of one (1) year from the date of shipment. If a

product proves defective during this warranty period, Tektronix, at its option, either will

repair the defective product without charge for parts and labor, or will provide a

replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the

defect before the expiration of the warranty period and make suitable arrangements for the

performance of service. Customer shall be responsible for packaging and shipping the

defective product to the service center designated by Tektronix, with shipping charges

prepaid. T ektronix shall pay for the return of the product to Customer if the shipment is to

a location within the country in which the Tektronix service center is located. Customer

shall be responsible for paying all shipping charges, duties, taxes, and any other charges for

products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or

improper or inadequate maintenance and care. Tektronix shall not be obligated to furnish

service under this warranty a) to repair damage resulting from attempts by personnel other

than Tektronix representatives to install, repair or service the product; b) to repair damage

resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a

product that has been modified or integrated with other products when the effect of such

modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER

WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS

DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY

TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF

THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE

FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR

HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description

Options 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Accessories 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Accessories 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting Tektronix 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features and Accessories

Configuration

Probe Offset 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Check

Deskew Fixture 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Calibration Errors 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Compatibility 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check for Hardware Problems 17. . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Basics

Handling the Probe 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Non-destructive Input Voltage 19. . . . . . . . . . . . . . . . .

Input Linear Dynamic Range 19. . . . . . . . . . . . . . . . . . . . . . . . . . .

Ground Lead Length 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helpful Hints

Low-Inductance Grounding 23. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SureFoot Grounding 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Tip Test Points 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P6249 4 GHz 5X Active Probe Instruction Manual

i

Page 6

Table of Contents

Specifications

Theory of Operation

Probe Head and Cable Assembly 36. . . . . . . . . . . . . . . . . . . . . . .

Compensation Box 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Offset Amplifier 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Identification EEPROM 36. . . . . . . . . . . . . . . . . . . . . . . . .

TEKPROBE Interface 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VCC, +7 V Regulator 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification

Equipment Required 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Setup 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Zero 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Attenuation Accuracy 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rise Time 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustments

Adjustment Locations 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Offset Zero 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Offset Range 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance

Replacing TEKPROBE Interface Pins 53. . . . . . . . . . . . . . . . . . .

Removing and Replacing the Compensation Box Covers 54. . . . .

Removing and Replacing the TEKPROBE Interface Collar 56. . .

Inspection and Cleaning 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement Parts 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation for Shipment 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting

Replaceable Parts

Parts Ordering Information 63. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List 64. . . . . . . . . . . . . . . . . . . . . . . .

ii

P6249 4 GHz 5X Active Probe Instruction Manual

Page 7

List of Figures

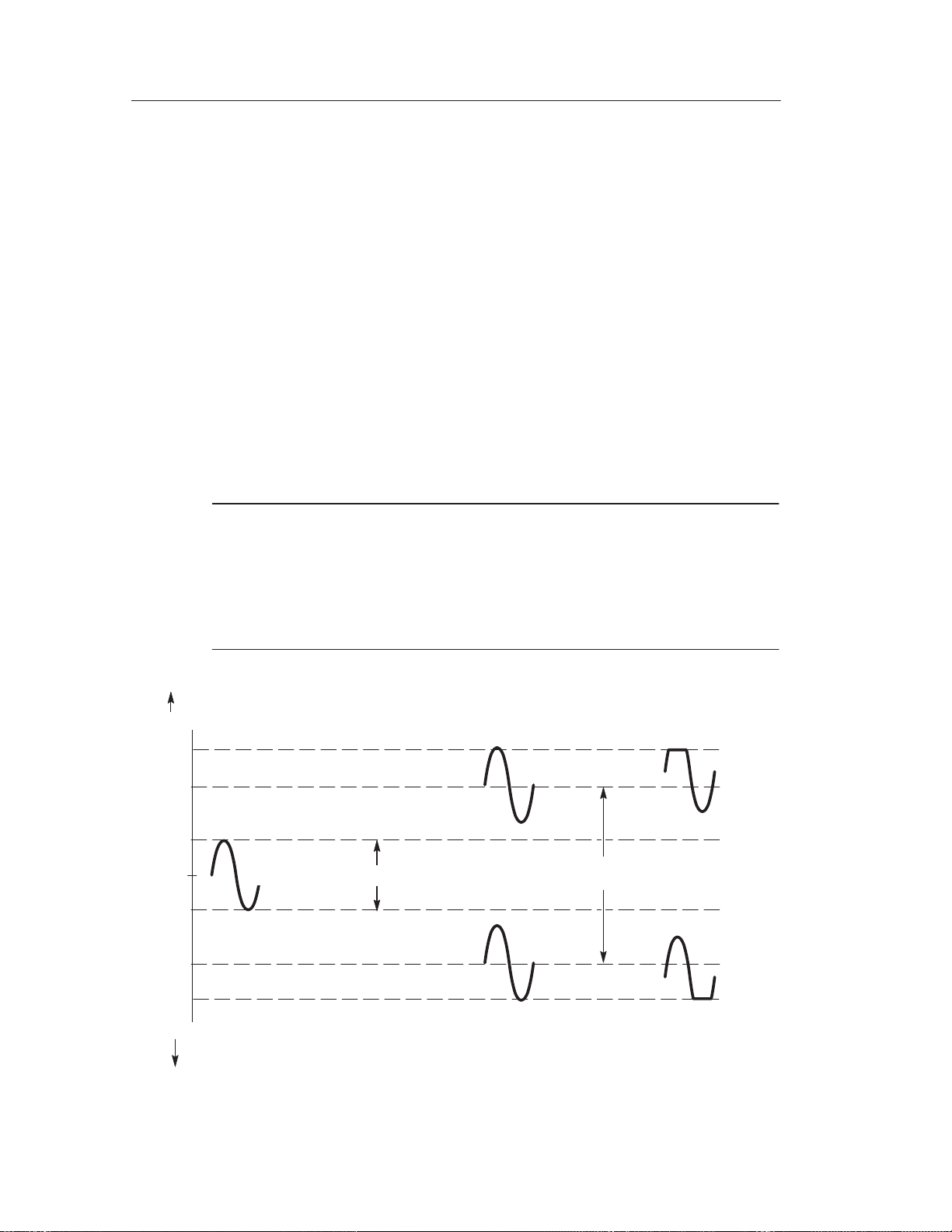

Figure 1: Dynamic and offset limitations 12. . . . . . . . . . . . . . . . .

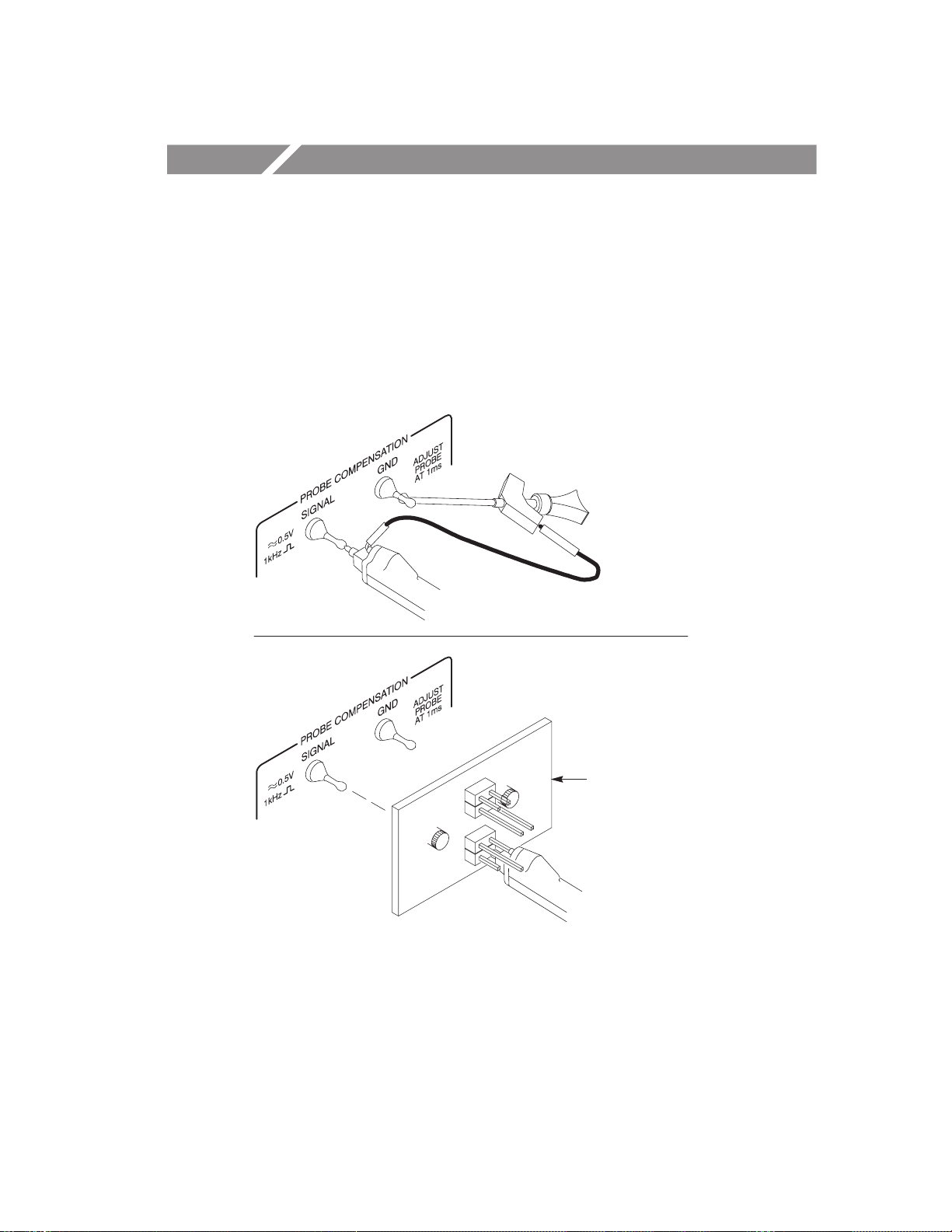

Figure 2: Probe functional check connections 13. . . . . . . . . . . . . .

Figure 3: Deskew fixture connections

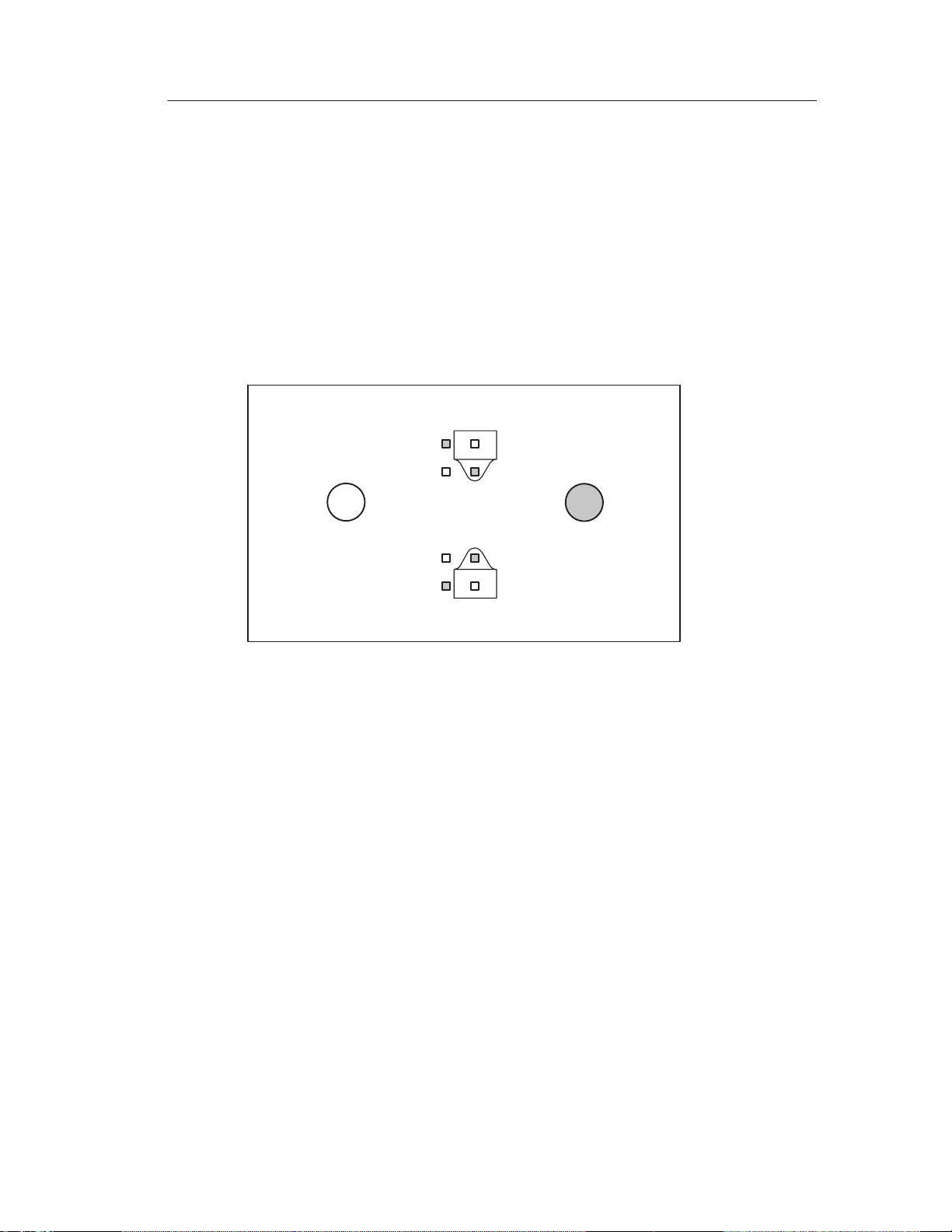

(two P6249 probes shown) 15. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4: Maximum frequency vs. measurement lead length 21. .

Figure 5: Low-inductance grounding 23. . . . . . . . . . . . . . . . . . . .

Figure 6: Using a SureFoot adapter for grounding 24. . . . . . . . . .

Figure 7: Using a probe tip as a test point 25. . . . . . . . . . . . . . . . .

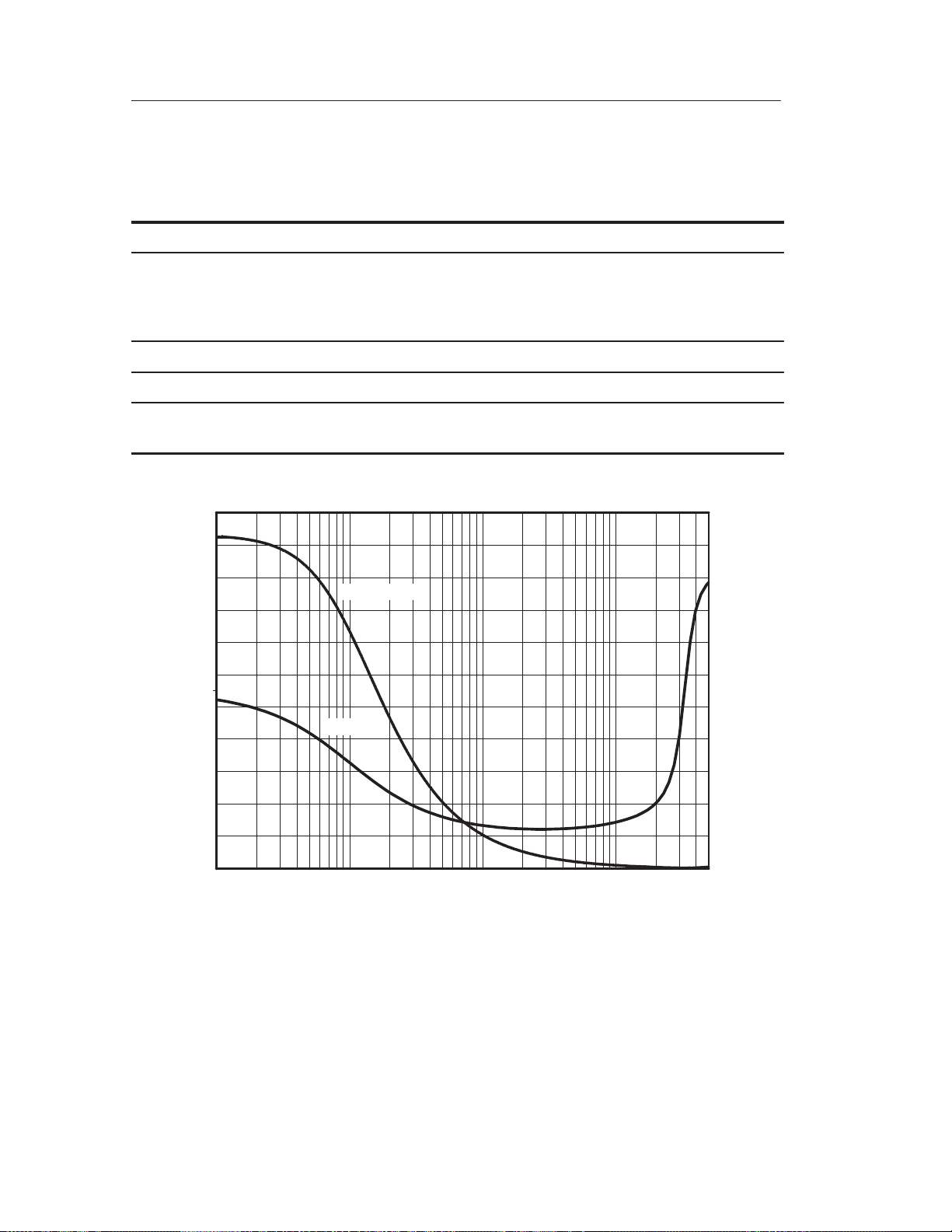

Figure 8: Typical input impedance and phase versus frequency 28

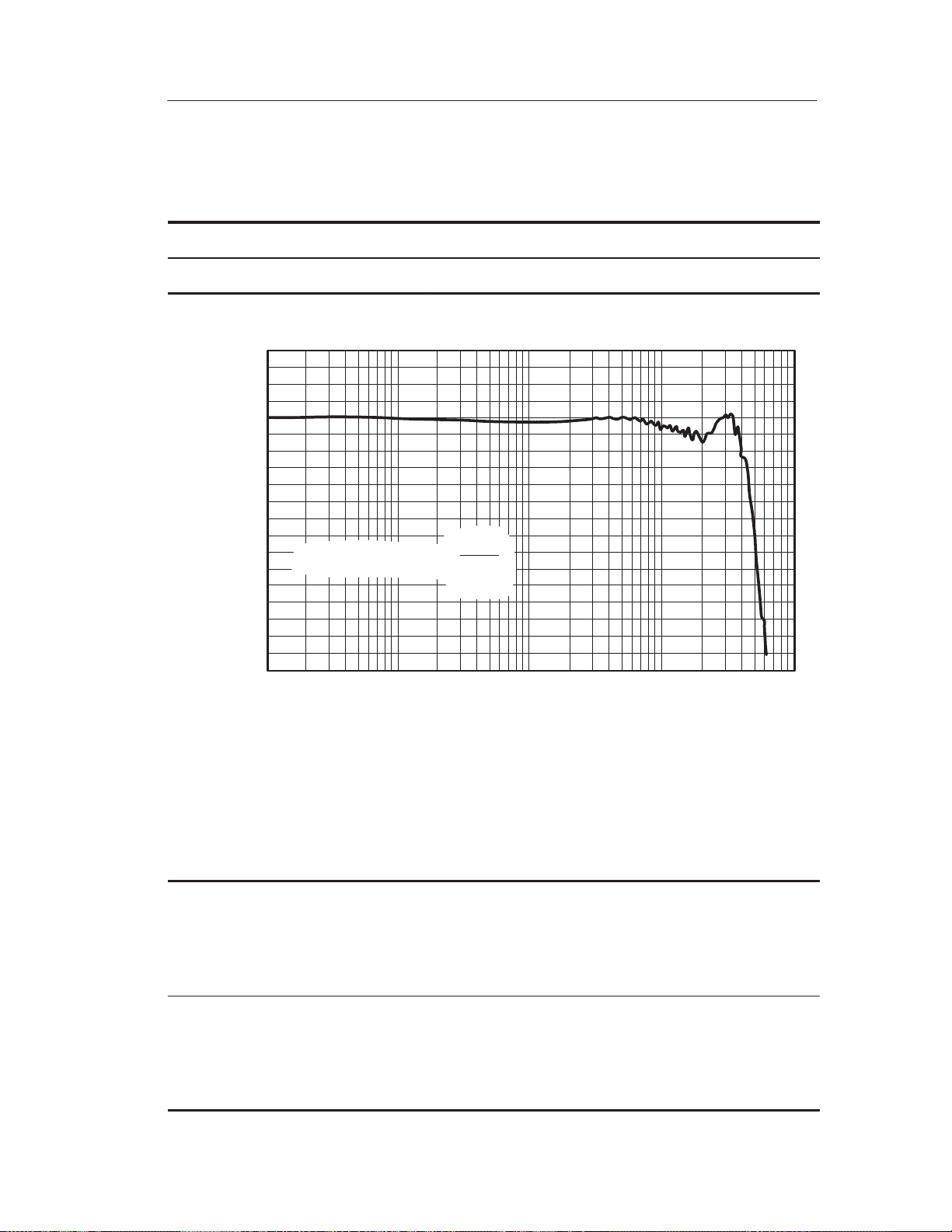

Figure 9: Typical bandwidth 29. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10: P6249 simplified schematic diagram 35. . . . . . . . . . . .

Figure 11: TEKPROBE interface 37. . . . . . . . . . . . . . . . . . . . . . .

Figure 12: Setup for output zero and DC attenuation accuracy 41

Figure 13: Test system rise time setup 44. . . . . . . . . . . . . . . . . . . .

Figure 14: Test system and probe rise time setup 45. . . . . . . . . . .

Figure 15: P6249 adjustment locations 49. . . . . . . . . . . . . . . . . . .

Figure 16: 1103 power supply of fset voltage location 51. . . . . . . .

Figure 17: P6249 offset range setup 52. . . . . . . . . . . . . . . . . . . . .

Figure 18: Replacing TEKPROBE interface pins 53. . . . . . . . . . .

Figure 19: Removing the compensation box covers 54. . . . . . . . .

Figure 20: Replacing the compensation box cover 55. . . . . . . . . .

Figure 21: Replacing the TEKPROBE interface collar 56. . . . . . .

Figure 22: Compensation box test point locations 60. . . . . . . . . .

Figure 23: P6249 replaceable parts 65. . . . . . . . . . . . . . . . . . . . . .

Figure 24: P6249 standard accessories 66. . . . . . . . . . . . . . . . . . .

Figure 25: P6249 optional accessories 68. . . . . . . . . . . . . . . . . . .

Table of Contents

P6249 4 GHz 5X Active Probe Instruction Manual

iii

Page 8

Table of Contents

iv

P6249 4 GHz 5X Active Probe Instruction Manual

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent

damage to this product or any products connected to it. To avoid

potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or Personal Injury

Connect and Disconnect Properly. Connect the probe output to the

measurement instrument before connecting the probe to the circuit

under test. Disconnect the probe input and the probe ground from the

circuit under test before disconnecting the probe from the measurement instrument.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe

all ratings and markings on the product. Consult the product manual

for further ratings information before making connections to the

product.

Connect the ground lead of the probe to earth ground only.

Do Not Operate Without Covers. Do not operate this product with

covers or panels removed.

Do Not Operate With Suspected Failures. If you suspect there is

damage to this product, have it inspected by qualified service

personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry .

P6249 4 GHz 5X Active Probe Instruction Manual

v

Page 10

General Safety Summary

Safety Terms and Symbols

Terms in This Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that

could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that

could result in damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you

read the marking.

WARNING indicates an injury hazard not immediately accessible as

you read the marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. These symbols may appear on the product:

CAUTION

Refer to Manual

vi

P6249 4 GHz 5X Active Probe Instruction Manual

Page 11

Service Safety Summary

Only qualified personnel should perform service procedures. Read

this Service Safety Summary and the General Safety Summary before

performing any service procedures.

Do Not Service Alone. Do not perform internal service or adjustments

of this product unless another person capable of rendering first aid

and resuscitation is present.

P6249 4 GHz 5X Active Probe Instruction Manual

vii

Page 12

Service Safety Summary

viii

P6249 4 GHz 5X Active Probe Instruction Manual

Page 13

Product Description

The Tektronix P6249 is a 4 GHz (probe only), 5X active FET probe

with 1 pF input capacitance. The P6249 has a low input capacitance

and high input resistance which minimize circuit loading over a wide

bandwidth range. The small profile and low-mass head of the P6249

make probing crowded circuits by hand fast and easy. The accessory

tips and adapters included with the probe enable the P6249 to be

used on a wide variety of circuit architectures.

The P6249 is powered through a TEKPROBE interface between the

probe compensation box and the oscilloscope. The P6249 can be

used with non-TEKPROBE oscilloscopes and instruments by using

the optional Tektronix 1103 Probe Power Supply .

Options

The following options are available when ordering the P6249 probe:

H Option D1 – Calibration Data

H Option C3 – 3 years Calibration Service

H Option D3 – 3 years Calibration Data

H Option R3 – 3 years Extended Warranty

Standard Accessories

The P6249 is shipped with the following standard accessories:

H Standard probe tips

H SureFoot adapter probe tips

H SureToe adapter probe tips

H SMT KlipChip microcircuit test leads

H Y-lead adapter

P6249 4 GHz 5X Active Probe Instruction Manual

1

Page 14

Product Description

H Right-angle adapter

H Three-inch ground lead

H Low-inductance ground pogo pin

H Color marker bands

H SMK4 Micro KlipChip adapters

H .100” square pin adapter

H Instruction manual

Optional Accessories

The following accessories are available for the P6249 probe:

H Deskew fixture

H Probe tip-to-SMA adapter

H 1103 Probe Power Supply

H Compensation box release tool

H Insulated adjustment tool

Refer to Features and Accessories on page 5 for more information on

using the probe and accessories.

For part number information for standard and optional accessories,

refer to Replaceable Parts on page 63.

2

P6249 4 GHz 5X Active Probe Instruction Manual

Page 15

Contacting Tektronix

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Product Description

Sales

support

Service

support

Technical

support

* This phone number is toll free in North America. After office

hours, please leave a voice mail message.

Outside North America, contact a T ektronix sales office or

distributor; see the Tektronix web site for a list of offices.

1-800-833-9200, select option 1*

1-800-833-9200, select option 2*

Email: techsupport@tektronix.com

1-800-833-9200, select option 3*

6:00 a.m. – 5:00 p.m. Pacific time

P6249 4 GHz 5X Active Probe Instruction Manual

3

Page 16

Product Description

4

P6249 4 GHz 5X Active Probe Instruction Manual

Page 17

Features and Accessories

The P6249 is provided with several features and accessories designed

to make probing and measurement a simpler task. Please familiarize

yourself with these items and their uses.

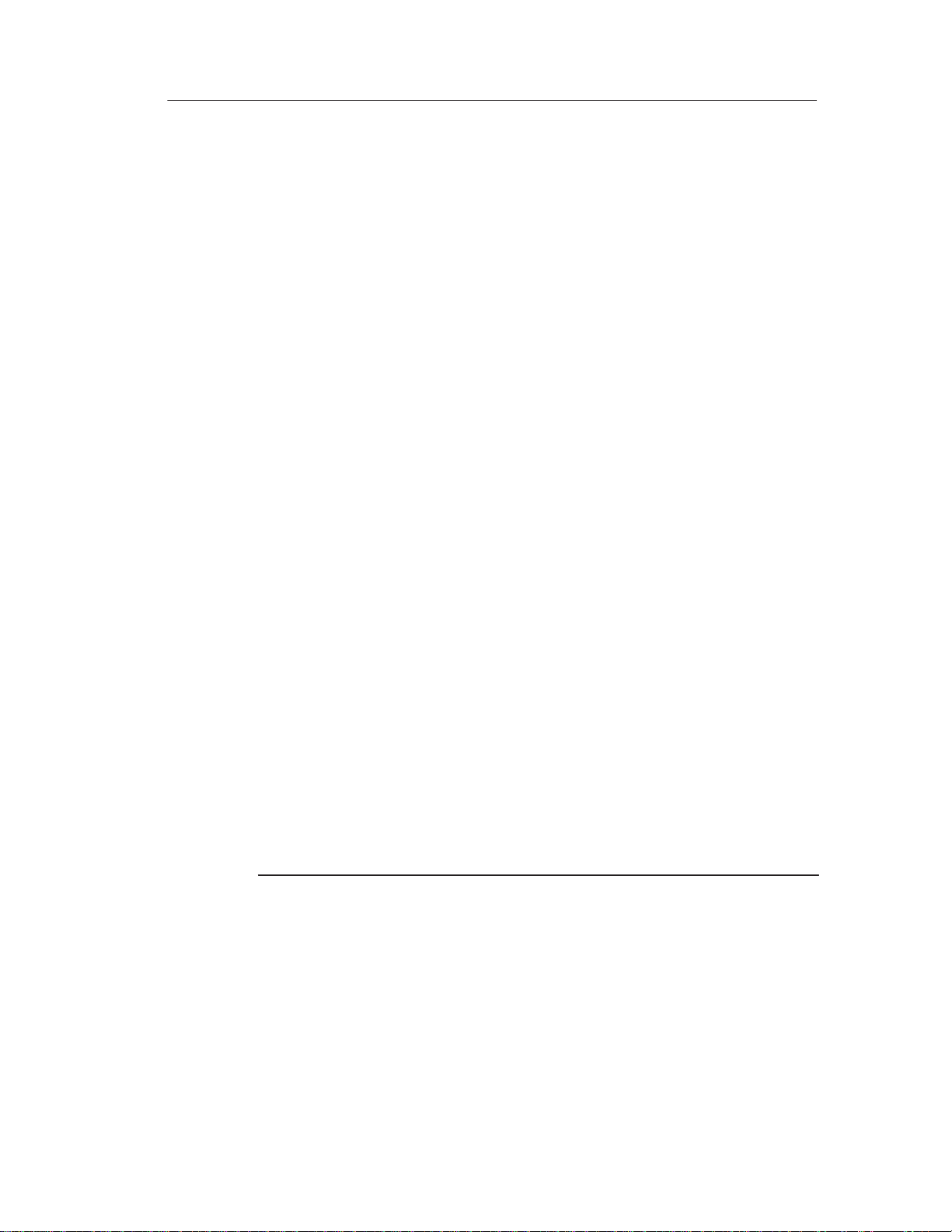

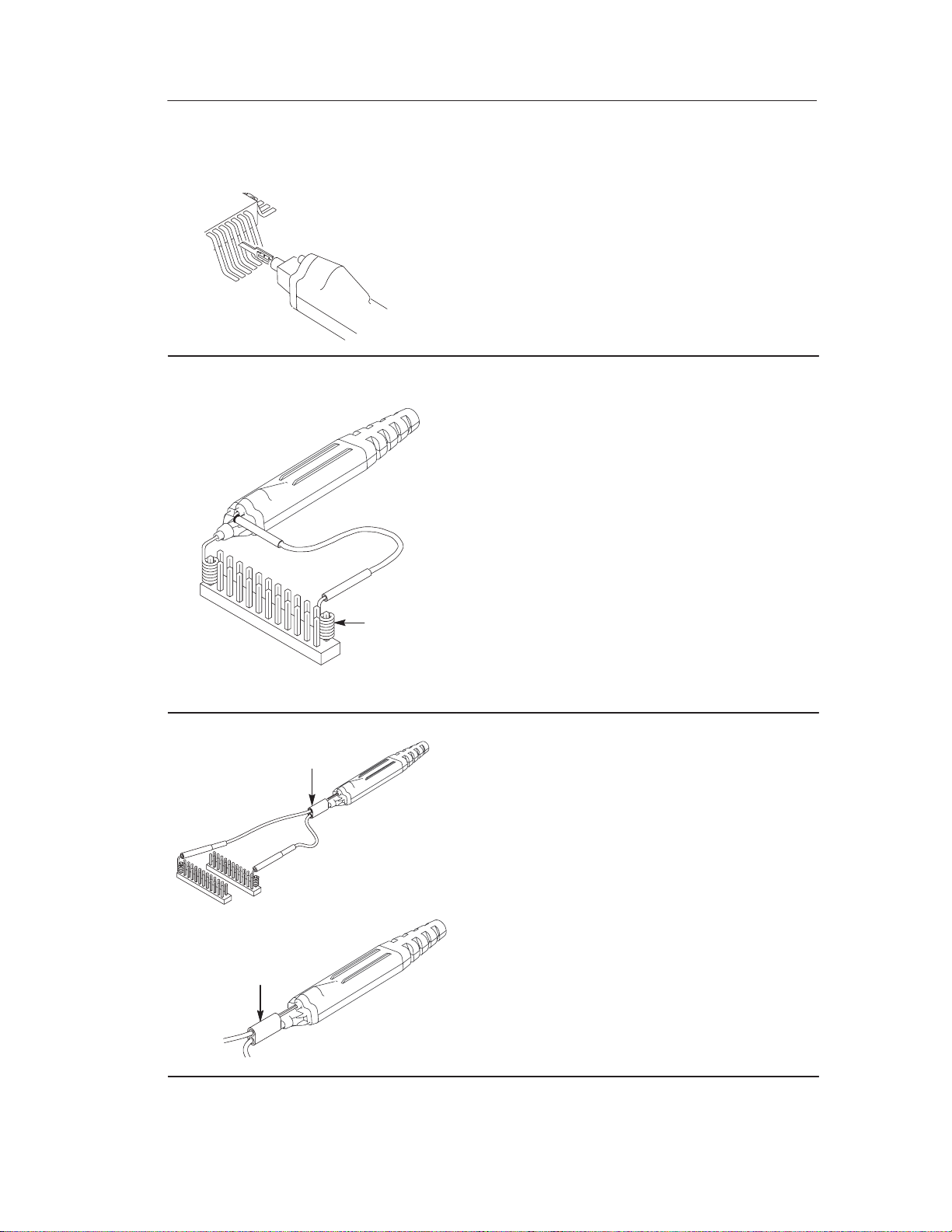

Probe head assembly. The probe head is

designed for ease of use and high performance.

Its small size makes it easy to handle in tight

Probe tip

socket

Ground

socket

Stabilization

notch

areas.

The probe tip socket is sized to easily press onto

0.025 inch pins for direct access. The ground

socket provides a short ground path for high

fidelity ground connections.

The stabilization notch permits you to use

adjacent pins to reduce stresses on the probe

and pins.

Push-in probe tip

TEKPROBE Interface. The TEKPROBE

interface provides a communication path between

the probe and the oscilloscope. Contact pins

provide power, signal, offset, and probe

characteristic data transfer. See page 37 for more

information.

If your oscilloscope does not support the

TEKPROBE interface, you can use the optional

1103 probe power supply as an effective

interface. Contact your local Tektronix representative for more information.

Push-in probe tip. Use the push-in probe tip

for general purpose probing by hand. The tip may

also be used as a temporary test point. See

page 25 for more information.

The push-in probe tip may also be used with the

other socketed leads and adapters.

P6249 4 GHz 5X Active Probe Instruction Manual

5

Page 18

Features and Accessories

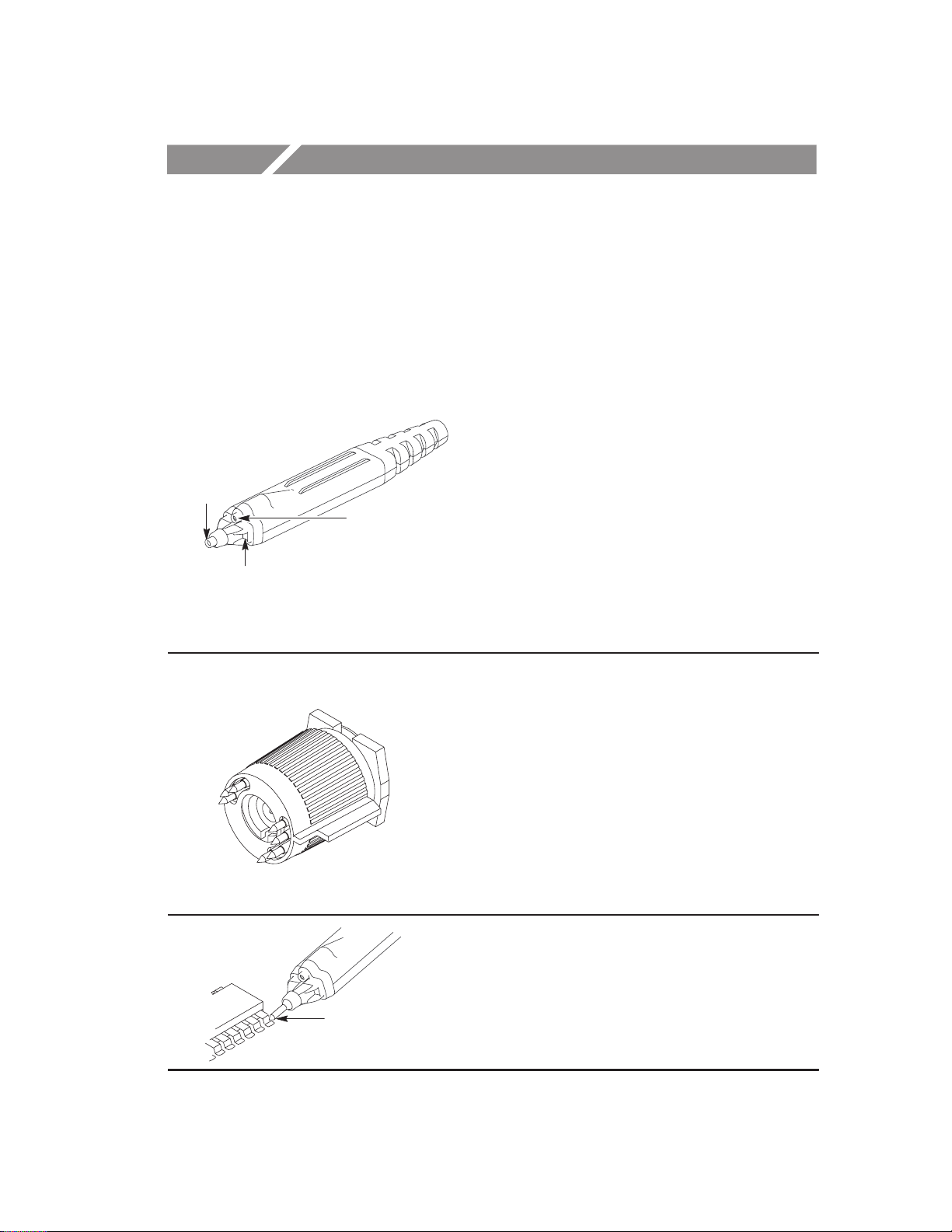

Installing the push-in probe tip. Attach the

push-in probe tip by seating the tip into the probe

tip socket and pushing the tip in until it is seated.

Either end of the tip may be used.

Do not force the tip. Also, be careful not to poke

yourself with the sharp probe-tip. To remove the

tip, gently grab the tip with small pliers and pull

the tip out.

SureFoot probe tip. The SureFoot tip is an

integral probe tip and miniature guide that

enables fault-free probing of fine-pitch SMD

packages. Attach SureFoot adapters the same

way as the push-in probe tips. They can be used

with any of the socketed accessory leads.

The orange, 0.050 inch SureFoot tip is compatible

with 50 mil JEDEC packages such as SOIC,

PLCC, CLCC, etc.

The blue, 0.025 inch SureFoot tip is compatible

with 0.65 mm JEDEC and EIAJ packages.

The red, 0.5 mm SureFoot tip is compatible with

EIAJ packages.

6

P6249 4 GHz 5X Active Probe Instruction Manual

Page 19

Features and Accessories

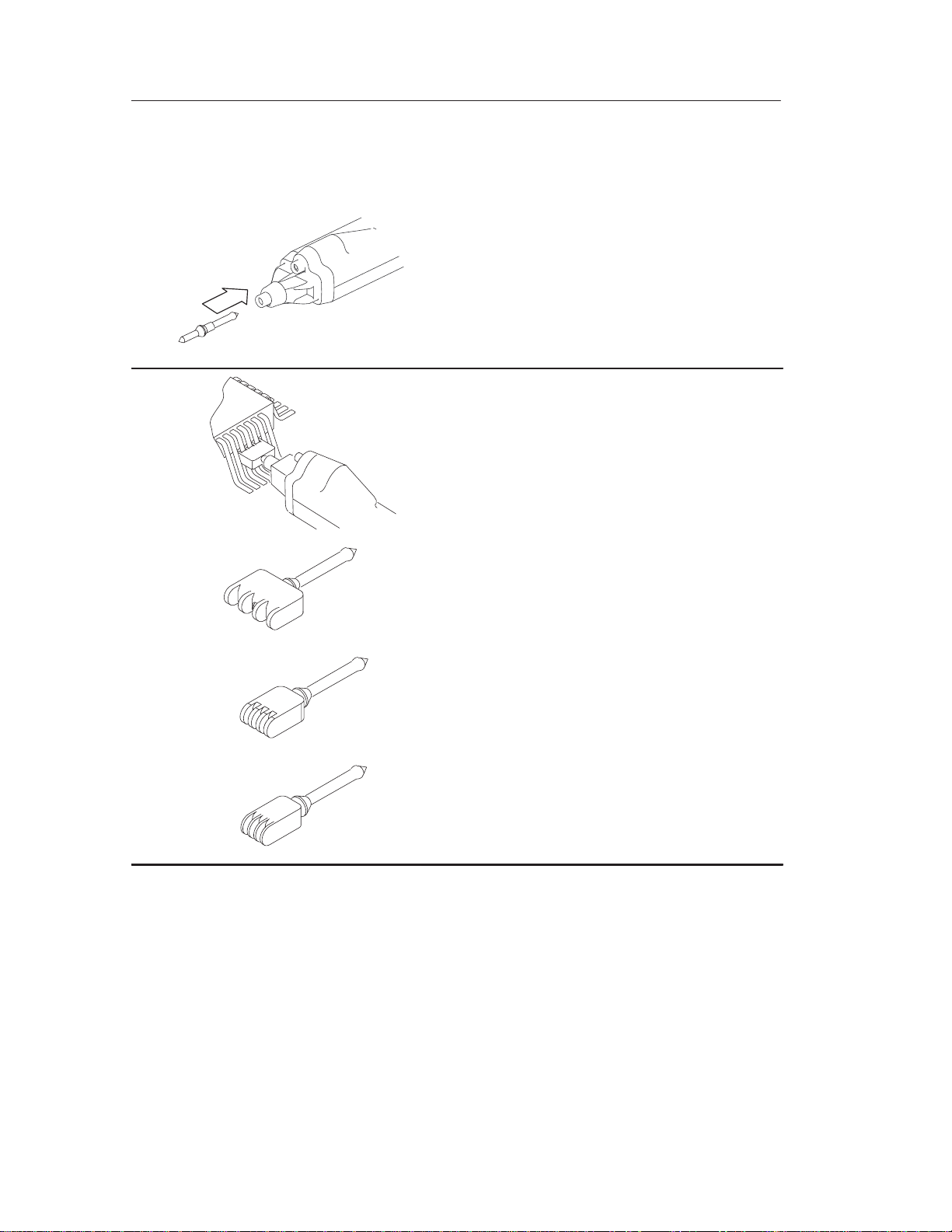

SureToe probe tip. The SureToe tip is a pointed

probe tip useful for probing in dense circuitry.

Attach the SureToe adapters the same way as

the push-in probe tips. Do not force the tip. Also,

be careful not to poke yourself with the sharp

probe tip. They can be used with any of the

socketed accessory leads.

Right-angle adapter . Use the right-angle

adapter for low-profile probing of 0.025 inch

diameter square pins.

The right-angle adapter allows the probe to lie flat

against a circuit board. This enables probing in

vertical circuits such as computer or communications backplanes, or in tight areas such as

between circuit cards.

Y-lead

adapter

Y-lead

adapter

Right

angle

adapter

The right-angle adapter can be used directly with

the probe head, or attached to the Y-lead adapter

or ground leads.

The right-angle adapter is attached the same way

as the push-in probe tip, and can be easily

removed by hand.

Y-lead adapter. Use the Y-lead adapter to

extend the physical reach of the probe and

ground when necessary. The Y-lead adapter

accepts any of the probe tips or adapters, and

can be pushed directly onto 0.025 inch pins.

When selecting the grounding connection,

maintain as short a ground path as possible.

Refer to page 20 for more information.

To attach the Y-lead adapter, gently press the

lead pins into the probe head tip and ground

receptacles. Using the black lead for ground is

recommended.

P6249 4 GHz 5X Active Probe Instruction Manual

7

Page 20

Features and Accessories

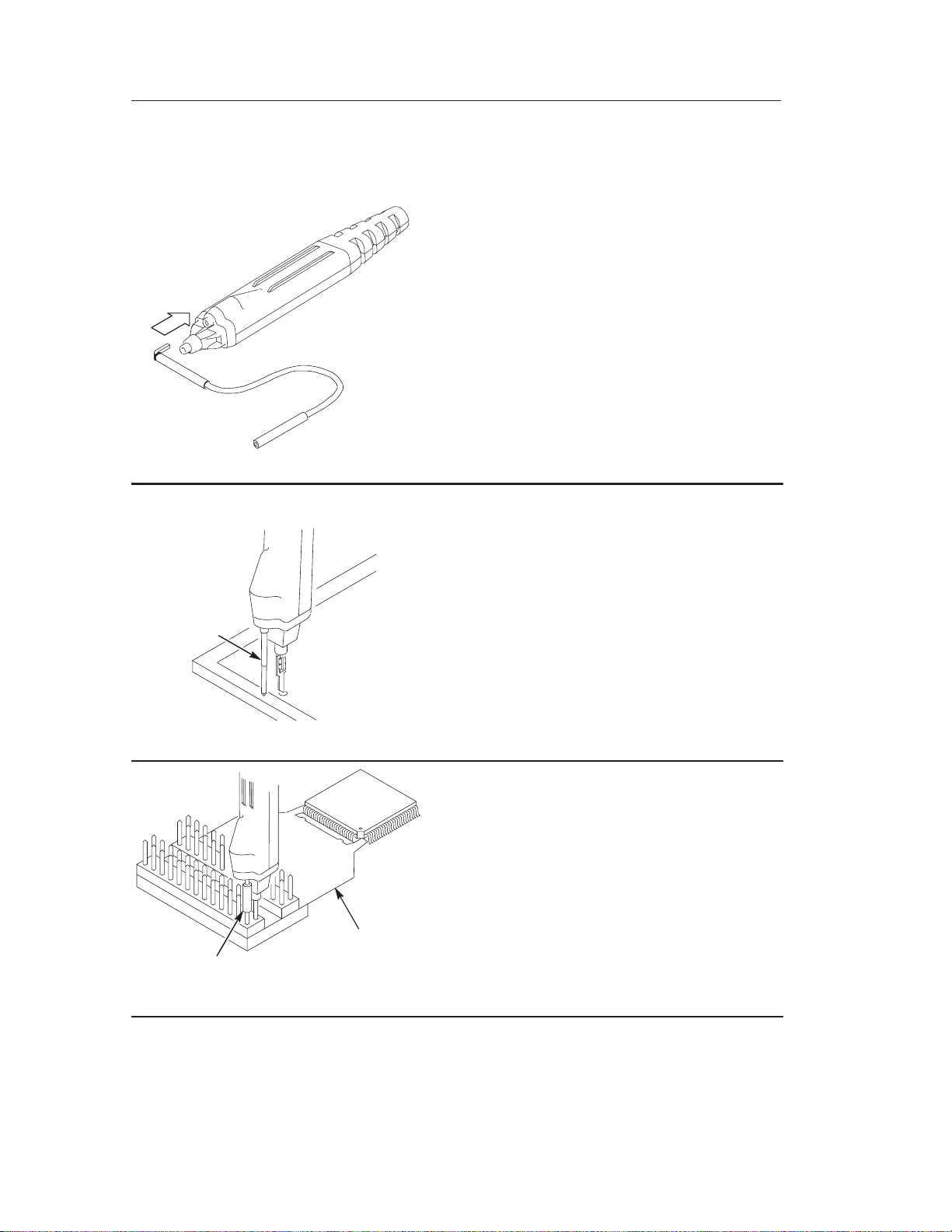

Pogo pin

Three-inch ground lead. Use the three-inch

ground lead for general probing. The socketed

end of the lead may be connected to any of the

probe tips and adapters or fitted onto 0.025 inch

pins.

To attach the ground lead, press and rotate the

lead pin connector into the ground socket on the

probe head. The lead may be removed by simply

pulling the pin out by hand.

When selecting the grounding connection,

maintain as short a ground path as possible.

Refer to page 20 for more information.

Low-inductance ground pogo pin. Use the

low-inductance ground pogo pin to substantially

reduce ground lead inductance. Because the

pogo pin simply touches the ground reference,

you can easily move the probe to different points

on the circuit under test.

To attach, press the pogo pin into the probe head

ground socket.

Signal ground

adapter

FlexLead

adapter

When selecting the grounding connection,

maintain as short a ground path as possible.

Refer to page 20 for more information.

Signal-Ground Adapter. The signal-ground

adapter is ideal for use with signal/ground pairs

on 0.100 inch header pins (such as FlexLead

adapters).

Attach the signal-ground adapter by gently

pressing it into the ground socket on the probe

head.

Be sure to use the stabilization notch whenever

possible, to avoid slipping and damaging the

probe or circuitry under test.

8

P6249 4 GHz 5X Active Probe Instruction Manual

Page 21

KlipChip

Features and Accessories

SMT KlipChip. Use the SMT KlipChip test clips

to access fragile, dense circuitry.

KlipChip test clips can be connected to the Y-lead

or three-inch ground leads. Simply press the lead

socket into the KlipChip handle.

Y-lead adapter

Color marker

bands

The KlipChip body freely turns, allowing better

probe orientation. To reduce stress and provide a

lower profile on components being tested, the

flexible sleeve of the KlipChip bends up to a

35 degree angle.

SMK4 Micro KlipChip adapters. Use the

adapters to probe the leads on integrated circuits

that are surface-mounted.

Color marker bands. Attach matching pairs of

the color marker bands onto the cable at the head

and compensation box of each probe. The marker

bands enable quick verification of which probe is

connected to which instrument channel.

P6249 4 GHz 5X Active Probe Instruction Manual

9

Page 22

Features and Accessories

10

P6249 4 GHz 5X Active Probe Instruction Manual

Page 23

Configuration

The P6249 provides the oscilloscope with the probe model number,

serial number, and attenuation factor. When connected to an

oscilloscope with a TEKPROBE interface, display readouts are

corrected for the probe attenuation factor, the instrument input is set

to 50 W, and the coupling is set to DC.

CAUTION. Do not attempt to install the P6249 on a non-TEKPROBE

connector. Damage to the probe and connector may result. If your

oscilloscope does not support the TEKPROBE interface, use the

optional Tektronix 1103 Probe Power Supply.

If the P6249 is used with the Tektronix 1103 Probe Power Supply, be

sure to have a 50 W termination at the oscilloscope. Also, set the

oscilloscope channel coupling to DC.

The probe offset control is controlled by the oscilloscope. If the

oscilloscope used does not support the TEKPROBE interface, use the

offset controls on the optional Tektronix 1103 Probe Power Supply.

Probe Offset

The probe offset is adjustable to permit operation within the linear

range of the probe. Using the offset to cancel DC signal components

enables optimal probe performance. See Figure 1 on page 12 for

more information.

NOTE. See your oscilloscope manual for specific instructions on its

operation and offset control.

P6249 4 GHz 5X Active Probe Instruction Manual

11

Page 24

Configuration

To set the probe offset, follow these steps:

1. Set the oscilloscope coupling to GND.

2. Use the vertical position control to set a zero reference level on

3. Set the oscilloscope coupling to DC and 5 V/div.

4. Attach the probe to the circuit.

5. Adjust the probe offset to bring the trace to the oscilloscope zero

6. Change the volts/division setting to the desired range, adjusting

NOTE. The P6249 has a ±5.0 V offset range. The linear operating

range is ±2.0 V. See Figur e 1. Also, see page 19 for more information.

the oscilloscope display .

reference.

the offset to keep the trace on the zero reference level.

If cursors are used on a TEKPROBE oscilloscope, the zero reference

will be at the probe offset voltage.

Nonoperating range (+30 V maximum nondestructive input voltage )

+7.0 V

+5.0 V

+2.0 V

0 V

–2.0 V

–5.0 V

–7.0 V

Nonoperating range (–30 V maximum nondestructive input voltage )

+5.0 V

Maximum offset rangeMaximum AC signal amplitude

–5.0 V

Figure 1: Dynamic and offset limitations

12

P6249 4 GHz 5X Active Probe Instruction Manual

Page 25

Functional Check

After installing the probe on the oscilloscope, a functional check

may be performed using the PROBE COMPENSATION connections

on the front panel of the oscilloscope. Use the optional deskew

fixture for optimum connections. See Figure 2.

A

B

Deskew fixture

Figure 2: Probe functional check connections

1. Connect the probe to the oscilloscope.

2. Set the oscilloscope to display the probe channel.

P6249 4 GHz 5X Active Probe Instruction Manual

13

Page 26

Functional Check

3. If you have the optional deskew fixture, connect it to the PROBE

COMPENSATION connections. Connect the probe to the deskew

fixture (see Figure 3 on page 15), and proceed to step 6.

4. Using a ground lead and a SMT KlipChip, connect the probe

ground to the PROBE COMPENSATION ground connection on

the oscilloscope.

5. Using a standard tip, hold the probe to the SIGNAL terminal on

the oscilloscope.

6. Adjust the oscilloscope to display a stable calibration waveform.

NOTE. If your instrument supports probe calibration routines, now is

a good time to perform them. However, certain firmware versions of

TDS series oscilloscopes will return a “Probe Cal Failed” message. If

this occurs, refer to Probe Calibration Errors on page 16.

7. Disconnect the probe from the deskew fixture or SIGNAL

terminal and ground the probe tip. (Connect the KlipChip to the

probe tip.)

8. With the probe offset set to 0.0 V, the oscilloscope display should

be at the ground reference.

9. Set the oscilloscope volts/division to 1 V.

10.Adjust the probe offset. The displayed waveform should vary

between approximately +2.0 V and –2.0 V.

NOTE. If no waveform is displayed, check the vertical coupling to be

sure that it is set to DC.

If the offset adjustment has no effect, set the vertical coupling to DC.

If you are using the Tektronix 1103 Probe Power Supply, and the

waveform is distorted, check to make sure that the oscilloscope

termination is 50 W.

14

If the probe does not pass this functional check, go to Troubleshooting on page 59.

P6249 4 GHz 5X Active Probe Instruction Manual

Page 27

Deskew Fixture

The optional deskew fixture provides a convenient way to connect

the probes in your system to the calibration signal for deskewing.

The deskew fixture is configured to allow you to connect different

probe models to the system. Refer to Figure 3 to see how two P6249

probes are connected.

Functional Check

P6249 probe

GroundSignal

P6249 probe

Figure 3: Deskew fixture connections (two P6249 probes shown)

For part number information for the deskew fixture, refer to

Replaceable Parts on page 63.

P6249 4 GHz 5X Active Probe Instruction Manual

15

Page 28

Functional Check

Probe Calibration Errors

If you get the message “Probe Cal Failed”, or other calibration

anomalies occur , you may be using an oscilloscope that is not fully

compatible with the P6249 probe, or you may have a hardware

problem.

Check Compatibility

Before suspecting a problem with your probe, compare your

oscilloscope firmware version with those listed in Table 1.

Table 1: TDS 500, 600, or 700 series oscilloscopes fully compatible

with the P6249 probe

Model number

TDS 520D greater than FV:6.3e

TDS 540D greater than FV:6.3e

TDS 580D greater than FV:6.3e

TDS 654C FV:5.1e or above

TDS 680C FV:5.1e or above

TDS 684C FV:5.1e or above

TDS 694C all versions compatible

TDS 724D greater than FV:6.3e

TDS 754D greater than FV:6.3e

TDS 784D greater than FV:6.3e

TDS 794D greater than FV:6.3e

Firmware version required

16

NOTE. You can take P6249 probe measurements with any TDS 500,

600, or 700 series oscilloscope, regardless of firmware version. The

fully compatible oscilloscopes listed in Table 1 give you enhanced

accuracy after successfully passing the probe calibration function.

P6249 4 GHz 5X Active Probe Instruction Manual

Page 29

Functional Check

Other TDS 500, 600, or 700 series oscilloscopes may give the error

message “Probe Cal Failed” when you run the probe calibration

function, but the probe will still meet its warranted specifications.

Check for Hardware Problems

If the firmware version on your TDS 500, 600, or 700 series

oscilloscope is fully compatible with the P6249 probe, do the

following:

1. Perform the Signal Path Calibration on the oscilloscope and wait

for it to complete.

2. Rerun the calibration routine on the P6249 probe.

3. If the oscilloscope returns the failure message again, initialize the

probe calibration and check probe offset zero:

H If offset zero is greater than ±25 mV, perform the Offset Zero

adjustment on page 50 in the Adjustments section.

H If offset zero is less than ±25 mV, check the Offset Range as

instructed on page 51 in the Adjustments section.

4. Rerun the probe calibration function on the P6249 probe. If the

probe calibration fails, run the calibration on another oscilloscope

channel.

5. If the problem persists, there is a hardware fault. Please contact

your nearest Tektronix Service Center for more information.

P6249 4 GHz 5X Active Probe Instruction Manual

17

Page 30

Functional Check

18

P6249 4 GHz 5X Active Probe Instruction Manual

Page 31

Operating Basics

Please follow these operating guidelines to get optimum performance

from your P6249.

Handling the Probe

Exercise care when using and storing the P6249. The probe and cable

are susceptible to damage caused by careless use. Always handle the

probe using the compensation box and probe head, avoiding undue

physical strain to the probe cable, such as kinking, excessive

bending, or pulling. Visible dents in the cable will increase signal

aberrations. Do not drop the probe or subject it to physical shock.

Damage to the probe may result.

Maximum Non-destructive Input Voltage

The P6249 is electrically protected against static voltage; however,

applying voltages above its design limits may damage the probe tip

amplifier. Please refer to Specifications on page 27 for the maximum

operating voltage and frequency derating information.

Input Linear Dynamic Range

The probe head amplifier used by the P6249 has a limited linear

operating range. To keep the input linearity error less than 0.1% you

must limit the apparent signal input voltage to ±2.0 V.

Use the DC offset adjustment to maintain the probe within its

dynamic range. The nominal offset adjustment range of the P6249 is

±5.0 VDC. For example: to offset a +2 VDC level in a circuit, set the

offset to +2 V.

NOTE. The probe can tolerate input voltages of ±30 V without

damage; however, the linearity error specification does not apply to

input voltages exceeding ±7.0 V (including any DC offset). See

Figure 1 on page 12.

P6249 4 GHz 5X Active Probe Instruction Manual

19

Page 32

Operating Basics

Ground Lead Length

When you are probing a circuit, you should always use as short a

ground lead as possible between the probe head and circuit ground.

When you touch your probe tip to a circuit element, you are

introducing a new resistance, capacitance, and inductance into the

circuit. This represents the characteristics of your probe and ground

lead.

You can determine if ground lead effects may be a problem in your

application if you know the self-inductance (L) and capacitance (C)

of your probe and ground lead path. A portion of the ground lead

path is uncontrollable since it is hard-wired on the circuit board

under test.

As a guide, refer to Figure 4 to estimate the maximum frequency you

can measure using additional lead length.

The total inductance can be calculated, with reference to the

measurement loop area formed by the ground lead path, using the

following formula:

L +

A

113

A = Measurement loop area in square inches

L = Inductance in microhenries

Once you have calculated the inductance, use 1 picofarad for the

capacitance of the P6249 and calculate the approximate resonant

frequency (f

) at which this parasitic circuit will resonate, using the

0

following formula:

f

+

0

1

Ǹ

2p LC

The preceding equation shows that reducing the ground lead

inductance will raise the resonant frequency. If your measurements

are affected by ringing, your goal is to lower the inductance of your

ground path until the resulting resonant frequency is at least 3 times

greater than the frequency of your measurements.

20

P6249 4 GHz 5X Active Probe Instruction Manual

Page 33

1000

900

800

700

Operating Basics

Frequency

(MHz)

600

500

400

300

200

100

0

123

1.2 1.4 1.6 1.8 2.2 2.4 2.6 2.8

Measurement lead length (Inches)

Figure 4: Maximum frequency vs. measurement lead length

In order to reach two test points with a P6249, a 2-inch length return

ground lead is used. What is the maximum circuit frequency which

should be measured?

Using the graph shown in Figure 4 as a guide, a 2-inch lead length

yields a 500 MHz maximum frequency.

The low-inductance ground contacts described in Accessories on

page 5 can help you reduce the effects of ground lead inductance on

your measurements.

P6249 4 GHz 5X Active Probe Instruction Manual

21

Page 34

Operating Basics

22

P6249 4 GHz 5X Active Probe Instruction Manual

Page 35

Helpful Hints

Follow these helpful hints to make probing easier and noise free.

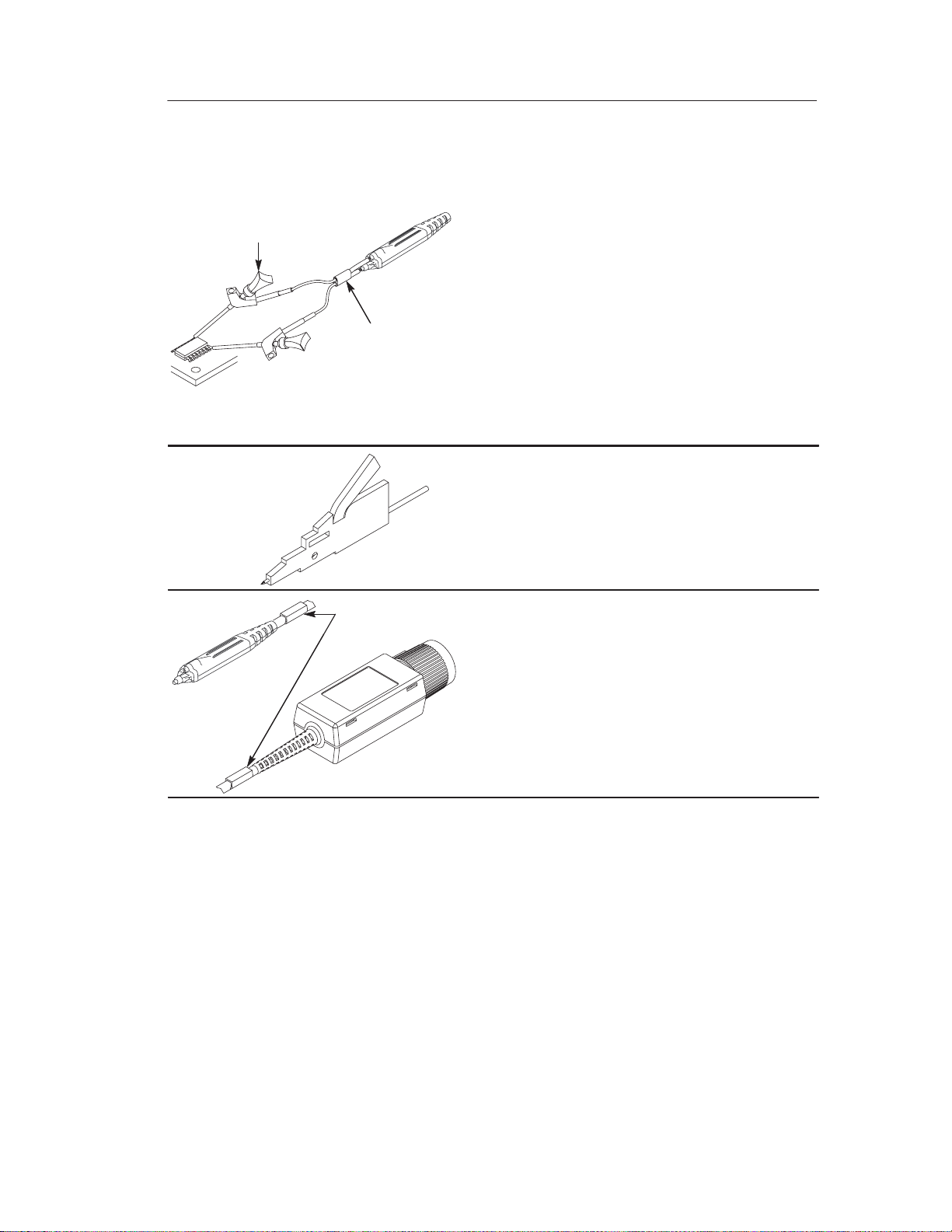

Low-Inductance Grounding

Placing a ground plane on top of a package being probed can

minimize ground lead length and inductance. See Figure 5.

Figure 5: Low-inductance grounding

Attach a small piece of copper clad on top of the package and

connect it to the package ground connection. Use the low-inductance

ground lead provided with the P6249 to keep the ground lead length

as short as possible.

P6249 4 GHz 5X Active Probe Instruction Manual

23

Page 36

Helpful Hints

This method is very useful when making many measurements on the

same package. Using a ground plane on the package makes probing

the package easier and avoids adding unnecessary ground lead length

and distortion.

SureFoot Grounding

If you cannot use the recommended low-inductance grounding

method, you may ground the probe to the package under test using a

SureFoot adapter. Refer to Figure 6.

24

Figure 6: Using a SureFoot adapter for grounding

Use a SureFoot adapter at the end of a short ground lead to connect

directly to the package ground. This method is preferred over using

an adjacent circuit ground because it is the shortest ground path

possible.

P6249 4 GHz 5X Active Probe Instruction Manual

Page 37

Probe Tip Test Points

You can solder the push-in probe tip or a 0.025 square pin to a

circuit, to be used as a temporary test point. See Figure 7.

Solder the tip onto a lead or pin with a low-power soldering iron.

Press the probe head onto the tip to make a measurement, and then

pull the probe head off when you are done.

The probe tip may be removed and reused by desoldering it from the

circuit, and soldering it into another circuit in the future.

Helpful Hints

Solder

Figure 7: Using a probe tip as a test point

NOTE. Do not use pieces of solid-core copper wire be used as test

points. If the wire breaks off in the probe tip socket, it may be

impossible to remove the wire, and it will prevent insertion of other

accessory tips.

P6249 4 GHz 5X Active Probe Instruction Manual

25

Page 38

Helpful Hints

26

P6249 4 GHz 5X Active Probe Instruction Manual

Page 39

Specifications

These specifications apply to a P6249 probe when used with a

TDS 694C oscilloscope.

The probe and oscilloscope must first be allowed to warm up for

20 minutes before measurements are taken.

CAUTION. Do not apply voltages beyond the non-destructive input

voltage range to the probe. Damage to the probe or circuit under test

may result.

Table 2: Warranted electrical specifications

DC Attenuation Accuracy (probe only) 0.2 ±2% (excludes offset error)

Output Zero ±10 mV or less at output of probe

Rise Time (probe only) ≤120 ps

Table 3: Typical electrical characteristics

Bandwidth, (probe only) 4 GHz (See Figure 9)

Linear Input Dynamic Range –2.0 V to +2.0 V.

(Equivalent to –0.4 V to +0.4 V

at the output of the probe.)

Linearity

Nondestructive Input Voltage Range

Input Resistance

Input Capacitance 1.0 pF

P6249 4 GHz 5X Active Probe Instruction Manual

"0.1% over a dynamic range of –1.75 V to

+1.75 V

"1.0% over a dynamic range of –2.0 V to

+2.0 V

–30 V to +30 V (DC + peak AC)

20 kW at DC. (See Figure 8)

27

Page 40

Specifications

T able 3: T ypical electrical characteristics (Cont.)

Offset Range –5.0 V to +5.0 V

DC Offset Drift

150 mV/°C or less at output of probe

0.75 mV/°C or less displayed on screen with

TEKPROBE interface

DC Offset Scale Accuracy ±2% (of 5X actual probe gain)

Delay Time 5.05 ns ±0.2 ns

System Noise

300 mV rms or less at output of probe with

probe tip grounded

110°

90°

70°

Magnitude

50°

30°

10°

–10°

Phase (degrees)

–30°

Phase

22 K

20 K

18 K

16 K

14 K

12 K

10 K

Magnuitude (ohms)

8 K

28

–50°

–70°

–90°

–110°

1 M 10 M 100 M 1 G 5 G

Frequency

Figure 8: Typical input impedance and phase versus frequency

P6249 4 GHz 5X Active Probe Instruction Manual

6 K

4 K

2 K

0

Page 41

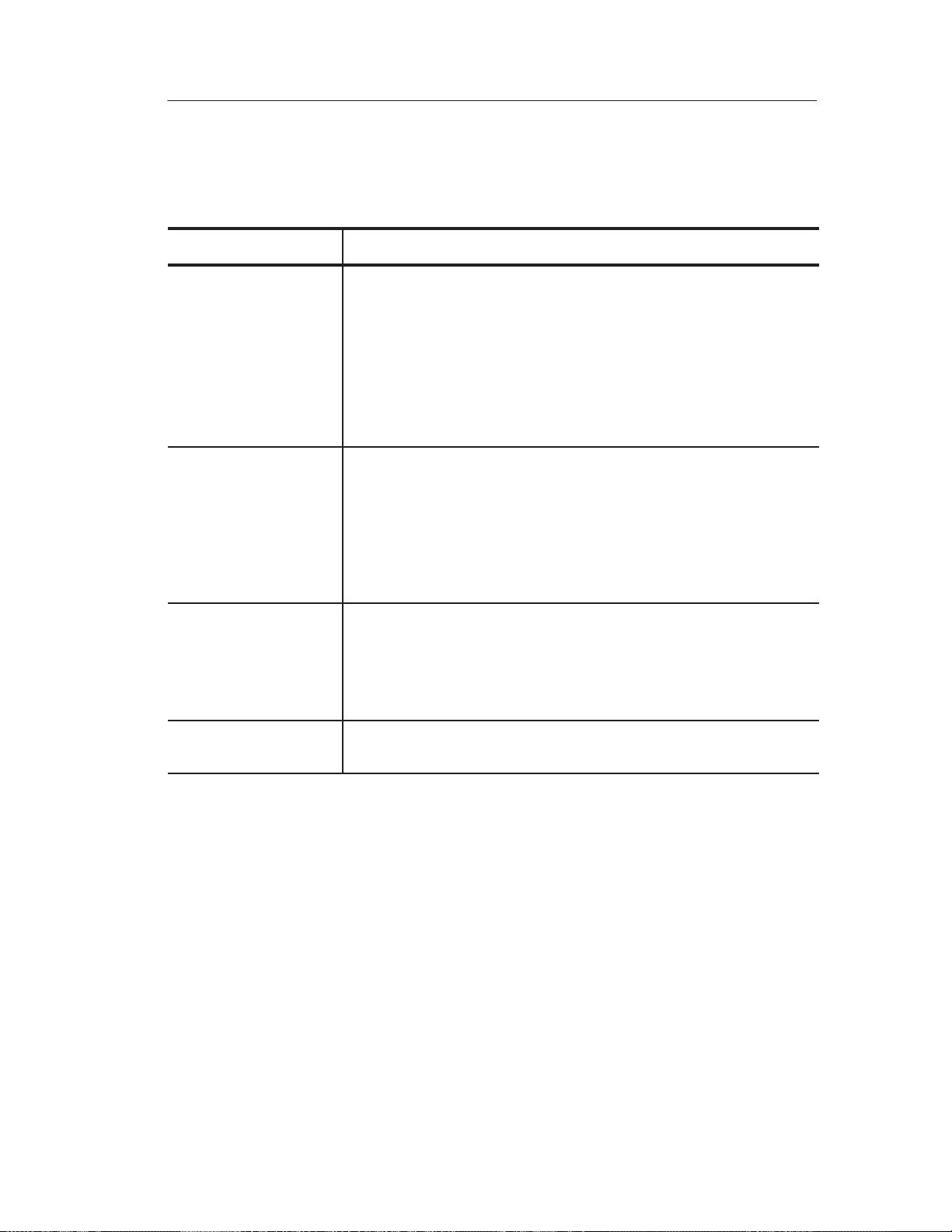

T able 4: Physical Characteristics

Net Shipping Weight 1.78 kg (3.93 lb)

Cable Length 1.3 meters

–10

–12

–14

–16

–18

Gain dB

–20

V

–22

–24

Gain + 20 Log

ǒ

V

OUT

IN

Ǔ

Specifications

–26

–28

10 MHz1 MHz 100 MHz 10 GHz

Frequency

Figure 9: Typical bandwidth

T able 5: Environmental characteristics

Operating Temperature 0° C to +40° C.

The environmental exposure is the procedure stated

in Tektronix Design Standard 062-2847-00 for Class 5

equipment.

Nonoperating Temperature –40° C to +71° C.

The environmental exposure is the procedure stated

in Tektronix Design Standard 062-2847-00 for Class 5

equipment.

1 GHz

P6249 4 GHz 5X Active Probe Instruction Manual

29

Page 42

Specifications

T able 5: Environmental characteristics (Cont.)

Humidity 80% RH at 40° C.

The environmental exposure is as stated in Tektronix

Design Standard 062-2847-00 for Class 5 equipment.

Packaged Product Vibration and

Shock

Electrostatic Immunity IEC 61000-4-2

EMC IEC 801–3

Altitude Operating: 15,000 ft.

Pollution Degree Pollution Degree 2

The packaged product qualifies under the Distribution

Cycle 1 Assurance Level II for packaged products 0 to

20 lbs. Test 2 for Warehouse and Vehicle Stacking

(Compression) is omitted.

Tektronix standard 062-2858-00, Rev. B, Class 5.

Non-Operating: 50,000 ft.

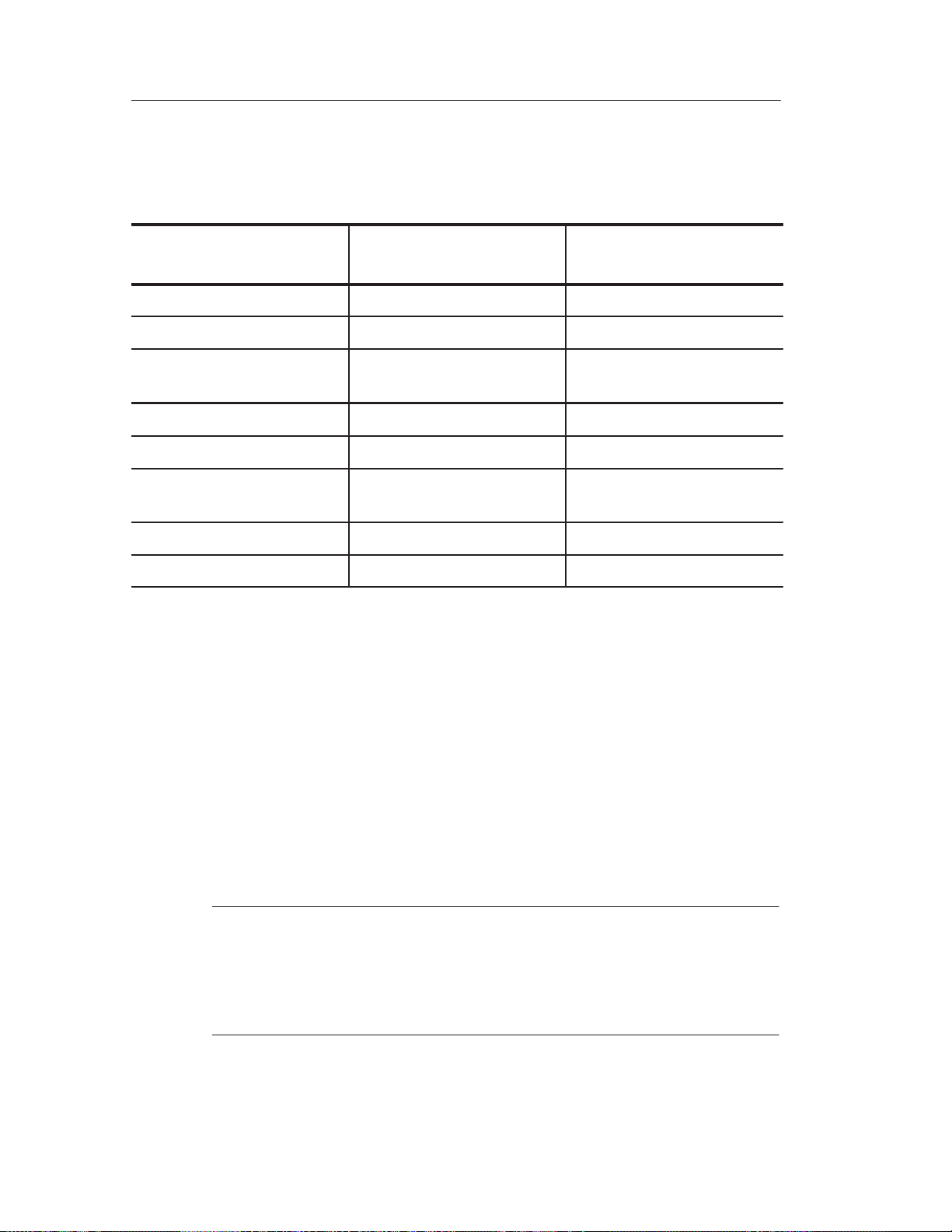

T able 6: Certifications and compliances

Category

EC Declaration of

Conformity – EMC

Standards or description

Meets intent of Directive 89/336/EEC for Electromagnetic

Compatibility. Compliance was demonstrated to the following

specifications as listed in the Official Journal of the European

Union:

30

EN 55011 Class A Radiated and Conducted Emissions

EN 55011 Class B Radiated and Conducted Emissions

EN 61000-3-2 AC Power Line Harmonic Emissions

EN 61000-3-3 AC Power Line Flicker

P6249 4 GHz 5X Active Probe Instruction Manual

Page 43

T able 6: Certifications and compliances (cont.)

Category Standards or description

EN 50082-1 Immunity:

IEC 61000-4-2 Electrostatic Discharge Immunity

IEC 61000-4-3 RF Electromagnetic Field Immunity

IEC 61000-4-4 Electrical Fast Transient/Burst Immunity

IEC 61000-4-5 Power Line Surge Immunity

IEC 61000-4-6 Radio Frequency Common Mode

IEC 61000-4-8 Power Frequency Magnetic Field

IEC 61000-4-11 Voltage Dips and Interruptions

Specifications

Australia/New Zealand

Declaration of

Conformity – EMC

EMC Compliance Meets the intent of Directive 89/336/EEC for Electromagnetic

FCC Compliance Emissions comply with FCC Code of Federal Regulations 47, Part

Complies with EMC provision of Radiocommunications Act

per the following standard(s):

AS/NZS 2064.1/2 Industrial, Scientific, and Medical

Equipment:1992

AS/NZS 3548 Information Technology Equipment: 1995

Compatibility when it is used with the product(s) stated in the

specifications table. Refer to the EMC specification published for

the stated products. May not meet the intent of the directive if used

with other products.

15, Subpart B, Class A Limits.

P6249 4 GHz 5X Active Probe Instruction Manual

31

Page 44

Specifications

T able 6: Certifications and compliances (cont.)

Category Standards or description

Pollution Degree A measure of the contaminates that could occur in the

environment around and within a product. Typically the internal

environment inside a product is considered to be the same as the

external. Products should be used only in the environment for

which they are rated.

Pollution Degree 1

No pollution or only dry, nonconductive pollution occurs.

Products in this category are generally encapsulated,

hermetically sealed, or located in clean rooms.

Pollution Degree 2

Normally only dry, nonconductive pollution occurs.

Occasionally a temporary conductivity that is caused by

condensation must be expected. This location is a typical

office/home environment. Temporary condensation occurs

only when the product is out of service.

32

P6249 4 GHz 5X Active Probe Instruction Manual

Page 45

WARNING

The following servicing instructions are for use only by

qualified personnel. To avoid injury, do not perform any

servicing other than that stated in the operating instructions

unless you are qualified to do so. Refer to all Safety

Summaries before performing any service.

Page 46

Page 47

Theory of Operation

There are no user replaceable parts within the probe or the

compensation box; however, this theory of operation is provided to

assist you in isolating failures to either the probe or the host

oscilloscope. Refer to Figure 10 for the simplified schematic.

Probe head Compensation box Oscilloscope

Probe tip

Probe tip

amplifier

Offset ampifier

EEPROM

Signal Out

Probe ID Out

Clock In

±1V Offset

Offset to probe

+7V

Linear

regulator

Probe

cable

Figure 10: P6249 simplified schematic diagram

+5

Offset

gain

Offset

zero

–5

+5V

–5V

Ground

TEKPROBE

Interface

P6249 4 GHz 5X Active Probe Instruction Manual

35

Page 48

Theory of Operation

Probe Head and Cable Assembly

The probe head assembly contains an active amplifier circuit that

buffers and amplifies the input signal. The amplifier receives power

and an offset level from the compensation box assembly via the

cable assembly .

All signal amplification and buffering is performed in the probe head

assembly. No further amplification takes place in the compensation

box.

Compensation Box

The compensation box contains the following circuits:

H Offset amplifier

H Probe identification EEPROM

H TEKPROBE interface

H V

Offset Amplifier

The offset amplifier is used to offset the input signal DC component

so that it stays at the optimal point of the probe linear dynamic

range. For more information on the linear dynamic range characteristic, refer to Input Linear Dynamic Range on page 19.

The offset amplifier receives offset information as a ±1 VDC voltage

from the oscilloscope. The amplfier then amplifies it to match the

probe characteristics and applies it to the probe head circuit.

The offset amplifier has two adjustments: offset zero and offset gain.

These adjustments rarely need attention; however, detailed

adjustment instructions are in the Adjustment section on page 49.

, +7 V linear regulator

CC

36

Probe Identification EEPROM

The probe identification EEPROM is used to configure the

oscilloscope to the probe. The EEPROM receives a clock input from

P6249 4 GHz 5X Active Probe Instruction Manual

Page 49

Theory of Operation

the oscilloscope, and information about the probe is passed to the

oscilloscope.

TEKPROBE Interface

The TEKPROBE interface provides a communication path between

the probe and the oscilloscope. Contact pins provide power, signal,

offset, and data transfer for the probe identification EEPROM.

, +7 V Regulator

V

CC

The +15 V input is regulated to +7 V to supply the IC, V

CC

.

Figure 11 shows the TEKPROBE interface pin functions. Refer to

your oscilloscope service documentation for more detailed

specifications.

–15 V

–5V

Offset

Ground

Signal

Data

Clock

+5 V

+15 V

Figure 11: TEKPROBE interface

P6249 4 GHz 5X Active Probe Instruction Manual

37

Page 50

Theory of Operation

38

P6249 4 GHz 5X Active Probe Instruction Manual

Page 51

Performance Verification

Use the following procedures to verify the warranted specifications

of the P6249 probe. Before beginning these procedures, refer to

page 47 and photocopy the test record and use it to record the

performance test results. The recommended calibration interval is

one year .

These procedures test the following specifications:

H Output offset voltage

H DC attenuation accuracy

H Rise time

Equipment Required

Refer to Table 7 for a list of the equipment required to verify the

performance of your probe.

T able 7: Equipment required for performance verification

Performance

Item Description

Oscilloscope TEKPROBE interface Tektronix TDS 694C

Sampling Oscilloscope Tektronix 11801

Sampling Head Tektronix SD24

TEKPROBE Power Supply Tektronix 1103

Calibration Step Generator 067-1338-0X

Adapter Probe tip 015-0678-00

DC Power Supply 1 VDC at 1 mA Tektronix PS280

DMM 0.5% accuracy at 2 VDC Tektronix TX3

Feedthrough Termination

P6249 4 GHz 5X Active Probe Instruction Manual

Requirement

50 W ±0.05 W

Recommended Example

011-0129-00

39

Page 52

Performance Verification

T able 7: Equipment required for performance verification (Cont.)

Performance

Item Description Recommended Example

Requirement

BNC-to-BNC coaxial cable

Coaxial cable Male-to-Male SMA, 20 in 174-1427-00

Precision coaxial cable Male-to-Male SMA, 1 ns

Adapter SMA Female-to-Female 015-1012-00

Adapters (2) SMA Female-to-BNC Male 015-0572-00

Adapter BNC Female-to-Dual

Adapter Y-lead adapter 196-3457-00

Adapters (2) Klip Chip adapter 206-0364-00

50 W coaxial cable

delay

Banana

012-1342-00

015-0562-00

103-0090-00

Equipment Setup

Use this procedure to set up the equipment to test the probe.

1. Connect the probe to the oscilloscope.

40

2. Connect a Y-lead adapter with KlipChip adapters attached to the

P6249.

3. Turn on the oscilloscope and enable the channel.

4. Allow 30 minutes for the equipment to warm up.

NOTE. If your oscilloscope has a probe calibration routine, run it

before making any of the following checks. However, certain

firmwar e versions of TDS series oscilloscopes will return a Probe Cal

Failed message. If this occurs, see Probe Calibration Errors on

page 16 for more information.

P6249 4 GHz 5X Active Probe Instruction Manual

Page 53

Output Zero

Use this procedure to verify the probe output zero.

1. Connect the test equipment as shown in Figure 12.

2. Attach the probe to a TEKPROBE interface on the 1103 power

supply.

3. Ground the probe tip by connecting the probe tip to the probe

ground socket. (Connecting two KlipChip adapters together is

recommended.)

4. Set the 1103 offset VAR/0V to 0V.

5. Observe the multimeter display and record the results on the test

record.

Performance Verification

The displayed DC level should be 0.00 V ±10 mV.

1103

Power supply

BNC-to-Dual

Banana Adapter

Digital multimeter

+

–

50W Precision

terminator

Figure 12: Setup for output zero and DC attenuation accuracy

Power supply

–+

P6249 4 GHz 5X Active Probe Instruction Manual

41

Page 54

Performance Verification

DC Attenuation Accuracy

Use this procedure to verify the probe DC attenuation accuracy.

Before beginning, read the procedure through completely.

1. Connect the test equipment as shown in Figure 12 on page 41.

2. Attach the probe to a TEKPROBE interface on the 1103 power

supply.

3. Set the 1103 offset VAR/0V to 0V.

4. Set the multimeter to read DC volts.

5. Connect the probe tip and ground to the power supply using the

Y-lead and KlipChip adapters.

6. Allow 30 minutes for the equipment to warm up.

Record the results of steps 7 through 10 separately. Use the results to

calculate the DC accuracy of the probe in step 11.

7. Set the power supply to +1.000 V. Record the power supply

output as Vmax.

8. Measure and record the multimeter reading as M1.

9. Set the power supply to –1.000 V. Record the power supply

output as Vmin.

10.Measure and record the multimeter reading as M2.

NOTE. If you are unable to set the power supply precisely, record the

actual readings and determine the absolute difference.

|Vmax – Vmin| = difference.

Divide the difference by 5 to account for the ideal probe attenuation

factor. For example: 0.8 is the difference between +2 and –2, divided

by 5.

42

P6249 4 GHz 5X Active Probe Instruction Manual

Page 55

Performance Verification

11. Determine the percent error by using the formula below:

%Error + [

M1 * M2

0.4

* 1] 100%

The calculated error should be ≤2%.

12.Record the results on the test record.

NOTE. An unaccceptable error value may result if a low tolerance

termination is substituted for the recommended termination.

P6249 4 GHz 5X Active Probe Instruction Manual

43

Page 56

Performance Verification

Rise Time

This procedure verifies that the probe meets rise time specifications.

The probe rise time is calculated from rise times obtained by

measuring the test system without the probe attached, and the test

system plus the probe.

1. Connect the test equipment as shown in Figure 13.

2. Set the oscilloscope trigger to internal clock.

3. Turn on channel 1 on the SD-24, and then set the oscilloscope

vertical scale to 50 mV/div.

4. Set the oscilloscope horizontal scale to 100 ps/div.

5. Adjust the oscilloscope horizontal and vertical position controls

to display a signal similar to that shown in Figure 13.

11801

BNC to SMA adapter

Precision coaxial cable

Internal

clock output

1103

Power supply

Input

Output

Generator

remote head

Calibration

step generator

Trigger Input

Figure 13: T est system rise time setup

6. Use the oscilloscope measurement capability to display rise time.

Rise time is determined from the 10% and 90% amplitude points

on the waveform. Record the rise time as t

s.

44

The system rise time (ts) that you measured in step 6 represents the

rise time of the test system without the probe.

P6249 4 GHz 5X Active Probe Instruction Manual

Page 57

Performance Verification

The following steps instruct you to assemble the test setup that

includes the probe, as shown in Figure 14. The system and probe rise

time (t

rise time (t

) that you measure in step 12 is used to calculate the probe

s+p

) in step 13.

p

7. Disconnect the calibration generator remote head from the 1103

power supply input. Remove the SMA-BNC adapter from the

1103 power supply input.

8. Use the BNC locking ring to connect the probe to the 1103 power

supply channel 1 input. Disable the offset control on channel 1 of

the 1103 power supply.

9. Connect the probe tip adapter to the calibration step generator

remote head using the SMA female-female adapter . Insert the

probe tip into the probe tip adapter.

BNC to SMA

adapter

Precision

coaxial cable

11801

Figure 14: T est system and probe rise time setup

1103 Power supply

Output Input

Input

Internal

clock output

P6249 Probe

50 W Terminator

Probe tip adapter

Generator remote head

Calibration

step generator

Trigger input

10.Press the AUTOSET button. Set the vertical to 10 mV/div and

horizontal to 100 ps/div. Turn averaging on.

11. Adjust the oscilloscope horizontal and vertical position controls

to display a signal similar to that shown in Figure 14.

P6249 4 GHz 5X Active Probe Instruction Manual

45

Page 58

Performance Verification

NOTE. Do not touch the probe tip adapter when making calibration

measur ements. Measurement accuracy is degraded when the probe

tip adapter is handled.

12.Use the oscilloscope measurement capability to display rise time.

Rise time is determined from the 10% and 90% amplitude points

on the waveform. Record the rise time as t

13.Calculate the probe only rise time using the following formula:

s+p

.

t

p

Ǹ

+ t

2

(s)p)

* t

2

s

14.Check that the calculated rise time meets the probe specification.

The rise time (t

) must be v120 ps.

p

15.Record the results on the test record.

46

P6249 4 GHz 5X Active Probe Instruction Manual

Page 59

Performance Verification

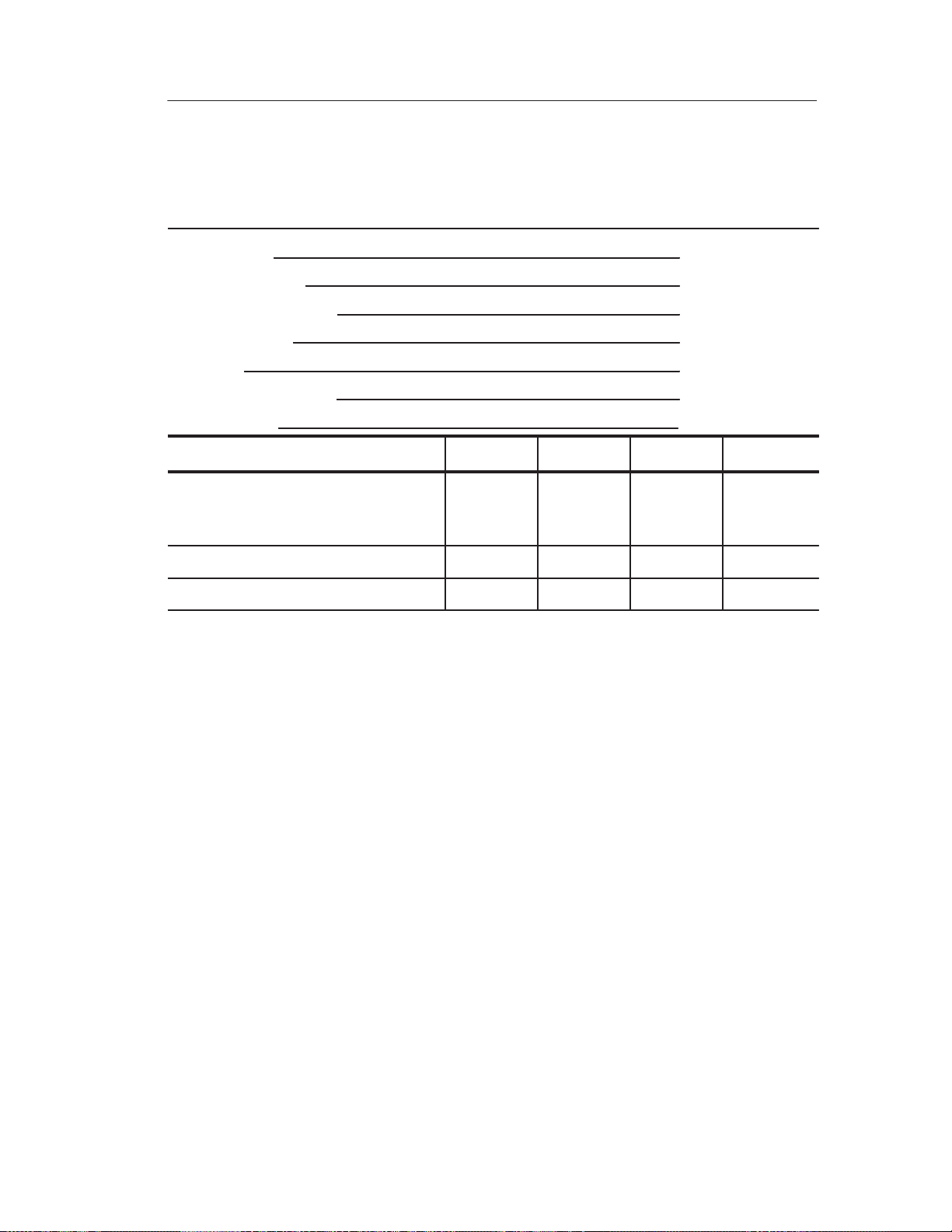

Test record

Probe Model:

Serial Number:

Certificate Number:

Temperature:

RH %:

Date of Calibration:

Technician:

Performance test Minimum Incoming Outgoing Maximum

Output zero voltage

(at probe output)

± 10 mV (20_ C to 30_ C)

– 10 mV ________ ________ + 10 mV

DC attenuation accuracy N/A ________ ________ ≤2 %

Rise time N/A ________ ________ ≤120 ps

P6249 4 GHz 5X Active Probe Instruction Manual

47

Page 60

Performance Verification

48

P6249 4 GHz 5X Active Probe Instruction Manual

Page 61

Adjustments

The P6249 has two internal controls: offset zero and offset range.

These controls rarely need to be adjusted, and only should be

changed after a probe calibration and functional check has been

performed on the oscilloscope.

In order to make adjustments to the probe, the compensation box top

cover needs to be removed with the optional release tool. Refer to

page 54. Use the optional adjustment tool for making any adjustments.

Adjustment Locations

Refer to Figure 15 for the location of the offset zero and offset range

controls.

Offset zero

adjust

Figure 15: P6249 adjustment locations

Offset range

adjust

J1

J4

P6249 4 GHz 5X Active Probe Instruction Manual

49

Page 62

Adjustments

Offset Zero

Use this procedure to adjust the probe offset zero.

NOTE. If your oscilloscope has a probe calibration routine, clear the

probe calibration constants at this time.

If the offset zero is adjusted, perform a functional check of the offset

range before closing the compensation box.

1. Ground the probe tip by connecting the probe tip to the probe

ground socket.

2. Set the channel vertical offset to 0.00 V.

3. Measure the displayed DC level.

4. Adjust Offset Zero for 0.00 ± 15 mV. (±3 mV when measured

directly without attenuation factor .)

50

P6249 4 GHz 5X Active Probe Instruction Manual

Page 63

Offset Range

Use this procedure to adjust the offset range of the probe. The offset

zero of the probe should be checked before making any adjustment

to the offset range. The offset range of the probe is approximately

–3.5 to +3.5 volts.

1. Power on the 1103 power supply and turn on the offset.

2. Using a DMM, adjust the 1103 of fset voltage to –0.5 V. Refer to

Figure 16 for the location of the offset voltage test point.

Adjustments

Figure 16: 1103 power supply offset voltage location

3. Connect the equipment as shown in Figure 17. Take care not to

disturb the offset level setting on the 1 103 power supply.

P6249 4 GHz 5X Active Probe Instruction Manual

Offset voltage

Ground

51

Page 64

Adjustments

Digital multimeter

1103

Power supply

Power supply

+

–

50W Precision

BNC-to-dual

Banana Adapter

terminator

Figure 17: P6249 offset range setup

4. Set the DC power supply (using the DMM) to +2.5 VDC.

5. Observe the DC value on the DMM.

6. Adjust Offset Range for a DMM reading of 0 V ±5 mV. Refer to

Figure 15 on page 49 for the location of the offset range

adjustment.

– +

52

NOTE. After the offset zero and offset range have been adjusted,

perform a probe calibration and functional check to verify performance.

P6249 4 GHz 5X Active Probe Instruction Manual

Page 65

Maintenance

This section describes the maintenance and repair procedures for the

P6249.

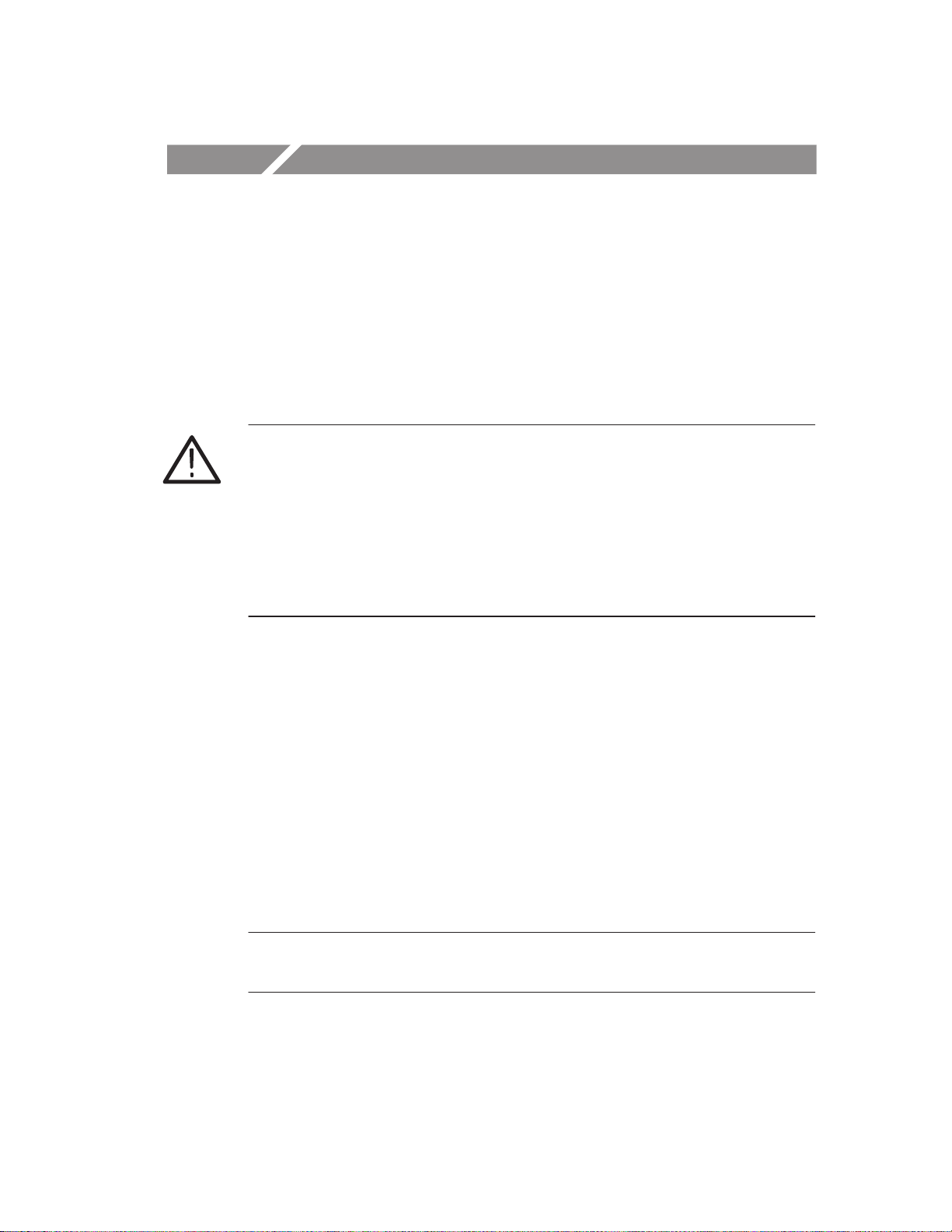

Replacing TEKPROBE Interface Pins

TEKPROBE interface pins can stick and fail to make contact after

time. Periodically check to see that each of the interface pins move

freely and fully extends out of the interface. If any pin fails to move

freely and fully extend, replace the pin.

To remove a TEKPROBE interface pin, firmly grasp the pointed tip

with pliers and pull the pin out of the connector. See Figure 18.

No tools are required to install a replacement pin. Insert a new pin

into the connector socket as far as possible using finger pressure. If

necessary, seat the pin into the connector by pressing the tip gently

but firmly against a hard surface, such as a wood block or table top.

Figure 18: Replacing TEKPROBE interface pins

P6249 4 GHz 5X Active Probe Instruction Manual

53

Page 66

Maintenance

Removing and Replacing the Compensation Box Covers

Follow these steps to open the compensation box.

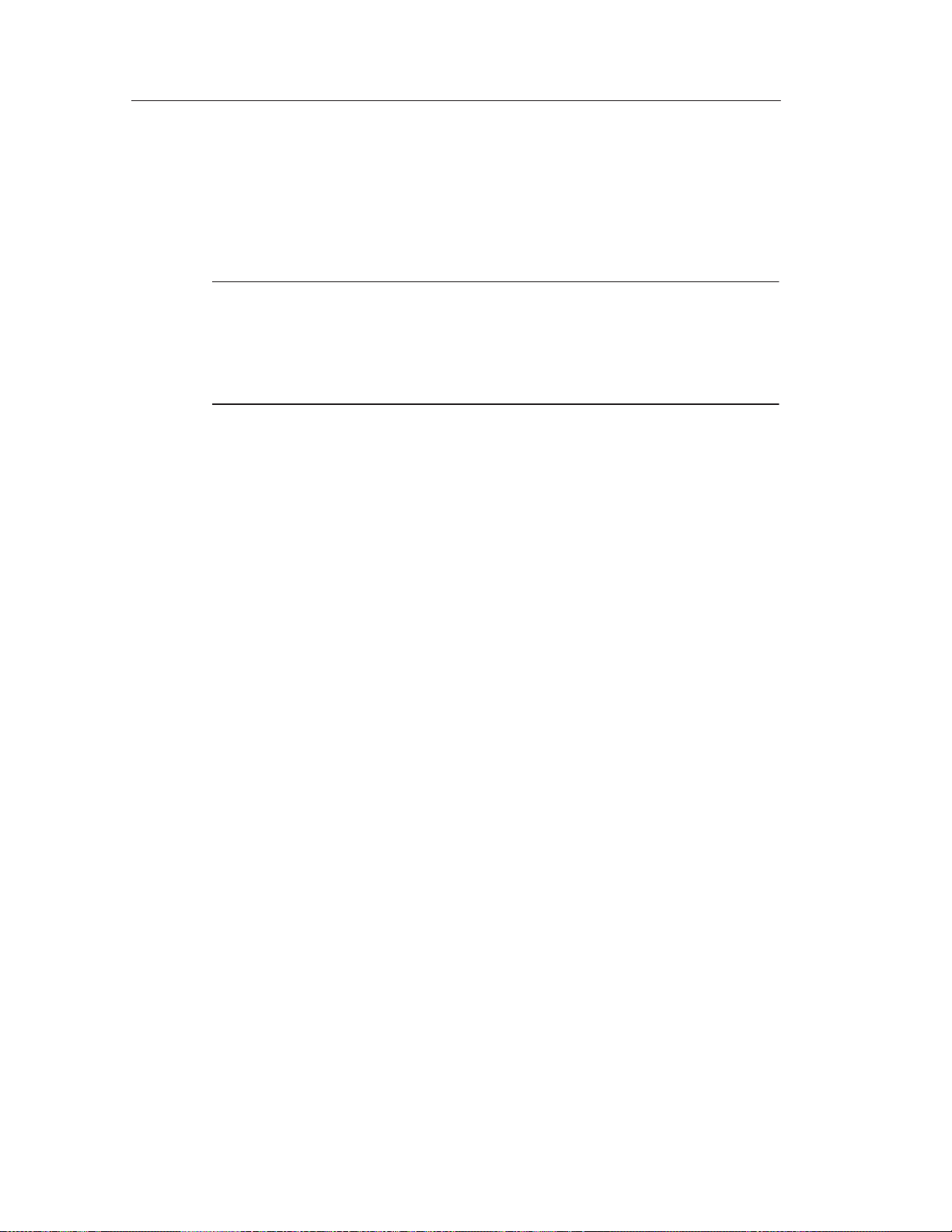

1. Press the optional release tool pins into the compensation box

cover catches and gently lift the cover off a small distance. Refer

to Figure 19.

2. Hold the open edge apart, and use the tool to open the other side

of the compensation box.

3. With both sides of the box open, gently separate the two halves of

the compensation box.

Optional

release

tool

Cover

catches

Figure 19: Removing the compensation box covers

54

P6249 4 GHz 5X Active Probe Instruction Manual

Page 67

Maintenance

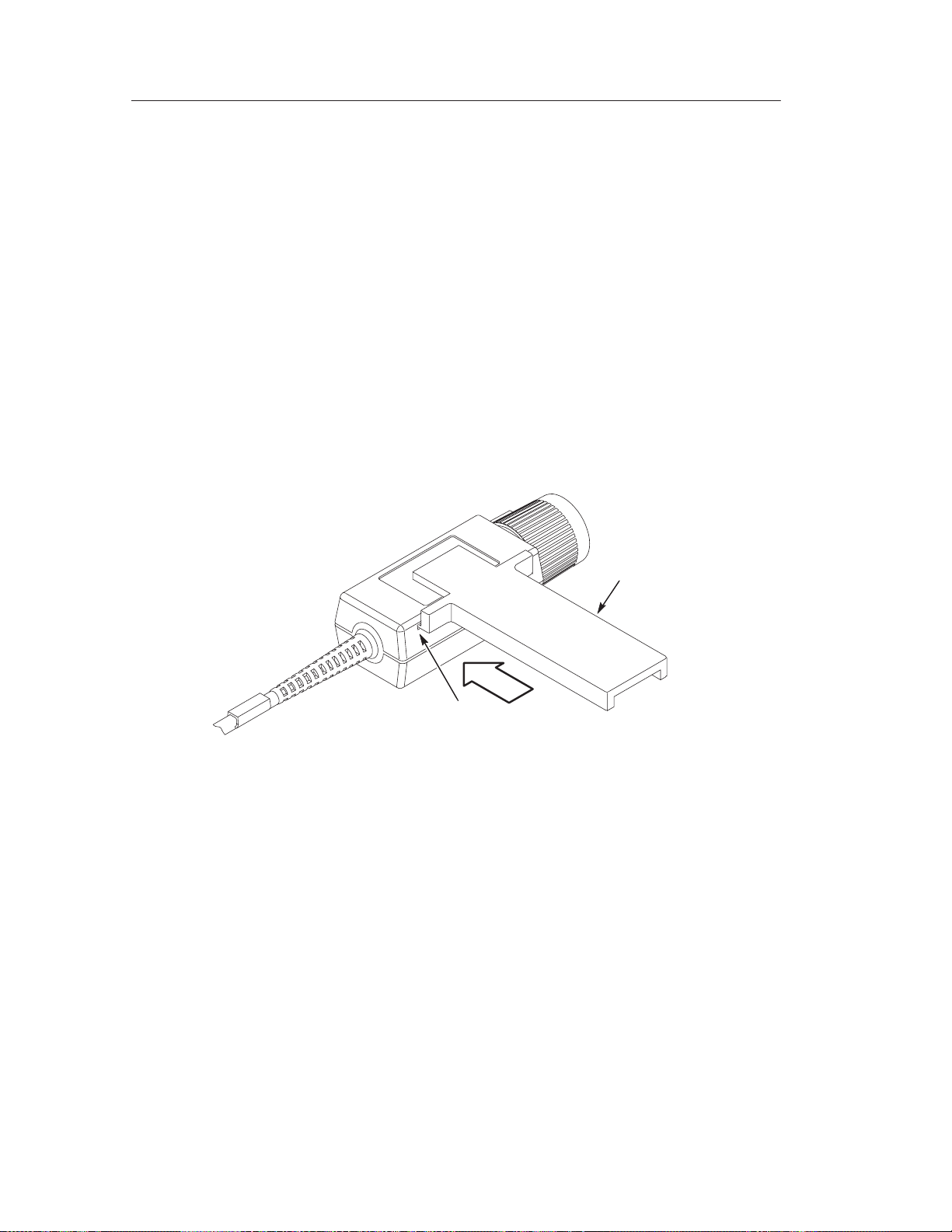

To replace the covers, follow these steps:

1. Align the tabs with the notches on the cover halves. Refer to

Figure 20.

2. Press the cover tabs in so that the cover can be lowered.

3. Slide the tabs into the notches.

4. Firmly press the pieces together until the cover catches snap into

place.

Tabs (4)

Figure 20: Replacing the compensation box cover

P6249 4 GHz 5X Active Probe Instruction Manual

55

Page 68

Maintenance

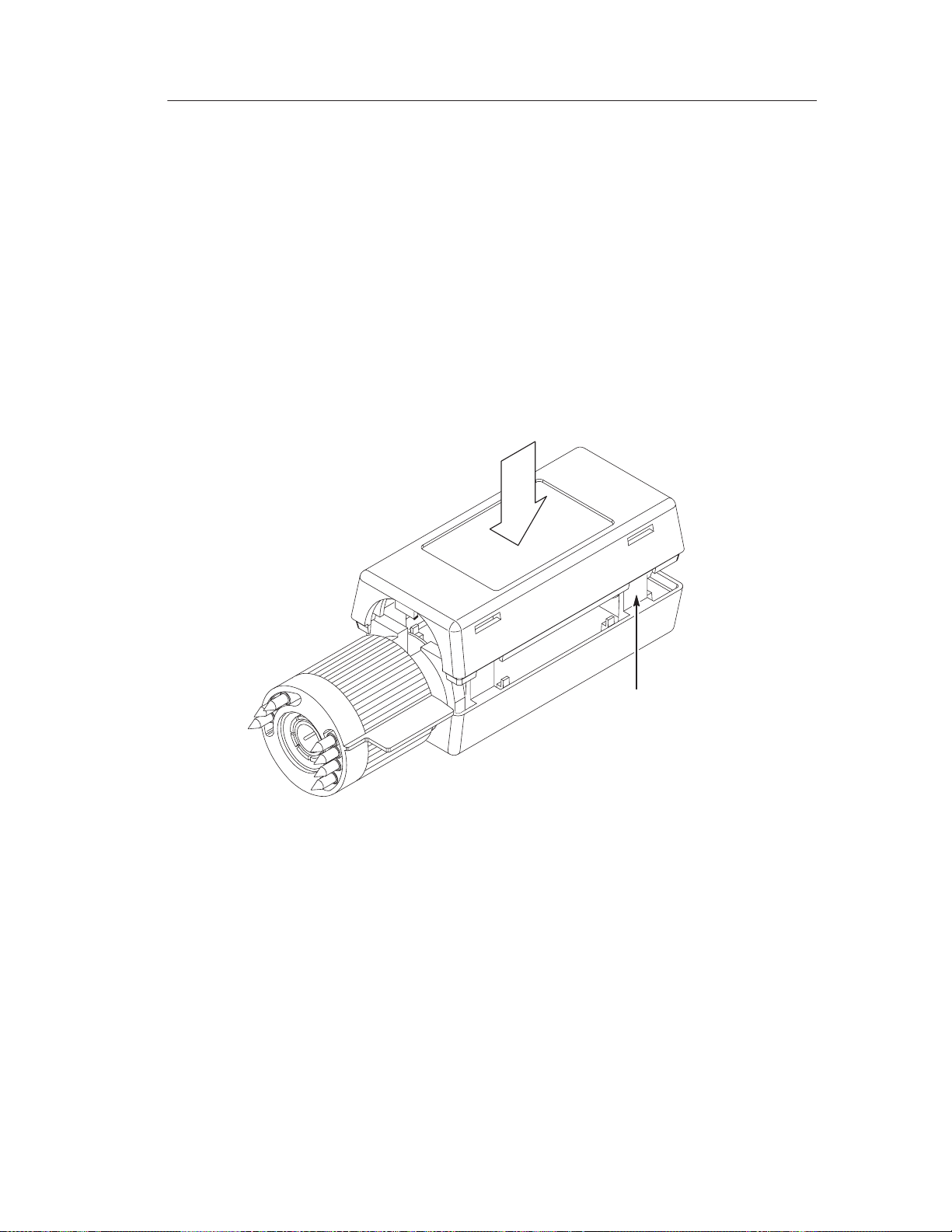

Removing and Replacing the TEKPROBE Interface Collar

To remove the TEKPROBE interface collar, firmly grasp the

compensation box body with one hand, and the TEKPROBE

interface collar with the other hand. Firmly pull the interface collar

off.

To replace the interface collar, first note the pin configuration on the

compensation box, and their holes in the interface collar . The group

of three pins fit through the smaller of the two holes in the interface

collar. See Figure 21.

Align the tab to the slot and gently press the two pieces together . See

Figure 21.

Once installed, the TEKPROBE interface collar should rotate freely

to lock and unlock.

56

Tab

Slot

Figure 21: Replacing the TEKPROBE interface collar

P6249 4 GHz 5X Active Probe Instruction Manual

Page 69

Inspection and Cleaning

To prevent damage to probe materials, avoid using chemicals that

contain benzine, benzene, toluene, xylene, acetone, or similar

solvents.

Do not immerse the probe or use abrasive cleaners.

Dirt may be removed with a soft cloth dampened with a mild

detergent and water solution, or isopropyl alcohol.

Replacement Parts

Refer to Replaceable Parts on page 63 for a list of customer

replaceable parts. Due to the sophisticated design of the P6249, there

are no user replaceable parts within the probe.

Maintenance

Preparation for Shipment

If the original packaging is unfit for use or not available, use the

following packaging guidelines:

1. Use a corrugated cardboard shipping carton having inside

dimensions at least one inch greater than the probe dimensions.

The box should have a carton test strength of at least 200 pounds.

2. Put the probe into a plastic bag or wrap to protect it from

dampness.

3. Place the probe into the box and stabilize it with light packing

material.

4. Seal the carton with shipping tape.

P6249 4 GHz 5X Active Probe Instruction Manual

57

Page 70

Maintenance

58

P6249 4 GHz 5X Active Probe Instruction Manual

Page 71

Troubleshooting

This troubleshooting documentation details isolation to either the

probe or the oscilloscope.

NOTE. Certain firmware versions of TDS series oscilloscopes will

return a “Probe Cal Failed” message when you run probe calibration

routines on the P6249 probe. If this occurs, refer to Probe Calibration

Errors on page 16.

To troubleshoot the P6249, the probe must be attached to an

operating TEKPROBE interface oscilloscope with the top cover of

the compensation box removed. Refer to page 54 for instructions on

opening the compensation box.

The oscilloscope should be set to the following settings:

H 50 W termination at instrument.

H DC coupling

CAUTION.

Observe caution when probing in the compensation

box. Operating voltages will be present. Be careful not to touch

or ground energized components.

Work at a Level 1 ESD workstation when performing troubleshooting. The compensation box contains static sensitive

devices.

P6249 4 GHz 5X Active Probe Instruction Manual

59

Page 72

Troubleshooting

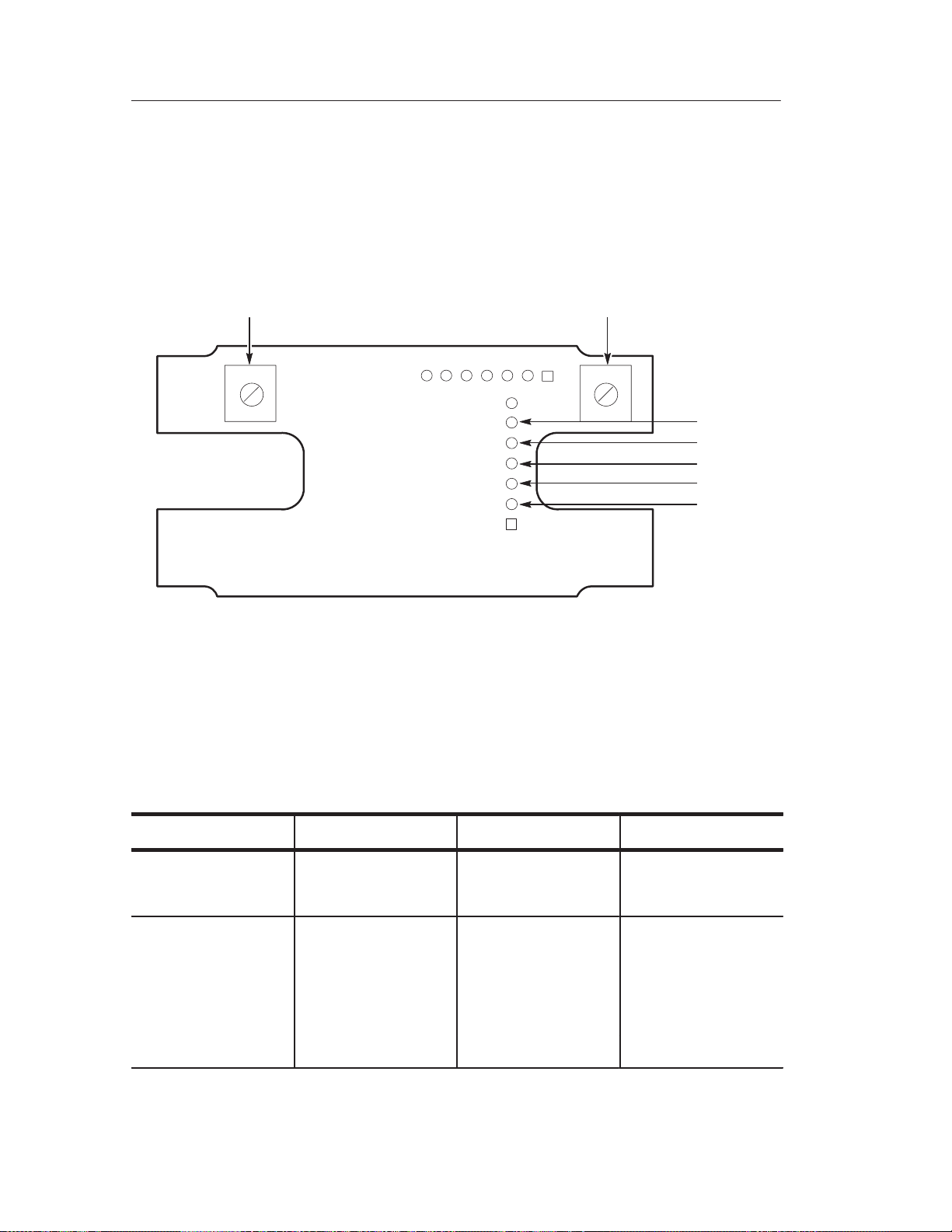

Refer to Table 8 for troubleshooting procedures, and Figure 22 for

troubleshooting test points.

Offset zero

adjust

+5

(Red)

Ground

(Black)

–5

(White)

Offset

(Blue)

Offset range

J1

J4

Figure 22: Compensation box test point locations

adjust

Offset

–5

Data

Clock

+5

Table 8: Troubleshooting guide

Symptom

Checks Result Action

No Signal Out Check known signal

Go to Probe Power

Distorted or

nonlinear signal

60

Is the instrument set

to 50 W termination?

P6249 4 GHz 5X Active Probe Instruction Manual

No signal.

Probe power OK.

Continue checks

Replace probe.

No Set termination to

50 W, or install a

feedthrough

termination at the

instrument input.

Yes Continue

Page 73

Table 8: T roubleshooting guide (Cont.)

Symptom ActionResultChecks

Troubleshooting

Distorted or

nonlinear signal

No Offset Adjust

(Signal present)

Probe Power Check the power

Is the signal within

linear dynamic

range? See page 19.

Go to Probe Power

row

Check variation of

offset input from host

instrument. See

Figure 22. Signal

should vary between

+1 V and –1V.

test points in the

compensation box.

See Figure 22.

No Set channel vertical

offset to match signal

characteristic.

Probe power OK Continue checks

Offset input OK

Offset input bad

Power OK Continue checks.

Replace probe.

Check TEKPROBE

interface pins on the

compensation box.

See page 53.

Check TEKPROBE

interface on host

instrument. (Try an

adjacent channel.)

Repair host

instrument

Power bad Check TEKPROBE

P6249 4 GHz 5X Active Probe Instruction Manual

interface pins on the

compensation box.

See page 53.

Check TEKPROBE

interface on host

instrument. (Try an

adjacent channel.)

Repair host

instrument

61

Page 74

Troubleshooting

62

P6249 4 GHz 5X Active Probe Instruction Manual

Page 75

Replaceable Parts

This section contains a list of replaceable parts for the P6249. Use

this list to identify and order replacement parts.

Parts Ordering Information

Replacement parts are available from or through your local

Tektronix, Inc. service center or representative.

Changes to Tektronix instruments are sometimes made to accommodate improved components as they become available and to give you

the benefit of the latest circuit improvements. Therefore, when

ordering parts, it is important to include the following information in

your order:

H Part number

H Instrument type or model number

H Instrument serial number

H Instrument modification number, if applicable

If a part you order has been replaced with a different or improved

part, your local Tektronix service center or representative will

contact you concerning any change in the part number .

P6249 4 GHz 5X Active Probe Instruction Manual

63

Page 76

Replaceable Parts

Using the Replaceable Parts List

The tabular information in the Replaceable Parts List is arranged for

quick retrieval. Understanding the structure and features of the list

will help you find the information you need for ordering replacement

parts.

Item Names

In the Replaceable Parts List, an Item Name is separated from the

description by a colon (:). Because of space limitations, an Item

Name may sometimes appear as incomplete. For further Item Name

identification, U.S. Federal Cataloging Handbook H6-1 can be used

where possible.

Indentation System

This parts list is indented to show the relationship between items.

The following example is of the indentation system used in the

Description column:

1ą 2ą 3ą 4ą 5 Name & Description

Assembly and/or Component

Attaching parts for Assembly and/or Component

(END ATTACHING PARTS)

Detail Part of Assembly and/or Component

Attaching parts for Detail Part

(END ATTACHING PARTS)

Parts of Detail Part

Attaching parts for Parts of Detail Part

(END ATTACHING PARTS)

Attaching parts always appear at the same indentation as the item it

mounts, while the detail parts are indented to the right. Indented

items are part of, and included with, the next higher indentation.

Attaching parts must be purchased separately, unless otherwise

specified.

64

Abbreviations

Abbreviations conform to American National Standards Institute

(ANSI) standard Y1.1

P6249 4 GHz 5X Active Probe Instruction Manual

Page 77

Replaceable Parts

Mfr. part no.

Mfr.

code

4

12345 name & description

Qty

Serial no.

Effective Dscont

2

3

Figure 23: P6249 replaceable parts

1

part no.

Tektronix

Fig. &

index no.

010-0622-00 1 PROBE, FET ACT:>4 GHZ,5X,1PF,TDS SERIES 80009 010-0622-00

23–1

–2 131-3627-02 1 CONTACT,ELEC:GOLD PLATED TIP 80009 131-3627-02

–3 205-0191-00 1 SHELL,ELEC CONN:BNC,ABS,DOVE GRAY 80009 205-0191-00

–4 016-1879-00 1 CASE,STORAGE:PLASTIC,W/FOAM 80009 016-1879-00

P6249 4 GHz 5X Active Probe Instruction Manual

65

Page 78

Replaceable Parts

7 8 9

6

5

4

3

2

1

12

11

10

Figure 24: P6249 standard accessories

P6249 4 GHz 5X Active Probe Instruction Manual 66

Page 79

Mfr. part no.

Mfr.

code

Replaceable Parts

80009 196-3456-00

STANDARD ACCESSORIES

12345 name & description

Qty

Serial no.

Effective Dscont

part no.

Tektronix

Fig. &

index no.

GROUND LEAD, TWO DIFFERENTIAL LEAD

24–1 196-3456-00 1 LEAD SET:ACCESSORY KIT , INCL THREE 3.0 INCH

–2 131-5638-30 1 PROBE,TIP:PACKAGE OF 30 80009 131-5638-30

–3 016-1772-00 1 ACCESSORY KIT:POGO PIN,PKG OF 15 80009 016-1772-00

–4 016-1773-00 1 ACCESSORY KIT:GND PIN LENGTH ADAPTER,PKG OF 15 80009 016-1773-00

–5 016-1774-00 1 ACCESSORY KIT:ADAPTER SPRING,PKG OF 10 80009 016-1774-00

–6 ST501 1 PROBE,TIP,SURETOE:PACKAGE OF 12 80009 ST501

–7 SF503 1 ADPTR,SUREFOOT:0.5 MM EIAJ,PKG OF 12 80009 SF503

–8 SF502 1 ADPTR,SUREFOOT:25 MIL JEDEC,PKG OF 12 80009 SF502

–9 SF501 1 ADPTR,SUREFOOT:50 MIL JEDEC,PKG OF 12 80009 SF501

P6249 4 GHz 5X Active Probe Instruction Manual

–10 016-1315-00 1 MARKER KIT,ID:CABLE MARKER BAND,2 EA, VAR COLRS 80009 016-1315-00

–11 013-0309-00 1 TIP,PROBE:MICROCKT TEST,PKG OF 2 80009 013-0309-00

–12 206-0364-00 2 TIP,PROBE:MICROCKT TEST,SMT KLIP CHIP 80009 206-0364-00

071-0538-XX 1 MANUAL,TECH:INSTRUCTION,P6249 80009 071-0538-XX

67

Page 80

Replaceable Parts

4

Mfr. part no.

Mfr.

code

80009 015-0678-00

3

OPTIONAL ACCESSORIES

12345 name & description

Qty

SIZE,TERMINATED INTO 50 OHM TEST FIXTURE

2

Serial no.

Effective Dscont

1

part no.

Tektronix

1103 1 TEKPROBE IF PS:W/OFFSET 2 CONN 80009 1103

Figure 25: P6249 optional accessories

Fig. &

index no.

25-1 003-1433-02 1 ADJUSTMENT TOOL 80009 003-1433-02

-2 003-1383-00 1 RLSE TOOL,COVER:COMP BOX, POLYCARBONATE 80009 003-1383-00

-3 679-4809-00 1 CKT BD SUBASSY:CALIBRATION 80009 679-4809-00

-4 015-0678-00 1 ADAPTER, PROBE:TIP,SMA 2 COMPACT

SMG50 1 MICROCKT TEST,SMT KLIP CHIP,PKG OF 20 (SEE 5–2–12) 80009 SMG50

P6249 4 GHz 5X Active Probe Instruction Manual 68

Page 81

BEAVER T ON OR 97077–0001

Replaceable Parts

CROSS INDEX – MFR. CODE NUMBER TO MANUFACTURER

Manufacturer Address City , State, Zip Code

Mfr.

Code

PO BOX 500

TEKTRONIX INC 14150 SW KARL BRAUN DR

80009

P6249 4 GHz 5X Active Probe Instruction Manual

69

Page 82

Replaceable Parts

P6249 4 GHz 5X Active Probe Instruction Manual 70

Loading...

Loading...