Page 1

Instruction Manual

P6105A

100 MHz 10X Passive Probe

070-5516-03

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

*P070551603*

070551603

Page 2

Copyright © T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

T ektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of purchase from an authorized T ektronix distributor. If any such product proves

defective during this warranty period, T ektronix, at its option, either will repair the defective product without charge for

parts and labor, or will provide a replacement in exchange for the defective product. Batteries are excluded from this

warranty .

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, shipping charges prepaid, and

with a copy of customer proof of purchase. T ektronix shall pay for the return of the product to Customer if the shipment is

to a location within the country in which the T ektronix service center is located. Customer shall be responsible for paying

all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE LISTED PRODUCTS IN LIEU OF

ANY OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUST OMER FOR BREACH OF THIS WARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Contacting Tektronix

Product

support

Service

support

For other

information

To write us

Web site

For questions about using T ektronix measurement products, call

toll free in North America:

1-800-833–9200

6:00 a.m. – 5:00 p.m. Pacific time

Or contact us by e-mail:

tm_app_supp@tek.com

For product support outside of North America, contact your local T ektronix distributor

or sales office.

T ektronix offers extended warranty and calibration programs as options on many

products. Contact your local T ektronix distributor or sales office.

For a listing of worldwide service centers, visit our web site.

In North America:

1-800–833–9200

An operator can direct your call.

T ektronix, Inc.

P.O. Box 500

Beaverton, OR 97077-1000

USA

www .tektronix.com

Page 5

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or Personal Injury

Symbols and Terms

Connect and Disconnect Properly . Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

The common terminal is at ground potential. Do not connect the common

terminal to elevated voltages.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry .

T erms in this Manual. The following terms may appear in this manual:

P6105A Instruction Manual

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

i

Page 6

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments to this

product unless another person capable of rendering first aid and resuscitation is

present.

ii

P6105A Instruction Manual

Page 7

P6105A Passive Probe

Thank you for choosing a Tektronix passive probe. This manual provides the

information necessary to begin making measurements with your P6105A probe.

Topics are presented in the following order:

H Description—A description of the probe and its options.

H Safety—A review of important safety considerations.

H Installation—Information about attaching the probe to an instrument, and

attaching accessories to the probe.

H Operating Considerations—Information about using the probe.

H Maintenance—Instructions for cleaning the probe and replacing major

assemblies.

H Replaceable Parts—An exploded view of the probe and a list of replaceable

parts.

Description

The P6105A is a miniature, 10X-attenuating passive probe that is compatible

with general purpose oscilloscopes having a 1 MW input impedance.

The P6105A is compatible with Tektronix oscilloscopes that automatically detect

and display the attenuation factor of the attached probe.

The P6105A has a ground-reference push button that momentarily grounds the

probe output. This feature allows you to quickly identify the oscilloscope display

associated with one of several attached probes as well as making ground-referenced measurements easier.

The P6105A is available with the following cable lengths:

Standard 2 meters

Option 01 1 meter

Each probe option is fully compatible with Tektronix accessories for miniature

probes.

P6105A Instruction Manual

1

Page 8

P6105A Passive Probe

Installation

This section describes both attaching the probe to an oscilloscope and using the

standard accessories with the probe.

Attaching the Probe to an

Oscilloscope

Using the Standard

Accessories

The probe uses a BNC connector to attach to an oscilloscope input connector. To

ensure optimum performance from your probe/oscilloscope measurement

system, verify that the probe and oscilloscope are appropriately matched. The

oscilloscope input impedance should be 1 MW. The oscilloscope input capaci-

tance should be between 15 and 35 pF. Refer to “Compensation Range” in

Table 1 on page 8 for more information.

Your P6105A is shipped with the following accessories:

H This instruction manual—Read these instructions to familiarize yourself

with he features, specifications, and operation of the P6105A passive probe.

H Accessory pouch—(not shown) Use the accessory pouch to store the probe

and its accessories when they are not being used.

H Adjustment tool—Use the insulated adjustment tool to adjust the low

frequency trimmer in the probe compensation box.

H IC protector tip—Use the IC protector tip to keep the metal sleeve of the

probe tip from accidentally shorting together the leads of an IC or other

circuit element. The shape of the protector tip helps you place the tip

accurately onto an IC lead.

H Retractable hook tip—Use the retractable hook tip to make hands-free

measurements. The hook tip attaches to components having leads, such as

resistors, capacitors, and discrete semiconductors. You can also grip stripped

wire, jumpers, busses, and test pins with the retractable hook.

For maximum flexibility with the hook tip, use the twelve-inch ground lead.

For precise measurements at high frequency, however, long ground leads

may have too much inductance. In these cases you should use the five-inch

ground lead.

To remove the hook tip, simply pull it off the probe. Reinstall it by pushing

it firmly onto the probe tip.

H Ground cover—Use the protective ground cover to keep the metal sleeve of

the probe tip from accidentally shorting circuit elements to ground. Remove

the ground cover before installing the retractable hook tip.

H Marker rings—Use the marker rings to help you keep track of individual

probes and signal sources when you have a complicated test setup. Use the

marker rings whenever you want to identify a particular probe for any

2

P6105A Instruction Manual

Page 9

P6105A Passive Probe

reason.To make probe identification easy, clip matching colored rings onto

the probe cable and tip as shown.

H Three-inch ground lead—Use the Three-inch ground lead to establish a

ground reference for your measurements. Whenever freedom from aberrations and amplitude accuracy are more important than probe reach and

flexibility, use the shortest ground lead possible.

To attach the ground lead to the probe, insert the spring clip into the

receptacle as shown. If the alligator clip is not attached, screw it onto the

threaded end of the lead.

H Five-inch ground lead—Use the long ground lead when a long reach is

important and high-frequency information is not. Because of the high

inductance associated with long ground leads, you should not use them for

precise measurements above approximately 30 MHz (or for pulses with rise

times less than about 11 ns). Long ground leads are ideal for quick troubleshooting when you are looking for the presence or absence of a signal and

are not concerned with the precision of the measurement.

The five-inch ground lead attaches in the same manner as the three-inch lead.

H Alligator clip—Use the alligator clip with one of the ground leads. Screw

the alligator clip onto the threaded end of a ground lead.

P6105A Instruction Manual

3

Page 10

P6105A Passive Probe

Operating Considerations

This information in this section will help you make the most effective use of

your P6105A probe.

Features and Controls

Readout Pin

Ground-reference

Push Button

Finger guard

H Readout pin—The BNC connector of the probe includes a spring-loaded pin

that connects to a mating contact ring on certain oscilloscopes. These

oscilloscopes recognize the attenuation factor of the probe and automatically

correct the oscilloscope indication of scale factor. You can determine if your

oscilloscope supports this feature by watching the oscilloscope vertical scale

factor readout when attaching the probe. If the displayed scale changes by a

factor of 10—for instance, from 10 mV to 100 mV—your oscilloscope

supports this feature.

H Ground-reference push button—Press the ground-reference push button to

momentarily short the signal output of the probe to ground (the signal under

test is not affected). Using the ground-reference push button allows you to

quickly note or verify the ground reference of a DC measurement. If your

oscilloscope is displaying several traces, pressing the ground-reference push

button also helps you to identify which trace is associated with the probe.

WARNING. To avoid electric shock when using the probe, keep fingers behind the

guard on the probe body.

Ground Lead Inductance

4

In order for an amplitude measurement to be meaningful, you must give the

measurement some point of reference. The ground lead provides access to this

ground reference.

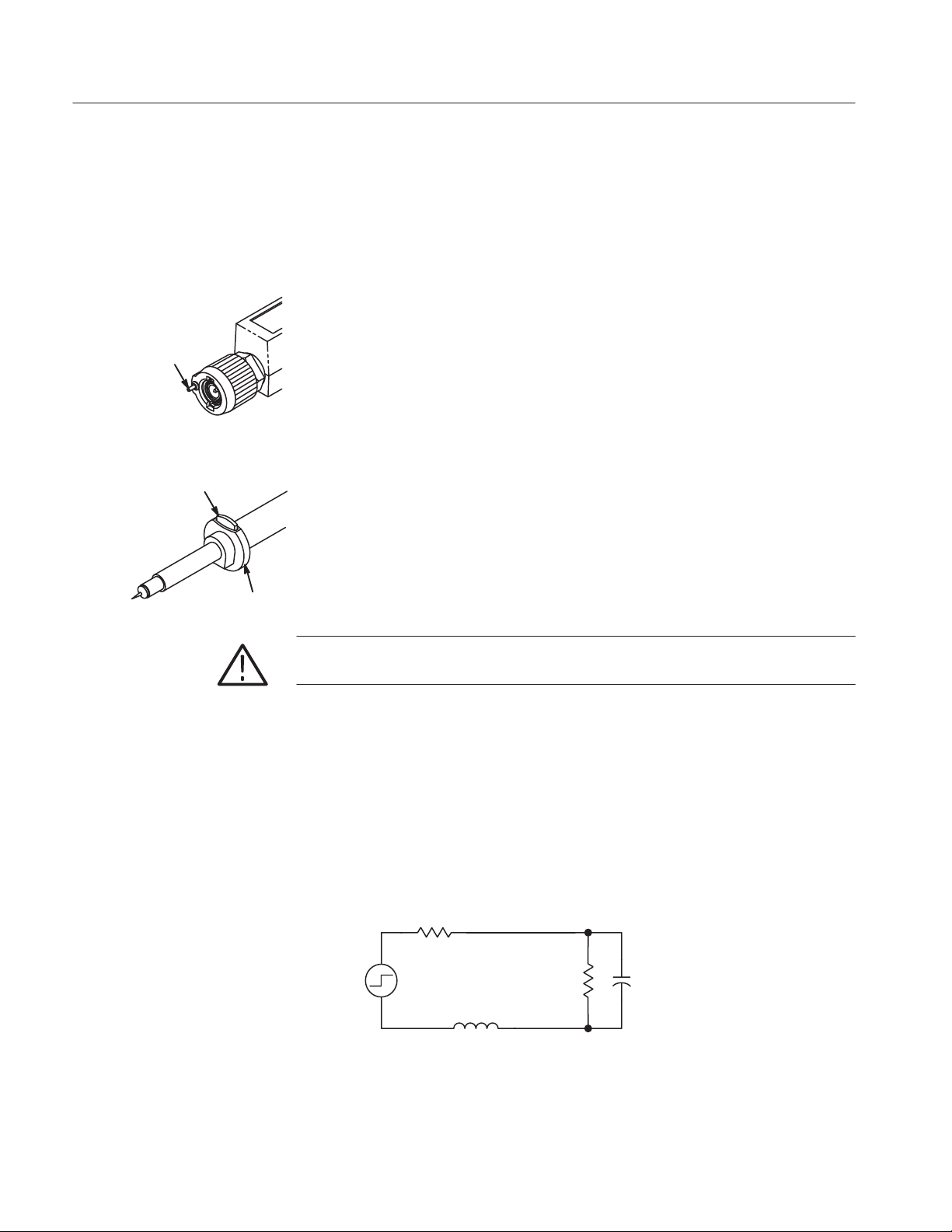

When you subsequently touch your probe tip to a circuit element, you introduce

additional resistance, capacitance, and inductance into the circuit (Figure 1).

Source

Resistance

Probe

V

source

Input

Resistance

Ground Lead Inductance

Probe Input

Capacitance

Figure 1: A Probe Adds Resistance, Capacitance, and Inductance

P6105A Instruction Manual

Page 11

P6105A Passive Probe

A passive probe is capacitive for high-frequency signals. For most circuits, the

high input resistance of a passive probe has a negligible effect on the signal. The

series inductances represented by the probe tip and ground lead, however, can

result in a parasitic resonant circuit that may “ring” within the bandwidth of the

oscilloscope. If the ringing is at a frequency within the oscilloscope bandwidth,

the ringing appears on the oscilloscope display as a distortion of the true

waveform. Figure 2 shows the effect on the same signal through the same probe

with different ground leads.

Long Ground Lead

Low-Frequency Probe

Compensation

Undercompensated

Short Ground Lead

Figure 2: Signal Distortion Introduced by Ground Lead Inductance

Reducing the ground lead inductance will raise the resonant frequency. Ideally,

the inductance is low enough that the resulting frequency is above the frequency

at which you want to take measurements. To maintain the best signal integrity,

use the shortest possible ground lead and signal input path.

Passive probes require compensation to ensure maximum distortion-free output

and to avoid high-frequency amplitude errors.

Because of variations in oscilloscope input characteristics, probe low-frequency

(LF) compensation may need adjustment after moving the probe from one

oscilloscope to another. Verify the compensation before making critical rise time

or amplitude measurements.

If a 1-kHz calibrated square wave displayed at 1 ms/division shows significant

differences between the leading and trailing edges (see figures at left), perform

the following steps to optimize low-frequency compensation.

Overcompensated

Properly Compensated

P6105A Instruction Manual

1. Connect the probe tip to a calibration signal. Most oscilloscopes have a front

panel test point for this purpose; if yours does not, use a signal generator that

produces a well-formed square wave at approximately 1 kHz.

5

Page 12

P6105A Passive Probe

2. Press AUTOSET (on many Tektronix oscilloscopes) or otherwise adjust the

oscilloscope so that it displays a waveform similar to those shown in this

section.

Optional: If your oscilloscope has a limited-bandwidth mode, enable it.

Filtering out high-frequency noise will make the adjustment easier to

perform.

3. Adjust the trimmer in the probe (refer to Figure 3) until you see a flat-top

square wave on the display.

High-Frequency Probe

Compensation

Figure 3: P6105A Probe Trimmer Adjustment

The probe high-frequency compensation should seldom require adjustment;

however, your probe may require high-frequency adjustment if any of the

following are true:

H the probe has excessive high-frequency aberrations

H the probe does not perform at the rated bandwidth

H you have installed the probe on an oscilloscope having an input capacitance

near the limits of the probe compensation range (see Table 1 on page 8)

To perform the high-frequency compensation adjustment you will need a signal

source that has all of the following characteristics:

H square-wave output at 1 MHz

H fast rise output with rise time less than 1 ns

H output terminated into 50 W load

6

P6105A Instruction Manual

Page 13

HF1

P6105A Passive Probe

NOTE. We strongly recommend that you use the optional probe tip-to-BNC

adapter (Tektronix part number 013-0084-04) to connect your probe to the

signal source.

1. Remove the covers from the probe compensation box by gently prying them

off with a fingernail or small screwdriver.

2. Connect the probe to the signal source and display a 1 MHz test signal on

your oscilloscope. Adjust your oscilloscope to .01 ms/division. The display

should be similar to that shown in Figure 4(a).

HF2

HF2

HF1

(a) Area Of Waveform Affected By Trimmers (b) Location of Trimmers

Figure 4: Adjusting High-Frequency Compensation

3. Adjust HF1 and HF2 to flatten and square the waveform.

LF

P6105A Instruction Manual

7

Page 14

P6105A Passive Probe

ttenuation

2

Specifications

T able 1: Electrical Characteristics

Characteristic Performance Requirement

A

Input resistance

Input Capacitance

1.0-meter (Option 01) 8.7 pF

2.0-meter (standard) 1 1.2 pF

Compensation Range

1.0-meter (Option 01) 15 pF to 35 pF

2.0-meter (standard) 15 pF to 35 pF

System Bandwidth (–3 dB)

1.0-meter (Option 01) 100 MHz

2.0-meter (standard) 100 MHz

Maximum Input Voltage

1

Probe installed on Tektronix 100 MHz (or less) 400 Series oscilloscope.

2

System characteristic.

3

As defined in EN61010-1. See Certifications and compliances in Table 3

4

RMS=Root Mean Square=rms=The square root of the average of the sum of the

squares of the instantaneous voltage in one cycle = .

2

3,4

1

10X: ±3.0% at DC

10 MW ±2.0% at DC

(see Figure 6)

450 V RMS CAT I or 450 V DC CAT I

300 V RMS CAT II or 300 V DC CAT II

150 V RMS CAT III or 150 V DC CAT III

630 V peak, @50% DF, <1 sec PW

1000 V peak, @20% DF, <1 sec PW

1050 V peak, @10% DF, <50 ms PW

See Figure 7 for voltage derating curve.

Ǹ

ȍ

(fxi)2ńn

300 VDC=300V RMS, 420 V Peak (sinewave)=300 V RMS See Figure 5

8

P6105A Instruction Manual

.

Page 15

@25% Duty Factor

=(1/2 Peak V) RMS

0V

@50% Duty Factor

=(1.414 (Peak V)) RMS

0V

Special case of square wave:

@20% Duty Factor

2

)

=[(V

Example: Maximum Input Voltage

=[(1000 V Pk)

(Duty Factor)]

Peak

2

(.20)]

1/2

1/2

= 450 V RMS

0V

Figure 5: Maximum input voltage calculation example

P6105A Passive Probe

(ohms)

in

Z

Frequency (Hz)

Figure 6: Input Impedance by Frequency

Phase (degrees)

P6105A Instruction Manual

9

Page 16

P6105A Passive Probe

Voltage (RMS)

Frequency (Hz)

Figure 7: Derating Curve for Determining Maximum Input Voltage

T able 2: Physical and Environmental Characteristics

Characteristic Performance Requirement

Net Weight

<1 10 g (0.24 lbs)

(including accessories)

T emperature Range

1

Operating –15_C to +65_C (+5_F to +149_F)

Nonoperating –62_C to +85_C (–80_F to +185_F)

Humidity

1

95% to 97% Relative Humidity

Altitude < 2000 meters

1

Tek Standard 062-2847-00, class 3. Refer to MIL-E-16400F, paragraph 4.5.9 through

4.5.9.5.1, class 4.

T able 3: Certifications and compliances

EC Declaration of

Conformity

Compliance was demonstrated to the following specification as listed in

the Official Journal of the European Communities:

Low Voltage Directive 73/23/EEC as amended by 93/68/EEC:

10

EN 61010-1/A2

EN 61010-2-031:1994

Safety requirements for electrical equipment

for measurement, control, and laboratory use

Particular requirements for hand-held probe

assemblies for electrical measurement and

test

P6105A Instruction Manual

Page 17

T able 3: Certifications and compliances (Cont.)

P6105A Passive Probe

Maintenance

Overvoltage

Category

Pollution Degree 2 Do not operate in environments where conductive pollutants may be

Safety UL31 11-1, First Edition & IEC61010-2-031, First Edition

Category: Examples of Products in this Category:

CA T III Distribution-level mains, fixed installation

CA T II Local-level mains, appliances, portable

equipment

CA T I Signal levels in special equipment or parts of

equipment, telecommunications, electronics

present.

CSA C22.2 No. 1010.1-92 & CAN/CSA C22.2 No. 1010.2.031-94

EN61010-1/A2

EN61010-2-031

Pollution Degree 2

The information in this section will help you maintain your probe for a long

service life.

Cleaning

Replacing Probe Modules

P6105A Instruction Manual

To prevent damage to probe materials, avoid using chemicals that contain

benzene, toluene, xylene, acetone, or similar solvents.

Remove accumulated loose dust from the probe exterior using a soft cloth or

small brush. Remaining dirt may be removed with a soft cloth dampened with a

mild detergent and water solution, or isopropyl alcohol. Do not immerse the

probe or use abrasive cleaners.

The probe can be disassembled into three easy-to-replace modules: the probe

head, the cable assembly, and the compensation box assembly. Refer to Figure 8.

Individual components within the compensation box are not replaceable.

NOTE. The probe head, cable, and compensation box are not interchangeable

between probe options. Be certain to specify Standard or Option 01 when

ordering replacement parts.

11

Page 18

P6105A Passive Probe

Probe Cable

Compensation Box

Probe Head

Figure 8: P6105A Replaceable Modules

H Probe head—To remove the probe head, simply pull it free from the cable.

To reinstall the probe head, push the cable end into the head until the

connector snaps into place.

Replacing Probe Tips

H Compensation box—To remove the compensation box, unscrew the tapered

retainer and slide it along the cable, away from the compensation box.

Withdraw the cable from the compensation box. To reinstall the compensation box, reverse the procedure.

H Probe cable—To replace the probe cable, remove the probe head and

compensation box as described above. To reassemble your probe, reverse the

procedure.

Replacement probe tips are available as optional accessories. Instructions for

replacing the probe tip are included in the package of replacement tips. Refer to

Replaceable Parts for more information.

12

P6105A Instruction Manual

Page 19

Replaceable Parts

P6105A Passive Probe

Figure 9: P6105A Exploded View

Replaceable mechanical parts list

Fig. &

index

number

9– PROBE,PASSIVE100 MHZ,10X W/RO 2M

–1 206–0334–00

–2 131–3219–00 1 ..CONN,RCPT,ELEC:BNC,MALE 24931 28P266–3

–3 200–3016–00 1 ..COVER,COMP BOX:TOP,ABS DOVE GRAY 80009 200–3016–00

–4 200–3017–00 1 ..COVER,COMP BOX:BOTTOM,ABS SLATE GRA Y 80009 200–3017–00

–5 200–3018–00 1 ..COVER,CABLE NIP:COMP BOX 0J260 ORDER BY DESC

–6 174–0976–00

–7 013–0107–07 1 .TIP,PROBE:MINI/COMPACT SIZE,RETRACT HOOK ASSY 80009 013–0107–07

Tektronix part

number

206–0331–00

174–0975–00

Serial no.

effective

Serial no.

discont’d

Qty Name & description

P6105A

(STANDARD ONLY)

PROBE,PASSIVE:100 MHZ,10X W/RO 1M

(OPTION 01 ONLY)

11.COMP BOX ASSY:2.0 METER

.(STANDARD ONLY)

.COMP BOX ASSY:1.0 METER

.(OPTION 01 ONLY)

11.CABLE ASSY,RF:39 OHM COAX,2.0 M

.(STANDARD ONLY)

.CABLE ASSY,RF:39 OHM COAX,1.0M

.(OPTION 01 ONLY)

Mfr.

code

80009

80009

80009

80009

Mfr. part number

206–0334–00

206–0331–00

174–0976–00

174–0975–00

P6105A Instruction Manual

13

Page 20

P6105A Passive Probe

Replaceable mechanical parts list (Cont.)

Fig. &

index

number

–8 206–0301–00

–9 206–0337–01

–10 196–3120–01 1 LEAD,ELECTRICAL:GROUND,23 AWG,6.0 L 80009 196–3120–01

–11 003–1433–02 1 SCREWDRIVER:ADJUSTMENT TOOL 80009 003–1433–02

–12 –––––––– 1 TIP,PROBE:IC TEST

–13 166–0404–01 1 COVER,GROUND: 80009 166–0404–01

–14 016–0633–00 1 MARKER SET,CA:2 EA VARIOUS COLORS 80009 016–0633–00

–15 016–1644–00 1 POUCH,ACCESSORY:6.25 X 9.25 80009 016–1644–00

Tektronix part

number

206–0328–00

206–0336–01

070–5516–03 1 SHEET,TECHNICAL:INSTRUCTION,P6105A 80009 070–5516–03

015–0201–07 1 TIP,PROBE:IC TEST,PKG OF 10 80009 015–0201–07

015–0201–08 1 TIP,PROBE:IC TEST,PKG OF 100 80009 015–0201–08

003–1433–02 1 SCREWDRIVER:ADJUSTMENT TOOL 80009 003–1433–02

016–0633–00 1 MARKER SET,CA:2 EA VARIOUS COLORS 80009 016–0633–00

344–0046–01 1 CLIP,ELECTRICAL:ALLIGA TOR 80009 344–0046–01

Serial no.

effective

Serial no.

discont’d

Name & descriptionQty

11.PROBE HEAD:2.0 METER

.(STANDARD ONLY)

.PROBE HEAD:1.0 METER CABLES,H951

.(OPTION 01 ONLY)

11..PROBE HEAD:2.0 METER,PKG OF 5

..(STANDARD ONLY)

..PROBE HEAD:1.0 METER,PKG OF 5

..(OPTION 01 ONLY)

STANDARD ACCESSORIES

(SEE OPTIONAL ACCESSORIES)

OPTIONAL ACCESSORIES

Mfr.

code

80009

80009

80009

80009

Mfr. part number

206–0301–00

206–0328–00

206–0337–01

206–0336–01

Manufacturers cross index

Mfr.

code

TK1556 CONSOLIDA TED VINYL SALES 1237 S SAN GABRIEL BLVD SAN GABRIEL CA 91776

0J260 COMTEK MFG OF OREGON PO BOX 4200 BEAVERTON OR 97076–4200

24931 FCI/BERG ELECTRONICS INC RF/COAXIAL DIV 2100 EARLYWOOD DR

80009 TEKTRONIX INC 14150 SW KARL BRAUN DR

14

Manufacturer Address City , state, zip code

PO BOX 547

PO BOX 500

FRANKLIN, IN 46131

BEAVERT ON OR 97077–0001

P6105A Instruction Manual

Loading...

Loading...