OM5110

xx

ZZZ

46 GBaud Multi-Format Optical Transmitter

User Manual

*P071320300*

071-3203-00

xx

OM5110

ZZZ

46 GBaud Multi-Format Optical Transmitter

User Manual

www.tektronix.com

071-3203-00

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges rese rved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

MATLAB is a registered trademark of The MathWorks, Inc.

LabVIEW is a trademark of National Instruments, Inc.

Intel and Pentium are registered trademarks of the Intel Corporation.

Other prod

uct and company names listed are trademarks and trade names of their respective companies.

Contacting Tektronix

Tektronix, Inc.

14150 SW

P.O . B o x 5 00

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In Nor

Worl d wide, vis it www.tektronix.com to find contacts in your area.

Karl Braun Drive

th America, call 1-800-833-9200.

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts , modules and replacement products used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, with shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other than Tektronix representatives to install, repair or service the product;

Table of Contents

Important safety information ........... .................................. ................................ ........ iv

General safety summary ..................................................................................... iv

Service safety summary.................. .................................. ................................ .. vi

Terms in this manual ....................... ................................ ................................. vii

Symbols and terms on the product ......................................................................... vii

Compliance information ........................................................................................... x

EMC compliance ....... .................................. ................................ ..................... x

Safety compliance ............................................................................................ xi

Environmental considerations.............................................................................. xiii

Preface .............................................................................................................. xv

Supported products ........................................................................................... xv

About this manual ............................................................................................ xv

Getting started.. ... . .. . ... ... . .. . ... ... ... . ... ... ... . ... ... ... . ... ... ... . ... ... ... . . .. . ... ... ... . ... ... ... . ... ... ... . 1

Product description ....... ................................ ................................ ..................... 1

Accessories ..................................................................................................... 2

Options.......................................................................................................... 2

First product inspection ....................................................................................... 3

Environmental operating requirements............................... ................................ ....... 4

Power requirements..................... .................................. ................................ ..... 4

PC requirements .................... ................................ .................................. ......... 5

Software installation........................................................................................... 6

Set the instrument IP address................................................................................. 8

Operating basics ................. .................................. ................................ ................ 13

OM5110 controls and connectors ........................................................................... 13

Connect the power cable ..................... ................................ ................................ 14

Power on the instrument ..................................................................................... 15

Theory of operation........................................... .................................. .............. 15

Equipment setup ........ ................................ ................................ ...................... 17

Software overview............................................................................................ 18

Appendix A: The automated test equipment (ATE) interface .............................. .................. 25

The LRCP ATE interface .................. .................................. ................................ 25

ATE functionality in MATLAB .. ... . ... ... . ... ... . ... ... . .. . ... ... . ... ... . ... ... . ... ... .. .. . ... ... . ... ... . . 37

Appendix B: Cleaning and maintenance.......... ................................ .............................. 39

Cleaning ....................................................................................................... 39

Maintenance................. ................................ ................................ .................. 39

Index

OM5110 User Manual i

Table of Contents

List of Figure

Figure 1: IP address setup (LRCP) ............................................................................... 8

Figure 2: OM

Figure 3: OM5110 rear panel .................................................................................... 14

Figure 4: OM5110 block diagram ............................................................................... 16

Figure 5: OM5110 connection diagram......................................................................... 17

Figure 6: OM5110 controls (LRCP)....................................... ................................ ...... 18

5110 front panel ....... ................................ ................................ ............ 13

s

ii OM5110 User Manual

List of Tables

Table 1: Standard and optional accessories...................................................................... 2

Table 2: OM5

Table 3: OM5110 environmental requirements .............. .................................. ................. 4

Table 4: AC line power requirements ............................................................................ 4

Table 5: Software install: controller d evice (PC or oscilloscope). . .. . ... ... . ... ... . ... ... . ... ... . . .. . ... ... . . 7

Table 6: OM5110 Laser controls (LRCP) ...................................................................... 20

Table 7: OM5110 Modulator controls (Auto-Set mode) (LRCP) ............................................ 21

Table 8: O

Table 9: OM5110 Driver Amp controls (LRCP)......................... ................................ ...... 24

110 options.......................................................................................... 2

M5110 Modulator controls (manual mode) (LRCP) .... ................................ .......... 22

Table of Contents

OM5110 User Manual iii

Important safety information

Important saf

ety information

This manual c

for safe operation and to keep the product in a safe condition.

To safely perform service on this product, additional information is provided at

the end of this section. (See page vi, Servicesafetysummary.)

General safety summary

Use the product only as specified. Review the following safety precautions to

avoid injury and prevent damage to this product or any products connected to it.

Carefully read all instructions. Retain these instructions for future reference.

Comply with local and national safety codes.

For correct and safe operation of the product, it is essential that you follow

generally accepted safety procedures in addition to the safety precautions specified

in this manual.

The product is designed to be used by trained personnel only.

Only qualified personnel who are aware of the hazards involved should remove

the cover for repair, maintenance, or adjustment.

ontains information and warnings that must be followed by the user

To avoid fire or personal

injury

Before use, always check the product with a known source to be sure it is

operating correctly.

This product is not intended for detection of hazardous voltages.

Use personal protective equipment to prevent shock and arc blast injury where

hazardous live conductors are exposed.

When incorporating this equipment into a system, the safety of that system is the

responsibility of the assembler of the system.

Use proper power cord. Use only the power cord specified for this product and

certified for the country of use.

Do not use the provided power cord for other products.

Ground the product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, make sure that the product is properly

Do not disable the power cord grounding connection.

Power disconnect. The power cord disconnects the product from the power

source. See instructions for the location. Do not position the equipment so that it

grounded.

iv OM5110 User Manual

Important safety information

is difficult to d

all times to allow for quick disconnection if needed.

Observe all terminal ratings. To av o i d fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do not float the common terminal above the rated voltage for that terminal.

The measuring terminals on this product are not rated for connection to mains or

Category II, III, or IV circuits.

Do not operate without covers. Do not o perate this product with covers or panels

removed, or with the case open. Hazardous voltage exposure is possible.

Avoid exposed circuitry. Do not touch exposed connections and components

when power is present.

Do not operate with suspected failures. If you suspect tha

product, have it inspected by qualified service personnel.

Disable the product if it is damaged. Do not use the product if it is damaged

or operates incorrectly. If in doubt about safety of the product, turn it off and

disconnect the power cord. Clearly mark the product to prevent its further

operation.

isconnect the power cord; it must remain accessible to the user at

t there is damage to this

Examine the exterior of the product before you use it. Look for cracks or missing

pieces.

Use only specified replacement parts.

Replace batteries properly. Replace batteries only with the specified type and

rating.

Use proper fuse. Use only the fuse type and rating specified for this product.

Wear eye protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

Do not operate in wet/damp conditions. Be aware that condensation may occur if

a unit is moved from a cold to a warm e nvironment.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry. Remove the input signals before you clean

the product.

Provide proper ventilation. Refer to the installation instructions in the manual for

details on installing the product so it has proper ventilation.

OM5110 User Manual v

Important safety information

Servi

ce safety summary

Slots and openi

otherwise obstructed. Do not push objects into any of the openings.

Provide a safe working environment. Always place the product in a location

convenient for v iewing the display and indicators.

Avoid improper or prolonged use of keyboards, pointers, and button pads.

Improper or prolonged keyboard or pointer use may result in serious injury.

Be sure your work area meets applicable ergonomic standards. Consult with an

ergonomics professional to avoid stress injuries.

Use care when lifting and carrying the product.

Warning- Use correct controls and procedure. Use of controls, adjustments, or

procedu

radiation exposure.

Do not directly view laser output. Under no circumstances should you use any

optical instruments to view the laser output directly.

res other than those listed in this document may result in hazardous

ngs are provided for ventilation and should never be covered or

The Service safety summary section contains additional information required to

safely perform service on the product. Only qualified personnel should perform

ice procedures. Read this Service safety summary and the G eneral safety

serv

summary before performing any service procedures.

To avoid electric shock. Do not touch exposed connections.

Do not service alone. Do not perform internal service or adjustments of this

oduct unless another person capable of rendering first aid and resuscitation is

pr

present.

Disconnect power. To avoid electric shock, switch off the product power and

disconnect the power cord from the mains power before removing any covers or

panels, or opening the case for servicing.

Use care when servicing with power on. Dangerous voltages or currents may exist

in this product. Disconnect power, remove battery (if applicable), and disconnect

test leads before removing protective panels, soldering, or replacing components.

Verify safety after repair. Always recheck ground continuity and mains dielectric

strength after performing a repair.

vi OM5110 User Manual

Terms in this manual

These terms may appear in this manual:

WAR N ING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Symbols and terms on the product

Important safety information

These ter

The following symbol(s) may appear on the product:

ms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read

the mark

WARNING indicates an injury hazard not immediately accessible as you

read th

CAUTION indicates a hazard to property including the product.

ing.

emarking.

When this symbol is marked on the product, be sure to consult the manual

to find out the nature of the potential hazards and any actions which have to

be taken to avoid them. (This symbol may also be used to refer the user to

ratings in the manual.)

OM5110 User Manual vii

Important safety information

Front panel lab

els

Item Description

1

Indicates the location of laser apertures

2

viii OM5110 User Manual

Important safety information

Rear panel labe

ls

Item Description

1 Instrument model and serial number label

2

3

Fuse safety information

COMPLIES WITH 21CFR1040.10 EXCEPT

FOR DEVIATIONS PURSUANT TO LASER

NOTICE NO. 50, DATED JUNE 24, 2007

OM5110 User Manual ix

Compliance information

Compliance in

EMC compliance

EC Declaration of

Conformity – EMC

formation

This section

environmental standards with which the instrument complies.

Meets intent of Directive 2004/108/EC for Electromagnetic Compatibility.

Compliance was demonstrated to the following specifications as listed in the

Official Journal of the European Communities:

EN 61326-1 2006. EMC requirements for electrical equipment for measurement,

control

CISPR 11:2003. Radiated and conducted emissions, Group 1, Class A

IEC 61000-4-2:2001. Electrostatic discharge immunity

IEC 61000-4-3:2002. RF electromagnetic field immunity

IEC 61000-4-4:2004. Electrical fast transient / burst immunity

IEC 61000-4-5:2001. Power line surge immunity

lists the EMC (electromagnetic compliance), safety, and

, and laboratory use.

123

1000-4-6:2003. Conducted RF immunity

IEC 6

IEC 61000-4-11:2004. Voltage dips and interruptions immunity

EN 61000-3-2:2006. AC power line harmonic emissions

EN 61000-3-3:1995. Voltage changes, fluctuations, and flicker

European contact.

ektronix UK, Ltd.

T

Western Peninsula

Western Road

Bracknell, RG12 1RF

United Kingdom

1

This product is intended for use in nonresidential areas only. Use in residential areas may cause electromagnetic

interference.

2

Emissions which exceed the levels required by this standard may occur when this equipment is connected to a

test object.

3

For compliance with the EMC standards listed here, high quality shielded interface cables should be used.

x OM5110 User Manual

Compliance information

Australia / New Zealand

Declaration of

Conformity – EMC

Safety complianc

EU declaration of

conformity – low voltage

Complies with t

following standard, in accordance with ACMA:

CISPR 11:2003. Radiated and Conducted Emissions, Group 1, Class A, in

accordance with EN 61326-1:2006.

Australia / New Zealand contact.

Baker & McKenzie

Level 27, AMP Centre

50 Bridge Street

Sydney NSW 2000, Australia

he EMC provision of the R adiocommunications Act per the

e

This section lists the safety standards with which the product complies and other

safety compliance information.

Compliance was demonstrated to the following specification as listed in the

Official Journal of the European Union:

Low Voltage Directive 2006/95/EC.

EN 61010-1. Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use – Part 1: General Requirements.

U.S. nationally recognized

testing laboratory listing

Canadian certification

Additional compliances

Equipment type

EN 60825-1. Safety of Laser Products - Part 1: Equipment classification

and requirements.

UL 61010-1. Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use – Part 1: General Requirements.

CAN/CSA-C22.2 No. 61010-1. Safety Requirements for Electrical

Equipment for Measurement, Control, and Laboratory Use – Part 1: General

Requirements.

IEC 61010-1. Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use – Part 1: General Requirements.

IEC 60825-1. Safety of Laser Products - Part 1: Equipment classification

and requirements.

This laser product complies with 21CFR1040.10 except for deviations

pursuant to Laser Notice No. 50, dated June 24, 2007.

Test and measuring equipment.

OM5110 User Manual xi

Compliance information

Safety class

Pollution degree

descriptions

Class 1 – ground

A measure of the contaminants that could occur in the environment around

and within a product. Typically the internal environment inside a product is

considered to be the same as the external. Products should be used only in the

environment for which they are rated.

Pollution degree 1. No pollution or only dry, nonconductive pollution occurs.

Products in this category are generally encapsulated, hermetically sealed, or

located in clean rooms.

Pollution degree 2. Normally only dry, nonconductive pol

Occasionally a temporary conductivity that is caused by condensation must

be expected. This location is a typical office/home environment. Temporary

condensation occurs only when the product is out of service.

Pollution degree 3. Conductive pollution, or dry, nonconductive pollution

that becomes conductive due to condensation. These are sheltered locations

where neither temperature nor humidity is controlled. The area is protected

from direct sunshine, rain, or direct wind.

Pollution degree 4. Pollution that generates persistent conductivity through

conductive dust, rain, o r snow. Typical outdoor locations.

ed product.

lution occurs.

Pollution degree rating

IP rating

Measurement and

overvoltage category

descriptions

Mains overvoltage

category rating

Pollution degree 2 (as defined in IEC 61010-1). Rated for indoor, dry location

use only.

IP20 (as defined in IEC 60529).

Measurement terminals on this product may be rated for measuring mains voltages

from one or more of the following categories (see specific ratings marked on

the product and in the manual).

Category II. Circuits directly connected to the building wiring at utilization

points (socket outlets and similar points).

Category III. In the building wiring and distribution system.

Category IV. At the source of the electrical supply to the building.

NOTE. Only mains power supply circuits have an overvoltage category rating.

Only measurement circuits have a measurement category rating. Other circuits

within the product do not have either rating.

Overvoltage category II (as defined in IEC 61010-1).

xii OM5110 User Manual

Environmental considerations

This section provides information about the environmental impact of the product.

Compliance information

Product end-of-life

handling

Restriction of hazardous

tances

subs

Observe the f

Equipment recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could be

harmful to the environment or human health if improperly handled at the product’s

end of life. To avoid release of such substances into the environment and to

reduce the

an appropriate system that will ensure that most of the materials are reused or

recycled appropriately.

Perchlorate materials. This product contains one or more type CR lithium

batteries. According to the state of California, CR lithium batteries are

ified as perchlorate materials and require special handling. See

class

www.dtsc.ca.gov/hazardouswaste/perchlorate for additional information.

This product is classified as an industrial monitoring and control instrument,

s not required to comply with the substance restrictions of the recast RoHS

and i

Directive 2011/65/EU until July 22, 2017.

ollowing guidelines when recycling an instrument or component:

use of natural resources, we encourage you to recycle this product in

This symbol indicates that this product complies with the applicable European

Union re

on waste electrical and electronic equipment (WEEE) and batteries. For

information about recycling options, check the Support/Service section of the

Tekt r on

quirements according to Directives 2002/96/EC and 2006/66/EC

ixWebsite(www.tektronix.com).

OM5110 User Manual xiii

Compliance information

xiv OM5110 User Manual

Preface

Preface

Supported products

About this manual

This manual d

Multi-Format Optical Transmitter.

The information in this manual applies to the following Tektronix product:

OM5110 46 G

This manu

Getting started shows you how to install and configure the OM5110 instrument.

Operating basics provides an overview of the front- and rear-panel controls

and connections, and basic operations.

Reference provides further information about specific instrument or software

operation.

escribes how to install and operate the OM5110 46 GBaud

Baud Multi-Format Optical Transmitter

al contains the following sections:

OM5110 User Manual xv

Preface

xvi OM5110 User Manual

Getting started

This section contains the following informationtogetyoustartedusingthe

instrument:

Product description

List of instrument accessories and options

Firstproductinspection

Operating requirements (environmental, power)

Product description

Key features

Software

The OM51

multi-format transmitter that can generate single and dual-polarization optical

signals with BPSK, QPSK, QAM, or arbitrary modulation up to 46 GBaud.

A remote interlock for the laser, located on the rear of the unit, allows for remote

locking of laser output.

Use the OM5110 instrument with a Tektronix OM4000 series Coherent Optical

Signal Analyzer, Tektronix real-time and equivalent-time oscilloscopes, and

coherent signal generators such as Tektronix AWG70001 or PPG3204 instruments,

for a complete, end-to-end coherent optical testing solution.

Baud rate up to 34 GBaud for arbitrary signals in small signal regime < 0.5 V

Baud rate up to 46 GBaud for NRZ bipolar signaling such as BPSK and

QPSK with input amplitude of 1 V

Up

16-QAM modulation; support for other popular modulation formats

, network, and hardware setup

10 46 GBaud Multi-Format Optical Transmitter is a dual-polarization

pp

to four driven electrical inputs to provide 1- and 2-pol BPSK, QPSK, and

pp

ssisted modulation setup using application note and AWG input files

A

Internal C- or L-band laser (option at time of order)

Optical bias is manually or automatically controlled through UI

Amplifier electrical bias is manually or automatically controlled through UI

UI has automatic test interface (ATE)

OM5110 User Manual 1

Getting started

Accessories

The following table lists the standard and optional accessories provided with

the OM5110 instrument.

Table 1: Standard and optional accessories

Tektronix

part

Accessory Std. Opt.

OM5110 46 GBaud Mult-Format Optical Transmitter

OM5110 46 GBaud Mult-Format Optical Transmitter U ser

Manual (this manual)

Software USB flashdrive

Ethernet cable, 7 ft.

RF Cable, 2.92 mm, 9 in. (4 cables)

Shorting cap for BNC interlock connector

Power cord

(See page 3, International power cord options.)

Reply card

Cleaning swab

China RoHS sheet

Patch Cord, Fiber, APC/APC, 8 in.

●

●

●

●

●

●

●

●

●

●

●

number

Varies by

option

071-3203-

650-5730-xx

174-6230-xx

174-6227-xx

131-8925-xx

Varies by

option

Not

orderable

Not

orderable

Not

orderable

174-6231-xx

xx

Options

e the following table to select options to order with the OM5110. See the

Us

46 GBaud Mult-Format Optical Transmitter OM5110 Datasheet (Tektronix

part number 54W-29475-X) for a complete listing of options and recommended

configurations.

Table 2: OM5110 options

odel

M

OM5110

2 OM5110 User Manual

ption

O

C One C-band laser

L

NL No laser

escription

D

One L-band laser

Getting started

International power cord

options

First product inspection

All of the avail

mechanism except as otherwise noted.

Opt. A0 – North

Opt. A1 – Universal EURO power

Opt. A2 – United Kingdom power

Opt. A3 – Australia power

Opt. A4 – North America power (240 V)

Opt. A5 – Switzerland power

Opt. A6 – J

Opt. A10 – China power

Opt. A11 – India power (no locking cable)

Opt. A12 – Brazil power (no locking cable)

Do the following when you receive your instrument:

able power cord options in the following list include a lock

America power (standard)

apan power

1. Inspect the shipping carton for external damage, whic h may indicate damage

to the instrument.

2. Remove the OM5110 instrument from the shipping carton and check that

the instrument was not damaged in transit. The instrument is thoroughly

inspected for mechanical defects before shipment. The exterior should not

have any scratches or impact marks.

TE. Save the shipping carton and packaging materials for instrument

NO

repackaging in case shipment becomes nece ssary.

erify that the shipping carton contains the basic instrument, the standard

3.V

accessories and any optional accessories that you ordered. (See Table 1.)

OM5110 User Manual 3

Getting started

Contact your lo

cal Tektronix Field Office or representative if there is a problem

with your instrument or if your shipment is incomplete.

Environmental operating requirements

Check that the location of your installation has the proper operating environment.

(See Table 3.)

CAUTION. Damage to the instrument can occur if this instrument is powered on at

temperatures outside the specified ambient temperature range.

Table 3: OM5110 environmental requirements

Parameter Description

Temperature

Relative

Humidity

Altitude

Operating +10 °C to +35 °C

Nonoperating

Operating 10% to 85% RH (Relative Humidity)

Nonoperating

Operating To 3,000 m (9,840 feet)

Nonoperating

–20 °C to +60 °C

10% to 85% RH to +35°C

Upper limit derates to 45% RH at +60°C

Maximum operating temperature decreases 1 °C each

300 m above 1.5 km.

To 12,000 m (39,360 feet)

ower requirements

P

There is a fan on the back left side of the box with an air intake under the left

front. A 2 inch (51 mm) clearance must be maintained on the left side of the

trument, and a 0.5 inch (13 mm) clearance must be maintained on the bottom

ins

of the instrument, for forced air flow. The mainframe should never be operated on

a bench with the feet removed, nor have any object placed nearby where it may be

drawn against the air vents. Also, provide enough rear clearance (approximately

2 inches/51 mm) so that connected cables are not damaged by sharp bends.

Table 4: AC line power requirements

Parameter Description

Line voltage range

Line frequency 50/60 Hz

100–240 V

, ±10%

AC

4 OM5110 User Manual

Getting started

Table 4: AC line power requirements (cont.)

Parameter Description

Maximum current 0.7 A

Fuse rating T3.15A, 250 V

WAR N ING. To reduce the risk of fire and shock, verify that the AC supply voltage

fluctuations do not exceed ±10% of the operating voltage range.

To avoid the possibility of electrical shock, do not connect your OM5110 to a

power source if there are any signs of damage to the instrument enclosure.

WAR N ING. Always connect the unit directly to a grounded power outlet.

Operating the OM instrument without connection to a grounded power source

could re

sult in serious electrical shock.

CAUTION. Protective features of the OM5110 instrument may be impaired if the

unit is used in a manner not specified by Tektronix.

PC requirements

The equipment and DUT used with the OM5110 determine the controller PC

irements.

requ

If you are using the OM5110 as a stand-alone instrument, the LRCP software

d with the OM5110 requires Windows 7 or Windows XP (32-bit or 64-bit)

use

operating systems with NET 4.0.

e following are the requirements to use the OM5110 with the Tektronix

Th

OM4000 series Optical Modulation Analyzers and the OM2210 Coherent

Receiver Calibration Source:

Item Description

Operating

ystem

s

Processor

RAM

Hard Drive

Space

U.S.A. Microsoft Windows 7 (32- or 64-bit)

U.S.A. Microsoft Windows XP (32- or 64-bit) Service Pack 3 (.NET 4.0

required)

Intel i7, i5 or equivalent; min clock speed 2 GHz

Minimum: Intel Pentium 4 or equivalent

Minimum: 4 GB

64-bit r eleases benefit from as much memory as is available

Minimum: 20 GB

>300 GB recommended for large data sets

OM5110 User Manual 5

Getting started

Item Description

Video Card

nVidia dedicated graphics board with 512+ MB minimum graphics memory

Software installation

NOTE. The colo

application on an oscilloscope or PC that does not use a n nVidia graphics

card

Networking

Display

Other

Hardware

MATLAB

Software

(for use with

OM4000 OU

software only)

Adobe Rea

Instal

der

l the program listed in the following table. The program is on the

Gigabit Ethernet (1 Gb/s) or Fast Ethernet (100 Mb/s)

20” minimum flat screen recommended for displaying multiple graph types

when using w

2 USB 2.0 por

DVD optical drive

For Windows 7 (64-bit): MATLAB version 2011b (64-bit)

For Windows XP (32-bit): MATLAB version 2009a (32-bit), .NET version 4

or later.

I

See the OM4006D and OM4106D User Manual for more information

Adobe reader required for viewing PDF format files (release notes,

installation instructions, user manuals).

r grade display is not available when running the

ith the OM4000 series software

ts

OM5110 software USB flashdrive.

NOTE. Read the installation notes or instructions that are in each application

installation folder before installing each item of software. Only install the software

that is appropriate for your OM instrument, PC, and oscilloscope configuration.

NOTE. If you are going to use the OM5110 as part of a test/calibration

system including OM4000 and OM2210/2012 instruments and measurement

oscilloscopes, do not install the software listed in the following table. Instead, use

e software installation instructions that are in the “OM4006D and OM4106D

th

Coherent Lightwave Signal Analyzer User Manual.” Those instructions include

loading the LRCP software.

6 OM5110 User Manual

Getting started

Install softwa

re on

the controller (PC or

oscilloscope)

Table 5: Soft

Item Description Path (from root directory of USB drive)

1

LRCP

AWG file

library

1

The OM5110 requires LRCP version 2.0 or greater.

ware install: controller device (PC o r oscilloscope)

Laser Receiver Control Panel.

Detects OM instruments on a

network, co

hardware settings.

Files to us

AWG70001A and AWG70002A

Arbitrary Waveform G enerators for

generatin

optical modulation signals. These

files are precompensated to work with

atypical

combination.

See the file OM5110 app note.pdf in

the AWG F

on using the AWG library files with

the OM5110.

ntrols laser and other

e with Tektronix

g standard and custom

AWG70001A and OM5110

iles folder for information

OM5110\Setup Tektronix LRCP_2.0.0.6105.exe

OM5110\AWG Files

OM5110 User Manual 7

Getting started

Set the instru

ment IP address

Use the Laser Receiver Control Panel (LRCP) application to verify and/or set

the IP address of OM instruments (OM5110, OM4106D, OM4006D, OM2210,

OM2012) if re

set to the same network subnet (DHCP-enabled networks do this automatically)

to communicate with each other using the LRCP and OM4000 or OM5110 User

Interface software.

quired for your network test setup. All OM instruments must be

Set IP address for

DHCP-enabled network

Figure 1: IP address setup (LRCP)

Before using LRCP, you must make sure that IP addresses of the OM series

instruments are set correctly to communicate with LRCP on your network. The

following sections describe how to set the OM instrument IP addresses for use

on DHCP and non-DHCP networks.

The OM instruments are set with automatic IP assignment (DHCP) enabled by

default. Therefore you do not need to specifically set the instrument IP address, as

the DHCP server automatically assigns an IP address during instrument power-on

when the rear-panel power switch is turned on.

The following procedure describes how to use LRCP software to verify

connectivity of an OM instrument to a DHCP-enabled network.

Prerequisite: OM instrument, and the controller PC (with LRCP installed), both

connected to the same DHCP-enabled network.

1. Connect the OM instrument to the DHCP-enabled network.

2. Power on the OM instrument with the rear power switch (set to 1). The

instrument queries the DHCP server to obtain an IP address. Wait until the

8 OM5110 User Manual

Getting started

front panel Ena

the front panel Enable/Standby button to enable the network connection

(button light turns On).

3. On a PC connected to the same network as the OM instrument, start the

LRCP program.

4. Enter password 1234 when requested.

5. When runnin

Configuration/Device Setup link on the application screen to open the

Device Setup window. Otherwise click the LRCP button and then the Device

Setup button (upper left of application window).

6. In the Device Setup dialog box, click the Auto Configure button. LRCP

searches the network and lists any OM instruments that it detects. If no devices

are detected, work with your IT resource to resolve the connection problem.

7. (optional) Use the Friendly Name fi eld to create a custom label for each

instrument. There is no limit to the size of the name you enter.

8. Click OK to close the configurationdialogboxandreturntotheLRCPmain

window. The main LRCP window displays a tab for each instrument detected.

Click a tab to display the laser controls for that instrument. Refer to the LRCP

docum

entation for help on using the software.

ble/Standby button light turns off indicating it is ready. Push

gLRCPforthefirst time after installation, click the

Set IP address for a

non-DHCP network

To connect the OM series instrument to a non-DCHP network, you must reset the

default IP address and related settings on the OM instrument to match those of

r non-DHCP network. All devices on this network (OM instruments, PCs

you

and other remotely accessed instruments such as oscilloscopes) need the same

subnet values (first three number groups of the IP address) to communicate, and

a unique instrument identifier (the fourth number group of the IP address) to

identify each instrument.

Work with your network a dministrator to obtain a unique IP address for each

device. Your network administrator may need the MAC addresses of the

computer, oscilloscope, and OM instrument. The MAC address is located on the

OM instrument rear panel label.

NOTE. Make sure to record the IP addresses used for each OM instrument, or

attach a label with the new IP address to the instrument.

OM5110 User Manual 9

Getting started

If you are setti

instruments, Tektronix recommends using the OM instrument default IP subnet

address of 172.17.200.XXX, where XXX is any number between 0 and 255. Use

the operating systems of the oscilloscope and computer to set their IP addresses.

NOTE. If you need to change the default IP address of more than one OM

instrument, you must connect each instrument separately to change the IP address.

There are two ways to change the IP address of an OM instrument:

Use LRCP on a PC connected to a DHCP-enabled network (easiest)

Use LRCP on a PC set to the same IP address subnet as the OM instrument to

change the OM instrument IP address

Use DHCP network to change instrument IP address. To use a DHCP network to

change the IP address of an OM series instrument:

1. Do steps 1 through 6 of the Set network access (DHCP network) procedure.

2. Enter (overwrite) the new IP address for your OM instrument in the

corresponding "IP Address" field.

3. Click the corresponding Set IP button.

ng up a new isolated network just for controlling OM and associated

4. A warning dialog box appears indicating that the IP address will be changed

and that you must record the new IP address. Losing the IP address will

require connecting the instrument to a DHCP router.

5. Click Ye s to set the IP

6. Exit the LRCP program.

7. Power off the OM instrument and connect it to the non-DHCP network.

8. Run LRCP and use the Auto Config button in the Device Setup dialog box to

verify that the instrument is listed with the new IP address.

Use direct PC connection to change instrument IP address. To use a direct PC

connection to change the default IP address of an OM series instrument, you

need to:

Install LRCP on the PC

UsetheWindowsNetworktoolstosettheIPaddressofthePCtomatchthat

of the current subnet setting of the OM series instrument whose IP address

youneedtochange

Connect the OM instrument directly to the PC, or through a hub or switch

(not over a network)

Use LRCP to change the OM instrument IP address

address.

10 OM5110 User Manual

Getting started

Do the followin

of an OM series instrument:

NOTE. The following instructions are for Windows 7.

NOTE. If you need to change the default IP address of more than one OM

instrument using this procedure, you must connect each instrument separately to

change the IP address.

1. On the PC with LRCP installed, click Start > Control Panel.

2. Open the Network and Sharing Center link.

3. Click the Manage Network Connections link to list connections for your PC

4. Right-click the Local Area Connection entry for the Ethernet connection and

select Properties to open the Properties d ialog box.

5. Select Internet Protocol Version 4 and click Properties.

6. Enter a new IP address for your PC, using the same first three numbers as

used by the OM instrument. For example, 172.17.200.200. This sets your

PC to the same subnet (first three number groups) as the default IP address

setting for the OM series instruments.

g steps to use a direct PC connection to change the IP address

7. Click OK to set the new IP address.

8. Click OK to exit the Local Area Connection dialog box.

9. Exit the Control Panel window.

10. Connect the OM instrument to the PC.

11. Power on the OM instrument with the rear power switch (set to 1). Wait until

front panel Enable/Standby button light turns off.

12. Push the Enable/Standby button again to enable the network connection

(button light turns On).

13. On the PC, start the LRCP program.

14. Enter password 1234 when requested.

15. Select LRCP > Device Setup from the menu to open the Device Setup

window.

16. Click the Auto Con fi gure button. LRCP lists the OM-series instrument

connected to the PC. If LRCP does not list the connected instrument, verify

that you entered a correct IP address into the PC and your Ethernet cable is

good. If the IP a ddress was entered correctly, you may need to connect the

OM instrument to a DHCP network to determine if the IP address you used to

set the computer was correct.

OM5110 User Manual 11

Getting started

17. (optional) Use

instrument. There is no limit to the size of the name you enter. Friendly Names

are retained and are associated with the MAC address of each instrument.

18. Enter (overwrite) the new IP address for your OM instrument in the

corresponding "IP Address" field. For example, 172.17.200.040

19. Click the Set IP button.

20. A warning di

and that you must record the new IP address.

NOTE. If you change the instrument to an IP address that is different than the

Subnet of the PC, and click Set IP, the instrument is no longer detectable or

viewable to that PC and LRCP. You must connect the instrument to a DHCP

router to reset the value.

21. Click Ye s to set the IP address.

22. Edit th

support).

23. Click

e Gateway and Net Mask (obtain this information from your network

OK.

the Friendly Name field to create a custom label for each

alog box appears indicating that the IP address will be changed

24. Exit the LRCP program.

25. Disconnect the network cable from between the PC and the OM instrument.

26. Connect the OM instrument to the target network switch/router.

27. Run the LRCP software on the PC connected to the same network as the

OM instrument.

28. Click Device Setup. Click Auto Config and verify that the instrument is

detected and listed on the display.

12 OM5110 User Manual

Operating basics

OM5110 contro

Figure 2: OM5110 front panel

ls and connectors

Front panel

1. Enable/Standby switch (hold for 10 seconds to reset instrument)

2. Laser output (PM FC/APC)

3. Optical Input (PM FC/APC input to the optical modulator)

4. X, Y I/Q inputs (2.92 mm RF connectors) to connect the signal generator

5. Modulated signal output (SMF FC/APC)

OM5110 User Manual 13

Operating basics

Rear panel

Figure 3: OM5110 rear panel

1. BNC connector for optional laser remote interlock to enable laser emission

2. Primary (AC) power switch

3. Fuse holder

4. Power c

5. 10/100/1000 Ethernet port

Connect the power cable

NOTE. Make sure that the Primary power stitch on the rear panel is set to Off

(O) before attaching the power cord.

Connect the power cord to the instrument first, and then connect the power c ord to

the AC power source.

NOTE. Install or position the OM5110 instrument to provide fast access to the

rear-panel Primary power switch.

able connector

14 OM5110 User Manual

Power on the instrument

1. Toggle the Primary power switch on the rear panel from Off to On. and

2. Push the front-panel Enable/Standby button.

Operating basics

Theory of operation

3. After poweri

is working. If the fan is not working, Power off the instrument (Push the

Enable/Standby button on front panel, then switch the rear panel Primary

power switch to Off). Power on the instrument again. If the fan still does not

work, repeat the power off sequence, disconnect the AC power cord, and

contact your local Tektronix Field Office or representative for help.

The OM5110 contains a dual-polarization IQ optical modulator capable of

produci

34 Gbaud for small-signal modulation. The optical modulator translates the

RF input signals to the frequency of the Optical Input using dual nested

Mach-Zehnder modulators to provide RF IQ modulation on two orthogonal

polarizations at the Optical Output.

The linear two-stage amplifiers increase the RF input signals by 20 dB

before going to the modulator. The amplifier gain reduces the input-referred

Vpi voltages of the modulators to approximately 350 mV. Full-amplitude

bina

700 mVpp but no more than 1 Vpp is required for complete saturation.

ng optical modulation a t up to 46 Gbaud for binary modulation and

ry-phase-shift-keyed modulation (BPSK) is achieved with signals greater than

ng on, make sure that the fan on the left side of the instrument

OM5110 User Manual 15

Operating basics

Figure 4: OM5110 block diagram

For 2-polarization IQ modulation, 4 RF input signals are required. If the OM5110

d for other modulation types, only the necessary number of inputs need

is use

be connected, for example, a single RF data signal is required for 1-pol BPSK.

The LRCP software is used to configure the optical modulator bias controller

for the modulation type. The optical bias controller makes sure that each of the

data modulators and IQ-phase control modulators are biased at the proper points

for IQ modulation. Each IQ RF-input pair should have minimum correlation to

ain the best result with automatic optical bias control. For example, putting

obt

exactly the same signal on I and Q will not necessarily result in the expected IQ

modulation unless manual optical bias control is used.

There are two primary modes of operation for the OM5110: large-signal and

small-signal. Large-signal modulation occurs from around 500 mVpp to where

the amplifier is completely saturated at 1 Vpp. In this range both the amplifier and

modulator have a nonlinear characteristic that provide higher quality modulation

for binary signals. As the amplifier becomes saturated, use the LRCP software

to adjust the amplitude and duty-cycle distortion (crossing-point) provided by

the amplifier’s second stage of gain. Factory settings provide 2Vpi modulation

amplitude and 50% crossing point, but you can adjust these to accommodate

different signal sources.

16 OM5110 User Manual

Operating basics

Equipme

nt setup

The small signa

used to create QAM signals. The amplifier remains linear up to 500 mVpp so

the amplitude and duty cycle adjustments will have little effect. In this case,

you adjust the first amplifier gain stage to equalize the small signal gains of

the different channels. The factory settings typically provide 2% amplitude

matching between input channels. Use this mode of operation to convey baseband

multi-leve

The OM5110 is ideally suited for use with the AWG70001A and RFxpress

applicati

the response of the AWG and the OM5110 to provide the desired modulated

optical waveform. See the ApplicationNoteprovidedwiththeOM5110AWG

file library for further information on using the OM5110 with the AWG70001A

and RFxpress.

See the following figure for how to connect the OM5110 instrument.

on software for creating arbitrary signals that are precompensated for

l mode of operation is most often used for multi-level inputs

l IQ signals such as 16-QAM to optical frequencies.

Figure 5: OM5110 connection diagram

OM5110 User Manual 17

Operating basics

Software over

view

The OM5110 is controlled by the LRCP software. The LRCP automates

locating and configuring all OM devices on the network. It also provides a

Windows Comm

local or remote process to operate the connected devices for ATE (automated

test equipment) applications. The LRCP program can control any number of

OM-series devices including the OM4000 and OM2000 series and the OM5110.

Each device that the LRCP controls is assigned a tab that is labeled with the

device name and IP address. Clicking on the tab brings the control pane for that

device to the front. The contents of the control pane depend on that tabs device.

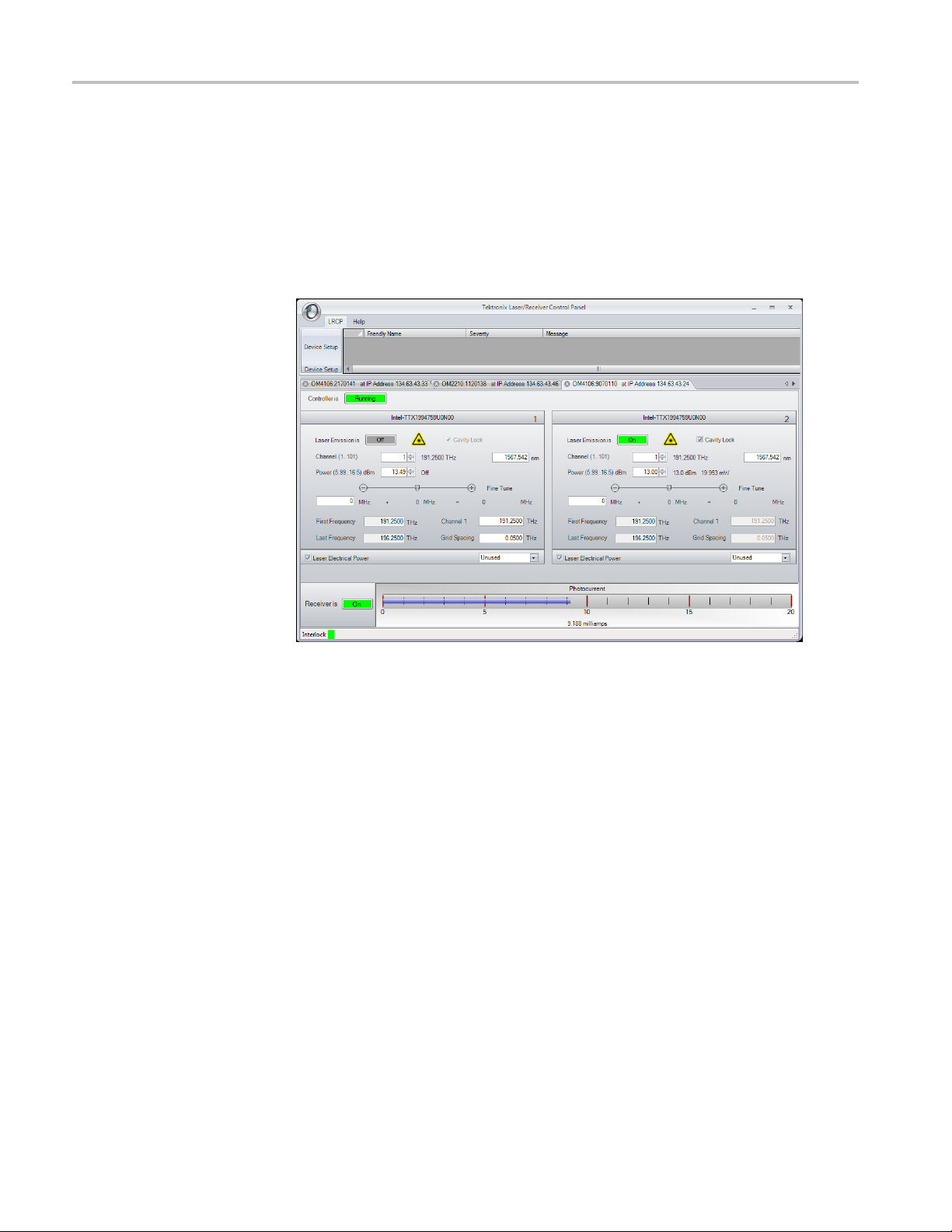

The following figure shows the pane for the OM5110.

unication Foundation (WCF) service interface to allow another

Figure 6: OM5110 controls (LRCP)

Device setup and auto

configure

18 OM5110 User Manual

Click the LRCP and D evice Setup button to open the Device Setup dialog

box. Use this dialog box on first setup of the controllers and any time network

configuration changes and devices are moved to a new IP address. Click the Auto

Configure button to have LRCP search for and list detected OM devices. Make

sure to exit the form by clicking the OK button to save changes.

An important setting on the Device Setup screen is the Friendly Name. The

Friendly Name field is a way to attach custom labels for each device, to help you

identify the type and/or location of the controllers. Friendly Names are retained in

the LRCP and are tied to the corresponding MAC Address.

Operating basics

Connecting to your OM

instruments

Use the Set IP bu

necessary in a network environment that is not using DHCP to automatically

assign IP Addresses. The Set IP button only changes the IP address and does not

save other modified fields like Friendly Name. How you manage IP addresses in

your network, namely with or without DHCP, determines the method you use to

connect the LRCP and d evices on your network. (See page 8, Set the instrument

IP address.

Once configured and detected, devices are listed as tabs on the main LRCP

screen. They are listed with the friendly name and IP address to allow for easy

identific

laser panels will populate with the laser manufacturer and model number.

Once the

the control p anel attaches to the OM4000 series or OM5110 instrument. First,

the button will turn yellow and read "Connecting…" indicating that a physical

network connection is being established over a socket. Second, the button will

turn teal and read "Connected…". This indicates that a session is established

between the device and Control Panel. Commands are sent to initialize the

commu

turns bright green when the controller and lasers are ready.

ation. Lasers are numbered and once the controller is brought online the

user presses the button that reads Offline the button will change colors as

nications with the laser and identify their capabilities. Finally, the button

tton to manually set the instrument IP address. This is only

)

NOTE. The button color scheme (bright green = running or active, gray = off line

or inactive, red = warning or error state) is consistent throughout the application.

The very first time the LRCP connects to an OM5110, there is a delay while the

LRCP calculates the initial modulator parameters so that they may be stored away

in the LRCP Program Files directory. The modulator parameters, including null

voltages and Vpi voltages for the various modulator sections, are needed to obtain

roper optical bias for the modulator. The LRCP saves the current state of each

p

OM5110 on first connection so that you c an restore the parameters if needed.

More information on setting the modulator parameters using the “Set Params”

button may be found below.

Once the controller tab is active and the panels have populated with information

received from the devices, you can change settings and turn on the laser if

required. When the controller establishes the connection with the OM4000 series

or OM5110 devices, it reads and displays the current state of the device in

the panel. Any time you exit the application, the current state of the device is

preserved by the device, including the emission state. If the device is powered

down, it will return to its default power-on state when it is switched back on.

OM5110 User Manual 19

Operating basics

The Laser controls

If the lasers ar

e used with the OM4000 User Interface (OUI) Software, the laser

usage type must be set using the dialog on the lower right corner of each laser

panel. The OUI uses the setting to determine the laser from which frequency

information is retrieved. A selected usage type (such as Reference) can only be

selected once among all of the OM devices to which you are connected.

NOTE. Only the Reference laser selection is important to OUI operation. The

other selec

tions are to help the user remember how each laser is being used.

The Laser control area of the LRCP software displays available laser control

function

s for the connected OM5110 (with optional internal laser).

Table 6: OM5110 Laser controls (LRCP)

Control Description

Channel Type a number or use the up/down arrows to choose a channel. The

range of channels available will depend on the type of laser, the First

Frequency, and the Grid. The finer the Grid, the more channels are

available for a given laser. The channel range is indicated next to

the word Channel. The laser channel can also be set by entering a

wavelength in the text box to the right of the channel entry. The laser

will tune to the nearest grid frequency.

Cavity Lock The Intel/Emcore ITLA laser that is included in the OM5110 instrument

has the ability to toggle its channel lock function. Ordinarily, Cavity

Lock s hould be checked so that the laser is able to tune, change power

level, and lock on to its frequency reference. However, once tuning is

complete and the laser has stabilized, you can clear this box to turn off

the frequency dither needed for locking the laser to its reference. The

laser can hold its frequency for days without the benefit of the frequency

dither. This feature is helpful where the lowest phase noise is required.

Power

Fine Tune

First F requency

Last Frequency

Channel 1 Settable when emission is off. This is the definition of Channel 1.

Grid Spacing Settable (with 100 MHz resolution) when emission is off. 0.1, 0.05

Sets the laser power level. Type or use the up/down arrows to select the

laser power level. The allowed power range is shown next to the control.

Enables tuning the laser off grid up to 12 GHz. Change this value by

typing a number in the text box or by dragging the slider. The sum of the

text box and slider values is sent to the laser. Once the laser accepts

the new value it is displayed after the ‘=’ sign.

Readout only. The lowest frequency to which you can tune the laser.

Readout only. The highest frequency to which you can tune the laser.

or 0.01THz are typical choices. Use 0.01 THz if tuning to arbitrary

(non-ITU-grid) frequencies. Using this grid plus Fine Tune, any

frequency in the laser band is accessible.

20 OM5110 User Manual

Table 6: OM5110 Laser controls (LRCP) (cont.)

Control Description

Laser Electrical

Power

Emission

Connected To

This should normally be checked. Unchecking this box turns off

electrical power to the laser module. This should only be needed to

reset the laser to its power-on state, or to preserve laser lifetime if a

particular laser is never used.

Click to turn on or off front panel laser emission. The emission status

is indicated both by the green background of the button and by the

corresponding green LED on the OM5110 instrument front panel.

Use the drop-down to select where this laser is connected. The control

software needs to know if this laser is being used as the Reference for

a coherent receiver. Select Reference if this laser is connected to the

Reference (LO) input of a coherent receiver.

Operating basics

The Modulator controls

Auto settings view

(Auto-Set check box

selected)

The Modulator section of the LRCP software is used to control the optical bias

settings of the optical modulator in the OM5110.

The Au

to-Set check box, at the bottom of the control area, enables or disables the

modulator automatic optical bias function s ettings screen. When the check box is

selected, settings are controlled automatically based on the specified signal level

and type. When Auto-Set is cleared, you can manually enter modulator settings.

Table 7: OM5110 Modulator controls (Auto-Set mode) (LRCP)

trol

Con

Input Signal

RF

Level (mVpp)

Signal Type Sets the input signal type.

Apply

Sig. Pwr (Readout only) The Modulated Output Signal power (abbreviated Sig.

Reset

cription

Des

t whether the input signal to each OM5110 input (X-I, X-Q, Y-I, and

Se

Y-Q) is less than or greater than the listed value.

Valid types are No Signal, Binary data signal, and Multi-level data signal.

Send the settings to the OM5110. When the wait circle disappears, your

ettings have been applied. The OM5110 retains these settings until

s

they are changed. No settings are sent or retained by the OM5110 until

you click the Apply button.

Pwr.) readout at the bottom of the Modulator control area. If the output

is too high or too low, it may temporarily affect the controller circuits

of the OM5110. In this case the power readout changes color and

mouse-over text is available to indicate that optical bias and power

readout may not be precise. There is no harm operating like this if the

input optical power is within the specified range.

Sets the optical bias control voltages to the default values. This is

helpful whenever a major change is made to the system such as turning

on the laser or input signals. Clicking Reset generally helps the system

reach steady-state operation the fastest.

OM5110 User Manual 21

Operating basics

Manual settings view

(Auto-Set check box

cleared)

The Manual Sett

ings View provides the greatest degree of control flexibility, but

is more complex than Automatic Settings View. Since each setting may take

five seconds to be stored in the OM5110 and possibly several minutes to reach

steady state, it is best to use the Automatic Settings View where all the settings

are established at once. The Manual Settings View is helpful when it is necessary

to make fine adjustments to optimize a signal, or when it is desirable to impair

the signal.

The following controls are available in the manual modulator view:

Table 8: OM

Control Description

Slope Usually - for > 500 mVpp inputs and + for < 500 mVpp inputs. The -

Control Mode Auto to use automatic optical bias control based on feedback from the

Voltage/Offset

Actual This column shows the voltages at the optical modulator bias inputs.

al Mode

Sign

Set Modulator

Parameters

5110 Modulator controls (manual mode) (LRCP)

causes lock at minimum attenuation and the + at maximum attenuation.

output o

Manual to set the optical modulator bias voltage to a particular value.

The sli

mode or to set the Offset when in Auto mode. Offset is the amount to

offset the bias from where it would normally be in Auto mode. The units

are arb

The O ffset must be tuned while observing the Modulated Optical Output

signal on an appropriate optical signal analyzer to obtain the desired

signa

The v

The o

of electrical signal input. Binary signals require 2-pol QPSK mode.

QAM signals generally require QAM mode. Again it is best to use the

Aut

Mode automatically.

The 6 modulator sections of the OM5110 modulator (X-I, X-Q, Y-I, YQ,

XP, and YP), each have particular null voltages where that section

ou

between null and peak transmission. This information is needed by

the OM5110 optical bias controller to properly control the modulator

se

The null voltages do change with time, and are different for different RF

drive levels. It is not important for these values to be very precise. You

s

achieve proper optical bias within a few minutes. Providing a better set

of null voltages speeds the time to proper optical bias.

T

and may be left at their factory-set values.

ptical signal.

der control is used to set the desired voltage when in Manual

itrary and vary based on Optical Input power.

l behavior.

alue in parentheses is the actual Offset value.

ptical bias controller behaves differently depending on the type

omatic Settings View which chooses the most appropriate S ignal

tputs m inimum optical power, and Vpi voltages, the voltage difference

ctions. The O M 5110 is preprogrammed at the factory.

hould update your modulator parameters only if the OM5110 fails to

he Vpi voltages do not change appreciably with time or temperature

To determine the optimal Null Voltage values:

22 OM5110 User Manual

Operating basics

1. Connect the OM5

the signal quality of the OM5110. Connect the necessary signal inputs and

turn on the laser source.

2. Use the Modulator Auto-Set view to set up the OM5110 for the required

signal types and drive levels. Click Apply. Wait for this step to complete.

3. Deselect the Auto-Set box to see the Manual Settings view. Wait for the

analyzer to report that the optical bias is correct.

4. If the optical bias does not meet your requirements, use the Manual Control

Mode or the Offset function to correct the optical bias.

5. Record the voltages shown on the Manual Settings view once the optical

bias value meets your requirements.

6. Click Set Params. Enter the voltages shown in the Manual Settings view

(step 5) as the Null Voltages in the Set Parameters dialog box.

NOTE. If using Set Params results in worse values, click Restore Initial Values

to reload the settings originally detected by the LRCP at first connection to the

OM511

0.

110 to an analyzer, such as the OM4106D, that will report

The Driver Amp controls

7. Click OK.

8. To verify the Null Voltage values, change every segment to Manual Control

Mode and click Reset. The voltages shown should match those found in

step 5) to within 0.01 V.

9. Return to the Auto-Set view and click Apply to return to automatic control.

e Driver Amp control area of the LRCP software controls the behavior of the

Th

optical modulator RF Input electrical amplifier. This two-stage amplifier can

work in both linear and nonlinear modes to enable both linear electrical-to-optical

conversion and binary optical signal generation which is insensitive to the

electrical input signal level.

OM5110 User Manual 23

Operating basics

Table 9: OM5110

Control Description

Stage 1 First stage of electrical amplification. You can adjust the gain of each

Stage 2 Second stage of electrical amplification. When operating with

Voltage Settings Save current voltages as power-on defaults, which stores all of the

Driver Amp controls (LRCP)

Stage 1 amplifier. This should not be needed for most applications, but

can be helpfu

the linear range (< 500 mVpp electrical input).

>500 mVpp electrical input, you can adjust the crossing point and

amplitude o

not effective in the linear range (< 500 mVpp) and can be left at their

default values.

current Dr

Restore to factory defaults, w hich loads the factory default values for

the Driver Amp, overriding the current values.

When the O

power switch, or when it loses mains power, only the “power-on default

settings,” and “factory defaults” are retained.

l to balance the amplitude of I- Q signals when operating in

f the signal driving the optical modulator. These controls are

iver A mp settings in the OM5110 as the new defaults.

M5110 is turned on and off by the rear-panel Primary

Each of the adjustments for linear gain, nonlinear crossing point, and nonlinear

ude are indicated by a value in percent. This value is provided to help

amplit

documentation of the amplifier settings. The control is not strictly proportional

to this value, so these settings must be determined experimentally using the

appropriate optical signal analyzer.

24 OM5110 User Manual

Appendix A: The automated test equipment (ATE) interface

LRCP has two types of WCF interface to allow control from a user application.

Both types of interface provide full functionality and compatibility with simple

interfaces s

The LRCP ATE interface

uch as MATLAB and client application programs.

Basic/Advanced WCF

service interface for the

LRCP

The Automa

through a Windows Communication Foundation (WCF) service. As the LRCP is

used with all OM4000 series or OM5110 instruments, its interface exposes more

commands than those used by the instrument CLSA.

The WCF services (basic and advanced) are available on port 9000 in the machine

that is running the LRCP. The service (basic and advanced) interface was

developed for incorporation into an ATE client application that you can develop in

your choice of .NET language, typically C# or VB.NET. Both services expose

most of the functionality that is available through the LRCP’s user interface.

The basic service, implemented using a wsBasicHTTPBinding, exposes the

same subset of commands as the advanced service. It was implemented using

asimp

page 37, ATE functionality in MATLAB.) or Labview that only support the

wsBasicHTTPBinding. The basic service is referenced at the following URL:

http://localhost:9000/LaserReceiverControlPanel/Laser_ReceiverServiceBasic/

The advanced service, implemented using a wsHTTPBinding, (and which is not

available in MATLAB) was developed for use with an ATE client application and

uses events to provide a time-efficient interface.

The advanced service is referenced at the following URL:

http://localhost:9000/LaserReceiverControlPanel/Laser_ReceiverService/

ted Test Equipment (ATE) interface exposes the LRCP functionality

ler binding for compatibility with applications like MATLAB (See

NOTE. For safety reasons, you cannot activate a laser from the basic or advanced

ervices; you can only activate a laser from the LRCP user interface.

s

OM5110 User Manual 25

Appendix A: The automated test equipment (ATE) interface

LRCP service interface

function list

The following a

re the available commands in both the basic and advanced service

interfaces and show their functionality using the MATLAB syntax.

int Available

Lasers(classname);

Description: Returns the count of available lasers on the active controller.

Controller T

Example:

ypes: All

AvailableLasers(Obj);

Returns: ans = 2

bool Calibrate();

Descripti

on: Performs an automatic modulator calibration to determine

the optimal modulator parameters. These are the same parameters that

are manually set using the user interface Set Params button, or the

SetManualCalibration() function.

Calibrate() is an automatic calibration that requires the modulator control mode

(see GetActualModulatorMode()) be set to 2-pol QPSK and that >500 mVpp

binary signals are applied to all four inputs. Longer patterns are better (2

PRBS is optimal). Each of the four input patterns should be different in some

way: a

different pattern, the same pattern delayed, or a different seed.

The modulator must receive adequate input power levels to produce a signal

power

that is high enough to avoid a power level warning. If these conditions

are not met the resulting calibration can result in unstable optical bias. See the

section on Set Paramaters to restore these values to initial (factory) values.

Controller Types: OM5110

Example:

Calibrate(Obj);

Returns: ans = true/false

31

bool Connect(classname);

Description: Connects to the active controller, starts controller running.

ntroller Types: All

Co

Example:

Connect(Obj);

Returns: ans = true

bool Disconnect(classname);

Description: Disconnects from the active controller, takes offline.

Controller Types: All

Example:

Disconnect(Obj);

Returns: ans = true

bool GetActualCavityLock(classname);

Description: Returns the actual cavity lock state for the active controller/laser.

Locked = True.

Controller Types: All

Example:

GetActualCavityLock(Obj);

Returns: ans = true

26 OM5110 User Manual

Appendix A: The automated test equipment (ATE) interface

double GetActu

alChannel(classname);

Description: Returns the actual channel number for the active controller/laser.

Controller Types: All

Example:

GetActualChannel(Obj);

Returns: ans = 1

double GetActualChannel1(classname);

Description: Returns the actual channel 1 frequency (in THz) for the active

laser.

Controlle

Example:

rTypes: All

GetActualChannel1(Obj);

Returns: ans = 191.5

controlmode GetActualControlMode(classname, modulatorenum);

Description: Returns the control mode for the modulator that is passed in

the ‘modulator’ parameter.

Controller Types: OM5110

Example:

Return

controlmode.automatic

controlmode.manual

controlmode.notset

GetActualControlMode(obj, modulatorenum.YQ);

s: ans = one of the following:

float GetActualCurrent(classname, string);

Description: Returns current (mA) associated with the specified input voltage.

Controller Types: OM5110

Example:

urns: ans = 30

Ret

GetActualCurrent(obj, “YQ G1”);

The following are valid string values:

"YQ G1", "YI G1", "YQ G2", "YI G2", "YQ D2", "YI D2" "XI D2", "XQ

D2", "XI G2", "XQ G2", "XI G1", "XQ G1"

bool GetActualEmitting(classname);

Description: Returns the emission status of the active laser. Emitting = True.

Controller Types: All

Example:

GetActualEmitting(Obj);

Returns: ans = true

byte GetActualFactoryDefault(classname, string);

Description: Returns the factory default value for the specified voltage, in

the range of 0 to 255.

Controller Types: OM5110

Example:

GetActualFactoryDefault(obj, “XQ D2”);

Returns: ans = 0

The following are valid string values: