Page 1

Instruction Manual

P6015A

1000X High Voltage Probe

070-8223-05

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are

owned by Tektronix or its subsidiaries or suppliers, and are protected by

national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and

pending. Information in this publication supercedes that in all previously

published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered tradem arks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

H In North America, call 1-800-833-9200.

H Worldwide, visit www.tektronix.com to find contacts in your area.

Page 3

Warranty 2

Tektronix warrants that this product will be free from defects in materials and

workmanship for a period of one (1) year from the date of shipment. If any such product

proves defective during this warranty period, Tektronix, at its option, either will repair the

defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product. Parts, modules and replacement products used by

Tektronix for warranty work may be new or reconditioned to like new performance. All

replaced parts, modules and products become the property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the

defect before the expiration of the warranty period and make suitable arrangements for the

performance of service. Customer shall be responsible for packaging and shipping the

defective product to the service center designated by Tektronix, with shipping charges

prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to

a location within the country in which the Tektronix service center is located. Customer

shall be responsible for paying all shipping charges, duties, taxes, and any other charges for

products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or

improper or inadequate maintenance and care. Tektronix shall not be obligated to furnish

service under this warranty a) to repair damage resulting from attempts by personnel other

than Tektronix representatives to install, repair or service the product; b) to repair damage

resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a

product that has been modified or integrated with other products when the effect of such

modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE

PRODUCT IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED.

TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE

PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE

CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS

VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX

OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Page 5

Table of Contents

General Safety Summary v............................

Service Safety Summary vii.............................

Environmental Considerations viii........................

User Information

Overview 1--1..........................................

Readout Option 1--3.....................................

Standard Accessories 1--4.................................

Options 1--4............................................

Setup 1--5.............................................

In Detail 1--7..........................................

General Guidelines 1--7..................................

Maximum Input Voltage 1--10..............................

Probe Grounding 1--13....................................

Probe Compensation 1--15.................................

Caring for the Probe 1--20.................................

Other Considerations 1--21.................................

Problems Encountered Using the Probe 1--21..................

Specifications 1--23......................................

Warranted Characteristics 1--23.............................

Typical and Nominal Characteristics 1--27....................

P6015A Instruction Manual

i

Page 6

Table of Contents

Service Information

Performance Verification 2--1............................

Adjustments 2--3.......................................

Test Equipment Required 2--3.............................

Preparation 2--3.........................................

Long-Form Procedure 2--5................................

Maintenance 2--11.......................................

Preventive Maintenance 2--11..............................

Troubleshooting and Repair 2--12...........................

Mechanical Disassembly and Assembly 2--13..................

Replaceable Parts 2--17...................................

Parts Ordering Information 2--17............................

Using the Replaceable Parts List 2--18........................

Index

ii

P6015A Instruction Manual

Page 7

List of Figures

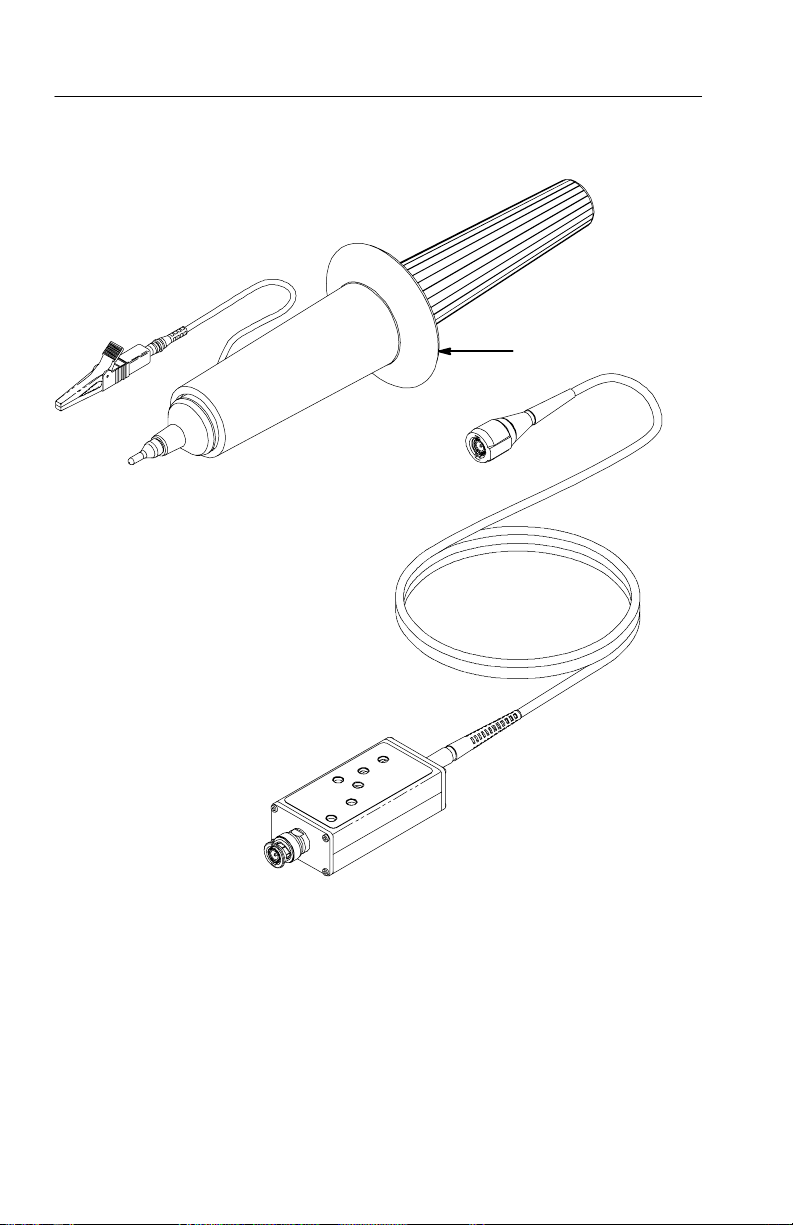

Figure 1--1: The P6015A High-Voltage Probe 1--2............

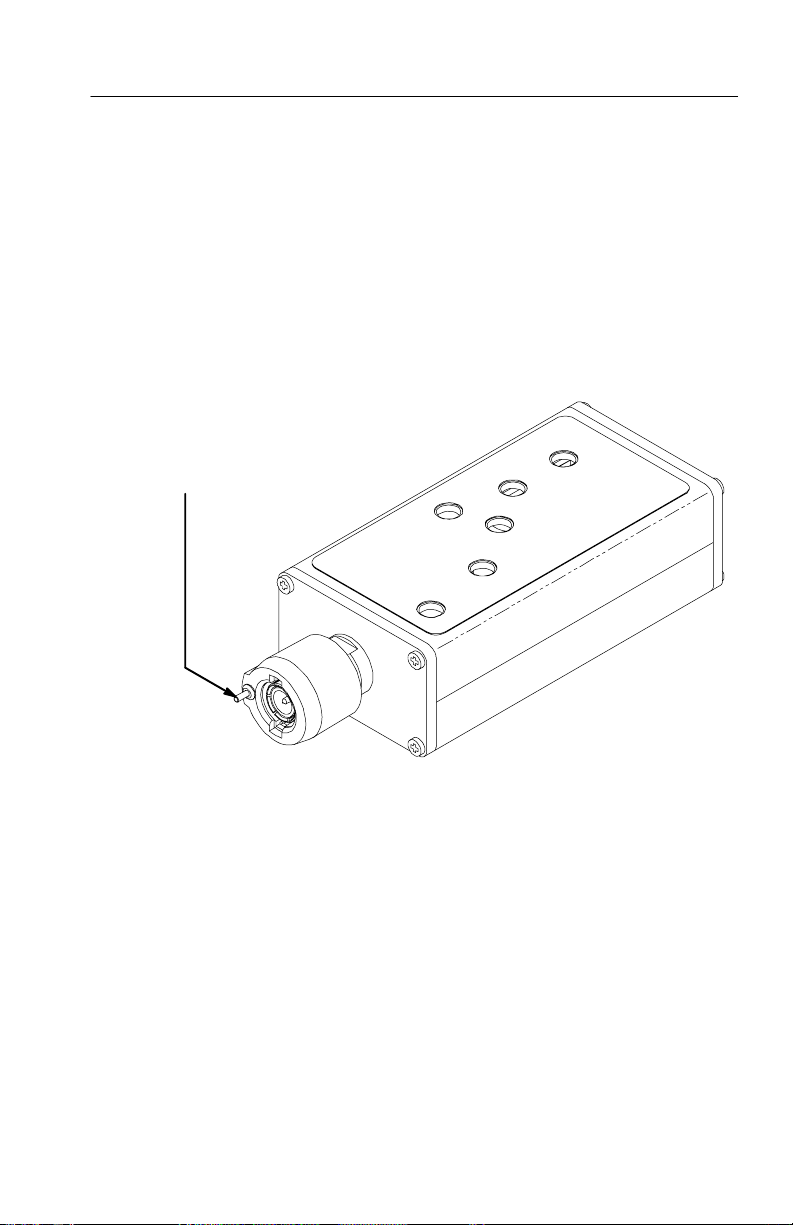

Figure 1--2: Compensation Box with Readout Option 1--3.....

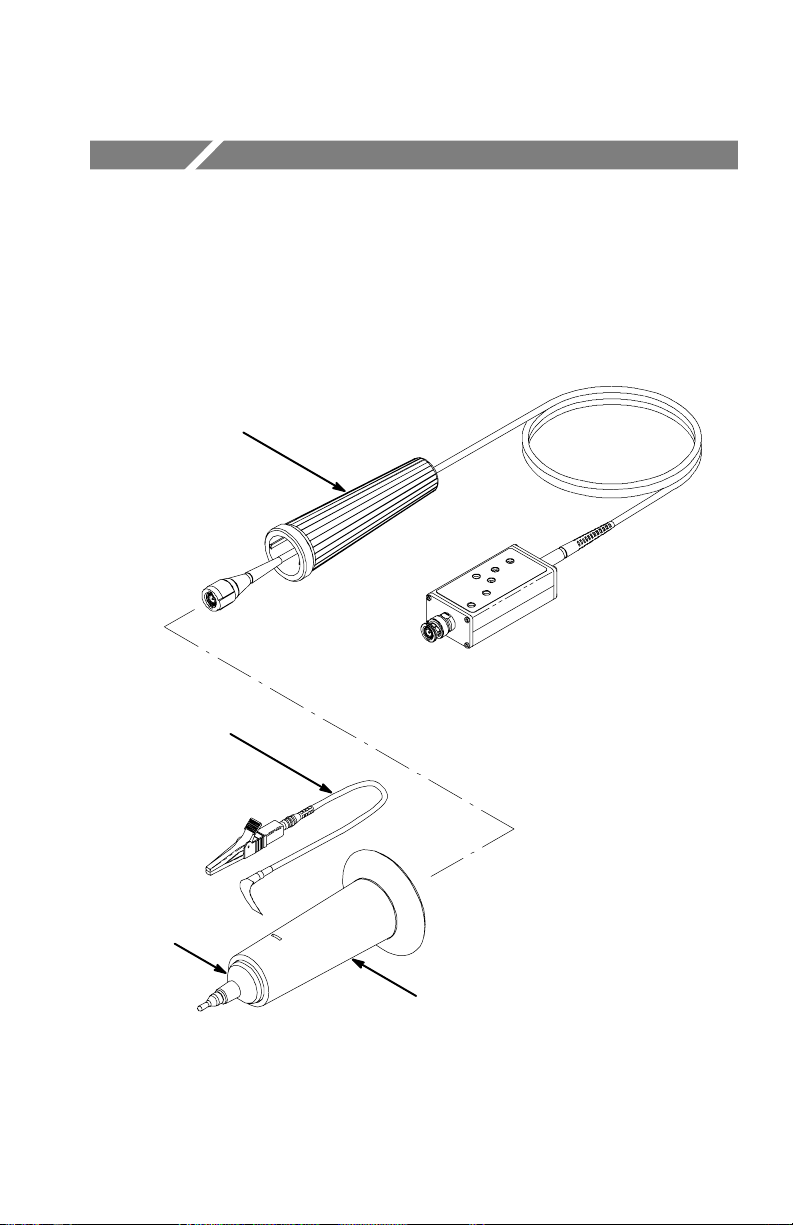

Figure 1--3: Assembling the P6015A 1--5...................

Figure 1--4: Maximum Input Voltage Derating

(DC + Peak AC) 1--12.................................

Figure 1-- 5: Peak Pulse Derating 1--13......................

Figure 1--6: Zones Affected by Compensation Adjustments 1--18

Figure 1-- 7: Humidity Derating Chart 1--26..................

Figure 1--8: Typical Input Impedance and Phase 1--26.........

Figure 2-- 1: Access to Long-Form Adjustments 2--5..........

Figure 2--2: Adjustment Locations 2--7.....................

Figure 2--3: Periods Affected by Compensation

Adjustments 2--8....................................

Figure 2--4: Removal and Replacement of Probe Head 2--14....

Figure 2--5: P6015A Exploded View 2--19....................

Table of Contents

P6015A Instruction Manual

iii

Page 8

Table of Contents

List of Tables

Table 1--1: Maximum Input Voltage1,2,3 1--10...............

Table 1--2: Test Equipment Required for

Short-Form Adjustment 1--16..........................

Table 1--3: Warranted Electrical Characteristics 1--24.........

Table 1--4: Warranted Environmental Characteristics 1--25....

Table 1--5: Typical Electrical Characteristics 1--27............

Table 1--6: Nominal Mechanical Characteristics 1--28.........

Table 2--1: Test Equipment Required for Long-Form

Adjustment 2--4....................................

iv

P6015A Instruction Manual

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent

damage to this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or Personal Injury

Connect and Disconnect Properly. Do not connect or disconnect probes

or test leads while they are connected to a voltage source.

Connect and Disconnect Properly. Connect the probe output to the

measurement instrument before connecting the probe to the circuit

under test. Connect the probe reference lead to the circuit under test

before connecting the probe input. Disconnect the probe input and

the probe reference lead from the circuit under test before disconnecting the probe from the measurement instrument.

Ground the Product. This product is indirectly grounded through the

grounding conductor of the mainframe power cord. To avoid electric

shock, the grounding conductor must be connected to earth ground.

Before making connections to the input or output terminals of the

product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all

ratings and markings on the product. Consult the product manual for

further ratings information before making connections to the product.

The inputs are not rated for connection to mains or Category II, III,

or IV circuits.

Connect the probe reference lead to earth ground only.

Do not apply a potential to any terminal, including the common

terminal, that exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate t his product with

covers or panels removed.

Do Not Operate With Suspected Failures. If you suspect there is damage

to this product, have it inspected by qualified service personnel.

]

P6015A Instruction Manual

v

Page 10

General Safety Summary

Avoid Exposed Circuitry. Do not touch exposed connections and

components when power is present.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Terms in this Manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that

could result in injury or loss of life.

CAUTION. Caution statements identify c onditions or practices that

could result in damage to this product or other property.

Symbols and Terms on the Product

These terms may appear on the product:

H DANGER indicates an injury hazard immediately accessible as

you read the marking.

H WARNING indicates an injury hazard not immediately

accessible as you read the marking.

H CAUTION indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

CAUTION

Refer to Manual

WARNING

High Voltage

vi

Earth Terminal

]

P6015A Instruction Manual

Page 11

Service Safety Summary

Only qualified personnel should perform service procedures. Read

this Service Safety Summary and the General Safety Summary before

performing any service procedures.

Do Not Service Alone. Do not perform internal service or adjustments

of this product unless another person capable of rendering first aid

and resuscitation is present.

Use Care When Servicing with Power On. Dangerous voltages or currents

may exist in this product. Disconnect power, remove battery (if

applicable), and disconnect test leads before removing protective

panels, soldering, or replacing components.

To avoid electric shock, do not touch exposed connections.

P6015A Instruction Manual

vii

Page 12

Environmental Considerations

This section provides information about the environmental impact of

the product.

Product End-of-Life Handling

Observe the following guidelines when recycling an instrument or

component:

Equipment Recycling. Production of this equipment required the

extraction and use of natural resources. The equipment may contain

substances that could be harmful to the environment or human health

if improperly handled at the product’s end of life. In order to avoid

release of such substances into the environment and to reduce the use

of natural resources, we encourage you to recycle this product in an

appropriate system that will ensure that most of the materials are

reused or recycled appropriately.

The symbol shown to the left indicates that this

product complies with the European Union’s

requirements according to Directive 2002/96/EC

on waste electrical and electronic equipment

(WEEE). For information about recycling

options, check the Support/Service section of the

Tektronix Web site (www.tektronix.com).

Restriction of Hazardous Substances

This product has been classified as Monitoring and Control

equipment, and is outside the scope of the 2002/95/EC RoHS

Directive. This product is known to contain lead, cadmium, mercury,

and hexavalent chromium.

viii

P6015A Instruction Manual

Page 13

User Information

Page 14

Page 15

Overview

The P6015A is a ground-referenced 100 MΩ, 3.0 pF high voltage

probe with 1000X attenuation. It adds high-voltage measurement

capability to oscilloscopes and other measurement devices having an

input resistance of 1 MΩ and an input capacitance of 7 pF to 49 pF.

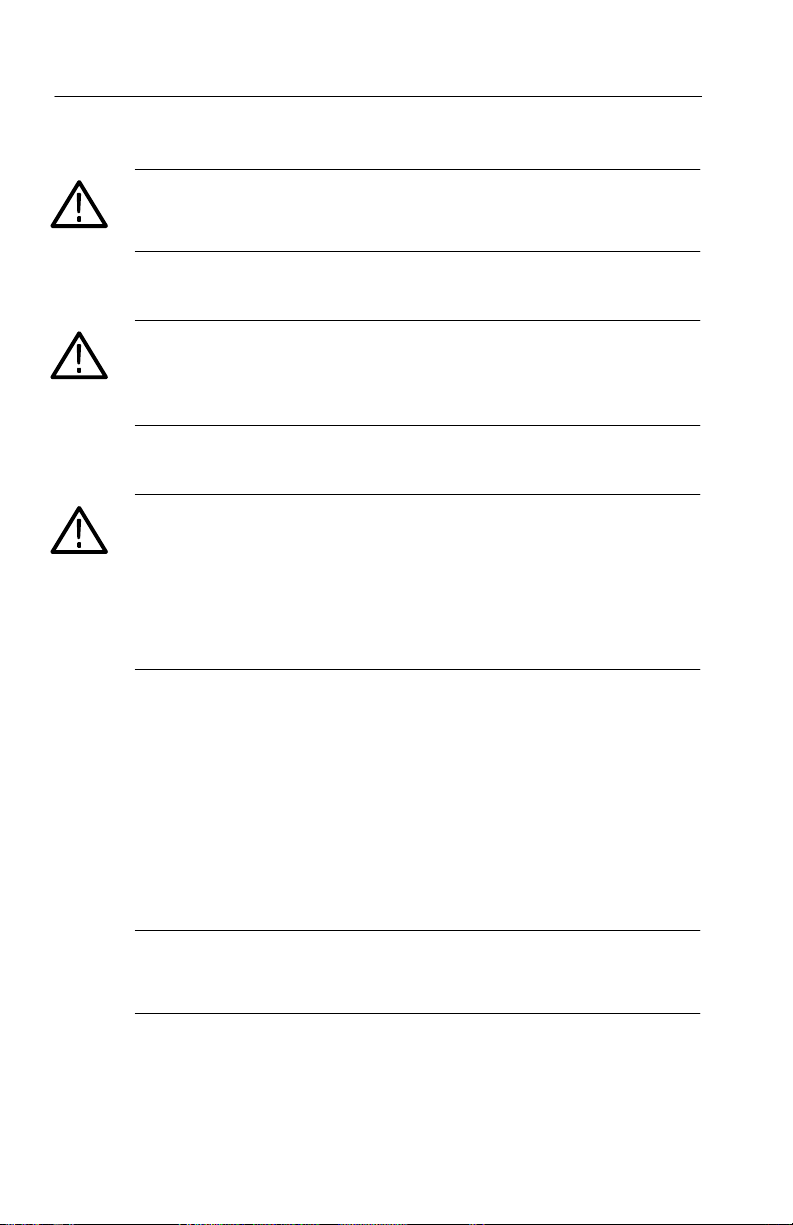

WARNING. Due to the inherent hazards associated with taking

high-voltage measurements, this product is intended for use by

qualified personnel who have had the training to take these types of

measurements.

Read and follow the precautions specified in this manual.

The P6015A consists of two major assemblies: the probe body and

the compensation box (see Figure 1--1).

H The probe body houses the probe tip, head, and ground lead. The

probe body is made of high-impact thermoplastic that provides

mechanical protection for the probe’s internal components and

electrical protection for the user.

H The compensation box connects a ground-referenced oscilloscope

or other grounded measuring device and has a cable that attaches

to the probe body. The compensation box contains an adjustment

network to optimize frequency response up to 75 MHz.

WARNING. To avoid shock, keep hands and fingers behind the guard

ring on the probe when the probe is connected to voltages.

P6015A Instruction Manual

1- 1

Page 16

Overview

Guard Ring

Figure 1- 1: The P6015A High-Voltage Probe

1- 2

P6015A Instruction Manual

Page 17

Readout Option

P6015A compensation boxes that feature the readout option have a

pin protruding from the BNC connector (Figure 1--2). Some models

of Tektronix oscilloscopes (11000 Series and Digital Storage

Oscilloscopes) read the code presented by this pin and automatically

scale the P6015A measurements by a factor of 1000 to compensate

for attenuation.

1000X Readout Pin

Overview

Figure 1- 2: Compensation Box with Readout Option

P6015A Instruction Manual

1- 3

Page 18

Overview

Standard Accessories

The P6015A comes with the following accessories:

H ground lead and plug-on clip

H hook-shaped probe tip

H banana-plug probe tip

H carrying case

H instruction manual

Options

The standard P6015A has a 10-ft cable without 1000X readout. The

following options are available:

H Option 1R: 10-ft cable and 1000X readout

H Option 25: 25-ft cable, no readout

H Option 2R: 25-ft cable and 1000X readout

1- 4

P6015A Instruction Manual

Page 19

Setup

Ground Lead

This section tells you how to assemble the P6015A modules as you

unpack them from the carrying case. Refer to Figure 1 --3 while

following these steps:

Handle

Inner Body

Figure 1- 3: Assembling the P6015A

P6015A Instruction Manual

Outer Body

1- 5

Page 20

Setup

1. Insert the end of the cable into the narrow end of the handle and

feed the BNC out the other side.

2. Connect the cable to the BNC on the probe head.

3. Screw the handle into the outer body.

4. Plug the crocodile ground clip onto the ground lead if it is not

already attached.

5. Read In Detail, beginning on page 1--7, before attempting to

make probe measurements.

1- 6

P6015A Instruction Manual

Page 21

In Detail

Before you make any oscilloscope measurement, observe all safety

precautions described in the user and service manuals for the

equipment you are working on. Some general rules about servicing

electrical equipment are worth repeating here.

H Observe the safety instruction symbols for the equipment you are

working on.

H Consult the service manual for the equipment you are working

on.

H Don’t operate or service an electrical device in an explosive

atmosphere.

H Avoid personal injury by never touching exposed connections or

components in the circuit-under-test when the power is on.

General Guidelines

To make high-voltage measurements with the P6015A probe, first

connect the BNC connector of the probe compensation box to the

measurement device (oscilloscope, digital voltmeter, etc.). Next,

connect the ground clip of the probe to a ground point of the circuit

under test. After you have made these connections, you are ready to

connect the probe tip to a high-voltage point.

Handheld Operation

The P6015A probe is designed for handheld use when used with the

straight or hook shaped probe tips. When using the straight tip, the

probe should be held by the plastic handle, behind the probe guard

ring, and the tip should be held against the high voltage test point.

The hook shaped tip can be used to hang the probe from a bus bar,

wire loop, or other test point.

P6015A Instruction Manual

1- 7

Page 22

In Detail

WARNING. When measuring high voltages, avoid contact with or

close proximity to any electrically conductive surface with your

body. Keep hands and fingers behind the guard ring on the probe.

WARNING. Make sure that the circuit is deenergized, and that any

stored energy is completely discharged before probe installation or

removal. Failure to discharge the circuit may cause serous or fatal

shock.

CAUTION. When mounting the probe into test fixtures, the duration

ratings in Table 1--1 on page 1--10 must be followed. Only clamp

onto the metal shield section of the probe when mounting the probe.

Intense electric fields are present when the probe is connected to a

high voltage source. Attaching a conductive or dielectric mount

beyond the metal shield may result in poor response characteristics

or probe damage.

1- 8

Readout

If your P6015A has the readout option and is being used with an

instrument having readout capability, the display automatically

corrects for the probe attenuation factor. (Refer to Overview on

page 1--1 for information about the P6015A readout option.)

If your instrument does not recognize the readout correction,

multiply your voltage measurements by 1000.

NOTE. Some oscilloscopes may misinterpret the 1000X attenuation

code. Contact your local Tektronix representative if you have

questions.

P6015A Instruction Manual

Page 23

In Detail

Probe Placement

CAUTION. Probe placement can be critical in some applicat ions.

To minimize Device-Under-Test circuit loading, the P6015A input

resistance is very large and input capacitance is very small. Small

changes in capacitance near the input resistor will affect the

accuracy of the measurement. These changes can result from placing

the probe tip near conductive surfaces. Changes in the input

capacitance will change the probe compensation, causing the leading

edge of pulses to overshoot or undershoot the true pulse amplitude.

The time constant will not be visible on shorter pulses where the

entire top of the measured waveform will appear to be the wrong

amplitude. Surfaces connected to the input signal will peak the

response, resulting in overshoot, while those that are static or

grounded will dampen the response, resulting in an undershoot.

To minimize the chance of changing the probe compensation, do not

allow the conductor, to which the probe is attached, to pass along the

side of the probe body. Keep the probe perpendicular to the attached

conductor or at the end of a dedicated test lead. If the test configuration does not allow this, minimize the error by readjusting the probe

compensation by connecting the probe to the calibration generator

that closely duplicates the physical configuration used in the actual

measurement.

P6015A Instruction Manual

1- 9

Page 24

In Detail

Maximum Input Voltage

Table 1--1 and the following paragraphs indicate conditions where

the maximum input of the P6015A is reduced.

Table 1- 1: Maximum Input Voltage

1,2,3

Max. On Time ≥30 Minutes <30 Minutes ≥15 Minutes <15 Minutes

Temperature

0to35 0to35 36 to 50 36 to 50

Range °C

4,5,6

V

RMS

V

DC

V

(DC+PK AC)

V

(Peak Pulse)

14 kV 20 kV 14 kV 20 kV

14 kV 20 kV 14 kV 20 kV

28 kV 40 kV 28 kV 40 kV

28 kV 40 kV 28 kV 40 kV

10% Duty Cycle

V

(Peak Pulse)

25 kV 36 kV 25 kV 36 kV

20% Duty Cycle

V

(Peak Pulse)

23 kV 33 kV 23 kV 33 kV

30% Duty Cycle

V

(Peak Pulse)

18 kV 28 kV 18 kV 28 kV

50% Duty Cycle

1

Voltage readings are based on a thermal time constant of 30 minutes with

no more than a 60_ internal temperature rise. Internal component heating

is not to exceed 4 W at less than 30 minutes or 2 W at greater than

30 minutes. If the 4 W limit is exceeded in less than 30 minutes, then a

cool-down period of up to 2.5 hours is required for any further probe use.

2

Voltage ratings are based on a thermal time constant of 30 minutes.

3

The maximum pulse duration must not exceed 100 ms (see the derating

chart in Figure 1- 5 on page 1- 13).

4

RMS=Root Mean Square=rms=The square root of the average of the sum of

Ꭹ

ᒑ

the squares of the instantaneous voltage in one cycle = .

5

RMS=(1/2 Peak V @ 25% DF)=(500 Vpk2)=250 V

6

RMS=[(V pk)2(DF)]

1/2

rms

(fxi)2ፒn

(DF = Duty Factor)

1- 10

P6015A Instruction Manual

Page 25

In Detail

The maximum input voltage of 20 kV (DC + peak AC) is derated at

frequencies above 460 kHz (See Figure 1--4 on page 1--12).

The maximum peak pulse of 40 kV (which must never exceed

20 kV

) is derated under the following conditions:

rms

H Duty cycles greater than 10% or durations longer than 100 ms

(Figure 1--5). Duty cycle is the ratio of pulse width to signal

period, expressed as a percentage.

H Altitudes higher than 8000 feet (2440 m). See tables 1--3 and

1--4.

H Relative humidity greater than 80% at 25° C, 70% at 35° C, or

30% at 50° C. See Tables 1--3 and 1--4.

H For voltages above Long Duration Line of Figure 1--5 on

page 1--13, the time e xposure is limited per Table 1-- 1 in any

2.5 hour period.

CAUTION. The ground lead is rated at 1 kV maximum. Make sure the

ground lead does not contact the probe tip or a high-voltage point on

the circuit under test.

NOTE. This probe is designed to take voltage measurements between

1.5 kV and 20 kV (DC + peak AC) and impulses up to 40 kV peak.

For taking voltage measurements below 1.5 kV, Tektronix makes a

variety of probes specifically for these applications.

P6015A Instruction Manual

1- 11

Page 26

In Detail

Maximum Displayed

Voltage-- 10 Foot Cable

Maximum

Input Voltage

Maximum Displayed

100 MHz10 MHz1MHz100 kMz10 kHz1kHz0.1

Voltage-- 25 Foot Cable

Maximum Input Voltage >1.5 kV

Sine Wave Frequency (100 kHz to 100 MHz)

>30 Minutes Duration

Maximum Input Voltage @

0.01

20 kV

10 kV

5kV

2kV

1kV

1.5 kV

Figure 1- 4: Maximum Input Voltage Derating (DC + Peak AC)

1- 12

P6015A Instruction Manual

Page 27

In Detail

40 kV

36 kV

33 kV

28 kV

20 kV

Maximum Voltage (peak)

10% Duty Cycle 100 ms on time

20%DutyCycle50msontime

30%DutyCycle40msontime

50%DutyCycle30msontime

100% Duty Cycle 100 ms on time

Figure 1- 5: Peak Pulse Derating

Probe Grounding

When making any measurement, use the probe ground connector to

form the basic two-terminal connection to the device under test.

CAUTION. The ground lead is rated at 1 kV maximum. Make sure the

ground lead does not contact the probe tip or a high-voltage point on

the circuit under test.

10 ms1ms

Duration

1sec100 ms

P6015A Instruction Manual

1- 13

Page 28

In Detail

NOTE. If you want to check the presence or absence of signals from

low-frequency equipment, and if the equipment is line-powered and

plugged into the same outlet system as the oscilloscope, then the

common three-wire ground system provides the signal ground return.

However, this indirect route adds inductance in the signal path,

which can produce ringing and noise on the displayed signal, and

therefore is not recommended.

Don’t assume that the ground in the circuit under test is the same as

the oscilloscope ground. Check the circuit ground by first attaching

the ground lead of the probe to a known earth ground, then touch the

probe tip to the point you think is ground. If there is any voltage

differential, then the point that the tip is connected to is not a valid

ground point. (Due to the 1000X attenuation of the P6015A, you

may have to increase the sensitivity of the oscilloscope in order to

see small voltage differentials.) Perform this check before you attach

the ground lead of the probe to a ground point on the circuit under

test. The oscilloscope ground should always be earth ground as long

as you are using the proper power cord and plug.

Ground Lead Inductance

When making any kind of absolute measurement, such as amplitude,

rise time or time delay measurements, use the shortest grounding

path possible.

1- 14

NOTE. Even with the shortest ground lead, probe capacitance and

ground lead inductance form a series-resonant circuit that has the

potential to ring. Such ringing oscillations depend on the high-frequency components of the transient you are measuring and will

distort the true waveform. The ability to see the ringing depends on

the oscilloscope bandwidth. The amount of displayed ringing can be

reduced by using the bandwidth limit function of the oscilloscope.

If you are going to be probing many different points in the same

circuit having signal frequencies less than 1 MHz, you can run a

ground wire from the circuit ground to the oscilloscope ground

terminal (if one is provided). Such a ground connection alleviates the

need to continually reconnect the probe ground lead.

P6015A Instruction Manual

Page 29

Probe Compensation

Short-Form Compensation Procedure

The short-form compensation procedure given in this section adjusts

for use of the probe on a different oscilloscope input or at a

drastically different temperature than that at which it was calibrated

(a difference greater than ±15_C). The adj ustments necessary under

these conditions are accessible through holes in the top cover of the

compensation box.

The long-form procedure is included in the Adjustments section of

Chapter 2. Use the long-form procedure when a part of the probe is

replaced, or when the probe has gone for a long time without

recompensation and cannot be compensated using the short-form

procedure. Should this become necessary, refer compe nsation to a

qualified service person.

The short-form procedure consists of three parts, which should be

performed in the order listed:

1. Adjust DC attenuation

In Detail

2. Adjust low-frequency compensation

3. Adjust transient response

Test Equipment Required. The test equipment listed in Table 1--2, or its

equivalent, is required for completion of this procedure. If equipment

is substituted, control settings or test equipment setup may need to

be altered. Any needed maintenance should be performed before

proceeding with compensation. Troubles that become apparent

during compensation should be corrected immediately.

P6015A Instruction Manual

1- 15

Page 30

In Detail

Table 1- 2: Test Equipment Required for Short-Form Adjustment

Item

Oscilloscope

Calibration

Generator

Minimum

Requirements

Input Impedance:1 MΩ

Sensitivity: 1 mV/div

Bandwidth: ≥100 MHz

Rise time: ≤10 ns

Repetition rate: 1 MHz

Recommended

Example Application

Tektronix 11402A

All adjustments

with 11A32 plugin, or Tektronix

TDS 460

Tektronix

PG 506A

1,2

All adjustments

Amplitude: ≥50 V

BNC Male-to-GR

Adapter

Tektronix

part number

All adjustments

017-0064-00

BNC 50 Ω

Termination

Tektronix

part number

011-0049-01

1

Oscilloscopes with less than 1mV/div sensitivity can be used while making

Transient

response

adjustment

most adjustments. However, because of the 1000X probe attenuation, the

system will not display sufficient defl ectio n for optimum adjustment of

transient response unless a calibration generator having higher amplitude

output is substituted.

2

Requires TM 500 or TM 5000 Series Power Module or equivalent.

1- 16

P6015A Instruction Manual

Page 31

In Detail

DC Attenuation

1. Connect the P6015A compensation box to the oscilloscope.

2. Connect a BNC male-to-GR adapter to the calibration generator

amplitude output. Connect the P6015A ground lead clip to the

outer fin of the GR connector.

WARNING. The calibration generator produces dangerous voltages

during these procedures. To avoid electrical shock, be careful not to

touch the GR center conductor or exposed portions of the probe tip

while the generator is on.

3. Insert the tip of the P6015A into the GR center conductor.

4. Set the calibration generator to standard amplitude output of

50 Volts. This setting on a PG 506A produces a 1 kHz square

wave.

5. Set the oscilloscope time base to display 500 s/div, and set the

vertical deflection to 10 mV/div (10 V/div when using the

readout option).

6. Center the waveform on the screen.

7. Adjust DC ATTEN (R9) for five divisions. Use the trailing portion

of the square wave if the leading corner is not flat.

P6015A Instruction Manual

1- 17

Page 32

In Detail

Low-Frequency Compensation

1. Set the calibration generator to high amplitude output, and set the

period to 1 ms. Set the pulse amplitude to display five divisions.

2. Set the oscilloscope time base to display 200 s/div.

3. Center the waveform on the screen.

4. Adjust LF COMP (C5) so that the leading corner of the square

wave is level with the trailing corner.

5. Adjust MID 1 (C1) to flatten the area 200 s from the leading

corner. Refer to Figure 1-- 6 to determine the zones affected by

this and the following adjustments.

200 s

Mid 1

100 s

Mid 2

50 s

Mid 3

Figure 1- 6: Zones Affected by Compensation Adjustments

1- 18

P6015A Instruction Manual

Page 33

In Detail

6. Adjust MID 2 (C2) to flatten the area 100 s from the leading

corner.

7. Adjust MID 3 (C4) to flatten the area 50 s from the leading

corner.

Some interaction exists between the LF COMP, MID 1, MID 2,and

MID 3 adjustments. Steps 4 through 7 may have to be repeated

several times to achieve optimum flatness of the square wave.

Transient Response

1. Set the calibration generator pulse amplitude to minimum.

2. Set the calibration generator output to a square wave with rise

time ≤10 ns. If you are using a PG 506A, do this by inserting a

50 Ω termination between the amplitude output and the BNC

male-to-GR adapter.

3. Set the oscilloscope time base to display 100 ns/div. Set the

oscilloscope vertical deflection to 1 mV/div (1 V/div when using

the readout option).

4. Set the calibration generator period to 1 s, and set the pulse

amplitude to display five divisions.

5. Center the waveform on the screen.

6. Adjust HF COMP (R6) for overall flatness of the front corner.

P6015A Instruction Manual

1- 19

Page 34

In Detail

Caring for the Probe

Follow these guidelines to prolong the life of your probe:

H Observe the time and temperature specifications for this product

shown in the Maximum Input Voltage Chart on page 1--4.

H Don’t connect a probe ground lead to elevated (“hot” ) circuitry.

The resultant damage is not covered by probe warranties.

H Don’t measure voltages in excess of the probe’s maximum

voltage rating.

H Don’t mount the probe into fixtures by its nonmetallic front end.

Mount the probe only by its metallic shield portion.

H Don’t attempt to remove the rubber cushioning ring from the

inner body assembly of the probe head.

H Don’t attempt to disassemble the inner body assembly.

H When you are not using the probe, place the probe and its

accessories in the case provided.

H Don’t use the probe to scrape through insulation, pry compo-

nents, or to move components.

1- 20

H When necessary, clean the probe with a damp cloth.

P6015A Instruction Manual

Page 35

Other Considerations

Component heating caused by changes in ambient temperature or

high voltage will cause a slight change in calibration accuracy.

With high-frequency signals, such as fast transients, ringing may

occur which will distort the actual waveform. This ringing is due to

resonance occurring between the capacitance of the probe and the

ground lead inductance.

Problems Encountered Using the Probe

If you experience problems making measurements with the probe,

consider the following remedies:

H Check low frequency compensation and adjust as necessary.

H If you have the probe connected to an oscilloscope, check the

front panel controls of the oscilloscope to verify that the signal is

displayed properly.

H Use a ground lead.

In Detail

H Don’t use ground leads that are too long (causing ringing).

H Because of probe characteristics, small differences in input

capacitance between oscilloscopes and scope channels can affect

the voltage measurement. The probe compensation should be

checked each time the probe is connecte d to a different input

channel or to a different oscilloscope.

P6015A Instruction Manual

1- 21

Page 36

In Detail

1- 22

P6015A Instruction Manual

Page 37

Specifications

Warranted Characteristics

This section lists the various warranted characteristics that describe

the P6015A High Voltage Probe. Included are warranted electrical

and environmental characteristics.

Warranted characteristics are described in terms of quantifiable

performance limits which are warranted.

The electrical characteristics listed in Table 1--3 apply under the

following conditions:

H The probe and instrument with which it is used must have been

calibrated at an ambient temperature of between +20 °Cand

+30 °C.

H The probe and instrument must be in an environment whose

limits are described in Table 1-3.

H The probe and instrument must have had a warm-up period of at

least 20 minutes before applying elevated voltages.

P6015A Instruction Manual

1- 23

Page 38

Specifications

Table 1- 3: Warranted Electrical Characteristics

Characteristic Information

Maximum input voltage

DC + peak AC

1

1.5 kV to 20 kV. See frequency derating curve in

Figure 1--4. (DC plus peak AC rating is limited to

temperatures below 35° C.)

Peak pulse 40 kVa(Never exceed 20 kV rms)

Duty cycle derating -- 100 ms maximum duration at 10%

maximum duty cycle. See duration and duty cycle

derating curve in Figure 1--5.

Altitude derating -- Peak pulse derated linearly from

40 kV at 8000 feet (2440 m) to 30 kV at 15,000 feet

(4570 m) altitude.

Relative Humidity (RH) derating -- Voltage derated with

increasing temperature and relative humidity (see

Figure 1--7).

Bandwidth (--3 dB) Test conditions: Test oscilloscope bandwidth must be

≥100 MHz, Z

10-ft cable

25-ft cable

Rise Time

10-ft cable

25-ft cable

2

75 MHz

25 MHz

≤4.67 ns (calculated from bandwidth)

≤14 ns (calculated from bandwidth)

DC attenuation 1000:1 ±3% (Excluding

oscilloscope error)

source

=25Ω

Test conditions: Oscilloscope input resistance

mustbe1MΩ ±2%

1

Characteristic not checked in manual

2

Tr(ns) = .35/BW (MHz)

1- 24

P6015A Instruction Manual

Page 39

Table 1- 4: Warranted Environmental Characteristics

Characteristic Information

Temperature

Nonoperating

Operating

DC + peak AC

-- 5 5 _Cto+75_C(--67_F to +167_F)

0_Cto+35_ C(+32_ Fto+95_F)

Specifications

Peak Pulse

Humidity

Nonoperating / Operating 95% relative humidity at +50 °C (+122 °F). See

Maximum altitude

Nonoperating 15,000 m (50,000 ft)

Operating 4,600 m (15,000 ft)

Vibration (random)

Nonoperating 3.48 g rms from 5 to 500 Hz. Ten minutes on each axis.

Operating 2.66 g rms from 5 to 500 Hz. Ten minutes on each axis.

Shock (nonoperating) 500 g, half sine, 0.5 ms duration, 18 shocks total in three

Time Limitations

Less than 70% of Rated

Input Voltage at 0--35_C

Greater than 70% of

Rated Input Voltage at

0--35_C

35--50_C

0_Cto+50_ C(+32_ F to +122_F)

(See Table 1--1 on page 1--10 and Time Limitations

Specification below)

Figure 1--7 for derating characteristics.

Peak pulse voltage derated from 40 kV at 8000 feet

(2440 m) to 30 kV at 15,000 feet (4570 m).

axis.

No time limit

30 minutes maximum

in any 2.5 hour period

15 minutes maximum

in any 2.5 hour period

P6015A Instruction Manual

1- 25

Page 40

Specifications

25 °C

35 °C

50 °C

0% 30% 70% 80%

40 kV

40 kV

40 kV

35 kV

Relative Humidity

Figure 1- 7: Humidity Derating Chart

100 M

10 M

1M

Phase Angle

100 k

Probe Impedance

10 k

1k

10

100 1 k 10 k 100 k 1 M 10 M 100 M

Frequency

35 kV

35 kV

25 kV

20 kV

95%

0°

-- 1 0 °

-- 2 0 °

-- 3 0 °

-- 4 0 °

-- 5 0 °

-- 6 0 °

-- 7 0 °

-- 8 0 °

-- 9 0 °

Figure 1- 8: Typical Input Impedance and Phase

1- 26

P6015A Instruction Manual

Page 41

Typical and Nominal Characteristics

This section lists the various typical and nominal characteristics that

describe the P6015A High Voltage Probe.

Nominal characteristics are determined by design and/or inspection.

Nominal characteristics do not have tolerance limits.

Typical characteristics are described in terms of typical or average

performance. Typical characteristics are not warrante d.

Table 1- 5: Typical Electrical Characteristics

Characteristic Information

Specifications

Input resistance

Input capacitance ≤3 pF when probe is properly LF compensated. See

LF compensation range 7pFto49pF

Aberrations 25% p-p for the first 200 ns on a 100 MHz oscilloscope

Temperature coefficient of DC

attenuation

Voltage coefficient of DC attenuation

Delay time 10 ft cable: 14.7 ns

1

Resistor temperature rose 60_Cat20kVrmsovera30minuteperiod.

100 MΩ ±2%. See Figure 1-- 8 for typical input

impedance curve.

Figure 1--8 for typical input impedance curve.

when used with 10 in (25.4 cm) ground lead.

<10% p-p typical after first 200 ns; ±5% after the first

400 ns.

0.006% per degree C

0.018% per kV

25 ft cable: 33.3 ns

1

P6015A Instruction Manual

1- 27

Page 42

Specifications

Table 1- 6: Nominal Mechanical Characteristics

Characteristic Information

Diameter (probe body) 8.9 cm (3.5 in) maximum

Length (probe body) 34.5 cm (13.6 in)

Length (cable)

10-ft cable 3.05 m (10 ft)

25-ft cable 7.62 m (25 ft)

Compensation box 2.5 × 4.1 × 8.3 cm (1 × 1.6 × 3.25 in)

Net weight (probe assembly)

10-ft cable 0.66 kg (1.47 lbs)

25-ft cable 0.75 kg (1.66 lbs)

Shipping weight (including

accessories)

10-ft cable 2.85 kg (6.27 lbs)

25-ft cable 2.93 kg (6.46 lbs)

1- 28

P6015A Instruction Manual

Page 43

WARNING

The following servicing instructions are for use only by

qualified personnel. To avoid injury, do not perform any

servicing other than that stated in the operating instructions

unless you are qualified to do so. Refer to all safety

summaries before performing any service.

Page 44

Page 45

Service Information

Page 46

Page 47

Performance Verification

The performance verification procedure verifies that the P6015A

performs as described in the Specifications section of Chapt er 1. This

procedure can also be used as an acceptance check. The procedure is

given in the next section, Adjustments.

The performance verification consists of the long-form compensation procedure with an additional step to check bandwidth and rise

time:

1. Check DC attenuation and adjust if necessary

2. Check low-frequency compensation and adjust if necessary

3. Check transient response and adjust if necessary

4. Check bandwidth and calculate rise time

P6015A Instruction Manual

2- 1

Page 48

Performance Verification

2- 2

P6015A Instruction Manual

Page 49

Adjustments

Recalibration ordinarily is necessary only if the P6015A is being

used on a different oscilloscope input or at a drastically different

temperature than that at which it was calibrated (a difference greater

than ±15_C). The adjustments necessary for recalibration under

these conditions are accessible through holes in the top cover of the

compensation box. The basic probe compensation procedure is given

in the In Detail section of Chapter 1 in this manual .

Limits, tolerances, and waveforms in this procedure are given as

adjustment guides. Refer to the Specifications section of this manual

for actual performance criteria.

Any needed maintenance should be performed before proceeding

with compensation. Troubles that become apparent during

compensation should be corrected immediately.

Test Equipment Required

The test equipment listed in Table 2--1 (or its equivalent) is required

for completion of this procedure. If equipment is substituted, control

settings or test equipment setup may need to be altered.

Preparation

Warm up the test equipment at least 20 minutes to stabilize it before

performing the checks and adjustments.

P6015A Instruction Manual

2- 3

Page 50

Adjustments

Table 2- 1: Test Equipment Required for Long-Form Adjustment

Item

Oscilloscope

Calibration

Generator

Minimum

Requirements

Input Impedance:1 MΩ

Sensitivity: 1 mV/div

Bandwidth: ≥100 MHz

Rise time: ≤10 ns

Repetition rate: 1 MHz

Recommended

Example Application

Tektronix 11402A

with 11A32 plug-

All checks and

adjustments

in, or Tektronix

TDS 460

Tektronix

PG 506A

1,2

All checks and

adjustments other

than bandwidth

Amplitude: ≥50 V

Leveled Sine

Wave Generator

BNC Male-to-GR

Adapter

Range: 50 kHz to 75 MHz

Amplitude: ≥5V

Tektronix SG 5032Bandwidth check

Tektronix

part number

All checks and

adjustments

017-0064-00

BNC 50 Ω

Termination

Tektronix

part number

011-0049-01

Transient

response check

and adjustment,

bandwidth check

1

Oscilloscopes with less than 1 mV/div sensitivity can be used while

making most checks and adjustments. However, because of the 1000X

probe attenuation, the system will not display sufficient deflection for

optimum adjustment of transient response unless a calibration generator

having higher amplitude output is substituted.

2

Requires TM 500 or TM 5000 Series Power Module or equivalent.

2- 4

P6015A Instruction Manual

Page 51

Long-Form Procedure

The long-form compensation procedure typically should be

necessary only under these conditions:

H the probe head or compensation box has been replaced

H the probe has come out of compensation because of aging effects

over a prolonged period

Access to adjustments in this procedure requires removal of the top

half of the compensation box (Figure 2--1). When reinstalling the

top, note that the edges are asymetrical and that the top will seat

securely only when it is correctly oriented. This ensures that the

adjustment holes are properly aligned with the circuit board.

Adjustments

Figure 2- 1: Access to Long-Form Adjustments

P6015A Instruction Manual

2- 5

Page 52

Adjustments

The long-form adjustment procedure consists of three parts which

must be performed in this order:

1. DC attenuation check and adjustment

2. Low-frequency compensation check and adjustment

3. Transient response check and adjustment

A fourth step, verification of bandwidth and rise time, is performed

only when this procedure is used as a performance verification

procedure.

DC Attenuation

1. Connect the P6015A compensation box to the oscilloscope.

2. Connect a BNC male-to-GR adapter to the calibration generator

WARNING. The calibration generator produces hazardous voltages

during these procedures. To avoid electrical shock, be careful not to

touch the GR center conductor or exposed portions of the probe tip

while the generator is on.

high/standard amplitude output. Connect the P6015A ground lead

to the outer fin of the GR connector.

2- 6

3. Insert the P6015A tip into the GR center conductor.

4. Set the calibration generator to standard amplitude output of

50 Volts. This setting on a PG 506A produces a 1 kHz square

wave.

5. Set the oscilloscope time base to display 500 s/div, and set the

vertical deflection to 10 mV/div (10 V/div when using the

readout option).

6. Center the waveform on the screen.

7. The waveform amplitude should be between 4.85 and 5.15

divisions. If necessary, adjust R9 for five divisions. Use the

trailing portion of the square wave if the leading corner is not

flat. See Figure 2--2 for the location of this and other adjustments.

P6015A Instruction Manual

Page 53

Adjustments

C7

R9

DC

ATTEN

R7

C4

MID 3

R6

HF

COMP

C5

LF

COMP

R5

C2

R4

C1

MID 1MID 2

R2

Figure 2- 2: Adjustment Locations

Low-Frequency Compensation

1. Set the calibration generator to high amplitude output, and set the

period to 1 ms. Set the pulse amplitude to display five divisions.

2. Set the oscilloscope time base to display 200 s/div.

3. Center the waveform on the screen.

4. The leading corner of the square wave should be level with the

trailing corner. If necessary, adjust C5.

5. The top of the waveform should be flat to within ±5% (±1.25 mi-

nor divisions). If necessary, perform steps 6 through 8.

P6015A Instruction Manual

2- 7

Page 54

Adjustments

200 s

R2,C1

100 s

R4,C2

50 s

R5,C4

Figure 2- 3: Periods Affected by Compensation Adjustments

2- 8

6. Adjust R2 and C1 to flatten the area 200 s from the leading

corner. Refer to Figure 2-- 3 to locate the zones affected by the

adjustments in this and the following steps.

NOTE. Figure 2--3 shows an idealized waveform. The displayed

waveform will include some ground lead ringing.

7. Adjust R4 and C2 to flatten the area 100 s from the leading

corner.

8. Adjust R5 and C4 to flatten the area 50 s from the leading

corner.

Adjustments R2, R4, R5, C1, C2, C4, and C5 interact. Steps 4 and 6

through 8 may have to be repeated several times to achieve optimum

flatness.

P6015A Instruction Manual

Page 55

Adjustments

Transient Response

1. Set the calibration generator pulse amplitude to minimum.

2. Set the calibration generator to output a square wave with rise

time ≤10 ns. If you are using a PG 506A, do this by inserting a

50 Ω termination between the high/standard amplitude output

and the BNC male-to-GR adapter.

3. Set the oscilloscope time base to display 100 ns/div. Set the

oscilloscope vertical deflection to 1 mV/div (1 V/div when using

the readout option).

4. Set the calibration generator period to 1 s, and set the pulse

amplitude to display five divisions.

5. Center the waveform on the screen.

6. The waveform should be flat overall, and the front corner should

be sharp without overshoot. If necessary, perform step s 7 and 8.

7. Adjust R6 for overall flatness of the front corner.

8. Adjust R7 and C7 for a sharp front corner without overshoot.

There is interaction between R6, R7, and C7. You may have to

repeat steps 7 and 8 to obtain optimum response.

P6015A Instruction Manual

2- 9

Page 56

Adjustments

Bandwidth and Rise Time Verification

The following check is part of the performance verification

procedure. You may omit it if you are performing the adjustment

procedure.

1. Substitute the sine wave generator for the calibration generator.

2. Set the oscilloscope vertical deflection to 1 mV/div (1 V/div

3. Set the generator frequency to 50 kHz, and set the amplitude to

4. Increase the generator frequency to:

when using the readout option), and set the time base to display

10 s/div.

display five divisions peak-to-peak.

H 75 MHz for a 10 ft. (3 m) cable.

H 25 MHz for a 25 ft. (7 m) cable.

while observing the oscilloscope display. Set the generator

frequency to the point of lowest amplitude at or below

75 MHz (10 ft. cable) or 25 MHz (25 ft. cable).

2- 10

5. The amplitude of the waveform should be at least 3.5 divisions

(0.707 of the amplitude in Step 3).

This procedure does not check rise time directly, but it can be

approximated by the ratio t

= 0.35 / bandwidth.

r

P6015A Instruction Manual

Page 57

Maintenance

The P6015A ordinarily requires very little maintenance except for

occasional cleaning. This section provides procedures for preventive

maintenance, corrective maintenance, and removal and replacement

of parts.

Preventive Maintenance

Preventive maintenance for the P6015A consists of cleaning and

visual inspection.

CAUTION. Do not attempt to remove the rubber cushioning ring from

the front of the probe. The ring is bonded to the probe body, and

removal of the ring may cause poor probe response or probe damage.

Cleaning

Accumulation of dirt on the probe body can provide a conduction

path that will result in electrical failure. The following procedures

describe how to clean the probe.

CAUTION. To prevent damage to the probe, do not expose it to sprays,

liquids, solvents or chemical cleaning agents. Avoid using chemicals

that contain benzine, benzene, toluene, xylene, acetone, or similar

solvents.

Probe Body. The part of the probe that is most vulnerable to arcing is

the space between the probe tip and the shield sleeve as shown in

Figure 2--4 on page 2--14. Inspect this area for dirt accumulation.

When necessary, clean the probe with a dry, lint-free cl oth or a

soft-bristle brush. If dirt remains, use a soft cloth or swab dampened

with a 75% isopropyl alcohol solution. A swab is useful for cleaning

narrow spaces on the probe, use only enough solution to dam pen the

P6015A Instruction Manual

2- 11

Page 58

Maintenance

swab or cloth. Do not use abrasive compounds on any part of the

probe.

Compensation Box. Cleaning the interior of the compensation box

should seldom be necessary. If cleaning is necessary, blow off any

accumulated dust with dry, low-velocity air stream. Remove any dirt

that remains with a soft brush. A cotton-tipped swab is useful for

cleaning in narrow spaces or for cleaning the circuit components.

Visual Inspection

Inspect the circuitry within the compensation box periodically for

loosely-seated or heat-damaged components. The corrective action

for most visible defects is obvious; however, particular care must be

taken if heat-damaged parts are found. Overheating usually indi cates

other problems in the probe or misuse; therefore, correct the cause of

overheating to prevent recurrence of the damage.

Troubleshooting and Repair

There are two repair options you should consider:

2- 12

H Tektronix Repair — You can ship your P6015A probe to us for

repair.

H Customer Repair — You can choose to repair the probe yourself.

If you decide to repair the probe yourself, order the replacement

part from your local Tektronix, Inc. service center or representative. See Replaceable Parts for part numbers.

Troubleshooting

Before using the probe, make sure it is properly compensated.

Compensate the probe to the vertical channel of the oscilloscope you

plan to use. Do not compensate it on one channel, then use it on

another. Also, check the vertical and horizontal system controls on

your oscilloscope to ensure that they are properly set to display the

signal from the device under test.

P6015A Instruction Manual

Page 59

Mechanical Disassembly and Assembly

This section contains mechanical procedures to aid in the replacement of parts within the probe head and compensation box

assemblies.

NOTE. Perform the long-form compensation procedure after

replacing a part.

Probe Head

The probe head consists of the parts shown in Figure 2--4. Refer to

that figure while performing the following steps to replace the inner

body or other parts.

Do Not Remove Rubber Ring

CAUTION. Do not attempt to remove the rubber cushioning ring at

the front of the inner probe body or the probe may be damaged and

its high voltage performance degraded. This ring is firmly attached

with an adhesive and is not designed to be removed.

Maintenance

Do Not Disassemble Inner Body

CAUTION. Do not attempt to disassemble the inner body assembly.

There are no user serviceable components in the inner body

assembly, and attempting to open the inner body assembly may result

in damage to its internal structure.

P6015A Instruction Manual

2- 13

Page 60

Maintenance

Handle

Shield Sleeve

Cushion Ring

Inner Body

Tip

2- 14

Outer Body

Figure 2- 4: Removal and Repl acement of Probe Head

P6015A Instruction Manual

Page 61

Maintenance

Removal.

1. Unscrew the probe tip.

2. Unscrew the plastic probe handle from the outer body, and slide

the handle back on the cable. Slide the plastic outer body off the

front of the assembly.

3. Disconnect the cable BNC from the assembly.

Replacement.

1. Insert the ground lead connector through the slot in the outer

body. Insert the inner body assembly into the outer body. You

may have to lift up and forward on the ground lead to allow the

assembly to pass.

2. Connect the cable to the probe head BNC.

3. Screw the handle in place.

4. Replace the tip.

P6015A Instruction Manual

2- 15

Page 62

Maintenance

Compensation Box

The compensation box assembly contains three parts that can be

replaced individually: the compensation box/circuit board assembly,

the cable, and the BNC that connects to the oscilloscope or other

instrument. Follow these procedures to replace either the cable or the

BNC, or to install them on a new compensation box. The procedures

are the same in each case.

Removal.

1. Remove the top half of the compensation box.

2. Unsolder the cable (or BNC) center conductor.

3. Unscrew the cable bushing (or BNC).

Replacement.

1. Screw the cable bushing (or BNC) into the end plate.

2. Form the conductor to the solder pad on the circuit board, then

3. Replace the top half of the compensation box. Note that the

solder the conductor in place.

edges are asymmetrical (as shown previously in Figure 2--1) and

that the top will seat securely only when it is correctly oriented.

This ensures that the adjustment holes are properly aligned with

the circuit board.

2- 16

P6015A Instruction Manual

Page 63

Replaceable Parts

This section contains a list of the components that are replaceable for

the P6015A. As described below, use this list to identify and order

replacement parts.

Parts Ordering Information

Replacement parts are available from or through your local

Tektronix, Inc. service center or representative.

Changes to Tektronix instruments are sometimes made to accommodate improved components as they become available and to give you

the benefit of the latest circuit improvements. Therefore, when

ordering parts, it is important to include the following information in

your order:

H Part number

H Probe type or model number, including option numbers

H Probe serial number

H Probe modification number, if applicable

The P6015A is serviced by module replacement. In some cases you

may exchange your module for a remanufactured module. These

modules cost significantly less than new modules and meet the same

factory specifications. For more information, contact you local

Tektronix, Inc. service center or representative.

If a part you order has been replaced with a different or improved

part, your local Tektronix service center or representative will

contact you concerning any change in the part number.

Change information, if any, is located at the rear of this manual.

P6015A Instruction Manual

2- 17

Page 64

Replaceable Parts

Using the Replaceable Parts List

The tabular information in the Replaceable Parts List is arranged for

quick retrieval. Understanding the structure and features of the list

will help you find all the information you need for ordering

replacement parts.

Item Names

In the Replaceable Parts List, an Item Name is separated from the

description by a colon (:). Because of space limitations, an Item

Name may sometimes appear as incomplete. For further Item Name

identification, U.S. Federal Cataloging Handbook H6-1 can be used

where possible.

Abbreviations

Abbreviations conform to American National Standards Institute

(ANSI) standard Y1.1

2- 18

P6015A Instruction Manual

Page 65

Replaceable Parts

7

6

11

4

3

5

8

9

10

2

1

Figure 2- 5: P6015A Exploded View

2- 19P6015A Instruction Manual

Page 66

Replaceable Parts

CLIP,ELECTRICAL:ALLIGATOR,2.5 L,W/PLUG & COVER

CONN,RF PLUG:BNC,;50 OHM,MALE,STR,

FEEDTHRU/FRONT PNL,1.555 L,0.285 L 0.375-- 32 THD,0.5L

22 AWG TAB,0.384 DIA MTG

STANDARD ACCESSORIES

BODY,PROBE:OUTER,FINISHED

--2 196-- 3363--00 1 LEAD ELECTRICAL:GROUND,STRD,18 AWG,10.0L

BODY,PROBE:OUTER,FINISHED

1

B019999 1

B010100

B020000

204-- 1106-- 01

--3 204-- 1106-- 00

--4 206-- 0116-- 00 1 TIP,PROBE:

--5 119--4636-- 02 1 PROBE,HV:75MHZ,10 FT;.COMP BOX ASSY

1

--6 367-- 0438--00 1 HANDLE,PROBE:6.0 L,NYLON,GRAY

--7 174-- 2579--00 1 CABLE ASSY,RF:50 OHM COAX,10FT L

--8 131-- 0602--00

STANDARD (10 FT CABLE- NO READOUT)

Name & Description

Qty

Dscont

Serial No. Effective

Part No.

Tektronix

Fig. &

Index No.

--1 344-- 0461--00 1 CLIP,ELEC:CROCODILE,82MM L,4MM

2--5--

CASE,CRYG,PROBE:

1

016-- 1147-- 00

MANUAL,TECH:INSTR,P6015A

1

B019999 1

B010100

070-- 8223--05

--9 344-- 0005--00

TIP,HOOK:PROBE

1

B020000

206-- 0463--00

--10 134-- 0016--00 B020000 1 PLUG,TIP:BANANA,10-- 32 INT THD END

--11 204-- 2202--02 1 BODY ASSY,PROBE; P6015A

2- 20 P6015A Instruction Manual

Page 67

Replaceable Parts

CLIP,ELECTRICAL:ALLIGATOR,2.5 L,W/PLUG & COVER

CONN,RCPT ASSY:ELEC WITH READOUT

STANDARD ACCESSORIES

BODY,PROBE:OUTER,FINISHED

--2 196-- 3363--00 1 LEAD ELECTRICAL:GROUND,STRD,18 AWG,10.0L

BODY,PROBE:OUTER,FINISHED

1

B019999 1

B010100

B020000

204-- 1106-- 01

--3 204-- 1106-- 00

1

--4 204-- 0116-- 01 1 BODY,VAR RES:PLASTIC

--5 119--4636-- 03 1 PROBE,HV:10 FT,W/READOUT;.COMP BOX ASSY

--6 367-- 0438--00 1 HANDLE,PROBE:6.0 L,NYLON,GRAY

--7 174-- 2579--00 1 CABLE ASSY,RF:50 OHM COAX,10FT L

--8 131-- 5320--00

OPTION 1R(10FT CABLE- W/READOUT)

Qty

Dscont

Serial No. Effective

Part No.

Tektronix

Fig. &

Index No. Name & Description

--1 344-- 0461--00 1 CLIP,ELEC:CROCODILE,82MM L,4MM

2--5--

CASE,CRYG,PROBE:

1

016-- 1147-- 00

MANUAL,TECH:INSTR,P6015A

1

B019999 1

B010100

070-- 8223--05

--9 344-- 0005--00

TIP,HOOK:PROBE

1

B020000

206-- 0463--00

--10 134-- 0016--00 B020000 1 PLUG,TIP:BANANA,10-- 32 INT THD END

--11 204-- 2202--02 1 BODY ASSY,PROBE; P6015A

2- 21P6015A Instruction Manual

Page 68

Replaceable Parts

CLIP,ELECTRICAL:ALLIGATOR,2.5 L,W/PLUG & COVER

CONN,RCPT ASSY:ELEC WITH READOUT

STANDARD ACCESSORIES

BODY,PROBE:OUTER,FINISHED

--2 196-- 3363--00 1 LEAD ELECTRICAL:GROUND,STRD,18 AWG,10.0L

BODY,PROBE:OUTER,FINISHED

1

B019999 1

B010100

B020000

204-- 1106-- 01

--3 204-- 1106-- 00

--4 206-- 0116-- 00 1 TIP,PROBE:

--5 119--4636-- 27 1 PROBE,HV:25 FT,W/READOUT;.COMP BOX ASSY

1

--6 367-- 0438--00 1 HANDLE,PROBE:6.0 L,NYLON,GRAY

--7 -- -------------- 1 CABLE ASSY,RF:31 OHM COAX,25FT L

--8 131-- 5320--00

OPTION 2R(25FT CABLE- W/READOUT)

Qty

Dscont

Serial No. Effective

Part No.

Tektronix

Fig. &

Index No. Name & Description

--1 344-- 0461--00 1 CLIP,ELEC:CROCODILE,82MM L,4MM

2--5--

CASE,CRYG,PROBE

1

016-- 1147-- 00

MANUAL,TECH:INSTR,P6015A

1

070-- 8223--05

TIP,HOOK:PROBE

B019999 1

B010100

--9 344-- 0005--00

1

B020000

206-- 0463--00

--10 134-- 0016--00 B020000 1 PLUG,TIP:BANANA,10-- 32 INT THD END

--11 204-- 2202--02 1 BODY ASSY,PROBE; P6015A

2- 22 P6015A Instruction Manual

Page 69

Replaceable Parts

CLIP,ELECTRICAL:ALLIGATOR,2.5 L,W/PLUG & COVER

CONN,RF PLUG:BNC,;50 OHM,MALE,STR,

FEEDTHRU/FRONT PNL,1.555 L,0.285 L 0.375-- 32 THD,0.5L

22 AWG TAB,0.384 DIA MTG

STANDARD ACCESSORIES

BODY,PROBE:OUTER,FINISHED

--2 196-- 3363--00 1 LEAD ELECTRICAL:GROUND,STRD,18 AWG,10.0L

BODY,PROBE:OUTER,FINISHED

1

B019999 1

B010100

B020000

204-- 1106-- 01

--3 204-- 1106-- 00

--4 206-- 0116-- 00 1 TIP,PROBE:

--5 119--4636-- 28 1 PROBE,HV:25 FT,W/NO READOUT;.COMP BOX ASSY

1

--6 367-- 0438--00 1 HANDLE,PROBE:6.0 L,NYLON,GRAY

--7 -- -------------- 1 CABLE ASSY,RF:31 OHM COAX,25 FT L

--8 131-- 0602--00

OPTION 25 (25FT CABLE- NO READOUT)

Qty

Dscont

Serial No. Effective

Part No.

Tektronix

Fig. &

Index No. Name & Description

--1 344-- 0461--00 1 CLIP,ELEC:CROCODILE,82MM L,4MM

2--5--

CASE,CRYG,PROBE:

1

016-- 1147-- 00

MANUAL,TECH:INSTR,P6015A

1

B019999 1

B010100

070-- 8223--05

--9 344-- 0005--00

TIP,HOOK:PROBE

1

B020000

206-- 0463--00

--10 134-- 0016--00 B020000 1 PLUG,TIP:BANANA,10-- 32 INT THD END

--11 204-- 2202--02 1 BODY ASSY,PROBE; P6015A

2- 23P6015A Instruction Manual

Page 70

Replaceable Parts

2- 24 P6015A Instruction Manual

Page 71

Index

Page 72

Page 73

Index

A

accessories, standard, 1-- 4

adjustments

access, 2--5

DC attenuation, 2--6

long-form procedure, 2--5

low-frequency compensation,

2--7

preparation, 2--3

test equipment required, 2--3, 2--4

transient response, 2--9

C

calibration, period, 2--3

characteristics, 1-- 21, 1-- 25

aberrations, 1--25

altitude, 1-- 23

bandwidth, 1-- 22

calibration temperature, 1--21

DC attenuation, 1--22

delay time, 1--25

general, 1--1

humidity, 1-- 23

input capacitance, 1--25

input impedance, 1--24

input resistance, 1--25

low-frequency compensation,

1--25

maximum input voltage, 1--9,

1--22

frequency derating curve, 1--10

peak pulse derating, 1--11

mechanical, 1-- 26

operations, 1-- 21

rise time, 1--22

shock, 1--23

temperature, 1--23, 1-- 25

vibrations, 1-- 23

voltage, 1-- 25

warm-up period, 1--21

compensation box

assembly, 2--16

cleaning, 2-- 12

description, 1-- 1

Contacting Tektronix, ix

crocodile clip, 1--6

cushioning ring, 2--11

D

distortion, high-frequency, 1--19

G

general information, 1--1

ground lead

distortion, 1-- 19

inductance, 1-- 12

lead length, 1--12

ringing, 1--19, 2--8

safety, 1--9, 1-- 11

M

maintenance

assembly, 2--13

cleaning, 2-- 11

general, 2--11

probe care, 1--18

probe cleaning, 1--18

solvents, 1--18

visual inspection, 2-- 12

P6015A Instruction Manual

Index- 1

Page 74

Index

O

operation, guidelines, 1--7

options, 1--4

readout, 1--3, 1--8

P

performance verification, general,

2--1

Phone number, Tektronix, ix

probe

assembly, 1--5, 2-- 13, 2-- 14, 2-- 15

body, 1-- 1

cleaning, 2-- 11

probe compensation, 1--13

long-form, 1--13

short-form, 1--13

DC attenuation, 1--15

low-frequency, 1--16

transient response, 1--17

test equipment required, 1--13

probe grounding, 1--11

inductance, 1-- 12

power cord, 1--12

ringing, 1--12

voltage differential, 1--12

problems, 1-- 19

front-panel controls, 1--19

grounding, 1--19

input capacitance, 1--19

low frequency compensation,

1--19

Product support, contact informa-

tion, ix

R

repair, 2-- 12

replacement parts

abbreviations, 2-- 18

general, 2--17

item names, 2--18

ordering, 2--17

probe, 20

ringing

ground lead, 1--19

power cord, 1--12

S

Service support, contact informa-

tion, ix

solvents, 2--11

specifications. See characteristics

T

Tektronix, contacting, ix

temperature, considerations, 1--19

troubleshooting, general, 2--12

V

verification

bandwidth, 2-- 10

rise time, 2--10

Index- 2

P6015A Instruction Manual

Loading...

Loading...