Page 1

ZZZ

xx

P5200

High Voltage Differential Probe

Instruction Manual

*P070901806*

070-9018-06

Page 2

Page 3

xx

ZZZ

P5200

High Voltage Different

Instruction Manual

ial Probe

www.tektronix.com

070-9018-06

Page 4

Copyright © Tektronix. All rights re

owned by Tektronix or its subsidiaries or suppliers, and are protected by national

copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pendin g.

Information in this publication supersedes that in all previously published

material. Specifications and p

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

served. Licensed software products are

rice change privileges reserved.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Brau n Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this produ

workmanship for a period of one (1) year from the date of shipment. If any such product

proves defective during this w

the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective

Tektronix for warranty work may be new or reconditioned to like new performance. All

replaced parts, modules and

In order to obtain service under this warranty, Customer must notify Tektronix of t he

defect before the expiration of the warranty period and make suitable arrangements for the

performance of service. Customer shall be responsible for packaging and shipping the

defective product to the service center designated by Tektronix, with shipping charges

prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to

a location within the country in which the Tektronix service center is located. Customer

shall be responsible for paying all shipping charges, duties, taxes, and any other charges

for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or

improper or inadequate maintenance and care. Tektronix shall not be obligated to furnish

service under this warranty a) to repair damage resulting from attempts by personnel other

than Tektronix representatives to install, repair or service the product; b) to repair damage

resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a

product that has been modified or integrated w ith other products when the effect of such

modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE

PRODUCT I

TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHAN

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE

SOLE AN

BREACH OF THIS WARRANTY. TEK TRONIX AND ITS VENDORS WILL NOT BE

LIABL

DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADV

[W2 – 15AUG04]

N LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED.

TABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

D EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR

E FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

ANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

ct will be free from defects in materials and

arranty period, Tektronix, at its option, either will repair

product. Parts, modules and replacement products used by

products become the property of Tektronix.

Page 6

Page 7

Table of Contents

General Safety Summary ............ ................................... ii

Service Safety Summary................................................ iv

Compliance Information .......... ....................................... v

EMC Compliance ..................... .............................. v

Safety Compliance ............................................... . vii

Environmental Considerations .... ................................ ix

Features and Accessories ... ............................................. 1

Getting Started ................................................ ............ 5

Installation .............. ............................................. 5

Functional Check.... ................................................ 6

Operating Basics....................................................... ... 7

Operating the Probe Safely .............. ........................... 7

Operating Characteristics and Probing Techniques............. 10

Specifications ................ ........................................... 15

Warranted Characteristics .................. ...................... 15

Typical Characteristics................ ............................ 16

Nominal Characteristics ........ .................................. 17

User Service ................. ........................................... 19

Cleaning............................................................ 19

Packaging for Shipment .................... ...................... 19

Performance Verification............................................... 21

Construction of Modified BNC Adapter ........... ............. 22

Setup................................. ............................... 23

Amplitude Accuracy ............ .................................. 24

Rise Time ...... ................................................... . 26

DC CMRR ........... .............................................. 27

Replaceable Parts . .. . . . . .. . . . ... . . . .. . . . .. . . . .. . . . ... . . . .. . . . . .. . . . .. . . . 29

Parts Ordering Information ....................................... 29

Using the Replaceable Parts List . . .. . . . .. . . . . .. . . . .. . . . ... . . . .. . . 30

P5200 Instruction Manual i

Page 8

General Safety Summary

General Safety Summary

Review the following safety precautions to avoid injury and prevent

damage to this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or Personal Injury

Connect and Disconnect Properly. Connect the probe output to the

measurement instrum ent before connectin g the probe to the circuit

under test. Connect th

before connecting the probe input. Disconn ect the probe input and the

probe reference lead from the circuit under test before disconnecting

the probe from the me

Ground the Product. This product is indirectly grounded through the

grounding conduc

shock, the grounding conductor must be connected to earth ground.

Before making connections to the input or output terminals of the

product, ensur

e that the pro duct is properly g rou nded.

e probe reference lead to the cir cui t under test

asurement instrument.

tor of the mainframe power cord. To avoid electric

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all

ratings and ma

further ratings information before making connections to the product.

Do Not Operat

or panels removed.

Do Not Oper

damage to this product, have it inspected by qualified service personnel.

Avoid Exp

components when power is present.

ii P5200 Instruction M an ual

rkings on the product. Consult the product manual for

e Without Covers.

ate With Suspected Failures.

osed Circuitry.

Do not operate this product with covers

If you suspect that there is

Do not touch exposed connections and

Page 9

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

General S afety Sum m ary

Provide Proper Ventilation.

Refer to the manual’s installation instructions

for details on installing the product so it has proper ventilation.

Terms in this Manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could

result in injury or loss of life.

CAUTION. Caution statements identify co nditions or prac tices that could

result in damage to this product or other property.

Symbols and Terms on the Product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you

read the marking.

WARNING indicates an injury hazard not immediately accessible

as you read the marking.

CAUTION indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

P5200 Instruction Manual iii

Page 10

Service S afety Sum mary

Service Safety Summary

Only qualified personnel should p erform service procedures. Read

this Service Safety Summary and the General Safety Summary before

performing any service procedures.

Do Not Service Alone. Do not p

of this product unless another person capable of rendering first aid and

resuscitation is present.

Disconnect Power. To avoid electric shock, switch off the instrument

power, then disconnect the power cord from the mains power.

Use Care W hen S ervici

may exist in this product. Disconnect power, remove battery (if

applicable), and disconnect test leads b efore removing p rotective panels,

soldering, or rep

To avoid electric shock , do not touch exposed co nnection s.

ng With Power On.

lacing components.

erform internal service or adjustments

Dangerous voltages or currents

iv P5200 Instruction Manual

Page 11

Compliance Information

This sectio n lists the EMC (ele

environmental standards with which the instrument complies.

EMC Compliance

EC Declaration of Conformity – EMC

Meets intent of Directive 2004/108/EC for Electromagnetic

Compatibility. Compliance was demon strated to the following

specifications as listed in the Official Journal of the European

Communities:

EN 61326-1:2006, EN 61326-2 -1:20 06. EMC requirements for electrical

equipment for measurement, control, and laboratory use.

CISPR 11:2003. Radiated and conducted emissions, Group 1,

Class A

IEC 61000-4-2:2001. Electrostatic discharge immunity

IEC 61000-4-3:2002. RF electromagnetic field immunity

IEC 61000-4-4:2004. Electrical fast transient / burst immunity

IEC 61000-4-5:2001. Pow er line surge immunity

IEC 61000-4-6:2003 . Conducted RF immunity

IEC 61000-4-11:2004. Voltage dips and interruptions immunity

ctromagnetic compliance), safety, and

123

4

EN 61000-3-2:2006. AC power line harmonic emissions

EN 61000-3-3:1995. Voltage changes, fluctuations, and flicker

European Contact.

Tektronix UK, Ltd.

Western Peninsula

West e rn Road

Bracknell, RG12 1RF

United Kingdom

P5200 Instruction Manual v

Page 12

Compliance Information

1

This product is intended for use in nonresidential areas only. Use in residential areas

may cause electromagnetic interference.

2

Emissions which exceed the levels required by this standard may occur when this

equipment is connected to a test o

3

To ensure compliance with the EMC standards listed here, high quality shielded interface

cables should be used.

4

Performance Criterion C applied at the 70%/25 cycle Voltage-Dip and the 0%/250 cycle

Voltage-Interruption test levels (IEC 61000-4-11).

Australia / New Zealand D eclaration of Conformity – EMC

Complies with the EMC provision of the Radiocommunications Act per

the following standard, in accordance with A CMA:

CISPR 11:2003. Radiated and Conducted Emissions, Group

1, Class A, in accordance with EN 61326-1:2006 and

EN 61326-2-1:2006.

bject.

vi P5200 Instruction Manual

Page 13

Safety Compliance

EC Declaration of Conformity – Low Voltage

Compliance was demonstrated to the following specification as listed in

the Official Journal of the European Communities:

Low Voltage Directive 73/23/EEC, as amended by 93/68/EEC:

EN 61010-1/A2:1995 – Safety requirements for electrical

equipment for measurement, control, and laboratory use

EN 6 101 0-2 -0 31:199 4 – Particular requirements for hand-held

probe assemblies for electrical measurement and test equipment.

U.S. Nationally Recognized Testing Laboratory Listing

UL3111-1 – Standard for electrical measuring and test equipment.

IEC 10106-2-031 – Particular requirements for hand-held probe

assemblies for electrical

Canadian Certification

CAN/CSA-C22.2 No. 1010.1-92 and CAN / CSA-C22.2 No.

1010.2.031-94 – Safety requirements for electrical equipment for

measurement, control, and laboratory use

Compliance Information

measurement and test

Installation (Overvoltage) Category Descriptions

Terminals on this product may have different installation (overvoltage)

category designations. The installation categories are:

CAT III Distribu tio n-level ma

Equipment at this level is typically in a fixed industrial location.

CAT II Local-level mains (wall sockets). Equipment at this

level in cludes appliances, portable too ls, and similar prod ucts.

Equipment is usually cord-connected.

CAT I Secondary (signal level) or battery-oper ated circuits of

electronic equipment.

ins (usually perm anently connected).

Pollution Degree

Pollution Degree 2. Do not operate in environments where conductive

pollutants may be present.

P5200 Instruction Manual vii

Page 14

Compliance Information

Radiated and Conducted Emissions

FCC Code 47 CFR. Part 15, Subpart B, Class A

VFG 0243 Enclosure: EN 5502 Class B limits for radiated emissions

AC Mains: EN 55022 Class B limits for conducted emissions and EN

60555-2 AC power harmonic emissions

To ensure compliance with the above requirements, only high quality

shielded inter face cables should be attached to this instrument. High

quality cables have a reliable, continuous outer shield (braid and foil)

that has low im pedan c e connections to sh ield ed connector housings at

both ends. The following cables m eet this criteria:

GPIB: Tektronix part num bers 012-0991-00, -01, -02 , -03

RS-232: Tektronix part number 012-1380-00

Printer: Tektronix part number 012-1250-00

Immunity, Enclosure, Radio Frequency Electromagnetic Field

IEC 801–3 Tested with TDS460 set to 50 mV/D iv vertically and

500 μs/ Div horizontally

Immunity, Enclosure, Electrostatic Discharge (ESD)

8 kV, IEC 801–2

Immunity, Fast Transients, Common Mode

IEC 801–4

Immunity, AC Power Line Transients

IEC 801–5

viii P5200 Instruction M an ual

Page 15

Environmental Considerations

This section provides information abou t the environmental impact of

the product.

Product End-of-Life Handling

Observe the following guidelines when recycling an instrument or

component:

Equipment Recycling. Production of this equipment required the

extraction and use of natural resources. The equipment may contain

substances that could b

if improperly handled at the product’s end of life. In order to avoid

release of such substances into the environment and to reduce the use

of natural resources

appropriate system that will ensure that most of the materials are reused

or recycled appropriately.

e harmful to the environment or human health

, w e encourage you to recycle this produ ct in an

Compliance Information

This symbol indica

applicable Europ

Directives 2002

electronic equi

about recyclin

the Tektronix

tes that this product complies with the

ean Union requirements according to

/96/EC and 2006/66/EC on waste electrical and

pment (WEEE) and batteries. For information

g options, check the Support/Service section of

Web site (www.tektronix.com).

Restriction of Hazardous Substances

This product has been classified as Monitoring and Control equipment,

and is outside the scope of the 2002/95/EC RoHS Directive.

P5200 Instruction Manual ix

Page 16

Compliance Information

x P5200 Instruction Manual

Page 17

Features and Accessories

The P5200 High Voltage Differential Probe provides a safe means of

measuring circuits with floating potentials up to 1,000 V

earth ground and up to 1,300 V (DC + peak AC) differential. This probe

must be connected to an oscilloscope or other measurement instrument

in which t he input BN C connector is at ground potential. The probe is a

safe alternative to the extremely dangerous practice of disconnecting

the oscilloscope ground to achieve a floating measurement.

The P5200 probe allows clear and accurate m easurements of high-speed

transitions and pro vid e s excellent common-mode rejection of noisy

signals. Both inputs have high impedance and low capacitance. Because

of these features, the probe can safely measure the fast voltage transients

in switching power devices such as IGBTs, power MOSFETs, thyristors,

GTOs, and bipolar transistors with out damaging these devices.

Other ap plications for the P5200 probe include testing hig h-voltage

motor control circuits and line connected circuits in switch-mode power

supplies.

WARNING. To avoid an electric shock, do not use the P5200 High

Voltage Differential Probe with oscilloscopes that have floating inputs

(isolated inputs), su ch as the Tektronix TPS2000 series oscilloscopes and

THS700 series oscillosco pes. The P5200 High Voltage Differential Probe

requires an oscilloscope or other measurement instrument with a grounded

input.

CAT II from

RMS

WARNING. To avoid RF burns, d o not handle the probe while the input

leads are connected to circuits above the voltage and frequency limits

specified. (See page 9, Safety limits.) Use on ly probe accessories that are

rated for the application.

CAUTION. Do not use the P5200 H igh Voltage Differential Probe above

1,000 V

AC) between the leads.

CAT I I from ground on either input or ± 1,300 V (DC + peak

RMS

P5200 Instruction Manual 1

Page 18

Features and Accessories

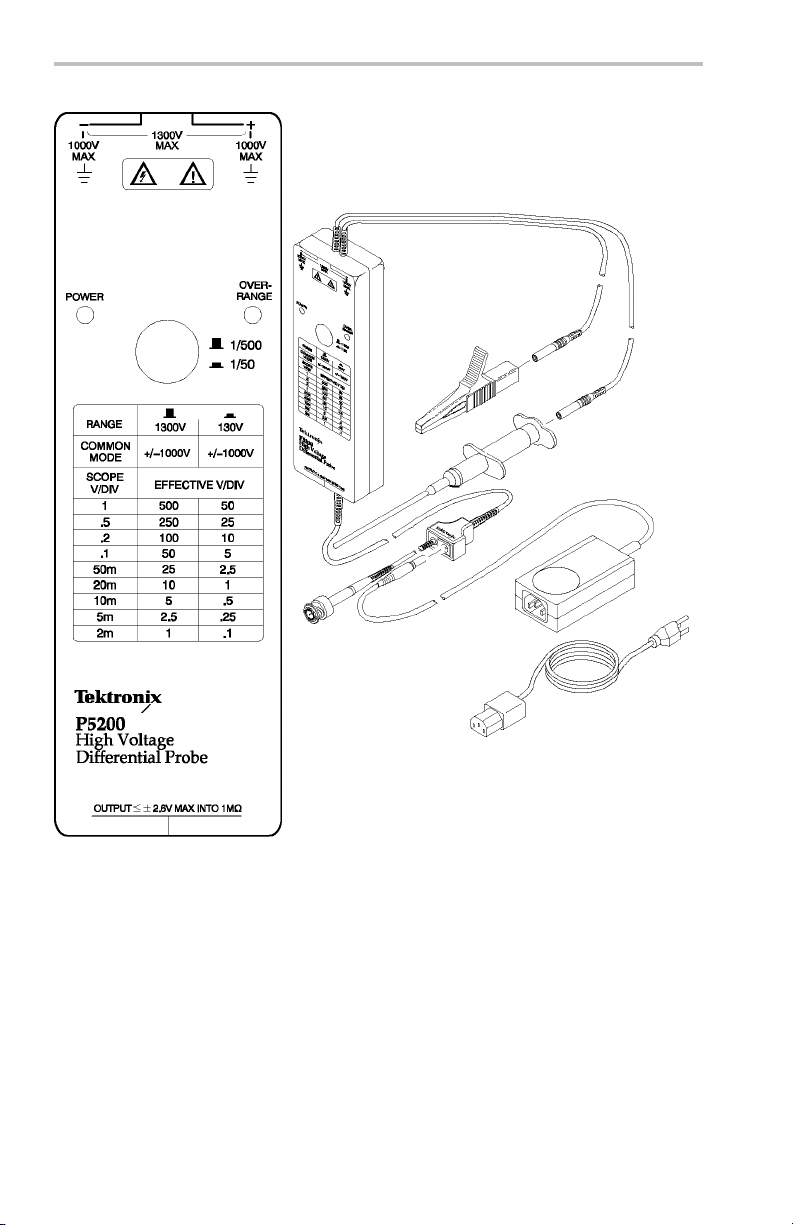

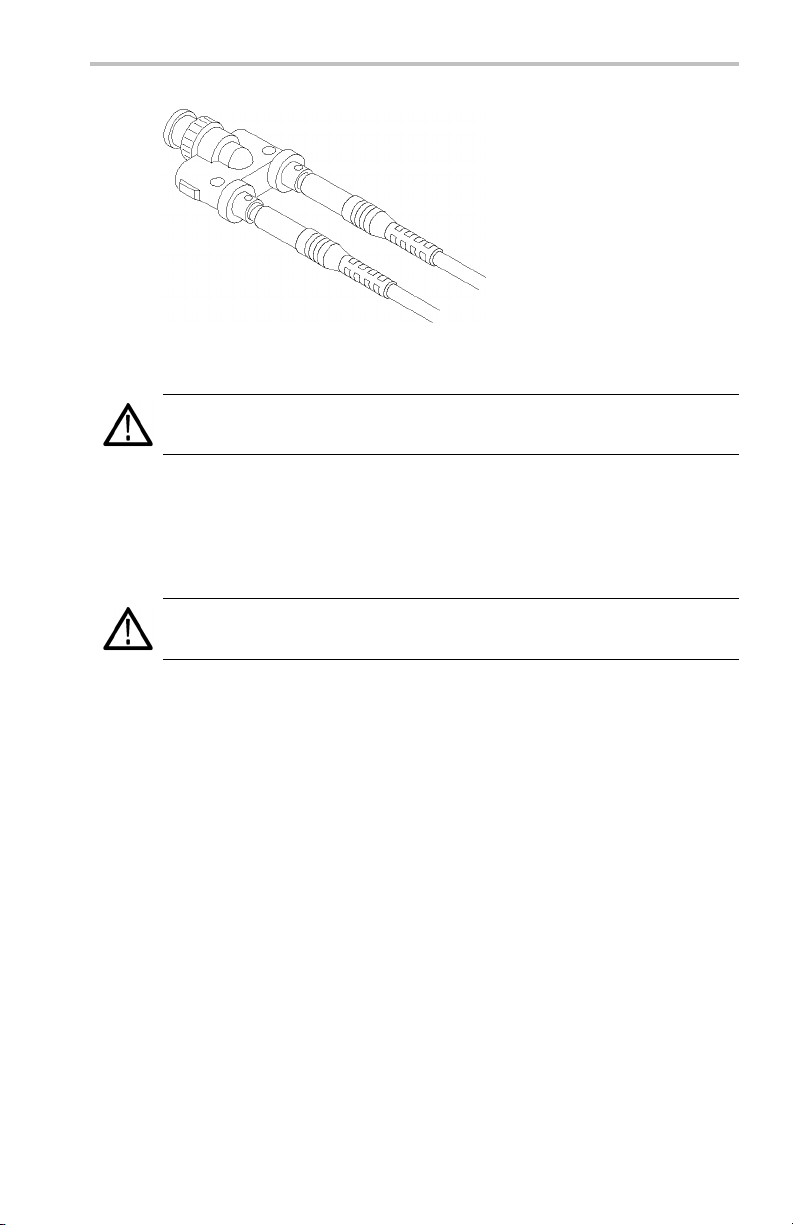

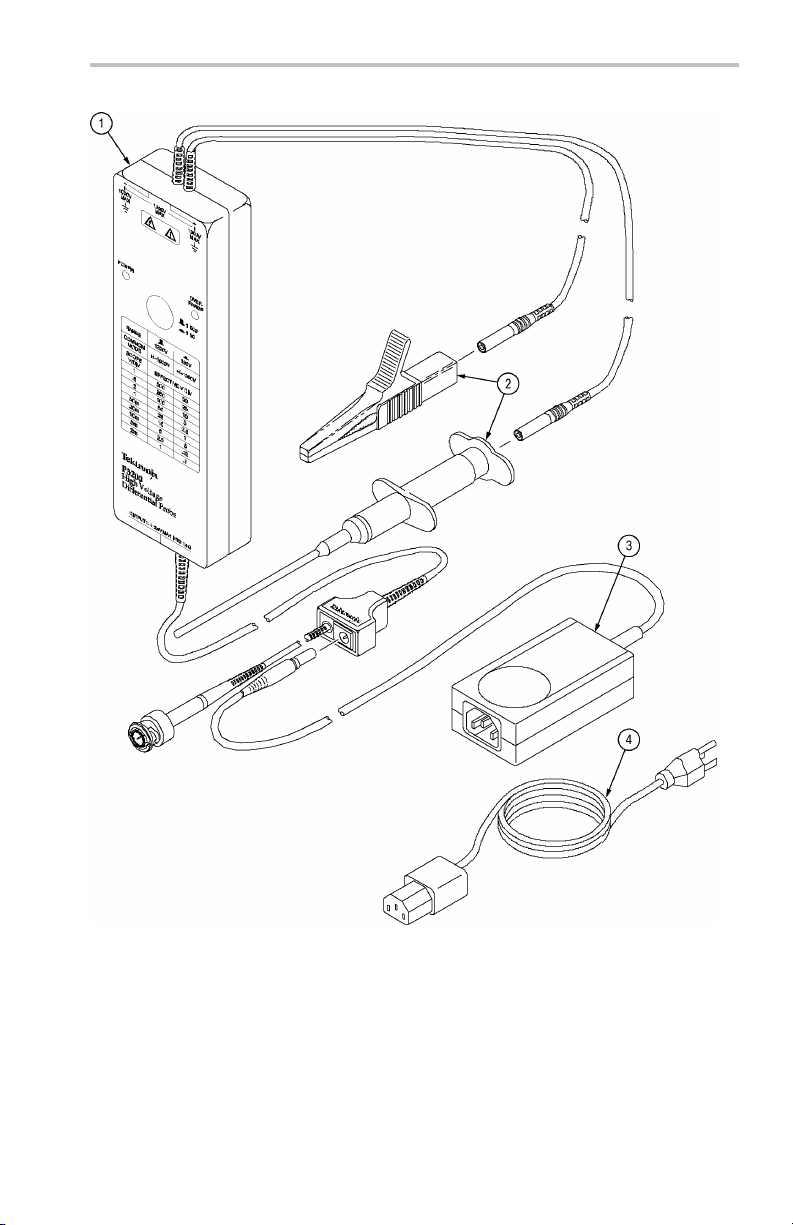

Figure 1: P5200 High Voltage Differential Probe

2 P5200 Instruction Manual

Page 19

Features and A ccessories

The P5200 has several features and accessories that make probing and

measurement a simpler task. Take a moment to familiarize yourself

with these items and their uses.

Power Indicator. The power indicator lights green

to show that power from the AC adapter is present.

Overrange Indicator. The overrange indicator

lights red if the voltage of the input signal exceeds

the linear range of the range setting. When this

happens, the signal on the probe output does not

accurately re present the signal on the probe input.

Range Button. In the raised position the

range button s ets the attenu ation to 1/500. In

the lowered position the range button sets the

attenuation to 1/50.

Use the 1/ 500 position for connections above

130 V up to a maximum of 1,300 V differential.

Use the 1/50 position for better signal resolution

on connections below 130 V (DC + peak AC).

Both range settings are rated for a maximum of

1,000 V

CAT II common mode.

RMS

Scale Conversion Chart. The chart lists the

effective volts per division for the 1/500 and 1/50

range settings a nd scale factors of 2 mV to 1 V on

the measurement instrument.

The effective volts per division is the a ttenua tion

factor of 500 or 50 multiplied by the scale factor

of the measurement instrument. For example,

with the range set to 1/500 and the measurement

instrument sensitivity set to 0.5 volts/division, the

effective volts per division equals 500× 0.5 or

250 V.

Differential Inputs. The inputs accept a maximum

of 1,000 V

CAT II between either input and

RMS

ground and a maximum difference of 1,300 V

(DC + peak AC) between the inputs. T hese input

ratings are valid for both range settings.

P5200 Instruction Manual 3

Page 20

Features and Accessories

Input Leads. The input leads of the differential

probe connect to the crocodile clips and plunger

probes that come with the probe. The connectors

are double insulated for safety.

NOTE. Use only the accessories provided with

the P5200 probe.

Plunger Probes. The plunger probes have long

probe sleeves with retracting hooks. These

probes connect safely to recessed test points that

are otherwise difficult to reac h. The connectors

are double insulated for safety.

Crocodile Clips. The large insulated clips

connect easily to large bolts or bus bars. The

connectors are double insulated for safety.

Output Lead. The BNC output connection to

the oscilloscope is calibrated to drive a high

impedance (1 MΩ) load.

Adapter Jack. The power supply jack on the

probe output connects to the 9 VDC p lug of the

AC adapter.

AC Adapter. The adapter converts AC line

voltage to 9 VDC for the probe power supply.

NOTE. The AC adapter that accompa nies the

P5200 probe is the only adapter specified for this

probe. Using any other adapter voids the product

warranty and may also produce electroma gnetic

interference. Adapters for the line voltages of

other countries are also available. Refer to the

Replaceable Parts section. (See page 29 .)

4 P5200 Instruction Manual

Page 21

Getting Started

To safely install and function

Differential Probe, follow the procedures in this section.

Installation

Install the P5200 probe as follows:

1. Connect the output of the

2. Connect the AC adapter to the jack located on the output lead of

3. Connect the AC adapter to the proper line voltage. The green power

4. Adjust the vertical offset (or position) of the measurement

5. Select the proper range setting. For higher resolution and less noise

6. Set the volts

ally check the P5200 High Voltage

probe to the BNC input of the oscilloscope

or other measurement instrument. The measurement instrument

input must have a ground reference.

the probe.

LED o n the probe should light.

instrument input.

when m easuri ng signals below 130 V, swit ch the attenuation to

1/50. If the ov

may not be accurate. Use the 1/500 setting instead.

the range indicated in the table on the front panel of the probe.

errange indicator lights or flashes, the output signal

per division setting on the measurement instrument to

WARNING. To avo id electrical shock, observe proper safety precautions

when working with voltages above 60 VDC or 30 VAC

levels pose a shock hazard. Make sure that the test leads are in good

condition. Use only the accessories supplied with the P5200 probe.

7. Using the appropriate probe accessories, connect the inputs of the

probe to the voltage source.

P5200 Instruction Manual 5

. These voltage

RMS

Page 22

Getting Started

CAUTION. To avoid damaging the input circuitry of the P5200 probe, do

not apply a voltage that is in excess of 1,000 V

input and ground or more than 1,300 V (DC + peak AC) between the two

inputs. This voltage rating applies to both 1/50 and 1/500 s ettings.

Functional Check

To make a sim ple functional check of the P5200 probe, select a source

that supplies AC line voltage and use the following procedure. This

procedure verifies a majority of the circuitry within the probe. For a

complete p erf or man ce verification, refer to Performance Verification

section. (See page 21.)

1. Use the installation procedure to connect the output of the P5200

probe to a measurement instrument. (See page 5, Installati on.)

2. Connect the inputs, set the range, and perform the check as each

line of the following table indicates.

Table 1: Functional check

CAT II between either

RMS

Input 1

(+ or –)

Hot

Hot

Hot

Input 2

(– or +)

Ground or

Neutral

Ground or

Neutral

Hot (same

connection)

Mode Range

Setting

Differential 1/500 (out)

Differential 1/50 (in) Overrange

Common

Mode

1/50 or 1/500

This completes the functional check procedure.

Check

Measurement

instrument

displays or

indicates the

line voltage

indicator

lights if the

input is

>130 Vp

No signal

6 P5200 Instruction Manual

Page 23

Operating Basics

To help you us e the P5200 Hig h Vo

effectively, this section provides important information about safety

limits, operating characteristics, and probing techniques.

WARNING. Due to the inherent hazards associated with taking high-voltage

measurements, the product is intende d for use by qualified personnel who

have had the training to make these types of measurements. Read and

follow the precautions specified in this manual.

Before you make any oscilloscope measurement, observe all safety

precautions described in the user and service manuals for the equipment

you are working on. Some general rules about using and servicing

electrical equipment are worth repeating here.

Observe the safety in stru ctio n symbols for t he equipment you are

working on.

Consult the instruction or service manuals for the equipment you

are working on.

Do not operate or service an electrical device in an explosive

atmosphere.

Avoid personal injury by never touching exposed connections or

components in the circuit-under-test when the power is on.

ltage Differential Probe safely and

Operating the Probe Safely

Before connecting the inputs of the probe to a circu it, read the safety

information in this section and attach the appropriate accessories to

the input connectors of the probe.

P5200 Instruction Manual 7

Page 24

Operating Basics

Minimizing Risk of RF Burn (probe leads)

WARNING. To avoid personal injury, do not handle the probe leads when

the leads are connected to a source that is above the voltage and frequency

limits. (See page 9, Safety limits.) The area above these limits poses a

risk of radio frequency (RF) burns.

If you need to use the p ro be within the risk area for RF burn, power off

the source before connec

Maximum Input Limits

CAUTION. To avoid damaging the input circuitry of the P5200 probe, do

not apply a voltage that is more than 1,000 V

input and ground or more than 1,300 V (DC + peak AC) between the two

inputs. Above 3 MHz, the voltage limit decreases as frequency increases.

(See page 9, Safety limits.) The input limit applies to both the 50X and

500X setting s.

ting or disconnecting the probe leads.

CAT II between either

RMS

8 P5200 Instruction Manual

Page 25

Operating Basics

Safety limits. This graph shows the voltage between either input a n d

earth ground.

1. Category II maximum voltage limit

2. RF burn risk a

rea (shaded)

3. Voltage derating with frequency

P5200 Instruction Manual 9

Page 26

Operating Basics

Operating Characteristics and Probing Techniques

This section explains the operating characteristics of the P5200 probe

along with techniques you can use to maximize t he performance of

the probe.

Operating L imits

The P5200 probe has two operating ranges that you select with the

ATTENUATION button on the front panel:

Select the 50X range for inputs o f 0 V to 130 V (DC + peak AC).

Select the 500X range fo r inputs of 130 V to 1300 V

(DC + peak AC).

Both ranges are rated for the maximum input limits, but you can obtain a

useful measurement only if the voltage you apply is within the specified

limits of the operating range.

Overrange Detection

Differential voltage outside the operating ran ge will overdrive the

circuitry of the probe and distort the output signal. When this

differential overrange occurs, the probe detects the condition and lights

the overrange indicator. With the Audible Overrange ON, the probe

will also emit an audible alarm.

Common-mode voltage greater than 1,000 V

can distort the output

RMS

signal, but the probe will not indicate an overrange condition.

Common-Mode Rejection

The comm on-mode rejection ratio (CMRR) is the specified ability of

P5200 High Voltage Differential Probe to reject signals th at are common

to both inputs. More precisely, C MRR is t he ratio of the differential gain

to the common-mode gain. The higher the ratio, the greater the ability

of probe to reject common-mode signals. For exact specifications, see

the Specifications section. (See Table 3 on page 16.)

Common mode rejection decreases as the input frequency increases.

The following Figure is a plot of typical CMRR of the probe versus

input frequency. For example, if you apply a 60 Hz line voltage of

500 V

80 dB (typical) and the signal appears as only a 50 mV

oscilloscope screen.

10 P5200 Instruction Manual

to both i npu t leads of the probe, the probe rejects the signal by

P-P

signal on the

P-P

Page 27

Operating Basics

Figure 2: Input impedance vs. frequency

To ma xim ize the rejection of common-mode signals, twist the input

leads together and do not use the extension leads. (See Figure 3.)

Twisting the Input Leads

Twisting the input leads helps to cancel noise that is induced into the

input leads, and t o improve the high frequency response o f the inputs.

For the best response possible, do not use the exten sion leads.

P5200 Instruction Manual 11

Page 28

Operating Basics

Figure 3: Twisting the inp ut leads

Extension Leads

The extension leads allow you to reach widely spaced connection

points. Connect the extension leads to the input leads using the adapters

provided. Be sure to use both extension leads so that the input leads

are the same length.

The extension leads, however, do affect the high-frequency performance

of the probe. With longer lead length, differential noise induced into

the input leads is greater. Also, because of the added inductance of

the leads, voltage measurements at frequencies above approximately

10 MHz may not be as precise. The following figure shows the effect

on HF transient response with (left waveform) and withou t (righ t

waveform). ( See Figure 4 on page 13.)

The extension leads do not affect the performance of the probe when

bandwidth is set to 5 MHz.

12 P5200 Instruction Manual

Page 29

Operating Basics

Figure 4: HF transient response with (left) and without (right) extension leads

Probe Loading

When you touch your probe tip to a circuit element, you are introducing

a new resistance, ca

Frequency and impedance of the source determine how much the probe

loads the circuit t

starts to increase beyond 1 kHz, the input impedance of the probe begins

to decrease. The lower the impedance of the probe relative to that of the

source, the more

pacitance, and inductance into the circuit.

hat you are measuring. As the frequency of the source

the probe loads the circuit under test.

The probe has virtually no loading effect on sources with relatively

low impedance

P5200 Instruction Manual 13

and low frequency.

Page 30

Operating Basics

14 P5200 Instruction Manual

Page 31

Specifications

The specifications in the follo

wing tables apply to a P5200 High Voltage

Differential Probe installed on a Tektronix TDS460A oscilloscope.

When the probe is used with another oscilloscope, the oscilloscope must

have an input impedance 1 M Ω an

15 and 20 pF, and a bandwidth not less than 100 MHz.

The probe must have a warm-u

p period of at least 20 minutes and be in

an environment that does not exceed the limits. (See Table 2.)

Specifications for the P

5200 probe fall into three categories: warranty,

typical, and nominal characteristics.

WARNING. Special fixtures are required to examine specifications at the

maximum frequency and voltage levels and should be conducted only by

qualified Service Personnel. See the Service section for more details.

Warranted Characteristics

The warranted characteristics describe guaranteed performance within

tolerance limits or certain type-tested requirements. Warranted

characteristics that have check procedures in the Performance

Ver i ficatio n section are marked with the

Table 2: Warranted Electrical Characteristics

input capacitance range of between

symbol.

Characteristics

Rise Time

DC Common Mode

Rejection Ratio

(20-30°C, <70% RH)

Bandwidth

Maximum Operating Input

Voltage

Description

<14 ns in

>3000:1 at 500 VDC

DC to 25 MHz (-3dB) in 1/50 range setting

1/500 differential: ±1.3 kV (DC + peak AC)

1/500 common mode: ±1 kV

1/50 differential: ±130 V (DC + peak AC)

1/50 common mode: ±1 kV

1/50 range setting

RMS

RMS

CAT II

CAT II

P5200 Instruction Manual 15

Page 32

Specifications

Table 2: Warranted Electrical Characteristics (cont.)

Characteristics

Maximum Nondestructive

Input Voltage

Range Accuracy

Temperature

Humidity

Description

1/500 and 1/50 differential: ±1.3 kV (DC + peak AC)

1/500 and 1/50 common mode: ±1 kV

±3% at 20-30 °C, <70% RH after 20 minute warm up

Operating: 0 to 40 °C

Nonoperating: –30 to +70 °C

Operating: 25 to 85% RH, +25 to +35 ° C

Nonoperating: 25 to 85% RH, +25 to +60 °C

Typical Characteristics

The typical characteristics in the following tables describe ty pical , but

not guaranteed, performance.

Table 3: Typical Electrical Characteristics

Characteristics

Rise Time

Bandwidth

AC Common-Mode Rejection

Ratio(20-30°C,<70%RH)

Noise (m easured tangentially)

Input Impedance and

Capacitance

DC Output Drift ±0.5 mV/°C

Propagation Delay

Description

<14nsin1/500rangesetting

DC to 25 MHz (–3dB) in 1/500 range setting

60 Hz: >10,000:1, –80 dB

100 kHz: >300:1, –50 dB

1 MHz: >300:1, –50 dB

<4 mV

RMS

8MΩ, 3.5 pF between inputs

4MΩ, 7 pF between each input and groun d

20 nS

RMS

CAT II

Table 4: Typical Mechanical Characteristics

Characteristics

Dimensions, Case

Dimensions, Input Leads

Description

185 mm × 66 mm × 32 mm

(7.2 in × 2.6 in × 1.3 in)

46 cm (18 in)

16 P5200 Instruction Manual

Page 33

Table 4: Typical Mechanical Characteristics (cont.)

Specifications

Characteristics

Dimensions, Output Cable 1.8 m (6 ft)

Unit Weight (probe only) 315 g (11 oz)

Shipping Weight (with

accessories)

Description

1.42 kg (3 lb, 2 oz)

Nominal Characteristics

The Nominal characteristics shown in the following table describe

guaranteed traits, but the traits do not have tolerance limits.

Table 5: Nominal Electrical Characteristics

Characteristics

Input Type

Output Type Single-ended, load impedance must be greater than

Range Settings Switchable: 1/50 and 1/500

Description

Balanced

50 kΩ for stated accuracy

differential

P5200 Instruction Manual 17

Page 34

Specifications

18 P5200 Instruction Manual

Page 35

User Service

The P5200 High Voltage Differe

components or adjustments. The accessories are replaceable. (See

page 29, Replaceable Parts.)

For terms of the product warranty, refer to the front o f this manual.

Should the probe require replacement under terms of the warranty,

return the probe to a Tektro

information: name of pu rchaser, return address, n ame and ph one

number of a p erson that Tektronix may contact, date of purchase, and

a description of the def

of the manual.

Cleaning

To prevent dam age to probe ma terials, avoid using chemicals that

contain benzine, benzene, toluene, xylene, acetone, or similar solvents.

Do not immerse the probe or use abrasive cleaners.

Dirt may be remov

of detergent and water, or isopropy l alcohol.

ed with a s o ft cloth dampened with a mild solution

Packaging for Shipment

ntial Probe contains no user serviceable

nix service center. Include the following

ect. See Contacting Tektronix at the beginning

If the original packaging is unfit for use or not available, use the

following p ackaging guidelines:

1. Select a sturdy shipping carton that has in side dimensions at least

one inch greater than the probe dimensions.

2. Put the probe into a plastic bag or wrap to p rotect it from dampness.

3. Place th

material. Seal the carton with shipping tape.

P5200 Instruction Manual 19

e pro be into the box and stabilize it with light packing

Page 36

User Service

20 P5200 Instruction Manual

Page 37

Performance Verification

The following procedure verifi

of the P5200 High Voltage Differential Probe. The following table

itemizes the equipment required, provides an example or part number of

the equipment, and explains t

Table 6: List of equipm e nt required

Description Minimum

requirements

Test oscilloscope Bandwidth:

≥100 MHz Vertical

Accuracy: ≤1.5%

Standard

amplitude

generator

Leveled sine wave

generator

DC voltage source

Plunger probe

(2 required)

Modified BNC

adapter

BNC adapter BNC-female-to-dual

Amplitude

accuracy:

≤0.75%

Rise time

(standard

amplitude): ≤3ns

Use probes

Included in

accessory kit

BNC-male-to-dual

binding post

banana

es the warranted electrical characteristics

he purpose of the equipment.

Example or part

number

TDS460A or

TDS784A

Fluke/Wavetek

9100 with

oscilloscope

option 250

Accessory kit

020-2106-00

103-0035-00 Interconnection

103-0090-00 Interconnection

Purpose

Display probe

output

Check probe

attenuation,

bandwidth,

common-mode

rejection ratio

Connection to

binding post

between probe

and generator.

(See Figure 5 on

page 22.)

between probe

and generator

P5200 Instruction Manual 21

Page 38

Performance Verification

Table 6: List of equipment required (cont.)

Description Minimum

requirements

Coaxial cables

(2 required)

Termination

36 in (0.9144 m),

precision 50 Ω

50 Ω precision

feed through

Example or part

number

012-0482-00 Interconnection

011-0049-01 Int erconne ction

Construction of Modified BNC Adapter

Construct the modified BNC Adapter from a BNC-male-to-dual binding

post adapter, Tektronix part number 103-0035-00. (See Figure 5.)

Purpose

between

oscilloscope and

generator

between probe

and generator

during rise time

measurements

Figure 5: BNC-male-to-dual binding post adapter

To expose the posts that you will connect the P5200 High-Voltage

Differential probe leads to, remove the black and red plastic post covers

of the BNC-male-to-dual adapter. Use a pair of pliers and a vise to

remove the plastic covers. ( See Figure 6.)

22 P5200 Instruction Manual

Page 39

Setup

Performance Verification

Figure 6: Removing plastic covers from binding posts

WARNING. These procedures require the application of high voltage to

the inputs of the P5200 probe. Because this adapter has exposed metal

surfaces, only qualified personnel should perform any testing with voltage

levels exceeding 30 V rms. All pertinent safety rules and guidelines for

elevated voltage measurements should be followed and adhered to.

1. Connect the output of the probe to the Channel 3 of the test

oscillos

2. Connect the 9 VDC o utp ut plug of the AC adapter to the input jack

of the pr

voltage. The green power LED o n the probe should light.

3. Make a

Table 7 on page 28.)

P5200 Instruction Manual 23

cope. Let the probe warm up for 20 minutes.

obe, and then connect the AC adapter to the correct line

copy of the test record to tabulate the test results. (See

Page 40

Performance Verification

Amplitude Accuracy

1. Set the volts/division on channel 2 of the oscilloscope to 2 V.

Trigger on channel 2.

Select 1 MΩ impedance (if option exists on oscilloscope).

Connect coaxial cable between TRIG OUT of the generator

(rear of Wavetek 9100) and channel 2 of the oscilloscope.

2. Set the volts/divisio n on channel 1 of the oscilloscope to 20 mV.

3. Set the seconds/div t o 200 µs an d the acquisition mode to

average 32.

4. Connect the coaxial cable from SIG OUT of the generator (rear of

Wavetek 9100) to channel 1 of the oscilloscope.

5. Set the generator to 0.1 V and 1 kHz (AUX, square w ave, 1 MΩ

load). Enable the output.

6. Select the amplitude m easurem ent on the oscilloscope and record

the DC amplitude (~100 mV) of square wave. This measurement

is the just oscilloscope.

7. Disable the generator output. Disconnect the coaxial cable from

channel 1 of the oscilloscope and SIG OUT of the generator.

8. Connect the output of the probe to channel 1 of the oscilloscope.

9. Attach the Modified BNC adapter to the SIG OUT o f the generator.

10. Attach the differential probe input leads (without attachment

accessories) by sliding the banana plug of the leads onto the binding

posts of the Modifi ed BNC adapter. (See Figure 7.)

24 P5200 Instruction Manual

Page 41

Performance Verification

Figure 7: Slide probe leads onto the binding posts

WARNING. To reduce the risk of shock, ensure the generator output is

disabled before setting the volage above 30Vrµs.

11. Set the probe range button on the probe to1/

(out). Set the

500

generator for a 50 V and 1 kHz standard amplitude (AU X , Square

wave, 1 M Ω load ) output.

WARNING. Generator produces hazardous voltage. To avoid risk of shock,

do not touch exposed metal parts after the generator output is enabled.

12. Enable the output of the generator.

13. Record the DC amplitude of the square wave. Divide into the

amplitude of just the oscilloscope (refer to step 6) .

Verify that only

the probe gain accuracy is ±3%.

14. Set t he calibration generator for 5 V standard amp

wave) output. Set the probe range button on the probe to

15. Record the DC amplitude of the square wave. Divid

litude (squ are

1

/50(in).

e into the

amplitude of the oscilloscope (refer to step 6). Verify that only

the probe gain accuracy is ±3%.

16. Reduce the amplitude on the generator to minimum, then disable

the generator output and disconnect the setup.

P5200 Instruction Manual 25

Page 42

Performance Verification

Rise Time

1. Configure the fast rise output of the generator for a 50 Ω load

(AUX, rise, 50 Ω load, rising edge).

WARNING. Generator produces hazardous voltage. To avoid risk of shock,

do not touch exposed metal parts after the generator output is enabled.

2. Attach a 50 Ω terminator to the generator fast-rise output and attach

the modified BNC adapter to the terminator.

3. Set the generator for fast rise (<3 ns), 100 kHz, 1 V.

4. Set the oscilloscope vertical to 5 mV/div and the horizontal to

20 ns/div or 25 µs/div, depending on the slope).

5. Set the probe range to

6. Attach the differential pro b e input leads (without attachment

accessories) by sliding the banana plug of the leads onto the binding

posts metal sleeves on the modified B N C adapter. (See Figure 7 on

page 25.) Enable the output of the generator.

1

/50(push in ).

7. C heck that the rise time is <14 ns between the 10% and 90% points

of the displayed pulse.

8. Reduce the amplitude on the generator to minimum , then disable

the generator output and disconnect the setup.

26 P5200 Instruction Manual

Page 43

DC CMRR

1. Set the range of the probe to1/50.

2. Set the osci llo scope in put coup ling to DC, the vertical to 50 mV/div,

3. Attach the BNC-female-to-dual-banana adapter to the DC output of

4. Attach the plunger clamps on the differential probe input leads.

5. Twist the input leads together and connect both probe inputs to

WARNING. Generator produces hazardous voltage. To avoid risk of shock,

do not touch exposed metal parts after the generator output is enabled.

6. Set the output of the calibrator to 500 V, and enable the output.

Performance Verification

and the seconds/div to 200 µs. Center the trace on the display. Set

the acquisition mode to average 32.

the generator (front of Wavetek 9100). Attach the modifi ed BNC

adapter to the BNC-female-to-dual-banana adapter.

the positive terminal o f the modified BNC adapter. (See Figure 3

on page 12.)

7. Check that the trace on the oscilloscope shifts less than

3.33 divisions (167 mV) from center.

WARNING. To reduce risk of electrical shock , ensure the gen erator is

disabled before modifying/disconnecting test setup or connections since the

exposed metal may be at a hazardous potential. it is recommended that the

generator output amplitude be reduced to a minimum prior to disabling the

output.

8. Disable the calibrator output, and disconnect all test equipment.

This completes the performance verification procedure.

P5200 Instruction Manual 27

Page 44

Performance Verification

Table 7: P5200 test record

Probe Serial Number: ___________Certificate Number: __________

Temperature: ___________RH % : _ _________

Date of Calibration: _____________Technician: _____________

Performance test Minimum Results Maximum

Amplitude accuracy

Rise time

DC CMRR

–3% +3%

—

–167 mV +167 mV

<14 ns

28 P5200 Instruction Manual

Page 45

Replaceable Parts

This section contains a list of the replaceable modul es for the P5200

High Voltage Differential Probe. Use this list to identify and order

replacement parts.

Parts Ordering Information

Replacement parts are available through your local Tektronix field

office or representative.

Changes to Tektronix instruments are sometimes made to accommodate

improved components as they become available and to give you the

benefitofthelatestcircuitimprovements. Therefore, when ordering

parts, it is important to include the following inform ation in your order:

Part number

Instrument type or model number

Instrument serial number

Instrument modification number, if applicable

If you order a part that has been replaced with a different or improved

part, your local Tektronix field office or representative will contact you

concerning any change in part number.

Module Exchange

You may exchange your module for a remanufactured module. These

modules cost significantly less than n ew modules and meet the same

factory specifications. For more information about the module exchange

program, refer to Contacting Tektronix at the beginning of the manual.

P5200 Instruction Manual 29

Page 46

Replaceable Parts

Using the Replaceable Parts List

This section contains a list of the mechanical and/or electrical

components that are replaceable for the P5200 probe. Use this list to

identify and order replacement parts. The following table describes

each colum n in the parts list.

Table 8: Parts List Column Descriptions

Column Column Name

1

2 Tektronix Part Numbe

3

4

Figure & Index Number Items in this section are referenced by

Qty This indicates the quantity of parts used.

Name & Description An item name is separated from the

Abbreviations

Abbreviations conform to American National Standard ANSI

Y1.1-1972.

Description

figure and index numbers to the exploded

view illustrations that follow.

r

Use this part number w

replacement parts fr

description by a colon (:). Because of

space limitations, an item name may

sometimes appea r as incomplete. Use the

U.S. Federal Catalog handbook H6-1 for

further item name identification.

om Tektronix.

hen ordering

30 P5200 Instruction Manual

Page 47

Replaceable Parts

Figure 8: P5200 High Voltage Differential Probe and replaceable accessories

P5200 Instruction Manual 31

Page 48

Replaceable Parts

Fig.

&

Index

No.

8-1 119-4784-00 1

-2 020-2106-00 1

-3 119-7538-00 1

-4

—

Tek tronix

Part No. Qty 12345 Name & Description

161-0066-00 1

161-0066-09 1

161-0066-10 1

161-0154-00 1

161-0298-00 1

161-0304-00 1

070-9018-XX 1

PROBE,DIF ACT:POWER,1KV,25 MHZ

STANDARD ACCESSORIES

ACCESS PKG:(1) RED,(1) BLACK CROCODILE

CLIP& (1) RED, (1) BLACK INSULATED

PLUNGER CLAMP CLIP,COMPONENT KIT

POWER SUPPLY; 11.7W, EXTERNAL,

DESK-TOP; 9VDC, 1.3A OUT; 100-240 VAC

IN, 47-63 HZ, 2.1 MM BARREL CONNECTOR,

ENERGY STAR COM PLI ANT, SAFETY

CONTROLLED

CABLE ASSY PWR; 3,18 AWG, 250V/10A, 98.0

L, STR, IEC320, RCPT X NEMA 5-15P, US,

SAFETY CONTROLLED, (OPTION A0)

CABLE ASSY, PWR; 3,0.75MM SQ, 250V/10A,

99.0 L, STR IEC320, RCPT, EUROPEAN,

SAFETY CONTROLLED, (OPTION A1)

CABLE ASSY, PWR; 3,1.0 MM SQ, 250V/10A, 2.5

METER, STR, IEC320, RCPT X 13A, FUSED UK

PLUG (13A F U SE), UNITED KINGDOM, SAFETY

CONTROLLED, (OPTION A2)

CA ASSY, PWR; 3,1.0MM SQ,250V/10A, 2.5

METER, STR, IEC320, RCPT, SWISS, SAFETY

CONTROLLED, (OPTION A5)

CABLE ASS Y, PWR; 3,125V/7A, JAPAN, 98

LONG, STR, NEMA 5-15P PLUG X IEC320/C-13

RECEPTACLE, SAFETY CONTROLLED,

(OPTION A6)

CABLE ASSY, PWR; 3,1.0MM SQ, 250V/10A,2.5

METER, STR, IEC320, 3C CERTIFICATION,

RCPT, CHINA, SAFETY CONTROLLED,

(OPTION A10)

MANUAL, TECH:INSTRUCTIONS, P5200, ENG,

(OPTION L0)

32 P5200 Instruction Manual

Loading...

Loading...