Page 1

Instructions

Option FHD

Front Hard Drive

071-1223-00

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

*P071122300*

071122300

Page 2

Copyright © Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered tradem arks of Tektronix, Inc.

Page 3

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Wear Eye Protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

Option FHD

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the instrument’s installation instructions for

details on installing the product so it has proper ventilation.

i

Page 4

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

Mains Disconnected

OFF (Power)

WARNING

High Voltage

Mains Connected

ON (Power)

Protective Ground

(Earth) Terminal

Standby

ii

Option FHD

Page 5

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

Option FHD

iii

Page 6

Service Safety Summary

iv

Option FHD

Page 7

Description and Operation

Option FHD is a removable hard-disk drive at the front of the instrument. With

this option the hard drive at the rear of the instrument and the floppy drive at the

front of the instrument are not available.

All instrument functions that require the floppy drive are unavailable. All

instrument functions that require a hard disk use the removable hard drive

located in the front panel. All other instrument functions remain the same as the

standard instrument.

CAUTION. Do not lift or support the instrument by the hard-drive handle.

Moving the Disk

If you move the hard disk to another instrument, you must perform a signal path

compensation.

1. To compensate the signal path, select Utilities and then Instrument Calibra-

tion.

Disk Removal

2. Read the Calibration Instructions.

3. Press the Calibrate button.

4. After the calibration successfully completes, the Status is Pass.

To remove the disk drive from the instrument, do the following procedure:

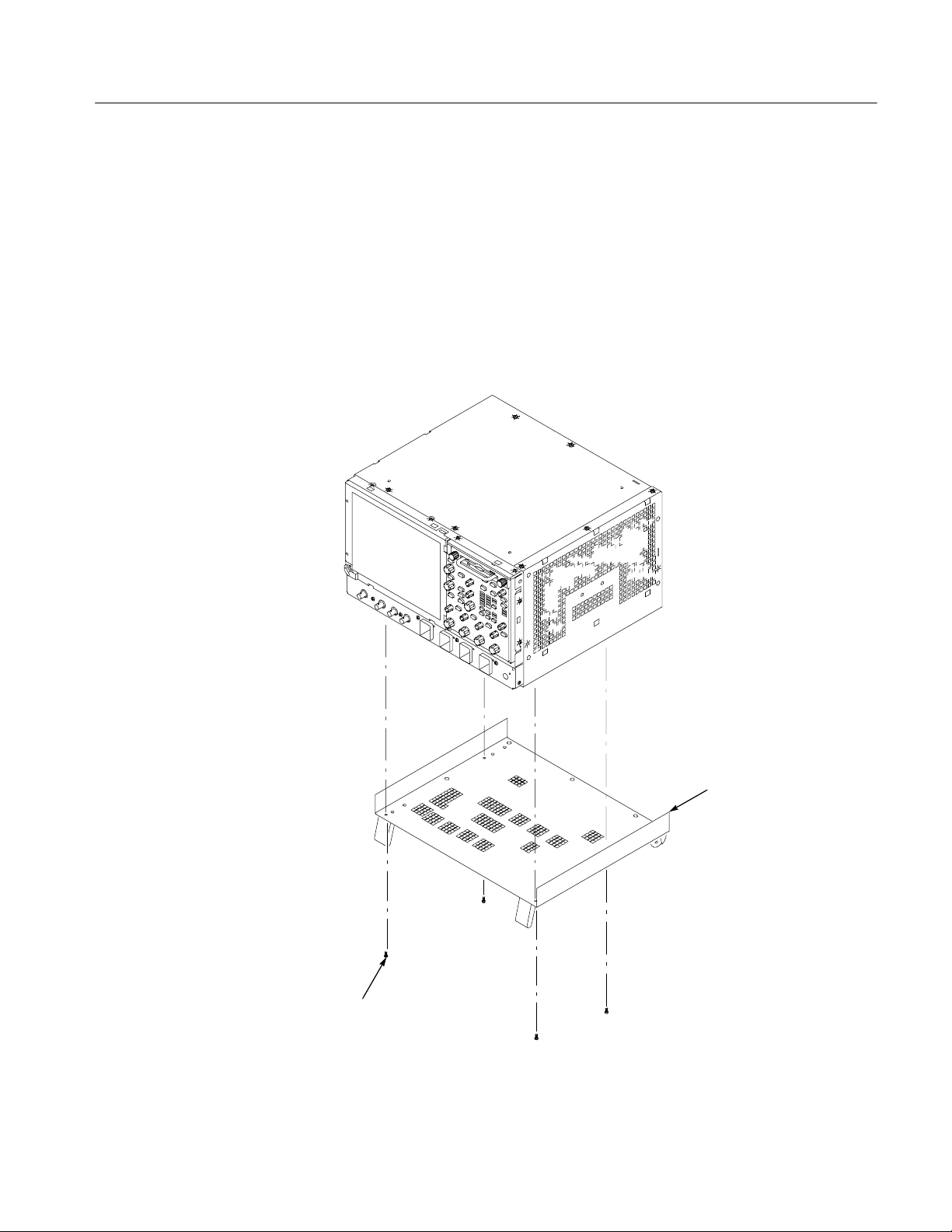

1. Set the oscilloscope so that its bottom is down on the work surface and its

front panel is facing you. See Figure 1--1 on page 1--2.

CAUTION. Do not remove the replaceable hard disk drive when the instrument is

powered on. The replaceable hard disk drive may be permanently damaged if it

is removed while the instrument is powered on.

a. Verify that the oscilloscope is powered off.

Option FHD

1- 1

Page 8

Description and Operation

b. To unlock the hard drive assembly, rotate both thumb screws counter-

clockwise.

c. Grasp the hard disk drive assembly by its handle, and pull the assembly

out of the instrument.

2. Reinstallation: Do in reverse step 1 to reinstall the hard disk drive assembly.

Handle

Thumb

screw (2)

1- 2

Figure 1- 1: Hard disk drive removal

Option FHD

Page 9

WARNING

The following servicing instructions are for use only by qualified personnel. To

avoid injury, do not perform any servicing other than that stated in the operating

instructions unless you are qualified to do so. Refer to all safety summaries before

performing any service.

Page 10

Page 11

Removal and Installation Procedures

This subsection contains procedures for removal and installation of all mechanical and electrical modules.

WARNING. Before doing this or any other procedure in this manual, read the

Safety Summaries found at the beginning of this manual.

This subsection contains the following items:

H List of tools required to remove and disassemble all modules.

H Procedures for removal and reinstallation of the electrical and mechanical

modules.

WARNING. Before doing any procedure in this subsection, disconnect the power

cord from the line voltage source. Failure to do so could cause serious injury or

death.

Equipment Required. Most modules can be removed with a screwdriver handle

mounted with a size T-15, Torx screwdriver tip. Use this tool whenever a

procedure step instructs you to remove or install a screw unless a different size

screwdriver is specified in that step.

Table 2- 1: Tools required for module rem oval

Item

no.

1 Screwdriver handle Accepts Torx-driver bits 620-440

2 T-10 Torx tip Used for removing the electrical or

3 T-15 Torx tip Used for removing most instrument

4

5 #0 Phillips screwdriver Screwdriver for removing small

6 MA-800G Soldering Aid Used to remove the front-panel trim Standard tool

Name Description

optical module chassis. Torx-driver

bit for T-10 size screw heads

screws. Torx-driver bit for T-15 size

screw heads

1

/8inch flat-bladed screw-

driver

Screwdriver for unlocking cable

connectors

Phillips screws

General tool

number

640-235

640-247

Standard tool

Standard tool

Option FHD

2- 1

Page 12

Removal and Installation Procedures

Procedures for External Modules

The following procedures are found here and are listed in order presented.

H Hard disk drive

H Trim (all)

H Bottom cover

H Left and Right covers

H Line Fuse and Line Cord

Disk Drive

To remove the hard disk drive from the cartridge, do the following procedure:

1. Remove the hard disk from the instrument. See Disk Removal on page 1--1.

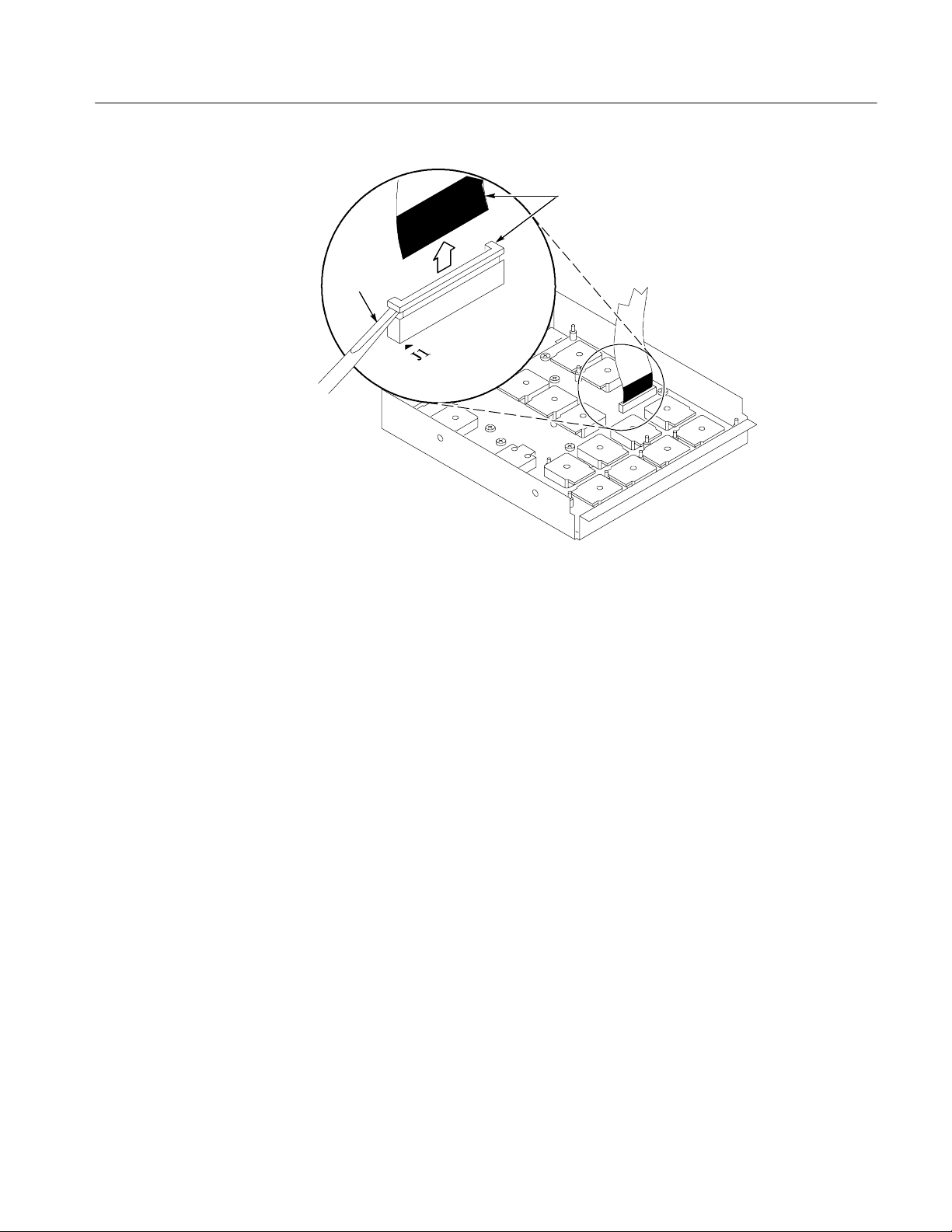

2. Remove the hard disk drive from the cartridge: SeeFigure2--1on

page 2--2.

a. Remove the four #0 Phillips screws that fasten the hard disk drive to the

cartridge.

b. Carefully remove the hard disk drive from the cartridge, and remove the

cable assembly from the connector on the hard disk drive.

Remove 4 screws

Trim and Carrying Handle

2- 2

Figure 2- 1: Removing the hard disk drive from the cartridge

1. Locate module to be removed: Locate the Trim in the locator diagram. See

Figure 2--2 on page 2--4.

2. Remove the front-panel trim: Use Figure 2--2 on page 2--4 as a guide.

a. To prevent the power button from falling out of the front-panel trim,

place a piece of tape over the button.

Option FHD

Page 13

Removal and Installation Procedures

b. Grasp the trim ring by its top edge and pull toward you to detach the

three plastic snaps. (Alternatively, you can use a flat-bladed screwdriver

or other small prying tool to help you detach the snaps.)

c. Swing the bottom of the ring upward and off the front panel.

3. Remove the acquisition trim: Use Figure 2--2 on page 2--4 as a guide.

a. Remove the three T-15 Torx screws that secure the acquisition trim to

the instrument.

b. Remove the acquisition trim from the instrument.

4. Remove the top cover trim: Use Figure 2--2 on page 2--4 as a guide.

a. Remove the accessory pouch; it snaps off.

b. Remove the four T-15 Torx screws that secure the top cover trim to the

instrument. The T-15 Torx screws also secure the snap studs to the top

cover.

c. Remove the top cover trim from the instrument.

5. Remove the carrying handle and the right/left side trim panels: Use

Figure 2--2 on page 2--4 as a guide.

a. Remove the T-15 Torx screws that secure the handle to the instrument.

Remove the handle from the instrument.

b. Slide the side trim panels towards the rear of the instrument allowing the

tabs to clear the cover openings, and then pull out to remove the panels

from the instrument.

6. Reinstallation: Do in reverse steps 2 through 5 to reinstall the appropriate

trim.

Option FHD

2- 3

Page 14

Removal and Installation Procedures

Front-panel trim

Left side trim

T-15 Torx screw

(4)

Snap stud (4)

Top cover trim

Right side trim

Front-panel cover

Figure 2- 2: Trim removal

Acquisition trim

Carrying handle

T-15 Torx

screw (3)

Soldering aid

To remove the trim ring, slide the flat

end of a soldering aid into the side

slot on the trim ring. Press in, lift up

to hook it underneath, and then pry

up.

T-15 Torx screw

(2)

2- 4

Option FHD

Page 15

Removal and Installation Procedures

Bottom Cover

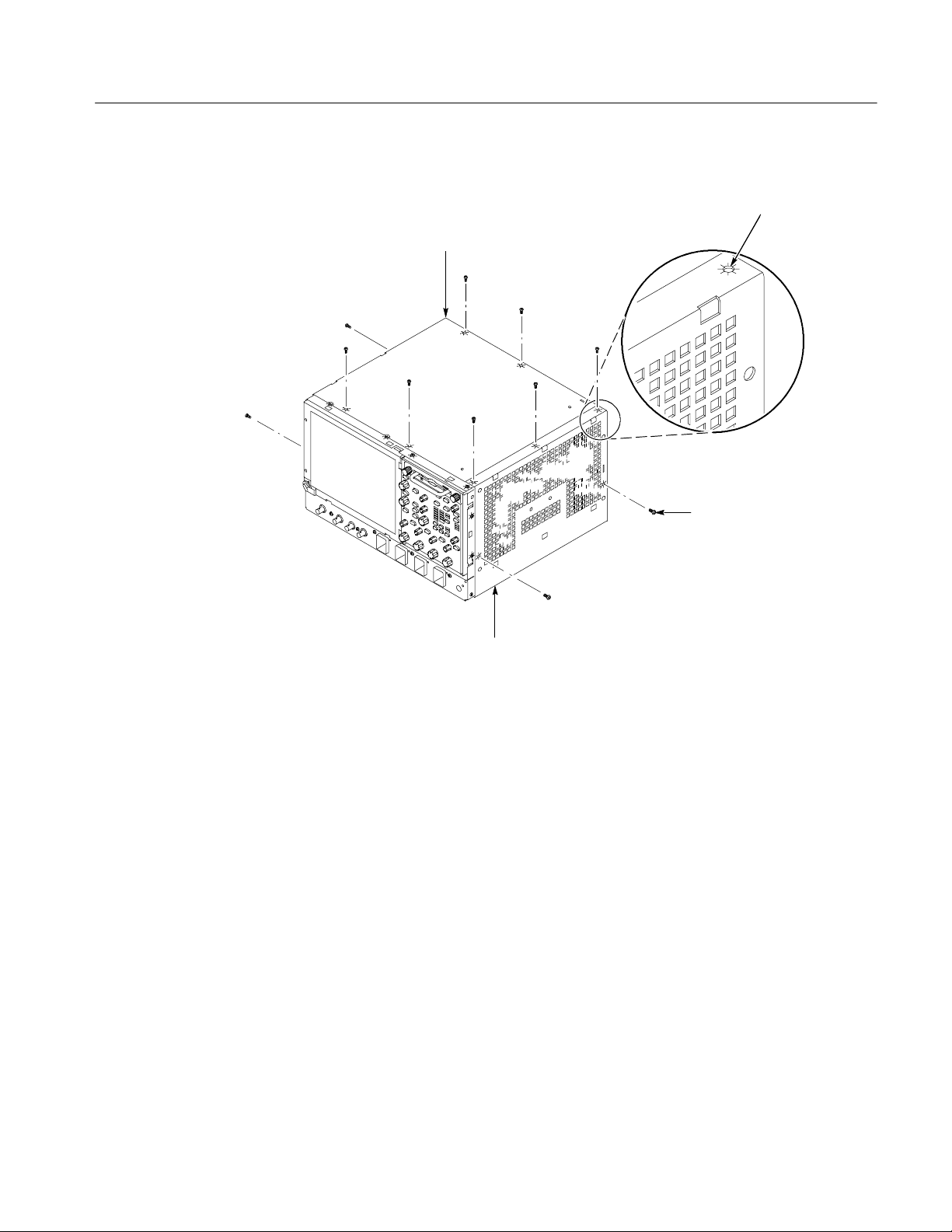

1. Remove the bottom cover: SeeFigure2--3onpage2--5.

2. Orient the instrument: Set the instrument so that its top is down on the work

surface and its bottom is facing you.

a. Remove the four T-15 Torx screws that secure the bottom cover to the

instrument.

b. Remove the bottom cover from the instrument.

3. Reinstallation: Do in reverse steps a and b to reinstall the bottom cover.

Option FHD

Bottom cover

T-15 Torx

screw (4)

Figure 2- 3: Bottom cover removal

2- 5

Page 16

Removal and Installation Procedures

Covers

1. Remove the left and right covers: See Figures 2--4 and 2--5 on pages 2--7

and 2--8.

H Trim (all)

H Bottom cover

2. Orient the instrument: Set the instrument so that its rear is on the work

surface and the front of the instrument is facing you.

NOTE. All mounting screw holes are indicated by a star etched around the

mounting hole.

a. Remove the eleven T-15 Torx screws that secure the covers to the top

and both sides of the chassis.

b. Remove the seven T-15 Torx screws that secure the covers to the bottom

of the chassis.

c. Pull the bottom-right cover down, and slide to the right to remove from

the instrument. Pull the top-left cover upward and slide to the left to

remove from the instrument.

CAUTION. Take care not to bind or snag the covers on the internal cabling of the

instrument as you remove or install.

3. Reinstallation: Do in reverse steps a through c to reinstall the cabinet covers.

2- 6

Option FHD

Page 17

Left side cover

Removal and Installation Procedures

All left and right cover

mounting holes are

indicated as shown.

T-15 Torx

screw (11)

Right side cover

Figure 2- 4: Cover removal

Option FHD

2- 7

Page 18

Removal and Installation Procedures

Left side cover

2- 8

Right side cover

T-15 Torx screw (7)

Figure 2- 5: Cover removal

Option FHD

Page 19

Procedures for Modules

Removal and Installation Procedures

You should have completed the Procedures for External Modules before doing

many of the procedures in this collection. The procedures found here are listed in

disassembly order:

H Front Panel assembly

H Hard Disk Drive

H NLX Board

H Acquisition Board

Front Panel Assembly

1. Locate module to be removed: Locate the Front-Panel assembly in

Figure 2--6 on page 2--10. Additional modules to be Removed:

H Trim (Front panel)

2. Remove the Front-Panel assembly: SeeFigure2--6onpage2--10.

3. Orient the instrument: Set the instrument so that its bottom is down on the

work surface and its front panel is facing you.

a. Remove the six T-15 Torxdrive screws that secure the front-panel

assembly to the front chassis.

b. Grasp the top of front-panel assembly and pull forward to allow access

to the ribbon-cable connector on the front-panel board.

1

c. Use the

connector lock up to disconnect the J1 flex cable from the display

module assembly. See Figure 2--7 on page 2--11. Note the connector

pin 1 index mark and the black stripe on the cable for later reassembly.

d. Pull the Front-Panel assembly forward and remove from the instrument.

4. Reinstallation: Do in reverse steps a through d to reinstall the front-panel

assembly.

@8inch flat-bladed screwdriver to carefully lift the J1 cable

Option FHD

2- 9

Page 20

Removal and Installation Procedures

Hard disk

support tab (2)

Chassis

slot (2)

J1 ribbon cable

Front-panel

assembly

Front-panel square

opening (2)

T--15 Torxdrive

screw (6)

Figure 2- 6: Front-panel assembly removal

2- 10

Option FHD

Page 21

Screwdriver

Removal and Installation Procedures

Black stripe

toward connector

Figure 2- 7: J1 flex cable connector removal

Option FHD

2- 11

Page 22

Removal and Installation Procedures

Hard Disk Drive Bracket

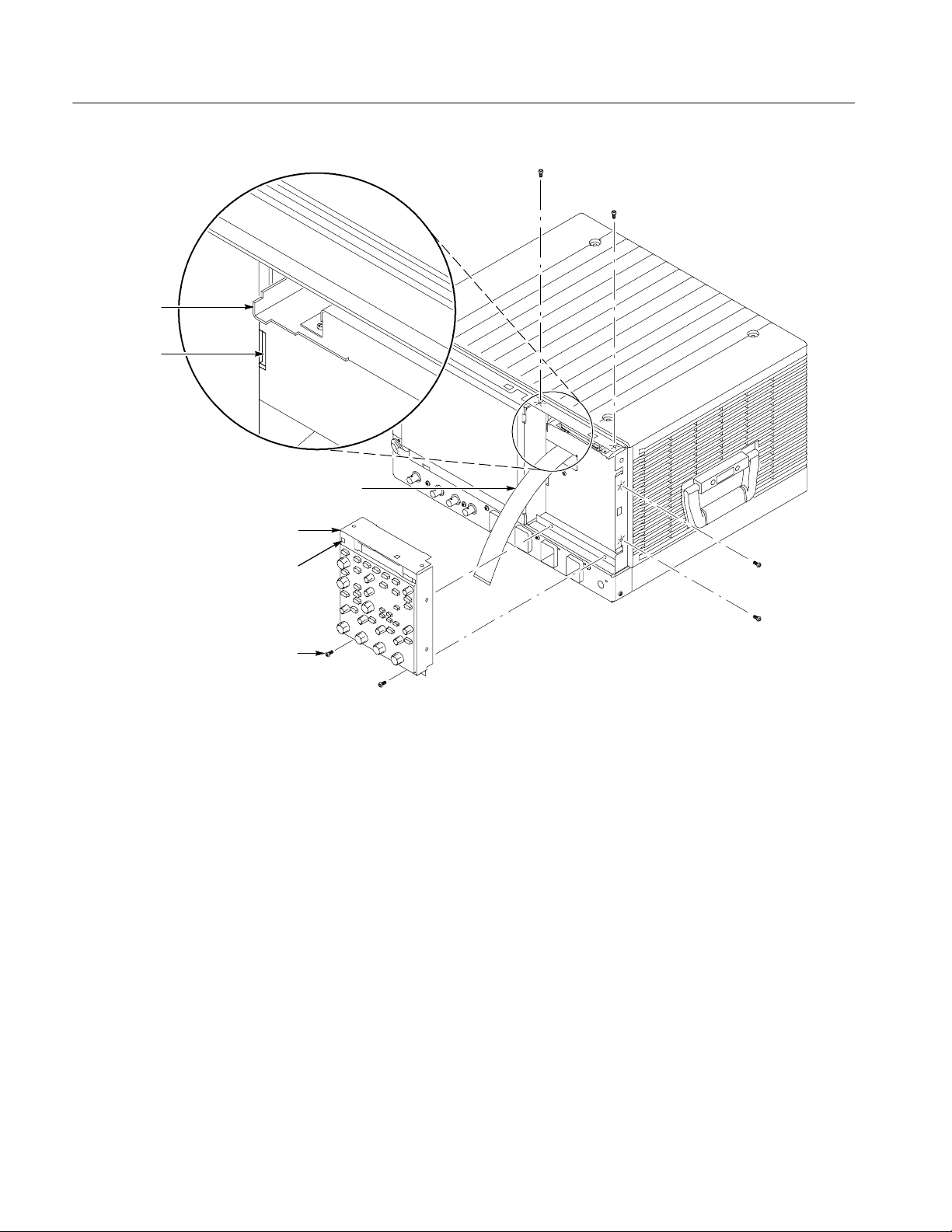

1. Locate modules to be removed: Locate the Hard Disk Drive in the locator

diagram Internal Modules, Figure 2--8 on page 2--13. Additional modules to

be Removed:

H Trim (front panel and top)

H Front Panel assembly

2. Remove the Hard disk drive assembly: Use Figure 2--9 on page 2--15 as a

guide.

3. Orient the instrument: Set the instrument so that its bottom is down on the

work surface and its front panel is facing you.

a. Remove the two T-15 Torx screws that secure the Hard disk drive

assembly to the bracket.

b. Remove the T-15 Torx screw that secures the hard disk drive assembly to

the CD drive bracket.

c. Slide the hard drive assembly out toward the front of the instrument far

enough to allow you to disconnect the ribbon cable connector.

d. Remove the hard drive bracket from the instrument.

4. Reinstallation: Do in reverse steps a through c to reinstall the hard disk drive

assembly.

2- 12

Option FHD

Page 23

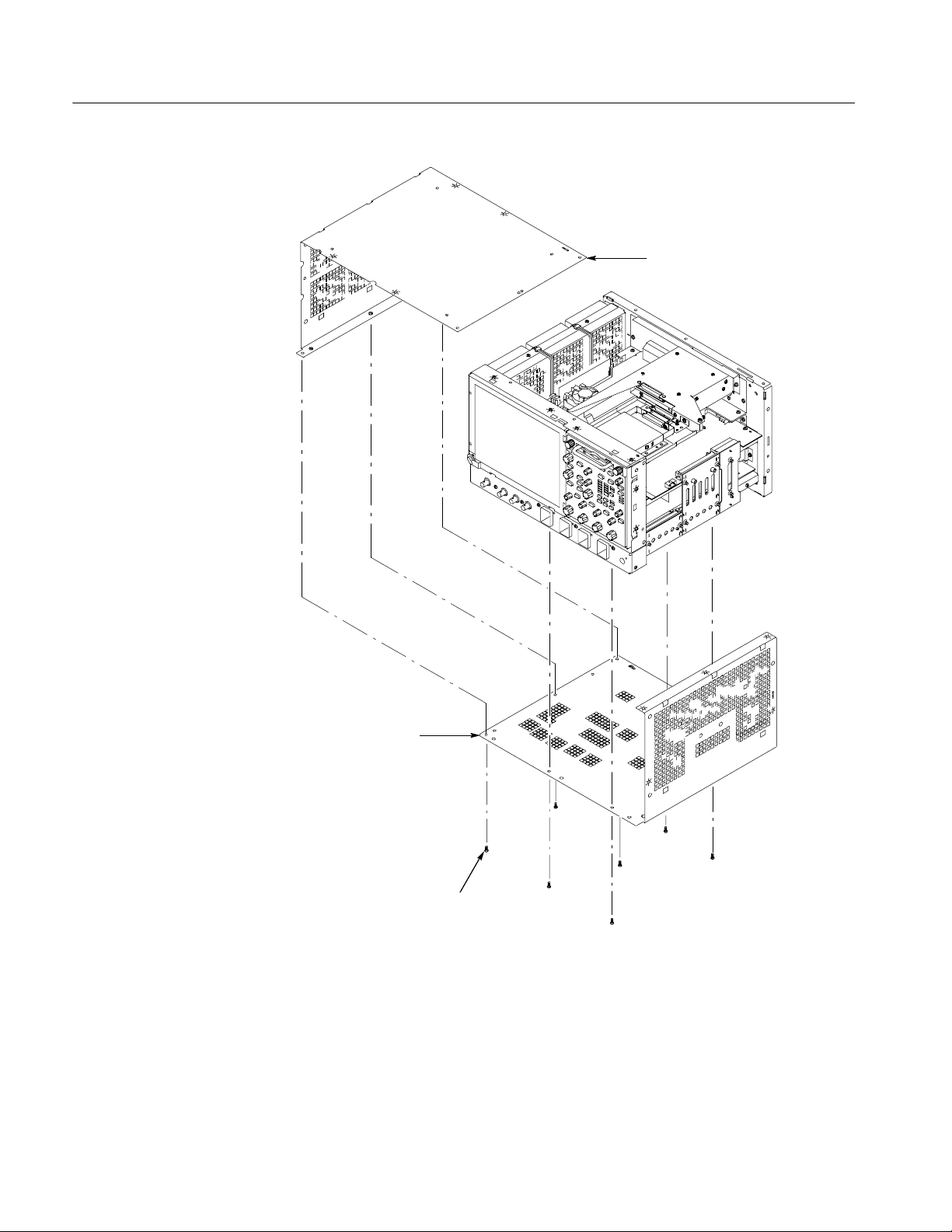

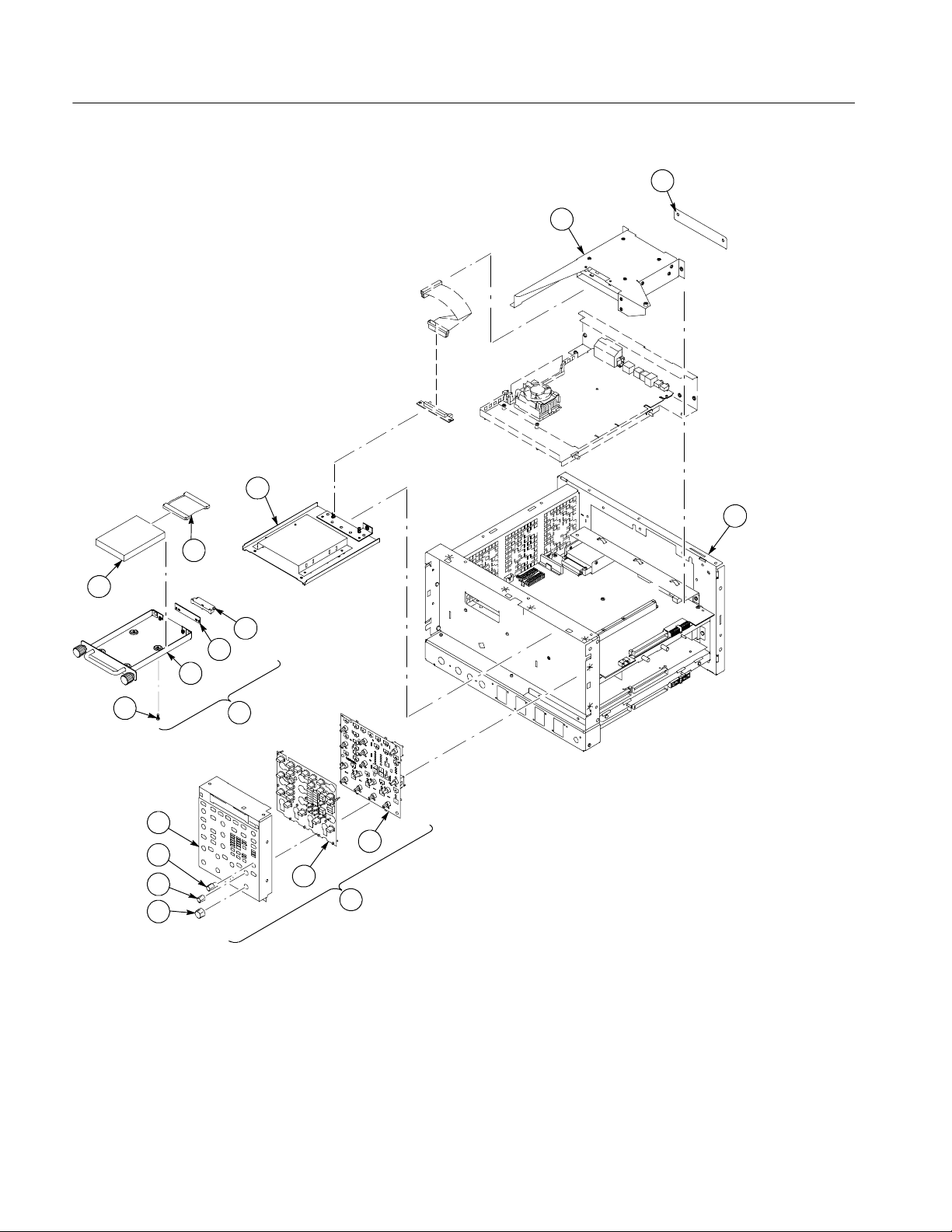

Fan assembly

Display adapter board

Hard drive

Removal and Installation Procedures

CD drive

CD drive Interface

board

Microprocessor,

fan and heat sink

NLX board

Riser board

THan

Power PC (PPC)

board

Low-voltage power

supply assembly

Power flex circuit

Display module assembly

Figure 2- 8: Internal modules

Front panel

assembly

Front panel

board

Front panel

keypad

Front

distribution

board

Acquisition board

PA bus

board

Rear

distribution

board

Option FHD

2- 13

Page 24

Removal and Installation Procedures

NLX Board

1. Locate module to be removed: Locate the NLX Board in the locator diagram

Internal Modules, Figure 2--8, on page 2--13. Additional modules to be

removed:

H Trim (all)

H Bottom cover

H Left and Right covers

H Front Panel

H Hard Drive assembly

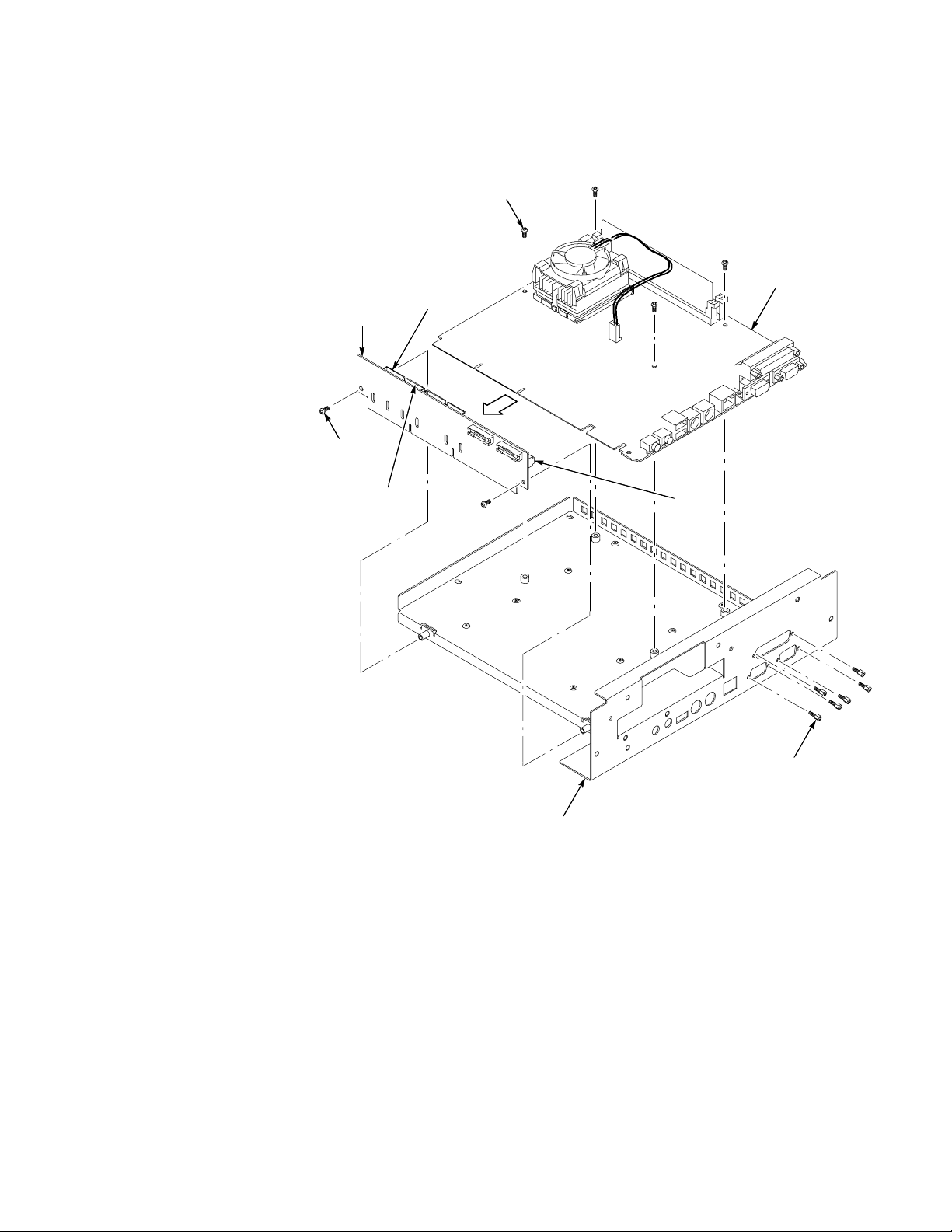

2. Remove the NLX Board assembly: See Figure 2--9 on page 2--15.

3. Orient the instrument: Set the instrument so that its bottom is down on the

work surface and its top is facing you.

a. Remove the five T-15 Torxdrive screws that secure NLX board assembly

to the chassis.

b. Remove the five T-15 Torxdrive screws that secure NLX board assembly

and the rear cover plate to the rear chassis. Remove the cover plate from

the instrument.

c. Grasp the front edge of the NLX board assembly and pull up on the

assembly to disconnect the Riser Adapter from the Processor board edge

connector.

d. Remove the NLX board assembly from the instrument.

2- 14

Option FHD

Page 25

T--15 Torx

NLX board

assembly

Riser adapter

board

T--15 Torx

screw (1)

T--15 Torx

screw (2)

Removal and Installation Procedures

Hard/CD drive

bracket

screw (5)

Option FHD

Remove hard

drive bracket

from front

chassis

Processor board

edge connector

Remove hard drive cable

T--15 Torx

screw (3)

T--15 Torx

screw( 2)

Figure 2- 9: NLX assembly and hard disk drive removal

4. Remove the Riser Adapter and NLX Boards: See Figure 2--10 on page 2--17.

a. Remove the two T-15 Torxdrive screws that secure Riser Adapter board

to the NLX support bracket.

b. Disconnect the ribbon cable connectors from the hard drive and CD

drive.

2- 15

Page 26

Removal and Installation Procedures

5. Reinstallation: Do in reverse steps 3 and 4 to reinstall the NLX board.

c. Grasp the Riser board and pull it straight out to disconnect J510 edge

card connector from the NLX board. Remove the Riser Adapter board

from the NLX board assembly.

d. Remove the four T-15 Torxdrive screws that secure NLX board to the

NLX support bracket.

e. Remove the six 3/16 nut posts that secure the three connectors to the rear

of the support bracket. Then remove the NLX board from the support

bracket.

f. Remove the NLX board from the support bracket.

2- 16

Option FHD

Page 27

T--15 Torx

screw (4)

Removal and Installation Procedures

Riser

adapter

board

T--15 Torx

screw (2)

CD drive cable

connector

Hard drive

cable

connector

NLX board

J510

Option FHD

Nut post (6)

NLX support

bracket

Figure 2- 10: Riser adapter and NLX board removal

2- 17

Page 28

Removal and Installation Procedures

2- 18

Option FHD

Page 29

Mechanical Parts List

This section contains a list of the replaceable modules for Option FHD. Use this

list to identify and order replacement parts. See your instrument service manual

for all other replacement parts

Mfr. Code to Manufacturer

Cross Index

The following table cross indexes codes, names, and addresses of manufacturers

or vendors of components listed in the parts list.

Manufacturers cross index

Mfr.

code

060D9 TENSOLITE COMPANY PRECISION HARNESS AND ASSEMBLY

0KB01 STAUFFER SUPPLY CO 810 SE SHERMAN PORTLAND, OR 97214--4657

22670 GM NAMEPLATE INCORPORATED 2040 15TH AVE WEST SEATTLE, WA 98119--2783

57924 BOURNS INC INTEGRATED TECHNOLOGY DIV.

7X318 KASO PLASTICS INC 5720--C NE 121ST AVE, STE 110 VANCOUVER, WA 98682

80009 TEKTRONIX INC 14150 SW KARL BRAUN DR

9F560 IBM CORPORATION 420 E SOUTH TEMPLE ST SALT LAKE CITY, UT 84145

TK1943 NEILSEN MANUFACTURING INC 3501 PORTLAND RD NE SALEM, OR 97303

Manufacturer Address City, state, zip code

VANCOUVER, WA 98661

3000 COLUMBIA HOUSE BLVD

#120

LOGAN, UT 84321

1400 NORTH 1000 WEST

BEAVERTON, OR 97077--0001

PO BOX 500

Replaceable Parts List

Fig. &

index

number

1--1 200--4794--00 1 COVER,FRONT:PROTECTIVE,FR110,TEK

--2 101--0161--01 1 TRIM,FRONT:PCABS,17.200W X 8.450H,SILVER GRAY 7X318 2TEK1648

Tektronix part

number

Serial no.

effective

Serial no.

discont’d

Qty Name & description

BLUE,TDS7404,TDS7154

Mfr.

code

7X318 200--4794--00

Mfr. part number

Option FHD

3- 1

Page 30

Mechanical Parts List

1

Figure 3- 1: External parts

2

3- 2

Option FHD

Page 31

Replaceable Parts List

Mechanical Parts List

Fig. &

index

number

2--1 441--2183--02 1 CHASSIS ASSY:REAR DRIVE BAY,HD & CD,0.050 AL TK1943 441-- 2183-- 02

--2 200--4782--00 1 COVER, REAR HD PLATE 7X318 200--4782--00

--3 441--2302--00 1 CHASSIS ASSY:SHEET METAL,TDS7404, TDS7154 TK1943 441-- 2302-- 00

--4 614--2762--00 1 PANEL ASSEMBLY:FRONT (ITEMS 5 THROUGH 10) 80009 614--2762--00

--5 679--5366--00 1 CKT BD SUBASSY:FRONT PANEL 57924 3777S--TEK--030

--6 260--2762--00 1 SWI TCH,KEYPAD:ELASTOMERIC,FRONT PANEL 22670 260--2762--00

--7 366--0821--00 7 KNOB,CAP:0.650 D,PC/ABS,SILVER GRAY 22670 366--0821--00

--8 366--0820--00 7 KNOB,CAP:0.425 DIA,PC/ABS,SILVER GRAY 22670 366--0820--00

--9 366--0819--00 1 KNOB,EPS:PUSH BUTTON,PC/ABS,SILVER GRAY 22670 366--0819--00

--10 333--4439--00

--11 650--4498--00 1 RHDD ASSEMBLY:W/O SW (ITEMS 12 THROUGH 17) 80009 650--4498--00

--12 674--4378--00 1 CKT BD SUBASSY:HARD DISK DRIVE INTERFACE 80009 679--4378--00

--13 679--4378--00 1 CKT BD SUBASSY:HARD DISK DRIVE INTERFACE 80009 679--4378--00

--14 437--0506--00 1 CABINET ASSY:REMOVEABLE HARD DISK DRIVE HOLDER 7X318 437-- 0506-- 00

--15 211--1081--00 4 SCREW,MACHINE:M3 X 0.5 X 3.5MM,FLAT WAFER

--16 119--6733--00 1 DISK DRIVE:WINCHESTER,2.5 IN,20GB,SINGLE PLATTER 9F560 07N8325

--17 174--4747--00 1 CA ASSY,SP:RIBBON,44,28 AWG,1MM,1.0 L,2 X 22 060D9 174--4747--00

--18 407--4917--00 1 BRACKET:FLOPPY DRIVE,6.064 X 5.075,AL TK1943 407-- 4917-- 00

Tektronix part

number

333--4444--00

Serial no.

effective

Serial no.

discont’d

Qty Name & description

11SUBPANEL ASSY:OFF SET,W/BEZEL,TDS7404

SUBPANEL ASSY:OFF SET,W/BEZEL, TDS7154

HD,PHL,0.0002 STL ZI PL

Mfr.

code

7X318

7X318

0KB01 211--1081--00

Mfr. part number

333--4439--00

333--4444--00

Option FHD

3- 3

Page 32

Mechanical Parts List

2

1

18

3

17

16

12

13

14

15

10

9

8

7

11

Figure 3- 2: Front panel and drives

5

6

4

3- 4

Option FHD

Loading...

Loading...