Page 1

Online Help

Option SST Serial ATA and Serial Attached SCSI

Analysis Module

077-0020-01

Adapted from Opt. SST Online Help

www.tektronix.com

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its

suppliers and are protected by United States copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this

publication supercedes that in all previously published material. Specifications and price change

privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Option SST Serial ATA and Serial Attached SCSI Analysis Module Online Help.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive or P.O. Box 500

Beaverton, OR 97077 USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

Page 3

Warranty 9(b)

Tektronix warrants that the media on which this software product is furnished and the encoding of the programs

on the media will be free from defects in materials and workmanship for a period of three (3) months from the

date of shipment. If any such medium or encoding proves defective during the warranty period, Tektronix will

provide a replacement in exchange for the defective medium. Except as to the media on which this software

product is furnished, this software product is provided “as is” without warranty of any kind, either express or

implied. Tektronix does not warrant that the functions contained in this software product will meet Customer’s

requirements or that the operation of the programs will be uninterrupted or error-free.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period. If Tektronix is unable to provide a replacement that is free from defects in materials and

workmanship within a reasonable time thereafter, Customer may terminate the license for this software product

and return this software product and any associated materials for credit or refund.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WAR RANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPLACE DEFECTIVE MEDIA OR REFUND CUSTOMER’S PAYMENT IS

THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS

WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT,

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER

TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Page 5

Table of Contents

Introduction .............................................................................................1

Using Online Help..........................................................................................1

Related Documentation.................................................................................2

Conventions....................................................................................................3

Updates through the Web Site......................................................................5

Feedback.........................................................................................................5

Getting Started.........................................................................................8

About the Option SST Analysis Modules ....................................................8

Compatibility..................................................................................................8

Recommended Accessories............................................................................9

Recommended Accessories............................................................................9

Requirements and Restrictions..................................................................... 9

Starting the Application..............................................................................10

Maximizing and Minimizing the Application............................................10

Returning to the Application......................................................................10

Exiting the Application................................................................................ 10

Application Directories and Usage.............................................................11

File Name Extensions...................................................................................12

Operating Basics...................................................................................14

Opt. SST Application View.........................................................................14

Application User Interface Items ...............................................................15

Serial ATA and SAS Measurements..........................................................16

Menus............................................................................................................17

Menus.....................................................................................................17

File Menu ...............................................................................................18

Measurements Menu.............................................................................19

Results Menu .........................................................................................20

Utilities Menu.........................................................................................20

Help Menu..............................................................................................20

Saving and Recalling Files....................................................................21

Option SST Serial ATA and Serial Attached SCSI Analysis Module

i

Page 6

Table of Contents

Taking Measurements ................................................................................ 22

Setting Preferences............................................................................... 22

Using a Limit File ................................................................................. 25

Control Panel........................................................................................ 26

Sequence Mode ..................................................................................... 26

Acquiring Data...................................................................................... 27

Editing a Serial ATA Mask File.......................................................... 27

How To... ..........................................................................................32

Set up the DUT............................................................................................ 32

Methods to Test a DUT........................................................................ 32

Test the Transmitter Host DUT using AWG Method....................... 33

Test the Transmitter Drive DUT using AWG Method ..................... 35

Test the Transmitter Host DUT using BIST FIS/User Method ....... 37

Test the Transmitter Drive DUT using BIST FIS/User Method...... 39

Test the Receiver Host DUT using AWG Method............................. 41

Test the Receiver Drive DUT using AWG Method ........................... 43

Test the Receiver Host DUT using BIST FIS/User Method ............. 45

Test the Receiver Drive DUT using BIST FIS/User Method............ 47

Select and Configure SATA Measurements............................................. 49

Select SATA Measurements ................................................................ 49

Configure SATA Measurements......................................................... 50

Enter Device Details............................................................................. 54

Virtual Keyboard.................................................................................. 54

Virtual Keyboard - Text ...................................................................... 55

Set up the AWG .......................................................................................... 56

Perform SATA Tests for Transmitter....................................................... 57

Transmitter Measurements................................................................. 57

Perform Transmitter Eye, Unit Interval, and Bit Rate Tests ................. 58

Perform Transmitter Differential Skew Test ........................................... 61

Perform Transmitter Rise and Fall Time Test......................................... 63

Perform Transmitter Differential Voltage Test ....................................... 66

Perform Transmitter AC CM Voltage Test.............................................. 71

ii

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 7

Table of Contents

Perform Transmitter COMINIT, COMWAKE, and COMRESET Tests73

Perform SATA Tests for Receiver..............................................................75

Receiver Measurements........................................................................75

Perform Receiver Eye, Unit Interval, and Bit Rate Tests........................75

Perform Receiver Differential Skew Test..................................................78

Perform Receiver Rise Time and Fall Time Test......................................80

Perform Receiver Differential Voltage Test..............................................82

Perform Receiver AC CM Voltage Test ....................................................87

View SATA Test Results .............................................................................89

Summary Results...................................................................................89

Detailed Results.....................................................................................90

Eye Results.............................................................................................92

Results Plot.............................................................................................96

Bit Rate Results for a SATA Device ....................................................98

Differential Skew Results for a SATA Device.....................................99

Rise and Fall Time Results for a SATA Device..................................99

Unit Interval Results for a SATA Device..........................................100

Differential Voltage Results for a SATA Device...............................101

AC CM Voltage Results for a SATA Device.....................................103

COMINIT Results for a SATA Device..............................................104

COMWAKE Results for a SATA Device..........................................105

COMRESET Results for a SATA Device..........................................106

Select and Configure SAS Measurements ...............................................107

Select SAS Measurements...................................................................107

Configure SAS Measurements...........................................................108

Perform SAS Tests for Transmitter......................................................... 112

Transmitter Measurements................................................................112

Perform Transmitter Rise Time and Fall Time Test..............................112

Perform Transmitter Differential Skew Test..........................................114

Perform Transmitter COMINIT, COMWAKE, and COMRESET Tests116

Perform SAS Tests for Receiver...............................................................118

Receiver Measurements......................................................................118

Perform Receiver Eye and Bit Rate Tests ...............................................118

Option SST Serial ATA and Serial Attached SCSI Analysis Module

iii

Page 8

Table of Contents

Perform Receiver Differential Skew Test ............................................... 121

Perform Receiver Rise Time and Fall Time Test................................... 123

View SAS Tests Results ............................................................................ 125

Summary Results................................................................................ 125

Detailed Results .................................................................................. 126

Eye Results.......................................................................................... 127

Results Plot.......................................................................................... 129

Bit Rate Results for a SAS Device..................................................... 131

Rise and Fall Time Results for a SAS Device................................... 132

Differential Skew Results for a SAS Device..................................... 133

COMINIT for a SAS Device.............................................................. 134

COMWAKE Results for a SAS Device............................................. 135

COMRESET Results for a SAS Device............................................ 136

Generating a Report............................................................................ 138

About Generating a Report...................................................................... 138

Report Generator File Directories........................................................... 138

Starting the Report Generator and Accessing the Online Help............ 138

Setting Up a Test Template and Layout for a Report ........................... 139

Generating and Printing a Report........................................................... 139

Creating a PDF File of the Compliance Report ..................................... 140

Test Template Menu................................................................................. 141

Report Layout Menu ................................................................................ 142

Report Generator Menu Options ............................................................ 143

Report Generate Menu............................................................................. 143

Report Generator Fields........................................................................... 143

Application Fields General Information List......................................... 144

Application Fields Configuration List and an Example........................ 145

Application Fields Results List and Specific Measurements Example. 146

Oscilloscope Fields and Native Fields Lists ............................................ 147

Reference ........................................................................................ 148

Shortcut Keys............................................................................................ 148

Error Messages.......................................................................................... 149

iv

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 9

Table of Contents

Default Settings..........................................................................................150

Default Settings for SATA Measurements (Part 1)..........................150

Default Settings for SATA Measurements (Part 2)..........................151

Default Settings for SATA Measurements (Part 3)..........................153

Default Settings for SATA Measurements (Part 4)..........................154

Default Settings for SAS Measurements (Part 1).............................155

Default Settings for SAS Measurements (Part 2).............................156

GPIB Commands.......................................................................................158

GPIB Information...............................................................................158

Remote GPIB Support........................................................................158

Introduction to GPIB Command Syntax ..........................................158

GPIB Reference Materials..................................................................159

Starting and Setting Up the Application Using GPIB......................159

Variable:Value RT-Eye Command ...................................................160

Variable:Value Command Arguments and Queries (Part 1)..........161

Variable:Value Command Arguments and Queries (Part 2)..........162

Measurements Results Queries..........................................................163

Worst Case Eye Measurement Names for the resultForWorstEye

Variable................................................................................................

SATA Measurement Names for the resultFor Variable..................164

SAS Measurement Names for the resultFor Variable .....................165

Measurement Algorithms..........................................................................165

Eye Diagram for Serial ATA.............................................................. 165

Eye Diagram for SAS..........................................................................167

Rise Time.............................................................................................. 169

Fall Time ..............................................................................................170

Bit Rate.................................................................................................171

Unit Interval.........................................................................................172

164

Differential Skew.................................................................................172

Differential Voltage.............................................................................172

AC Common Mode Voltage ...............................................................175

Jitter Measurements using TDSJIT3 v2..................................................176

Serial ATA Transmitter Jitter Measurements using TDSJIT3 v2 .176

Option SST Serial ATA and Serial Attached SCSI Analysis Module

v

Page 10

Table of Contents

Serial ATA SSC time domain profile extraction using TDSJIT3 v2177

TDSJIT3 v2 Setup to measure Tj/Dj, 5 UI for a Gen1i device....... 179

TDSJIT3 v2 Setup to measure Tj/Dj, 250 UI for a Gen1i device... 180

TDSJIT3 v2 Setup to measure Tj/Dj for a Gen1x device................ 182

TDSJIT3 v2 Setup to measure Tj/Dj, Clk-Data, fBaud/500 for a

Gen2i device........................................................................................

TDSJIT3 v2 Setup to measure Tj/Dj for a Gen2x device................ 183

TDSJIT3 v2 Setup to measure Tj/Dj, Clk-Data for a Gen2i device183

SAS Receiver Jitter Measurements using TDSJIT3 v2................... 184

TDSJIT3 v2 Setup for a SAS 1.5 Gbps device................................. 184

TDSJIT3 v2 Setup for a SAS 3.0 Gbps device................................. 185

182

vi

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 11

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

To Avoid Fire or Personal Injury:

Connect and Disconnect Properly: Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Observe All Terminal Ratings: To avoid fire or shock hazard, observe all

ratings and markings on the product. Consult the product manual for further

ratings information before making connections to the product.

Do Not Operate With Suspected Failures: If you suspect there is damage to

this product, have it inspected by qualified service personnel.

Symbols and Terms: The following terms and symbols may appear in the online

help.

WARNING. Warning statements identify conditions or practices that could

result injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could

result in damage to this product or other property.

Terms on the Product: The following terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you

read the marking.

CAUTION indicates a hazard to property including the product.

Option SST Serial ATA and Serial Attached SCSI Analysis Module

vii

Page 12

General Safety Summary

Symbols on the Product: The following symbol(s) may appear in the product:

CAUTION

Refer to Help

viii

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 13

Introduction

Using Online Help

Online help has many advantages over a printed manual because of advanced

search capabilities. You can select Help> Topics on the right side of the

application menu bar to display the Help file.

The main (opening) Help screen shows three tabs across the top, each of which

offers a unique mode of assistance:

Contents (TOC) tab - organizes the help into book-like sections. Select a

book icon to open a section; select any of the topics listed under the book.

Index tab - enables you to scroll a list of alphabetical keywords. Select the

topic of interest to display the corresponding help page.

Find tab - allows a text-based search. Follow these steps:

1. Type the word or phrase you want to find in the search box.

2. If the word or phrase is not found, try the Index tab.

3. Select some matching words in the next box to narrow your search.

4. Choose a topic in the lower box, and then select the Display button.

Note: The Find tab function does not include words found in graphics

To print a topic, select the Print button from the help topics menu bar.

Select the Back button to return to the previous help window. Sometimes you can

jump from one topic to another through a hyperlink. If the Back button is grayed

out, or a jump is not available, choose the Help Topics button to return to the

originating help folder.

Option SST Serial ATA and Serial Attached SCSI Analysis Module

1

Page 14

Introduction

Browse buttons (Next >> and << Previous) allow you to move forward and

backward through topics in the order of the Table of Contents (TOC).

A Note: in the topic text indicates important information.

Note: Green-underlined text indicates a jump (hyperlink) to another topic. Select

the green text to jump to the related topic. For example, select the green text to

jump to the topic on Feedback to contact Tektronix.

You can tell when the cursor is over an active hyperlink (button, jump, or

popup), because the arrow cursor changes to a small pointing hand cursor.

The light bulb icon and word Tip in the graphic above indicates additional

information to help you operate the application more efficiently.

Related Documentation

In addition to the online help, the Serial ATA and SAS test modules, Optional

Applications Software on a Windows-Based Oscilloscope CD-ROM includes a

Quick Reference guide in PDF format. Refer to the Option SST Serial ATA and

Serial Attached SCSI Test Module Application Reference for the following

information:

A short tutorial to help you quickly take measurements

An overall menu map of the entire application

In addition to the online help for the SATA and SAS test modules, you can refer

to the RT-Eye Serial Data Compliance and Analysis Application online help for

information about how to use the RT-Eye application.

Refer to the Optional Applications Software on Windows-Based Oscilloscope

Installation Manual for the following information:

Software warranty

List of all available applications, compatible oscilloscopes, and relevant

software and firmware version numbers

2

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 15

Introduction

Applying a new label

Installing an application

Enabling an application

Downloading updates from the Tektronix Web site

Note: You can view PDF file of the installation manual from the CD Installation

Browser and from the Documents directory on the Optional Applications

Software on a Windows-Based Oscilloscope CD-ROM.

For complete information on Tektronix Methods of Implementation (MOI) for

SATA Interoperability tests, refer to the document titled Serial ATA

Interoperability Program - Tektronix MOI for Device PHY, TSG and OOB

Tests located at

http://www.tek.com/Measurement/applications/serial_data/sata.html

Conventions

Reference to Standards

Serial ATA-II specifications PHYii Spec Rev 1_0 052604.pdf.

SAS specifications ANSI INCITS 376-2003 dated 30th October 2003

Online help topics use the following conventions:

The term "module", "SATA or SAS test module" or "application" refers to

the Serial ATA or SAS plug-in software modules.

The term "RT-Eye application" refers to the Tektronix RT-Eye Serial Data

Compliance and Analysis Application with which the Serial ATA and SAS

modules can be run.

The term "oscilloscope" refers to any product on which this application runs.

The term "select" is a generic term that applies to the two mechanical

methods of choosing an option: with a mouse or with the touch screen.

The term "channel" is context dependent. It can refer to the transmit channel

of the device under test or to an oscilloscope channel.

The term "DUT" is an abbreviation for Device Under Test.

Option SST Serial ATA and Serial Attached SCSI Analysis Module

3

Page 16

Introduction

When steps require a sequence of selections using the application interface,

the ">" delimiter marks each transition between a menu and an option. For

example, one of the steps to recall a setup file would appear as File> Recall.

4

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 17

Updates through the Web Site

You can find information about this and other applications at the Tektronix Inc.

Web site, www.tektronix.com

information about our application.

Feedback

Tektronix values your feedback on our products. To help us serve you better,

please send us your suggestions, ideas, or comments on the application.

Direct your feedback via email to techsupport@tektronix.com or sata2feedback@tek.com or FAX at (503) 627-5695 and include the following

information. Please be as specific as possible.

General information:

Introduction

. Check this site for firmware updates and other

Instrument model number and hardware options if any, with serial number

Probes used

Your name, company, mailing address, phone number, FAX number, email

address

Please indicate if you would like to be contacted by Tektronix about your

suggestion or comments

Application specific information:

Software version number

Description of the problem such that technical support can duplicate the

problem

The setup file of the oscilloscope and the application is also required to

identify the problem

If possible, save the waveform on which you are performing the

measurement as a .wfm file

Note: To find the Software version number, click Help> About in the application.

Option SST Serial ATA and Serial Attached SCSI Analysis Module

5

Page 18

Introduction

Once you have gathered this information, you can contact technical support by

fax or through email. If using email, be sure to enter "Option SST Software

Problem" in the subject line, and attach the .wfm files.

You can then attach the file to your email (depending on the capabilities of your

email editor).

6

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 19

Introduction

7

Option SST Serial ATA and Serial Attached SCSI Analysis Module Online Help

Page 20

Getting Started

Getting Started

About the Option SST Analysis Modules

The Option SST Analysis Modules consist of two modules−Serial ATA and

SAS− that are plug-in software modules to the Tektronix RT-EYE Serial

Compliance and Analysis application that runs on some Tektronix Windowsbased oscilloscopes.

You can use these modules to test storage devices as per the Serial Advanced

Technology Attachment or SATA (Gen I and Gen II) and Serial Attached SCSI

(SAS) standards. After the measurements are taken, the results are displayed to

show whether the device has passed or failed the test.

Compatibility

Other features include:

Performs Eye, Timing, and Amplitude measurements, and OOB tests

according to industry standard methods

Selects and configures multiple measurements using differential or single-

ended probe inputs for receiver and transmitter devices

Creates, formats, and generates reports

The measurements that are available in the Serial ATA module are: Eye, Bit

Rate, Differential Skew, Rise and Fall Time, Unit Interval, Differential Voltage,

AC CM Voltage, COMINIT, COMWAKE, and COMRESET.

The measurements that are available in the SAS module are: Eye, Bit Rate, Rise

and Fall Time, Differential Skew, COMINIT, COMWAKE, and COMRESET.

For information on oscilloscope compatibility, refer to the Optional Applications

Software on Windows-Based Oscilloscopes Installation Manual, Tektronix part

number 071-1888-XX. The manual is available as a PDF file.

8

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 21

Getting Started

Recommended Accessories

The Option SST Test Modules support the following probes:

P7380SMA

P7380

SMA Cables

14dB Attenuator: Tektronix 5X Attenuator (SMA male-to-female) - (Order

015-1002-01.)

Test fixtures: Crescent Heart Software (www.c-h-s.com)

Requirements and Restrictions

The RT-EYE Serial Compliance and Analysis application must be installed

for the Option SST Test Modules to run.

The Sun Java Run-Time Environment (JRE) V1.4.0 and The Mathworks

MATLAB Run-Time Server are components of the Option SST test

modules. When you install the application, the InstallShield Wizard

automatically installs the proper software components.

MATLAB Server. The MATLAB server is dedicated to the RT-Eye application

and cannot be used for other purposes. Do not close the MATLAB Server icon in

the oscilloscope task bar because this will disrupt the operation of the Option

SST Test Modules. The application will close the MATLAB sever when you exit

the application.

Option SST Serial ATA and Serial Attached SCSI Analysis Module

9

Page 22

Starting the Application

Getting Started

For supported non-B series oscilloscopes, on the oscilloscope menu bar, select

File> Run Application> RT-Eye Serial Compliance and Analysis. For supported

B-series oscilloscopes, on the oscilloscope menu bar, click App> RT-Eye Serial

Compliance and Analysis. For DPO oscilloscopes, select Analyze> RT-Eye

Serial Compliance and Analysis.

To start the Serial ATA module, from the RT-EYE Serial Compliance and

Analysis application, select Module> Serial ATA.

To start the SAS module, from the RT-EYE Serial Compliance and Analysis

application, select Module> SAS.

The application starts and displays the Measurements Select menu.

You can move between modules by selecting the module name from the Modules

menu in the application menu bar.

Maximizing and Minimizing the Application

To minimize the application and selected module, select File> Minimize in the

application menu bar.

To maximize the application and selected module, select

task bar.

To hide the application and the selected module, select the

Returning to the Application

For supported non-B series oscilloscopes, to return to the application, click the

APP button on the top right of the oscilloscope display. For supported B-series

oscilloscopes, click App> Restore Application from the menu bar.

Exiting the Application

To exit the RT-Eye application and the selected module, select File> Exit or the

(Exit) command button in the application menu bar. When you exit the

in the

Hide button.

Option SST Serial ATA and Serial Attached SCSI Analysis Module

10

Page 23

application, you can elect to keep the oscilloscope setup currently in use with the

application or to restore the oscilloscope setup that was present before you started

the application.

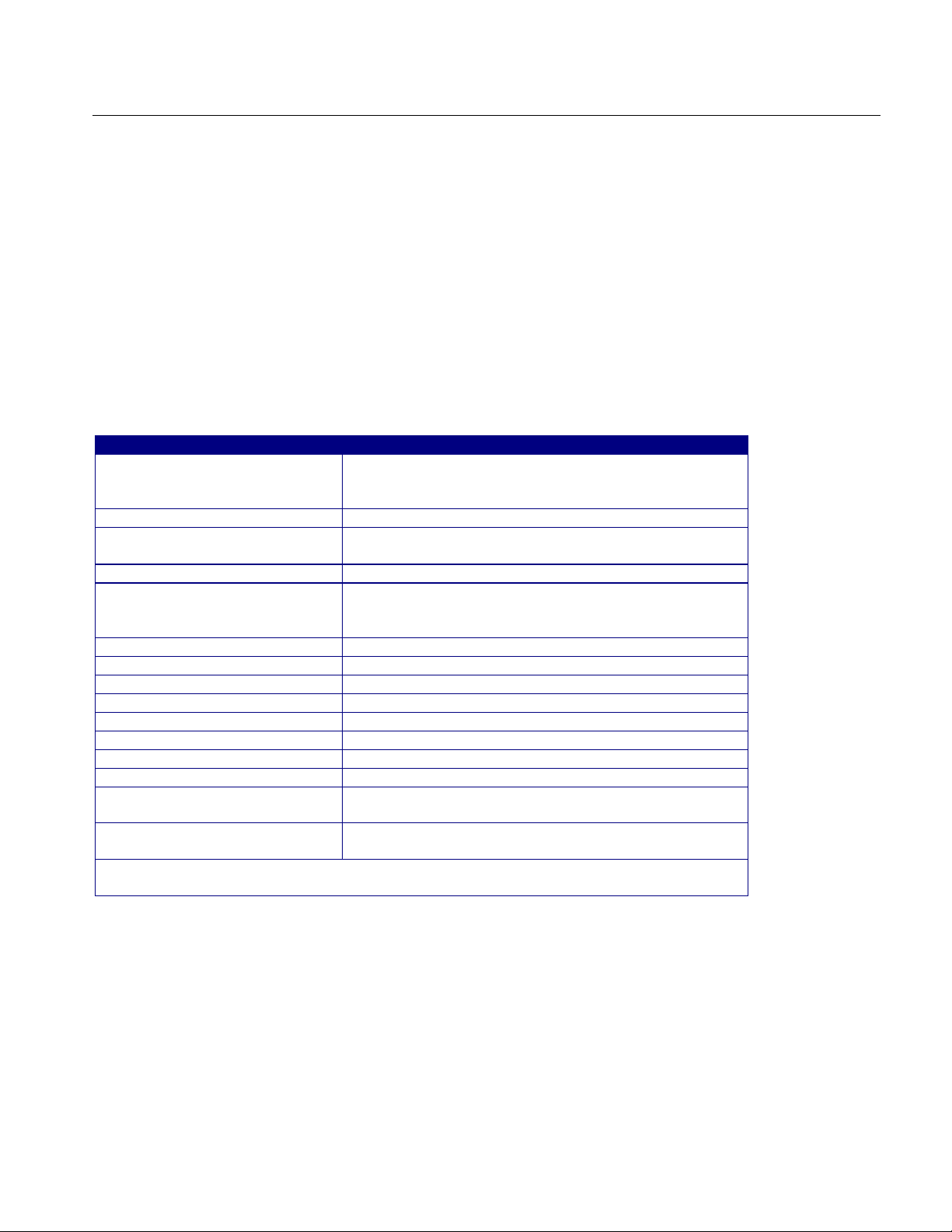

Application Directories and Usage

The modules use directories to save and recall setup files and use file name

extensions to identify the file type.

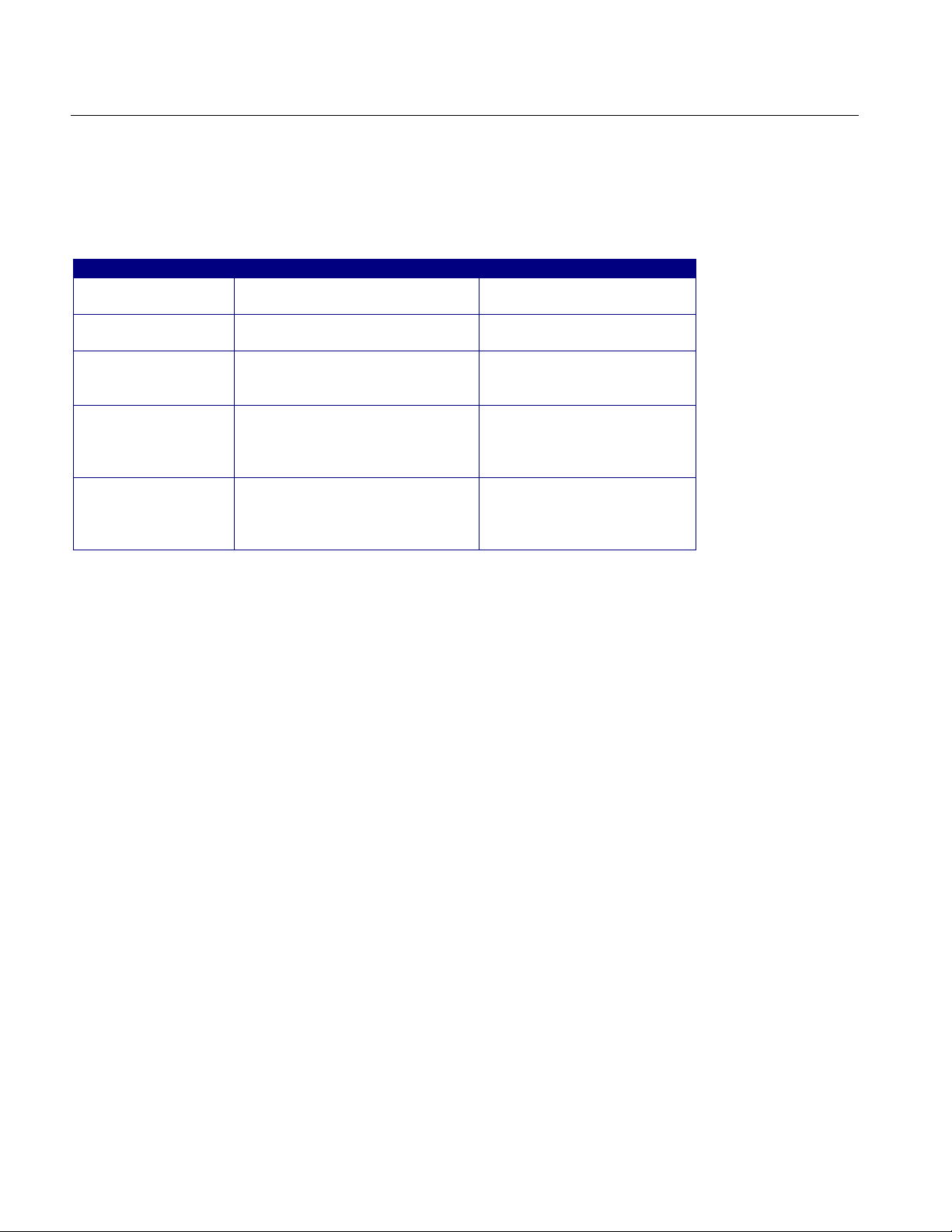

The following table lists the default directory names:

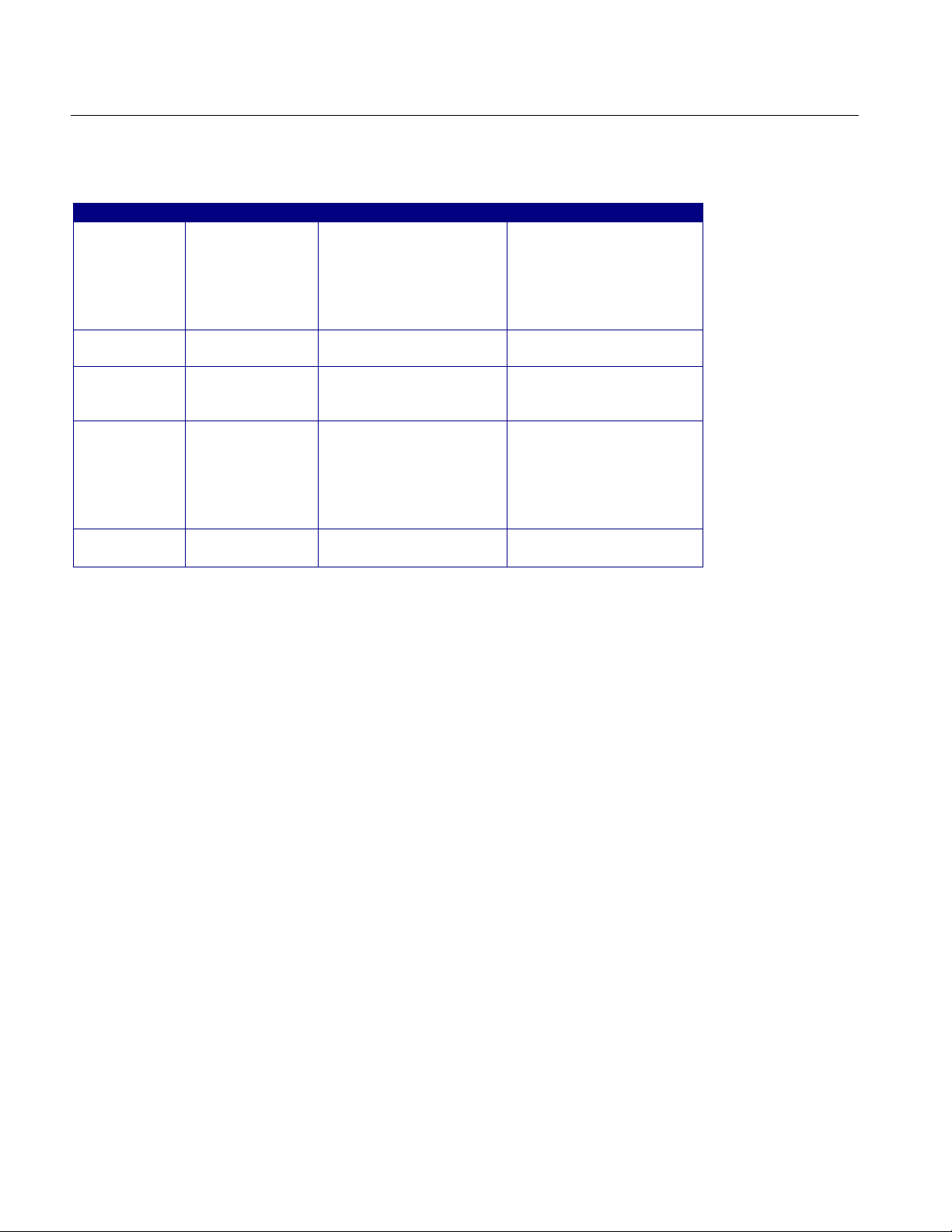

Table 1: Default directory names and their use

Default dir e c t or y na m e s * Directory use

C:\Program

Files\TekApplications\tdsrteye\modules\SATA

\modules\SATA\AWGFiles AWG files used by Serial ATA

\modules\SATA\limits Limit f iles for Pass or Fail compliance tests for Serial

\modules\SATA\setup Setup files for Serial ATA

C:\Program

Files\TekApplications\tdsrteye\modules\SAS

\modules\SAS\AWGFiles AWG files used by SAS

\modules\SAS\limits Limit f iles for Pass or Fail compliance tests for SAS

\modules\SAS\setup Setup files for SAS

\Examples\Masks Mask files for serial data standards

\Examples\RemoteCtrl Sample remote control program

\Examples\WFMS Waveforms for learning

\temp Temporary files

\images Plot files

\ReportGenerator\modules\SATA

\Reports

\ReportGenerator\modules\SAS\

Reports

* All subdirect ories are located in the c:\T ekApplications\td srt - eye di rectory, except

the home location of th e Op tion SST test modules.

Serial ATA application home location

ATA

SAS application home location

Files creat ed for the Serial ATA module by the Repor t

Generator util ity

Files creat ed for the SAS module by the Report

Generator util ity

Getting Started

Option SST Serial ATA and Serial Attached SCSI Analysis Module

11

Page 24

Getting Started

File Name Extensions

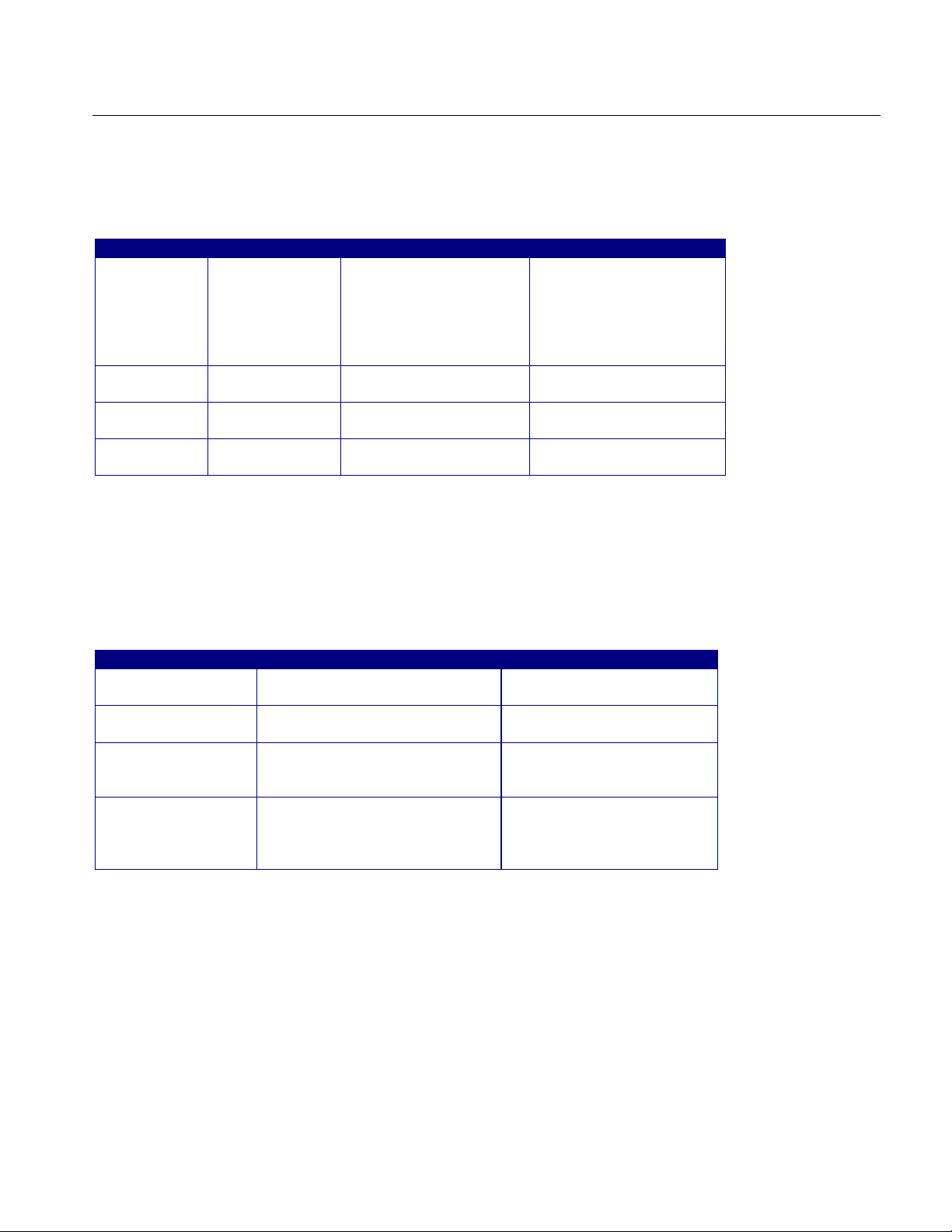

The following table lists the file name extensions and their descriptions:

Table 2: File name extensions and their descriptions

Extension Description

.bmp File that uses a "bitmap" format

.csv File that uses a "comm a separated variabl e" f ormat

.dat File with binar y f ormat

.fig Plot file with binary data

.gif File that uses a "graphic interchange format"

.ini Application setu p file

.jpg File that uses the a "j oint phot o gr aphic experts group"

format; al so known as JPEG

.lim Limits file used with Pass/Fail compliance

.mat MAT LA B waveform vector header sav ed to the hard disk

.msk Waveform mask file used with plots

.pdf File that uses a "portable dat a format"

.png File that uses a "port able network graphic s" f o rmat

.rgt F ile that defines the report template

.rpl File that defi nes t he r epor t layout

.rpt F ile created by the Report Generator utility

.rtf File that uses a "rich text format"

.set Oscilloscope setup f ile saved that is recall ed wi th an

application .ini file; both fil es will have the same name

.wfm Waveform file; can be recalled into Refer enc e memor y

12

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 25

Getting Started

Option SST Serial ATA and Serial Attached SCSI Analysis Module

13

Page 26

Operating Basics

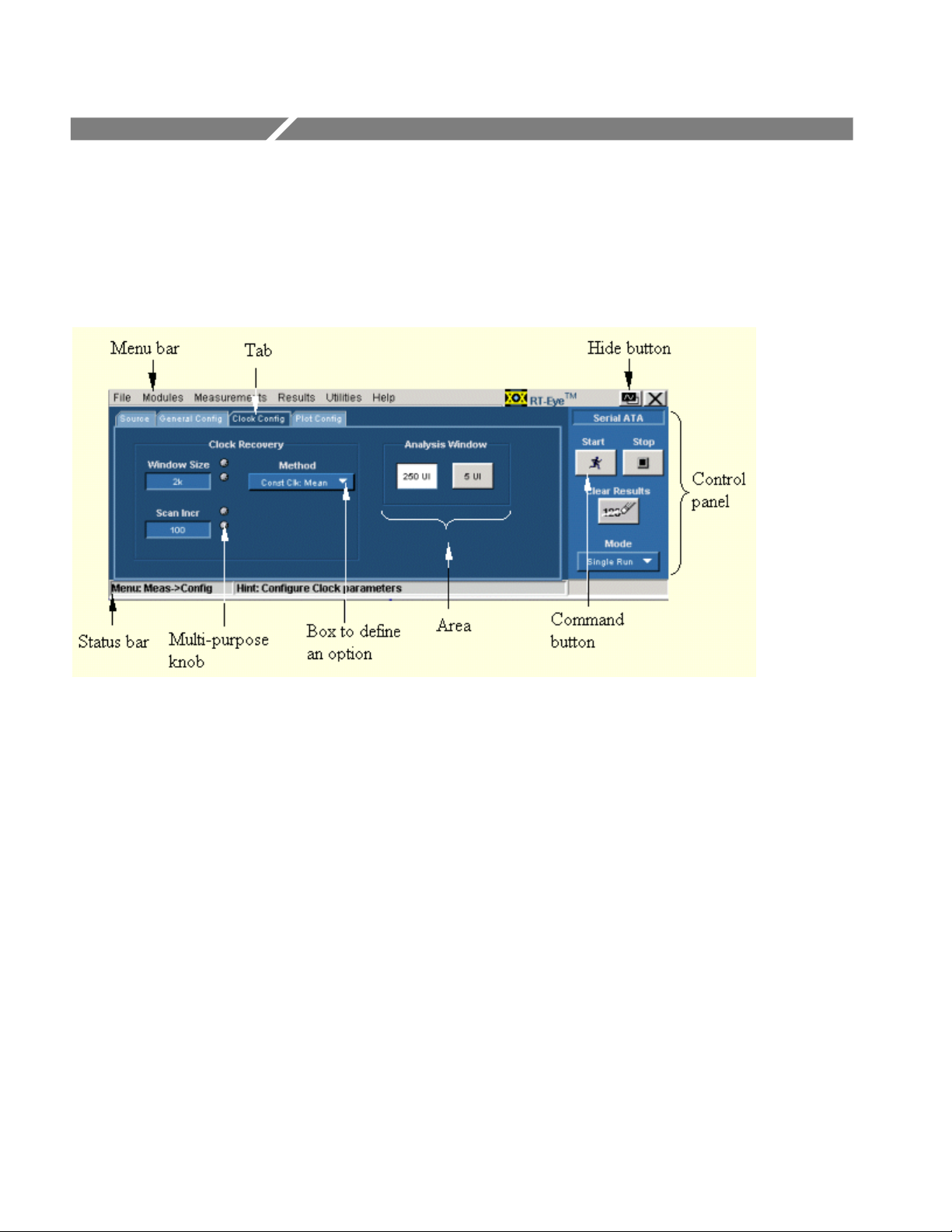

Opt. SST Application View

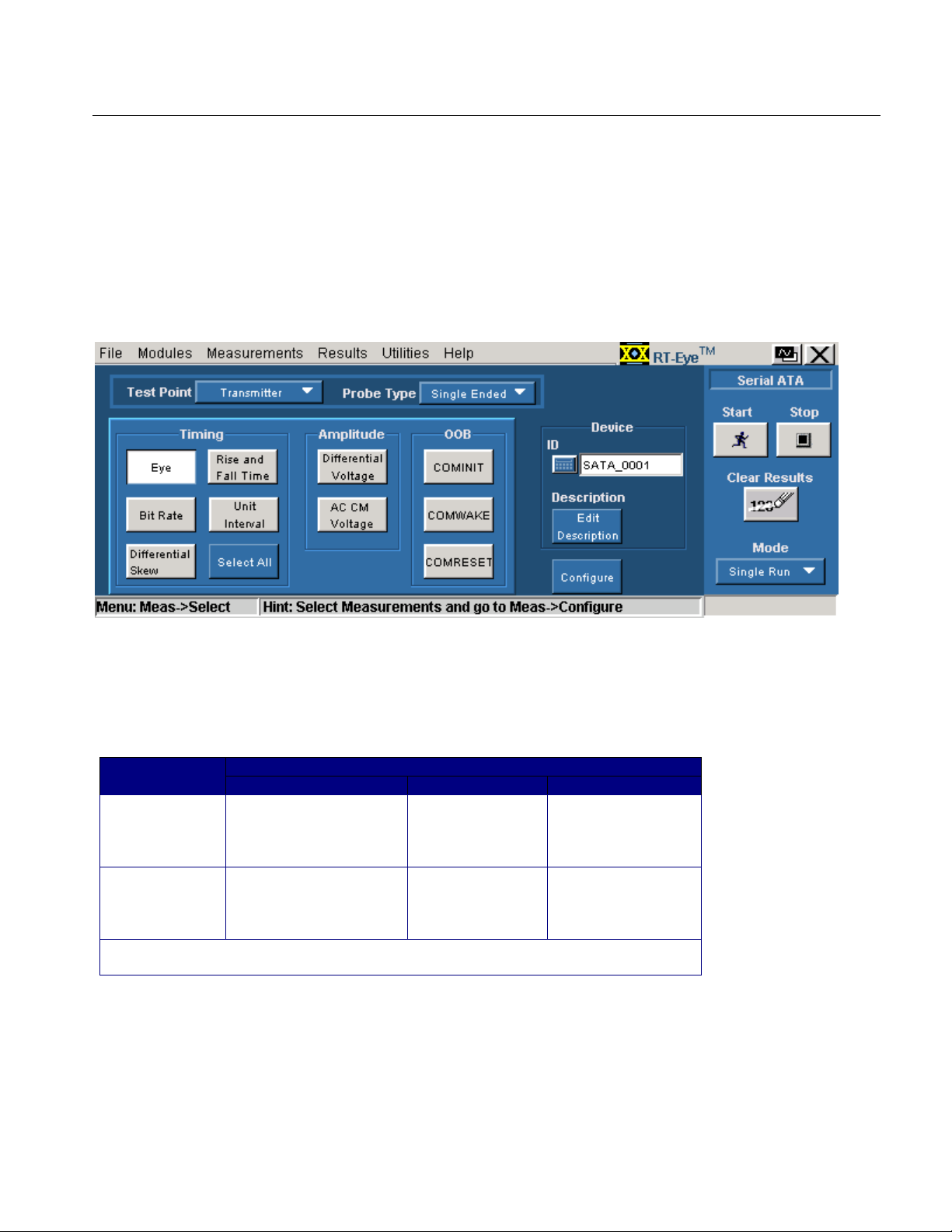

Figure 1: Application view

Option SST Serial ATA and Serial Attached SCSI Analysis Module

14

Page 27

Application User Interface Items

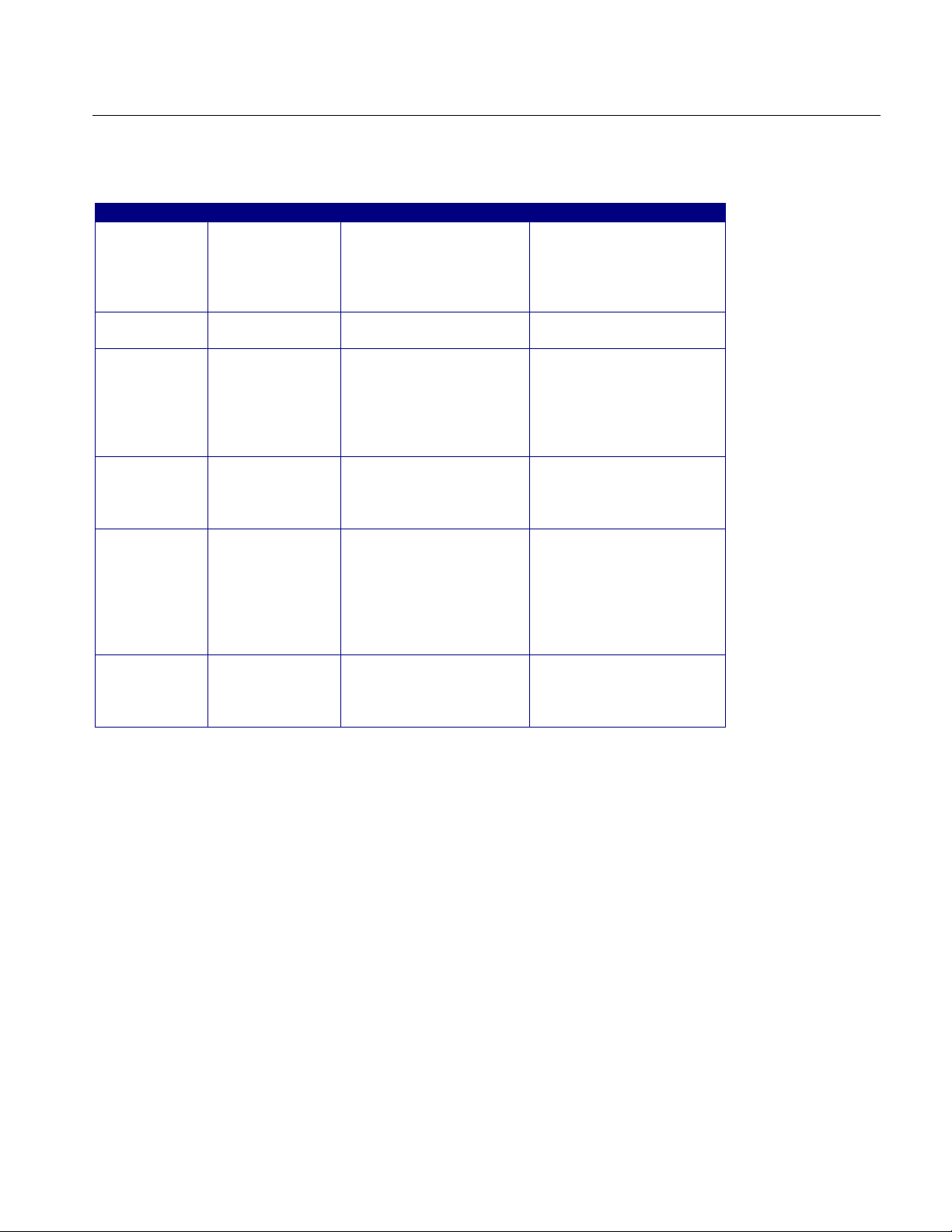

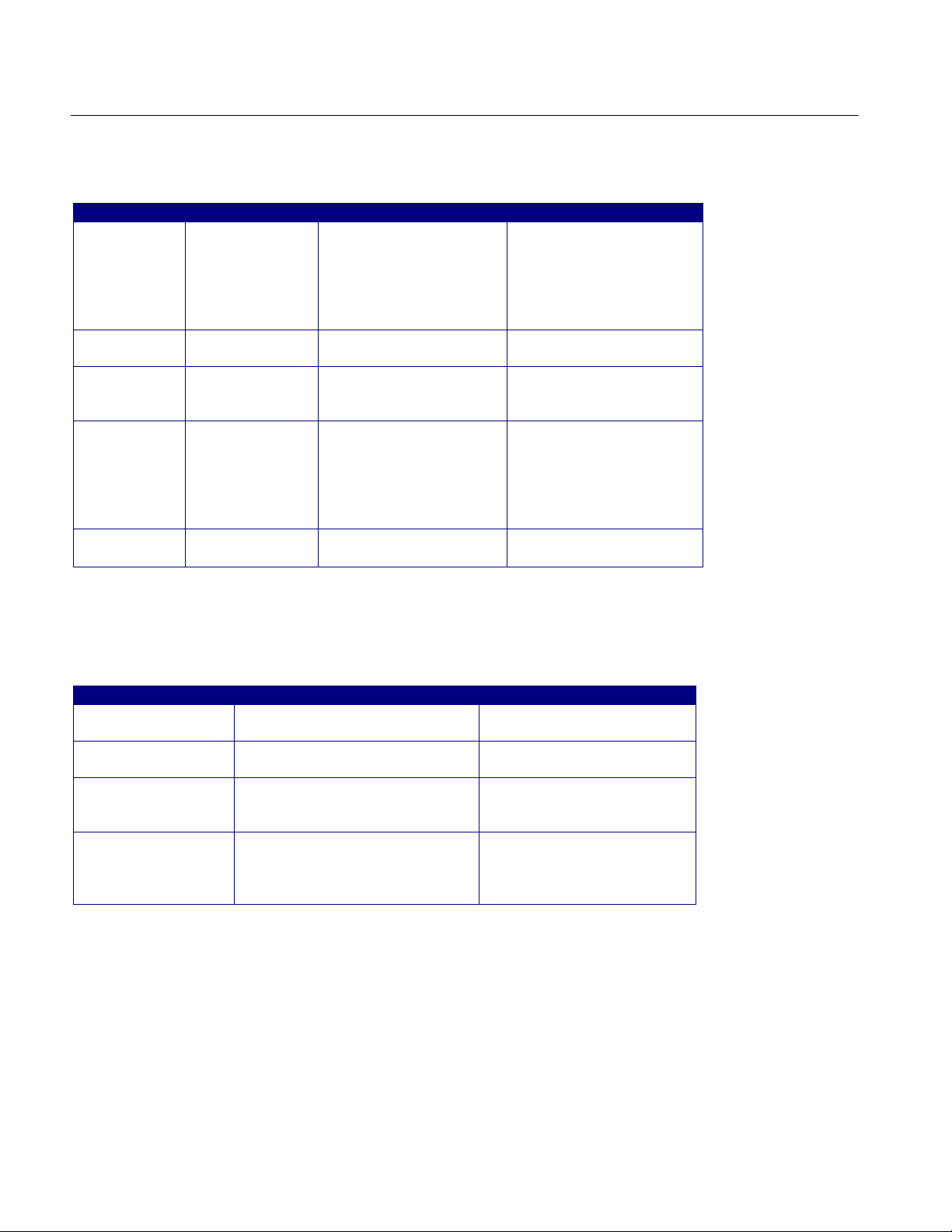

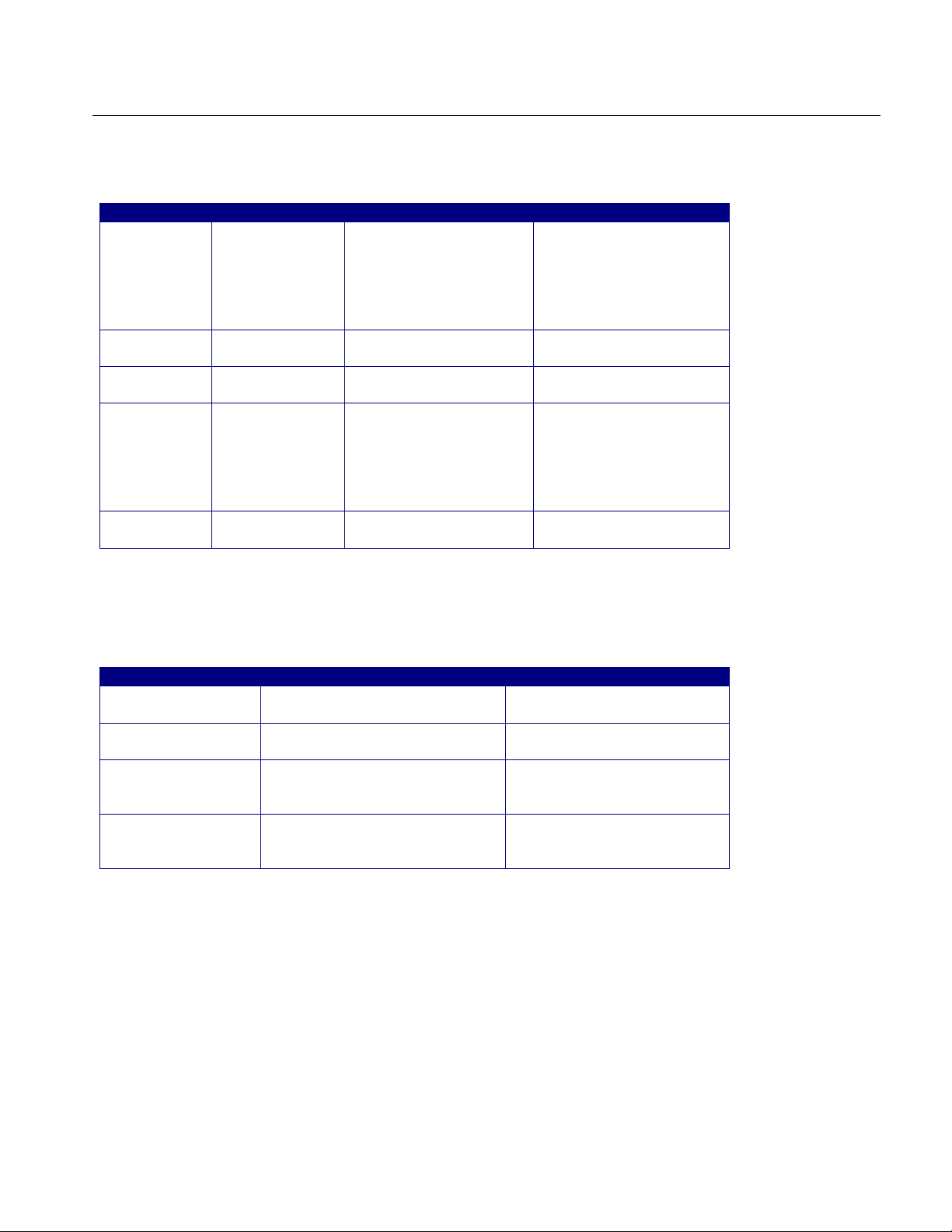

Table 3: Application user interface and their description

Item Description

Area Visual frame that encloses a set of related options

Box Use to define an option; enter a value with the keypad or

multipurpose knob

Browse Displays a window where you can look through a list of dir ectori es

and files

Button Use to define an options; not a command button

Check box Use to select or clear an option

Command button Initiates an immediate action, such as the Star t command button in

the Control panel

Control panel Locat ed to the right of the applic ation; contains command butt ons t hat

you use often

List box Use to define from a list

Menu All options in the application window (except the Control panel) that

display when you select a menu bar item

Menu bar Located at the top of the application display and c ontains the

application menus

Option Any named button (other than the command button) or any named

box that defines a contr ol or task

Status bar Line located at the bottom of the application displ ay that shows the

name of the current menu (location) and the next step that y ou mi ght

take (action)

Scroll bar Vertical or horizontal bar at the side or bottom of a display area that

you use to move around in that area

Tab Short cut to a menu in the menu bar or a category of menu options;

most tabs are short cuts

Virtual keyboard On-screen keyboard t hat you can use to enter values (numeri c

keyboard) or al phanumer ic strings (text) for descriptions and fil e

names

Operating Basics

Option SST Serial ATA and Serial Attached SCSI Analysis Module

15

Page 28

Operating Basics

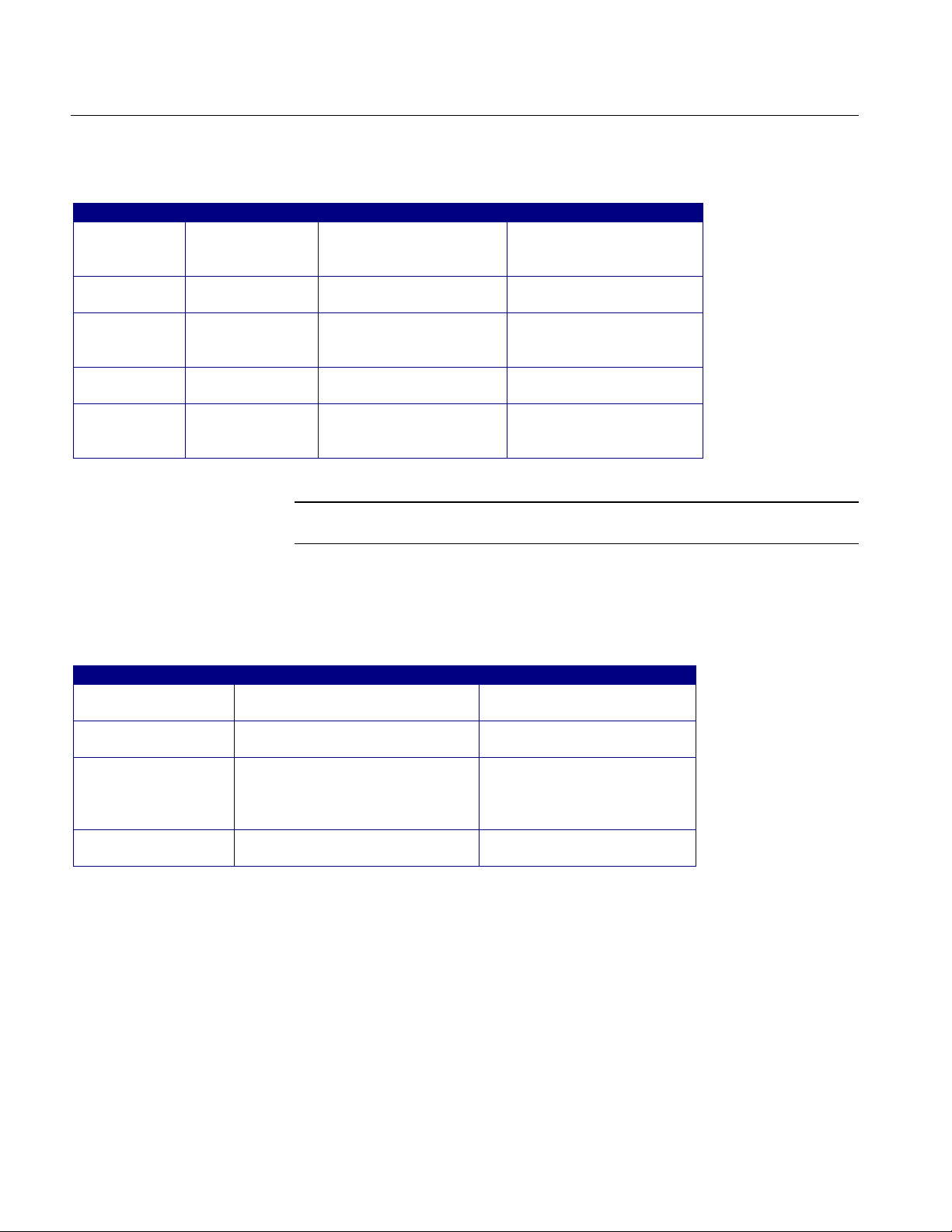

Serial ATA and SAS Measurements

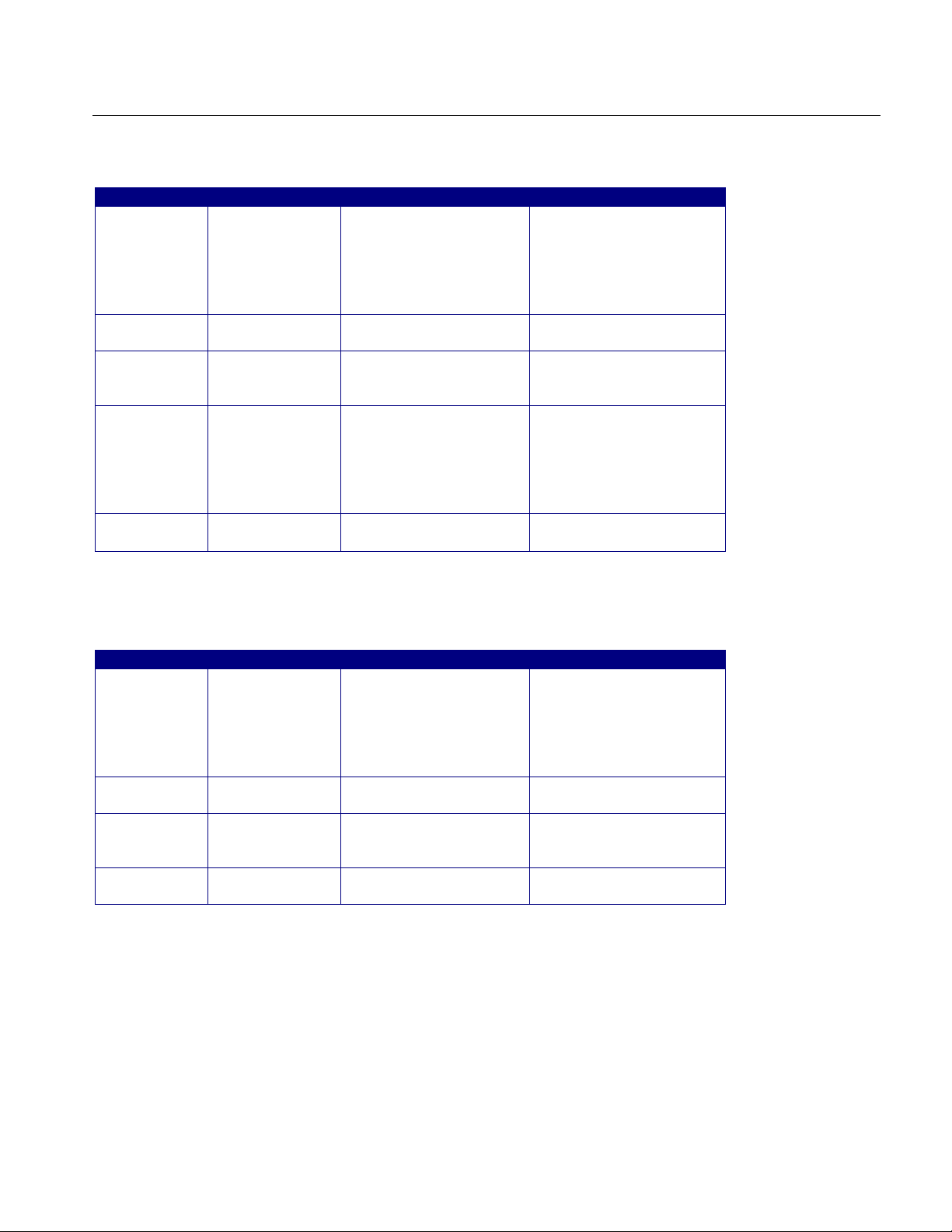

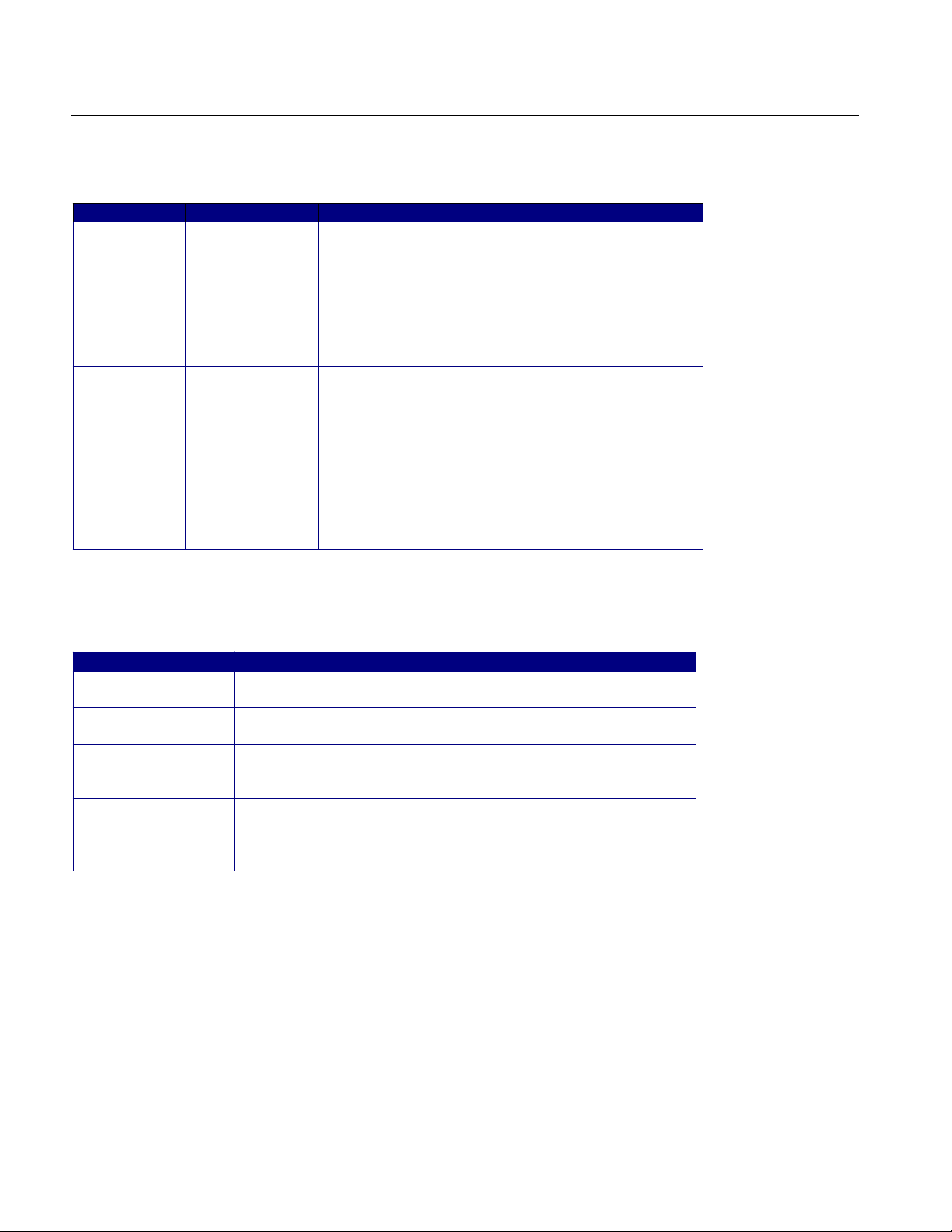

The following tables list the Serial ATA and SAS measurements that the modules

support.

Table 4: Default directory names and their use

Measurement Description

Eye Measures, analyzes, and c har ac terizes the differ ential

output voltage, jitter, rise and fall time for transition and

non-transition bits

Bit Rate Measures the inverse of the average bit time for the

clock recovery window

Differential Skew Measures the time difference between the single-ended

mid-point of the TX+/ RX+ si gnal ri si ng/falling edge and

the single-ended mid-point of the TX−/RX− signal

falling/rising edge

Rise and Fall Time Measure s the rise and fall times of the waveform. The

rise and fall times are defined over a 20%-80% output

level change from the High and Low reference levels

Unit Interval Measures the tim e requi red to transmit one bit

Differential Voltage Measures the minimum and maximum differential

voltage amplitude for a given data pattern

AC Common Mode Voltage Measures the maxim um sinusoi dal amplitude

16

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 29

Out Of Band Tests

Table 5: Default directory names and their use

Out of Band Tests Description

COMINIT Is used by the device t o request a reset from the host in

accordance with a par ticular sequence of bur sts

COMRESET Is indicated by transmitting bursts of data separated by

an idle bus condit ion. The OOB COMRESET signal

consists of no less than six data bursts with i nter- burst

temporal spaci ng

COM WAKE The OOB COMWAKE signaling consists of no less than

six data bursts inc luding inter-burst spacing

Menus

Operating Basics

Menus

The Option SST application consists of two software plug-in modules that run on

the RT-Eye Serial Data Compliance and Analysis application − Serial ATA

(SATA) and SAS. Each module has a menu that allows you to save and recall

files, select measurements and configure them, view results, and generate reports.

Option SST Serial ATA and Serial Attached SCSI Analysis Module

17

Page 30

Operating Basics

Figure 2: Default directory names and their use

File Menu

You can use the File menus to save and recall different application setups and

recently accessed files.

Note: The File> Save function saves application settings in an .ini file and the

settings of the oscilloscope application in a .set file with a matching name.

If an oscilloscope .set file with a matching name is found when you recall an

application setup file, then the oscilloscope settings are also recalled. If the .set

file is missing or cannot be opened by the oscilloscope, then the application

recalls the application settings and displays a message that the Recall of the .set

file failed.

Do not edit a setup file or recall a file not generated by the application.

Click File from the application menu bar.

18

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 31

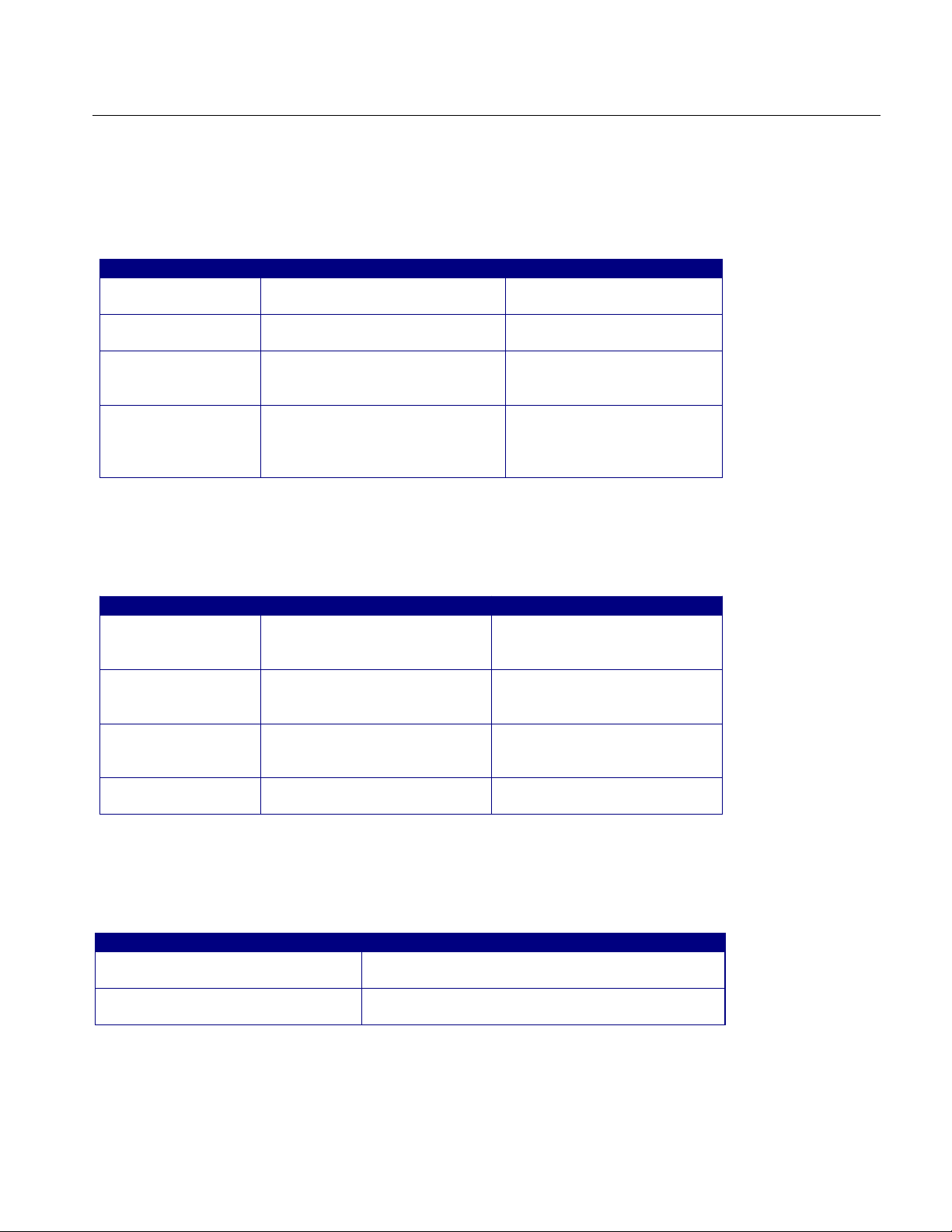

The File menu has the following selections:

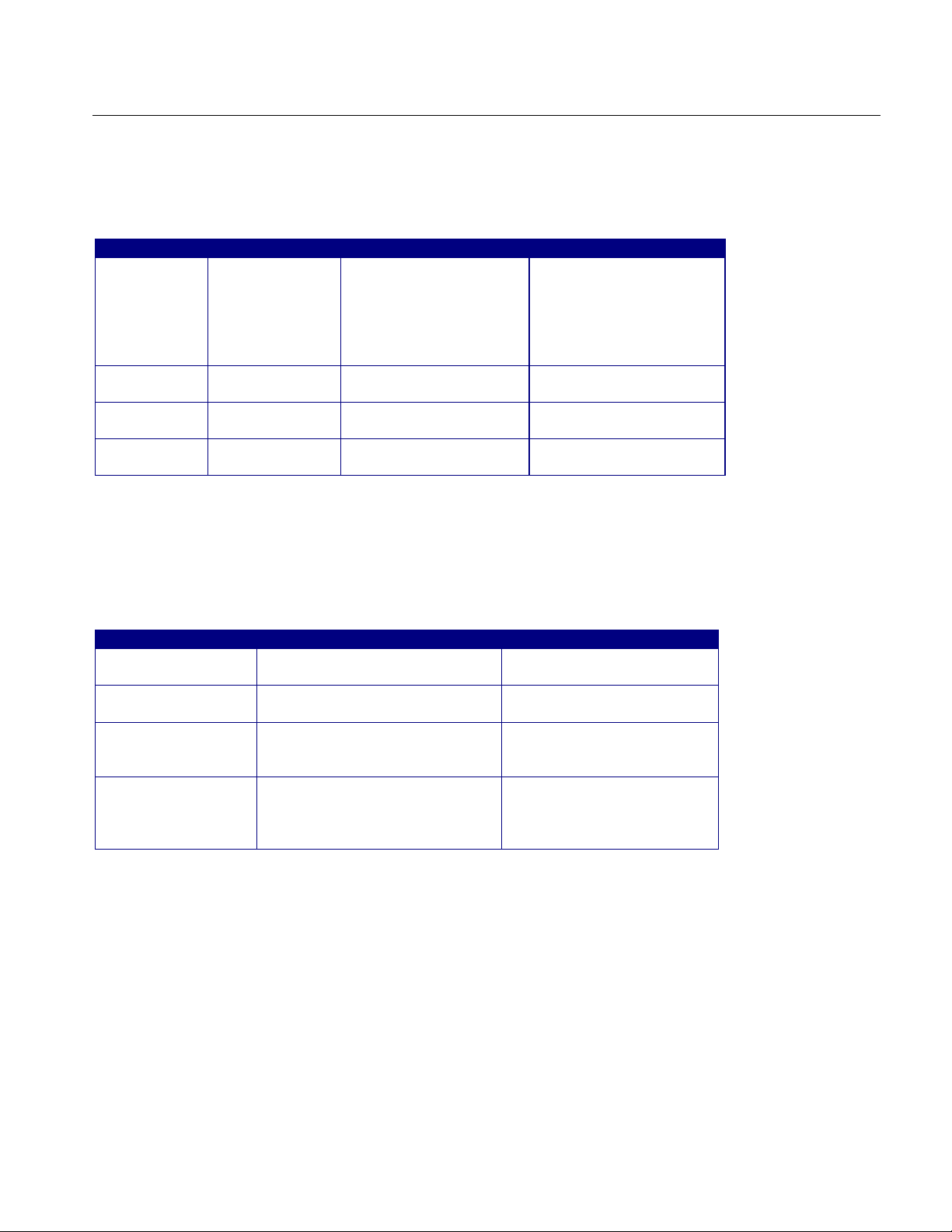

Table 6: File menu and their descriptions

Menu/function Description or function

Recall Default Recalls most default parameters for the active

module (Serial ATA or SAS)

Recall* Browse to select an application setup (.ini) file to

recall the setup fil e. Recall restores the applic ation

to the values saved in the setup

Save* Saves the curr ent application settings in a .i ni file

Recall Recent Select from the list of four most recently accessed

setup files (saved or recalled) and recall t hat setup

Preferences Displays the Preferences menu, settings apply until

you exit the application; saved setup files incl ude

the settings

Minimize Minimizes the application

Exit Exits the application; you can choose to retain t he

current oscilloscope settings or restore the

oscilloscope to the settings prior to star ting the

application

* Save or Recall functions also save or recall the associat ed oscilloscope

setup file (.ini); an oscilloscope file is recalled if the application finds a .set

with a matching name

Operating Basics

Measurements Menu

You can use the Measurements Menu to select and configure the measurement

that you want to make.

Click Measurement from the application menu bar. The Measurement menu has

the following selections:

Table 7: Measurement menu and their descriptions

Menu/function Description or function

Select Displays the Measurements for the selected m odule

Configure Displays the configurati on tabs for the selected

measurements

Limits Displays the Limits file

Click Measurement > Configure from the application menu bar. You can use the

Configure menu item to select and configure the measurements that you have

selected.

Option SST Serial ATA and Serial Attached SCSI Analysis Module

19

Page 32

Operating Basics

The Configure menu item has the following selections:

Table 8: Configure menu and their descriptions

Menu item Description

Source Displays the source parameters to confi gure for

the selected tests

General Config Displays the general parameters to configure for

the selected tests

Clock Config* Displays the clock parameter s to configure for

the selected tests

Plot Config** Displays the plot par am eters to plot an eye

diagram

* This tab is not available for SAS measurements

** This tab is enabled only for Eye measurement

Results Menu

You can view the results of the measurements using the Results Menu.

Click Results from the application menu bar. The Results Menu has the

following selections:

Table 9: Results menu and their descriptions

Menu item Description

Summary Display s a summary of the results of the

measurement or test

Details Displays the details of the result s of the

measurement or test

Worst Case Eye* Displays the plot of the Eye Diagram

* This selection is not avail able for the SAS module

Utilities Menu

You can use the Utility Menu to open the report generator pane. You can create

custom layouts and templates to generate custom reports. Click Utilities from the

application menu bar.

Help Menu

20

You can use the Help Menu to open the common help file for the plug-in SATA

and SAS modules, and version information about the modules.

Click Help from the application menu bar.

The Help menu has the following selections:

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 33

Table 10: Help menu and their descriptions

Menu item Description

Help Topics Displays the help file for the modules

PDF Help Displays the PDF file adapted fr om t he online help

About RT-EYE Displays the About box with version information

Saving and Recalling Files

To save the application and oscilloscope settings to a setup file, follow these

steps:

1. Select File> Save. View the Save browser.

2. The Save dialog box appears. To view details about the file, such as size,

type, and date modified, select the Details tool.

3. In the file browser, select the directory in which to save the setup file or use

the current directory.

Operating Basics

4. Select or use the keyboard to enter a new file name. The application appends

an ".ini" extension to the name of the application setup file.

5. Select the

command button.

Note: The application also saves the oscilloscope setup to a ".set" file when you

save an application setup. Both the application .ini file and oscilloscope .set file

have the same file name.

To recall the application and oscilloscope settings from saved setup files, follow

these steps:

1. Select File> Recall. View the Recall browser.

2. The Recall dialog box appears. To view details about the file, such as size,

type, and date modified, select the Details tool.

3. In the Recall dialog box, select the directory from which to recall the setup

file.

4. Select a setup file name, and then select Open.

Note: The application recalls the .ini setup file and the associated oscilloscope

setup if the application can find a .set file with a matching name.

Option SST Serial ATA and Serial Attached SCSI Analysis Module

21

Page 34

Operating Basics

CAUTION. Do not edit setup files. If you try to recall a setup file that has

been edited, the recall operation fails.

CAUTION. If a matching .set file is not found or if the .set file does not

recall correctly to the oscilloscope, then you are notified that the oscilloscope

recall failed while the application recall succeeded.

To recall the default application settings, select File> Recall Default.

Note: Most of the settings for the active module are recalled to the default state.

To recall a recently saved or accessed setup file, select File> Recall Recent… and

then select the file from the drop down list of setup file names.

Taking Measurements

Note: The application also recalls the associated oscilloscope setup if the

application can find a .set file with a matching name.

CAUTION. Do not edit setup files. If you try to recall a setup file that has

been edited, the recall operation fails.

CAUTION. If a matching .set file is not found or if the .set file does not

recall correctly to the oscilloscope, then you are notified that the oscilloscope

recall failed while the application recall succeeded.

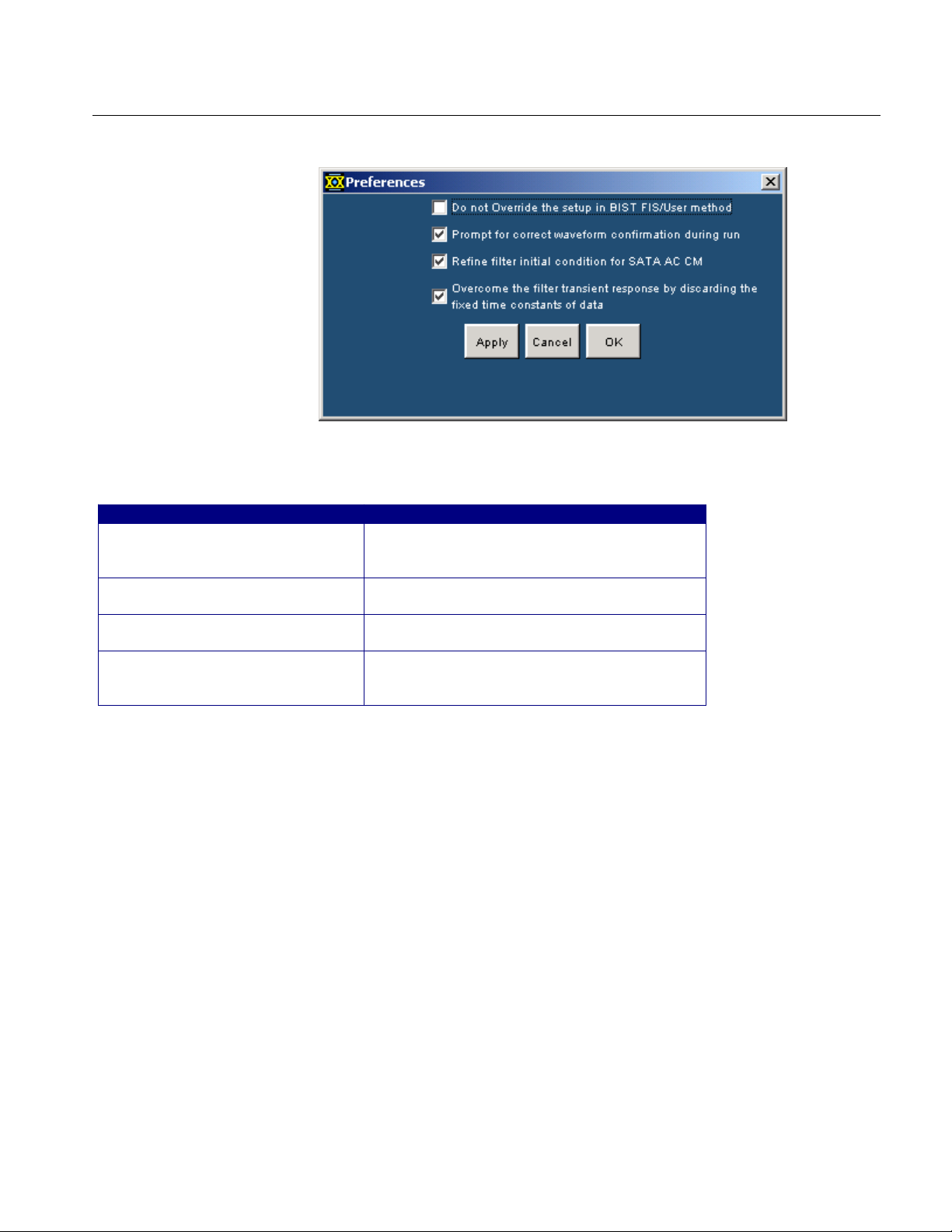

Setting Preferences

You can set preferences for the selected module. To set preferences, select File>

Preferences from the application menu.

22

The following diagram and table list the preferences that you can set for the

Serial ATA module and their descriptions:

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 35

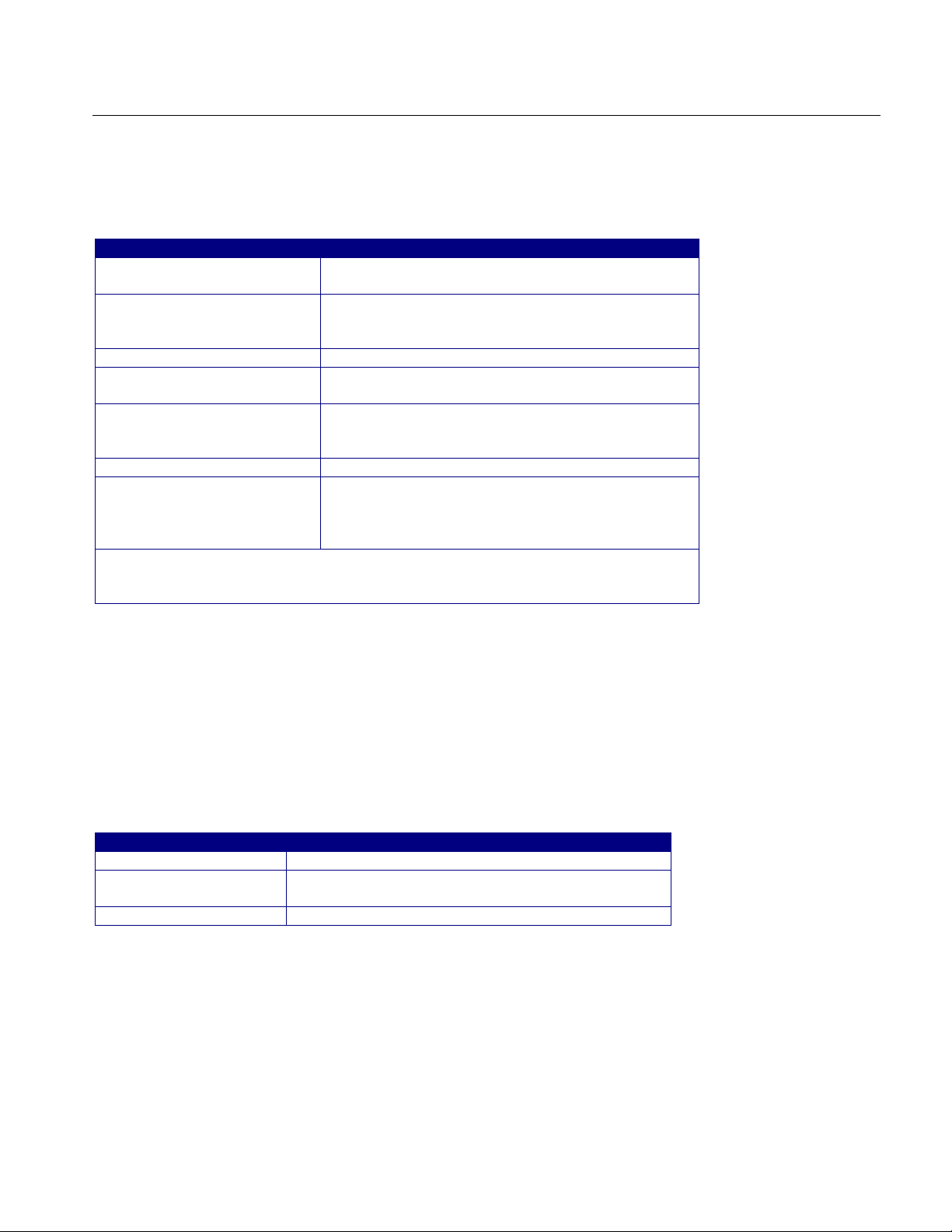

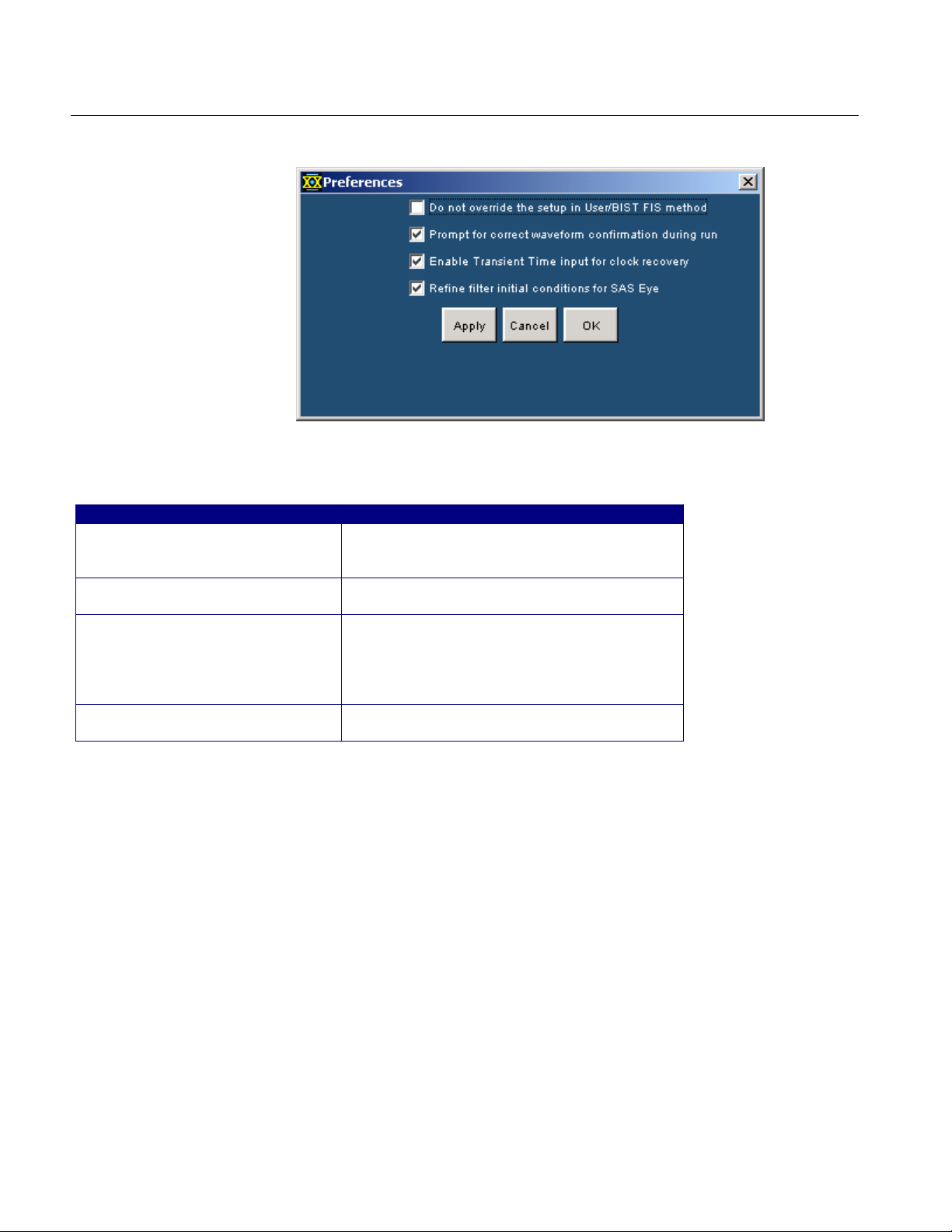

Figure 3: SATA Preferences

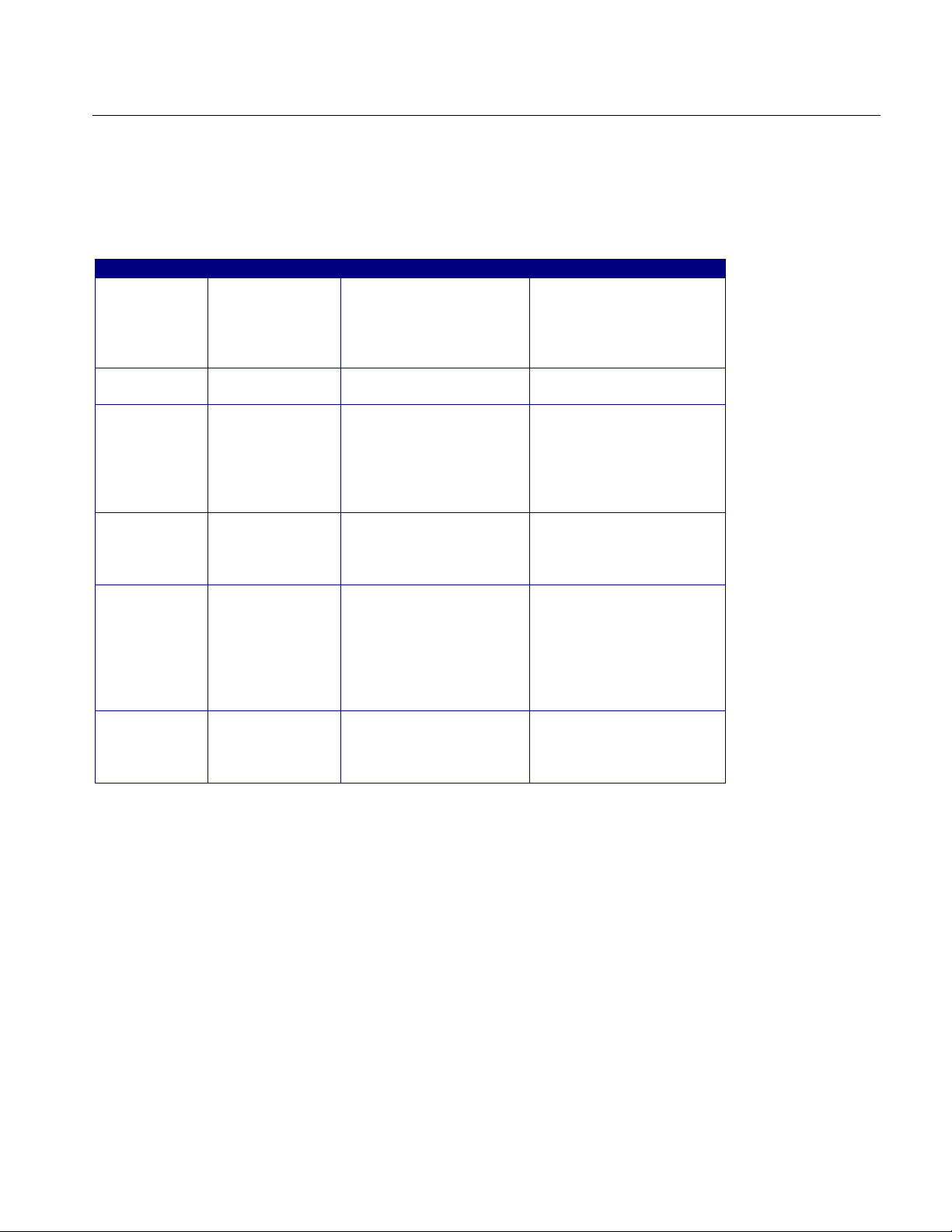

Table 11: Preferences for SATA measurements

Preference Description

Do not override the setup i n BIST

FIS/User method

Prompt for correct waveform

confirmation during run

Refine fi lter initial condit io n for

SATA AC CM

Overcome the filter transient

response by discarding the fixed

time constants of data

Enable this to use the default BIST FIS/User

method setup. The oscilloscope setup will not

be overwritten

Enable this to be prompted for the corr ec t

waveform after acquiring the data

Enable this to calcul ate t he initial conditions for

the low pass filter

Enable this to discard a fixed number of data

points for filtering the acquired data. The first

five time constants are discarded

Options two, three, and four are selected by default. If options three and four

have been cleared, we recommend that you select them to get accurate results.

Operating Basics

If neither option is selected then, filter operation will start from an arbitrary

sample point and filtered data can be affected by the filter transient response. The

filter transient response depends on the initial jitter on the data.

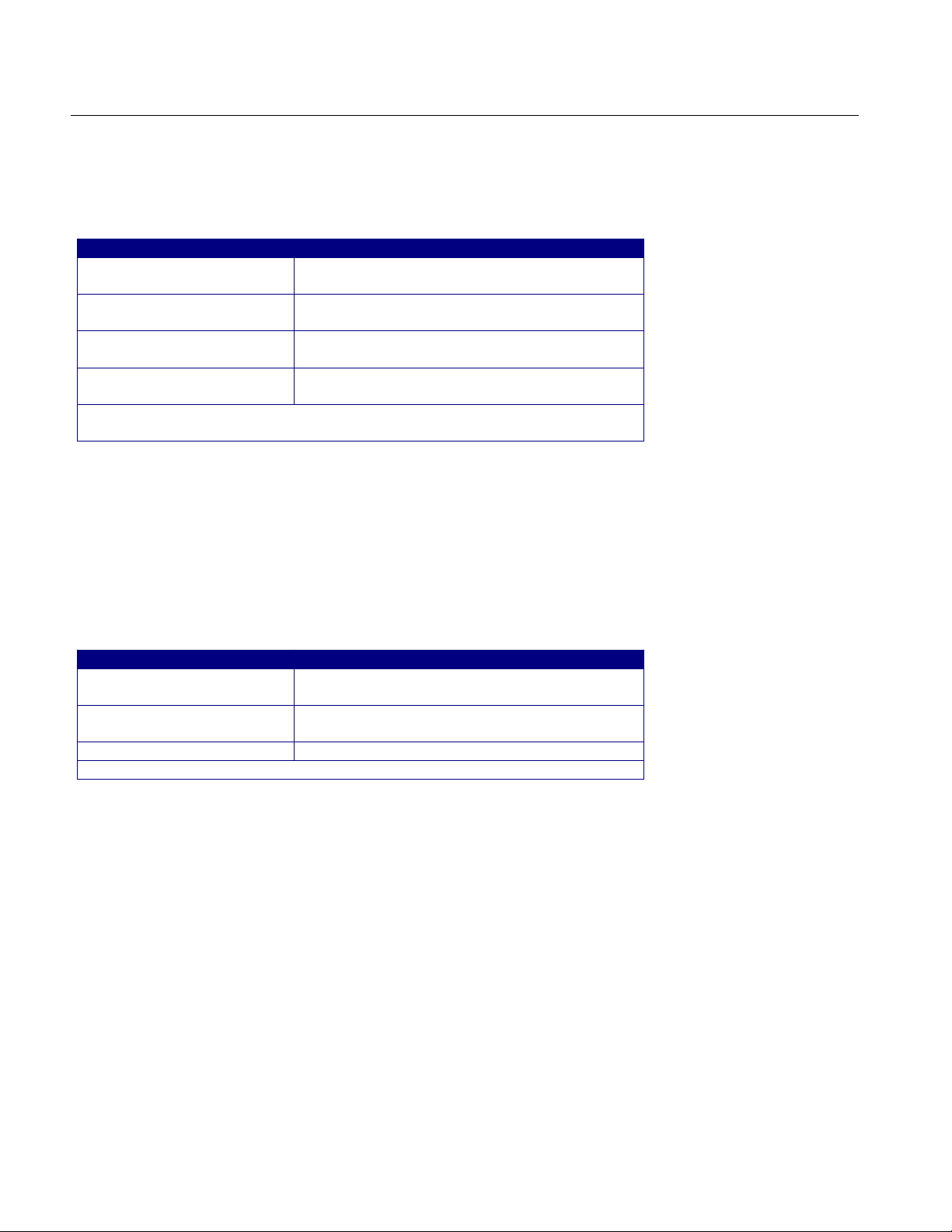

The following diagram and table list the preferences that you can set for the SAS

module and their descriptions.

Option SST Serial ATA and Serial Attached SCSI Analysis Module

23

Page 36

Operating Basics

Figure 4: SAS Preferences

Table 12: Preferences for SAS measurements

Preference Description

Do not override the setup i n BIST

FIS/User method

Prompt for correct waveform

confirmation during run

Enable Transient Time input for

clock recovery

Refine filter initial conditions for

SAS Eye

Enable this to use the default BIST FIS/User

method setup. The oscilloscope setup will not

be overwritten

Enable this to be prompted for the corr ec t

waveform after acquiring the data

Enable this to select the desired data point for

filtering from the acquired data. All data points

before the desired point will be discarded. You

can enter the transient time value in the

general confi gur ation tab

Enable this to calcul ate t he initial conditions for

the low pass filter

Options two, three, and four are selected by default. If options three and four

have been cleared, we recommend that you select them to get accurate results for

the Eye measurement for the SAS module.

24

If neither option is selected then, filter operation will start from an arbitrary

sample point and filtered data can be affected by the filter transient response. The

filter transient response depends on the initial jitter on the data.

When you select option three, the configured transient time should be greater

than three times the number of clock transitions. The number of transitions is 550

otherwise the application displays the error message indicating that enough UI

edges are not available to calculate eye height. The eye generation fails to

complete successfully. For example, in the TDS7704B oscilloscope for align.pat

the recommended horizontal scale is > 40 ns for sufficient clock transitions.

When you select option four, ensure that the acquired waveform has more than

550 clock transitions otherwise the application displays the error message

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 37

Operating Basics

indicating that enough UI edges are not available to calculate eye height. The eye

generation fails to complete successfully.

The SAS Eye measurement requires at least three data packets that has ≥ 550

clock transitions in the acquired data to calculate clock recovery correctly. If the

acquired pattern has insufficient clock transitions (550) then you need to acquire

more packets for sufficient clock transitions.

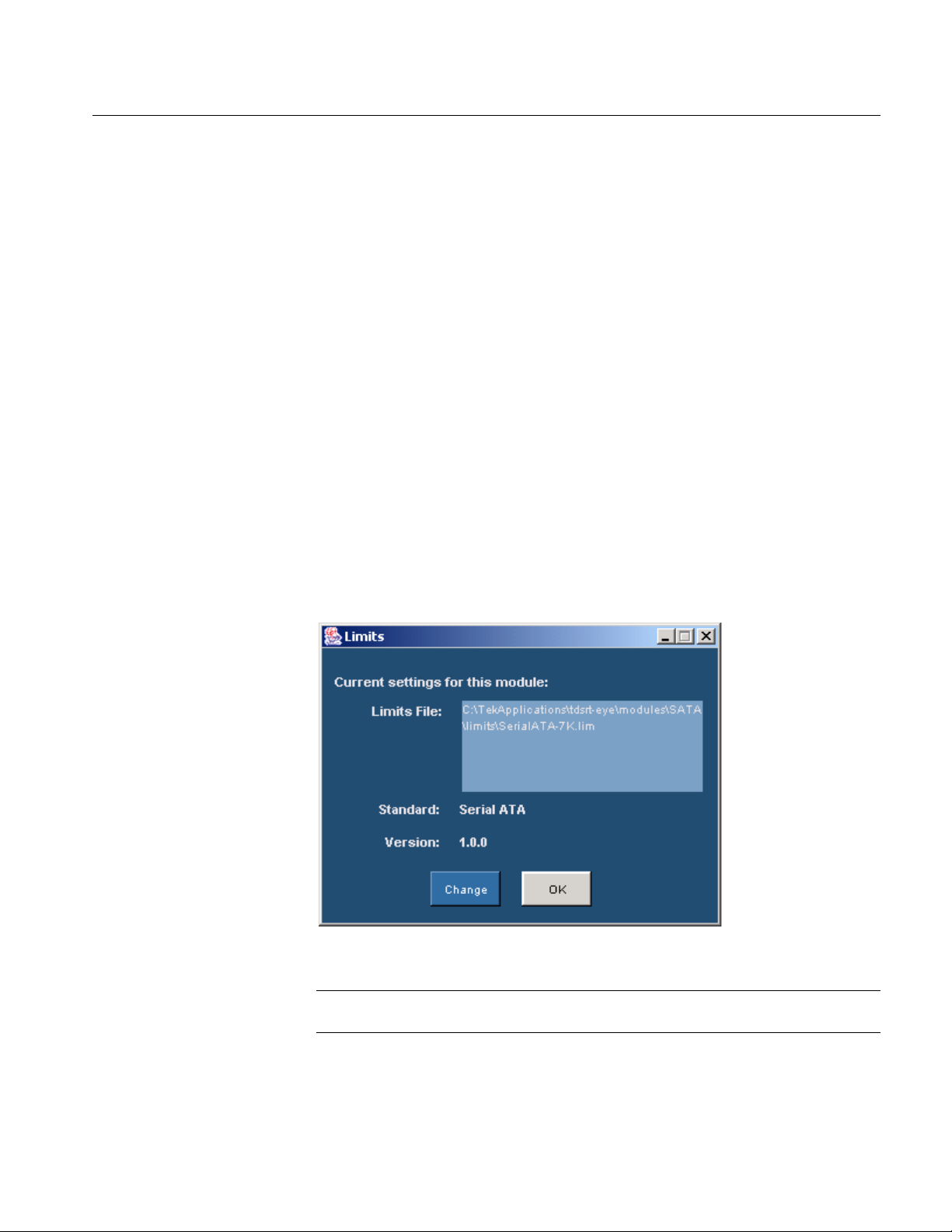

Using a Limit File

Each module (SATA and SAS) provides a limit file that includes the

measurements and their range of permitted values. The module uses the limit file

to determine the Pass or Fail status for the measurements.

To change the limit file that your module uses, select Measurements> Limits.

Browse to the directory and select a limit file to use with a .lim file name

extension.

For the Serial ATA module, the files SerialATA-6k.lim and SerialATA-7k.lim

are available for the TDS6000 and TDS7000 series of supported oscilloscopes.

For the SAS module, the files SAS-6k.lim and SAS-7k.lim are available for the

TDS6000 and TDS7000 series of supported oscilloscopes.

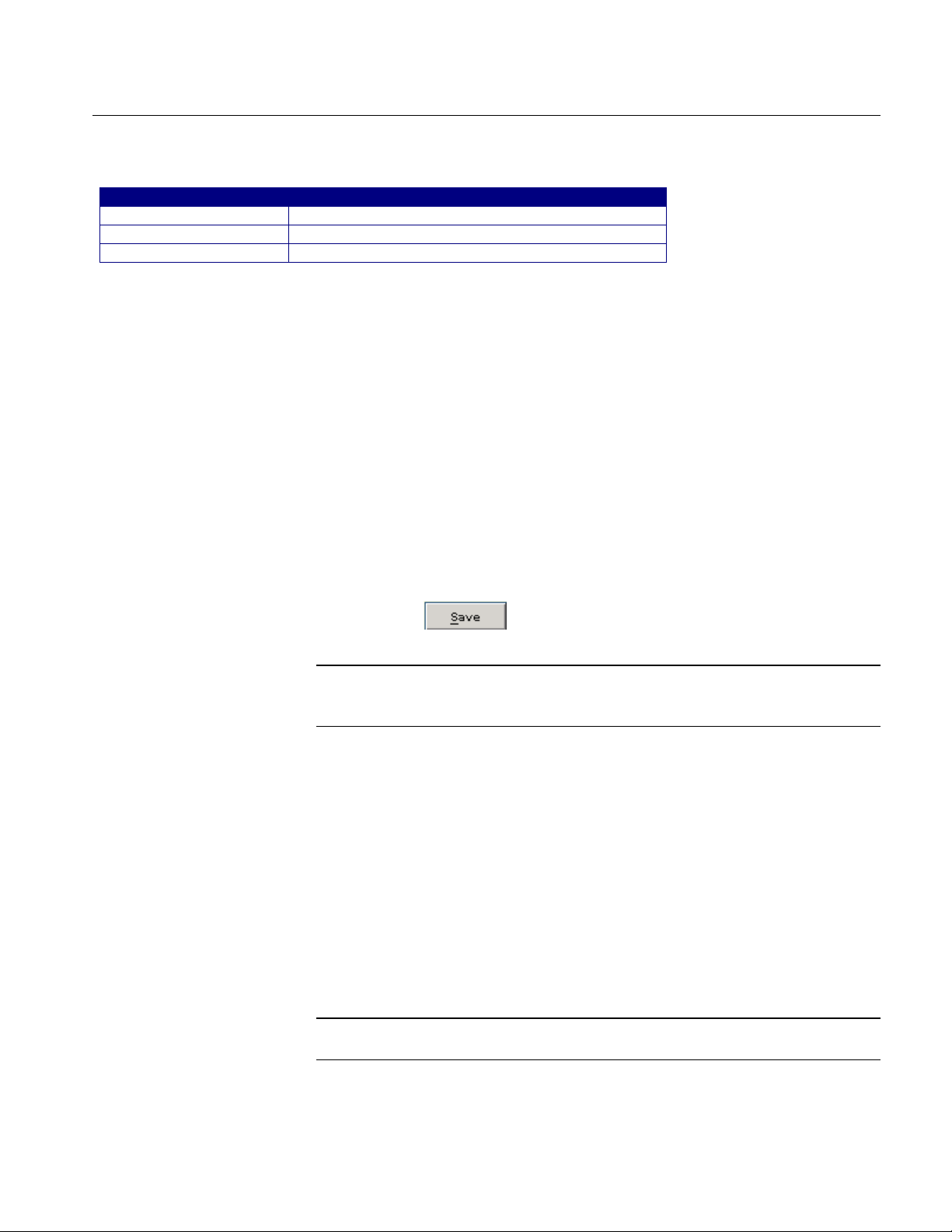

Figure 5: Changing Limit Files

Note: You must not edit the limits file. If you edit the limit file, the measurements

will not execute.

Option SST Serial ATA and Serial Attached SCSI Analysis Module

25

Page 38

Operating Basics

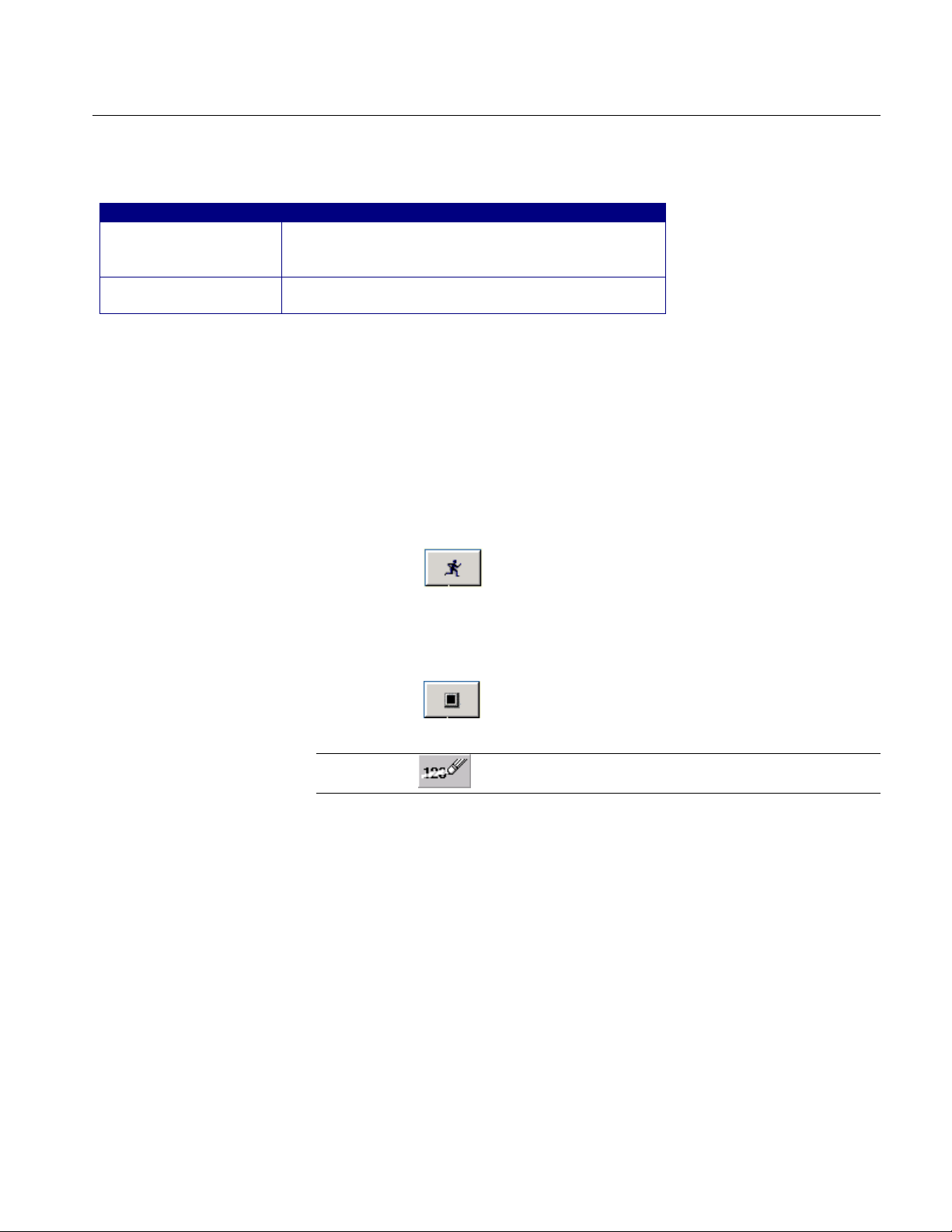

Control Panel

You use the Control Panel to start or stop the sequence of processes for the

application and oscilloscope to acquire information from a waveform. The

application then determines if the algorithm for the selected measurement can be

applied to the waveform information. Sequencing is the steps to acquire

waveform information, determine if the information is usable for the

measurement, take the measurement, and display the results.

Figure 6: Control panel

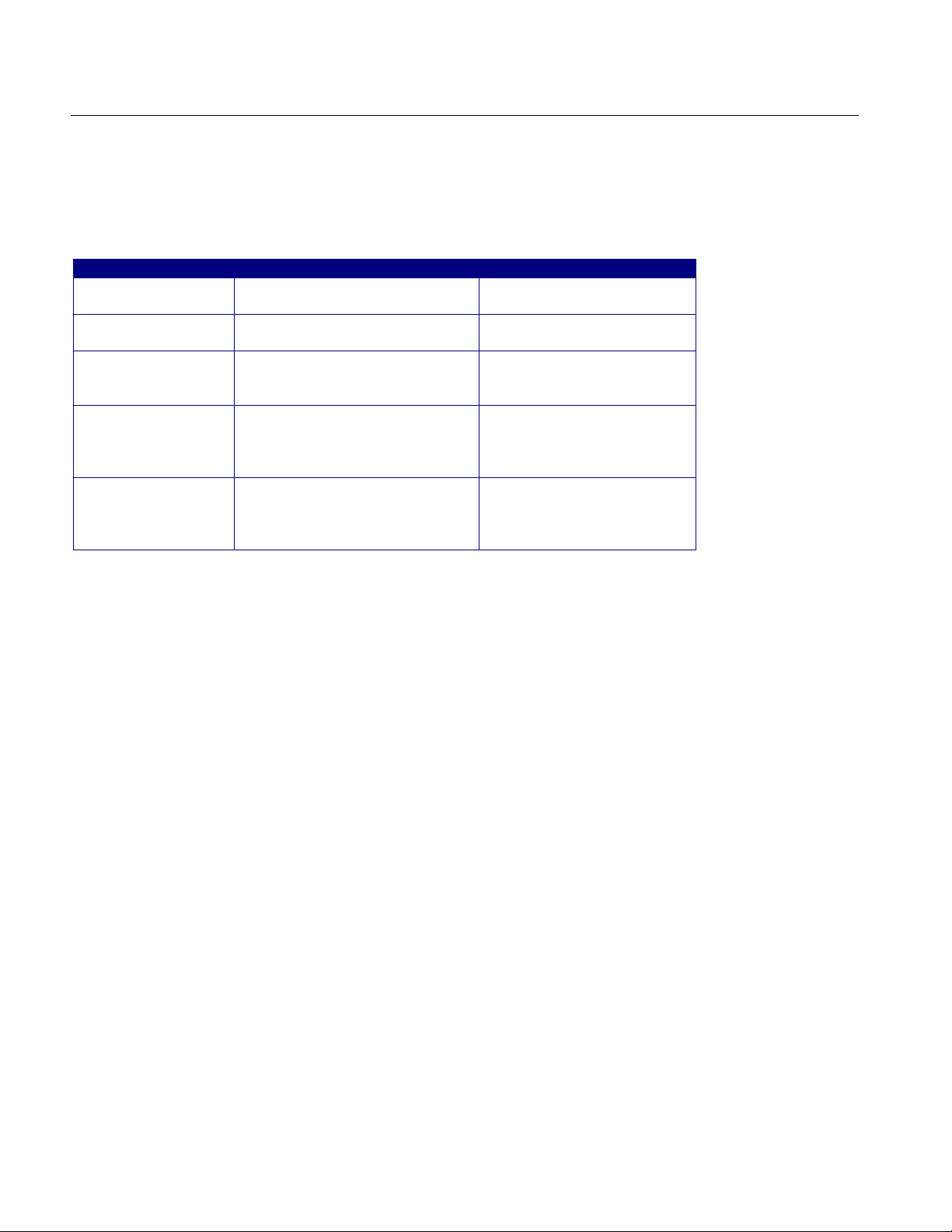

Table 13: Control panel buttons and their descriptions

Command butto n Description

Start Start command button; use to start the sequencing

based on the selected Sequence Mode

Stop S top command button; use to stop sequencing

Clear Results Clear results command button; use to cl ea r all

previous results in the Results Summary menu,

Results Detai ls menu

Mode Select Mode; Single or Single No A c q

Sequence Mode

There are two Sequencing modes: Single Run and Single No Acq. The following

table lists the modes and their descriptions:

26

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 39

Table 14: Sequence modes and their descriptions

Mode Description

Single Run Acquires a new waveform if the source is Ch1, Ch2,

Ch3, or Ch4, Ref waveforms, or from file; for all

sources the appli c ation sequences until complet e

Single No Acq Recalculates the selected measurements without

acquiri ng new data

Acquiring Data

To acquire data from waveforms and take measurements, follow these steps:

1. In the Control Panel (on the right side of the application display), select a

Sequence mode.

2. The application uses the Sequence mode to acquire waveforms and take

measurements when you select the Start command button. The choices are:

Single Run and Single No Acq.

Operating Basics

3. Select the

button for continuous acquisitions or for measurements

on a new or existing acquisition.

4. If you select the Single Run or the Single No Acq mode, the application

displays the results when the sequencing is complete.

5. Select the

Note: Use the

Stop button to stop the sequencing.

command button to delete all measurement results.

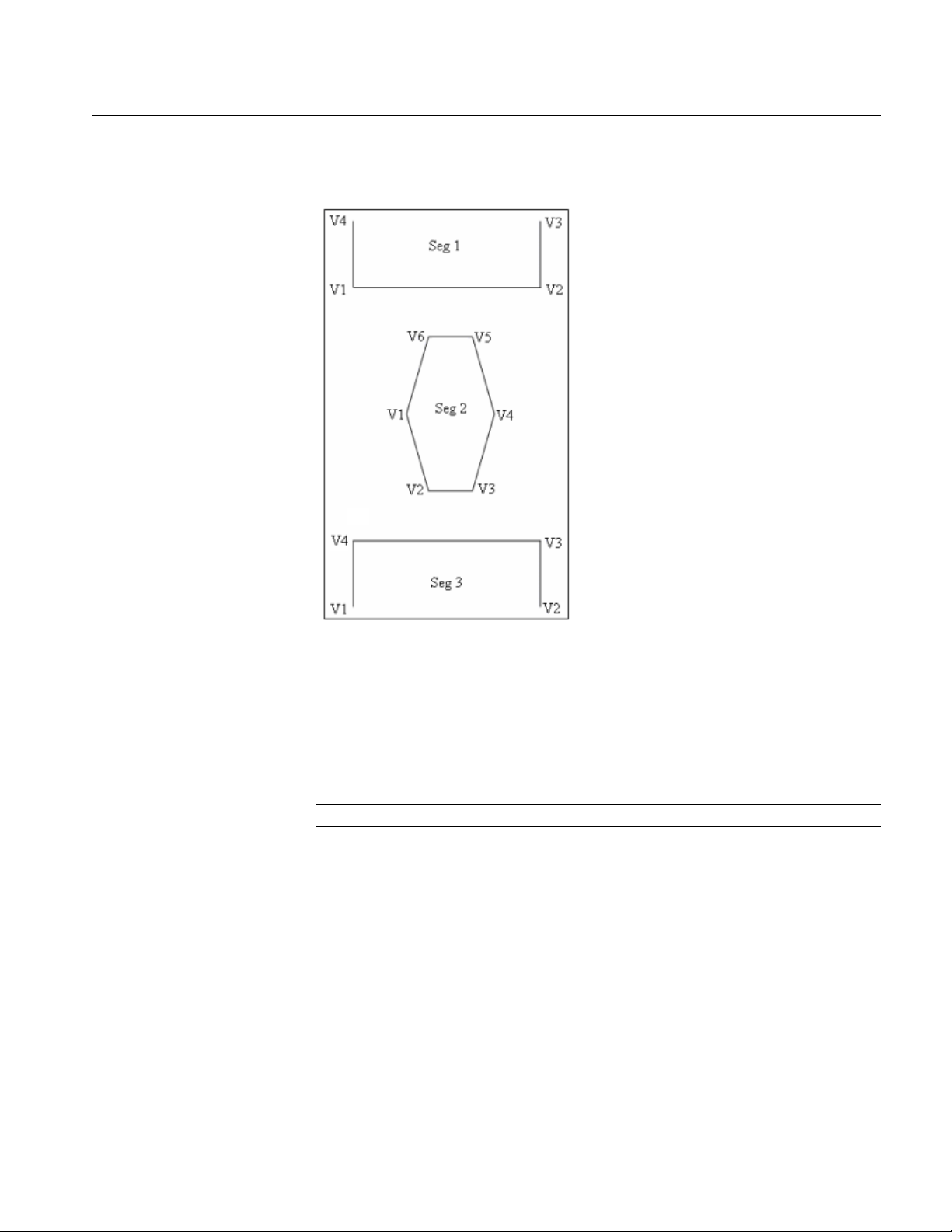

Editing a Serial ATA Mask File

The mask files for Serial ATA are located in C:\Program

Files\TekApplications\tdsRT-Eye\lib\RTEye. The mask file name indicates the

technology, test point, number of unit intervals, and the device usage model. For

example, for the file SataTX250G1i.msk, "Sata" indicates the technology, "TX"

indicates transmitter, "250" indicates the number of unit intervals, and

"G1i"indicates the device usage model.

Option SST Serial ATA and Serial Attached SCSI Analysis Module

27

Page 40

Operating Basics

Figure 7: Example of a mask file

28

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 41

Operating Basics

The following diagram shows a typical eye mask, the segments, and vertices.

Figure 8: Example of mask template

The Serial ATA specifications do not specify eye mask geometry. The Serial

ATA module provides tentative mask geometry for the eye mask test. You can

edit the mask file (.msk) and modify the segment vertices to suit your needs. You

can open the .msk file in Notepad, and after editing, save it in the same location

with the same file name.

Note: Before you overwrite the mask file, ensure that you backup the file.

Option SST Serial ATA and Serial Attached SCSI Analysis Module

29

Page 42

Operating Basics

The following Serial ATA mask files are available for a transmitter and receiver:

Transmitter mask files Receiver mask files

SataTX250G1i SataRX250G1i

SataTX250G1m SataRX250G1m

SataTX250G1x SataRX250G1x

SataTX250G2i SataRX250G2i

SataTX250G2m SataRX250G2m

SataTX250G2x SataRX250G2x

SataTX5G1i SataRX5G1i

SataTX5G1m SataRX5G1m

SataTX5G1x SataRX5G1x

SataTX5G2i SataRX5G2i

SataTX5G2m SataRX5G2m

SataTX5G2x SataRX5G2x

30

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 43

Operating Basics

Option SST Serial ATA and Serial Attached SCSI Analysis Module

31

Page 44

How To...

Set up the DUT

Methods to Test a DUT

You can set up the Device Under Test (DUT) and test it in two ways: using the

Arbitrary Waveform Generator (AWG), or the BIST FIS/User-defined method.

In the AWG method, the AWG provides an external stimulus to the DUT. The

DUT, in turn, responds with the OOB signals and Align Patterns on which the

Serial ATA and SAS test modules can make measurements.

In the BIST FIS/User method, you can program the DUT to emit or transmit

various patterns on which the Serial ATA and SAS test modules can make

measurements.

The following table lists the test fixture connectors and the signals that are

connected to the test fixture:

Table 15: Test fixture, host, and drive connections

Test fixture

connectors

J2 Tx+ Rx+

J3

J4

J5 Rx+ Tx+

Host connections Drive connection s

Tx

Rx

−

−

Rx

Tx

−

−

Option SST Serial ATA and Serial Attached SCSI Analysis Module

32

Page 45

How To…

Test the Transmitter Host DUT using AWG Method

To test a transmitter host device using an AWG, set up the equipment as follows:

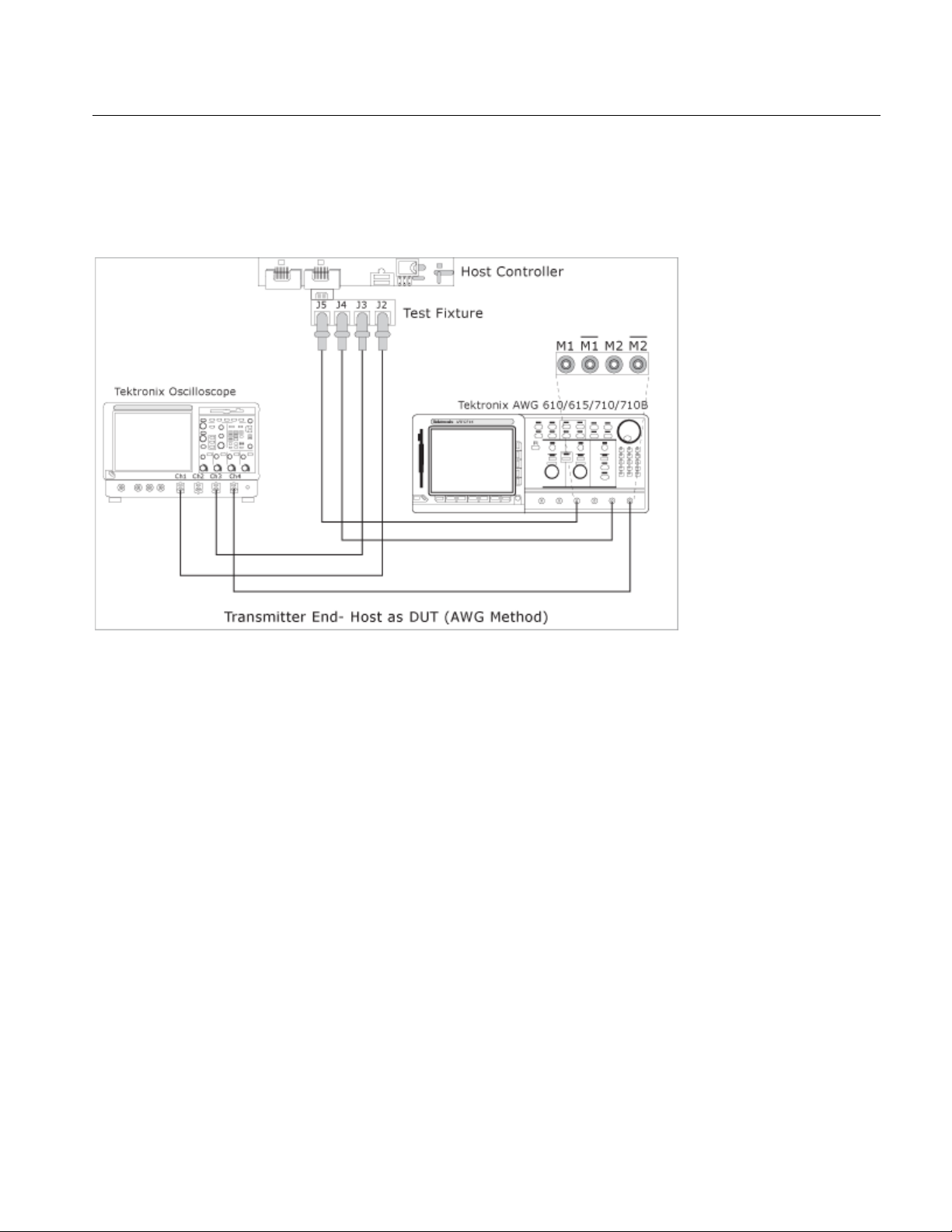

Figure 9: Test the transmitter host DUT using AWG method

You can use SMA cables or P7380SMA cables to connect the DUT to the

oscilloscope and the AWG.

For a Host as the DUT, connect the SMA cables (single-ended probes) as

follows:

AWG Marker 1 to J5 (Rx+)

AWG Marker 2 to J4 (Rx−)

Oscilloscope Channel 1 to J2 (Tx+)

Oscilloscope Channel 3 to J3 (Tx−)

Option SST Serial ATA and Serial Attached SCSI Analysis Module

33

Page 46

How To…

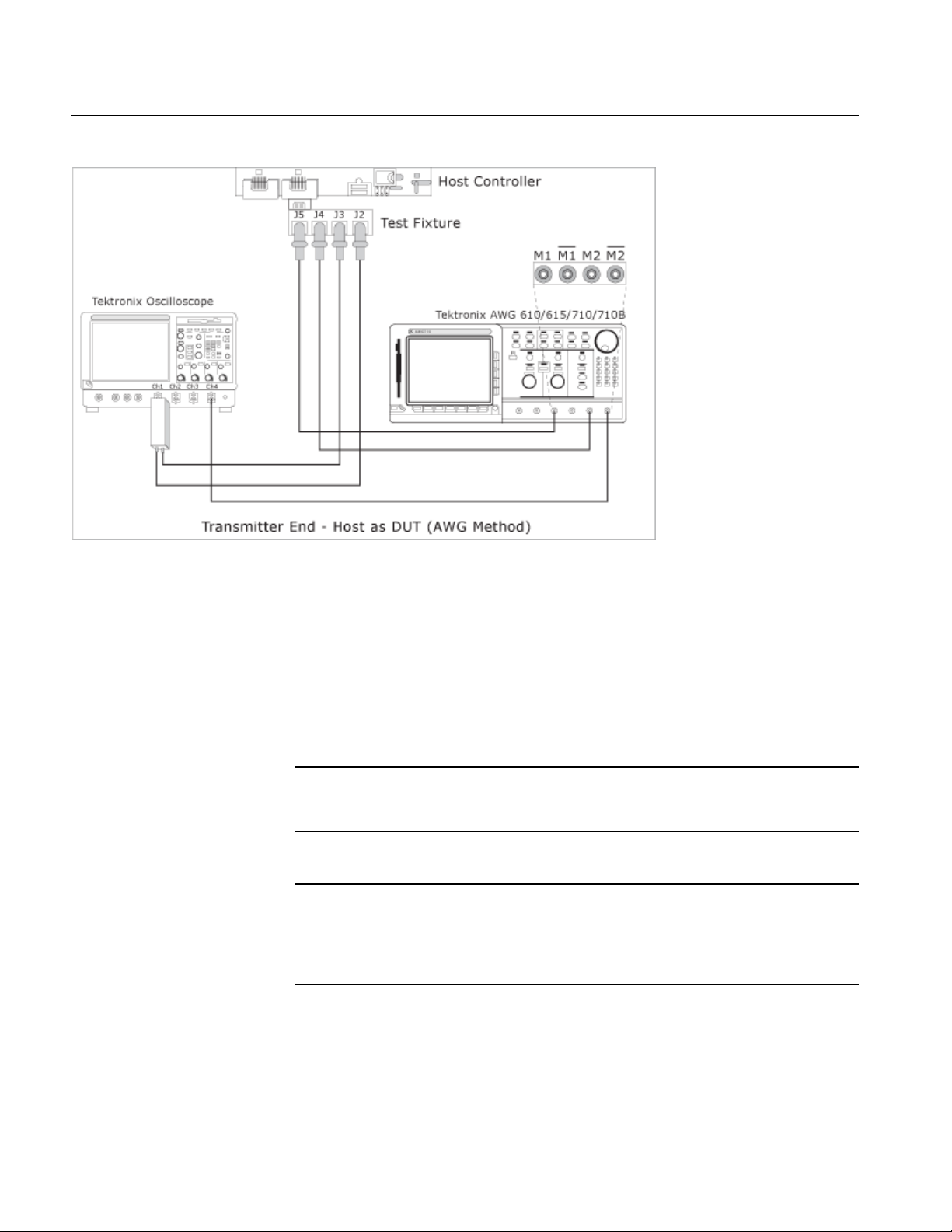

Figure 10: Test the transmitter host DUT using AWG method

For a Host as the DUT, connect the P7380SMA cables (differential probes) as

follows:

AWG Marker 1 to J5 (Rx+)

AWG Marker 2 to J4 (Rx−)

Oscilloscope Channel 1 or 3 to J2 (Tx+) or J3 (Tx−)

Note: If you use oscilloscope channels 1 and 3 for Tx+ and Tx

oscilloscope channels 2 or 4 as trigger. If you use oscilloscope channels 2 and 4

−

for Tx+ and Tx

Note: When you use a P7380SMA probe, and if the peak-to-peak signal

amplitude is more than 625 mV, set Attenuation Dynamic Range of the probe to

12.5X. If the signal peak to peak amplitude is less than 625 mV, set Attenuation

Dynamic Range of the probe to 2.5X. Ensure that the V term Source is set to

Auto.

, then use oscilloscope channels 1 or 3 as trigger.

−

, then use

34

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 47

How To…

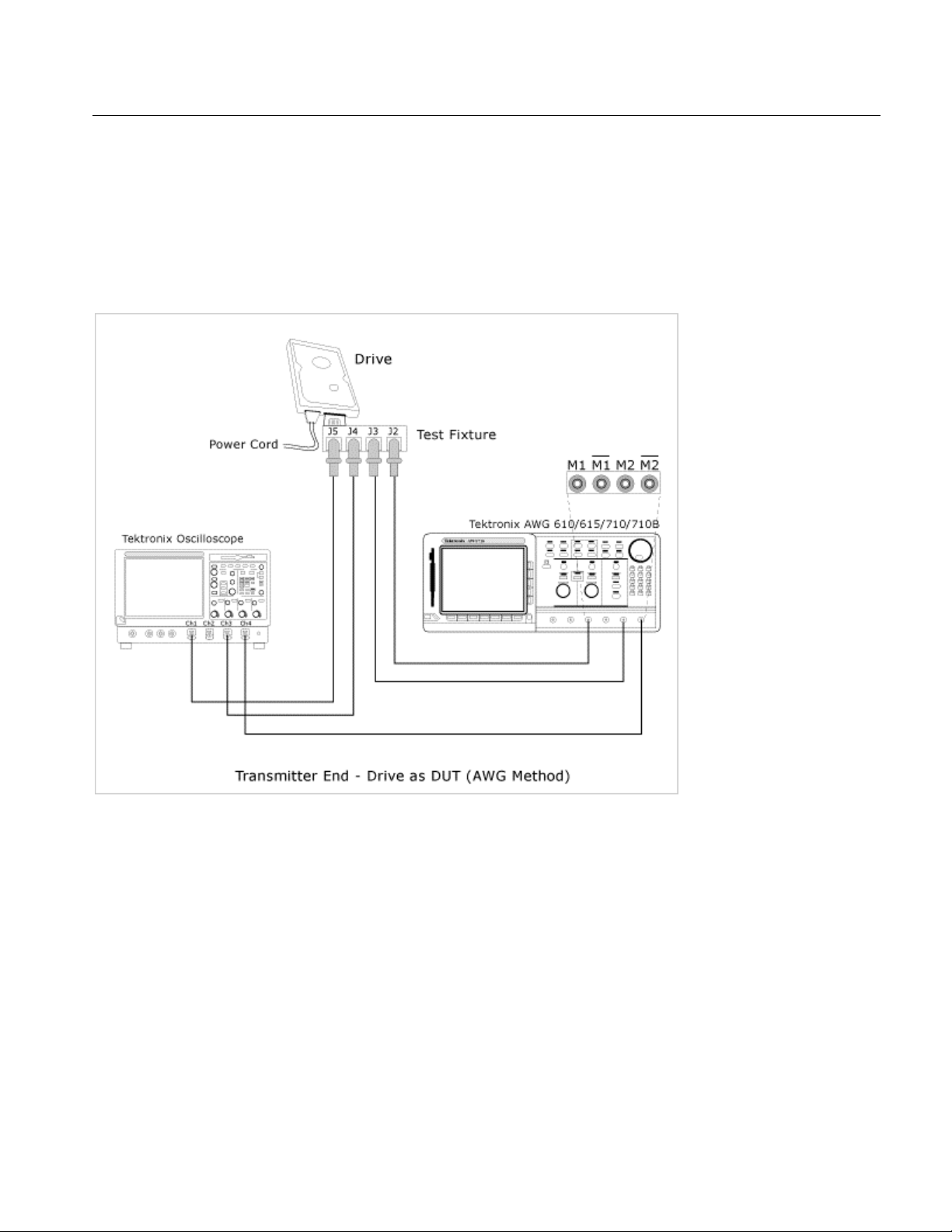

Test the Transmitter Drive DUT using AWG Method

To test a transmitter drive device using an AWG, set up the equipment as

follows:

Figure 11: Test the transmitter drive DUT using AWG method

You can use SMA cables or P7380SMA cables to connect the DUT to the

oscilloscope and the AWG.

For a Drive as the DUT, connect the SMA cables (single-ended probes) as

follows:

AWG Marker 1 to J2 (Rx+)

AWG Marker 2 to J3 (Rx−)

Oscilloscope Channel 1 to J5 (Tx+)

Oscilloscope Channel 3 to J4 (Tx−)

Option SST Serial ATA and Serial Attached SCSI Analysis Module

35

Page 48

How To…

Figure 12: Test the transmitter drive DUT using AWG method

For a Drive as the DUT, connect the P7380SMA cables (differential single-ended

probes) as follows:

AWG Marker 1 to J2 (Rx+)

AWG Marker 2 to J3 (Rx−)

Oscilloscope Channel 1 or 3 to J5 (Tx+) and J4 (Tx−)

Note: If you use oscilloscope channels 1 and 3 for Tx+ and Tx

oscilloscope channels 2 or 4 as trigger. If you use oscilloscope channels 2 and 4

−

for Tx+ and Tx

Note: When you use a P7380SMA probe, and if the peak-to-peak signal

amplitude is more than 625 mV, set Attenuation Dynamic Range of the probe to

12.5X. If the signal peak to peak amplitude is less than 625 mV, set Attenuation

Dynamic Range of the probe to 2.5X. Ensure that the V term Source is set to

Auto.

, then use oscilloscope channels 1 or 3 as trigger.

−

, then use

36

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 49

How To…

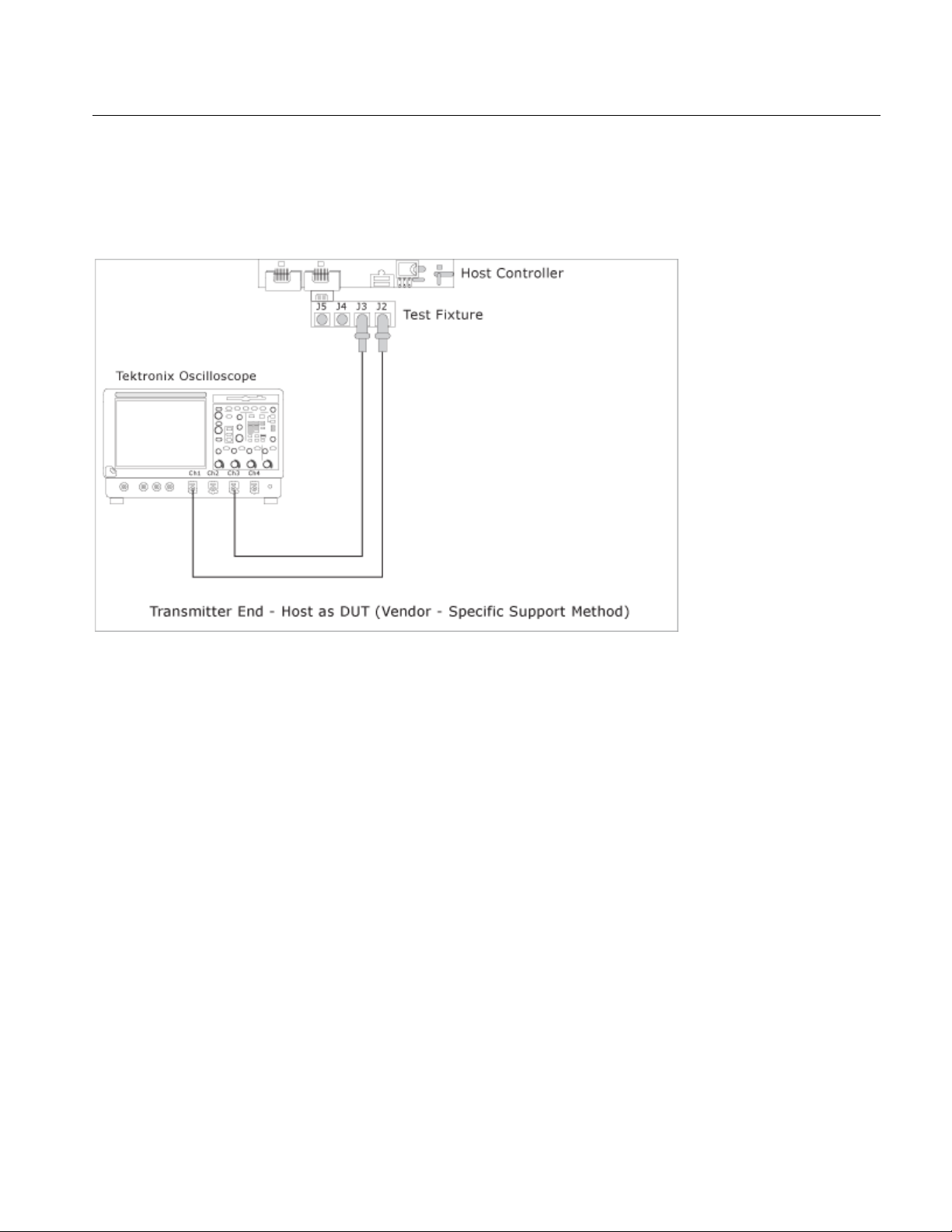

Test the Transmitter Host DUT using BIST FIS/User Method

To test a transmitter host device using a vendor-specific method (or BIST FIS),

set up the equipment as follows:

Figure 13: Test the transmitter host DUT using BIST FIS/User method

For a Host as the DUT, connect the SMA cables (single-ended probes) as

follows:

Oscilloscope Channel 1 to J2 (Tx+)

Oscilloscope Channel 3 to J3 (Tx−)

Option SST Serial ATA and Serial Attached SCSI Analysis Module

37

Page 50

How To…

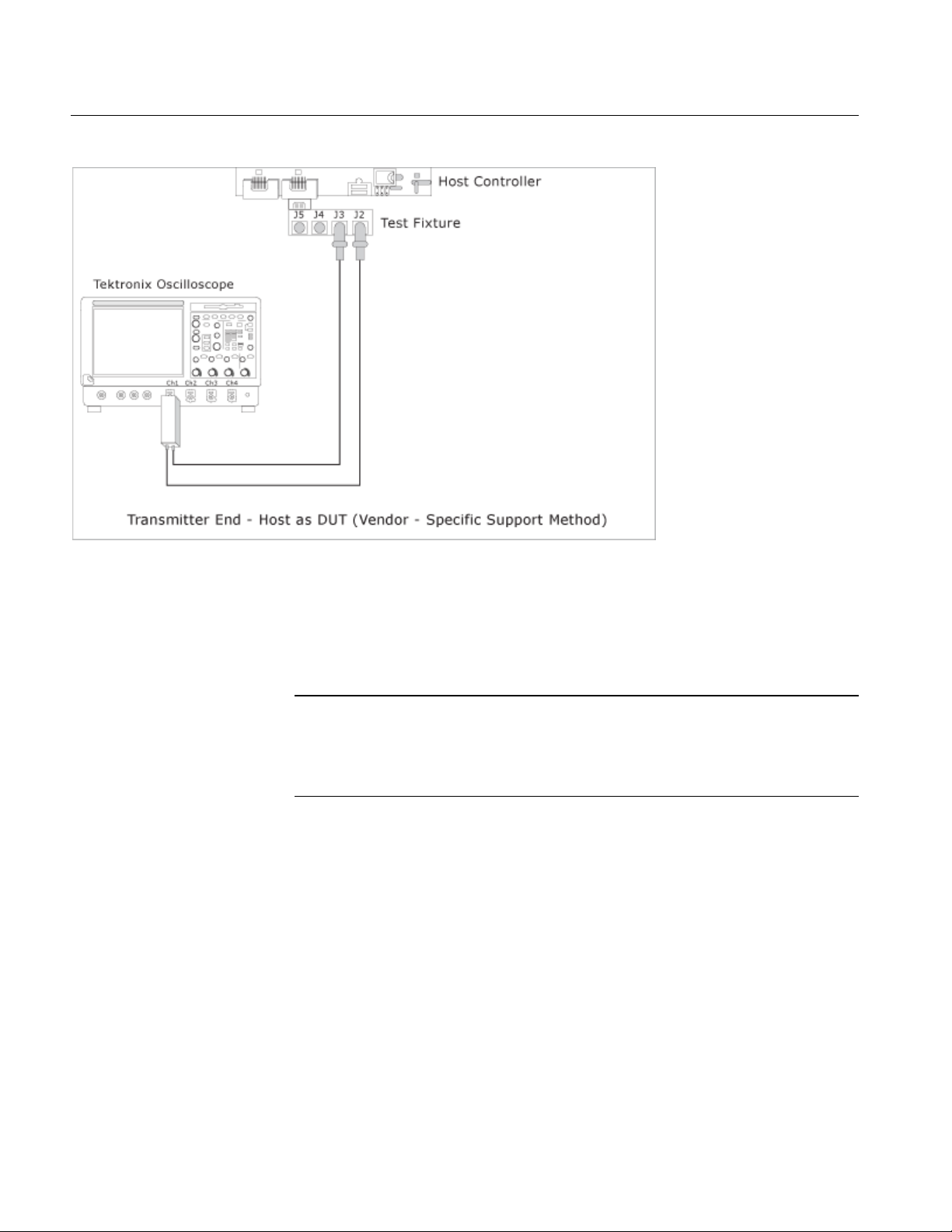

Figure 14: Test the transmitter host DUT using BIST FIS/User method

For a Host as the DUT, connect the P7380SMA cables (differential probes) as

follows:

Oscilloscope Channel 1 or 3 to J2 (Tx+) or J3 (Tx−)

Note: When you use a P7380SMA probe, and if the peak-to-peak signal

amplitude is more than 625 mV, set Attenuation Dynamic Range of the probe to

12.5X. If the signal peak to peak amplitude is less than 625 mV, set Attenuation

Dynamic Range of the probe to 2.5X. Ensure that the V term Source is set to

Auto.

38

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 51

How To…

Test the Transmitter Drive DUT using BIST FIS/User Method

To test a transmitter drive device using a vendor-specific method (or BIST FIS),

set up the equipment as follows:

Figure 15: Test the transmitter drive DUT using BIST FIS/User meth od

For a Drive as the DUT, connect the SMA cables (single-ended probes) as

follows:

Oscilloscope Channel 1 to J5 (Tx+)

Oscilloscope Channel 3 to J4 (Tx−)

Option SST Serial ATA and Serial Attached SCSI Analysis Module

39

Page 52

How To…

Figure 16: Test the transmitter drive DUT using BIST FIS/User meth od

For a Drive as the DUT, connect the P7380SMA cables (differential probes) as

follows:

Oscilloscope Channel 1 or 3 to J5 (Tx+) and J4 (Tx−)

Note: When you use a P7380SMA probe, and if the peak-to-peak signal

amplitude is more than 625 mV, set Attenuation Dynamic Range of the probe to

12.5X. If the signal peak to peak amplitude is less than 625 mV, set Attenuation

Dynamic Range of the probe to 2.5X. Ensure that the V term Source is set to

Auto.

40

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 53

How To…

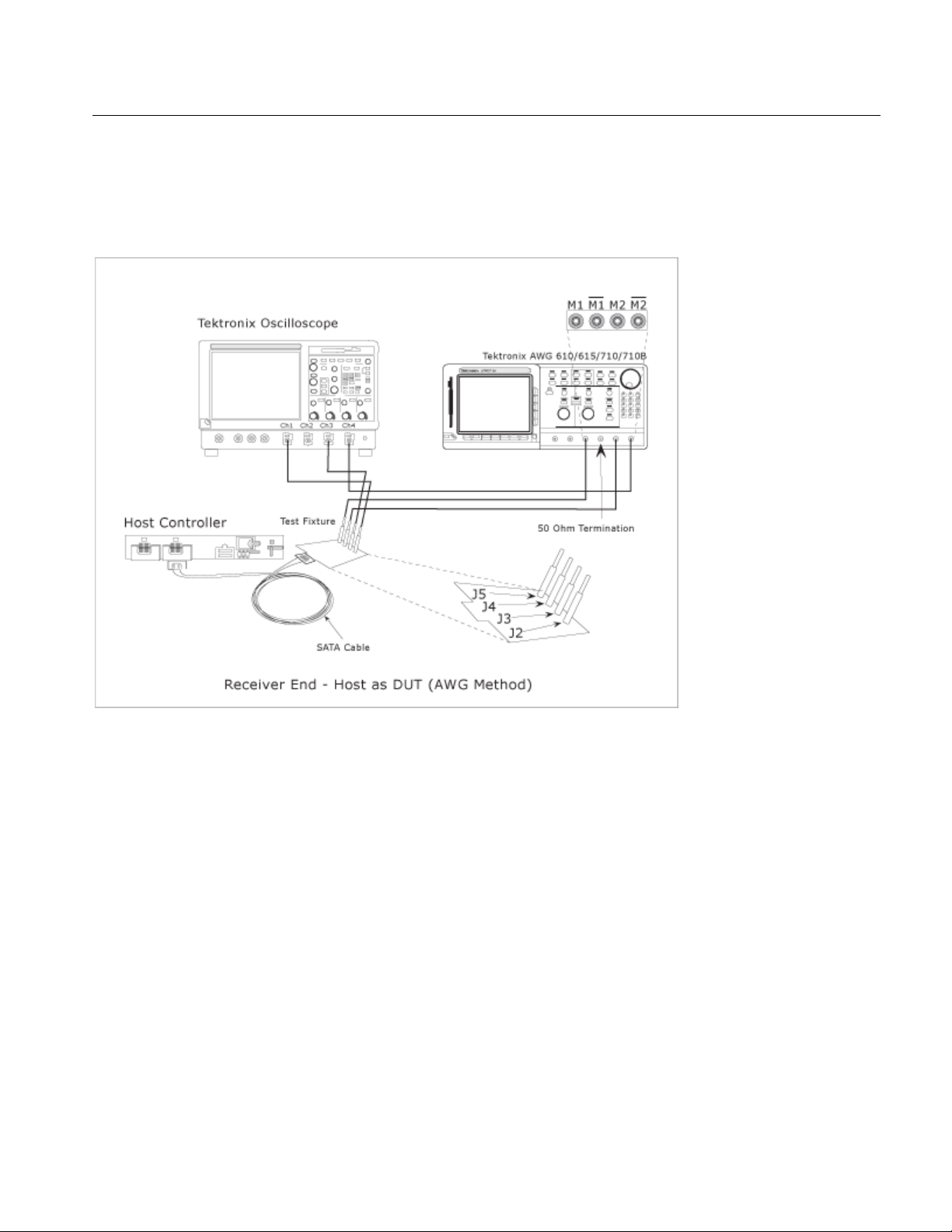

Test the Receiver Host DUT using AWG Method

To test a receiver host device using an AWG, set up the equipment as follows:

Figure 17: Test the receiver host DUT using AWG method

You can use SMA cables or P7380SMA cables to connect the DUT to the

oscilloscope and the AWG.

For a Host as the DUT, connect the SMA cables (single-ended probes) as

follows:

AWG Marker 1 to J5 (Rx+)

AWG Marker 2 to J4 (Rx−)

Oscilloscope Channel 1 to J2 (Tx+)

Oscilloscope Channel 3 to J3 (Tx−)

Option SST Serial ATA and Serial Attached SCSI Analysis Module

41

Page 54

How To…

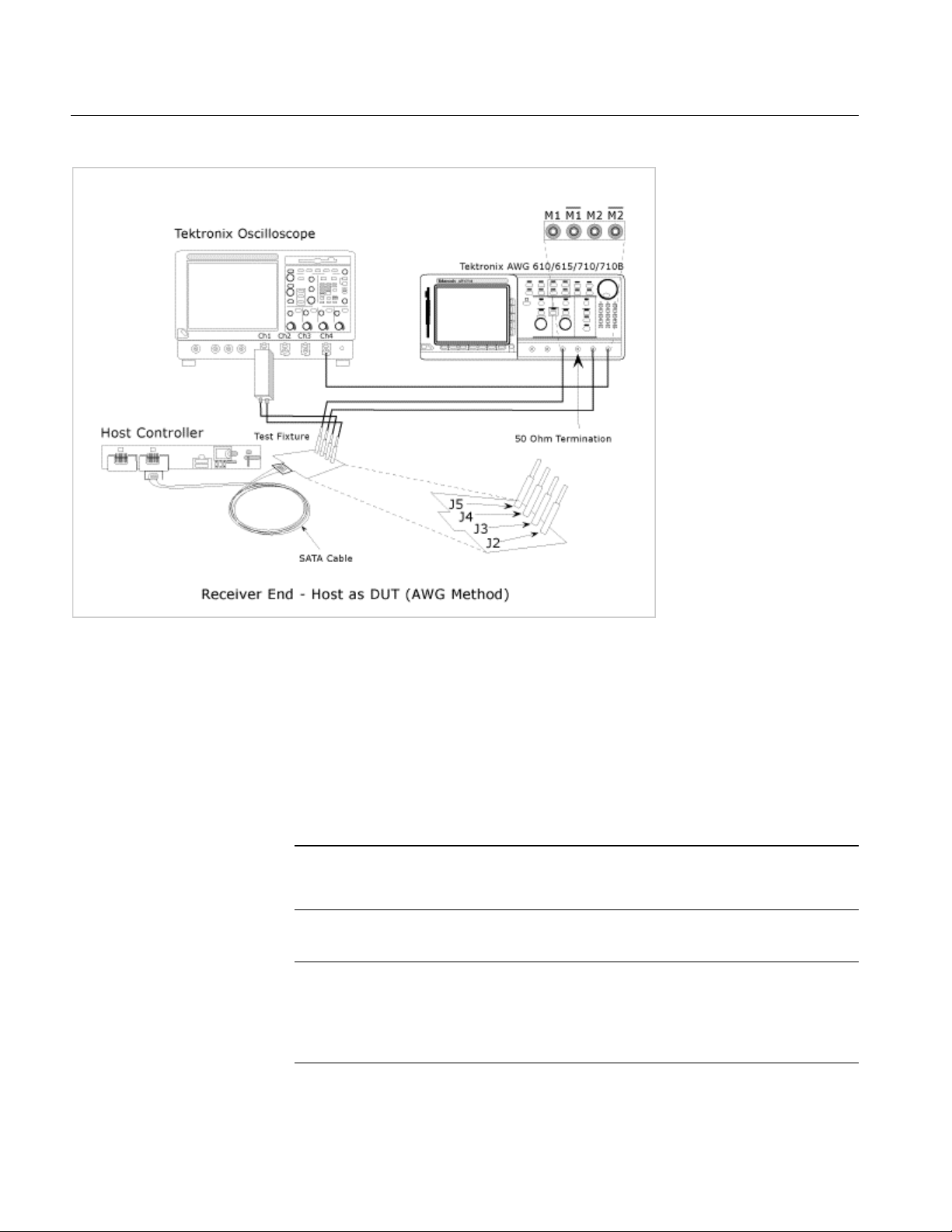

Figure 18: Test the receiver host DUT using AWG method

For a Host as the DUT, connect the P7380SMA cables (differential probes) as

follows:

AWG Marker 1 to J5 (Rx+)

AWG Marker 2 to J4 (Rx−)

Oscilloscope Channel 1 or 3 to J2 (Tx+) or J3 (Tx−)

Note: If you use oscilloscope channels 1 and 3 for Tx+ and Tx

oscilloscope channels 2 or 4 as trigger. If you use oscilloscope channels 2 and 4

−

for Tx+ and Tx

Note: When you use a P7380SMA probe, and if the peak-to-peak signal

amplitude is more than 625 mV, set Attenuation Dynamic Range of the probe to

12.5X. If the signal peak to peak amplitude is less than 625 mV, set Attenuation

Dynamic Range of the probe to 2.5X. Ensure that the V term Source is set to

Auto.

, then use oscilloscope channels 1 or 3 as trigger.

−

, then use

42

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 55

How To…

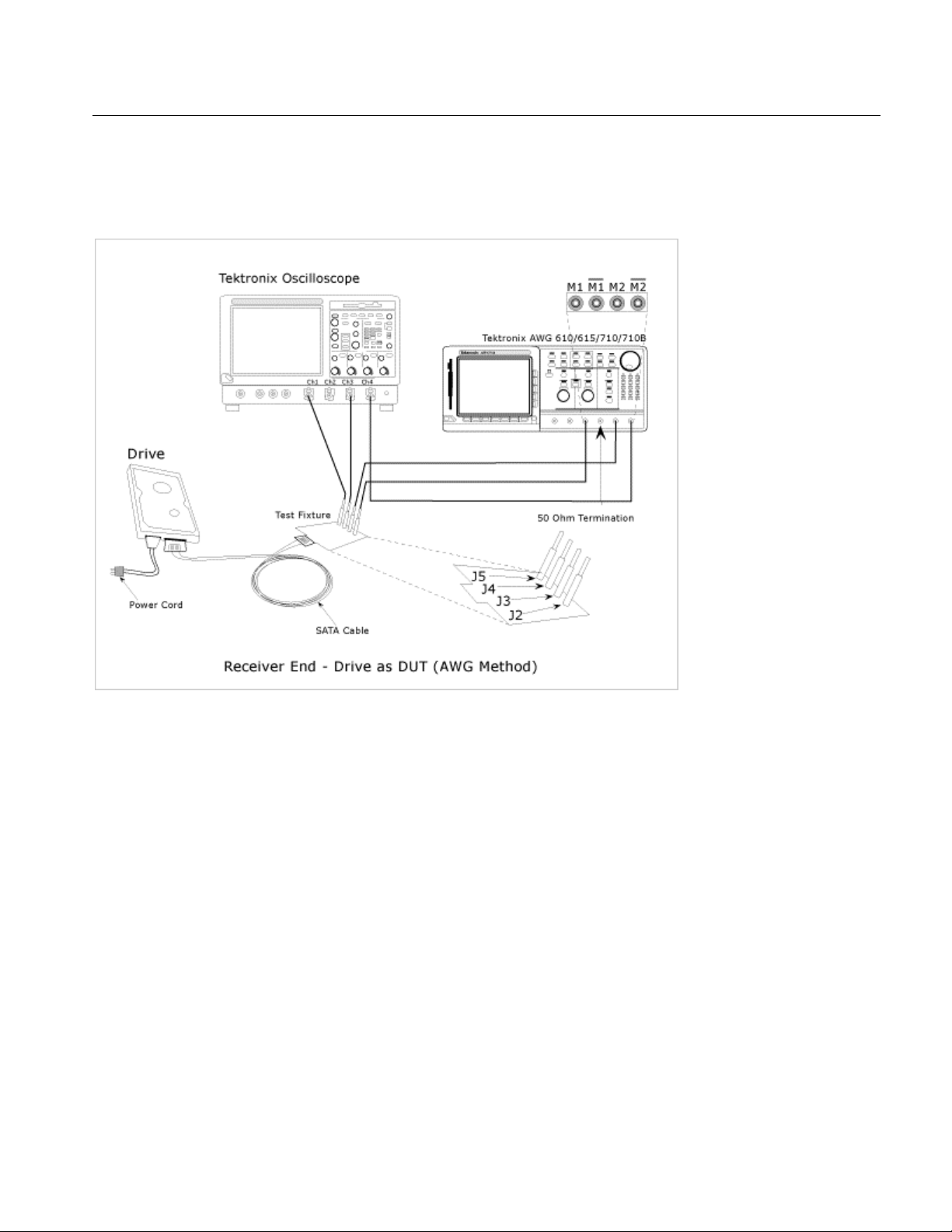

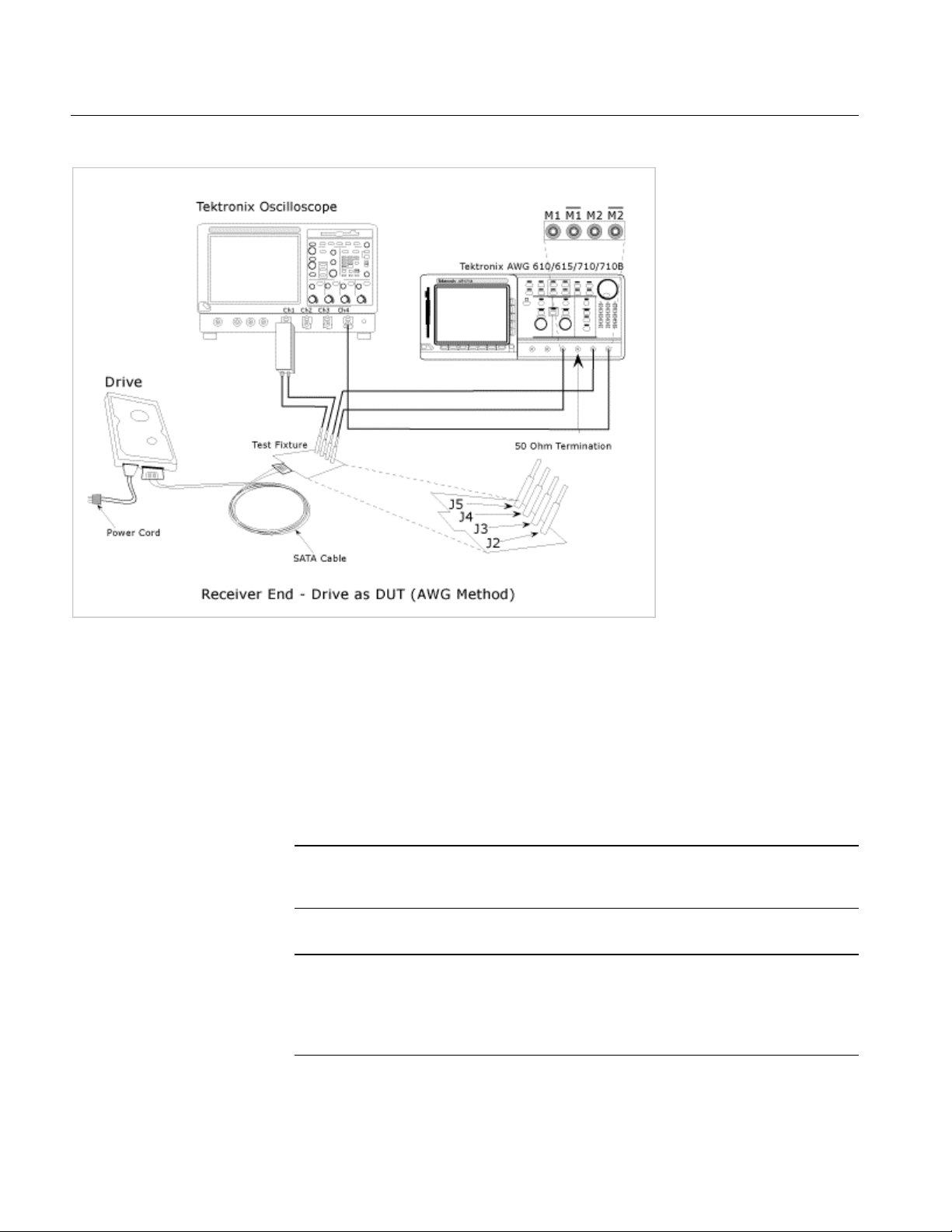

Test the Receiver Drive DUT using AWG Method

To test a receiver drive device using an AWG, set up the equipment as follows:

Figure 19: Test the receiver drive DUT using AWG method

For a Drive as the DUT, connect the SMA cables (single-ended probes) as

follows:

AWG Marker 1 to J2 (Rx+)

AWG Marker 2 to J3 (Rx−)

Oscilloscope Channel 1 to J5 (Tx+)

Oscilloscope Channel 3 to J4 (Tx−)

Option SST Serial ATA and Serial Attached SCSI Analysis Module

43

Page 56

How To…

Figure 20: Test the receiver drive DUT using AWG method

For a Drive as the DUT, connect the P7380SMA cables (differential probes) as

follows:

AWG Marker 1 to J2 (Rx+)

AWG Marker 2 to J3 (Rx−)

Oscilloscope Channel 1 or 3 to J5 (Tx+) and J4 (Tx−)

Note: If you use oscilloscope channels 1 and 3 for Tx+ and Tx

oscilloscope channels 2 or 4 as trigger. If you use oscilloscope channels 2 and 4

for Tx+ and Tx

Note: When you use a P7380SMA probe, and if the peak-to-peak signal

amplitude is more than 625 mV, set Attenuation Dynamic Range of the probe to

12.5X. If the signal peak to peak amplitude is less than 625 mV, set Attenuation

Dynamic Range of the probe to 2.5X. Ensure that the V term Source is set to

Auto.

−

, then use oscilloscope channels 1 or 3 as trigger.

−

, then use

44

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 57

How To…

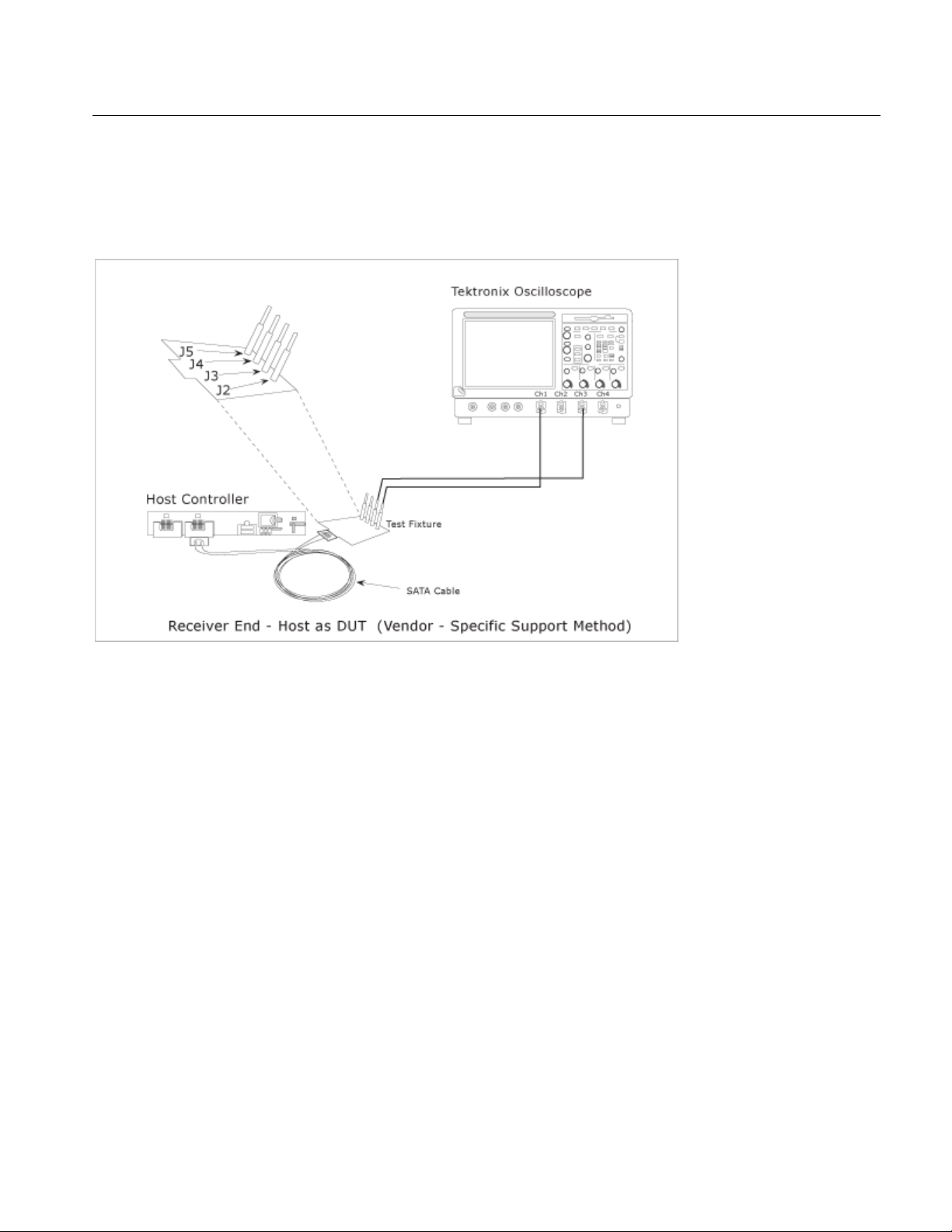

Test the Receiver Host DUT using BIST FIS/User Method

To test a receiver host device using a vendor-specific method (or BIST FIS), set

up the equipment as follows:

Figure 21: Test the receiver host DUT using BIST FIS/User method

For a Host as the DUT, connect the SMA cables (single-ended probes) as

follows:

Oscilloscope Channel 1 to J2 (Rx+)

Oscilloscope Channel 3 to J3 (Rx−)

Option SST Serial ATA and Serial Attached SCSI Analysis Module

45

Page 58

How To…

Figure 22: Test the receiver host DUT using BIST FIS/User method

For a Host as the DUT, connect the P7380SMA cables (differential probes) as

follows:

Oscilloscope Channel 1 to J2 and J3

Note: When you use a P7380SMA probe, and if the peak-to-peak signal

amplitude is more than 625 mV, set Attenuation Dynamic Range of the probe to

12.5X. If the signal peak to peak amplitude is less than 625 mV, set Attenuation

Dynamic Range of the probe to 2.5X. Ensure that the V term Source is set to

Auto.

46

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 59

How To…

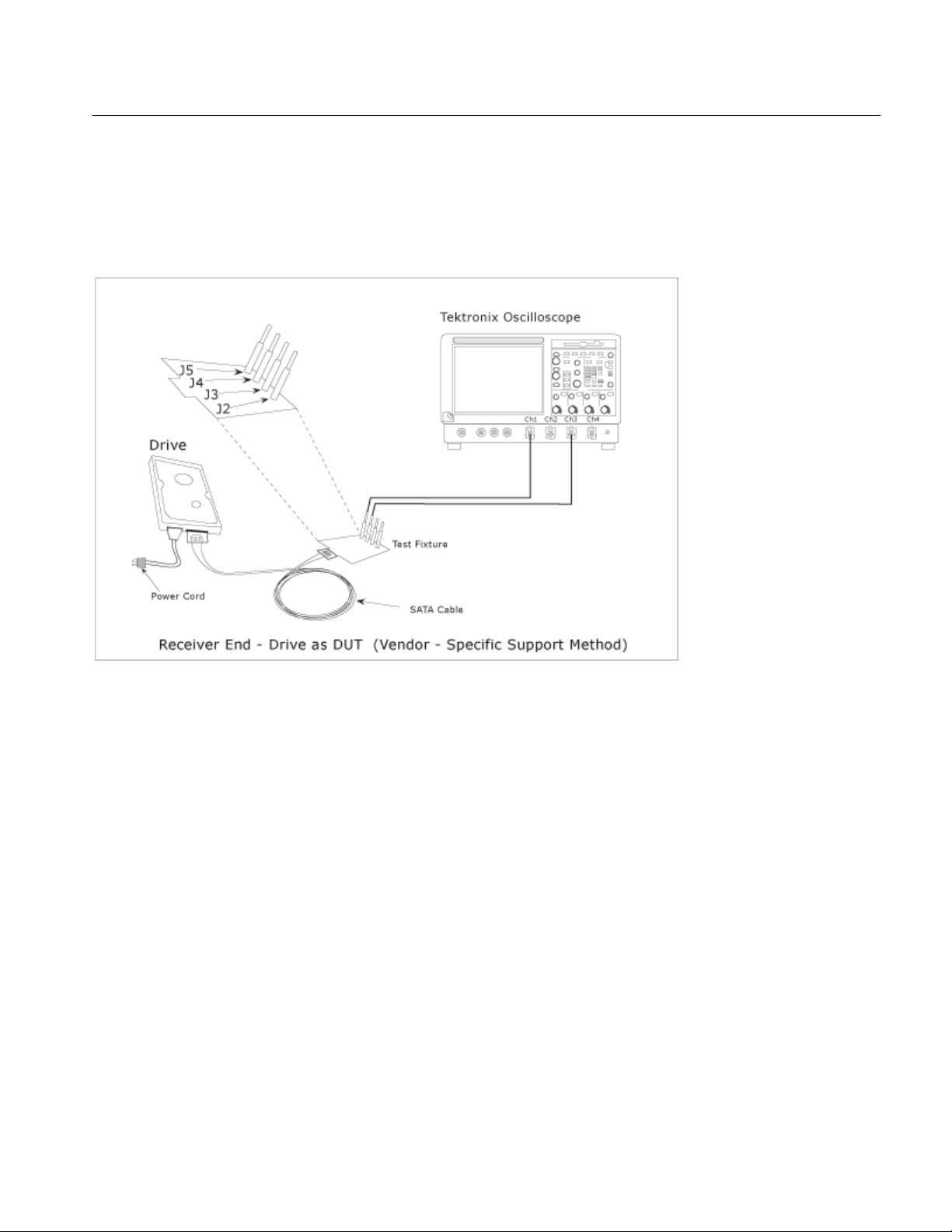

Test the Receiver Drive DUT using BIST FIS/User Method

To test a receiver drive device using a vendor-specific method (or BIST FIS), set

up the equipment as follows:

Figure 23: Test the receiver drive DUT using BIST FIS/User method

For a Drive as the DUT, connect the SMA cables (single-ended probes) as

follows:

Oscilloscope Channel 1 to J5 (Tx+)

Oscilloscope Channel 3 to J4 (Tx−)

Option SST Serial ATA and Serial Attached SCSI Analysis Module

47

Page 60

How To…

Figure 24: Test the receiver drive DUT using BIST FIS/User method

For a Drive as the DUT, connect the P7380SMA cables (differential probes) as

follows:

Oscilloscope Channel 1 to J4 and J5

Note: When you use a P7380SMA probe, and if the peak-to-peak signal

amplitude is more than 625 mV, set Attenuation Dynamic Range of the probe to

12.5X. If the signal peak to peak amplitude is less than 625 mV, set Attenuation

Dynamic Range of the probe to 2.5X. Ensure that the V term Source is set to

Auto.

48

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 61

Select and Configure SATA Measurements

Select SATA Measurements

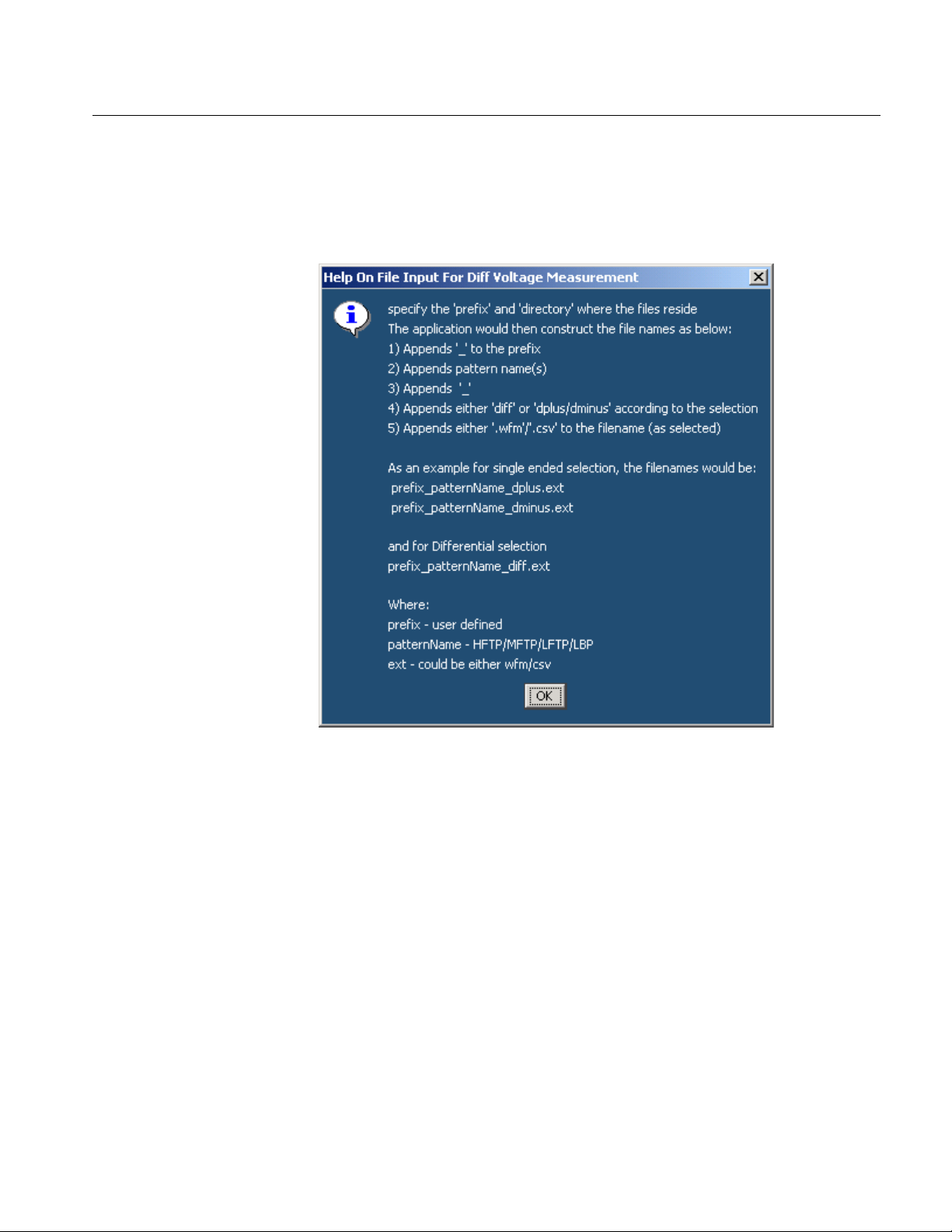

To select a measurement, select Measurements> Select from the menu bar. The

following screen appears:

How To…

Figure 25: Measurements screen

The Serial ATA measurements that are available for transmitter and receiver

devices are as follows:

Table 16: SATA measurements for transmitter and receiver

MeasurementsDevice

Timing Amplitude Out Of Band

Transmitter Eye, Bit Rate,

Differential Ske w*, Rise

and Fall Time, Unit

Interval

Receiver Eye, Bit Rate,

Differential Ske w*, Rise

and Fall Time, Unit

Interval

*

These measuremen ts are avail abl e on ly when you use a single-ended probe

(SMA cable).

Differential

Voltage, AC CM

Voltage*

Differential

Voltage, AC CM

Voltage*

COMINIT,

COMWAKE,

COMRESET

−

You can select one or more Timing measurements at a time by clicking the

buttons. You can select all Timing measurements by clicking the Select All

button.

Option SST Serial ATA and Serial Attached SCSI Analysis Module

49

Page 62

How To…

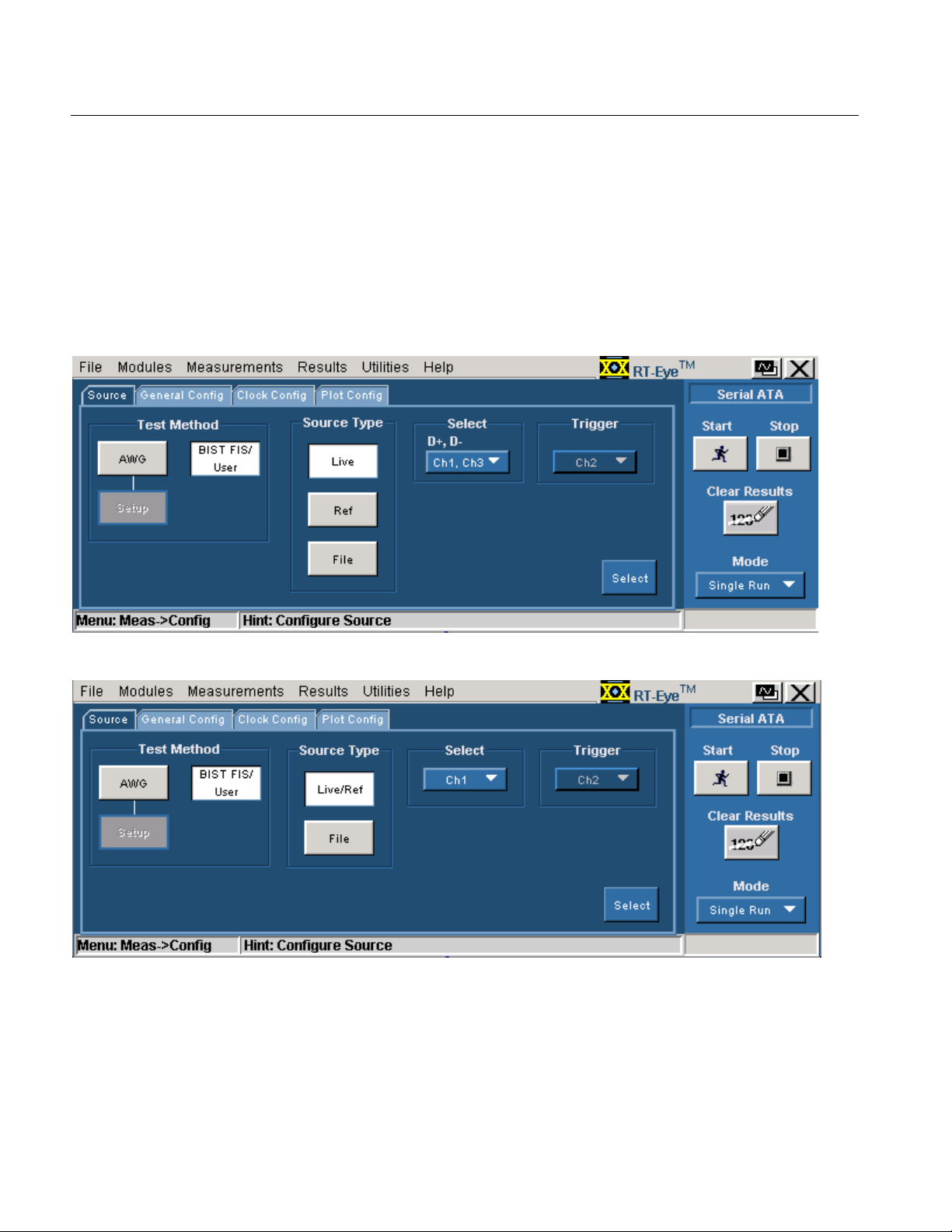

Configure SATA Measurements

To configure one or more measurements, select Measurements> Configure from

the application menu bar, or click the Configure button in the Measurement

screen.

The Configure screen has the following tabs: Source, General Config, Clock

Config, and Plot Config. The Plot Config tab, with parameters to generate an eye

diagram, is available only for the Eye Measurement.

Figure 26: Configure Source panel for a single-ended probe

Figure 27: Configure Source panel for a differential probe

50

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 63

Figure 28: Configure General Config panel

How To…

Figure 29: Configure Clock Config panel

Option SST Serial ATA and Serial Attached SCSI Analysis Module

51

Page 64

How To…

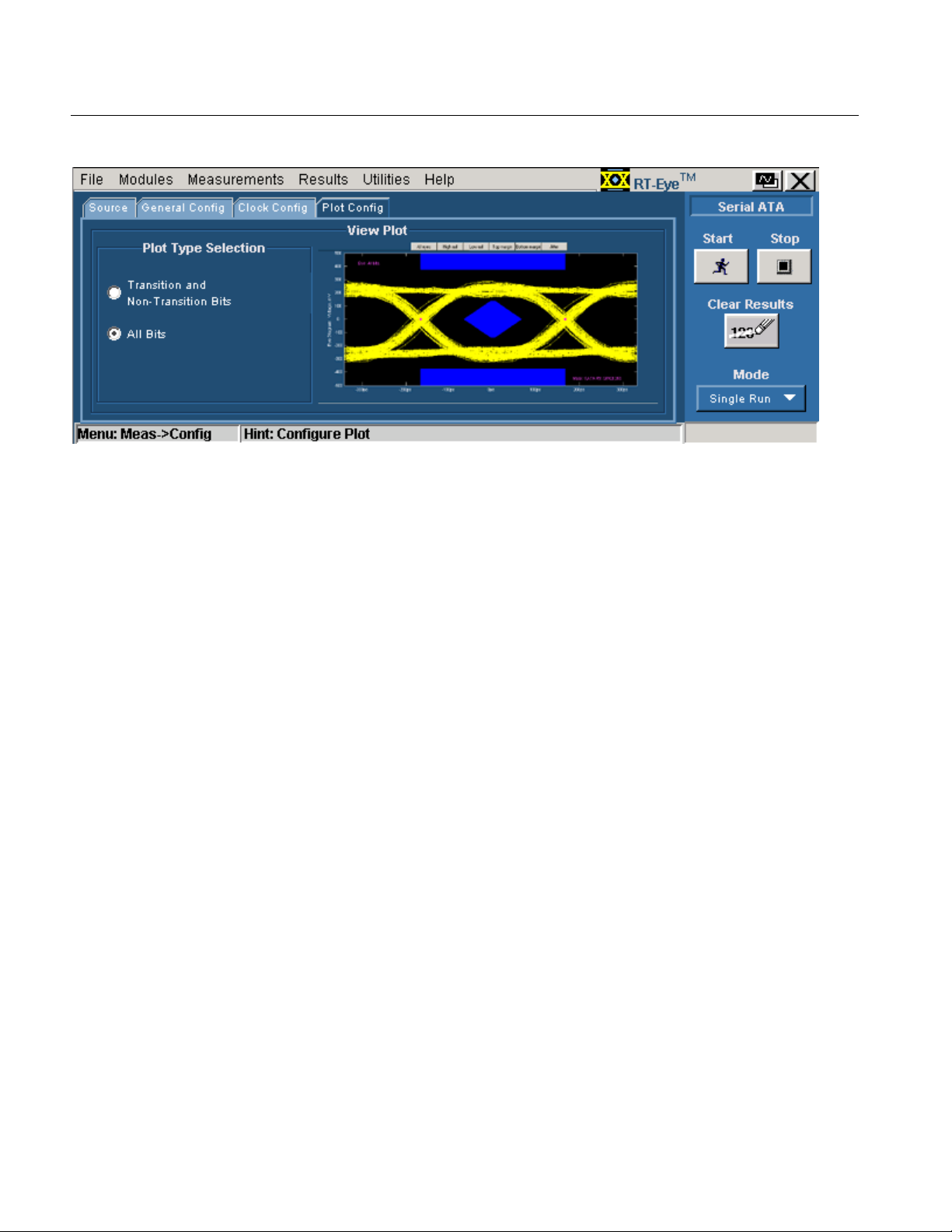

Figure 30: Configure Plot Config panel

The following table lists the configuration parameters for the Serial ATA

measurements:

52

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 65

How To…

Option SST Serial ATA and Serial Attached SCSI Analysis Module

53

Page 66

How To…

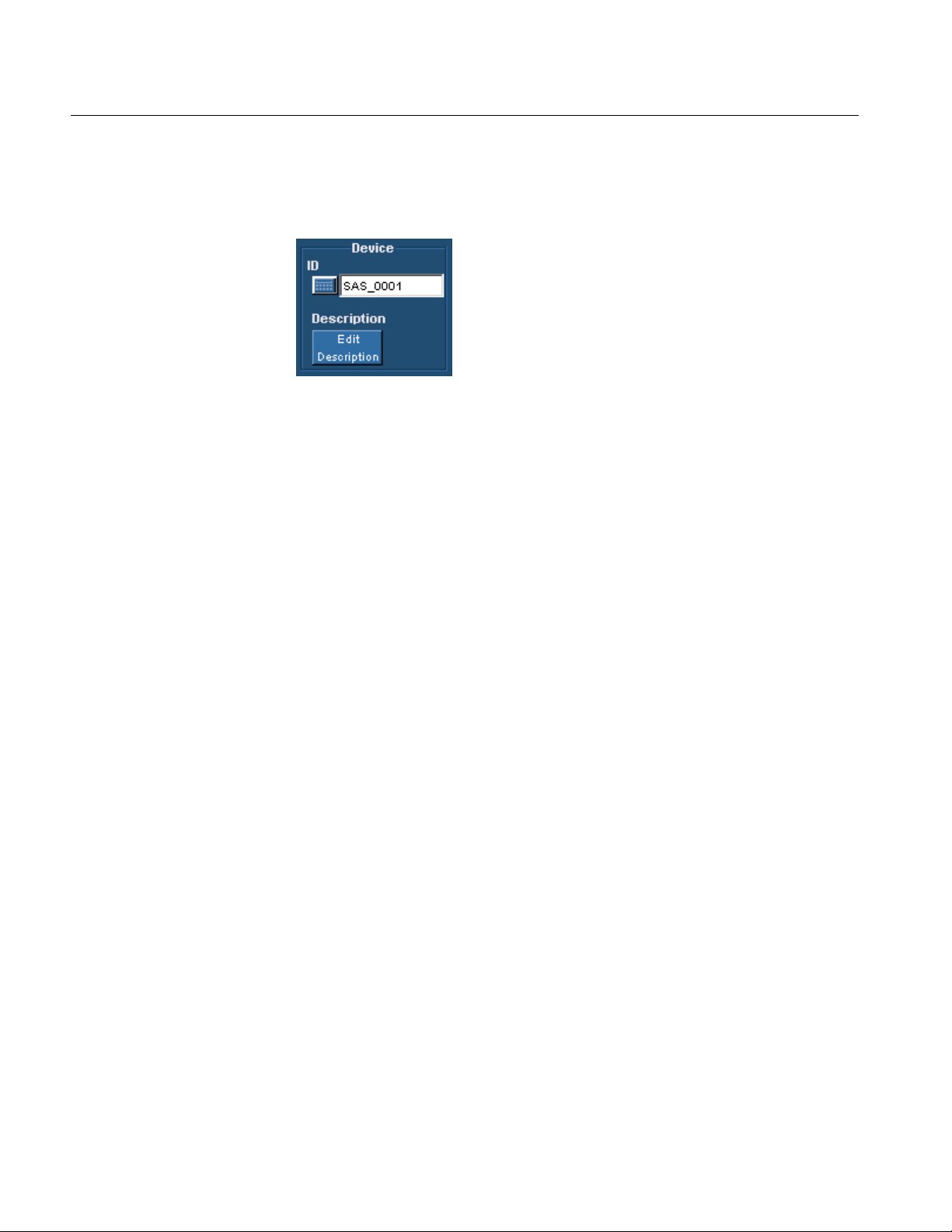

Enter Device Details

You can enter the details of the device that you are testing.

Figure 31: Enter device details

To do this, follow these steps:

1. Select Measurements> Select from the application menu.

2. Under Device, type the device ID that you want to use. You can also use the

virtual keyboard to enter the text.

3. Click Edit Description to type in a description of the device or edit an

existing description. You can also use the virtual keyboard to enter the text.

Virtual Keyboard

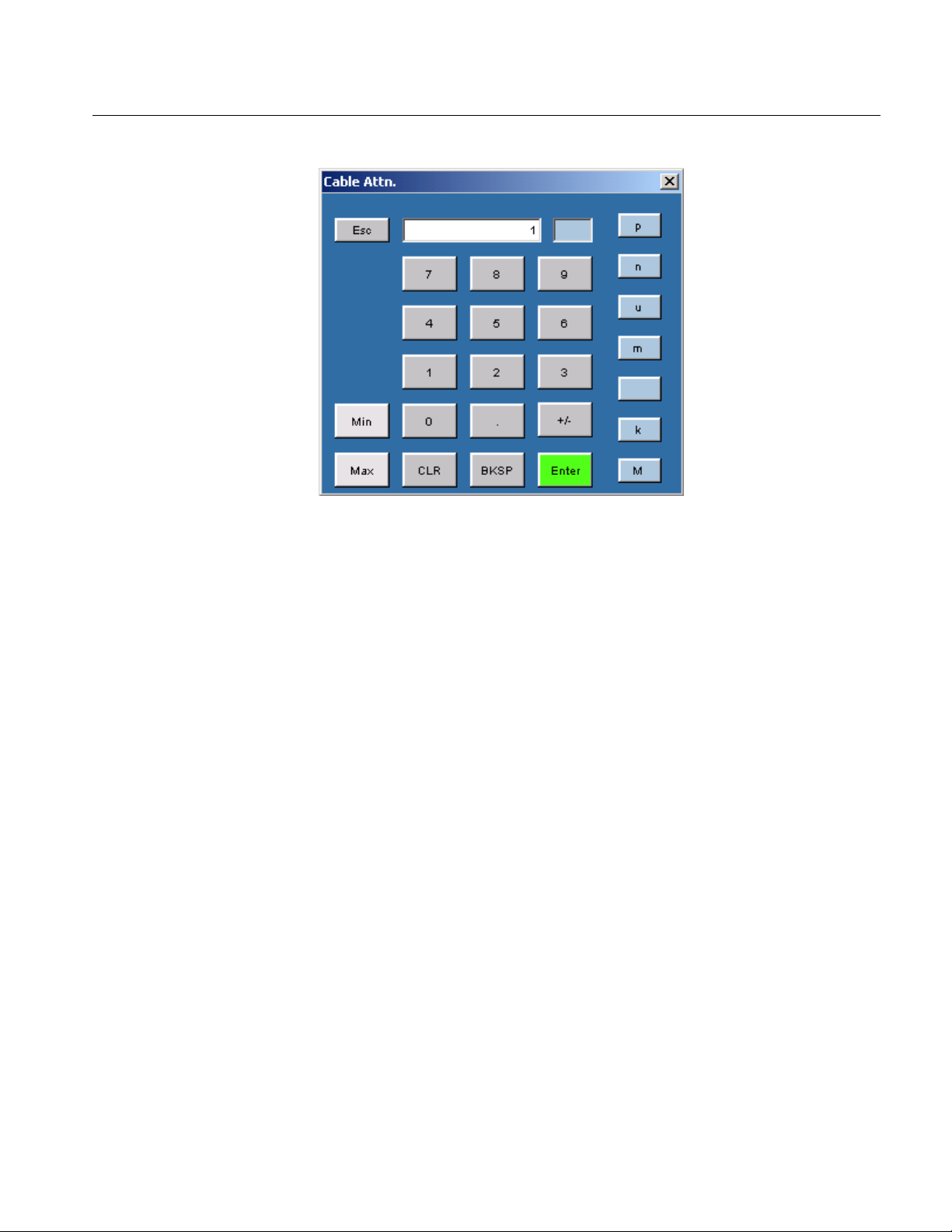

Virtual Keyboard - Numeric

1. Click any number box to display the icon for the numeric keyboard.

2. Click the icon to display the numeric keyboard.

54

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 67

How To…

Figure 32: Virtual keyboard - Numeric

3. Click the number keys to enter the desired value.

4. Select a unit of measure.

5. Click Enter to confirm your entry. Selections are not effective until you

click Enter.

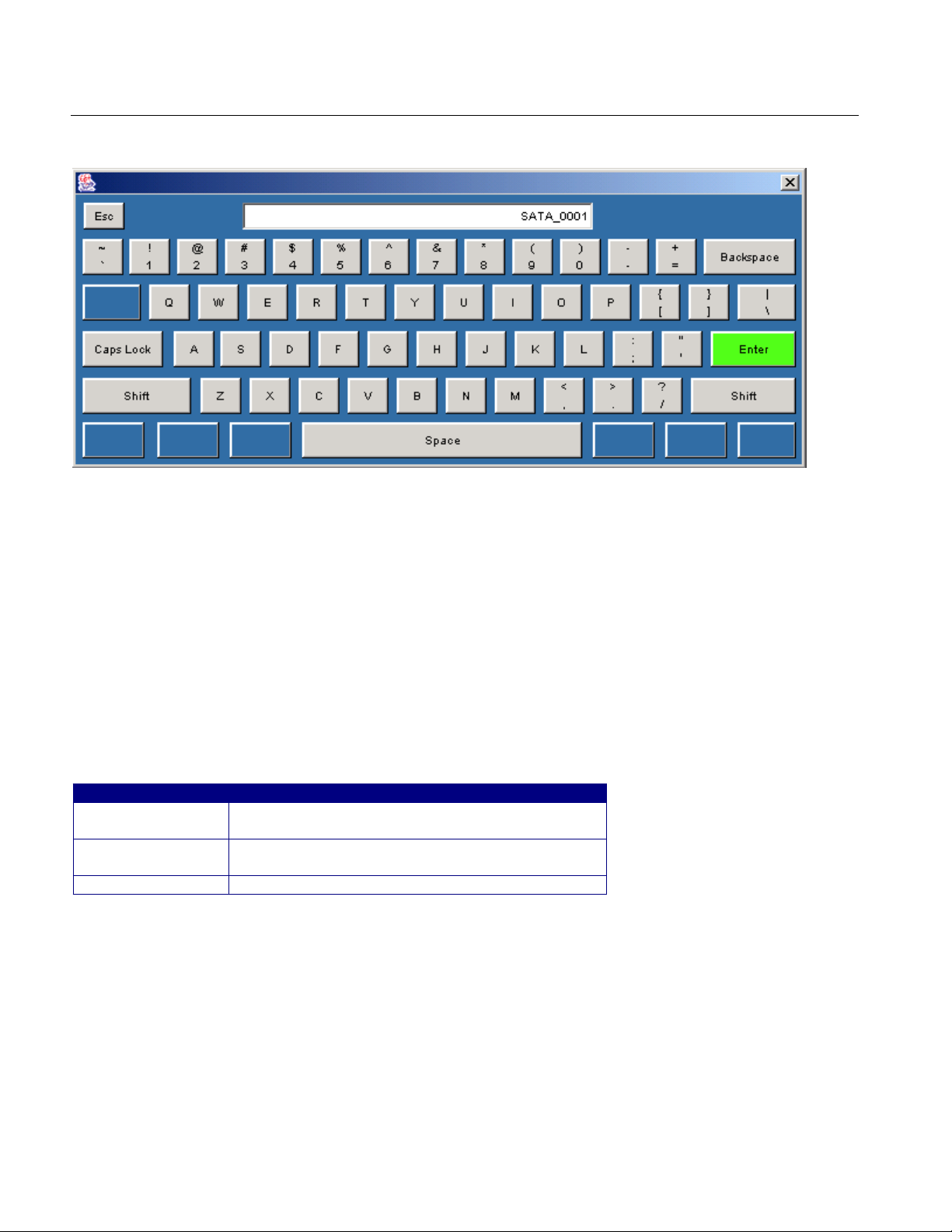

Virtual Keyboard - Text

1. Click any text box to display the icon for the text keyboard.

2. Click the icon to display the text keyboard.

Option SST Serial ATA and Serial Attached SCSI Analysis Module

55

Page 68

How To…

Figure 33: Virtual keyboard - Text

3. Use the text keyboard to enter the required text (such as a file name).

4. Click Enter to confirm your entry. Selections are not effective until you

click Enter.

Set up the AWG

You can set up the Arbitrary Waveform Generator (AWG) in three ways: GPIB,

Network, and Manual. From the Source tab, select the Test method as AWG and

click Setup. The following options are available:

Table 17: AWG setup modes

Options To Do

Network Connect to the AWG using the LAN or peer-to- peer

and set up the connection automatically

GPIB Connect to the AW G using the GPI B and set up the

connection automatically

Manual Connect to the AWG manually

To connect to and set up the AWG using the Network option, follow these steps:

1. Click Network from the AWG Setup screen.

56

2. Enter the IP Address of the AWG.

3. Select the AWG Drive (Floppy or Main) on which the source pattern files

for the test is located.

Option SST Serial ATA and Serial Attached SCSI Analysis Module

Page 69

How To…

4. Click Test Connection to verify whether the oscilloscope is connected

correctly to the AWG. When you click Test Connection, the application:

Detects the AWG model

Sets the AWG marker values

Sets the AWG clock speed

To connect to and set up the AWG using the GPIB option, follow these steps:

1. Click GPIB from the AWG Setup screen.

2. Select the Board Type, GPIB Address (Primary and Secondary), and the

Time Out value.

3. Select the AWG Drive (Floppy or Main) on which the source pattern files

for the test is located.

4. Click Test Connection to verify whether the oscilloscope is connected

correctly to the AWG. When you click Test Connection, the application:

Detects the AWG model

Sets the AWG marker values

Sets the AWG clock speed

To connect to and set up the AWG using the Manual option, follow these steps:

1. Click Manual from the AWG Setup screen.

2. Select the AWG Type from the AWG Setup screen.

3. Follow the on-screen prompts to connect the AWG and the oscilloscope.

Perform SATA Tests for Transmitter

Transmitter Measurements

Timing measurements that are available for a Serial ATA Transmitter are Eye,

Bit Rate, Differential Skew, Rise and Fall Time, and Unit Interval. You can

select one or more measurements at a time. You can select all measurements by

clicking the Select All button. The Differential Skew measurement is available

only when you use a single-ended probe (SMA cable).

Amplitude measurements that are available for a Serial ATA Transmitter are

Differential Voltage and AC CM Voltage. The AC CM Voltage measurement is