Page 1

xx

P5960

High-Density D-MAX Probe

ZZZ

for TLA6400 Series Logic Analyzers

Instruction Manual

Revision A

Warning

The servicing instructions are for use by qualified personnel

only. To avoid personal injury, do not perform any servicing

unless you are qualified to do so. Refer to all safety summaries

prior to performing service.

www.tektronix.com

P077063700*

*

077-0637-00

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are c overed by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

D-Max is a registered trademark of Tektronix, Inc. MagniVu is a trademark of Tektronix, Inc.

cLGA is a registered trademark of Amphenol Intercon Systems, Inc.

Velcro is a registered trademark of Velcro Industries B.V.

Contacting Tektronix

Tektro ni

14150 SW Karl Braun Drive

P.O . Bo x 5 00

Beaverton, OR 97077

USA

For pro

x, Inc.

duct information, sales, service, and t echnical support:

In North America, call 1-800-833-9200.

World wi d e, visi t www.tektronix.com to find contacts in your area.

Page 3

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, modules and p roducts become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, with shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other than Tektronix representatives to install, repair or service the product;

Page 4

Page 5

Table of Contents

General safety summary ................ .................................. ................................ ......... v

Service safety summary.......................................................................................... vii

Compliance information ......................................................................................... viii

Environmental considerations .............................................................................. viii

Preface.............................................................................................................. ix

Related documentation ................................. ................................ ...................... ix

Operating basics ........................... ................................ .................................. ....... 1

Product description ......... ................................ ................................ ................... 1

P5960 probe accessory information ......................................................................... 2

Probe label overview ................. ................................ ................................ ......... 3

Apply the labels to the probe.... ................................ .................................. ........... 5

Probe connection overview ................................................................................... 7

Probe head handling guidelines .............................................................................. 7

Connect the probe to the instrument .............................. ................................ ........... 9

Connect the probes to the SUT................ .................................. ............................. 9

Dress the probe cables........................................................................................ 11

Store the probe head when not in use......................................... .............................. 12

Probe connection troubleshooting guidelines........................................ ...................... 12

Reference ....... ................................ ................................ .................................. .. 15

Clocks and qualifiers ... ................................ ................................ ...................... 15

Multiplexed buses . . .... .. ... . .... .. ... . .... .. ... . .... .. ... . .... .. ... . .... .. ... . .... .. ... . .... .. ... . .... .. ... . 16

High-Resolution timing ...................................................................................... 17

Range recognizers ...... ................................ .................................. .................... 17

Probe dimensions ............... .................................. ................................ ............ 18

Retention assembly dimensions and keepout areas ....... ................................ ................ 18

Retention assembly side-by-side and end-to layout dimensions......................................... 20

Retention post dimensions and keepout areas ............................................................. 20

Retention post side-by-side and end-to-end layout dimensions ......................................... 22

Signal routing ..................... ................................ .................................. .......... 23

Mechanical considerations................................................................................... 23

Electrical considerations ..................................................................................... 23

Probe footprint dimensions ................ ................................ ................................ .. 24

Via-in-Pad design considerations ........................................................................... 25

Probe pinout definition a nd channel assignment . . ... . ... . .... .. ... . ... . ... . ... . . . ... . ... . ... . ... . .... .. .. 27

Specifications...... ................................ ................................ ............................ 29

Maintenance........................................................................................................ 31

Probe calibration information ................... .................................. .......................... 31

Probe service strategy information.......................................................................... 31

Perform the functional check...... ................................ .................................. ........ 31

P5960 Logic Analyzer Probe Instruction Manual i

Page 6

Table of Contents

Inspect or clea

Replace the cLGA clip ....................................................................................... 32

Repackage the probe ............... ................................ ................................ .......... 33

Replaceable parts .......................... ................................ ................................ ........ 35

Parts ordering information......... .................................. ................................ ........ 35

Appendix A: Probe retention assembly installation information............. ................................ 37

Clean the co

Install the probe retention assembly ........................................................................ 37

Retention post information .......... .................................. ................................ ...... 38

Replace the retention post wires .... ................................ ................................ ........ 39

Install the retention posts on the PCB .......................... ................................ ............ 39

Glossary

Index

n the probe.................................................................................... 32

mpression footprints on the SUT..................... .................................. ...... 37

ii P5960 Logic Analyzer Probe Instruction Manual

Page 7

List of Figures

Figure 1: P5960 High-Density probe with D-Max probing technology...................................... 1

Figure 2: P5960 probe label sheet. ............................................................................... 4

Figure 3: Attaching labels to the P5960 probe .................................................................. 6

Figure 4: Pr

Figure 5: Storing the probe head.................................................................................. 8

Figure 6: Connecting the logic analyzer probe.................................................................. 9

Figure 7: Connecting the probes to the SUT ................................................................... 10

Figure 8: Proper dressing of the probe cables.................. ................................ ................ 11

Figure 9: Protecting the probe head ... ................................ ................................ .......... 12

Figure 1

Figure 11: Retention assembly dimensions..................................................................... 19

Figure 12: Retention assembly keepout area... ................................ ................................ 19

Figure 13: Retention assembly side-by-side layout........ ................................ .................... 20

Figure 14: Retention assembly end-to-end layout ............................................................. 20

Figure 15: Retention posts dimensions ......................................................................... 21

re 16: Retention posts keepout area ........................................................................ 21

Figu

Figure 17: Retention posts side-by-side layout ................................................................ 22

Figure 18: Retention posts end-to-end layout .................................................................. 22

Figure 19: Signal routing on the SUT....................... ................................ .................... 23

Figure 20: High-Density probe load model..................................................................... 24

Figure 21: Probe footprint dimensions on the PCB............................................................ 25

gure 22: Optional Via-in-Pad placement recommendation ............................. .................... 26

Fi

Figure 23: P5960 single-ended PCB footprint pinout detail.................................................. 27

Figure 24: Replacing the cLGA clip .................... .................................. ...................... 33

Figure 25: Installing the probe retention assembly ... .. ... . .... .. ... . ... . .... .. ... . ... . . . ... . ... . . . ... . ... . ... 38

Figure 26: Replacing the wires on the retention posts......................................................... 39

Figure 27: Installing the retention posts on the PCB . . .... .. ... . ... . . . ... . ... . .... .. ... . ... . . . ... . ... . . . ... . .. 40

Figure 28: Soldering the retention posts on the PCB........ ................................ .................. 41

oper handling of the interface clip.................................................................. 7

0: P5960 probe dimensions............................................................................. 18

P5960 Logic Analyzer Probe Instruction Manual iii

Page 8

Table of Contents

List of Tables

Table 1: Probe section and label combinations.................................................................. 3

Table 2 : Log

Table 3: Half channel demultiplexing source-to channel assignments . .. ... . .... .. ... . ... . .... .. ... . ... . ... 16

Table 4: Channel assignment for a P5960 single-ended logic analyzer probe.............................. 27

Table 5: Mechanical and electrical specifications...................................... ........................ 29

Table 6: Environmental specifications .............. .................................. .......................... 29

Table 7: Service options ............ ................................ ................................ .............. 31

ic analyzer clock and qualifier availability .. .. ... . ... . .... .. ... . ... . .... . . ... . ... . ... . . . ... . ... . 15

iv P5960 Logic Analyzer Probe Instruction Manual

Page 9

General safety summary

General safet

To avoid fire or personal

injury

y summary

Review the fo

this product or any products connected to it.

To avoid pot

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions r

Connect and disconnect properly. Connect the probe output to the measurement

instrument before connecting the probe to the circuit under test. Connect the

probe reference lead to the circuit under test before connecting the probe input.

Disconnect the probe input and the probe reference lead from the circuit under test

before

Ground the product. This product is indirectly grounded through the grounding

condu

conductor must be connected to earth ground. Before making connections to

the input or output terminals of the product, ensure that the product is properly

grounded.

disconnecting the probe from the measurement instrument.

ctor of the mainframe power cord. To avoid electric shock, the grounding

llowing safety precautions to avoid injury and prevent damage to

ential hazards, use this product only as specified.

elated to operating the system.

Observe all terminal ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

The inputs are not rated for connection to mains or Category II, III, or IV circuits.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Power disconnect. The power cord disconnects the product from the power source.

Do not block the power cord; it must remain accessible to the user at all times.

Do not operate without covers. Do not operate this product with covers or panels

removed.

Do not operate with suspected failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Avoid exposed circuitry. Do not touch exposed connections and components when

power is present.

Use proper fuse. Use only t he fuse type and rating specified for this product.

P5960 Logic Analyzer Probe Instruction Manual v

Page 10

General safety summary

Termsinthismanual

Symbols and terms on the

product

Do not operate i

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

Provide prop

on installing the product s o it has proper ventilation.

These terms may appear in this manual:

WARNING.

in injury or loss of life.

CAUTION

damage to this product or other property.

These t

erms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read

the ma

n wet/damp conditions.

er ventilation. Refer to the manual's installation instructions for details

Warning statements identify conditions or practices that could result

. Caution statements identify conditions or practices that could result i n

rking.

WARNING indicates an injury hazard not immediately accessible as you

the marking.

read

CAUTION indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

vi P5960 Logic Analyzer Probe Instruction Manual

Page 11

Service safety summary

Service safet

ysummary

Only qualifie

safety summary and the General safety summary before performing any service

procedures.

Do not service alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use care when servicing with power on. Dangerous voltages or currents may exist

in this p

test leads before removing protective panels, soldering, or replacing components.

To avoi

d personnel should perform service procedures. Read this Service

roduct. Disconnect power, remove battery (if applicable), and disconnect

d electric s hock, do not touch exposed connections.

P5960 Logic Analyzer Probe Instruction Manual vii

Page 12

Compliance information

Compliance in

formation

This section

environmental standards with which the instrument complies.

Environmental considerations

This section provides information about the environmental impact of the product.

Product end-of-life

handling

Observe the following guidelines when recycling an instrument or component:

Equipment recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could be

harmful to the environment or human health if improperly handled at the product’s

end of life. To avoid release of such substances into the environment and to

reduce the use of natural resources, we encourage you to recycle this product in

an appr

recycled appropriately.

opriate system that will ensure that most of the materials are reused or

lists the EMC (electromagnetic compliance), safety, and

This symbol indicates that this product complies w ith the applicable European

Union requirements according to Directives 2002/96/EC and 2006/66/EC

on waste electrical and electronic equipment (WEEE) and batteries. For

information about recycling options, check the Support/Service section of the

Tektronix Web site (www.tektronix.com).

Restriction of hazardous

tances

subs

This product is classified as Monitoring and Control equipment, and is outside the

pe of the 2002/95/EC RoHS Directive.

sco

viii P5960 Logic Analyzer Probe Instruction Manual

Page 13

Preface

Related documentation

This document provides information on using and servicing the P5960 logic

analyzer probe.

The following list and table provide information on the related documentation

available

for your Tektronix product. For additional information, refer to the

Tektronix Web site (www.tektronix.com/manuals).

Related documentation

Item Purpose

TLA Quick Start User Manuals

Online Help

Installation Reference Sheets High-level installation information

lation Manuals

Instal

XYZs of Logic Analyzers

Declassification and Securities instructions Data security concerns specific to sanitizing

Application notes

Product Specifications & Performance

Verification Procedures

TPI.NET Documentation

Field upgrade kits

ptional Service Manuals

O

High-lev

In-dept

Detailed first-time installation information

Logic a

or removing memory devices from Tektronix

prod

Coll

specific notes

TLA Product specifications and performance

verification procedures

Detailed information for controlling the logic

an

Up

S

mainframes

el operational overview

h operation and UI help

nalyzer basics

ucts

ection of logic analyzer application

alyzer using .NET

grade information for your logic analyzer

elf-service documentation for modules and

P5960 Logic Analyzer Probe Instruction Manual ix

Page 14

Preface

x P5960 Logic Analyzer Probe Instruction Manual

Page 15

Operating basics

Product description

This section provides a b rief description of the Tektronix P5960 High-Density

Logic Analyzer Probe, information on attaching color-coded p robe labels, and

probe and ada

The P5960 Probe is a 34-channel, high-density connectorless probe with D-Max

probing technology.

The P5960 Probe consists of one probe head that has 34 channels (32 data and 2

clock/qual). (See Figure 1.)

pter connection instructions from the logic analyzer to the SUT.

Figure 1: P5960 High-Density probe with D-Max probing technology

The following list details the capabilities and qualities of the P5960 probe:

Single-ended data and single-end

cLGA contact eliminates need for built-in connector

Footprint supports direct signal pass-through

Supports PCB thickness of 1.27 mm to 6.35 mm (0.050 in to 0.250 in)

Consists of one independent probe head of 34 channels (32 data and 2

clock/quals), and two 17-channel logic analyzer-end connectors.

Half channel demux mode, (for example, 1:2 demultiplexing) uses one-half

of the probe head

P5960 Logic Analyzer Probe Instruction Manual 1

ed clock inputs

Page 16

Operating basics

Color-coded ke

-2.5 V to +5 V input operating range

300 mV minimum single-ended signal amplitude

Minimal loading of 20 kΩ, 0.8 pF to ground

P5960 probe accessory information

The P5960 probe includes accessories to connect the logic analyzer to the SUT.

The following accessories are available for the P5960 probe:

Component kit cLGA interface clip kit (Tektronix part number, 020-2622-xx)

Primary p

tworetentionassemblysocketsandmanual

Probe la

P5960 Logic Analyzer Probe Instructions (Tektronix part number,

071-29

P5960 High-Density Logic Analyzer Probe Instruction Manual (Tektronix

part n

downloadable from the Tektronix Web site: www.tektronix.com/manuals)

robe retention kit (Tektronix part number, 020-2908-xx); includes

bels, one sheet (Tektronix part number, 335-2737-xx)

76-xx)

umber, 077-0637-xx, available on the TLA Documentation CD or

yed attachment

2 P5960 Logic Analyzer Probe Instruction Manual

Page 17

Probe label overview

Operating basics

The logic analyzer probe comes with a sheet of labels to apply to the probe before

connecting the probe to the instrument and SUT.

When you purchase the logic analyzer probe, apply the color-coded labels as

described in this section. The labels help you identify the probe connections at the

logic analyzer end and at the SUT end.

The following table lists the probe section and label color combinations. Refer to

the table when you attach the probe labels.

Table 1: Probe section and label combinations

Probe

section Channels

A3-A2

D3-D2

C3-C2 CK3,

E3-E2

CK0,

A3:7-0,

A2:7-0

QUAL0,

D3:7-0,

D2:7-0

C3:7-0,

C2:7-0

QUAL3,

E3:7-0,

E2:7-0

Label

color

Brown A1-A0

Blue D1-D0

White

Green

Probe

section Channels

C1-C0 QUAL1,

E1-E0

CK1,

A1:7-0,

A0:7-0

CK2,

D1:7-0,

D0:7-0

C1:7-0,

C0:7-0

QUAL2,

E1:7-0,

E0:7-0

Label

color

Orange

Yellow

Gray

Violet

P5960 Logic Analyzer Probe Instruction Manual 3

Page 18

Operating basics

The following fi

gure shows a sample probe label sheet.

Figure 2: P5960 probe label sheet.

4 P5960 Logic Analyzer Probe Instruction Manual

Page 19

Apply the labels to the probe

Attach the labels to the logic analyzer-end of the probe and to both sides of the

probe head.

NOTE. Use flat-nosed tweezers to remove the labels from the sheet of labels.

Never peel labels with your fingers. The labels are made of soft vinyl and can

stretch and

right corner while removing it from the sheet of labels.

Operating basics

distort easily. To avoid stretching the label, always hold it from the top

The adhesi

the intended outline on the logic analyzer-end and probe head before attaching it

to the probe. Once labels are placed on the probe, they become very difficult to

remove.

Use the following steps to attach the probe labels:

1. Identify the logic analyzer-ends of the probes.

The side of the probe that contains a black label has an area for the color-coded

label.

NOTE. Note the indents and the outdents on the probe labels. Use the indents and

outd

2. From the sheet of labels, locate the color-coded label for the logic analyzer

end

3. Locate the probe head and attach the matching colored label to the probe

he

4. Turn the probe over and repeat Step 3 to apply the other labels to the probe

as

ve on the vinyl labels is extremely s trong. Carefully align each label to

ents as guides to position the labels on the probes. (See Figure 3 on page 6.)

of the probe cable and attach it to the logic analyzer probe connector.

ad.(See Figure 3 on page 6.)

shown in the illustration.

P5960 Logic Analyzer Probe Instruction Manual 5

Page 20

Operating basics

Figure 3: Attaching labels to the P5960 probe

6 P5960 Logic Analyzer Probe Instruction Manual

Page 21

Probe connection overview

The P5960 probe connects a TLA6400 Series logic analyzer to probe retention

assemblies installed on the circuit board on the SUT.

If the retention assemblies are not already installed on the SUT, refer to the

procedures for installing the retention assemblies. (See page 37, Probe retention

assembly installation information.)

Probe head handling guidelines

The cLGA interface clip in the probe head should always be handled with care.

Use the following guidelines when you handle the probe head and cLGA interface

clip:

Always handle the cLGA interface clip by the outer edges, and be careful to

avoid the contacts in the center. Do not touch the contacts with your fingers,

tools, wipes, or any other devices. (See Figure 4.)

Operating basics

Figure 4: Proper handling of the interface clip

Do not expose the connector to liquids or dry chemicals.

If the board pad array needs to be cleaned, only use isopropyl alcohol and

lint-free cloth. (See page 37, Clean the compression footprints on the SUT.)

Immediately following cleaning, or immediately prior to placement of

connector to circuit board, blow off the board pad array and connector contact

array with clean, oil-free dry air or nitrogen to remove loose debris. First start

P5960 Logic Analyzer Probe Instruction Manual 7

Page 22

Operating basics

the blowing pro

across the pad and contact arrays in a repeated motion to remove loose debris.

Place the conn

for alignment. Use care to prevent incidental contact with other surfaces or

edges in the connector contact array area prior to board placement.

Always store the probe head in the protective cover when not in use. (See

Figure 5.)

cess by aiming away from the array areas, and then sweep

ector onto the board pad array using the bosses or locator p ins

Figure 5: Storing the probe head

8 P5960 Logic Analyzer Probe Instruction Manual

Page 23

Operating basics

Connect the pr

obe to the instrument

The P5960 probe connects a TLA6400 Series logic analyzer to the SUT. You can

connect the P5960 probe to the SUT without turning off the power to the SUT.

Apply the labels to the probes before connecting the probes to the instrument

andtotheSUT.

1. Match the color-coded labels of the probe to the same color-coded connector

on the logic analyzer.

2. Connect the logic analyzer probe as shown. The probe will latch into place.

To disconnect the probe, press the button at the center of the probe to release

the latch and then pull the probe away from the logic analyzer.

Figure 6: Connecting the logic analyzer probe

Connect the probes to the SUT

e probe heads connect to the retention assembly on the SUT.

Th

Verify that one or more retention assemblies are installed on the SUT before you

tempt to connect the probes. If they are not installed refer to the instructions for

at

installing them. (See page 37, Install the probe retention assembly.)

P5960 Logic Analyzer Probe Instruction Manual 9

Page 24

Operating basics

Connect the pro

1. Align the silver screw on the probe to the silver side of the retention assembly.

bes to the SUT using the following steps.

Figure 7: C onnecting the probes to the SUT

2. Start both screws in the retention assembly, and tighten them evenly

(approximately 1 in-lb) to make sure that the probe approaches and mates

squarely to the circuit board.

ION. When attaching the probe head to the target system, use care to evenly

CAUT

tighten probe head screws until they are snug. First tighten both screws until the

nut bar makes contact with the circuit board surface, then snug each screw to 1

in-lb (max). Under-tightening the probe head screws can result in intermittence.

Over-tightening can result in damage to the cLGA clip and s tripped screws.

If access is limited, use the adjustment tool that came with your probe. The

probe is completely fastened when the screws stop in the assembly.

10 P5960 Logic Analyzer Probe Instruction Manual

Page 25

Dress the probe cables

Operating basics

Use the Velcro cable managers to combine the cables together or to help relieve

strain on the probe connections.

Hang the probe cables so that you relieve the tension on the probes at the retention

posts as shown in the following figure.

Figure 8: Proper dressing of the probe cables

P5960 Logic Analyzer Probe Instruction Manual 11

Page 26

Operating basics

Store the prob

e head when not in use

To protect the interface clip, it is important to properly store the probe head when

the probe is not in use. Use the protective cover as shown in the following figure.

Figure 9: Protecting the probe head

Probe connection troubleshooting guidelines

Refer to the guidelines in this section to identify probe connection problems.

The most obvious symptom of a p roblem with the probe installation is seeing

incorrect data in the logic analyzer acquisition. The nature of the incorrect data

has a very consistent characteristic; the data from multiple channels go to a logic

low and stay there. Intermittent bad data, or a single dead channel are not failures

typically associated with probe installation problems.

Slightly move the probe head to either side, or press down on the probe head

while making new acquisitions.

If good data is now being acquired, then the probe mounting is most likely

the cause.

If good data is not acquired, then remove the probe and check the retention

assemblyfortoomuchplay.

If there is significant play, then the probe mounting is most likely the cause.

12 P5960 Logic Analyzer Probe Instruction Manual

Page 27

Operating basics

If the retentio

the bottom of the assembly and the circuit board surface, then move the probe

with bad data f rom one logic analyzer probe location to another.

If the problem follows the probe, then the probe is the problem.

Visu a lly in

missing c-spring metal contacts.

Ifthereisd

missing, replace the cLGA interface clip. (See page 32, Replace the cLGA

clip.)

If the problem does not follow the probe, it is either the logic analyzer or the

probe connection at its previous location.

Move the probe back to the original location to be certain it was not a

connection problem at the logic analyzer end.

Place another probe in the retention assembly of the original probe. If the new

probe acquires data, then the old probe is probably at fault.

n assembly has m inimal play and you cannot see a gap between

spect the cLGA interface clip on the probe for any damage or

amage to the interface clip, or if any c-spring metal contacts are

P5960 Logic Analyzer Probe Instruction Manual 13

Page 28

Operating basics

14 P5960 Logic Analyzer Probe Instruction Manual

Page 29

Reference

Clocks and qualifiers

This section provides reference information for the P5960. After you have

determined which probe is required, use the information in this section to design

the appropri

ate connector into your SUT circuit board.

Use the clo

logic analyzer stores data.

Every log

as clocks can cause the logic analyzer to store data. Qualifier channels can be

logically ANDed and ORed with clocks to further define when the logic analyzer

should latch data from the SUT. Routing the appropriate signals from your design

to these inputs ensures that the logic analyzer can acquire data correctly. Unused

clocks can be used as qualifi er signals.

Depending on the channel width, each TLA6400 Series logic analyzer will have a

different set of clock and qualifier channels. The following table shows the clock

and qu

Table 2: Logic analyzer clock and qualifier availability

Product

TLA6401 X X

TLA6402 XXXX

TLA6403 XXXXXX

TLA6404 XXXXXXXX

Clock inputs Qualifier inputs

CLK:0 CLK:1 CLK:2 CLK:3 QUAL:0 QUAL:1 QUAL:2 QUAL:3

ck and qualifier probe connections from the SUT to define how the

ic analyzer has some special purpose input channels. Inputs designated

alifier channels available for each instrument.

All clock and qualifier channels are stored. The logic analyzer always stores the

logic state of these channels every time it latches data.

Since clock and qualifier channels are stored in the logic analyzer memory, there

is no need to double probe these signals for timing analysis. When switching

from state to timing analysis, all of the clock and qualifier signals are visible.

This allows you to route signals not needed for clocking to the unused clock

and qualifier channels.

It is a g ood practice to take advantage of the unused clock and qualifier channels

to increase your options for when you will latch data. Routing several clocks and

strobes in your design to the logic analyzer clock inputs will provide you with a

greater flexibility in the logic analyzer Setup menu.

P5960 Logic Analyzer Probe Instruction Manual 15

Page 30

Reference

Multip

lexed buses

As an example, l

ook at a processor with a master clock, data strobe, and an

address strobe. Routing all three of these signals to logic analyzer clock inputs

will enable you to latch data on the processor master clock, only w hen data is

strobed, or only when address is strobed. Some forethought in signal routing can

greatly expand the ways to latch and analyze data.

A processor also provides a good example of signals that can be useful as

qualifiers. There are often signals that indicate data reads versus data writes

(R/W), signals that show when alternate bus masters have control of the processor

buses (DMA

), and signals that show when various memory devices are being

used (ChipSe l). All of these signals are good candidates for assignment to

qualifier channels.

By logically ANDing the clock with one of these qualifiers you can p rogram the

logic analyzer to store only data reads or data writes. Using the DMA signal as a

qualifier provides a means of filtering out alternate bus master cycles. Chip selects

can limit data latching to specific memory banks, I/O ports, or peripheral devices.

TLA6400 Series logic analyzers support half channel demultiplexing.

Each signal on a dual multiplexed bus can be demultiplexed into its own logic

analyzer channel. See the following table to determine the correct channel groups

to use.

le 3: Half channel demultiplexing source-to channel assignments

Tab

Destination channels receiving SUT test dataSource

connecting

nnel

cha

groups TLA6404 TLA6403 TLA6402 TLA6401

:7-0

A3

A2:7-0 D2:7-0 D2:7-0

A1:7-0 D1:7-0 D1:7-0 D1:7-0

0:7-0

A

3:7-0

C

C2:7-0 C0:7-0 C0:7-0

E3:7-0 E1:7-0

E2:7-0 E0:7-0

D3

D

C

:7-0

0:7-0

1:7-0

D3

D

C

:7-0

0:7-0

1:7-0

0:7-0

D

A3:7-0 A3:7-0

A2:7-0 A2:7-0

When demultiplexing data there is no need to connect the destination channels to

the multiplexed bus. Data from the source channels are routed to the destination

channels internal to the logic analyzer.

16 P5960 Logic Analyzer Probe Instruction Manual

Page 31

Reference

High-Resolution timing

Range r

ecognizers

Demultiplexin

means that the MagniVu memory is filled with data from whatever is connected to

the demultiplexing destination channel probe inputs. This provides an opportunity

to acquire high resolution MagniVu data on a few extra channels. Connecting the

demultiplexing destination channels to other signals will allow viewing of their

activity in the MagniVu memory but not the main memory.

The high-resolution timing mode provides double the normal 800 MHz sample

rate on one

channels can be sampled at a 1.6 GHz rate with double the memory depth.

Obtain ex

signals to the demultiplexing source channels. Since demultiplexing affects only

the main memory you will still have the MagniVu data available for all of the

signals that are disconnected from the main memory when you switch to the

high resolution timing modes.

g affects only the main memory for the destination channels. This

-half of the channels. By trading half of the channels, the remaining

tra timing resolution where it is most needed by assigning critical

When using range recognizers, the probe groups and probe channels must be

in hardware order.

Probe groups must be used from the most-significant probe group to the

least-significant probe group based on the following order:

C3 C2 C1 C0 E3 E2 E1 E0 A3 A2 D3 D2 A1 A0 D1 D0 Q3 Q2 Q1 Q0

CK3 CK2 CK1 CK0

Probe channels must be from the most-significant channel to the least-significant

channel based on the following order:

76543210

The above examples assumes a 136-channel logic analyzer. The missing channels

in logic analyzers with fewer than 136 channels are ignored.

P5960 Logic Analyzer Probe Instruction Manual 17

Page 32

Reference

Probe dimensions

The following figure shows the dimensions for the P5960 probe.

Figure 10: P5960 probe dimensions

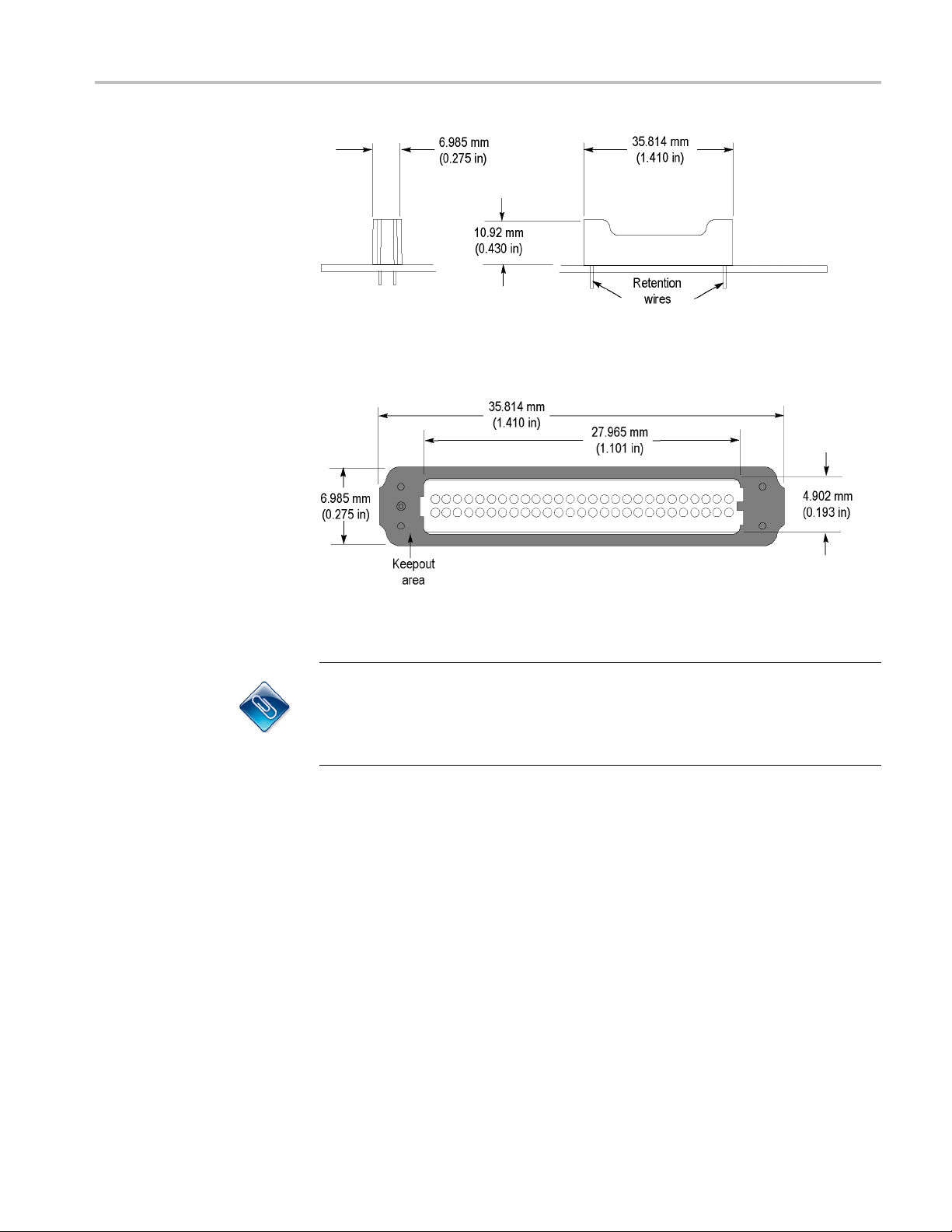

Retention assembly dimensions and keepout areas

The retention assembly provides a housing around the probe connector footprint

to stabilize the probe. The following figure shows the dimensions of the retention

assembly. All dimensions are per standard IPC tolerance, which is ±0.004 in.

(See Figure 11.)

UTION. To avoid solder creep, bend the assembly wires out after you insert the

CA

wires in the board, and then solder the wires.

18 P5960 Logic Analyzer Probe Instruction Manual

Page 33

Reference

Figure 11: Retention assembly dimensions

The following figure shows the keep out area required for the retention assembly.

Figure

NOTE. Tektronix has provided a 3D CAD solid model file (named

dmax_

footprint information for your circuit board. The file is attached to this PDF file.

To access the attached file, open the PDF fileandclickonthepaperclipiconon

theleftsideofthedocumentviewer.

12: Retention assembly keepout area

socket_assembly.stp) for the plastic retention assembly. It also includes

P5960 Logic Analyzer Probe Instruction Manual 19

Page 34

Reference

Retention assembly side-by-side and end-to layout dimensions

The following figure shows the dimensions for side-by-side footprint layout.

(See Figure 17.)

Figure 13: Retention assembly side-by-side layout

The following figure shows the dimensions for an end-to-end footprint layout.

Figure 14: Retention assembly end-to-end layout

Retention post dimensions and keepout areas

Retention posts provide another means for attaching the probes to the PCB.

etention posts hold the probe securely to the board, and ensure a reliable

the r

electrical and mechanical connection and pin-to-pad alignment to your design.

Board thicknesses that are supported include 1.27 mm (0.050 in) to 6.35 mm

(0.250 in). The dimensions of the retention posts are shown in the following

figure. (See Figure 15.)

All dimensions are per standard IPC tolerance, which is ±0.004 in.

CAUTION. To avoid solder creep, bend the post wires out after you insert the posts

in the board, and then solder the post wires. You can solder the retention wires

rom the top or bottom of the circuit board.

f

20 P5960 Logic Analyzer Probe Instruction Manual

Page 35

Reference

Figure 15: Retention posts dimensions

The following figure shows the keepout area required for the retention posts. (See

Figure 16.) Vias m ust be placed outside of the keepout area. Any traces routed on

the top layer of the board must stay outside of the keepout area. Traces can be

routed on inner layers of the board through the keepout area.

Figure 16: Retention posts keepout area

P5960 Logic Analyzer Probe Instruction Manual 21

Page 36

Reference

Retention post side-by-side and end-to-end layout dimensions

The following figure shows the dimensions for side-by-side footprint layout.

(See Figure 17.)

Figure 17:

The follo

(See Figure 18.)

Figure 18: Retention posts end-to-end layout

wing figure shows the dimensions for an end-to-end footprint layout.

Retention posts side-by-side layout

22 P5960 Logic Analyzer Probe Instruction Manual

Page 37

Reference

Signal routin

g

The following figure shows examples of pass-through signal routing for a

single-ended data configuration.

Figure 19: Signal routing on the SUT

Mechanical considerations

The PCB holes, in general, do not have an impact upon the integrity of your

signals when the signals routed around the holes have the corresponding return

current plane immediately below the signal trace for the entire signal path from

driver to receiver.

NOTE. For optimum signal integrity, there should be a continuous, uninterrupted

ground return plane along the entire signal path.

Electrical considerations

Load models are important electrical considerations when working with the probe.

The compression land pattern pad is not part of the load model. Make sure that

you include the compression land pad in the modeling.

Transmission lines

Due to the high performance nature of the interconnect, make sure that stubs,

which are greater than 1/4 length of the signal rise time, are modeled as

transmission lines.

P5960 Logic Analyzer Probe Instruction Manual 23

Page 38

Reference

P5960 probe load model

The following e

High-Density Single-Ended Probe.

Figure 20: High-Density probe load model

Probe footprint dimensions

Use the probe footprint dimensions to lay out your circuit board pads and holes

for attaching the retention posts.

(See Figure 21 on page 25.) If you are using the alternate retention assembly, all

dimensions remain the same as shown below, except the overall length and width.

(See Figure 11 on page 19.) Pad finishes that are supported include immersion

gold, immersion silver, and hot air solder level.

All dimensions are per standard IPC tolerance, which is ±0.004 in.

lectrical model includes a low-frequency model of the

NOTE. Tektronix recommends using immersion gold surface finish for best

rmance.

perfo

Tektronix also recommends that the probe attachment holes float or remain

nnected to a ground plane. This prevents overheating the ground plane

unco

and promotes quicker soldering of the retention posts to your PCB. The probe

retention posts are designed to allow you to solder the retention posts from either

side of your PCB.

NOTE. Tektronix has provided a 3D CAD solid model file (named

dmax_socket_assembly.stp) for the plastic retention assembly. It also includes

footprint information for your circuit board. The file is attached to this PDF file.

To access the attached file, open the PDF file and click on the paperclip icon on

he left side of the document viewer.

t

24 P5960 Logic Analyzer Probe Instruction Manual

Page 39

Reference

Figure 21: Probe footprint dimensions on the PCB

NOTE. Maintain a solder mask web between the pads when traces are routed

between pads on the same layer. The solder mask must not encroach onto the pads

within the pad dimensions. (See Figure 16 on page 21.)

Via-in-Pad design considerations

Traditional layout techniques require vias to be located next to a pad and a signal

ed to the pad causing a stub and more PCB board area to be used for the

rout

connection.

new digital designs require you to minimize the electrical effects of the

Many

logic analyzer probing that you design into the circuit board. Using via-in-pad

to route signals to the pads on the circuit board allows you to minimize the stub

length of the signals on your board, thus providing the smallest intrusion to your

signals. It also enables you to minimize the board area that is used for the probe

footprint and maintain the best electrical performance of your design.

The following figure shows a footprint example where two pads use vias. Detail

A describes the recommended position of the via with respect to the pad.

All dimensions are per standard IPC tolerance, which is ±0.004 in.

P5960 Logic Analyzer Probe Instruction Manual 25

Page 40

Reference

Figure

22: Optional Via-in-Pad placement recommendation

26 P5960 Logic Analyzer Probe Instruction Manual

Page 41

Reference

Probe pinout d

efinition and channel assignment

Probe pinout definitions and channel assignments provide useful information for

your design for use with the logic analzyer.

The following figure shows the pad assignments, pad numbers, and signal names

for the PCB footprint of the P5960 single-ended logic analyzer probe. The P5960

probe has 32

data channels, one clock, and one qualifier for each footprint.

Figure 23: P5960 single-ended PCB footprint pinout detail

The following table lists the channel mapping to a TLA6400 Series logic analyzer

for a P5960 single-ended logic analyzer probe.

Table 4: Channel assignment for a P5960 single-ended logic analyzer probe

Number of channels 136 136 or 102 136 or 102 136 or 102 68 68 or 34

Pin Signal Probe4 Probe 3 Probe 2 Probe 1 Probe 2 Probe 1

A1 D0 E2:0 A2:0 A0:0

A2 D1 E2:1 A2:1 A0:1

A3

A4 D4 E2:4 A2:4 A0:4

A5 D5 E2:5 A2:5 A0:5

A6

A7

A8

A9

A10 D10 E3:2 A3:2 A1:2

A11 D11 E3:3 A3:3 A1:3

A12

A13 D14 E3:6 A3:6 A1:6

A14 D15 E3:7 A3:7 A1:7

A15

A16 D18 E1:5 D3:5 D1:5

A17 D19 E1:4 D3:4 D1:4

A18

A19 D22 E1:1 D3:1 D1:1

A20 D23 E1:0 D3:0 D1:0

GND GND GND GND GND GND GND

GND GND GND GND GND GND GND

CK1 Q3 CK0 CK1 CK3 CK1 CK3

NC NC NC NC NC NC NC

GND GND GND GND GND GND GND

GND GND GND GND GND GND GND

GND GND GND GND GND GND GND

GND GND GND GND GND GND GND

C2:0

C2:1

C2:4

C2:5

C3:2

C3:3

C3:6

C3:7

C1:5

C1:4

C1:1

C1:0

A0:0

A0:1

A0:4

A0:5

A1:2

A1:3

A1:6

A1:7

D1:5 A3:5

D1:4 A3:4

D1:1 A3:1

D1:0 A3:0

C2:0

C2:1

C2:4

C2:5

C3:2

C3:3

C3:6

C3:7

P5960 Logic Analyzer Probe Instruction Manual 27

Page 42

Reference

Table 4: Channel assignment for a P5960 single-ended logic analyzer probe (cont.)

Number of channels 136 136 or 102 136 or 102 136 or 102 68 68 or 34

Pin Signal Probe4 Probe 3 Probe 2 Probe 1 Probe 2 Probe 1

A21

A22 D24 E0:7 D2:7 D0:7

A23 D25 E0:6 D2:6 D0:6

A24

A25 D28 E0:3 D2:3 D0:3

A26 D29 E0:2 D2:2 D0:2

A27

B1

B2 D2 E2:2 A2:2 A0:2

B3 D3 E2:3 A2:3 A0:3

B4

B5 D6 E2:6 A2:6 A0:6

B6 D7 E2:7 A2:7 A0:7

B7

B8 D8 E3:0 A3:0 A1:0

B9 D9 E3:1 A3:1 A1:1

B10

B11 D12 E3:4 A3:4 A1:4

B12 D13 E3:5 A3:5 A1:5

B13

B14 D16 E1:7 D3:7 D1:7

B15 D17 E1:6 D3:6 D1:6

B16

B17 D20 E1:3 D3:3 D1:3

B18 D21 E1:2 D3:2 D1:2

B19

B20

B21

B22

B23 D26 E0:5 D2:5 D0:5

B24 D27 E0:4 D2:4 D0:4

B25

B26 D30 E0:1 D2:1 D0:1

B27 D31 E0:0 D2:0 D0:0

GND GND GND GND GND GND GND

C0:7

C0:6

GND GND GND GND GND GND GND

C0:3

C0:2

GND GND GND GND GND GND GND

GND GND GND GND GND GND GND

C2:2

C2:3

GND GND GND GND GND GND GND

C2:6

C2:7

GND GND GND GND GND GND GND

C3:0

C3:1

GND GND GND GND GND GND GND

C3:4

C3:5

GND GND GND GND GND GND GND

C1:7

C1:6

GND GND GND GND GND GND GND

C1:3

C1:2

GND GND GND GND GND GND GND

NC NC NC NC NC NC NC

CK2Q2Q0CK2Q1CK2CK0

GND GND GND GND GND GND GND

C0:5

C0:4

GND GND GND GND GND GND GND

C0:1

C0:0

D0:7 A2:7

D0:6 A2:6

D0:3 A2:3

D0:2 A2:2

A0:2

A0:3

A0:6

A0:7

A1:0

A1:1

A1:4

A1:5

D1:7 A3:7

D1:6 A3:6

D1:3 A3:3

D1:2 A3:2

D0:5 A2:5

D0:4 A2:4

D0:1 A2:1

D0:0 A2:0

C2:2

C2:3

C2:6

C2:7

C3:0

C3:1

C3:4

C3:5

28 P5960 Logic Analyzer Probe Instruction Manual

Page 43

Reference

Specification

s

The following tables list the electrical and environmental specifications for the

P5910 probe.

The electrical specifications apply when the probe is connected between a

compatible logic analyzer and the SUT. Refer to the Tektronix TLA6400

Logic Analy

(available on the Tektronix Logic Analyzer Family Product Documentation CD or

downloadable from the Tektronix Web site) for a complete list of specifications,

including overall system specifications.

Table 5: Mechanical and electrical specifications

Characte

Number o

mpedance

Input i

Analog

um input signal

Minim

ting signal range

Opera

Maximum nondestructive input signal to

e

prob

nel to channel skew

Chan

ay from probe tip to input connector

Del

obe length (including probe head and

Pr

probe connector)

zer Product Specifications & Performance Verification document

ristic

f input channels

bandwidth

P5960

34, (32 d

channels)

20 kΩ, 0.8 pF to ground

2GHz

300 mV

-2.5Vto5V

-4.5 V to +13 V

±60ps,withinasingleprobe

±125

6.39 ns

1.

ata channels, 2 clock/qualifier

p-p

ps, between probes

593 m (62.7 in)

The following table lists environmental specifications for the probe. The probe is

designed to meet Tektronix standard 062-2847-00.

Table 6: Environmental specifications

Characteristic P59xx

Temperature

Operating -10 °C to +55 °C (14 °F to +131 °F)

Non-operating

Humidity

Operating 5% to 95% relative humidity ≤ 30 °C (86 °F)

-51 °C to +71 °C (-60 °F to +160 °F)

5% to 45% relative humidity 30 °C to 55 °C

(86 °F to 131 °F), non condensing

P5960 Logic Analyzer Probe Instruction Manual 29

Page 44

Reference

Table 6: Environmental specifications (cont.)

Characteristic P59xx

Non-operating

Altitude Operating

Non-operating

5% to 95% relative humidity ≤ 30 °C (86 °F)

5% to 45% relative humidity 30 °C to 71 °C

(86 °F to 160 °F), non condensing

To 3,000 m (9843 ft )

To 12,000 m (39,370 ft )

30 P5960 Logic Analyzer Probe Instruction Manual

Page 45

Maintenance

Probe calibration information

The probe does not require calibration. If a probe failure occurs, return the entire

probe to your Tektronix representative for repair.

Probe service strategy information

The following service options are available when you order your Tektronix

product:

Table 7: Service options

Option Description

C3 Calibration Service 3 Years

C5 Calibration Service 5 Years

R3

R5

R3DW

R5DW

Includes initial certifications plus two annual calibrations

Includes initial certifications plus four annual calibrations

Repair Service 3 Years

Return product to Tektronix for servicing

Repair Service 5 Years

Return product to Tektronix for servicing

Repair Service Coverage 3 Years

(includes product warranty period). 3-year period starts at time of

instrument purchase

Repair Service Coverage 5 Years

(includes product warranty period). 5-year period starts at time of

instrument purchase

Perform the functional check

A functional check verifies basic functionality of the probe.

onnect the probe to the logic analyzer and to an active signal source.

1.C

2. Open the logic analyzer Setup window.

3. Set the threshold voltage to the appropriate value for the active signal source.

4. Check for signal activity in the Setup window for the attached probe.

P5960 Logic Analyzer Probe Instruction Manual 31

Page 46

Maintenance

Inspect or clean the probe

Inspect and clean the probe as often as operating conditions require. Dirt acts as

an insulating blanket, preventing efficient heat dissipation. Dirt also provides an

electrical conduction path that can cause failures, especially under high-humidity

conditions.

Replace the cLGA clip

CAUTION. To

the exposed edge of the interface clip. Do not drag the contacts against a hard

edge or corner.

Perform the following steps to clean the probe:

1. Keep the p

electrical probe connection.

Avoid br

2. Remove dirt and dust with a soft brush.

3. Use only a damp cloth for more extensive cleaning.

Never use abrasive cleaners or organic solvents.

The P5960 probe uses replaceable c-spring cLGA clips. If a probe failure other

than the cLGA clip occurs, return the entire probe to your Tektronix service

center for repair.

prevent damage during the probe connection process, do not touch

robes free of dirt, dust, and contaminants to maintain a reliable

ushing or rubbing the c-spring contacts.

To replace the cLGA clip, perform the following steps:

1. Gently pull one side of the clip away from the probe head and then remove

the entire clip. (See Figure 24.)

2. Align the new clip with the probe head and gently snap it into place.

3. Test the probe to confirm that all channels are functional.

32 P5960 Logic Analyzer Probe Instruction Manual

Page 47

Maintenance

Repackage the probe

Figure 24:

For repla

The foll

probe, or to return the probes to the factory.

1. Use the

If the original packaging is not available, use a corrugated cardboard shipping

carto

2. Add cushioning material to prevent the probes from moving inside the

3. Enclose the following information when shipping the probe to a Tektronix

Replacing the cLGA clip

cement part number information, refer to the Replaceable Parts list.

owing information describes how to repackage the probe, to store the

original packaging, if possible.

n.

ping container.

ship

ter:

Cen

Owner’s address

Name and phone number of a contact person

Type of probe

Reason for return

Full description of the service required

P5960 Logic Analyzer Probe Instruction Manual 33

Page 48

Maintenance

34 P5960 Logic Analyzer Probe Instruction Manual

Page 49

Replaceable parts

Parts ordering information

Replacement parts are available through your local Tektronix field office or

representative.

The P5960 probe contains no user-replaceable parts. However, probe accessories

can be replaced. (See page 2, P5960 probe accessory information.) Contact your

local Tektronix representative for replacement information.

Changes to Tektronix products are sometimes made to accommoda t e improved

components as they become available and to give you the benefit of the latest

improvements. When o rdering parts, include the following information in your

order:

If you order a part that has been replaced with a different or improved part, your

local Tektronix field office or representative will contact you concerning any

change in the part number.

Part number

Instrument type or model number

Instrument serial number

Instrument modification number, if applicable

P5960 Logic Analyzer Probe Instruction Manual 35

Page 50

Replaceable parts

36 P5960 Logic Analyzer Probe Instruction Manual

Page 51

Appendix A: Probe retention assembly installation

information

Clean the c

The P5960 prob

SUT. Two different retention assembles are available: a single piece retention

assembly, and a two-piece post assembly (for connecting a probe with limited

space on the SUT. This appendix describes the procedures for installing both

retention assemblies.

es connect to the retention assemblies on the circuit board of the

ompression footprints on the SUT

To provide good electrical contacts, clean the compression footprints before

installing the retention assemblies on the SUT.

CAUTION

the compression footprint.

The fol

Clean the compression foot prints on the circuit board of the SUT before

conne

1. Use a lint-free, clean-room cloth lightly moistened with electronic/reagent

. To avoid electrical damage, always power off the SUT before cleaning

lowing procedure is recommended to obtain best performance.

cting the probe.

e isopropyl alcohol, and gently wipe the footprint surface.

grad

2. Remove any remaining lint using a nitrogen air gun or clean, oil-free dry air.

Install the probe retention assembly

The p robe retention assembly provides a single-piece housing around the

nnector footprint to help stabilize the probe.

co

To install the probe retention assembly on the circuit board, do the following:

1. Locate the correct footprint on the SUT. If you intend to use multiple probes,

your PCB has multiple footprints. Be careful to select the correct one.

2. Clean the compression footprint as described above. (See page 37, Clean the

compression footprints on the SUT.)

3. Align the retention assembly over the footprint so that the keying pin on the

retention assembly lines up with the keying pin hole on the footprint.

P5960 Logic Analyzer Probe Instruction Manual 37

Page 52

Appendix A: Probe retention assembly installation information

Figure 25: Installing the probe retention assembly

4. Insert the retention assembly into the holes in the footprint on the PCB.

NOTE. The following two steps are important to be sure that the retention

assembly is correctly mounted and that the probe makes proper contact with

the PCB.

5. Hold t

6. Using a pair of needle-nose pliers, hold one of the posts. Using the circuit

7. Solder the anchoring posts to the PCB.

Retention post information

The retention posts are available as on optional accessory kit (Tektronix part

number: 020-2539-xx). The retention posts are mounted on a plastic carrier for

easy installation to the PCB. Two lengths of wire are shipped with the posts to

llow use with thicker PCBs.

a

he retention assembly so that it is firmly flush with the surface of

the footprint, and the four anchoring posts extend through the circuit board

to the opposite side.

board hole as a fulcrum, bend the post outward so that it is flush with the

PCB surface, anchoring the assembly to the PCB. Bend the other three posts

in the same manner.

If the PCB is less than or equal to 0.120 inches thick, use the wires that come

preattached to the posts. If the PCB thickness is greater than 0.12o in., use the

longer wire that is included with the posts. The longer wires are embedded in the

protective foam of the retention post kit.

38 P5960 Logic Analyzer Probe Instruction Manual

Page 53

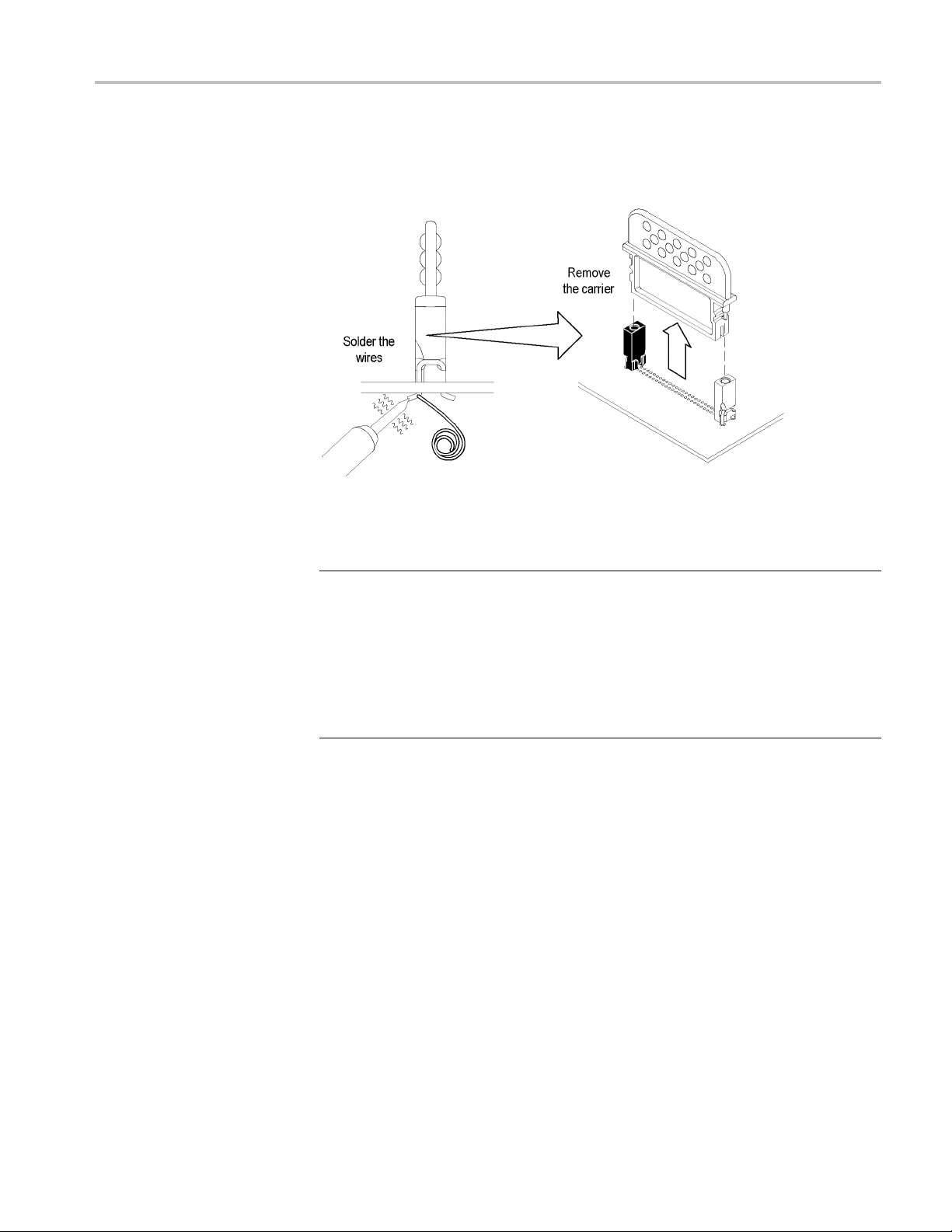

Replace the retention post wires

Perform the following procedure to replace the shorter retention post wires with

the longer wires:

1. Remove the old wire by pulling the side of the wire over the retaining tab and

lifting the wire away from the post.

2. Place the new wire in the slot side without the tab, and then wrap the wire over

the tab side until it engages in the slot (you will feel or hear a slight click).

Appendix A: Probe retention assembly installation information

Figure 26: Replacing the wires on the retention posts

Install the retention posts on the PCB

To install the retention posts on the PCB, do the following:

1. On the retention post/carrier assembly, locate the black retention post (the

post with the keying pin) and align it to the keying pin hole on the PCB.

eFigure27.)

(Se

2. Press the retention posts into the holes on the footprint on the PCB.

TE. The following two steps – bending and soldering the wires to the circuit

NO

board – are the two most important steps in assuring that the probe retaining

posts are correctly mounted. Bending the wires before soldering them helps

prevent long-term cold solder flow.

P5960 Logic Analyzer Probe Instruction Manual 39

Page 54

Appendix A: Probe retention assembly installation information

3. Press down on th

the PCB. Ensure the assembly is perpendicular to the PCB when bending

and soldering the post wires.

The bend point in the retaining wire should be as close to the circuit board

surface as possible. Grip the wire with a pair of needle-nose pliers about

1/8-inch above the circuit board surface and let the side of the through-hole

(not the pliers) act as the fulcrum point for bending the wire. This method

pulls the probe mounting posts tightly against the circuit board surface.

e carrier and bend the post wires out to anchor the posts to

Figure 27: Installing the retention posts on the PCB

40 P5960 Logic Analyzer Probe Instruction Manual

Page 55

Appendix A: Probe retention assembly installation information

4. Solder the post

the top or bottom of the circuit board, but it is best to solder the bottom to

avoid the heat-sinking effects of the posts on top.

Figure 2

5. Pull off

NOTE. The posts may have a small amount of movement after you solder them to

the circuit board. This is normal and accounted for in the post design.

8: Soldering the retention posts on the PCB

s to the PCB. (See Figure 28.) The posts can b e soldered from

the carrier from the posts.

The probe should mate firmly to the board when the two screws are tightened to

the mounting posts. The screws have a mechanical stop on them to prevent overtightening the probe to the board.

After a probe has been installed and removed, there may be slightly more play in

the posts. This is also normal and accounted for in the probe design.

P5960 Logic Analyzer Probe Instruction Manual 41

Page 56

Appendix A: Probe retention assembly installation information

42 P5960 Logic Analyzer Probe Instruction Manual

Page 57

Glossary

cLGA

An acronym for compression Land Grid Array, a connector that provides an

electrical connection between a PCB and the probe input circuitry.

Compression footprint

A connecto

Connection is obtained by applying pressure between your PCB and the probe

through a cLGA c-spring.

D-Max probing technology

The name that describes the technology used in the P5960 high-density logic

analyzer probe.

Functional check procedure

Functional check procedures verify the basic functionality of the p robes by

confirming that the probes recognize signal activity at the probe tips.

Keep out area

An area on a printed circuit board in which component, trace, and/or via

placement may be restricted.

Logic analyzer-end

The end of the probe which connects to the logic analyzer.

PCB

An acronym for Printed Circuit Board.

rless, solderless contact between your PCB and the P5960 probes.

robe head

P

The end of the probe that connects to the SUT.

SUT

System-Under-Test. Also known as the target system. The logic analyzer

connects to the SUT through the probe.

P5960 Logic Analyzer Probe Instruction Manual 43

Page 58

Glossary

44 P5960 Logic Analyzer Probe Instruction Manual

Page 59

Index

Symbols and Numbers

3D CAD file, 19, 24

A

accessories, 2

attaching labels, 5

C

calibration, 31

channel mapping, 27

channel

cleaning, 32

cLGA interface clip, 7

cLGA Interface Clip

clock channels, 15

clock

compression footprints

connecting

width, 15

replacing, 32

s, 15

cleaning, 37

probes to logic analyzer, 9

probes to the SUT, 9

D

multiplex data, 16

de

destination channels, 16

dimensions

probe, 18

retention assembly, 18

retention assembly

footprint, 20

retention assembly

side-by-side layout, 20

retention post footprint, 22

retention post side-by-side

layout, 22

retention posts, 20

double probing signals, 15

E

electrical considerations, 23

electrical model, 24

electrical specifications, 29

environmental specifications, 29

F

file attachments, 19, 24

footprint

footprints

functional check, 31

, 18, 27

dimensions, 24

retention assembly

dimensions, 20

retention assembly layout, 20

retention post dimensions, 22

on post layout, 22

retenti

cleaning, 37

H

handling the probe head, 7

hardware order, 17

I

pection and cleaning, 32

ins

installing retention posts, 39

interface clip

protecting, 12

K

keep out area

retention assembly, 19

keepout area

retention posts, 21

keying pin, 37

L

label

installation, 5

labels, 3

load model, 24

logic analyzer

connecting probes, 9

M

MagniVu memory, 17

main me mory

extra timing, 17

maintenance

functional check, 31

inspection and cleaning, 32

probe calibration, 31

probe rep

service strategy, 31

mechanical considerations, 23

mechanical specifications, 29

multiplexed buses, 16

ackaging, 33

O

ordering parts, 35

P

signments, 27

pad as

pad finishes, 24

PCB board area, 25

probe

cable managers, 11

connecting probes to the

,9

SUT

connection problems, 12

cover, 12

description, 1

dimensions, 18

dress the probe cables, 11

footprint dimensions, 24

labels, 3

repackaging, 33

storing the probe head, 12

troubleshooting, 12

probe connections

to the instrument, 9

to the logic analyzer, 9

probe head

handling, 7

protective cover, 8

P5960 Logic Analyzer Probe Instruction Manual 45

Page 60

Index

Q

qualifier channels, 15

R

range recog

related documentation, ix

repackage the probe, 33

replacement parts, 35

replacing the cLGA interface

clip, 32

retentio

dimensions, 18

footprint dimensions, 20

footprint layout, 20

installing, 37

nizers, 17

n assembly, 24

retention post

dimensions, 20

footprint dimensions, 22

footprint layout, 22

installing, 39

keepout area, 21

wires, 39

s, 38

S

Safety Summary, v

service options, 31

signal names, 27

signal routing, 23

solder mask, 25

source c

hannels, 16

demultiplexing, 17

specifications

electrical, 29

environmental, 29

mechanical, 29

SUT

connecting probes, 9

T

timing ana

transmission lines, 23

troubleshooting

lysis, 15

probe connections, 12

V

via-in-pad, 25

vias, 25

Vias, 2

1

46 P5960 Logic Analyzer Probe Instruction Manual

Loading...

Loading...