Page 1

Instruction Manual

P6131

10X Passive Probe

for 2400 Series Oscilloscopes

070-5514-03

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

*P070551403*

070551403

Page 2

Copyright © T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

T ektronix, Inc., P.O. Box 500, Beaverton, OR 97077-1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of purchase from an authorized T ektronix distributor. If any such product proves

defective during this warranty period, T ektronix, at its option, either will repair the defective product without charge for

parts and labor, or will provide a replacement in exchange for the defective product. Batteries are excluded from this

warranty .

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, shipping charges prepaid, and

with a copy of customer proof of purchase. T ektronix shall pay for the return of the product to Customer if the shipment is

to a location within the country in which the T ektronix service center is located. Customer shall be responsible for paying

all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE LISTED PRODUCTS IN LIEU OF

ANY OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUST OMER FOR BREACH OF THIS WARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Contacting Tektronix

Product

support

Service

support

For other

information

To write us

Web site

For questions about using T ektronix measurement products, call

toll free in North America:

1-800-833–9200

6:00 a.m. – 5:00 p.m. Pacific time

Or contact us by e-mail:

tm_app_supp@tek.com

For product support outside of North America, contact your local T ektronix distributor

or sales office.

T ektronix offers extended warranty and calibration programs as options on many

products. Contact your local T ektronix distributor or sales office.

For a listing of worldwide service centers, visit our web site.

In North America:

1-800–833–9200

An operator can direct your call.

T ektronix, Inc.

P.O. Box 500

Beaverton, OR 97077-1000

USA

www .tektronix.com

Page 5

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or Personal Injury

Symbols and Terms

Connect and Disconnect Properly . Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

The common terminal is at ground potential. Do not connect the common

terminal to elevated voltages.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry .

T erms in this Manual. The following terms may appear in this manual:

P6131 Instruction Manual

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

i

Page 6

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments to this

product unless another person capable of rendering first aid and resuscitation is

present.

ii

P6131 Instruction Manual

Page 7

Operating Basics

Lead Inductance

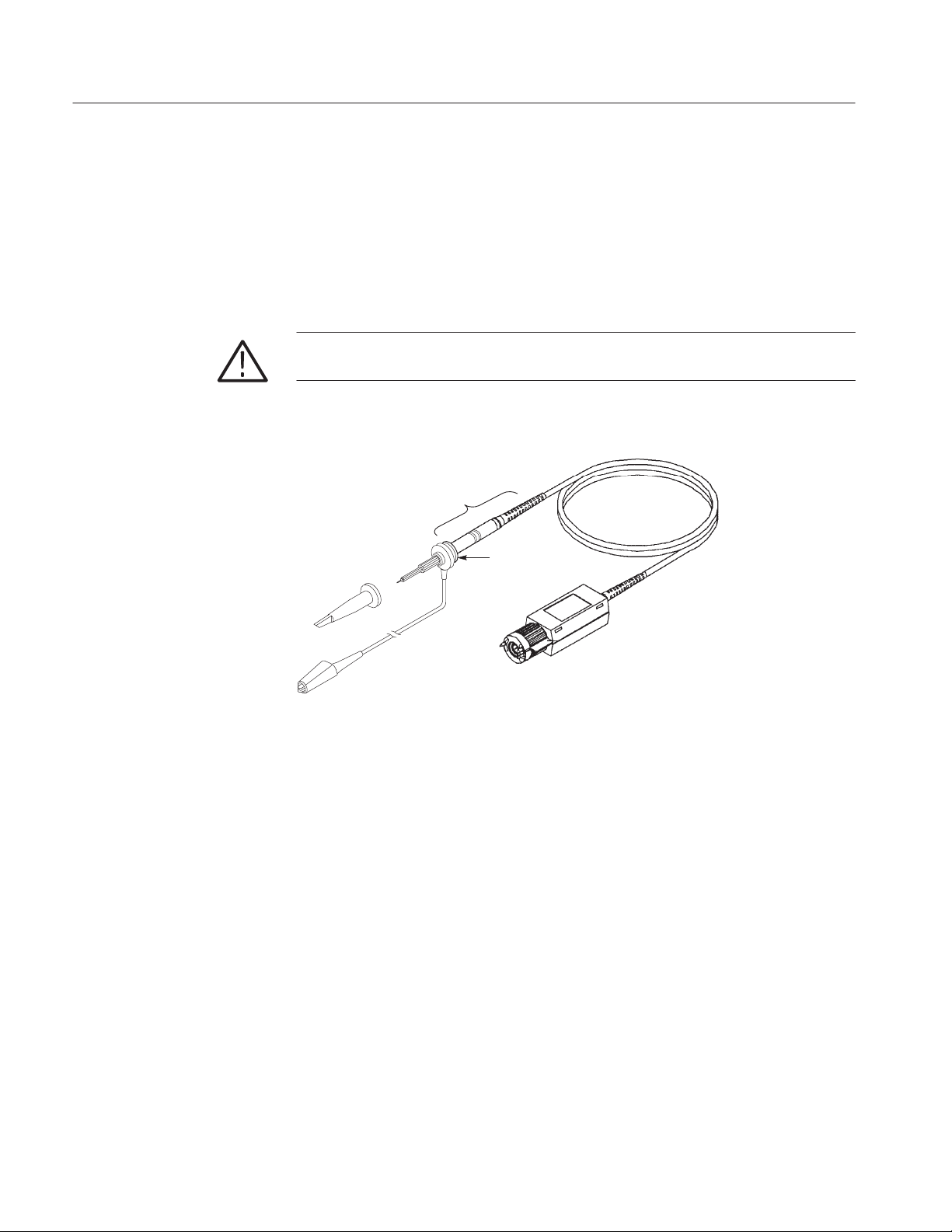

The P6131 probe is a subminiature, 10X, passive probe designed specifically for

use with Tektronix 2400 Series oscilloscopes. It is fully compatible with the

Tektronix family of subminiature probe accessories. The P6131 is available

with 1.3 and 2 meter cable.

WARNING. To avoid electric shock when using the probe, do not touch the

metallic portions of the probe head while connected to a voltage source.

Inductance introduced by long leads can form resonant circuits that ring and

distort the true waveform if driven by signals containing significant frequency

components at or above resonance. To maintain optimum waveform fidelity,

keep the ground lead and signal input connection as short as possible.

Probe Compensation

Due to variations in oscilloscope input characteristics, probe low-frequency

compensation should be checked and or adjusted if you move the probe from one

oscilloscope input to another. Connect the probe tip to a 1 kHz square wave

signal (such as the oscilloscope calibrator output) and use a nonconductive

low-reactance alignment tool to adjust the compensation capacitor.

High-frequency compensation seldom requires adjustment. However, if the probe

has excessive high-frequency aberrations or insufficient bandwidth, you can

adjust the high-frequency compensation through holes in the compensation box

inner metal shield.

For complete low-frequency and high-frequency compensation adjustment

procedures, see page 10.

P6131 Instruction Manual

1

Page 8

Operating Basics

Grounding the Probe

Connect the probe to the instrument and connect the ground lead to ground

before making any measurement. Ensure that no part of the ground lead contacts

voltage in the circuit under test. Except for the probe tip and BNC center

conductor, all accessible metal (including the ground clip) is connected to the

BNC shell.

WARNING. To avoid electric shock when using the probe, keep your fingers

behind the finger guard on the probe body. See Figure 1 below.

Hand contact area

Finger guard

Figure 1: Probe finger guard and hand contact area

2

P6131 Instruction Manual

Page 9

Specifications

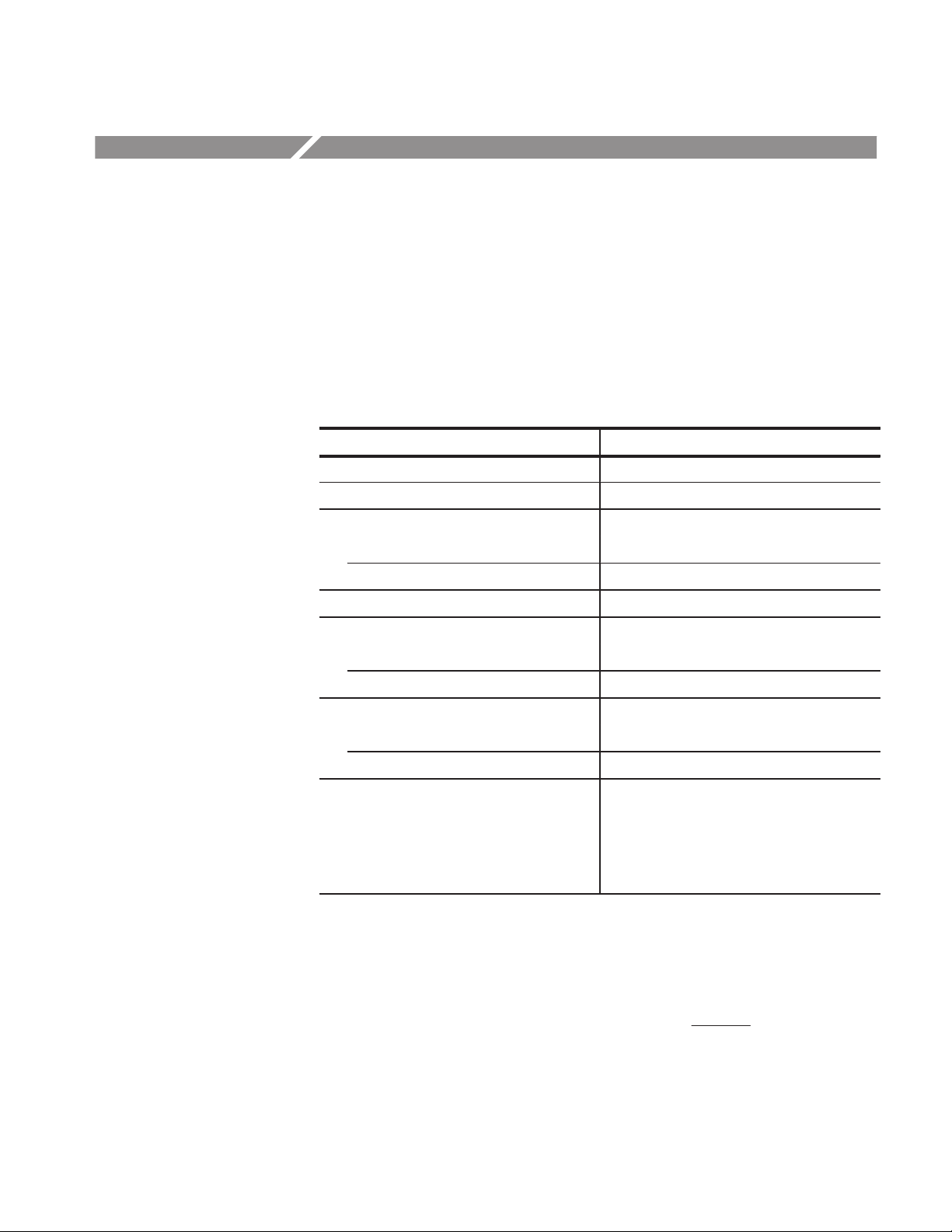

The characteristics listed in Table 1 apply to P6131 probes installed on Tektronix

2445 and 2465 oscilloscopes or 7A42 plug-ins, unless otherwise noted.

Specifications apply when the instruments warm up for a period of at least

20 minutes in an environment that does not exceed the limits described in

Table 2 on page 5.

T able 1: Electrical characteristics

Characteristic Description

Attenuation

Input resistance

Input capacitance

Compensation range 14 pF to 18 pF

Signal delay

2

2,3

3

1.3 m 10.8 pF

2 m 13.5 pF

1

10X: ±1% at DC

10 MW ±1% at DC

1.3 m 6.3 ns ±100 ps

2 m 9.0 ns ±200 ps

System bandwidth (–3 dB) On a 2465 or 7A42: On a 2445:

1.3 m ≥300 MHz ≥150 MHz

2 m ≥250 MHz ≥150 MHz

Maximum Input Voltage

1

Probe installed on Tektronix 150 MHz (or less) 2400 Series oscilloscope.

2

System characteristic.

3

Also see Figure 3.

4

As defined in EN61010-1. See Certifications and compliances in Table 4

5

RMS=Root Mean Square=rms=The square root of the average of the sum of the

squares of the instantaneous voltage in one cycle = .

300 VDC=300V RMS, 420 V Peak (sinewave)=300 V RMS See Figure 2

4,5

300 V RMS CAT I or 300 V DC CAT I

150 V RMS CAT II or 150 V DC CAT II

100 V RMS CAT III or 100 V DC CAT III

425 V peak, @50% DF, <1 sec PW

750 V peak, @10% DF, <50 ms PW

See Figure 4 for voltage derating curve.

Ǹ

ȍ

(fxi)2ńn

.

P6131 Instruction Manual

3

Page 10

Specifications

@25% Duty Factor

=(1/2 Peak V) RMS

@50% Duty Factor

=(1.414 (Peak V)) RMS

Special case of square wave:

@20% Duty Factor

2

)

=[(V

Example: Maximum Input Voltage

=[(650 V Pk)

(Duty Factor)]

Peak

2

(.20)]

1/2

1/2

= 290 V RMS

0V

0V

0V

Figure 2: Maximum input voltage calculation example

10M

RP and XP ()

1M

100K

10K

1M

100

0.01 0.1 1 10 100 1000

Frequency (MHz)

Figure 3: Typical P6131 Xp and Rp versus frequency

4

P6131 Instruction Manual

Page 11

Voltage

(RMS)

500

100

10

1 10 100

Frequency (MHz)

Figure 4: Typical P6131 voltage derating versus frequency

Specifications

T able 2: Environmental characteristics

Characteristic Description

Temperature range

Operating –15_ C to 65_ C (+5_ F to 149_ F)

Nonoperating –62_ C to 85_ C (–80_ F to 185_ F)

Humidity Five cycles (120 hr) at 95% to 97% relative

humidity, per Tektronix standard 062-2847-00,

Class 3.

Refer to MIL-E016400F, paragraph 4.5.9

through 4.5.9.5.1, class 4.

Altitude < 2000 meters

T able 3: Physical characteristics

Characteristic Description

Net weight

Probe cable length 1.3 meter (4.3 ft)

1

1

Includes accessories

1.3 meter, 108 g (3.8 oz)

2 meter, 129 g (4.8 oz)

2 meter (6.6 ft)

P6131 Instruction Manual

5

Page 12

Specifications

T able 4: Certifications and compliances

EC Declaration of

Conformity

Overvoltage

Category

Pollution Degree 2 Do not operate in environments where conductive pollutants may be

Safety UL31 11-1, First Edition & IEC61010-2-031, First Edition

Compliance was demonstrated to the following specification as listed in

the Official Journal of the European Communities:

Low Voltage Directive 73/23/EEC as amended by 93/68/EEC:

EN 61010-1/A2

EN 61010-2-031:1994

Category: Examples of Products in this Category:

CA T III Distribution-level mains, fixed installation

CA T II Local-level mains, appliances, portable

CA T I Signal levels in special equipment or parts of

present.

CSA C22.2 No. 1010.1-92 & CAN/CSA C22.2 No. 1010.2.031-94

EN61010-1/A2

EN61010-2-031

Pollution Degree 2

Safety requirements for electrical equipment

for measurement, control, and laboratory use

Particular requirements for hand-held probe

assemblies for electrical measurement and

test

equipment

equipment, telecommunications, electronics

6

P6131 Instruction Manual

Page 13

Service Information

WARNING. The following instructions are for use by qualified service personnel

only. To avoid electrical shock, do not disassemble or maintain the probe while it

is connected to a signal source other than those specified in this procedure.

This section contains detailed performance checks, adjustments, and maintenance procedures. These procedures use external traceable test equipment to

directly check warranted characteristics. If you substitute equipment, always

choose instruments that meet or exceed the minimum specified requirements.

Performance V erification Procedure

Use the following procedure to verify that P6131 probe performs as warranted.

For a list of the warranted specifications, see page 3.

Table 5 lists the test equipment needed to perform the performance verification

and adjustment procedures.

T able 5: Performance verification and adjustment test equipment

Description Minimum requirements Example product

Oscilloscope

Calibration generator Pulse Rise Time: ≤1 ns

Leveled sine wave generator Amplitude: adjustable to 1 V

Precision coaxial cable 50 BNC, 36 inch length T ektronix 012-0482-XX

10X attenuator 50 BNC Tektronix 011-0059-XX

Adapter Subminiature probe-tip-to-BNC male T ektronix 013-0195-XX

2

The P6131 probe is designed specifically for use

with Tektronix 2445 and 2465 oscilloscopes and

the 7A42 plug-in.

Amplitude: ≥0.5 V into 50

Rep Rate: 100 kHz

Accuracy: ±0.25%

Direct error readout

into 50

Frequency range:1 MHz to 300 MHz

p-p

Fixed 50 kHz reference

2

Tektronix 2445, 2465, or 7A42 plug-in

Wavetek 9500 High-Performance

Oscilloscope Calibrator

3

P6131 Instruction Manual

7

Page 14

Service Information

T able 5: Performance verification and adjustment test equipment (cont.)

Description Example productMinimum requirements

T ermination 50 BNC Tektronix 011-0049-XX

Low-reactance alignment tool 2 inch shaft, .050 inch bit size Tektronix 003-0675-XX

2

To confirm the full bandwidth specification of the P6131 probe, use the following equipment: a Tektronix 2465 oscilloscope or 7904 oscilloscope with 7B92A time base and 7A42 vertical amplifier and a leveled sine wave generator capable

of 300 MHz output. If you use the probe with a Tektronix 2445 oscilloscope, the bandwidth specification is lower; see

Table 1 on page 3.

3

The maximum sensitivity of the 7A42 plug-in is 20 mV/division. When using the 7A42 to check P6131 probes, double the

amplitude settings in the procedures to follow.

NOTE. To ensure accurate measurements, warm up all test equipment for at least

20 minutes before beginning any performance verification or adjustment

procedure.

Bandwidth Check

To check probe bandwidth do the following:

1. Connect the test setup as shown in Figure 5.

Leveled sine wave

Output

generator

50 Termination

Subminiature

probe-tip-to-BNC

adapter

P6131

probe head

Test oscilloscope

Compensation

box

Figure 5: Bandwidth check setup

2. Set the test oscilloscope controls as follows:

Volts/Division 0.1 V (includes 10X probe attenuation)

Time/Division 1 ms

Input Coupling DC

Bandwidth Full

Vertical input

3. Set the leveled sine wave generator to 50 kHz.

8

P6131 Instruction Manual

Page 15

Service Information

4. Adjust the sine wave generator output amplitude to produce a 6-division

display on the test oscilloscope. Center the waveform on screen.

5. Set the sine wave generator to the high-frequency range and slowly increase

the variable frequency control until the display amplitude decreases to

4.2 divisions (–3 dB) on the oscilloscope.

6. Verify that the sine wave generator frequency readout is greater than or equal

to the values listed in Table 6 for your instrument.

T able 6: Probe bandwidths

2465 Oscilloscope

Probe type

1.3 meter length 300 MHz 150 MHz

2.0 meter length 250 MHz 150 MHz

7A42 Plug-in

2445 Oscilloscope

Attenuation Accuracy

Check

7. If the generator frequency readout is less than the specified value, perform

the low-frequency and high-frequency compensation adjustments beginning

on page 10.

8. Disconnect the test setup.

To check the probe attenuation accuracy do the following:

1. Connect the calibration generator standard amplitude output to the test

oscilloscope vertical input with the precision coax cable.

2. Set the calibration generator controls as follows:

Amplitude Standard

Output 50 mV

Frequency 1 kHz

3. Set the oscilloscope controls as follows:

Volts /Division 10 mV

Time/Division 10 ms

Input Coupling DC

Triggering Obtain a stable display

P6131 Instruction Manual

4. Adjust the calibration generator variable amplitude control to produce a

precise 5-division display on the oscilloscope.

5. Note the oscilloscope deflection error directly from the calibration generator

display for the calculation in step 9 below (Example: +1%).

9

Page 16

Service Information

6. Remove the coax cable from the test setup. Connect the P6131 probe output

to the same vertical input on the oscilloscope.

7. Connect the probe tip through the probe-tip-to-BNC adapter to the standard

amplitude output of the calibration generator. (You must remove the light

gray probe-body shell before inserting the probe tip into the probe-tip-toBNC adapter.)

8. Set the calibration generator output amplitude to 0.5 V and fine tune the

amplitude to produce a precise 5-division display on the oscilloscope.

9. The deflection error indicated by the calibration generator must be within

0.75% of the error noted in step 5 above (probe attenuation accuracy of ±1%

minus the generator uncertainty). Example: if the error noted in step 5 is

+1%, the calibration generator display must now indicate between 0.25%

and 1.75%.

NOTE. You can also check the probe attenuation accuracy with an ohmmeter

having a 10 MW range and ±0.05% or greater accuracy.

Adjustment Procedure

An attenuation accuracy of ±1.0% is assured if the oscilloscope input resistance

is 1 MW ±0.55% (±0.5% tolerance plus 0.05% reading uncertainty) and the

probe-tip-to-output series resistance is indicated to be 9 MW ±0.35% (±1.0%

attenuation accuracy minus ±0.6% input resistance uncertainty minus ±0.05%

reading uncertainty).

10. Disconnect the test setup.

This section contains procedures to adjust the P6131 probe low-frequency and

high-frequency compensations. Always perform the low-frequency compensation

adjustment before proceeding to the high-frequency adjustment.

For a list of test equipment needed to perform the adjustments, see Table 5 on

page 7.

10

P6131 Instruction Manual

Page 17

Service Information

Low-Frequency

Compensation

Adjustment

To adjust the probe low-frequency compensation do the following:

1. Connect the probe output to the test oscilloscope vertical input.

2. Set the oscilloscope controls as follows:

Volts /Division 0.1 V (includes 10X probe attenuation)

Time/Division 1 ms

Input Coupling DC

Bandwidth Full

3. Connect the probe input with hook tip to the oscilloscope calibrator output.

4. Set the oscilloscope triggering for a stable display. The square wave should

be five cycles in length, four divisions in amplitude, and centered on-screen.

5. Using the low-reactance alignment tool, adjust C2010 to optimize the square

wave front corner edge. See Figure 6 for the adjustment location; see

Figure 7 for waveform optimization criteria.

6. Disconnect the test setup.

Metal-shell version

C2010

Plastic-shell version

Figure 6: Low-frequency compensation adjustment locations

P6131 Instruction Manual

11

Page 18

Service Information

Over compensated

Correct

Under compensated

Figure 7: Low-frequency compensation, optimizing the waveform

High-Frequency

Compensation

Adjustment

To adjust the probe high-frequency compensation do the following:

1. Connect the positive-going fast-rise output of the calibration generator to the

test oscilloscope with the precision coax cable and 10X attenuator.

2. Set the oscilloscope controls as follows:

Volts /Division 10 mV (includes 10X probe attenuation)

Time/Division 0.02 ms

Input Coupling DC

Bandwidth Full

3. Set the calibration generator to produce a fast-rise output with a repetition

rate of 10 ms (100 kHz). Adjust the output amplitude to produce a 5 division

display on the oscilloscope.

4. Adjust the oscilloscope triggering for a stable display and center the

waveform on screen.

5. Note the pulse shape and system aberrations for analysis in step 10.

6. Remove the precision coax cable from the test setup.

7. Remove the probe compensation box cover as described below.

Metal shell version: Unscrew the compensation box retainer nut

approximately two complete turns and lift the cover out and up. Press

the cable connector in firmly and retighten the retainer.

12

Plastic shell version: Pry off the darker portion of the plastic shell by

inserting your thumbnails into the seam between the two cover pieces;

then remove the lighter portion from the inner metal shield.

P6131 Instruction Manual

Page 19

Service Information

8. Connect the probe output to the oscilloscope vertical input.

9. Connect the probe tip through the probe-tip-to-BNC adapter and a 50 W

termination to the positive-going fast-rise output of the calibration generator.

(The light gray probe-body shell must be removed before inserting the probe

tip into the probe-tip-to-BNC adapter.)

10. Verify that the high-frequency aberrations do not exceed +6% (5.30

divisions), –6% (4.70 divisions), or 9% (0.45% division) peak to peak, in

addition to the system aberrations noted in step 5 above.

11. If the probe aberrations are within tolerance, proceed to step 14 below. If the

probe aberrations are not within tolerance, continue with step 12 below.

12. Adjust R2021 for the best overall waveform flat response. See Figure 8 for

the location of all adjustments.

13. Adjust R2020, R2010, and C1010 for the best corner response without

ringing. See Figure 9 for the waveform area effected by each adjustment.

NOTE. High-frequency compensation adjustments affect probe bandwidth.

Following the compensation adjustments, verify the probe bandwidth specification using the procedure on page 8. A small overshoot on the leading edge of

the pulse may be tolerated in order to meet the bandwidth specification. The

overshoot should not exceed the typical aberrations described in step 10 above.

14. Reinstall the compensation box cover by performing the procedure described

in step 7 above in reverse order.

15. Disconnect the test setup.

P6131 Instruction Manual

13

Page 20

Service Information

R2010

C1010

R2021

R2020

Metal-shell version

R2010

R2020

R2021

C1010

C2010

Plastic-shell version

Figure 8: High-frequency compensation adjustment locations

≈20 ns

R2021

≈5 ns

R2021

≈3 ns

R2021

C1010

14

Figure 9: High-frequency compensation, optimizing the waveform

P6131 Instruction Manual

Page 21

Maintenance

Service Information

Use the following procedures to clean and maintain the P6131 probe.

Cleaning

Probe Module

Replacement

To remove accumulated dirt from the probe exterior, use a soft cloth dampened

with a nonresidue cleaner, preferably isopropyl alcohol. In particular, avoid

solvents such as benzene, toluene, xylene, or acetone.

Modular construction has been used in the design of the probe to simplify repair.

The probe head, tip assembly, compensation box, and cable are available as

separate units through your local Tektronix field office or representative.

Individual components within the compensation box are not replaceable. See

page 19 for a list of replaceable parts.

The entire probe-head can be replaced by simply pulling the probe-head

assembly away from the cable and pushing a new unit in place. To remove the

compensation box, unscrew the retainer and pull the cable until it separates from

the box.

The probe tip is easily replaced by following the replacement procedure included

with the replacement tips.

P6131 Instruction Manual

15

Page 22

Service Information

16

P6131 Instruction Manual

Page 23

Replaceable Parts

This section contains a list of the replaceable modules for the P6131 probe. Use

this list to identify and order replacement parts.

Parts Ordering Information

Replacement parts are available through your local Tektronix field office or

representative.

Changes to Tektronix products are sometimes made to accommodate improved

components as they become available and to give you the benefit of the latest

improvements. Therefore, when ordering parts, it is important to include the

following information in your order:

H Part number

H Instrument type or model number

H Instrument serial number

H Instrument modification number, if applicable

Module Servicing

If you order a part that has been replaced with a different or improved part, your

local Tektronix field office or representative will contact you concerning any

change in part number.

Change information, if any, is located at the rear of this manual.

Modules can be serviced by selecting one of the following three options. Contact

your local Tektronix service center or representative for repair assistance.

Module Exchange. In some cases you may exchange your module for a reman-

ufactured module. These modules cost significantly less than new modules and

meet the same factory specifications.

Module Repair and Return. You may ship your module to us for repair, after which

we will return it to you.

New Modules. You may purchase replacement modules in the same way as other

replacement parts.

P6131 Instruction Manual

17

Page 24

Replaceable Parts

Using the Replaceable Parts List

This section contains a list of the replaceable mechanical and electrical components for the P6131 probe. Use this list to identify and order replacement parts.

The table below describes the content of each column of the parts list.

Parts list column descriptions

Column Column name Description

1 Figure & index number Items in this section are referenced by figure and index numbers to the exploded view

illustrations that follow.

2 Tektronix part number Use this part number when ordering replacement parts from Tektronix.

3 and 4 Serial number Column three indicates the serial number at which the part was first effective. Column four

indicates the serial number at which the part was discontinued. No entry indicates the part is

good for all serial numbers.

5 Qty This indicates the quantity of parts used.

6 Name & description An item name is separated from the description by a colon (:). Because of space limitations, an

item name may sometimes appear as incomplete. Use the U.S. Federal Catalog handbook

H6-1 for further item name identification.

7 Mfr. code This indicates the code of the actual manufacturer of the part.

8 Mfr. part number This indicates the actual manufacturer’s or vendor’s part number.

Abbreviations

Mfr. Code to Manufacturer

Cross Index

Abbreviations conform to American National Standard ANSI Y1.1–1972.

The table titled Manufacturers Cross Index shows codes, names, and addresses

of manufacturers or vendors of components listed in the parts list.

18

P6131 Instruction Manual

Page 25

Replaceable Parts

1

6

5

16

11

12

13

17

14

10

3

9

8

15

2

4

7

Figure 10: P6131 probe with standard accessories

Replaceable parts: P6131 probe and standard accessories

Fig. &

index

number

10 –1 206–0314–00 1 COMP BOX ASSY:1.3 METER

–2 131–3219–00 1 CONN,RF PLUG:BNC,MALE,STR,THD,10X 24931 28P266–3

–3 200–3018–00 8430 1 COVER,CABLE NIP:COMP BOX 0J260 ORDER BY DESC

–4 200–3017–00 8430 1 COVER,COMP BOX:BOTTOM,ABS SLATE GRAY TK2565 200–3017–00

–5 200–3016–00 8909 1 COVER,COMP BOX:TOP,ABS DOVE GRAY

Tektronix

part number

206–0321–00 1 COMP BOX ASSY:2 METER

200–3016–00 8909 1 COVER,COMP BOX:TOP,ABS DOVE GRAY

Serial no.

effective

Serial no.

discont’d

Qty Name & description Mfr. code Mfr. part number

P6131 PROBE

80009 206–0314–00

(STANDARD ONLY)

80009 206–0321–00

(OPTION 02 ONLY)

TK2565 200–3016–00

(STANDARD ONLY)

TK2565 200–3016–00

(OPTION 02 ONLY)

P6131 Instruction Manual

19

Page 26

Replaceable Parts

Replaceable parts: P6131 probe and standard accessories (cont.)

Fig. &

index

number

10 –6 174–0972–00 8805 1 CABLE ASSY,RF:39 OHM COAX,3.0M

–7 013–0208–02 8820 1 TIP,PROBE:SUBMINIATURE SIZE TK2565 013–0208–02

–8 204–0925–01 1 BODY SHL,PROBE TK2565 204–0925–01

–9 206–0265–10 8628 1 TIP,PROBE:10X,10.3PF,CLEAR/BLUE

–10 196–3305–00 1 LEAD,ELECTRICAL:22 AWG,6.0 L,W/CLIP 060D9 196–3305–00

–11 016–1644–00 1 POUCH,ACCESSORY:6.25 X 9.25 05006 501494

–12 352–0351–00 8924 1 HOLDER,PROBE:BLACK ABS P6000 SERIES 7X318 1127

–13 195–4240–00 1 LEAD,ELECTRICAL:0.025 DIA,COPPER,2.3 L TK2469 195–4240–00

–14 016–0633–00 1 MARKER SET,CA:2 EA VARIOUS COLORS 80009 016–0633–00

–15 343–1003–01 1 COLLAR,GND TK2565 343–1003–01

–16 206–0364–00 9004 1 TIP,PROBE:MICROCKT TEST,0.05 CTR 80009 206–0364–00

–17 003–1433–02 8845 1 SCREWDRIVER:ADJUSTMENT TOOL TK2565 003–1433–02

Tektronix

part number

174–0971–00 8818 1 CABLE ASSY,RF:39 OHM COAX,2.0M

206–0265–12 8628 1 TIP,PROBE:10X,12.5PF,CLEAR YELLOW

196–3113–02 1 LEAD,ELECTRICAL:STRD,22 AWG,6.0 L,8–N TK2469 196–31 13–02

070–5514–03 1 SHEET,TECHNICAL:INSTR,P6131,DP TK2548 070–5514–03

Serial no.

effective

Serial no.

discont’d

Mfr. part numberMfr. codeName & descriptionQty

TK2469 174–0972–00

(STANDARD ONLY)

TK2469 174–0971–00

(OPTION 02 ONLY)

80009 206–0265–10

(STANDARD ONLY)

80009 206–0265–12

(OPTION 02 ONLY)

P6131 PROBE STANDARD ACCESSORIES

20

P6131 Instruction Manual

Page 27

1 2 3 4 5 6

7 8 9 10 11 12

Replaceable Parts

13

14

Figure 11: P6131 probe optional accessories

Replaceable parts: P6131 probe optional accessories

Fig. &

index

number

11 –1 131–5030–00 8926 1 CONNECTOR,PROBE:PKG OF 25,SUBMINIATURE 80009 131–5030–00

–2 013–0195–00 1 ADAPTER,CONN:BNC TO PROBE 24931 28P264–1

–3 013–0202–03 8727 1 ADAPTER,PROBE:SUBMINIATURE/COMPACT TO

–4 015–0325–01 1 ADAPTER,PROBE:PROBE TO CONNECTOR PINS TK2565 015–0325–01

Tektronix

part number

Serial no.

effective

Serial no.

discont’d

Qty Name & description Mfr. code Mfr. part number

P6131 PROBE OPTIONAL ACCESSORIES

TK2565 013–0202–03

MIN

THE SUBMINIATURE–TO–MINIATURE PROBE–TIP

ADAPTER IS REQUIRED TO USE ACCESSORIES IN

INDEX NUMBERS 6 THRU 11

P6131 Instruction Manual

21

Page 28

Replaceable Parts

Replaceable parts: P6131 probe optional accessories (cont.)

Fig. &

index

number

11–5 206–0364–00 8851 1 TIP,PROBE:MICROCKT TEST,0.05 CTR 80009 206–0364–00

–6 013–0084–04 1 ADAPTER,CONN:BNC TO PROBE 80009 013–0084–04

–7 013–0085–00 1 TIP,PROBE:GROUNDING 80009 013–0085–00

–8 352–0670–00 1 HOLDER,PROBE:ATTENUATOR TIPS (3) TK2565 352–0670–00

–9 206–0268–00 1 TIP ASSY,PROBE:1X,SUBMINIATURE 80009 206–0268–00

–10 003–1433–02 8845 1 SCREWDRIVER:ADJUSTMENT TOOL 80009 003–1433–02

–11 016–0633–00 1 MARKER SET,CA:2 EA VARIOUS COLORS 80009 016–0633–00

–12 013–0253–00 9307 1 ADAPTER,CONN:BNC TO PROBE TIP,MALE 24931 28P–302–1

–13 196–3286–00 8921 1 LEAD,ELECTRICAL:26 AWG,10.222 L,0–N

–14 196–3302–00 9004 1 LEAD,ELECTRICAL:23 AWG,6.0 L TK2469 196–3302–00

Tektronix

part number

070–5514–03 1 MANUAL,TECH:INSTR,P6131 TK2548 070–5514–03

Serial no.

effective

Serial no.

discont’d

Mfr. part numberMfr. codeName & descriptionQty

TK2469 196–3286–00

W/ALLIGATOR CLIP

Manufacturers cross index

Mfr.

code

05006 20TH CENTURY BOK 3628 CRENSHAW BOULEVARD

0J260 COMTEK MANUFACTURING OF OREGON P O BOX 4200

24931 BERG ELECTRONICS INC BERG ELECTRONICS RF/COAXIAL DIV

7X318 KASO PLASTICS INC 11013 A NE 39TH VANCOUVER, WA 98662

80009 TEKTRONIX INC 14150 SW KARL BRAUN DR

TK2469 UNITREK CORPORATION 3000 LEWIS & CLARK HWY

TK2548 XEROX CORPORA TION 14181 SW MILLIKAN WA Y BEAVERTON, OR 97005

TK2565 VISION PLASTICS INC 26000 SW PARKWAY CENTER DRIVE WILSONVILLE, OR 97070

Manufacturer Address City , state, zip code

LOS ANGELES, CA 90016

ATTN: CUSTOM DEPARTMENT

BEAVERT ON, OR 970764200

M/S 16–207

FRANKLIN, IN 46131

2100 EARLYWOOD DR

PO BOX 547

BEAVERT ON, OR 97077–0001

PO BOX 500

VANCOUVER, W A 98661

SUITE 2

22

P6131 Instruction Manual

Loading...

Loading...