Page 1

Instruction Manual

P5102

100 MHz High-Voltage Probe

070-9294-02

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and

pending. Information in this publication supercedes that in all previously

published material. Specifications and price change privileges reserved.

Tektronix, Inc., P.O. Box 500, Beave rton, OR 97077

TEKTRONIX, TEK, TekTools, and TekScope are registered trademarks of

Tektronix, Inc.

Page 3

WARRANTY

Tektronix warrants that this product will be free from defects in materials and

workmanship for a period of one (1) year from the date of purchase from an authorized

Tektronix distributor. If any such product proves defective during this warranty period,

Tektronix, at its option, either will repair the defective product without charge for parts and

labor, or will provide a replacement in exchange for the defective product. Batteries are

excluded from this warranty.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect

before the expiration of the warranty period and make suitable arrangements for the

performance of service. Customer shall be responsible for packaging and shipping the

defective product to the service center designated by Tektronix, shipping charges prepaid,

and with a copy of customer proof of purchase. Tektronix shall pay for the return of the

product to Customer if the shipment is to a location within the country in which the

Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or

improper or inadequate maintenance and care. Tektronix shall not be obligated to furnish

service under this warranty a) to repair damage resulting from attempts by personnel other

than Tektronix representatives to install, repair or service the product; b) to repair damage

resulting from improper use or connection to incompatible equipment; or c) to repair

damage resulting from improper use of connection to incompatible equipment; or d) to

service a product that has been modified or integrated with other products when the effect

of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS

PRODUCT IN LIEU OF ANY OTHER WARRANTIES, EXPRESSED OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE

DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY

PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Contacting Tektronix

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales

support

Service

support

Technical

support

* This phone number is toll free in North America. After office

hours, please leave a voice mail message.

Outside North America, contact a Tektronix sales office or

distributor; see the Tektronix Web site for a list of offices.

1-800-833-9200, select option 1*

1-800-833-9200, select option 2*

Email: techsupport@tektronix.com

1-800-833-9200, select option 3*

6:00 a.m. -- 5:00 p.m. Pacific time

Page 5

Table of Contents

General Safety Summary iii............................

Features and Accessories 1.............................

Operating Basics 5...................................

Observe Voltage Derating Information 5...................

Common Lead Length 5................................

Probe Loading 6......................................

Adjustment Proce dures 7..............................

LF Compensation 7....................................

HF Compensation 8...................................

Performance Verification 13............................

Maintenance 15.......................................

Cleaning Instructions 15.................................

Customer Support 15...................................

Preparation for Shipment 16..............................

Specifications 17......................................

Replaceable Parts 22...................................

P5102 Instruction Manual

i

Page 6

Table of Contents

List of Figures

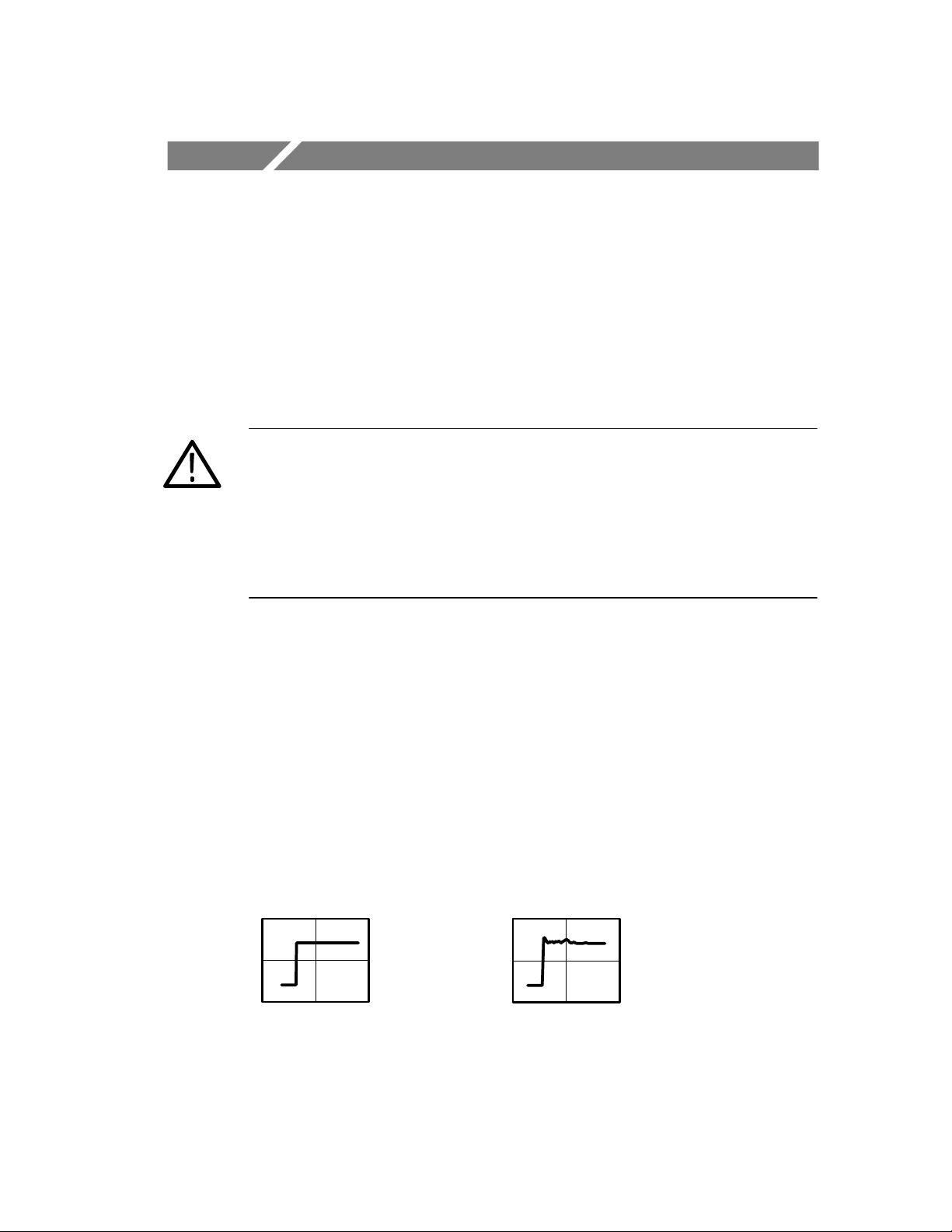

Figure 1: Waveform Distortion from Common Lead Length 5..

Figure 2: Probe Loading Equivalent Circuit 6...............

Figure 3: LF Compensation Setup 7.......................

Figure 4: LF Compensation Adjustment 8..................

Figure 5: Signal Source Characteristics for HF Compensation 8

Figure 6: Opening the Compensation Box 9................

Figure 7: HF Compensation Setup 10......................

Figure 8: HF Compensation Adjustments 11.................

Figure 9: HF Compensation Regions of Fast Rise Signal 12.....

Figure 10: Bandwidth Test Setup 14.......................

Figure 11: Maximum Voltage Derating Curves

(V

RMS

Figure 12: Typical Input Impedance 19.....................

Figure 13: Typical Input Phase 20.........................

Figure 14: P5102 Replaceable Parts 22.....................

, DC Coupled) 18..............................

List of Tables

Table 1: Required Test Equipment 13......................

Table 2: Warranted Electrical Specifications 17..............

Table 3: Typical Electrical Characteristics 19................

Table 4: Typical Mechanical Characteristics 21..............

Table 5: Environmental Specifications 21...................

ii

P5102 Instruction Manual

Page 7

General Safety Summary

Review the following safety precautions to avoid injury and prevent

damage to this product or any products connected to it.

Only qualified personnel should perform service procedures.

Injury Precautions

Avoid Electric Overload. To avoid injury or fire haz ard, do not appl y

potential to any input, including the common inputs, that varies from

ground by more than the maximum rating for that input.

Avoid RF Burns While Handling Probe To avoid RF burns, do not handle

the probe while the common lead is connected to circuits above the

voltage and frequency limits specified in Figure 11b on page 18.

Avoid Electric Shock. To avoid inj ury or loss of life, do not connect or

disconnect probes or test leads while they are connected to a voltage

source.

Do Not Operate Without Covers. To avoid electric shock or fire hazard,

do not operate this product with covers or panels removed.

Do Not Operate in an Explosive Atmosphere. To avoid injury or fire

hazard, do not operate this product in an explosive atmosphere.

Keep Probe Surface Clean and Dry. To avoid electric shock and

erroneous readings, keep probe surface clean and dry.

Product Damage Precautions

Do Not Operate With Suspected Failures. If you suspect there is damage

to this product, have it inspected by qualified service personnel.

Do Not Immerse in Liquids. Clean the probe using only a damp cloth.

Refer to cleaning instructions on page 15.

P5102 Instruction Manual

iii

Page 8

General Safety Summary

Safety Terms and Symbols

Terms in This Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that

could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that

could result in damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you

read the marking.

WARNING indicates an injury hazard not immediately accessible as

you read the marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. These symbols may appear on the product:

DANGER

High Voltage

Protective Ground

(Earth) Terminal

ATTENTION

Refer to Manual

Double

Insulated

Certifications and Compliances

Compliances. Consult the product specifications for Overvoltage

Category and Safety Class.

Overvoltage Category. Overvoltage categories are defined as follows:

CAT III: Distribution level mains, fixed installation

iv

CAT II: Local level mains, applianc es, portable equipment

CAT I: Signal level , special equipment or parts of equipment,

telecommunication, electronics

P5102 Instruction Manual

Page 9

Features and Accessories

The P5102 is a high-voltage passive probe designed for use with

TekScope THS700 series instruments. The probe features a floating

common and is ideal for measuring and troubleshooting power

supplies and high-voltage devices. The probe provides 10X

attenuation of signals up to 1000 V

to 100 MHz. The P5102 probe is certified to international safety

standards.

The P5102 probe has features and accessories to make high-voltage

measurements safer and easier. Please take a moment to familiarize

yourself with these features and accessories and their uses.

WARNING. Do not substitute accessories from other products for

those provided with the P5102. The accessories for the P5102 have

been safety tested. The use of non-tested accessories may cause

injury.

RMS

and derated performance up

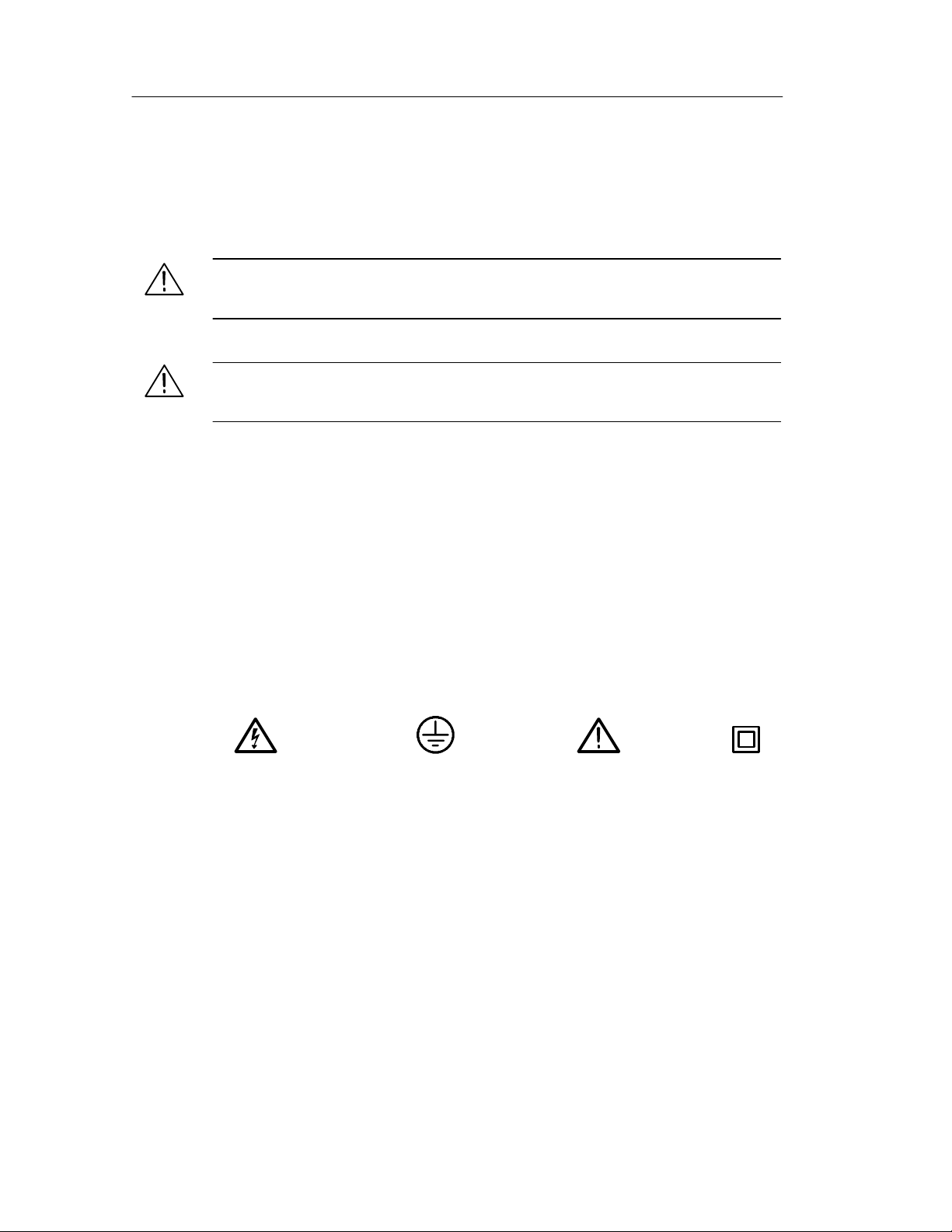

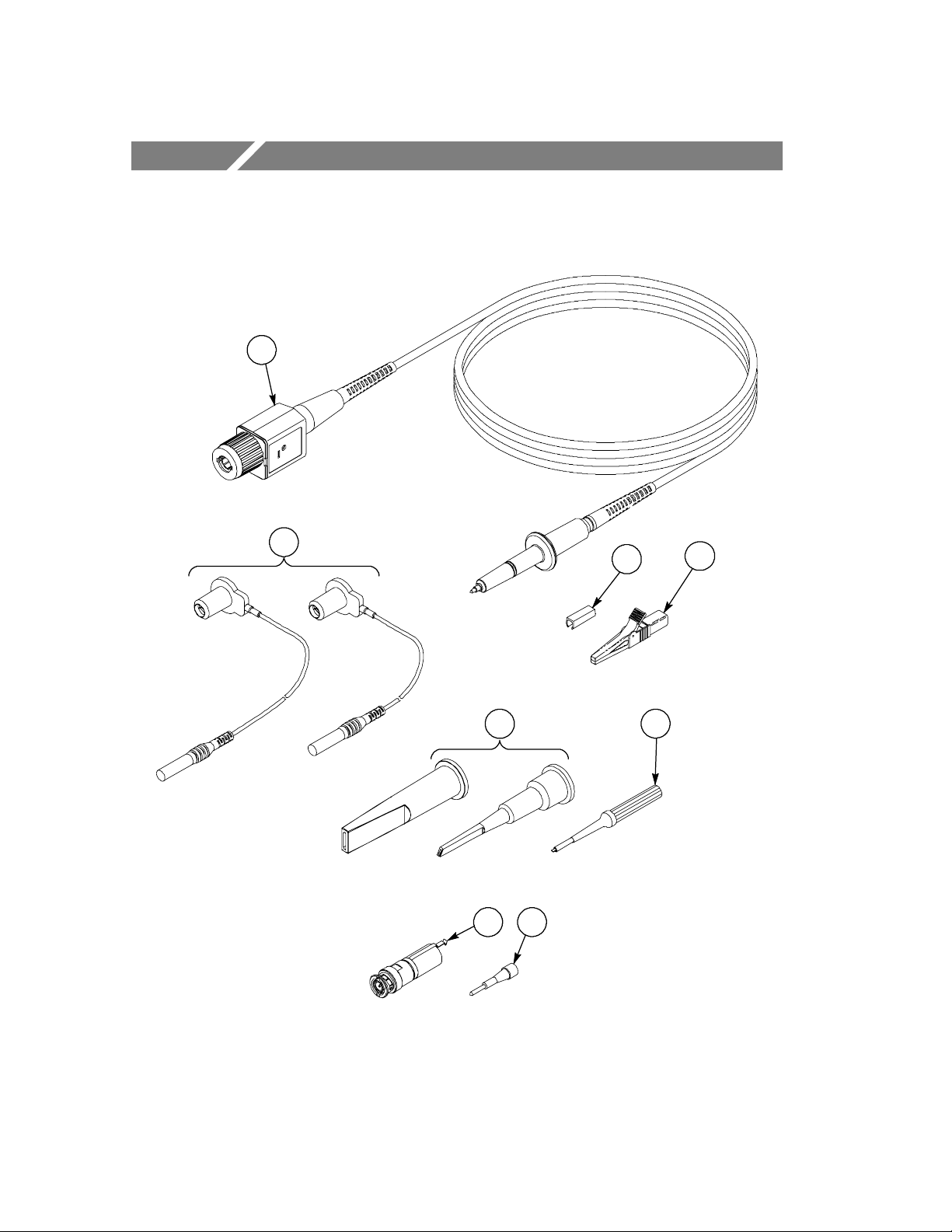

P5102 Features and Standard Accessories

Finger

Guard

Probe

Common

6-32 Probe Tip

Probe Body -- The P5102 probe body is designed for personal

safety, ergonomic comfort, and signal fidelity.

The finger guard provides protection when the hook tips are not being

used. Keep your fingers behind the finger guard whenever possible to

reduce the risk of a shock from the circuit under test.

The probe tip is a 6--32 threaded post that accepts both standard and

optional accessories.

Keep the probe body and accessories clean to reduce the risk of shock

due to surface conduction.

P5102 Instruction Manual

1

Page 10

Features and Accessories

P5102 Features and Standard Accessories (Cont.)

Compensation Box -- The compensation box contains low- and

high-frequency compensation adjustments. The high-frequency adjustments are accessible by removing the compensation box cover. Refer

to Adjustment Procedures on page 7.

Adjustment Tool -- Use the supplied adjustment tool for probe

compensation adjustments. Do not use metallic or conductive tools

while making adjustments.

Color Markers -- The matching markers help you identify probe

inputs at a glance. Clip one marker near the probe head and the

matching marker near the compensation box as shown.

Matching

Markers

Small Hook Tip -- Use the small hook tip for making connections to

small conductors such as component leads.

Install the small hook tip by sliding it over the body of the probe and

screwing it onto the threaded probe tip.

To use the tip, hold the probe body and pull the tip shield back. Hook

the tip onto the circuit and release the shield. The hook tip will firmly

hold the conductor under test.

2

P5102 Instruction Manual

Page 11

P5102 Features and Standard Accessories (Cont.)

Large Hook Tip -- Use the large hook tip when working with larger

components such as bolt terminals and buss bars typically found in

power distribution equipment.

Install the large hook tip by sliding it over the body of the probe and

screwing it onto the threaded probe tip.

To use the tip, hold the probe body and pull the tip shield back. Hook the

tip onto the circuit and release the shield. The hook tip will firmly hold the

conductor under test.

Features and Accessories

Common Leads -- The P5102 probe comes with a long and a short

floating common lead. Both common leads connect to a removable

crocodile clip.

Attach the common lead to the probe body by inserting the probe head

into common lead as shown.

The length of the common lead directly impacts the fidelity of high-frequency signals. The longer the common lead, the more the signal will

be distorted. For more information about the common lead and signal

quality, go to page 5.

Crocodile Clip -- The large crocodile clip attaches to the insulated

banana connector on the common leads.

WARNING. For safe electrical connections, use the crocodile clip

provided. Do not attempt to substitute the crocodile clip with any

other accessory.

P5102 Instruction Manual

3

Page 12

Features and Accessories

P5102 Optional Accessories

Probe Tip Extender (P6000) -- Use the probe tip extender to con-

nect the probe to larger test sockets located in equipment or on printed

circuit boards.

Connect the probe tip extender by screwing it onto the threaded

probe tip.

Ground

Clip

Probe

Common

Probe-to-BNC Adapter -- Use the probe-to-BNC adapter to

connect the probe directly to BNC connectors. The adapter is

recommended for use when verifying or adjusting the probe.

Attach the adapter by pressing it onto the 6-32 probe tip and making

sure that the ground clip makes contact with the probe common.

WARNING. Do not connect the adapter to a floating or high-voltage

source. The BNC adapter is only rated to 500 V (DC + peak AC)

with the probe common connected to earth ground.

4

P5102 Instruction Manual

Page 13

Operating Basics

To get guaranteed performance from the P5102 probe, ple ase read

and apply the information in this section.

Observe Voltage Derating Information

WARNING. To avoid personal injury, do not handle the probe when

the common lead is connected to a source that is above the voltage

and frequency limits specified in Figure 11b on page 18.

To avoid personal injury or damage to the probe, do not connect the

probe input to a source that is above the maximum non-destructive

input voltage and frequency limits given in Figure 11a on page 18.

Common Lead Length

Always use as short a common lead as possible between the probe

head and circuit common for high frequency or fast rise time signals.

The input capacitance of the probe and the series inductance added

by the probe tip and common lead can result in a resonant circuit;

this circuit may cause parasitic “ringing” visible within the

bandwidth of your oscilloscope. Refer to Figure 1.

6-inch Common 18-inch

Figure 1: Waveform Distortion from Common Lead Length

Common

P5102 Instruction Manual

5

Page 14

Operating Basics

Parasitic ringing is not a concern when the probe is used with low

frequency or slow rise time signals and is not apparent if the

frequency content is beyond the bandwidth of the oscilloscope.

Probe Loading

When you touch your probe tip to a circuit element, you are

introducing a new resistance, capacitance, and inductance into the

circuit. Refer to Figure 2.

R

source

Probe C

11.2 pF

in

V

source

L

(common lead)

cl

Probe R

5MΩ

in

Figure 2: Probe Loading Equivalent Circuit

Frequency and impedance of the source determine how much the

probe loads the circuit you are measuring. As the frequency of the

source starts to increase beyond 1 kHz, the input impedance of the

probe begins to decrease. The lower the impedance of the probe

relative to that of the source, the more the probe loads the circuit

under test. Refer to Figure 12 on page 19 for a graph of frequency

versus input impedance.

The probe has virtually no loading effect on sources with relatively

low impedance and low frequency.

6

P5102 Instruction Manual

Page 15

Adjustment Procedures

The low-frequency (LF) compensation of the P5102 probe must be

checked every time the probe is connected to a different oscilloscope

input.

The high-frequency (HF) compensation should be checked if the

probe was repaired or fails to meet rated bandwidth specifications.

Check the probe using the performance verification procedures on

page 13 to determine if adjustment is required.

LF Compensation

Before taking any measurements with the probe, first check the LF

compensation of the probe and adjust it to match the channel input it

is connected to.

1. Connect the probe to the Probe Comp signal on your TekScope

instrument and then press AUTORANGE. See Figure 3.

Ch 1

Probe reference lead to

ProbetiptoPROBECOMP

AUTORANGE

Figure 3: LF Compensation Setup

P5102 Instruction Manual

7

Page 16

Adjustment Procedures

2. Compensate the probe by adjusting the trimmer in the probe

compensation box so that the corners of the signal are square. See

Figure 4.

LF

Figure 4: LF Compensation Adjustment

≈1 kHz

HF Compensation

To compensate the probe for high frequencies, you will need a

properly terminated signal source that has the characteristics given in

Figure 5. Refer to Table 1 on page 13 for a complete list of required

test equipment.

1MHz

1Vpp

Figure 5: Signal Source Characteristics for HF Compensation

tr<1 ns

90%

10%

To access the HF adjustments of the probe, you must open the cover

of the compensation box using the procedure that follows.

8

P5102 Instruction Manual

Page 17

Adjustment Procedures

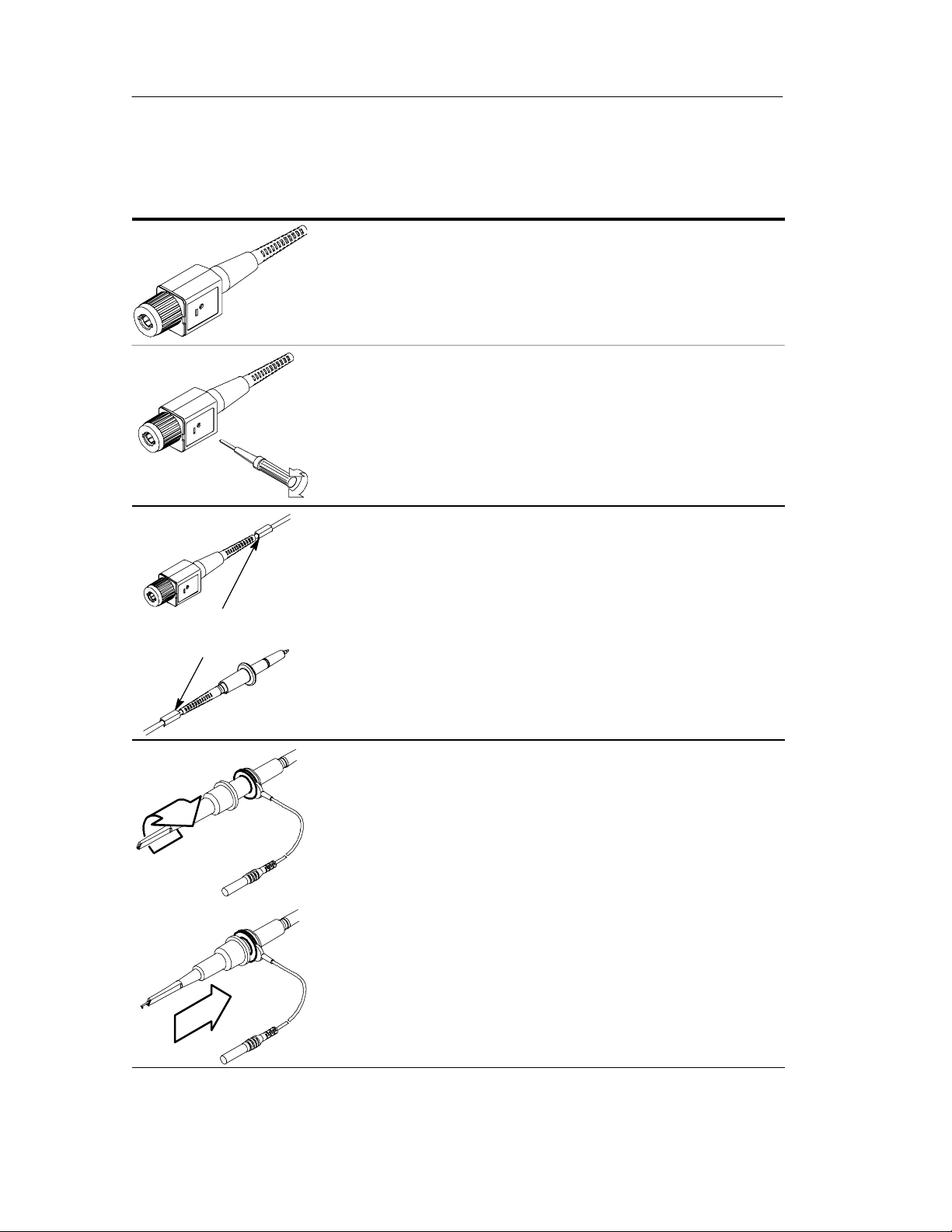

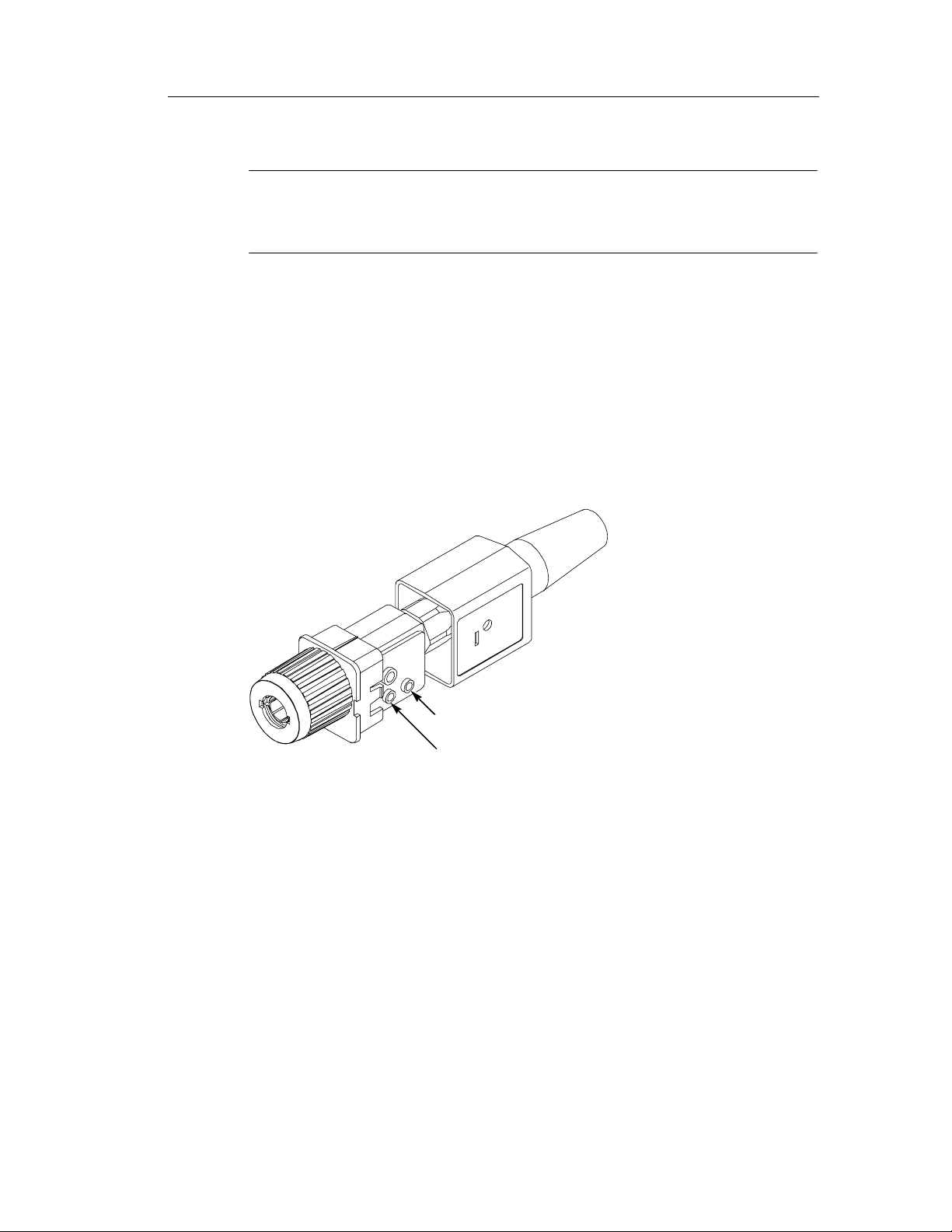

Opening the Compensation Box

NOTE. This procedure should be performed by qualified service

personnel only.

To open the cover, obtain two small screwdrivers and use them to

unlatch the tab as shown in Figure 6.

WARNING. Avoid damaging the tab. A damaged tab will allow the

cover to easily separate and expose the user to the electrical

potential of the common connection.

To avoid damaging the tab, do not attempt to press on the tab

through the hole in the cover where it latches. In the event of a

damaged tab, replace the probe.

1. Insert the flat blade of small screwdriver (A) into the location

shown in Figure 6. Insert the blade until it stops against the back

of the tab.

B

Tab

Insert up to the Tab

A

Figure 6: Opening the Compensation Box

P5102 Instruction Manual

9

Page 18

Adjustment Procedures

2. While holding screwdriver (A) in place, insert small screwdriver

(B) between the ridge on the front of the compensation box and

the edge of the cover.

3. Gently twist the blade of screwdriver (B) to separate the cover

and unlatch the tab.

4. After unlatching the tab, slide the cover back to expose the

internal adjustments.

HF Compensation Procedure

After opening the compensation box, perform the following

procedure to compensate the probe for high frequencies.

1. Connect a 50 Ω feedthrough termination to the positive going

FAST RISE output of the calibration generator. See Figure 7.

Calibration

Generator

FAST RISE Output

50 Ω Termination

Probe-to-BNC Adapter

P5102 Probe

Figure 7: HF Compensation Setup

2. Refer to page 4 and use the optional probe-to-BNC adapter to

connect the probe to the termination.

10

3. Set the Calibration Generator to 1 MHz.

4. Set the PULSE AMPLITUDE to 0.5 V

.

P-P

P5102 Instruction Manual

Page 19

Adjustment Procedures

NOTE. If you have changed the default setting for the probe type,

access the vertical menu of the TekScope instrument and return the

setting to 10X.

5. Set the oscilloscope to 100 mV/division.

6. Set the oscilloscope averaging to 4.

7. Set the oscilloscope to 10 ns/div (100 ns, X10 magnification)

Adjust the oscilloscope as necessary to view the leading edge of

the waveform.

8. Locate the HF1 and HF2 adjustments. See Figure 8.

HF1

HF2

Figure 8: HF Compensation Adjustments

9. Preset HF1 counterclockwise and HF2 clockwise.

10. Adjust HF2 for flatness and adjust HF1 for the best front corner.

SeeFigure9.BecauseHF1 and HF2 interact, readjust HF2 and

HF1 as necessary to achieve the best rise time with the smallest

aberrations.

P5102 Instruction Manual

11

Page 20

Adjustment Procedures

6%

Aberrations

Figure 9: HF Compensation Regions of Fast Rise Signal

HF2

(20 ns)

HF1

(10 ns)

11. After compensating the HF, carefully slide the cover bac k until

the tab latches securely into place.

12

P5102 Instruction Manual

Page 21

Performance Verification

Oscill

Calibrati

Use the procedure in this section to verify that the P5102 probe

meets the warranted bandwidth specification highlighted with

boldface type in the Specifications section on page 17. The steps of

this procedure must be performed in the order gi ven using a THS720

TekScope instrument and other equipment that meets the minimum

requirements listed in Table 1.

Table 1: Required Test Equipment

Description

Oscilloscope Use a THS720 only. The

Calibration Generator

(for HF adjustment only)

Leveled Signal Generator 50 kHz to 250 MHz

Termination, 50 Ω

feedthrough

Adapter, probe tip to BNC ProbetiptomaleBNC Tektronix part number

Minimum Requirements Example

THS720

probe is optimized to match

the input characteristics and

bandwidth of the THS720

≤1 ns rise time square wave Wavetek 9100 Universal

Calibration System with

oscope

Module (Option 250)

50 Ω male to female BNC

Tektronix part number

011-0049-01

013-0291-00

NOTE. Compensate the probe for LF before performing this

procedure. The LF compensation procedure begins on page 7.

on

If the probe does not meet the bandwidth requirement of this

procedure, perform the adjustments beginning on page 7 and retest.

P5102 Instruction Manual

13

Page 22

Performance Verification

1. Connect the test setup as shown in Figure 10.

Leveled

Sine Wave

Generator

50 Ω Termination

P5102 Probe

Test

Oscilloscope

Output

Probe Tip to

BNC Adapter

Figure 10: Bandwidth Test Setup

2. Set the leveled signal generator output frequency to 1 MHz.

NOTE. If you have changed the default setting for the probe type,

access the vertical menu of the TekScope instrument and return the

setting to 10X.

14

3. Set the oscilloscope to 50 mV/division. (The effective setting

with the 10X attenuation of the probe is 500 mV/division.)

4. Adjust the Leveled Signal Generator for a display exactly 6

divisions peak-to-peak.

5. Increase the Leveled Signal Generator frequency until the display

is 4.2 divisions peak-to-peak. (This represents the . 707 or

half-power amplitude.)

6. Note that the frequency is greater than 100 MHz.

P5102 Instruction Manual

Page 23

Maintenance

This section contains information necessary for the maintenance and

repair of the P5102 probe.

NOTE. The P5102 probe has no replaceable components. Accessory

parts may be ordered as indicated in the replaceable parts list.

Cleaning Instructions

Clean the probe using a soft cloth dampened with a mild detergent

and water solution. Do not use any other chemicals or abrasives.

Customer Support

Refer to Contacting Tektronix at the front of this manual for a listing

of the various ways to contact Tektronix, Inc. for operational and

service support of this product.

P5102 Instruction Manual

15

Page 24

Maintenance

Preparation for Shipment

If you need to ship your probe, pack it carefully to prevent damage

while in transit. If the original pa ckaging is unfit for use or not

available, use the following packaging guidelines:

1. Use a corrugated cardboard shipping carton having inside

dimensions at least one inch greater than the probe dimensions.

The box should have a carton test strength of at least 200 pounds.

2. Put the probe into a plastic bag or wrap to protect it from

dampness in transit.

3. Place the probe into the box and stabilize it with light

packing material.

4. Seal the carton with shipping tape.

16

P5102 Instruction Manual

Page 25

Specifications

The warranted specifications of Table 2 that appear in boldface type

are specifications checked in the Performance Verification section.

Specifications that are not warranted are typical (Tables 3 and 4) and

are provided as general information for your convenience.

The specifications apply to a P5102 probe installed on a Tektronix

THS720 oscilloscope. The instrument must have a warm-up period

of at least 10 minutes and be in an environment that does not exceed

the limits described in Table 5.

Table 2: Warranted Electrical Specifications

Attenuation

(DC coupled system)

Bandwidth

(--3 dB, DC coupled system)

Maximum Rated Input Voltage IEC 1010-1 Installation C ategory

Between probe tip and probe common

or between probe tip and earth ground

(Refer to Figure 11a for derating with

frequency)

Between probe common and earth ground

(Refer to Figure 11b for safe-handling limits

for overload and RF)

Safety

X10, ±2%

DC to 100 MHz (THS720)

DC to 60 MHz (THS710)

I II III

1000

600 600 300

UL 3111--1 First Edition

CSA 22.2 No. 1010.1--92, Series M89

EN 61010-1

EN 61010-2-031

1000 600

IEC Installation Category Category II

IEC Pollution Degree Degree 2

IEC Safety Class Class 2

(Double/Reinforced Insulation)

P5102 Instruction Manual

17

Page 26

Specifications

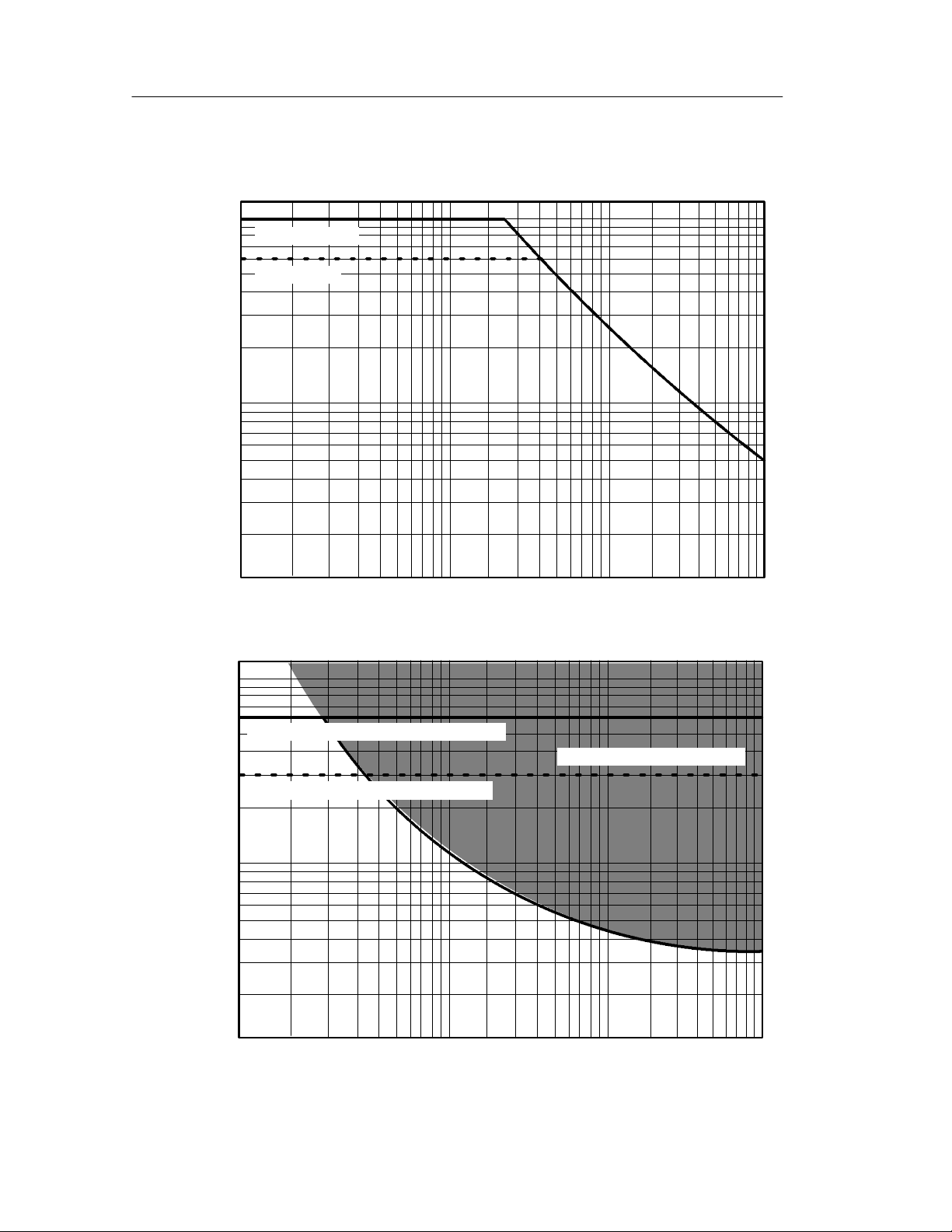

a. Maximum non-destructive input voltage (probe tip to common or earth ground)

1000V

500V

Voltage

)

(V

RMS

100V

50V

b. Maximum safe-handling limits (probe common to earth ground)

DC or 0

Category I & II

Category III

100k

500k

1M 5M 10M 50M 100M

Frequency (Hz)

1000V

Category I & II maximum voltage limit

Category III maximum voltage limit

DC or 0 10M1M 5M 50M500k100k

Frequency (Hz)

Voltage

(V

RMS

500V

)

100V

50V

Figure 11: Maximum Voltage Derating Curves (V

RF burn risk area (shaded)

, DC Coupled)

RMS

100M

18

P5102 Instruction Manual

Page 27

Table 3: Typical Electrical Characteristics

Specifications

Rise Time (System)

Checked using optional BNC adapter

Input Resistance (System)

3.5 ns (THS720)

5.8 ns (THS710)

5MΩ

SeeFigure12

Input Phase (System) (See Figure 13)

Compensation Range 23 pF to 27 pF

Input Capacitance (System)

11.2 pF

Probe connected to instrument and properly

compensated. Checked at 1 MH z

10 MΩ

1MΩ

100 kΩ

10 kΩ

1kΩ

100 Ω

1kDC or 0

10 k 100 k 1 M 10 M 100 M

Figure 12: Typical Input Impedance

Frequency (Hz)

P5102 Instruction Manual

19

Page 28

Specifications

-10_

-20_

-30_

-40_

-50_

-60_

-70_

-80_

-90_

10 k 100 k 1 M 10 M 100 M1kDC or 0

Figure 13: Typical Input Phase

Frequency (Hz)

20

P5102 Instruction Manual

Page 29

Table 4: Typical Mechanical Characteristics

Specifications

Net Weight

(including accessories)

Cable Length 2 m (6.56 ft)

0.26 kg (0.57 lb)

Table 5: Environmental Specifications

Temperature Operating: --15 °Cto+55°C

(+5 °F to +131 °F)

Nonoperating: --62 °Cto+85°C

(--79.6 °F to +185 °F)

Humidity Nonoperating and operating; five cycles (120 hr. total)

+40 °C or below: ≤95% relative humidity

(+104 °F or below)

+41 °Cto+50°C: ≤75% relative humidity

(+105 °F to +122 °F)

Transportation Tektronix Standard 062-9537-00 Revision C

P5102 Instruction Manual

21

Page 30

Replaceable Parts

1

6

2

Standard Accessories

7

8

3

45

Figure 14: P5102 Replaceable Parts

22

Optional Accessories

P5102 Instruction Manual

Page 31

3

3

4

-

-

1

2

7

5

-

-

0

4

2

C

L

IPC

A

B

LEM

K

R

:YE

L

L

O

W

P

L

A

S

T

I

C

0

JR0

5

O

r

d

e

r

b

y

d

e

s

c

r

i

p

t

i

o

n

3

3

4

4

0

4

6

1

0

0

1CL

I

P

C

A

B

LEM

K

R

Y

E

L

L

O

W

P

L

A

S

T

I

C

C

L

I

P

E

L

E

C

:

C

R

O

C

O

D

I

L

E

8

2

M

M

L4M

M

J

R

T

K

2

4

8

3

O

d

b

y

d

i

i

on

X

K

0

8

1

5

0

1

3

0

2

9

0

0

1

1CL

L

L

L

H

O

O

K

T

IPS

E

T

:

H

O

O

K

T

IPA

S

S

Y

L

A

R

G

E

A

N

D

S

M

A

L

L

T

K

2

4

6

9

0

1

3

0

2

9

0

0

1

L

L

L

,

,

pt

escr

Replaceable Parts

Mfr. Part No.

Mfr.

Code

12345 Name & Description

STANDARD ACCESSORIES

Order by description

0JR05

CLIP, CABLE MKR: RED, PLASTIC

er

r

05

0

,

:

,

Order by description

0JR05

CLIP, CABLE MKR: GREEN, PLASTIC

XK--081

TK2483

,4MM

E, 82MM

EC: CROCODI

IP,E

TK2469 013029001

ARGE AND SMA

SCREWDRIVER: ADJUSTMENT TOOL

HOOKTIP, SET: HOOKTIP ASSY,

LEAD SET ASSY: COMMON, P5102, 1) 18.0 L 1) 6.0 L

MANUAL, TECH: INSTRUCTIONS, P5102 80009 0709294XX

OPTIONAL ACCESSORIES

Qty

Serial No.

Effective Dscont

Part No.

Tek t r o n ix

-- -- -- -- -- -- -- -- -- -- -- 1 PROBE, HI VOLTAGE: F L OATING, 10X, 100 MHZ, P5102

No.

Index

Fig. &

14--1

2

-- 2 334--1275--02

2

334--1275--04

2

334--1275--05

1

344--0461--00

-- 3

1

See Opt. Acc.

-- 4

1

013--0290--01

-- 5

1

196--3424--00

-- 6

070--9294--XX 1

-- 7 206--0060--00 1 TIP, PROBE: P6000 80009 206006000

--8 013--0291--00 1 ADAPTER, PROBE: PROBE TO BNC 80009 013029100

--4 003--1433--01 1 SCREWDRIVER: ADJU STMENT TOOL, PKG OF 5 80009 003143301

23P5102 Instruction Manual

Page 32

Replaceable Parts

D--4300 ESSEN 11 (W GERMANY)

MESSTECHNISCHE WERKE

CATHOSTRASSA 7

BEAVERTON OR 97077--0001

PO BOX 500

CROSS INDEX - MFR. CODE NUMBER TO MANUFACTURER

24

Mfr.

Manufacturer Address City, State, Zip Code

Code

TRIQUEST CORP

0JR05

TK2483 HEINRICH C KOSMEIER

GMBH--ESSEN

TK2469 UNITREK CORPORATION 3000 LEWIS & CLARK HWY VANCOUVER WA 98661

80009 TEKTRONIX INC 14150 SW KARL BRAUN DR

P5102 Instruction Manual

Loading...

Loading...