Page 1

ZZZ

xx

P6243

1 GHz 10X Active Probe

Service Manual

*P070940904*

070-9409-04

Page 2

Page 3

xx

ZZZ

P6243

1 GHz 10X Active Probe

Service Manual

www.tektronix.com

070-9409-04

Page 4

Copyright © Tektronix. All rights re

owned by Tektronix or its subsidiaries or suppliers, and are protected by national

copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pendin g.

Information in this publication supersedes that in all previously published

material. Specifications and p

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

TEKPROBE is a registered tr

ademark of Tektronix, Inc.

served. Licensed software products are

rice change privileges reserved.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For pro duct information, sales, service, and technical support:

In North Am erica, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this produ

workmanship for a period of one (1) year from the date of shipment. If any such product

proves defective during this w

the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective

Tektronix for warranty work may be new or reconditioned to like new performance. A ll

replaced parts, modules and

In order to obtain service under this warranty, Customer must notify Tektronix of the

defect before the expiration of the warranty period and make suitable arrangements for the

performance of service. Customer shall be responsible for packaging and shipping the

defective product to the service center designated by Tektronix, with shipping charges

prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to

a location within the country in which the Tektronix service center is located. Customer

shall be responsible for paying all shipping charges, duties, taxes, and any other charges

for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or

improper or inadequate maintenance and care. Tektronix shall not be obligated to furnish

service under this warranty a) to repair damage resulting from attempts by personnel other

than Tektronix representatives to install, repair or service t he product; b) to repair damage

resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a

product that has been modified or integrated with other products when the effect of such

modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE

PRODUCT I

TEKTRONIX AND ITS VENDORS D ISCLAIM ANY IMPLIED WARRANTIES OF

MERCHAN

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE

SOLE AN

BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABL

DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADV

[W2 – 15AUG04]

N LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED.

TABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

D E XCLUSIV E REMEDY PROVIDED TO THE CUSTOMER FOR

E FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

ANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

ct will be free from defects in materials and

arranty period, Tektronix, at its option, either will repair

product. Parts, modules and replacement products used by

products become the property of Tektronix.

Page 6

Page 7

Table of Contents

General Safety Summary iii............................

Specifications 1......................................

Operating Basics 9...................................

Maximum Non-destructive Input Voltage 9.................

Input Linear Dynamic Range 9..........................

Theory of Operation 10................................

Probe Head and Cable Assembly 10.......................

Compensation Box 11...................................

Performance Verification 12............................

Equipment Required 12.................................

Equipment Setup 12....................................

Output Zero 13........................................

DC Attenuation Accuracy 13.............................

Maintenance 16.......................................

Replacing TEKPROBE™ Interface Pins 16..................

Removing and Replacing the Compensation Box Covers 17....

Removing and Replacing the TEKPROBE™ Interface Collar 19.

Inspection and Cleaning 20..............................

Replacement Parts 20...................................

Preparation for Shipment 20..............................

Replaceable Parts 21...................................

P6243 Service Manual

i

Page 8

Table of Contents

List of Figures

Figure 1: Typical Frequency Response 3...................

Figure 2: Typical Linearity Error vs. V

Figure 3: Typical Input Impedance vs. Frequency 5..........

Figure 4: Typical Non-Destructive Peak Voltage Derating vs.

Frequency 6.......................................

Figure 5: P6243 Simplified Schematic Diagram 10...........

Figure 6: TEKPROBE Interface 11........................

Figure 7: P6243 DC Attenuation Accuracy Setup 14..........

Figure 8: Replacing TEKPROBE Interface Pins 16...........

Figure 9: Removing the Compensation Box Covers 17.........

Figure 10: Replacing the Compensation Box Cover 18.........

Figure 11: Replacing the TEKPROBE Collar 19..............

Figure 12: P6243 Replaceable Parts 22.....................

Figure 13: P6243 Standard Accessories 24..................

Figure 14: P6243 Optional Accessories 26..................

List of Tables

IN

4.................

Table 1: Warranted Electrical Specifications 1..............

Table 2: Typical Electrical Characteristics 2................

Table 3: Physical Characteristics 7........................

Table 4: Environmental Characteristics 7..................

Table 5: Equipment Re quired for Performance Verification 12..

ii

P6243 Service Manual

Page 9

General Safety Sum mary

Review the following safety precautions to avoid injury and prevent

damage to this product or any products connected to it.

Only qualified personnel should perform service procedures.

Injury Precautions

Avoid Electric Overload. To avoid electric shock or fire hazard, do not

apply a voltage to a terminal that is outside the range specified for

that terminal.

Do Not Operate Without Covers. To avoid electric shock or fire hazard,

do not operate this product with covers or panels removed.

Do Not Operate in Wet/Damp Conditions. To avoid elec tric shock, do not

operate this product in wet or damp conditions.

Do Not Operate in an Explosive Atmosphere. To avoid inj ury or fire

hazard, do not operate this product in an explosive atmosphere.

Product Damage Precautions

Use Proper Power Source. Do not operate this product from a power

source that applies more than the voltage specified.

Do Not Operate With Suspected Failures. If you suspect there is damage

to this product, have it inspected by qualified service personnel.

Do Not Immerse in Liquids. Clean t he probe using only a damp cloth.

The cloth must be dampened with either isopropyl alcohol or a mild

detergent and water solution. Do not use any other chemicals or

abrasives to clean the probe.

P6243 Service Manual

iii

Page 10

General Safety Summary

Safety Terms and Symbols

Terms in This Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that

could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that

could result in damage to this product or other property.

Terms on the Product. These te rms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you

read the marking.

WARNING indicates an injury hazard not immediately accessible as

you read the marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. These symbols may appear on the product:

DANGER

High Voltage

Protective Ground

(Earth) Terminal

iv

ATTENTION

Refer to Manual

P6243 Service Manual

Double

Insulated

Page 11

Specifications

The warranted specifications in Table 1 appl y to a P6243 Active

Probe when the probe and the host instrument are allowed to warm

up for 20 minutes before measurements are taken. The warranted

specifications that appear in boldface type are specifications checked

in the Performance Verification section of the service manual.

The specifications in Tables 2 through NO TAG are provided as

general information for your convenience.

CAUTION. Do not apply voltages beyond the non-destructive input

voltage range to the probe. Damage to the probe or circuit under test

may result. Refer to Figure 4 on page 6.

Table 1: Warranted Electrical Specifications

Analog Bandwidth (probe only)

at +20 °Cto+30°C

(+68 °Fto+86°F)

DC Attenuation Accuracy

(probe only)

at +20 °Cto+30°C

(+68 °Fto+86°F)

Output Zero

at +20 °Cto+30°C

(+68 °Fto+86°F)

Rise Time (probe only)

at +20 °Cto+30°C

(+68 °Fto+86°F)

P6243 Service Manual

>1.0 GHz

10:1 ±2%

±10 mV or less at output of probe

±100 mV or less displayed on screen with

TEKPROBE interface

<350 ps

1

Page 12

Specifications

Table 2: Typical Electrical Characteristics

Frequency Response (probe only) SeeFigure1

Linear Input Dynamic Range -- 8 V t o + 8 V .

(Equivalent to -- 0.8 V to + 0.8 V

at the output of the probe)

Linearity 4% or less of dynamic range

Linearity Error vs. V

Input Resistance

IN

SeeFigure2

1MΩ at DC. (See Figure 3)

Input Capacitance <1.0 pF

Non-Destructive Input Voltage Range

-- 15 V to + 15 V (DC + peak AC)

(See Figure 4 on page 6)

DC Offset Drift

100 V/°C or less at output of probe

1mV/°C or less displayed on screen with

TEKPROBE interface

Delay Time 5.3 ns ±0.2 ns

2

P6243 Service Manual

Page 13

+2 dB

+1 dB

0dB

-- 1 d B

-- 2 d B

-- 3 d B

-- 4 d B

-- 5 d B

-- 6 d B

-- 7 d B

-- 8 d B

1MHz 1GHz100 MHz10 MHz

Figure 1: Typical Frequency Response

Specifications

P6243 Service Manual

3

Page 14

Specifications

Display Error

150 mV

100 mV

50 mV

0mV

-- 5 0 m V

-- 100 mV

-- 150 mV

-- 20 V 0 V-- 10 V 10 V 20 V

V

IN

Figure 2: Typical Linearity Error vs. V

4

IN

P6243 Service Manual

Page 15

10 MΩ

1MΩ

100 kΩ

10

kΩ

1kΩ

100 Ω

10 Ω

100 Hz 1 GHz100 kHz1 kHz 10 kHz 1 MHz 10 MHz 100 MHz

Figure 3: Typical Input Impedance vs. Frequency

Specifications

P6243 Service Manual

5

Page 16

Specifications

25 V

20 V

15 V

10 V

10V at 1 GHz

5V

0V

1 MHz 10 MHz 100 MHz

6V at 3 GHz

1GHz

Figure 4: Typical Non-Destructive Peak Voltage Derating vs. Frequency

6

P6243 Service Manual

Page 17

Table 3: Physical Characteristics

Net Weight 63.8 g (2.25 ounces)

Cable Length 1.3 meter (4.3 ft)

Table 4: Environmental Characteristics

Operating Temperature 0 °Cto+50°C

(+32 °F to +122 °F)

The environmental exposure is the procedure stated

in Tektronix Design Standard 062--2847--00 for

Class 5 equipment

Non-operating Temperature -- 4 0 °Cto+71°C

(-- 40 °F to + 160 °F)

The environmental exposure is the procedure stated

in Tektronix Design Standard 062--2847--00 for

Class 5 equipment

Specifications

Humidity The environmental exposure is the procedure stated

in Tektronix Design Standard 062--2847--00 for

Class 5 equipment

Packaged Product Vibration and

Shock

Altitude Operating: 4,572 m (15,000 ft)

The packaged product qualifies under the Distribution

Cycle 1 Assurance Level II for packaged products

0 -- 20 lbs. Test 2 for Warehouse and Vehicle Stacking

(Compression) is omitted

Tektronix standard 062--2858--00, Rev. B, Class 5

Non--Operating: 15,240 m (50,000 ft)

P6243 Service Manual

7

Page 18

Specifications

8

P6243 Service Manual

Page 19

Operating Basics

Please follow these operating guidelines to get optimum performance

from your P6243 Active Probe.

Maximum Non-destructive Input Voltage

The P6243 Active Probe is electrically protected against static

voltage; however, applying voltages above its design limits may

damage the probe tip amplifier. Please refer to the Specifications

section of this manual for the maximum non-destructive input

voltage and frequency derating information.

Input Linear Dynamic Range

The probe head amplifier used by t he P6243 Active Probe has a

limited linear operating range. To keep the input linearity error less

than 4% you must limit the signal input voltage to ±8V(DC+

peak AC).

NOTE. The probe can tolerate input voltages of ±15 V without

damage; however, the linearity error specification does not apply to

input voltages exceeding ±8 V (DC + peak AC).

P6243 Service Manual

9

Page 20

Theory of Operation

There are no user replaceable parts within the probe or the

compensation box; however, this theory of operation is provided to

assist you in isolating failures to either the probe or the host

oscilloscope. Refer to Figure 5 for a simplified schematic of the

probe.

Probe Head Compensation Box Oscilloscope

Probe Tip

Probe-Tip

Amplifier

Probe

Cable

EEPROM

Signal Out

Probe ID Out

Clock In

+5 V

-- 5 V

Ground

TEKPROBE

Interface

Figure 5: P6243 Simplified Schematic Di agram

Probe Head and Cable Assembly

The probe head assembly contains an active amplifier circuit that

buffers and amplifies the input signal. T he amplifier receives power

from the compensation box assembly via the cable assembly. All

signal amplification and buffering is performed in the probe head

assembly. No further amplification takes place in the compensation

box.

10

P6243 Service Manual

Page 21

Compensation Box

The compensation box contains the following circuits:

H Probe identification EEPROM

H TEKPROBE interface

Probe Identification EEPROM

The probe identification EEPROM is used t o configure the

oscilloscope to the probe. The EEPROM receives a clock input from

the oscilloscope, and information about the probe is passed to the

oscilloscope.

TEKPROBE™ Interface

The TEKPROBE interface provides a communication path between

the probe and the oscilloscope. Contact pins provide power, signal,

and data transfer for the probe identification EEPROM.

Figure 6 shows the TEKPROBE interface pin functions. Refer to the

service documentation of your oscilloscope for more detailed

specifications.

Theory of Operation

-- 5 V

Ground

Signal

Figure 6: TEKPROBE Interface

P6243 Service Manual

Data

Clock

+5 V

11

Page 22

Performance Verif ication

This section contains the procedures for verifying the performance of

the P6243 Active Probe.

Equipment Required

Table 5: Equipment Required for Performance Verification

Performance

Item Description

Oscilloscope TEKPROBE interface Tektronix TDS 744A

TEKPROBE Power Supply Tektronix 1103

DC Power Supply 10.00 ±.01VDCat1mA Tektronix PS281

DC Voltmeter 0.5% accuracy at 2 VDC Tektronix CDM250

Feedthrough Termination

BNC to BNC coaxial cable

BNC to Banana adapter BNC Female to Dual

Requirement

50 Ω ± 0.50 Ω

50 Ω coaxial cable

Banana

Recommended Example

011-0129-00

012-1342-00

103-0090-00

Equipment Setup

1. Connect the probe to the oscilloscope.

2. Connect a Y-lead adapter with KlipChip adapters attached to the

P6243 probe head.

3. Turn on the oscilloscope and enable the channel.

4. Turn on the power supply and set to +2.00 VDC.

5. Turn on the 1103 power supply.

6. Allow 30 minutes for the equipment to warm up.

12

P6243 Service Manual

Page 23

NOTE. If your oscilloscope has a probe calibration routine, run it

before making any of the following checks. Refer to the instruction

manual of the oscilloscope for more information.

Output Zero

Use this procedure to verify the output zero of the probe is within

specified limits.

1. Ground the probe tip by connecting the probe tip to the probe

ground socket. (Connecting the two KlipChip a dapters together is

recommended.)

2. Set the oscilloscope input coupling channel to ground and adjust

the vertical position to center screen.

3. Set the oscilloscope input coupling channel to DC and set the

vertical scale to 100 mV/division.

4. Measure the displayed DC level.

Performance Verification

The displayed DC level should be 0.00 V ±100 mV. (±10 mV when

measured directly without the probe atte nuation factor.)

DC Attenuation Accuracy

Use this procedure to verify the DC attenuation accuracy of the

probe. Before beginning, read the procedure through completely.

1. Connect the test equipment as shown in Figure 7.

2. Attach the probe to a TEKPROBE interface on the 1103 power

supply.

3. Set the 1103 offset VAR/0V to 0V.

4. Set the multimeter to read DC volts.

P6243 Service Manual

13

Page 24

Performance Verification

5. Connect the probe tip and ground to the power supply using the

Y-lead and KlipChip adapters.

Digital Multimeter

1103

Power Supply

Power Supply

+

--

50 Ω Precision

BNC to Dual

Banana Adapter

Terminator

Figure 7: P6243 DC Attenuation Accuracy Setup

6. Set the power supply to +2.000 V. (This setting will be referred to

later on as Vmax).

7. Record the value measured by the multimeter as M1. (With the

10X attenuation of the probe, the voltage measured will be about

+0.200 V.)

8. Set the power supply to --2.000 V. (Thi s setting will be referred to

later on as Vmin).

9. Record the value measured by the multimeter as M2. (With the

10X attenuation of the probe, the voltage measured will be about

--0.200 V.)

-- +

14

P6243 Service Manual

Page 25

Performance Verification

NOTE. If you are unable to set the power supply precisely, record the

settings displayed on the power supply and determine the absolute

difference. |Vmax -- Vmin| = difference.

Divide the difference by 10 to account for the ideal attenuation

factor of the probe. For example, 0.42 is the difference between

+2.200 and --2.000, divided by 10. Use this calculated value in place

of the denominator of the formula that follows.

10. Determine the percent error by using the formula below:

%Error = [

The calculated error should be ≤2%.

NOTE. An unacceptable error value may result if a low tolerance

termination is substituted for the recommended termination.

M1 − M2

0.4

− 1] × 100%

P6243 Service Manual

15

Page 26

Maintenance

This section details the maintenance, repair, and troubleshooting

procedures for the P6243.

Replacing TEKPROBE™ Interface Pins

TEKPROBE interface pins can stick and fail to make contact after

time. Periodically check to see that each of the interface pins move

freely and fully extends out of the interface. If any pin fails to move

freely and fully extend, it should be replaced.

To remove a TEKPROBE i nterface pin, firmly grasp the pointed tip

with pliers and pull the pin out of the connector. See Figure 8.

No tools are required to install a replacement pin. Insert a new pin

into the connector socket as far as possible using finger pressure. If

necessary, seat the pin into the connector by pressing the ti p gently

but firmly against a hard surface, such as a wood block or table top.

16

Figure 8: Replacing TEKPROBE Interface Pins

P6243 Service Manual

Page 27

Maintenance

Removing and Replacing the Compensation Box Covers

Follow these steps to open the compensation box.

1. Press the optiona l release tool pins into the compensation box

cover catches and gently lift the cover off a small distance. Refer

to Figure 9.

2. Hold the open edge apart, and use the tool to open the other side

of the compensation box.

3. With both sides of the box open, gently separate the two halve s of

the compensation box.

Figure 9: Removing the Compensation Box Covers

P6243 Service Manual

Cover

Catches

17

Page 28

Maintenance

To replace the covers, follow these steps:

1. Align the TEKPROBE interface and the strain relief notches with

2. Press the cover catches in so that the cover can be lowered.

3. Slide the tab into the notch.

4. Firmly press the pieces together until the cover catches snap into

the tabs on the cover. Refer to Figure 10.

place.

Tab

18

Figure 10: Replacing the Compensation Box Cover

P6243 Service Manual

Page 29

Maintenance

Removing and Replacing the TEKPROBE™ Interface Collar

To remove the TEKPROBE interface collar, firmly grasp the

compensation box body with one hand, and the TEKPROBE

interface collar with the other hand. Firmly pull the interface collar

off.

To replace the collar, first note the pin configuration on the

compensation box, and their holes in the interface collar. The group

of three pins fit through the smaller of the two holes in the interface

collar. See Figure 11.

Align the tab to the slot and gently press the two pieces together. See

Figure 11.

Once installed, the TEKPROBE collar should rotate freely to lock

and unlock.

Slot

Figure 11: Replacing the TEKPROBE Collar

P6243 Service Manual

Tab

19

Page 30

Maintenance

Inspection and Cleaning

To prevent damage to probe materials, avoid using chemicals that

contain benzine, benzene, toluene, xylene, acetone, or similar

solvents.

Do not immerse the probe or use abrasive cleaners.

Dirt may be removed with a soft cloth dampened with a mild

detergent and water solution, or isopropyl alcohol.

Replacement Parts

Refer to the Replaceable Parts section for a list of customer

replacement parts. Due to the sophisticated design of the P6243,

there are no user replaceable parts within the probe.

Preparation for Shipment

If the original packaging is unfit for use or not available, use the

following packaging guidelines:

20

1. Use a corrugated cardboard shipping carton having inside

dimensions at least one inch greater than the probe dimensions.

The box should have a carton test strength of at least 200 pounds.

2. Put the probe into a plastic bag or wrap to protect it from

dampness.

3. Place the probe into the box and stabilize it with light packing

material.

4. Seal the carton with shipping tape.

P6243 Service Manual

Page 31

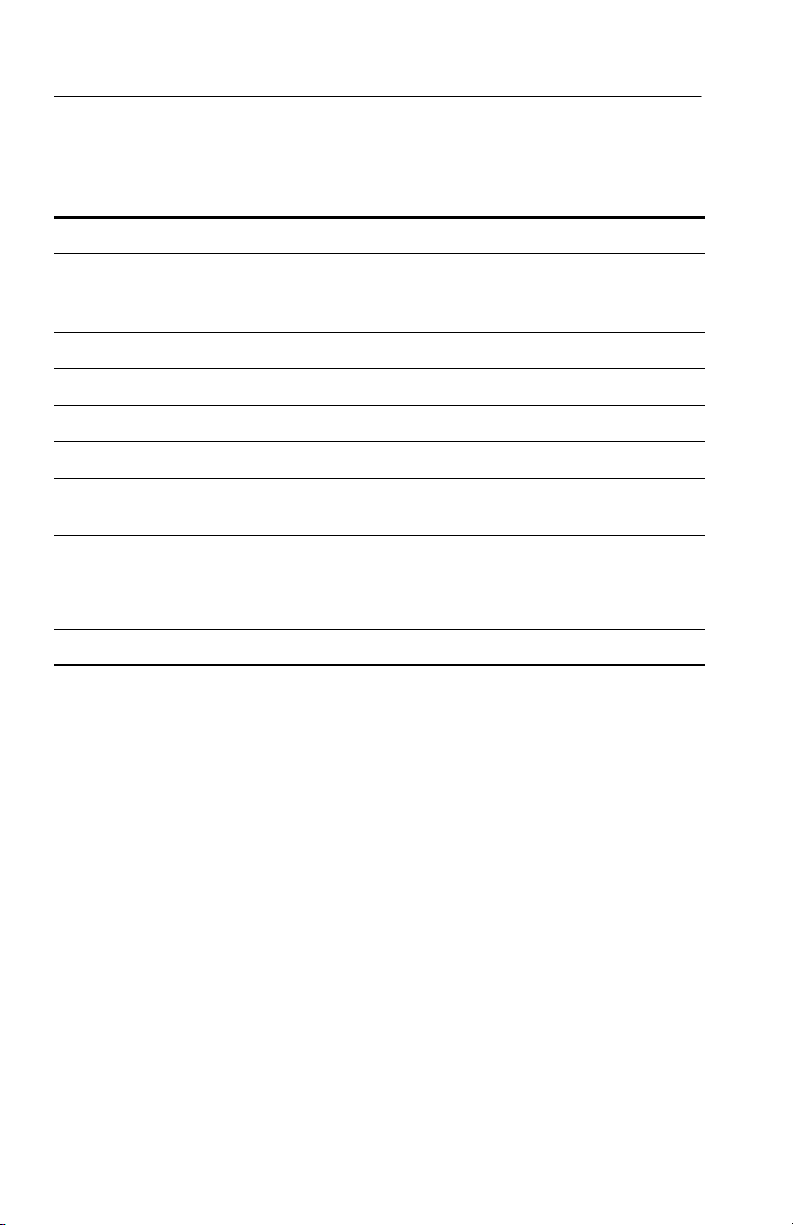

Replaceable Parts

This section contains a list of the replaceable parts for the P6243

Active Probe. Use this list to identify and order replacement parts.

Parts Ordering Information

Replacement parts are available from or through your local

Tektronix, Inc. service center or representative.

Changes to Tektronix instruments are sometimes made to accommodate improved components as they become available and to give you

the benefit of the latest circuit improvements. Therefore, when

ordering parts, it is important to include the following information in

your order:

H Part number

H Instrument type or model number

H Instrument serial number

H Instrument modification number, if applicable

If a part you order has been replaced with a different or improved

part, your local Tektronix service center or representative will

contact you concerning any change in the part number.

P6243 Service Manual

21

Page 32

Replaceable Parts

NOTE: Parts illustrated

with dashed lines are not

replaceable

22

3

3

2

1

Figure 12: P6243 Replaceable Parts

P6243 Service Manual

Page 33

Replaceable Parts

Mfr. Part No.

Mfr.

Code

80009 200-4276-00

12345 Name & Description

Qty

Serial No.

Effective Dscont

Part No.

Tektronix

P6243 1 PROBE, FET ACT:>1.5 GHZ,10X,<1PF,TDS SERIES 80009 P6243

Fig. &

Index No.

--1 205-0191-XX 1 SHELL,ELEC CONN:BNC,ABS,DOVE GRAY 80009 205-0191-XX

12

RELEASE TOOLS

--2 131-3627-01 1 CONTACT,ELEC:GOLD PLATED TIP 80009 131-3627-01

--3 200-4276-00 1 COVER,COMP BOX:TOP AND BOTTOM, W/LABELS &

P6243 Service Manual 23

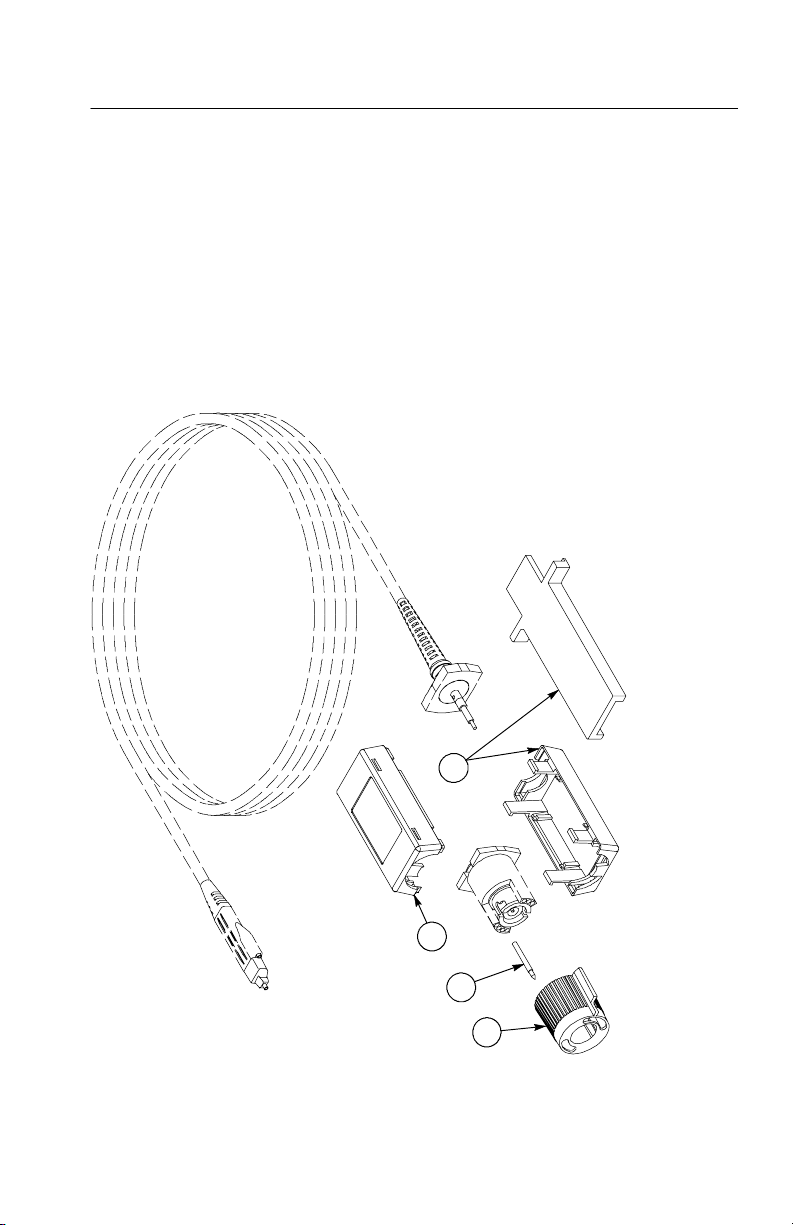

Page 34

Replaceable Parts

2

3

24

4

1

56

Figure 13: P6243 Standard Accessories

P6243 Service Manual

Page 35

Replaceable Parts

Mfr. Part No.

Mfr.

Code

80009 196-3425-00

80009 016-1315-00

STANDARD ACCESSORIES

12345 Name & Description

Qty

Serial No.

Effective Dscont

Part No.

Tektronix

Fig. &

Index No.

13

3.0 L BLACK & WHITE 22 AWG,JACK TIP,TERM

CONN MALE PIN;TWO Z--LEAD

COLORS

070--9408--XX 1 MANUAL,TECH:INSTRUCTION,ENGLISH,DP,P6243 TK2548 070-9408-XX

070--9409--XX 1 MANUAL,TECH:SERVICE,DP,P6243 TK2548 070-9409-XX

070--9410--XX 1 MANUAL,TECH:INSTRUCTION,FRENCH,DP,P6243 TK2548 070-9410-XX

070-- 9411--XX 1 MANUAL,TECH:INSTRUCTION,GERMAN,DP,P6243 TK2548 070-9411-XX

070--9412--XX 1 MANUAL,TECH:INSTRUCTION,SPANISH,DP,P6243 TK2548 070-9412-XX

--1 196--3425--00 1 LEAD,SET:ONE 3.0 L; ONE 6.O L;STRD,22 AWG & ONE

--2 016--1315--00 1 MARKER KIT,ID:CABLE MARKER BAND,2 EACH, VARIOUS

--3 131--5638--11 1 PROBE,TIP:PACKAGE OF 10 80009 131-5638-11

--4 214--4227--00 1 SPRING ADAPTER:RIGHT ANGLE 80009 214-4227-00

--5 131--5777--00 1 CONN,CONTACT 80009 131-5777-00

--6 206--0364--XX 2 TIP,PROBE:MICROCKT TEST 80009 206-0364-XX

P6243 Service Manual 25

Page 36

Replaceable Parts

26

2 3 4

1

Figure 14: P6243 Optional Accessories

P6243 Service Manual

Page 37

Replaceable Parts

Mfr. Part No.

Mfr.

Code

12345 Name & Description

OPTIONAL ACCESSORIES

Qty

Serial No.

Effective Dscont

Part No.

Tektr o n ix

No.

Index

Fig. &

14-1 003-1383-00 1 RLSE TOOL,COVER:COMP BOX, POLYCARBONATE 80009 003-1383-00

--2 SF503 1 ADAPTER,SUREFOOT:0.5 MM EIAJ,PKG OF 12 80009 SF503

--3 SF502 1 ADAPTER,SUREFOOT:25 MIL JEDEC,PKG OF 12 80009 SF502

--4 1103 1 TEKPROBE IF PS:W/OFFSET 2 CONN 80009 1103

13--6 SMG50 1 TIP,PROBE:MICROCKT TEST, PKG OF 20 80009 SMG50

P6243 Service Manual 27

Page 38

Replaceable Parts

BEAVERTON OR 97077--0001

28

14181 SW MILLIKAN WAY BEAVERTON OR 97077

PO BOX 500

CROSS INDEX - MFR. CODE NUMBER TO MANUFACTURER

Manufacturer Address City, State, Zip Code

XEROX BUSINESS SERVICES

DIV OF XEROX CORPORATION

Mfr.

Code

TK2548

80009 TEKTRONIX INC 14150 SW KARL BRAUN DR

P6243 Service Manual

Page 39

Loading...

Loading...