Page 1

Instruction Manual

P6245AD

10X Active Probe

-0687-00

071

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and

pending. Information in this publication supercedes that in all previously

published material. Specifications and price change privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX, TEK, TEKPROBE, and SureFoot are registered trademarks of

Tektronix, Inc.

FlexLead and KlipChip are trademarks of Tektronix, Inc.

Page 3

WARRANTY

Tektronix warrants that this product will be free from defects in materials and

workmanship for a period of three (3) months from the date of shipment. If any such

product proves defective during the three–month period, Tektronix, at its option, either

will repair the defective product without charge for parts and labor, or will provide a

replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the

defect before the expiration of the respective warranty period and make suitable

arrangements for the performance of service. Customer shall be responsible for packaging

and shipping the defective product to the service center designated by Tektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if

the shipment is to a location within the country in which the Tektronix service center is

located. Customer shall be responsible for paying all shipping charges, duties, taxes, and

any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or

improper or inadequate maintenance and care. Tektronix shall not be obligated to furnish

service under this warranty a) to repair damage resulting from attempts by personnel other

than Tektronix representatives to install, repair or service the product; b) to repair damage

resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non–Tektronix supplies; or d) to service a

product that has been modified or integrated with other products when the effect of such

modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE

LISTED PRODUCTS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE

DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY

PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE OR ANY INDIRECT ,

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF

THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

Getting Started

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting Tektronix viii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Accessories 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features and Accessories 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Offset 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Check 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Basics

Operating Basics 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Nondestructive Input Voltage 2–1. . . . . . . . . . . . . . . . . .

Input Linear Dynamic Range 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Ground Lead Length 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helpful Hints 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Low-inductance Grounding 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SureFoot Grounding 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Tip Test Points 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Tip Stabilization 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications

Specifications 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Information

Theory of Operation 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Head and Cable Assembly 4–1. . . . . . . . . . . . . . . . . . . . . . .

Compensation Box 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Offset Amplifier 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Probe Identification EEPROM 4–2. . . . . . . . . . . . . . . . . . . . . . .

P6245AD Instruction Manual

i

Page 6

Table of Contents

TEKPROBE Interface 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Setup 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Offset Zero 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Accuracy 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustments 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Locations 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Offset Zero 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Offset Range 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing TEKPROBE Interface Pins 4–11. . . . . . . . . . . . . . . . . . .

Removing and Replacing the Compensation Box Covers 4–12. . . . .

Removing and Replacing the TEKPROBE Interface Collar 4–14. . .

Inspection and Cleaning 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement Parts 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation for Shipment 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 4–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Parts

Replaceable Parts 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List 5–2. . . . . . . . . . . . . . . . . . . . . . . .

Item Names 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Indentation System 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Abbreviations 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

P6245AD Instruction Manual

Page 7

List of Figures

Figure 1–1: Dynamic and Offset Limitations 1–8. . . . . . . . . . . .

Figure 1–2: Probe Functional Check Connections 1–9. . . . . . . .

Figure 2–1: Waveform Distortion

from Ground Lead Length 2–2. . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–2: Ground Lead Equivalent Cir cuit 2–3. . . . . . . . . . . .

Figure 2–3: Low-inductance Grounding 2–5. . . . . . . . . . . . . . . .

Figure 2–4: Using a SureFoot Adapter for Gr ounding 2–6. . . .

Figure 2–5: Using a Probe T ip as a Test Point 2–7. . . . . . . . . . .

Table of Contents

Figure 2–6: Probe T ip Stabilizing Notch 2–8. . . . . . . . . . . . . . . .

Figure 3–1: Typical Voltage Derating vs. Frequency 3–3. . . . . .

Figure 3–2: Typical Linearity Error vs V

Figure 3–3: Typical Input Impedance vs. Frequency 3–4. . . . . .

Figure 4–1: P6245AD Simplified Schematic Diagram 4–1. . . . .

Figure 4–2: TEKPROBE Interface 4–3. . . . . . . . . . . . . . . . . . . .

Figure 4–3: P6245AD DC Accuracy Setup 4–6. . . . . . . . . . . . . .

Figure 4–4: P6245AD Adjustment Locations 4–8. . . . . . . . . . . .

Figure 4–5: Replacing TEKPROBE Interface Pins 4–11. . . . . . .

Figure 4–6: Removing the Compensation Box Covers 4–12. . . . .

Figure 4–7: Replacing the Compensation Box Cover 4–13. . . . .

Figure 4–8: Replacing the TEKPROBE collar 4–14. . . . . . . . . . .

Figure 4–9: Compensation Box Test Point Locations 4–17. . . . . .

IN

3–3. . . . . . . . . . . . .

Figure 5–1: P6245AD Replaceable Parts 5–4. . . . . . . . . . . . . . . .

Figure 5–2: P6245AD Standard Accessories 5–6. . . . . . . . . . . . .

Figure 5–3: P6245AD Optional Accessories 5–8. . . . . . . . . . . . .

P6245AD Instruction Manual

iii

Page 8

Table of Contents

iv

P6245AD Instruction Manual

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent

damage to this product or any products connected to it. To avoid

potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or Personal Injury

Connect and Disconnect Properly. Do not connect or disconnect probes

or test leads while they are connected to a voltage source.

Connect and Disconnect Properly. Connect the probe output to the

measurement instrument before connecting the probe to the circuit

under test. Disconnect the probe input and the probe ground from the

circuit under test before disconnecting the probe from the measurement instrument.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all

ratings and markings on the product. Consult the product manual for

further ratings information before making connections to the product.

Do Not Operate Without Covers. Do not operate this product with

covers or panels removed.

Avoid Exposed Circuitry. Do not touch exposed connections and

components when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage

to this product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Safety Terms and Symbols

Terms in This Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that

could result in injury or loss of life.

P6245AD Instruction Manual

v

Page 10

General Safety Summary

CAUTION. Caution statements identify conditions or practices that

could result in damage to this product or other property .

vi

P6245AD Instruction Manual

Page 11

Preface

This manual is divided into user information and servicing

information. These sections are described below.

User Information

This section contains the information necessary to install and use the

P6245AD.

H Getting Started

This section contains the product description, description of

accessories, probe setup configuration, and how to check the

probe for normal operation.

H Operating Basics

This section contains basic information and operating suggestions

for optimal probe performance

H Specifications

This sections list the specifiecations for this product.

Service Information

This section contains the information necessary to maintain and

service the P6245AD.

H Theory of Operation

H Performance Verification

H Adjustments

H Maintenance

H Troubleshooting

Replaceable Parts

This section lists the replaceable parts, stadard accessories, and

optional accessories that are available for this product.

P6245AD Instruction Manual

vii

Page 12

Preface

Contacting Tektronix

Product

support

Service

support

Toll–free

Number

For questions about using Tektronix measurement

products, call toll free in North America:

1-800-833-9200

6:00 a.m. – 5:00 p.m. Pacific time

Or contact us by e-mail:

tm_app_supp@tek.com

For product support outside of North America,

contact your local Tektronix distributor or sales

office.

Tektronix offers a range of services, including

Extended Warranty Repair and Calibration services.

Contact your local Tektronix distributor or sales

office for details.

For a listing of worldwide service centers, visit our

web site.

In North America:

1-800-833-9200

An operator can direct your call.

viii

Postal

Address

Web site

Tektronix, Inc.

Department or name (if known)

P.O. Box 500

Beaverton, OR 97077

USA

www.tektronix.com

P6245AD Instruction Manual

Page 13

Getting Started

Page 14

Page 15

Product Description

The Tektronix P6245AD is a 10X active FET probe with less than

1 pF input capacitance. The low input capacitance and high input

resistance minimize circuit loading over a wide bandwidth range.

The small profile and low-mass head of the P6245AD makes probing

crowded circuits by hand fast and easy. The accessory tips and

adapters enable the P6245AD to be used on a wide variety of circuit

architectures.

The P6245AD is powered through a TEKPROBE interface between

the compensation box of the probe and the oscilloscope. The

P6245AD may be used with nonTEKPROBE oscilloscopes and

instruments by using the optional Tektronix 1 103 Probe Power

Supply.

In order to fully appreciate the probe’s capabilities, please read the

Getting Started and Operating Basics sections of this manual.

Standard Accessories

The P6245AD is shipped with the following standard accessories:

H standard probe tips

H SureFoot adapter probe tips

H SMT KlipChip microcircuit test leads

H Y-lead adapter

H right-angle adapter

H signal-ground adapters

H three- and six-inch ground leads

H low-inductance ground lead

H marker rings

H Instruction Manual

P6245AD Instruction Manual

1–1

Page 16

Getting Started

For service information, refer to the service section beginning at the

yellow page.

For part number information for standard and optional accessories,

refer to the Replaceable Parts section of this manual.

1–2

P6245AD Instruction Manual

Page 17

Features and Accessories

The P6245AD is provided with several features and accessories

designed to make probing and measurement a simpler task. Please

take a moment to familiarize yourself with these items and their

uses.

Probe Head Assembly. The probe head is

designed for ease of use and high performance.

Its small size makes it easy to handle in tight

areas.

Probe Tip

Socket

Ground

Socket

Stabilization

Notch

The probe tip socket is sized to easily press onto

0.025 inch pins for direct access. The ground

socket provides a short ground path for high

fidelity ground connections.

The stabilization notch permits you to use

adjacent pins to reduce stresses on the probe

and pins. See pages 1–6 and 2–8 for more

information.

Push-In Probe Tip

TEKPROBE Interface. The TEKPROBE

interface provides a communication path between

the probe and the oscilloscope. Contact pins

provide power, signal, offset, and probe

characteristic data transfer. See page 4–2 for

more information.

If your oscilloscope does not support the

TEKPROBE interface, you can use the optional

1103 probe power supply as an effective

interface. Contact your local Tektronix representative for more information.

Push-in Probe Tip. Use the push-in probe tip for

general purpose probing by hand. The tip may

also be used as a temporary test point. See page

2–7 for more information.

The push-in probe tip may also be used with the

other socketed leads and adapters.

P6245AD Instruction Manual

1–3

Page 18

Features and Accessories

Installing the Push-in Probe Tip. Attach the

push-in probe tip by seating the tip into the probe

tip socket and pushing the tip in until it is seated.

Either end of the tip may be used. Do not force

the tip. Also, be careful not to poke yourself with

the sharp probe-tip. To remove the tip, gently

grab the tip with small pliers and pull the tip out.

SureFoot probe tip. The SureFoot tip is an

integral probe tip and miniature guide that

enables fault-free probing of fine-pitch SMD

packages. Attach the SureFoot adapters the

same way as the push-in probe tips. They can be

used with any of the socketed accessory leads.

Right Angle

Adapter

The yellow, 0.050 inch SureFoot tip is compatible

with 50 mil JEDEC packages such as SOIC,

PLCC, CLCC, etc.

The blue, 0.025 inch SureFoot tip is compatible

with 0.65 mm JEDEC and EIAJ packages.

The red, 0.5 mm SureFoot tip is compatible with

EIAJ packages.

Right-angle adapter. Use the right-angle

adapter for low-profile probing of 0.025 inch

diameter square pins.

The right-angle adapter allows the P6245AD to

lie flat against a circuit board. This enables

probing in vertical circuits such as computer or

communications backplanes, or in tight areas

such as between circuit cards.

The right-angle adapter can be used directly with

the probe head, or attached to the Y-lead adapter

or ground leads.

The right-angle adapter is attached the same way

as the push-in probe tip, and can be easily

removed by hand.

1–4

P6245AD Instruction Manual

Page 19

Y-lead

Adapter

Features and Accessories

Y-lead adapter. Use the Y-lead adapter to extend

the physical reach of the probe and ground when

necessary. The Y-lead adapter accepts any of the

probe tips or adapters, and can be pushed

directly onto 0.025 inch pins.

When selecting the grounding connection,

maintain as short a ground path as possible.

Refer to page 2–2 for more information.

To attach the Y-lead adapter, gently press the

lead pins into the probe head tip and ground

receptacles. Using the black lead for ground is

recommended.

3- and 6-inch ground leads. Use the three- and

six-inch ground leads for general probing. The

socketed end of the leads may be connected to

any of the probe tips and adapters, or fitted onto

0.025 inch pins.

To attach the ground leads, press and rotate the

lead pin connector into the ground socket on the

probe head. The lead may be removed by simply

pulling the pin out by hand.

When selecting the grounding connection,

maintain as short a ground path as possible.

Refer to page 2–2 for more information.

Low-inductance ground lead. Use the

low-inductance ground adapter to substantially

reduce ground lead inductance. Because the

ground lead simply touches the ground reference,

you can easily move the probe to different points

on the device under test.

To attach, press the ground lead into the probe

head gound socket.

P6245AD Instruction Manual

When selecting the grounding connection,

maintain as short a ground path as possible.

Refer to page 2–2 for more information.

1–5

Page 20

Features and Accessories

Signal Ground

Adapter

Signal-Ground Adapter. The signal-ground

adapter is ideal for use with signal/ground pairs

on 0.100 inch header pins (such as FlexLead

adapters).

Attach the signal-ground adapter by gently

pressing it into the ground socket on the probe

head.

Be sure to use the stabilization notch whenever

possible. See page 2–8 for further details.

FlexLead

Adapter

KlipChip

Y-lead

Adapter

Color Marker

Bands

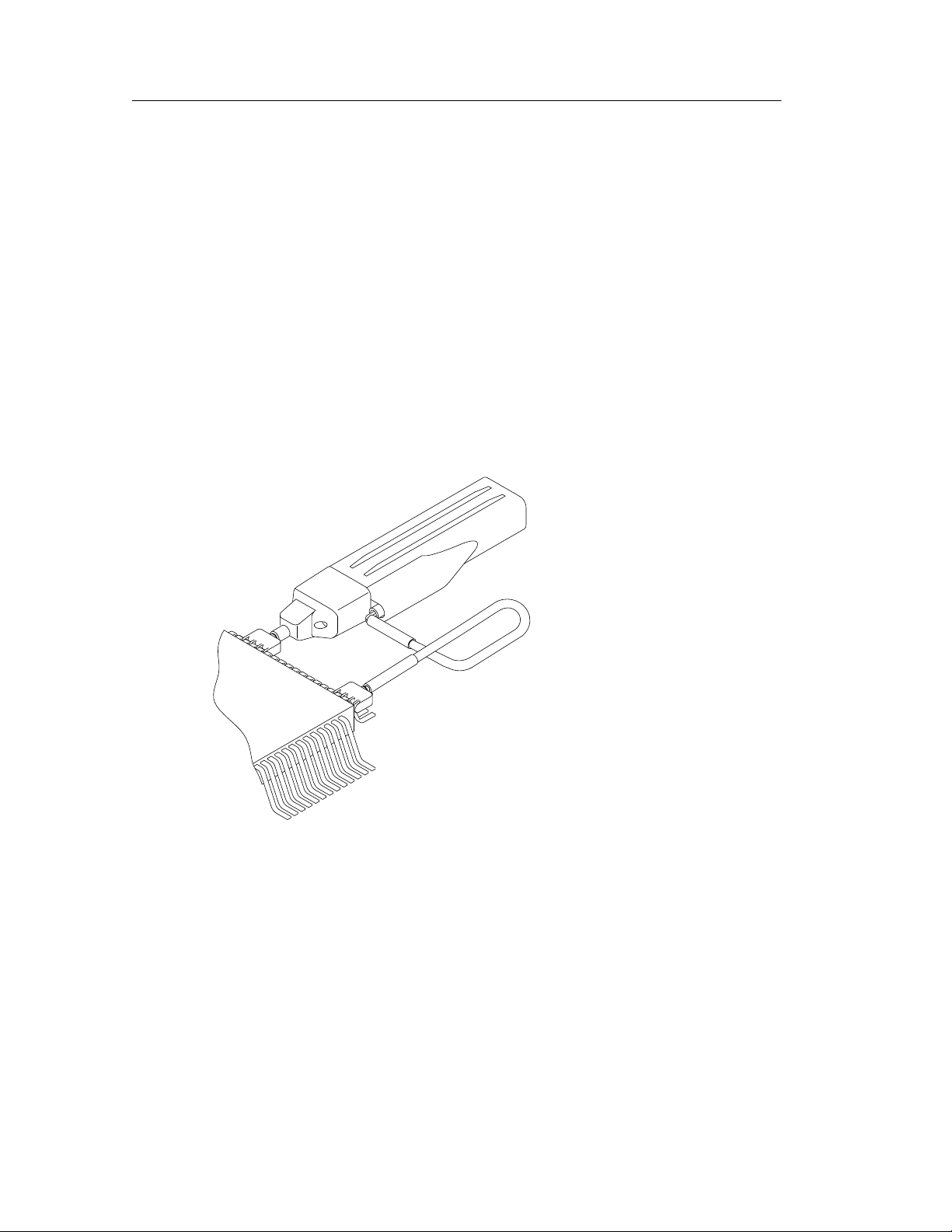

SMT KlipChip. Use the SMT KlipChip test clips

to access fragile, dense circuitry.

KlipChip test clips can be connected to the Y-lead

or three- or six-inch ground leads. Simply press

the lead socket into the KlipChip handle.

The KlipChip body freely turns, allowing better

probe orientation. To reduce stress and provide a

lower profile on components being tested, the

flexible sleeve of the KlipChip bends up to a

35 degree angle.

Color Marker Bands. Attach matching pairs of

the color marker bands onto the cable at the

head and compensation box of each probe. The

marker bands enable quick verification of which

probe is connected to which instrument channel.

1–6

P6245AD Instruction Manual

Page 21

Configuration

The P6245AD provides the oscilloscope with the probe model

number, serial number, and attenuation factor. When connected to a

TEKPROBE oscilloscope, display readouts are corrected for the

probe attenuation factor, the instrument input is set to 50 W, and the

coupling is set to DC.

CAUTION. Do not attempt to install the P6245AD on a

nonTEKPROBE connector. Damage to the probe and connector may

result. If your oscilloscope does not support the TEKPROBE

interface, use the optional Tektronix 1103 Probe Power Supply .

If the P6245AD is used with the Tektronix 1103 Probe Power Supply,

be sure to have a 50 W termination at the oscilloscope. Also, set the

oscilloscope channel coupling to DC.

The probe offset control is controlled by the oscilloscope. If the

oscilloscope used does not support the TEKPROBE interface, the

offset controls on the optional Tektronix 1103 Probe Power Supply

can be used.

Probe Offset

The probe offset is adjustable to permit operation within the linear

range of the probe. Using the offset to cancel DC signal components

enables optimal probe performance. See Figure 1–1 on page 1–8.

NOTE. See your oscilloscope manual for specific instructions on its

operation and offset control.

P6245AD Instruction Manual

1–7

Page 22

Configuration

To set the probe offset, follow these steps:

1. Set the oscilloscope coupling to GND.

2. Use the vertical position control to set a zero reference level on

3. Set the oscilloscope coupling to DC and 5 V/div.

4. Attach the probe to the circuit.

5. Adjust the probe offset to bring the trace to the oscilloscope zero

6. Change the volts/division setting to the desired range, adjusting

NOTE. The P6245AD has a ±10 V offset range. The linear operating

range is ±8 V. See Figure 1–1. Also, see page 2–1 for more

information.

the oscilloscope display .

reference.

the offset to keep the trace on the zero reference level.

If cursors are used on a TEKPROBE oscilloscope, the zero reference

will be at the probe offset voltage.

Nonoperating Range (+40 V Maximum Non-destructive Input Voltage )

+18 V

+10 V

+8 V

0 V

–8 V

–10 V

–18 V

Nonoperating Range (–40 V Maximum Non-destructive Input Voltage )

+10 V

Maximum Offset RangeMaximum AC Signal Amplitude

–10 V

Figure 1–1: Dynamic and Offset Limitations

1–8

P6245AD Instruction Manual

Page 23

Functional Check

After installing the probe on the oscilloscope, a functional check

may be performed using the PROBE COMPENSATION connections

on the front panel of the oscilloscope. See Figure 1–2.

Figure 1–2: Probe Functional Check Connections

1. Connect the probe to the oscilloscope.

2. Set the oscilloscope to display the probe’s channel.

3. Using a ground lead and a SMT KlipChip, connect the probe

ground to the PROBE COMPENSATION ground connection on

the oscilloscope.

4. Using a standard tip, hold the probe to the SIGNAL terminal on

the oscilloscope.

5. Press AUTOSET (or adjust the oscilloscope) to display the

calibration waveform.

P6245AD Instruction Manual

1–9

Page 24

Functional Check

NOTE. If your instrument supports probe calibration routines, now is

a good time to perform them.

6. Disconnect the probe from the SIGNAL terminal and ground the

probe tip. (Connect the KlipChip to the probe tip.)

7. With the probe offset set to 0.0 V, the oscilloscope display should

be at the ground reference.

8. Set the oscilloscope volts/division to 5 V.

9. Adjust the probe offset. The displayed waveform should vary

between approximately +10 V and –10 V. (A +10 V offset

displays a –10 V level on your instrument.)

NOTE. If no waveform is displayed, check the vertical coupling to be

sure that it is set to DC.

If the offset adjustment has no effect, set the vertical coupling to DC.

If you are using the Tektronix 1103 Probe Power Supply, and the

waveform is distorted, check to make sure that the oscilloscope

termination is 50 W.

If the probe does not pass this functional check, go to the Troubleshooting section of this manual.

1–10

P6245AD Instruction Manual

Page 25

Operating Basics

Page 26

Page 27

Operating Basics

Please follow these operating guidelines to get optimum performance from your P6245AD.

Maximum Nondestructive Input Voltage

The P6245AD is electrically protected against static voltage;

however, applying voltages above its design limits may damage the

probe tip amplifier. Please refer to the Specifications section of this

manual for the maximum operating voltage and frequency derating

information.

Input Linear Dynamic Range

The probe head amplifier used by the P6245AD has a limited linear

operating range. To keep the input linearity error less than 4% you

must limit the signal input voltage to ±8 V (including any DC

offset).

Use the DC offset adjustment to maintain the probe within its

dynamic range. The nominal offset adjustment range of the

P6245AD is ±10 VDC. For example: to offset a +5 VDC level in a

circuit, set the offset to +5 V.

NOTE. The probe can tolerate input voltages of ±40 V without

damage; however, the linearity error specification does not apply to

input voltages exceeding ±18 V (including any DC offset). See

Figure 1–1 on page 1–8.

P6245AD Instruction Manual

2–1

Page 28

Operating Basics

Ground Lead Length

When you are probing a circuit, you should always use as short a

ground lead as possible between the probe head and circuit ground.

The series inductance added by the probe tip and ground lead can

result in a resonant circuit; this circuit may cause parasitic ringing

within the bandwidth of your oscilloscope. Refer to Figure 2–1.

Low-inductance

Ground

Three-inch

Ground

Six-inch

Ground

Figure 2–1: Waveform Distortion from Ground Lead Length

Ground Lead Inductance

When you touch your probe tip to a circuit element, you are

introducing a new resistance, capacitance, and inductance into the

circuit. Refer to Figure 2–2.

2–2

P6245AD Instruction Manual

Page 29

R

Operating Basics

source

V

source

(Ground Lead)

L

gl

Probe R

1MW

in

Probe C

1pF

Figure 2–2: Ground Lead Equivalent Circuit

Ringing and rise time degradation can be masked if the frequency

content of the signal degradation is beyond the bandwidth of the

oscilloscope.

You can determine if ground lead effects may be a problem in your

application if you know the self-inductance (L) and capacitance (C)

of your probe and ground lead. Calculate the approximate resonant

frequency (f

) at which this parasitic circuit will resonate with the

0

following formula:

+

f

0

1

Ǹ

2p LC

in

The preceding equation shows that reducing the ground lead

inductance will raise the resonant frequency. If your measurements

are affected by ringing, your goal is to lower the inductance of your

ground path until the resulting resonant frequency is well above the

frequency of your measurements.

The low-inductance ground contacts described in Accessories can

help you reduce the effects of ground lead inductance on your

measurements.

P6245AD Instruction Manual

2–3

Page 30

Operating Basics

2–4

P6245AD Instruction Manual

Page 31

Helpful Hints

Follow these helpful hints to make probing easier and noise free.

Low-inductance Grounding

Placing a ground plane on top of a package being probed can

minimize ground lead length and inductance. See Figure 2–3.

Figure 2–3: Low-inductance Grounding

Attach a small piece of copper clad on top of the package and

connect it to the package ground connection. Use the low-inductance

ground lead provided with the P6245AD to keep the ground lead

length as short as possible.

P6245AD Instruction Manual

2–5

Page 32

Helpful Hints

This method is very useful when making many measurements on the

same package. Using a ground plane on the package makes probing

the package easier, and avoids adding unnecessary ground lead

length and distortion.

SureFoot Grounding

If you cannot use the low-inductance grounding method recommended, the probe may be grounded to the package under test using

a SureFoot adapter. Refer to Figure 2–4.

2–6

Figure 2–4: Using a SureFoot Adapter for Grounding

Use a SureFoot adapter at the end of a short ground lead to connect

directly to the package ground. This method is preferred over using

an adjacent circuit ground because it is the shortest ground path

possible.

P6245AD Instruction Manual

Page 33

Probe Tip Test Points

The push-in probe tip or a 0.025 square pin can be soldered into a

circuit to be used as a temporary test point. See Figure 2–5.

Solder the tip onto a lead or pin with a low-power soldering iron.

Press the probe head onto the tip to make a measurement, and then

pull the probe head off when you are done.

The probe tip may be removed and reused by desoldering it from the

circuit, and soldering it into another circuit in the future.

Helpful Hints

Solder

Figure 2–5: Using a Probe Tip as a Test Point

NOTE. It is not recommended that pieces of solid-core copper wire be

used as test points. If the wire breaks off in the probe tip socket, it

may be impossible to remove the wire, and it will prevent insertion of

other accessory tips.

P6245AD Instruction Manual

2–7

Page 34

Helpful Hints

Probe Tip Stabilization

The P6245AD probe head has a stabilizing notch for use with 0.100

inch spaced header pins. See the probe head detail on page 1–3.

As the probe is pressed onto the header pin, an adjacent pin can be

inserted into the probe’s stabilizing notch. See Figure 2–6. This

prevents unnecessary force from being applied directly to the probe

tip or pins.

Stabilization Notch

Figure 2–6: Probe Tip Stabilizing Notch

The signal-ground adapter then rests on the stabilized pin without a

risk of its moving out of place.

2–8

P6245AD Instruction Manual

Page 35

Specifications

Page 36

Page 37

Specifications

These specifications apply to a P6245AD when used with a

Tektronix TDS 684C (or similar) oscilloscope.

The probe and instrument must first be allowed to warm up for

20 minutes before measurements are taken.

CAUTION. Do not apply voltages beyond the nondestructive input

voltage range to the probe. Damage to the probe or circuit under test

may result.

Table 3–1: Warranted Electrical Specifications

DC Attenuation Accuracy

(probe only)

Output Zero ±5 mV or less at output of probe

10:1 ±2%

±50 mV or less displayed on screen with

TEKPROBE interface

P6245AD Instruction Manual

3–1

Page 38

Specifications

Table 3–2: T ypical Electrical Characteristics

Analog Bandwidth (probe only) 1.0 GHz on ≥10GHz oscilloscope

Rise Time (probe only) 400ps on ≥10 GHz oscilloscope

Linear Input Dynamic Range – 8 V to + 8 V.

(Equivalent to – 0.8 V to + 0.8 V

at the output of the probe.)

Linearity " 4% or less of dynamic range

Nondestructive Input Voltage Range

Input Resistance

Input Capacitance ≤1.0 pF

Offset Range –10 V to +10 V

DC Offset Drift

Delay Time 18.02 ns

– 40 V to + 40 V (DC + peak AC)

(See Figure 3–1.)

1MW at DC. (See Figure 3–3.)

100 mV/°C or less at output of probe

1 mV/°C or less displayed on screen with

TEKPROBE interface

3–2

P6245AD Instruction Manual

Page 39

50 V

40 V

30 V

20 V

10 V

Specifications

20V at 400 MHz

8V at 1 GHz

0 V

Figure 3–1: T ypical Voltage Derating vs. Frequency

150 mV

100 mV

50 mV

0 mV

Display Error

–50 mV

–100 mV

1 GHz1 MHz 10 MHz 100 MHz

–150 mV

–20 V 0 V–10 V 10 V 20 V

Figure 3–2: Typical Linearity Error vs V

P6245AD Instruction Manual

V

IN

IN

3–3

Page 40

Specifications

10 MW

100 kW

10 kW

100 W

1 MW

1 kW

10 W

100 Hz 1 GHz100 kHz1 kHz 10 kHz 1 MHz 10 MHz 100 MHz

Figure 3–3: T ypical Input Impedance vs. Frequency

3–4

P6245AD Instruction Manual

Page 41

T able 3–3: Physical Characteristics

Shipping Weight 539.4 g (1.18 lb)

Cable Length 4.6 m (15 ft)

T able 3–4: Environmental Characteristics

Operating Temperature 0° C TO +50° C.

The environmental exposure is the procedure stated

in Tektronix Design Standard 062–2847–00 for Class

5 equipment.

Nonoperating Temperature – 40° C TO + 71° C.

Specifications

The environmental exposure is the procedure stated

in Tektronix Design Standard 062–2847–00 for Class

5 equipment.

Humidity The environmental exposure is the procedure stated

in Tektronix Design Standard 062–2847–00 for Class

5 equipment.

Packaged Product Vibration and

Shock

Altitude Operating: 15,000 ft.

The packaged product qualifies under the Distribution

Cycle 1 Assurance Level II for packaged products 0 –

20 lbs. Test 2 for Warehouse and Vehicle Stacking

(Compression) is omitted.

Tektronix standard 062–2858–00, Rev. B, Class 5.

Nonoperating: 50,000 ft.

P6245AD Instruction Manual

3–5

Page 42

Specifications

3–6

P6245AD Instruction Manual

Page 43

WARNING

The following servicing instructions are for use only by

qualified personnel. To avoid injury, do not perform any

servicing other than that stated in the operating instructions

unless you are qualified to do so. Refer to all safety

summaries before performing any service.

Page 44

Page 45

Service Information

Page 46

Page 47

Theory of Operation

There are no user replaceable parts within the probe or the

compensation box; however, this theory of operation is provided to

assist you in isolating failures to either the probe or the host

oscilloscope. Refer to Figure 4–1 for the probe’s simplified

schematic.

Probe Head Compensation Box Oscilloscope

Probe Tip

Probe-Tip

Ampifier

Offset Ampifier

EEPROM

Signal Out

Probe ID Out

Clock In

±1V Offset

Offset to probe

+5

Offset

Gain

Probe

Cable

Figure 4–1: P6245AD Simplified Schematic Diagram

Probe Head and Cable Assembly

The probe head assembly contains an active amplifier circuit that

buffers and amplifies the input signal. The amplifier receives power

Offset

Zero

–5

+5V

–5V

Ground

TEKPROBE

Interface

P6245AD Instruction Manual

4–1

Page 48

Theory of Operation

and an offset level from the compensation box assembly via the

cable assembly .

All signal amplification and buffering is performed in the probe head

assembly. No further amplification takes place in the compensation

box.

Compensation Box

The compensation box contains the following circuits:

H Offset amplifier

H Probe identification EEPROM

H TEKPROBE interface

Offset Amplifier

The offset amplifier is used to offset the input signal’s DC compo-

nent so that it stays at the optimal point of the probe’s linear

dynamic range. For more information on the linear dynamic range

characteristic, refer to the notes on page 2–1.

The offset amplifier receives offset information as a ±1 VDC voltage

from the oscilloscope. The amplfier then amplifies it to match the

probe characteristics and applies it to the probe hybrid circuit.

The offset amplifier has two adjustments: offset zero and offset gain.

These adjustments rarely need attention; however, detailed

adjustment instructions are in the Adjustments section on page 4–8.

Probe Identification EEPROM

The probe identification EEPROM is used to configure the

oscilloscope to the probe. The EEPROM receives a clock input from

the oscilloscope, and information about the probe is passed to the

oscilloscope.

TEKPROBE Interface

4–2

The TEKPROBE interface provides a communication path between

the probe and the oscilloscope. Contact pins provide power, signal,

offset, and data transfer for the probe identification EEPROM.

P6245AD Instruction Manual

Page 49

Theory of Operation

Figure 4–2 shows the TEKPROBE interface pin functions. Refer to

the service documenation for your oscilloscope for more detailed

specifications.

–15 V

–5V

Offset

Ground

Signal

Data

Clock

+5 V

+15 V

Figure 4–2: TEKPROBE Interface

P6245AD Instruction Manual

4–3

Page 50

Performance Verification

Equipment Required

Table 4–1: Equipment Required for Performance Verification

Performance

Item Description

Oscilloscope TEKPROBE interface Tektronix TDS 684C

TEKPROBE Power Supply Tektronix 1103

DC Power Supply 10.00±.01 VDC at 1 mA Tektronix PS281

DC Voltmeter 0.5% accuracy at 2 VDC Tektronix CDM250

Requirement

Recommended Example

Feedthrough Termination

BNC to BNC coaxial cable

BNC to Banana adapter BNC Female to Dual

50 W ± 0.50 W

50 W coaxial cable

Banana

Equipment Setup

1. Connect the probe to the oscilloscope.

2. Connect a Y-lead adapter with KlipChip adapters attached to the

P6245AD.

3. Turn on the oscilloscope and enable the channel.

4. Set the channel’s vertical offset to 0.00 V.

5. Turn on the power supply and set to +2.00 VDC.

6. Connect the meter to measure the power supply output.

7. Allow 30 minutes for the equipment to warm up.

011–0129–00

012–1342–00

103–0090–00

4–4

P6245AD Instruction Manual

Page 51

NOTE. If your oscilloscope has a probe calibration routine, run it

before making any of the following checks. Refer to the oscilloscope’s instruction manual for more information.

Offset Zero

Use this procedure to verify the offset zero of the probe.

1. Ground the probe tip by connecting the probe tip to the probe

ground socket. (Connecting the two KlipChip adapters together is

recommended.)

2. Set the channel’s vertical offset to 0.00 V.

Performance Verification

3. Measure the displayed DC level.

The displayed DC level should be 0.00 V ±50 mV. (±5 mV when

measured directly without the probe attenuation factor .)

P6245AD Instruction Manual

4–5

Page 52

Performance Verification

DC Accuracy

Use this procedure to verify the DC accuracy of the probe. Before

beginning, read the procedure through completely.

1. Connect the test equipment as shown in Figure 4–3.

2. Attach the probe to a TEKPROBE interface on the 1103 power

supply.

3. Set the 1103 offset VAR/0V to 0V.

4. Set the multimeter to read DC volts.

5. Connect the probe tip and ground to the power supply using the

Y-lead and KlipChip adapters.

6. Allow 30 minutes for the equipment to warm up.

Digital Multimeter

+

–

50 W Precision

BNC to Dual

Banana Adapter

Terminator

Figure 4–3: P6245AD DC Accuracy Setup

7. Set the power supply to +2.000 V. Record the power supply

output as Vmax.

8. Measure and record the multimeter reading as M1.

1103

Power Supply

Power Supply

–+

4–6

9. Set the power supply to –2.000 V. Record the power supply

output as Vmin.

P6245AD Instruction Manual

Page 53

Performance Verification

10.Measure and record the multimeter reading as M2.

NOTE. If you are unable to set the power supply precisely, record the

actual readings and determine the absolute difference.

|Vmax – Vmin| = difference.

Divide the difference by 10 to account for the probe’s ideal

attenuation factor. For example: 0.4 is the difference between +2

and –2, divided by 10.

11. Determine the percent error by using the formula below:

%Error + [

The calculated error should be ≤2%.

NOTE. An unaccceptable error value may result if a low tolerance

termination is substituted for the recommended termination.

M1 * M2

0.4

* 1] 100%

P6245AD Instruction Manual

4–7

Page 54

Adjustments

The P6245AD has two internal controls: offset zero and offset range.

These controls rarely need to be adjusted, and only should be

changed after a probe calibration and functional check has been

performed on the oscilloscope.

To make adjustments to the probe, the compensation box top cover

needs to be removed with the optional release tool. Refer to page

4–12. Use the optional adjustment tool for making any adjustments.

Adjustment Locations

Refer to Figure 4–4 for the location of the offset zero and offset

range controls.

EEPROM

4–8

Offset Range

Adjust

Figure 4–4: P6245AD Adjustment Locations

Offset Amp

Offset Zero

Adjust

P6245AD Instruction Manual

Page 55

Offset Zero

Use this procedure to adjust the offset zero of the probe.

NOTE. If your oscilloscope supports a probe calibration routine,

clear the probe calibration constants at this time.

If the offset zero is adjusted, perform a functional check of the offset

range before closing the compensation box.

1. Ground the probe tip by connecting the probe tip to the probe

ground socket.

Adjustments

2. Set the vertical offset of the channel to 0.00 V.

3. Measure the displayed DC level.

4. Adjust Offset Zero for 0.00 ± 50 mV. (±5 mV when measured

directly without attenuation factor .)

P6245AD Instruction Manual

4–9

Page 56

Adjustments

Offset Range

Use this procedure to adjust the offset range of the probe. The offset

zero of the probe should be checked before making any adjustment

to the offset range.

The offset range of the probe is approximately –10 to +10 volts. The

offset range is not warranted; however , this adjustment procedure is

provided for your convenience.

NOTE. If you are using an 1103 Probe Power Supply, make sure that

the oscilloscope is set to 50 W termination with DC coupling.

See Figure 4–4 for the location of the offset range adjustment.

1. Set the power supply (using the DMM) to +10.00 VDC. (If

10.00 V cannot be set exactly, set the power supply just below

10.00 V.)

2. Connect the probe to the power supply as shown in Figure 4–3.

3. Set the channel’s vertical offset to match the DMM reading.

4. Set the vertical range of the channel to 0.1 V/div.

5. Observe the DC value of the displayed trace.

6. Adjust Offset Range for an oscilloscope reading that matches the

DMM reading.

NOTE. After the offset zero and offset range have been adjusted,

perform a probe calibration and functional check to verify

performance.

4–10

P6245AD Instruction Manual

Page 57

Maintenance

This section details the maintenance and repair procedures for the

P6245AD.

Replacing TEKPROBE Interface Pins

TEKPROBE interface pins can stick and fail to make contact after

time. Periodically check to see that each of the interface pins move

freely and fully extends out of the interface. If any pin fails to move

freely and fully extend, it should be replaced.

To remove a TEKPROBE interface pin, firmly grasp the pointed tip

with pliers and pull the pin out of the connector. See Figure 4–5.

No tools are required to install a replacement pin. Insert a new pin

into the connector socket as far as possible using finger pressure. If

necessary, seat the pin into the connector by pressing the tip gently

but firmly against a hard surface, such as a wood block or table top.

Figure 4–5: Replacing TEKPROBE Interface Pins

P6245AD Instruction Manual

4–11

Page 58

Maintenance

Removing and Replacing the Compensation Box Covers

Follow these steps to open the compensation box.

1. Press the optional release tool pins into the compensation box

cover catches and gently lift the cover off a small distance. Refer

to Figure 4–6.

2. Hold the open edge apart, and use the tool to open the other side

of the compensation box.

3. With both sides of the box open, gently separate the two halves

of the compensation box.

Cover

Catches

Figure 4–6: Removing the Compensation Box Covers

4–12

P6245AD Instruction Manual

Page 59

Maintenance

To replace the covers, follow these steps:

1. Align the TEKPROBE interface and the strain relief notches with

the tabs on the cover. Refer to Figure 4–7.

2. Press the cover catches in so that the cover can be lowered.

3. Slide the tab into the notch.

4. Firmly press the pieces together until the cover catches snap into

place.

Tab

Figure 4–7: Replacing the Compensation Box Cover

P6245AD Instruction Manual

4–13

Page 60

Maintenance

Removing and Replacing the TEKPROBE Interface Collar

To remove the TEKPROBE interface collar , firmly grasp the

compensation box body with one hand, and the TEKPROBE

interface collar with the other hand. Firmly pull the interface collar

off.

To replace the collar , first note the pin configuration on the

compensation box, and their holes in the interface collar . The group

of three pins fit through the smaller of the two holes in the interface

collar. See Figure 4–8.

Align the tab to the slot and gently press the two pieces together . See

Figure 4–8.

Once installed, the TEKPROBE collar should rotate freely to lock

and unlock.

4–14

Tab

Slot

Figure 4–8: Replacing the TEKPROBE collar

P6245AD Instruction Manual

Page 61

Inspection and Cleaning

To prevent damage to probe materials, avoid using chemicals that

contain benzine, benzene, toluene, xylene, acetone, or similar

solvents.

Do not immerse the probe or use abrasive cleaners.

Dirt may be removed with a soft cloth dampened with a mild

detergent and water solution, or isopropyl alcohol.

Replacement Parts

Refer to the Replaceable Parts section for a list of customer

replacement parts. Due to the sophisticated design of the P6245AD,

there are no user replaceable parts within the probe.

Maintenance

Preparation for Shipment

If the original packaging is unfit for use or not available, use the

following packaging guidelines:

1. Use a corrugated cardboard shipping carton having inside

dimensions at least one inch greater than the probe dimensions.

The box should have a carton test strength of at least 200 pounds.

2. Put the probe into a plastic bag or wrap to protect it from

dampness.

3. Place the probe into the box and stabilize it with light packing

material.

4. Seal the carton with shipping tape.

P6245AD Instruction Manual

4–15

Page 62

Troubleshooting

This troubleshooting documentation details isolation to either the

probe or the TEKPROBE oscilloscope.

To troubleshoot the P6245AD, the probe must be attached to an

operating TEKPROBE interface oscilloscope with the top cover of

the compensation box removed. Refer to page 4–12 for instructions

on opening the compensation box.

The host instrument should be set to the following settings:

H 50 W termination at instrument.

H DC coupling

CAUTION.

Observe caution when probing in the compensation

box. Operating voltages will be present. Be careful not to touch

or ground energized components.

Work at a Level 1 ESD workstation when performing troubleshooting. The compensation box contains static sensitive devices.

4–16

P6245AD Instruction Manual

Page 63

Troubleshooting

+5

(Red)

Ground

(Black)

–5

(White)

Offset

(Blue)

Offset

–5

Data

Clock

+5

Figure 4–9: Compensation Box Test Point Locations

Refer to Table 4–2 for troubleshooting proceedures, and Figure 4–9

for troubleshooting test points.

Table 4–2: Troubleshooting Guide

Symptom Checks Result Action

No Signal Out Check known signal

Go to Probe Power

Distorted or

nonlinear signal

Instrument set to

50 W termination?

No signal.

Probe power OK.

Continue checks

Turn in probe.

No Set termination to

50 W, or install a

feedthrough

termination at the

instrument input.

Yes Continue

Distorted or

nonlinear signal

Signal within linear

dynamic range? See

page 2–1.

No Set channel’s vertical

offset to match signal

characteristic.

P6245AD Instruction Manual

4–17

Page 64

Troubleshooting

Table 4–2: Troubleshooting Guide (Cont.)

Symptom ActionResultChecks

No Offset Adjust

(Signal present)

Probe Power Check the power

Go to Probe Power Probe power OK Continue checks

Check variation of

offset input from host

instrument. See

Figure 4–9. Signal

should vary between

+1 V and –1V.

test points in the

compensation box.

See Figure 4–9.

Offset input OK

Offset input bad

Power OK Continue checks.

Turn in probe.

Check TEKPROBE

interface pins on the

compensation box.

See page 4–11.

Check TEKPROBE

interface on host

instrument. (Try an

adjacent channel.)

Repair host

instrument

4–18

Power bad Check TEKPROBE

interface pins on the

compensation box.

See page 4–11.

Check TEKPROBE

interface on host

instrument. (Try an

adjacent channel.)

Repair host

instrument

P6245AD Instruction Manual

Page 65

Replaceable Parts

Page 66

Page 67

Replaceable Parts

This section contains a list of the replaceable parts for the P6245AD.

Use this list to identify and order replacement parts.

Parts Ordering Information

Replacement parts are available from or through your local

Tektronix, Inc. service center or representative.

Changes to Tektronix instruments are sometimes made to accommodate improved components as they become available and to give you

the benefit of the latest circuit improvements. Therefore, when

ordering parts, it is important to include the following information in

your order:

H Part number

H Instrument type or model number

H Instrument serial number

H Instrument modification number, if applicable

If a part you order has been replaced with a different or improved

part, your local Tektronix service center or representative will

contact you concerning any change in the part number .

P6245AD Instruction Manual

5–1

Page 68

Replaceable Parts

Using the Replaceable Parts List

The tabular information in the Replaceable Parts List is arranged for

quick retrieval. Understanding the structure and features of the list

will help you find the all the information you need for ordering

replacement parts.

Item Names

In the Replaceable Parts List, an Item Name is separated from the

description by a colon (:). Because of space limitations, an Item

Name may sometimes appear as incomplete. For further Item Name

identification, U.S. Federal Cataloging Handbook H6-1 can be used

where possible.

Indentation System

This parts list is indented to show the relationship between items.

The following example is of the indentation system used in the

Description column:

1ą 2ą 3ą 4ą 5 Name & Description

Assembly and/or Component

Attaching parts for Assembly and/or Component

(END ATTACHING PARTS)

Detail Part of Assembly and/or Component

Attaching parts for Detail Part

(END ATTACHING PARTS)

Parts of Detail Part

Attaching parts for Parts of Detail Part

(END ATTACHING PARTS)

Attaching parts always appear at the same indentation as the item it

mounts, while the detail parts are indented to the right. Indented

items are part of, and included with, the next higher indentation.

Attaching parts must be purchased separately, unless otherwise

specified.

Abbreviations

5–2

Abbreviations conform to American National Standards Institute

(ANSI) standard Y1.1

P6245AD Instruction Manual

Page 69

5–3

Replaceable Parts

CROSS INDEX – MFR. CODE NUMBER TO MANUFACTURER

Mfr.

Code

Manufacturer Address City , State, Zip Code

80009

TEKTRONIX INC 14150 SW KARL BRAUN DR

P6245AD Instruction Manual

BEAVER T ON OR 97077–0001

PO BOX 500

Page 70

Replaceable Parts

3

3

2

1

P6245AD Instruction Manual 5–4

Figure 5–1: P6245AD Replaceable Parts

Page 71

5–5

Replaceable Parts

Fig. &

Index No.

5–1

–1 205–0191–00 1 .SHELL,ELEC CONN:BNC,ABS,DOVE GRAY 80009 205019100

–2 131–3627–01 1 .CONTACT,ELEC:GOLD PLATED TIP 80009 131362701

–3 200–4195–00 1 .COVER,COMP BOX:TOP AND BOTTOM, W/LABELS &

Tektronix

Part No.

P6245AD 1 PROBE, FET ACT:10X,<1PF,TDS SERIES 80009 P6245AD

P6245AD Instruction Manual

Serial No.

Effective Dscont

Qty

12345 Name & Description

.RELEASE TOOLS

Mfr.

Code

80009 200419500

Mfr. Part No.

Page 72

P6245AD Instruction Manual 5–6

1

89

Figure 5–2: P6245AD Standard Accessories

7

3456

2

Replaceable Parts

Page 73

5–7

Replaceable Parts

Fig. &

Index No.

5–2

–1 196–3410–00 1 LEAD,SET:TWO 3.0 L & 6.O L,STRD,22 AWG & TW

–2 016–1315–00 1 MARKER KIT ,ID:CABLE MARKER BAND,2 EACH, VARIOUS

–3 131–5638–11 1 PROBE,TIP:PACKAGE OF 10 80009 131563811

–4 –––––––– 2 ADAPTER,PROBE:0.050 HOUSING

–5 –––––––– 2 ADAPTER,PROBE:0.025 HOUSING

P6245AD Instruction Manual

–6 –––––––– 2 ADAPTER,PROBE:0.0196 HOUSING

–7 214-4227-00 2 SPRING ADAPTER:RIGHT ANGLE 80009 214-4227-00

–8 131-5777-00 2 CONN,CONTACT: 80009 131-5777-00

–9 –––––––– 4 TIP,PROBE:MICROCKT TEST

Tektronix

Part No.

071–0687–00 1 MANUAL,TECH:INSTRUCTION,P6245AD,DP 80009 071–0687–00

Serial No.

Effective Dscont

Qty

12345 Name & Description

STANDARD ACCESSORIES

O 3.0 L BLACK & WHITE 22 AWG,JACK TIP,TERM

CONN MALE PIN,TWO Z–LEAD

COLORS

Mfr.

Code

80009 196341000

80009 016131500

Mfr. Part No.

Page 74

Replaceable Parts

1 2

Figure 5–3: P6245AD Optional Accessories

P6245AD Instruction Manual 5–8

Page 75

5–9

Fig. &

Index

No.

Tektronix

Part No.

Serial No.

Effective Dscont

Qty

12345 Name & Description

Mfr.

Code

Mfr. Part No.

Replaceable Parts

5-3

-1 003-1433-02 1 SCREWDRIVER:ADJUSTMENT TOOL,PKG OF 1 80009 003143302

-2 003-1383-00 1 RLSE TOOL,COVER:COMP BOX,

1103 1 TEKPROBE IF PS:W/OFFSET 2 CONN 80009 1103

SF501

SF502

P6245AD Instruction Manual

SF503

SMG50

OPTIONAL ACCESSORIES

POLYCARBONATE

(SEE FIGURE 5-1-3)

1

ADPTR,SUREFOOT:50 MIL JEDEC,PKG OF 12

(SEE 5-2-5)

ADPTR,SUREFOOT:25 MIL JEDEC,PKG OF 12

1

(SEE 5-2-6)

ADPTR,SUREFOOT:0.5 MM EIAJ,PKG OF 12

1

(SEE 5-2-4)

PKG OF 20 (SEE 5-2-9)

1

80009 003138300

80009

80009

80009

80009

SF501

SF502

SF503

SMG50

Page 76

Replaceable Parts

P6245AD Instruction Manual 5–10

Page 77

Page 78

Loading...

Loading...