Page 1

Instructions

P3010

100 MHz 10X Passive Probe

With Readout

071-0466-00

Page 2

Copyright © Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and

pending. Information in this publication supercedes that in all previously

published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

Tektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Page 3

General Safety Summary

Review the following safety precautions to avoid injury and prevent

damage to this product or any products connected to it. To avoid

potential hazards, use this product only as specified.

To Avoid Fire or Personal Injury

Observe Maximum Working Voltage. Do not use the P3010 probe above

300 V

Connect and Disconnect Properly. Connect the probe output to the

measurement instrument before connecting the probe to the circuit

under test. Disconnect the probe input and the probe ground from the

circuit under test before disconnecting the probe from the measurement instrument.

Do Not Elevate the Common Terminal. The common terminal is at

ground potential. Do not connect the common terminal to elevated

voltages.

, CAT II. Refer to the derating chart, Figure 2, on page 12.

RMS

Do Not Operate With Suspected Failures. If you suspect there is damage

to this product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Safety Terms and Symbols

Terms in This Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that

could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that

could result in damage to this product or other property.

P3010 Passive Probe Instructions

1

Page 4

Features and Accessories

The P3010 probe is compatible with TDS3000 series 100 MHz

oscilloscopes. The probe is also compatible with Tektronix

oscilloscopes that automatically detect probe attenuation and adjust

the scale readout accordingly.

NOTE. Remove and discard the protective cover on the tip of the

probe before attempting to connect a probe tip accessory.

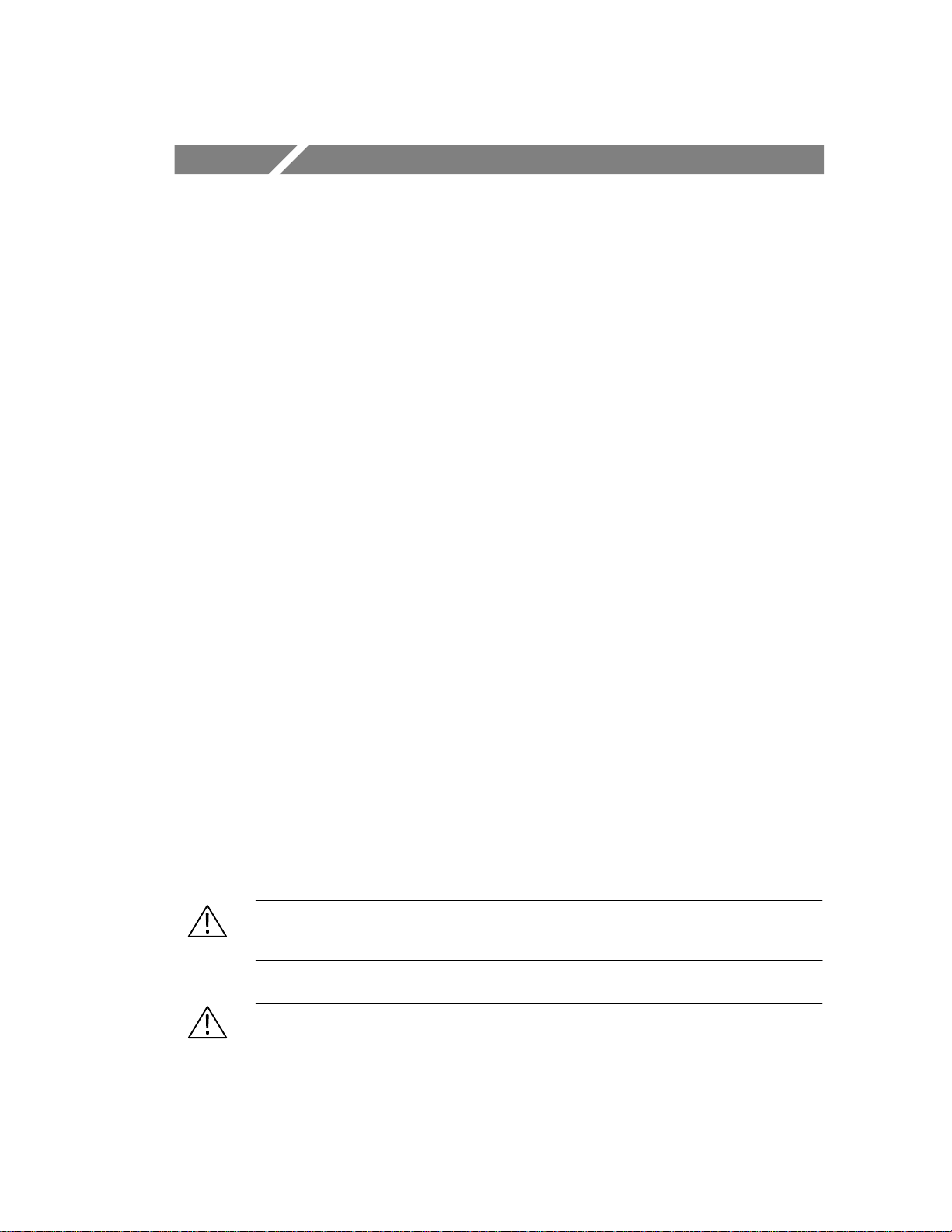

BNC-to-probe tip adapter. T o install the adapter,

push the wide end firmly into a BNC connector .

Then insert the probe tip firmly into the adapter.

Retractable hook tip. Use the retractable hook tip to

make hands-free measurements.

Readout Pin

NOTE.

twist the hook tip onto the probe tip before using.

Readout pin. The P3010 is compatible with Tektronix oscilloscopes that automatically detect and

display the attenuation factor of the probe.

For a solid connection, firmly push and

2

P3010 Passive Probe Instructions

Page 5

Features and Accessories

Marker rings. Attach the matching colored rings

onto the probe cable and tip as shown.

Adjustment tool. Use the adjustment tool for probe

compensation adjustments.

P3010 Passive Probe Instructions

3

Page 6

Features and Accessories

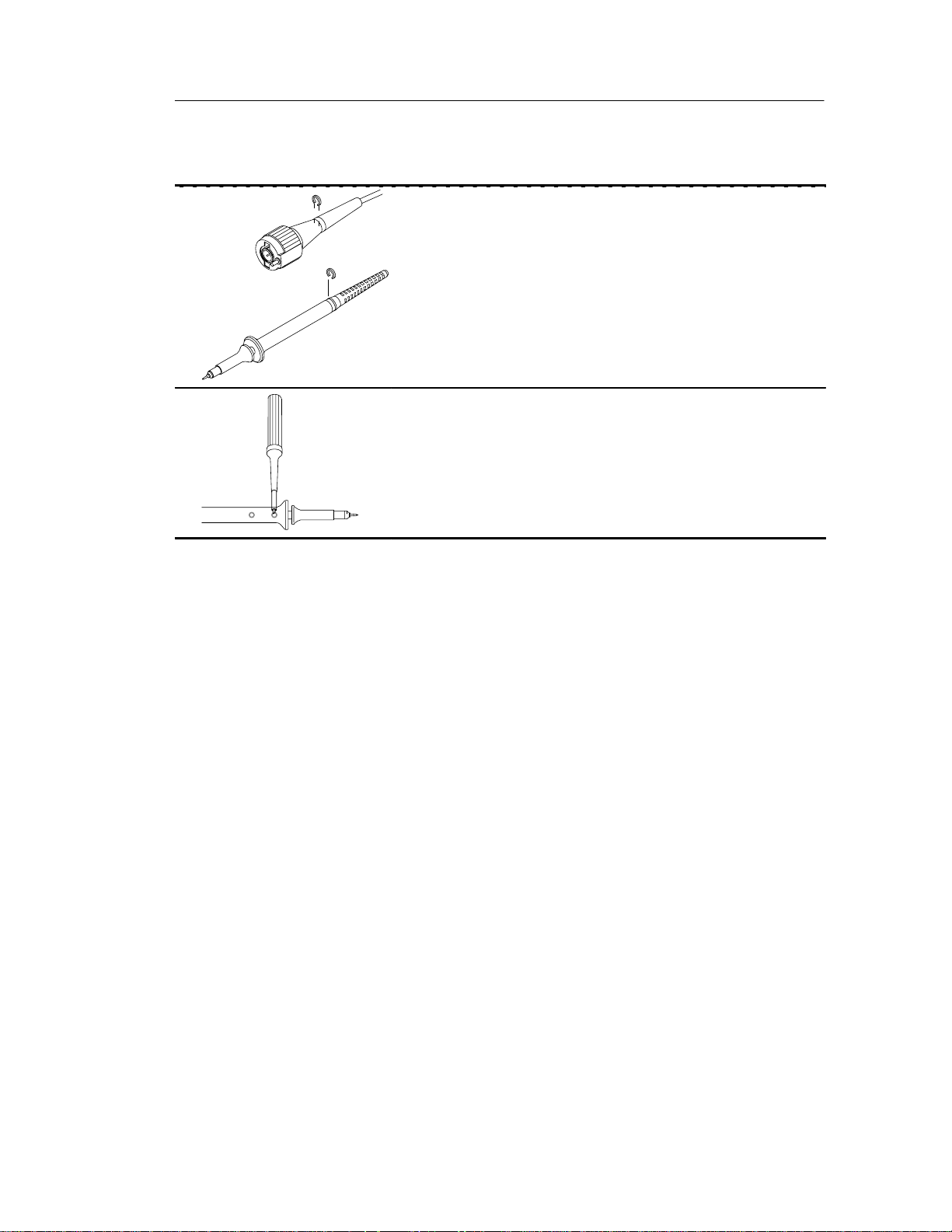

Guard

WARNING. To avoid electric shock when using the probe, keep

fingers behind the guard on the probe body.

Guard. The guard provides a finger barrier for

protection from electric shock.

Ground Lead. Use the alligator clip to attach the

probe to a ground reference.

Long Ground Lead

Short Ground Lead

To see the best signal, use the shortest possible ground lead and

signal path.

4

P3010 Passive Probe Instructions

Page 7

Maintenance

This section describes how to maintain the probe.

Low-Frequency Probe Compensation

Before taking any measurements using a probe, first check the

compensation of the probe and adjust it to match the channel inputs.

Most oscilloscopes have a square wave reference signal available at

a terminal on the front panel used to compensate the probe.

1. Connect the probe to the signal source to display a 1 kHz test

signal on your oscilloscope.

2. Adjust the LF trimmer on the probe so that the corners of the

square wave are square and the top is flat.

LF trimmer

1 kHz

P3010 Passive Probe Instructions

5

Page 8

Maintenance

High-Frequency Probe Compensation

The probe high-frequency compensation should seldom require

adjustment; however , your probe may require high-frequency

adjustment if any of the following are true:

H the probe has high-frequency aberrations

H the probe does not perform at the rated bandwidth

H you have installed the probe on an oscilloscope having an input

capacitance near the limits of the probe compensation range (See

Table 1.)

To perform the high-frequency compensation adjustment you will

need a signal source that has all of the following characteristics:

1 MHz

>1 V

p-p

H square-wave output at 1 MHz

H fast rise output with rise time less than 1 ns

H output properly terminated

tr<1 ns

90%

10%

6

P3010 Passive Probe Instructions

Page 9

Maintenance

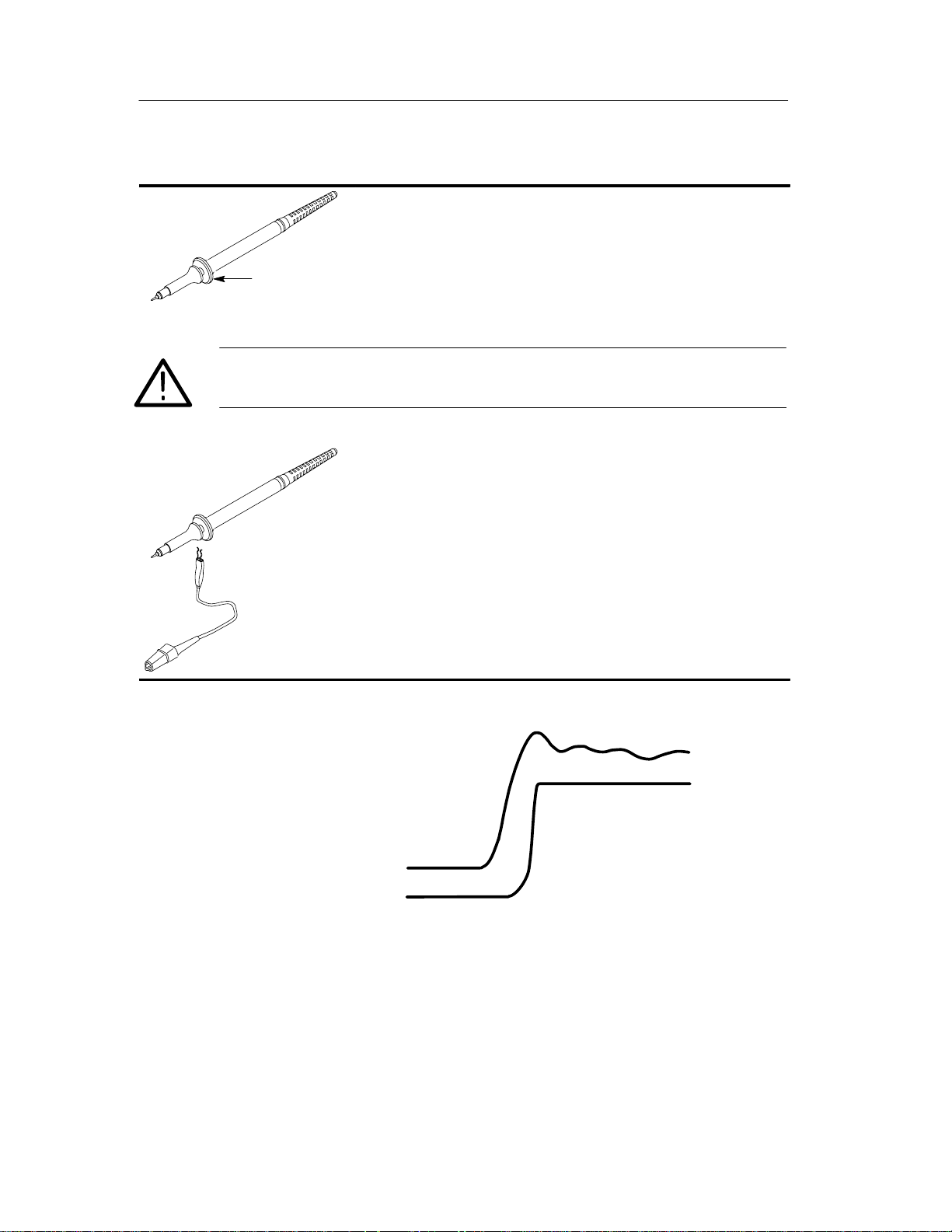

1. Connect the probe to the signal source to display a 1 MHz test

signal on your oscilloscope. The display should be similar to that

shown in Figure 1(a).

2. Adjust the HF trimmer until the waveform is flat on top and has a

square leading edge.

10 ns

(a) Area Of Waveform Affected By

HF Adjustment

Figure 1: HF Compensation

Cleaning

To prevent damage to probe materials, avoid using chemicals that

contain benzine, benzene, toluene, xylene, acetone, or similar

solvents.

Do not immerse the probe or use abrasive cleaners.

Dirt may be removed with a soft cloth dampened with a mild

detergent and water solution, or isopropyl alcohol.

HF trimmer

(b) Location of HF Adjustment

P3010 Passive Probe Instructions

7

Page 10

Maintenance

Replacing Probe Parts

Other than accessories, only the probe tip is replaceable.

Replacement probe tips are available as optional accessories. Refer

to the replaceable parts list at the end of this manual for more

information.

To remove a tip assembly, firmly grasp the pointed tip with pliers

and withdraw the assembly from the barrel.

No tools are required to install a replacement tip. Insert a new probe

tip into the probe barrel as far as possible using finger pressure. If

necessary, seat the plastic portion of the tip against the probe barrel

by pressing the tip gently but firmly against a hard surface, such as a

wood block or table top.

8

P3010 Passive Probe Instructions

Page 11

Specifications

Table 1

lectrical Character

These characteristics apply to a P3010 probe installed on a

Tektronix TDS3000 series 100 MHz oscilloscope.

The instrument must have a warm-up period of at least 20 minutes

and be in an environment that does not exceed the limits described in

Table 2.

: E

Attenuation (system) 10X"2.5% at DC

Input Resistance (system), typical

Input Capacitance, typical 13.3 pF

Compensation Range, typical 10 pF to 15 pF

System Bandwidth (–3 dB) DC to 100 MHz

Maximum Working

Input Voltage

Rise time (system), typical 3.5 ns

Input impedance and phase, typical See Figure 3 on page 13

istics

10 MW

300 V

35%, pulse width < 100 msec)

150 V

pulse width < 100 msec)

See derating information in Figure 2 on page 12

, CAT I & II (500 V peak, duty factor <

RMS

, CAT III (250 V peak, duty factor < 35%,

RMS

P3010 Passive Probe Instructions

9

Page 12

Specifications

Table 2

cal an

ronmental Character

: Physi

Net Weight

(including accessories)

Cable Length 2 meters

Temperature Range

Operating

Nonoperating

Humidity

Altitude

1

T ektronix Standard 062-2847-00, class 3. Refer to MIL-T-28800E for class 3

1

Operating

Nonoperating

d Envi

1

istics

t320 g

–15° C to +55°C

–62° C to +85° C

95% to 97% Relative Humidity

(30°C to 55°C)

< 3000 meters

< 15240 meters

equipment.

10

P3010 Passive Probe Instructions

Page 13

T able 3: Certifications and compliances

Specifications

EC Declaration of

Conformity – Low

Voltage

Approvals UL3111-1 – Standard for electrical measuring and test equipment

Installation Category

Descriptions

Compliance was demonstrated to the following specification as

listed in the Official Journal of the European Communities:

Low Voltage Directive 73/23/EEC, as amended by 93/68/EEC:

EN 61010-1/A2:1995

Safety requirements for electrical equipment for

measurement, control, and laboratory use

EN 61010-2-031:1994

Particular requirements for hand-held probe assemblies for

electrical measurement and test equipment

IEC 61010-2-031 – Particular requirements for hand-held probe

assemblies for electrical measurement and test

CAN/CSA-C22.2 No. 1010.1-92 and CAN/CSA-C22.2 No.

1010.2.031-94 – Safety requirements for electrical equipment for

measurement, control, and laboratory use

Terminals on this product may have different installation category

designations. The installation categories are:

CAT III Distribution-level mains (usually permanently

connected). Equipment at this level is typically

in a fixed industrial location

CAT II Local-level mains (wall sockets). Equipment at

this level includes appliances, portable tools,

and similar products. Equipment is usually

cord-connected

CAT I Secondary (signal level) or battery operated

circuits of electronic equipment

Pollution Degree 2 Do not operate in environments where conductive pollutants may

be present.

P3010 Passive Probe Instructions

11

Page 14

Specifications

400V

300V

200V

Category I & II

Category III

10V

0

Frequency (Hz)

Voltage

(V

RMS

100V

)

Figure 2: Maximum Working Voltage Derating Curve (V

5M 50M

10M 100M1M

)

RMS

200M

12

P3010 Passive Probe Instructions

Page 15

Specifications

10 MW

1 MW

100 kW

10 kW

1 kW

+50°

+25°

0°

–25°

–50°

100 W

10 W

1 W

100 Hz

1 kHz 10 kHz 100 kHz 1 MHz

Impedance (W)

Phase (°)

Figure 3: Typical input impedance and phase

10 MHz

–75°

–100°

–125°

100 MHz

P3010 Passive Probe Instructions

13

Page 16

Replaceable Parts

2

1

5

3

7

4

Standard Accessories

8

6

9

Figure 4: P3010 replaceable parts

14

Optional Accessories

P3010 Passive Probe Instructions

Page 17

P3010 Passive Probe Instructions 15

Replaceable Parts List

Fig. &

index

number

4– ––––––––––– 1 PROBE,PASSIVE:P3010

Tektronix

part number

Serial no.

effective

Serial no.

discont’d

Qty Name & description Mfr. code Mfr. part number

STANDARD ACCESSORIES

020–2134–01 1 ACCESSORY KIT:MINIATURE SIZE

(Includes items 1, 3, 4, 5, & 6)

–1 013–0107–08 1 TIP,PROBE:MINIATURE/COMPACT SIZE TK2565 013–0107–08

–2 See Opt. Acc 1 CONTACT,ELEC:PROBE TIP W/INSULATOR ASSY

–3 196–3120–01 1 LEAD,ELECTRICAL:PROBE GND,6.0 L 80009 196–3120–01

–4 016–0633–00 1 MARKER SET,CA:2 EA VARIOUS COLORS 80009 016–0633–00

–5 See Opt. Acc. 1 SCREWDRIVER:ADJUSTMENT TOOL

–6 013–0277–00 1 ADAPTER,CONN:BNC TO MINIATURE PROBE TIP 24931 33A129–1

071–0466–00 1 MANUAL,TECH:INSTR, P3010, DP 80009 071–0466–00

OPTIONAL ACCESSORIES

–2 131–4997–01 1 CONTACT,ELEC:2 TIP–INSULATOR W/INFO CARD 80009 131–4997–01

–5 003–1433–01 1 SCREWDRIVER:ADJUSTMENT TOOL,PKG OF 5 80009 003–1433–01

–7 196–3120–21 1 LEAD,ELECTRICAL:PROBE GND,28.0 L 80009 196–3120–21

–8 196–3121–01 1 LEAD,ELECTRICAL:PROBE GND,12.0 L 80009 196–3121–01

–9 015–0201–07 1 TIP,PROBE:IC TEST,PKG OF 10 80009 015–0201–07

80009 020–2134–01

Replaceable Parts

Page 18

Manufacturers Cross Index

Mfr.

code

Manufacturer Address City, state, zip code

Replaceable Parts

P3010 Passive Probe Instructions16

24931 BERG ELECTRONICS INC BERG ELECTRONICS RF/COAXIAL DIV

2100 EARLYWOOD DR

PO BOX 547

80009 TEKTRONIX INC 14150 SW KARL BRAUN DR

PO BOX 500

TK2565 VISION PLASTICS INC 26000 SW PARKW AY CENTER DRIVE WILSONVILLE, OR 97070

FRANKLIN, IN 46131

BEAVER T ON, OR 97077–0001

Page 19

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects

in materials and workmanship for a period of one (1) year from the date of shipment. If a

product proves defective during this warranty period, Tektronix, at its option, either will

repair the defective product without charge for parts and labor, or will provide a

replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the

defect before the expiration of the warranty period and make suitable arrangements for the

performance of service. Customer shall be responsible for packaging and shipping the

defective product to the service center designated by Tektronix, with shipping charges

prepaid. T ektronix shall pay for the return of the product to Customer if the shipment is to

a location within the country in which the Tektronix service center is located. Customer

shall be responsible for paying all shipping charges, duties, taxes, and any other charges for

products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or

improper or inadequate maintenance and care. Tektronix shall not be obligated to furnish

service under this warranty a) to repair damage resulting from attempts by personnel other

than Tektronix representatives to install, repair or service the product; b) to repair damage

resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a

product that has been modified or integrated with other products when the effect of such

modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER

WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS

DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY

TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF

THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE

FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR

HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Loading...

Loading...